Desulfurization additive as well as applications and using method of same

An additive, wet desulfurization technology, applied in the chemical industry, can solve the problems of high operating cost, poor desulfurization effect, and easy fouling of equipment, and achieves the effect of good effect, improved reaction activity, and improved reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

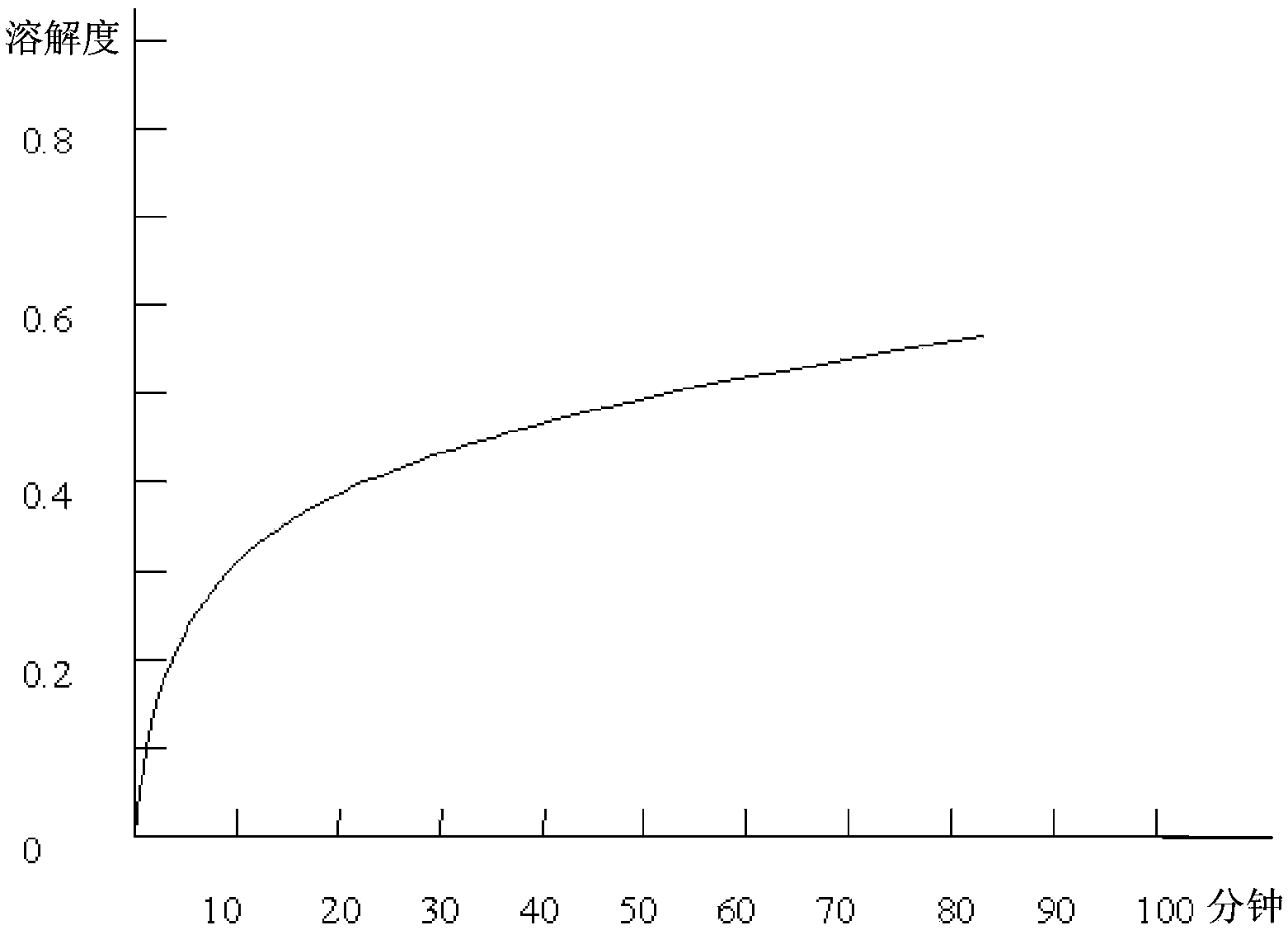

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0022] An embodiment of the present invention provides a desulfurization additive, the raw materials of which include: in parts by mass, 30-40 parts of accelerator, 50-60 parts of activator, and 5-15 parts of catalyst.

[0023] The embodiment of the present invention also provides the use of the above-mentioned desulfurization additive, which is used in limestone or lime gypsum wet flue gas desulfurization process.

[0024] The embodiment of the present invention also provides a method for using the above-mentioned desulfurization additive, including:

[0025] Add desulfurization additives to the circulation loop of the limestone wet desulfurization circulation system;

[0026] stir;

[0027] The desulfurization additive is added at a set frequency.

[0028] The principle of desulfurization additives in limestone w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap