Anti-boiling-water vegetable protein-based wood adhesive, preparation method and application of same

A wood adhesive and vegetable protein technology, which is applied in the field of boiling water-resistant vegetable protein-based wood adhesives for wood-based panels and its preparation, can solve the problems that hinder the development and popularization of vegetable protein-based adhesives, such as slow curing speed and solid Low content and other problems, to achieve the effect of excellent structure adjustment, low manufacturing cost, and increased solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] Example 1 Preparation of boiling water-resistant vegetable protein-based wood adhesive

[0039] A boiled water-resistant vegetable protein-based wood adhesive for wood-based panels, with a formula: 65Kg of softened water, 35Kg of vegetable protein meal, 8Kg of water-based polyurethane adhesive, and 4Kg of water-based epoxy resin crosslinking agent (glycidyl ether).

[0040] The preparation method of the above boiling water-resistant vegetable protein-based wood adhesive includes the following steps:

[0041] S1 In a reactor equipped with a stirrer, add demineralized water and vegetable protein meal according to the ratio and stir evenly;

[0042] S2 is added to the water-based polyurethane adhesive according to the proportion and stirred evenly;

[0043] S3 adds water-based epoxy resin crosslinking agent (glycidyl ether) according to the proportion and performs homogenizer treatment, and the pressure of homogenization treatment is 25MPa.

[0044] Three batches of parallel samples wer

Example Embodiment

[0045] Example 2 Preparation of boiling water-resistant vegetable protein-based wood adhesive

[0046] A boiling water-resistant vegetable protein-based wood adhesive for wood-based panels. The formula: softened water 70Kg, vegetable protein meal 30Kg, water-based polyurethane adhesive 7Kg, and water-based epoxy resin crosslinking agent (PAE) 3Kg.

[0047] The preparation method is the same as in Example 1.

[0048] Three batches of parallel samples were prepared in the same way, and the performance and quality indexes of the prepared adhesives are shown in Table 1.

Example Embodiment

[0049] Example 3 Preparation of boiling water-resistant vegetable protein-based wood adhesive

[0050] A boiling water-resistant vegetable protein-based wood adhesive for wood-based panels. The formula: 75Kg of softened water, 25Kg of vegetable protein meal, 6Kg of water-based polyurethane adhesive, and 2Kg of water-based epoxy resin crosslinking agent (PAE).

[0051] The preparation method is the same as in Example 1.

[0052] Three batches of parallel samples were prepared in the same way, and the performance and quality indexes of the prepared adhesives are shown in Table 1.

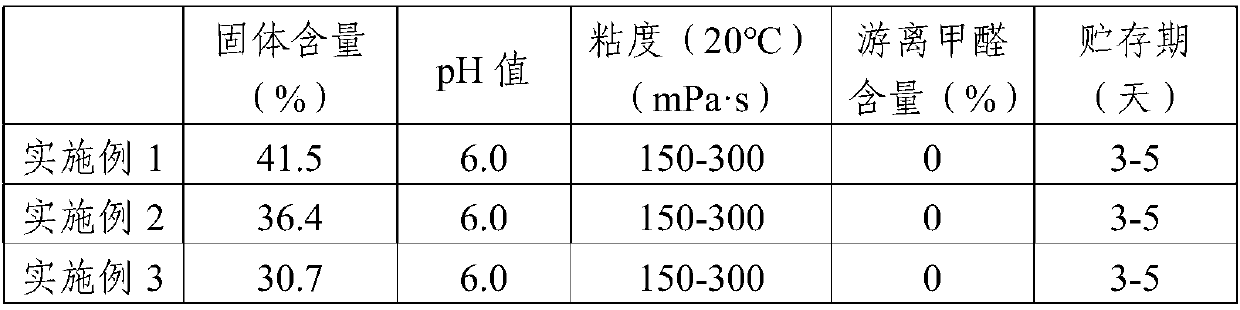

[0053] Table 1 Performance indicators of soy protein adhesive

[0054]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap