Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115 results about "Epoxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy is either any of the basic components or the cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups.

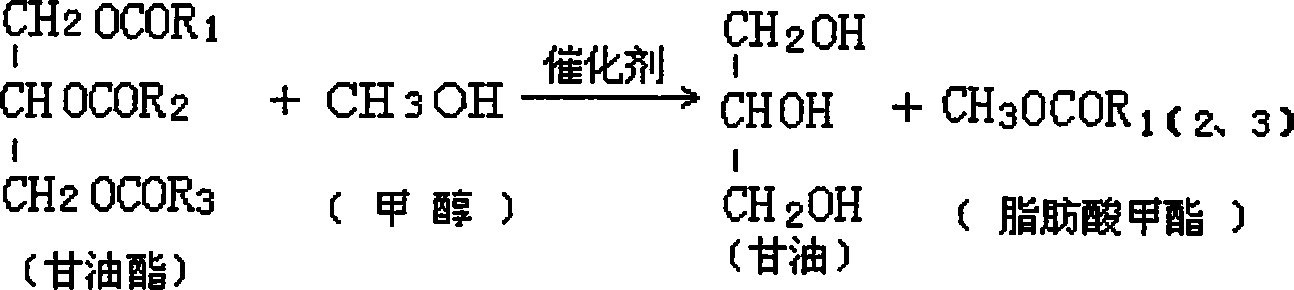

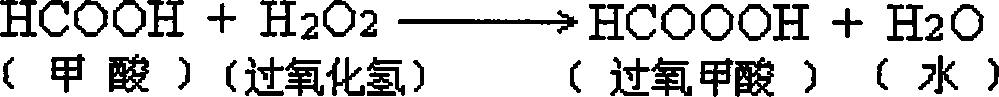

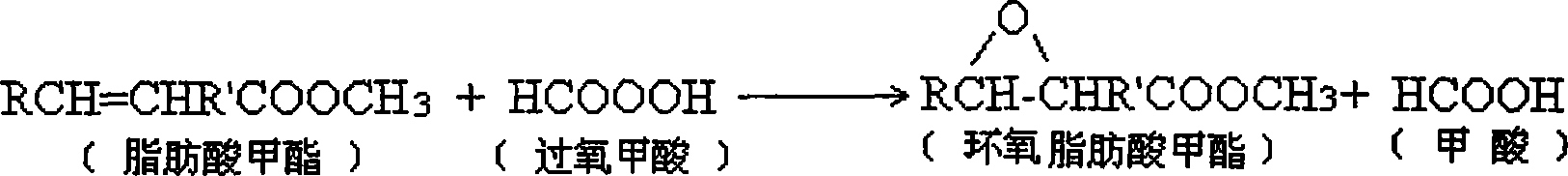

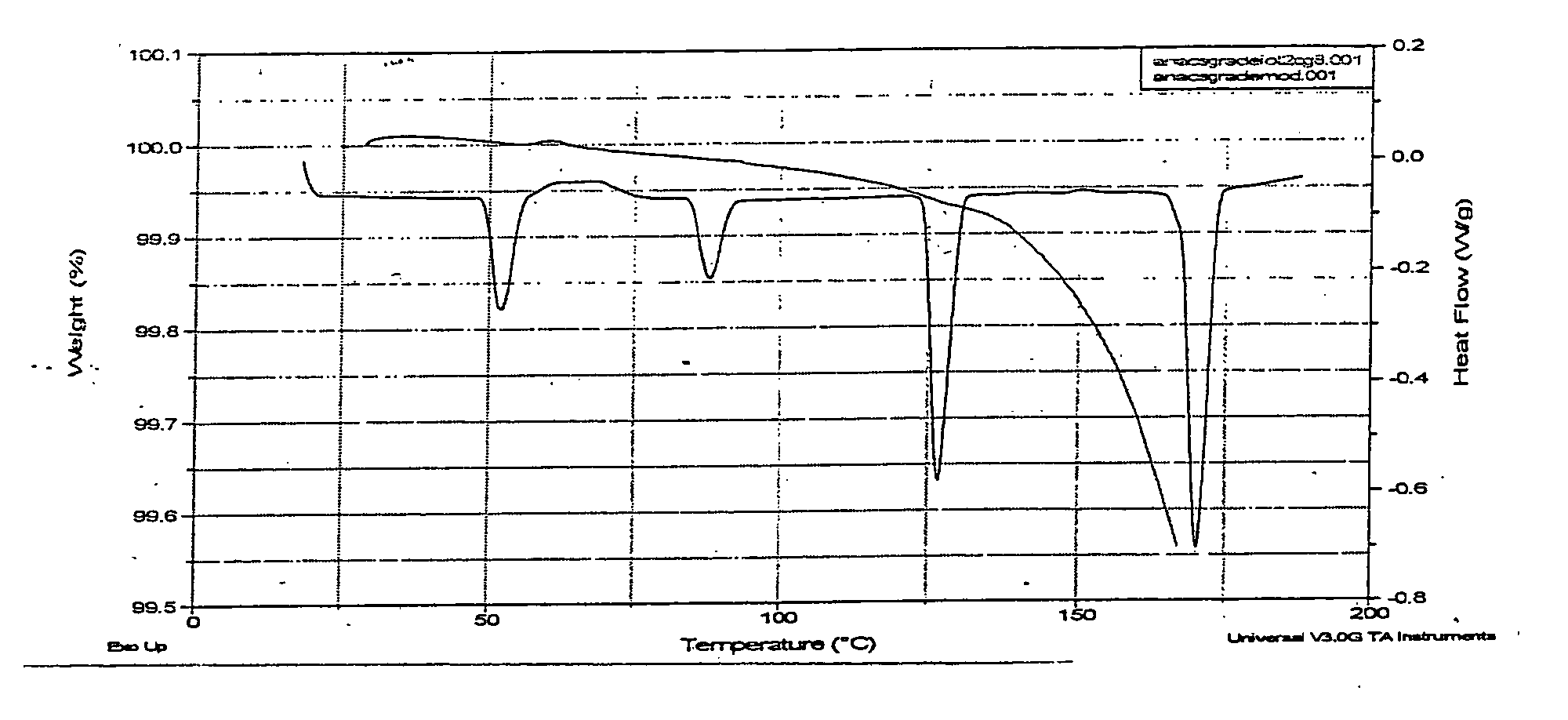

Method for producing epoxy plasticizer using waste grease

InactiveCN101070510AHarm reductionReduce dosageFatty oils/acids recovery from wasteFatty acid esterificationEpoxyDistillation

Owner:江苏向阳科技有限公司

Electrically controlled solid propellant

Owner:DIGITAL SOLID STATE PROPULSION

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

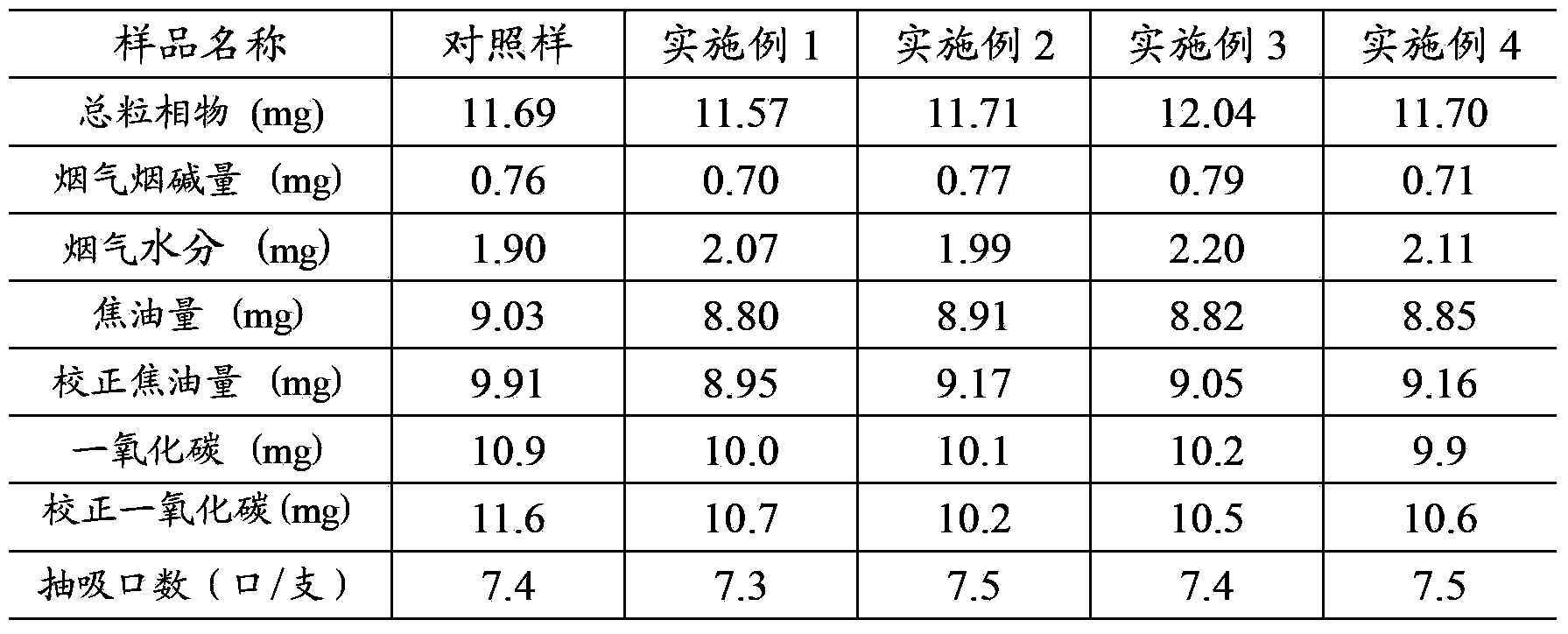

Solid-type filter stick formed by granular assembling and preparation method thereof

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Synthesis method for terpolymer block silicone oil

ActiveCN103214676ANo demulsification and delaminationNo self-emulsifying propertiesSilicon organic compoundsFibre treatmentDisiloxaneEpoxy

Owner:ZHEJIANG JIEFA TECH

Resin composition and semi-solidifying sheet for printed board prepared from the same

Owner:GUANGDONG SHENGYI SCI TECH

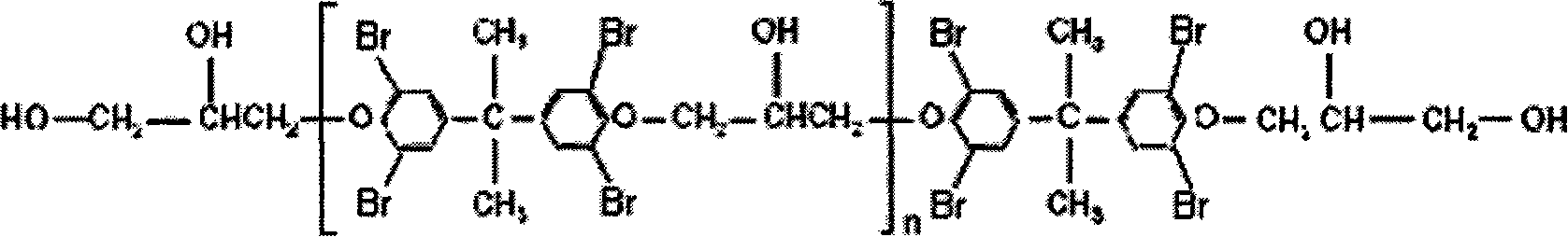

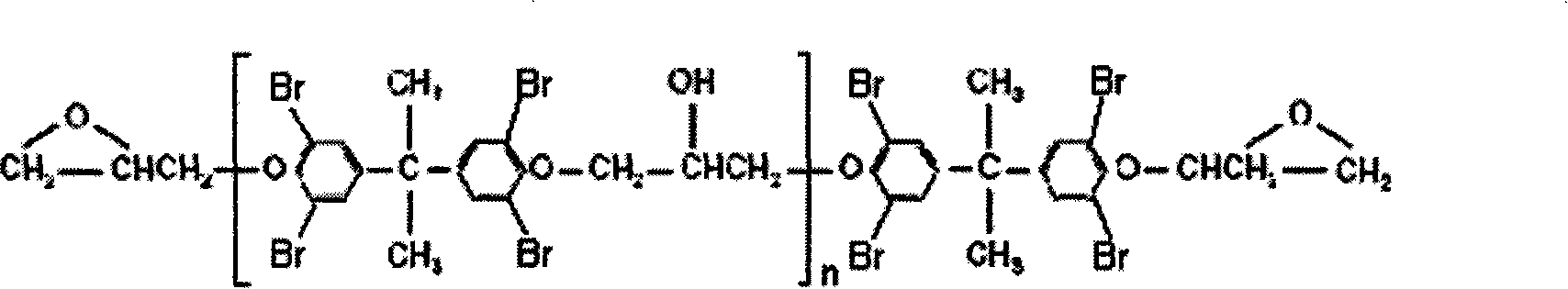

Halogen-free resin composition and cover film prepared from the same

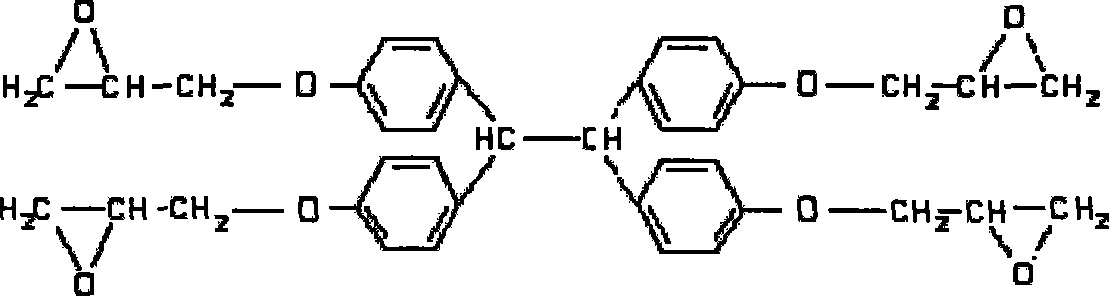

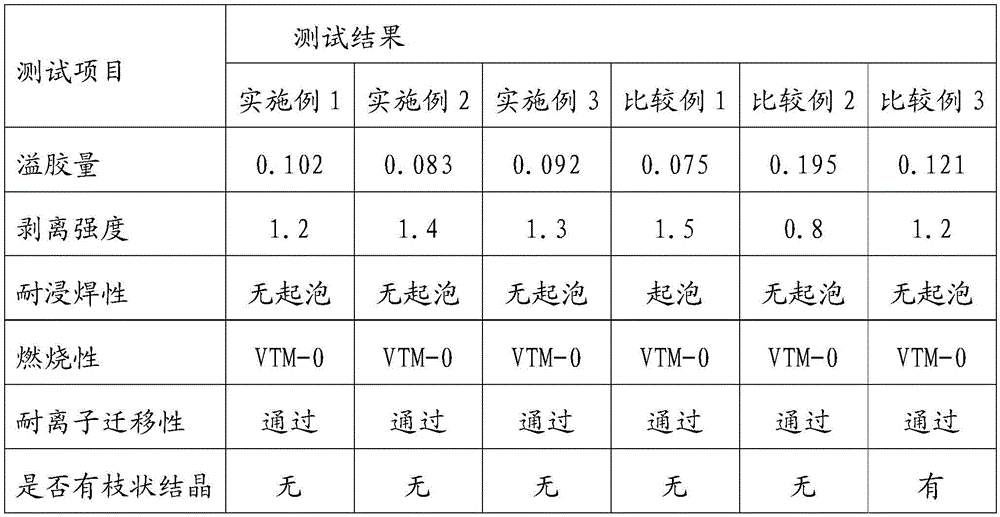

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

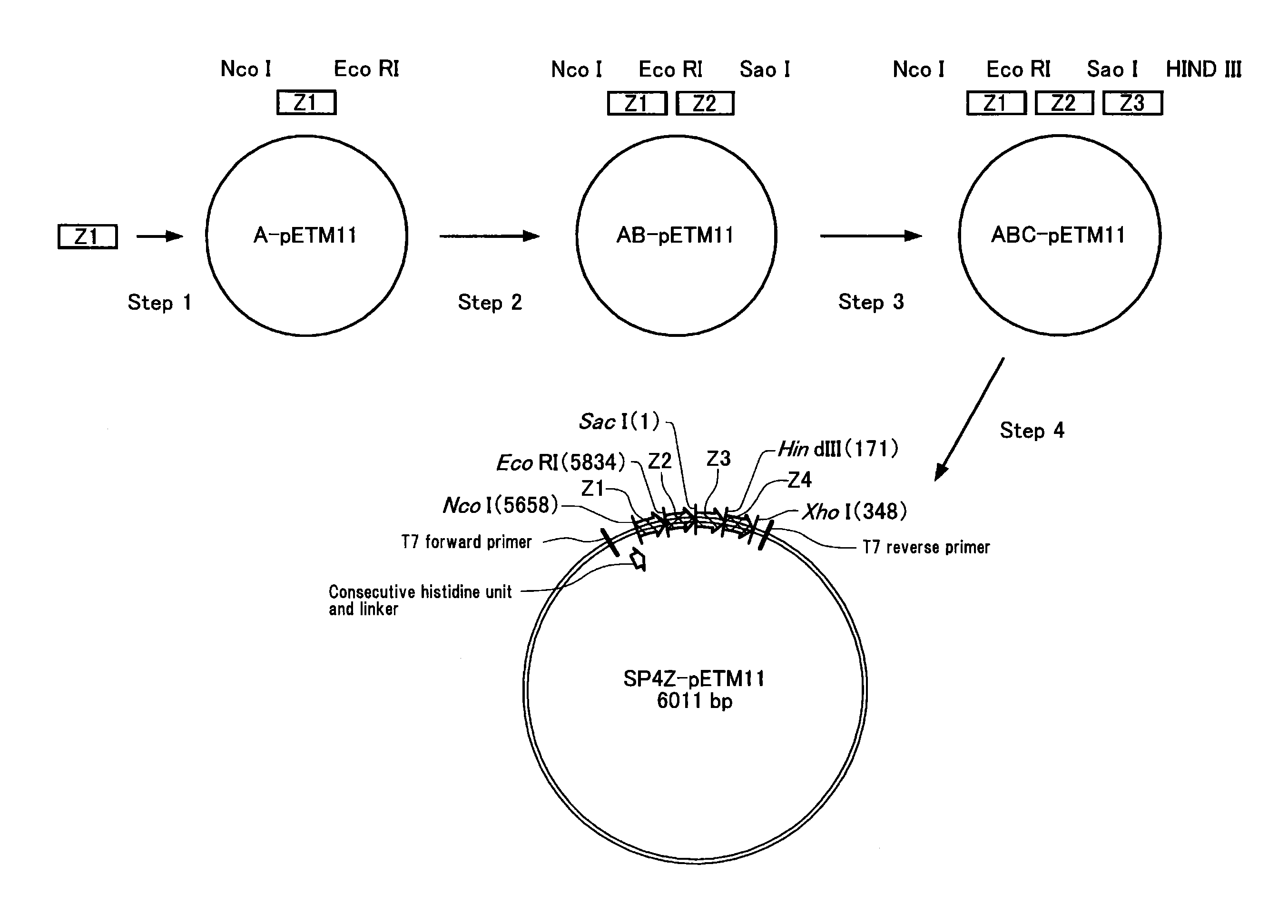

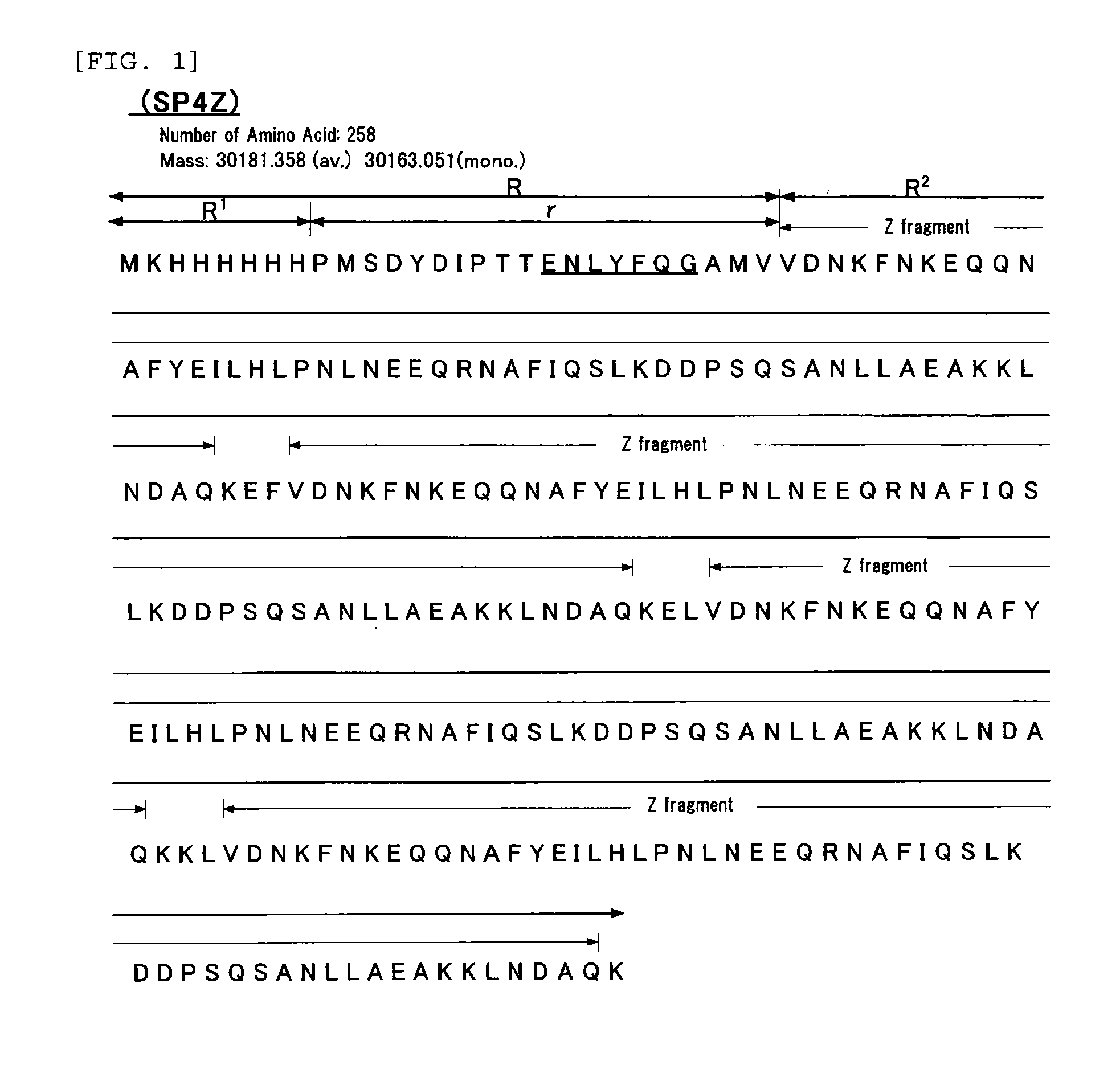

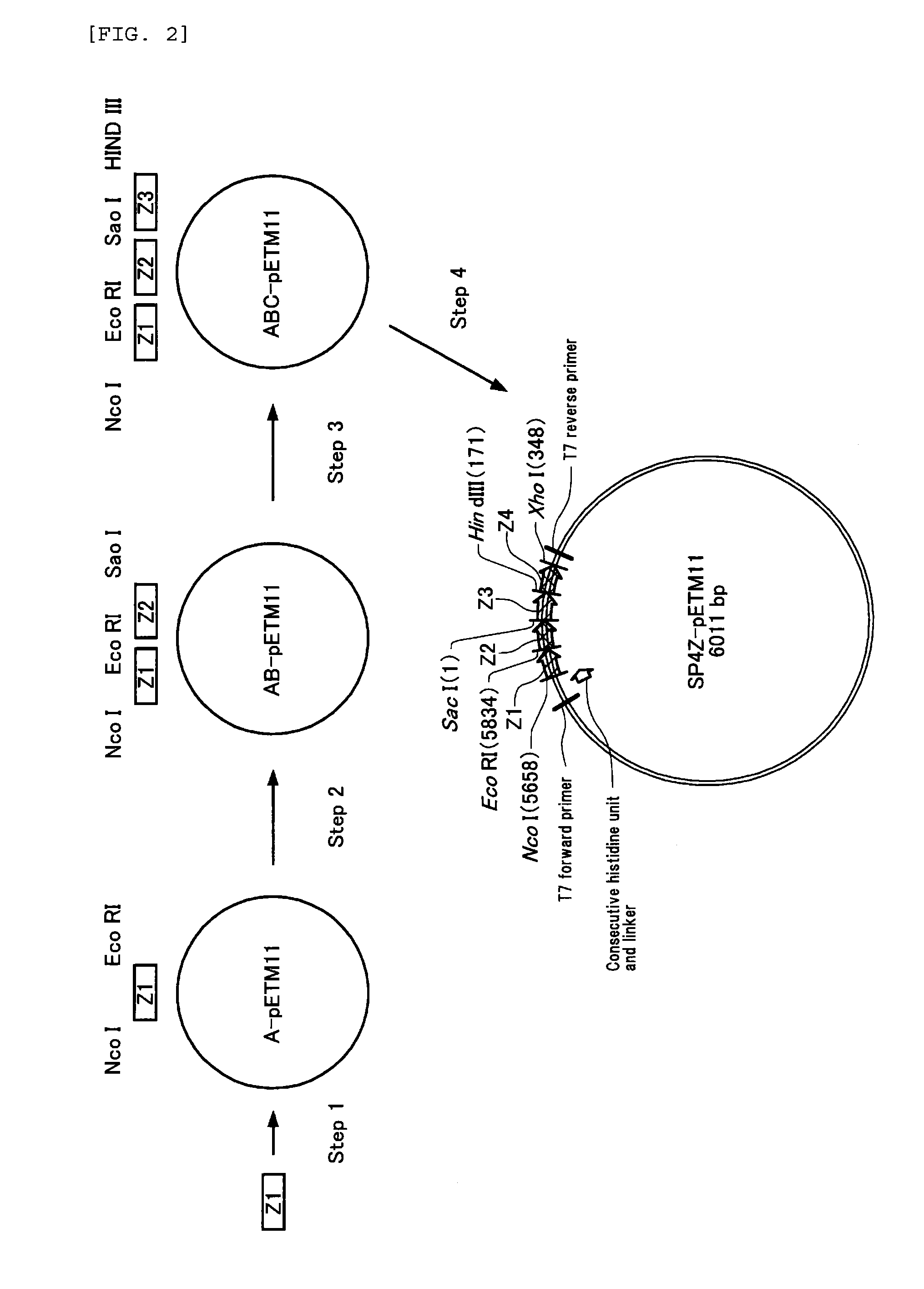

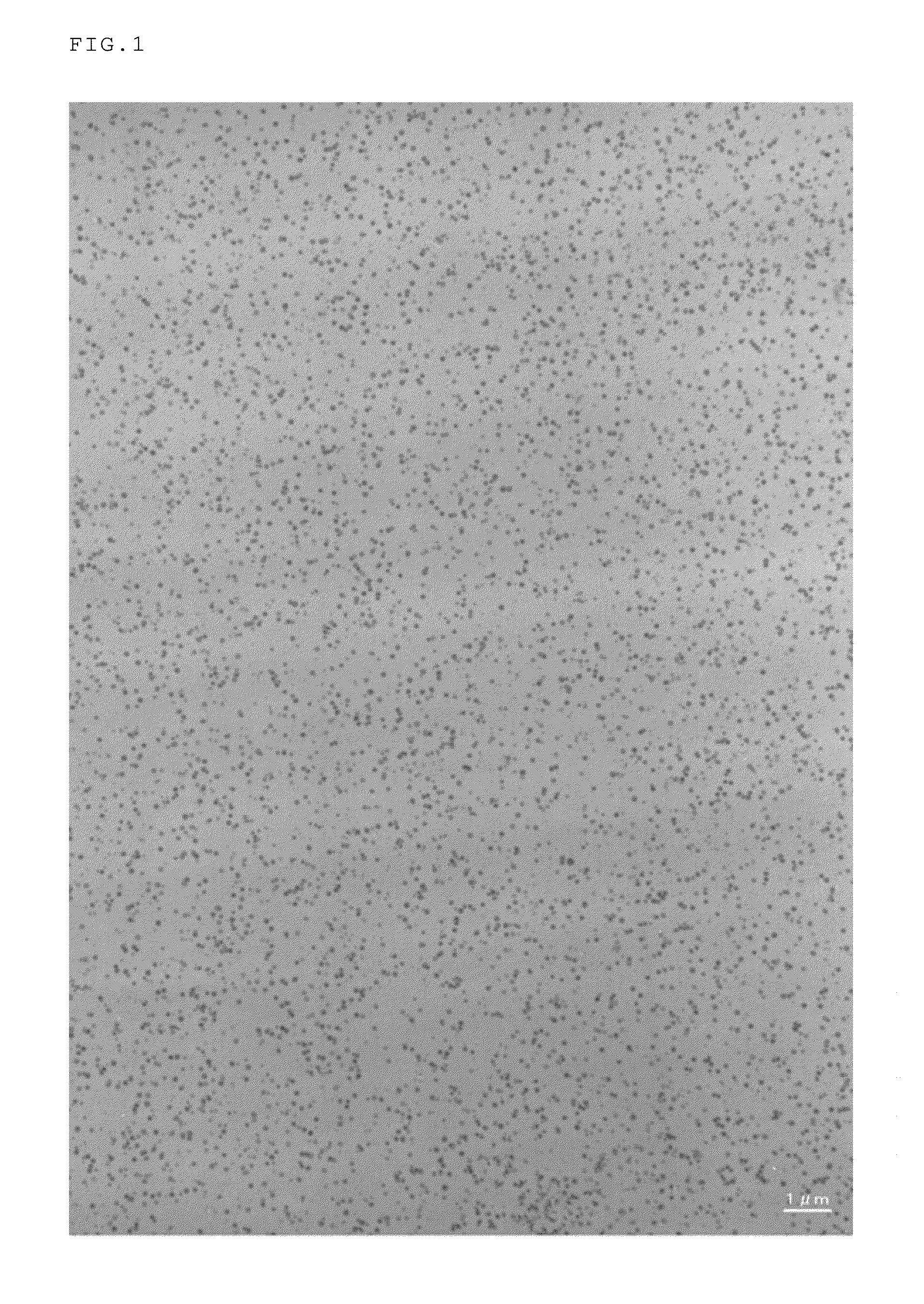

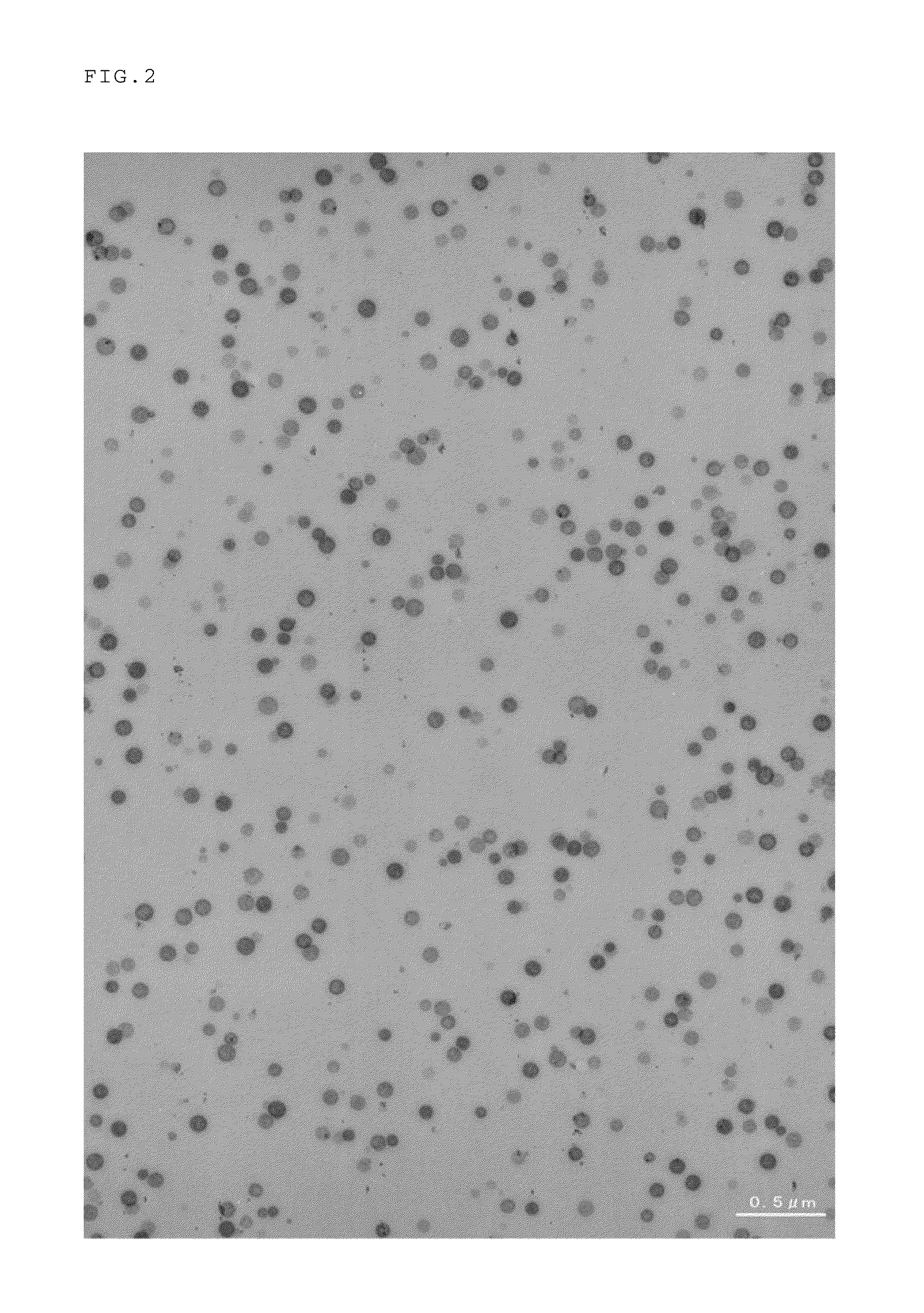

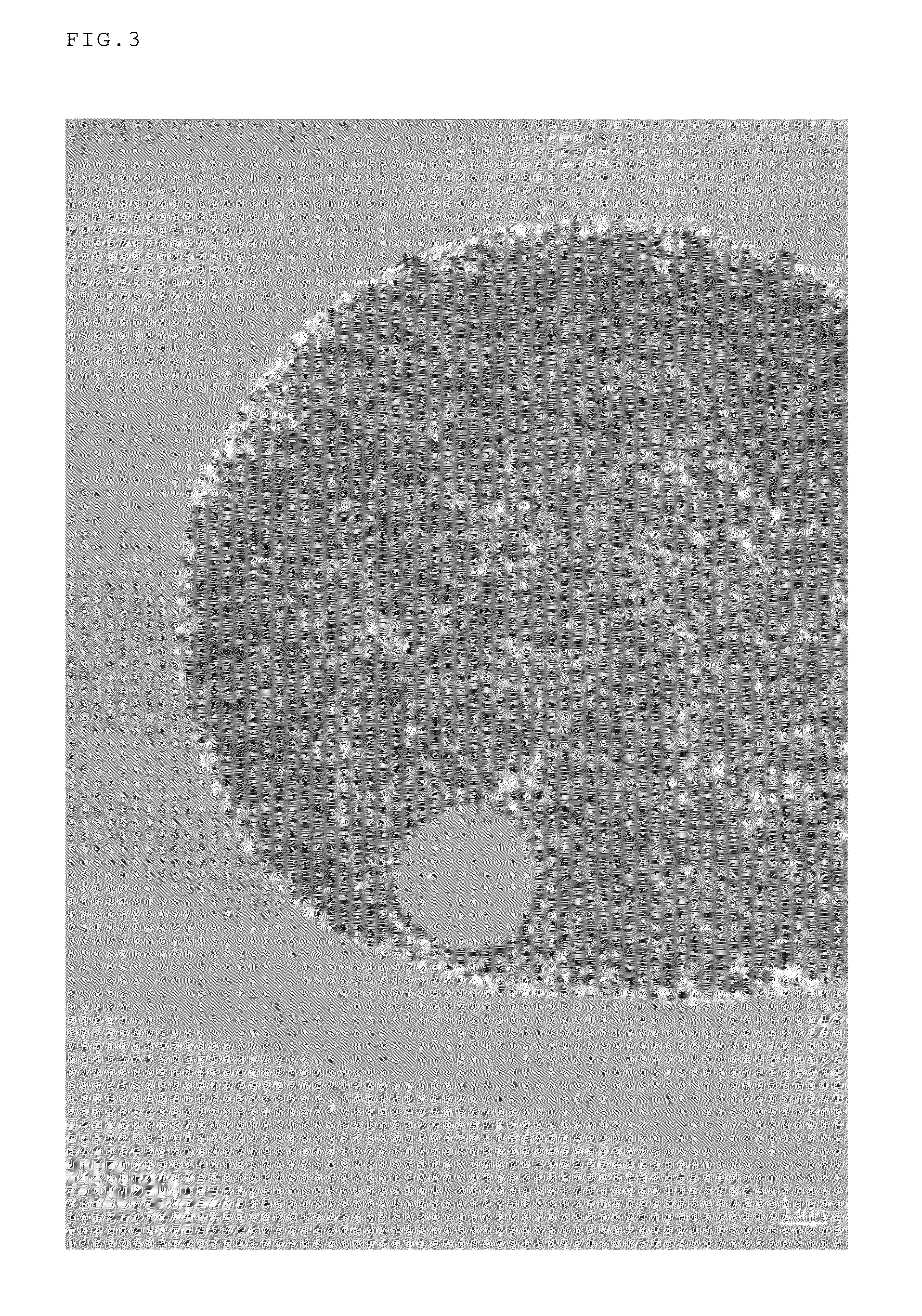

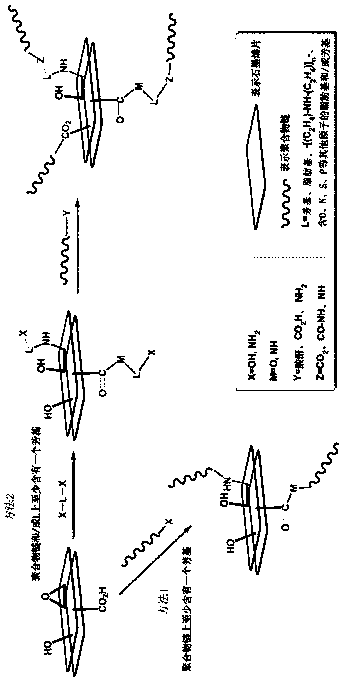

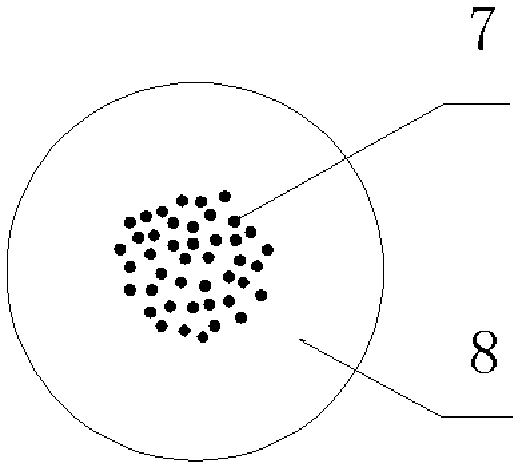

Filler for affinity chromatography

ActiveUS20130085199A1High dynamic binding capacityGood alkali resistanceSolid sorbent liquid separationImmunoglobulinsEpoxyPorous particle

Owner:JSR CORPORATIOON

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

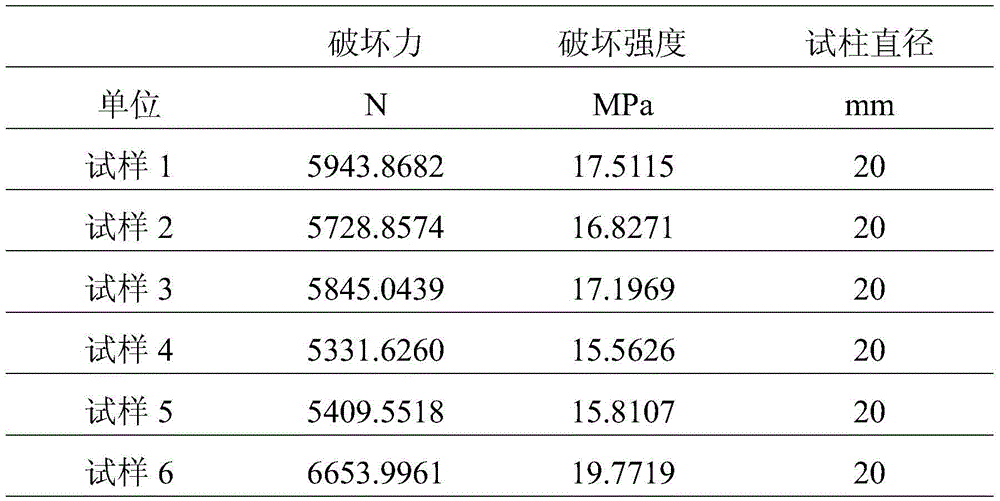

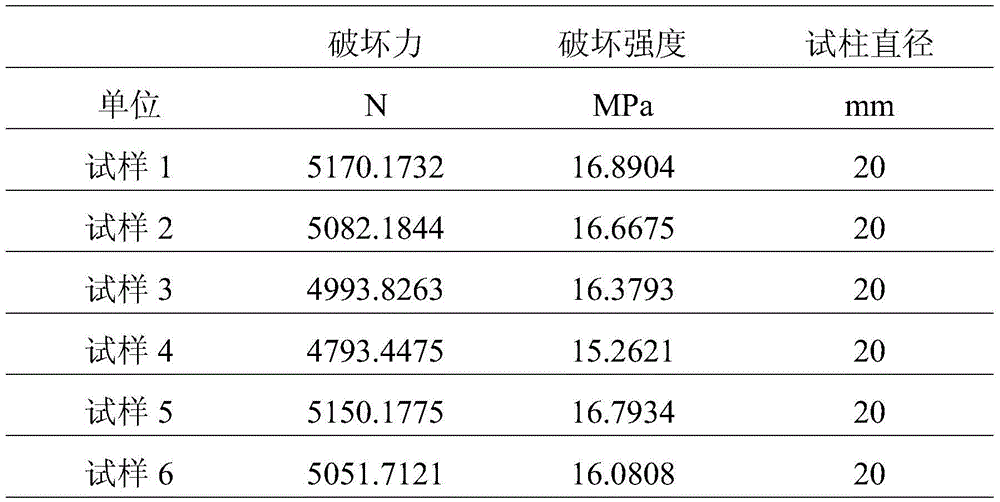

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

Curable resin composition containing polymer microparticles

Owner:KANEKA NORTH AMERICA +1

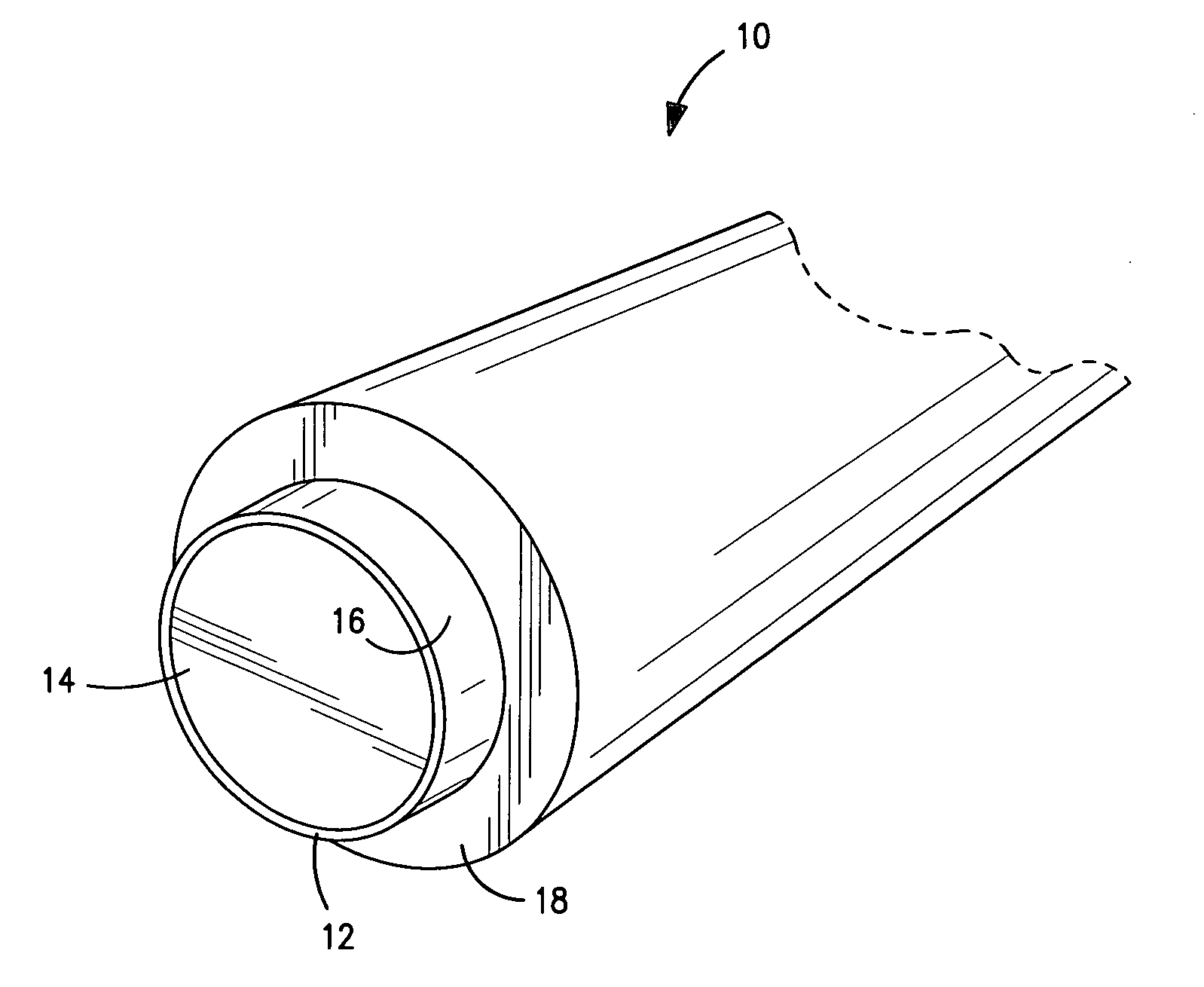

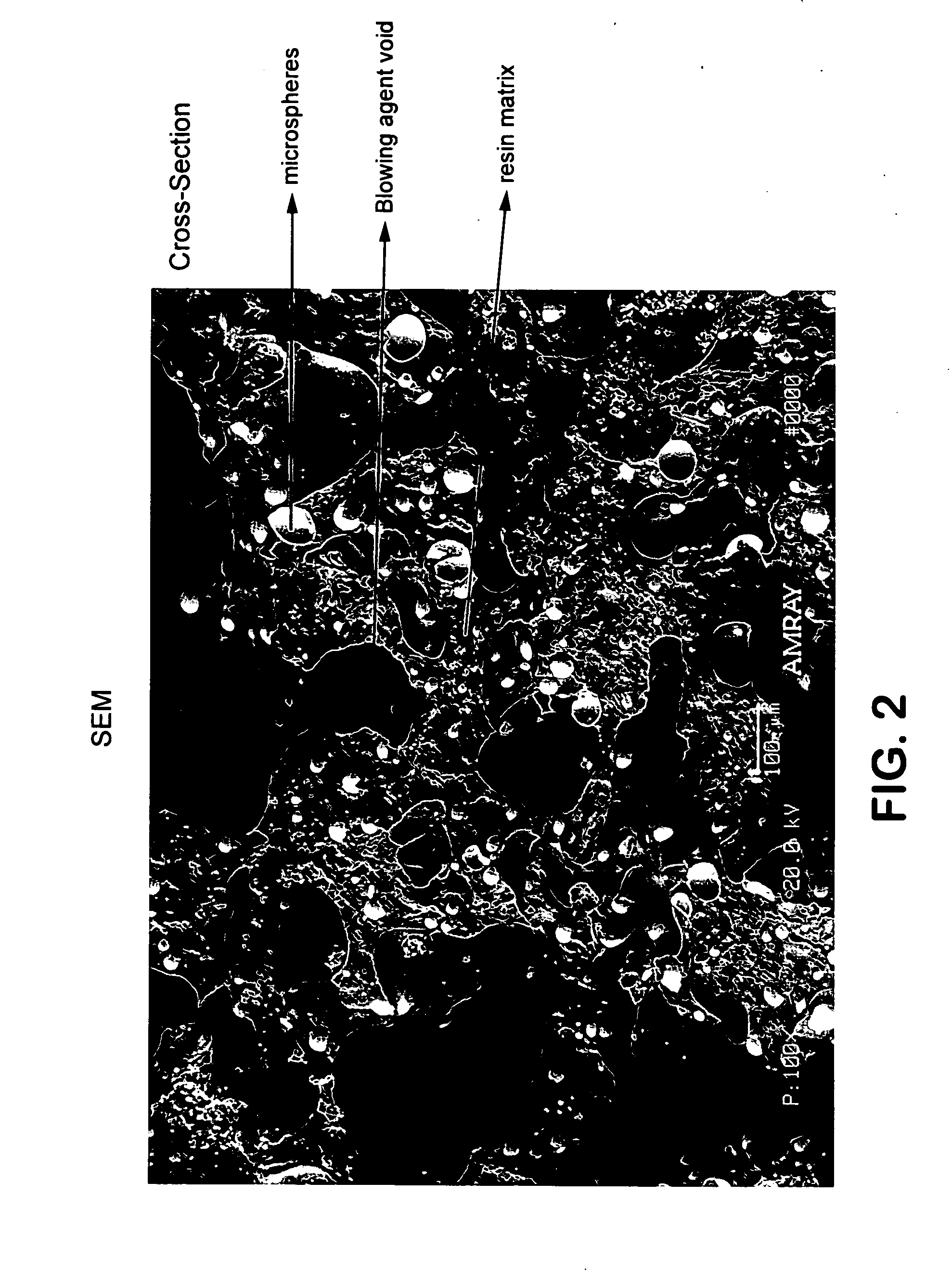

Syntactic Foam Compositions, Pipelines Insulated with Same, and Method

InactiveUS20110017340A1Improve thermal insulation propertiesIncrease buoyancyThermal insulationSolid waste managementEpoxyFoaming agent

Owner:CABOT CORP

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

Phosphor-silicon-containing aggregated flame retardant and preparation method thereof

ActiveCN107266685AOvercome the disadvantage of easy precipitationHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyPolymer science

Owner:宁波塑之华塑化有限公司

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

Process for producing latent catalyst and epoxy resin composition

InactiveUS20090234080A1High yieldGood fluidityOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPhosphonium

Owner:SUMITOMO BAKELITE CO LTD

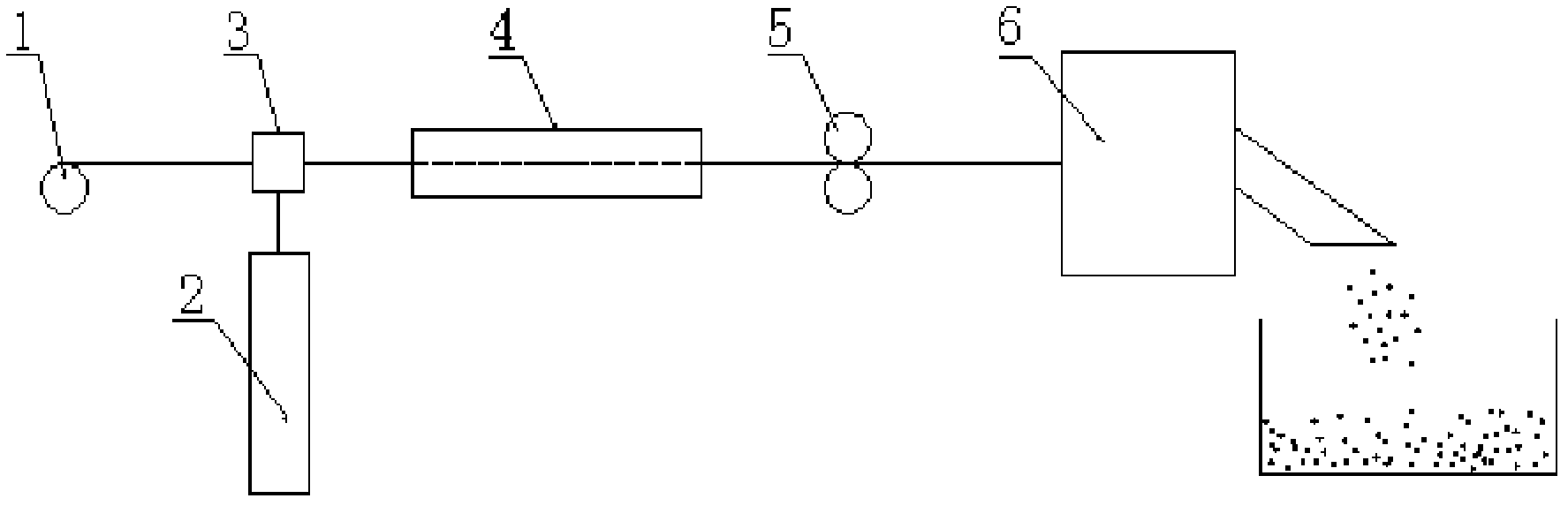

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

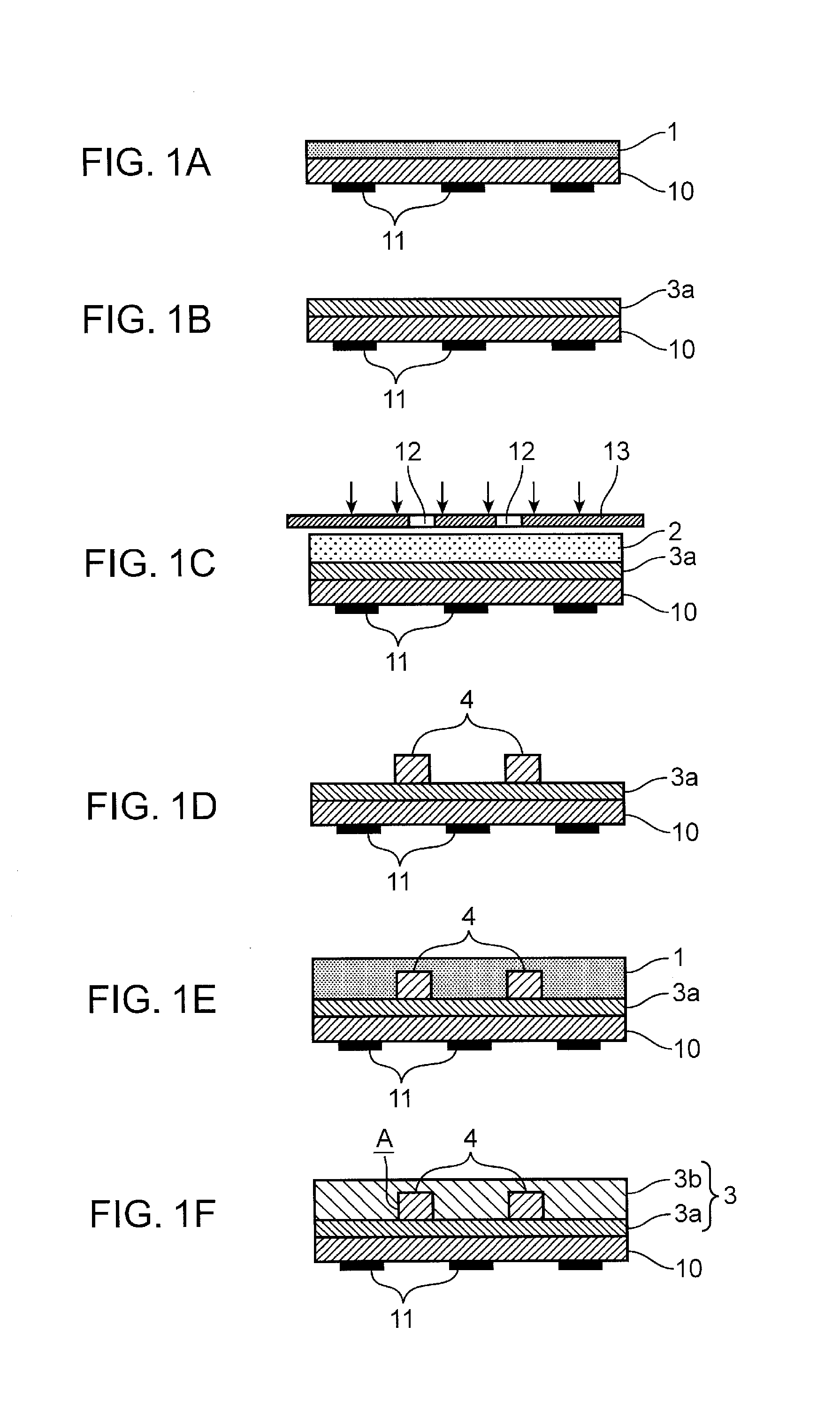

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

High-performance water-based bicomponent epoxy zinc rich primer and preparation method thereof

ActiveCN107573816AReduce usageImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyCollocation

The invention relates to a high-performance water-based bicomponent epoxy zinc rich primer and a preparation method thereof. A water-based bicomponent epoxy zinc rich coating A in the high-performancewater-based bicomponent epoxy zinc rich primer comprises a water-based epoxy curing agent, an additive A, a complex solubilizer, zinc powder, zinc and an anti-settling agent; a water-based bicomponent epoxy zinc rich coating B comprises a water-based epoxy emulsion and an additive B; the weight ratio of the coating A to the coating B is at 100 to (10-30). The preparation method comprises the following steps: (1) uniformly mixing the components in the coating A at ratio and using a 100-mesh screen for filtering; (2) uniformly mixing the components in the coating B at ratio; and uniformly mixing the coating A with the coating B at the weight ratio in a use process and regulating the construction viscosity. When the high-performance water-based bicomponent epoxy zinc rich primer is used, water is taken as a solvent, so that the use of the organic solvent is greatly reduced and the environmental protection is benefited. The collocation of the anti-settling agent is utilized to solve the problems of storage and construction.

Owner:SHANDONG QIWEI NEW MATERIALS CO LTD

Ultraviolet (UV) gloss oil and preparation method thereof

Owner:上海奇想青晨新材料科技股份有限公司

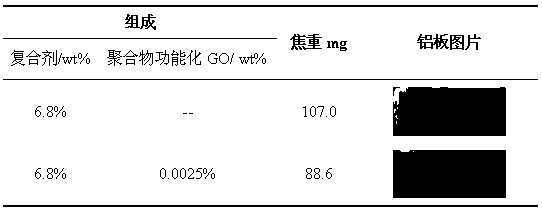

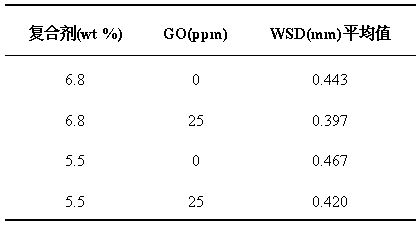

Polymer functional graphene and preparation method and application thereof

Owner:江西福安路润滑材料有限公司 +1

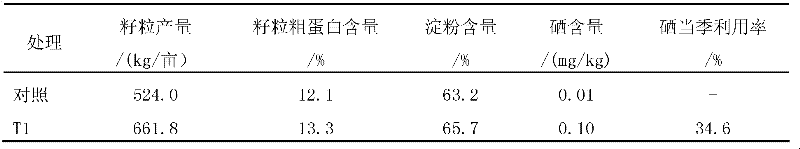

Selenium-containing coating agent for sustained release fertilizer special for selenium-rich agricultural products and preparation method for selenium-containing coating agent

ActiveCN102503669AIncrease profitMeet the needs of the whole growth periodFertilizer mixturesEpoxyPolyvinyl alcohol

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing stainless steel fiber resin matrix composite conductive plastics

ActiveCN102617986AImprove mechanical propertiesImprove conductivityNon-conductive material with dispersed conductive materialMethod testEpoxy

Owner:SHENZHEN FRD SCI & TECH

Single-component epoxy structure adhesive for waterproof sealing and preparation method thereof

InactiveCN110564347AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHigh humidity

Owner:上海汉司实业有限公司

Acrylic flame retardant adhesive composition and acrylic flame retardant adhesive sheet

Owner:SHIN ETSU CHEM IND CO LTD

Method for producing lead acid battery pole plate corrosion layer through mounting

ActiveCN104505517ADoes not damage the organizational structureIncrease the second sample mounting processElectrode carriers/collectorsLead-acid accumulator electrodesEpoxyWire cutting

Owner:CHAOWEI POWER CO LTD

Epoxy resin composition and prepreg and printed circuit board made therefrom

ActiveCN102260402AImprove heat resistanceGood chemical resistanceCircuit susbtrate materialsMetal layered productsEpoxyManganese oxide

The invention relates to an epoxy resin composition which comprises (a) epoxy resin; (b) a hardening agent; and (c) manganese oxide used as inorganic filler.

Owner:TAIWAN POWDER TECH CO LTD

Strong anti-corrosion treatment technique for surface of carbon steel valve

ActiveCN105772370AImprove anti-corrosion performanceEasy to usePretreated surfacesSpecial surfacesEpoxyCross cut

Owner:浙江标盛阀门制造有限公司

Preparation technology of perfluoropolyether for resin

Owner:XUZHOU ZENITH COATING

Resin composition for optical waveguide, dry film, optical waveguide, and photoelectric composite wiring board using same

ActiveUS20140004321A1High transparencyLow coefficient of linear expansionDuplicating/marking methodsDecorative surface effectsEpoxyPolymer science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap