Filler for affinity chromatography

a technology of affinity chromatography and filter, which is applied in the direction of synthetic resin layered products, natural mineral layered products, peptides, etc., can solve the problem of not being able to use affinity chromatography for protein purification repeatedly, and achieve excellent alkali resistance, high dynamic binding capacity of proteins, and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

2. Examples

[0158]Hereinafter, the filler for affinity chromatography of the present invention will be more specifically described by way of Examples. Furthermore, the following descriptions generally illustrate embodiments of the present invention, and the present invention is not intended to be limited by such descriptions without any particular reasons.

2.1. Evaluation Methods

[0159]2.1.1. Epoxy Group Content

[0160]The epoxy group content of the porous particles prior to ligand binding was quantitatively determined by measuring the mass of an aqueous dispersion of porous particles in a polyethylene bottle, the aqueous dispersion of porous particles having a mass concentration that is accurately known at around 10% such that the molar number of epoxy groups calculated from the amount of epoxy group-containing monomer used in the polymerization is 2.00 mmol; adding thereto 25 mL of an aqueous solution of calcium chloride at a concentration of 38% and 2.00 mL of 2 Normal hydrochloric acid;

experimental example

2.2. Experimental Example

2.2.1. Example 1

[0173](i) Suspension Polymerization of Porous Particles

[0174]8.50 g of polyvinyl alcohol (PVA-217 manufactured by Kuraray Co., Ltd.), 0.43 g of sodium dodecyl sulfate (EMAL 10G, manufactured by Kao Corp.), and 21.3 g of sodium sulfate were added to 4251 g of pure water. The mixture was stirred overnight, and thus an aqueous solution (S-1) was prepared. On the day of performing polymerization, 20 g of the solution (S-1) was isolated and set aside.

[0175]Next, 82.4 g of (M-1) glycerol monomethacrylate (manufactured by NOF Corp.), 16.5 g of (M-2) glycidyl methacrylate (manufactured by Mitsubishi Rayon Co., Ltd.), and 65.9 g of (M-3) trimethylolpropane trimethacrylate (manufactured by Sartomer USA LLC.) were dissolved in 246 g of 2-octanone (manufactured by Toyo Gosei Co., Ltd.) and 61.7 g of acetophenone (manufactured by Wako Pure Chemical Industries, Ltd.), and thus a monomer solution was prepared. Further, the numbers of parts of the respective mo

example 2

2.2.2. Example 2

[0216](i) Production of Ligand

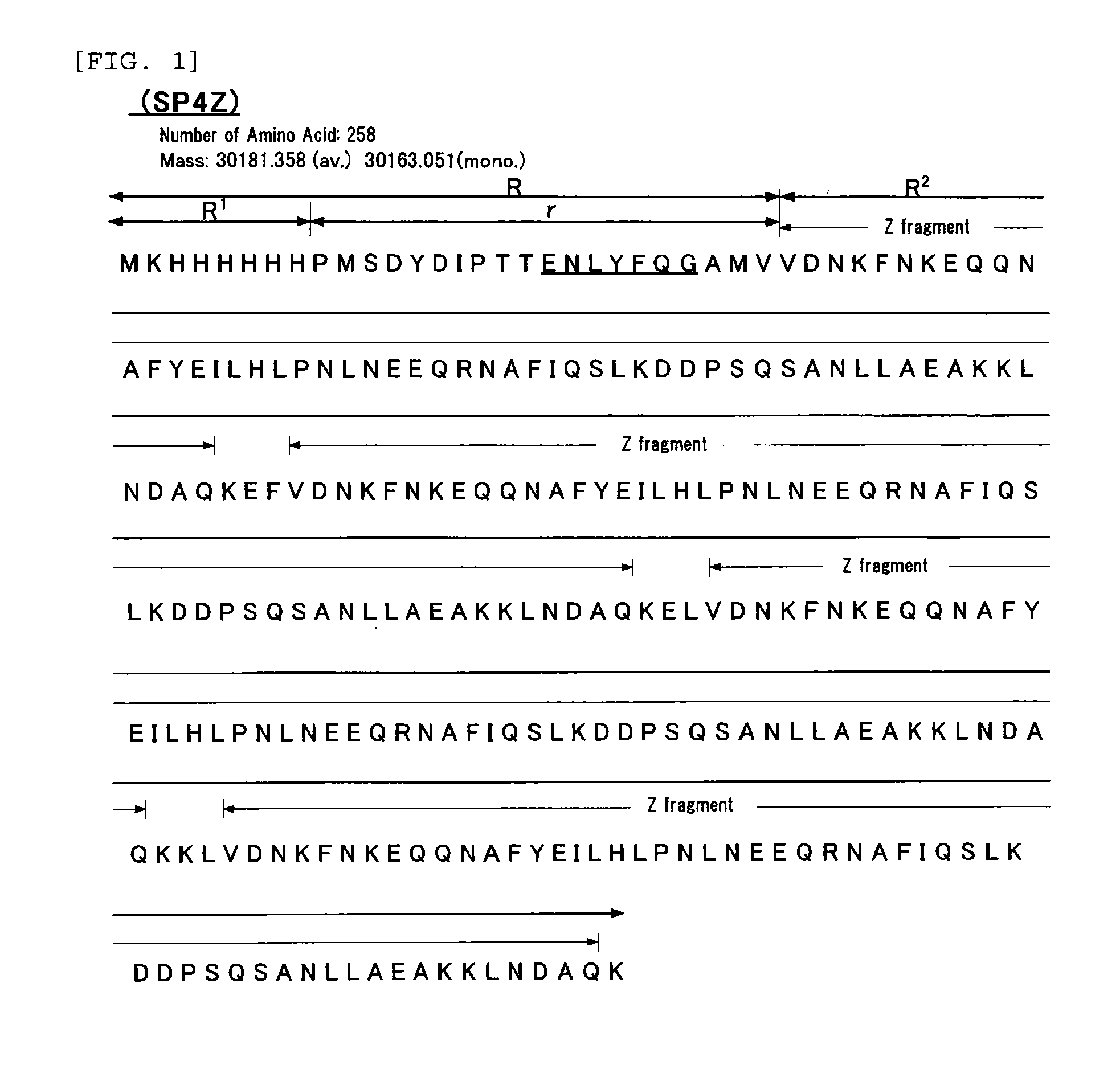

[0217]An immunoglobulin binding protein having the amino acid sequence presented in FIG. 3 (SPATK (SEQ ID NO: 4)) was prepared by Preparation Examples (1) to (5) that will be described below.

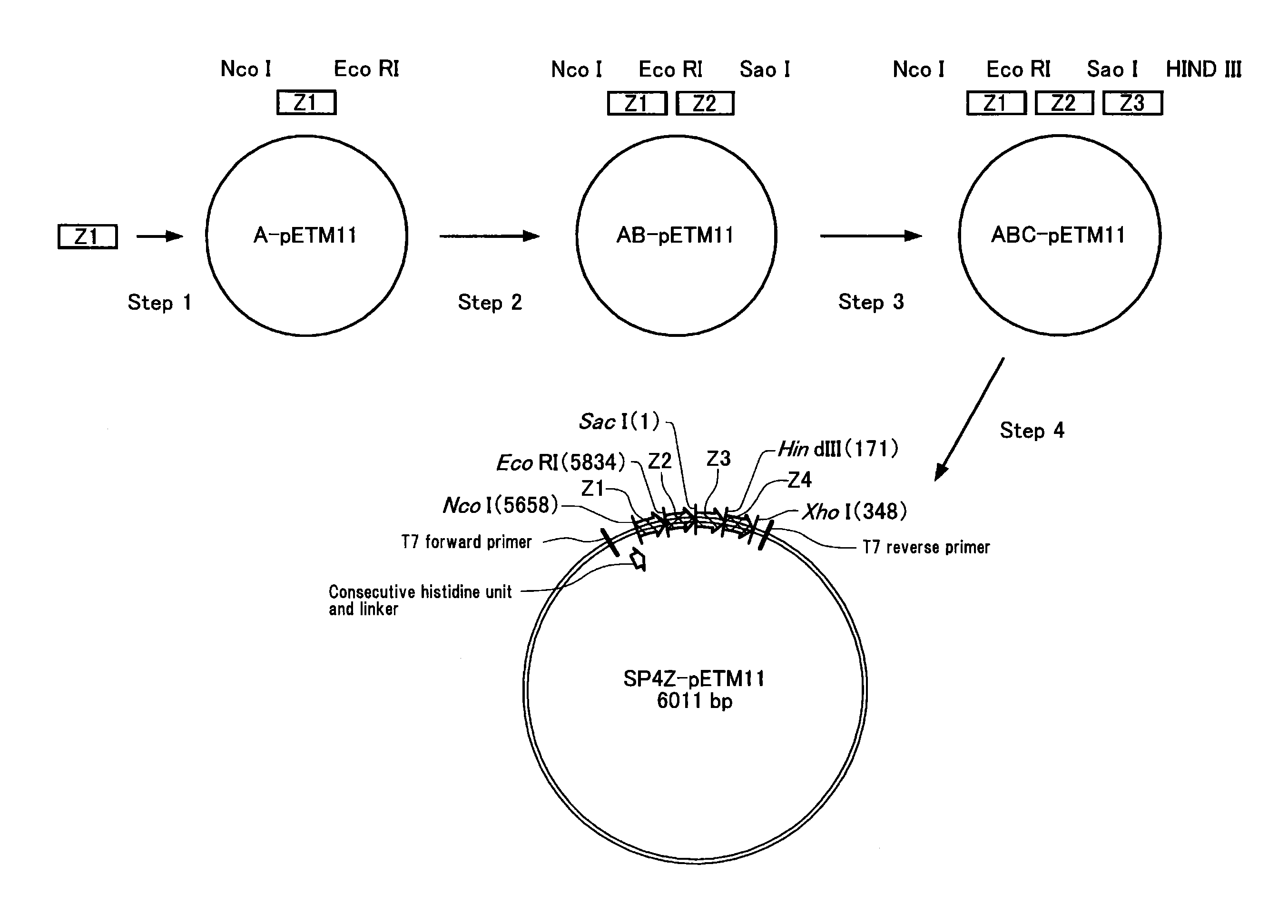

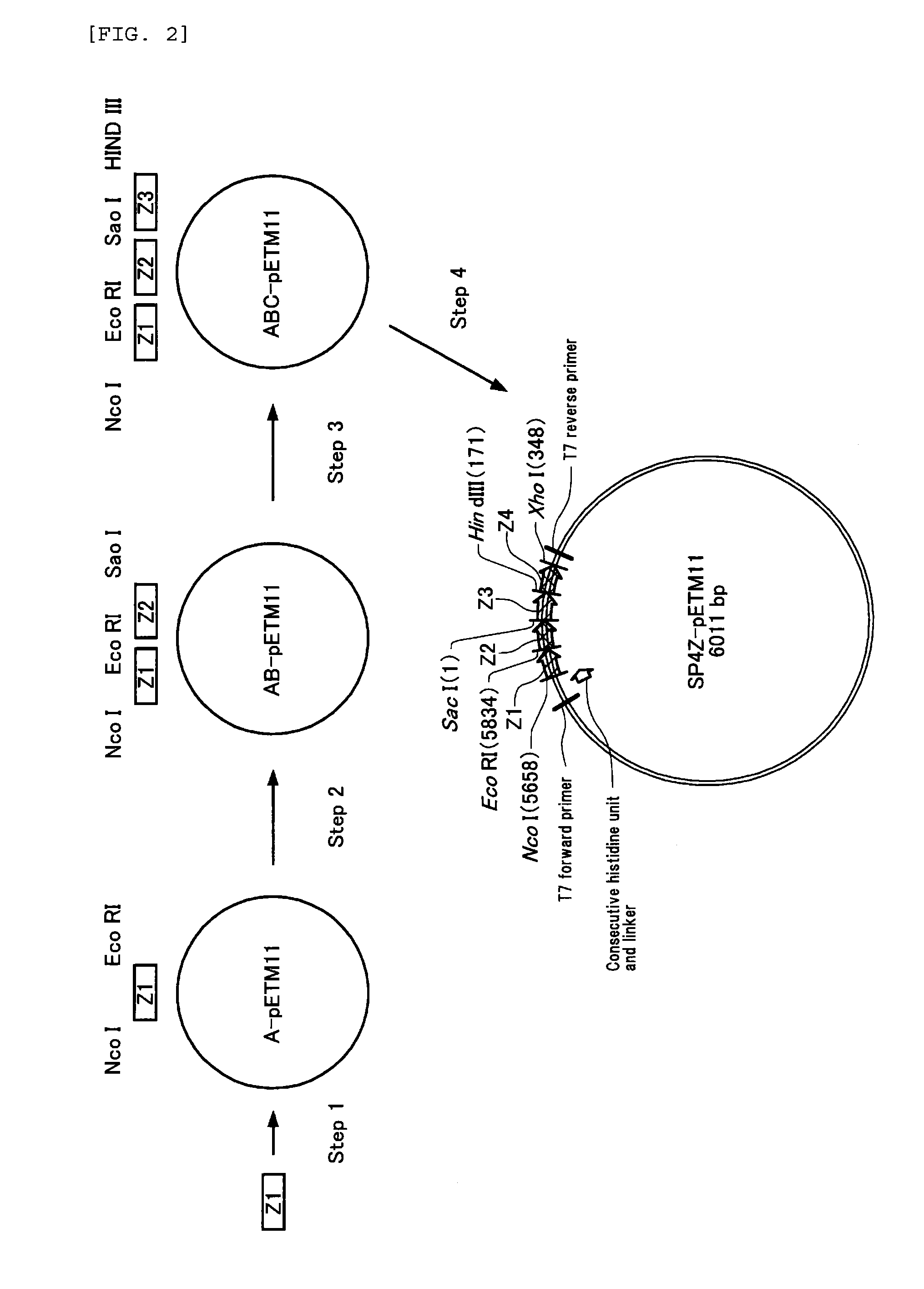

[0218](1) Step 1

[0219]A DNA encoding a D-A domain was obtained by PCR by using the genomic DNA of Staphylococus aureus as a template, and by using a primer having a restriction enzyme NcoI site (Primer 11) and a primer having restriction enzyme BamHI and HindiIII sites (Primer 12). This DNA was cleaved with restriction enzymes NcoI and HindIII, and was ligated to a pETM11 that had been cleaved with the same restriction enzymes NcoI and HindIII. Thus, a SPAK plasmid was constructed.

[0220](2) Step 2

[0221]Next, a DNA encoding a new D-A domain was obtained by PCR by using the SPAK plasmid obtained as described above as a template, and by using a primer having a restriction enzyme BamHI site (Primer 13) and a primer having a restriction enzyme HindIII site (

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap