Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A copolymer is a polymer derived from more than one species of monomer. The polymerization of monomers into copolymers is called copolymerization. Copolymers obtained by copolymerization of two monomer species are sometimes called bipolymers. Those obtained from three and four monomers are called terpolymers and quaterpolymers, respectively.

Bioadhesive compositions and their use in medical electrodes

InactiveUS20070196320A1Poor adhesionImprove skinBiocideNon-fibrous pulp additionBioadhesiveCopolymer

Owner:MANTRA INT

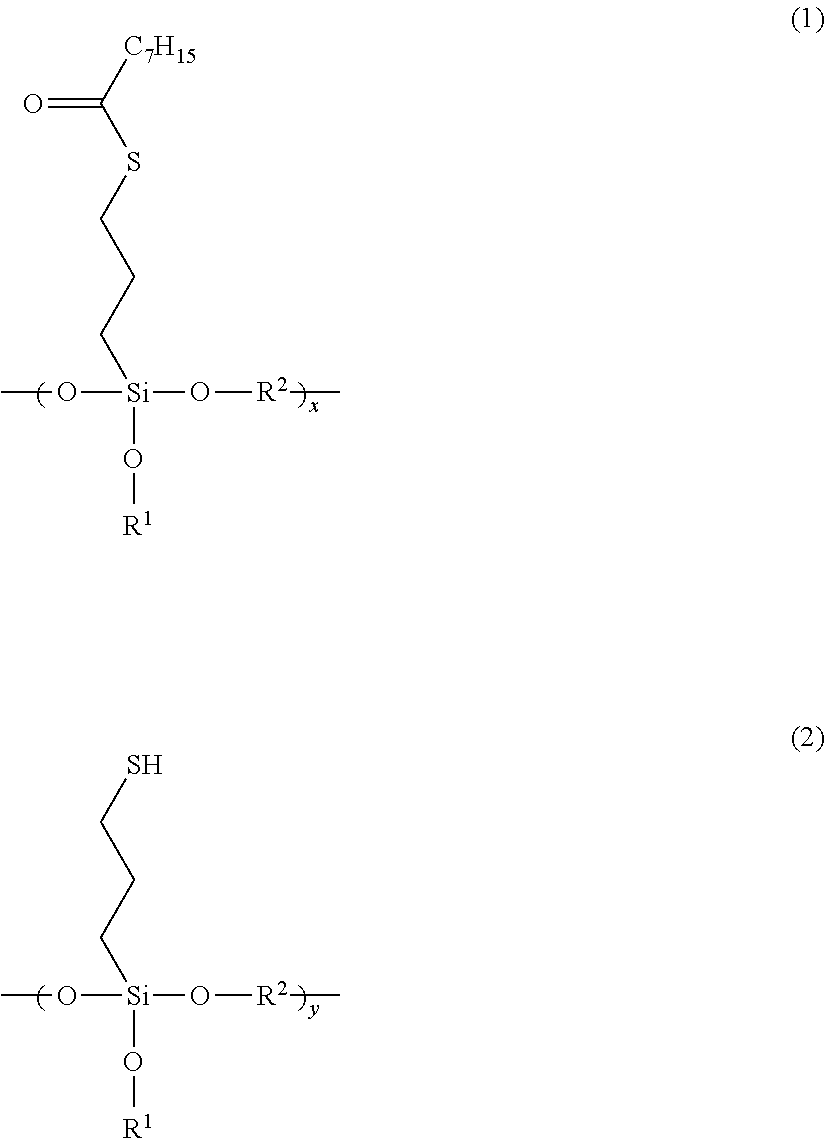

Tire rubber composition and pneumatic tire

InactiveUS20110136962A1Improve wet grip performanceImprove balanceSilicon organic compoundsSpecial tyresPolymer scienceSilicon dioxide

Owner:SUMITOMO RUBBER IND LTD

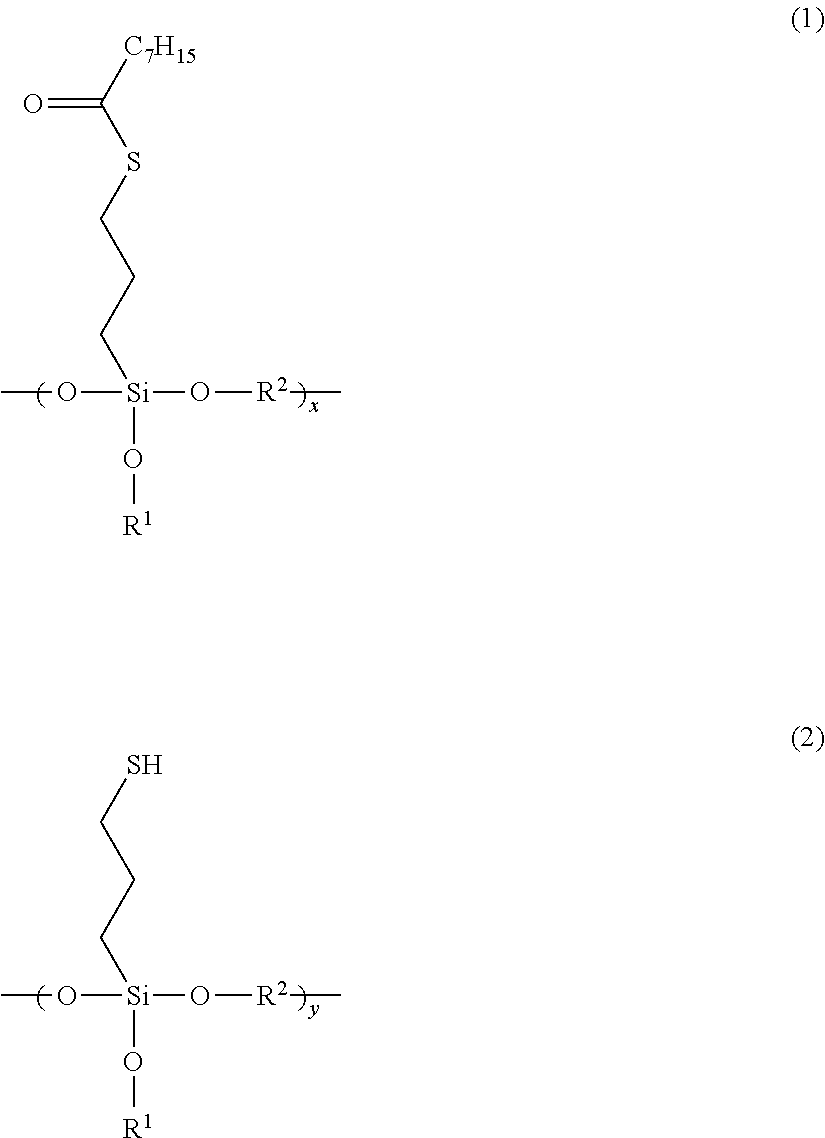

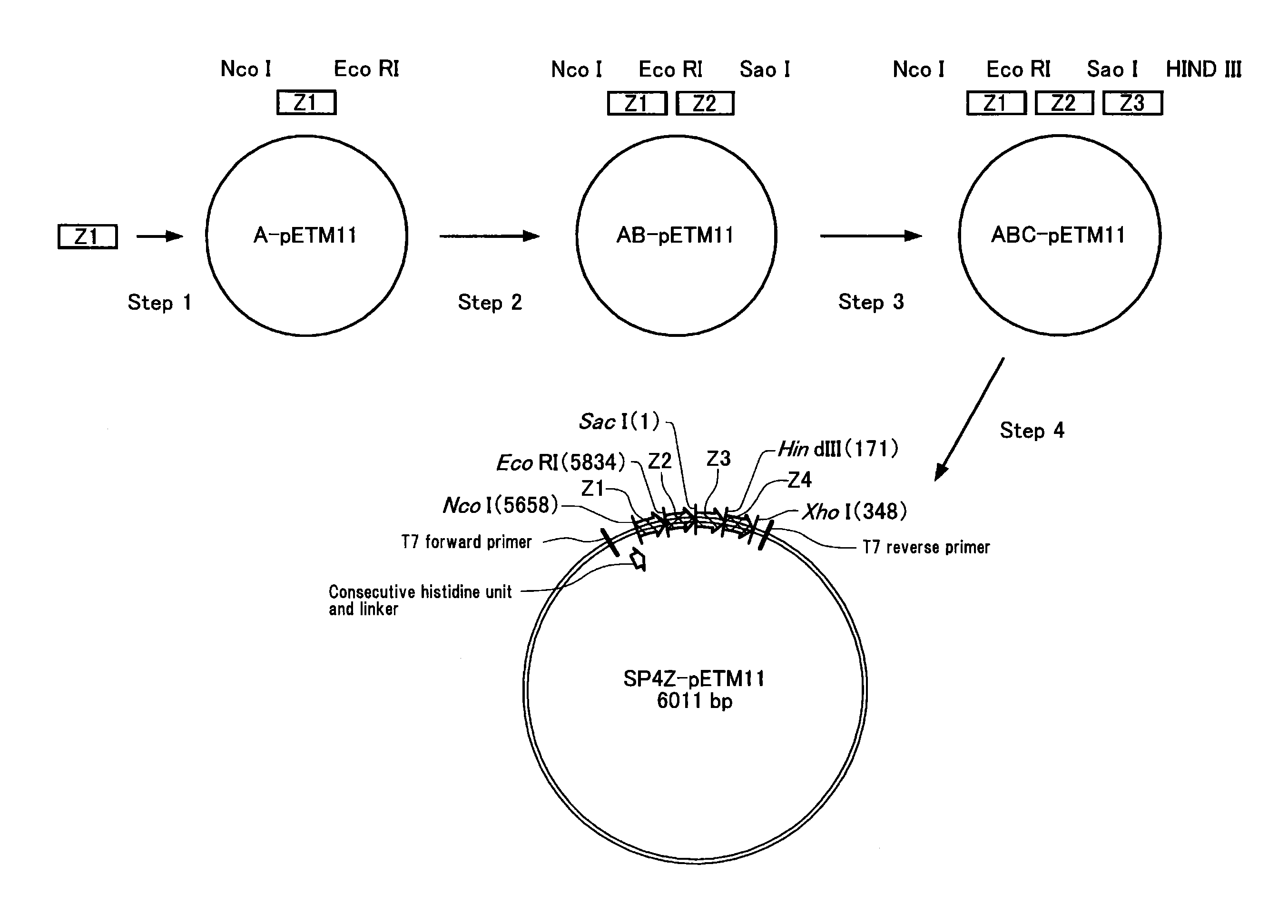

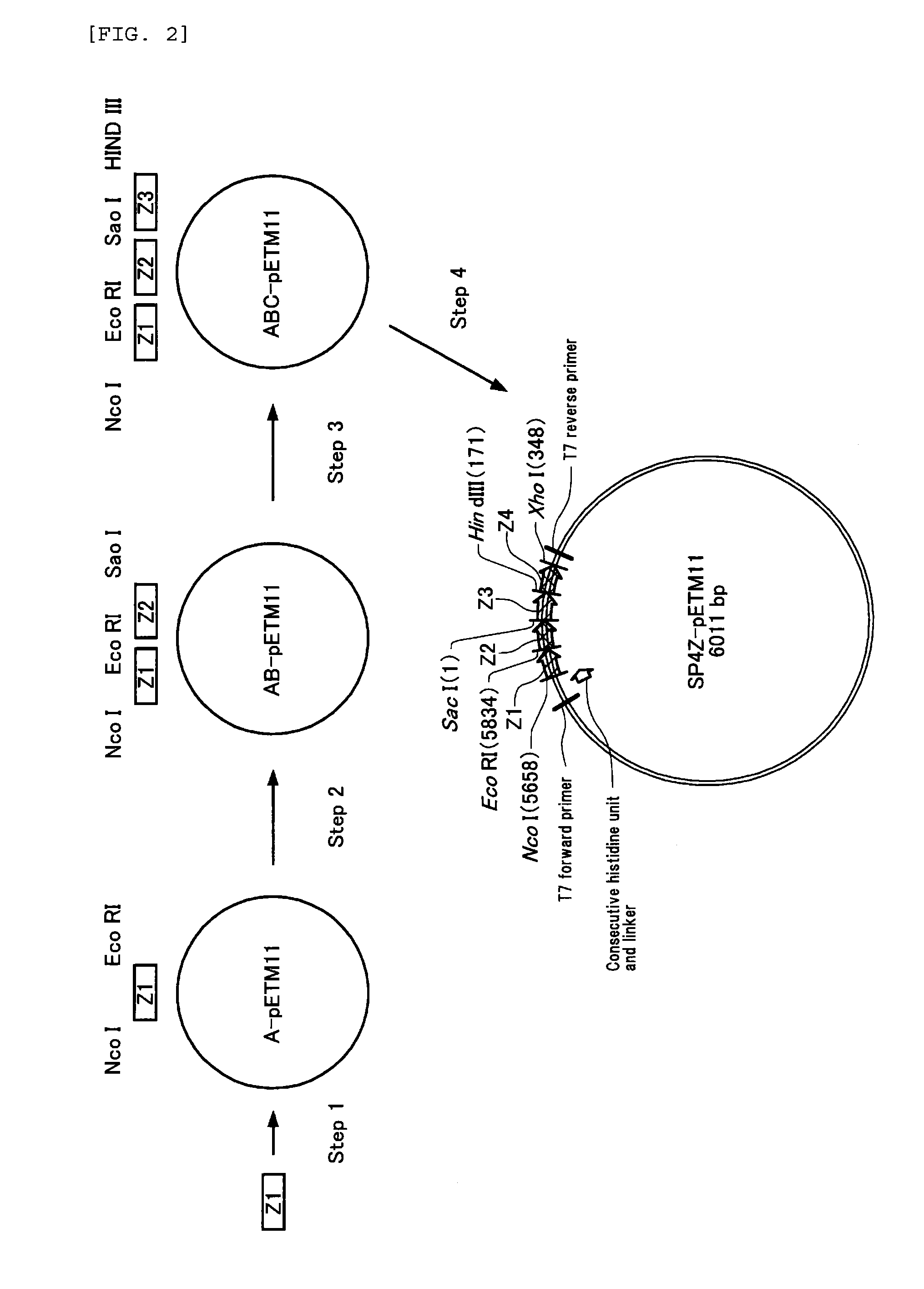

Filler for affinity chromatography

ActiveUS20130085199A1High dynamic binding capacityGood alkali resistanceSolid sorbent liquid separationImmunoglobulinsEpoxyPorous particle

Owner:JSR CORPORATIOON

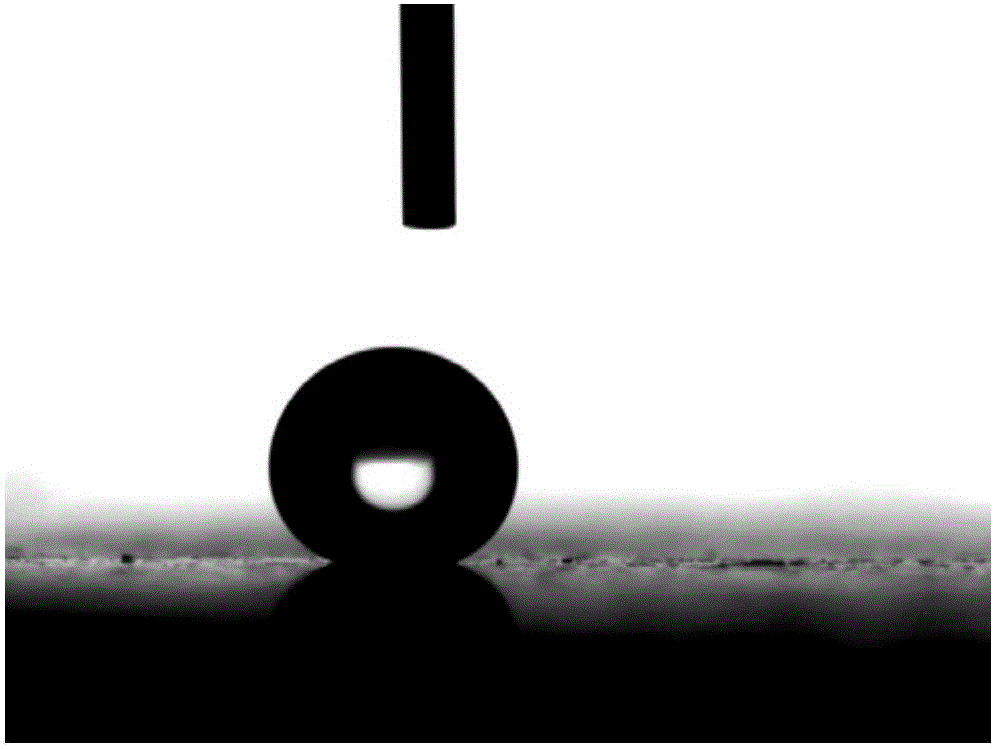

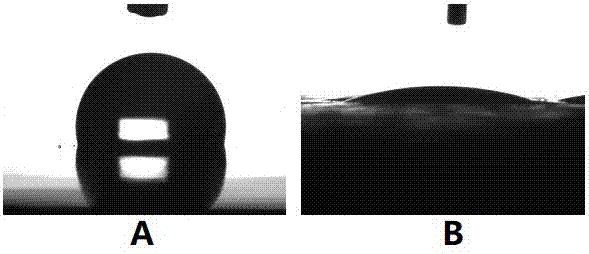

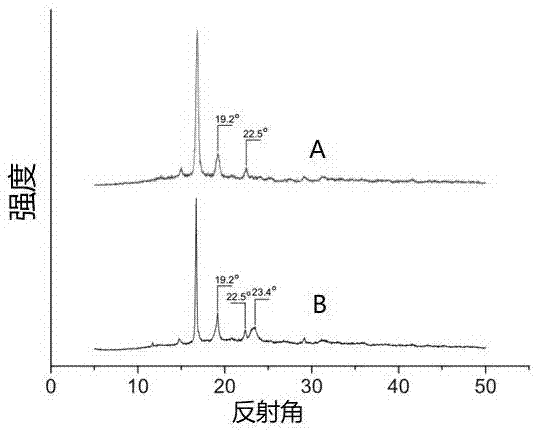

Super-hydrophobic polypropylene film and preparation method thereof

Owner:ZHEJIANG UNIV

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

Foams and methods for making the same

InactiveUS20040001942A1Low compression setReduce loadLayered productsThin material handlingPolymer chemistryCopolymer

A foam profile prepared by a process comprising the steps of foaming a thermoplastic vulcanizate, where the thermoplastic vulcanizate is prepared by a process comprising the step of dynamically vulcanizing a rubber within a mixture that includes from about 15 to about 95 percent by weight of the rubber and from about 5 to about 85 percent by weight of a thermoplastic component based upon the total weight the rubber and thermoplastic component combined, where the thermoplastic component includes from about 65 to about 90 percent by weight of a conventional thermoplastic resin and from about 10 to about 35 percent by weight of a random propylene copolymer based upon the total weight of the thermoplastic component.

Owner:ADVANCED ELASTOMER SYST LP

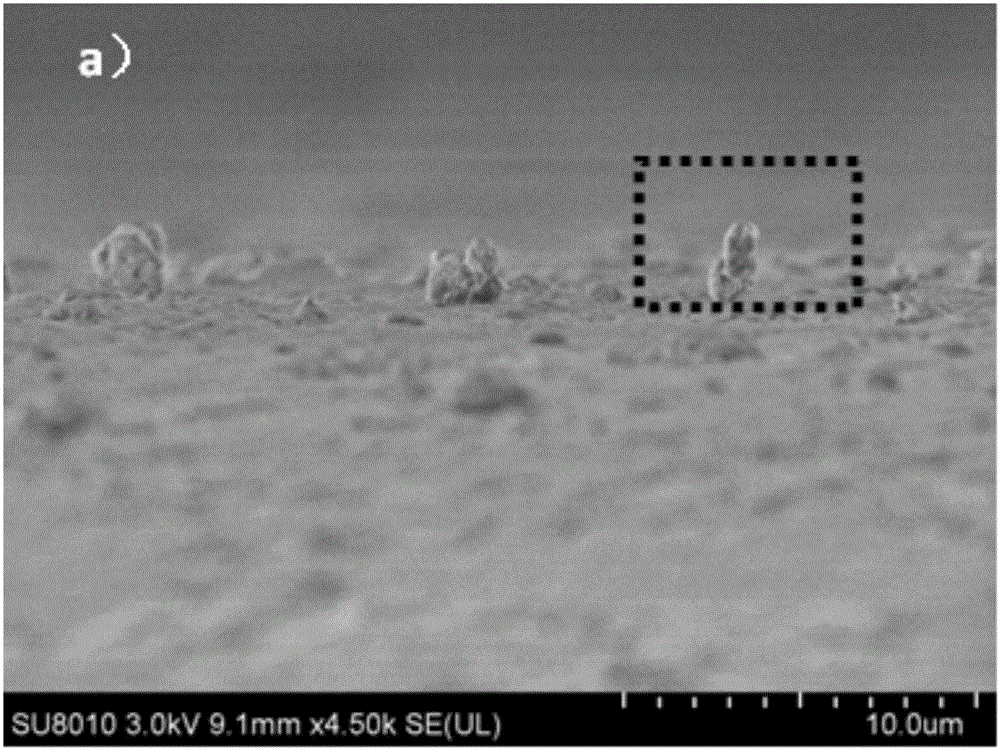

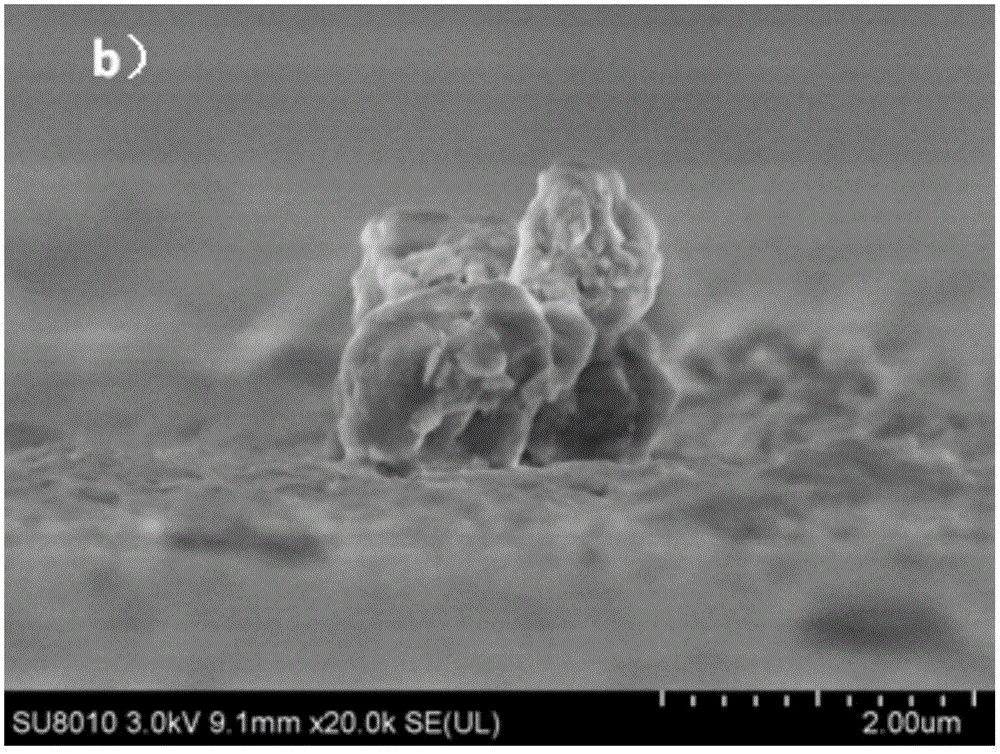

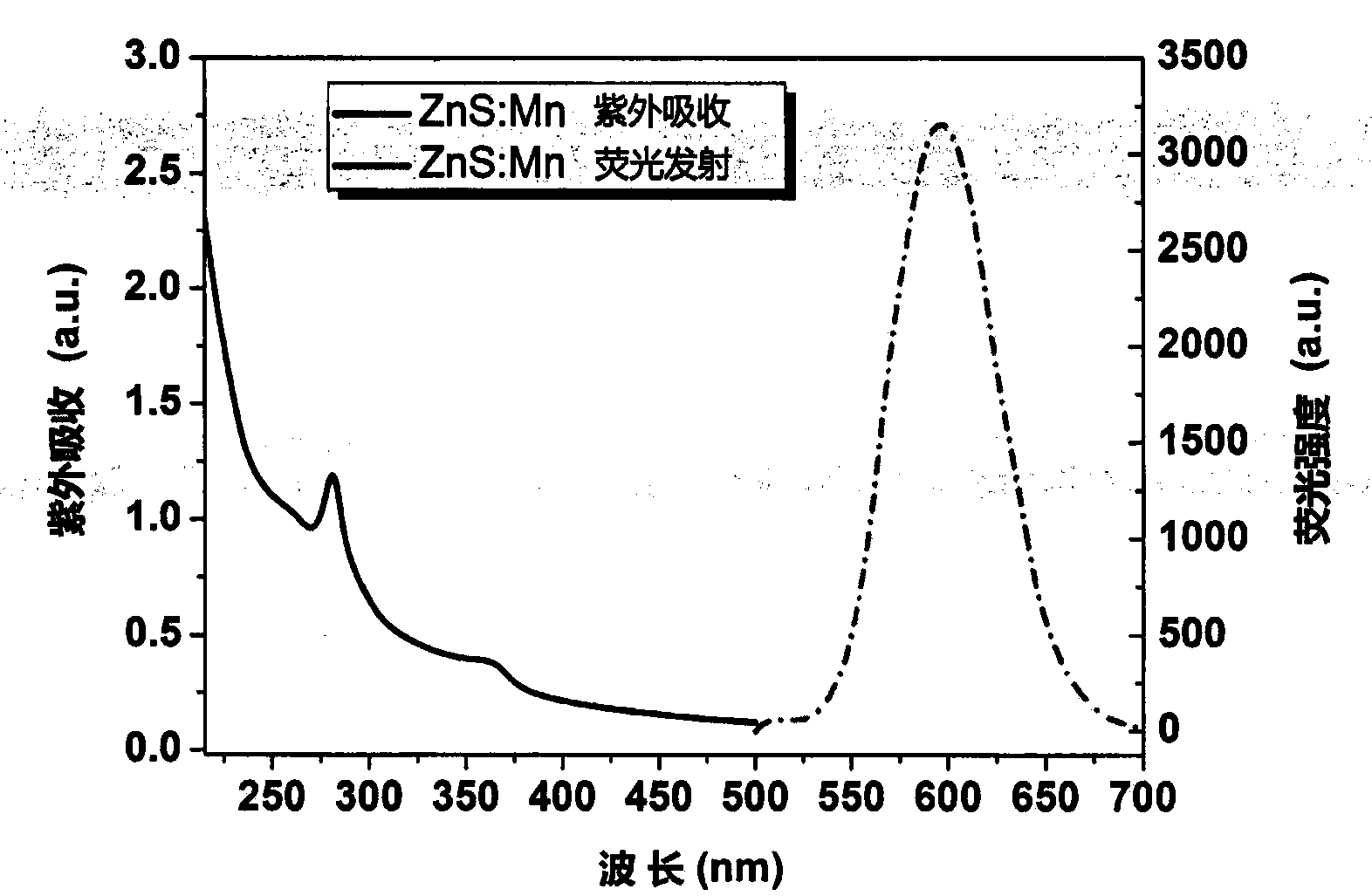

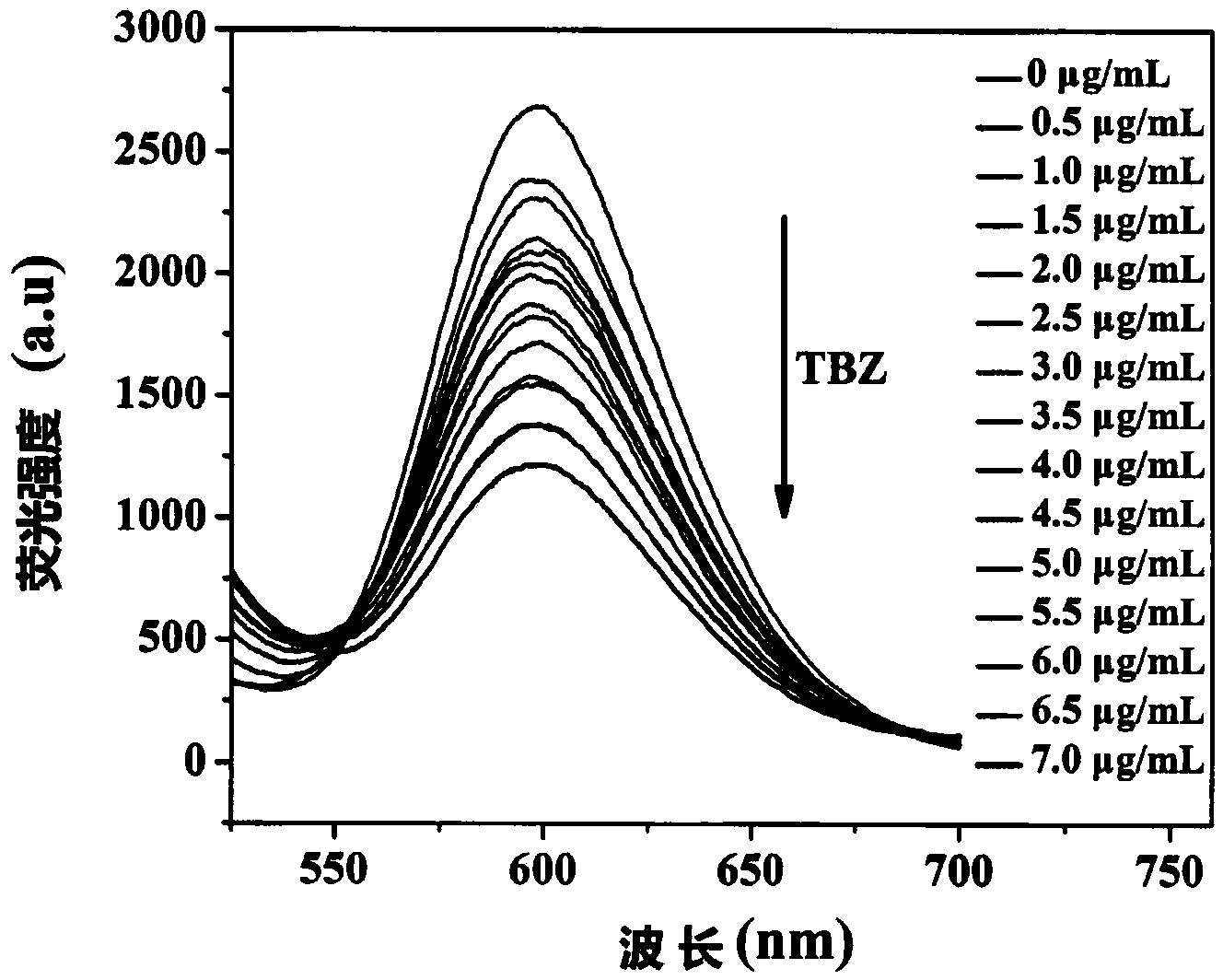

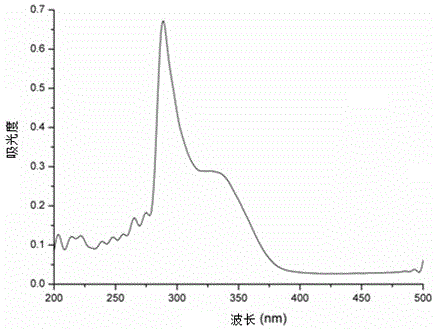

Building method of molecularly imprinted fluorescent probe, and application thereof in benzimidazole detection

InactiveCN103709433AHigh sensitivityImprove featuresFluorescence/phosphorescenceMicrosphereQuenching

Owner:TIANJIN POLYTECHNIC UNIV

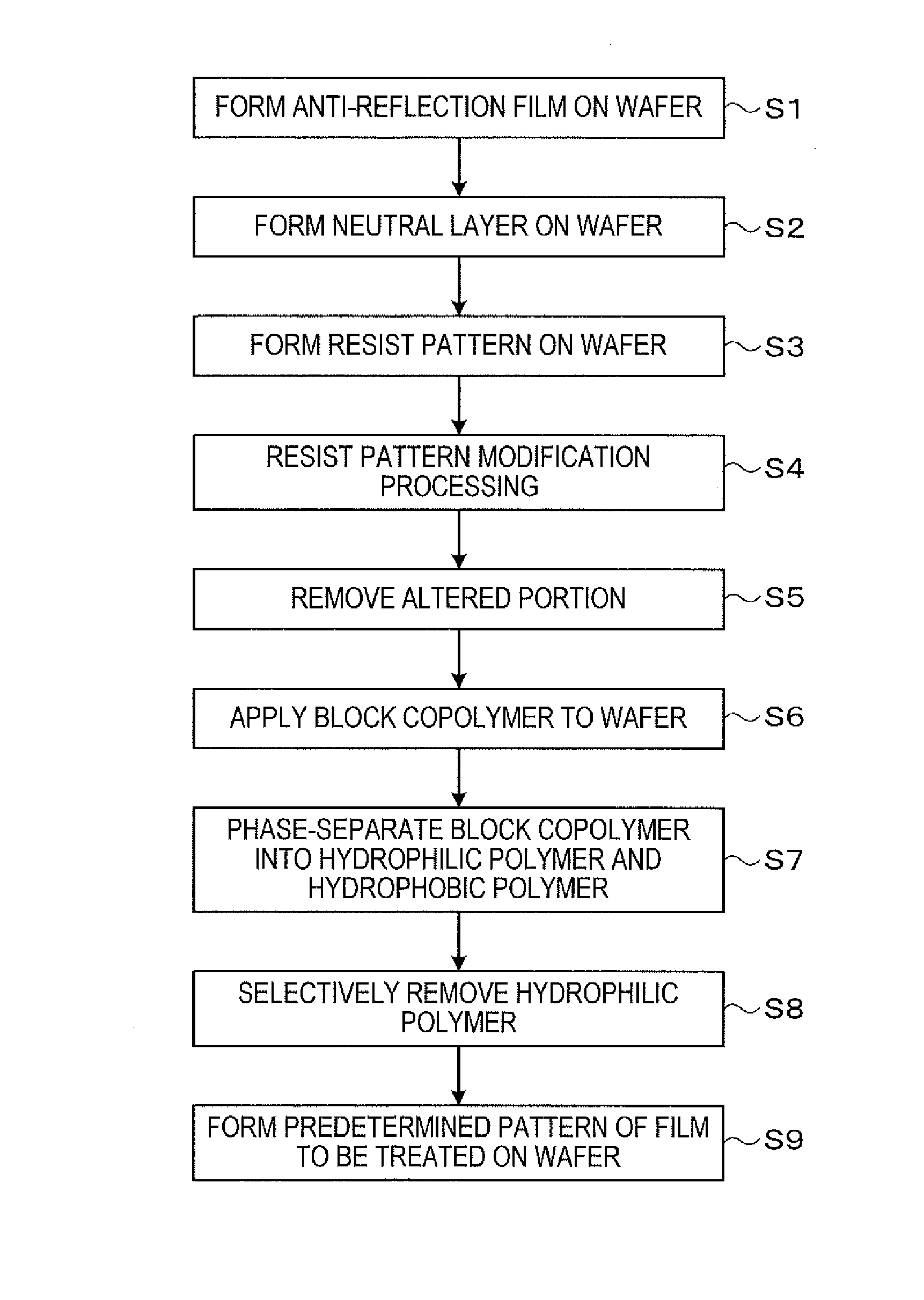

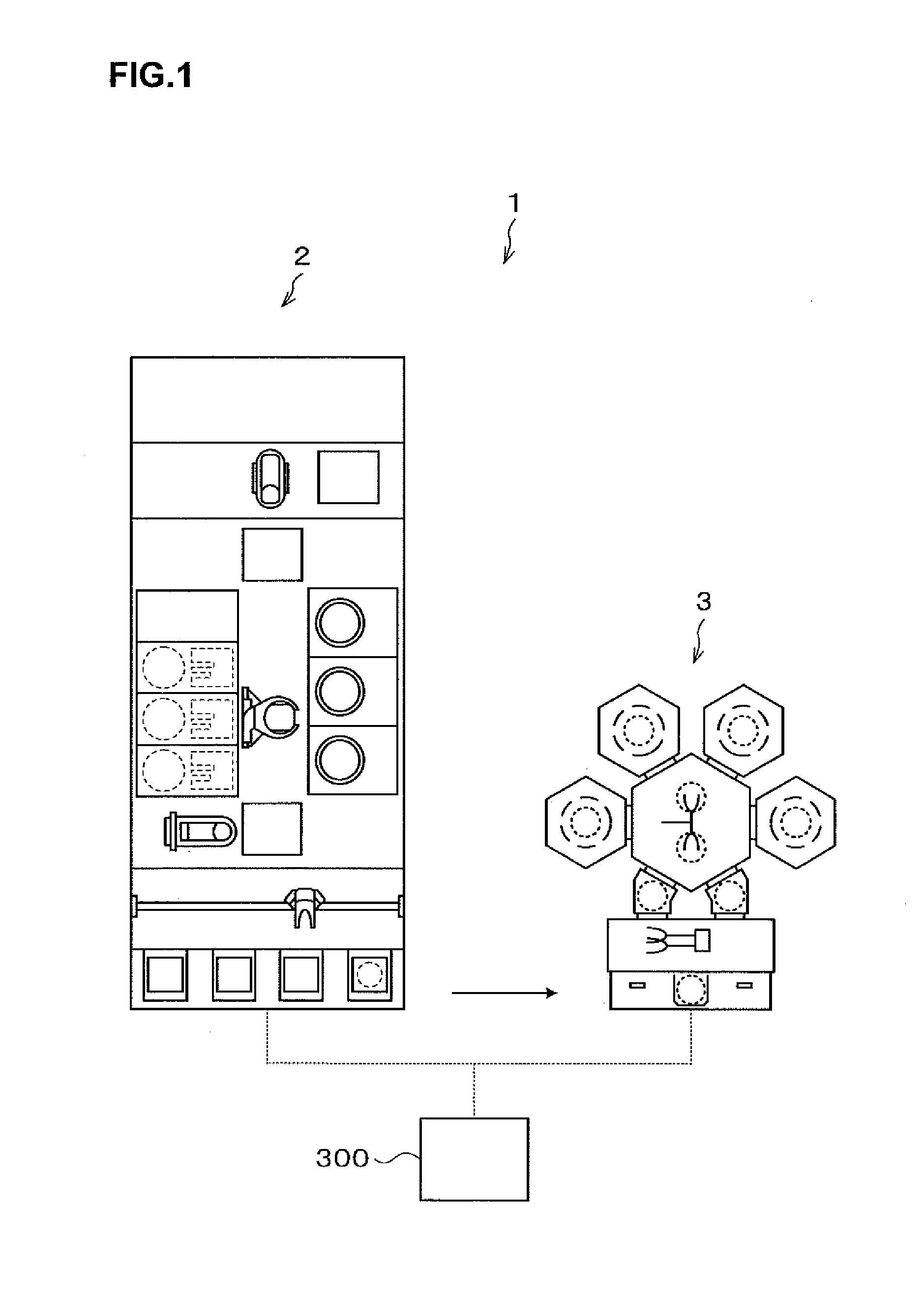

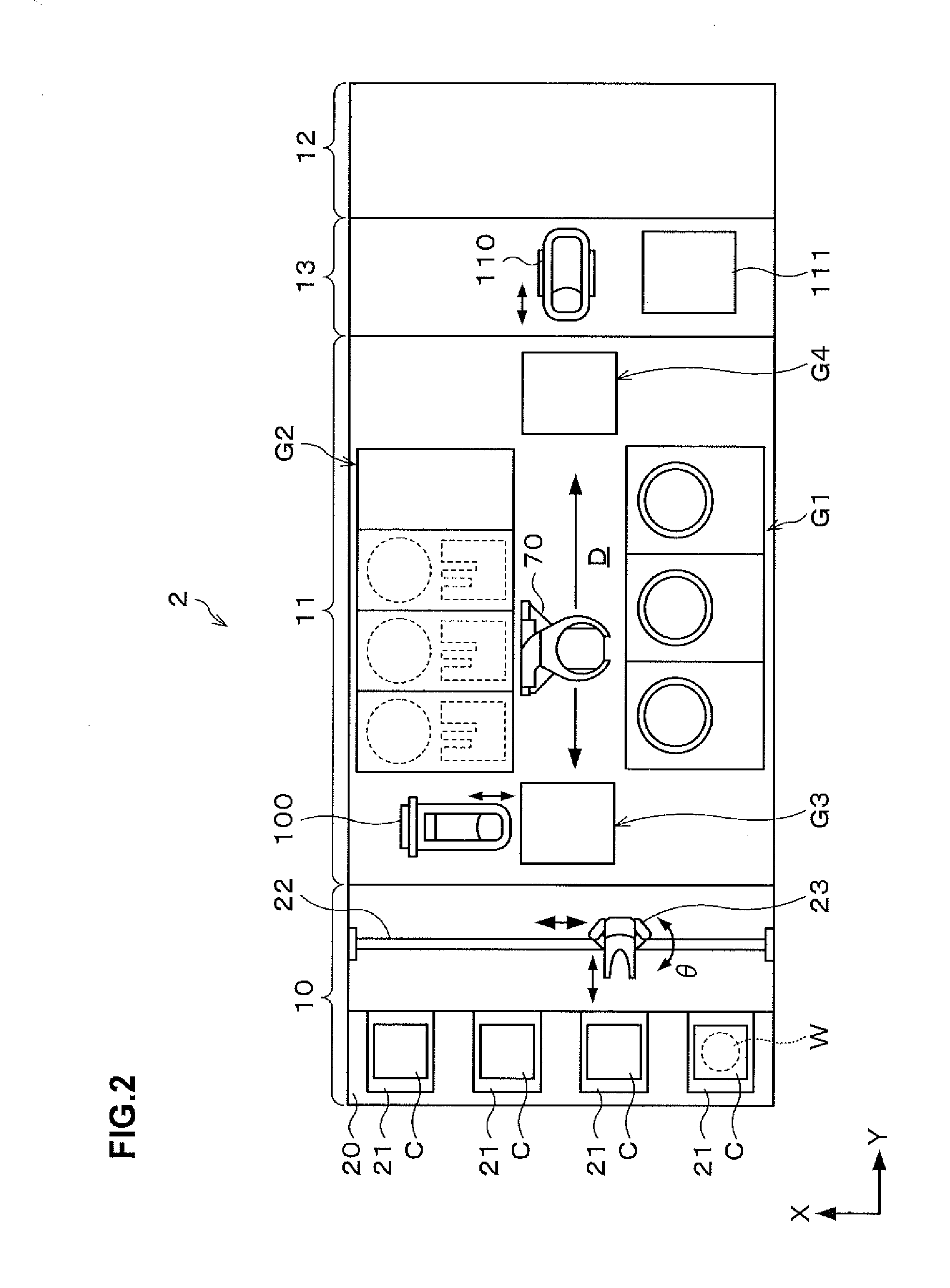

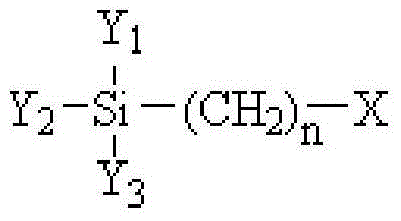

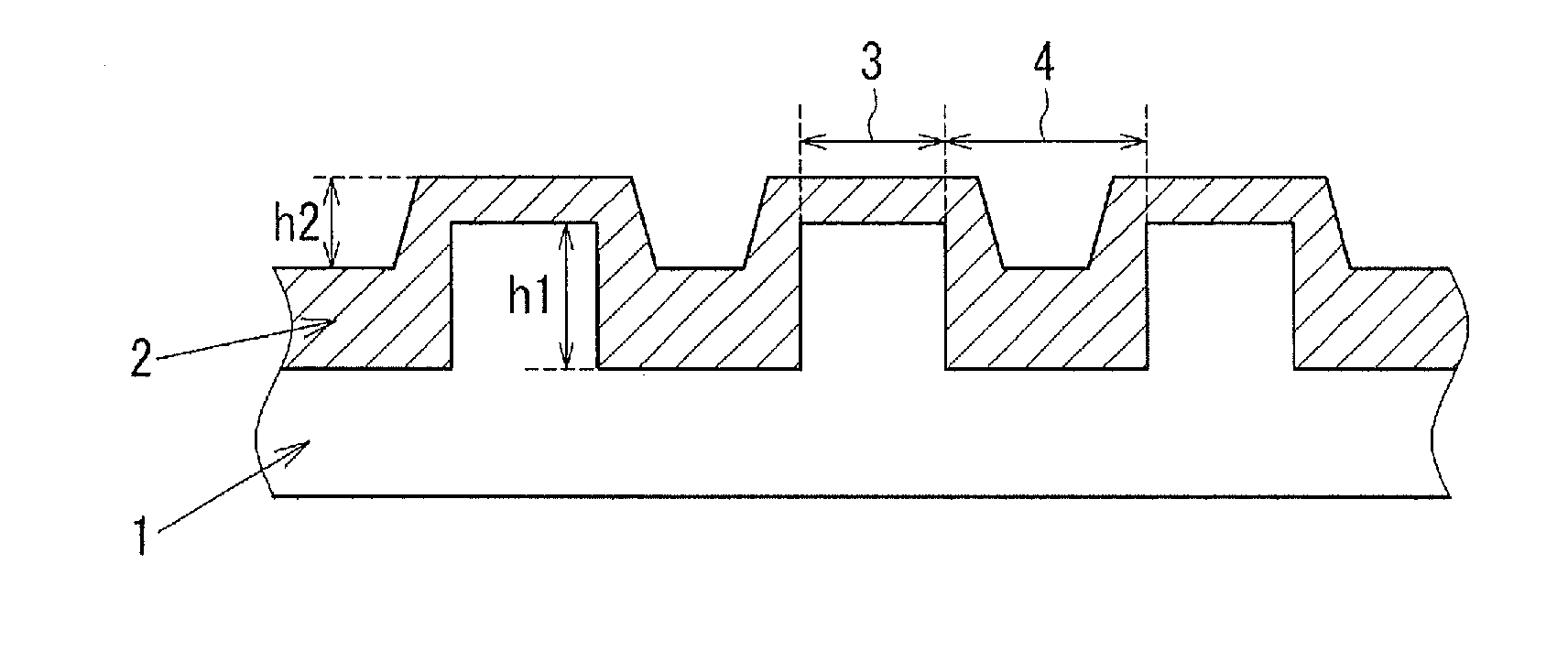

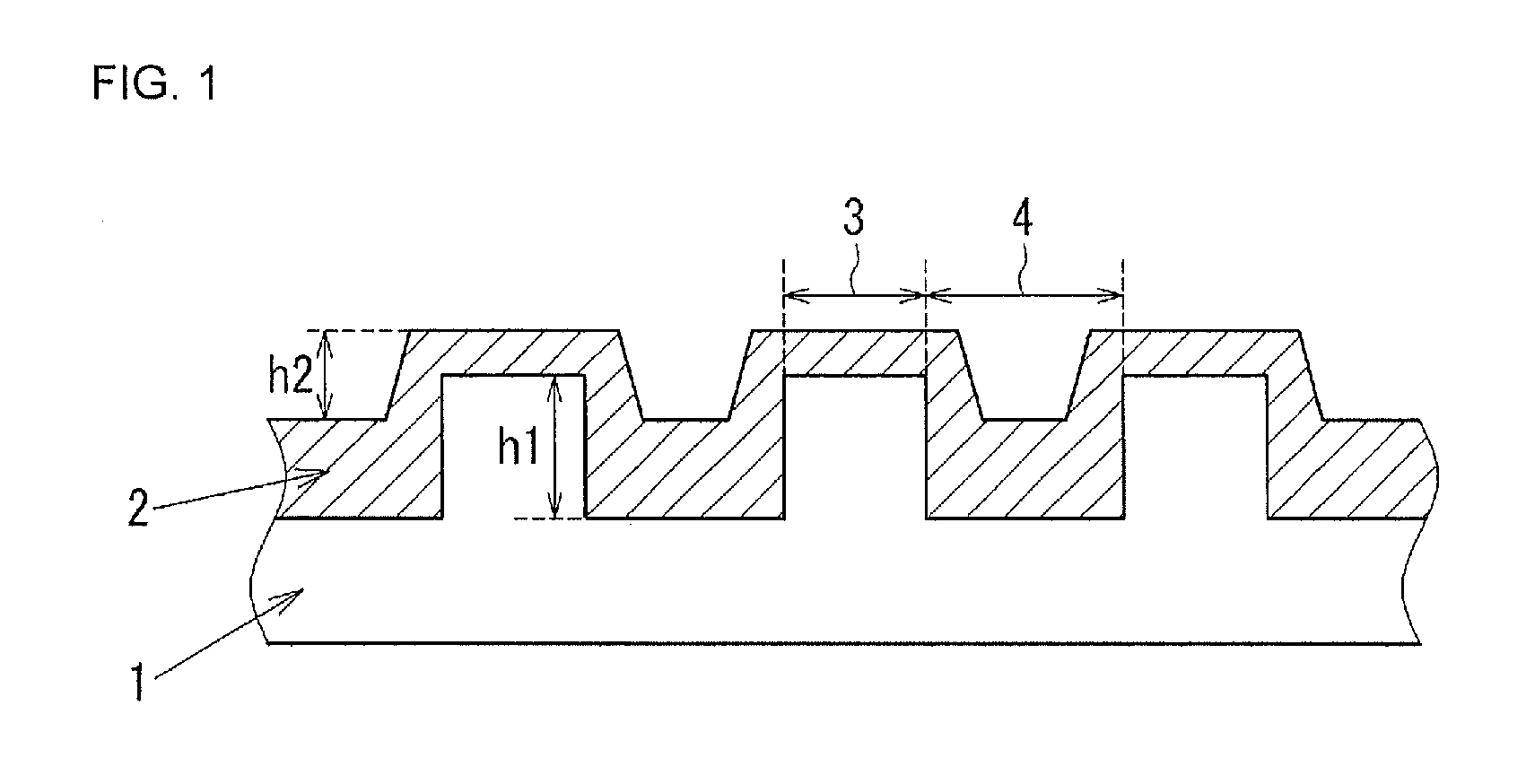

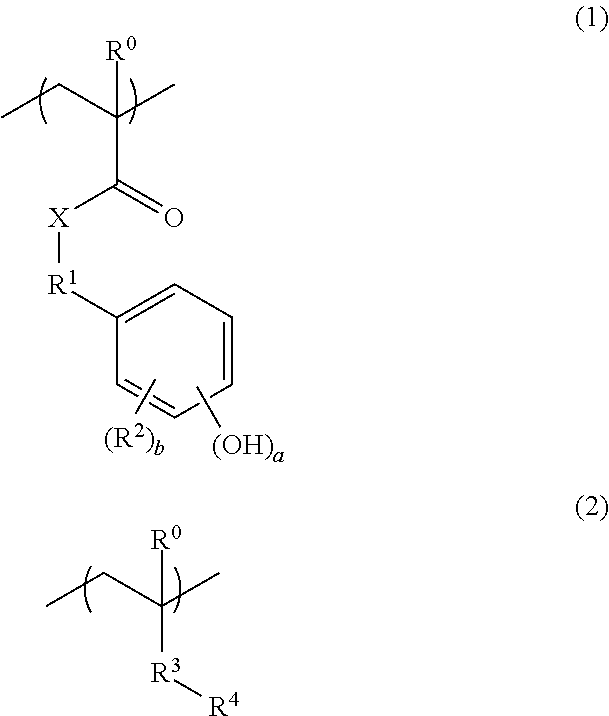

Substrate treatment method, computer storage medium, and substrate treatment system

ActiveUS20150255271A1Electric discharge tubesSemiconductor/solid-state device manufacturingResistHydrophilic polymers

Owner:TOKYO ELECTRON LTD

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

Method of Treating Paper Forming Wire Surface

ActiveUS20120043040A1Non-fibrous pulp additionFats/resins/pitch/waxes removal in pulpPolymer sciencePolyethylene glycol

A method for inhibiting resinous and sticky substances from filling or forming deposits on or within papermaking forming wire, by applying to said wire an effective inhibiting amount of a composition comprising at least one cationic agent selected from the group consisting of (a) cationic polyureas, (b) hydrophobically modified cationic polymers, (c) alkylammonium or / and alkylimidazolium salts, and optionally at least one nonionic amphiphilic copolymer selected from (i) hydrophobically modified polyethylene glycols], (ii) hydrophobically modified cellulose ethers, (iii) copolymers of vinyl alcohol and vinyl alkonate, (iv) polyoxyalkylene block copolymers, and (v) hydrophilically modified polydimethylsiloxanes.

Owner:SOLENIS TECH CAYMAN

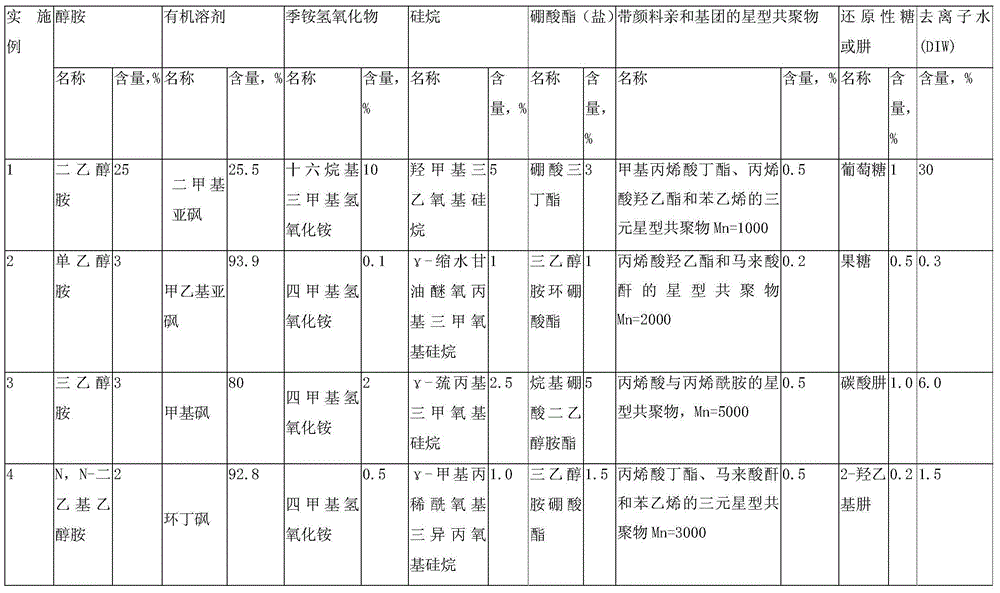

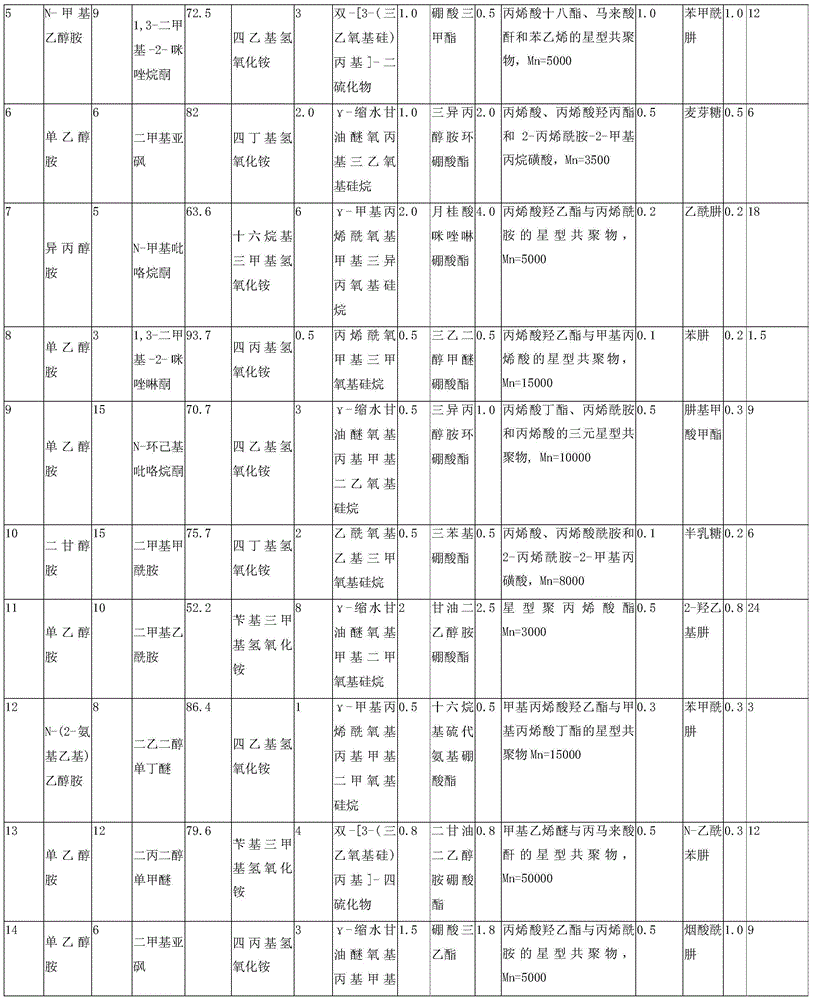

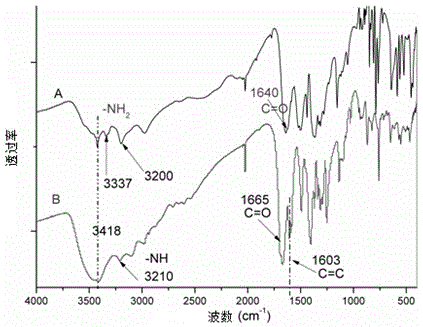

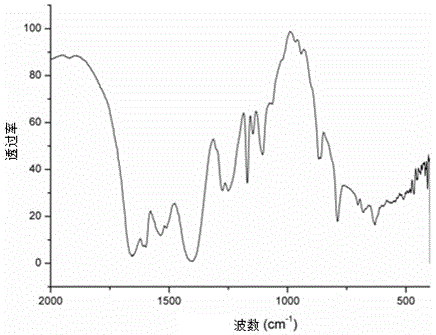

Photoresist cleaning fluid

InactiveCN105527802AEfficient removalLarge operating windowPhotosensitive material processingSilanesSolvent

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Decomposable environmentally-friendly heat-insulation packaging bag

Owner:桐城市人和包装有限公司

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

Preparation method of ternary terbium complex monomer and copolymer luminescent material of ternary terbium complex monomer and MMA

InactiveCN105061481AImprove internal quantum efficiencyHigh color purityGroup 3/13 element organic compoundsLuminescent compositionsN dimethylformamideFluorescence

Owner:CHONGQING UNIV OF TECH

Curved lenses configued to decode three-dimensional content

Owner:SCHLUMBERGER TECH CORP

Non-photosensitive resin composition

ActiveUS20150338556A1Good chemical resistanceImprove heat resistanceOptical filtersOptical articlesEpoxyOrganic group

Owner:NISSAN CHEM IND LTD

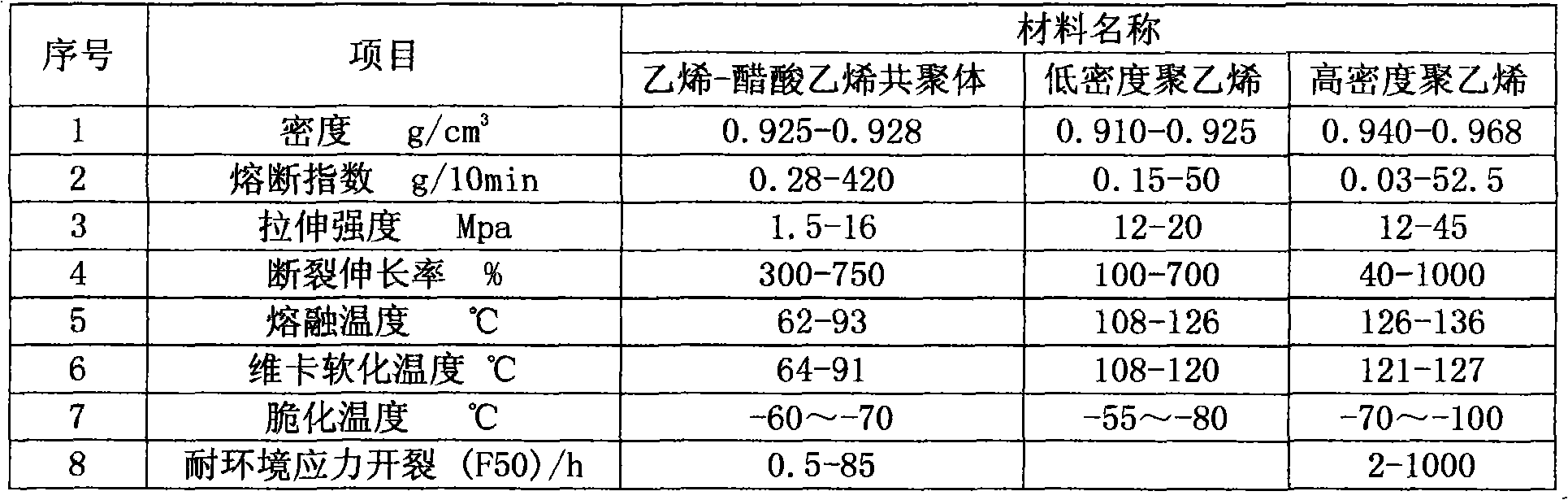

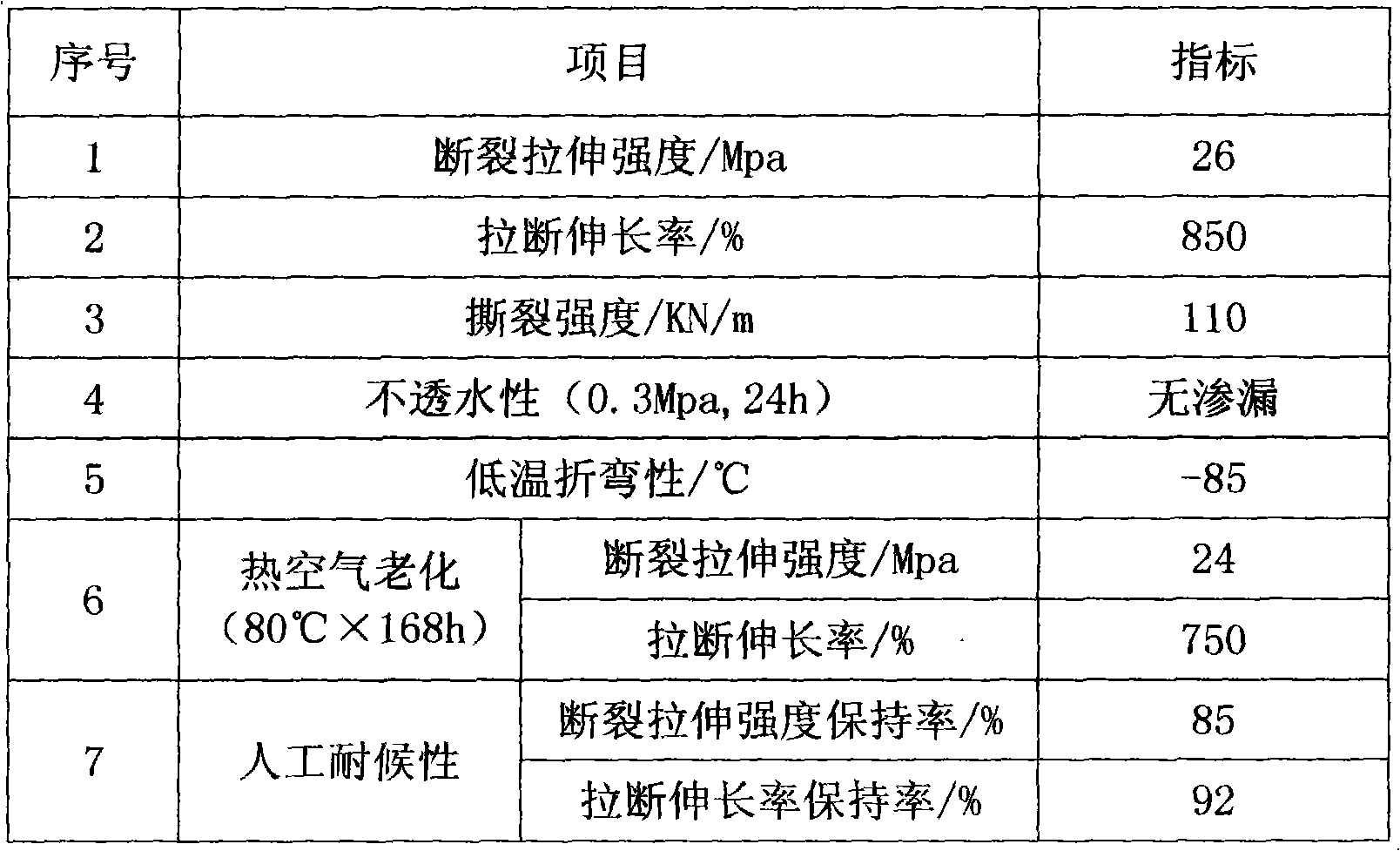

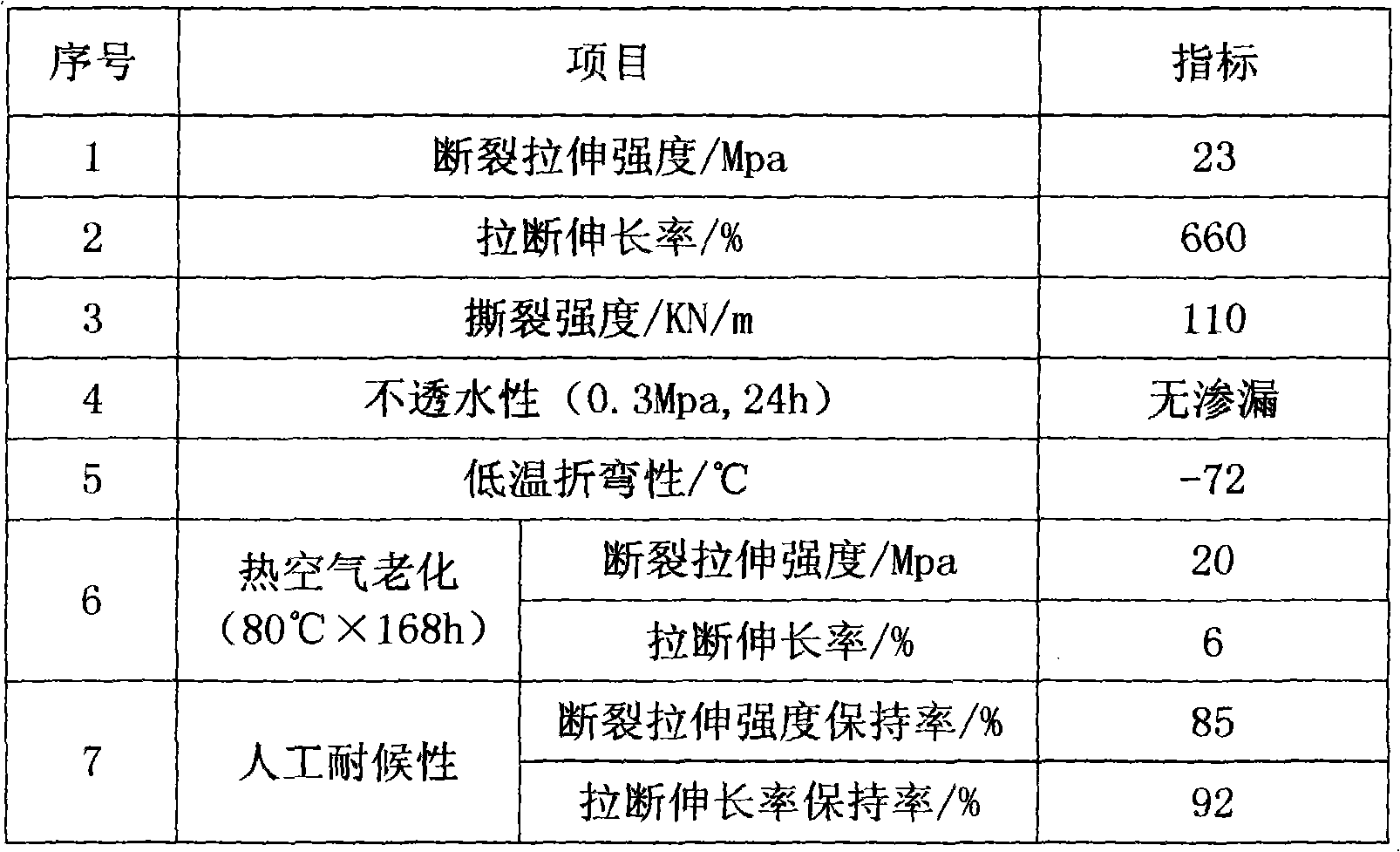

High-temperature-resistant and corrosion-resistant waterproof board for tunnels and production process thereof

ActiveCN103541745AEasy to useImprove toughnessUnderground chambersSynthetic resin layered productsGround temperatureAntioxidant

Owner:HONGXIANG NEW GEO MATERIAL

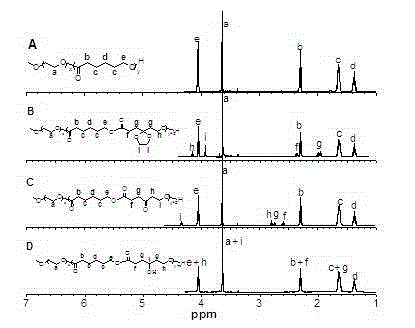

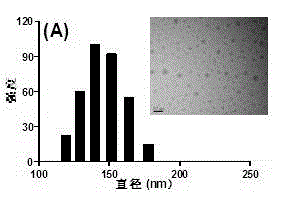

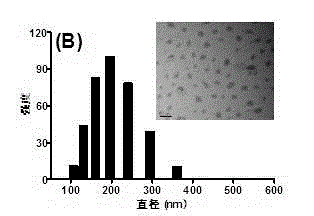

Water-soluble hypocrellin PLGA nanoparticle and preparation method thereof

InactiveCN103933568AGood biocompatibilitySmall particlesPowder deliveryEnergy modified materialsSolubilitySide effect

The invention relates to the technical field of medicines, and particularly relates to a water-soluble hypocrellin PLGAnanoparticle and a preparation method thereof. The preparation method comprises the following steps: by taking poly(lactic-co-glycolic acid) (PLGA) as a carrier, dissolving PLGA and hypocrellin into an organic solvent to prepare an oil phase, adding into freeze-drying excipient-containing water phase under high-speed stirring, and finally obtaining the hypocrellin nanoparticle by adopting an emulsification freeze-drying method. By using a biodegradable medical polymer material PLGA used in the preparation method and approved by the food and drug administration (FDA) of the United States, the toxic and side effects of a common drug-carrying material can be reduced, the water solubility of the drug can be improved, the particle size of the prepared nanoparticle ranges from 20-200nm, the drug has red shift, the absorption of the nanoparticle in a phototherapy window (600-900nm) can be increased, and the dark toxicity of the drug can be reduced. The preparation method is simple in raw materials and easy to operate.

Owner:NANJING NORMAL UNIVERSITY

Polyester/polyethyleneglycol block copolymer containing hydroxyl pendant group and application of polyester/polyethyleneglycol block copolymer

InactiveCN102911348AGood biocompatibilityPromote degradationPowder deliveryPharmaceutical non-active ingredientsPolyesterPolymer science

Owner:TIANJIN UNIV

Photovoltaic glass panel surface layer anti-damping coating and preparation method thereof

ActiveCN107163783AWith lotus leaf effectDoes not affect the photovoltaic conversion rateAntifouling/underwater paintsPaints with biocidesSilicon dioxideCopolymer

Owner:广东拓扑中润科技发展有限公司

Wear-resistant and high-temperature resistant capacitor aluminum case film coating paint and preparation method thereof

InactiveCN102373006AEffective protectionExtended service lifePolyurea/polyurethane coatingsMeth-Ketone

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

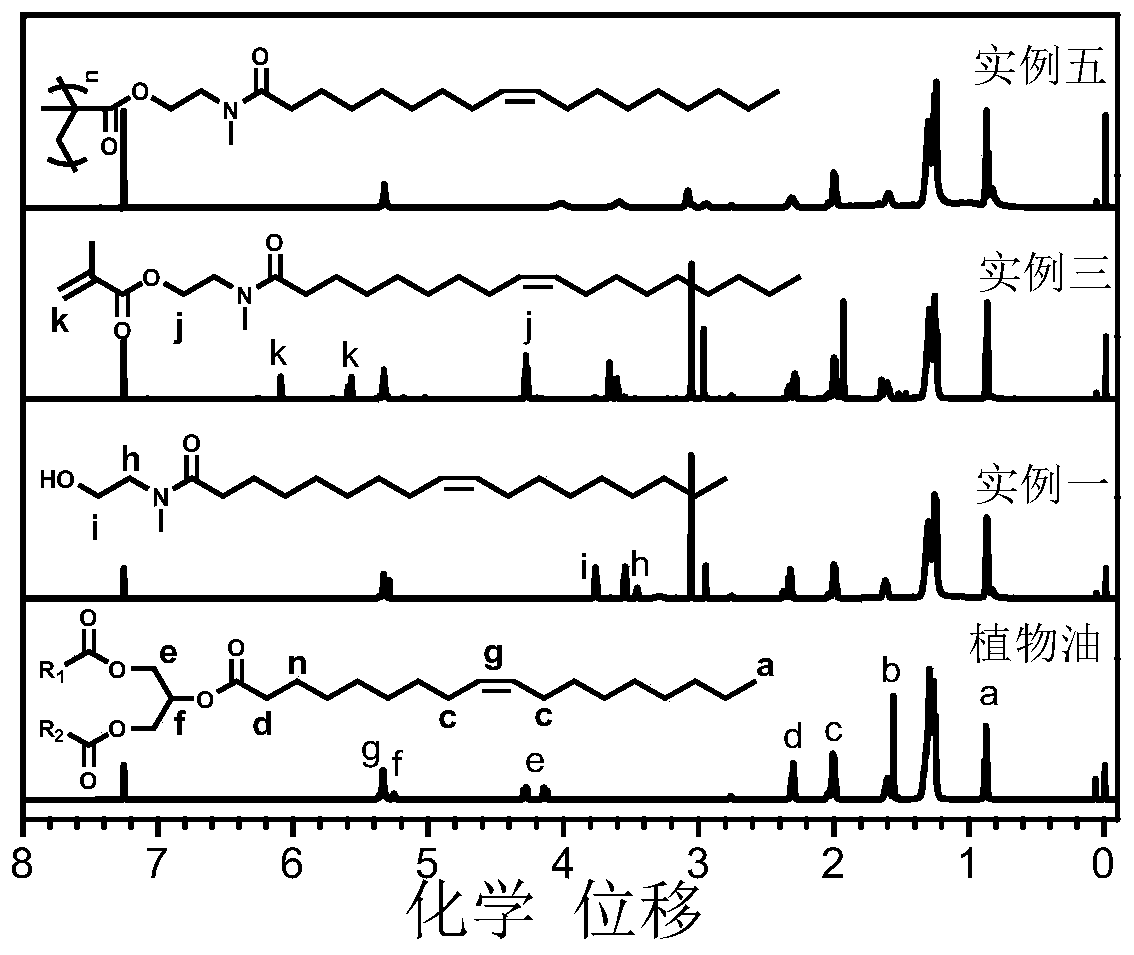

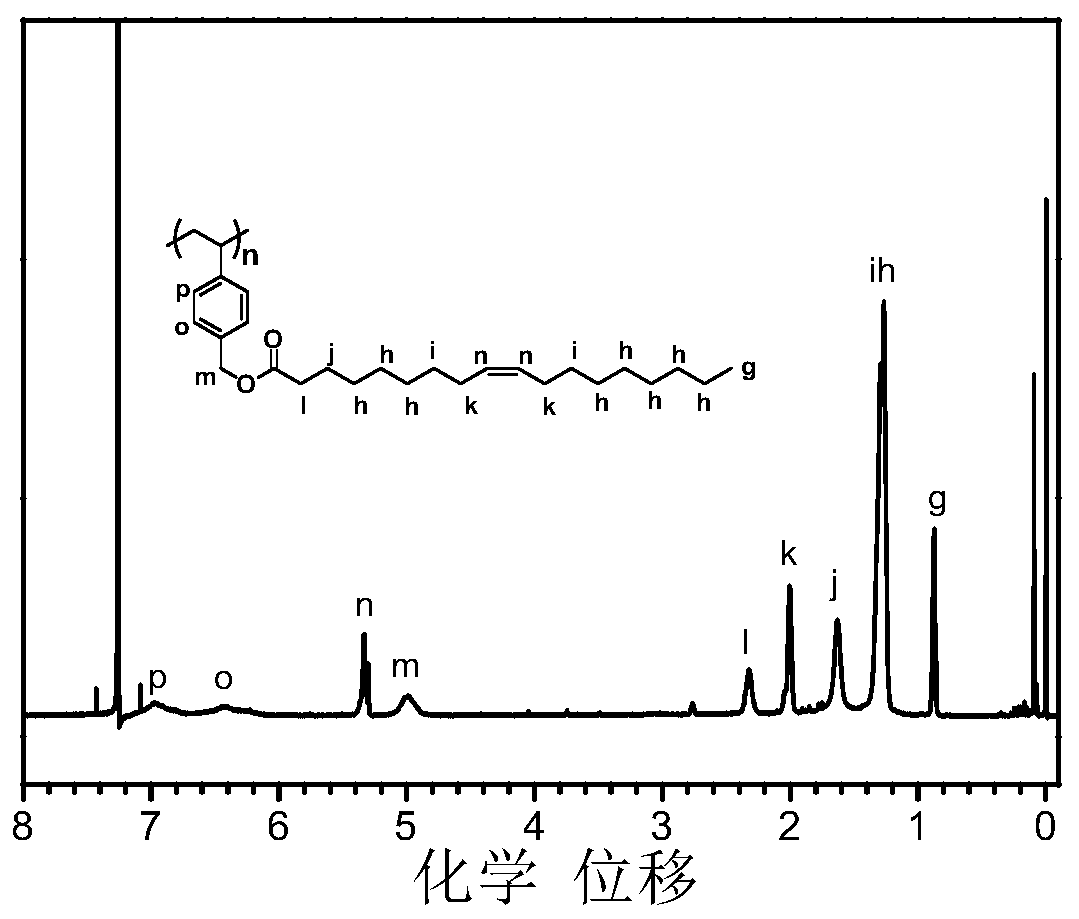

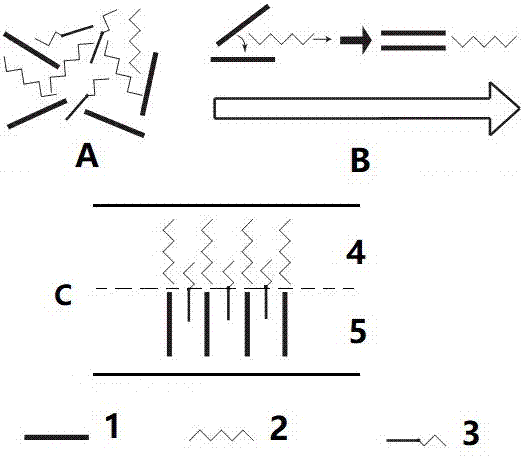

Grease-based epoxy polymer and epoxy copolymer, and preparation methods thereof

InactiveCN110804109AImprove mechanical propertiesIn line with the theme of sustainable developmentEpoxyPolymer science

Owner:ANHUI AGRICULTURAL UNIVERSITY

Block copolymer modified amphipathy polylactic acid composite membrane and preparation method

Owner:上海理振工业技术有限公司

Preparation method of low-density low-VOC scraping-resistant modified polypropylene composite material

The invention discloses a low-density low-VOC scraping-resistant modified polypropylene composite material and a preparation method thereof. The composite material consists of the following raw materials in parts by weight: 60-80 parts of polypropylene, 15.5-31 parts of a toughening-VOC adsorption compound additive, 1-2 parts of a scraping agent, 0.02-0.05 part of an antioxidant and 2-4 parts of pure water. The toughening-VOC adsorption compound additive consists of the following raw materials in parts by weight: 3-8 parts of ethylene-octene copolymer (POE), 1 part of a compatilizer, 1 part ofa coupling agent, 0.5-1 part of nano vermiculite and 10-20 parts of diatomite with micropores in the surface. The composite material has low density, low VOC and high scraping resistance, and is suitable for automotive trim.

Owner:QINGDAO DONG PLASTIC CO LTD

Polyurethane-nylon 6 block copolymer, preparation method thereof and polyurethane-nylon 6 elastic fiber

ActiveCN112127007AHigh mechanical strengthImprove wear resistanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides a polyurethane nylon 6 block copolymer, a preparation method thereof and a polyurethane nylon 6 elastic fiber. The polyurethane nylon 6elastic fiber is obtained by performing melt spinning on the polyurethane nylon 6 block copolymer. The polyurethane nylon 6 block copolymer is an ABA type block copolymer, wherein the block A is an amino-terminated polyamide chain segment, the block B is an isocyanate-terminated polyurethane chain segment, the mass content of the isocyanate-terminated polyurethane chain segment is 20-60wt%, and amino-terminated polyamide and isocyanate-terminated polyurethane are subjected to polymerization reaction according to a molar ratio of 1.2:1 to 1.3:1 by adopting a hydrolytic polymerization method. The molecular structure of the polyurethane-nylon 6 copolymer is designed, so that the copolymer has excellent properties of polyurethane and nylon, copolymer slices meeting melt spinning requirements are obtained, and the polyurethane-nylon 6copolymer elastic fiber with high strength and high resilience is obtained through melt spinning.

Owner:WUHAN TEXTILE UNIV

Shell plastic for computer display screens and preparation method of shell plastic

InactiveCN107163494AGood acid and alkali resistanceGood high temperature resistancePolyvinyl chlorideEngineering

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

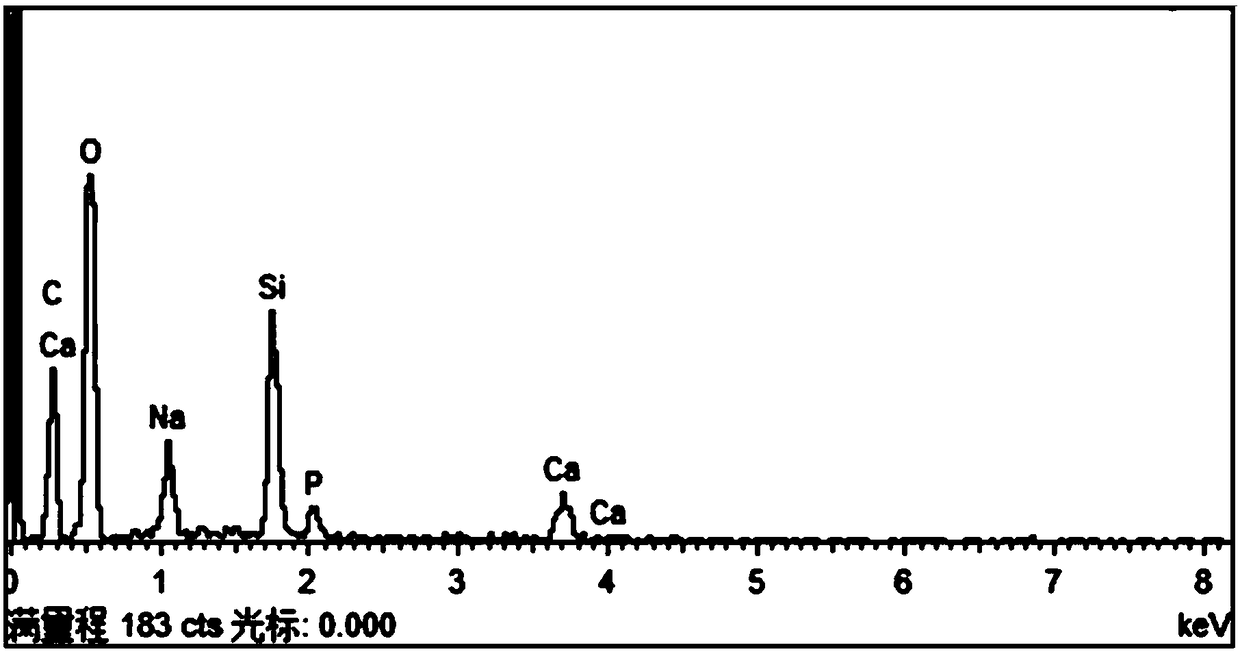

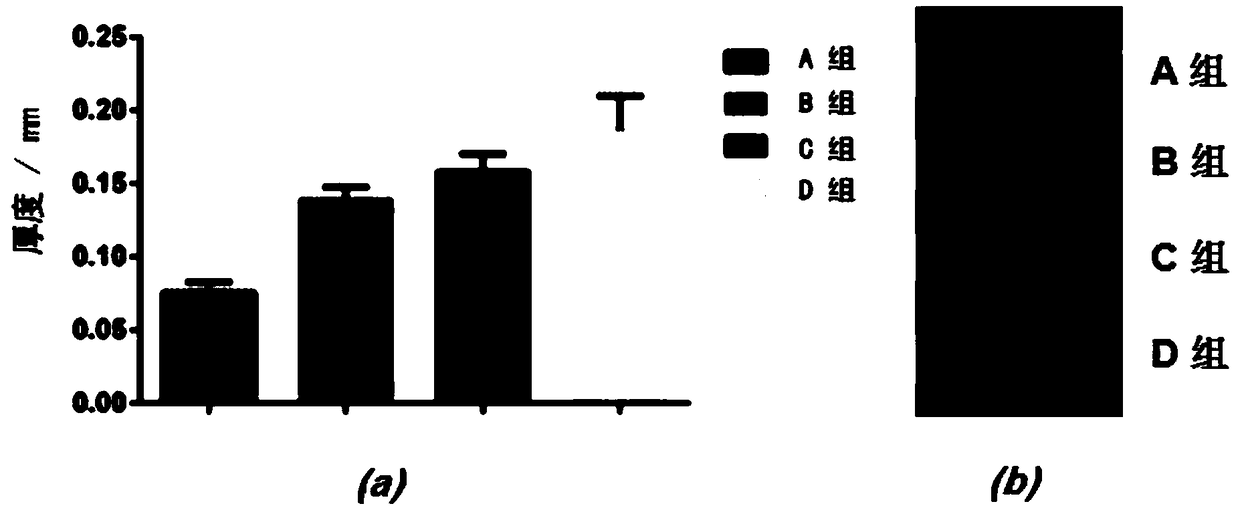

Bioactive glass composite film as well as preparation method and application thereof

ActiveCN108186614ADesensitizationPromote recoveryOrganic active ingredientsInorganic phosphorous active ingredientsComposite filmBiocompatibility Testing

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

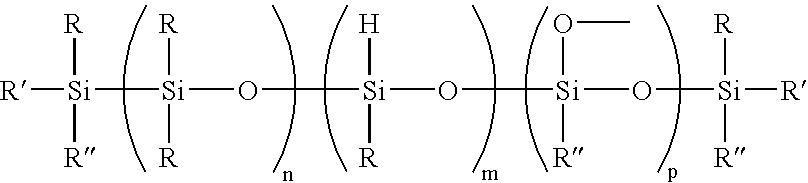

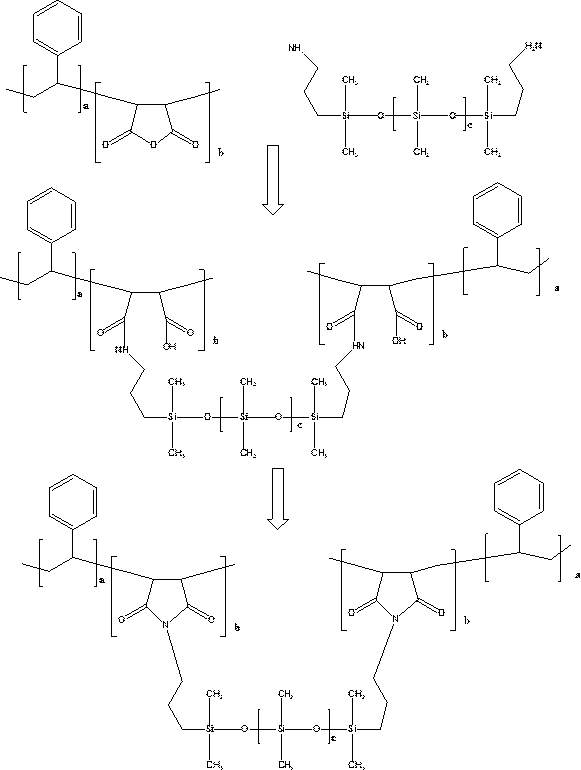

Synthesis of end amino silicone oil modified stryenemaleic anhydride copolymer

InactiveCN109337085AFlexible structure adjustmentControl Molecular Weight DistributionElastomerPolyolefin

Owner:YANTAI DARBOND TECH

Amorphous alpha-olefin copolymer improved paper-based friction material and preparation method thereof

ActiveCN112855811AEasy to processImprove high temperature stabilityOther chemical processesFriction liningFiberPolymer science

Owner:NORTHWESTERN POLYTECHNICAL UNIV

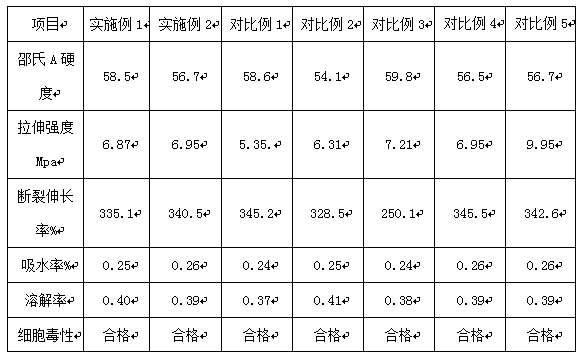

Antibacterial and anti-aging denture soft lining material

InactiveCN109646313AExcellent adhesionImprove aging resistanceImpression capsDentistry preparationsSolubilitySodium acetate

Owner:蚌埠佳美仕义齿有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap