Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Polyurethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane (PUR and PU) is a polymer composed of organic units joined by carbamate (urethane) links. While most polyurethanes are thermosetting polymers that do not melt when heated, thermoplastic polyurethanes are also available.

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

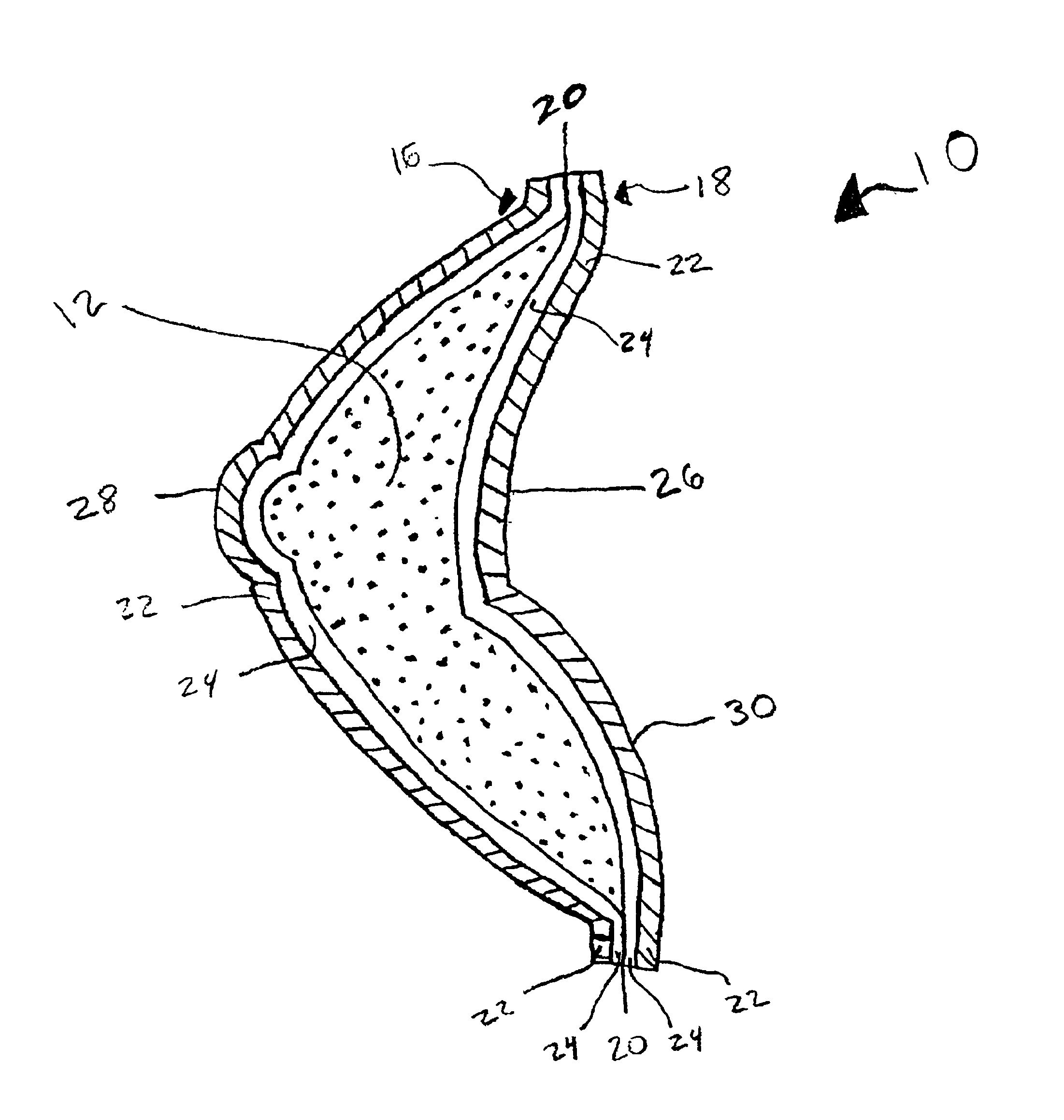

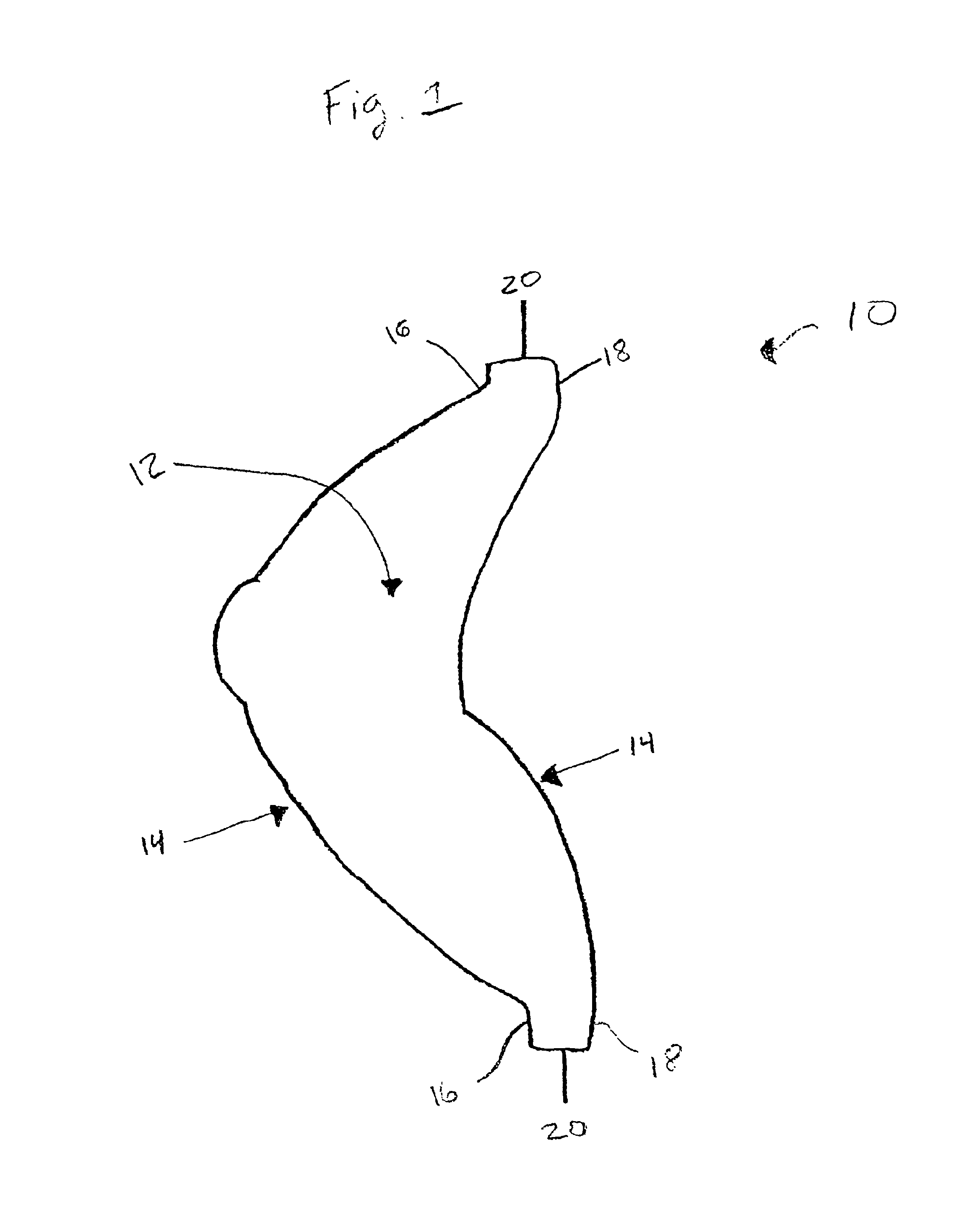

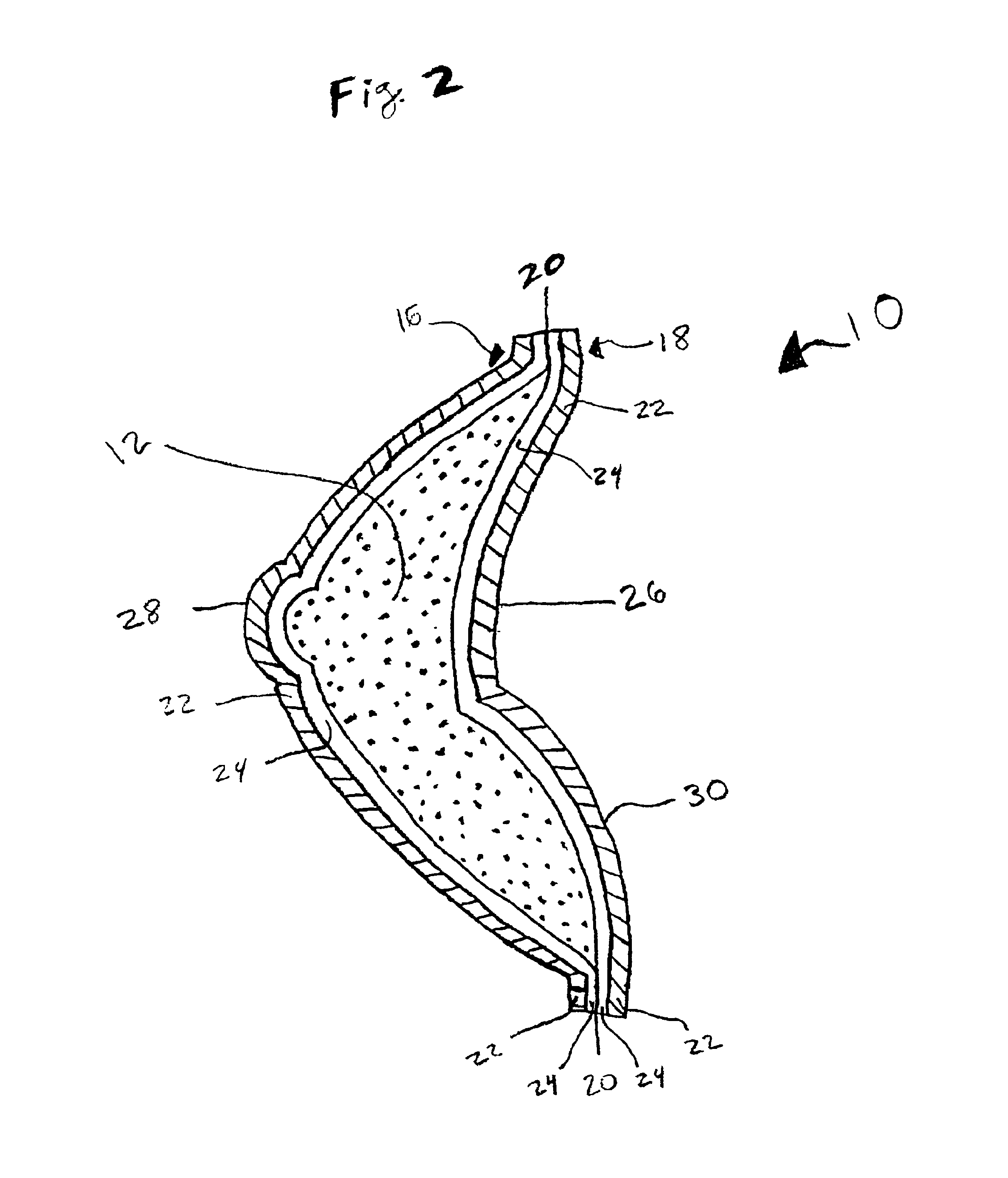

Breast form encased with fabric laminated thermoplastic film

InactiveUS6857932B2Prevent movementGarmentsBrassieresThermoplasticSilicone Gels

Owner:BRAGEL INT INC

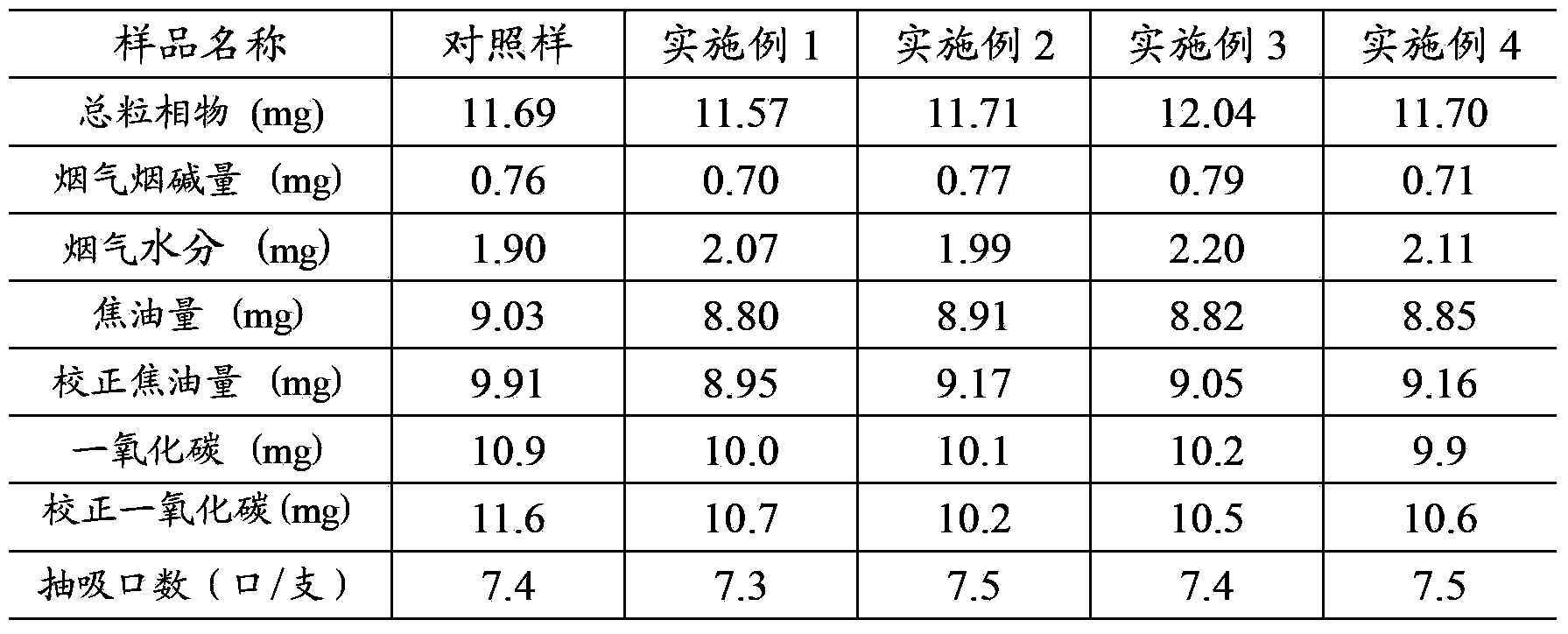

Solid-type filter stick formed by granular assembling and preparation method thereof

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

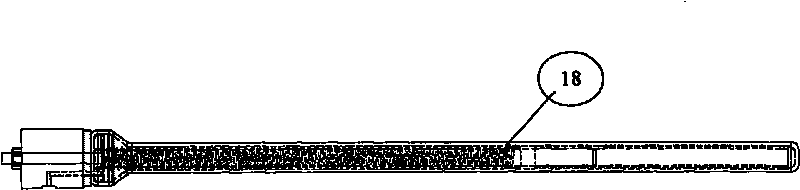

Quick Repair Method of Existing Expansion Joints in Railway Concrete Bridges

A rapid repair method for the existing expansion joints of railway concrete bridges, comprising the following steps: a, removing residual water-stop rubber strips; b, removing dirt and garbage on the concrete base surface and the exposed surface of metal edge beams, and then Drying; c, installing and positioning the underlayment and side lining; d, spraying the primer; e, pouring the repair material; f, spraying the top coat; g, after the repair material is basically cured, the repair is completed. The repair method of the invention can adapt to various irregular sizes of bridge joints; installation and replacement are fast and convenient; the polyurethane repair material itself has good durability and weather resistance, and is suitable for rapid repair; the price is moderate, and it is convenient for mass use.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

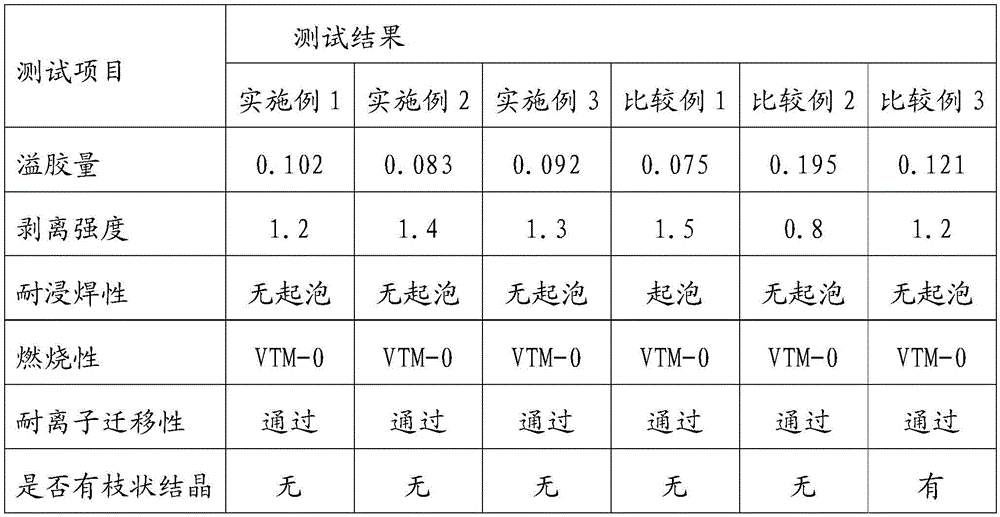

Halogen-free resin composition and cover film prepared from the same

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

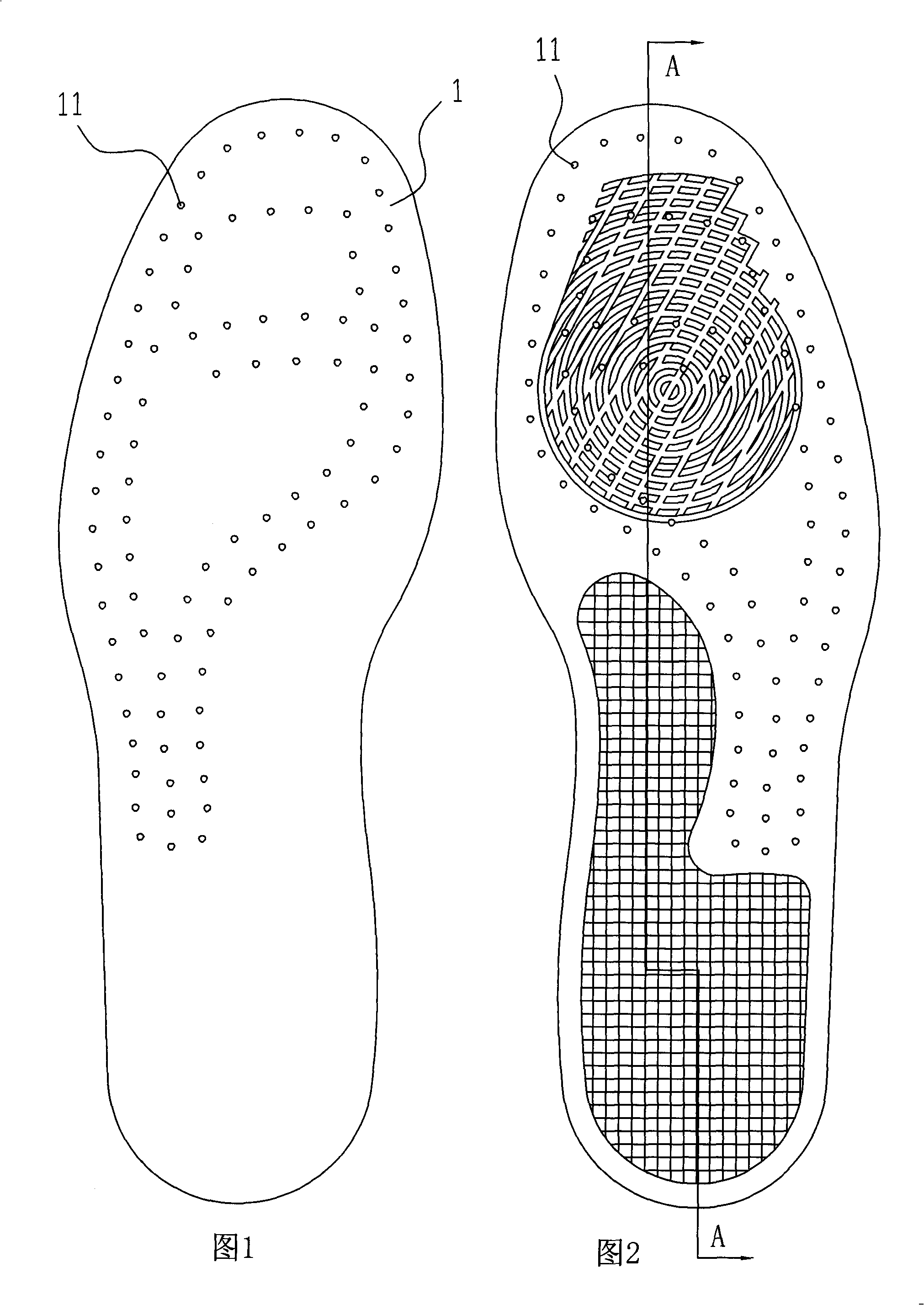

Method for making shoe-pad

InactiveCN101352905AEliminates the problem of slippery insolesAnti-vibration is goodDomestic articlesMetal working apparatusMembrane surfaceEngineering

Owner:汪士抗

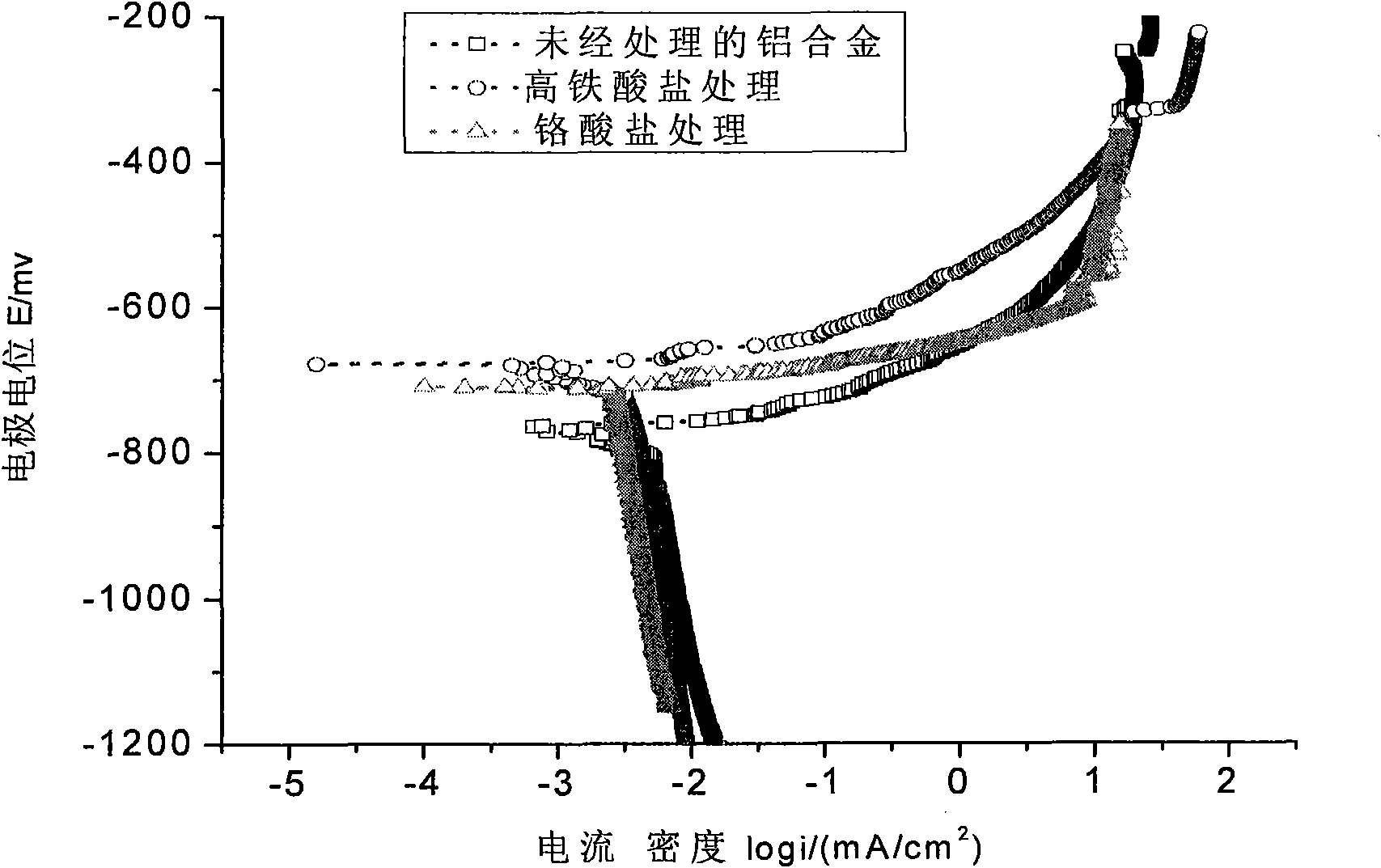

Organic and inorganic composite aluminium alloy non-chromium passivation treatment fluid

InactiveCN101565826AWith "self-healing" functionImprove corrosion resistanceMetallic material coating processesAcrylic resinPhosphoric acid

Owner:UNIV OF SCI & TECH BEIJING

Polymer dispersed LCD bistable film and method of manufacture

Owner:HEBEI UNIV OF TECH

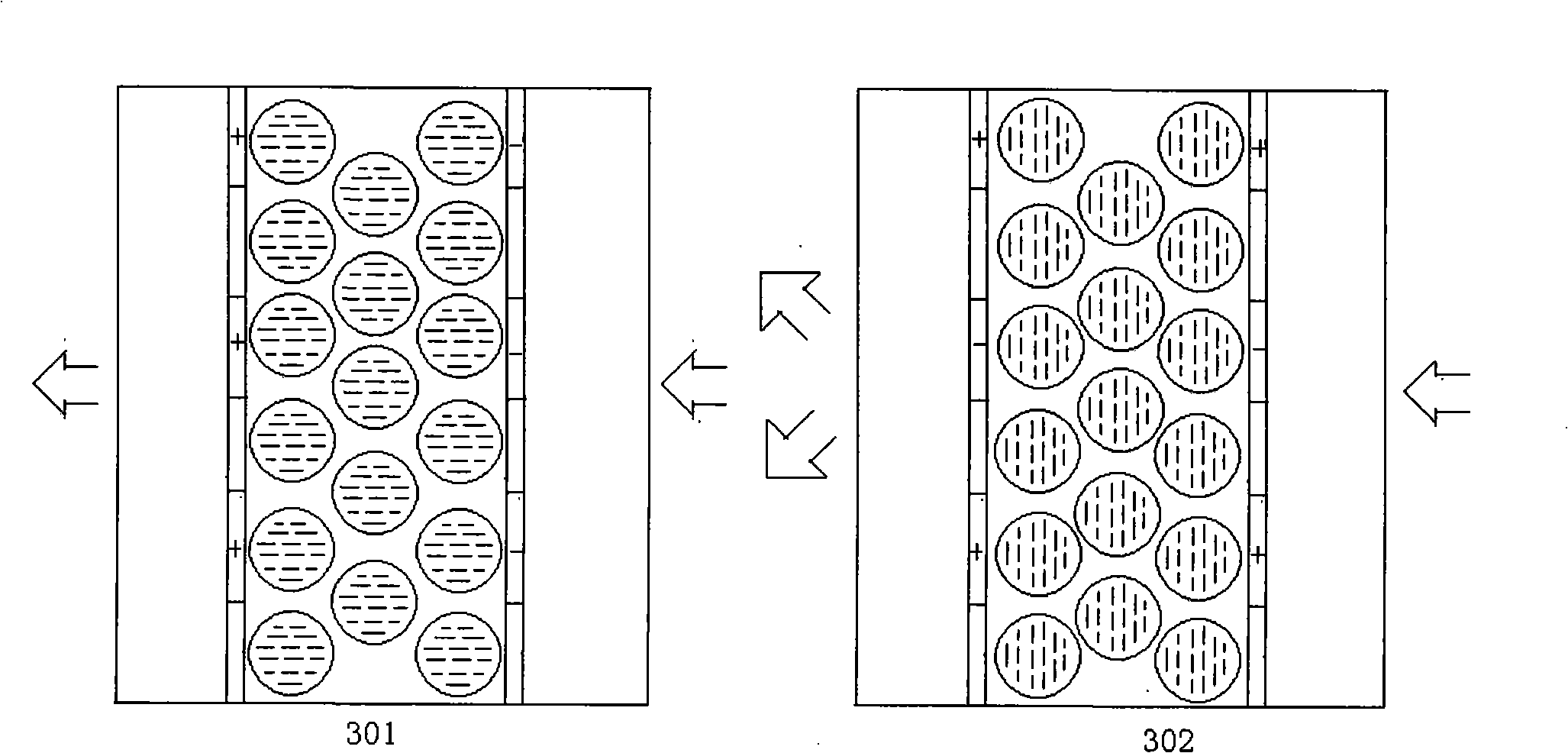

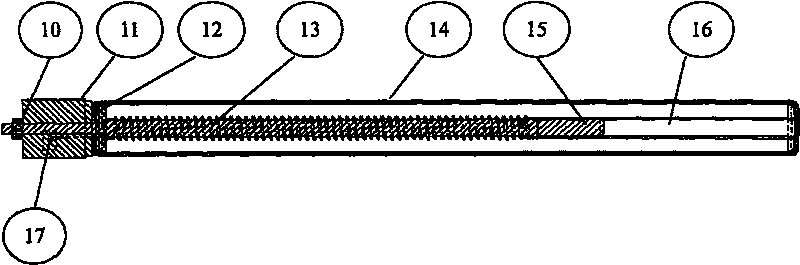

Polyurethane blended hollow fiber membrane and method for preparing same

InactiveCN1883778AWide applicabilityPracticalSemi-permeable membranesHollow fibre membranePolymer science

Owner:TIANJIN POLYTECHNIC UNIV

Method for fracturing coal seam by employing high-pressure gas

ActiveCN104405358ASolve the problem of air leakageGuaranteed gas pressureFluid removalSealing/packingParticulatesProduct gas

Owner:TAIYUAN UNIV OF TECH

Inkjet printing fluid

InactiveUS20120277366A1High optical densityPolyurea/polyurethane coatingsWater dispersiblePolymer science

An inkjet printing fluid composition comprising water, colorant, acrylic latex polymer, and a water dispersible polyurethane additive having an acid number greater than 50, preferably between 50 and 150, more preferably from 60 to 100, and most preferably from 60 to 90. The invention provides inkjet printing fluid compositions, such as pigment-based inkjet printing inks, which contain an acrylic latex polymer which provides increased optical density for printed images, and a water dispersible polyurethane additive that enables the latex-containing printing fluid to be recirculated for extended periods in a recirculating printing fluid printing system without significant fluid destabilization or pressure build up or filter clogging. The invention further provides a method for printing an inkjet image comprising: I) providing an inkjet printing fluid according to the invention; and II) jetting the inkjet printing fluid in the form of ink drops onto a recording element to form a printed image.

Owner:EASTMAN KODAK CO

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

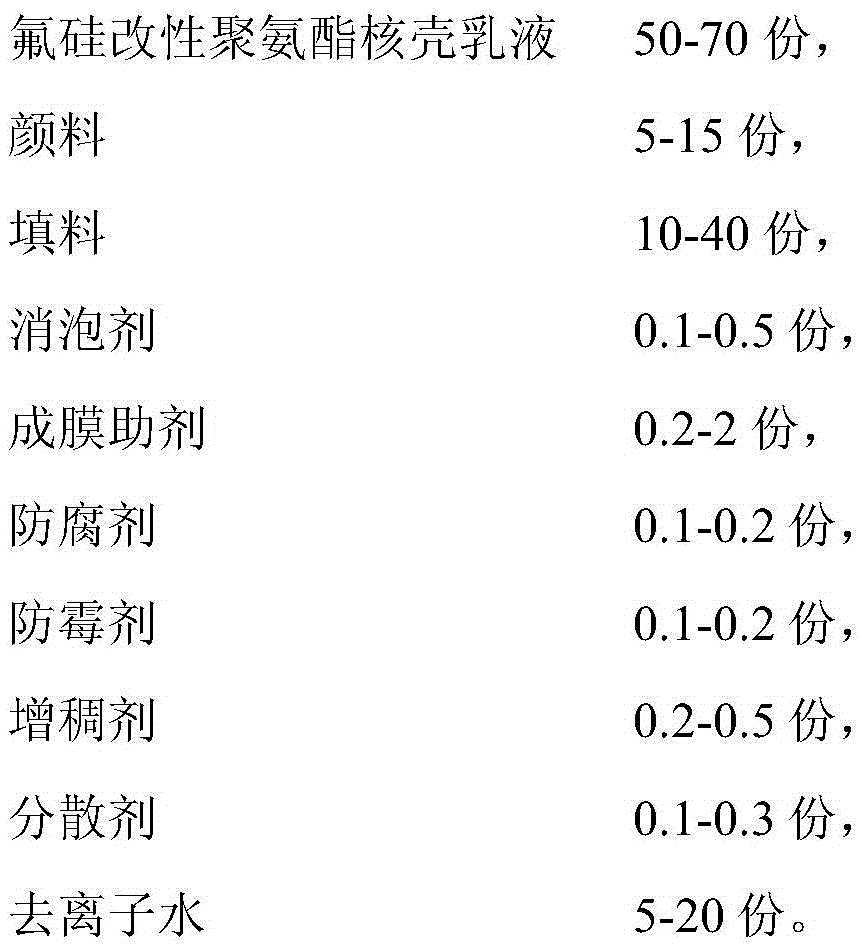

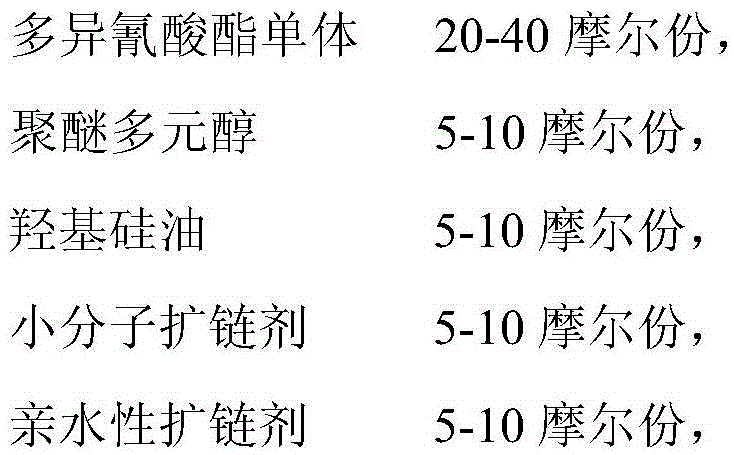

Water-based anti-doodling paint and preparation method thereof

ActiveCN105482604ALow VOC emissionsLow weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedDefoaming Agents

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

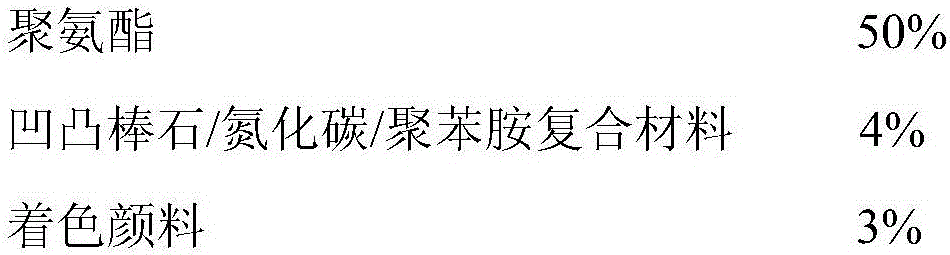

Preparation method of attapulgite-carbon nitride-polyaniline composite material and application thereof in anticorrosive paint

InactiveCN105754092AAvoid reunionReduce manufacturing costAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nitrideGraphite

Owner:CHANGZHOU UNIV

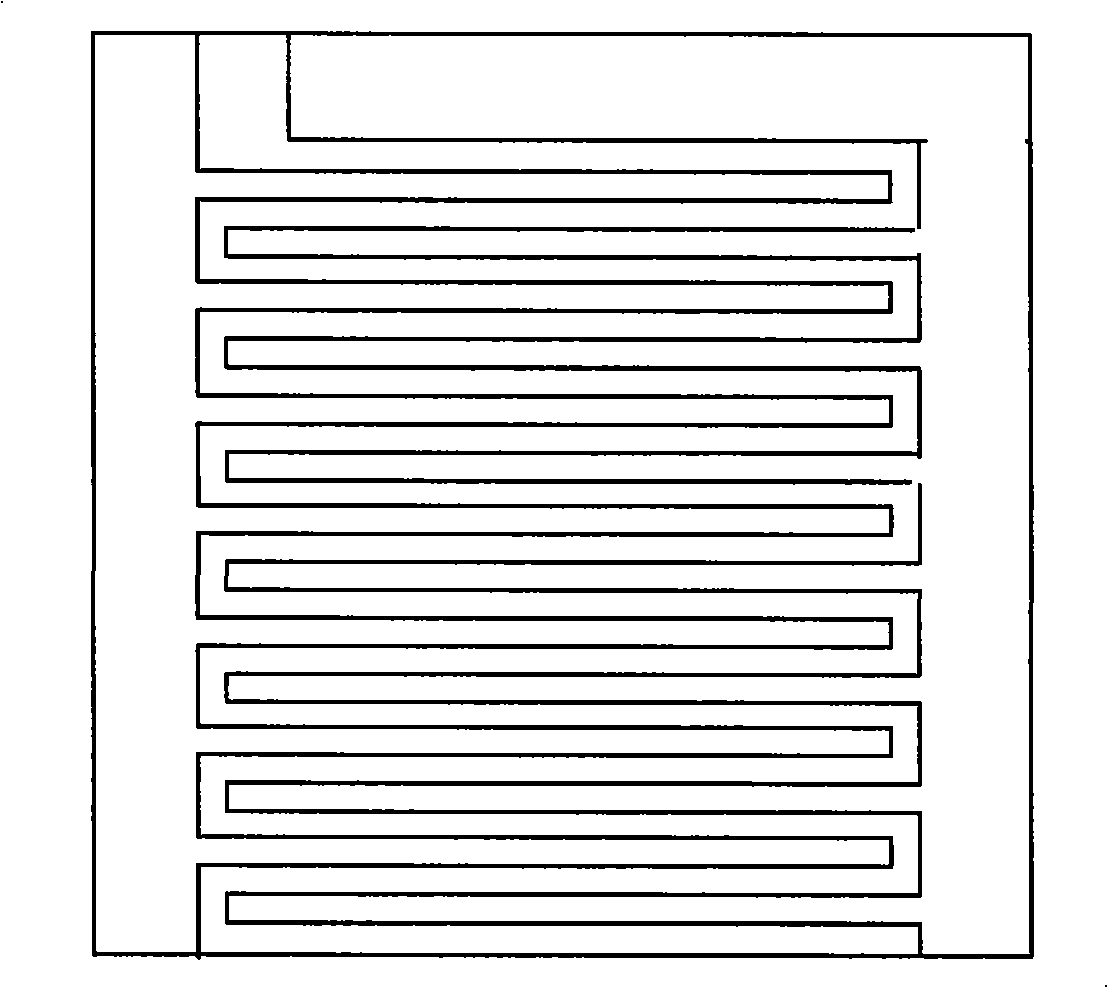

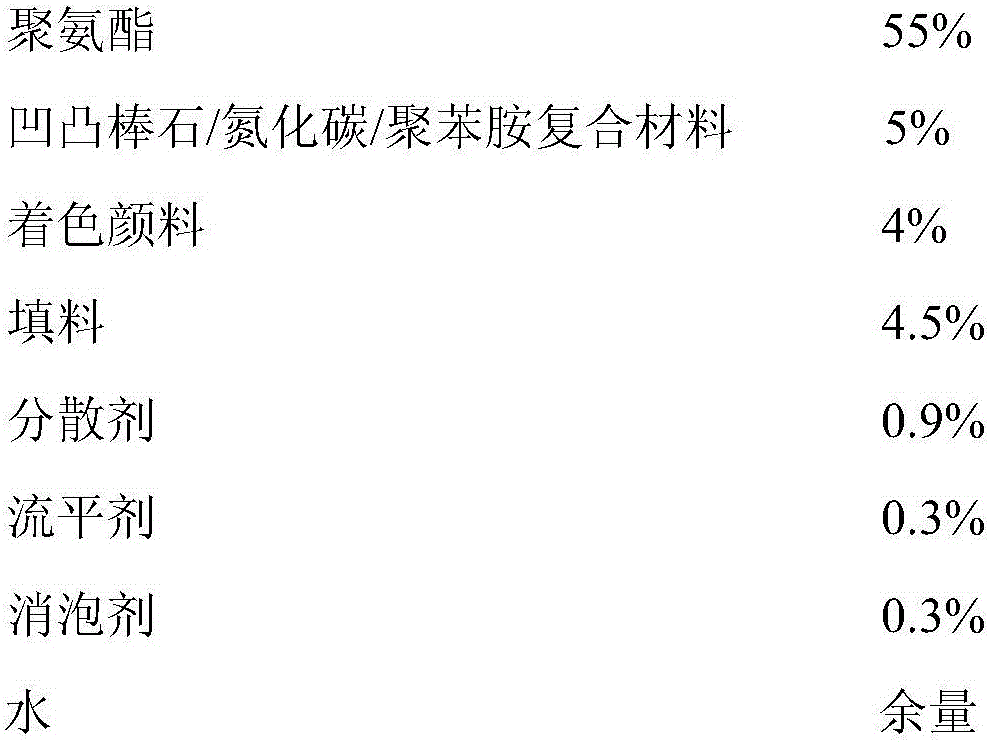

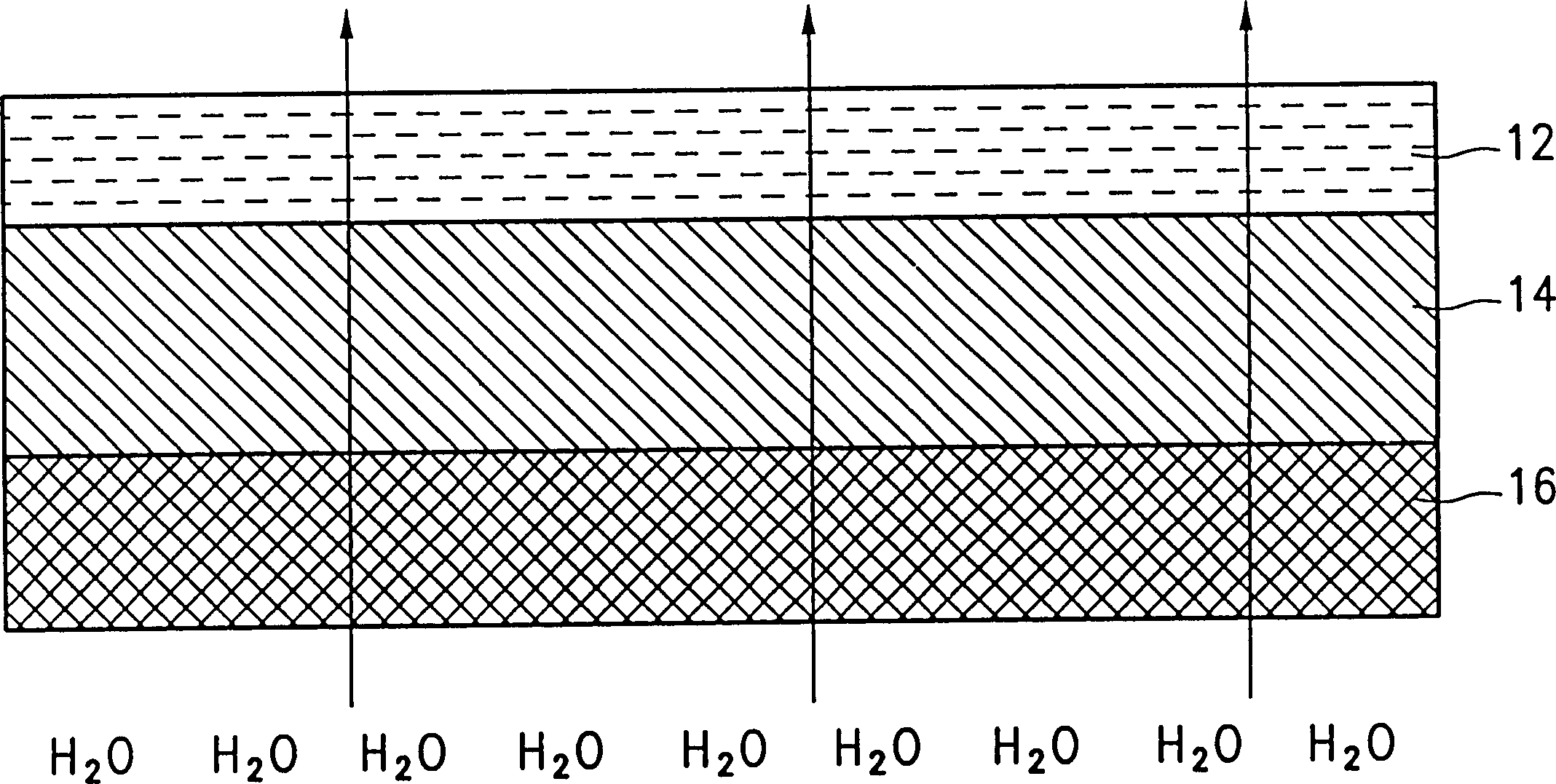

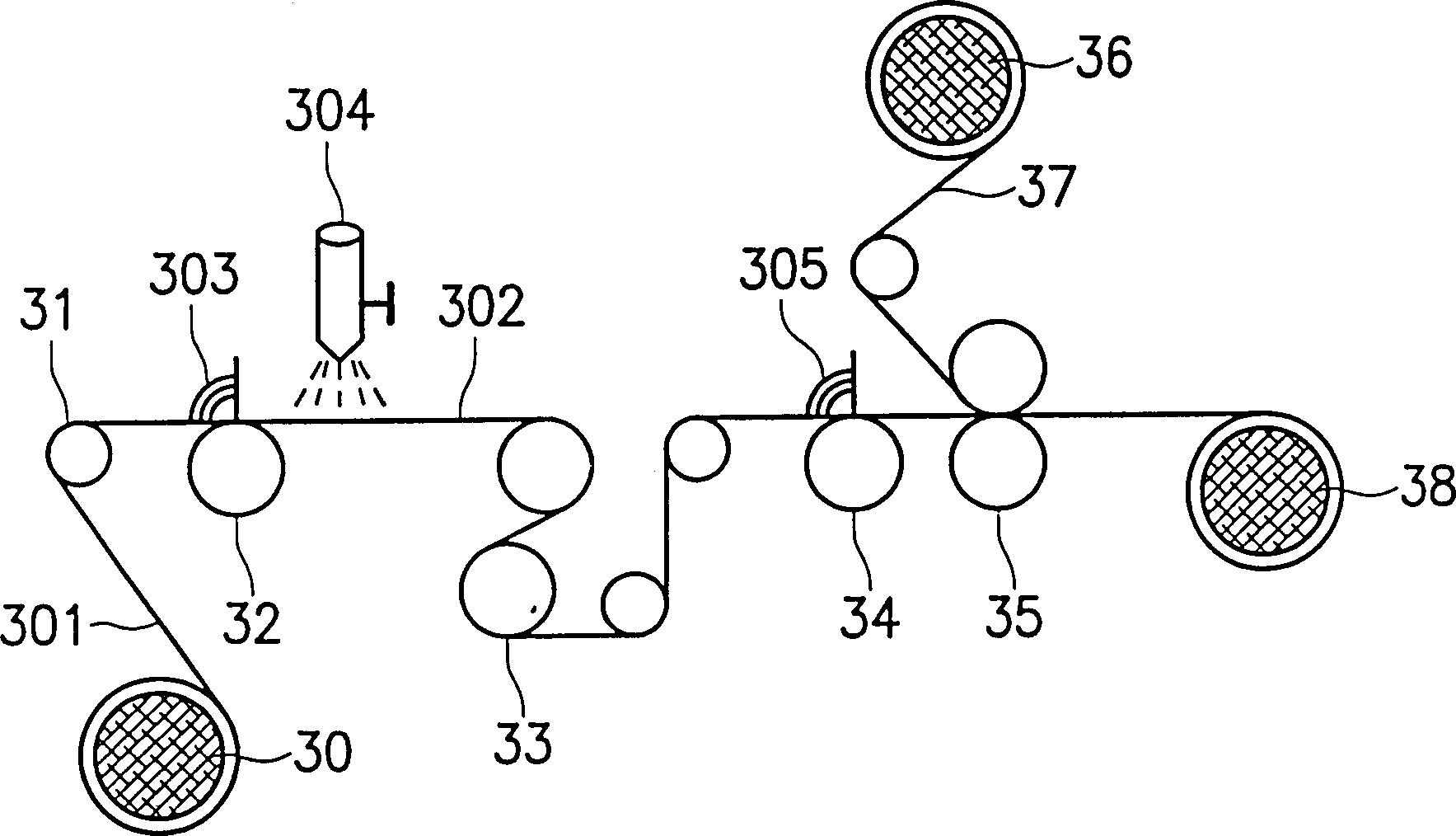

Manufacturing method of synthetic leather possessing air permeability

InactiveCN1410625ADrying step to reduce evaporationReduce pollutionTextiles and paperSolventChemistry

Owner:IND TECH RES INST

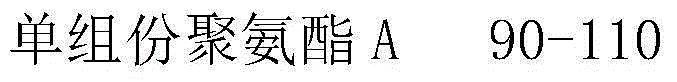

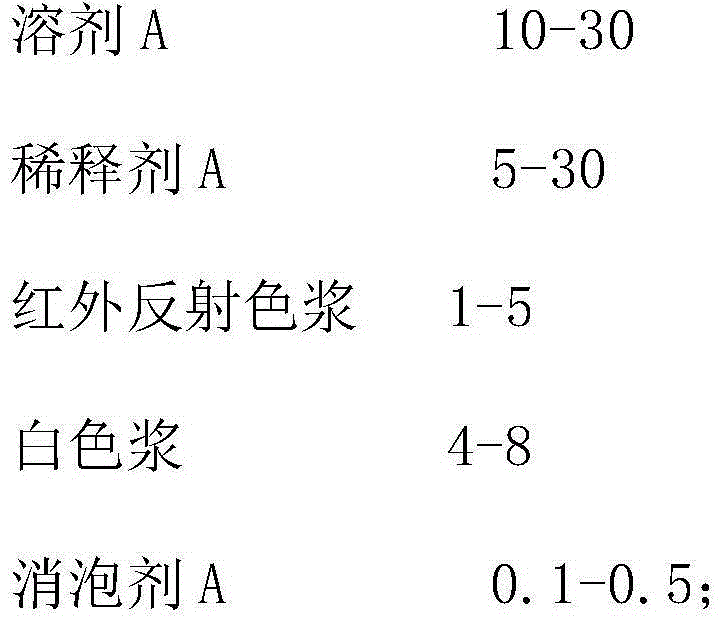

Infrared stealth textile coating fabric

ActiveCN105034523ALow infrared reflectanceImprove stealth performanceSynthetic resin layered productsCross-linkPolymer science

Owner:CTA HI TECH TEXTILES

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

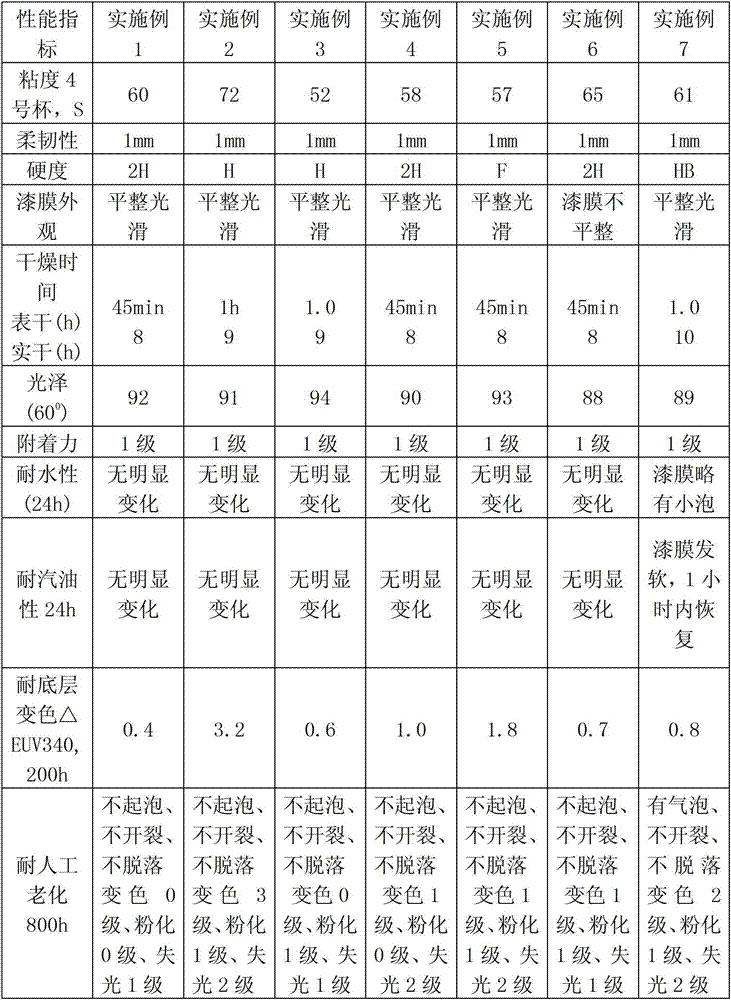

Varnish resisting ultraviolet and preventing bottom-layer discoloration, and preparation method thereof

ActiveCN102850880ALong-term effective absorptionPrevent discolorationCoatingsAcrylic resinDual effect

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

Water-based environment-friendly color-changing nail polish

PendingCN109381372AImprove stabilityKeep for a long timeCosmetic preparationsToilet preparationsWater basedRetention time

Owner:胡余飞

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Polylactic acid/starch whole biological-base composite material and preparation method of composite material

The invention discloses polylactic acid / starch whole biological-base composite material and a preparation method of the composite material. Based on 100 parts by weight of total raw materials, the composite material is prepared from the raw materials: 40-85 parts by weight of polylactic acid, 5-25 parts by weight of dextral polylactic acid-polyurethane and 7-50 parts of starch. The composite material is safe, non-toxic, and biodegradable, and has excellent mechanical properties. The preparation method comprises the following steps: uniformly mixing the raw material components, then adding themixed materials into a double-screw extruder for melting and blending, then performing pulling and pelletizing to obtain granular mixed resin, and performing drying to obtain the polylactic acid / starch whole biological-base composite material. The preparation method is simple and is easy to control; the operability is high; the implementation is easy; the production cost is low; the preparation method is easy for industrial large-scale production; and the prepared composite material can be applied to the fields of foaming materials, thin films, fibers, other special-shaped materials and the like.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Thermoplastic Elastomer Compositions Comprising Intumescent Flame Retardants and Non-Phosphorous-Based Flame Retardant Synergists

ActiveUS20120125657A1Plastic/resin/waxes insulatorsInsulated cablesThermoplastic elastomerPolyphosphate

Owner:UNION CARBIDE CORP

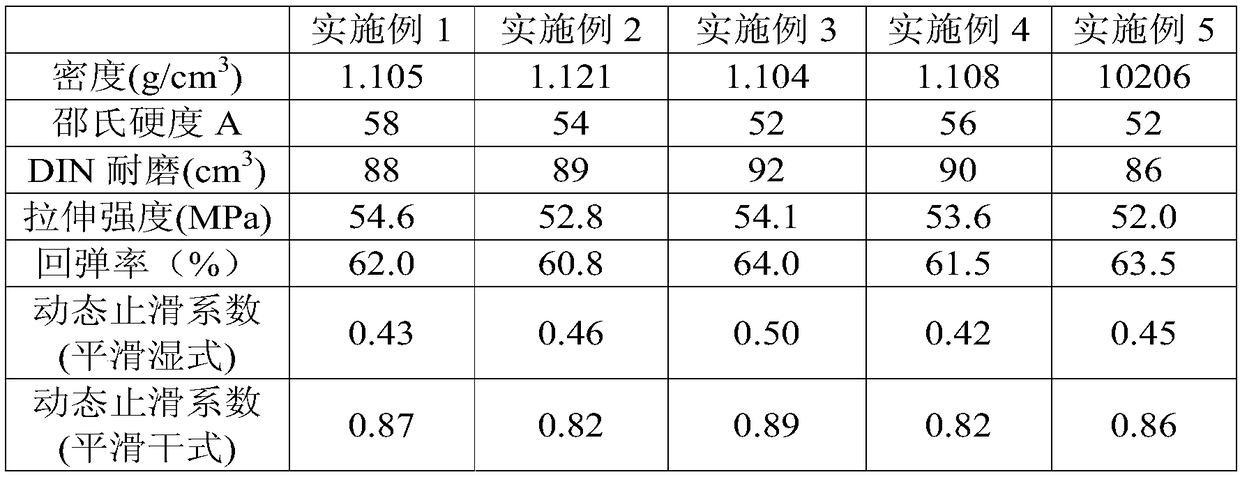

Fireproof anti-abrasion rubber shoe sole material and preparation method thereof

InactiveCN109354817AImprove wear resistanceGood mechanical propertiesSolesPolymer scienceMechanical property

Owner:JINJIANG XINQIMEI SHOES MATERIAL DEV

Ironing-free fabric and manufacturing method thereof

The invention aims to provide an ironing-free fabric and a manufacturing method thereof. On the premise that a resin finishing agent is not used for finishing, the ironing-free fabric still has good anti-wrinkle effect, and the problems of wrinkling, deformation, difficult finishing and the like when the traditional fabrics are washed are solved. The ironing-free fabric is woven by using warps and wefts, wherein the warps are luster polyester filament yarns, and the wefts are cotton yarns. The manufacturing method is characterized in that: a jacquard process is used for weaving; and luster polyester fibers, polyurethane fibers and cotton yarns are dyed at different temperatures during later dyeing respectively. The luster polyester filament yarns are used as the yarns of the ironing-free fabric, so the cloth cover effect is more finished; and the cotton yarns with elastic fibers are used as the wefts, so the ironing-free fabric achieves the handfeel of cotton fabrics and has rebound capability at the same time. Therefore, the fabric has good shape memory function and special ironing-free effect.

Owner:WUJIANG MINGSHIDA TEXTILE

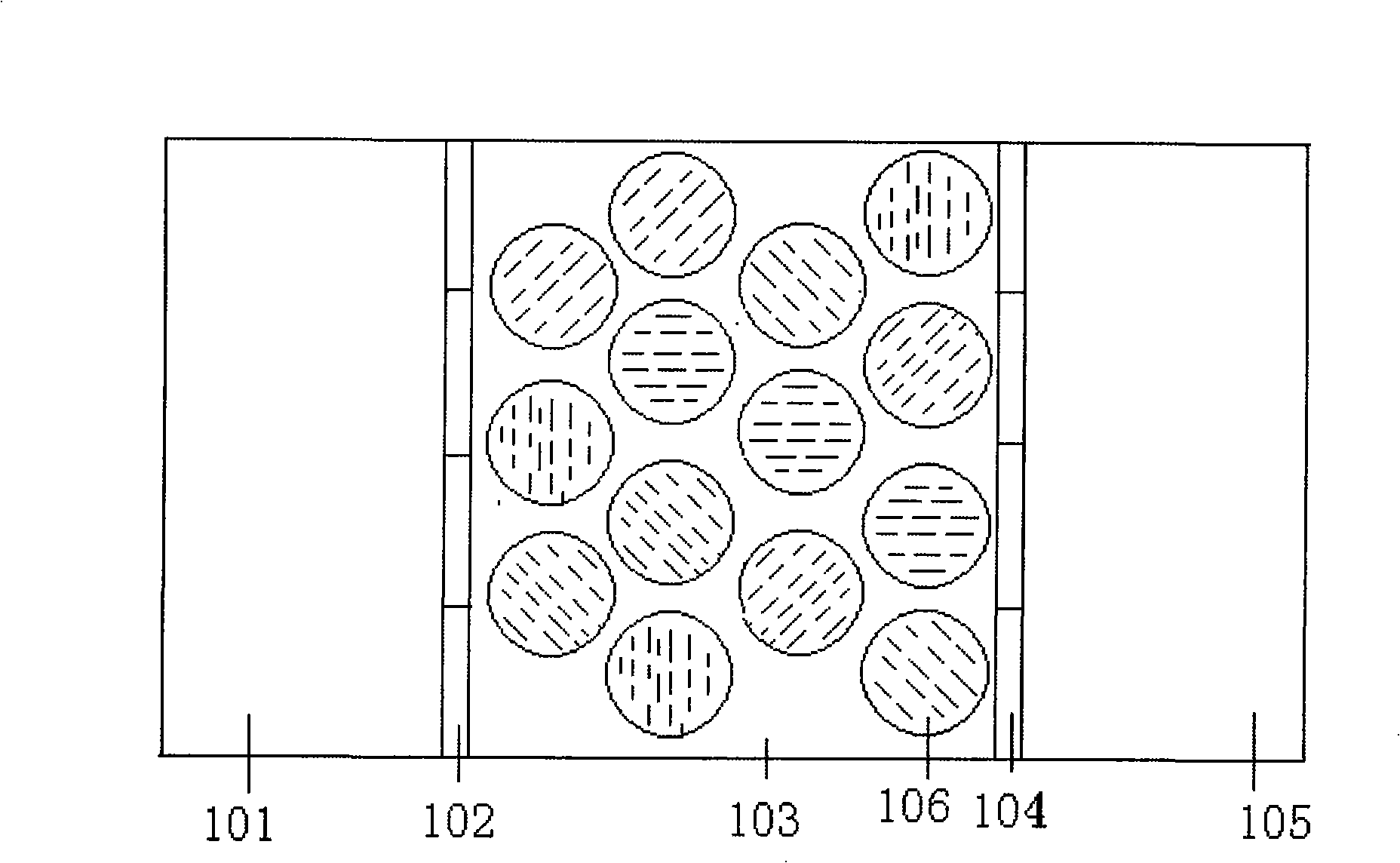

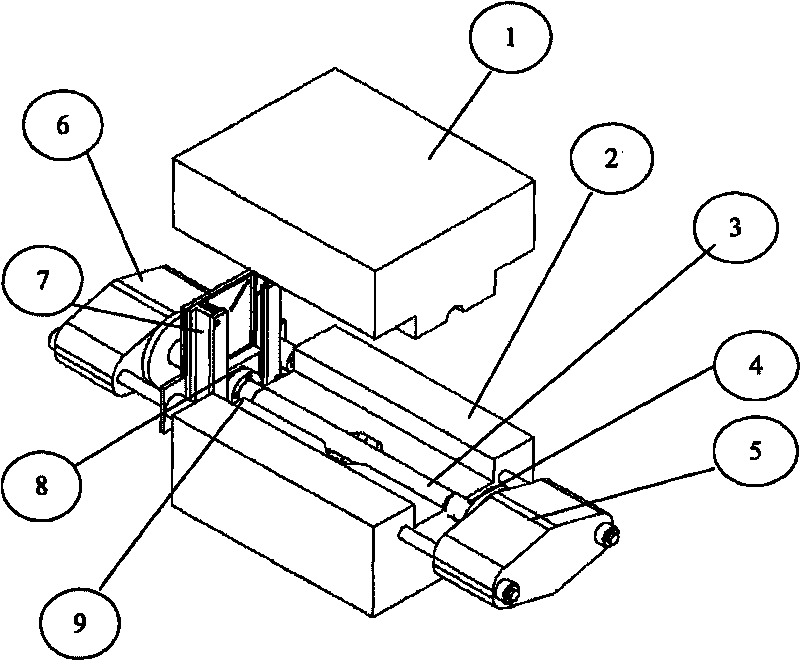

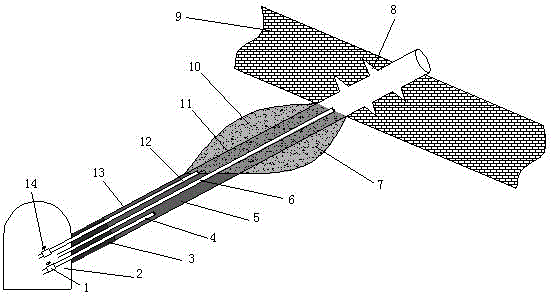

Low-rigidity pull pressure pad structure for realizing uniform loading of radome

InactiveCN110567803ASolve the problem of local reinforcementDoes not change the local stiffnessMaterial gluingMaterial strength using tensile/compressive forcesRadarEngineering

The invention belongs to the field of experimental mechanics, and particularly relates to a low-rigidity pull pressure pad structure for realizing uniform loading of a radome. The structure is composed of a plurality of symbol-shaped polyurethane blocks, a transition steel plate and a pull ring; the polyurethane blocks and the pull ring are respectively connected to both surfaces of the transitionsteel plate; and the pull ring is arranged at a resultant force point of a loading subarea, and the resultant force point is overlapped with the gravity center of the steel plate. The structure proposed by the invention can solve the problems that the stress of the radome is too concentrated when a canvas belt applies a load, and that the load is locally strengthened when a wooden block / steel structure applies the load, the uniform application of the load of the radome can be guaranteed, and the local rigidity of the radome is not changed; and in addition, since the pull pressure pad structure designed by the patent is composed of the plurality of polyurethane blocks with small bonding areas, and a certain gap is reserved between each polyurethane block, compared with an entire large polyurethane block, the air permeability is good, and the bonding quality is ensured.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

Heat-resistant modified asphalt

Owner:WUJIANG HUAWEI SPECIAL OIL

Microcapsule Type Thermochromic Pigment and Preparation Method and Use Thereof, Thermochromic Ink and Use Thereof

The disclosure provides a microcapsule type thermochromic pigment and a preparation method and use thereof, and a thermochromic ink and use thereof. The microcapsule type thermochromic pigment provided by the disclosure includes a core material and a wall material wrapping the core material, wherein the core material includes the following components: a leuco dye, a developer and stearic acid 2-[4-(phenylmethoxy)phenyl]ethyl ester, and the wall material is self-emulsifying polyurethane or self-emulsifying epoxy resin.

Owner:WUHAN ZHONGKE ADVANCED MATERIAL TECH CO LTD

UV (ultraviolet)-highly-clear curtaining finish

Owner:JIANGSU HIMONIA TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap