Organic and inorganic composite aluminium alloy non-chromium passivation treatment fluid

An inorganic composite, chromium-free passivation technology, applied in the field of passivation treatment liquid and metal material surface treatment, can solve the problems of short corrosion resistance durability and weakened organic matter, and achieve the effect of excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The main components of the organic and inorganic composite passivation solution with ferrate as the main inorganic salt are:

[0025] Potassium ferrate 0.7g

[0026] Phosphoric acid 0.5g

[0027] Waterborne Polyurethane 150g

[0028] Sodium silicate 10g

[0029] Deionized water 838.8g

[0030] The substrate used is aluminum alloy. The coating process is pH 4, dip-coating at room temperature, and drying at 150°C for 5 minutes.

[0031] The comparative examples are untreated aluminum alloy and chromate treated aluminum alloy.

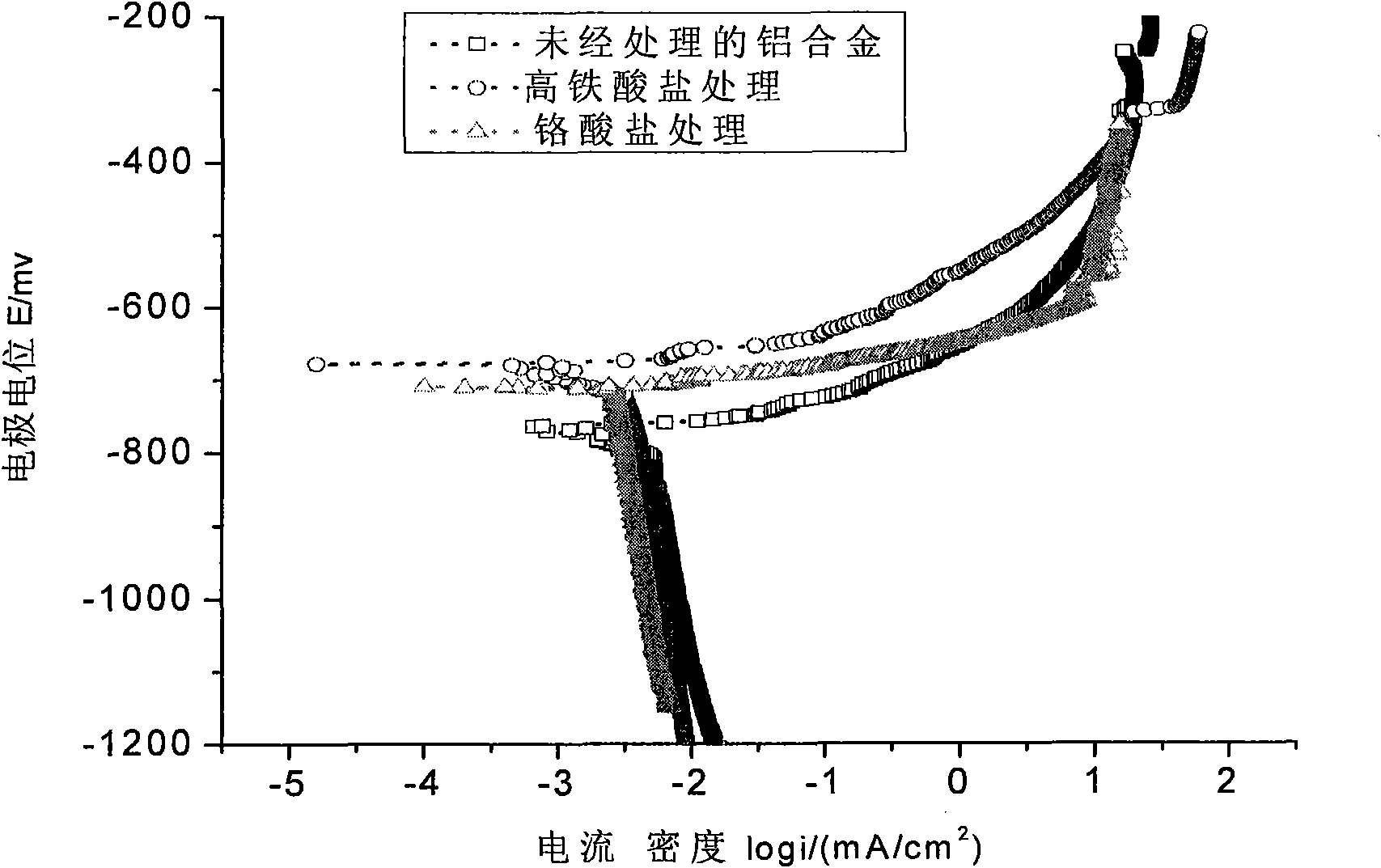

[0032] figure 1 Polarization curves of various passivating solutions. Depend on figure 1 It can be seen that the corrosion resistance of the present invention is significantly improved compared with the blank sample, and is also equivalent to the passivation result of chromate.

[0033] The neutral salt spray test of the passivation film can reach 72 hours, and the adhesion can reach level 1.

Embodiment 2

[0035] Potassium ferrate 1g

[0036] Waterborne Polyurethane 150g

[0037] Phosphoric acid 0.5g

[0038] Sodium silicate 4g

[0039] m-xylylenediamine 3g

[0040] Deionized water 841.5g

[0041] The substrate used is aluminum alloy. The treatment process of the coating is pH 4, dip-coating at room temperature, and drying at 100° C. for 5 minutes.

[0042] The neutral salt spray test of the passivation film can reach 72 hours, and the adhesion can reach level 1.

[0043] In a word, the experimental results show that the passivation solution of the present invention can be used to obtain a passivation film with excellent adhesion on the metal surface. Stronger, so it can replace chromate, and in some respects, permanganate to achieve an environmentally friendly passivation film.

[0044] Because the passivation solution of the present invention does not contain chromate, it not only greatly reduces environmental pollution, but also meets the requirements of WEES and ROHS instr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap