Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Metallic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

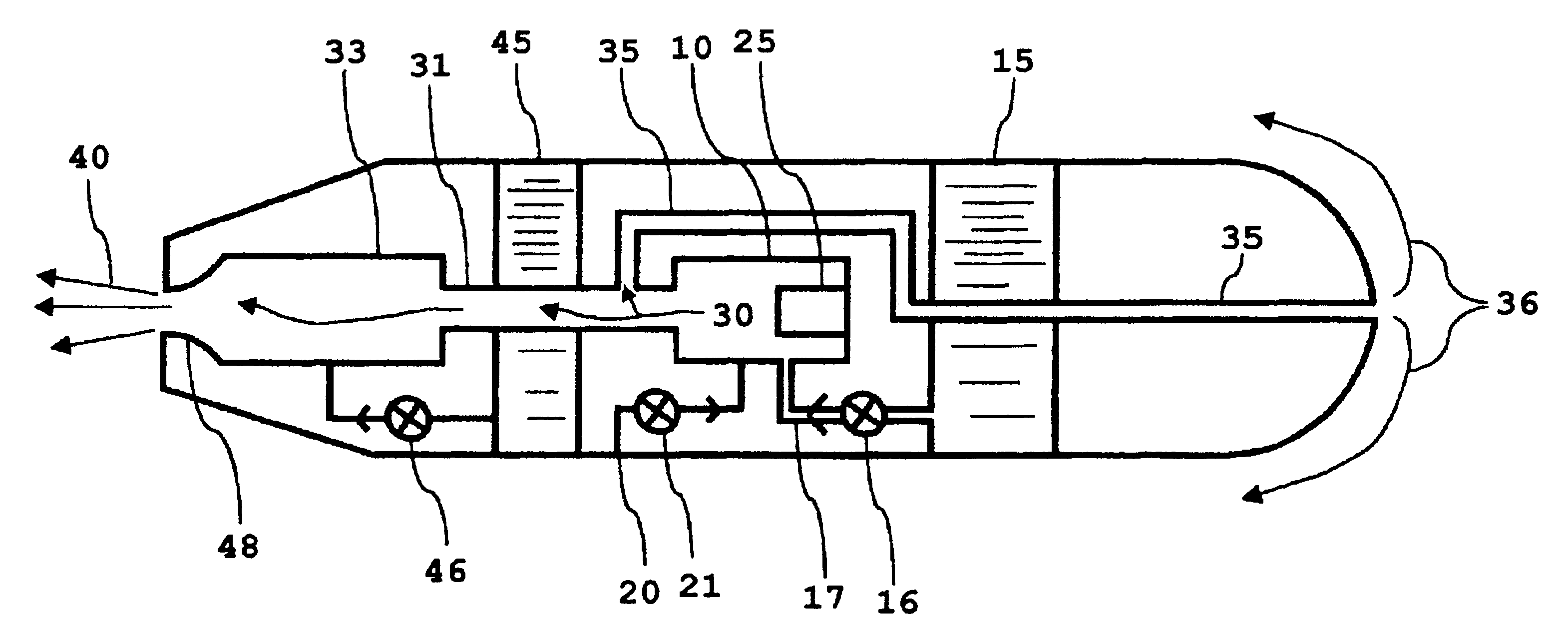

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

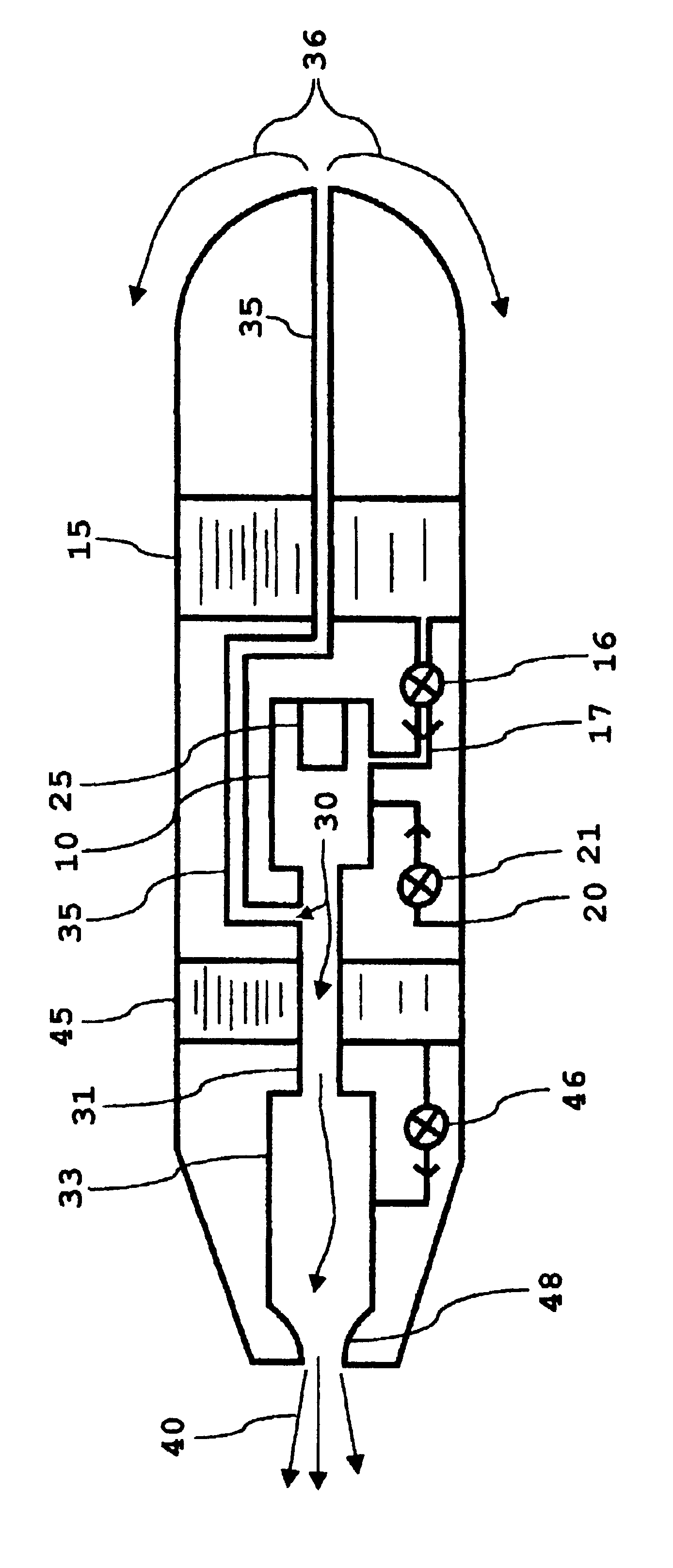

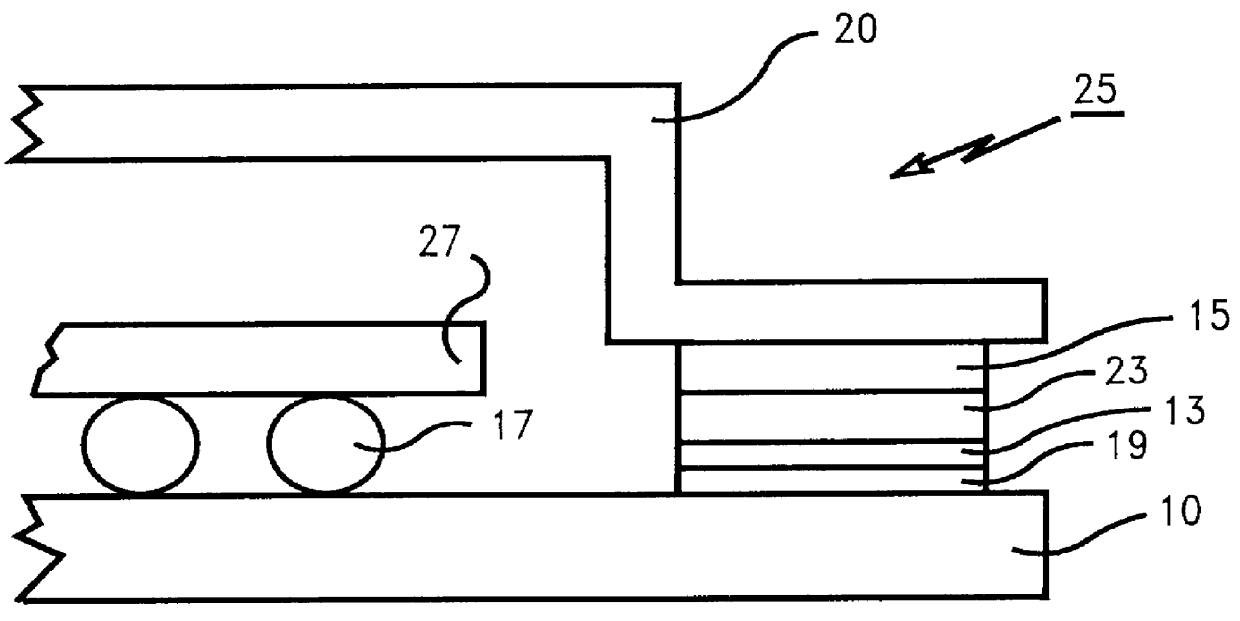

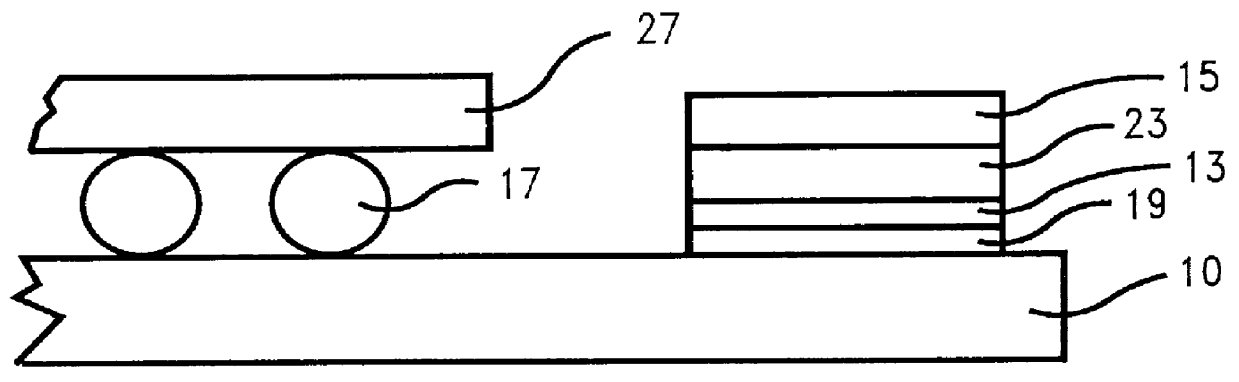

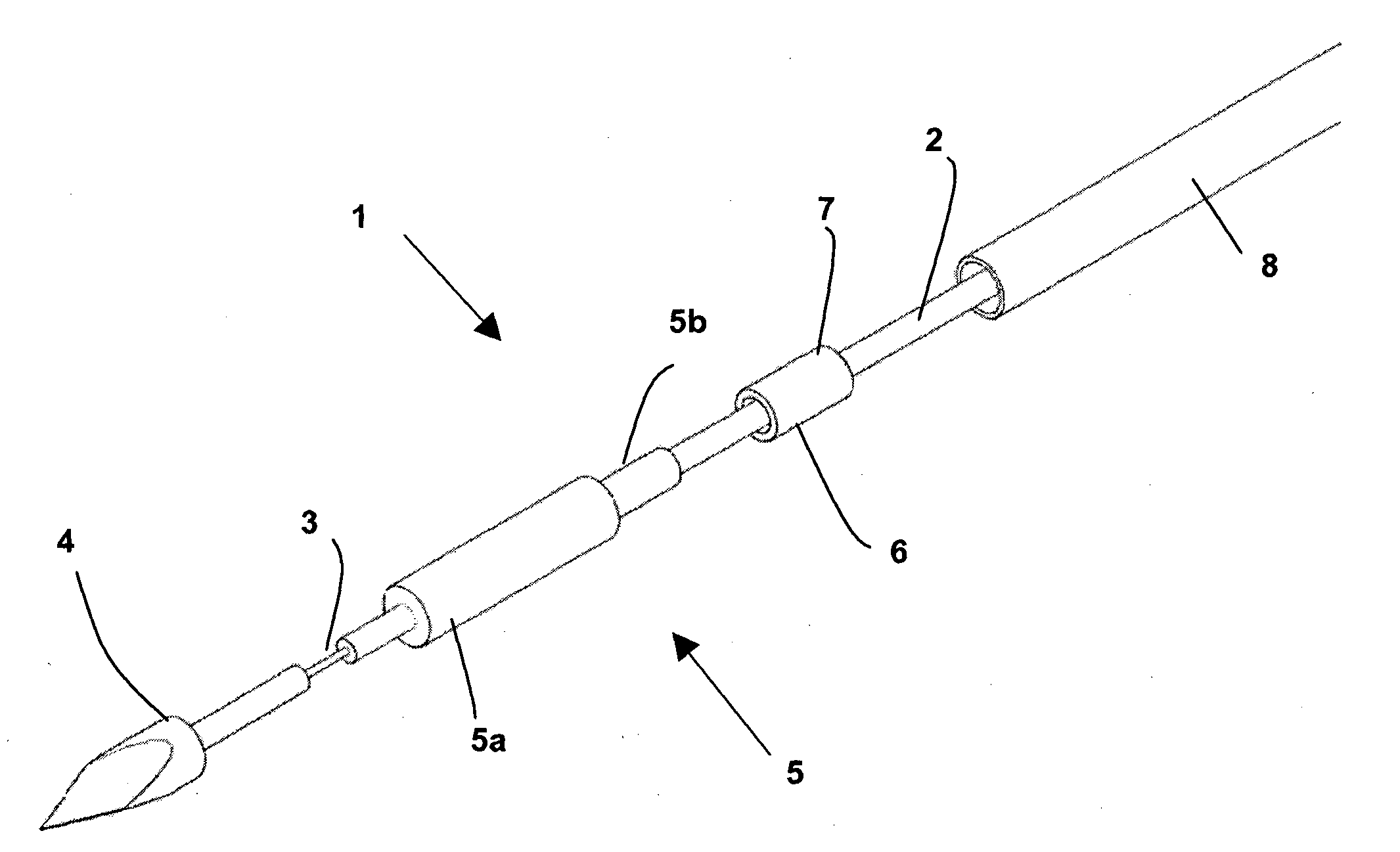

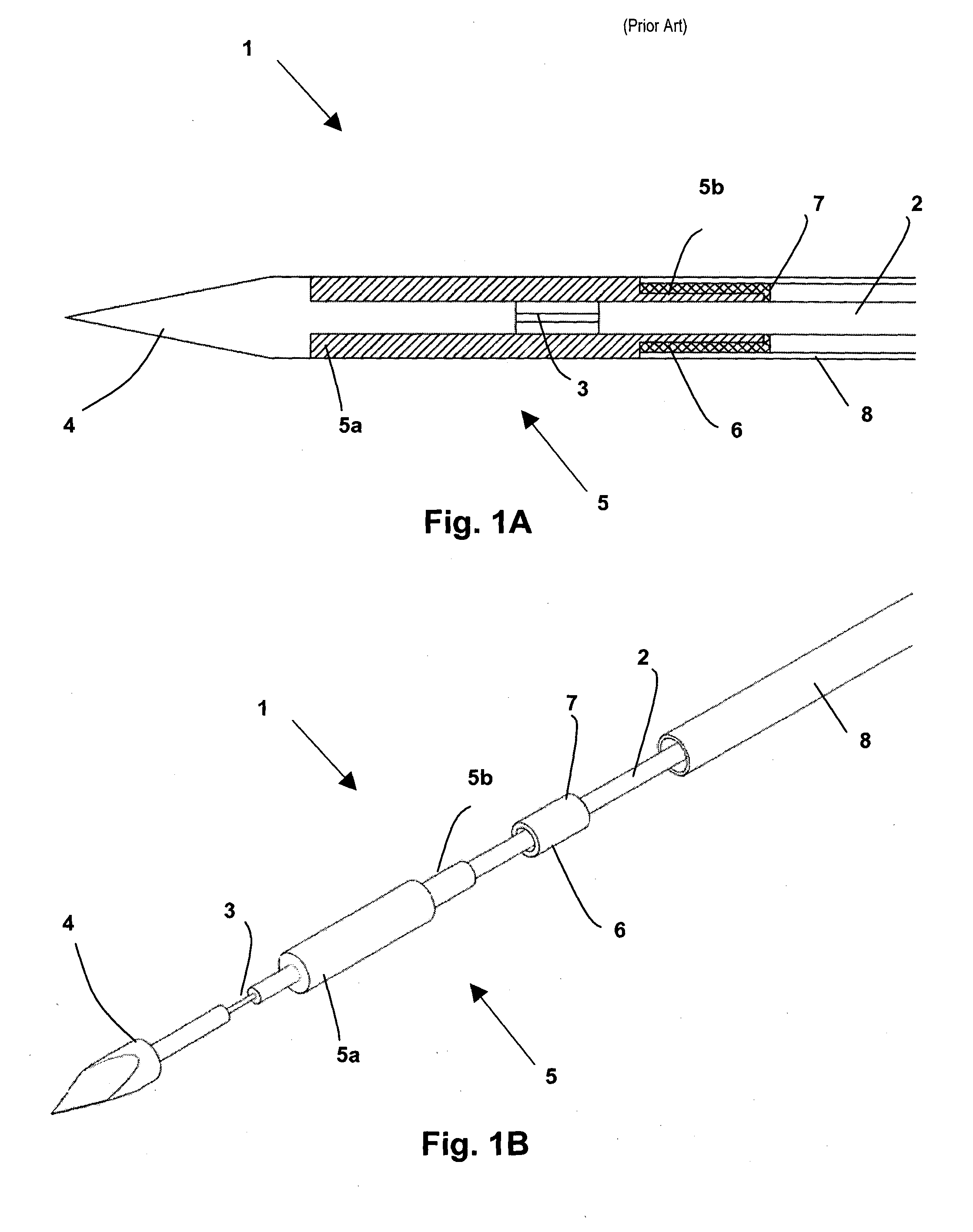

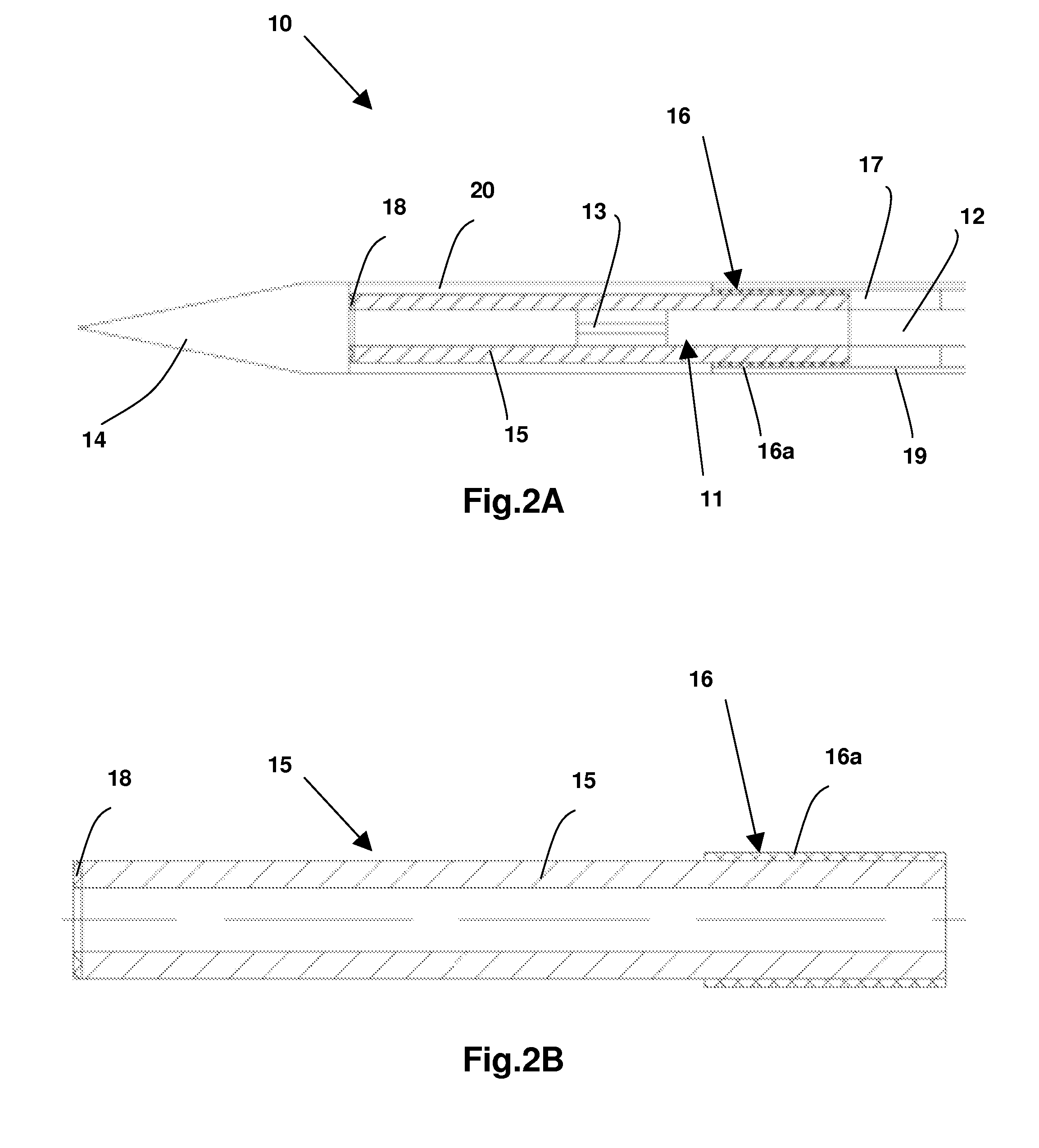

Heated hose apparatus and method

InactiveUS20080298788A1Reduce manufacturing stepsLess susceptible to wear and breakagePipe heating/coolingMachines/enginesInter layerMetallic materials

A heated hose assembly includes: an extruded inner liner; an intermediate layer comprising strands of a nonmetallic material and at least one heating wire each of the nonmetallic material and heating wire interwoven about the exterior of the extruded inner liner; an outer coating dispersed throughout the strands of the intermediate layer, and; a crimp attachment component for attaching the at least one heating wire to a power source.

Owner:TELEFLEX FLUID SYSTEMS INC

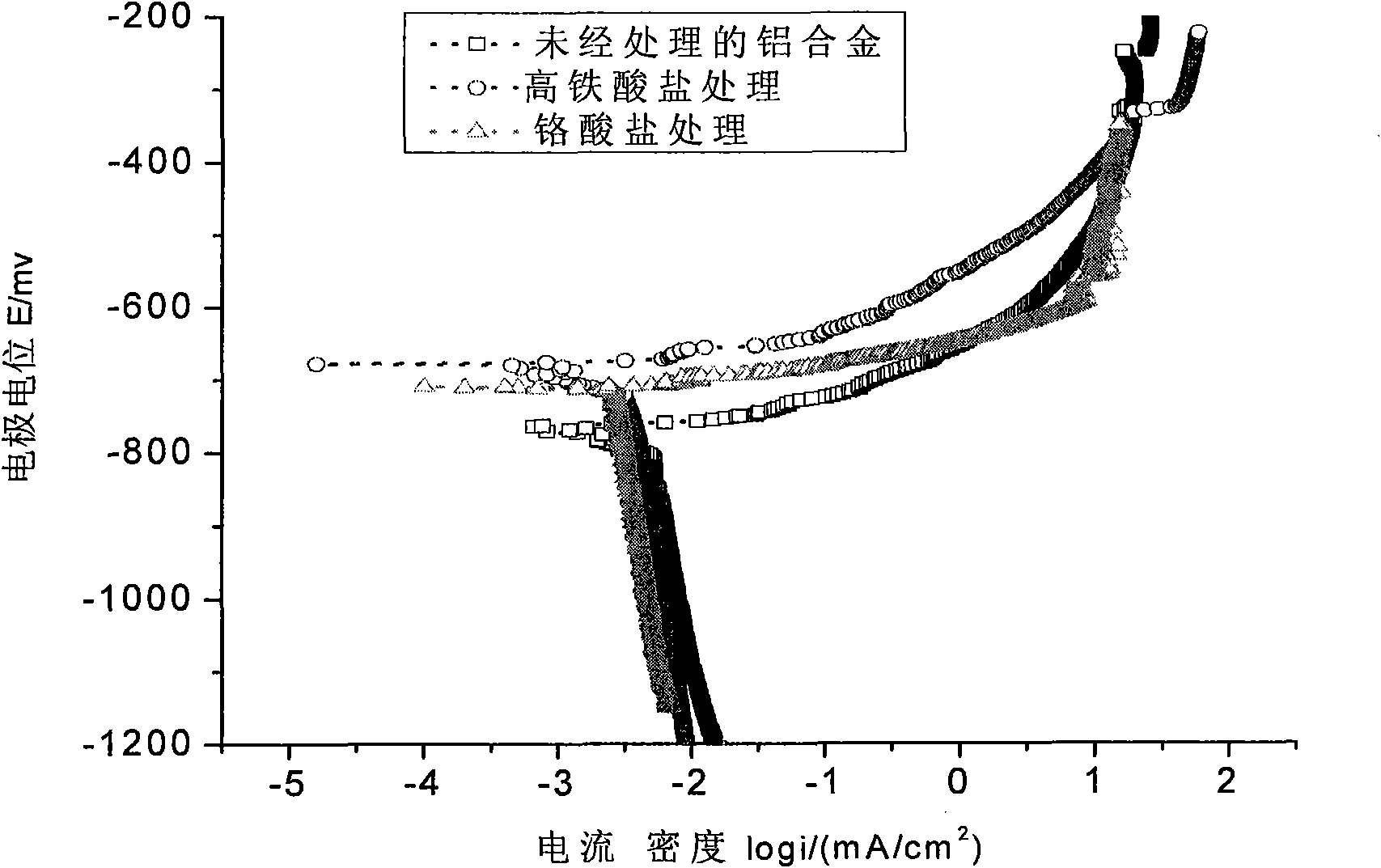

Organic and inorganic composite aluminium alloy non-chromium passivation treatment fluid

InactiveCN101565826AWith "self-healing" functionImprove corrosion resistanceMetallic material coating processesAcrylic resinPhosphoric acid

Owner:UNIV OF SCI & TECH BEIJING

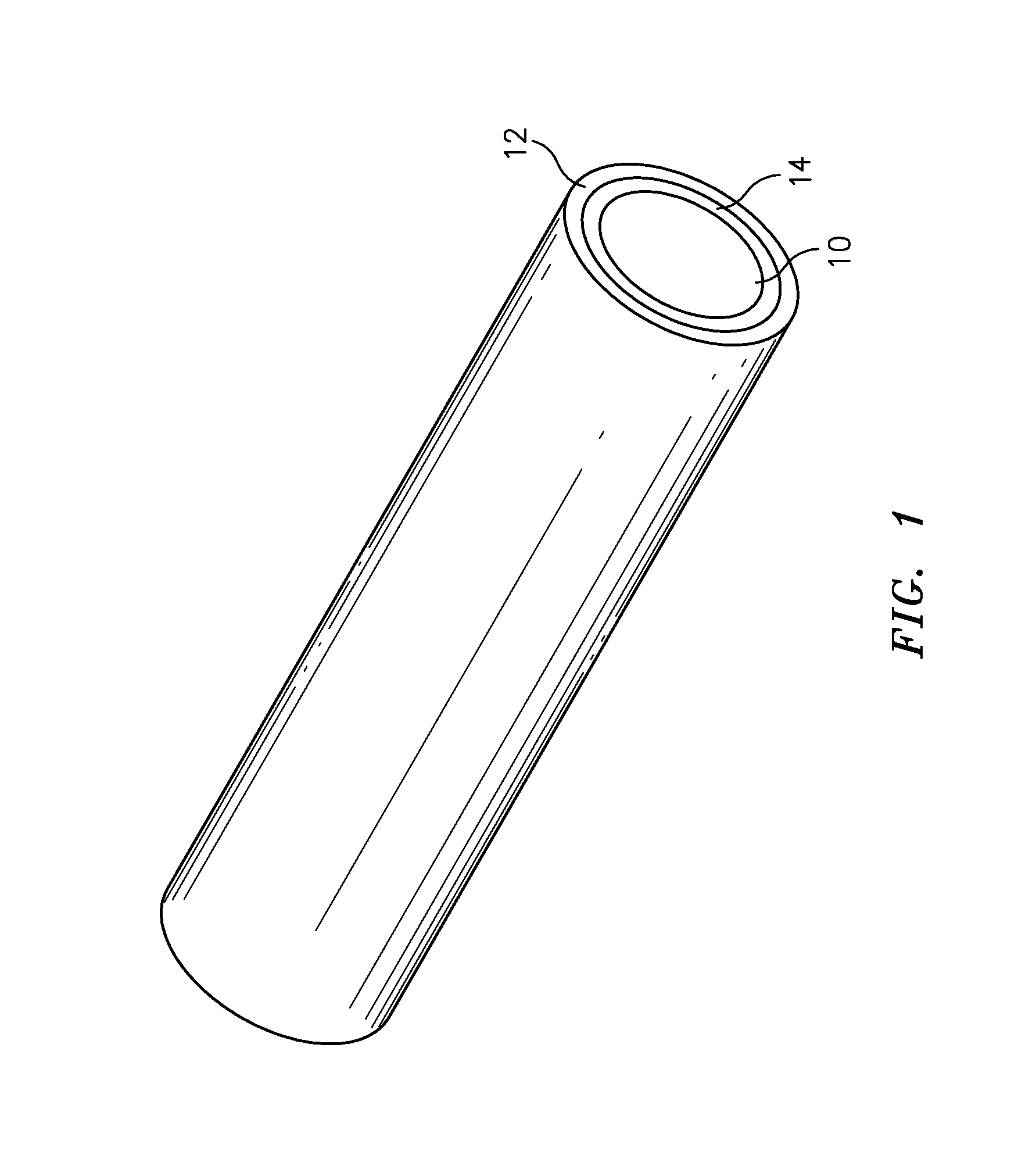

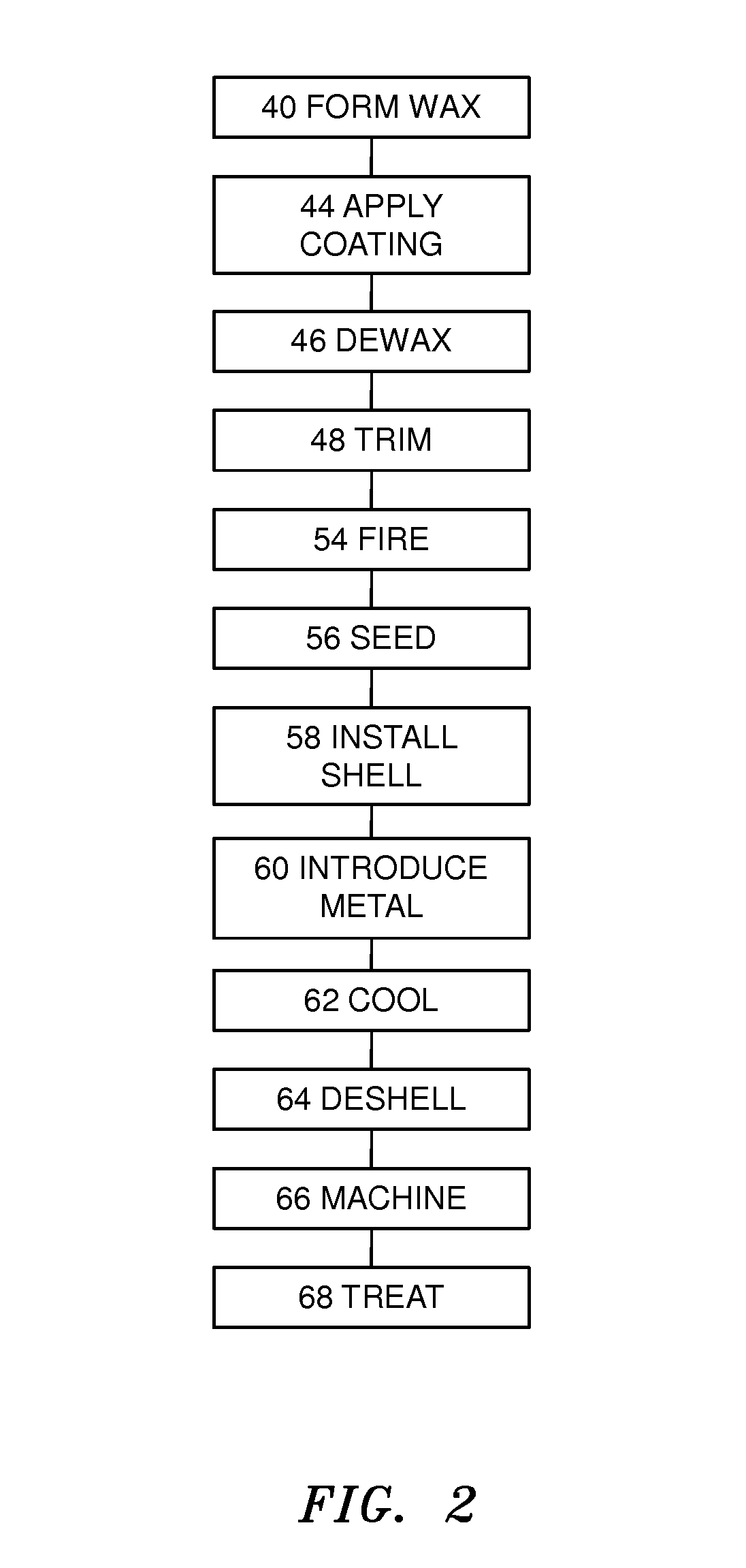

Metallic coated cores to facilitate thin wall casting

Owner:RAYTHEON TECH CORP

Hermetic sealing of a substrate of high thermal conductivity using an interposer of low thermal conductivity

InactiveUS6037193AReduce heat transferImprove air tightnessSemiconductor/solid-state device detailsSolid-state devicesThermal conductivityMetallic materials

Owner:IBM CORP

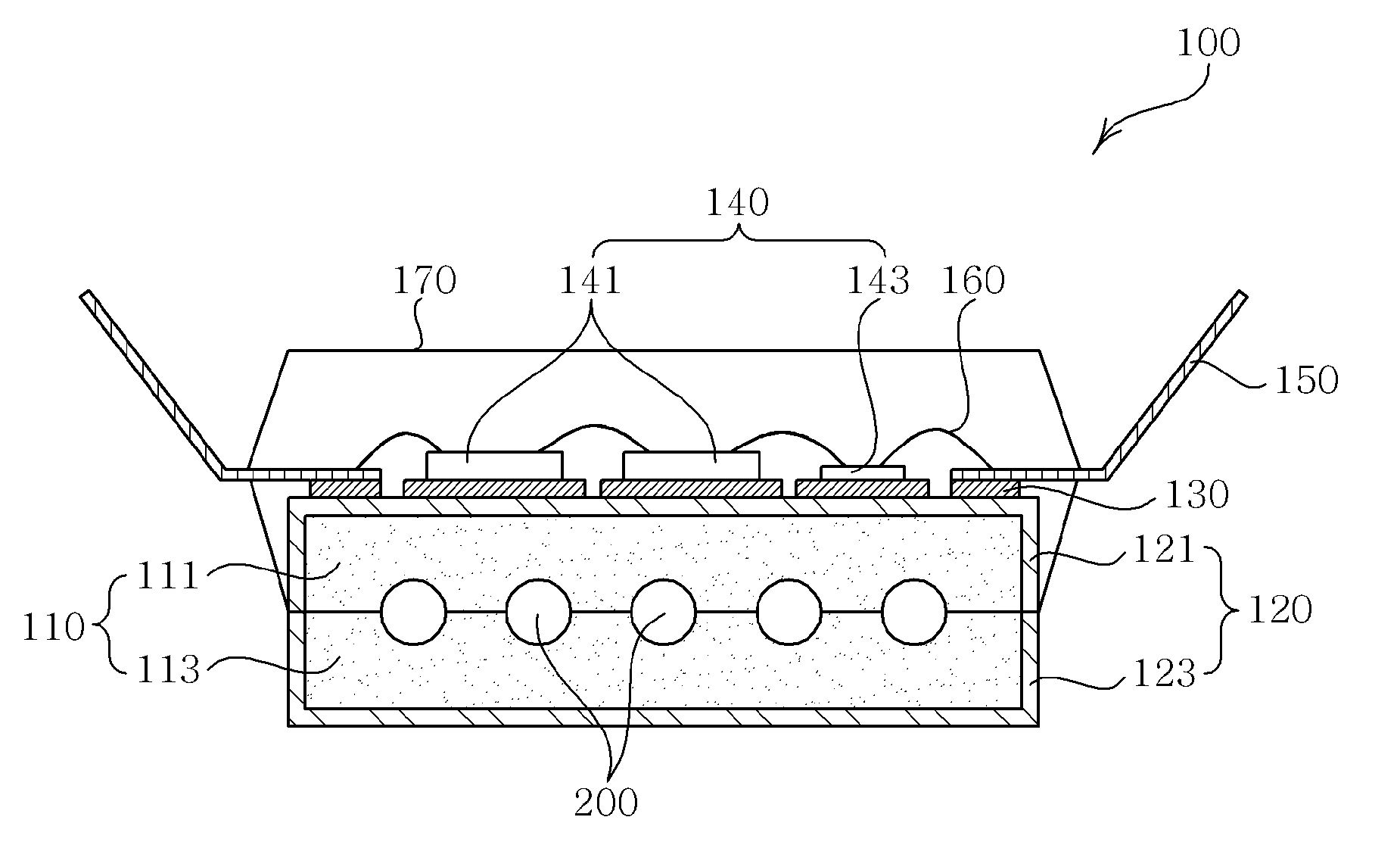

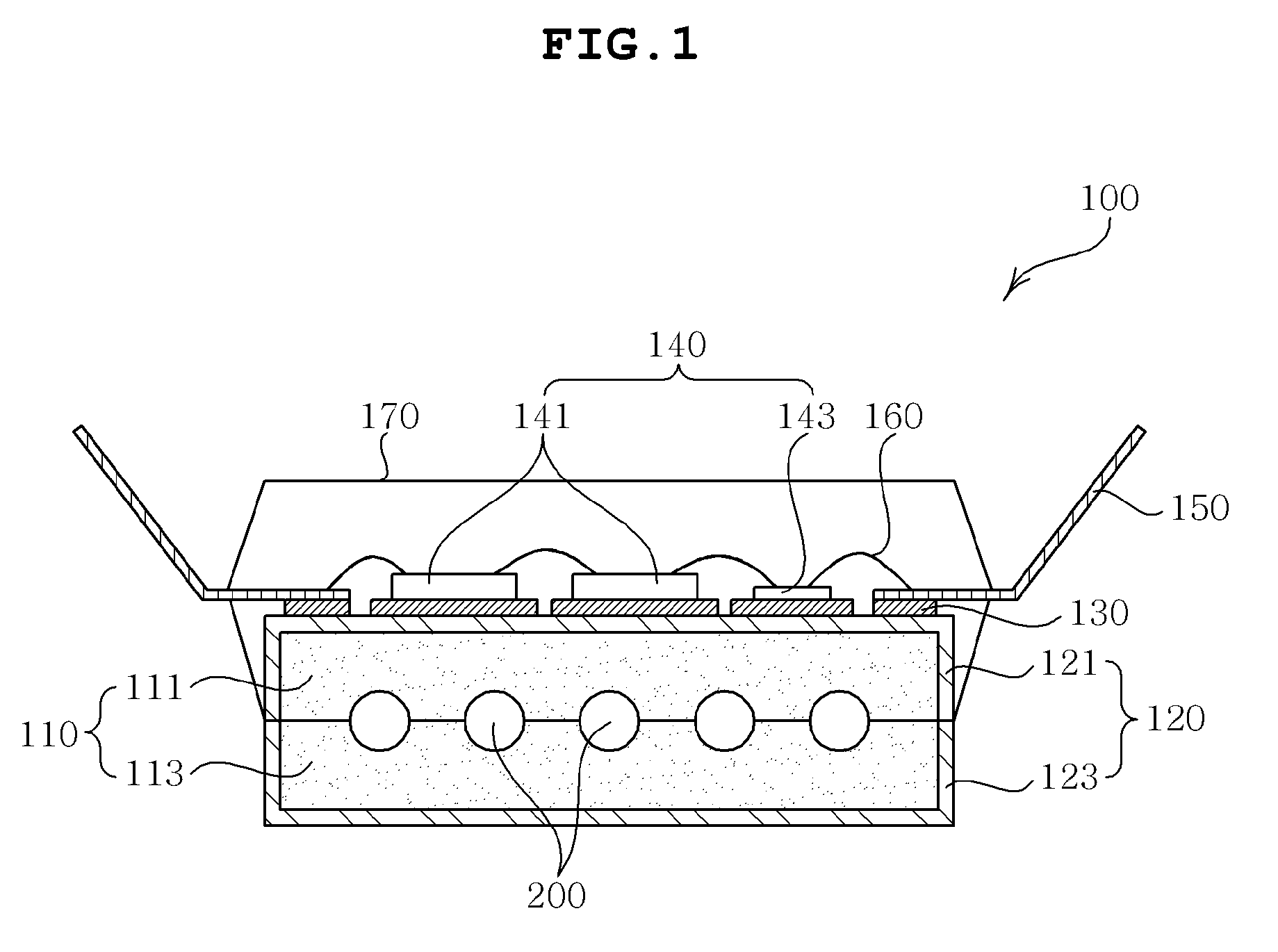

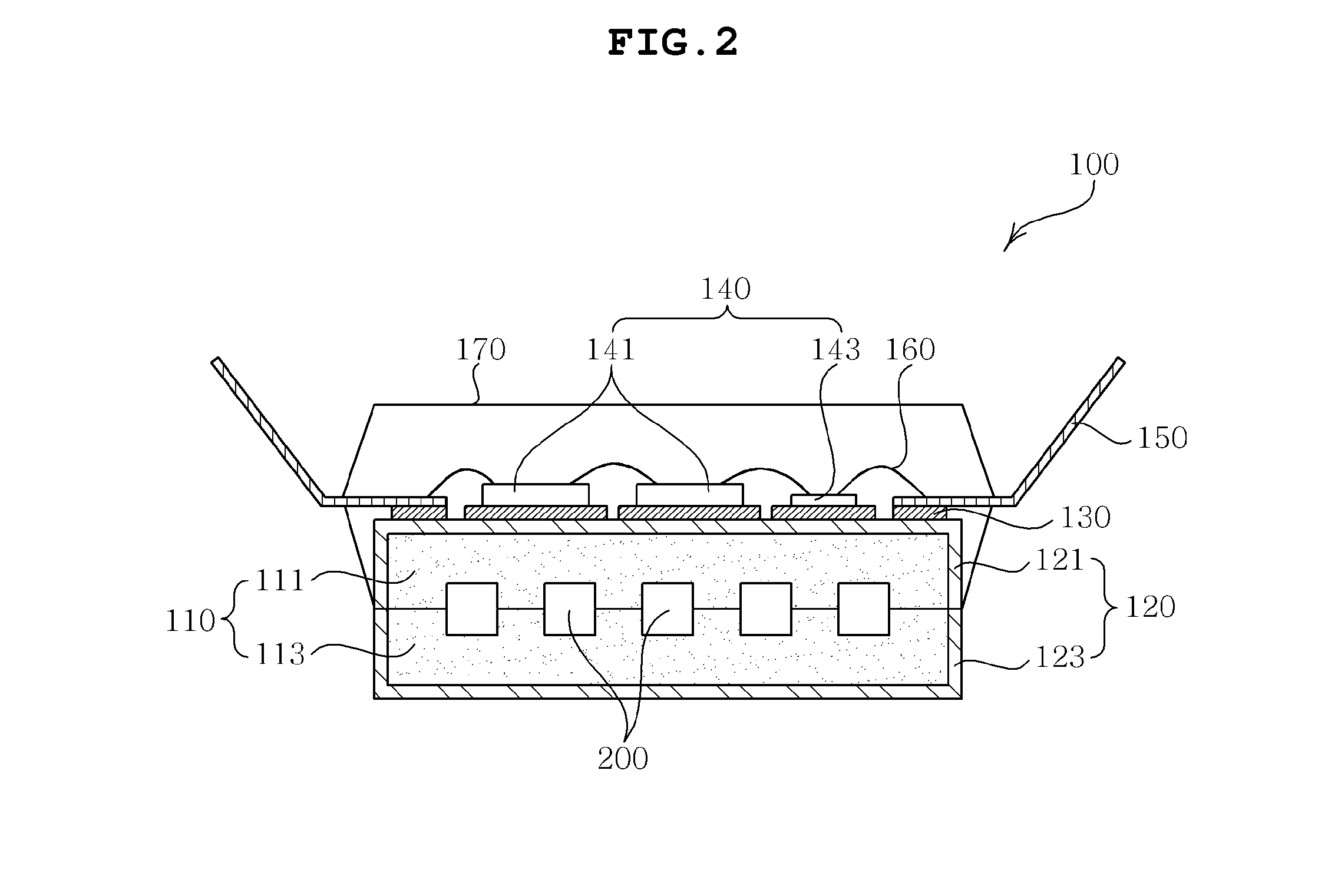

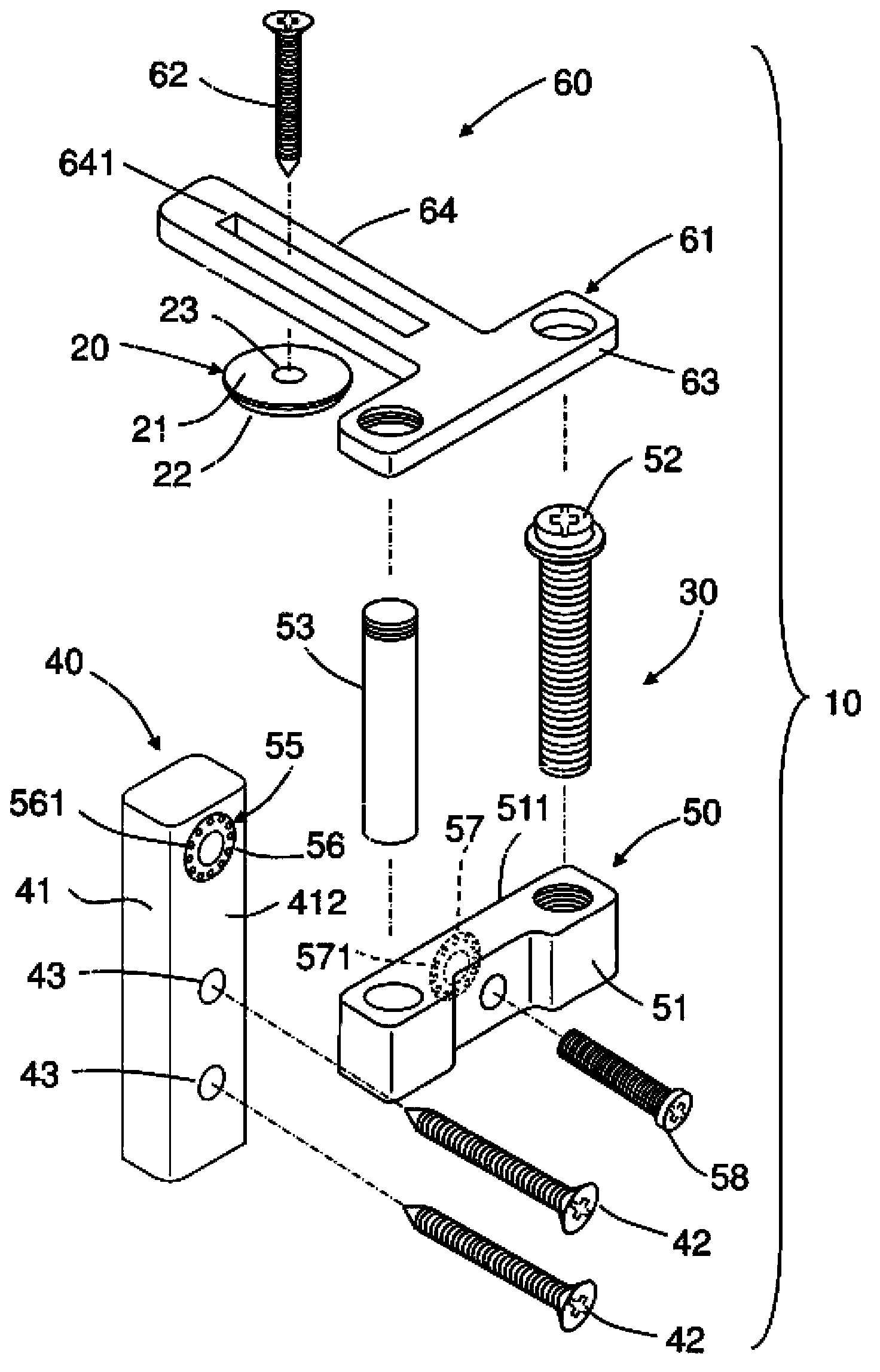

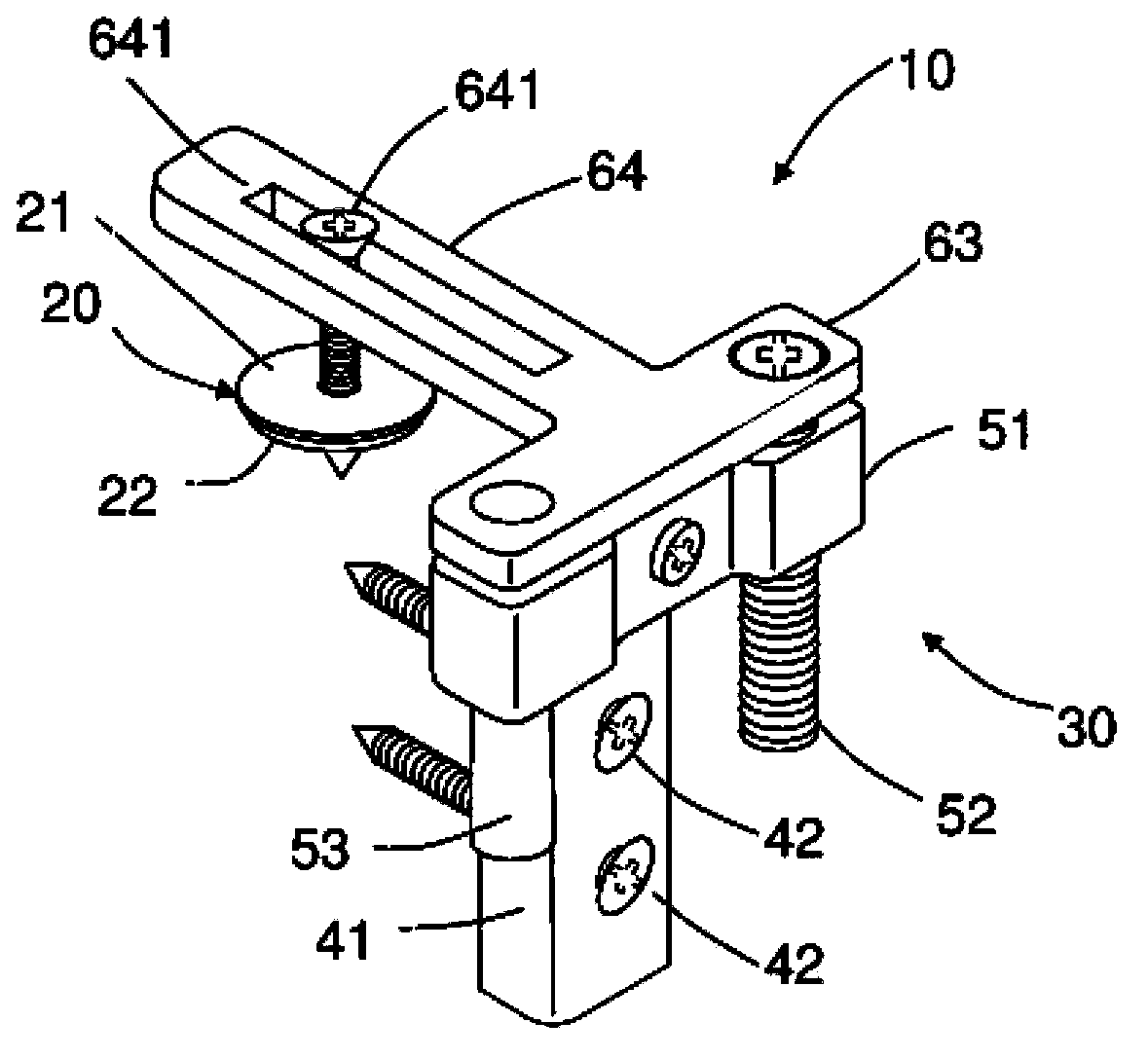

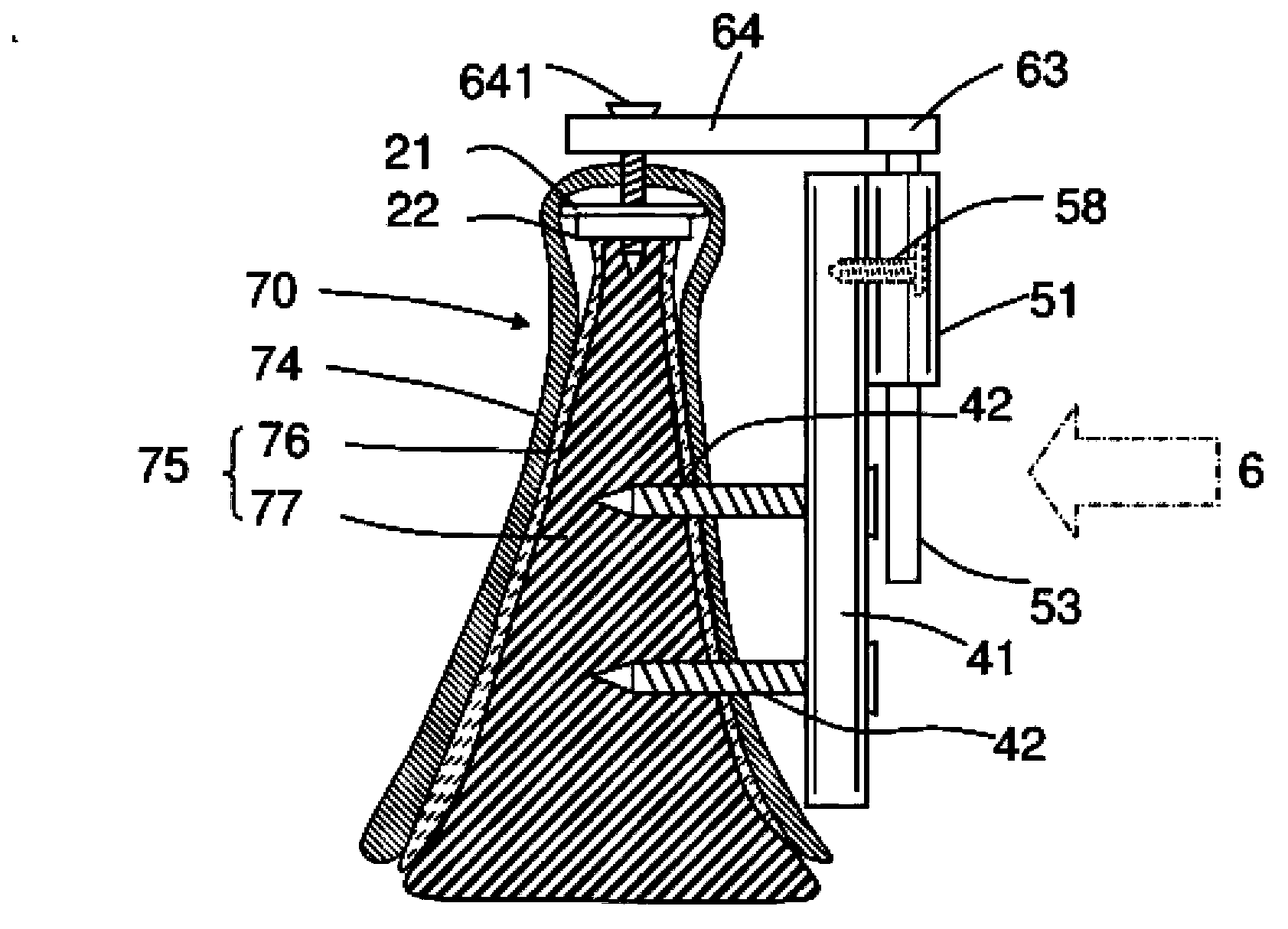

Power module package and method for manufacturing the same

InactiveUS20130010425A1Semiconductor/solid-state device detailsSolid-state devicesCooling channelMetallic materials

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

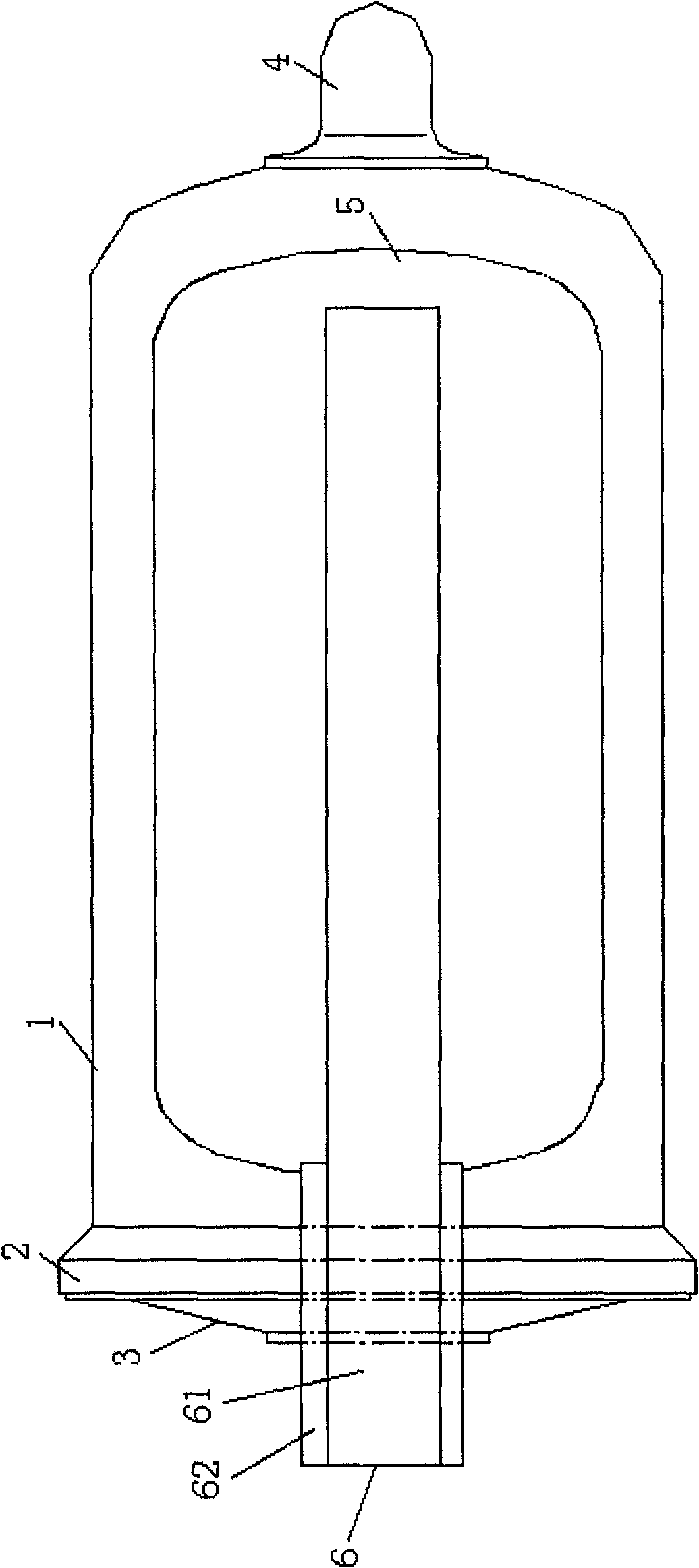

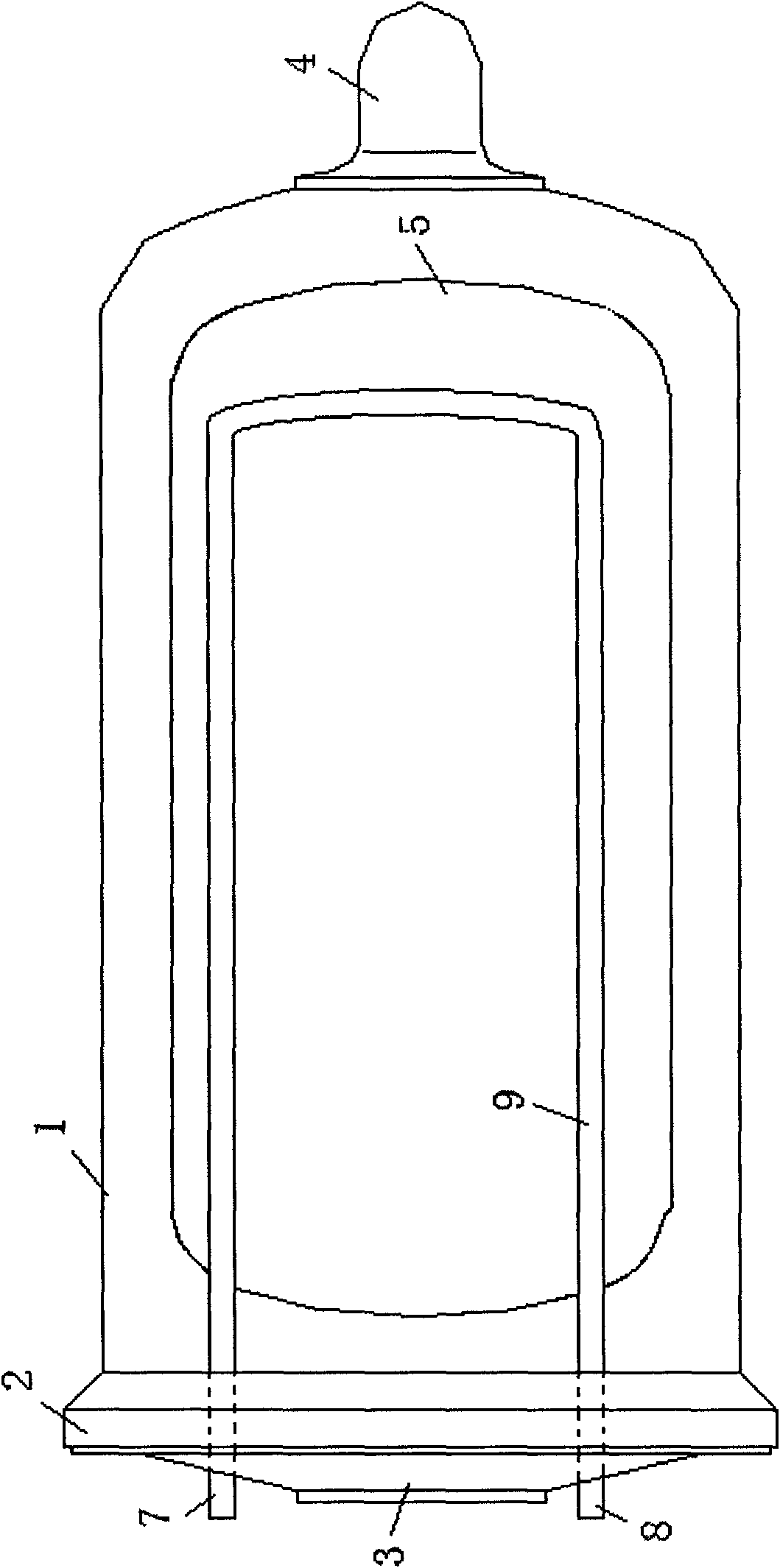

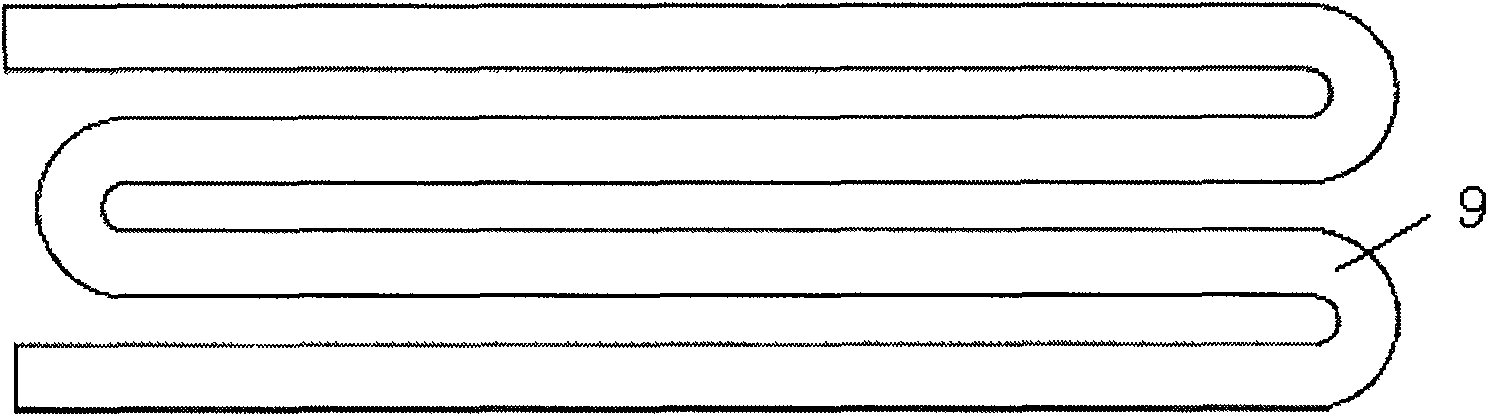

Thermal storage type vacuum tube

InactiveCN101639296AExtended service lifeIncrease the heat exchange areaHeat storage plantsSolar heat devicesSolar waterMetallic materials

Owner:北京桑达太阳能技术有限公司

Optical module with fiber feedthrough

Owner:LUMENTUM OPERATIONS LLC

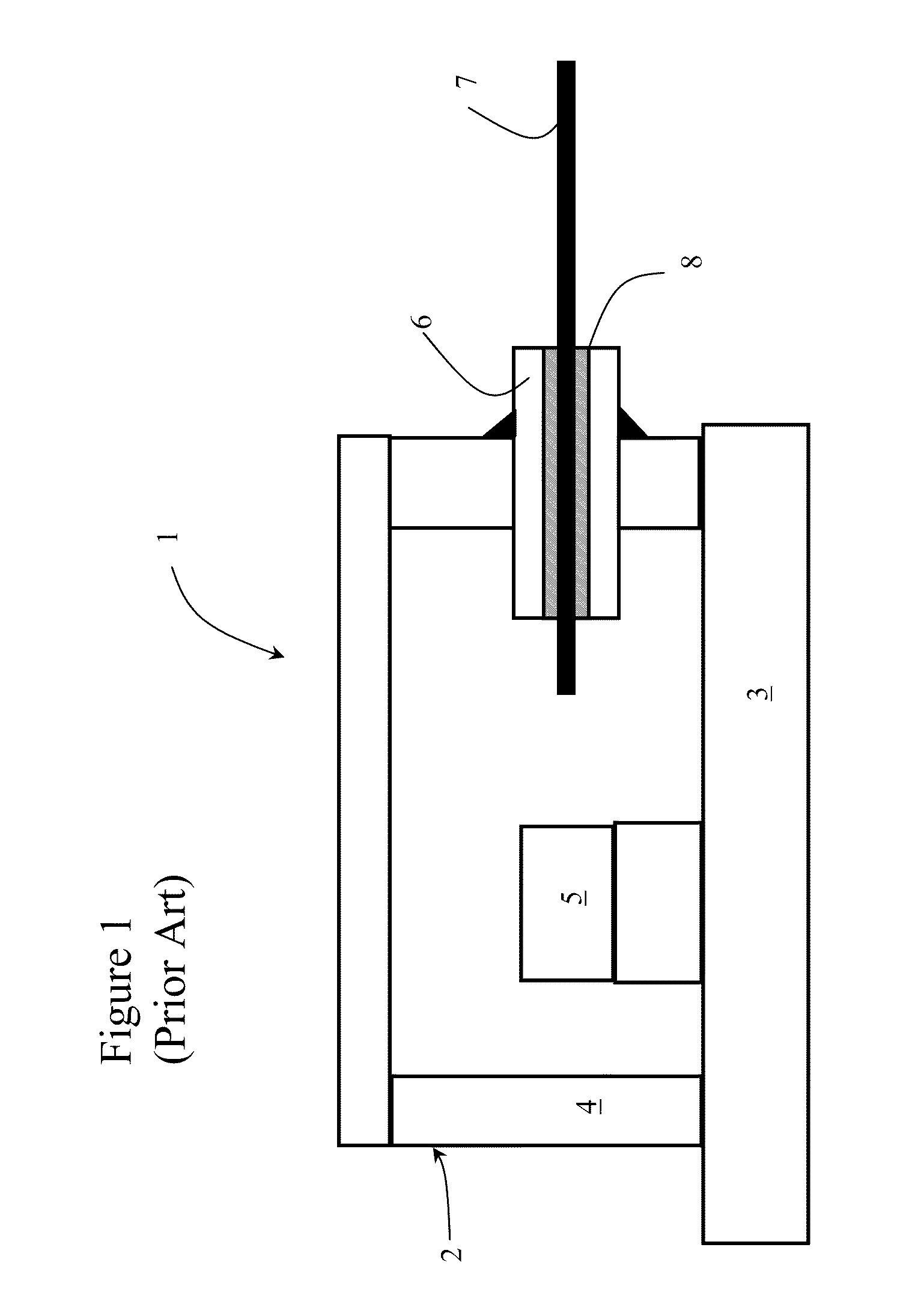

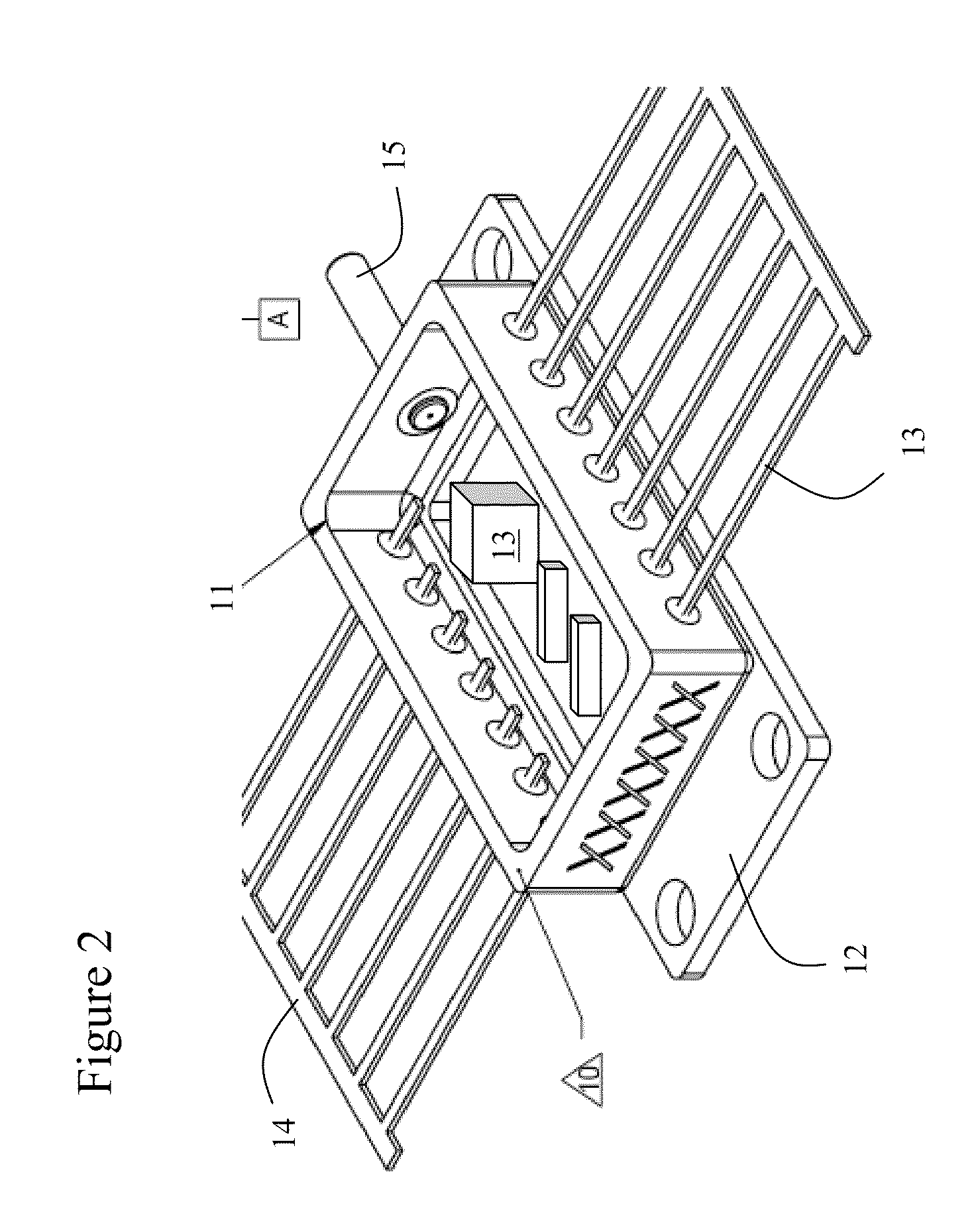

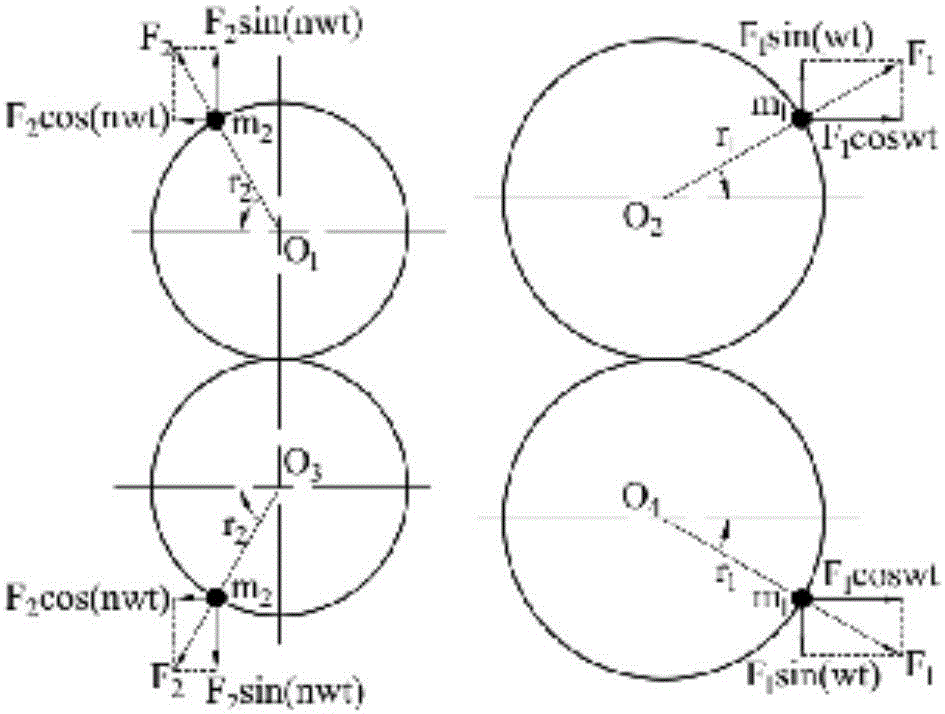

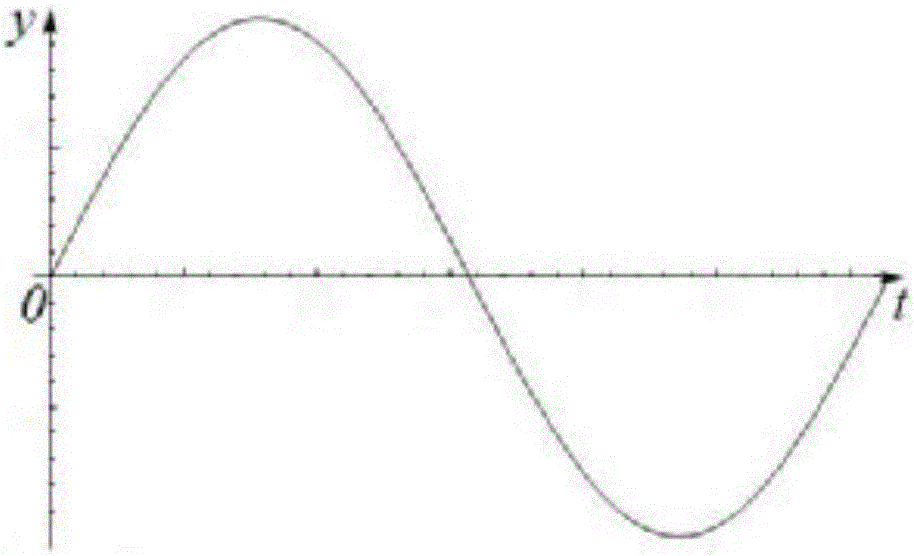

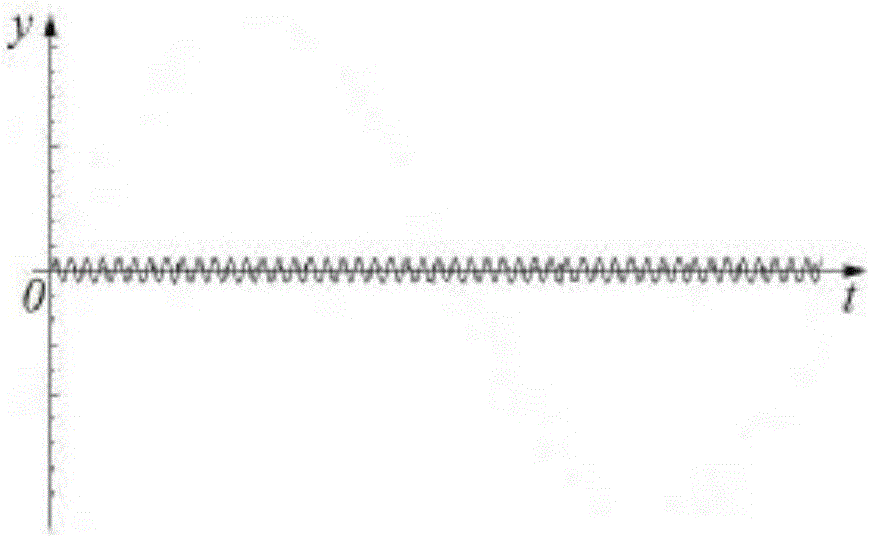

Unloading method based on high/low-frequency vibration load loading

InactiveCN106475758AReduce consumptionImprove efficiencyMechanical vibrations separationStress concentrationVibration amplitude

Owner:JIANGNAN UNIV

Microwave Device For Tissue Ablation

ActiveUS20150038956A1Good mechanical resistanceIncreased mechanical toughnessSurgical needlesSurgical instruments for heatingDielectricElectrical conductor

Owner:H S HOSPITAL SERVICE

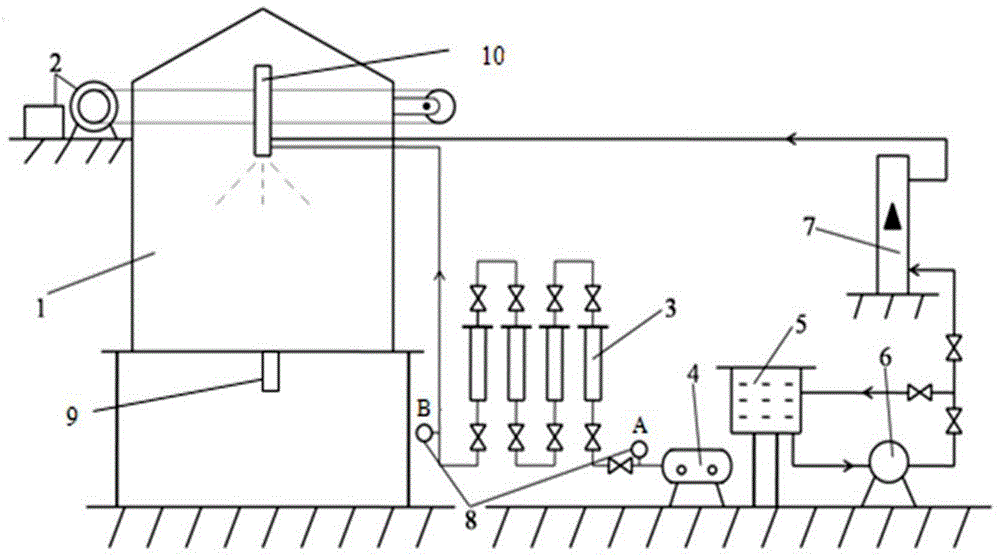

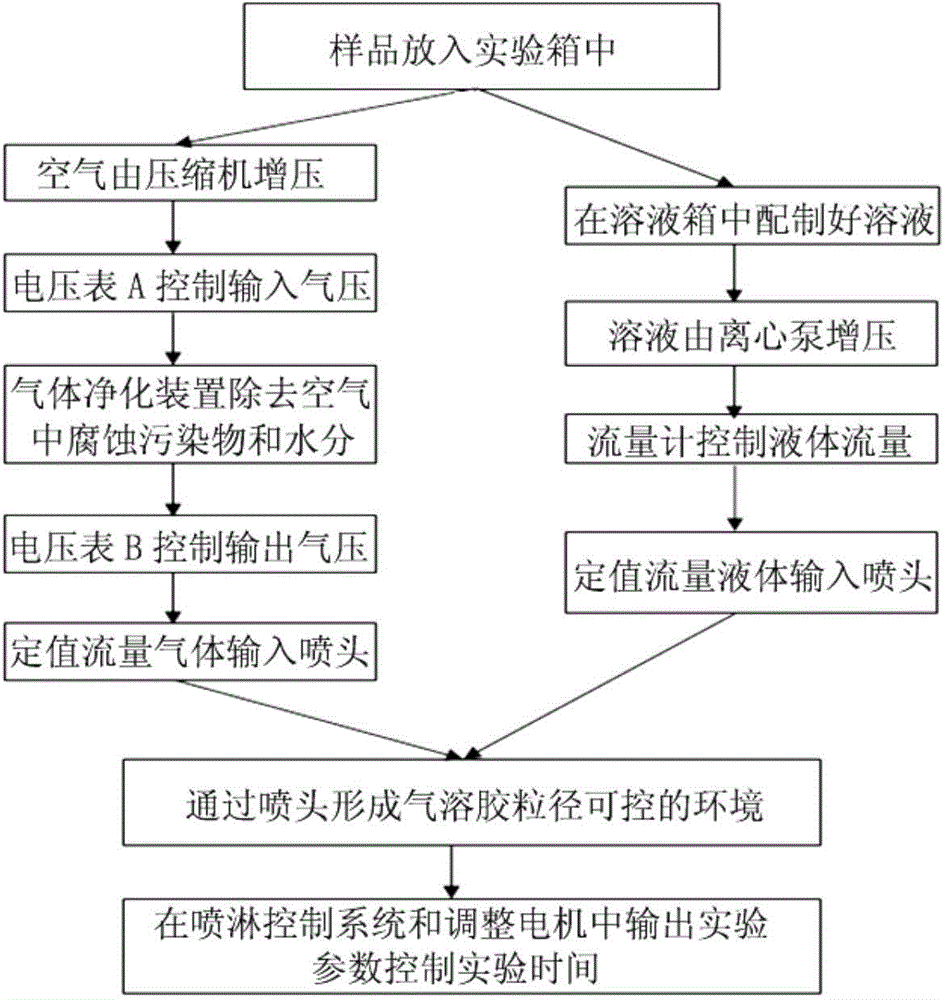

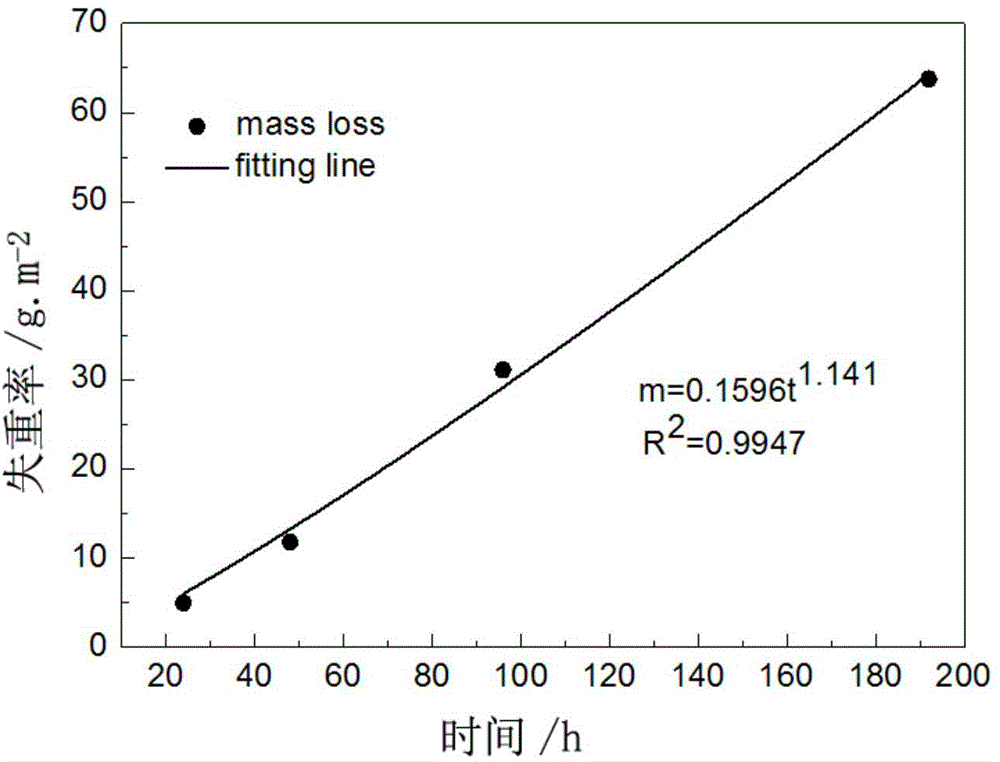

Simulated accelerated test device and method of acidic marine aerosol-caused influence on steel atmospheric corrosion

InactiveCN105987872AResolution cycleSettlement feeWeather/light/corrosion resistanceControl systemMetallic materials

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

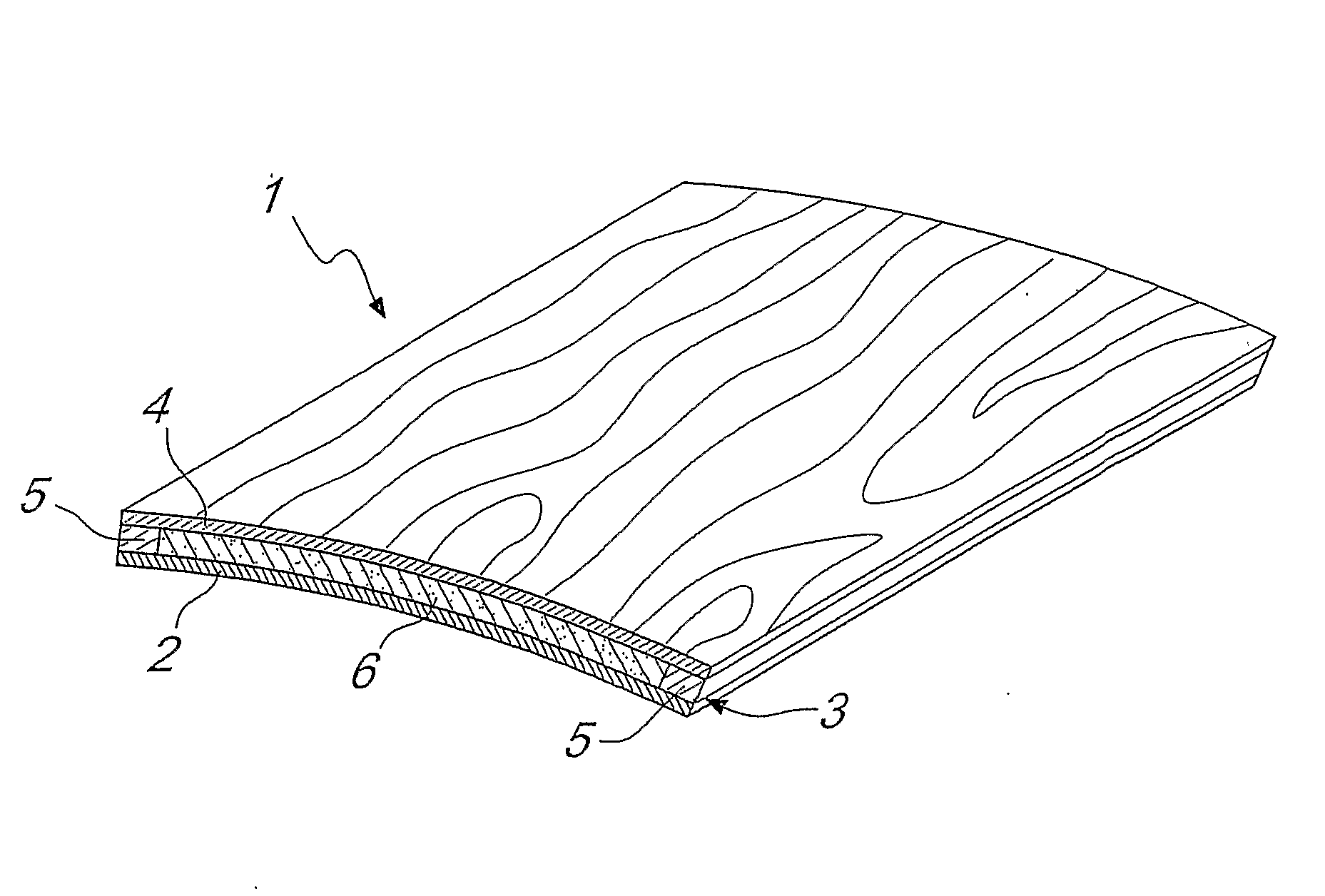

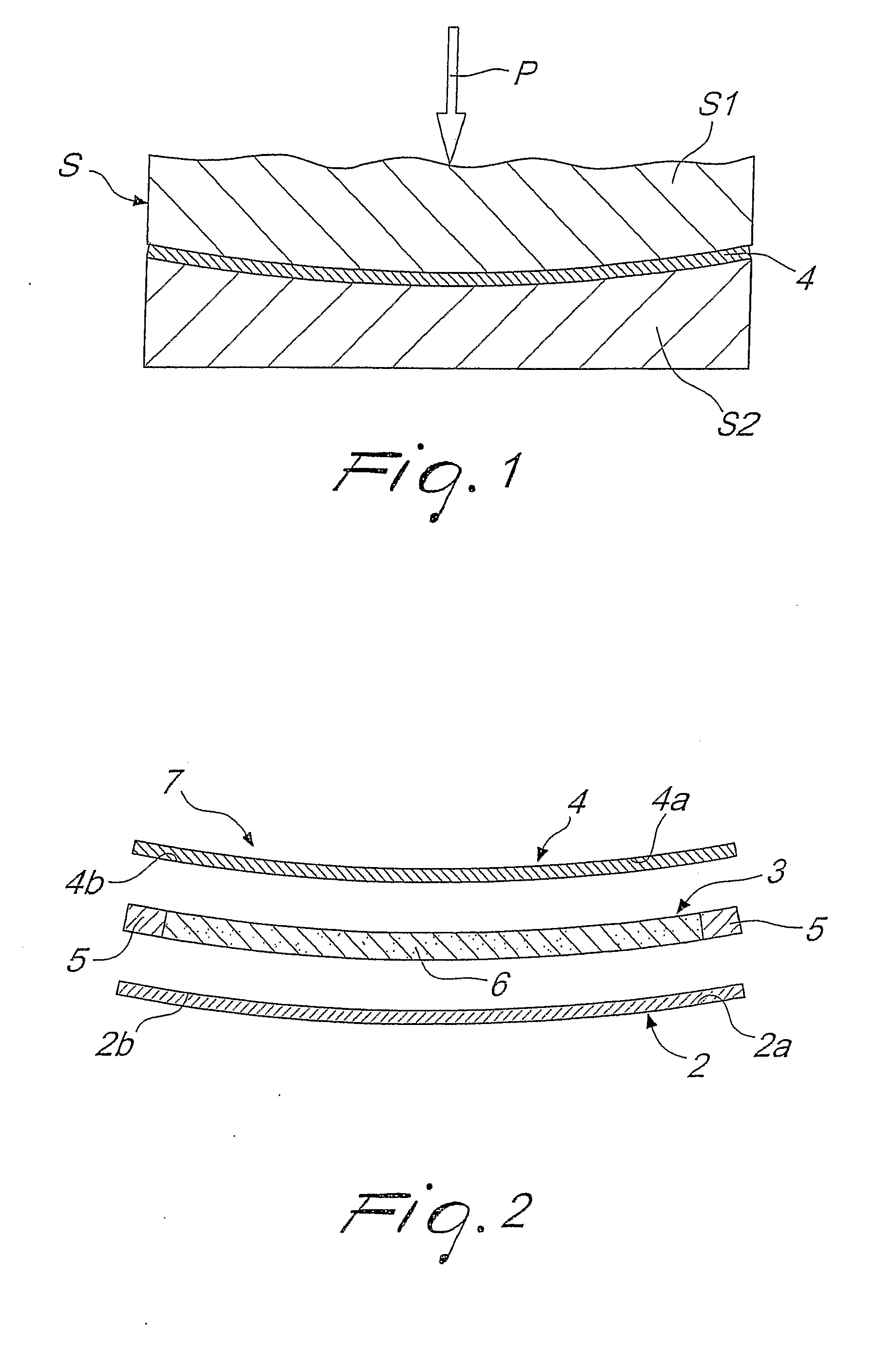

Method for Manufacturing Curved Components for Furniture, Particularly Doors for Furniture

InactiveUS20090218038A1Drawback can be obviatedLow production costLamination ancillary operationsLaminationMetallic materialsEngineering

Owner:TECNOFORM

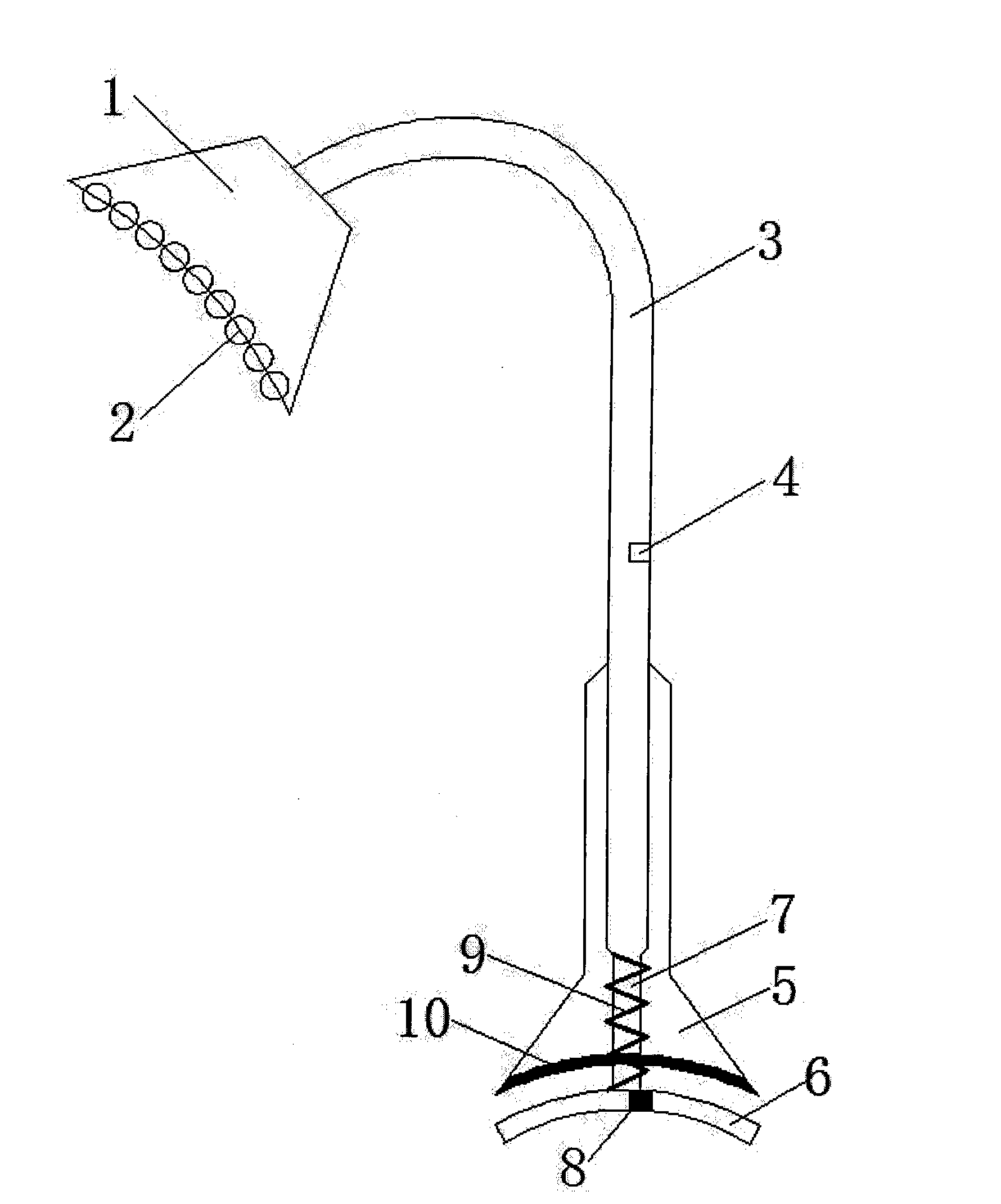

Sucking-disk-type myopia-prevention desk lamp

InactiveCN103383081AEasy to useReduce harmPoint-like light sourceLighting support devicesMetallic materialsEngineering

Owner:熊健勇

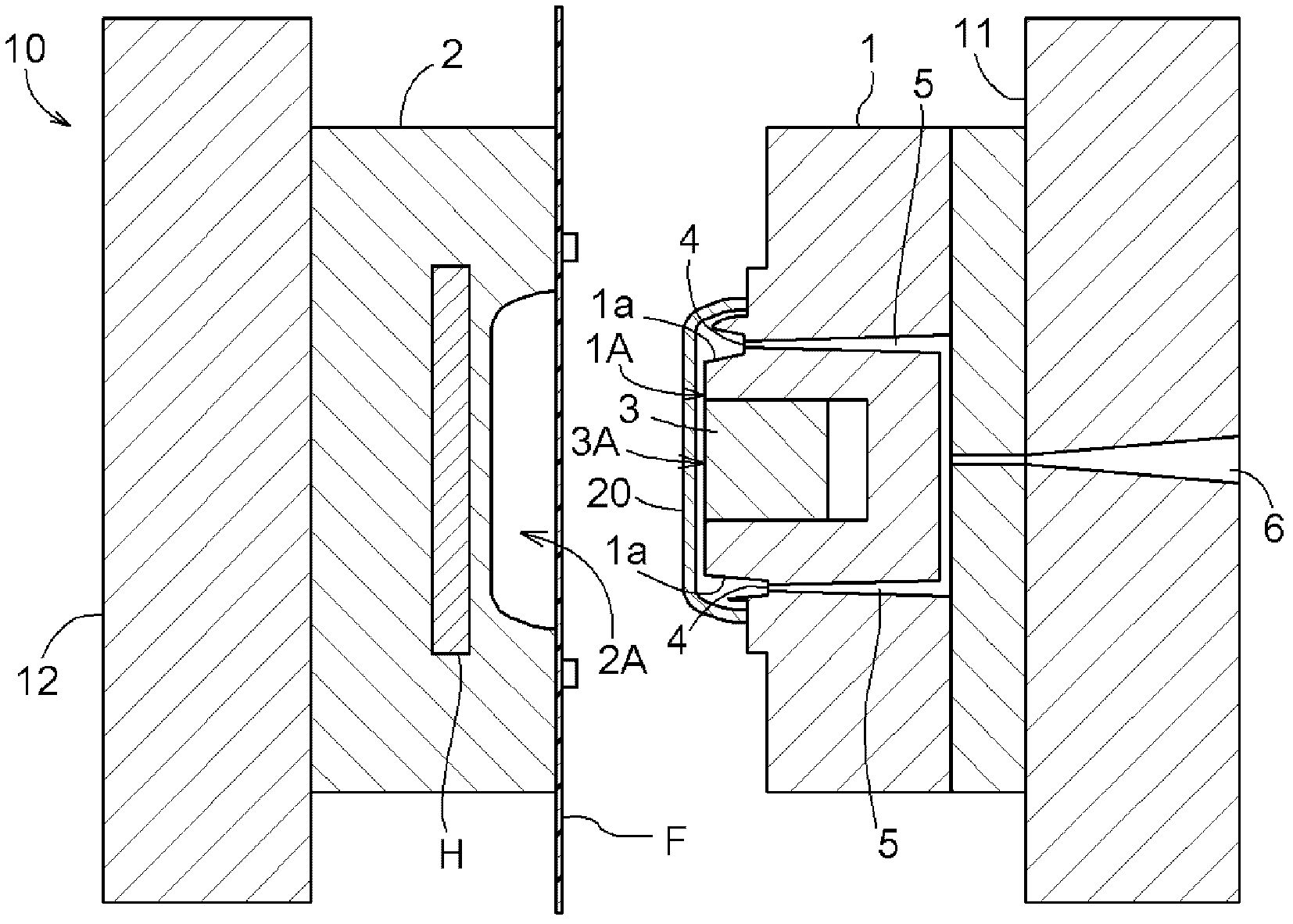

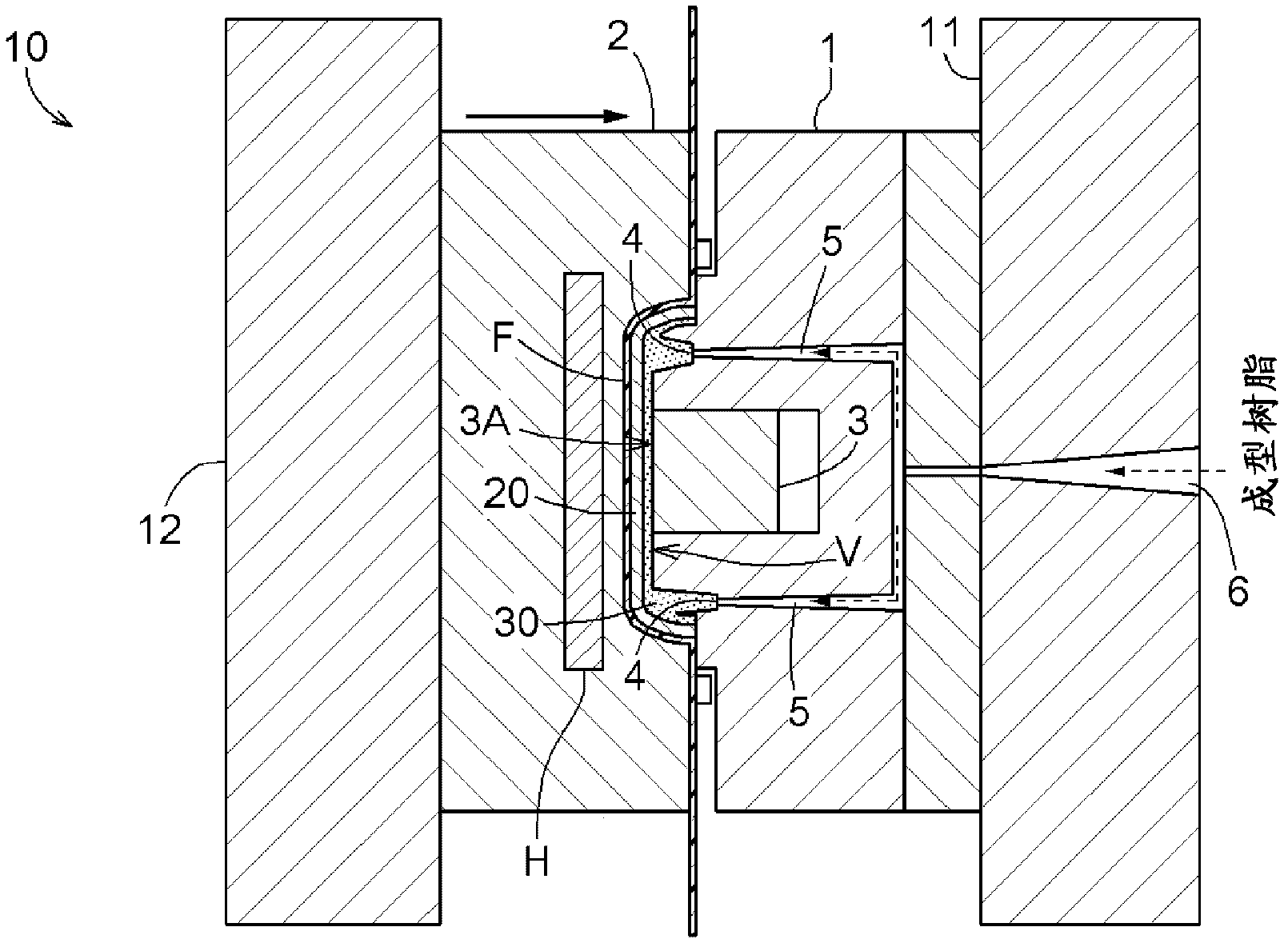

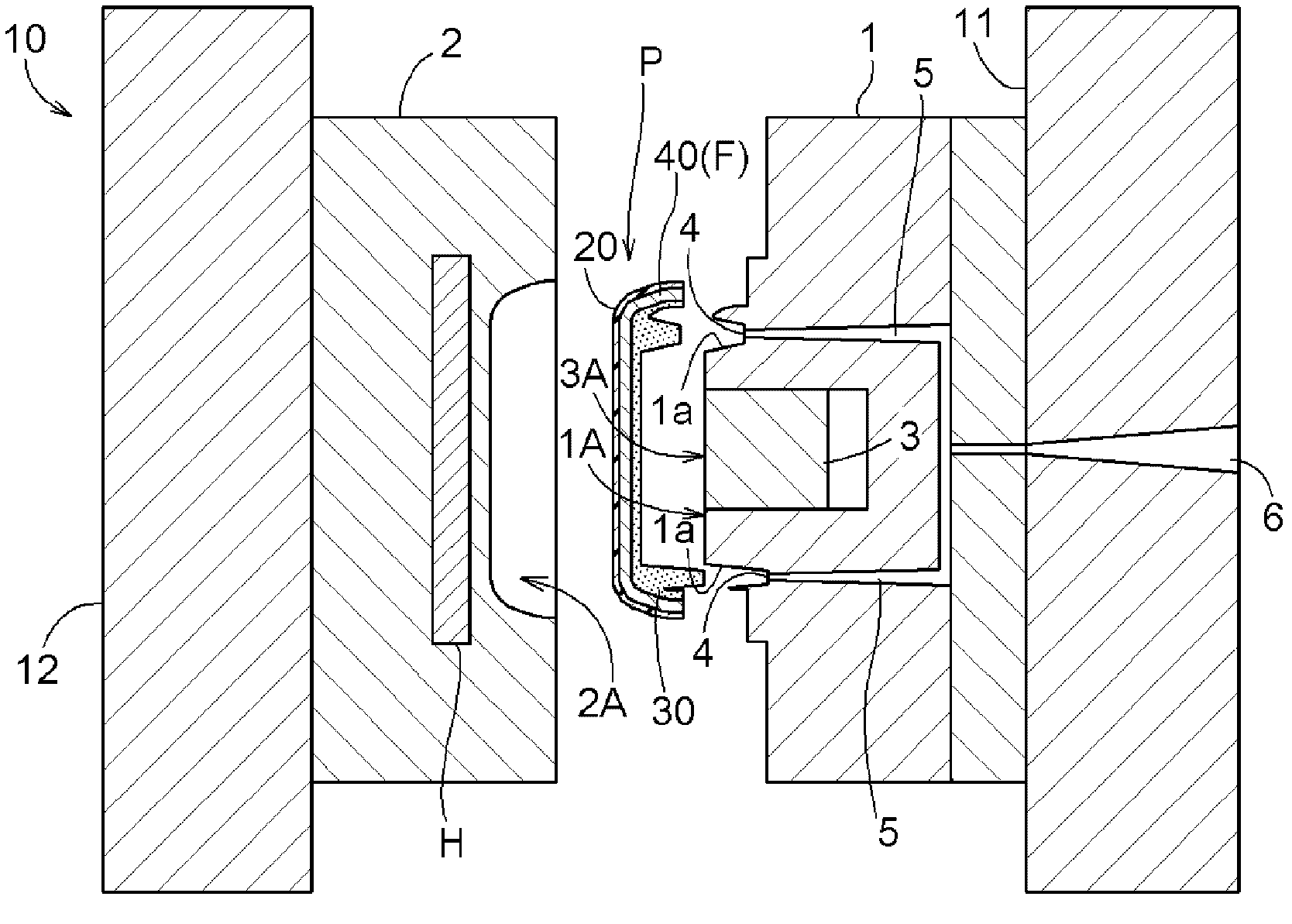

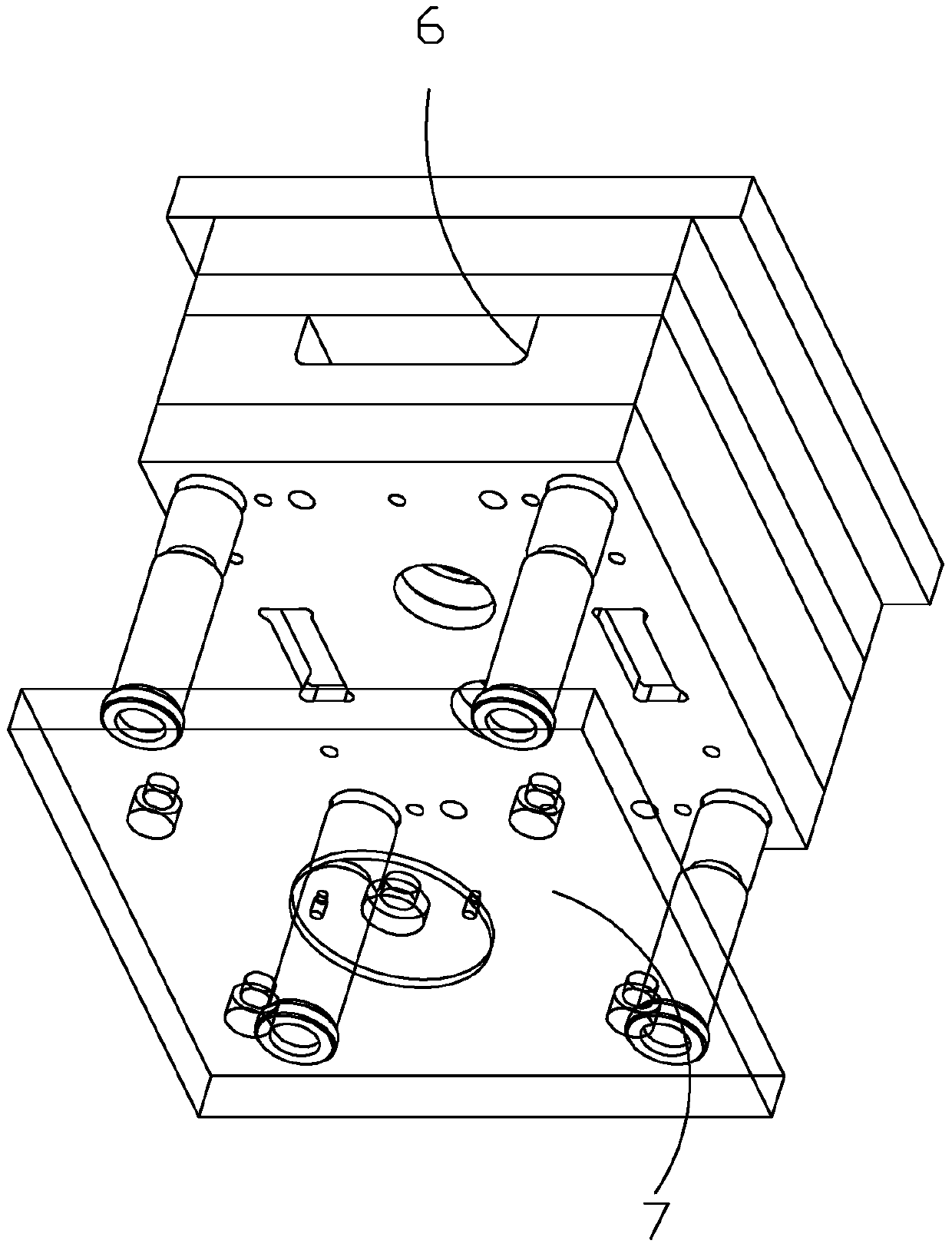

Molding die for injection molding and method for producing composite product

Owner:NISSHA PRINTING COMPANY

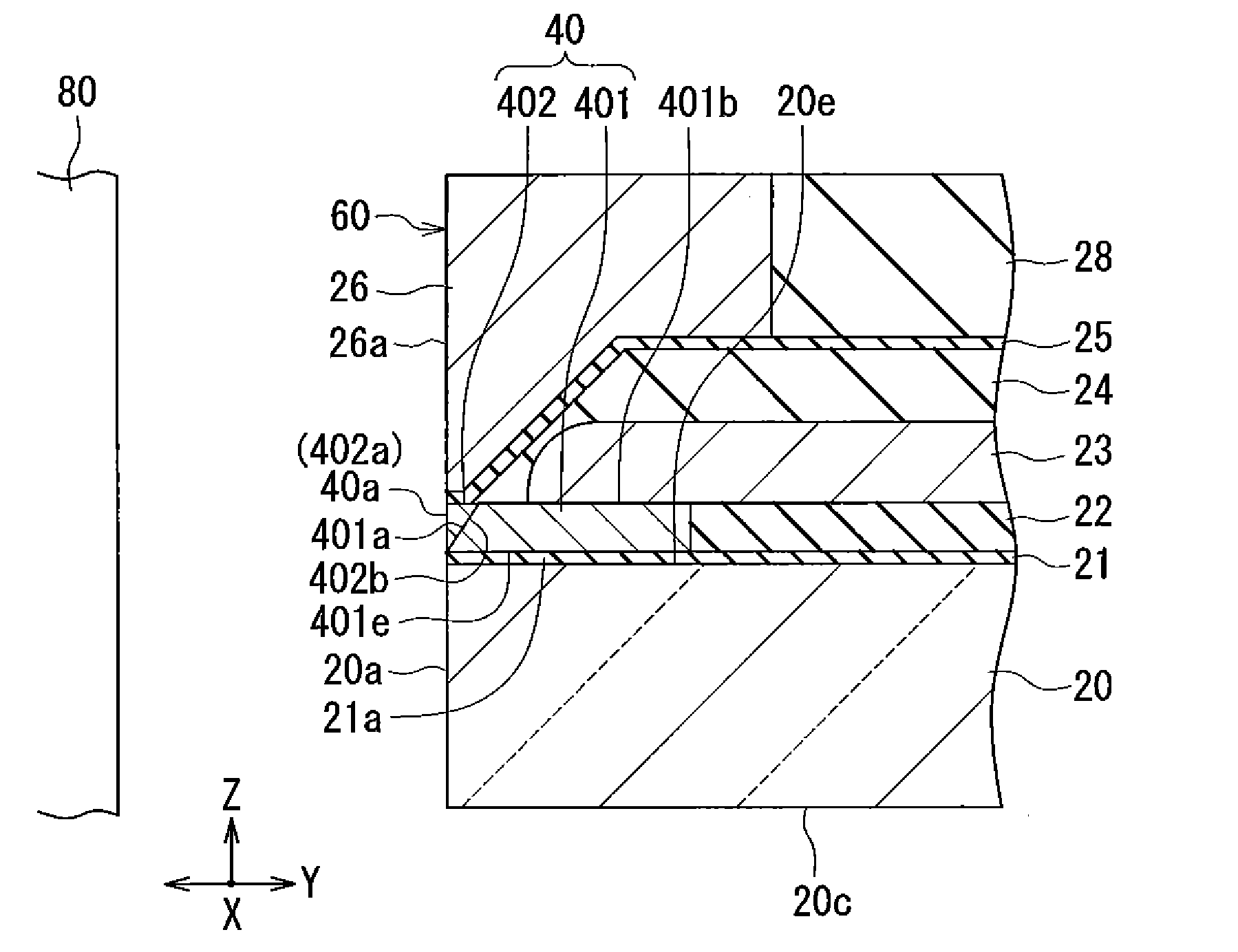

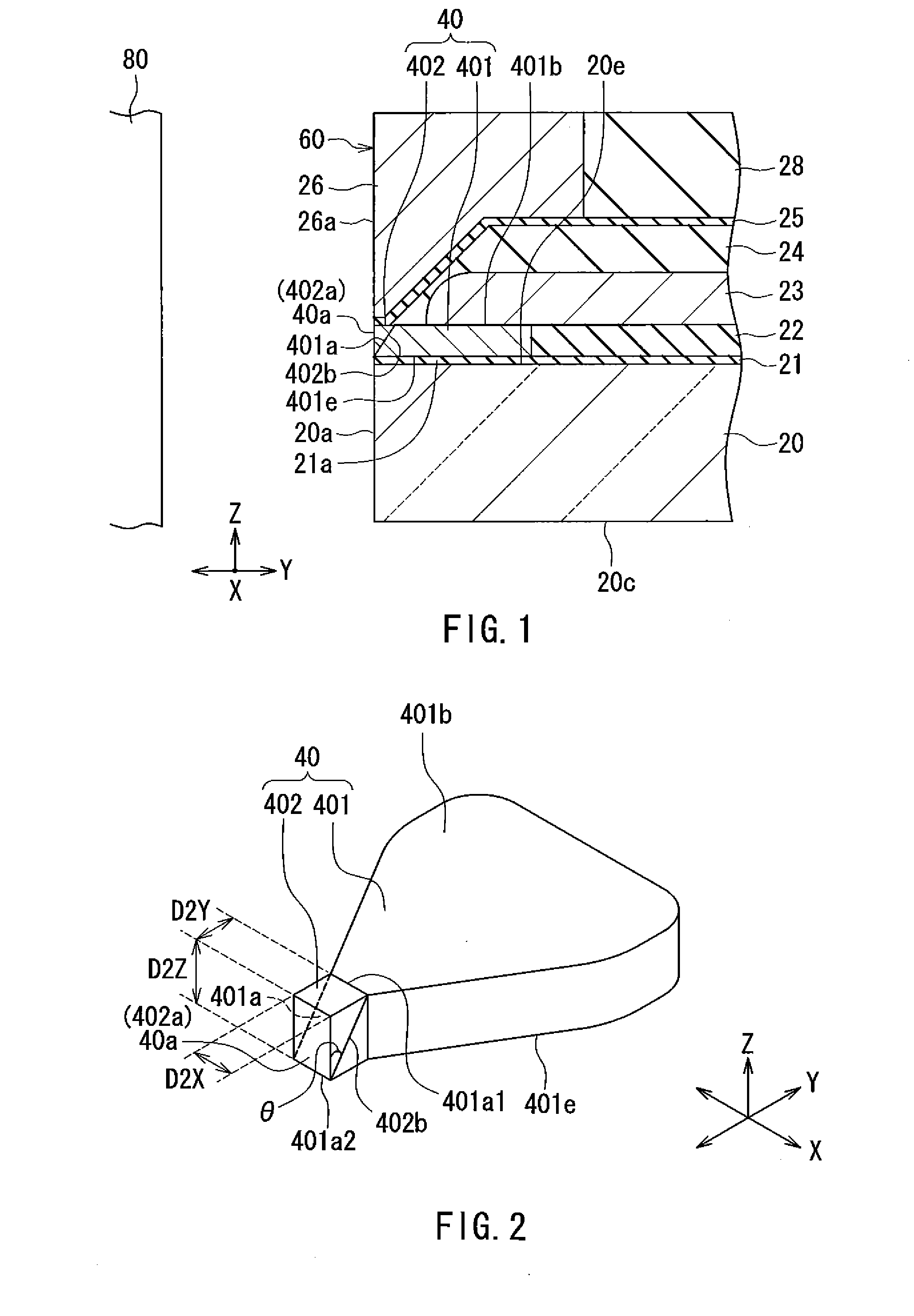

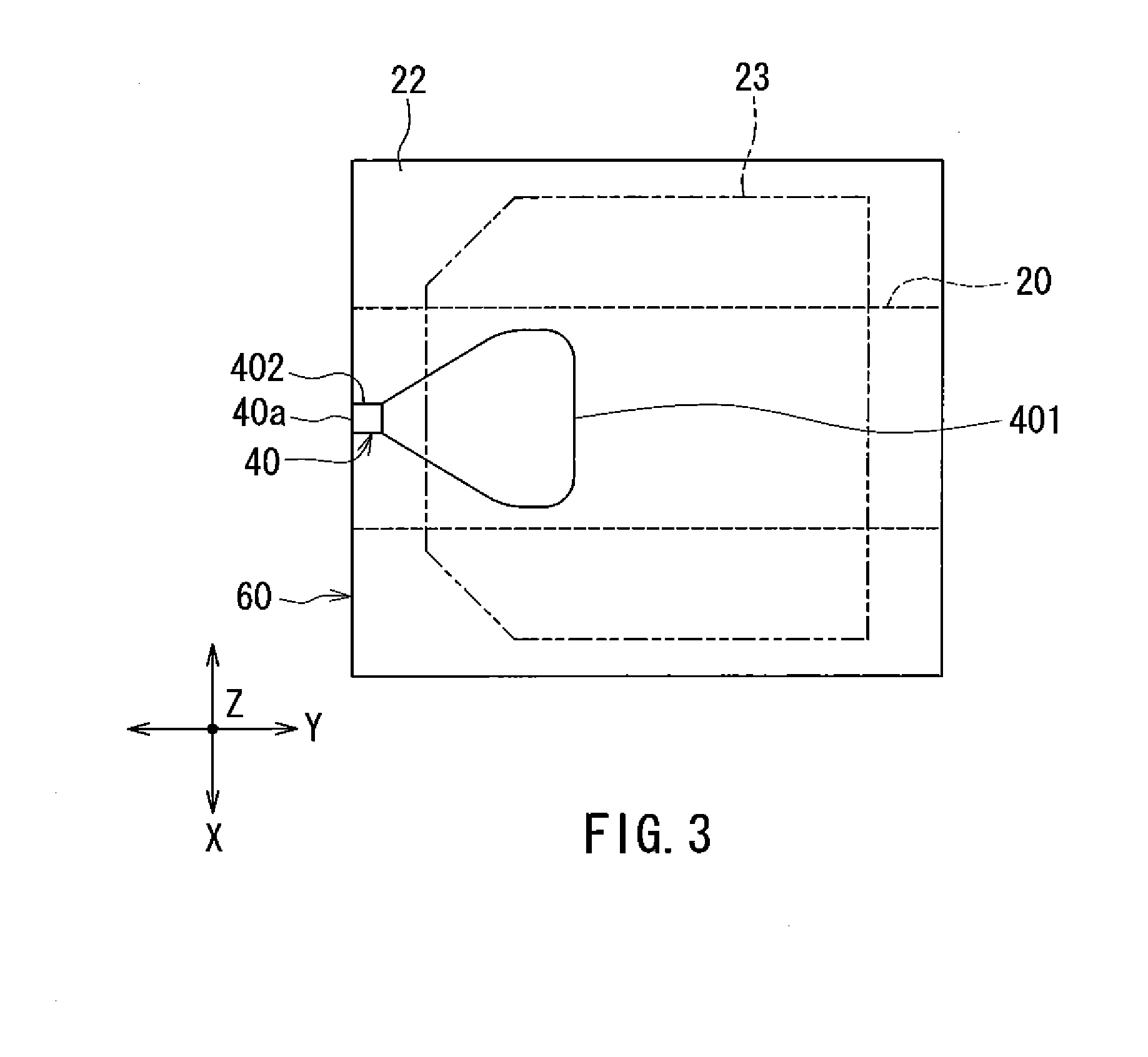

Plasmon generator including two portions made of different metals

ActiveUS20140247706A1Improve reliabilityEfficient disseminationCombination recordingRecord information storageMetallic materialsPlasma generator

Owner:HEADWAY TECH INC +1

PCB non-metallic material steel-plastic compound plate tray, preparing production line and preparing method

InactiveCN106005678AHigh tensile strengthImprove bending abilityPackage recyclingDomestic articlesProduction lineShrinkage rate

Owner:王传华

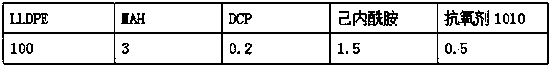

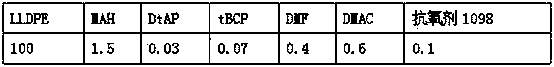

Grafted LLDPE (Linear Low-Density Polyethylene) based metal bonding film

ActiveCN103436193AImprove adhesionGood compatibilityFilm/foil adhesivesGraft polymer adhesivesLinear low-density polyethyleneLow-density polyethylene

Owner:成都雨田新材料有限责任公司

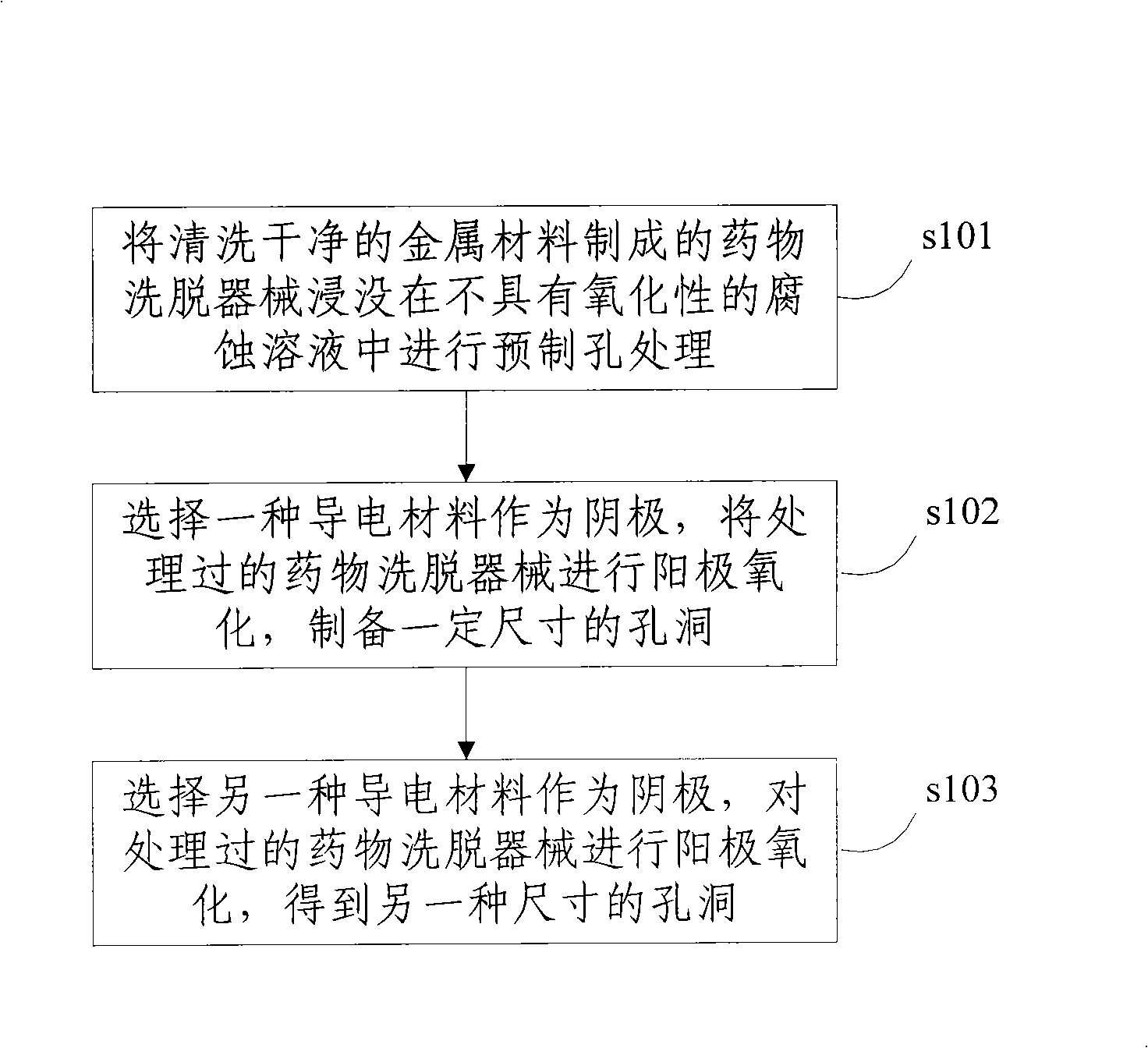

Method for manufacturing holes with different diameter on instrument surface with medicament elution

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

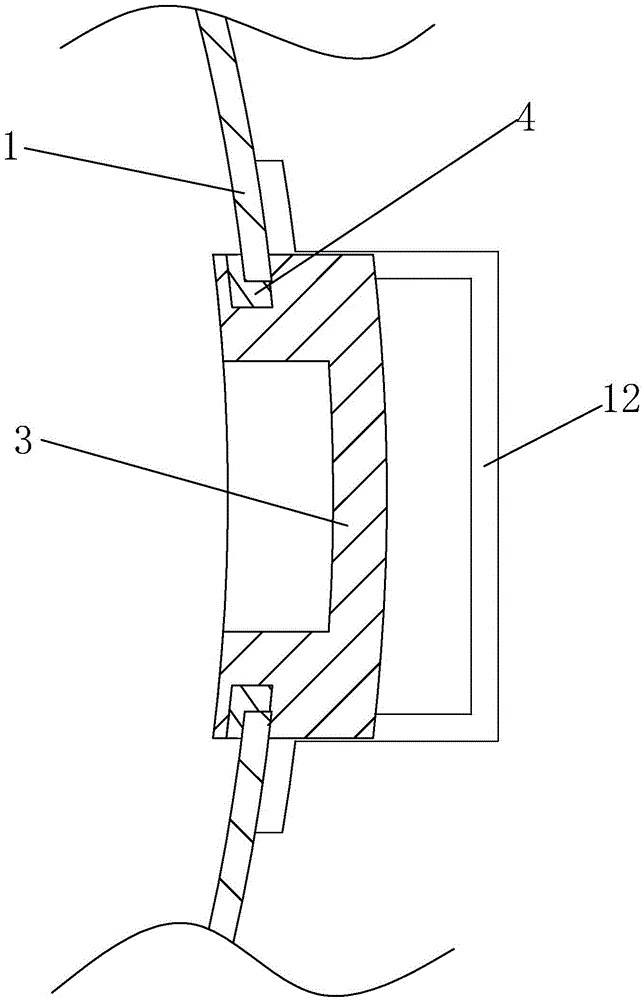

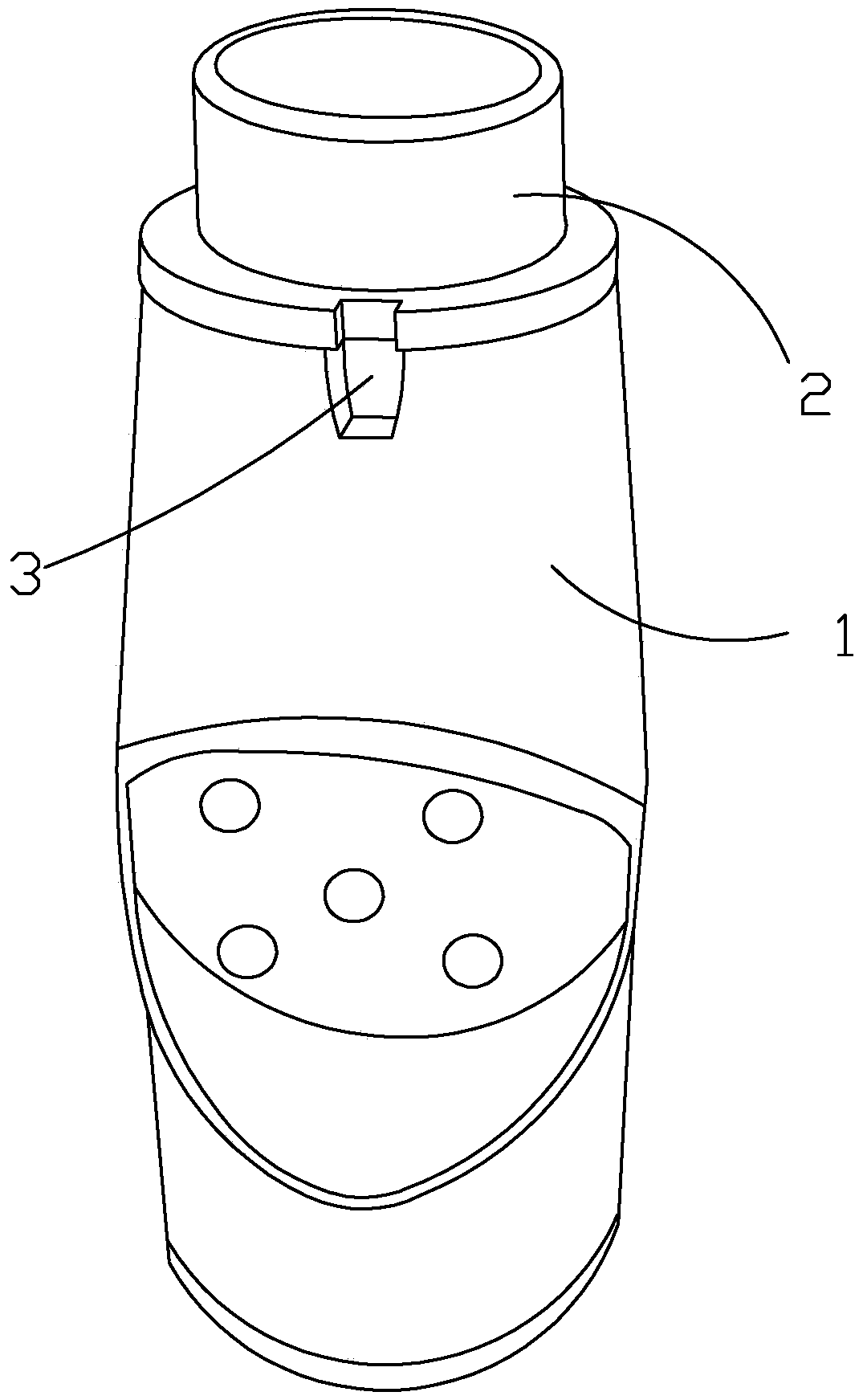

Kettle

InactiveCN105640321AEasy to replaceEasy to remove the gaugeWater-boiling vesselsMetallic materialsEngineering

Owner:李均辉

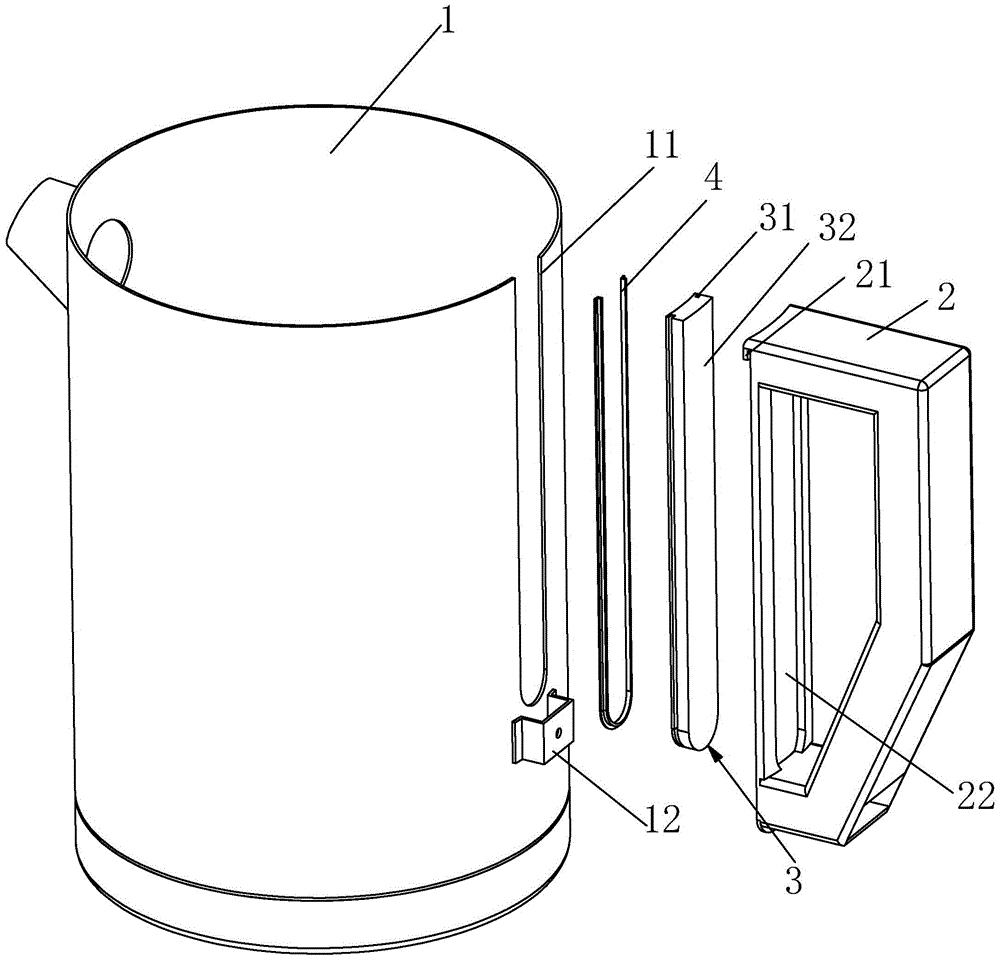

Soft wind instrument

InactiveCN105185358AStrong enoughTough enoughWind musical instrumentsVegetal fibresSound sourcesWind instrument

Owner:SHENYANG NORMAL UNIV

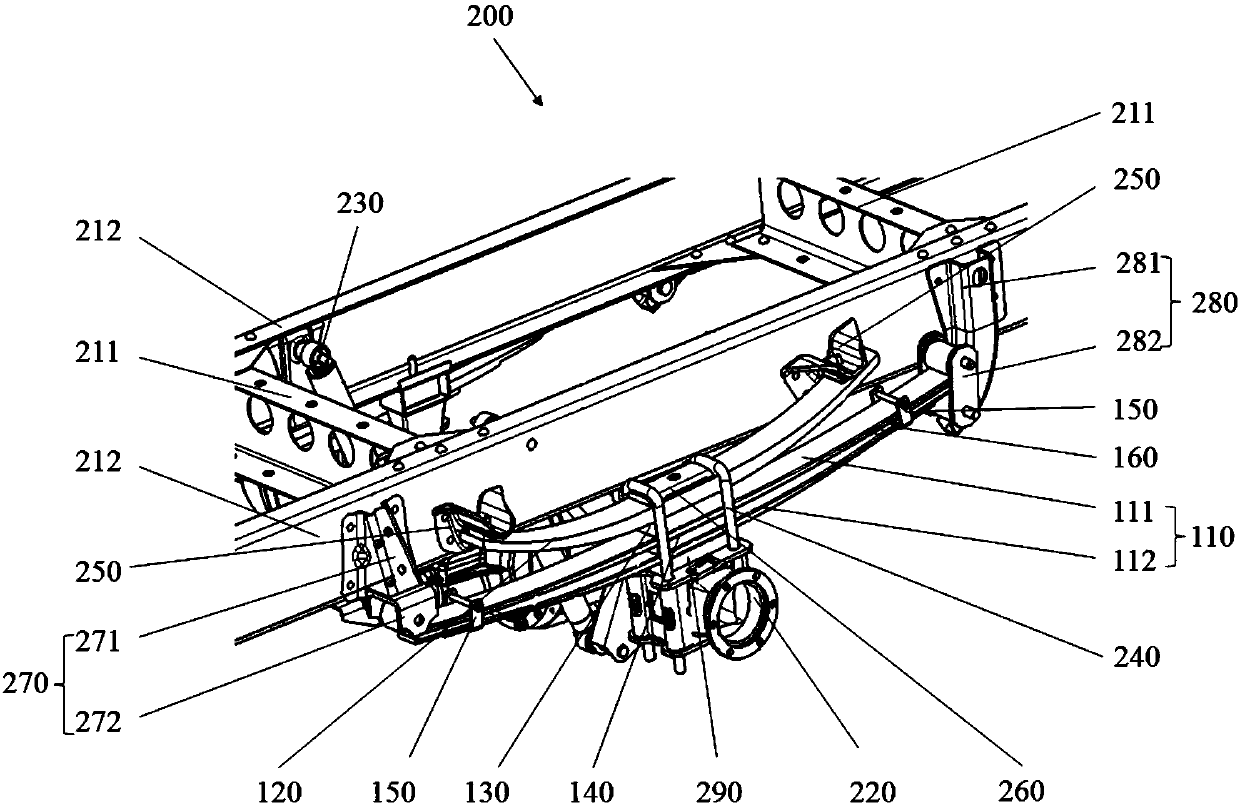

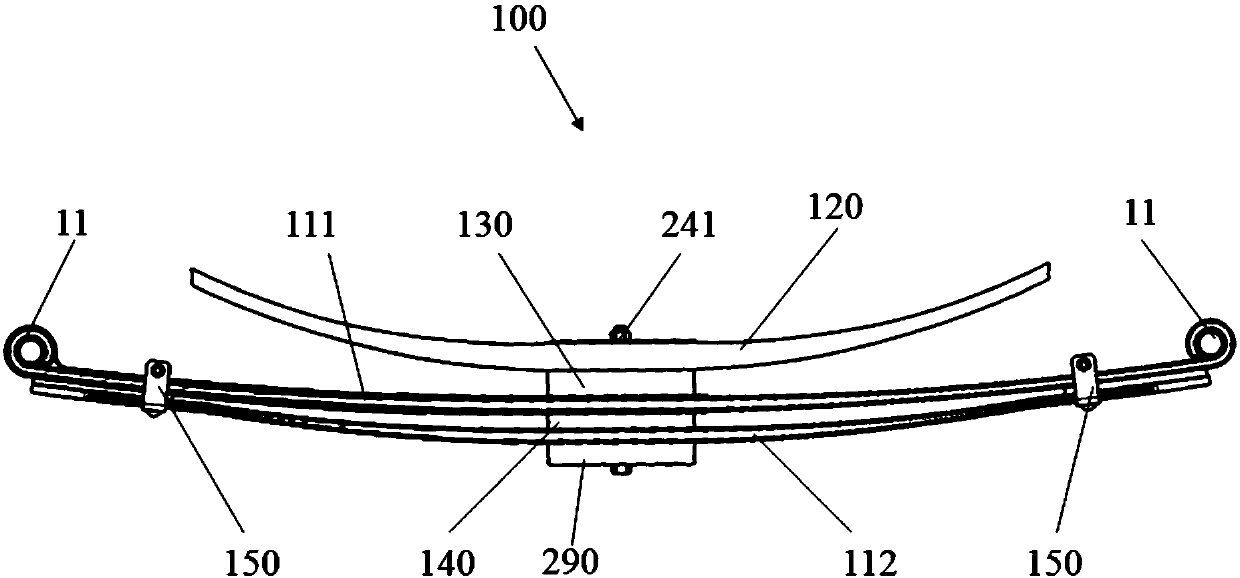

Composite material main and auxiliary spring assembly and suspension

ActiveCN107618330AReduce weightStrong corrosion resistanceResilient suspensionsMetallic materialsEngineering

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +2

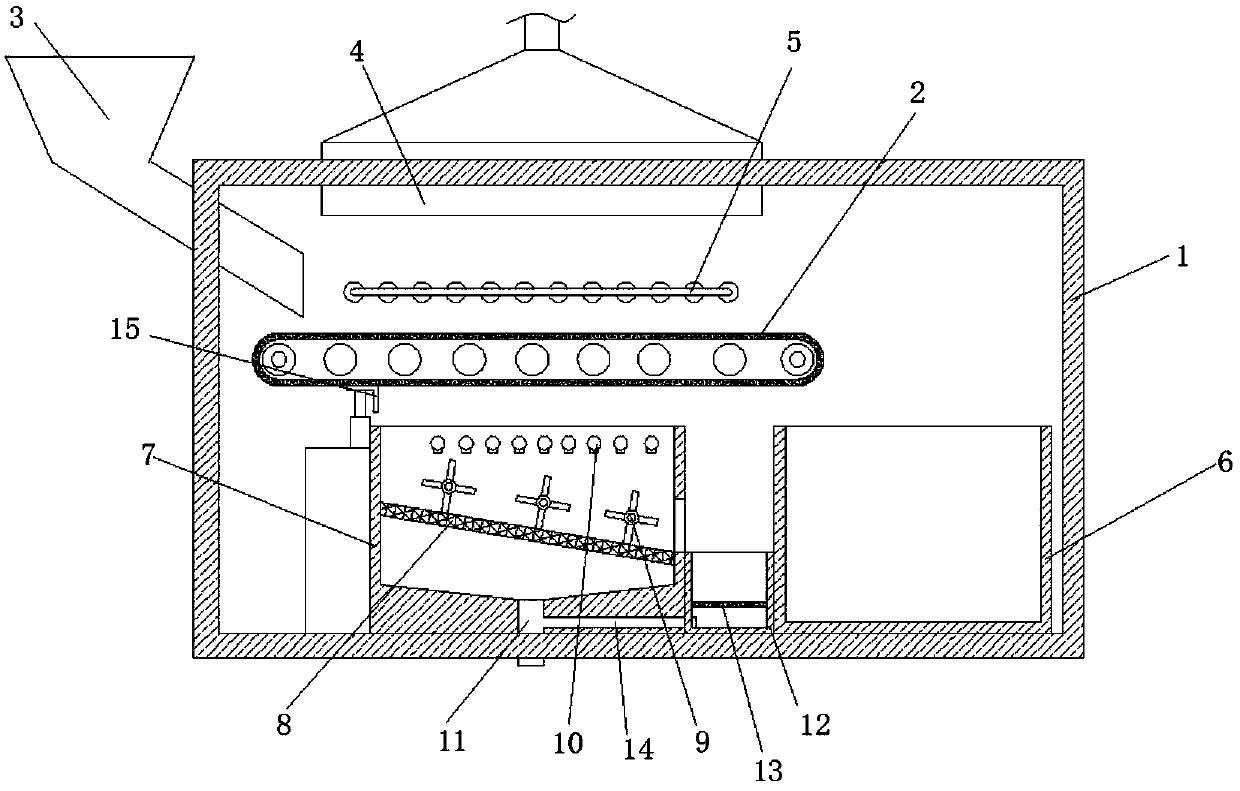

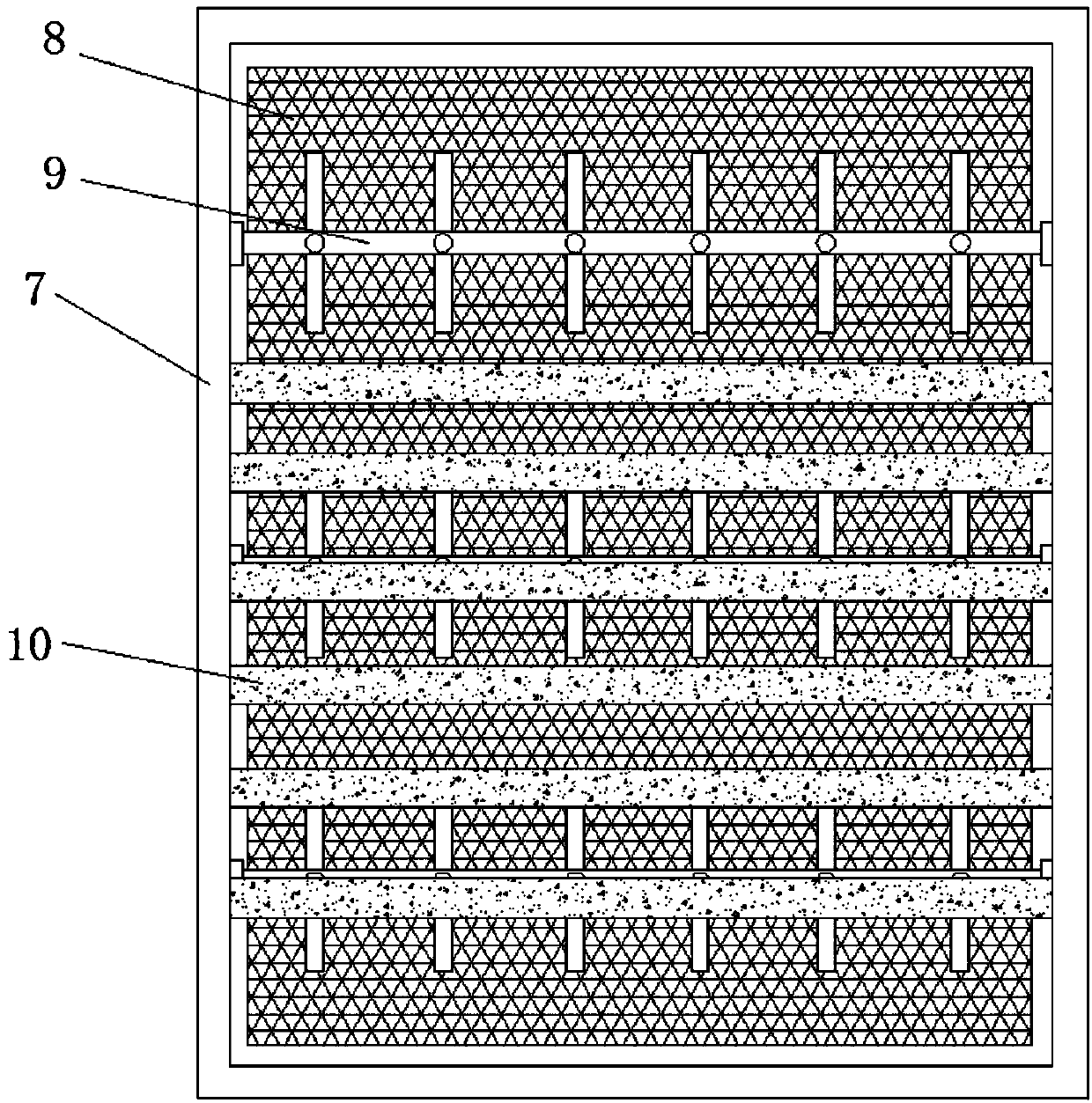

Sorting device for parts of hardware and electrical appliances

InactiveCN109926204AHigh purityImprove qualityCleaning using gasesMagnetic separationMetallic materialsEngineering

Owner:李婷

Water tap and manufacturing process thereof

ActiveCN105508681APrevent too lightCorrosion does not occurValve housingsMetallic materialsWater flow

Owner:黄振波

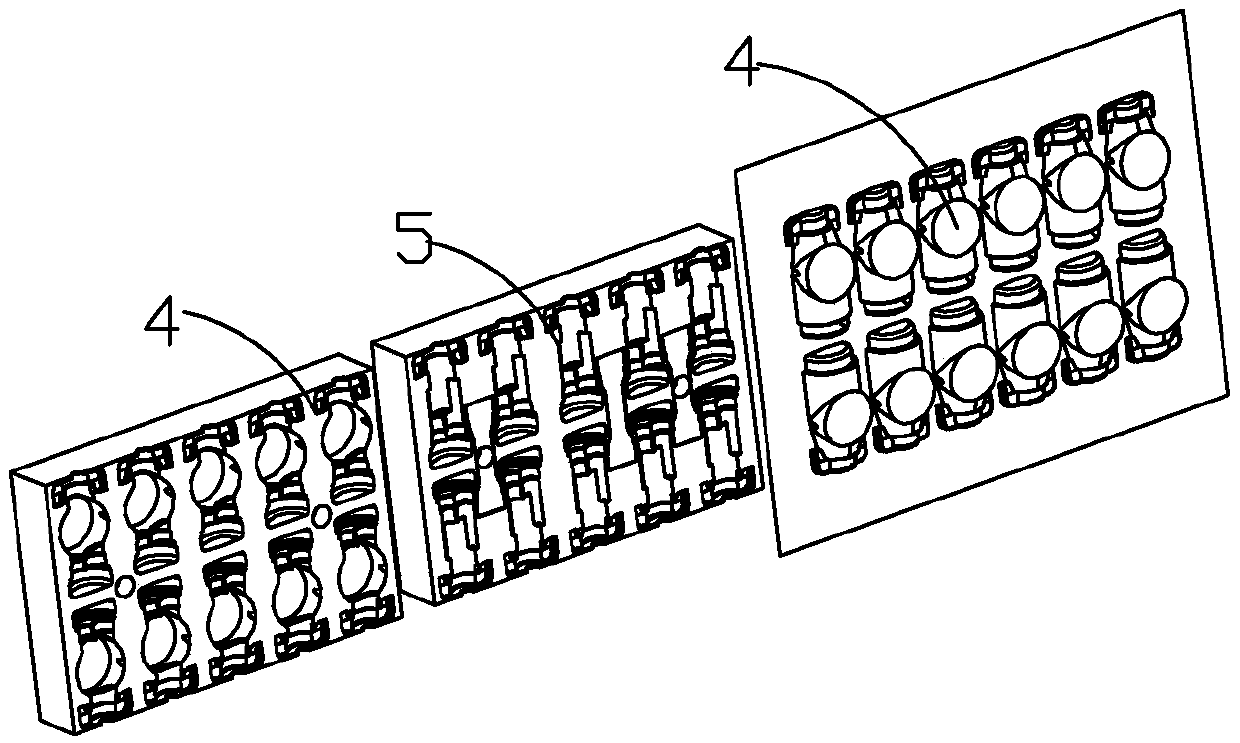

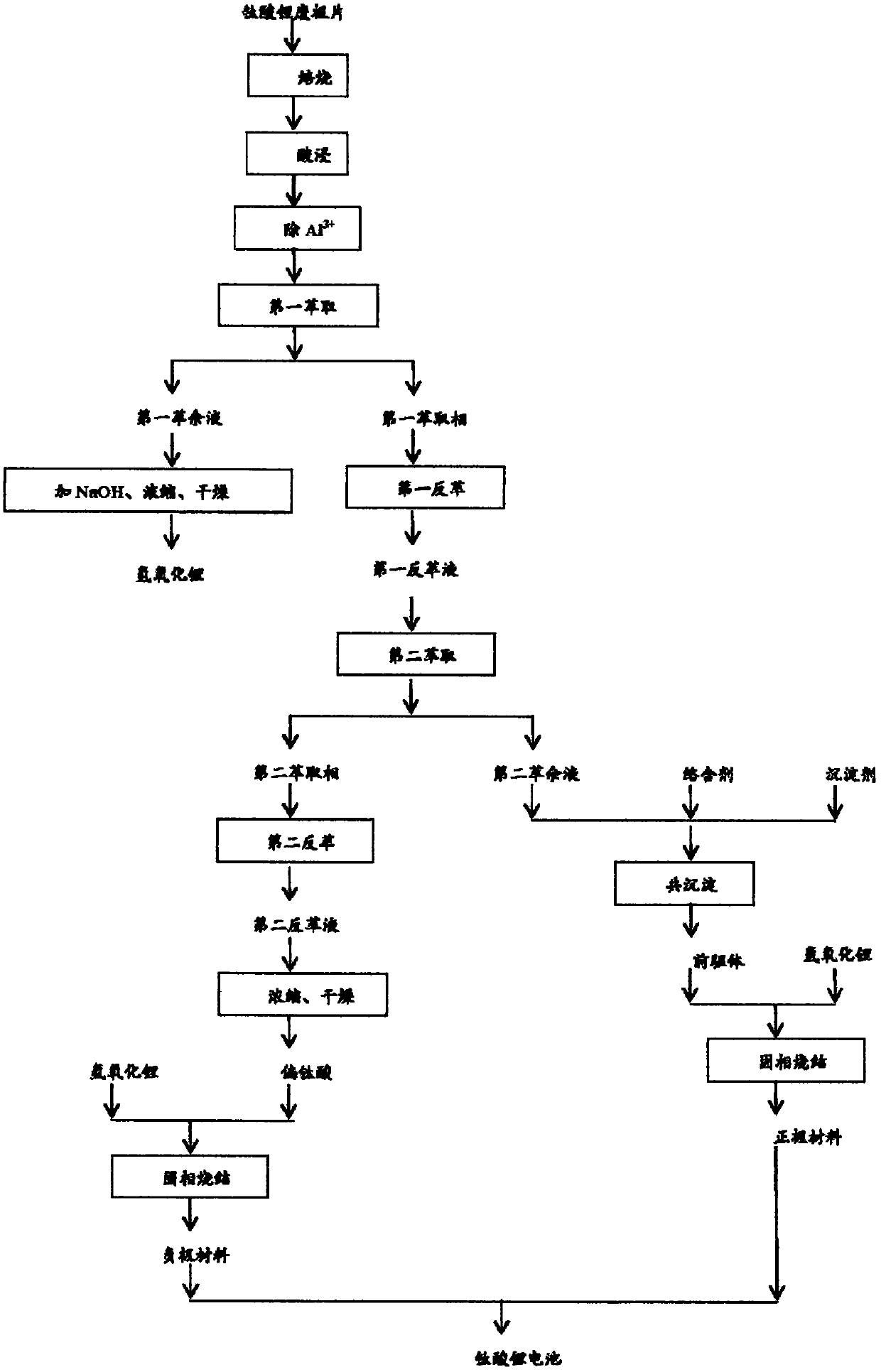

Method of recycling electrode metal material from waste lithium titanate battery

ActiveCN110735038AAvoid pollutionRealize recyclingWaste accumulators reclaimingProcess efficiency improvementMetallic materialsEnvironmental engineering

Owner:浙江遨优动力系统有限公司

Hollow tube forming technology

ActiveCN111229858AThe extension direction is easy to controlReduce defective rateMetal rolling arrangementsMetallic materialsManufactured material

Owner:深圳市鸿亨珠宝首饰有限公司

Manufacturing method of composite cutter bits and composite cutter bits

ActiveCN111360232AHigh hardnessImprove wear resistanceSlitting machinesFurnace typesMetallic materialsAlloy

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Alveolar bone amplification device as well as transverse amplification suite and longitudinal amplification suite thereof

InactiveCN103654978AAmplification inductionDental implantsBone implantMetallic materialsHyperostoses

Owner:陈碧芝

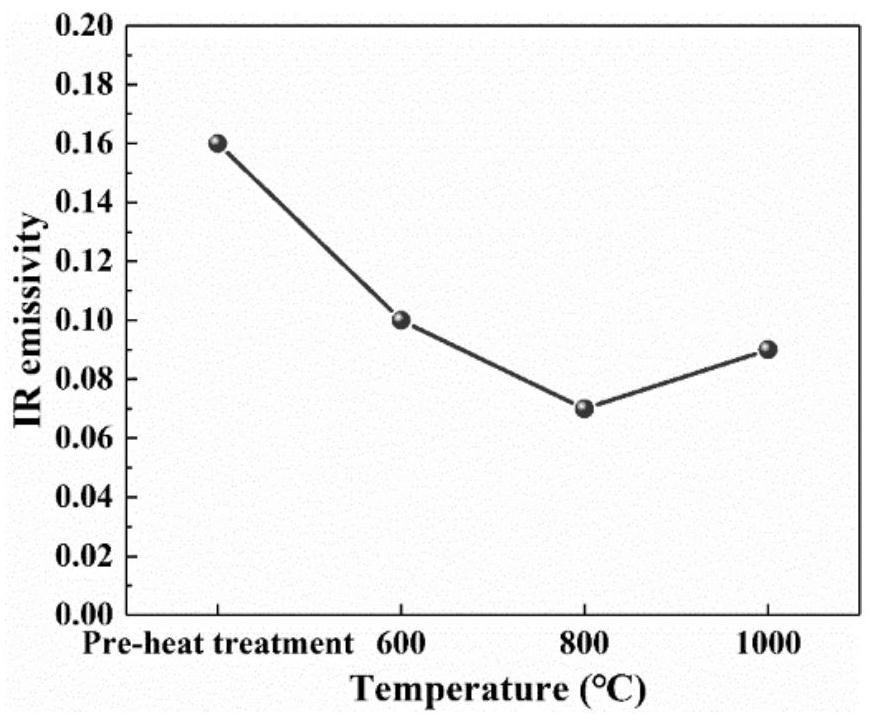

High-temperature-resistant, water-oxygen-resistant and low-infrared-emissivity composite film for ceramic-based composite material and preparation method

ActiveCN113403594AReduce IR emissivityEasy to useVacuum evaporation coatingSputtering coatingComposite filmLow emissivity

Owner:NORTHWESTERN POLYTECHNICAL UNIV

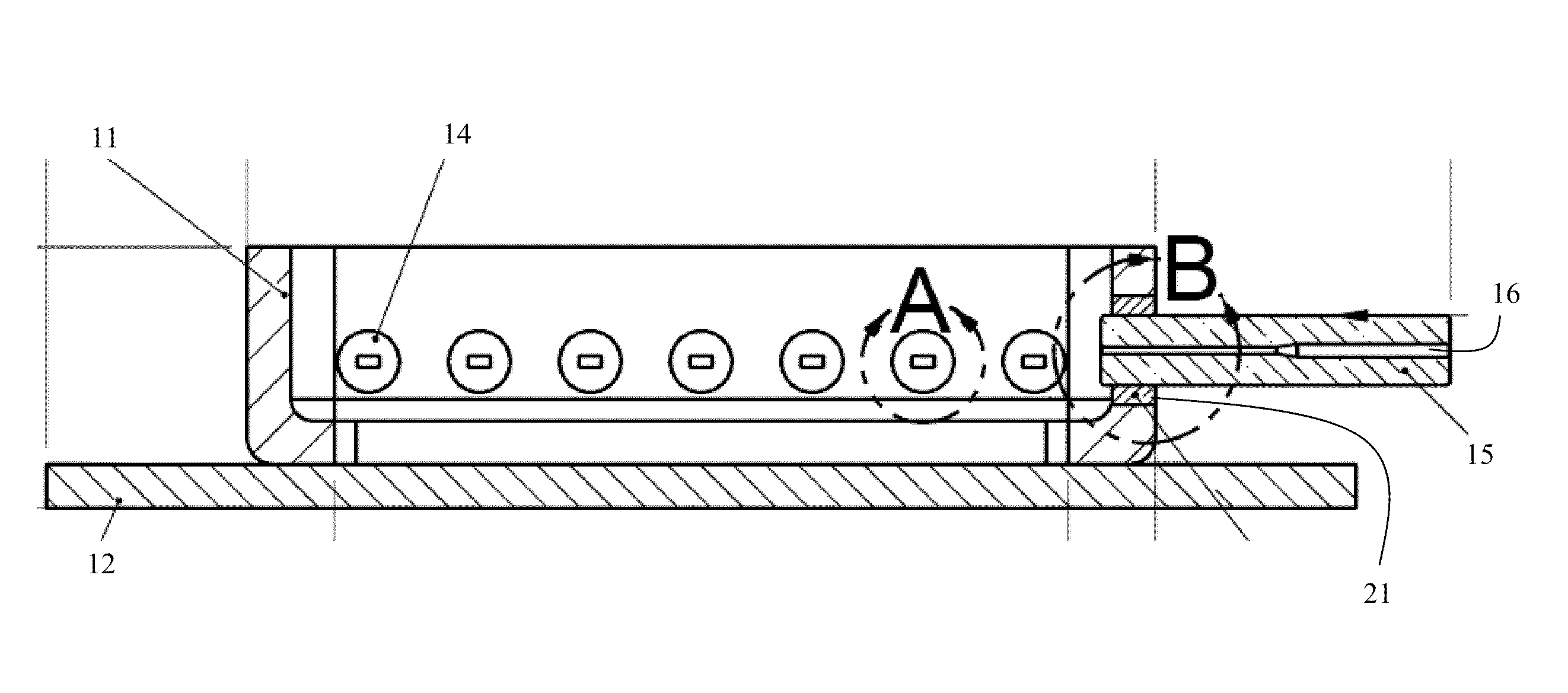

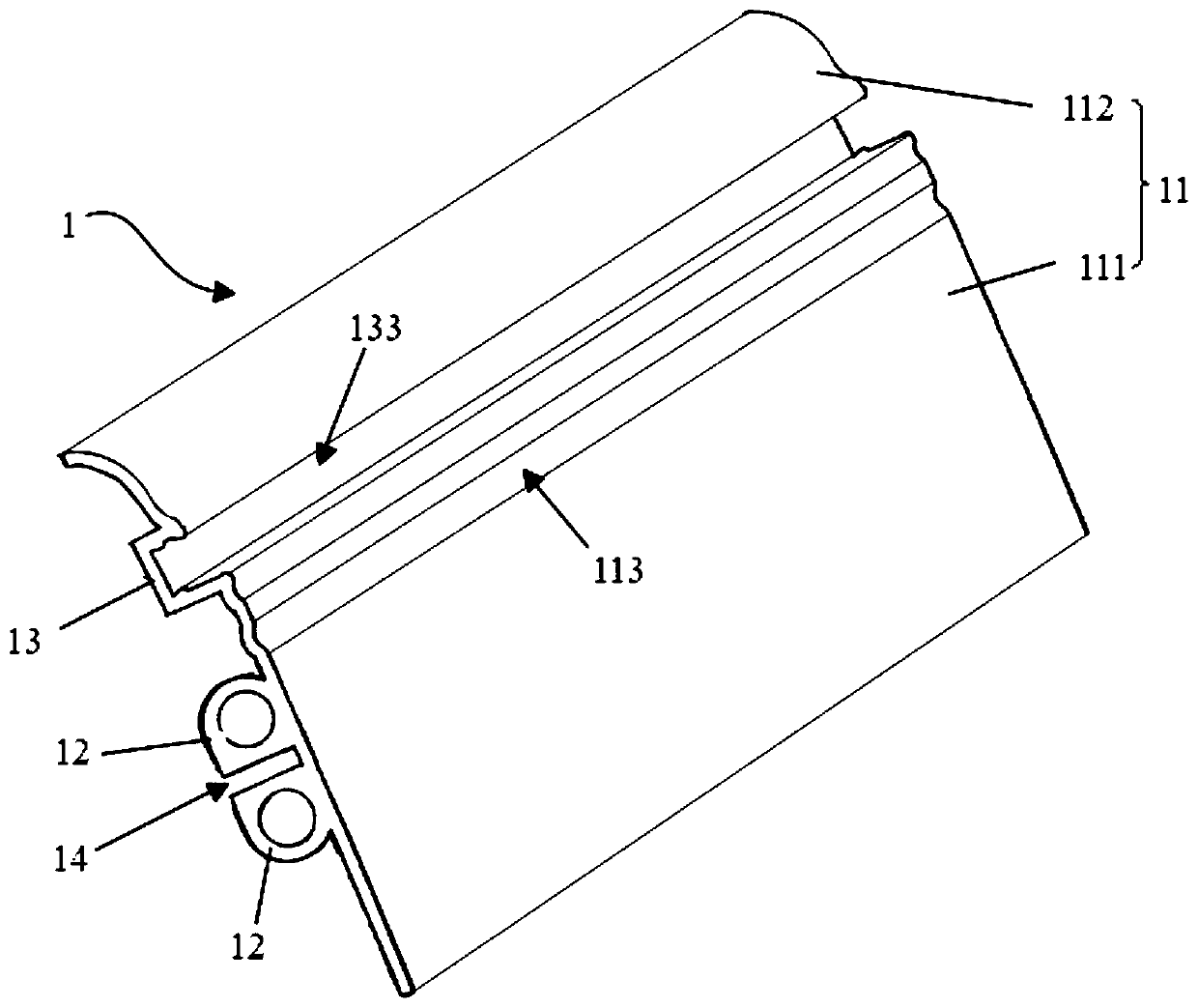

Skirting line and heating system

ActiveCN111576792AMeet the needs of useSimple structureHeating fuelCovering/liningsMetallic materialsEngineering

Owner:南京亿奇智能科技有限公司

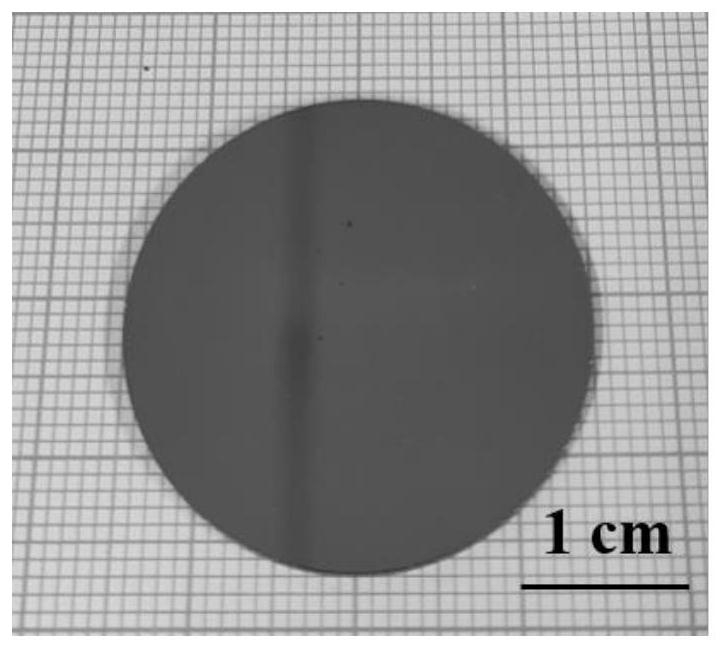

Atomic-scale precision lossless layer-by-layer etching method for two-dimensional layered material

ActiveCN113421826APrecise control of diffusion depthAtomic precision controlFinal product manufactureSemiconductor/solid-state device manufacturingEtchingChemical reaction

The invention provides an atomic-scale precision lossless layer-by-layer etching method for a two-dimensional layered material. The method comprises the following steps of: manufacturing lattice defects on the surface layer of a material to be etched by using a surface treatment technology; depositing a thermal diffusion sacrificial material on the surface layer of the material to be etched; performing thermal annealing on the material to be etched at a certain temperature, so that the diffusion sacrificial material is diffused into the surface layer of the material to be etched to form an alloy layer; and removing the diffusion sacrificial material and the alloy layer thereof by using a selective chemical reaction to finish local etching, wherein the two-dimensional layered material to be etched comprises one or a combination of metal sulfide, metal selenide, metal telluride, graphene and black phosphorus, and the diffusion sacrificial material comprises one or combination of low-atomic-radius metal, low-atomic-radius non-metal material and small-molecular organic matter. The sacrificial layer does not diffuse into an internal retention layer of the material to be etched, so that the etching process does not damage crystal lattices of the material retention layer, the intrinsic electrical property of the material is maintained, and the atomic-scale precision lossless layer-by-layer etching method is a lossless etching technology.

Owner:NANJING UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap