Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about "Process efficiency improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

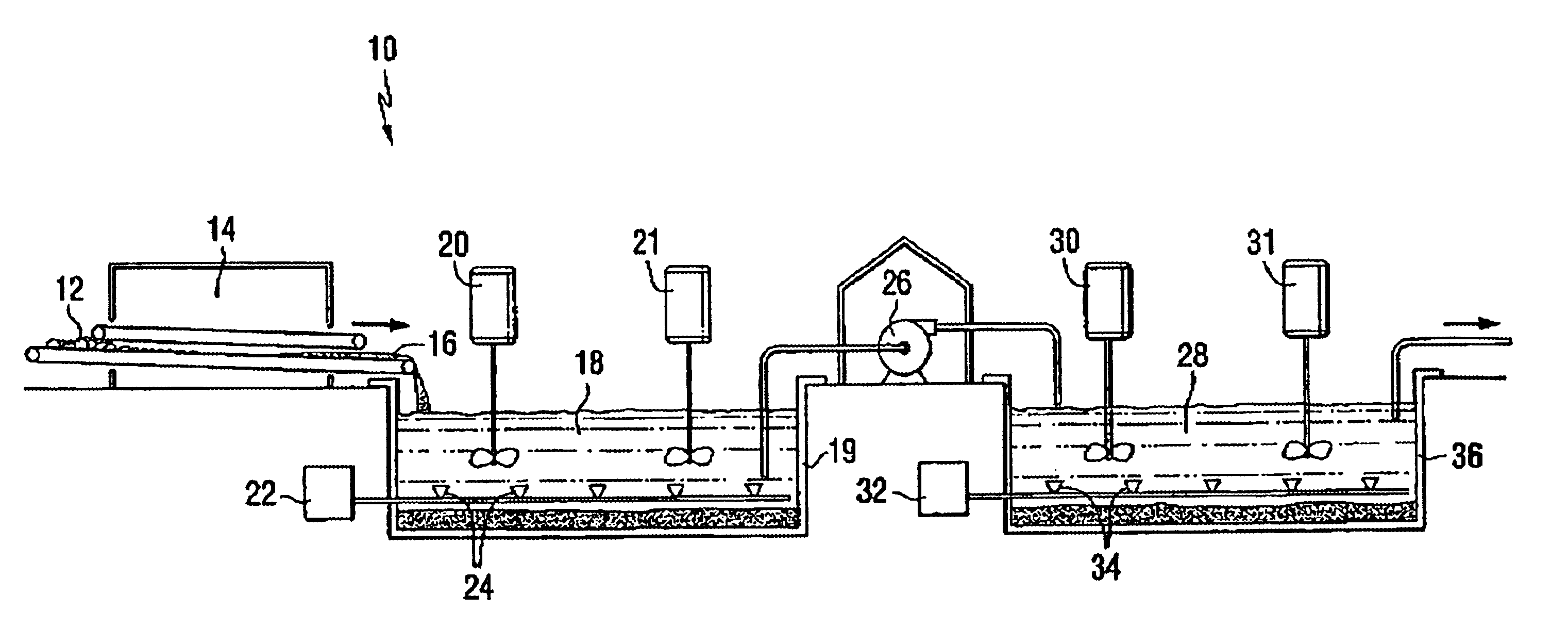

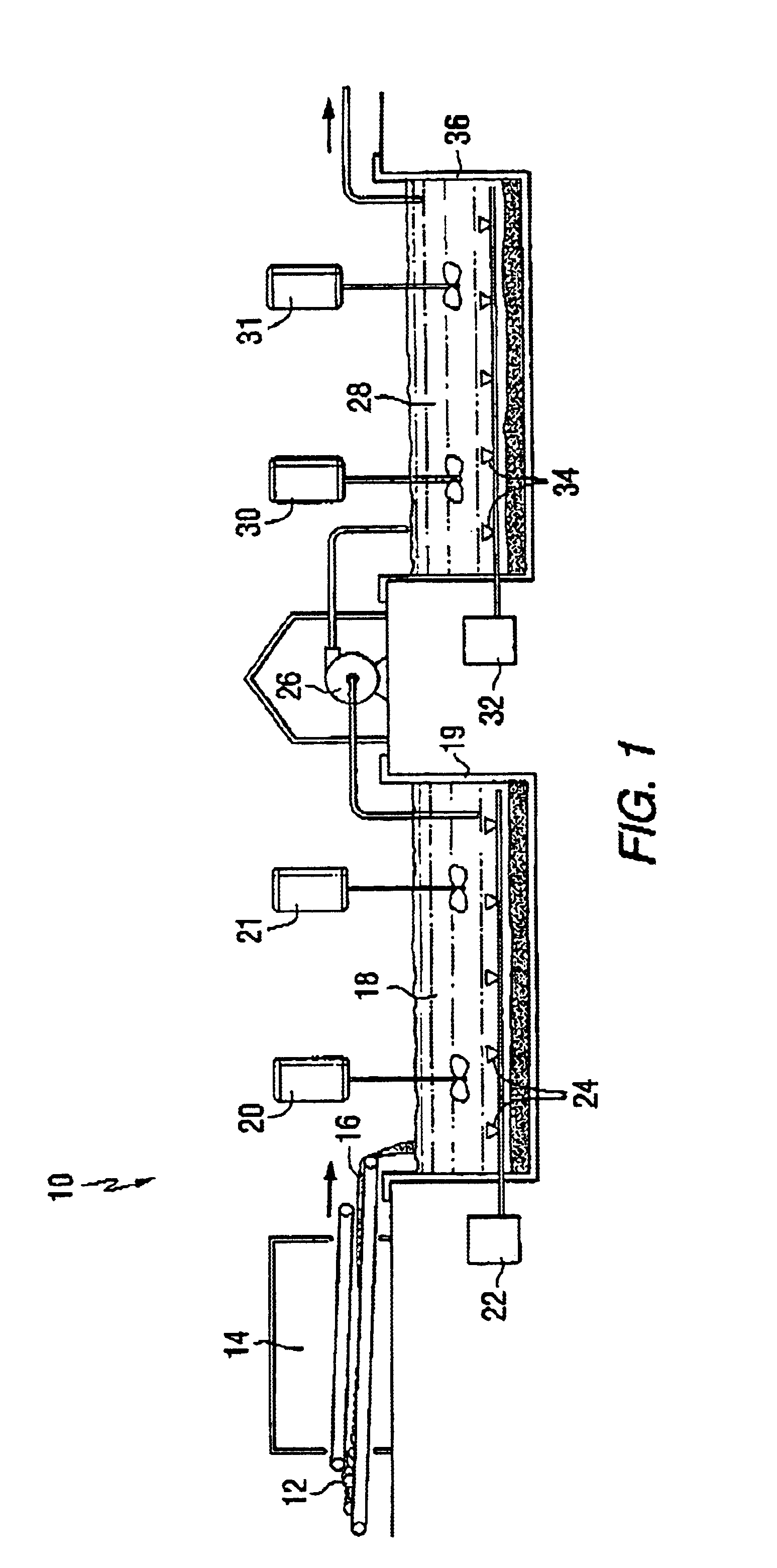

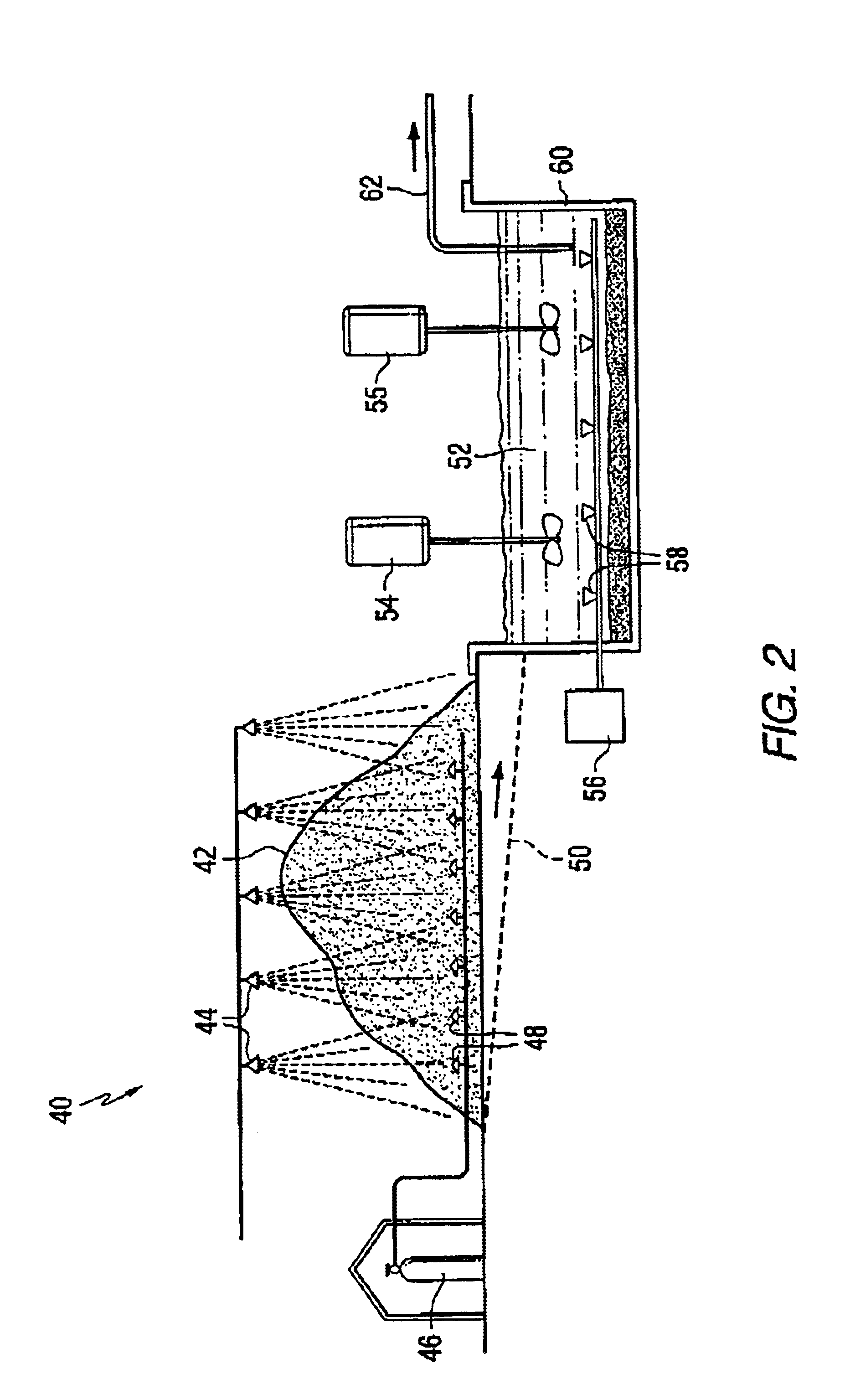

Method and apparatus for recovery of metals with hydrocarbon-utilizing bacteria

InactiveUS6875356B2Treatment using aerobic processesTreatment with aerobic and anaerobic processesSprinkler systemBioleaching

Owner:GLOBAL BIOSCI

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

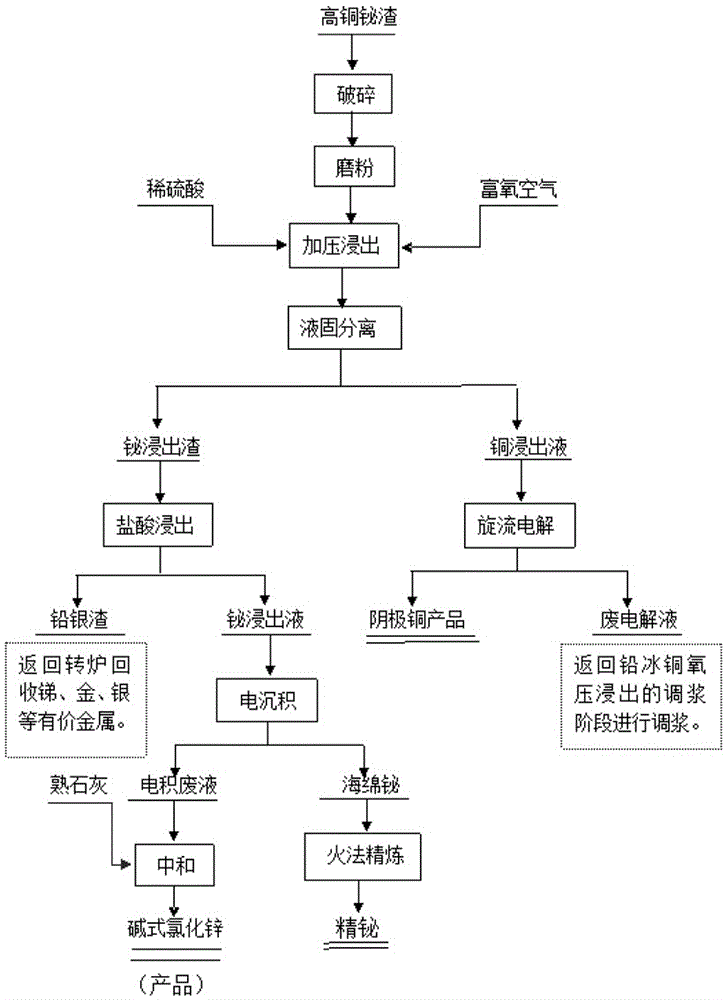

Method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

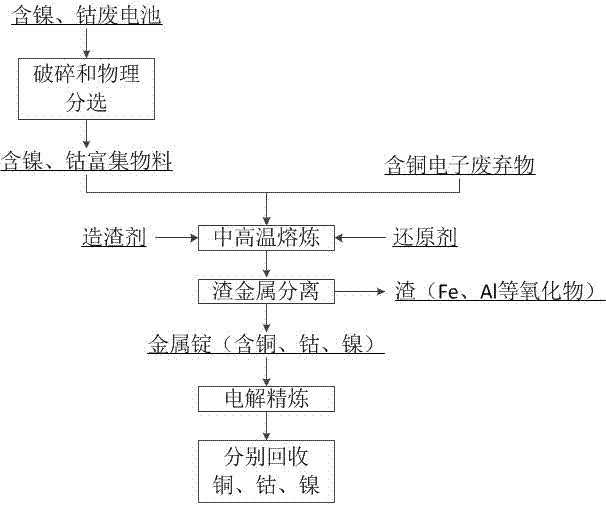

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Nickel slag processing method for efficiently recovering iron resource

InactiveCN104988302APromote resource reuseSafe and easy to recycleProcess efficiency improvementSlagMagnetic separation

The invention provides a nickel slag processing method for efficiently recovering an iron resource. The method includes the steps that nickel slag is fused, the temperature is kept, a modification agent is added, heat preservation is carried out, and modified nickel slag with the alkalinity ranging from 1.0 to 1.4 is obtained after complete reacting is made; air or oxygen is blown from the bottom or from the top below the liquid face, weak oxidation treatment is carried out on the modified nickel slag, and oxidized nickel slag is obtained; after the temperature of the oxidized nickel slag falls to 1200 DEG C with the temperature fall rate smaller than or equal to 5 DEG C / min, water quenching cooling is carried out, and solidified nickel slag is obtained after complete solidification; the solidified nickel slag is crushed and ground until the particle size is smaller than 200 meshes; and magnetic separation is carried out on slag obtained after cracker grinding, magnetic materials are recovered, and nickel slag processing is completed. By means of the processing method, the iron resource can be recovered from the nickel slag, harmful elements in the nickel slag cannot be brought into iron-rich phases, and an iron ore concentrate can be completed replaced in use. Low-energy-consumption, low-cost and safe and easy processing recovery of the iron resource is achieved, and the method is of great significance in promoting nickel slag resource recycling, enterprise energy saving and emission reduction and environmental protection.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for utilizing eutecticevaporate solvent for leaching valuable metal in waste lithium ion batteries

InactiveCN111690813AStrong penetrating powerPromote leachingWaste accumulators reclaimingProcess efficiency improvementEnvironmental engineeringLithium-ion battery

The invention discloses a method for utilizing eutecticevaporate solvent for leaching valuable metal in waste lithium ion batteries and relates to the technical field of comprehensive recovery and utilization of waste lithium ion battery materials. The method comprises the following steps that firstly, the waste lithium ion battery materials are added into eutecticevaporate solvent, ultrasonic oscillation is carried out on the condition of 20 DEG C-40 DEG C, and standing is carried out; and secondly, slurry obtained after ultrasonic treatment is filtered, and separated to obtain a leaching solution containing the valuable metal. The method has the beneficial effects that the eutecticevaporate solvent is adopted for leaching the valuable metal in the waste lithium ion batteries, ultrasonicwaves are adopted for treating a solution obtained after the eutecticevaporate solvent and the waste lithium ion battery materials are mixed, by means of the cavitation effect of the ultrasonic waves,penetrating power of the eutecticevaporate solvent can be increased, the eutecticevaporate solvent can leach out the valuable metal in the waste lithium ion battery materials in a reinforced manner,and thus the leaching efficiency and the leaching rate of the valuable metal in the waste lithium ion battery materials can be improved greatly.

Owner:NANCHANG HANGKONG UNIVERSITY

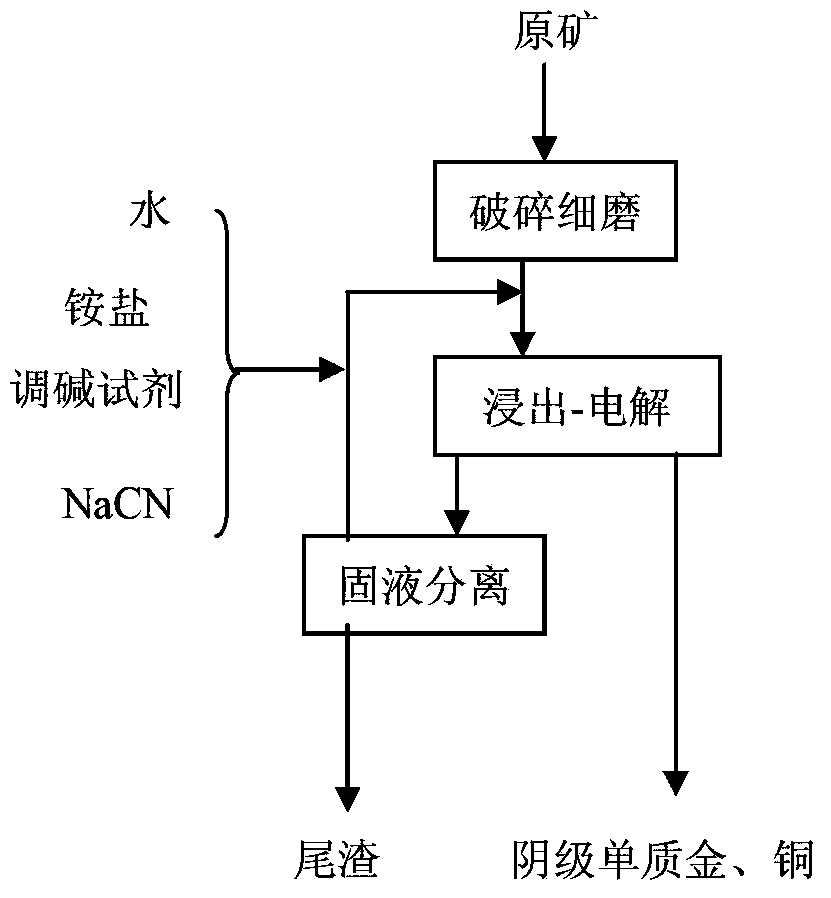

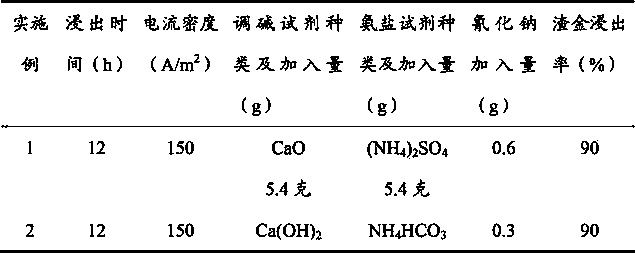

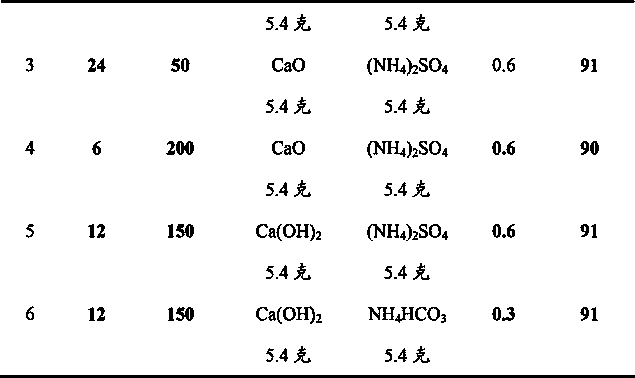

Stripping Gold Components and the Method of Stripping Gold

ActiveUS20120292201A1Not affect and environmentNot to damageElectrolysis componentsRecycling and recovery technologiesCyanideChemical compound

Owner:UWIN NANOTECH

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

Ultra-pure gadolinium oxide and electrochemical reduction fully-closed type extracting production process thereof

ActiveCN101824537AEfficient removalLarge amount of processingRare earth metal compoundsProcess efficiency improvementRare-earth elementPhase ratio

Owner:QIANDONG RARE EARTH GRP

Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

ActiveCN103627906AShort processReduce recycling costsProcess efficiency improvementLiquid wasteEconomic benefits

The invention discloses a comprehensive recycling treatment method of a waste rare-earth fluorescent lamp, which comprises the steps that S1, waste fluorescent powder, a waste glass tube and mercury-containing waste liquid are separated and recycled from the waste rare-earth fluorescent lamp; S2, the waste fluorescent powder is roasted; an obtained roasted ore is leached; a leaching solution and a leaching residue are obtained; S3, the leaching solution is subjected to extraction, reverse extraction and separation; alumina and rare-earth oxide are obtained; and S4, the leaching residue is subjected to digestion, extraction and purification; and a strontium-containing product is obtained. The waste rare-earth fluorescent lamp is separated, the obtained waste fluorescent powder and the obtained mercury-containing waste liquid are comprehensively recycled respectively by technologies of roasting, leaching, extraction, reverse extraction and the like, and then secondary valuable resources such as alumina, various rare-earth oxide and the strontium-containing product are comprehensively recycled from the waste fluorescent powder. The method is short in technological process and low in recycling cost, solves the problems of stockpiling, environmental pollution and the like caused by the industrial waste rare-earth fluorescent lamp, and has certain economic benefits and industrial significance.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Process for recovering valuable metal from residues containing zinc

ActiveCN101845551AReduce contentRealize continuous operationProcess efficiency improvementHearthOxygen

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Roasting-leaching method of fine vanadium slags

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for preparing sodium antimonate from antimony oxide ore via alkaline approach

ActiveCN103866121AHigh recovery rateImprove qualityProcess efficiency improvementWastewaterPre treatment

The invention discloses a method for preparing sodium antimonate from an antimony oxide ore via an alkaline approach. The method comprises the following steps: (1) leaching the antimony oxide ore, (2) purifying filtrate, and (3) oxidizing the purified filtrate. The method is high in recovery rate, the leaching rate of antimony is 95-99%, the direct recovery rate of sodium antimonate is 90-95%, the whole process is performed under an alkaline environment, the requirement on corrosion resistance of equipment is not high, no complicated pretreatment is required in the process, the needed raw materials are nontoxic and harmless, the alkaline liquid is recyclable, neither waste water nor waste gas is generated in the process, and waste residues are nontoxic and harmless.

Owner:XIKUANG SHANXING ANTIMONY CO LTD

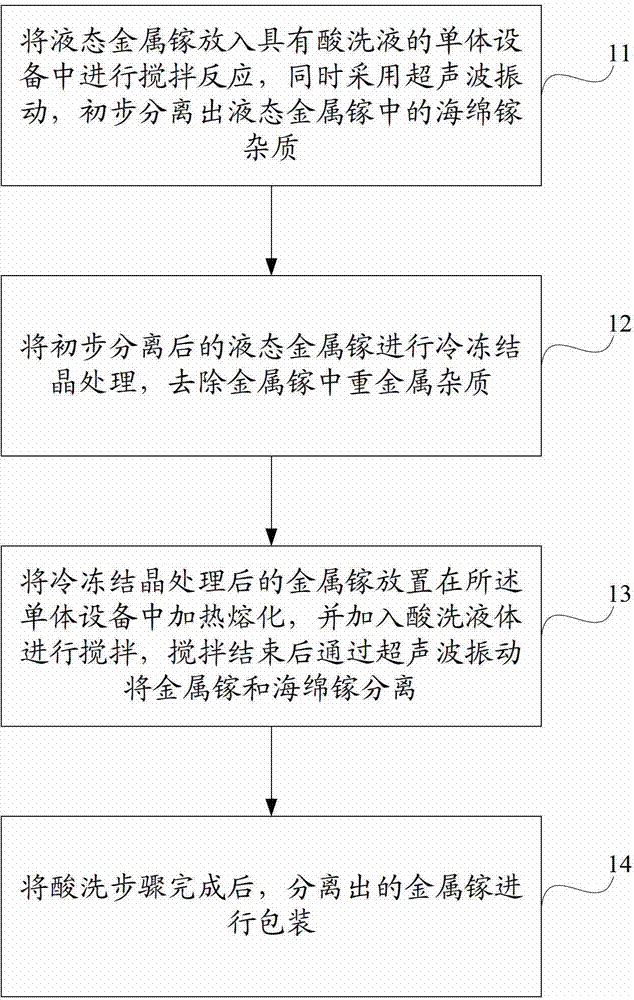

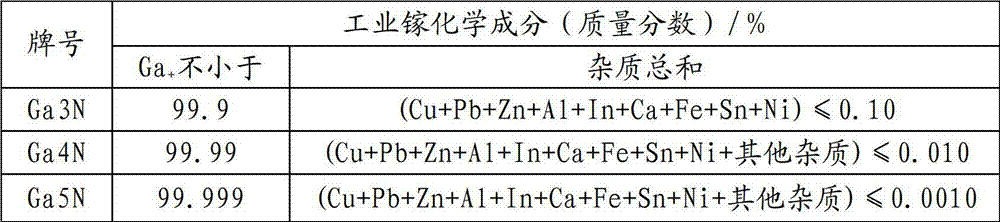

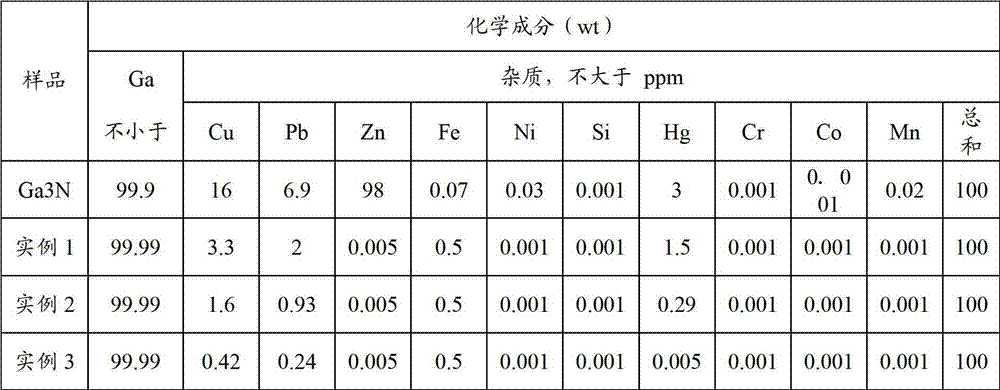

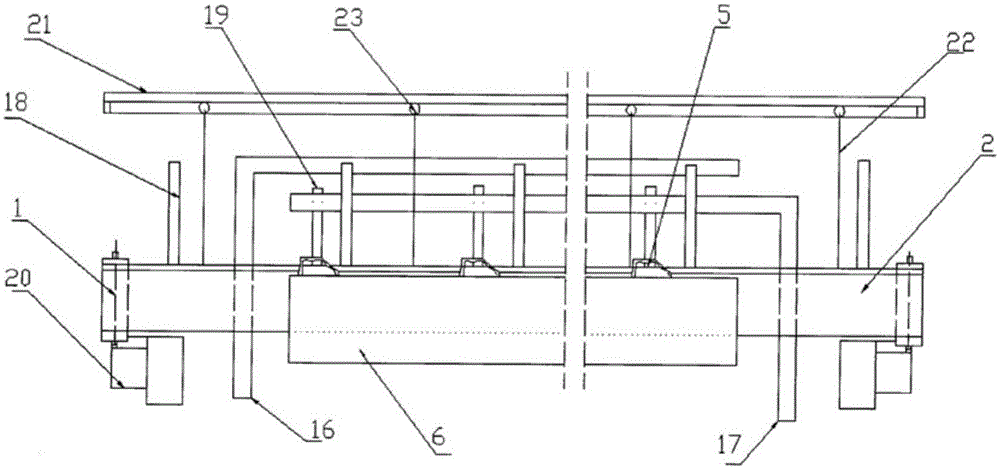

Purification method for gallium

ActiveCN103031450AQuality assuranceTo achieve the purpose of purificationProcess efficiency improvementAutomatic controlPurification methods

Owner:BEIJING JIYA SEMICON MATERIAL

Wet method electrolytic metal full-automatic production system

ActiveCN105063661APhotography auxillary processesProcess efficiency improvementDirect productionVoltage

Owner:湘西自治州丰达合金科技有限公司

Method for digesting spent rhodium catalyst in carbonyl group synthetic reaction

Owner:CHINA NAT OFFSHORE OIL CORP +1

Process for smelting low-grade laterite

InactiveCN102660672ARotary drum furnacesProcess efficiency improvementBrown iron oxideSmelting process

Owner:刘光火

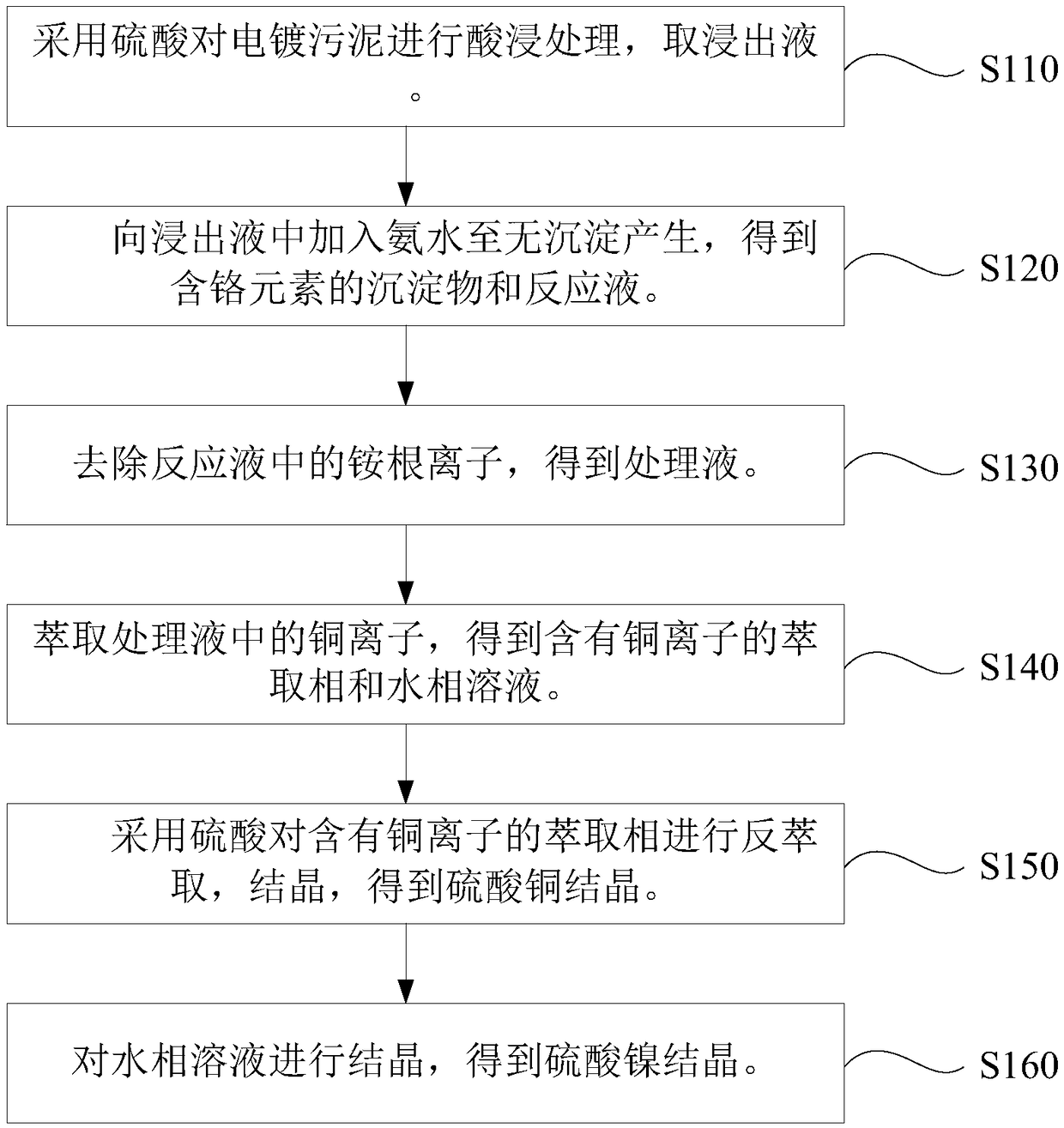

Method for recovering copper, nickel and chromium in electroplating sludge

Owner:GUANGZHOU XINGUANGHE ENVIRONMENTAL PROTECTION TECH

Method for preparing industrial molybdenum trioxide by roasting ammonia leaching residue

InactiveCN102251121AShort processHigh metal recovery rateProcess efficiency improvementAmmoniaMolybdenum trioxide

Owner:JINDUICHENG MOLYBDENUM CO LTD

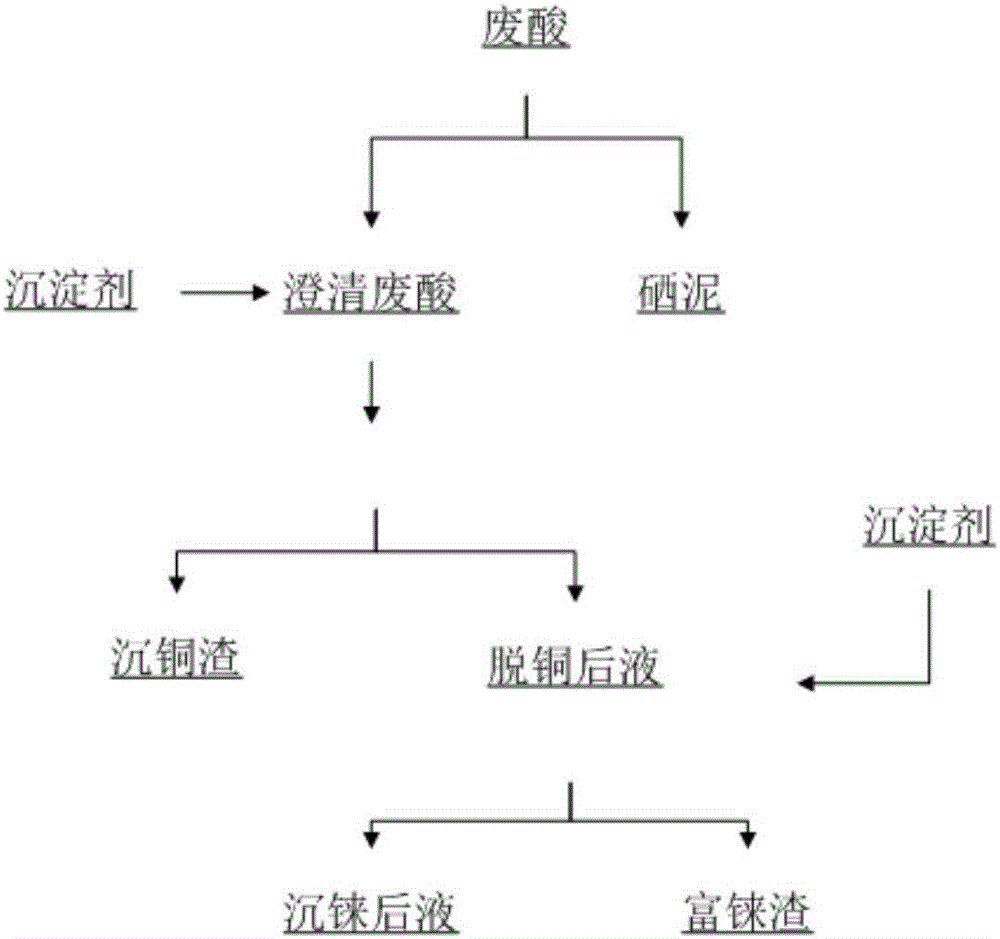

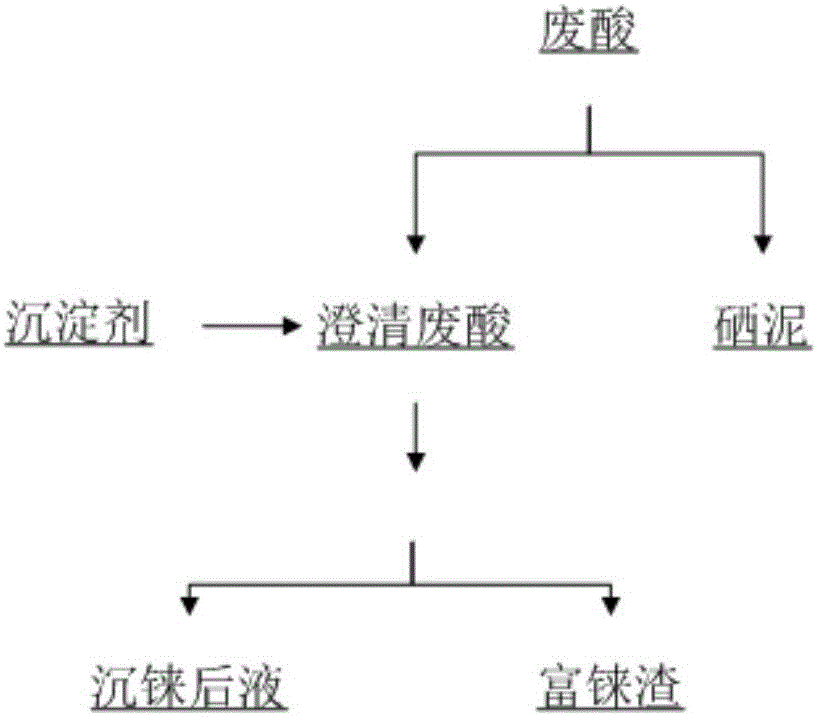

Method for recycling rhenium from copper smelting smoke washing waste acid

Owner:YANGGU XIANGGUANG COPPER

Method for extracting arsenic from gold ore

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

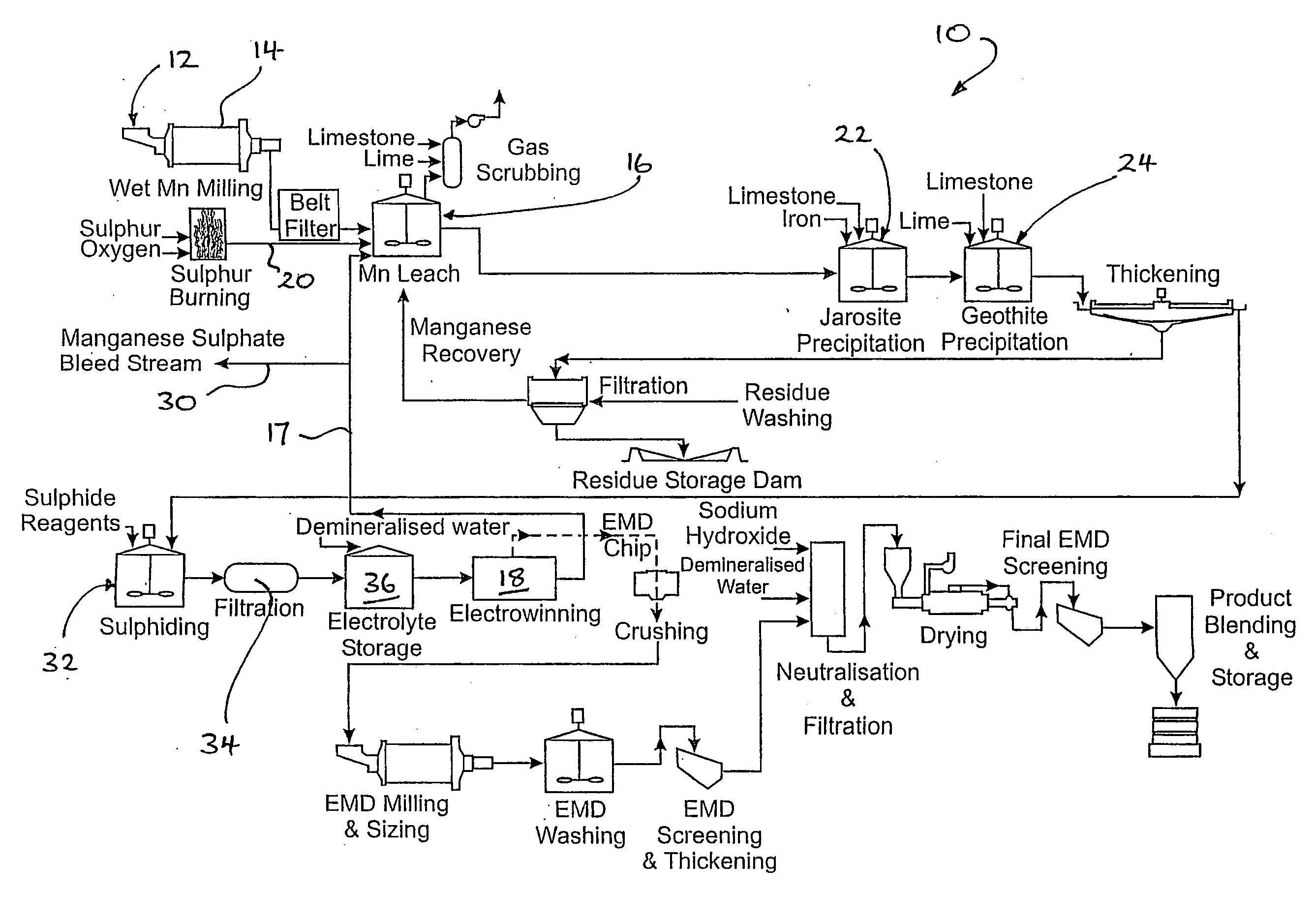

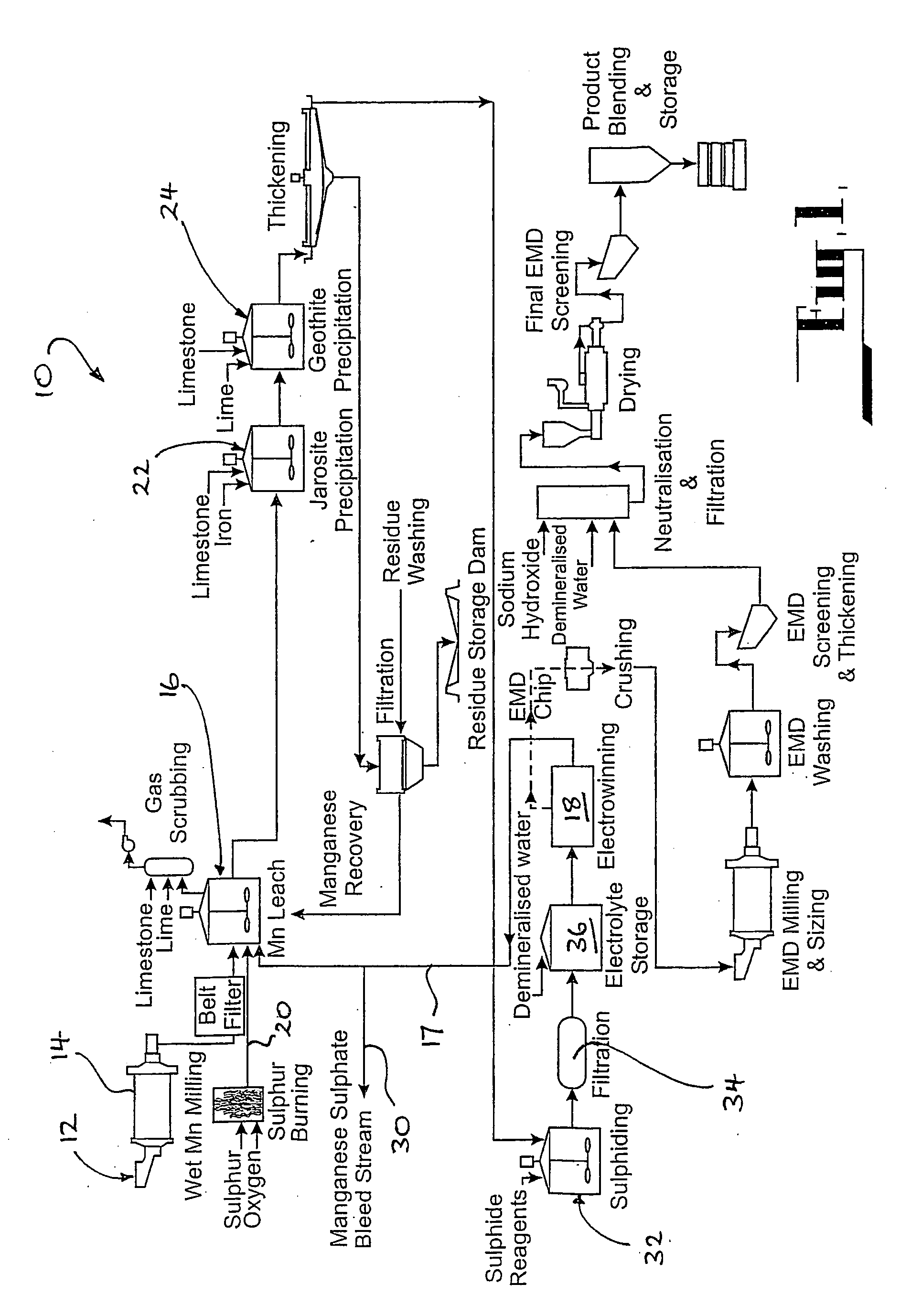

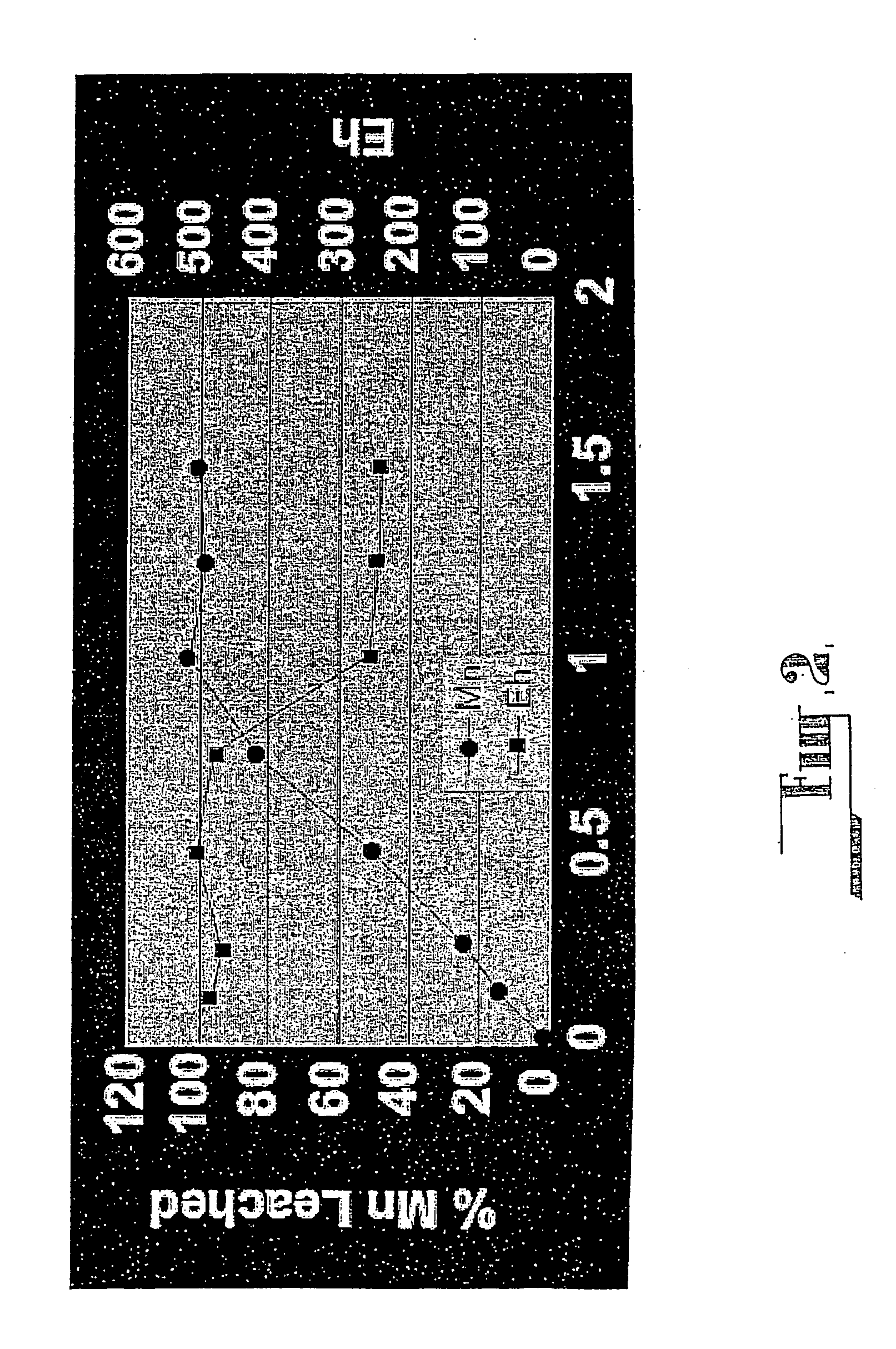

Hydrometallurgical processing of manganese containing materials

Owner:AUVEX RESOURCES PTY LTD

Microwave enhancement of the segregation roast

Owner:CATO RES CORP

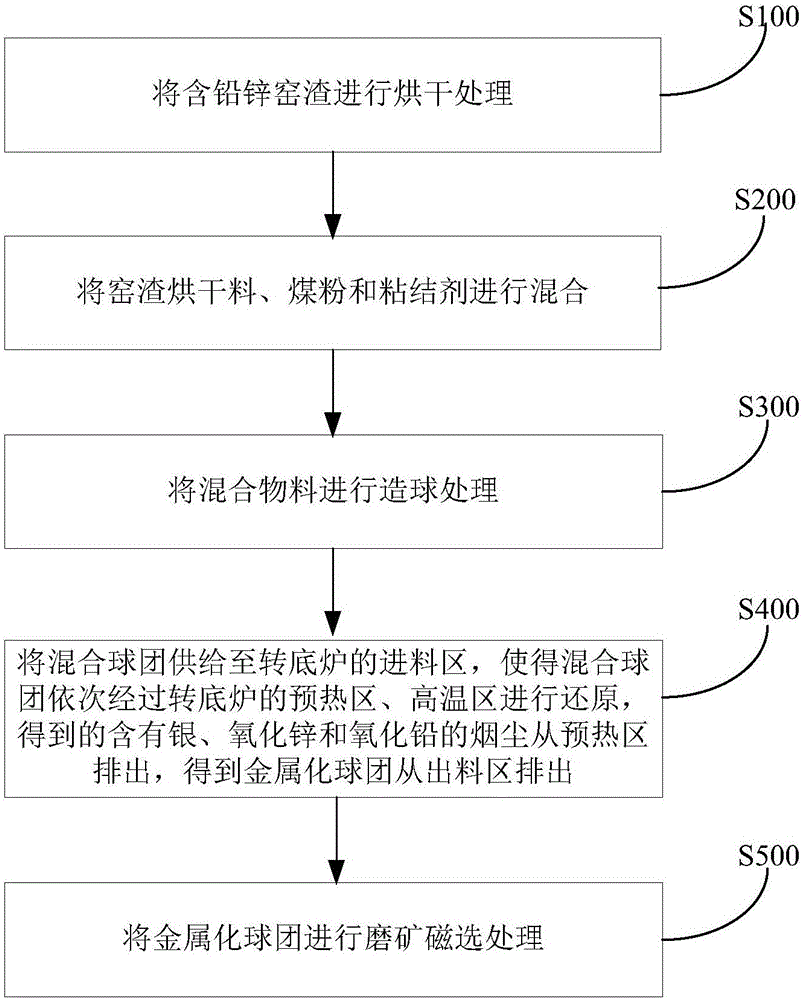

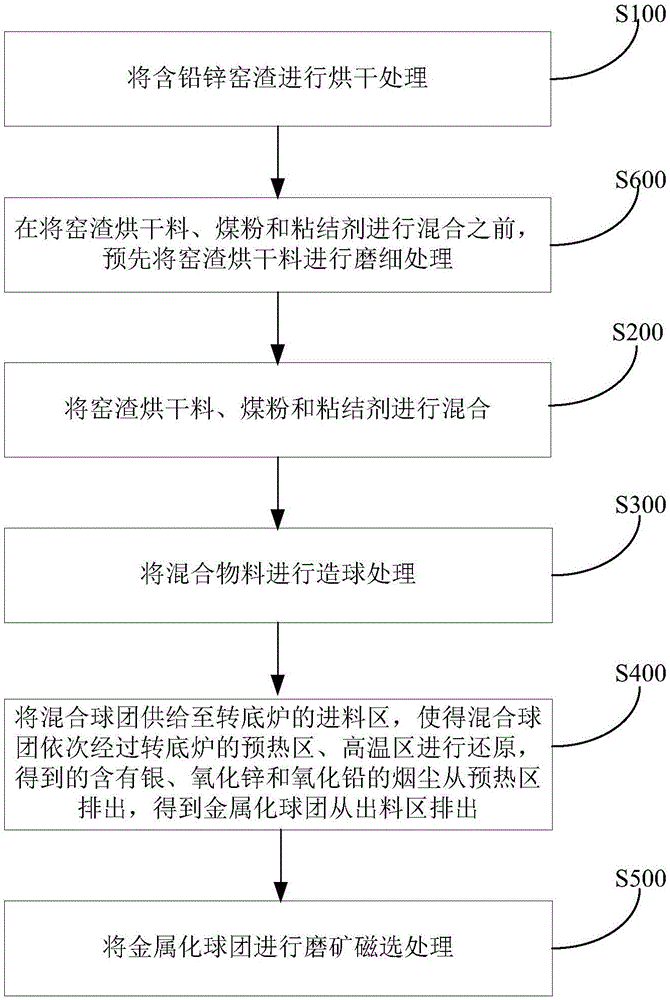

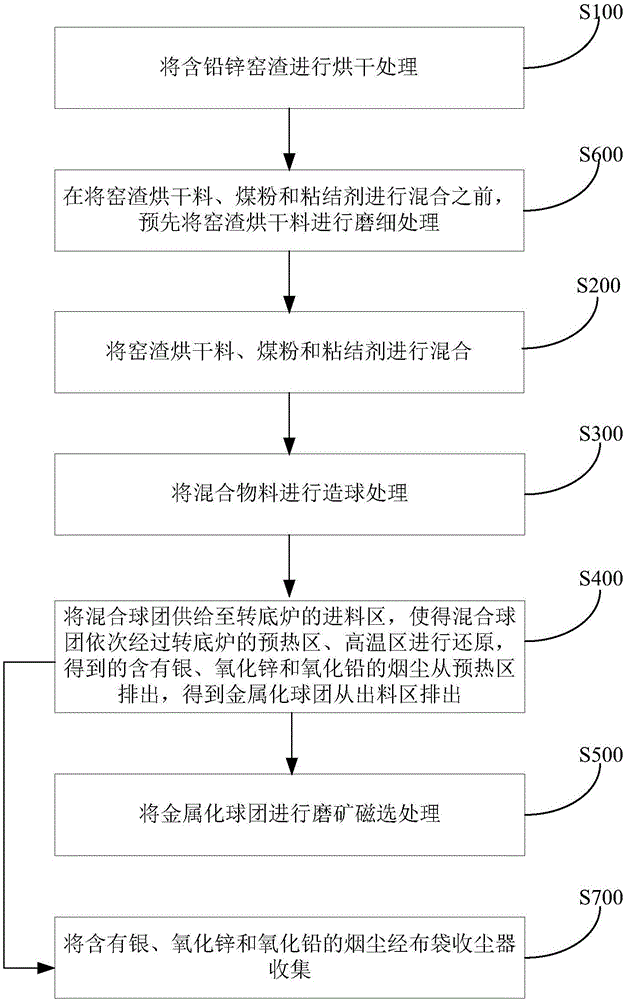

Method and system for treatment of kiln slag including lead and zinc

InactiveCN106148715AAchieve recyclingRealize resource utilizationProcess efficiency improvementIron powderSlag

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

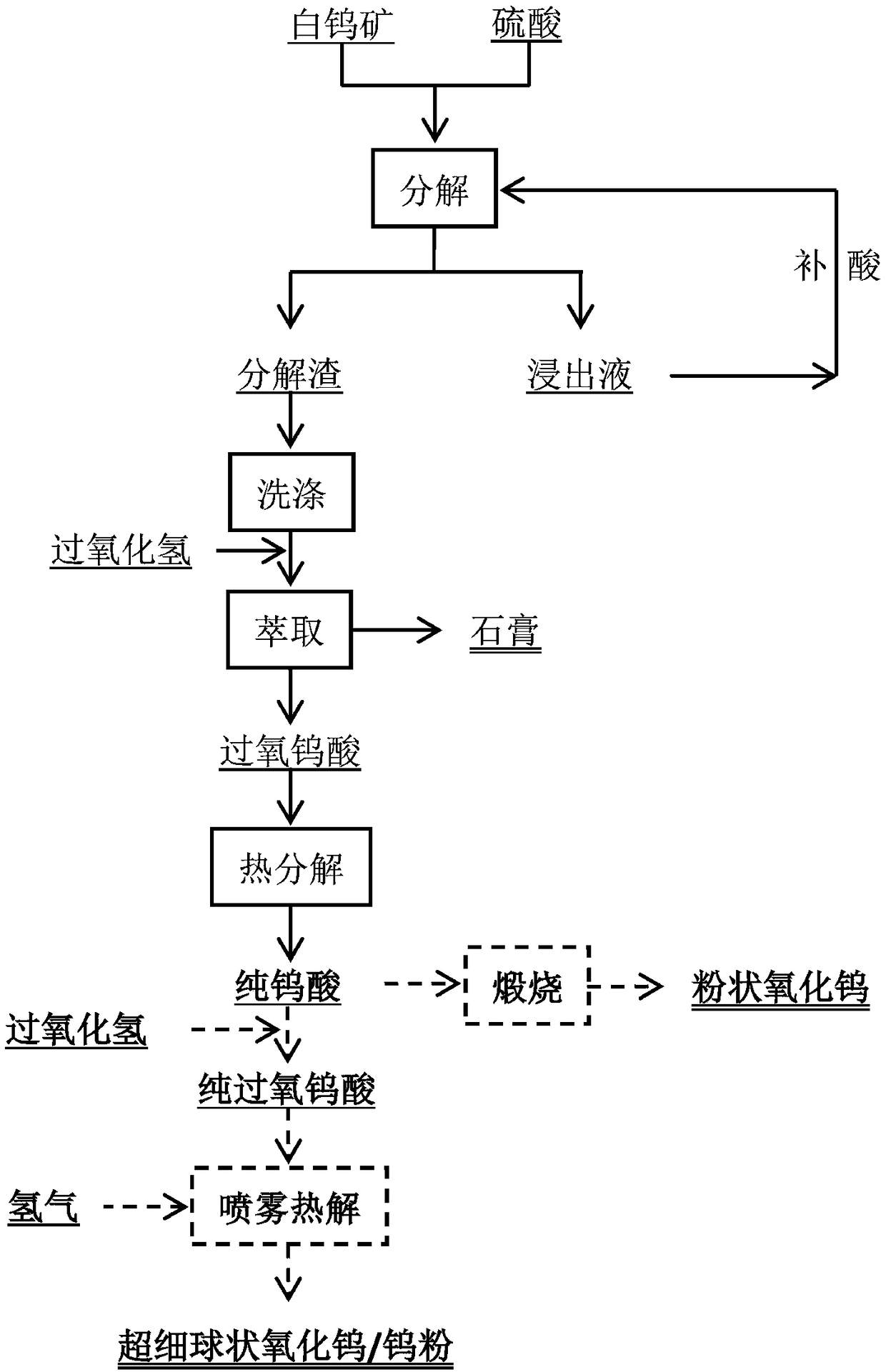

Method for preparing tungsten oxide and tungsten powder from scheelite

ActiveCN108640156AReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementDecompositionCalcination

Owner:CENT SOUTH UNIV

Method and apparatus for processing a suspension

ActiveUS7425273B2High purityBlast furnace detailsWater/sewage treatmentProcess engineeringFilter element

The invention relates to a method and apparatus for processing a suspension. According to the invention, a suspension is led into a washing column in which at least one filter element is present, so that near the filtering element, a packed bed of particles forms. The bed is disintegrated under the influence of the impulse of a washing liquid, while particles from the bed are incorporated in the washing liquid.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK TNO

Method for extracting valuable metal elements from coal gangue

ActiveCN113061728ALow chemical stabilityAchieve primary separationSilicaCarbon compoundsFerric hydroxideCalcium silicate

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for recovering indium from waste LCDs

Owner:ZHUZHOU KENENG NEW MATERIAL CO LTD

Boron-phosphorus alloy cast iron used in air compressor cylinder block and its manufacturing process

InactiveCN102268587AImprove wear resistanceImprove tensile propertiesProcess efficiency improvementElectric furnaceAlloyCylinder block

Owner:ZHUJI HUAJIA AIR COMPRESSOR

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap