Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry and manufacturing, electrolysis is a technique that uses a direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential.

Preoxidized-composite electrolyzing method for removing arsenic in groundwater

InactiveCN101139150ALow toxicityImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisFenton reagent

A method to remove arsenic in underwater by preoxidation-combined electrolyzing relates to a method to remove arsenic from underwater, belonging to the technical field of water treatment. The present invention has solved the defect that more expensive pure nulvalent iron and slower corrosion speed of the pure nulvalent iron have limited the absorption of arsenic on the nulvalent iron. The present invention includes the following steps: the underwater containing arsenic is pre-oxidized by ozone, potassium ferrate, potassium permanganate, H2O2, photocatalysis oxidation reagent or Fenton reagent, thereby transferring As(III) to As(V). The water pre-oxidized passes through a filtering bed containing cast-iron scrap and carbon granules. The oxidizer left in the preoxidation section promotes the reaction of the step.

Owner:HARBIN INST OF TECH

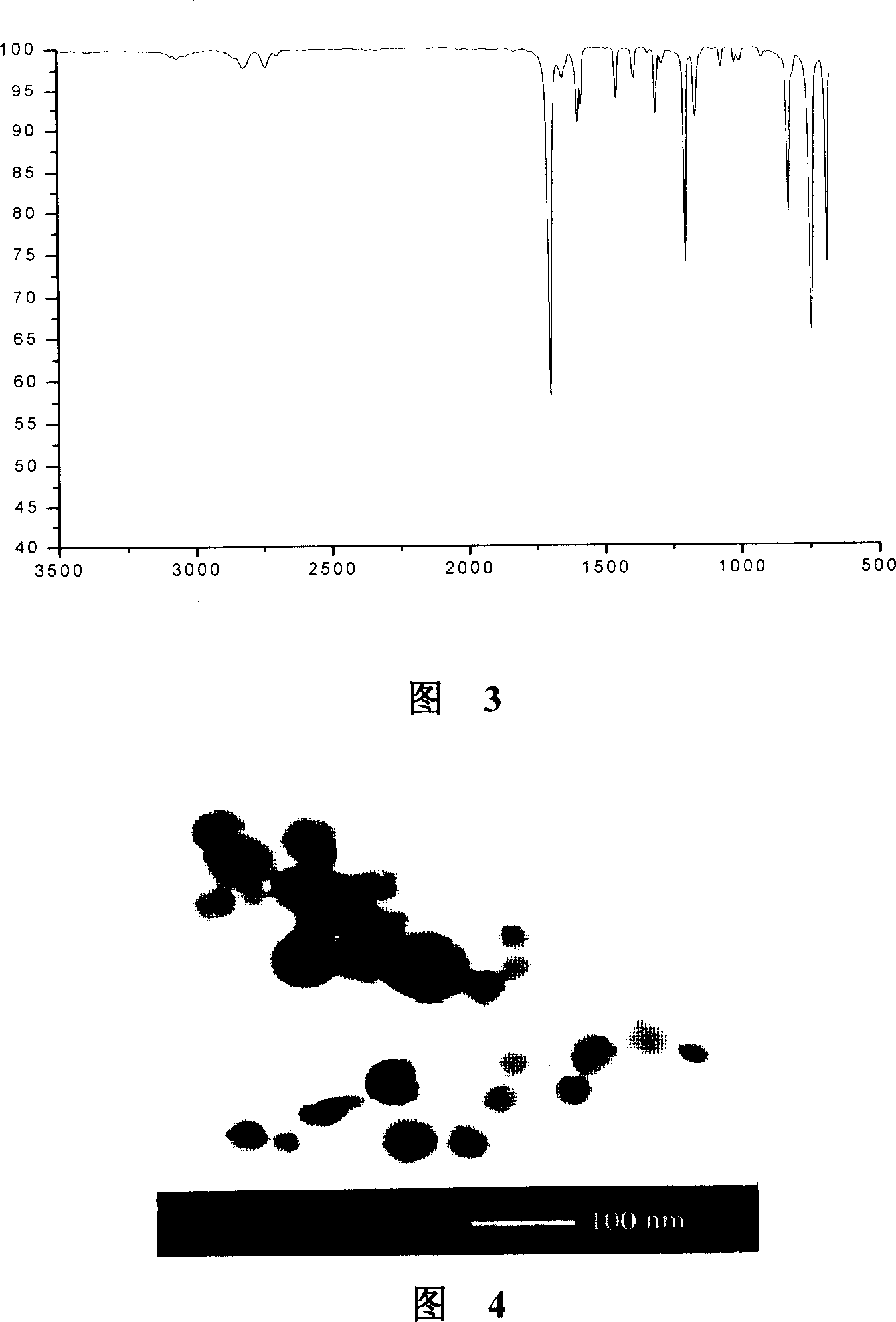

Solid Electrolytic Capacitor Containing a Poly(3,4-Ethylenedioxythiophene) Quaternary Onium Salt

ActiveUS20120147529A1Highly solubleEasily and cost-effectively formedMaterial nanotechnologyHybrid capacitor electrolytesDielectricElectrolysis

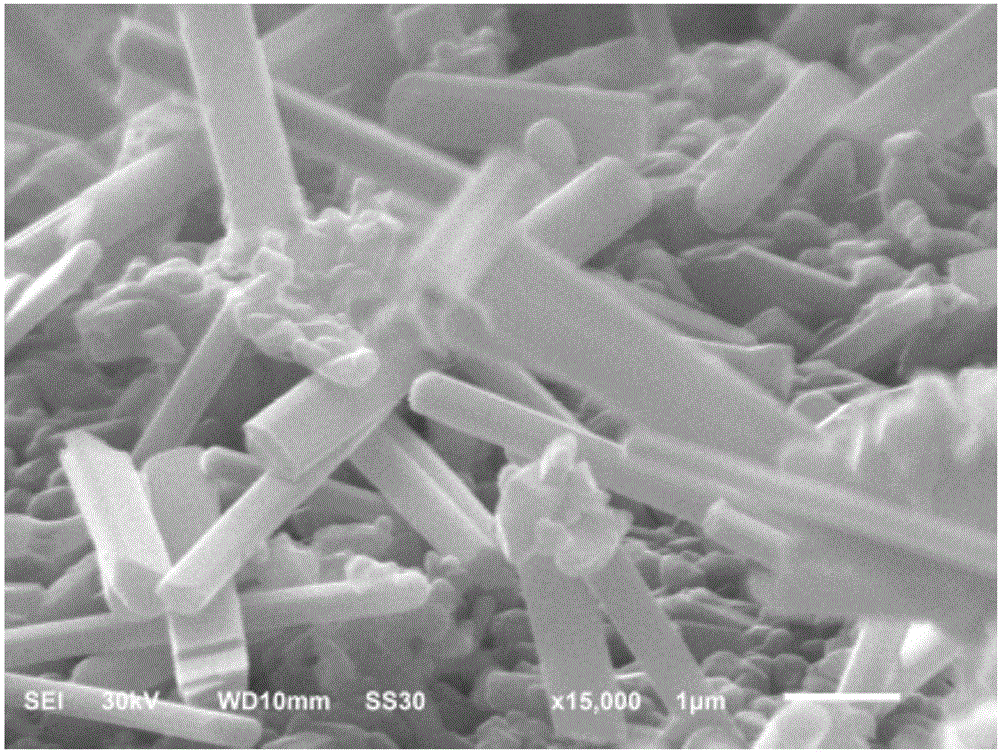

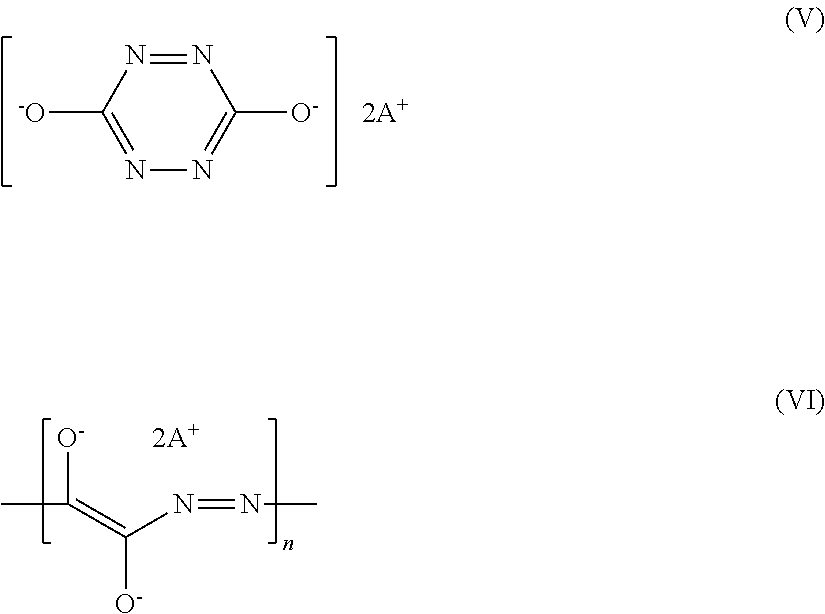

A solid electrolytic capacitor a solid electrolytic capacitor that includes an anode body, a dielectric overlying the anode body, and a solid electrolyte overlying the dielectric is provided. The capacitor also comprises a conductive polymer coating that overlies the solid electrolyte and includes nanoparticles formed from a poly(3,4-ethylenedioxythiophene) quaternary onium salt.

Owner:CENT FOR ORGANIC CHEM +1

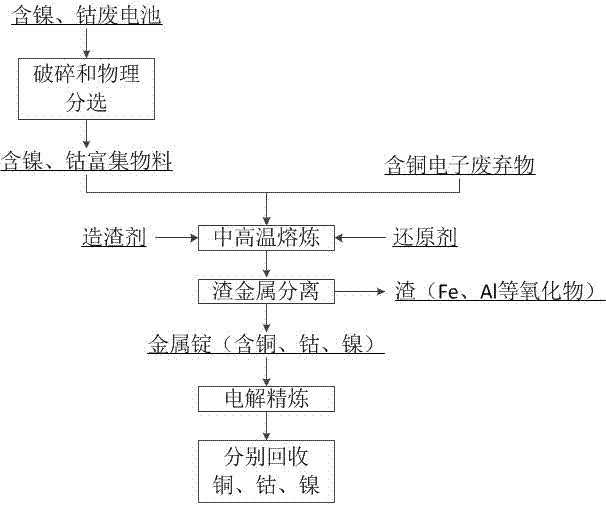

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

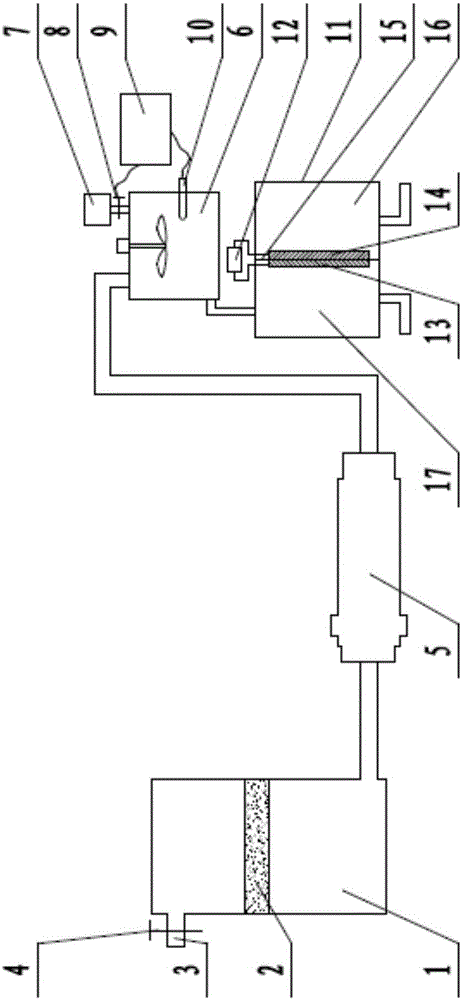

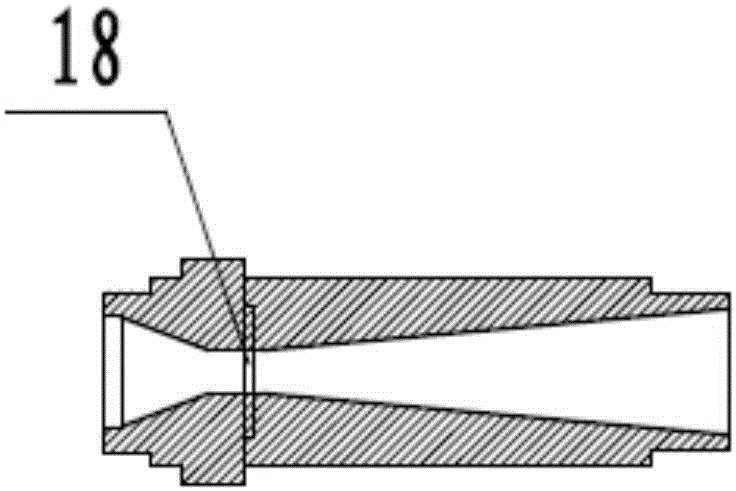

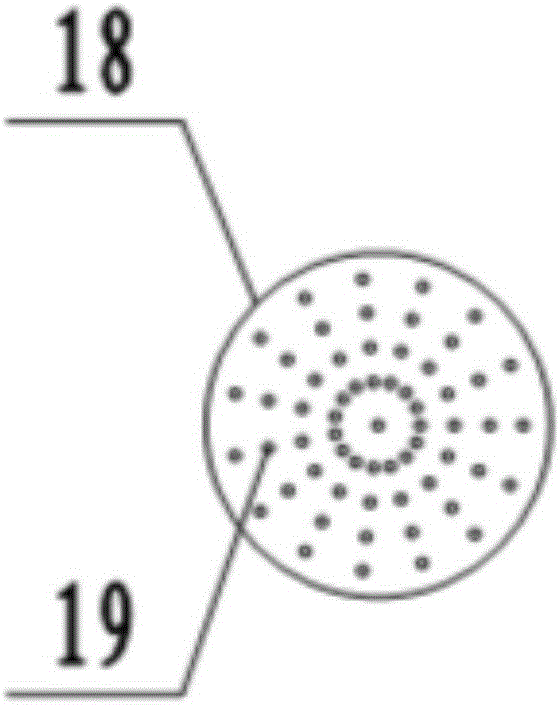

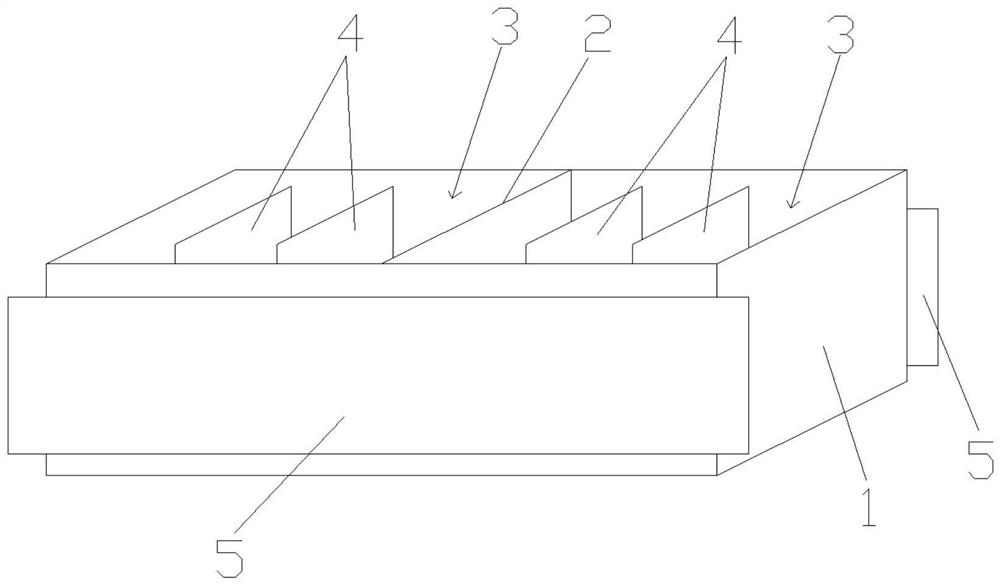

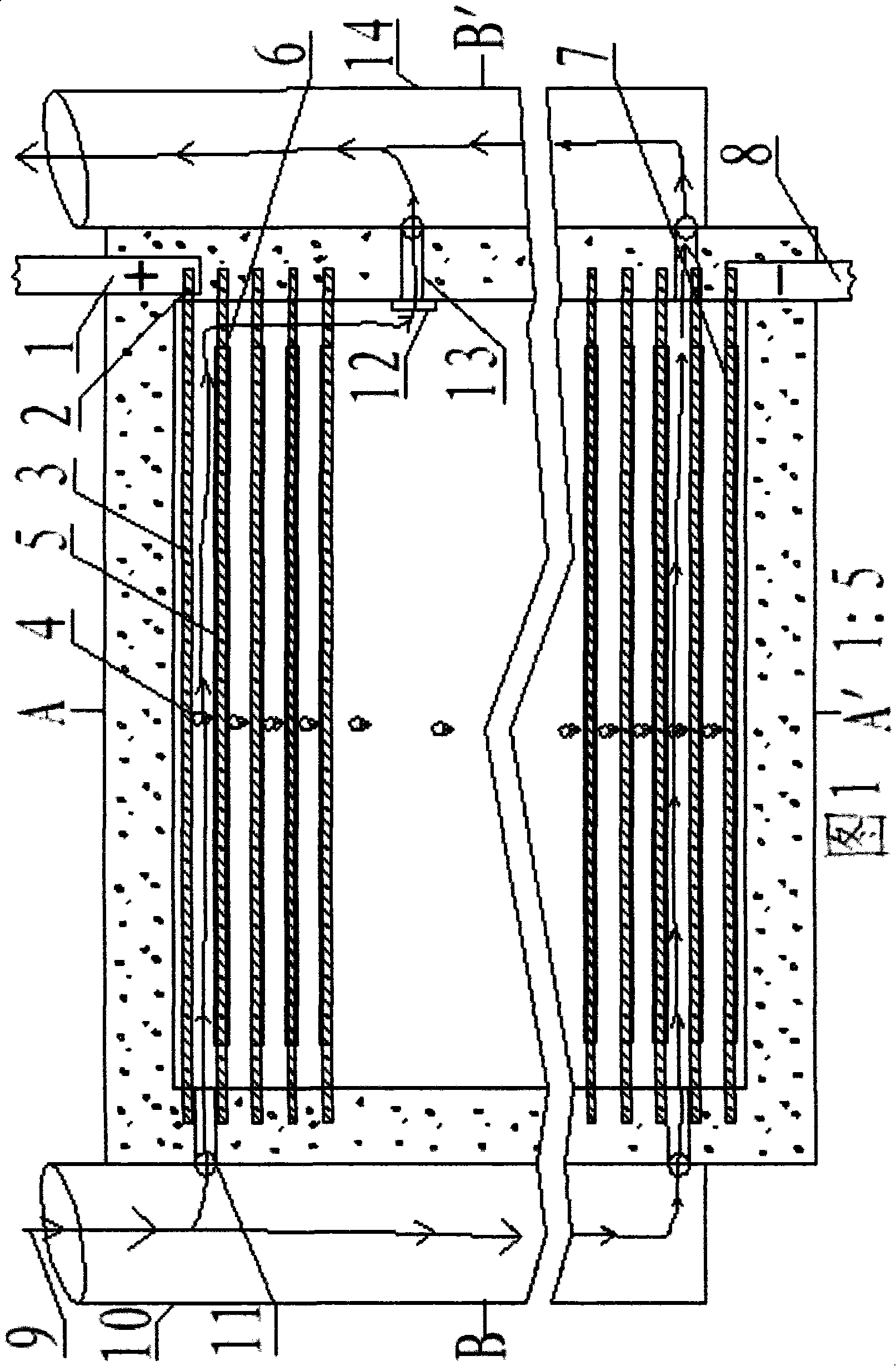

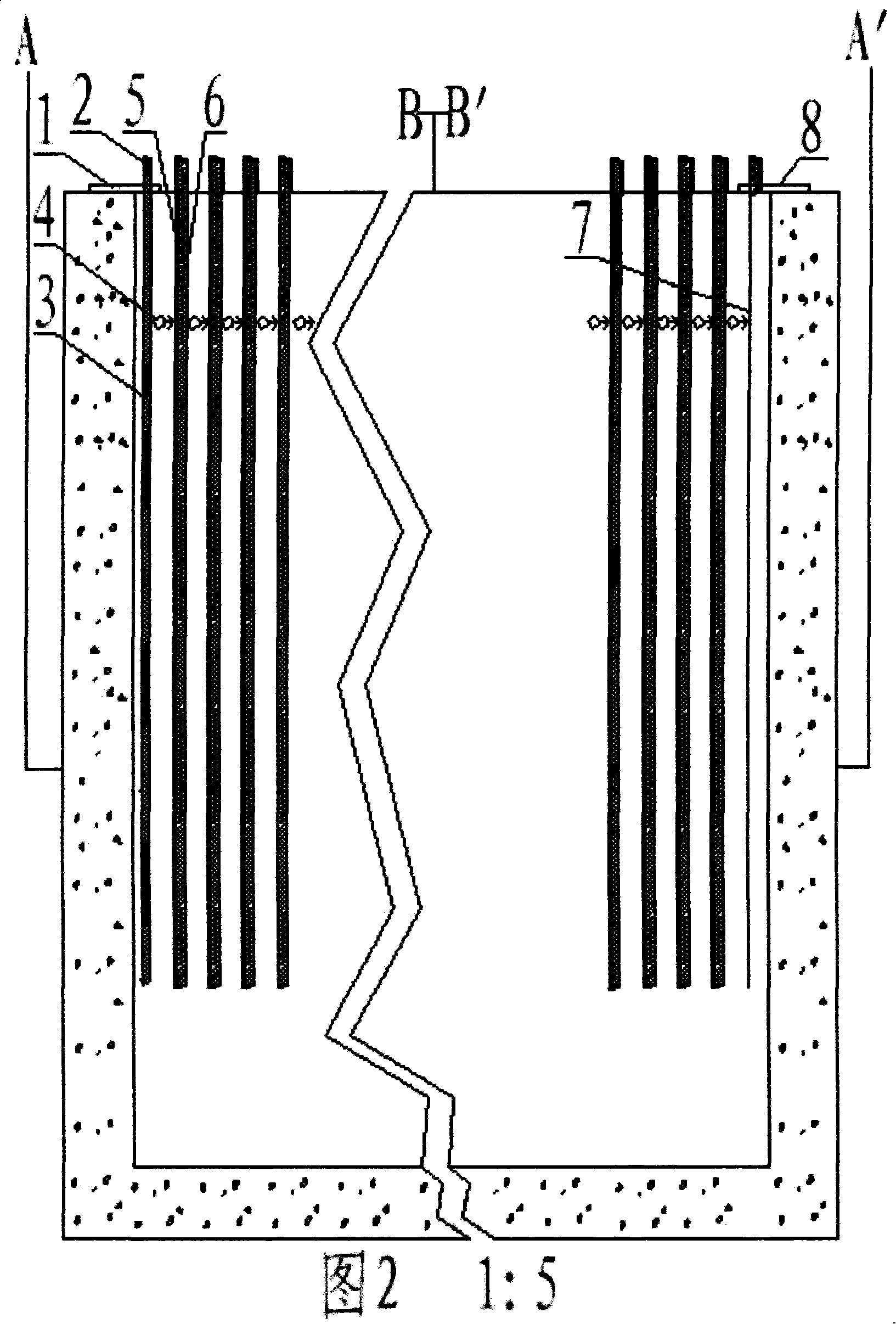

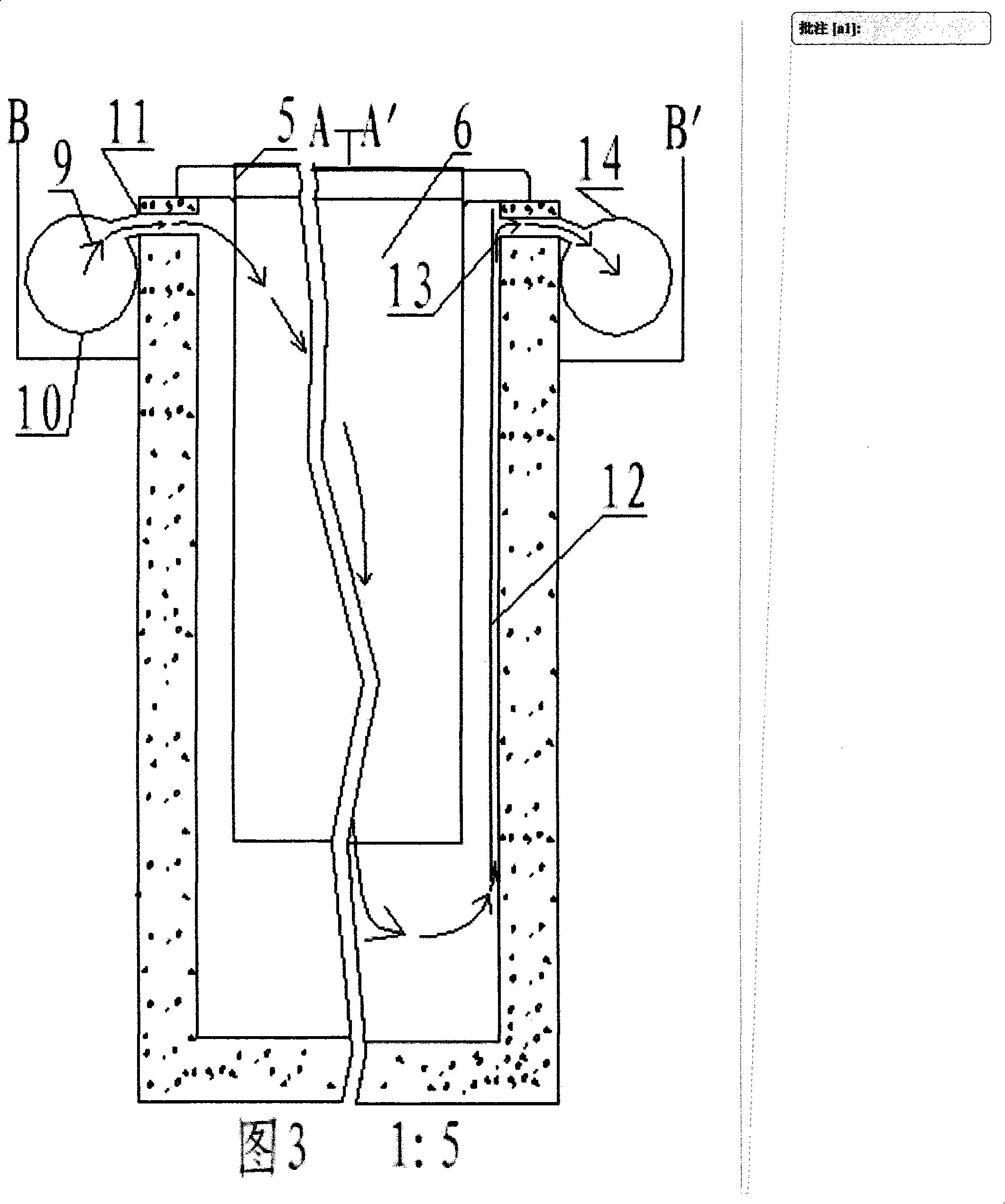

Method and device for electrolytic machining of massive array tiny pits through wedge-shaped runner

ActiveCN103600144APrevent inflowConsistent strengthMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses a method and a device for electrolytic machining of massive array tiny pits through a wedge-shaped runner, and belongs to the technical field of electrolytic machining. The method includes processing the surface of a mask plate to enable the surface to fit with the surface of a workpiece anode; fixing a wedge-shaped tool cathode above the mask plate to enable the wedge-shaped runner to be formed between the wedge-shaped tool cathode and the mask plate; connecting the workpiece anode and the wedge-shaped tool cathode with an anode and a cathode of a power source respectively; feeding an electrolyte into the wedge-shaped runner, wherein the electrolyte reaches the surface of the workpiece anode through penetrating group holes in the mask plate; switching on the power source for electrolytic machining. The runner is arranged to be wedge-shaped, so that electric field intensity and electrolyte flowing speed are enabled to be progressively increased along the direction of the runner, both corrosion strength and speed of a workpiece are enabled to tend to be uniform, and uniformity and machining accuracy of electrolytic machining are improved. A PDMS (polydimethylsiloxane) template is taken as the mask plate, bonding strength of the mask plate and the workpiece anode can be guaranteed, stray corrosion, of the electrolyte, to places around a machining area can be effectively reduced, and locality and uniformity of electrolytic machining can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Hydrogen on demand electrolysis fuel cell system

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

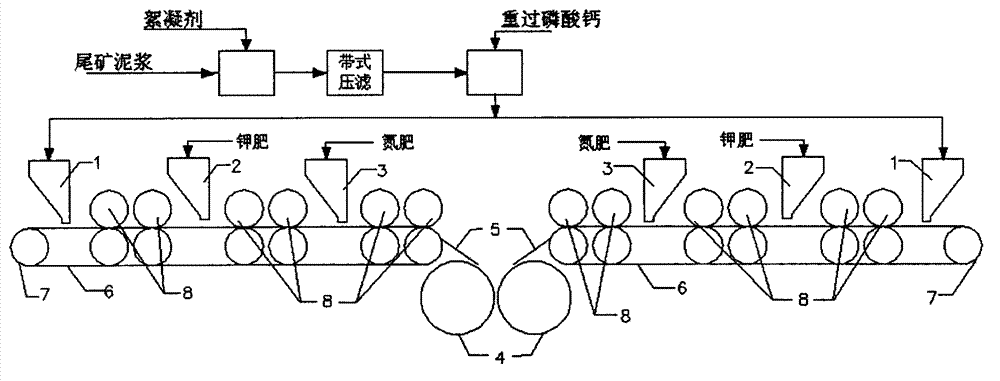

Method and equipment for producing slow-release compound fertilizer from manganese ore tailings

InactiveCN103204743AReduce processing costsSolving Stacking Handling IssuesFertiliser formsFertilizer mixturesElectrolysisManganese

Owner:赵阳臣

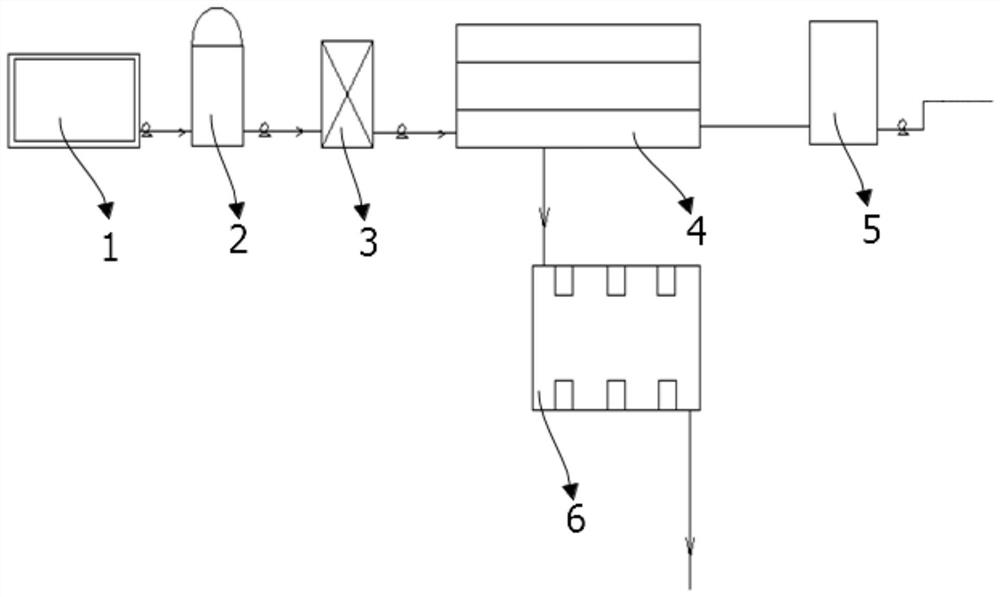

System and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy

The invention discloses a system and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy. The system comprises a renewable energy generation module, a power conditioning module, a urea-containing wastewater pretreatment module, an alkaline urea electrolytic hydrogen production module, a gas / liquid separation, drying and purifying module, an alkaline liquor circulating pump, a hydrogen storage tank and an anode product storage module, wherein an output end of the renewable energy generation module is connected with an input end of the power conditioning module, and an output end of the power conditioning module is connected with the alkaline urea electrolytic hydrogen production module. By means of the system, nearby in-time consumption of renewable energy power is facilitated, the hydrogen production cost is r educed, the tolerance of the hydrogen production system to the volatility and intermittence of a power supply is improved, a hydrogen production technology is combined with a water treatment technology, and while the hydrogen production energy consumption is reduced, environmental pollution is avoided; the applicability of the system is wide, the stability is high, the hydrogen produced by the system is high in purity, the process is simple, and industrial production is facilitated.

Owner:闫巍

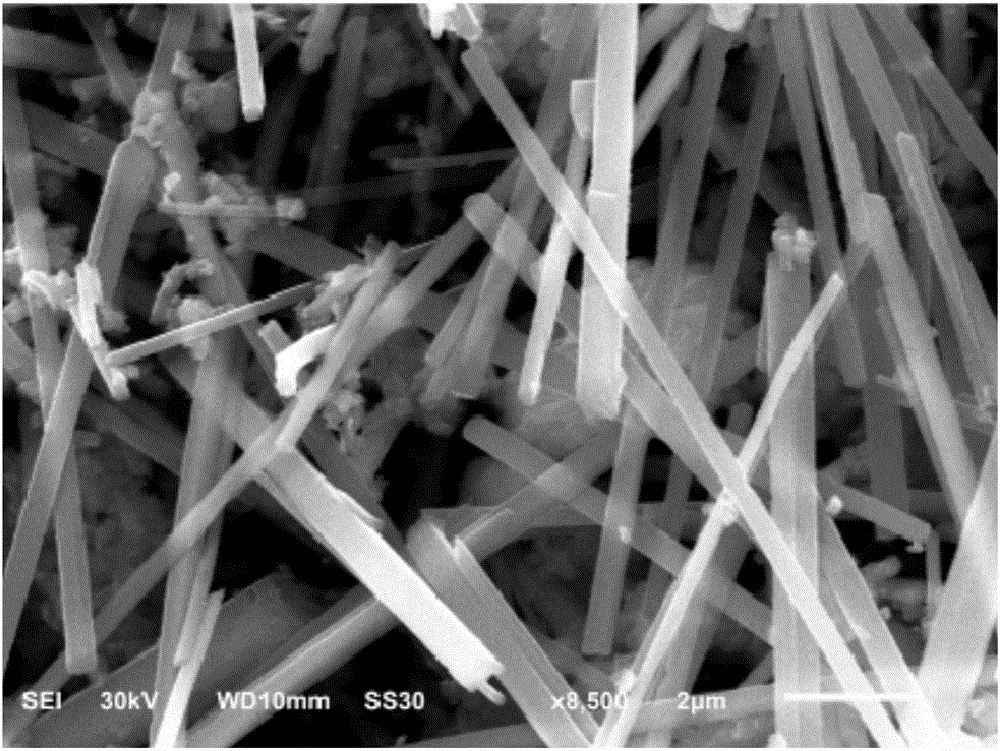

Electrochemical pretreatment method of cathode for electrolytic extraction of metal gallium

ActiveCN102268714ANo corrosionReduced induction periodAnodisationPhotography auxillary processesPretreatment methodElectrolysis

Belonging to the technical field of electrolytic extraction of metal gallium, the invention provides an electrochemical pretreatment method of a cathode for electrolytic extraction of metal gallium. The method comprises the processes of: subjecting the cathode for electrolytic extraction of gallium to an oil and rust removal treatment; in an acidic, neutral or alkaline electrolyte, carrying out an electrochemical pretreatment to the cathode for gallium electrolytic extraction as an anode, with the cathode made of but not limited to stainless steel, and maintaining the pretreatment at a temperature of 15-40DEG C for 3min-2h, with an anodic current density of 0.01-0.2A / cm<2>. The electrode subjected to an electrochemical pretreatment has a smoother microscopic surface and a uniform surface current distribution. And as the surface of the electrode undergoing the electrochemical pretreatment exposes a partial crystal lattice structure, so the bonding force of electrodeposited gallium and the electrode surface becomes stronger, and the return dissolubility of the electrodeposited gallium in an alkaline condition can be reduced. Thus, continuous metal gallium layers are more likely to be electrodeposited and the induction time of electrodeposition can be shortened. The electrochemical pretreatment method of an electrode in the invention has the advantages of simple process, easy operation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Integrated electrolysis atomization module and atomization device

PendingCN111825170ASmall footprintEasy maintenanceLavatory sanitoryLiquid spraying apparatusElectrolysisEngineering

The invention provides an integrated electrolysis atomization module and atomization device. The integrated electrolysis atomization module comprises an electrolysis assembly and an atomization assembly, the atomization assembly comprises an installation base and a flat plate atomization piece installed on the installation base, and the flat plate atomization piece is used for atomizing liquid above the flat plate atomization piece and spraying the atomized liquid upwards; the integrated electrolysis atomization module is characterized in that the electrolysis assembly comprises at least one electrolysis electrode pair, namely a first electrolysis electrode and a second electrolysis electrode, an electrical isolation distance is formed between the first electrolysis electrode and the second electrolysis electrode, the first electrolysis electrode and the second electrolysis electrode are connected to the installation base, and the projection of the electrolysis assembly avoids the flatplate atomization sheet when viewed from top to bottom; electric signal connection between the electrolysis electrode and the control circuit board is achieved through the conductive bolt (or in combination with the mounting base), mechanical connection of the electrolysis electrode can be achieved at the same time, the overall structure is simple, and a simple sealing structure can be adopted.

Owner:FOSHAN NANHAI KERI ELECTRONICS

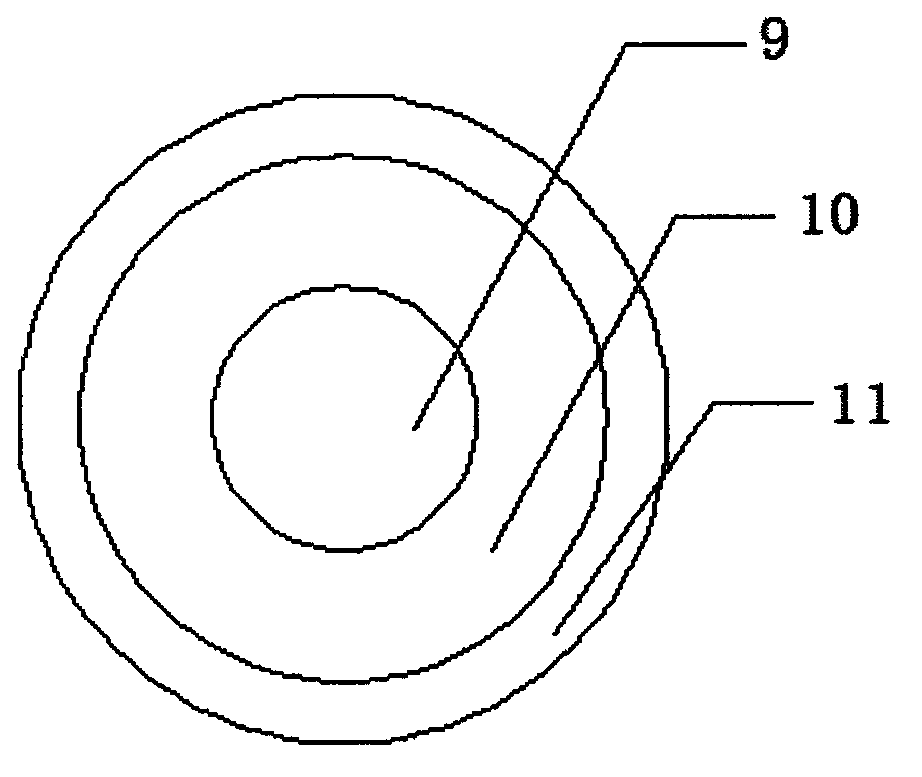

Stainless steel welding rod improving vertical welding process performance

ActiveCN112975199AIncrease the solidification rateImprove vertical welding operabilityWelding/cutting media/materialsSoldering mediaElectrolysisSS - Stainless steel

The invention provides a stainless steel welding rod improving vertical welding process performance. The stainless steel welding rod comprises a stainless steel core wire and a coating wrapping the surface of the stainless steel core wire, the coating is prepared from the following raw materials, in parts by weight, 30-40 parts of rutile, 3-8 parts of zircon quartz, 5-10 parts of feldspar, 10-18 parts of marble, 2-6 parts of fluorite, 2-8 parts of dolomite, 1-5 parts of magnesia, 1-5 parts of aluminum oxide, 5-10 parts of electrolytic manganese metal, 5-10 parts of chromium metal, 3-6 parts of ferrotitanium, 2-7 parts of iron powder, 1-2 parts of sodium alginate and 1-2 parts of microcrystalline cellulose. According to the stainless steel welding rod improving the vertical welding process performance, the excellent flat welding process performance of an acid coating stainless steel welding rod is reserved, meanwhile, by designing the coating of the welding rod, the welding rod melting rate is reduced, the slag forming number in unit time is reduced, the slag solidification rate is improved, vertical welding slag is stably solidified and does not flow downwards, and the vertical welding operability of the stainless steel welding rod is improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Preparation method of ferric vanadate photocatalysts

InactiveCN106311258AHigh purityEasy to impurityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereElectrolysis

Owner:SHANGHAI INST OF TECH

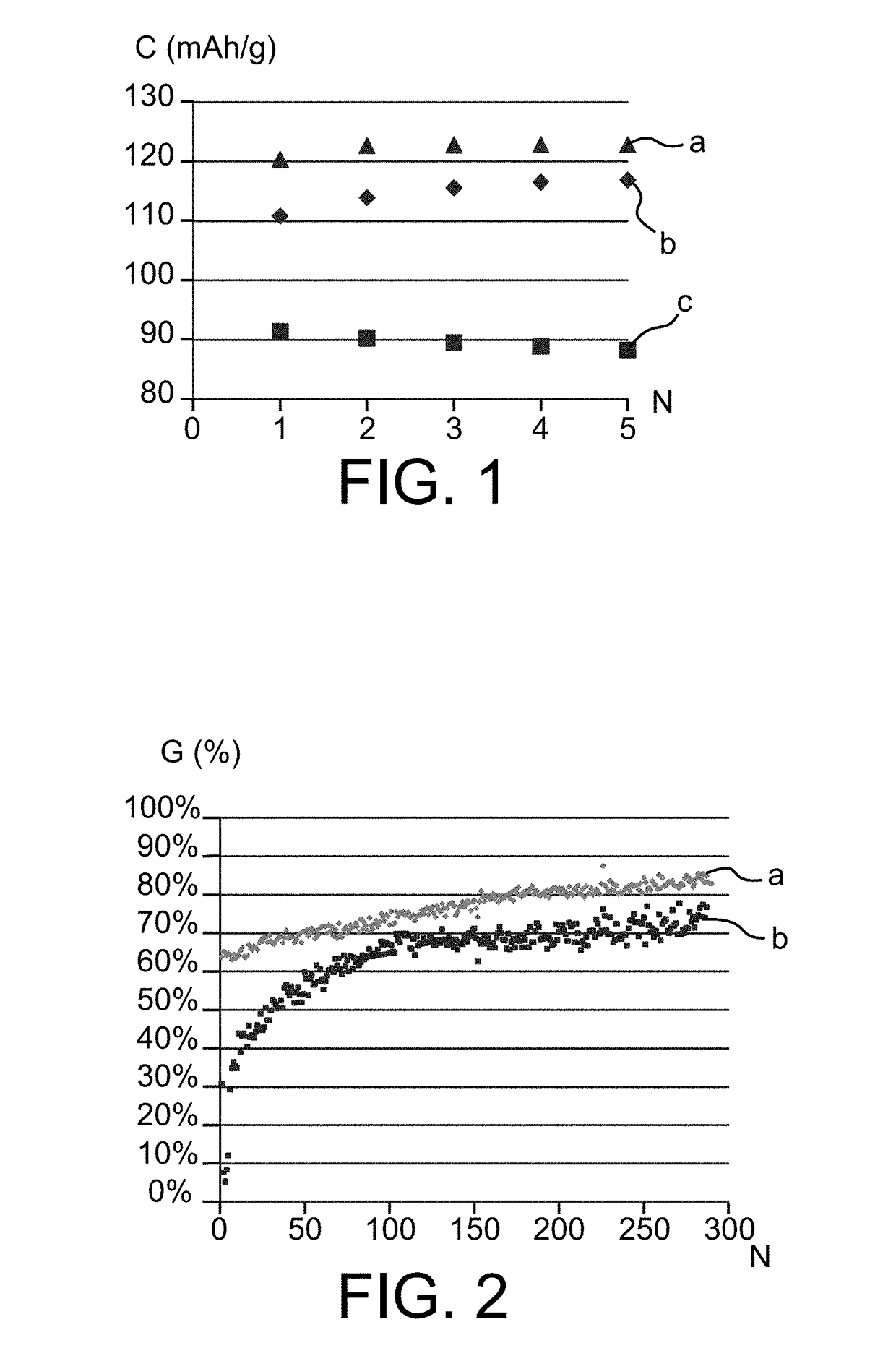

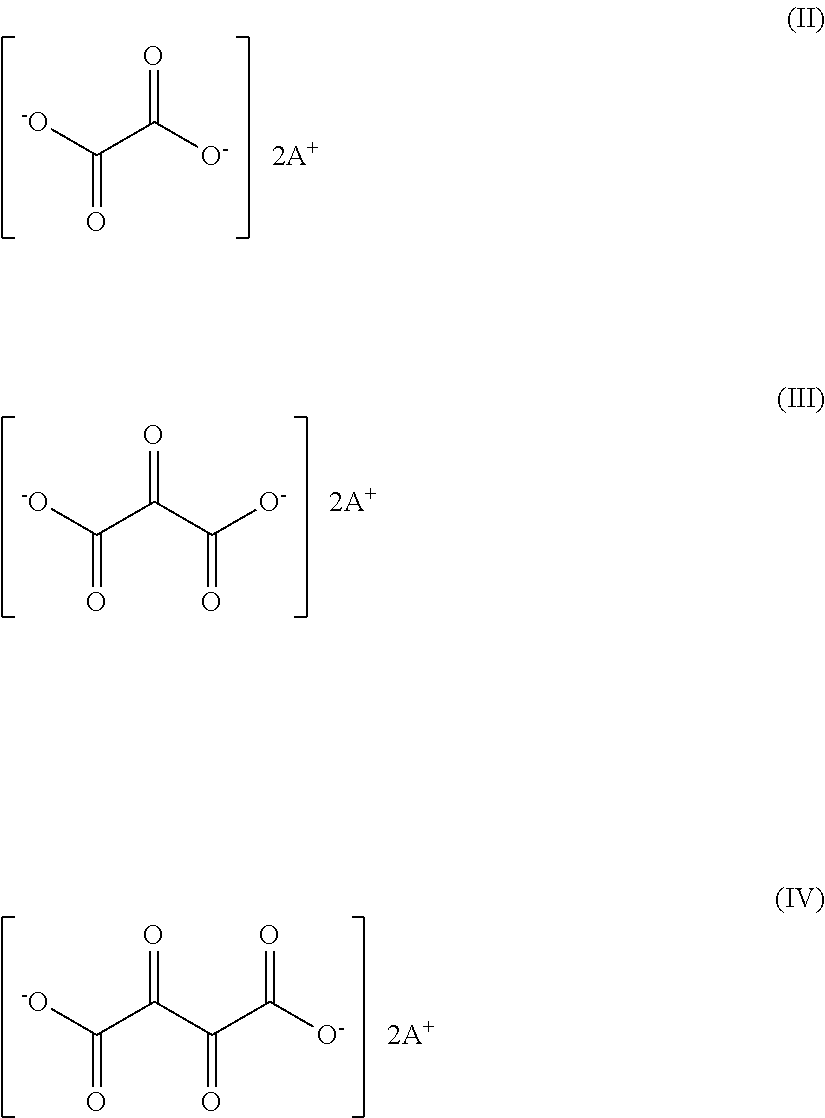

Method for producing a sodium-ion battery

InactiveUS20180316044A1Loss in capacity of battery is lessFinal product manufactureElectrode collector coatingElectrolysisDecomposition

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Water Purification

InactiveUS20140367344A1Water treatment parameter controlWater treatment compoundsEnvironmental resistanceElectrolysis

This invention relates to a method and apparatus (10) for purifying water, wherein oxygen is introduced into the water by electrolysis of the water; and the water is treated with at least one ionized transition metal. In a preferred embodiment of the invention, the electrolysis of the water takes place by passing an electric current through paired electrodes (22) made from stainless steel; and the water is treated with ionized silver, copper and zinc produced at silver (16), copper (18) and zinc (20) electrodes that are supplied with electric current. The invention prevents and combats growth of bacteria fungal and viral pathogens in water, and provides a non-toxic and environmentally friendly method of ensuring the public health in both public and private applications.

Owner:WET TRUST

Method for recovering gold from printed circuit board of waste mobile phone

ActiveCN108642289AImprove adsorption efficiencyAchieve reuseOther chemical processesProcess efficiency improvementElectrolysisResource utilization

Owner:NANKAI UNIV

Method for recycling waste gas generated by combusting water or water vapor and hydrogen

InactiveCN101691850AReduce electricity costsReduce manufacturing costNon-fuel substance addition to fuelInternal combustion piston enginesElectricityHydrogen

Owner:JIANGYIN SHANGFENG NEW ENERGY TECH DEV

Method for preparing electrolytic manganese by using pyrolusite

PendingCN110331284AAchieve regenerationAchieve recyclingPhotography auxillary processesProcess efficiency improvementElectrolysisPyrolusite

The invention discloses a method for preparing electrolytic manganese by using pyrolusite, and the method comprises the following steps of leaching manganese ore: crushing pyrolusite, mixing a mixed solution containing ammonium sulfate, manganese sulfate and ferrous sulfate with pyrolusite particles to obtain slurry, and leaching; neutralizing and precipitating iron: adding calcium-based neutralizer into the slurry, adjusting pH value, adding oxidant to enable Fe<2+> concentration in the solution to be lower than 1 mg / L, and filtering to obtain manganese sulfate solution and iron hydroxide filter residue; carrying out heavy metal removal: adding a vulcanizing agent into the manganese sulfate solution to enable the concentration of heavy metal ions in the solution to be lower than 1 mg / L, and then filtering to obtain vulcanized slag and electrolyte; and carrying out electrolytic recovery of manganese metal: electrolyzing the obtained electrolyte to prepare electrolytic manganese and electrolytic manganese anolyte containing sulfuric acid. The method can effectively solve the problem that dithionate is generated in the pyrolusite sulfur dioxide leaching method, thereby causing the problems of high electrolysis energy consumption, high sulfur content of electrolytic manganese and large amount of iron-containing waste residue generated in the pyrolusite ferrous sulfate leaching method.

Owner:GUIZHOU UNION MAGANESE CORP CO LTD

Method for degrading industrial organic wastewater by ultrasonic wave ozone-microelectrolysis coupling

InactiveCN110776191AReduce surface tensionImprove permeabilitySpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsMolecular sievePtru catalyst

Owner:JIANGHUA WATER TREATMENT EQUIP PLANT JIANGSU

Alkali-process zinc powder combined smelting method

The invention discloses an alkaline-process zinc powder combined smelting method. The method comprises a zinc deposition process, a filtering process, an alkaline leaching process, an electrolysis process, a washing process, a size mixing process and a purification process, and a stock solution before zinc deposition in the zinc deposition process is a new electrolytic solution in a zinc hydrometallurgy process. The alkaline-process zinc powder combined smelting method adopts an alkaline-process zinc powder preparation and wet-process purification combined smelting mode and simultaneously utilizes a zinc powder wet adding technology, so that the problems of high equipment price, high cost and high energy consumption in the existing alkaline-process zinc powder drying process and severe operation environment in the zinc powder transferring process are solved; and meanwhile, the problems that the grade of alkaline leaching raw materials of alkaline-process zinc powder is unstable, the impurity content is high, and a purification procedure needs to be added to remove impurities are solved. The combined smelting method has the characteristics of low use cost, good effect and excellent working environment, and meets the requirements of low carbon, greenness and environmental protection.

Owner:YUNNAN YUNTONG ZINC CO LTD

Novel device for generating electrolytic ionized water and method for preparing electrolytic ionized water

InactiveCN106630308AGood effectEfficient electrolysisSpecific water treatment objectivesTreatment involving filtrationElectrolysisSolenoid valve

Owner:淄博水韵之生生物科技有限公司

Ammonia-nitrogen electrolysis tail gas treatment system

InactiveCN107670473AReduce fugitiveReduce odorGas treatmentDispersed particle separationElectrolysisAcid substances

The invention provides an ammonia-nitrogen electrolysis tail gas treatment system. The ammonia-nitrogen electrolysis tail gas treatment system has the advantages that a first washing tower and a second washing tower are connected with the rear of a tail gas emission opening of an electrolytic tank, and peculiar smell of ammonia-nitrogen waste gas emitted from the electrolytic tank can be reduced by reducing chemicals at the first washing tower; dissipation smell of ammonia gas under the condition of high PH (potential of hydrogen) values can be removed by acidic materials such as sulfuric acidor hydrochloric acid in the second washing tower, accordingly, peculiar smell of electrolyzed tail gas can be reduced, and dissipation of the ammonia gas can be decreased; a PH value of washing liquid of the first washing tower keeps higher than 8 in procedures for reducing the smell of the gas by the aid of the reducing chemicals, and the usage amount of reducing agents can be effectively reduced.

Owner:CONCORD TECH CO LTD

Method for preparing enriched precious lead from precious antimony

The invention discloses a method for preparing enriched precious lead from precious antimony. The method comprises the following steps: (1) smelting precious antimony; (2) removing impurities from precious antimony; (3) performing cupellation on the precious antimony; (4) adding lead and further performing cupellation. The method has a short technological process, and the whole process only needs8-12 days; enriched precious lead, not precious antimony, is prepared from precious antimony, and the recovery rate can reach 99% and above; the enriched precious lead is more convenient to smelt thanprecious antimony; the precious metal can be extracted by multiple ways such as electrolysis; therefore, the method is worthy of large-range popularization.

Owner:GUANGXI WANSHIZHI RARE & PRECIOUS METAL TECH CO LTD

Preparation method of composite metal ion water

PendingCN113023836AControl concentrationPrecisely control the quantityMultistage water/sewage treatmentWater/sewage treatment by substance additionChemical physicsElectrolysis

Owner:陕西益康潇生物科技有限公司

Method for preparing sodium hypochlorite by using reverse osmosis concentrated water

PendingCN114108008ASolve disposal problemsReduce foulingCellsHypochloriteElectrolysisWater storage tank

The invention discloses a method for preparing sodium hypochlorite by using reverse osmosis concentrated water, which comprises the following steps: S1, the reverse osmosis concentrated water enters a softener for softening treatment and then enters a carbon adsorption device, the softened water subjected to carbon adsorption treatment enters a water storage tank, and the water storage tank pumps the softened water into an electrolytic bath for electrolysis to prepare sodium hypochlorite; s2, when the reverse osmosis concentrated water is electrolyzed in the electrolytic tank, an aeration device is used for carrying out bottom aeration treatment on the solution, aerated gas and gas generated by electrolysis enter a chlorine gas collecting system together, sodium hypochlorite generated by the chlorine gas collecting system and the electrolytic tank is guided into a sodium hypochlorite storage tank to be stored, and gas generated by the chlorine gas collecting system is discharged. The reverse osmosis concentrated water is used as an electrolysis raw material, so that the problem of water plant concentrated water treatment is effectively solved, and sodium hypochlorite can be produced as a disinfectant for each process of a water plant for later use.

Owner:LINHUAN WATER CO LTD

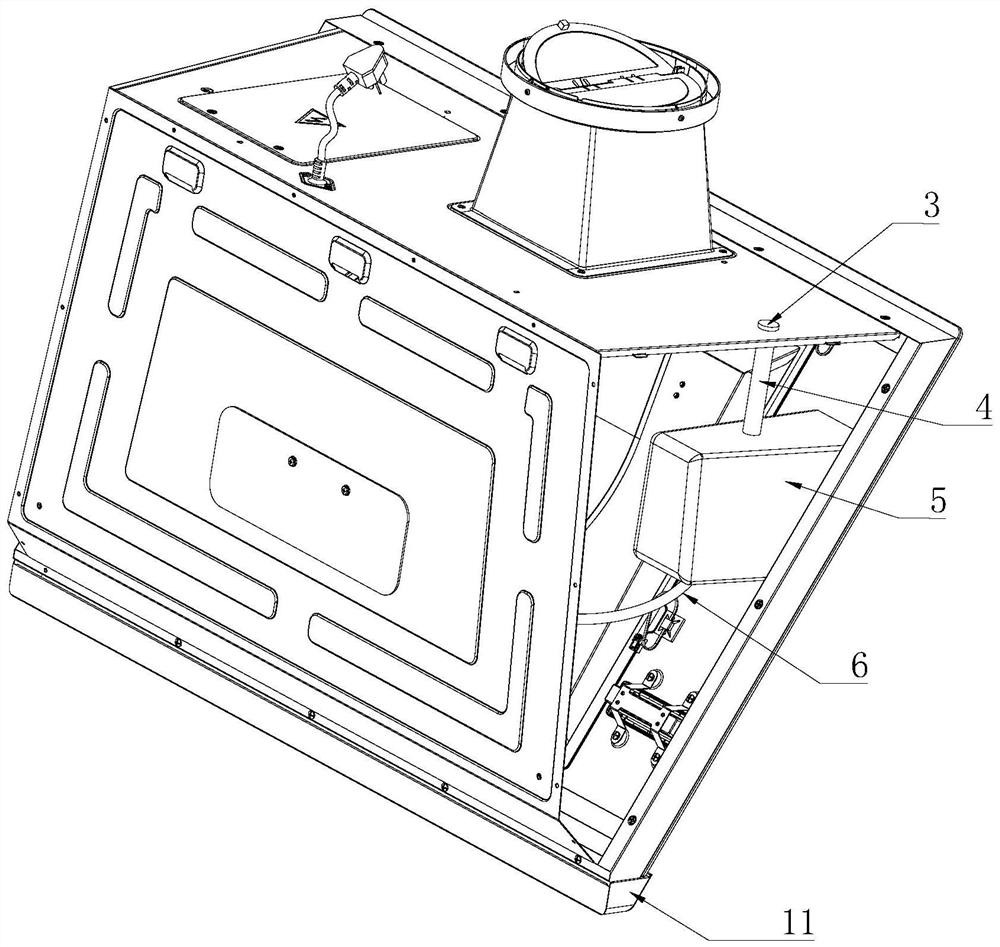

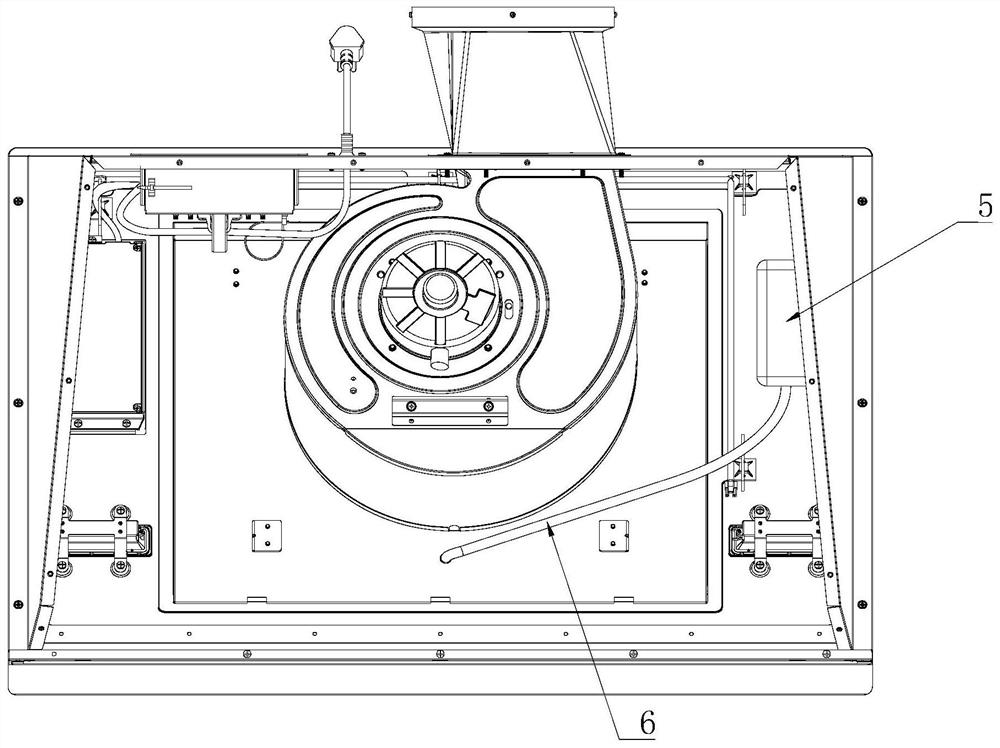

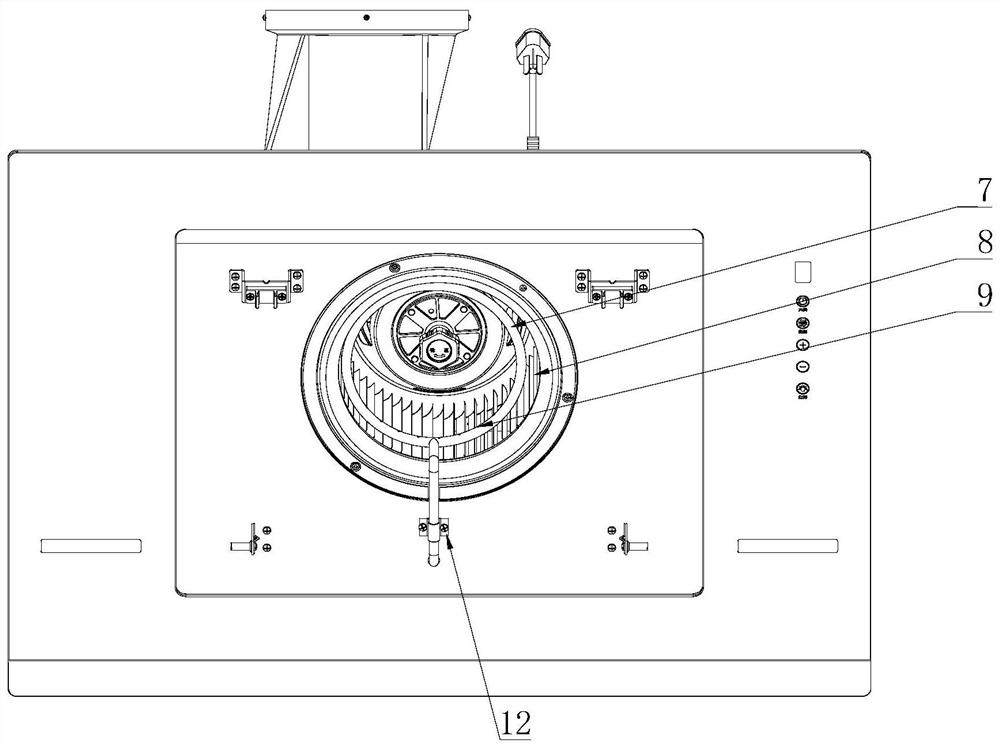

Extractor hood

PendingCN112212381AAchieve cleaningAchieve disinfectionDomestic stoves or rangesLighting and heating apparatusElectrolysisDisinfectant

Owner:GREE ELECTRIC APPLIANCES INC

Wastewater recycling method

InactiveCN112723616ARecycle worksSimple processScale removal and water softeningWaste water treatment from metallurgical processWater useElectrolysis

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

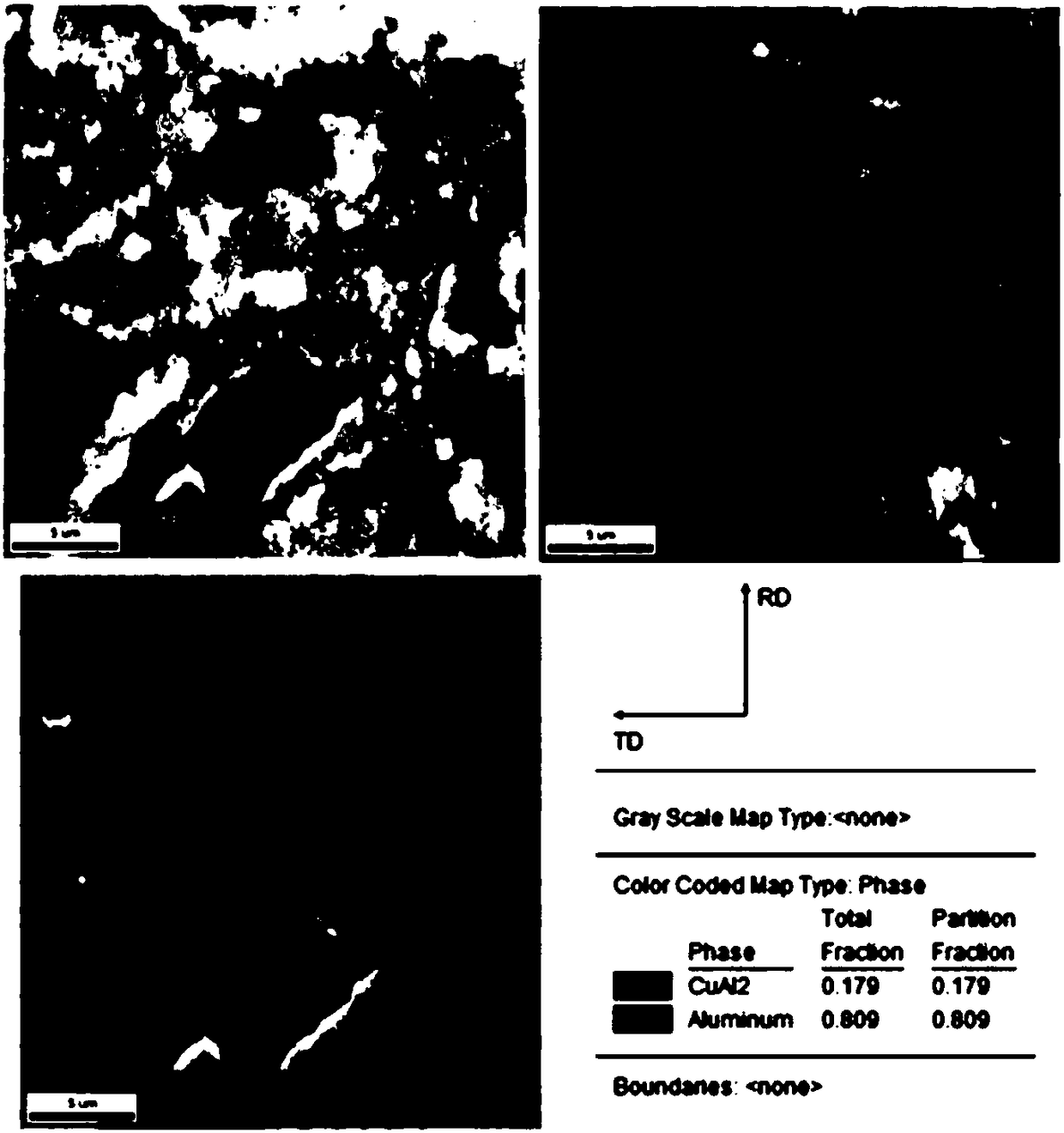

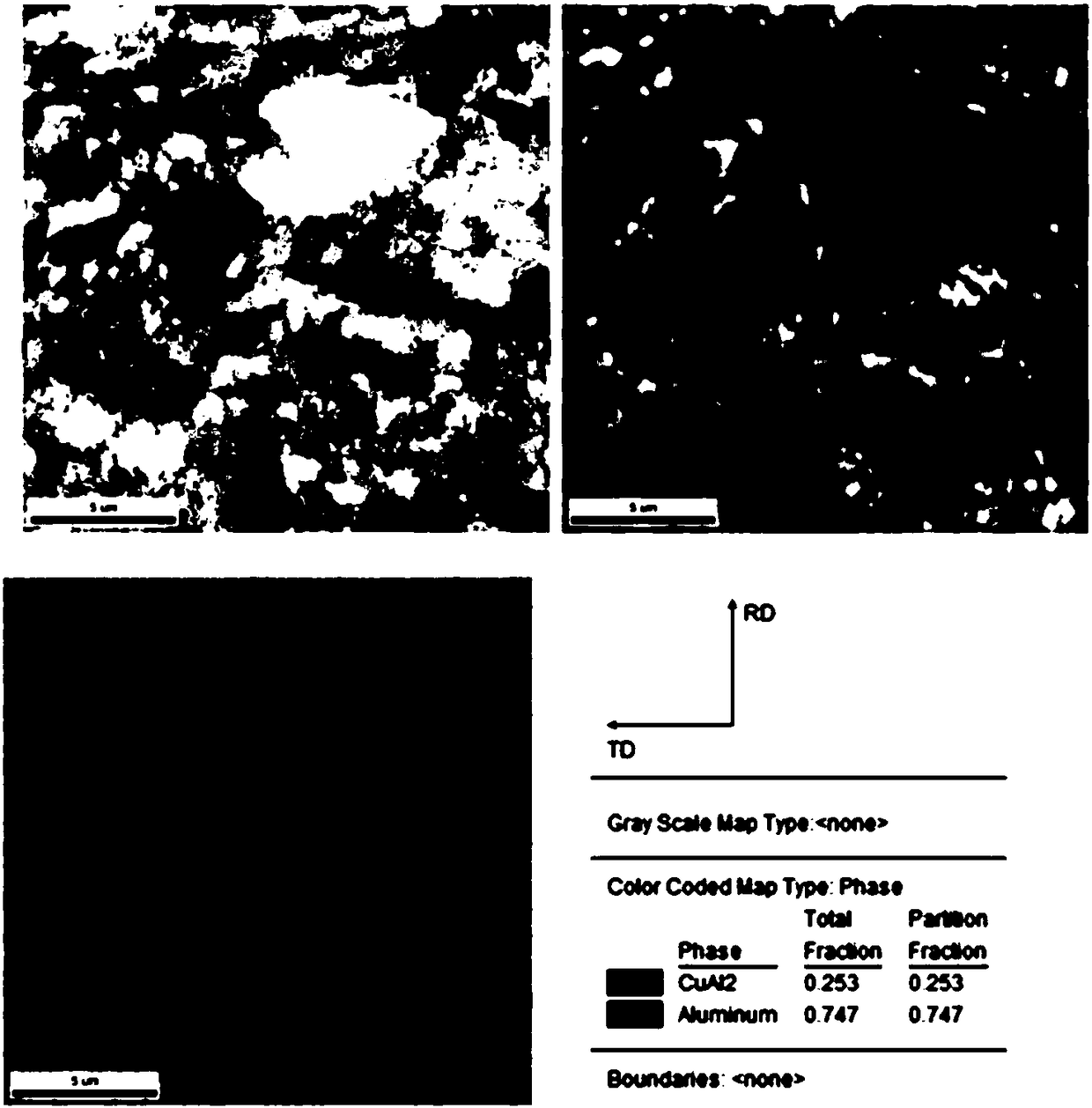

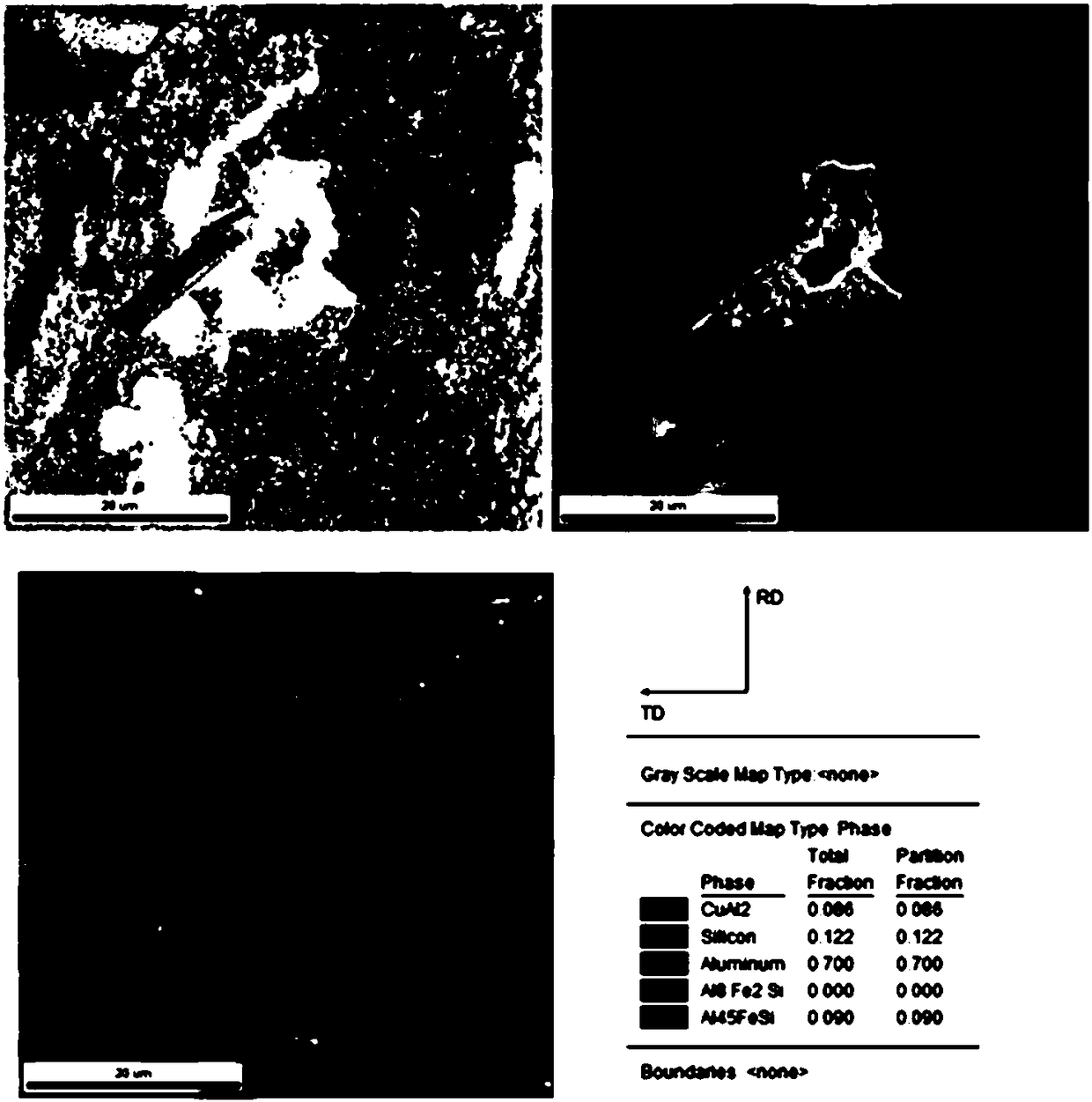

Aluminum alloy EBSD sample alkaline electrolysis polishing liquid and preparation method and electrolysis polishing method thereof

Owner:ZHEJIANG HAILI GROUP

System for chemical and/or electrolytic surface treatment

A system for chemical and / or electrolytic surface treatment of a substrate in a process fluid, a device for chemical and / or electrolytic surface treatment of a substrate in a process fluid, and a method for chemical and / or electrolytic surface treatment of a substrate in a process fluid are all described. The system for surface treatment comprises a basin, a fluid passage, an expansion tank, and acontrol unit. The basin is configured for the surface treatment of the substrate in the process fluid. The fluid passage links the basin and the expansion tank. The expansion tank is configured to hold an expansion volume of the process fluid. The control unit and the fluid passage are configured to maintain a level of the process fluid in the basin at an essentially constant level.

Owner:SEMSYSCO GMBH

Non copper pipe lead electrolytic refining energy-saving high-efficiency environment protection novel technique

InactiveCN101250721AReduce energy consumptionAvoid enteringPhotography auxillary processesElectrolysisSlag

Owner:涂德友 +1

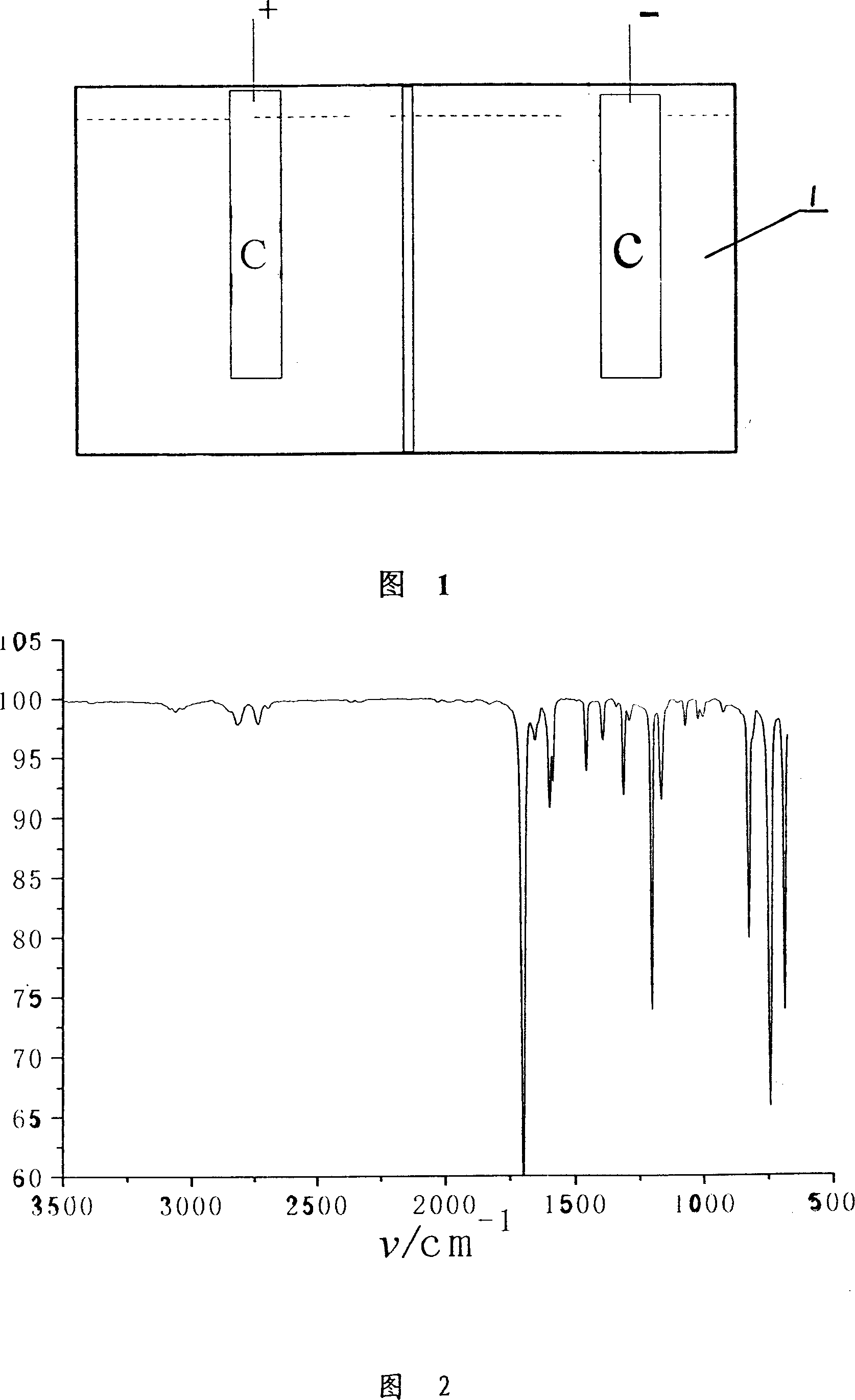

Method for preparing benzaldehyde by nano MnO2

InactiveCN101089230AReduce pollutionMild reaction conditionsElectrolysis componentsElectrolytic organic productionLiquid productElectrolysis

Owner:FUJIAN NORMAL UNIV

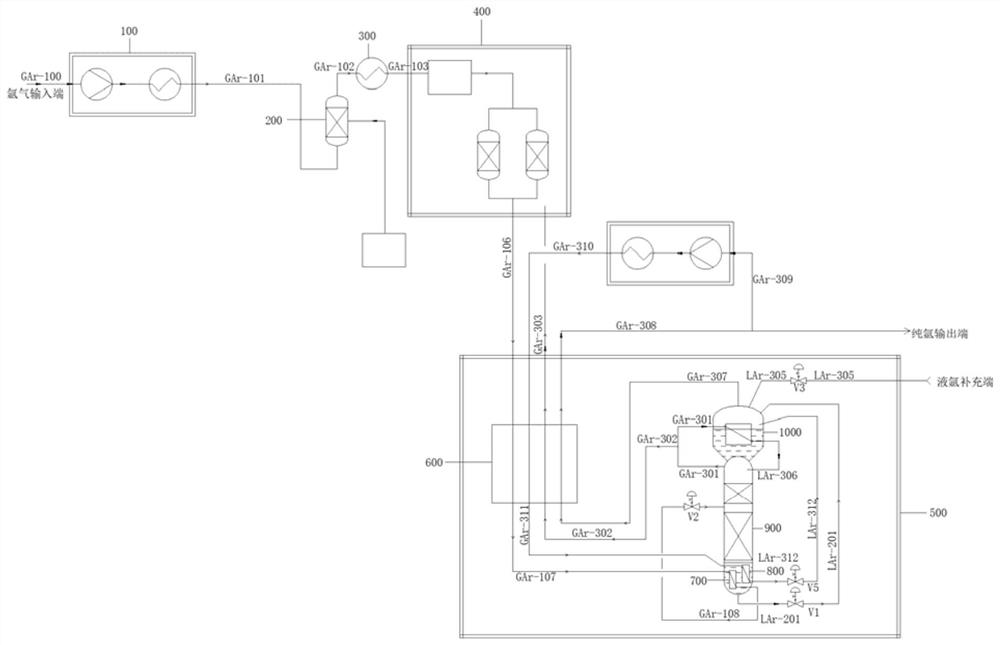

Argon recovery device for removing carbon monoxide through rectification method and operation method

Owner:上海联风企业管理有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap