Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Gallium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gallium is a chemical element with the symbol Ga and atomic number 31. Elemental gallium is a soft, silvery blue metal at standard temperature and pressure; however in its liquid state it becomes silvery white. If too much force is applied, the gallium may fracture conchoidally. It is in group 13 of the periodic table, and thus has similarities to the other metals of the group, aluminium, indium, and thallium. Gallium does not occur as a free element in nature, but as gallium(III) compounds in trace amounts in zinc ores and in bauxite. Elemental gallium is a liquid at temperatures greater than 29.76 °C (85.57 °F), above room temperature, but below the normal human body temperature of 37 °C (99 °F). Hence, the metal will melt in a person's hands.

Composite phase change material for LED thermal interface and preparation method thereof

Owner:东莞市益飞迅光电科技有限公司

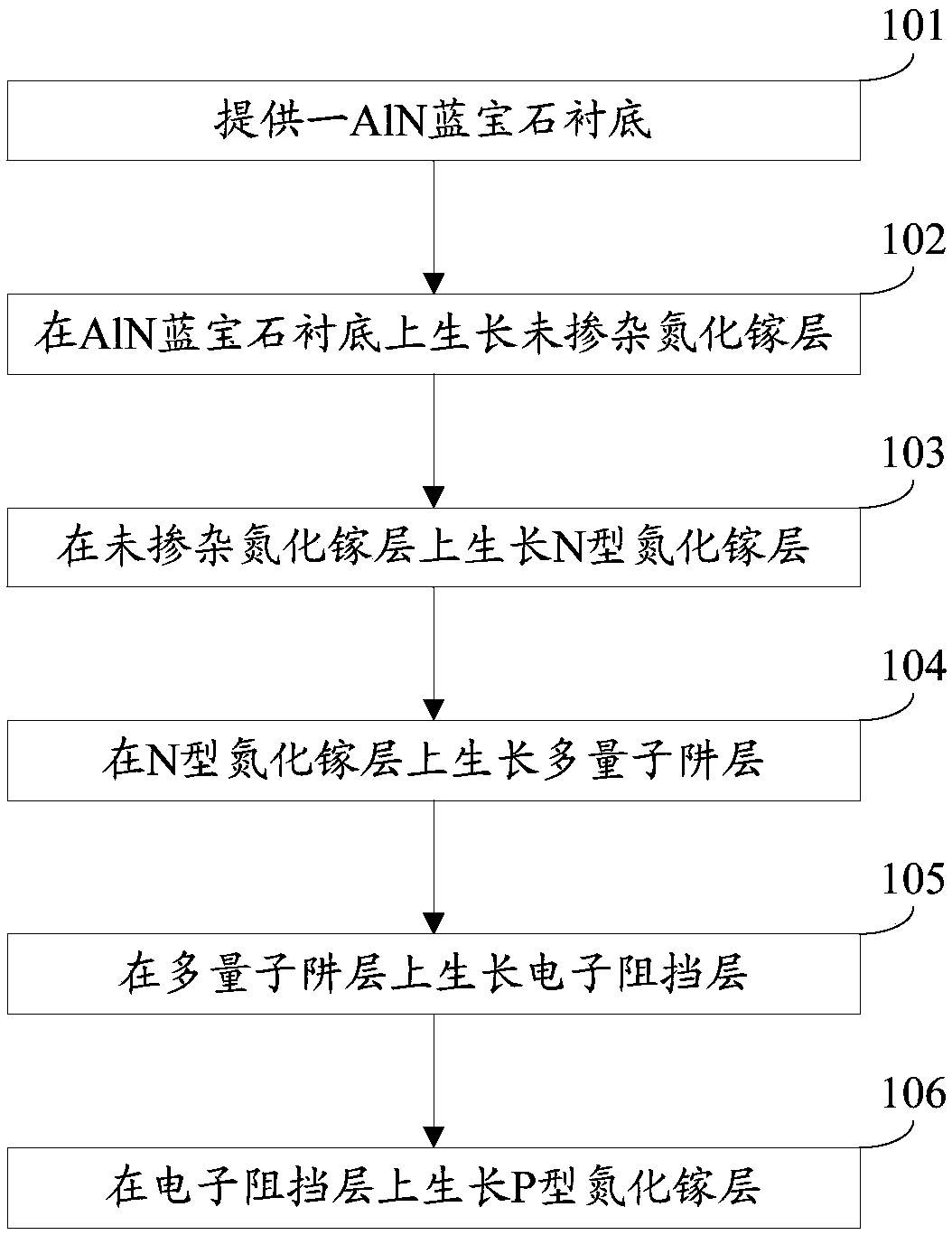

Preparation method of light emitting diode epitaxial wafer

Owner:HC SEMITEK SUZHOU

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap