Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Titanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a lustrous transition metal with a silver color, low density, and high strength. Titanium is resistant to corrosion in sea water, aqua regia, and chlorine.

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:FOSHAN SHUNDE QINGDA RUNCAI COATING CO LTD

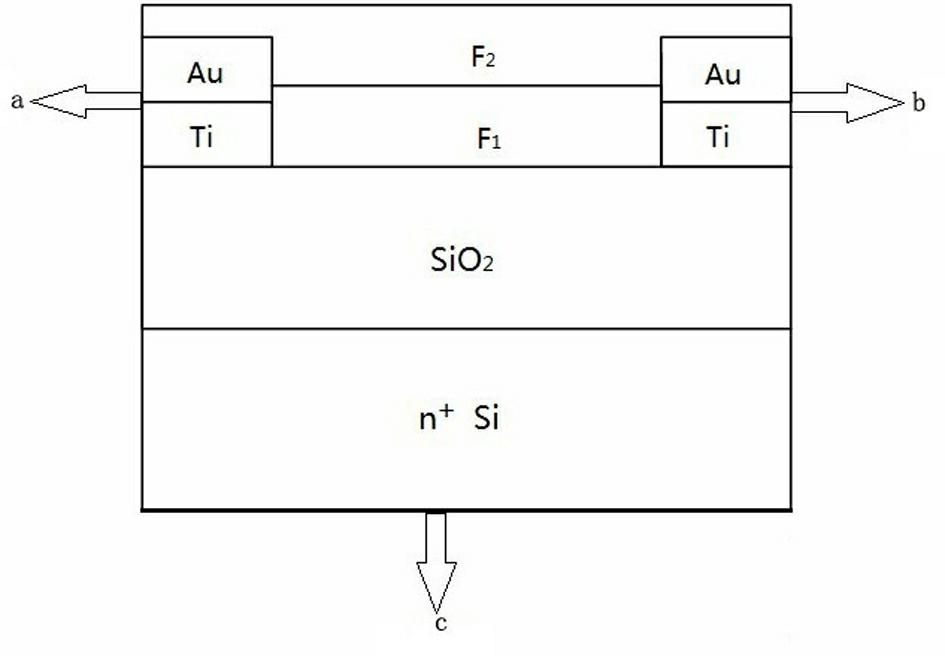

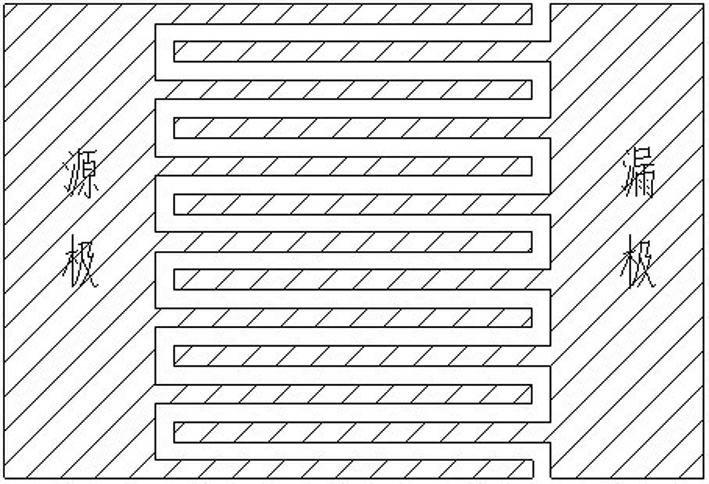

Multilayer thin film OTFT (organic thin film transistor) formaldehyde gas sensor and preparation method thereof

InactiveCN102636544ADecorative surface effectsMaterial analysis by electric/magnetic meansTitaniumOxide

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Coating composition containing high-refractive-index metal oxide fine particles, and curable coating film obtained by applying the coating composition onto base

Owner:JGC CATALYSTS & CHEM LTD

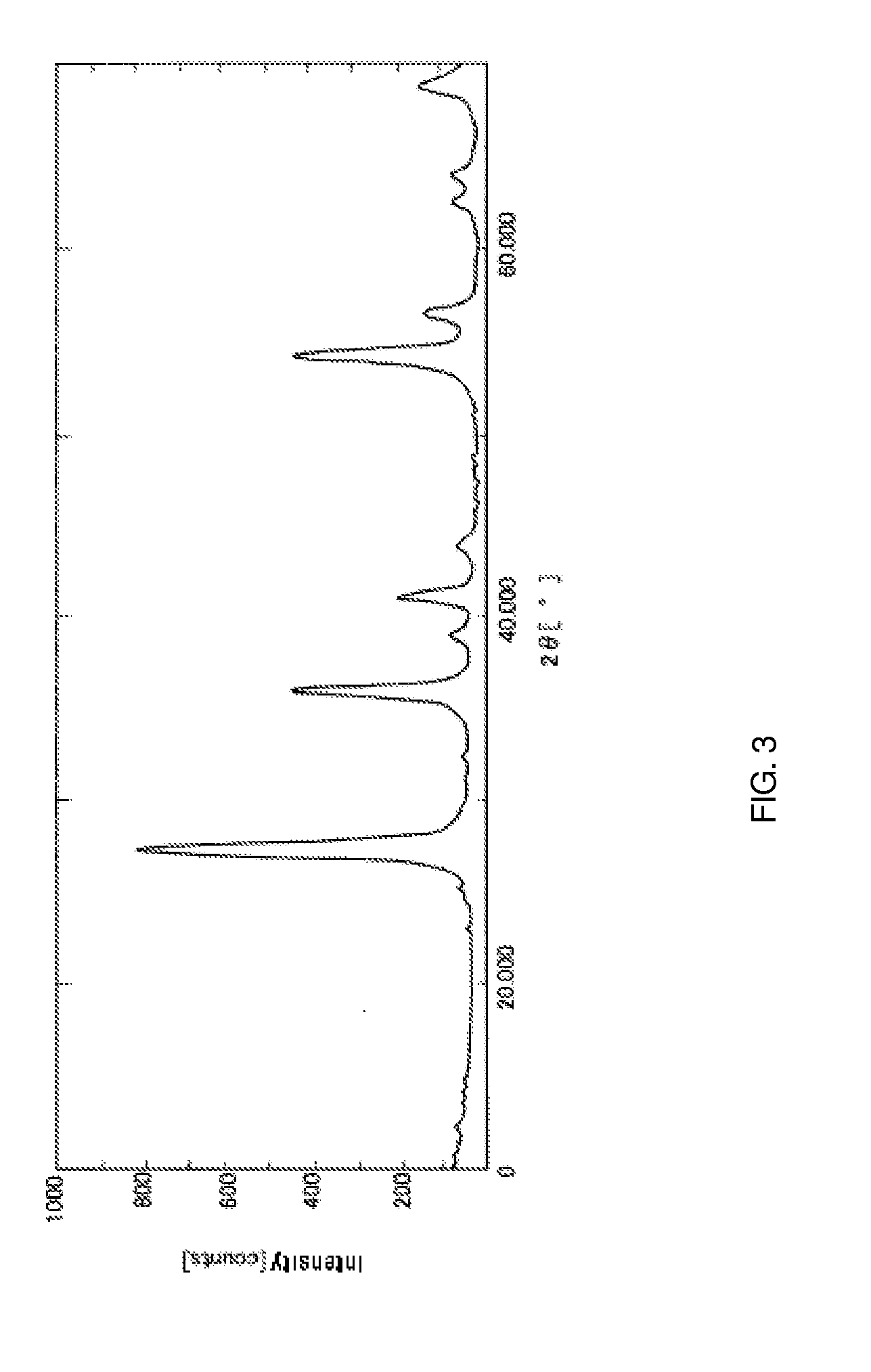

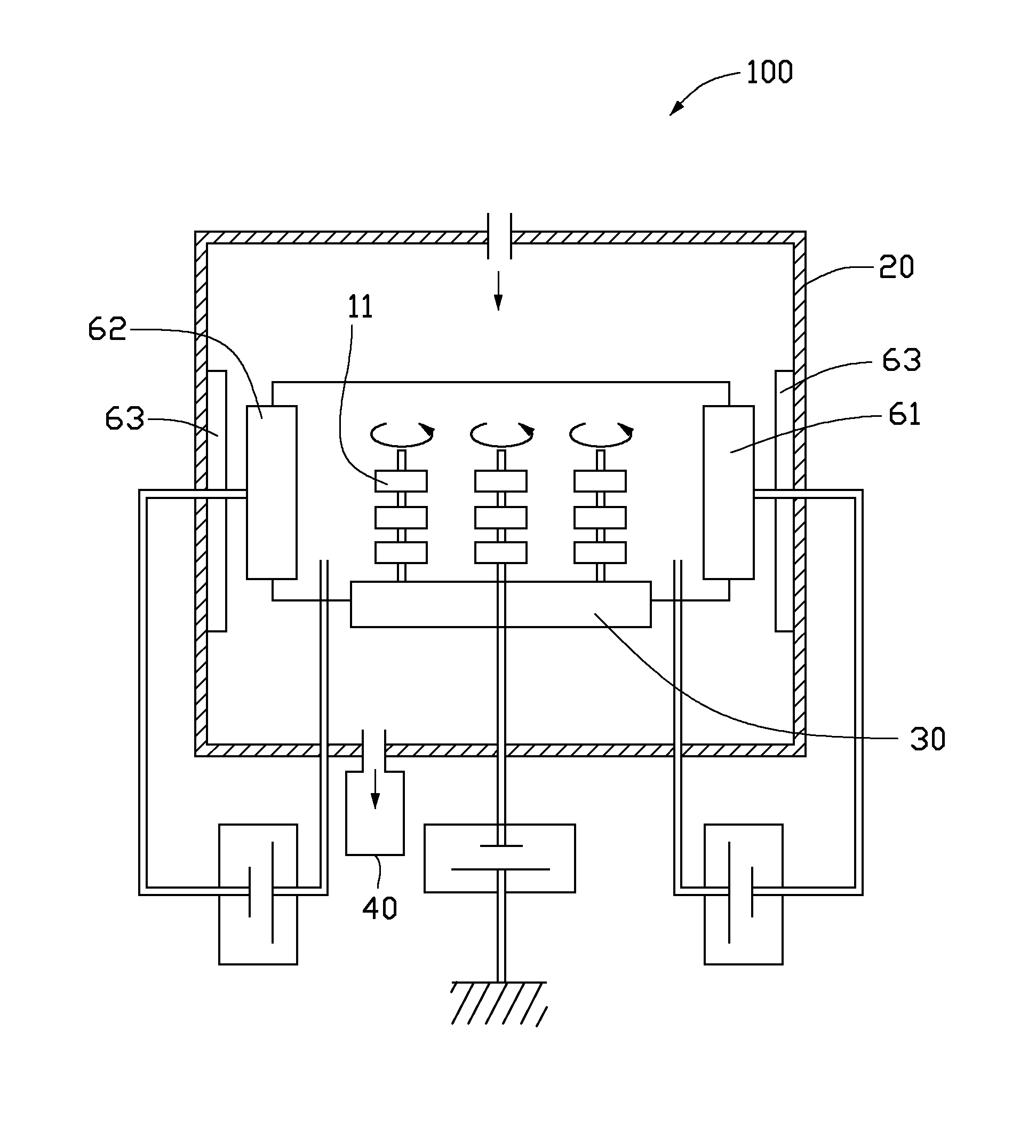

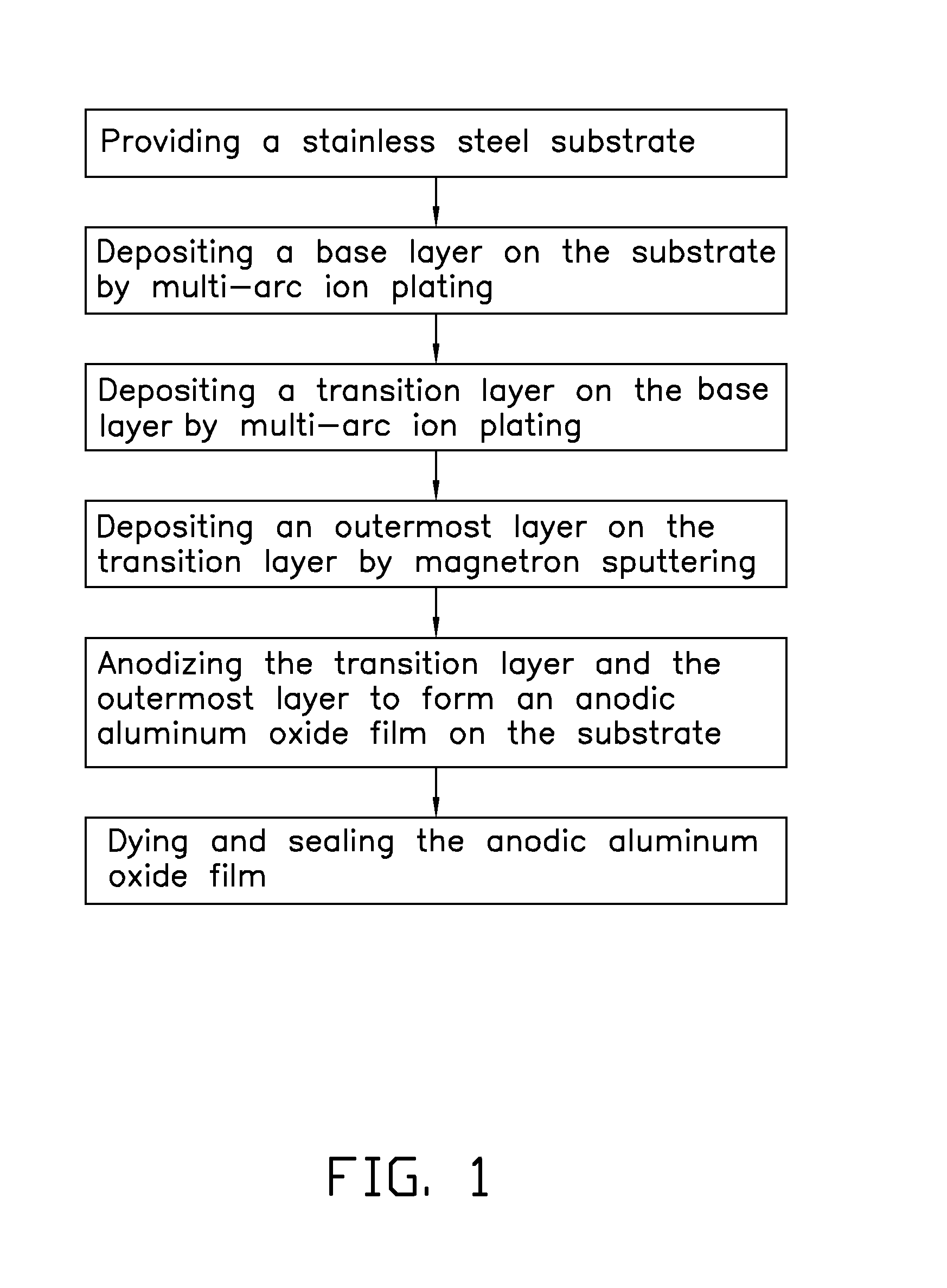

Surface treatment method for stainless steel and housing made from the treated stainless steel

InactiveUS20140186654A1Surface reaction electrolytic coatingVacuum evaporation coatingAnodic oxidationTitanium

A surface treatment method for stainless steel as a colorful and smooth housing includes the steps of: a base layer including titanium is deposited on the stainless steel substrate by multi-arc ion plating. An aluminum transition layer is deposited on the titanium base layer by multi-arc ion plating, and an outermost layer including aluminum is deposited on the transition layer by magnetron sputtering. The transition layer and the outermost layer are anodized to form an anodic aluminum oxide film; and the anodic aluminum oxide film is sealed after being dyed. An article manufactured by the method is also provided.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

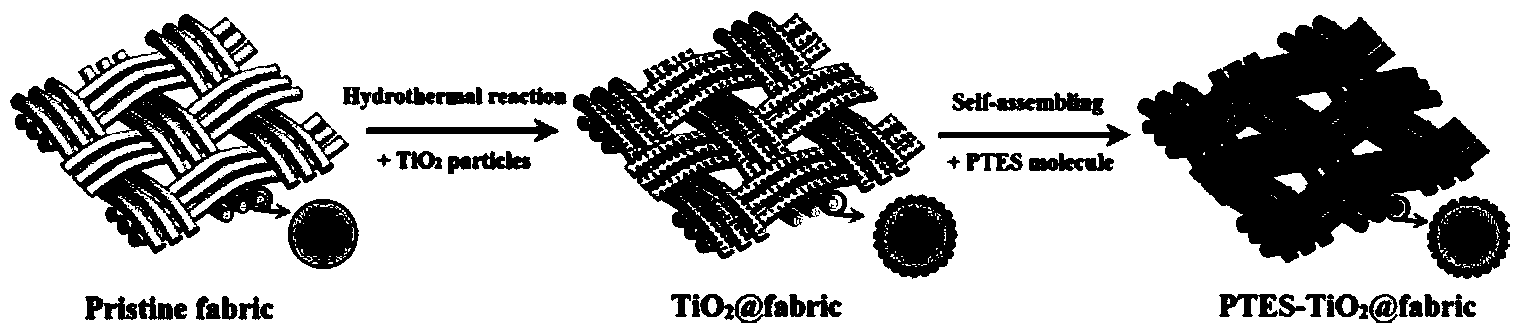

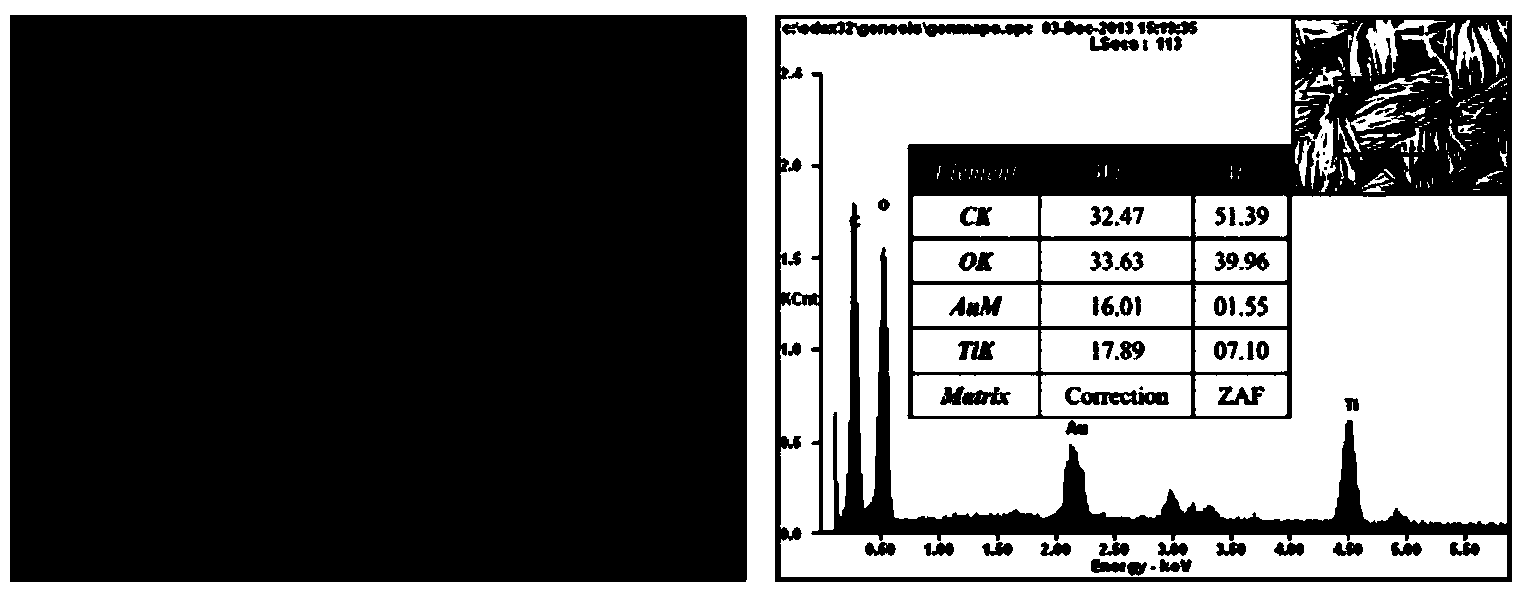

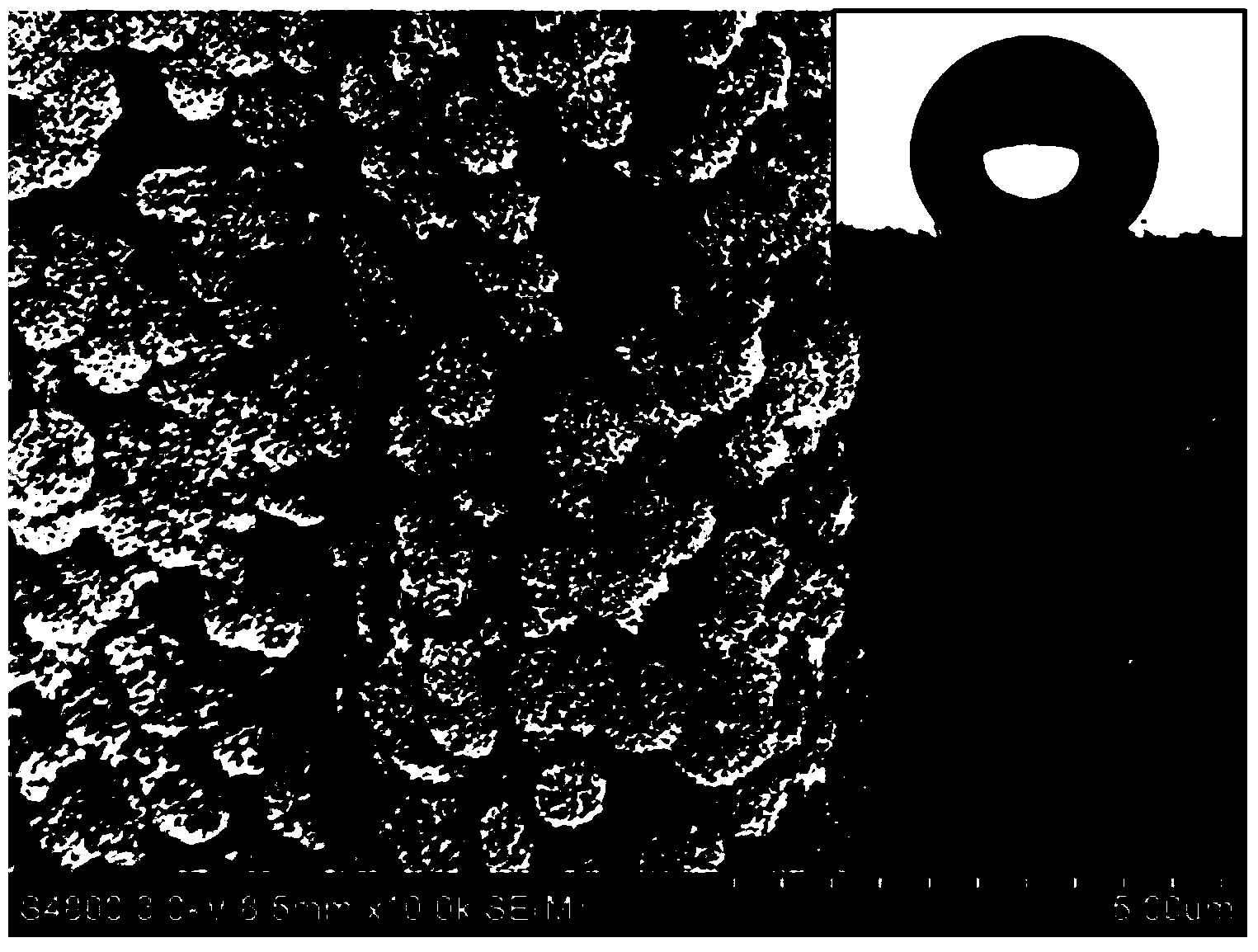

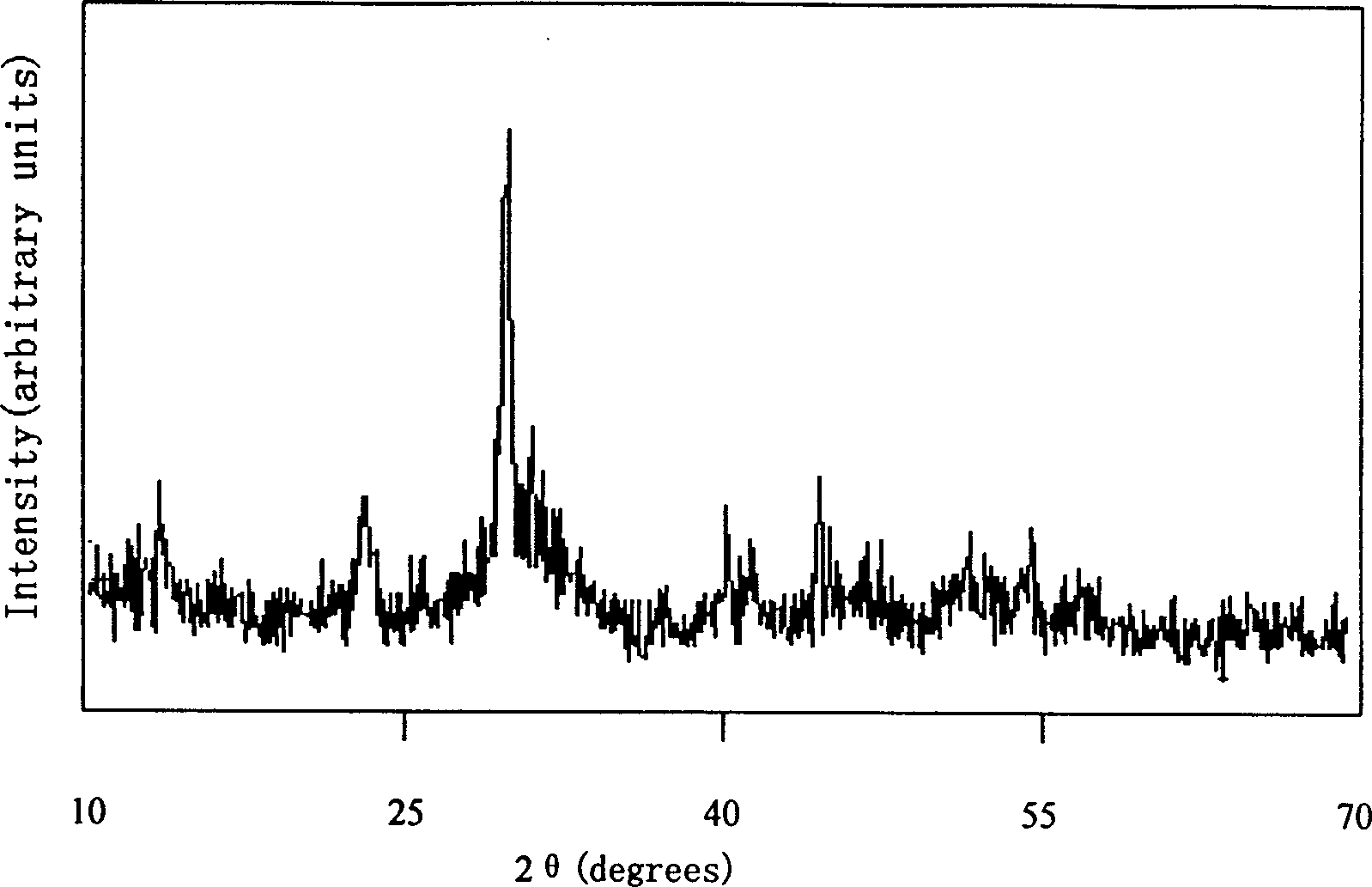

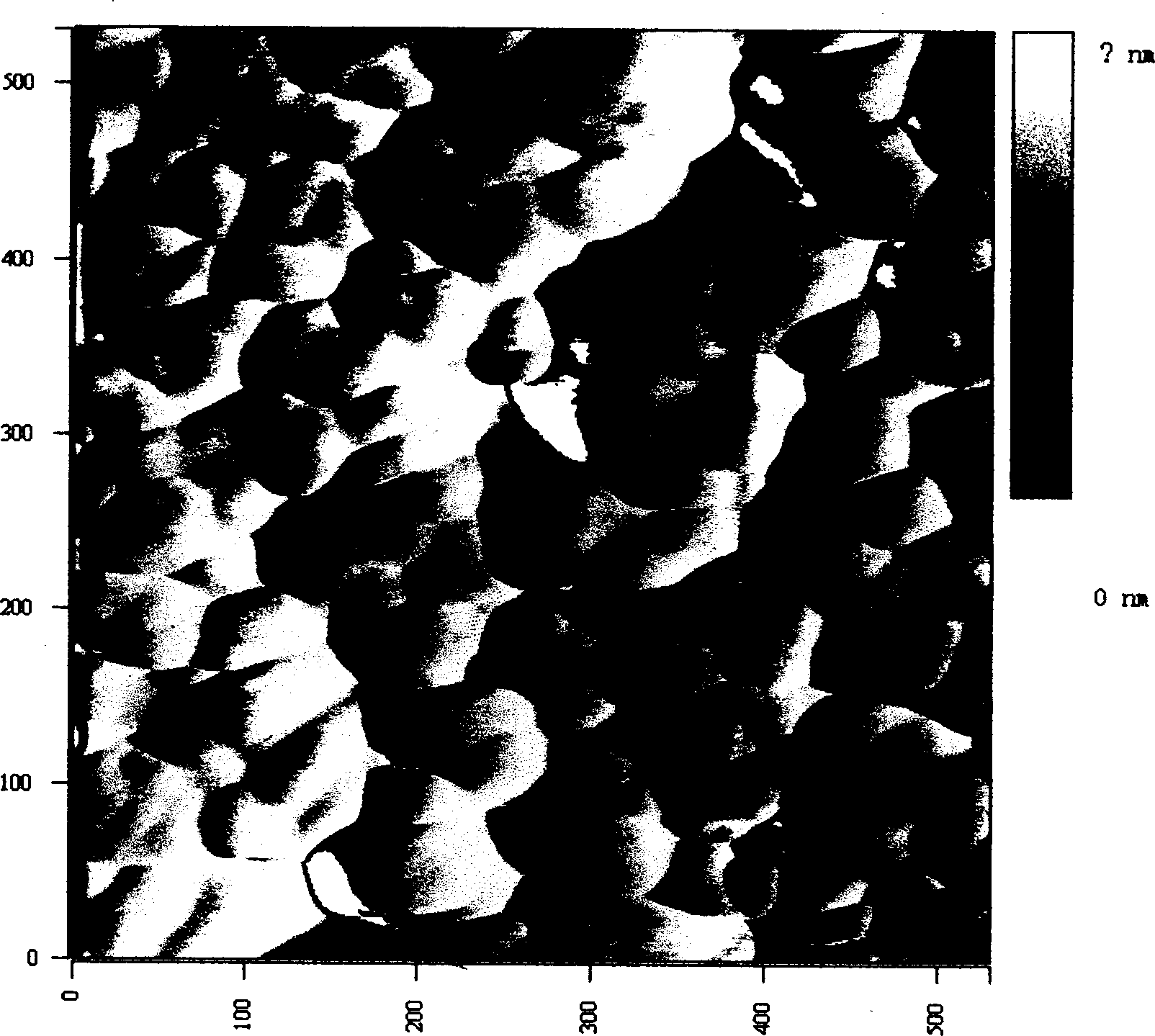

Preparation method of special-infiltration functional fabric surface with self-cleaning and oil-water separation functions

Owner:SUZHOU UNIV

Flux for removing iron from Mg alloy and its preparing process

Owner:SHANGHAI JIAO TONG UNIV

Nano-grade lanthanum titanium compound oxide, its preparation method and application

InactiveCN1394680AReduce viscosityReduce the temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOligomerLactide

Owner:CHONGQING UNIV

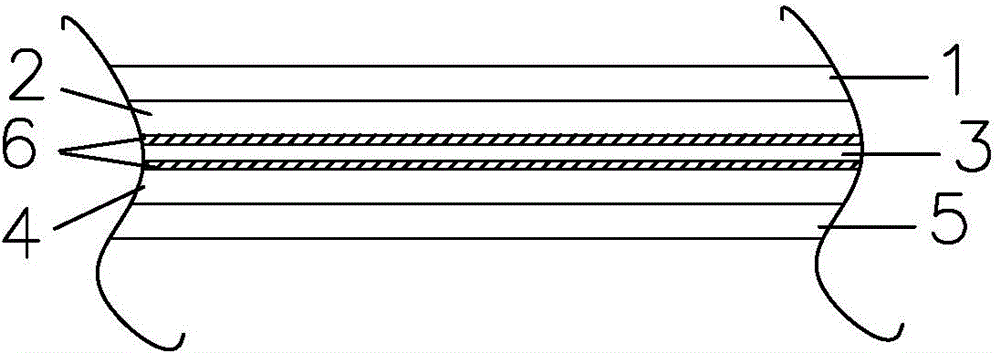

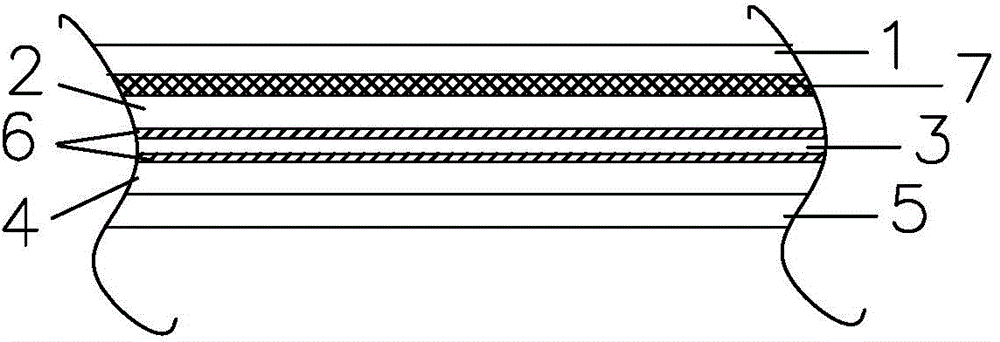

Quantum dot molecular light emitting device

InactiveCN102097564ABroad luminescence spectrumHigh strengthLaser detailsSemiconductor lasersMetal electrodesWaveguide

The invention relates to a quantum dot molecular light emitting device, which sequentially comprises the following structures from bottom to top: a lower gold germanium nickel metal electrode layer (1), a gallium arsenic substrate (2), a gallium arsenic buffer layer (3), a n-type aluminum gallium arsenic lower cladding layer (4), a gallium arsenic lower waveguide limiting layer (5), a quantum dotmolecular active area, a gallium arsenic upper waveguide limiting layer (9), a p-type aluminum gallium arsenic upper cladding layer (10), a p-type gallium arsenic ohmic contact layer (11), a dioxide silicon insulating layer (12) and an upper titanium platinum gold metal electrode layer (13), wherein the quantum dot molecular active area comprises n quantum dot molecular layers each of which comprises quantum dot molecules (6), a stress buffer layer (7) and an isolated layer (8), and n is a natural number not less than 1. According to the invention, the laterally coupled quantum dot molecules are utilized to manufacture an active area structure and corresponding light emitting devices, thereby widening the applicable scope of quantum dot and improving the performance of low dimension semiconductor device.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

Alloy material with high temperature coefficient of resistance and preparation method thereof

The invention provides an alloy material with high temperature coefficient of resistance. The alloy material is prepared by adding six metal components as the additives to nickel-ferrum alloy, and smelting same to obtain the product, wherein the six metal components are respectively germanium, zirconium, cerium, titanium, aluminum and ferrum; and the alloy material comprises the following components in percentage by weight: 50-65% of component Ni, 14-21% of component Cr, 0.1-0.9% of component Ge, 0.15-0.5% of component Ce, 0.2-1% of component Zr, 1.1-3.5% of component Ti, 0.5-2% of component Al, and the balance of component Fe. The invention also provides a preparation method of the alloy material. The alloy material prepared by the preparation method provided by the invention is of 8.2g / cm<3> based on the density, and has the resistivity of 1.53 (microhm.megabyte.20 DEG C); and the alloy material has temperature coefficient of resistance of 240aR / *10<-6>DEG / C under 100-800 DEG C; and the temperature is in good linear relation to the resistivity.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

Implantable medical device

Owner:CHANGZHOU RUISHENAN MEDICAL DEVICES

Carrier and two-component developer

Owner:SHARP KK

Method for preparing titanium salt for cyanideless electro-plating cadmium titan

The invention provides a method of preparing titanium salts for cyanideless electroplating cadmium-titanium, relating to a method for preparing titanium salts which are main materials in cyanideless electroplating cadmium-titanium process, belonging to surface treatment technique. The method is characterized in that: the preparation method comprises the steps of preparations of drugs and titanium salts. The method of the invention is capable of preparing the titanium salts with high quality needed in the cyanideless electroplating cadmium-titanium technique, meets requirements of the cyanideless electroplating cadmium-titanium technique, and facilitates the popularization of the cyanideless electroplating cadmium-titanium technique.

Owner:HARBIN

Foaming-ceramic heat insulating board and preparing method thereof

InactiveCN105503238ALow thermal conductivityHigh compressive and flexural strengthCeramicwarePorosityPotassium

Owner:韩功篑

Optical recording medium and its manufacturing method

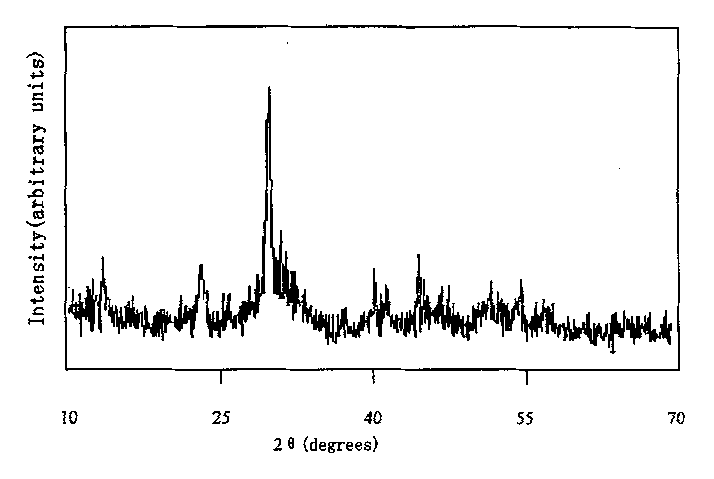

InactiveUS20080233389A1Increased durabilityGood storage stabilityLiquid surface applicatorsRecord information storageTitaniumOptical recording

An optical recording medium having an inorganic recording film, wherein the inorganic recording film has: a first recording film containing titanium Ti; and a second recording film containing oxides of germanium Ge and tin Sn.

Owner:SONY CORP

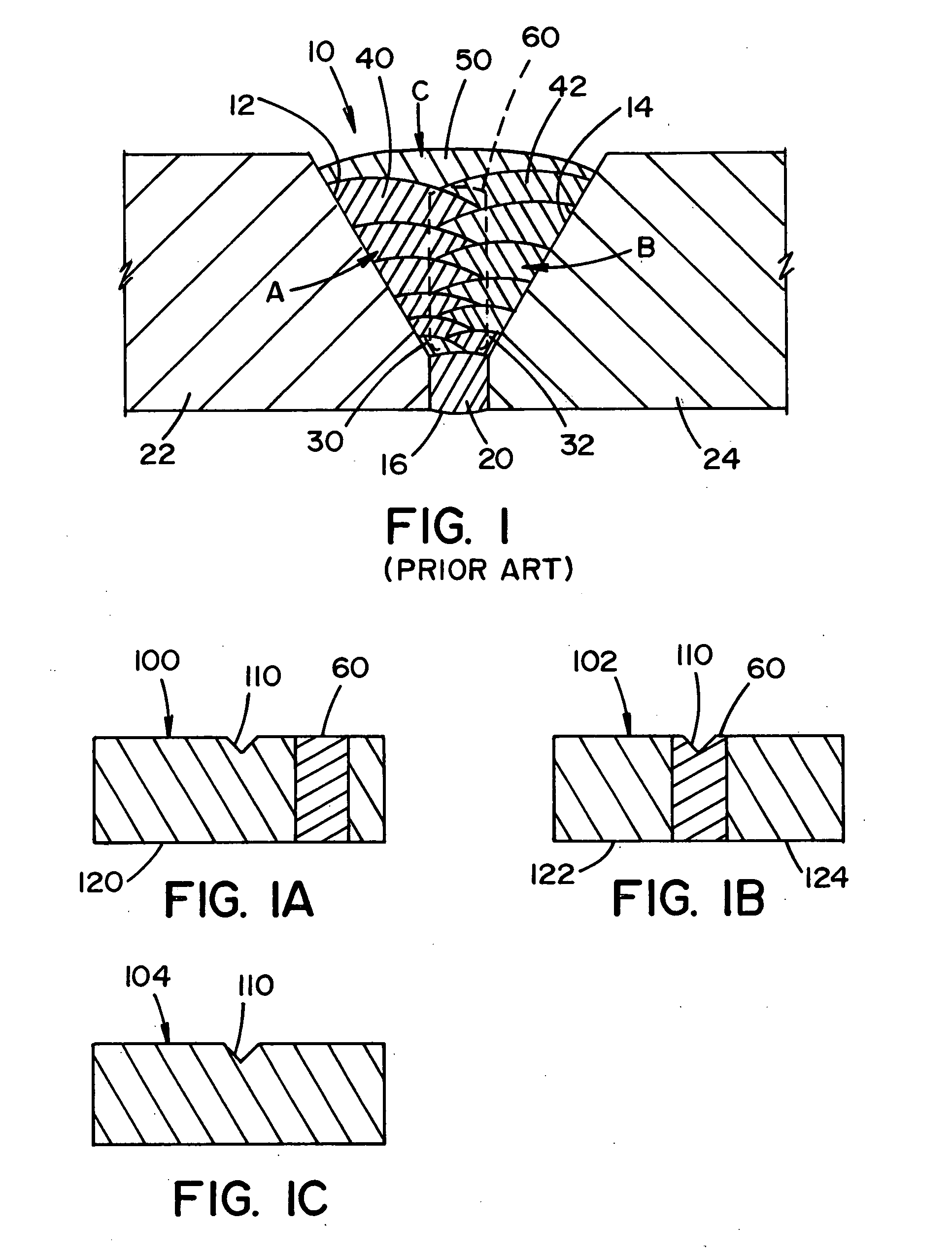

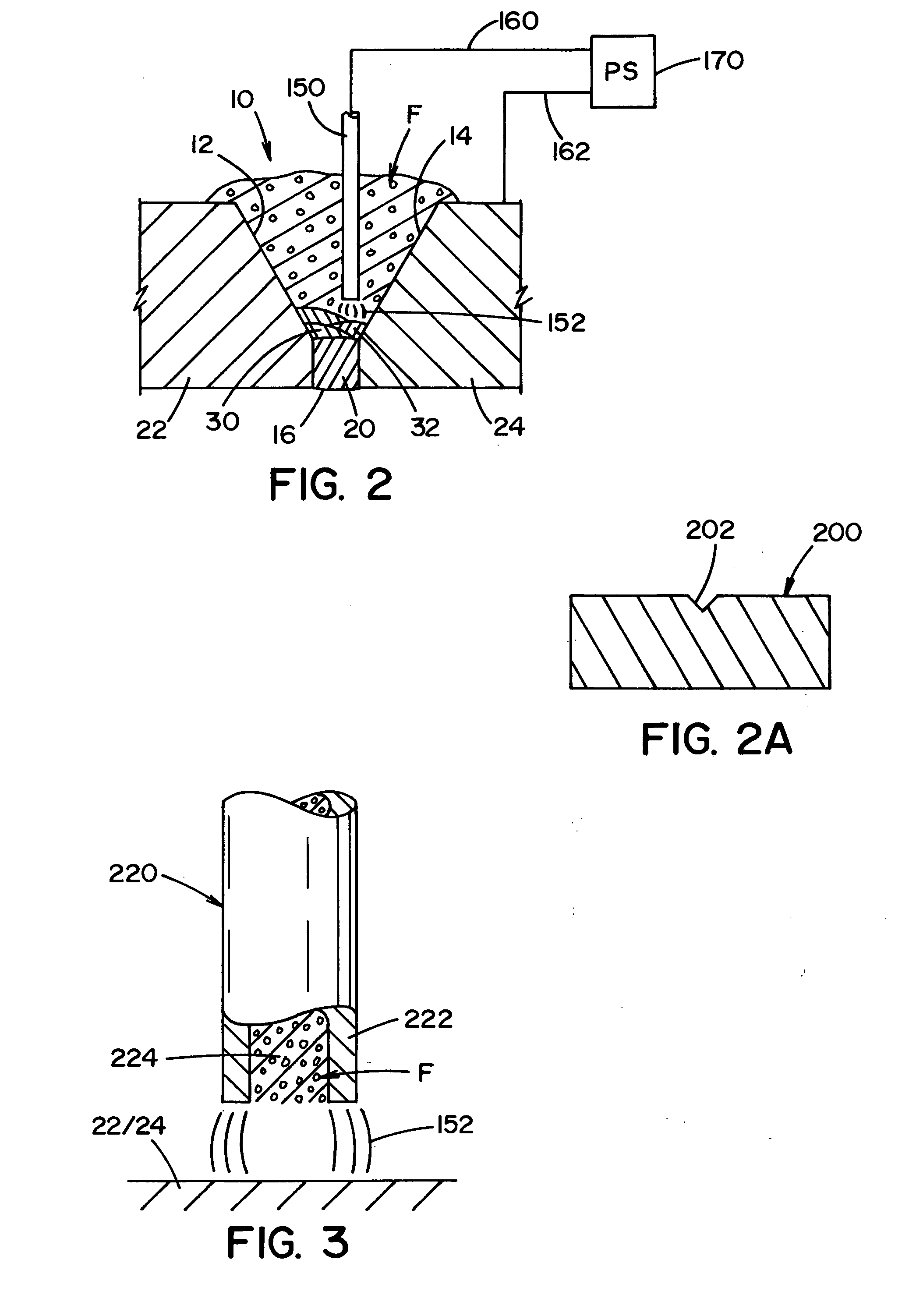

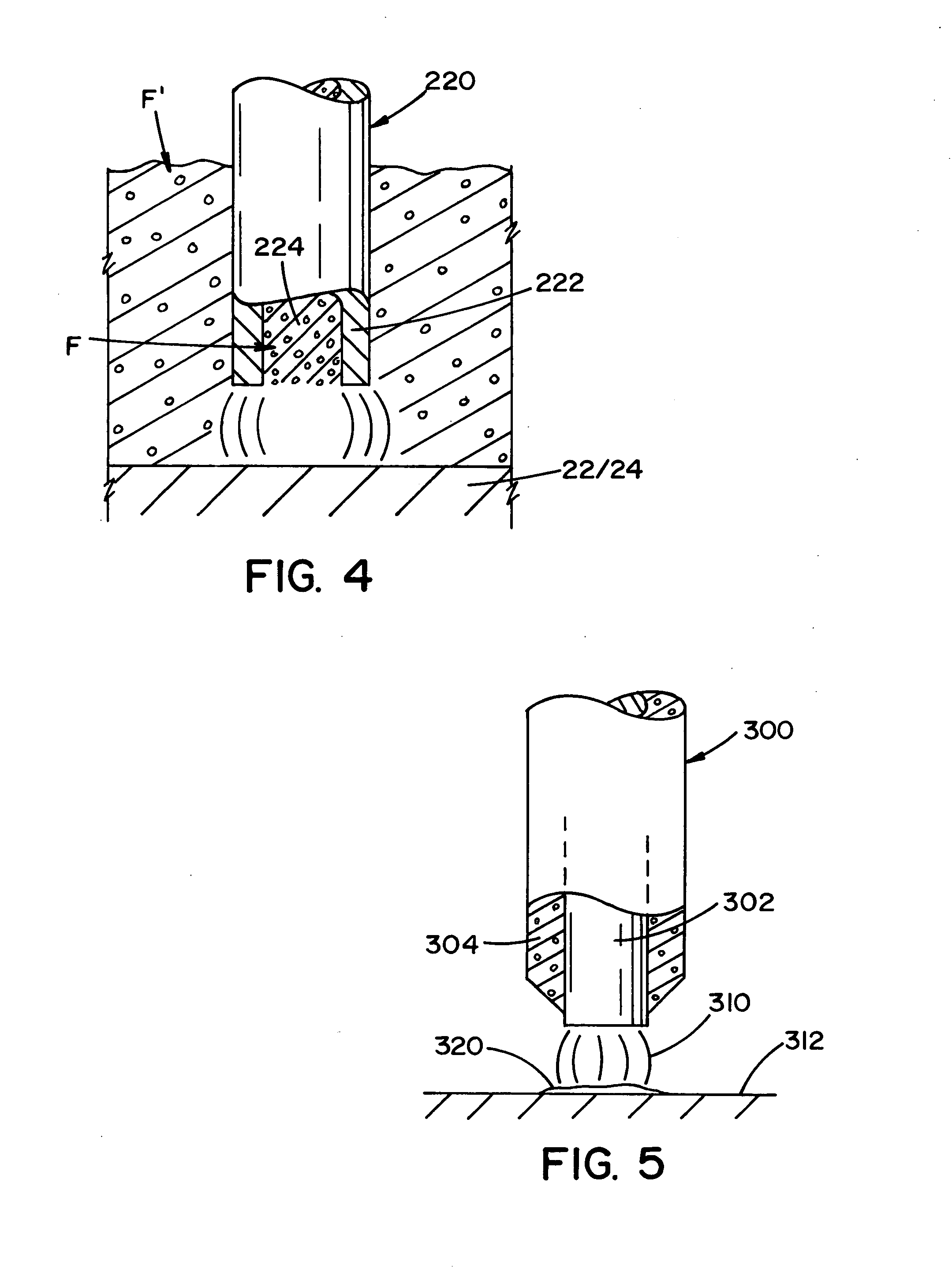

Saw flux system for improved as-cast weld metal toughness

ActiveUS20080078809A1Improve toughnessInhibited and prevented grain growthCooking-vessel materialsArc welding apparatusSlagTitanium

Owner:LINCOLN GLOBAL INC

Nano-level ultra-high heat-conducting titanium-carbon composite material and preparation method thereof

InactiveCN101191050ASimple processReduce manufacturing costHeat-exchange elementsCarbon compositesTitanium

Owner:晟茂(青岛)先进材料有限公司

Solid micro-powder fuel

The present invention relates to fuel, in particular to solid micro powder fuel, the micro powder particle is cellulosine and (or) straw, the degree of fineness is not larger than 30 micro meter, the fuel is a mixture, which contains combustion improver and catalyst, 1 to 3 percent calcium carbonate powder, 3to 5 percent epoxide resin powder, 2 to 4 percent organobentonite powder, 1 to 3 percent magnesium powder, 1 to 2 percent phenolic resin powder and 0.2 to 0.6 percent titanium pigment, the waste cellulosine and (or) the straw is dehydrated through hot wind (dryer) and degreased, the crasher is adopted for crashing, and 60 to 100 mu sieve is applied, the calcium carbonate powder, the epoxide resin powder, the organobentonite powder, the coal powder, the phenolic resin powder and the titanium pigment are added according to the ratio and mixed sufficiently, after the mixture is dried by hot wind (dryer) through continuous high temperature, the mixture can be fractionally packed. The fuel has the advantages of low cost, clean and environmental friendly and high thermal efficiency.

Owner:吕尧波 +1

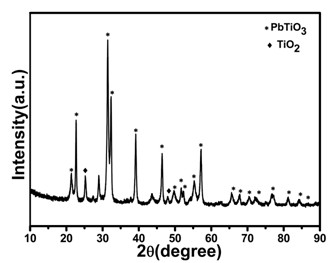

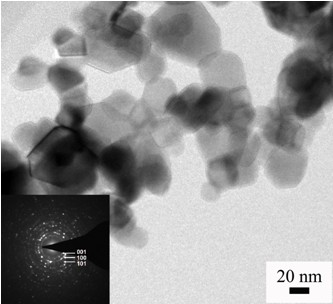

Preparation method of perovskite structure lead titanate single crystal nanoparticles

ActiveCN102677145AAchieve synthesisEasy to separatePolycrystalline material growthFrom normal temperature solutionsDispersityNanoparticle

Owner:ZHEJIANG UNIV

Positive Electrode Active Material for Lithium Secondary Battery

Provided is a novel positive electrode active material which can effectively suppress the quantity of gas generated by the reaction with an electrolytic solution. Proposed is a positive electrode active material for a lithium secondary battery including positive electrode active material particles obtained by equipping the entire surface or a part of a surface of lithium manganese-containing composite oxide particles (also referred to as the “core particles”) operating at a charging voltage in a region exceeding 4.3 V in a metal Li reference potential with a layer A containing at least titanium (Ti), aluminum (Al), zirconium (Zr), or two or more kinds of these.

Owner:MITSUI MINING & SMELTING CO LTD

Method for manufacturing miniature spring mechanical sensor for film performance test

InactiveCN101343033AReduce tensionHigh resolutionDecorative surface effectsChemical vapor deposition coatingEngineeringLinearity

Disclosed is a manufacturing method of a micro spring mechanics sensor used for the film performance test in the testing technology field; the method includes the steps that: the metal Ti layer is sputtered on the glass sheet and processed with oxidation treatment; the whirl coating of negative photoresist, front drying and development are processed on the glass sheet after the sputtering and oxidation treatment; the graphical display of the photoresist structure is realized according to the shape of the micro spring mechanics sensor designed by the mask plate; the Ni spring layer is electroformed on the processed titanium oxides layer; the micro spring mechanics sensor is processed with flatness machining; the sedimentation of the aligning marking and the displacement marking is processed on the Ni electroplated coating through the electrodeposition technology; the micro spring mechanics sensor is finally obtained after negative photoresist, the residual glass and the Ti sputtering layer are removed. The micro spring mechanics sensor prepared by the manufacturing method in the invention has the advantages of good linearity, simple process, high resolution, low cost and being easy to be integrated with the film mechanics performance test system.

Owner:SHANGHAI JIAOTONG UNIV

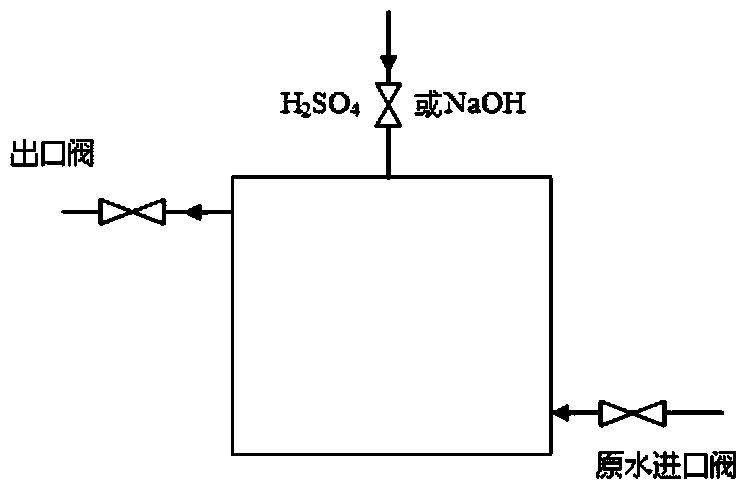

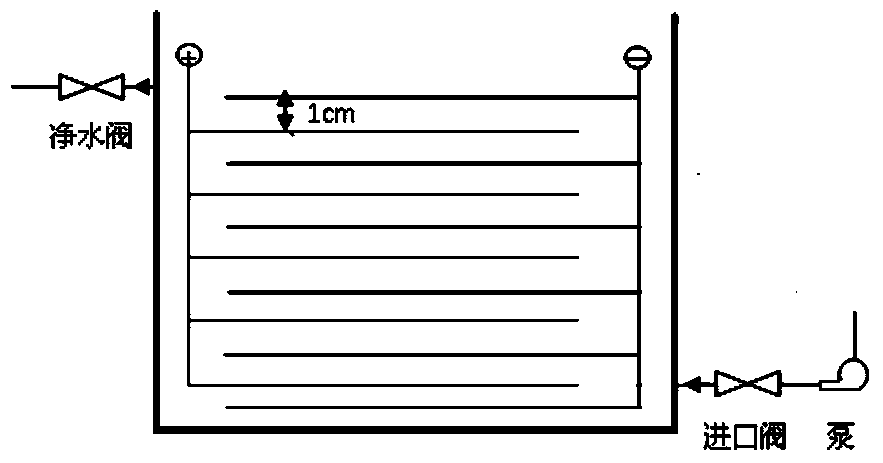

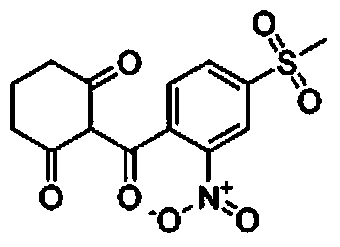

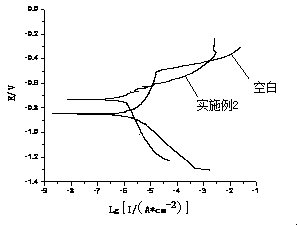

Method for electrochemical pretreatment on methyl sulcotrione pesticide wastewater

InactiveCN104030409AImprove biodegradabilitySimple methodWater/sewage treatmentTin dioxideHigh concentration

Owner:YANCHENG INST OF TECH

Aluminum alloy surface titanium dioxide conversion coating solution and using method thereof

InactiveCN103924229AUniform colorImprove corrosion resistanceMetallic material coating processesTitanium oxideConversion coating

Owner:无锡铱美特科技有限公司 +1

Hydraulic lifting device and method based on inverted mounting method for chimney titanium steel inner pipe

ActiveCN110306864AImprove splicing efficiencyImprove accuracyTowersStructural engineeringMechanical engineering

The embodiment of the invention discloses a hydraulic lifting device based on an inverted mounting method for a chimney titanium steel inner pipe. The hydraulic lifting device based on the inverted mounting method for the chimney titanium steel inner pipe comprises a feeding base arranged on the bottom part of an assembling barrel, wherein a clamping and lifting device and a clamping and rotatingdevice are arranged on the periphery of the assembling barrel from top to bottom; the clamping and lifting device comprises a short-range lifting frame; an arc-shaped clamping sliding block is arranged on the short-range lifting frame; an elastic guide pillar is arranged at the lower end of the arc-shaped clamping sliding block; the clamping and rotating device comprises a rotating support and anarc-shaped rotating and clamping block used for clamping a lower-layer assembling barrel and capable of radially rotating along the rotating support; and a guide slot corresponding to the elastic guide pillar is formed in the upper end of the arc-shaped rotating and clamping block. A method comprises the steps of assembling the device, lifting an upper-layer assembling barrel, positioning the lower-layer assembling barrel, and lifting the lower-layer assembling barrel. According to the hydraulic lifting device and the hydraulic lifting method based on the inverted mounting method for the chimney titanium steel inner pipe provided by the invention, by utilizing the manner of the clamping and rotating device, up-and-down center alignment and angle alignment between the two upper and lower adjacent assembling barrels are realized, and the assembling efficiency and the assembling precision degree of the chimney titanium steel inner pipe are improved.

Owner:HENAN MINING IND CONSTR GRP CO LTD

Preparation method of far infrared antibacterial ceramic

InactiveCN106866115AReduce manufacturing costTake advantage ofCeramic materials productionClaywaresSpray GranulationEmissivity

Owner:SICHUAN UNIV

Self-peelable protective coating for cogging and forging process of pure titanium or titanium alloy and production process of self-peelable protective coating

InactiveCN104371385ASimple coating processGood molding effectAlkali metal silicate coatingsProduction rateTitanium

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV

Multi-element composite titanium pot and manufacturing process

Owner:SUZHOU XINJINGYI TITANIUM PROD

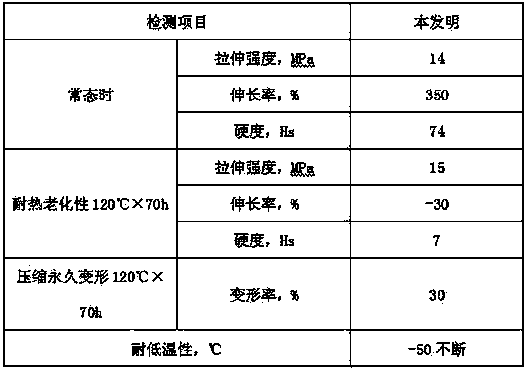

Rubber tube and preparation method thereof

ActiveCN104072973AImprove high temperature resistanceImprove low temperature resistancePolymer scienceAntimony trioxide

Owner:LIUZHOU YINGHANG AUTO PARTS

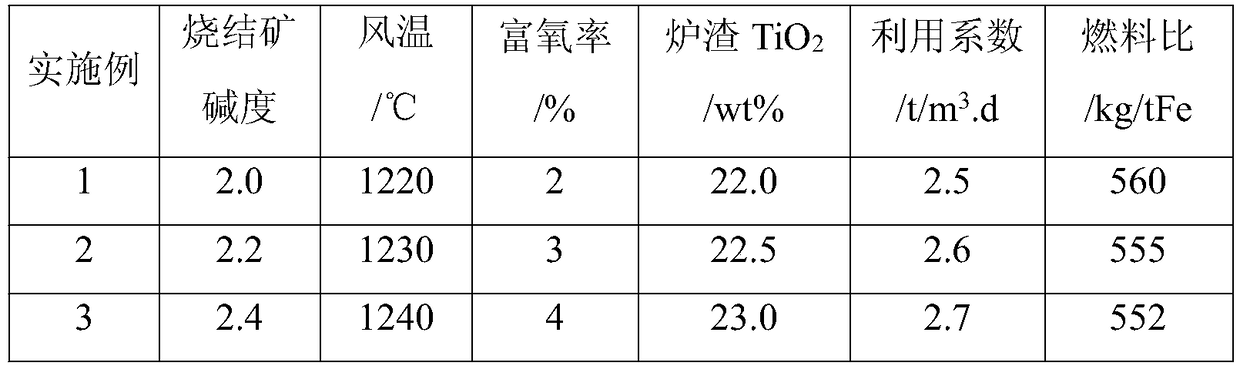

Blast furnace smelting method of high-grade vanadium-titanium magnetite

InactiveCN108950111ABlast furnace detailsProcess efficiency improvementBlast furnace smeltingTitanium

Owner:PANZHIHUA LIYU MINING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap