Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Cerium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium is a chemical element with the symbol Ce and atomic number 58. Cerium is a soft, ductile and silvery-white metal that tarnishes when exposed to air, and it is soft enough to be cut with a knife. Cerium is the second element in the lanthanide series, and while it often shows the +3 oxidation state characteristic of the series, it also exceptionally has a stable +4 state that does not oxidize water. It is also considered one of the rare-earth elements. Cerium has no biological role in humans and is not very toxic.

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

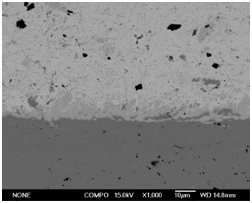

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

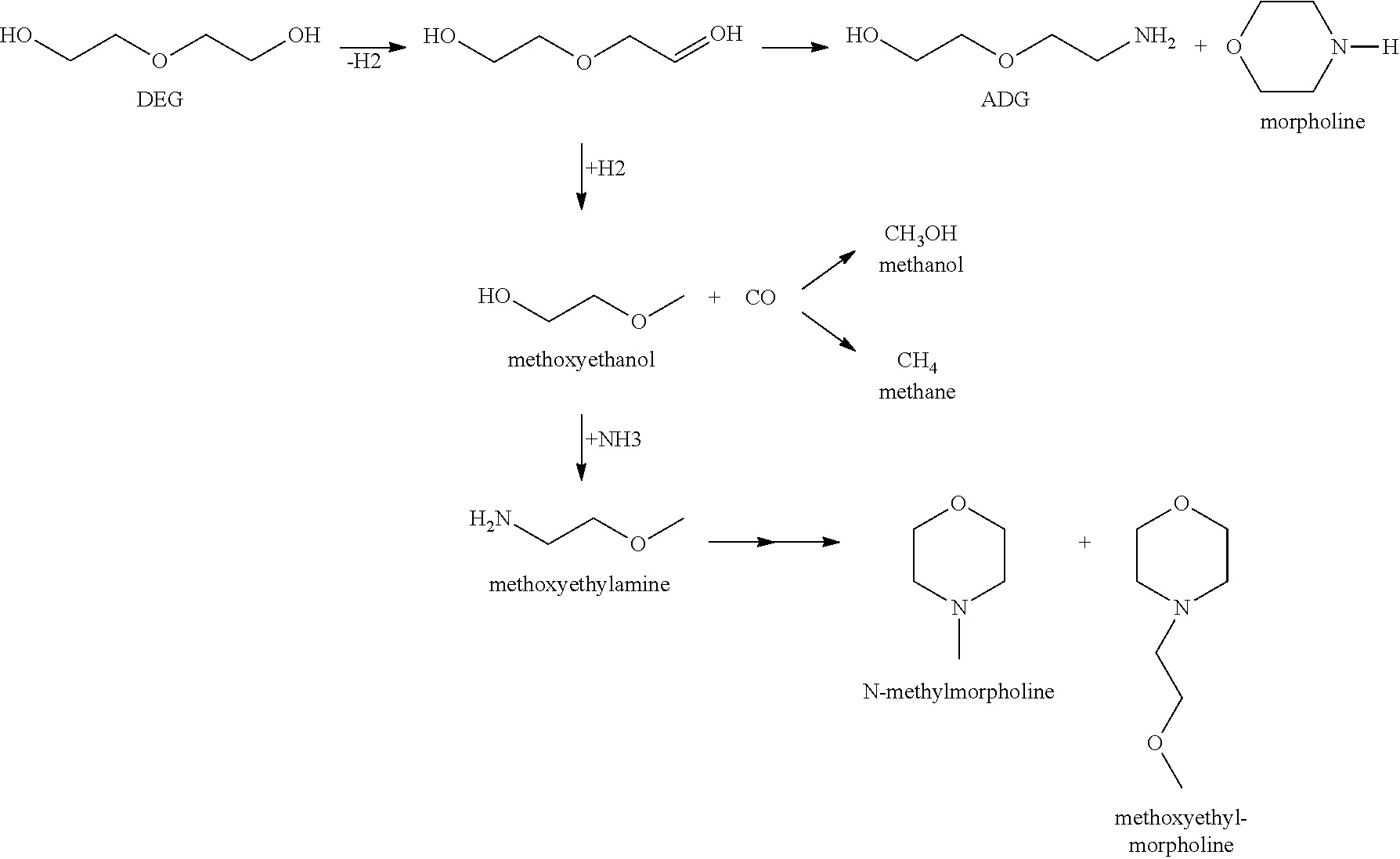

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

High-strength high-conductivity rare earth copper-magnesium alloy contact wire and manufacturing method thereof

InactiveCN106555073AMeet performance requirementsHigh elongationSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementCerium

Owner:HENAN UNIV OF SCI & TECH

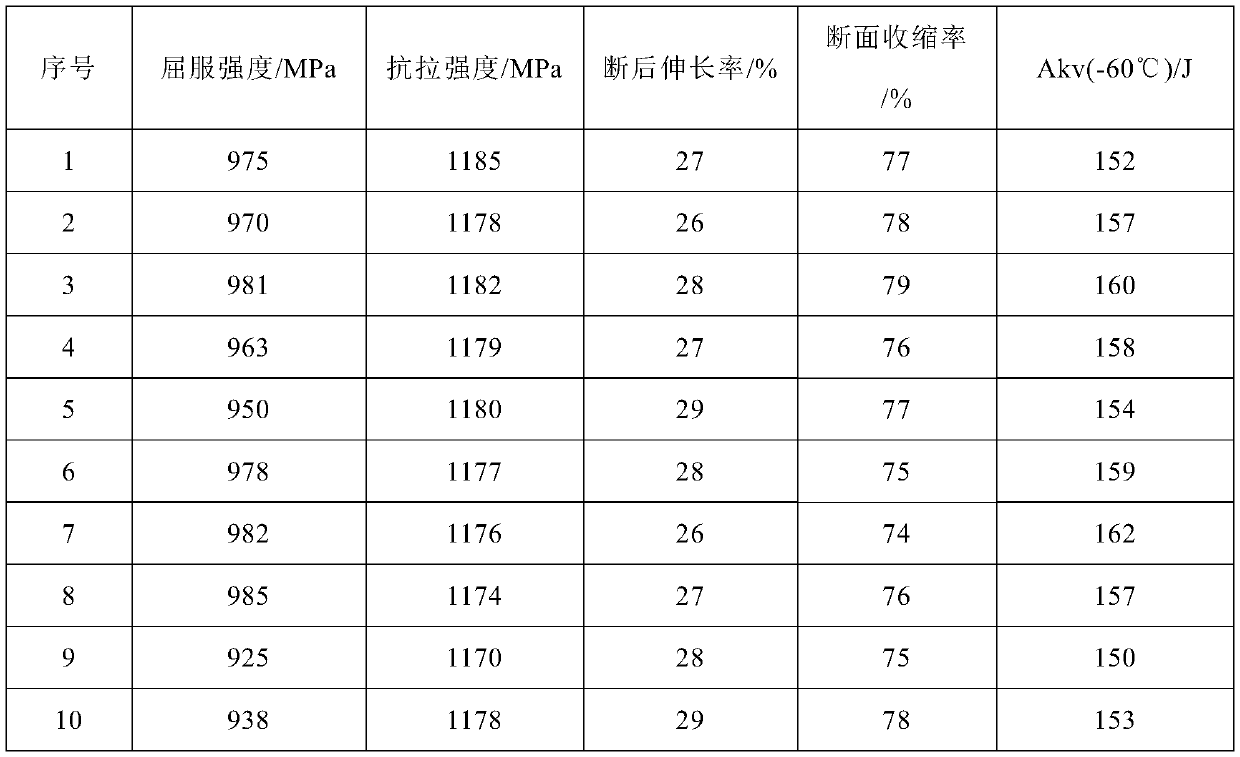

High-strength 23Mn2CrNiMnVERA steel for railway train connection and preparation method thereof

Owner:SHANDONG XIWANG SPECIAL STEEL

Combination material of fluorine-free flux and cadmium-free silver solder for copper-brass brazing

InactiveCN106342015BNot corrosiveImprove wettabilityWelding/cutting media/materialsSoldering mediaCeriumCadmium Cation

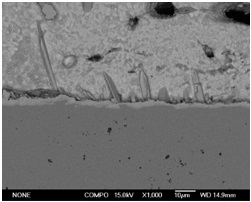

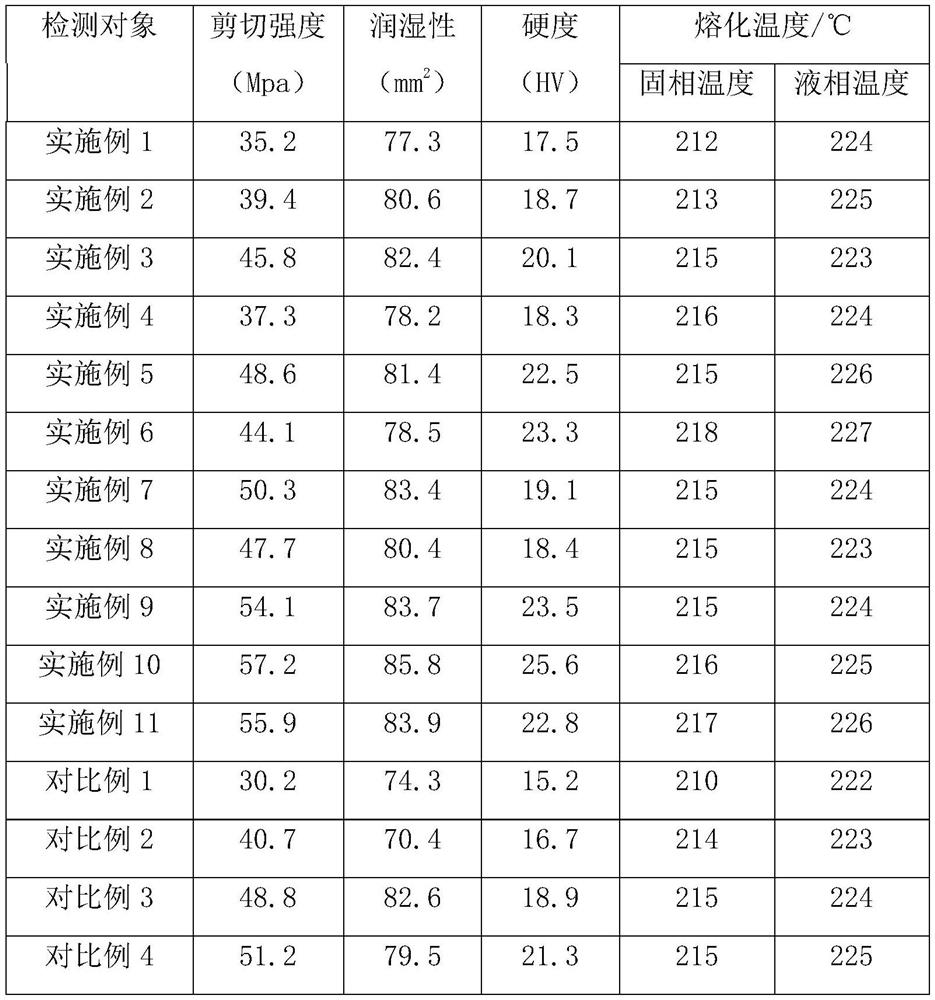

The invention relates to a composite material of fluorine-free brazing flux and cadmium-free silver brazing filler metal for copper-brass brazing, belonging to brazing materials. This brazing material is a combination of fluorine-free flux and cadmium-free silver solder, wherein the fluorine-free flux includes 2% to 8% boric acid (H3BO3), 28% to 38% boric anhydride (B2O3), 5% to 15% % carbonate (K2CO3 or Na2CO3), 0.1% to 1.0% nitrate (KNO3 or NaNO3), the rest is borate (K2B4O7 or Na2B4O7); cadmium-free silver solder includes 15% to 45% silver (Ag) , 3% to 10% of phosphorus (P), 0.001% to 0.030% of zirconium (Zr), 0.001% to 0.010% of cerium (Ce), and the rest is copper (Cu). The composite material has good wettability when brazing copper-copper, brass-brass, and copper-brass, and the brazing joint has good plasticity and comprehensive mechanical properties, and there is no residual fluorine ion at all. It is especially suitable for brazing copper materials that are used in harsh environments (high humidity, high temperature, high salt spray, etc.).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Low-silver high-strength lead-free tin-based brazing filler metal and preparation method thereof

PendingCN114871628AImprove reliabilityReduce pollutionWelding/cutting media/materialsSoldering mediaCeriumCobalt

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Textile fiber product containing rare earth elements

InactiveCN107190503AStrong magneticTo achieve the effect of health carePhysical treatmentNatural fibresRare-earth elementTextile fiber

Owner:屈维勇

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap