Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24 results about "Boric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boric acid, also called hydrogen borate, boracic acid, and orthoboric acid is a weak, monobasic Lewis acid of boron. However, some of its behaviour towards some chemical reactions suggest it to be tribasic acid in Bronsted sense as well. Boric acid is often used as an antiseptic, insecticide, flame retardant, neutron absorber, or precursor to other chemical compounds. It has the chemical formula H₃BO₃ (sometimes written B(OH)₃), and exists in the form of colorless crystals or a white powder that dissolves in water. When occurring as a mineral, it is called sassolite.

Acidic electroplating zinc-nickel alloy electrolyte, preparation method and electroplating method

Owner:南通创源电化学科技有限公司

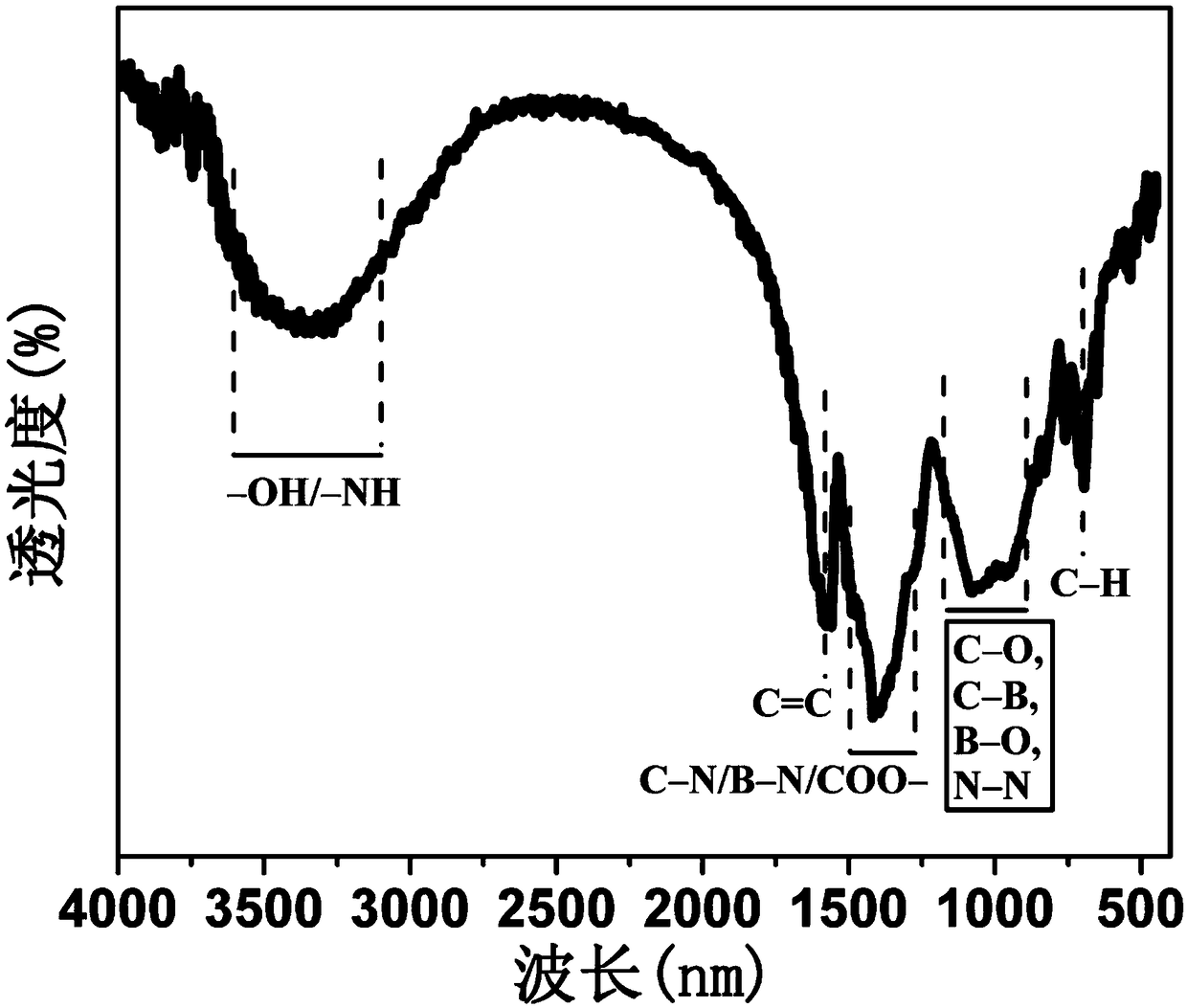

Preparation method of solid carbon dot fluorescent powder with high quantum yield and application of solid carbon dot fluorescent powder in LED (Light Emitting Diode) lamp bead

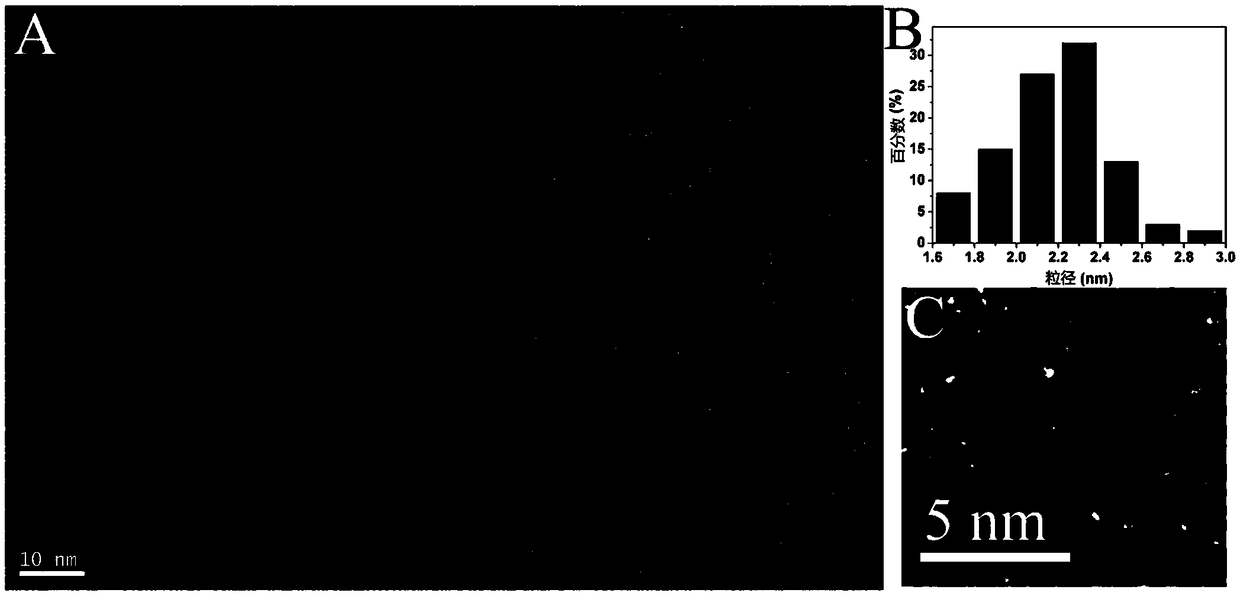

InactiveCN108795423ALow costFast preparationNanoopticsLuminescent compositionsQuantum yieldSolid carbon

Owner:JILIN UNIV

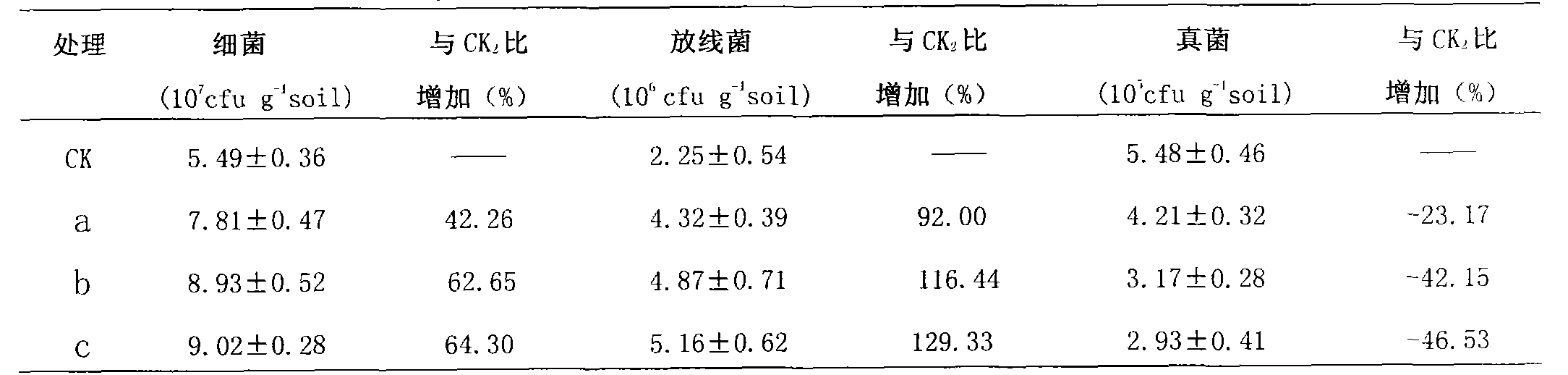

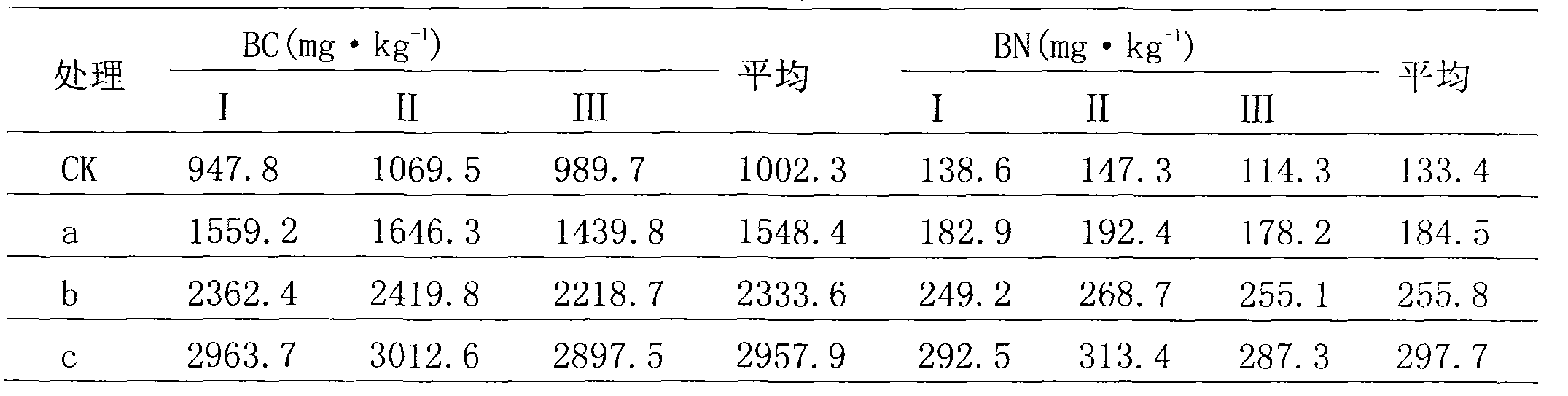

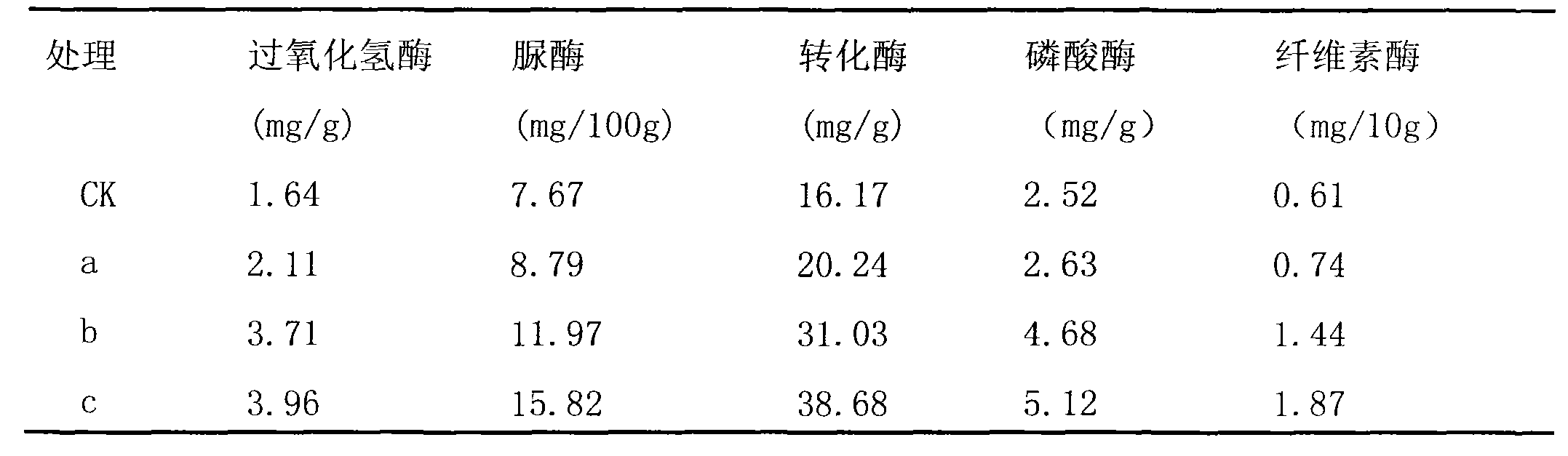

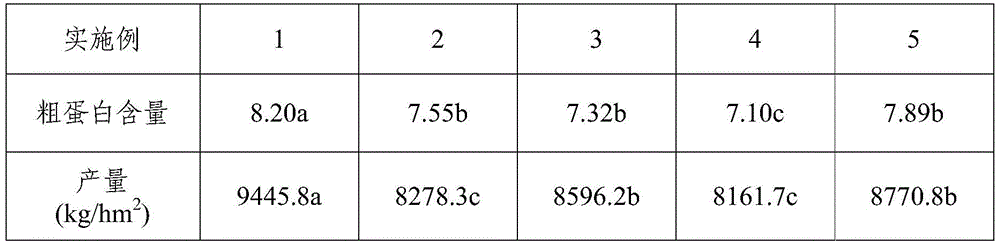

Soil bio-activator for ginseng continuous cropping

InactiveCN103254022AImprove the growing environmentPrevent Soilborne DiseasesFertilizer mixturesContinuous croppingPhosphate

Owner:JILIN AGRICULTURAL UNIV

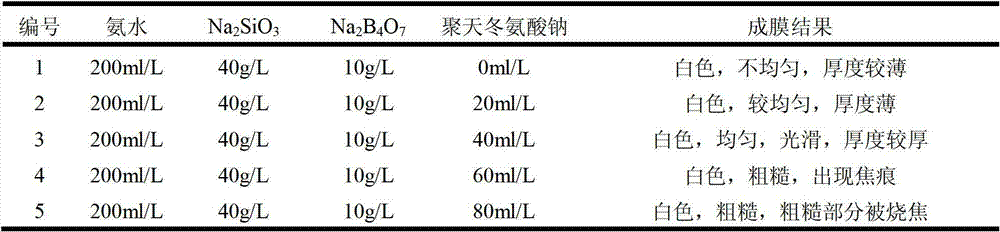

Electrolyte used for magnesium alloy anode oxidation treatment and treatment method

ActiveCN102828218AImprove corrosion resistanceStable temperatureAnodisationElectrolytic agentOxidative treatment

Owner:戚威臣

Skin-care permanently-antibacterial DP finishing liquid for shirts and finishing method

InactiveCN106436329AImprove antibacterial propertiesGood non-ironing effectBiochemical fibre treatmentLiquid/gas/vapor removalN dimethylformamideSkin care

Owner:阜阳市豹子头服饰科技有限公司

Sodium bentonite processing agent for blue-green algae and preparation method thereof

InactiveCN104495960AFast gatheringQuick gather salvageBiocideDisinfectantsSodium BentoniteEutrophication

A sodium bentonite processing agent for blue-green algae is prepared from the following raw materials in parts by weight: 10-20 parts of serpentine, 40-45 parts of sodium-base bentonite, 2-3 parts of magnesium chloride, 8-13 parts of calcium chloride, 15-20 parts of potassium ferrate(VI), 12-16 parts of equisetum hyemale, 13-16 parts of pericarpium granati, 3-5 parts of polymaleic acid, 3-4 parts of sodium pyrophosphate, 2-3 parts of urea, 3-5 parts of anhydrous sodium sulfate, 3-5 parts of boric acid, 4-6 parts of polyvinyl alcohol, proper amount of water, and 3-4 parts of an adsorption auxiliary agent. By adding potassium ferrate(VI), the processing agent for blue-green algae has synergic effects of oxidation, adsorption, flocculating, precipitation, sterilization, disinfection, decoloring and deodoring, also does not generate any toxic and harmful substances, is capable of increasing water dissolved-oxygen content, has good removal effects on ammonia nitrogen, nitrites and algae in water, and is used to remove fulvic acid and suspensions in water and eutrophication phenomenon in fresh water. The processing agent for blue-green algae is good in dispersing suspending property and good in adsorption property, and can help to rapidly aggregate and salvage blue-green algae.

Owner:WUHU XIANGRONG FOOD

Humic acid-containing complete-element water soluble fertilizer, and preparation method and application thereof

InactiveCN105669297AIncrease profitPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserSolubilityPhosphate

Owner:HUNAN TAIGU BIOTECH

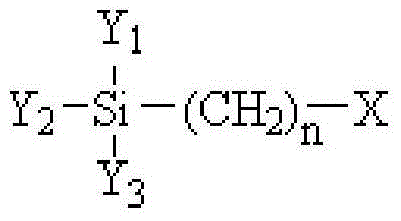

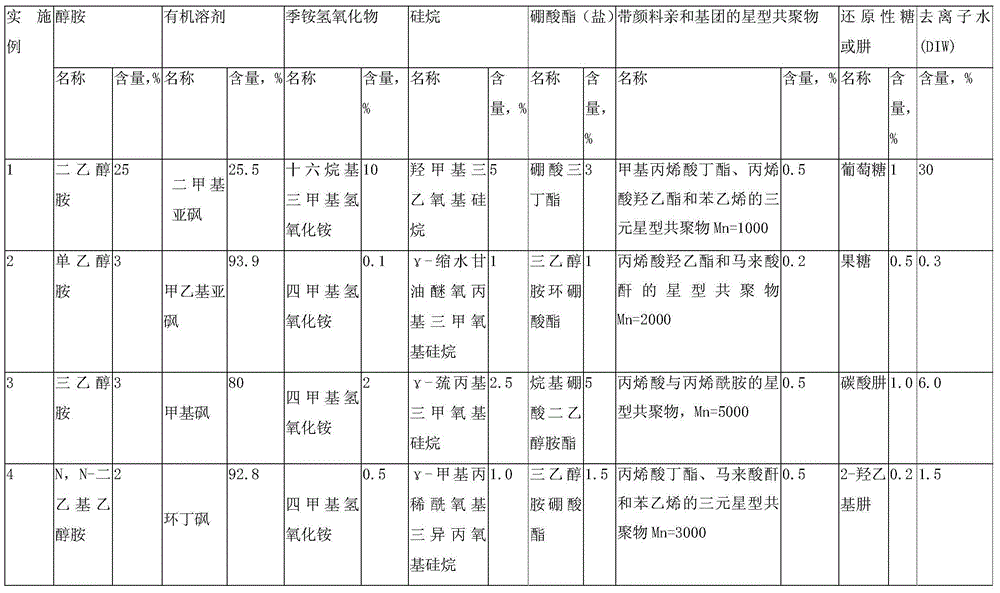

Photoresist cleaning fluid

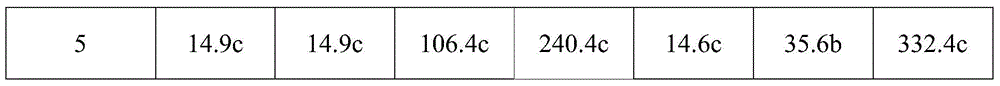

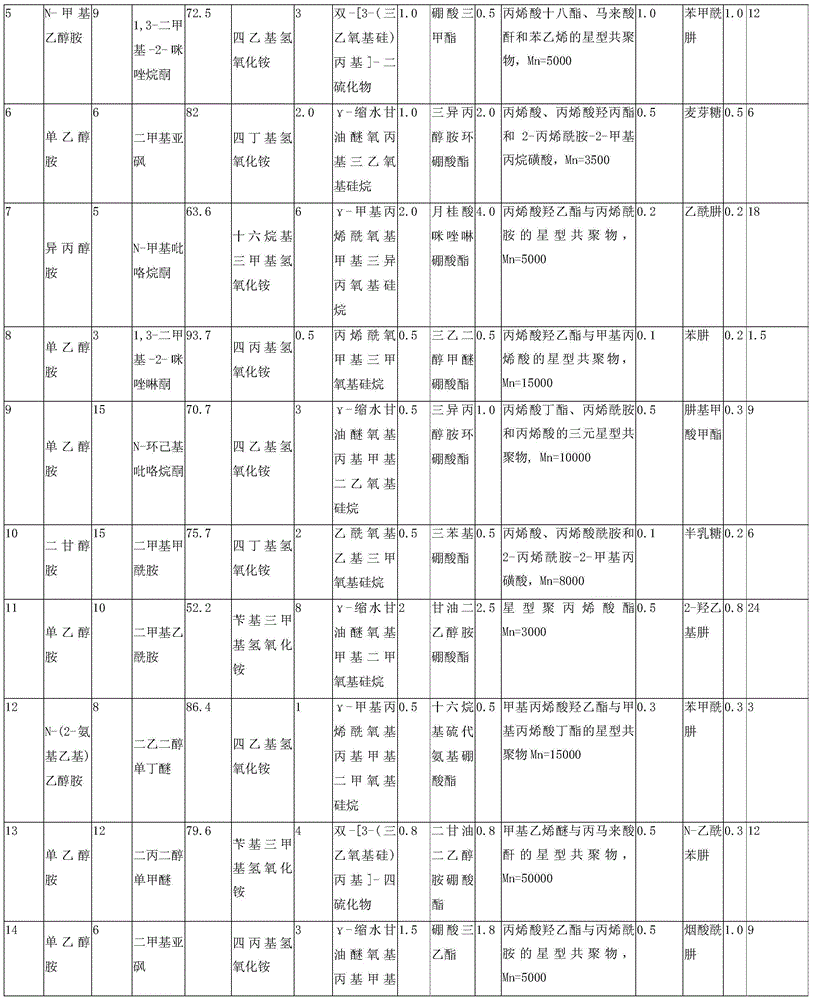

InactiveCN105527802AEfficient removalLarge operating windowPhotosensitive material processingSilanesSolvent

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Compound fertilizer for improving saline-alkali land

InactiveCN107200663ARaise the pHImprove alkaline environmentCalcareous fertilisersBioloigcal waste fertilisersBacillus licheniformisAlkali soil

The invention discloses a compound fertilizer for improving saline-alkali soil and solves the problem that an organic fertilizer in the prior art cannot continuously improve soil condition of the saline-alkali land for a long time. The compound fertilizer disclosed by the invention comprises a bag A and a bag B, wherein the bag A is prepared from the following raw materials in parts by weight: 10 to 15 parts of black alum, 5 to 12 parts of flue gas desulfurization gypsum, 40 to 60 parts of organic fertilizer, 12 to 30 parts of boric acid and 14 to 40 parts of nitrogen phosphorus potassium compound fertilizer, and the bag B is a biological bacterium agent which is prepared from the following ingredients in parts by weight: 10 to 15 parts of trichoderma agent, 20 to 50 parts of bacillus subtilis agent and 20 to 30 parts of bacillus licheniformis agent. The compound fertilizer disclosed by the invention has an effect of continuously improving soil condition for a long time.

Owner:CHENGDU ZHONGYI HESHENG TECH CO LTD

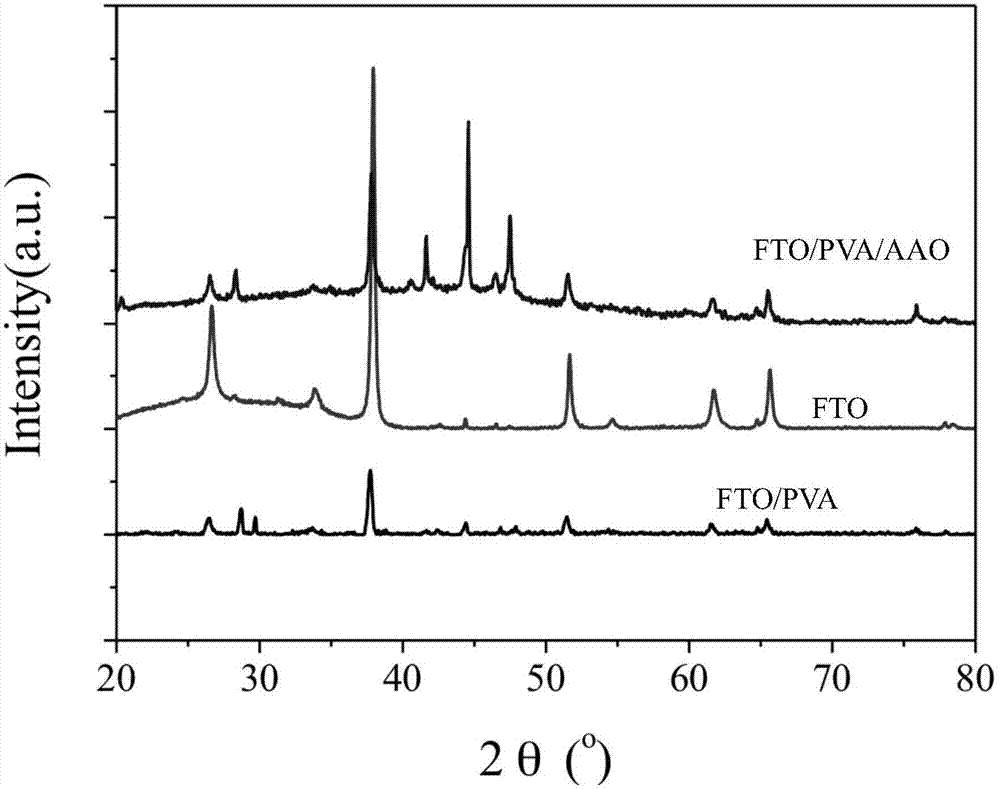

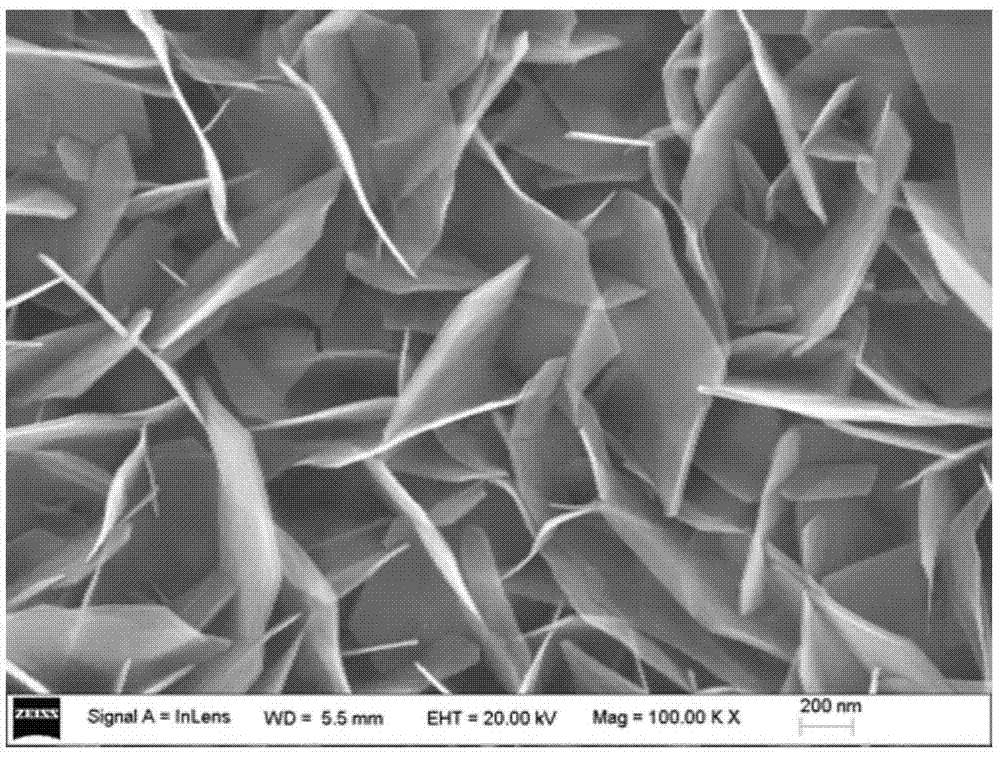

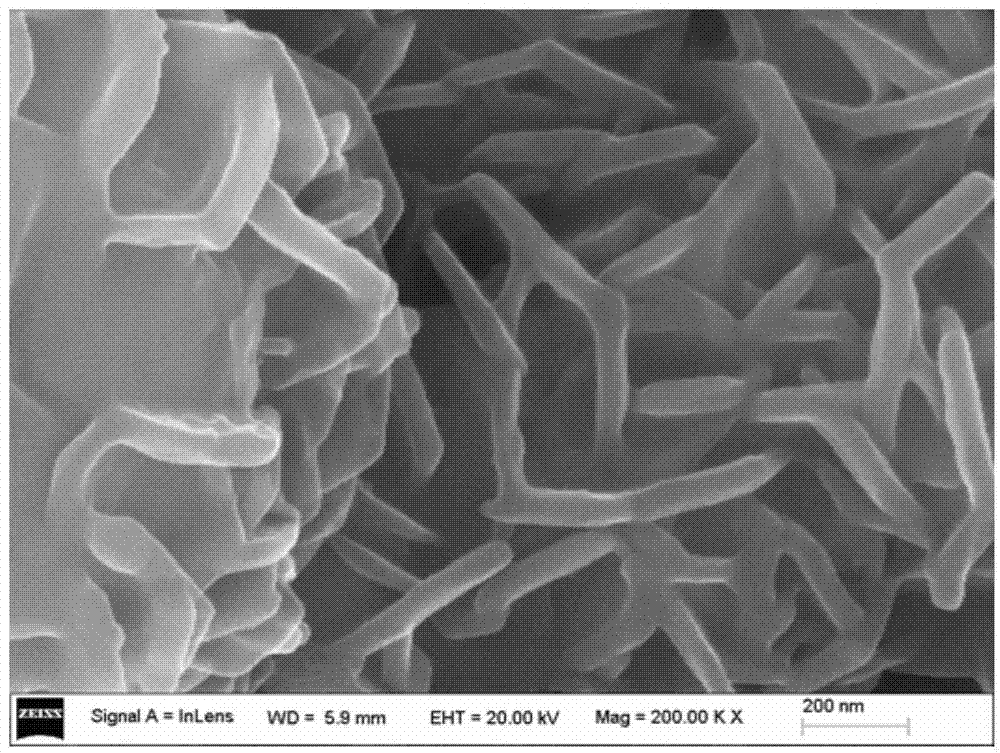

Method for preparing flowerlike nanometer cobalt by using anodised aluminum template, and product of same

ActiveCN104846411AThe method is simple and fastMild reaction conditionsNanotechnologyAdhesivePolyvinyl alcohol

Owner:BEIHANG UNIV

Method for electroplating goldfinger with thick gold layer

ActiveCN103233250AAvoid Bubble ProblemsInhibit sheddingJewellerySolder maskGold layer

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

High-strength crack-resistant concrete and producing method thereof

Owner:南京加豪新型建筑材料有限公司

Preparation method of pearlescent anti-crease waterproof moisture-permeable polyurethane synthetic leather

InactiveCN105568701AImprove wear resistanceImprove wrinkle resistanceTextiles and paperWater basedFiber

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Flame-retardant and wear-resisting rubber material for borehole cable sheath and preparation method of flame-retardant and wear-resisting rubber material

InactiveCN105175824AImprove high temperature resistanceImprove wear resistanceRubber insulatorsPolymer scienceDibenzoyl Peroxide

Owner:华泓喆

Efficient total-nutrient chelate fertilizer and preparation method thereof

InactiveCN109467475ACan't overcomeOvercoming the defects of phosphate for compoundingCalcareous fertilisersMagnesium fertilisersRare-earth elementPhosphate

Owner:HENAN JIENONG BIOLOGICAL & CHEM CO LTD

Aluminum alloy and preparation method thereof

Owner:CHANGCHUN UNIV OF TECH

Isotactic polypropylene/tall oil acid/polybutadiene composite sound absorbing cotton and preparation method thereof

InactiveCN103726222AImprove breathabilityImprove tensile propertiesSynthetic resin layered productsNon-woven fabricsParaffin waxVoid ratio

Owner:芜湖跃飞新型吸音材料股份有限公司

Seedling-raising substrate and preparation method thereof

InactiveCN106069334AImprove germination rateNormal differentiationGrowth substratesCulture mediaFiberBud

Owner:ANHUI MEILAN LANDSCAPE ENG CO LTD

Dendrobium crepidatum tissue culture method

InactiveCN107926707AImprove germination rateStrong seedlingsHorticulture methodsPlant tissue cultureHydrolysateThiamine hcl

The invention discloses a dendrobium crepidatum tissue culture method. The method comprises the following four steps: culturing and germinating dendrobium crepidatum seeds to obtain protocorm, performing strong seedling culture, performing root induction and hardening seedlings. In the step of culturing and germinating dendrobium crepidatum seeds to obtain protocorm, the used seed medium comprisesthe following components: 1600mg / L of potassium nitrate, 1250mg / L of ammonium nitrate, 370mg / L of magnesium sulfate, 170mg / L of monopotassium phosphate, 440mg / L of calcium chloride, 0.025mg / L of copper sulfate, 0.025mg / L of cobalt chloride, 16.9mg / L of manganese sulfate, 8.6mg / L of zinc sulfate, 6.2mg / L of boric acid, 0.83mg / L of potassium iodide, 0.25mg / L of sodium molybdate, 37.3mg / L of Na2-EDTA, 21.8mg / L of ferrous sulfate, 2.0mg / L of glycine, 0.1mg / L of thiamine hydrochloride, 0.5mg / L of pyridoxine hydrochloride, 0.5mg / L of nicotinic acid, 100mg / L of inositol, 0.5-2.0mg / L of NAA, 0.5-3.0mg / L of 6-BA, 100000mg / L of potatoes, 250mg / L of carbon dust, 30000mg / L of sucrose, 700mg / L of lactoalbumin hydrolysate and 4500mg / L of agar. According to the method, the dendrobium crepidatum seed germination rate is high to 90% or higher, and the reproduction rate is greatly improved.

Owner:RONGXIAN MINGXI DENDROBIUM CANDIDUM PLANTING FARM (MICRO-ENTERPRISE)

Insecticide-fertilizer for out-of-season fruit green radish and preparation method thereof

Owner:潍坊市绿旺达生物肥料科技有限公司

Combination material of fluorine-free flux and cadmium-free silver solder for copper-brass brazing

InactiveCN106342015BNot corrosiveImprove wettabilityWelding/cutting media/materialsSoldering mediaCeriumCadmium Cation

The invention relates to a composite material of fluorine-free brazing flux and cadmium-free silver brazing filler metal for copper-brass brazing, belonging to brazing materials. This brazing material is a combination of fluorine-free flux and cadmium-free silver solder, wherein the fluorine-free flux includes 2% to 8% boric acid (H3BO3), 28% to 38% boric anhydride (B2O3), 5% to 15% % carbonate (K2CO3 or Na2CO3), 0.1% to 1.0% nitrate (KNO3 or NaNO3), the rest is borate (K2B4O7 or Na2B4O7); cadmium-free silver solder includes 15% to 45% silver (Ag) , 3% to 10% of phosphorus (P), 0.001% to 0.030% of zirconium (Zr), 0.001% to 0.010% of cerium (Ce), and the rest is copper (Cu). The composite material has good wettability when brazing copper-copper, brass-brass, and copper-brass, and the brazing joint has good plasticity and comprehensive mechanical properties, and there is no residual fluorine ion at all. It is especially suitable for brazing copper materials that are used in harsh environments (high humidity, high temperature, high salt spray, etc.).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Wood fire-proofing agent and preparation method thereof

InactiveCN108214777AOvercome permeabilityOvercome fire resistanceWood treatment detailsWood impregnation detailsBoric acidMelamine

Owner:池海波

Flame-retardant ethylene propylene diene monomer

Owner:佛山市高明区生产力促进中心

Soil oxygen-increasing agent and preparation method thereof

InactiveCN107400514ANeutralize acidityImprove breathabilityAgriculture tools and machinesOrganic fertilisersPlant rootsOxygen

Owner:张娟

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap