Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Zirconium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium is a chemical element with the symbol Zr and atomic number 40. The name zirconium is taken from the name of the mineral zircon (the word is related to Persian zargun (zircon;zar-gun, "gold-like" or "as gold")), the most important source of zirconium. It is a lustrous, grey-white, strong transition metal that closely resembles hafnium and, to a lesser extent, titanium. Zirconium is mainly used as a refractory and opacifier, although small amounts are used as an alloying agent for its strong resistance to corrosion. Zirconium forms a variety of inorganic and organometallic compounds such as zirconium dioxide and zirconocene dichloride, respectively. Five isotopes occur naturally, three of which are stable. Zirconium compounds have no known biological role.

Preparation method of zirconium oxide-silicon oxide composite aerogel

ActiveCN103214034ALow densityLow thermal conductivitySilicon compoundsZirconium oxidesAlcoholSilicon oxide

The invention relates to a preparation method of zirconium oxide-silicon oxide composite aerogel. The method comprises the following steps of: dissolving siloxane in alcohol and uniformly stirring the solution to obtain alcohol solution of the siloxane; titrating concentrated nitric acid with 65-68% of mass concentration, titrating deionized water after stirring uniformly and continuously stirring; titrating the concentrated nitric acid to the pre-hydrolyzed siloxane solution, titrating zirconium alkoxide after mixing uniformly, adding the deionized water after stirring uniformly and stirring continuously to obtain clear and transparent gel; transferring the gel to a mould, and still standing and aging the gel to obtain the zirconium oxide-silicon oxide composite wet gel; soaking the wet gel by using aging solution; and finally soaking the gel by using absolute ethyl alcohol or isopropanol solvent. The blocky zirconium oxide-silicon oxide composite aerogel featured with low density and low thermal conductivity prepared by the invention basically keeps the former microcosmic undefined structure after thermal treatment at 1000 DEG C, and has specific area up to 353m<2> / g and good high-temperature stability.

Owner:LINXIAO (TIANJIN CHINA) TECH CO LTD

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Zirconium-molybdenum oxide catalyst for methane oxidation to synthesize formaldehyde and its preparation method

InactiveCN1394681AEasy to prepareHigh mechanical strengthMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureOxygen

The molecular formula of zirconium-molybdenum oxide catalyst for synthesizing formaldehyde by means of methane oxidation is (ZrO2)x(Zr(MoO4)2)y (MoO3)z, and its preparalcon method includes the following steps: using zirconium dioxide powder ammonium molbdate powder as raw material, metering and weighing ammonium molybdate powder according to the above-mentioned molecular formula, using deionized water to prepare ammonium modybdate aqueous solution with a certain concentration, adding said aqueous solution into zirconium dioxide powder, drying the mixture, high-temp. roasting, mechanical grinding, press-forming, screening granules so as to obtain the catalyst.

Owner:TSINGHUA UNIV

Alloy material with high temperature coefficient of resistance and preparation method thereof

The invention provides an alloy material with high temperature coefficient of resistance. The alloy material is prepared by adding six metal components as the additives to nickel-ferrum alloy, and smelting same to obtain the product, wherein the six metal components are respectively germanium, zirconium, cerium, titanium, aluminum and ferrum; and the alloy material comprises the following components in percentage by weight: 50-65% of component Ni, 14-21% of component Cr, 0.1-0.9% of component Ge, 0.15-0.5% of component Ce, 0.2-1% of component Zr, 1.1-3.5% of component Ti, 0.5-2% of component Al, and the balance of component Fe. The invention also provides a preparation method of the alloy material. The alloy material prepared by the preparation method provided by the invention is of 8.2g / cm<3> based on the density, and has the resistivity of 1.53 (microhm.megabyte.20 DEG C); and the alloy material has temperature coefficient of resistance of 240aR / *10<-6>DEG / C under 100-800 DEG C; and the temperature is in good linear relation to the resistivity.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

Decorative and thermal-insulation integrated novel lightweight walling material made from polishing brick waste

Owner:ZIBO YONGXU REFRACTORY MATERIALS

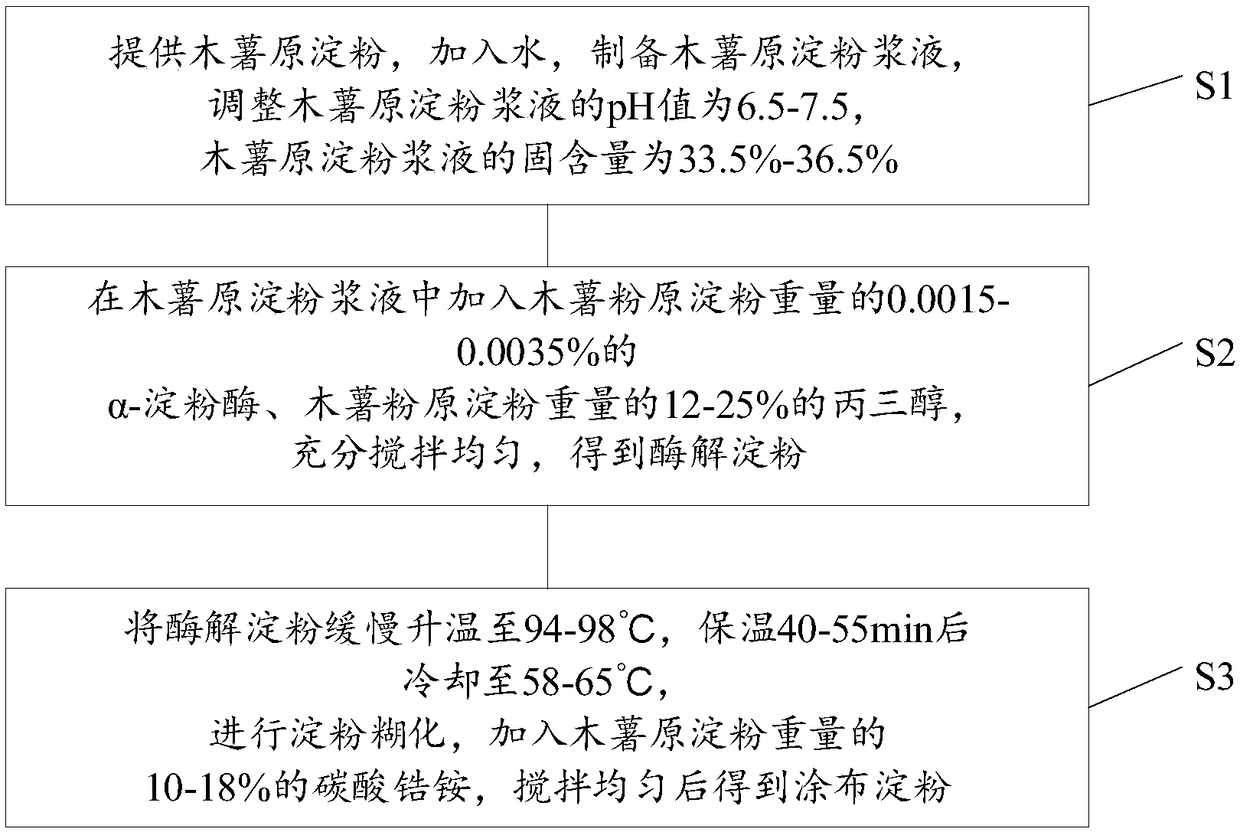

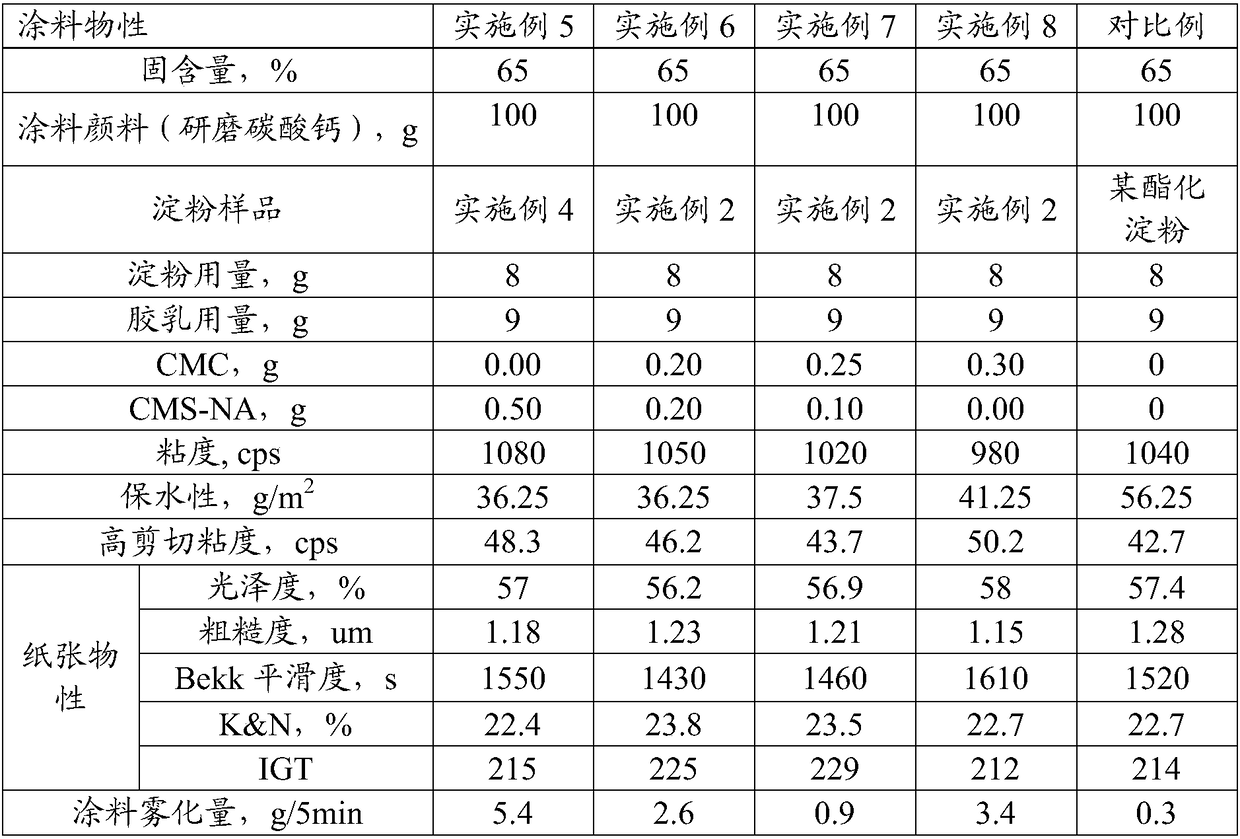

Coating starch, coating starch preparation method and papermaking coating

InactiveCN108411696ASolve the problem of not being suitable for coating, especially metering size press coating processPaper coatingFermentationAlpha-amylaseSlurry

Owner:GOLD EAST PAPER JIANGSU

Positive Electrode Active Material for Lithium Secondary Battery

Provided is a novel positive electrode active material which can effectively suppress the quantity of gas generated by the reaction with an electrolytic solution. Proposed is a positive electrode active material for a lithium secondary battery including positive electrode active material particles obtained by equipping the entire surface or a part of a surface of lithium manganese-containing composite oxide particles (also referred to as the “core particles”) operating at a charging voltage in a region exceeding 4.3 V in a metal Li reference potential with a layer A containing at least titanium (Ti), aluminum (Al), zirconium (Zr), or two or more kinds of these.

Owner:MITSUI MINING & SMELTING CO LTD

High-temperature-resistant high-performance rare earth permanent magnet material

InactiveCN105374488AHigh temperature resistance and high performanceImprove stabilityInorganic material magnetismRare-earth elementTemperature resistance

Owner:南通长江电器实业有限公司

Anode of medium-low temperature solid oxide fuel cell and preparation method thereof

InactiveCN104617308AReduce poisonHigh catalytic activityCell electrodesSolid electrolyte fuel cellsFuel cellsPhysical chemistry

Owner:ANYANG INST OF TECH

Bismaleimide resin/silicone rubber ablation-resistant thermal insulation composite material and preparation method thereof

Owner:湖北三江航天江北机械工程有限公司

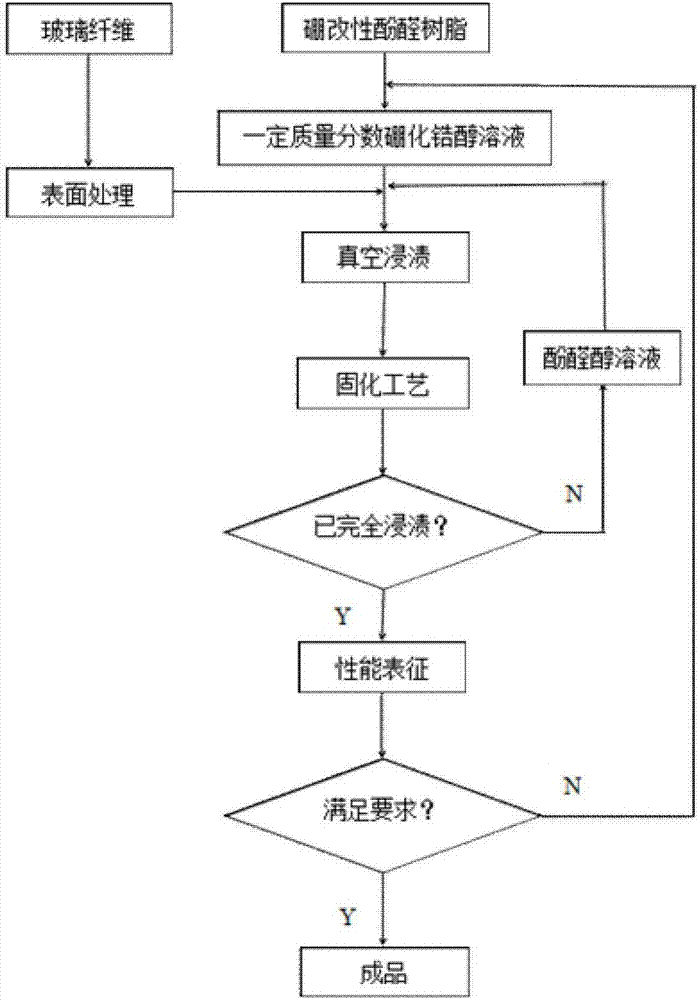

Preparation method of phenolic resin impregnation glass fiber composite material

Owner:BEIJING JIAOTONG UNIV

Baking-free long water gap for large-plate-blank continuous casing low-carbon and low-silicon steel and preparation process of baking-free long water gap

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Processing method of zirconium oxygen-free copper forging rod

InactiveCN111408632ABreak through the problem that ultrasonic flaw detection cannot be performedNon-destructive monitoring of internal qualityMetal-working apparatusFurnace typesSolution treatmentEngineering

The invention discloses a processing method of a zirconium oxygen-free copper forging rod. A rod material adopts zirconium oxygen-free copper casting billets. After forging and blanking, the casting billets are produced by hot forging, upsetting and stretching, solid solution treatment, cold forging, machining, aging and machining again. The specification can reach Phi (100-300)*(500-1500) mm. Theimportant thing to note that after the rod material is subjected to cold forging and machining, ultrasonic flaw detection is needed for nondestructive testing of internal quality. The processing method can successfully realize the feasibility of nondestructive flaw detection and avoid the problem that no echo exists or echo is weak in the ultrasonic flaw detection process of the rod material, sothat the detection requirement cannot be met. The product is applied to inner wall shrinkage parts of a power chamber groove of a rocket engine, the tensile strength and yield strength are still above150MPa at 500 DEG C, and the elongation rate is also above 15%.

Owner:SHENYANG TONGXING IND

Ultrawhite stoneware and production process

Owner:SHENYANG SHUNXIN CERAMIC

Dispersing method of inorganic filler

The invention discloses a dispersing method of inorganic filler. The method specifically includes: subjecting the inorganic filler to ultrasonic soaking in an aprotic polar solvent, and dispersing theobtained mixed liquid in a sand mill containing zirconium beads of different particle sizes at specific rotation speed. By using the method to disperse the inorganic filler, a good dispersing effectis achieved, the obtained inorganic filler dispersed slurry is used for preparing a black matte polyimide film, the obtained film is high in mechanical performance and electric strength, low in shading rate and good in matte performance, and filter element replacing frequency during film preparation is lowered.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Preparation method of niobium-zirconium 10 alloy tube

InactiveCN104561575ANo segregationImprove tissue uniformityNiobiumDehydrogenation

Owner:BAOJI TIANBO METAL MATERIAL

Method for treating or pretreating containers

InactiveUS7344757B2Simpler and cost-effective processIncrease chanceHot-dipping/immersion processesPretreated surfacesBottleAluminium alloy

Owner:CHEMETALLGMBH

Special magnesium alloy material for vehicle crankshaft and preparation method thereof

The invention discloses a special magnesium alloy material for a vehicle crankshaft and a preparation method thereof. The special magnesium alloy material for the vehicle crankshaft comprises the following components in percentage by weight: 4.0-7.0% of silicon, 3.7-5.8% of copper, 2.5-4.0% of lithium, 0.4-0.6% of tungsten, 0.5-0.9% of chromium, 0.04-0.07% of titanium, 0.02-0.07% of boron, 0.001-0.004% of nickel, 0.001-0.003% of vitriol, 0.001-0.003% of zirconium, and the balance of magnesium. The high-performance magnesium alloy material with higher strength and hardness is prepared through selecting the specific formula, has the advantages of lightness and wear resistance, is excellent in heat dissipating capacity, and can satisfy the quality requirement of the vehicle crankshaft.

Owner:YUYAO WANZHEN HARDWARE FACTORY

Fire ion detector

PendingCN106841445AAvoid safety hazardsSolve the big problem of difficult monitoringComponent separationChemical industryNitrogen gas

Owner:成都凯圣捷科技有限公司

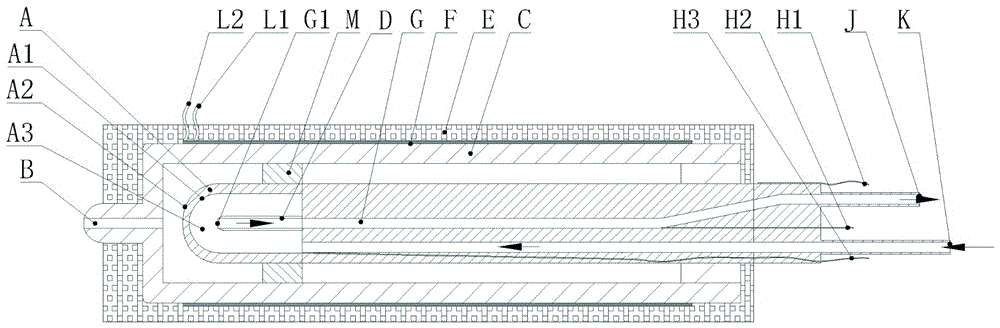

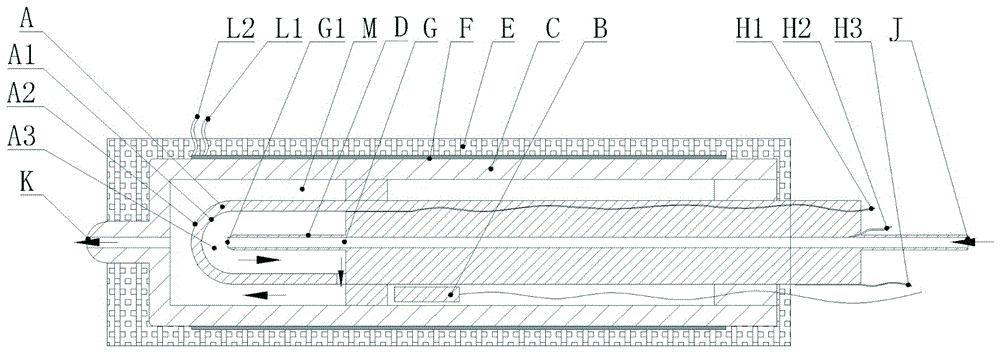

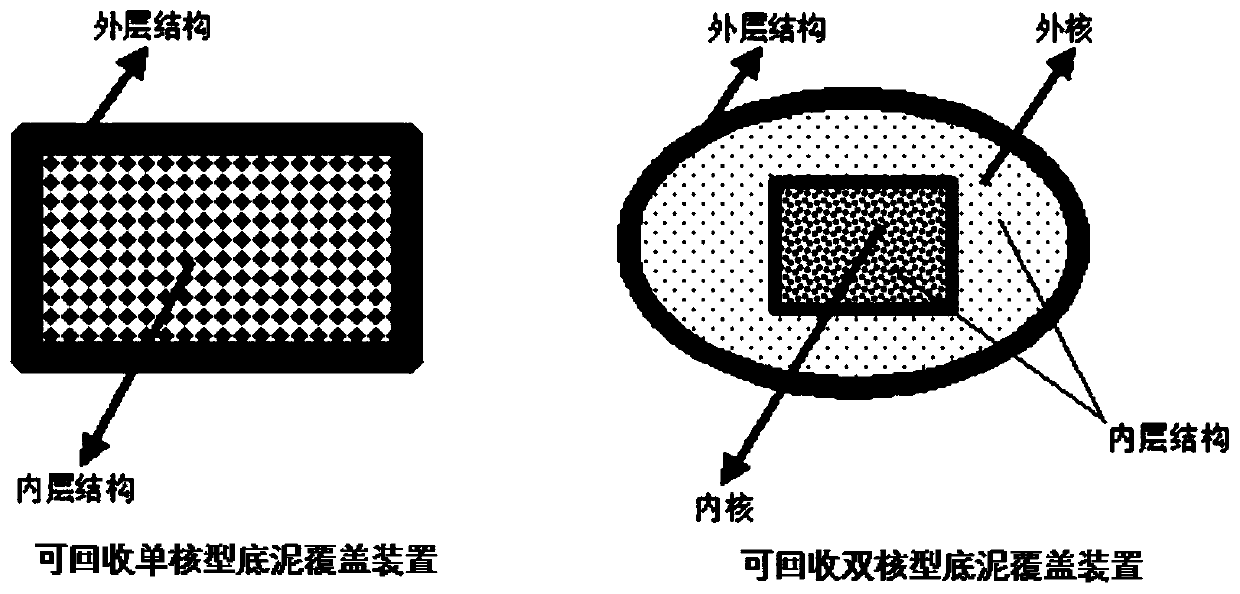

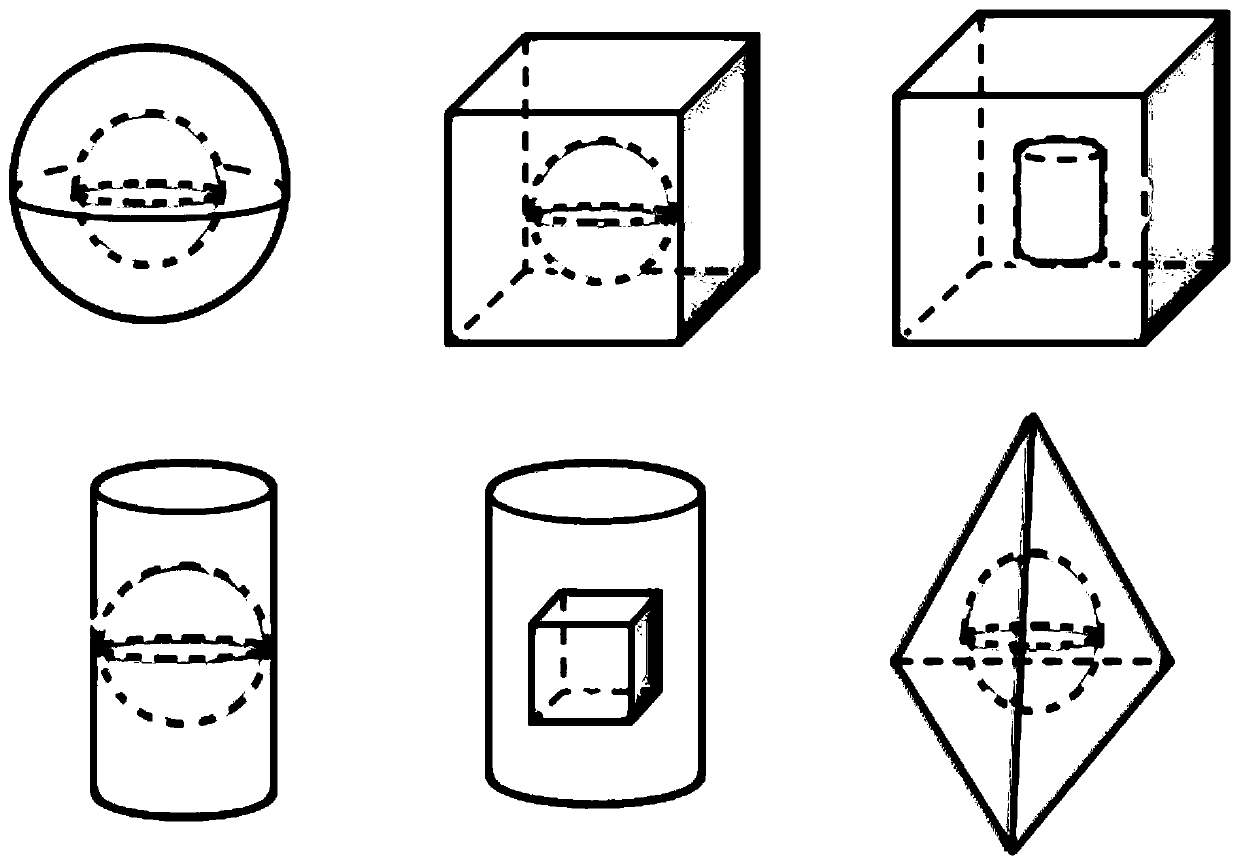

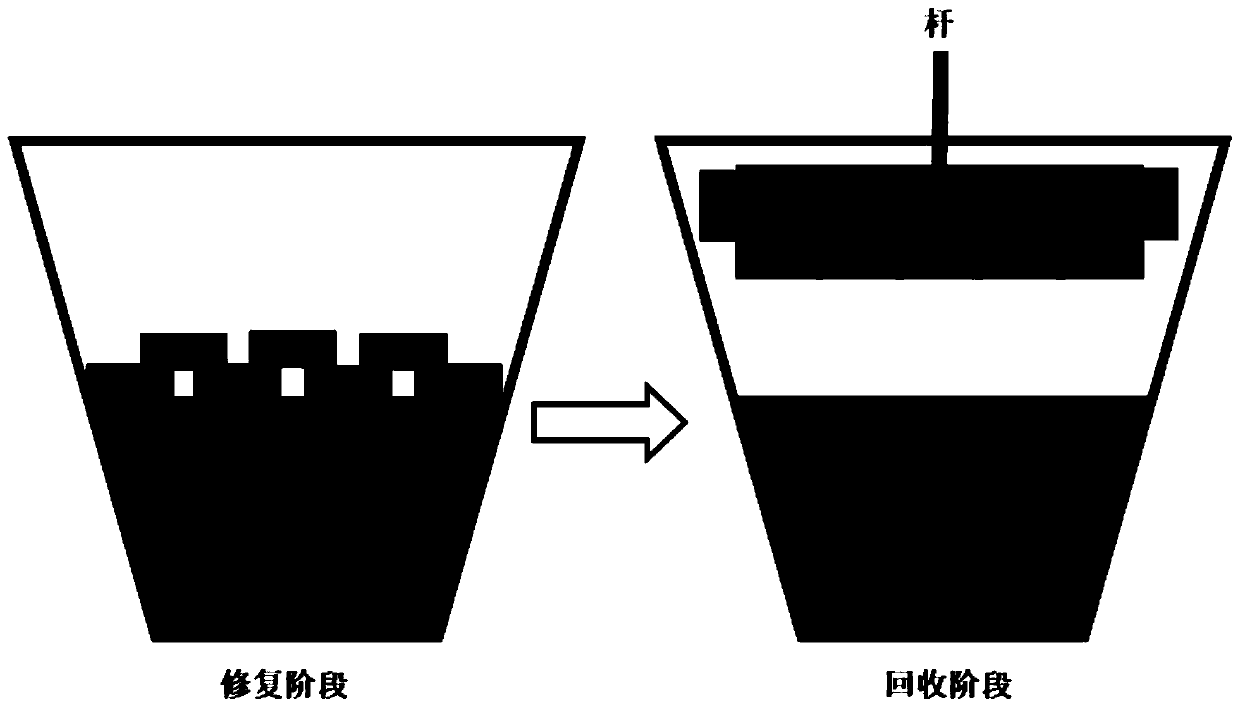

Recyclable sediment covering device and application thereof

InactiveCN111186971AReduce repair costsAvoid churnSludge treatmentOther chemical processesEngineeringStructural engineering

Owner:SHANGHAI OCEAN UNIV

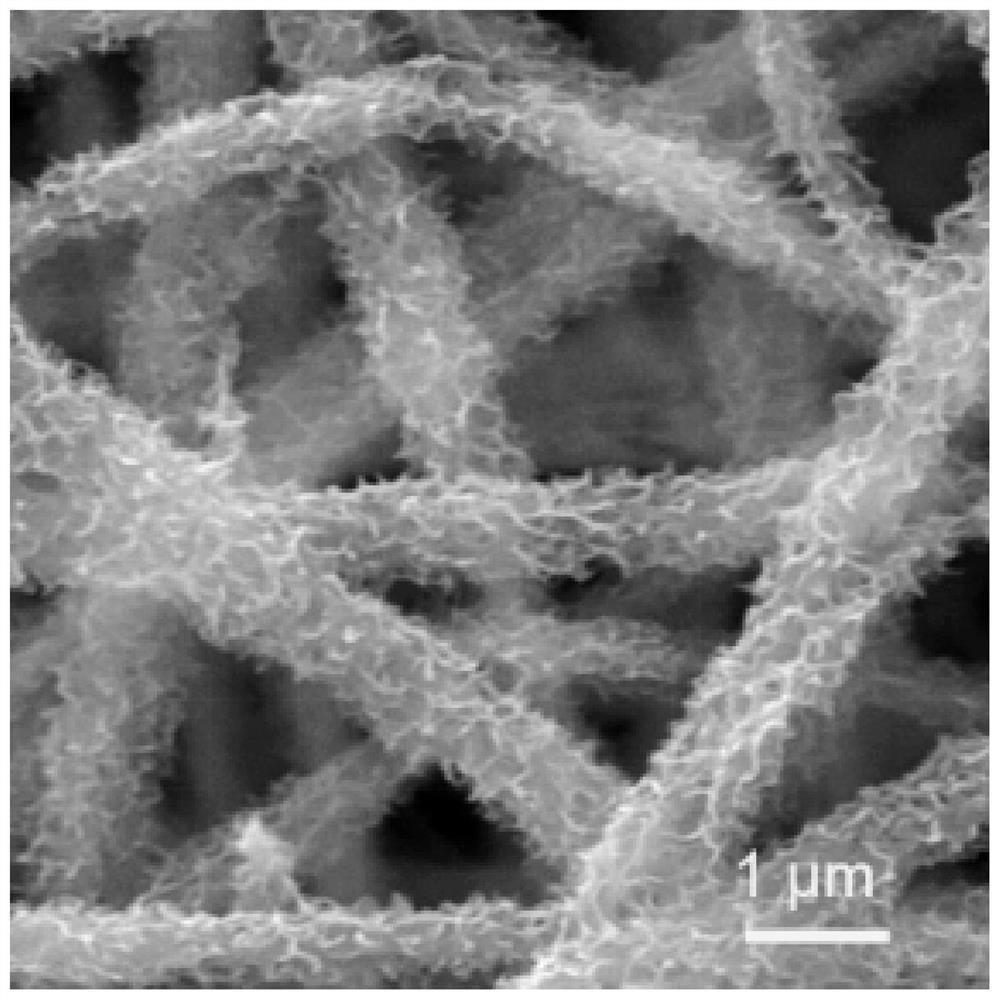

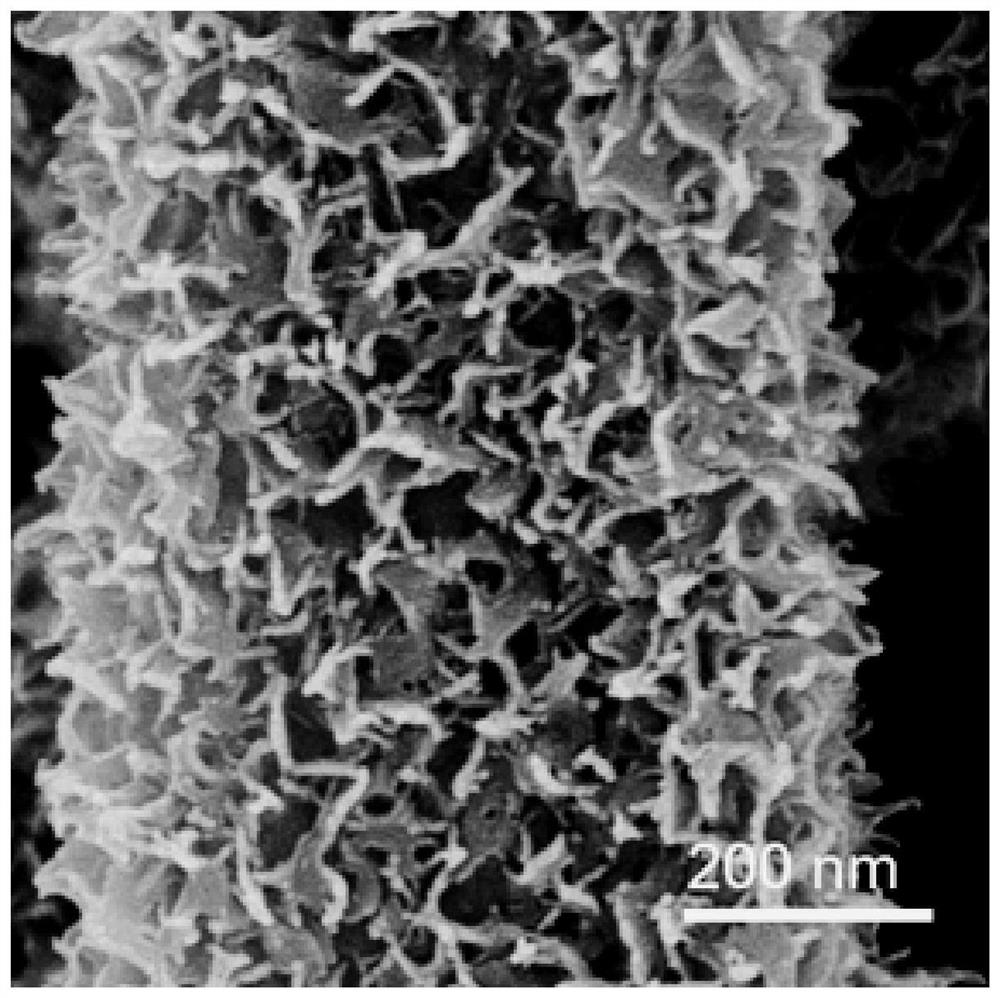

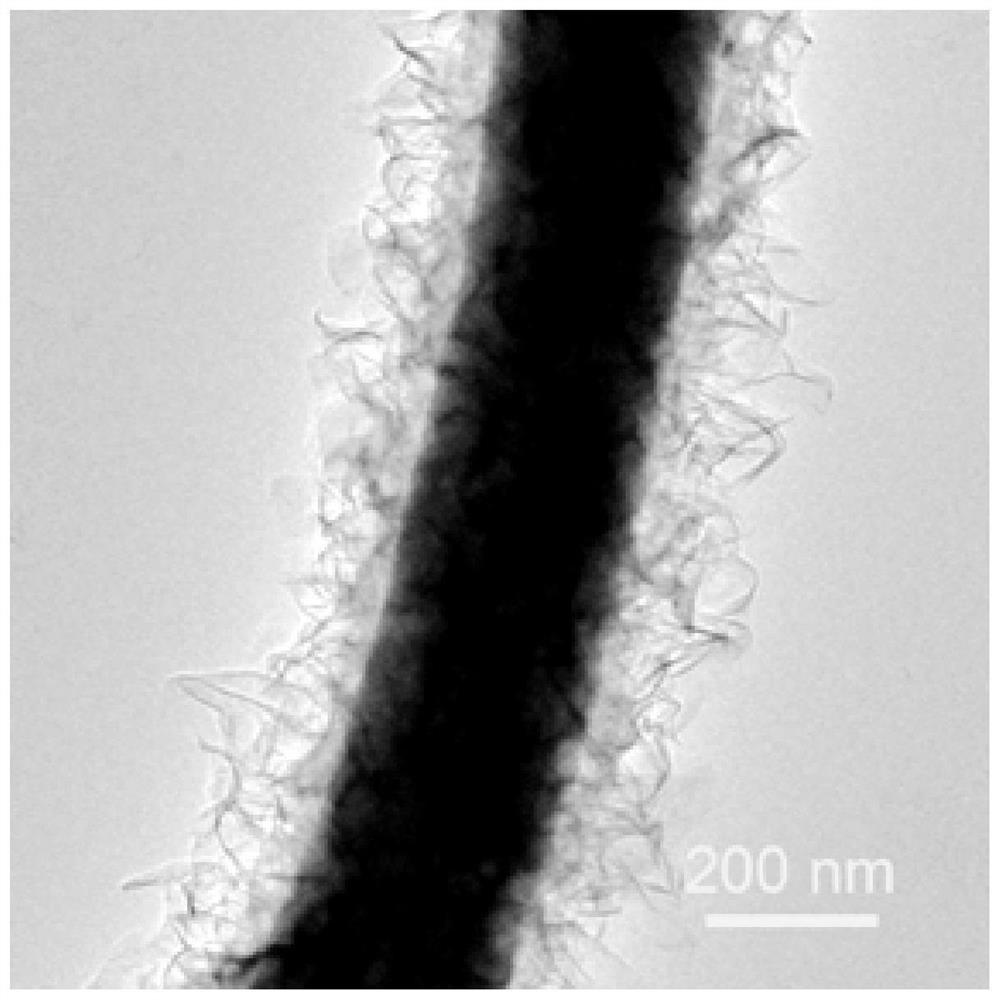

Zirconium hydroxide nanosheet/nanofiber composite membrane and preparation method thereof

Owner:DONGHUA UNIV

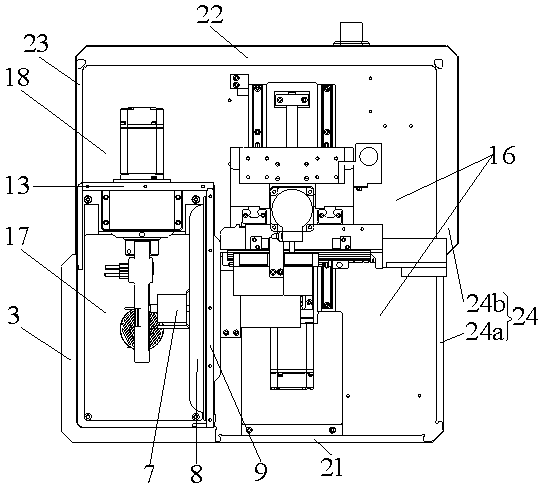

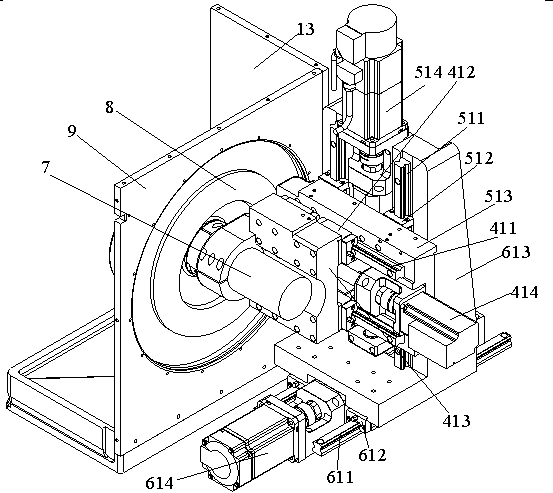

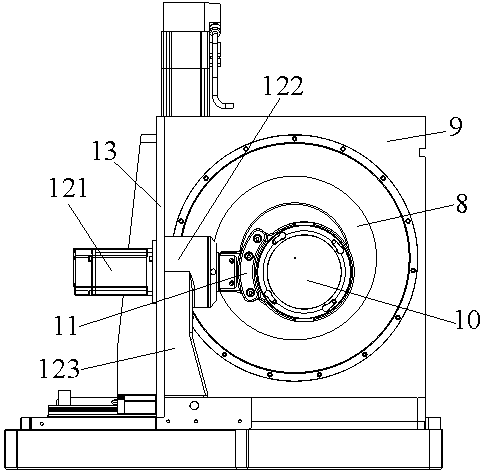

Zirconium-oxide processing equipment and four-axis processing structure

PendingCN107738110ASimple structureSimplify complexityLarge fixed membersPositioning apparatusEngineeringMechanical engineering

Owner:沈阳机床(东莞)智能装备有限公司

Combination material of fluorine-free flux and cadmium-free silver solder for copper-brass brazing

InactiveCN106342015BNot corrosiveImprove wettabilityWelding/cutting media/materialsSoldering mediaCeriumCadmium Cation

The invention relates to a composite material of fluorine-free brazing flux and cadmium-free silver brazing filler metal for copper-brass brazing, belonging to brazing materials. This brazing material is a combination of fluorine-free flux and cadmium-free silver solder, wherein the fluorine-free flux includes 2% to 8% boric acid (H3BO3), 28% to 38% boric anhydride (B2O3), 5% to 15% % carbonate (K2CO3 or Na2CO3), 0.1% to 1.0% nitrate (KNO3 or NaNO3), the rest is borate (K2B4O7 or Na2B4O7); cadmium-free silver solder includes 15% to 45% silver (Ag) , 3% to 10% of phosphorus (P), 0.001% to 0.030% of zirconium (Zr), 0.001% to 0.010% of cerium (Ce), and the rest is copper (Cu). The composite material has good wettability when brazing copper-copper, brass-brass, and copper-brass, and the brazing joint has good plasticity and comprehensive mechanical properties, and there is no residual fluorine ion at all. It is especially suitable for brazing copper materials that are used in harsh environments (high humidity, high temperature, high salt spray, etc.).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Preparation method of galvanizing solution for metal workpieces

InactiveCN112195432AImprove protectionExtended service lifeHot-dipping/immersion processesAlloyMetal

Owner:和县卜集振兴标准件厂

Material formula for diamond bit

InactiveCN108746592AReduce manufacturing costHigh tensile strengthTransportation and packagingMetal-working apparatusNiobiumSilicon dioxide

Owner:如皋千骏工具有限公司

Adhesive for glass fiber mat and preparation method thereof

InactiveCN104877613AImprove surface activityGood temperature and shear resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkGlass fiber

Owner:合肥启华环保科技有限公司

Application of organic zirconate

The invention discloses an application of organic zirconate. The application is characterized by being applied as a drier for painting. The organic zirconate is prepared from zirconium carbonate and organic acid through a reaction. The organic zirconate as the drier has good application performance, can completely replace a toxic lead naphthenate drier, and is safe and non-toxic during use.

Owner:GUANGXI LIUZHOU YUFENG ZHIQI CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap