Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

442 results about "Solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solvent (from the Latin solvō, "loosen, untie, solve") is a substance that dissolves a solute (a chemically distinct liquid, solid or gas), resulting in a solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. The quantity of solute that can dissolve in a specific volume of solvent varies with temperature. Common uses for organic solvents are in dry cleaning (e.g. tetrachloroethylene), as paint thinners (e.g. toluene, turpentine), as nail polish removers and glue solvents (acetone, methyl acetate, ethyl acetate), in spot removers (e.g. hexane, petrol ether), in detergents (citrus terpenes) and in perfumes (ethanol). Water is a solvent for polar molecules and the most common solvent used by living things; all the ions and proteins in a cell are dissolved in water within a cell. Solvents find various applications in chemical, pharmaceutical, oil, and gas industries, including in chemical syntheses and purification processes.

Polyaniline-graphene composite based anticorrosive paint and preparation method thereof

Owner:HARBIN ENG UNIV

Method and apparatus for treating a substrate with an ozone-solvent solution

InactiveUS6982006B1Improve user securityLighting and heating apparatusHollow article cleaningSolventAqueous solution

Owner:BOYERS DAVID G +1

Low Viscosity Liquid Polymeric Delivery System

InactiveUS20090181068A1Heavy metal active ingredientsNervous disorderPolymer sciencePolymer solution

Owner:DUNN RES & CONSULTING

Ionic solvents used in ionic polymer transducers, sensors and actuators

InactiveUS20050103706A1Stable responseSolve the stability is not highMaterial nanotechnologySemi-permeable membranesIonomerTransducer

Ionic liquids are incorporated into transducers, actuators or sensors which employ the ionic polymer membranes. The ionic liquids have superior electrochemical stability, low viscosity and low vapor pressure. The transducers, actuators and sensors which utilize ionic polymer membranes solvated with ionic liquids have long term air stability. Superior results are achieved when a conductive powder and ionomer mixture is applied to the ionic polymer membrane to form the electrodes during or after the ionic liquid is imbibed into the ionic polymer membrane.

Owner:VIRGINIA TECH INTPROP INC +1

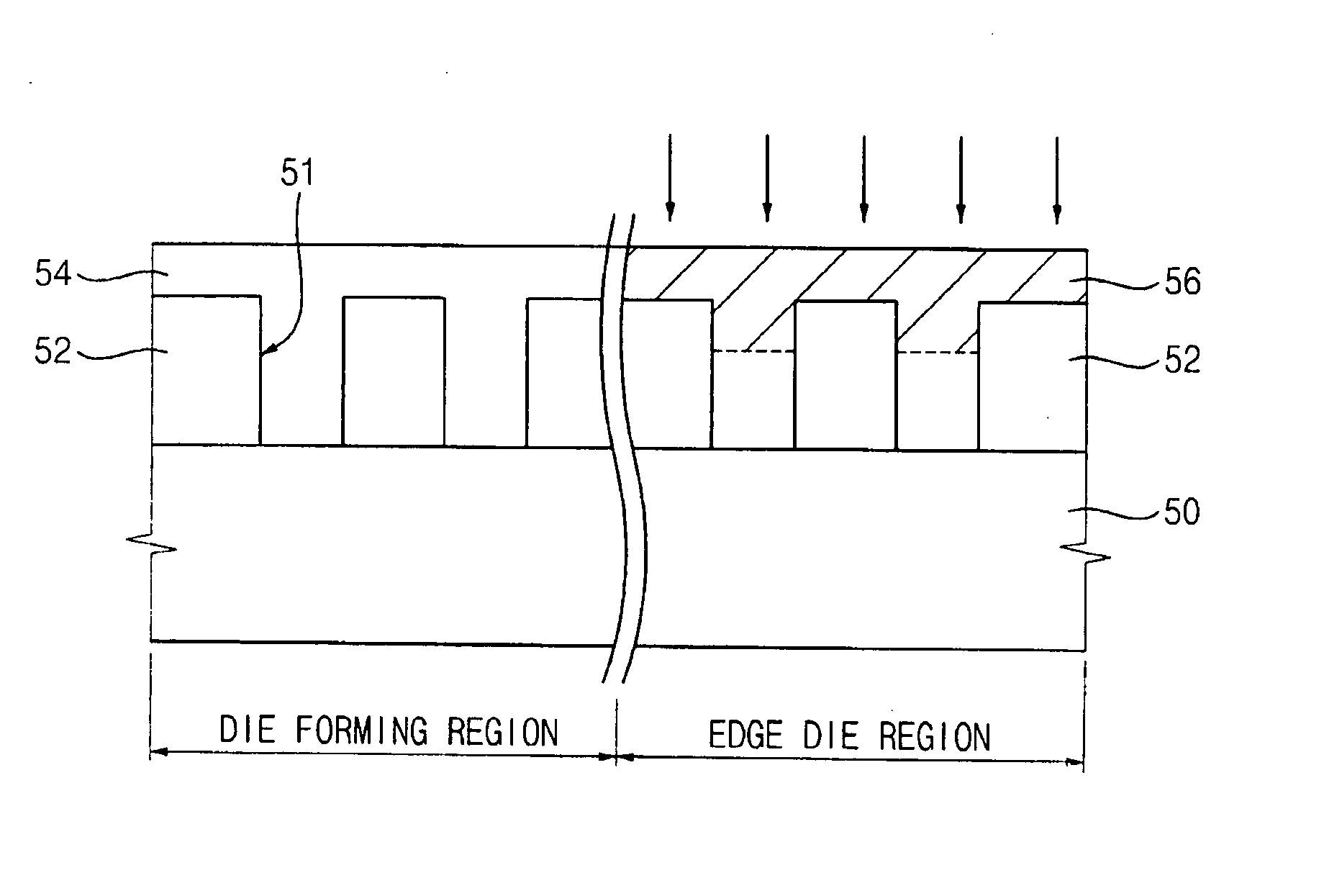

Polymer resin composition, related method for forming a pattern, and related method for fabricating a capacitor

InactiveUS20070249117A1Reduce in quantityReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingCross-link(Hydroxyethyl)methacrylate

Owner:SAMSUNG ELECTRONICS CO LTD

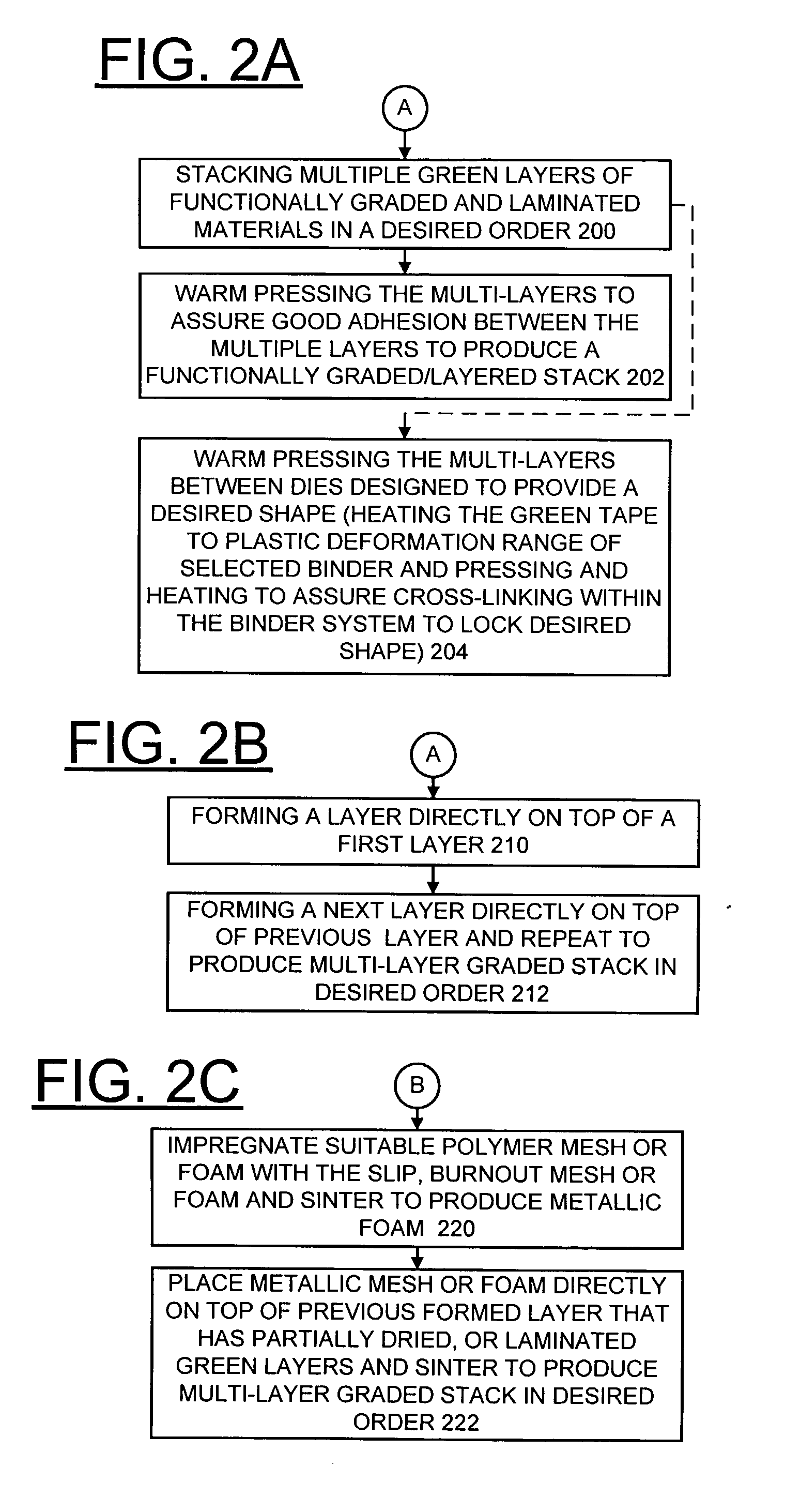

Compositionally graded metallic plates for planar solid oxide fuel cells

Owner:UCHICAGO ARGONNE LLC +1

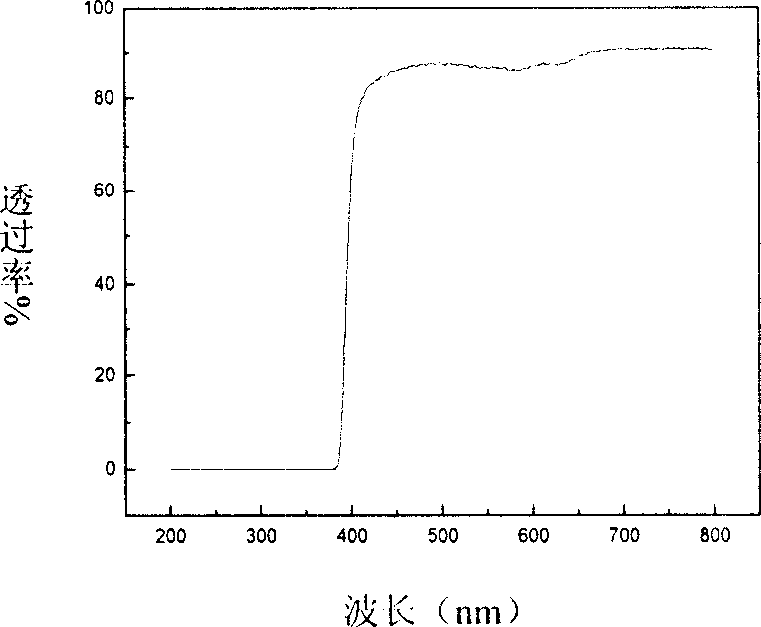

High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

InactiveCN1699488AHigh refractive indexHigh transparencyCoatingsOptical elementsComposite filmRefractive index

Owner:JILIN UNIV

Electrophoretic fluid

The present invention is directed to a display fluid comprising charged composite pigment particles dispersed in a solvent. The composite pigment particle comprises at least a core pigment particle, a shell coated over the core pigment particle and steric stabilizer molecules on the surface of the composite pigment particle, wherein the shell is formed from a monomer and a co-monomer. A display fluid comprising the composite pigment particles provides improved display performance.

Owner:E INK CALIFORNIA

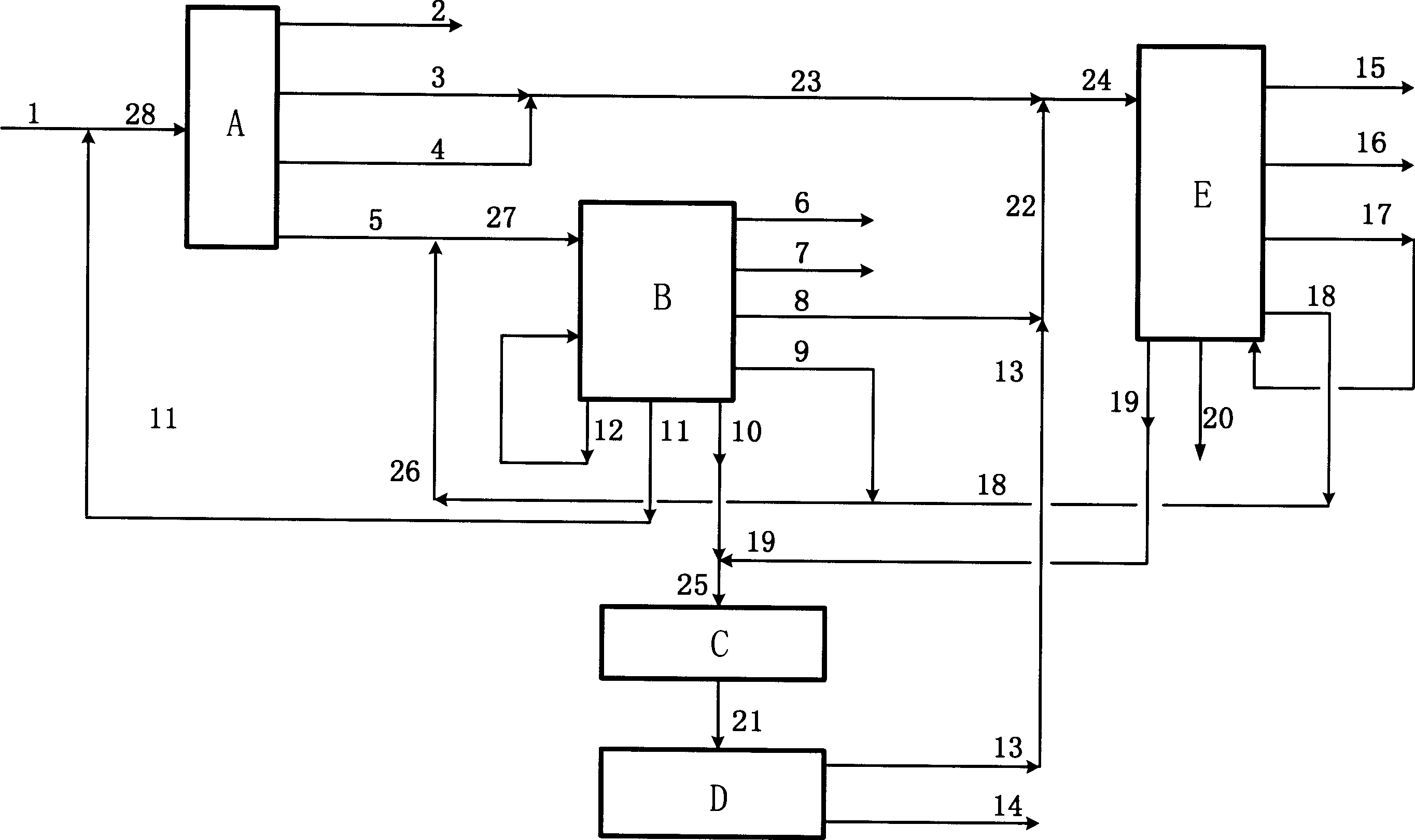

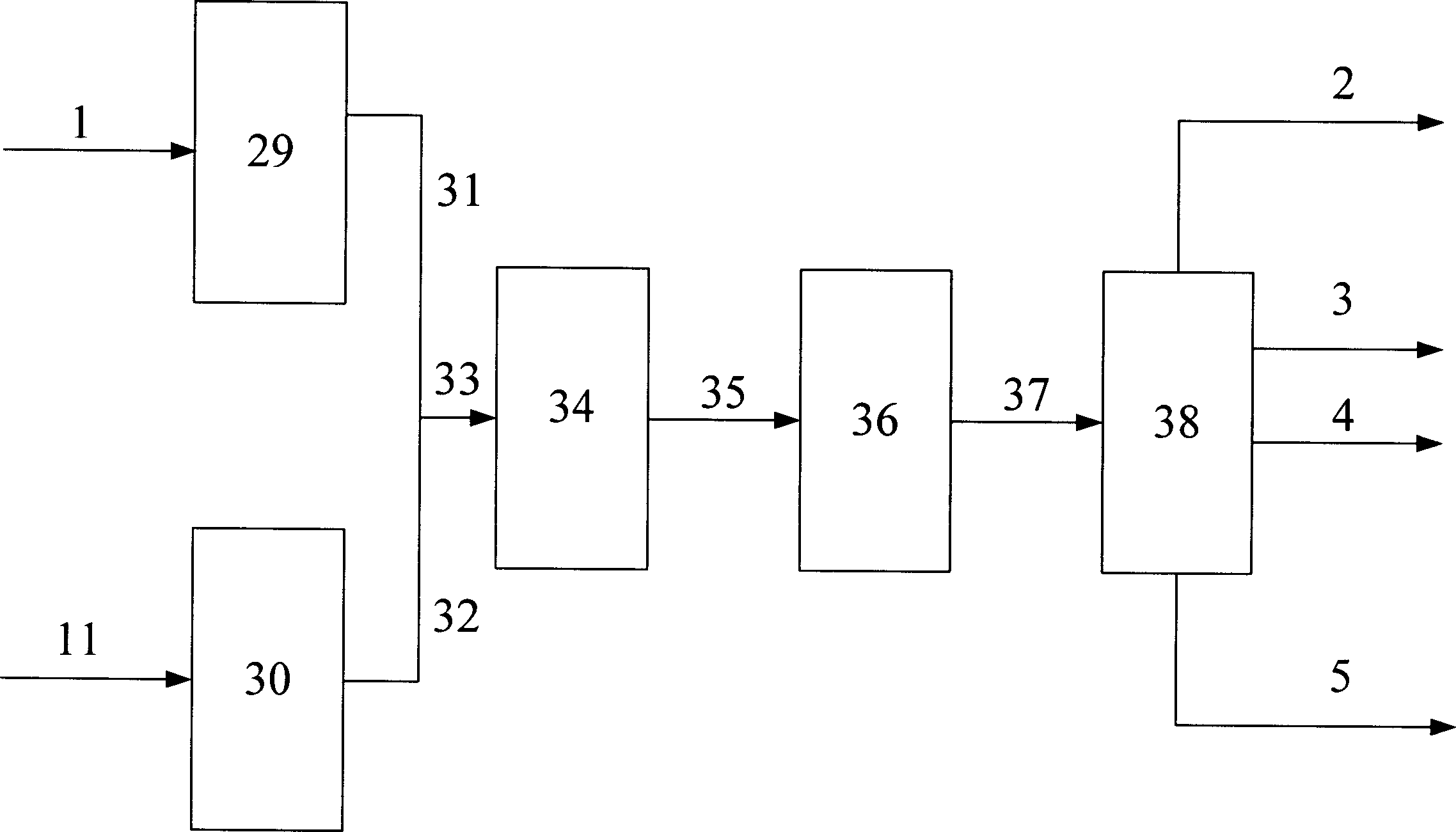

Method and device for preparing low carbon olefine and arene

Owner:CHINA PETROLEUM & CHEM CORP +1

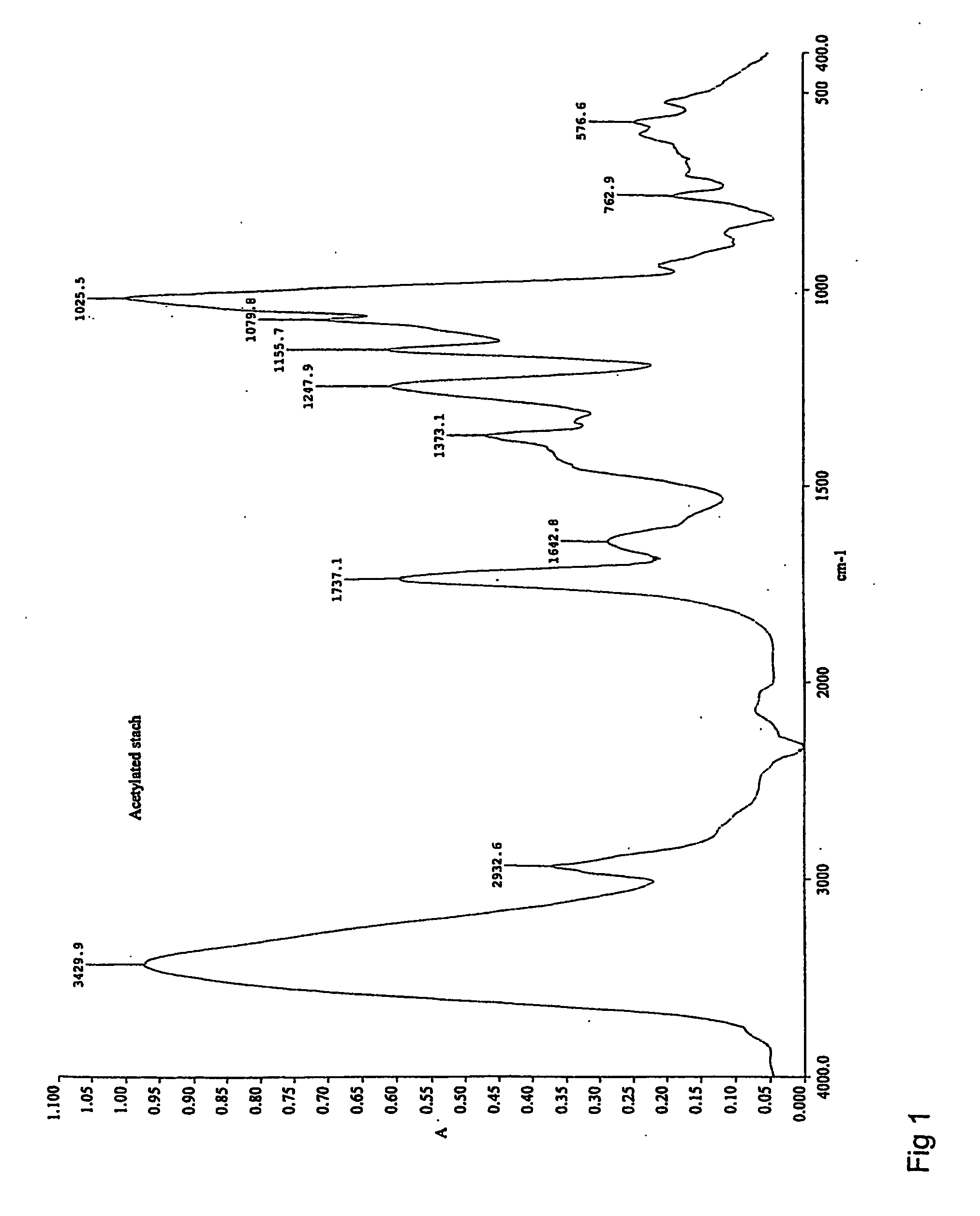

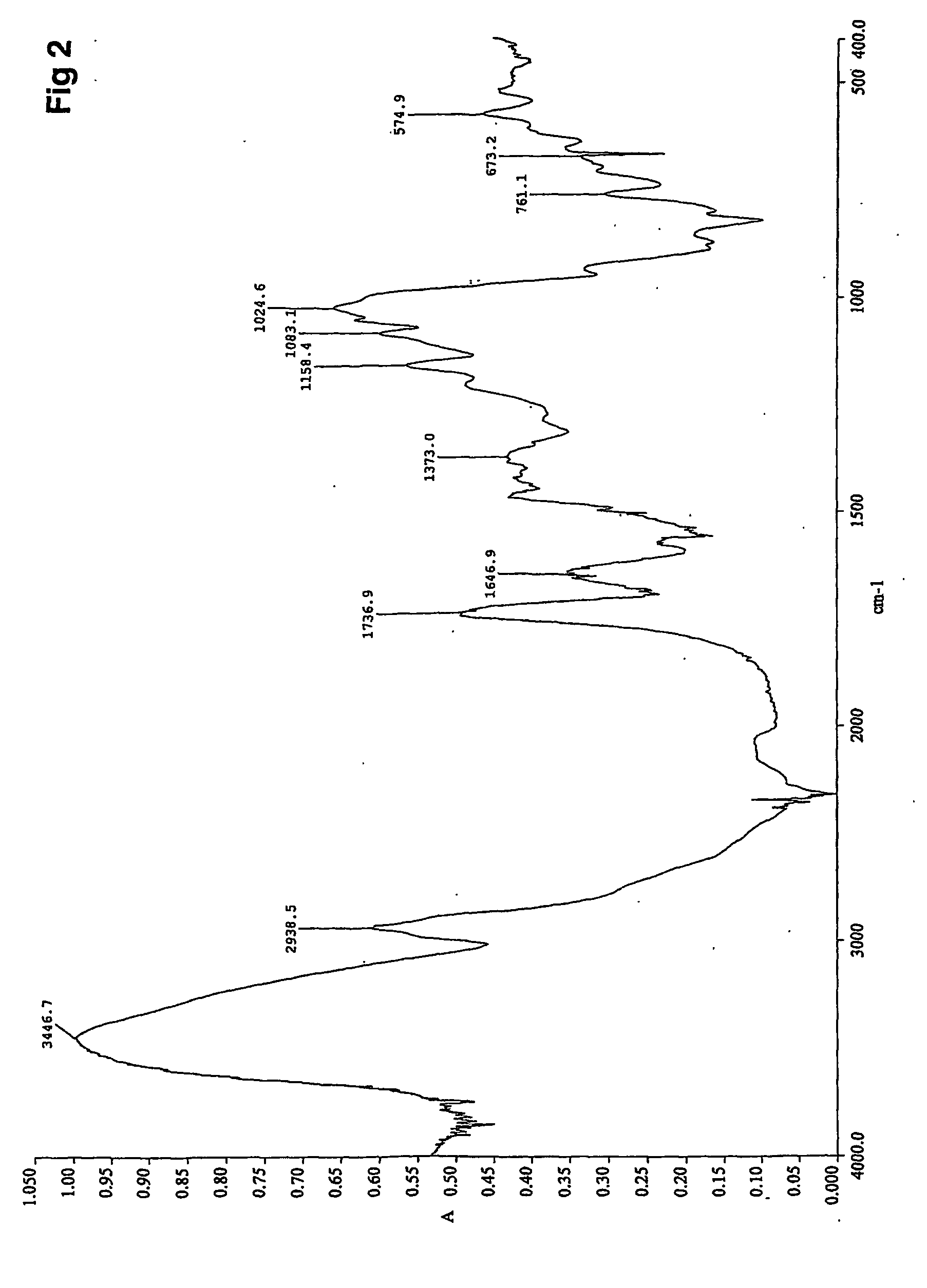

Starch esterification method

InactiveUS20070073051A1Efficient and gentle and environmentally benign preparationSimple and economical separationBulk chemical productionDissolutionSolvent

Owner:VESA MYLLYMAKI +1

Copolymer, process for producing the same, and resist composition

InactiveUS6706826B1Improve adhesionImprove solubilityOriginals for photomechanical treatmentPhotosensitive materials for photomechanical apparatusSolventResist

The present invention relates to a copolymer for use in paints, resists, and the like; a method for manufacturing the same; and a resist composition using the same. The copolymer according to the present invention is obtained by means of polymerizing at least one monomer containing an alicyclic structure and one monomer containing a lactone structure, and the distribution of the copolymer composition of said monomer containing a lactone structure in said copolymer is in the range of -10 to +10 mol % of the average copolymer composition of said monomer containing a lactone structure in said entire copolymer. In addition, the copolymer according to the present invention is obtained by means of polymerizing a monomer containing an alicyclic structure, a monomer containing a lactone structure, and another vinyl monomer comprising a higher polarity than said monomer containing an alicyclic structure, but a lower polarity than said monomer containing a lactone structure. The copolymer according to the present invention exhibits superior adhesion properties to surfaces possessing a high polarity, such as metal surfaces and the like, in addition to excellent hydrophobic and thermal resistance properties, and also displays a favorable solubility in solvents used for paints, resists, and the like.

Owner:MITSUBISHI CHEM CORP

Method of manufacturing bulk single crystal of gallium nitride

Owner:AMMONO SP Z O O (PL) +1

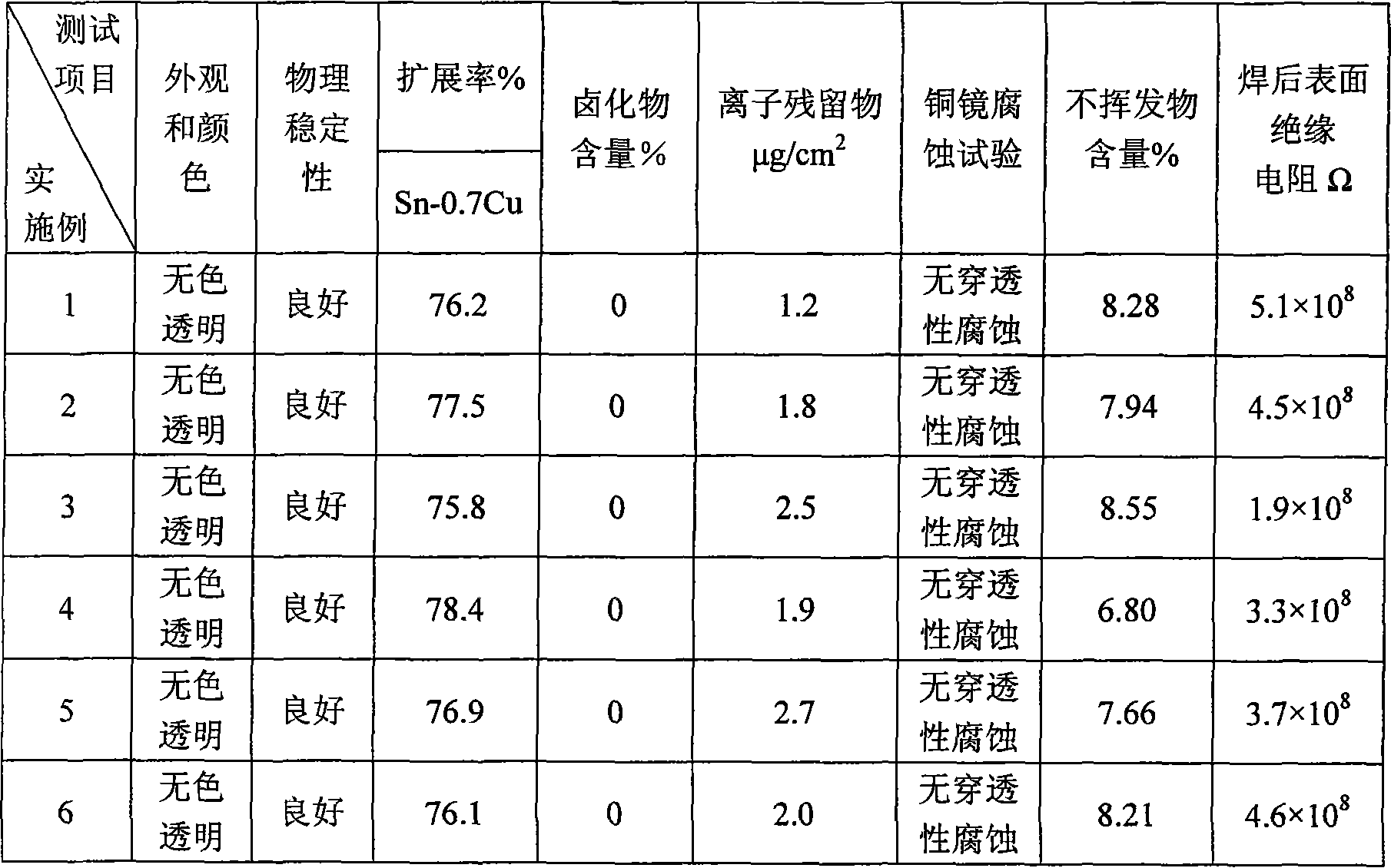

Free from cleaning soldering flux without halogen and rosin in use for solder without lead

InactiveCN101049661AImprove solderabilitySolderability is sufficientWelding/cutting media/materialsSoldering mediaHalogenSoldering

Owner:BEIJING UNIV OF TECH

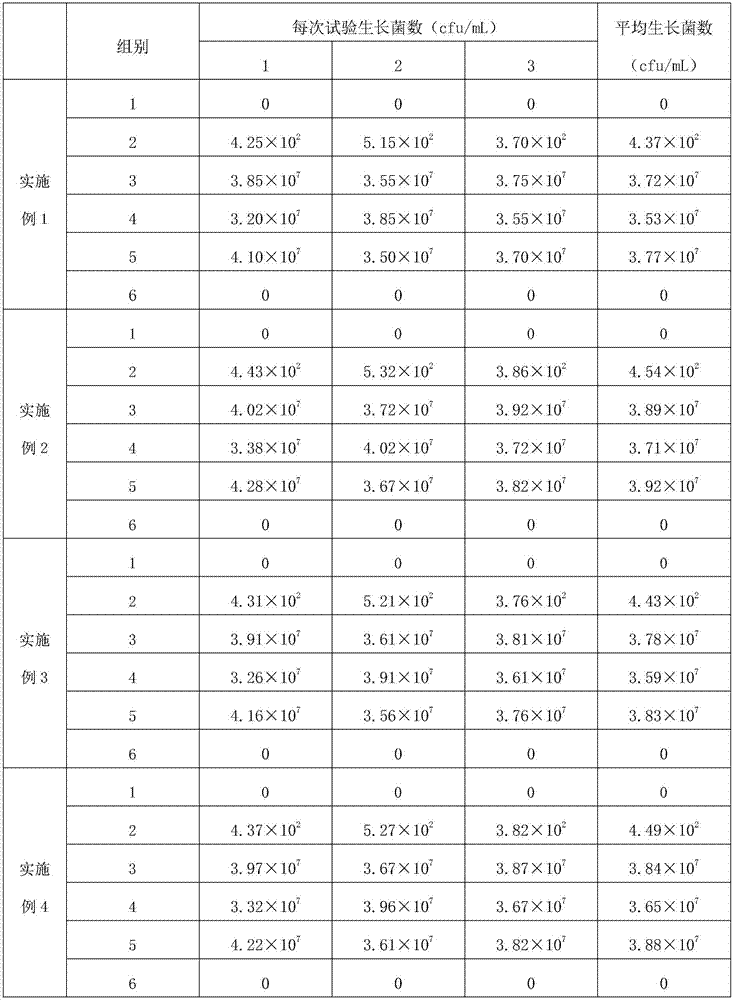

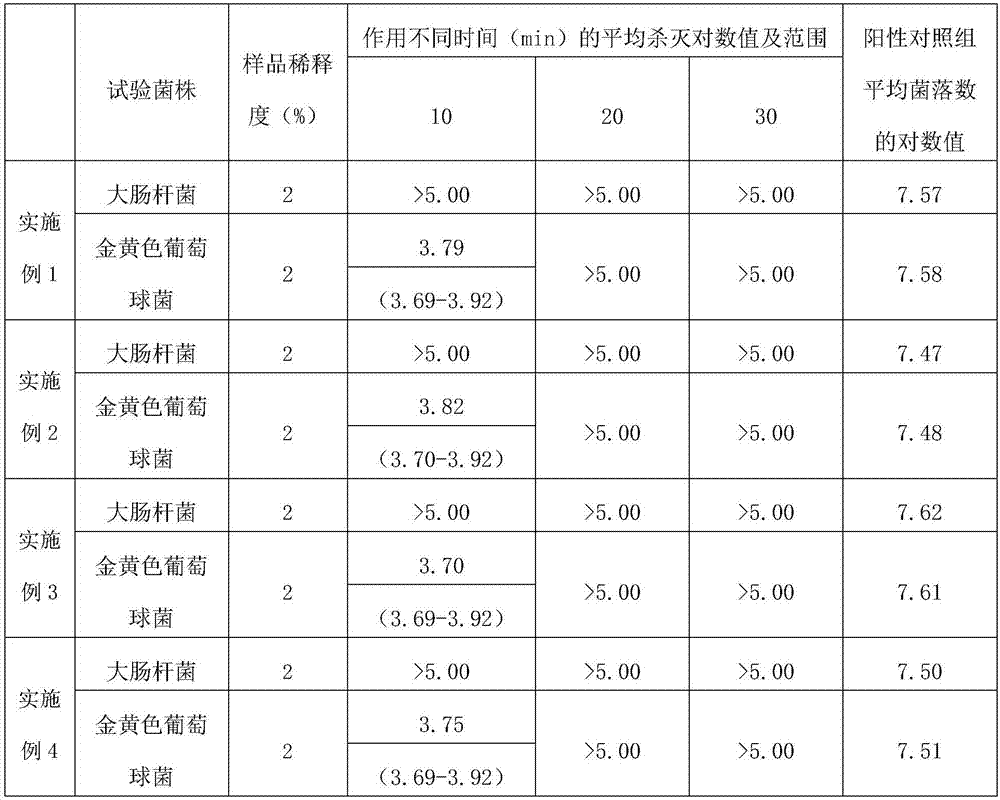

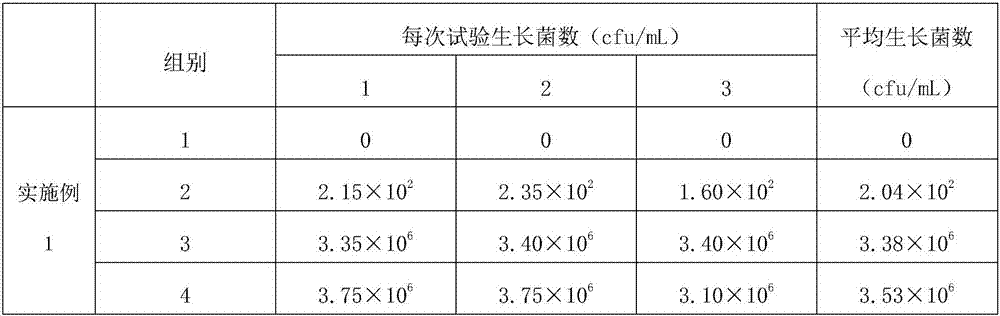

Stink and odor removal liquid with sterilizing plants, and preparation method and application thereof

Owner:深圳市寰保化工科技有限公司

Ink set for ink-jet recording, ink-jet recording method and ink-jet recording apparatus

InactiveUS20050012796A1Measurement apparatus componentsDuplicating/marking methodsWater solubleSolvent

Owner:FUJIFILM BUSINESS INNOVATION CORP

Propellant for fireworks and crackers

Owner:LILING HENGDA FIREWORKS

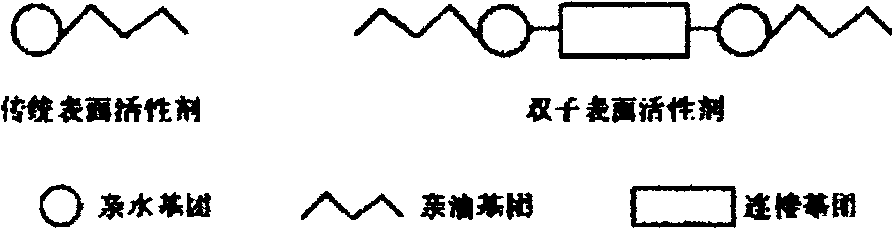

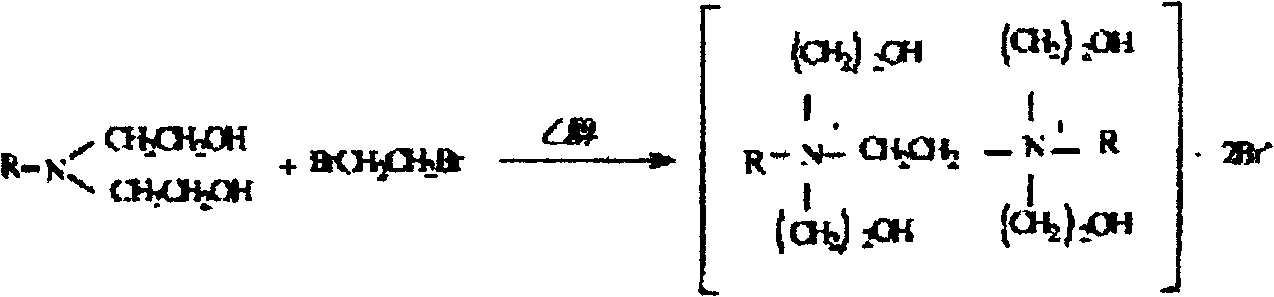

Synthetic method of gemini quaternary ammonium salt surfactant and application as drag reduction agent

Owner:TIANJIN VOCATIONAL INST

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareImprove performanceLiquid carbonaceous fuelsFuel additivesNew energyOil additive

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:YONGZHOU JINZHEN NEW ENERGY DEV CO LTD

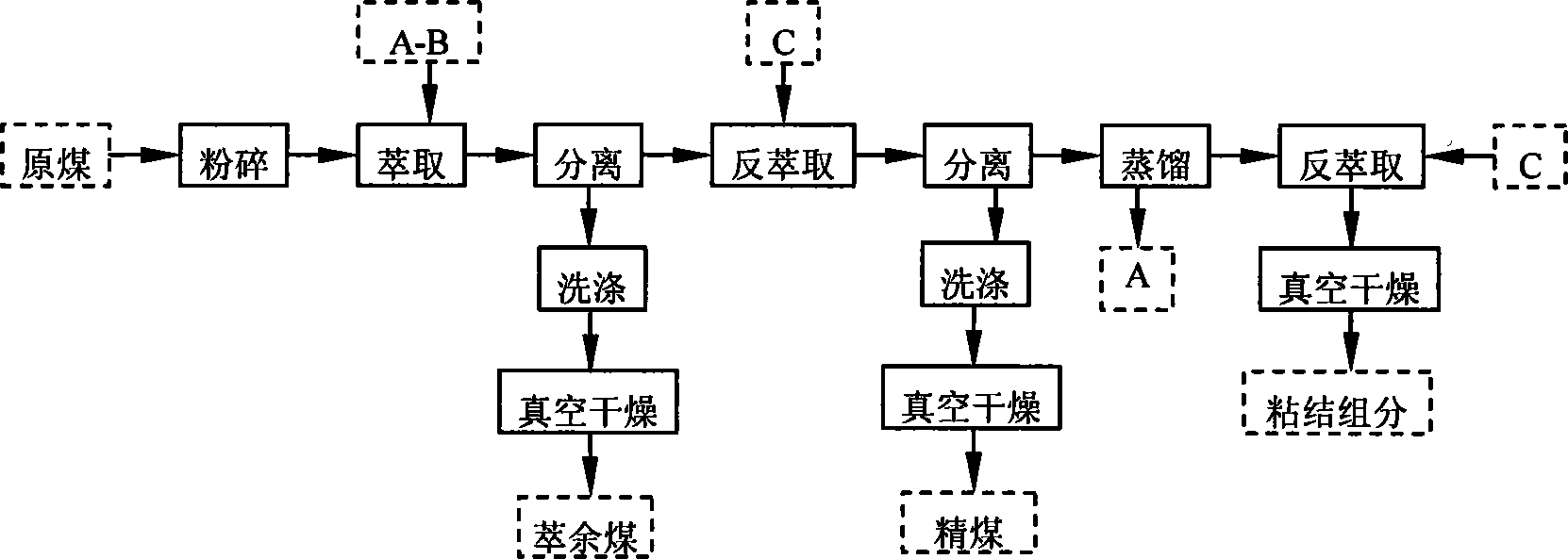

Mild coal-family component separation method based on extraction and back extraction

InactiveCN101070495AEasy to useImprove environmental benefitsSolid fuelsSolid solvent extractionWater useDistillation

Owner:CHINA UNIV OF MINING & TECH

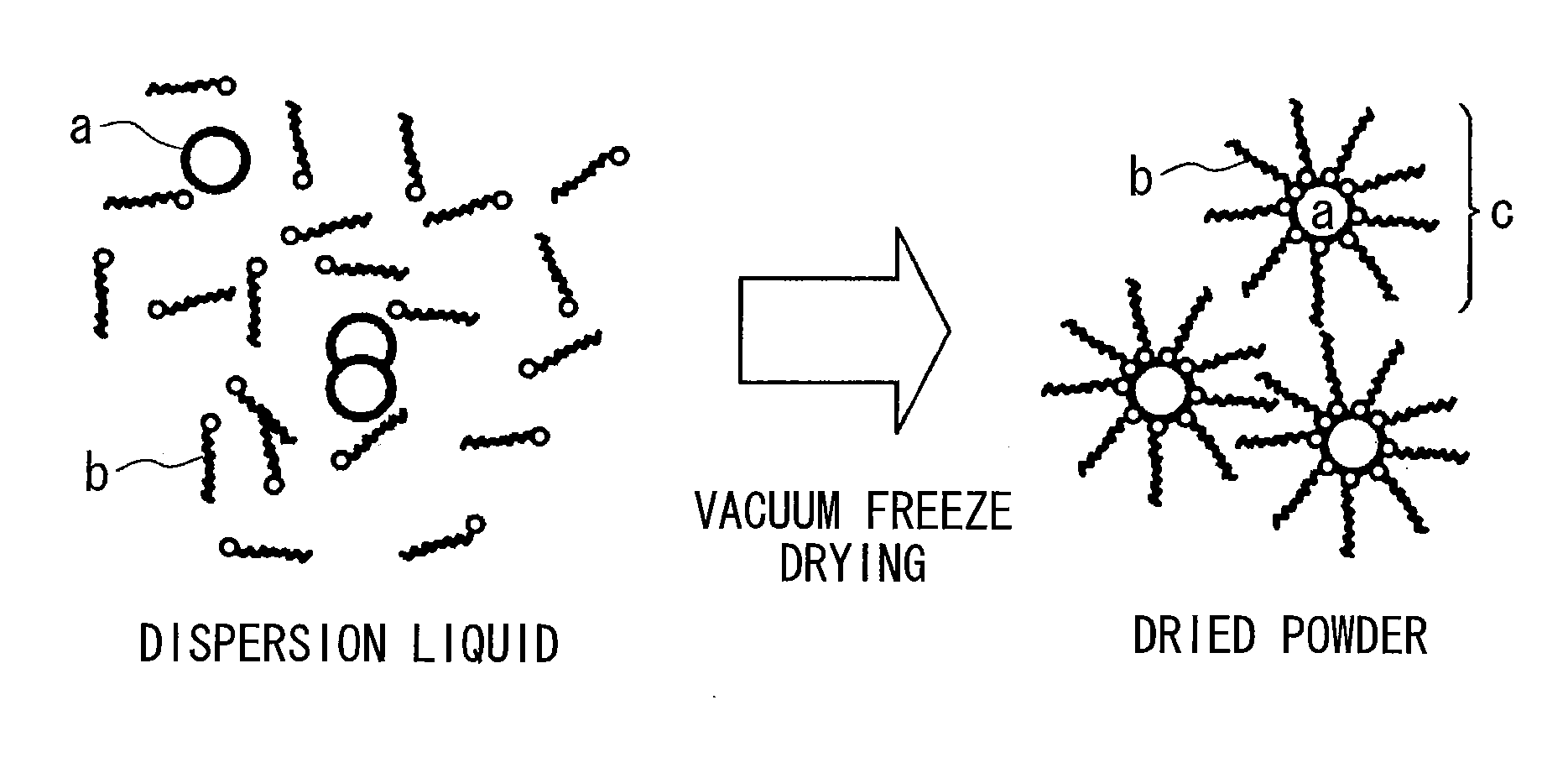

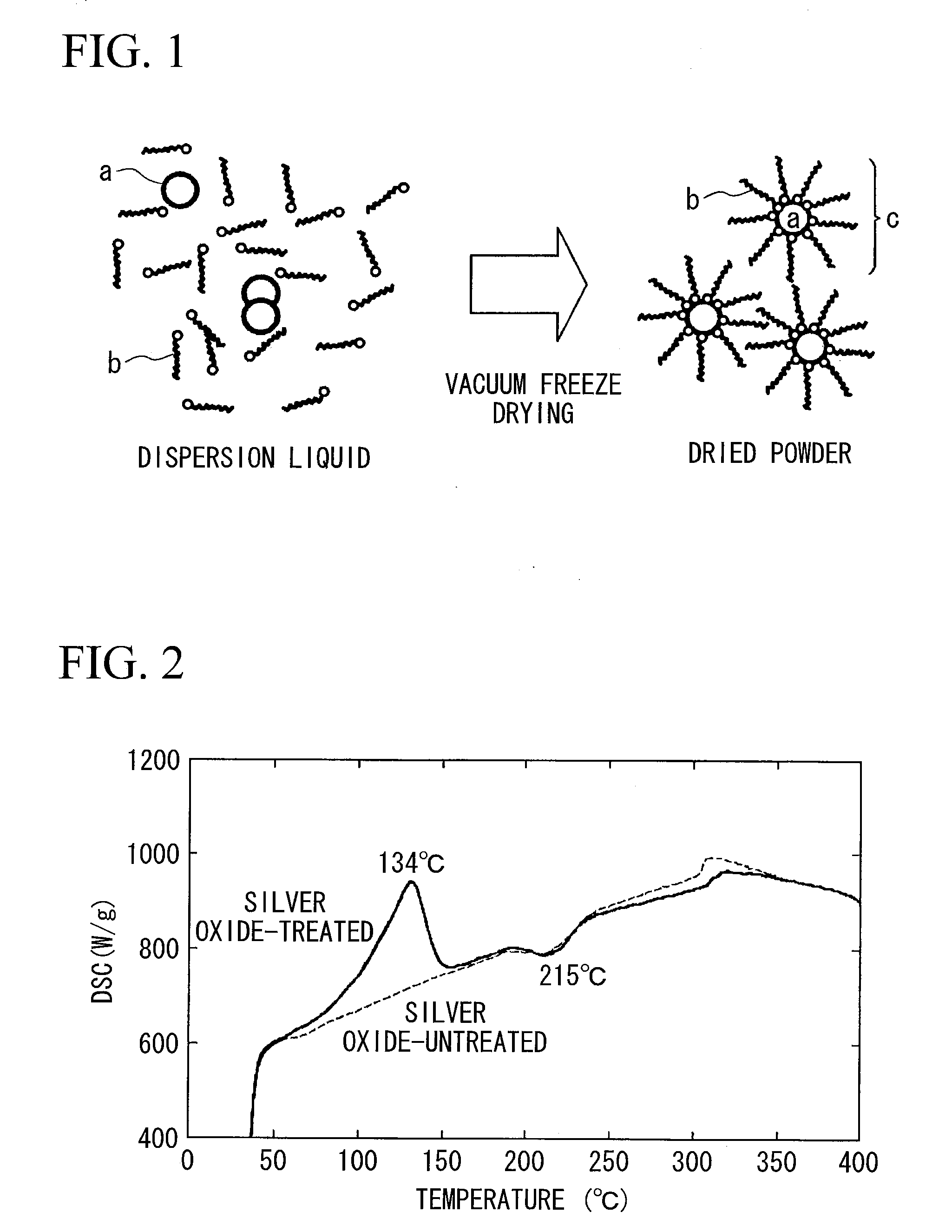

Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

InactiveUS20090146117A1Easy to produceConvenient and stableMetal-working apparatusConductive materialSilver pastePhosphate

Owner:DAINIPPON INK & CHEM INC

Method for sealing holes of micro arc oxidation film at room temperature

Owner:SOUTHWEST PETROLEUM UNIV

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1587457AImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The present invention relates to preparation process of precursor fiber of cellulose base carbon fiber in chemical fiber production. The preparation process includes mixing concentrated NMMO aqua and carbon black for carbon black water in the weight ratio of 20-10000, decomprssion distillation to obtain NMMO / carbon black solution with water content 24-28 wt%, adding the mixtue of sliced cellulose pulp and NMMO / carbon black solution in the weight ratio of 5-15 to 100 into dissolving reactor, swelling and stirring at 70-90 deg.c, raising the temperature to 90-120 deg.c, stirring and decomprssion distillation to eliminate water and form cellulose / NMMO / carbon black spinning liquid with water content of 12-14 wt%, and dry-wet spinning to obtain the precursor fiber. The present invention has high carbonizing yield, high mechanical performance of the carbon fiber, raised spinnability of the spinning liquid, non-toxic solvent, high solvent recovering rate and environment friendship.

Owner:DONGHUA UNIV

Surface-aided melt infiltration for producing a ceramic matrix composite

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

Resin composition and semi-solidifying sheet for printed board prepared from the same

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of nemadectin

Owner:CHONGQING DAXIN PHARMA +2

Preparation method of zirconium oxide-silicon oxide composite aerogel

ActiveCN103214034ALow densityLow thermal conductivitySilicon compoundsZirconium oxidesAlcoholSilicon oxide

The invention relates to a preparation method of zirconium oxide-silicon oxide composite aerogel. The method comprises the following steps of: dissolving siloxane in alcohol and uniformly stirring the solution to obtain alcohol solution of the siloxane; titrating concentrated nitric acid with 65-68% of mass concentration, titrating deionized water after stirring uniformly and continuously stirring; titrating the concentrated nitric acid to the pre-hydrolyzed siloxane solution, titrating zirconium alkoxide after mixing uniformly, adding the deionized water after stirring uniformly and stirring continuously to obtain clear and transparent gel; transferring the gel to a mould, and still standing and aging the gel to obtain the zirconium oxide-silicon oxide composite wet gel; soaking the wet gel by using aging solution; and finally soaking the gel by using absolute ethyl alcohol or isopropanol solvent. The blocky zirconium oxide-silicon oxide composite aerogel featured with low density and low thermal conductivity prepared by the invention basically keeps the former microcosmic undefined structure after thermal treatment at 1000 DEG C, and has specific area up to 353m<2> / g and good high-temperature stability.

Owner:LINXIAO (TIANJIN CHINA) TECH CO LTD

Crystal form G of ibrutinib and preparation method

InactiveCN105646499AImprove stabilityHigh purityOrganic active ingredientsOrganic chemistry methodsSolubilitySolvent

The invention discloses a crystal form G of ibrutinib. The crystal form G is characterized in that X-ray powder diffraction (X-RPD) which adopts Cu-Kalpha radiation and is represented with a 2theta angle has diffraction peaks in positions at angles of 5.0 degrees plus or minus 0.2 degrees, 7.3 degrees plus or minus 0.2 degrees, 10.1 degrees plus or minus 0.2 degrees, 12.0 degrees plus or minus 0.2 degrees, 13.2 degrees plus or minus 0.2 degrees, 17.1 degrees plus or minus 0.2 degrees, 19.5 degrees plus or minus 0.2 degrees, 20.8 degrees plus or minus 0.2 degrees, 22.3 degrees plus or minus 0.2 degrees, 24.3 degrees plus or minus 0.2 degrees, 27.4 degrees plus or minus 0.2 degrees and 31.2 degrees plus or minus 0.2 degrees. Related solvents in a preparation process of the crystal form G are cheap, the conditions are mild, the operation is simple, good controllability and reproducibility are realized, further, the prepared crystal form has great stability, the HPLC (high performance liquid chromatography) purity is higher than 99%, and the phenomenon of crystal transformation can be avoided; besides, the solubility is high, the dissolubility is good, and the bioavailability is high.

Owner:孙霖

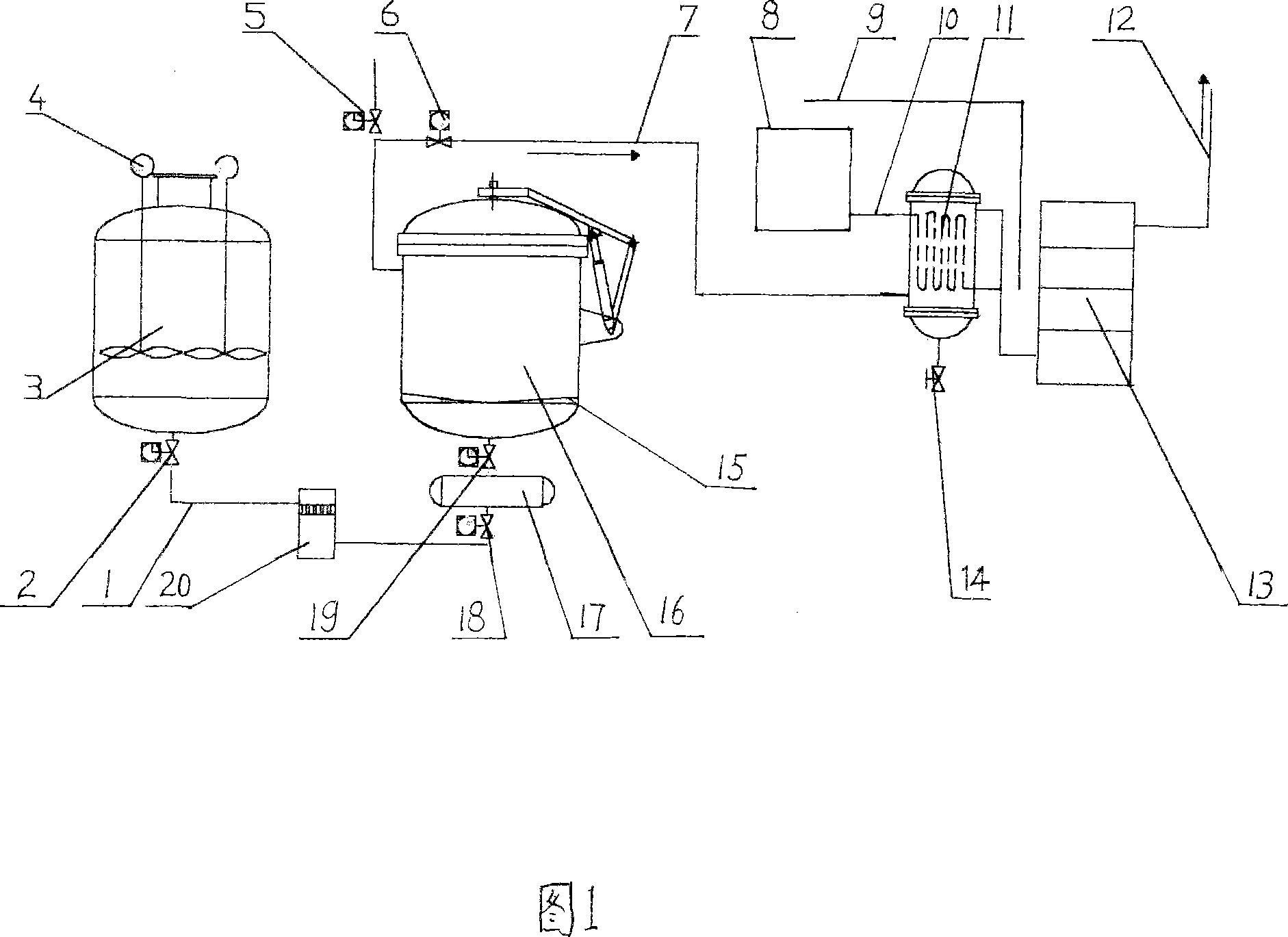

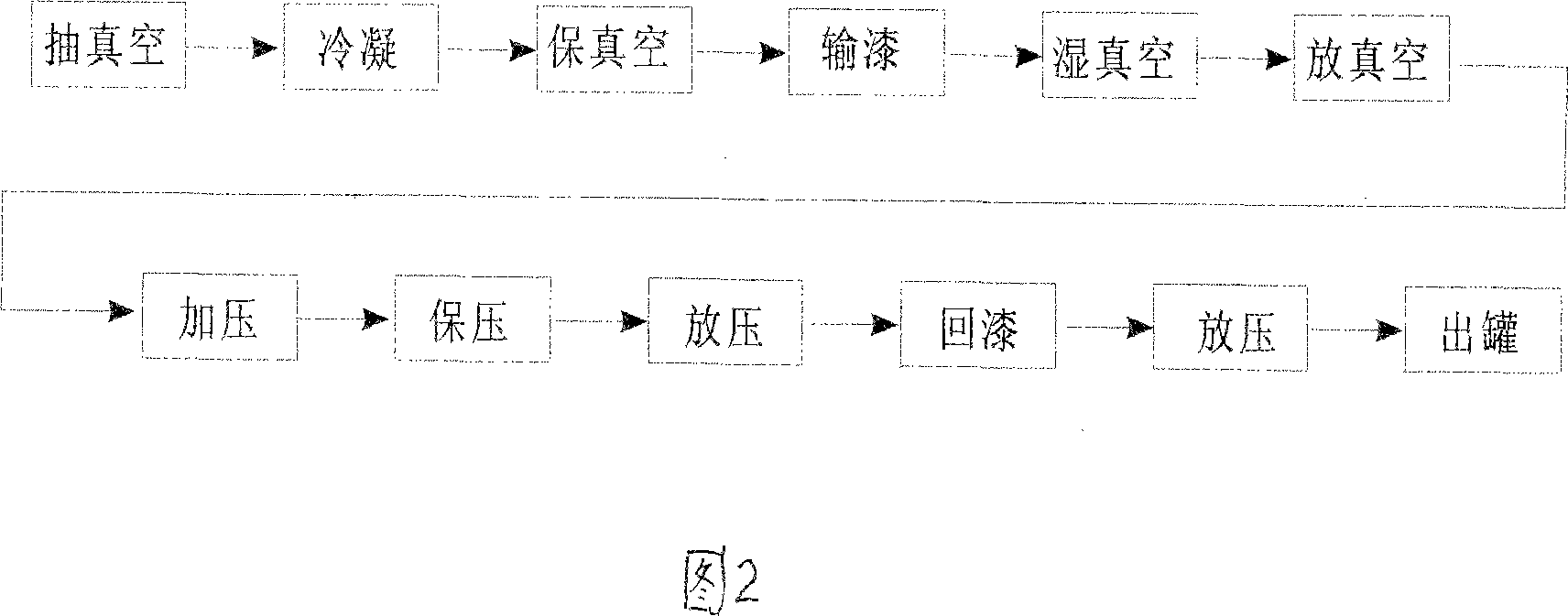

Anti-explosion vacuum pressure varnished insulation apparatus and its technical method

InactiveCN101064456ALiquid surface applicatorsManufacturing dynamo-electric machinesSolventVacuum pressure

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

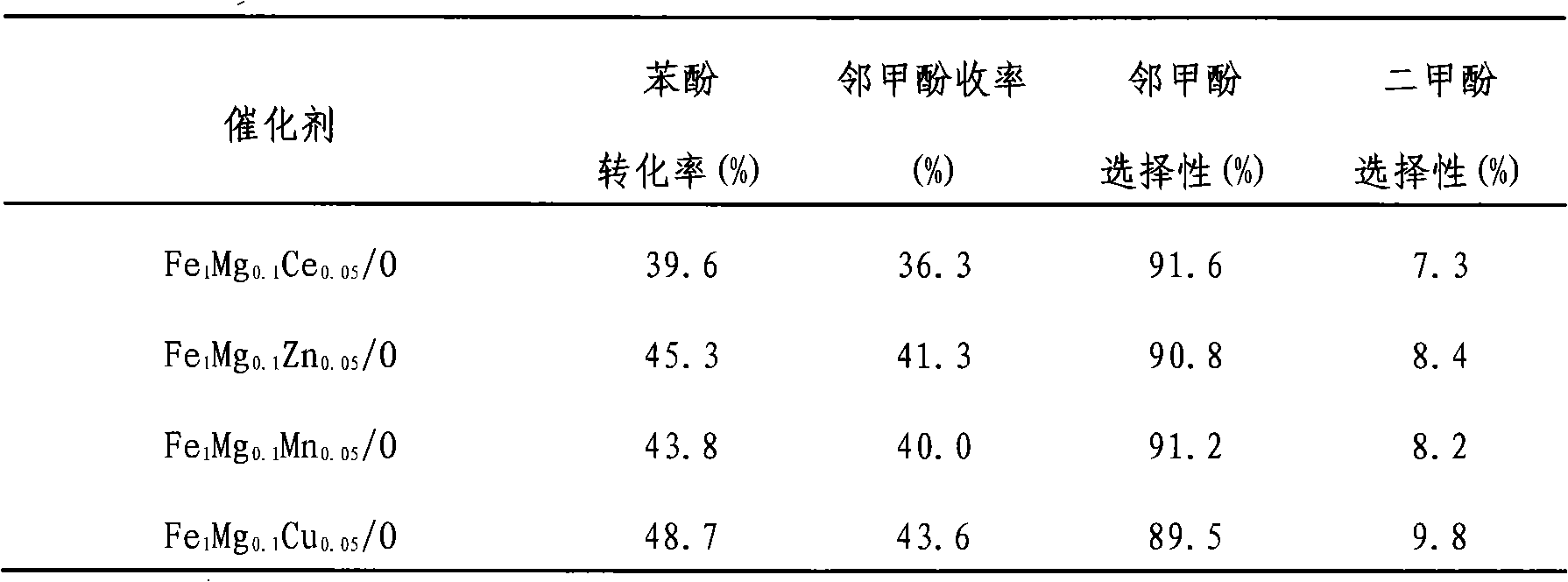

Phenol ortho-methylation catalyst and preparation method thereof

ActiveCN101513614AEasy to makeLow reaction temperatureOrganic chemistryOrganic compound preparationMagnesium saltOrtho position

Owner:HUNAN XINLING CHEM CO LTD

High abrasion-proof PU printing ink for silicon rubber surface

Owner:东莞市贝特利新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap