Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Batch production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch production is used for many types of manufacturing that may need smaller amounts of production at a time to ensure specific quality standards or changes in the process. This is opposed to large mass production or continuous production methods where the product or process does not need to be checked or changed as frequently or periodically.

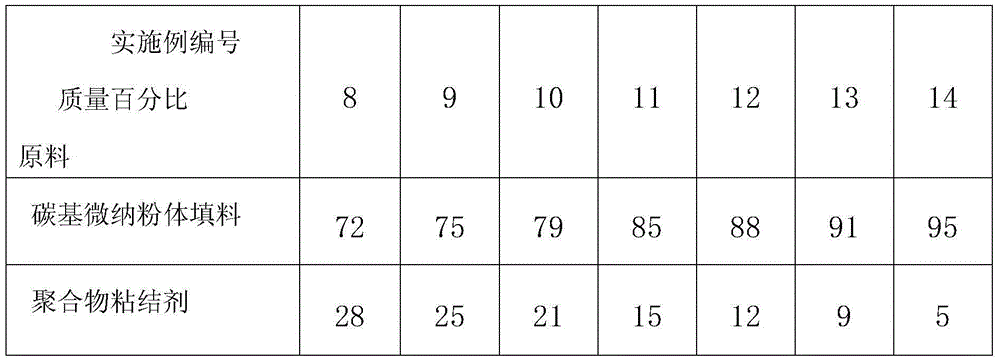

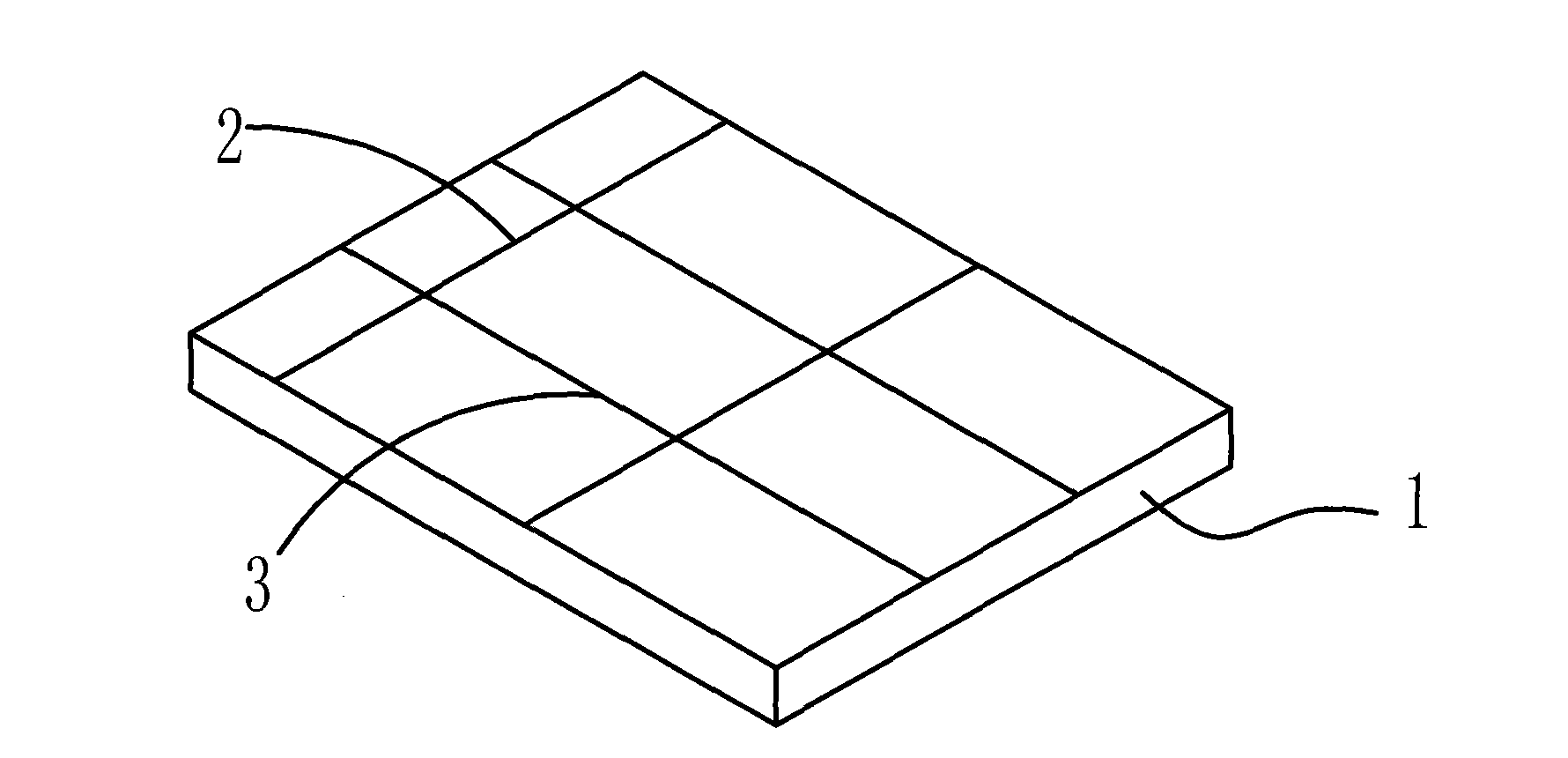

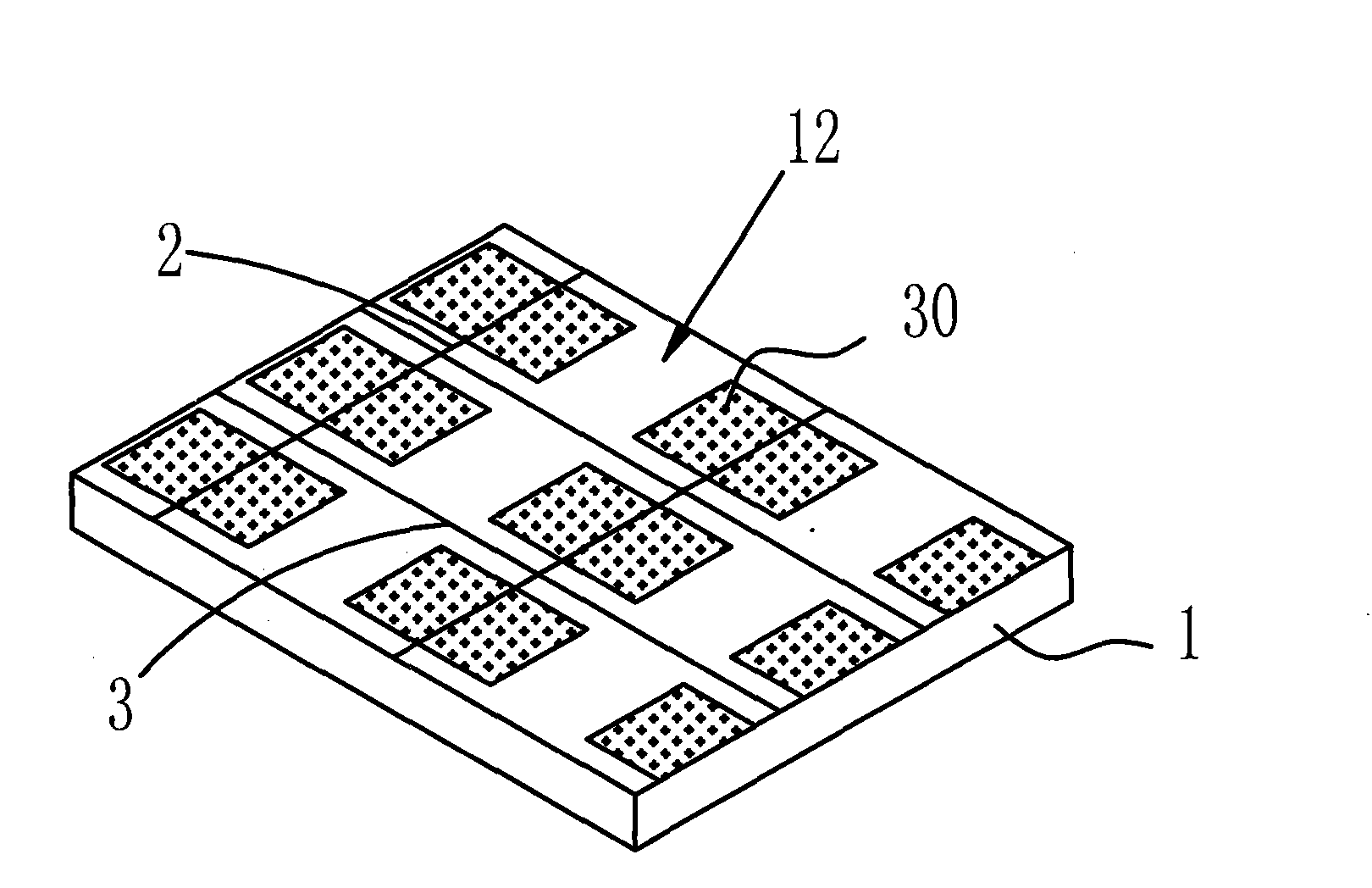

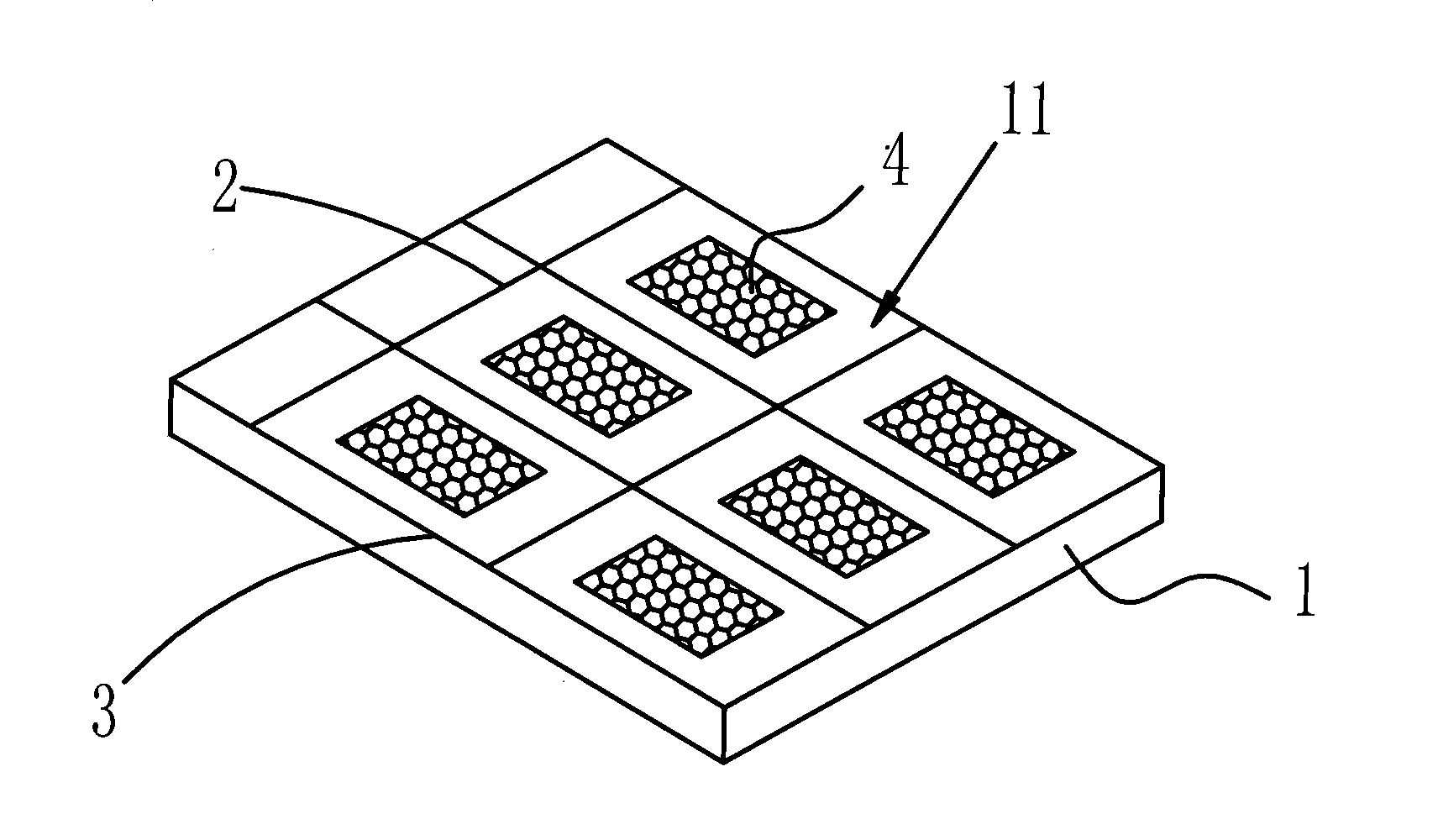

High-thermal-conductivity high-electrical-conductivity carbon nano-grade composite material and preparation method thereof

InactiveCN104130753AImprove production efficiencyGood thermal conductivityHeat-exchange elementsDisplay deviceElectron

Owner:SOUTHWEAT UNIV OF SCI & TECH

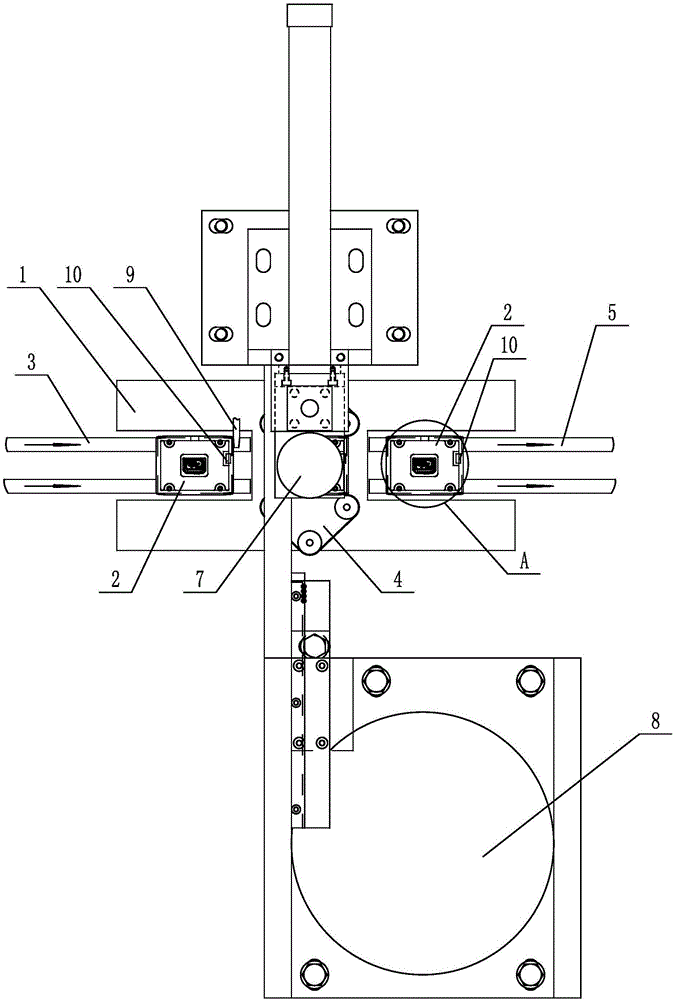

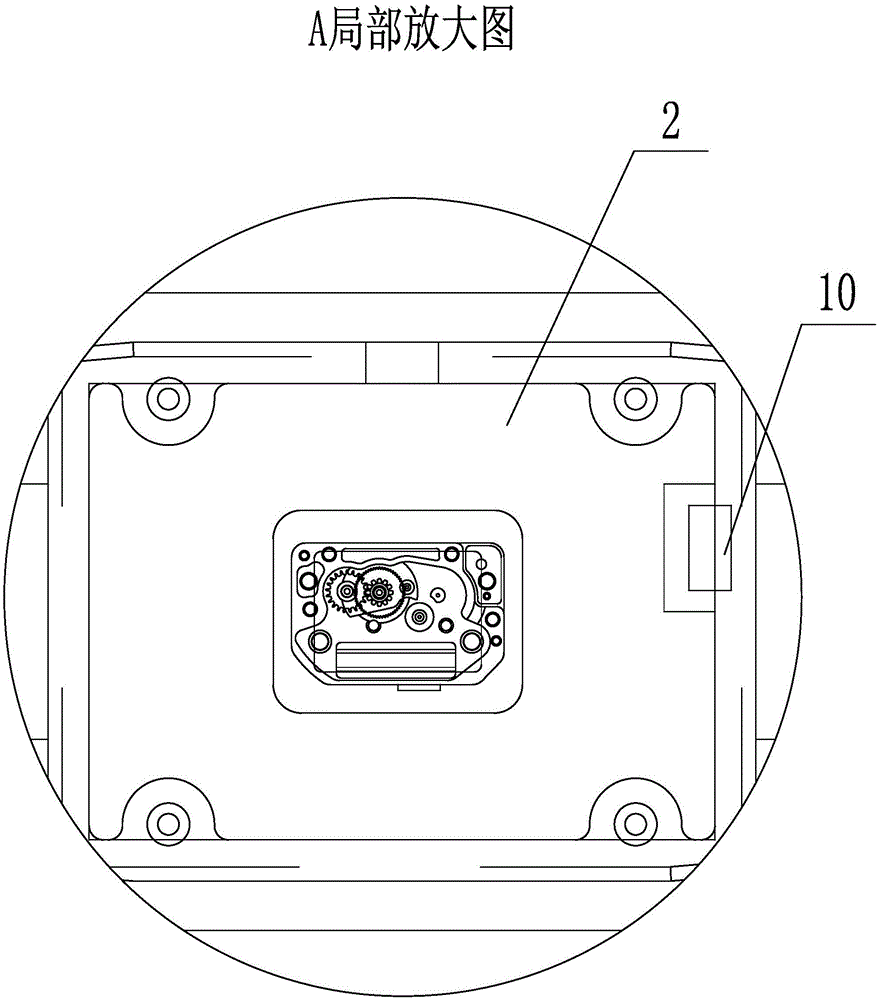

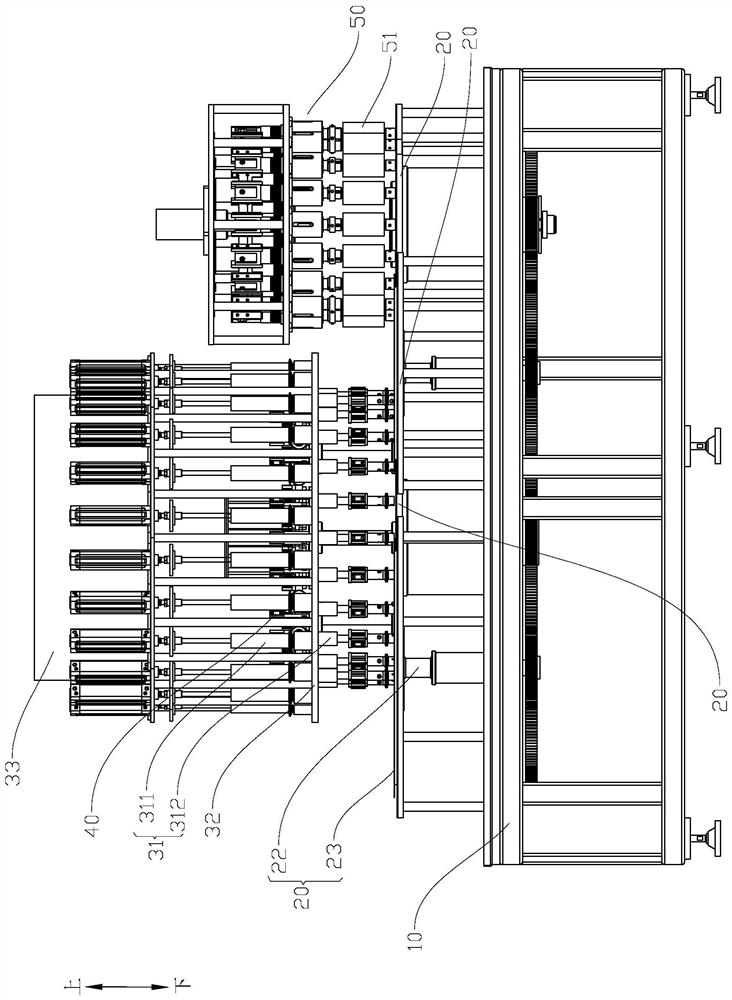

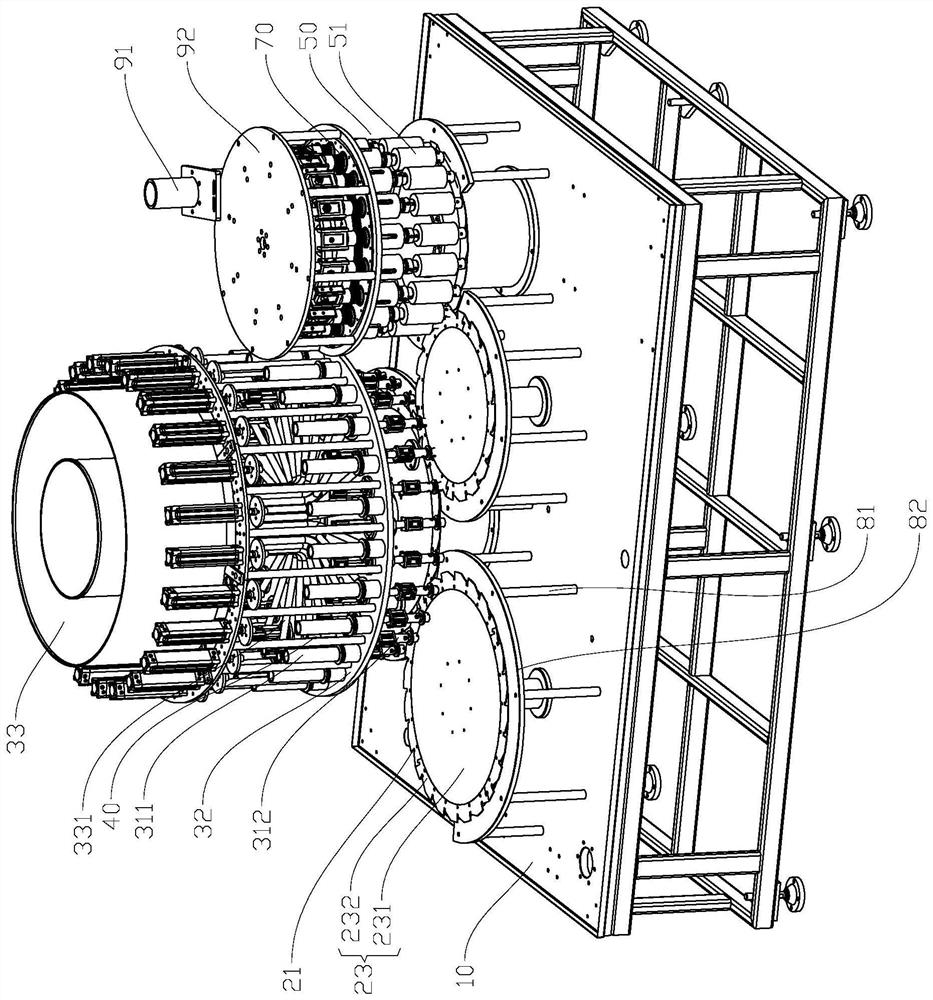

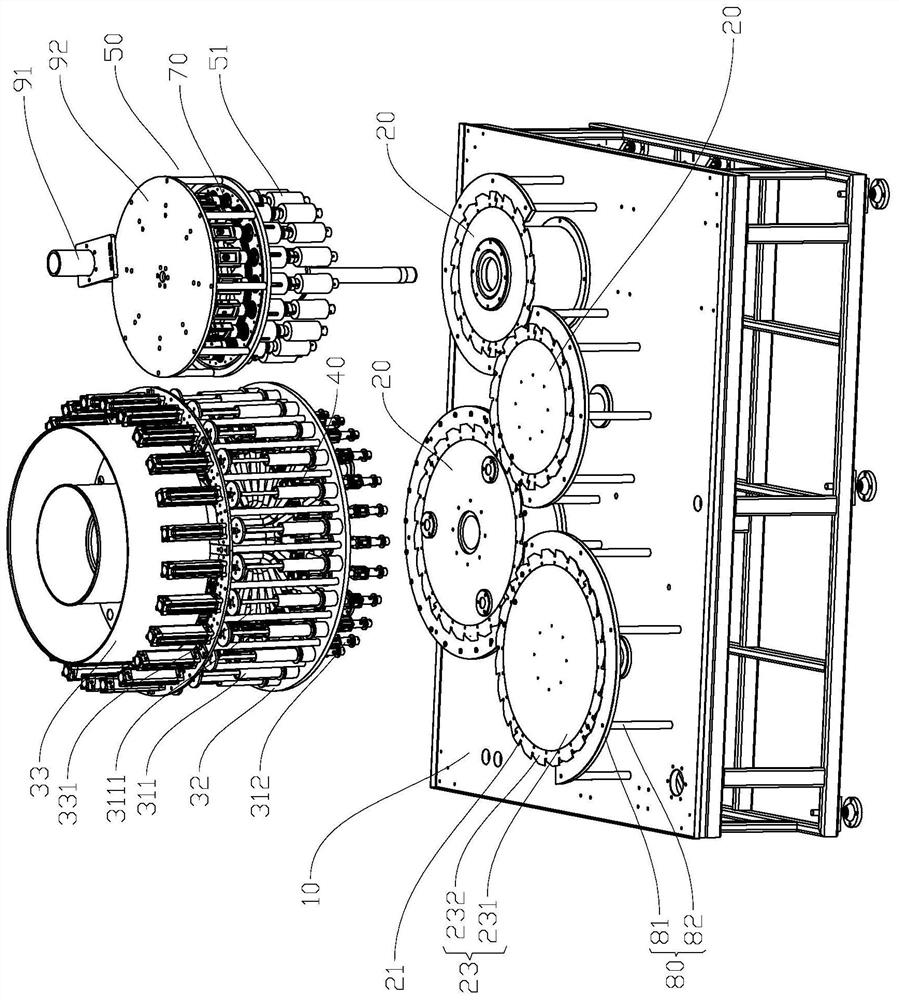

Watch movement gear automatic assembly production line

ActiveCN105710645AFully automatedIncrease productivityAssembly machinesProduction lineManufacturing cost reduction

Owner:FUJIAN GUOYI SHANGRUN INVESTMENT CO LTD

Method for adjusting resistance value of NTC thermistor chip

InactiveCN102136328AHigh precisionRealize precise resistance adjustment processNegative temperature coefficient thermistorsTemperature controlElectrical resistance and conductance

Owner:ZHAOQING EXSENSE ELECTRONICS TECH

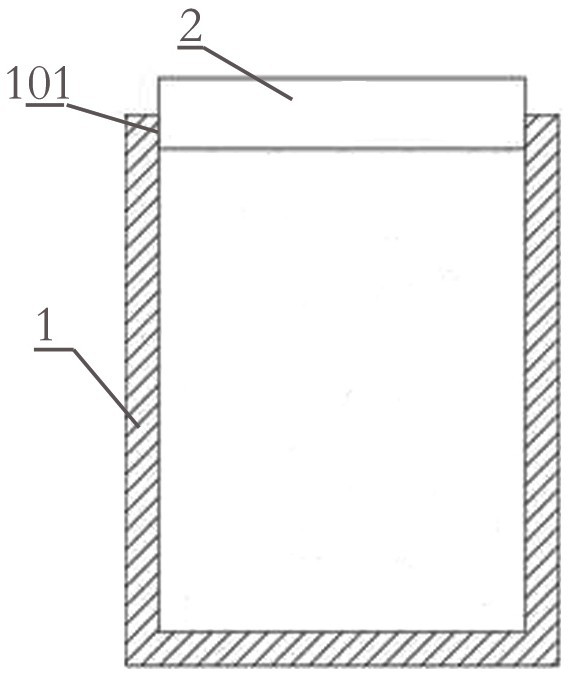

Method for hot-rolling manufacture of ultra-pure ferrite stainless steel

ActiveCN103506383ASolve hot rolling sticking problemSolve sticking problemsMetal rolling arrangementsReduction rateMaterials science

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

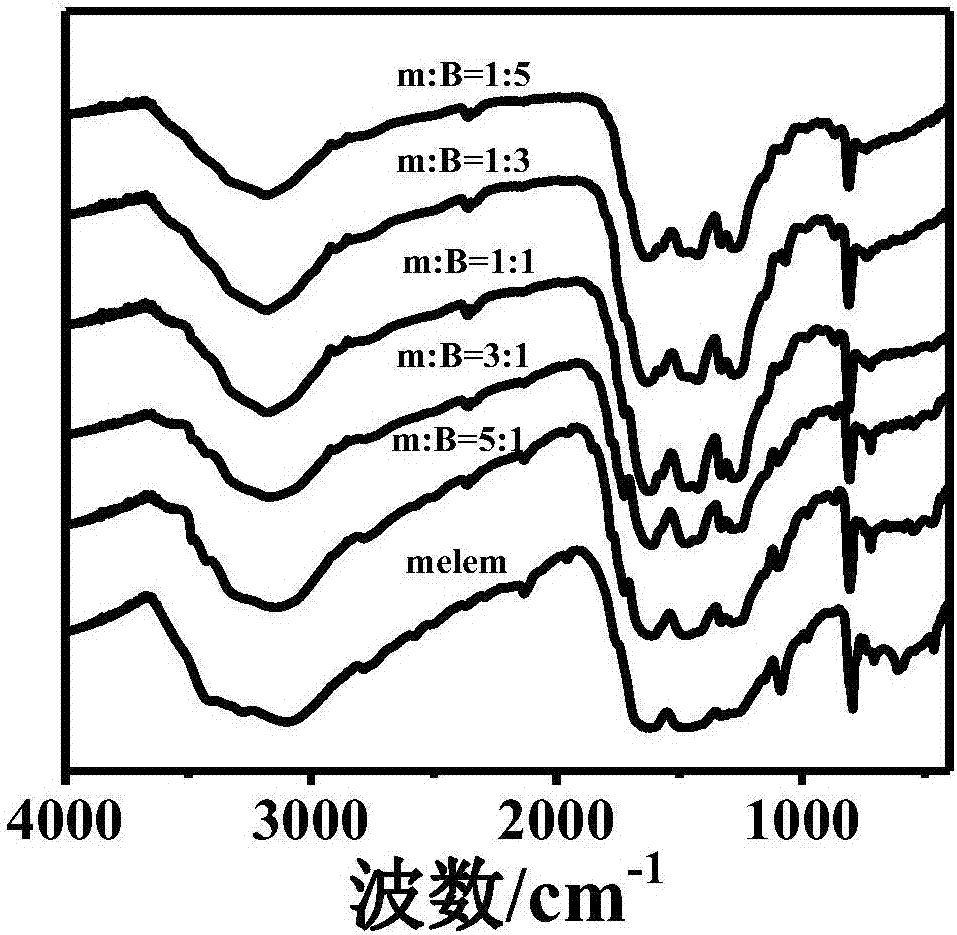

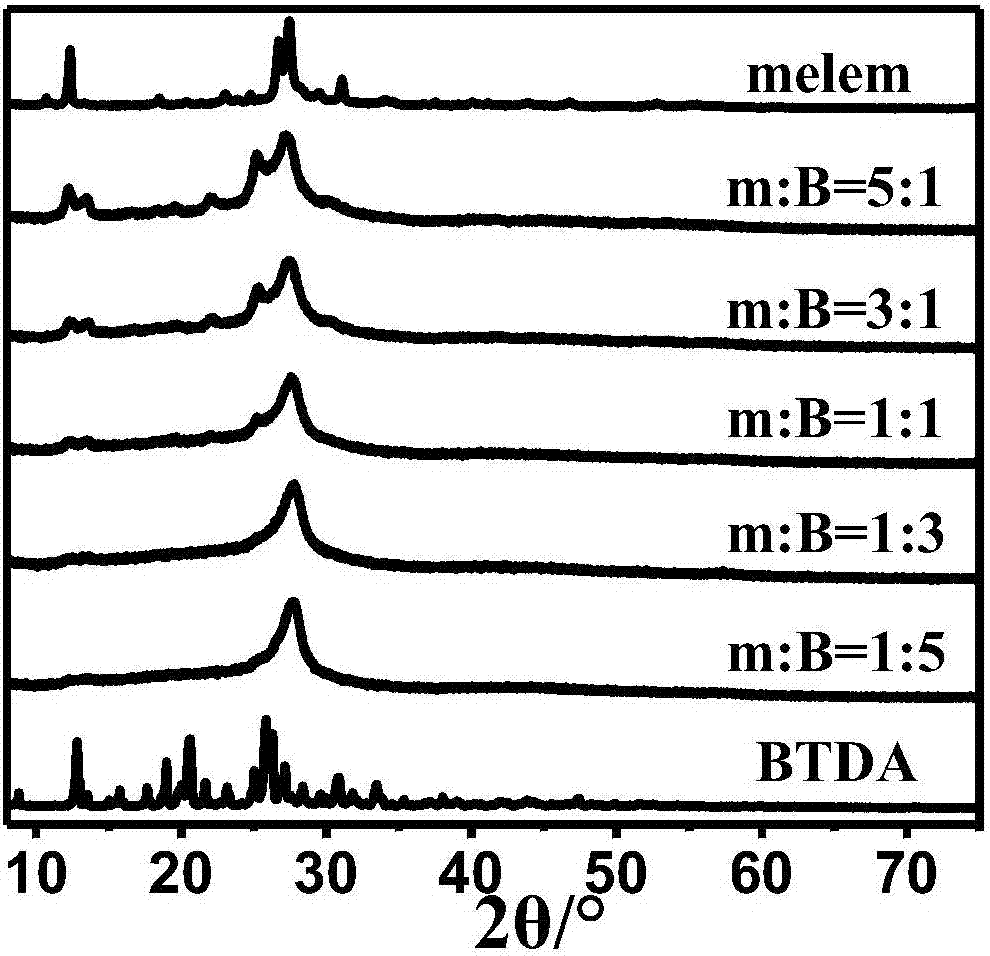

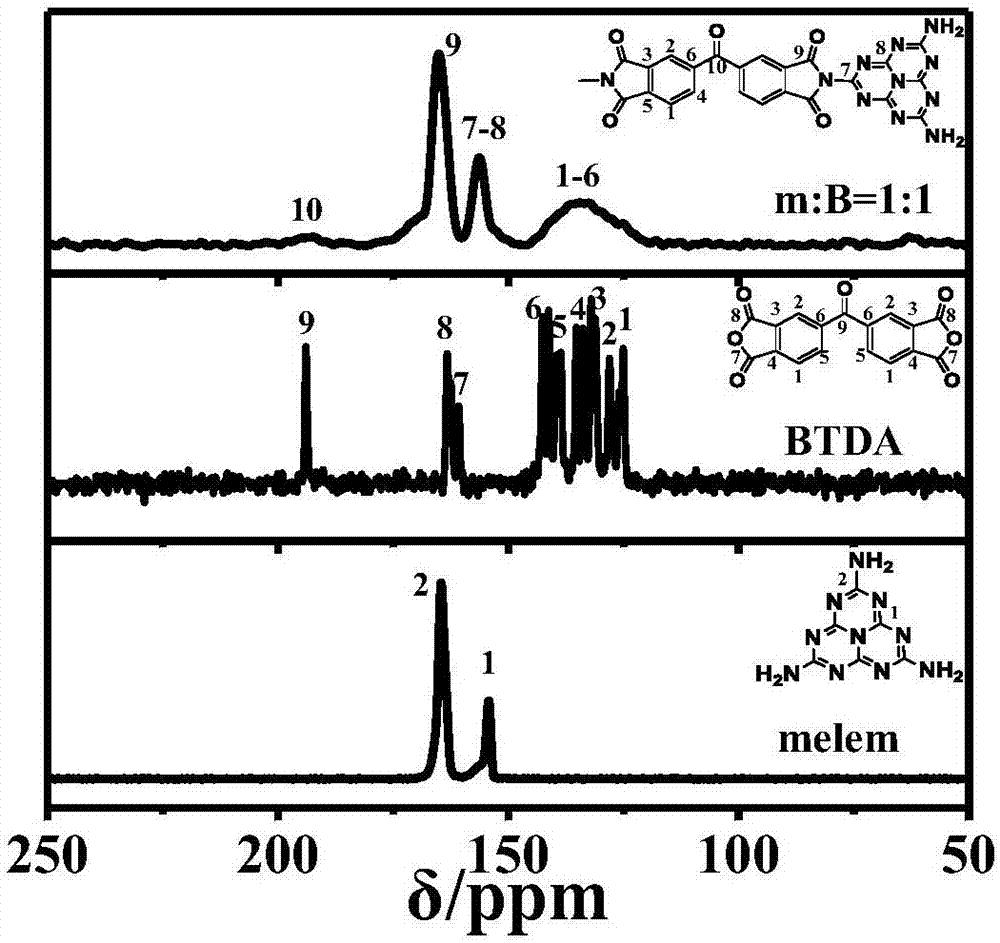

One-step copolymerization method for preparing efficiently-selective carbon nitride photocatalyst

ActiveCN106902876AEasy to separateRaw materials are easy to getQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsValence bandSinglet oxygen

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Manufacturing method of surface mounted device resistor

ActiveCN102082017ALow costReduce dosageResistors adapted for applying terminalsSilver pasteSputtering

Owner:UNIROYAL ELECTRONICS IND

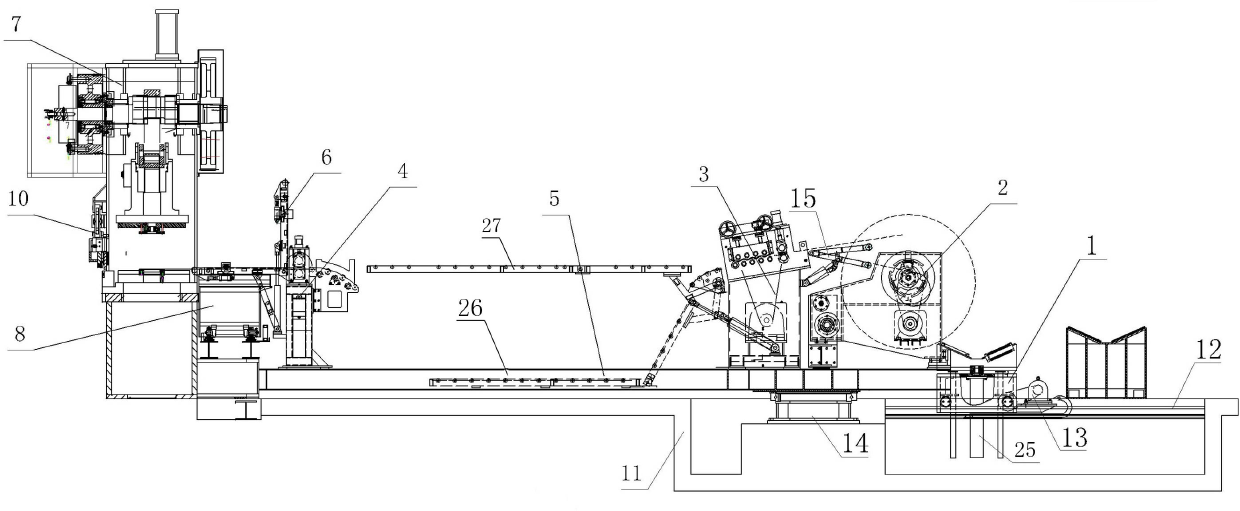

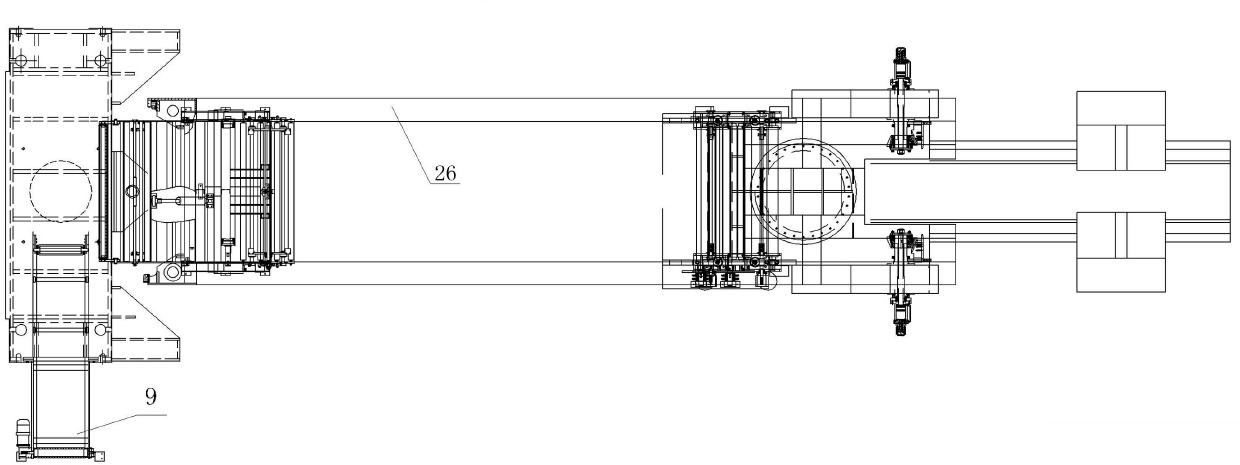

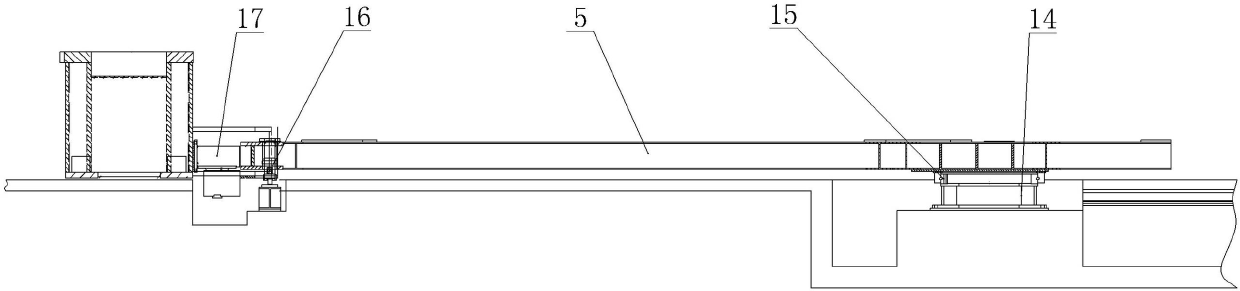

Wafer blanking production equipment and processing method

Owner:江苏华工蓝天智能科技有限公司

Mold cutter with improved mould-cutting knife structure suitable for reel material

InactiveCN101497202ALow mechanical strength requirementLow cost requirementsMetal working apparatusControl systemEngineering

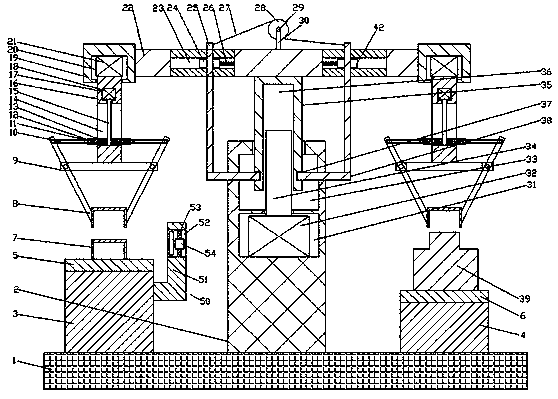

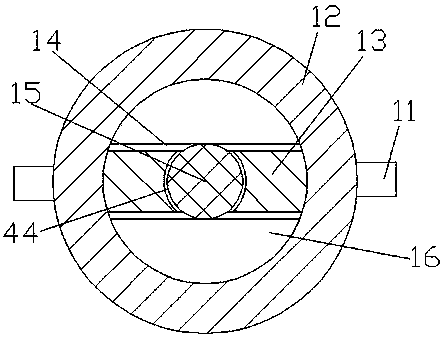

The invention discloses a die-cutting machine with improved die-cutting tool structure applicable to coiled materials, which can solve the technical problems that die-cutting tools in the prior art are high in cost, long in manufacturing period, poor in durability, complex in machine adjustment, heavy in machine, low in die-cutting quality, low in die-cutting speed, unsuitable for small-batch production, and the like. The die-cutting machine comprises a frame, as well as a coiled-material pulling unit, a coiled-material tensioning device, a mark detecting unit and at least one feed unit which are connected with a control system, wherein the coiled-material pulling unit controls coil material to move forwards along the length direction of the coiled material; the coiled-material tensioning device controls the coiled materials to move reversely along the length direction of the coiled materials; the mark detecting unit comprises marks arranged on the coiled material and a mark detecting sensor; the feed unit controls a die-cutting tool to move along the width direction of the coiled material and controls the die-cutting tool to penetrate or retract relative to the coiled materials; and the feed unit comprises a guide rail arranged along the width direction of the frame, a tool rest which is positioned on the guide rail and connected with a feeding motor, as well as a tool arranged on the tool rest.

Owner:杜建刚

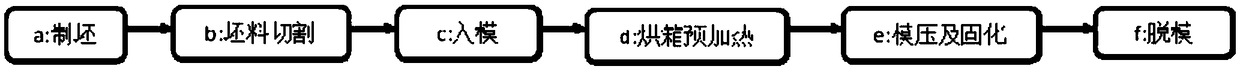

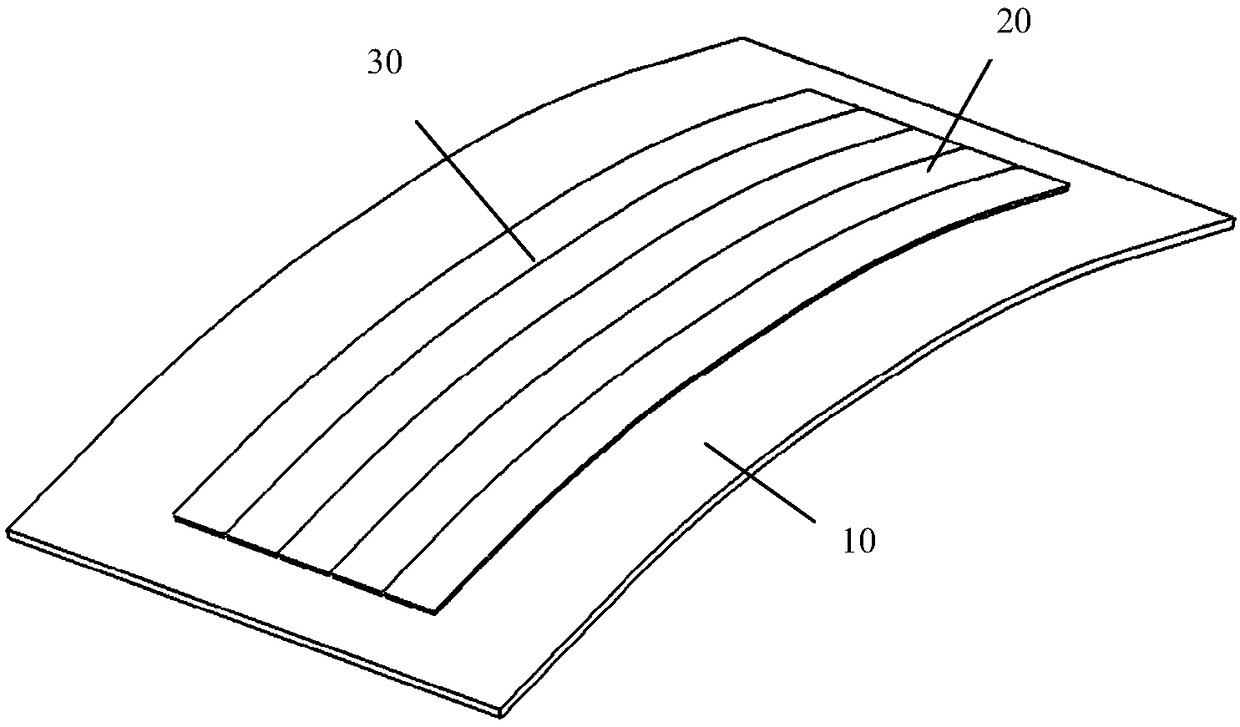

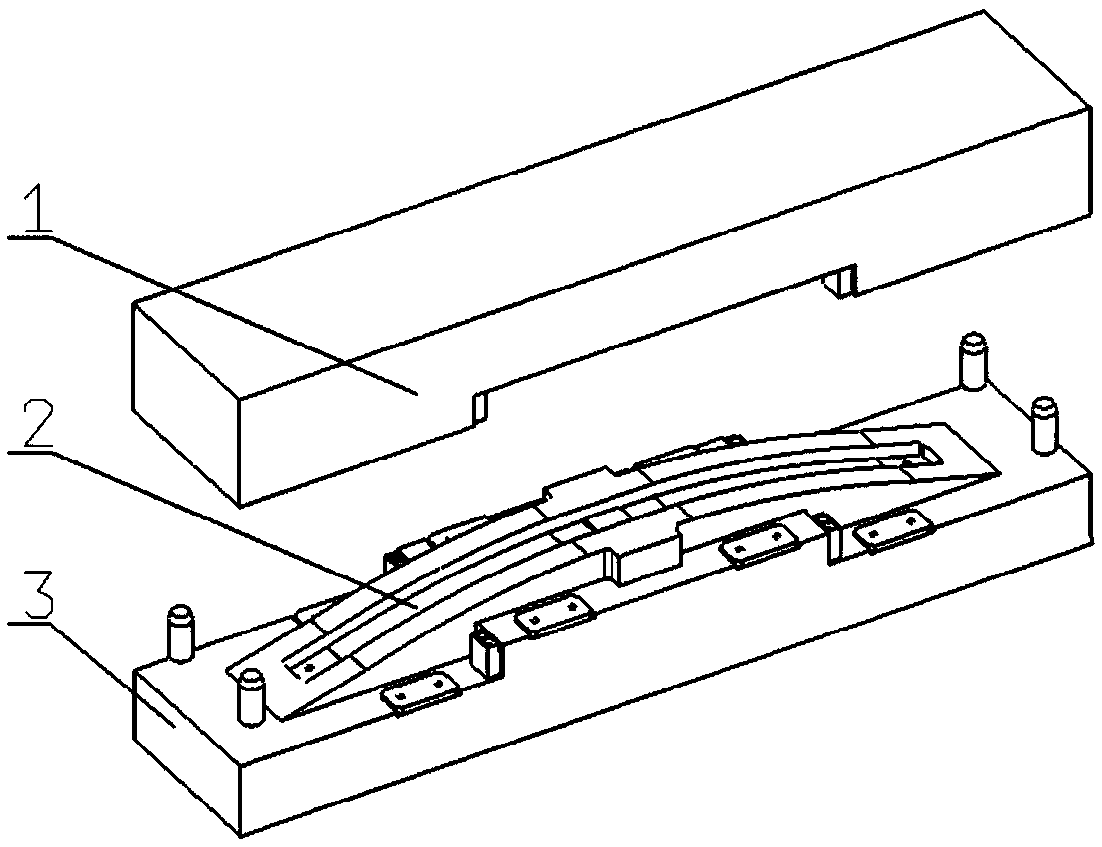

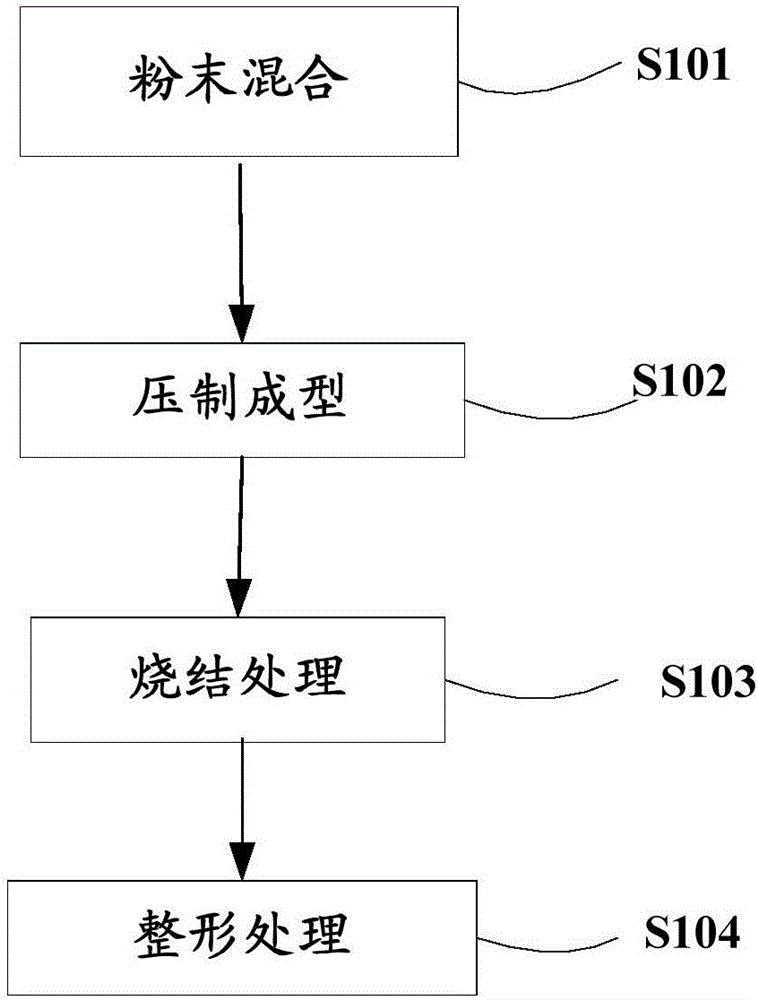

Production process method for die pressing composite material leaf springs

ActiveCN109228398ASolve the problem of high cost and unable to meet market demandIncrease productivityResin matrixResin-Based Composite

Owner:AVIC COMPOSITES

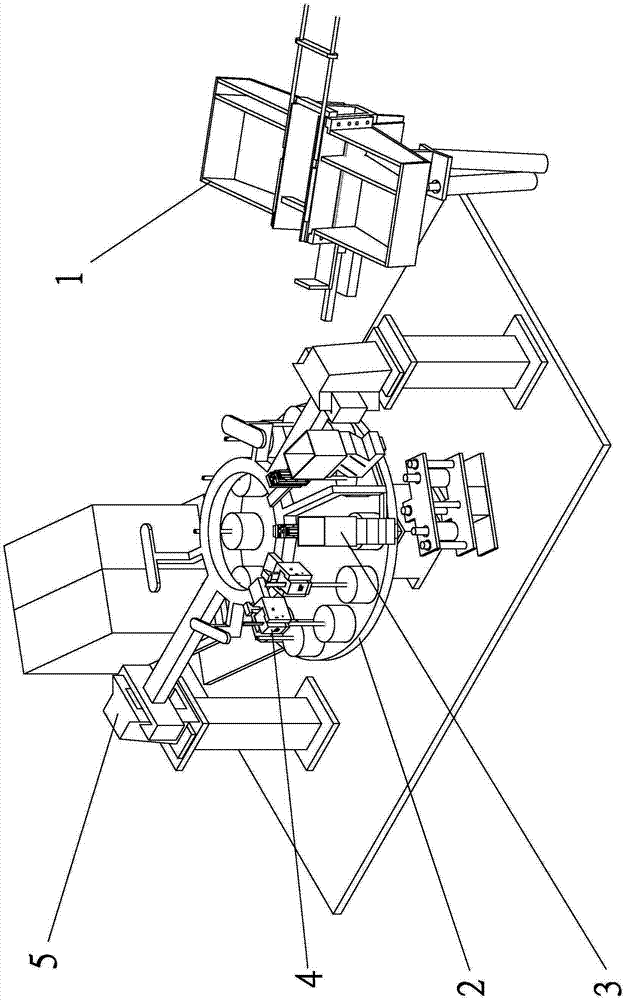

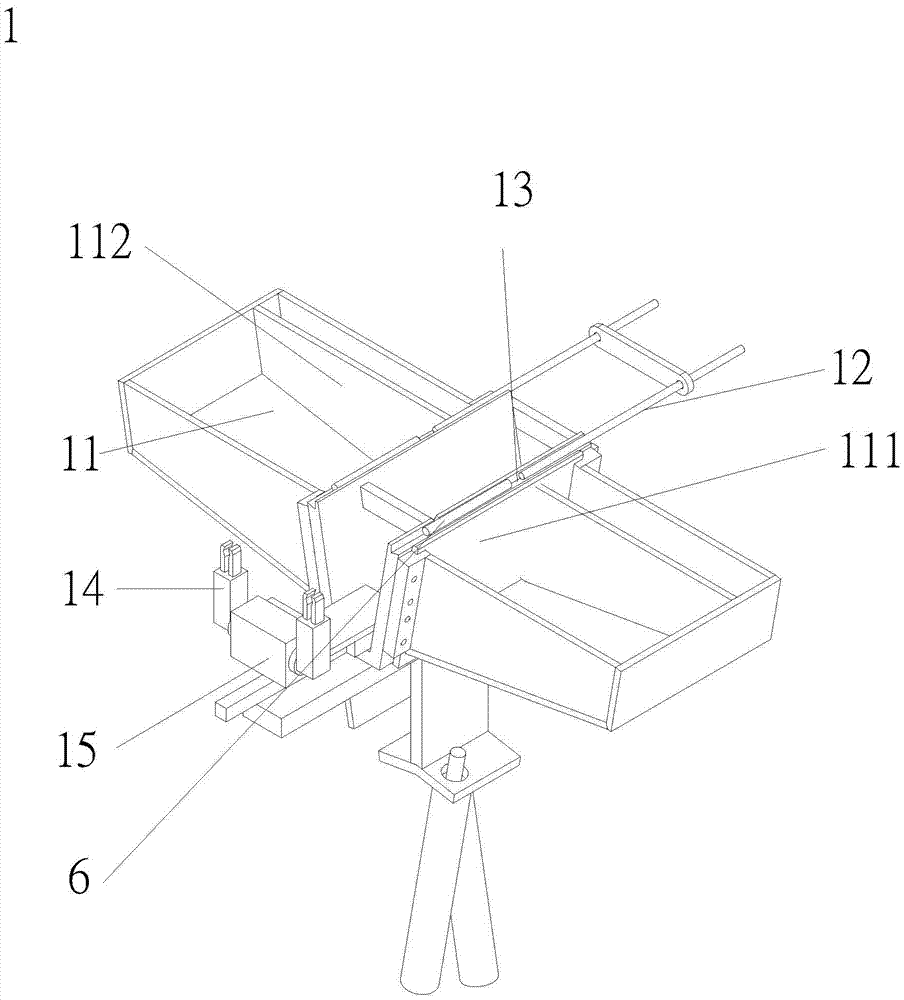

Nickel alloy automobile starting motor planetary gear and manufacturing method thereof

InactiveCN106270527AHigh precisionAvoid defects such as high noise and wear resistanceMetal-working apparatusPortable liftingHigh energyGear wheel

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

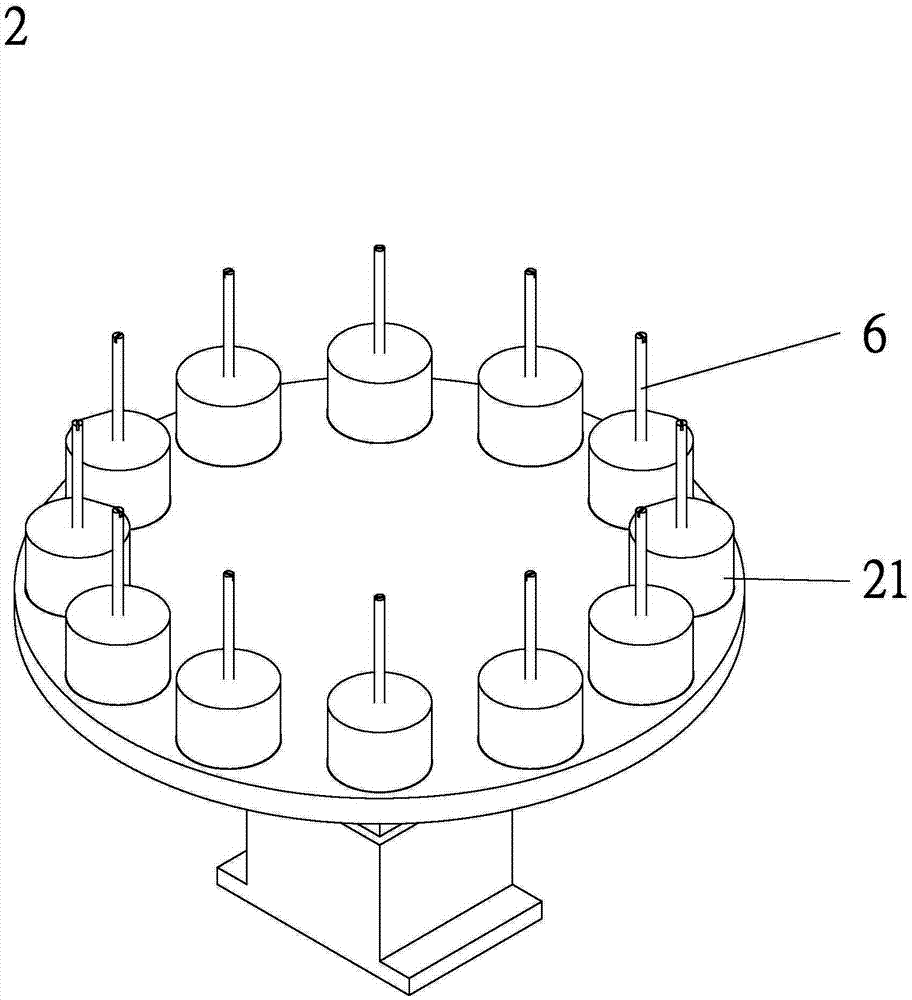

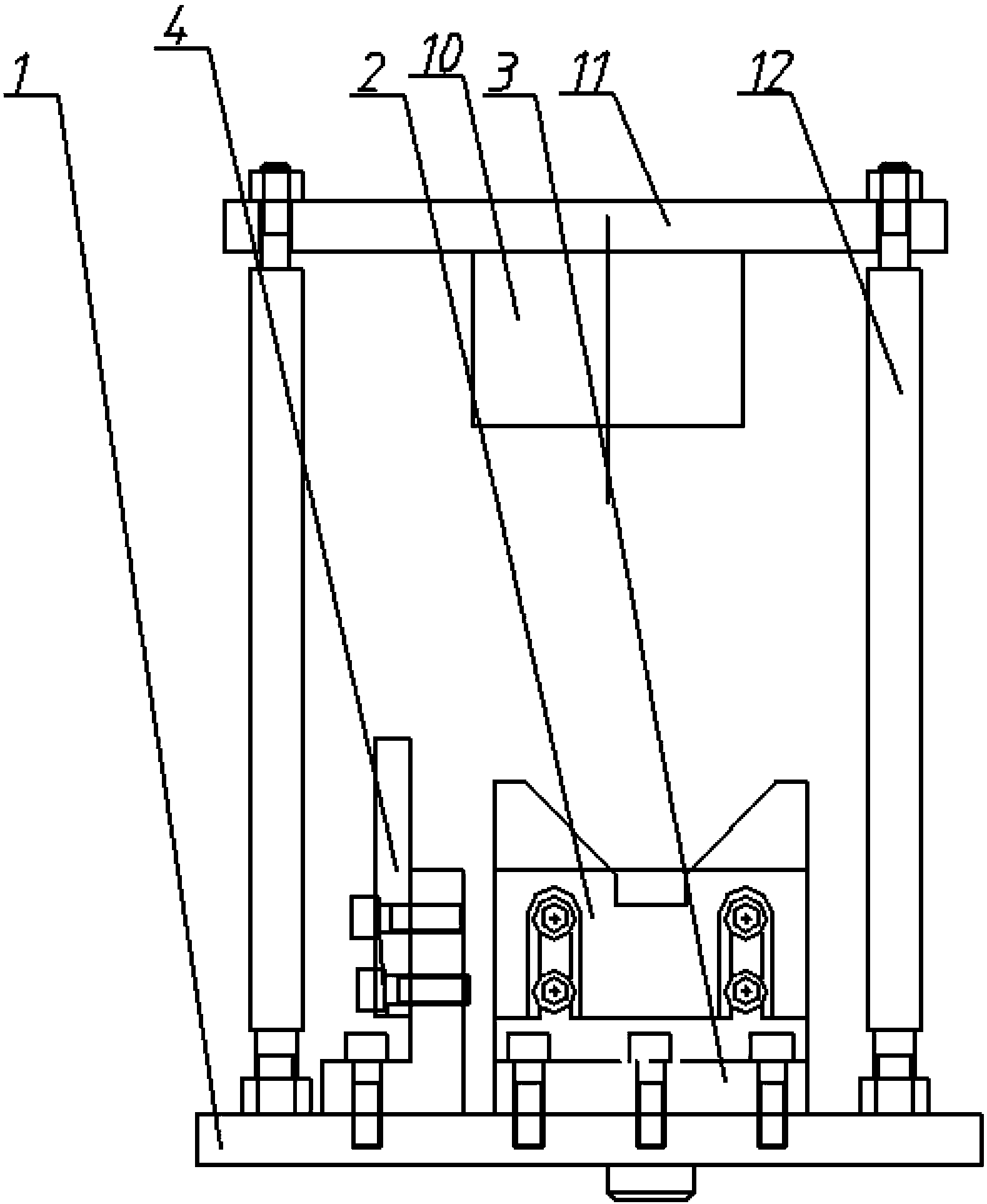

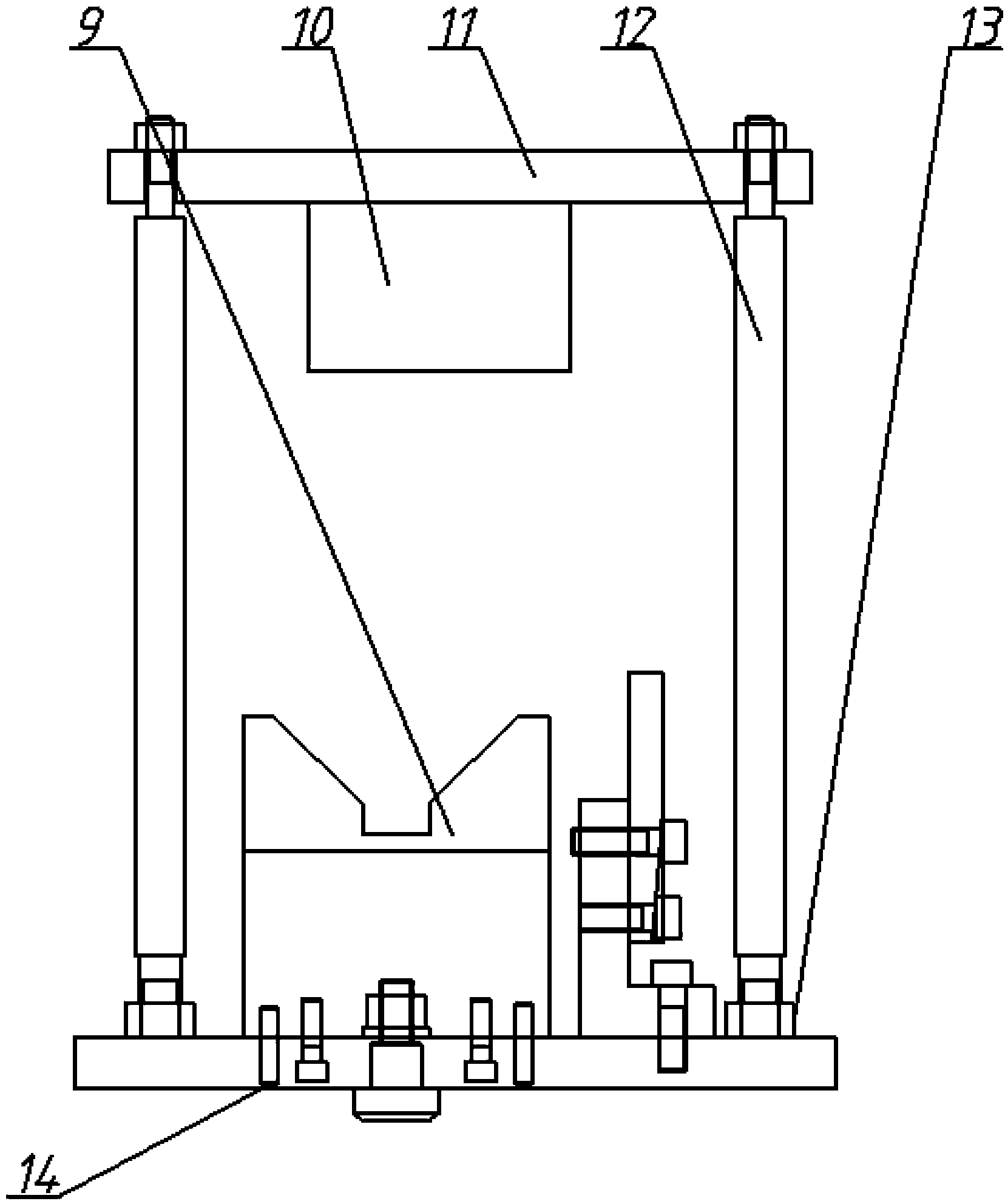

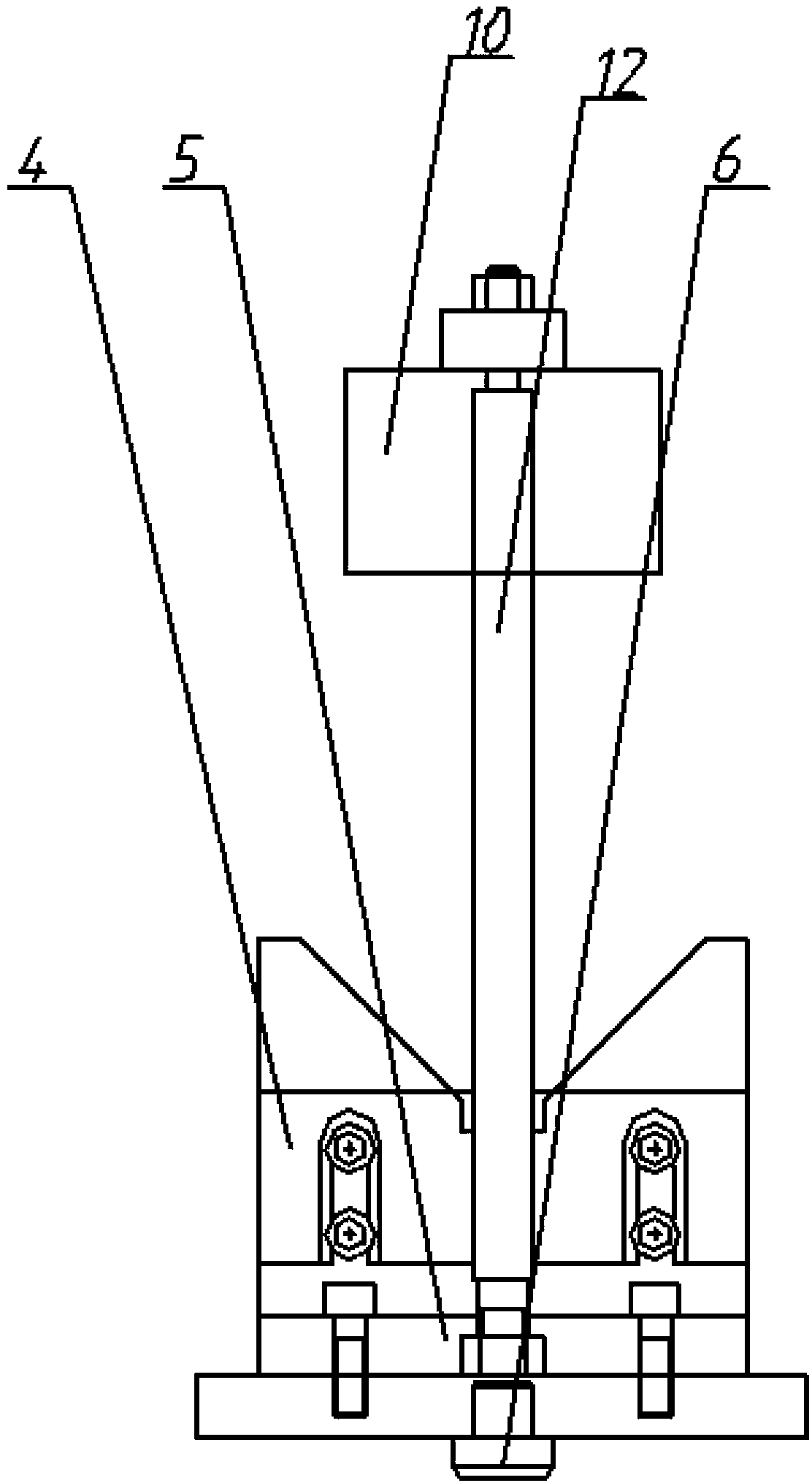

Vertical rotary disk type automatic indexing and welding machine for drill bits

InactiveCN105436732ARealize automatic feeding weldingImprove welding stabilityWelding/cutting auxillary devicesAuxillary welding devicesHigh volume manufacturingAutomatic indexing

Owner:YUEQING JIANLI TOOLS CO LTD

Horizontal multi-azimuth processing locating device

Owner:JIANGSU JIANGXU CASTING GROUP

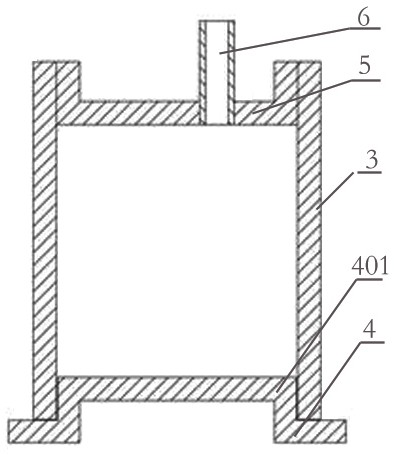

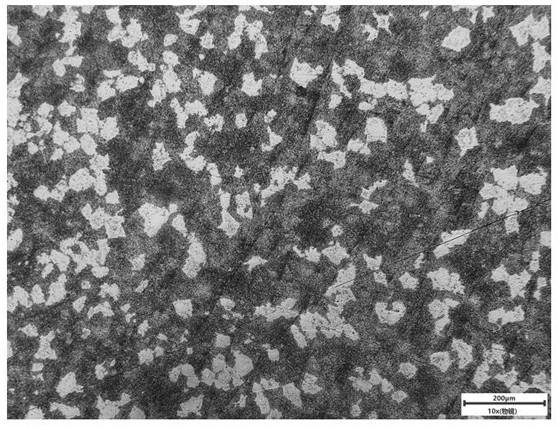

Preparation method of high-quality tungsten-titanium sputtering target material

PendingCN112391596AUniform tissueFine grainVacuum evaporation coatingSputtering coatingHigh volume manufacturingTitanium

Owner:丰联科光电(洛阳)股份有限公司

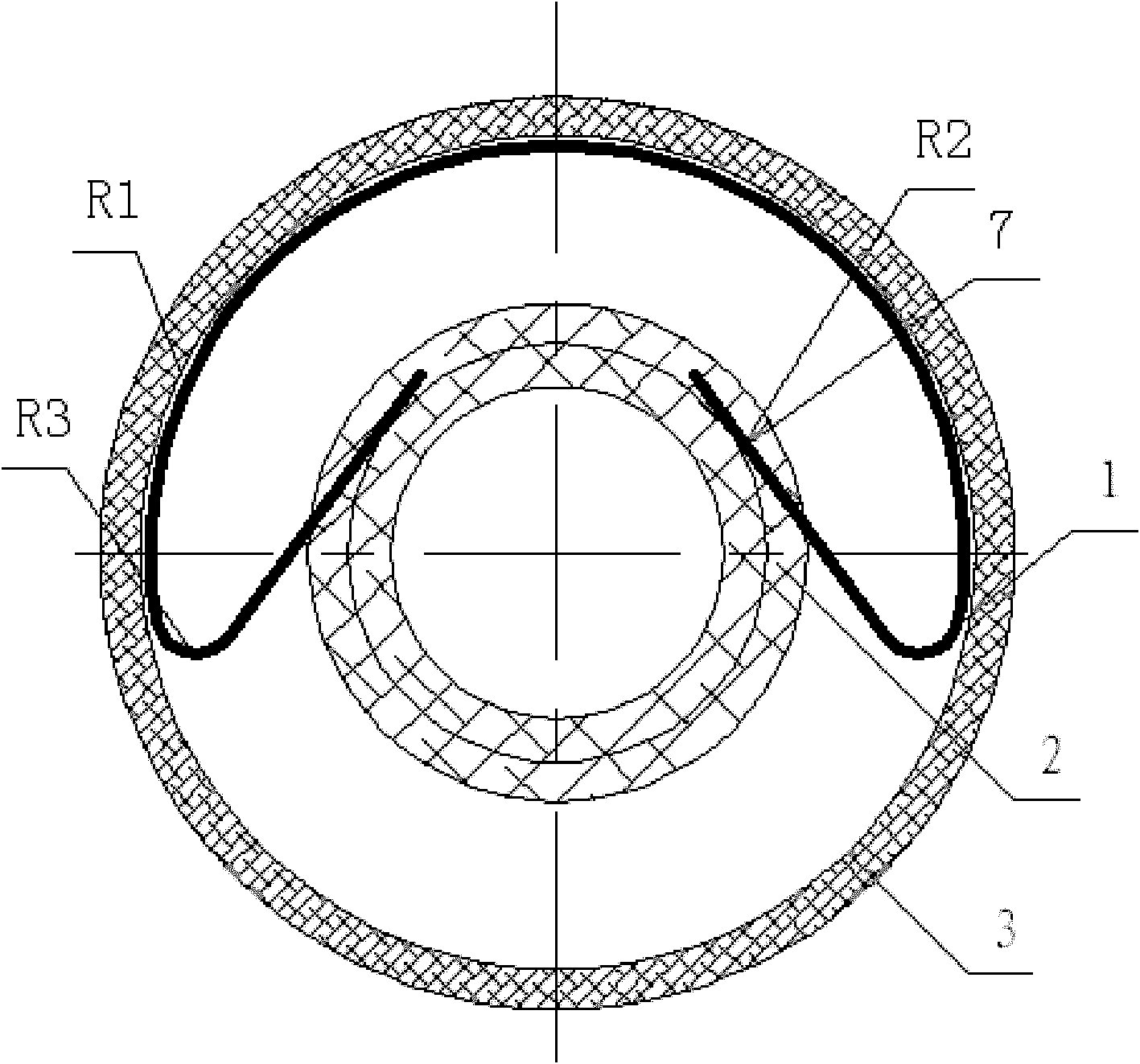

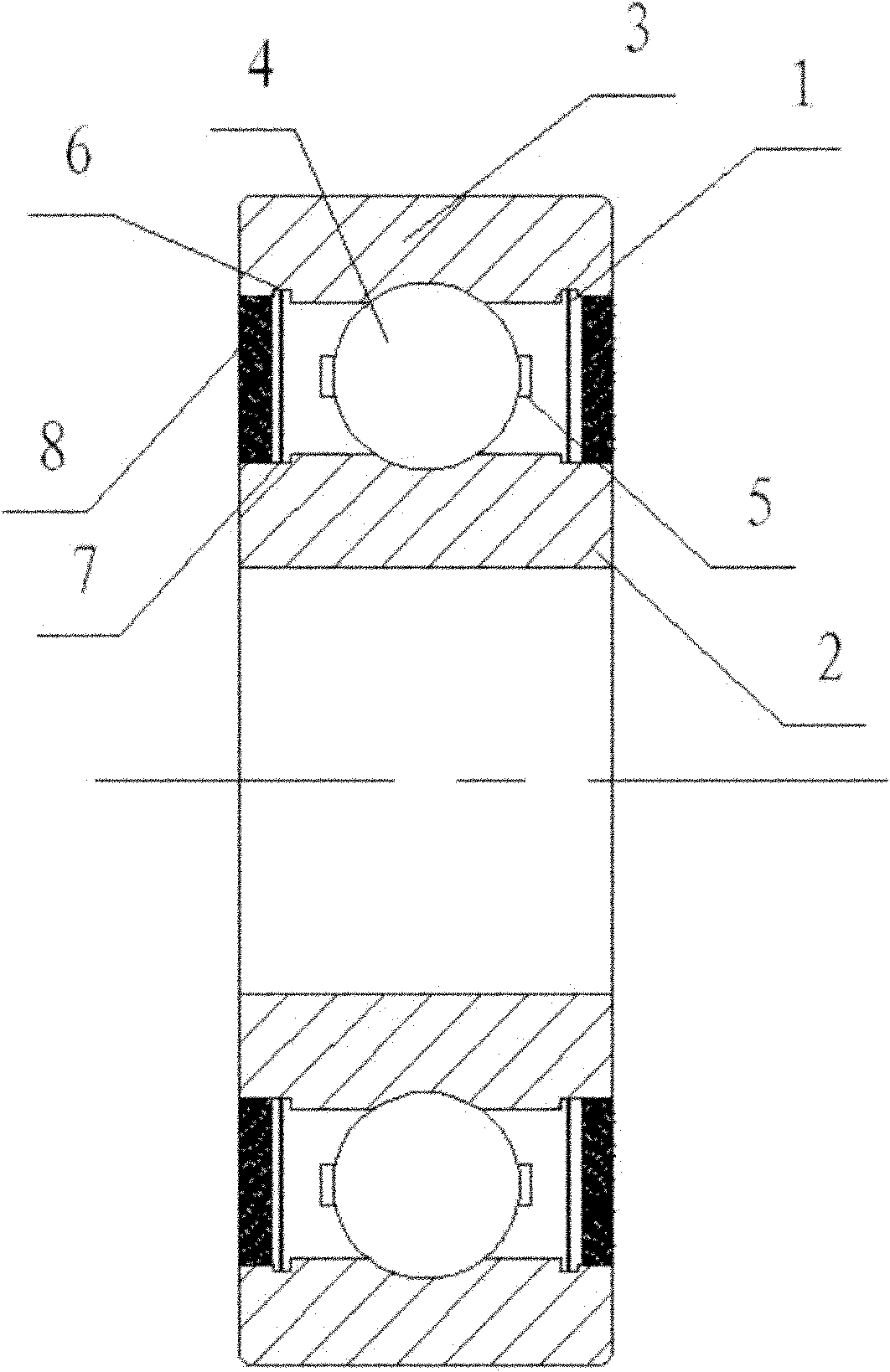

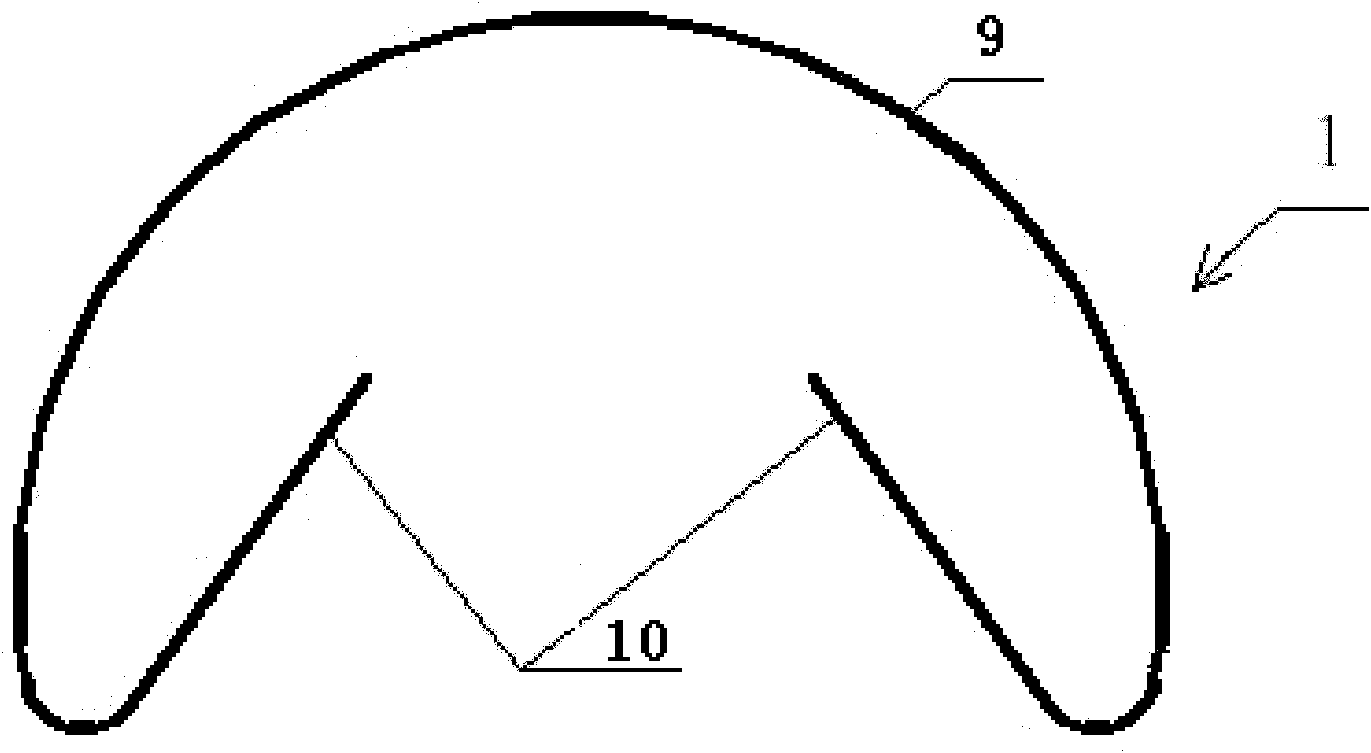

Electric corrosion preventing bearing

InactiveCN102032274AExtended service lifeZero voltage differenceBearing componentsHigh volume manufacturingPotential difference

Owner:WOLONG ELECTRIC GRP CO LTD +1

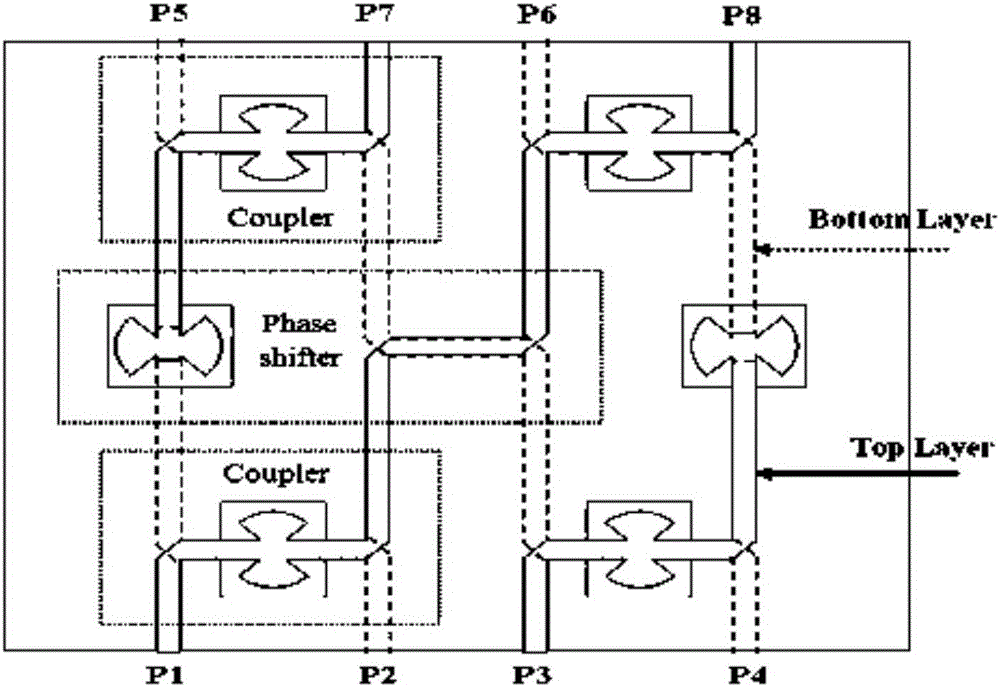

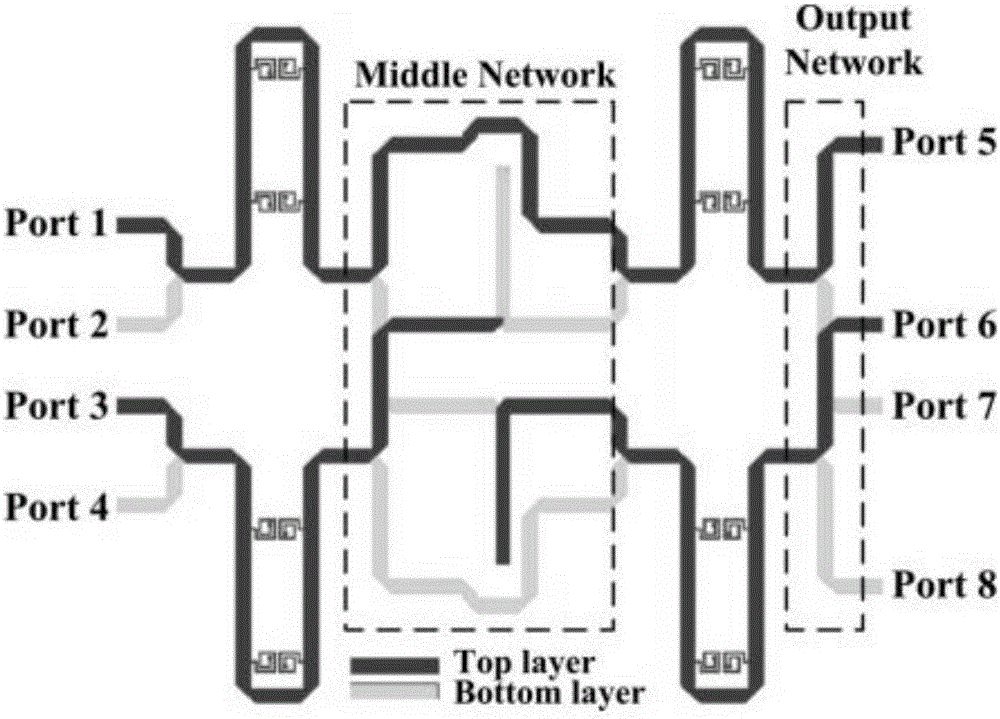

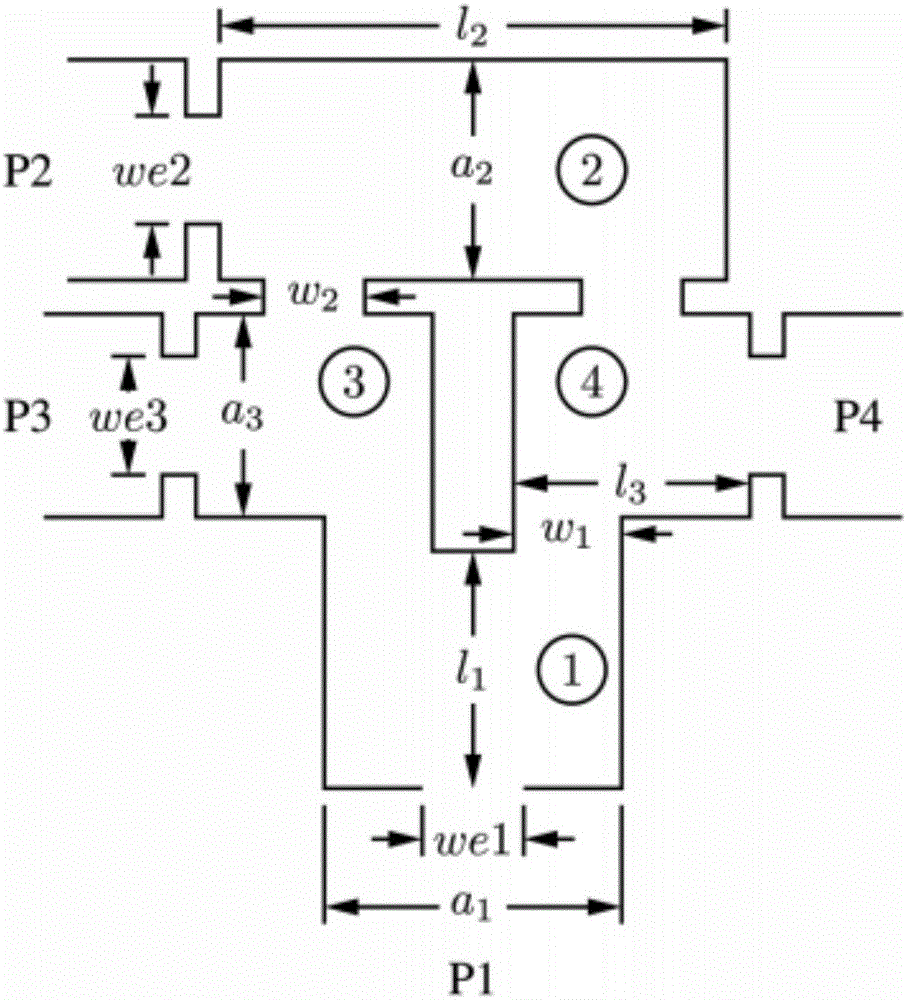

Microstrip line Butler matrix provided with bandpass filtering characteristic and based on stub-loaded resonators

InactiveCN105914468ASimple structureRealize the bandpass filter characteristicAntenna arraysElectricityBandpass filtering

Owner:SOUTH CHINA UNIV OF TECH

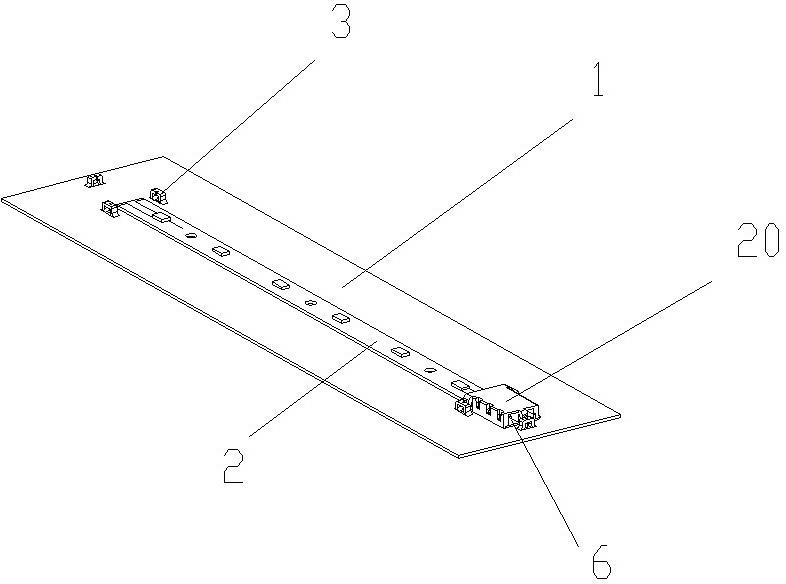

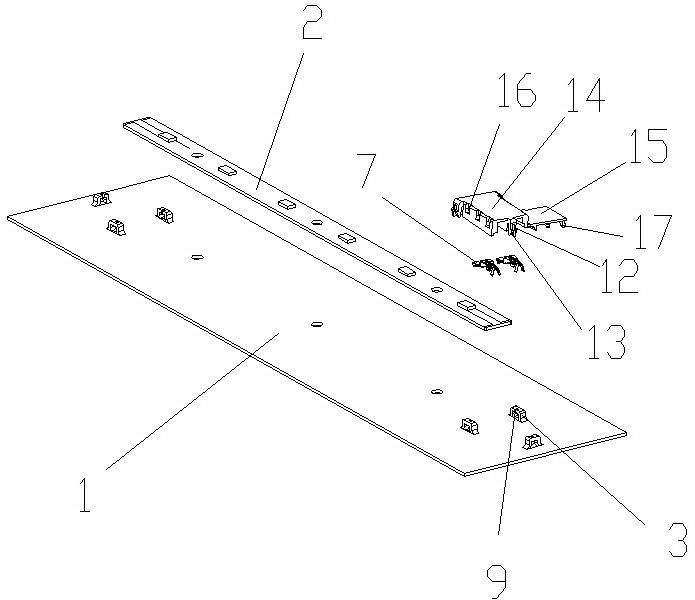

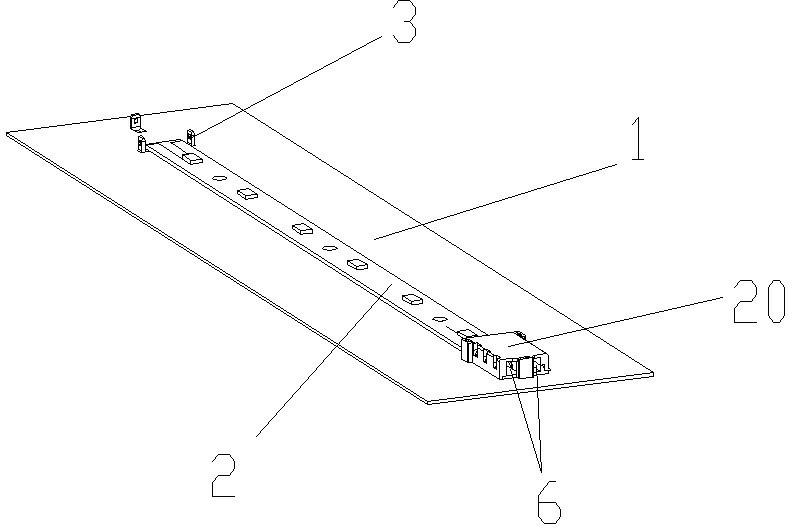

Quick connector of LED (Light Emitting Diode) bar

Owner:JIANGMEN KREALUX ELECTRICAL APPLIANCES

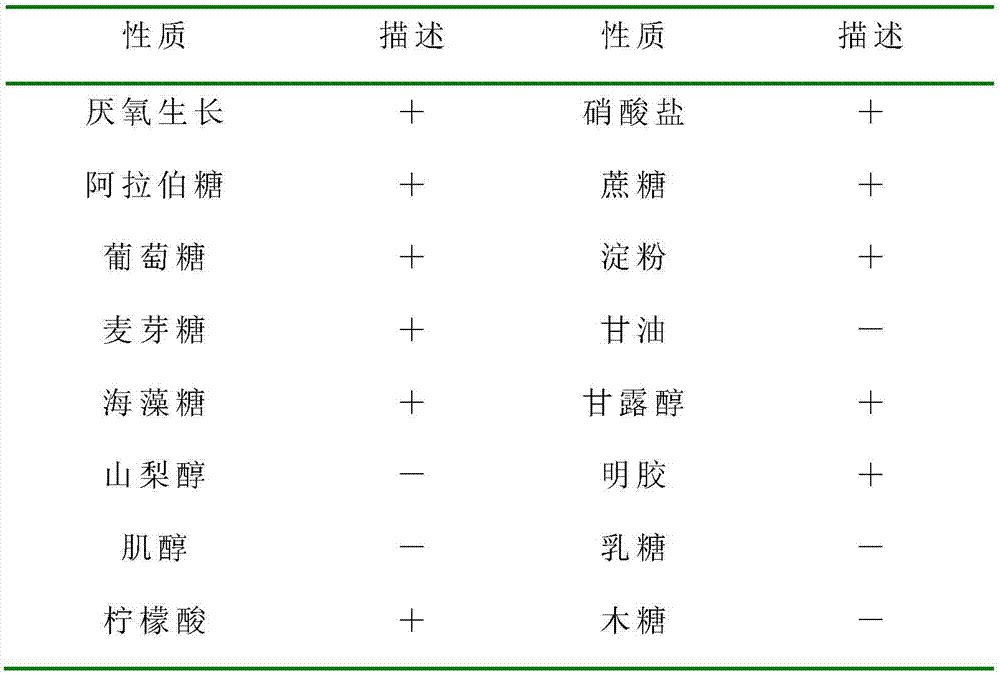

Technology for preparing biopesticide by compounding bacillus cereus and antibiotic

InactiveCN107094797AImprove survival rateHigh antibacterial efficiencyBiocideDead animal preservationBacillus cereusCulture mediums

Owner:NANJING UNIV OF TECH

Method for manufacturing LED package

Owner:江苏丰庆源科技有限公司

Filling and capping machine

PendingCN113336163AQuick loading and unloadingImprove filling efficiencyCapsThreaded caps applicationEngineeringMachine

Owner:中山市爱儿乐食品有限公司

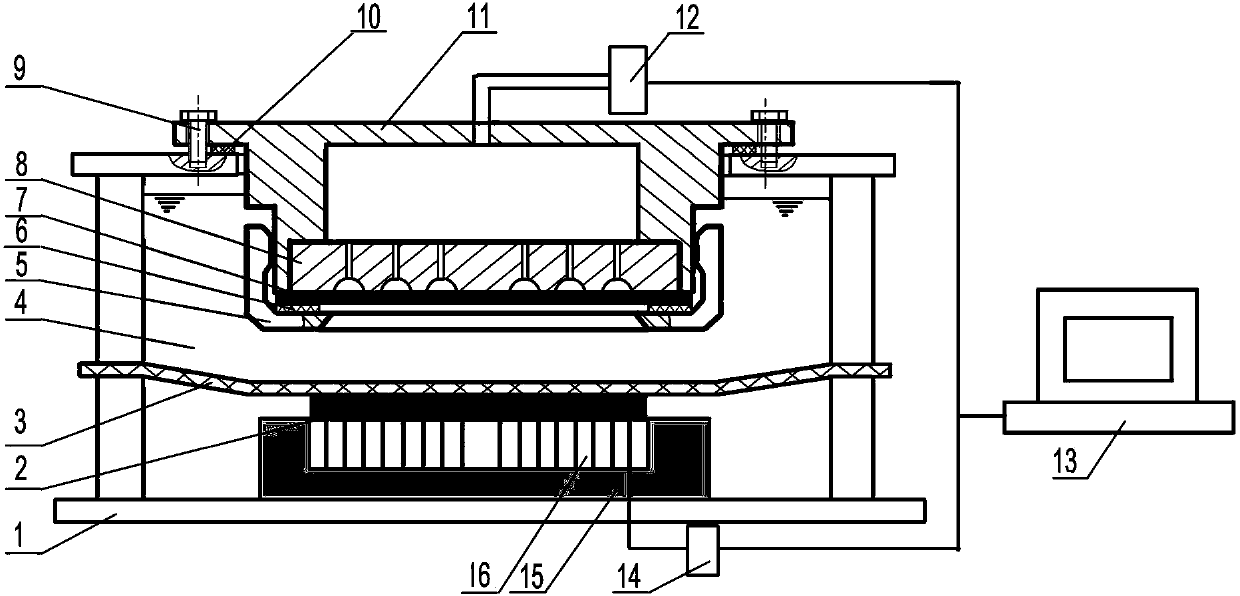

Sheet micro-forming method and device

Owner:JIANGSU UNIV

Dyeing and finishing long vehicle finishing method of bio-enzyme treatment

ActiveCN111394917AIncrease productivityImprove quality stabilityTextile storage in superimposed formSucessive textile treatmentsTextile printerProcess engineering

Owner:鲁丰织染有限公司

Seedling-raising substrate and preparation method thereof

InactiveCN106069334AImprove germination rateNormal differentiationGrowth substratesCulture mediaFiberBud

Owner:ANHUI MEILAN LANDSCAPE ENG CO LTD

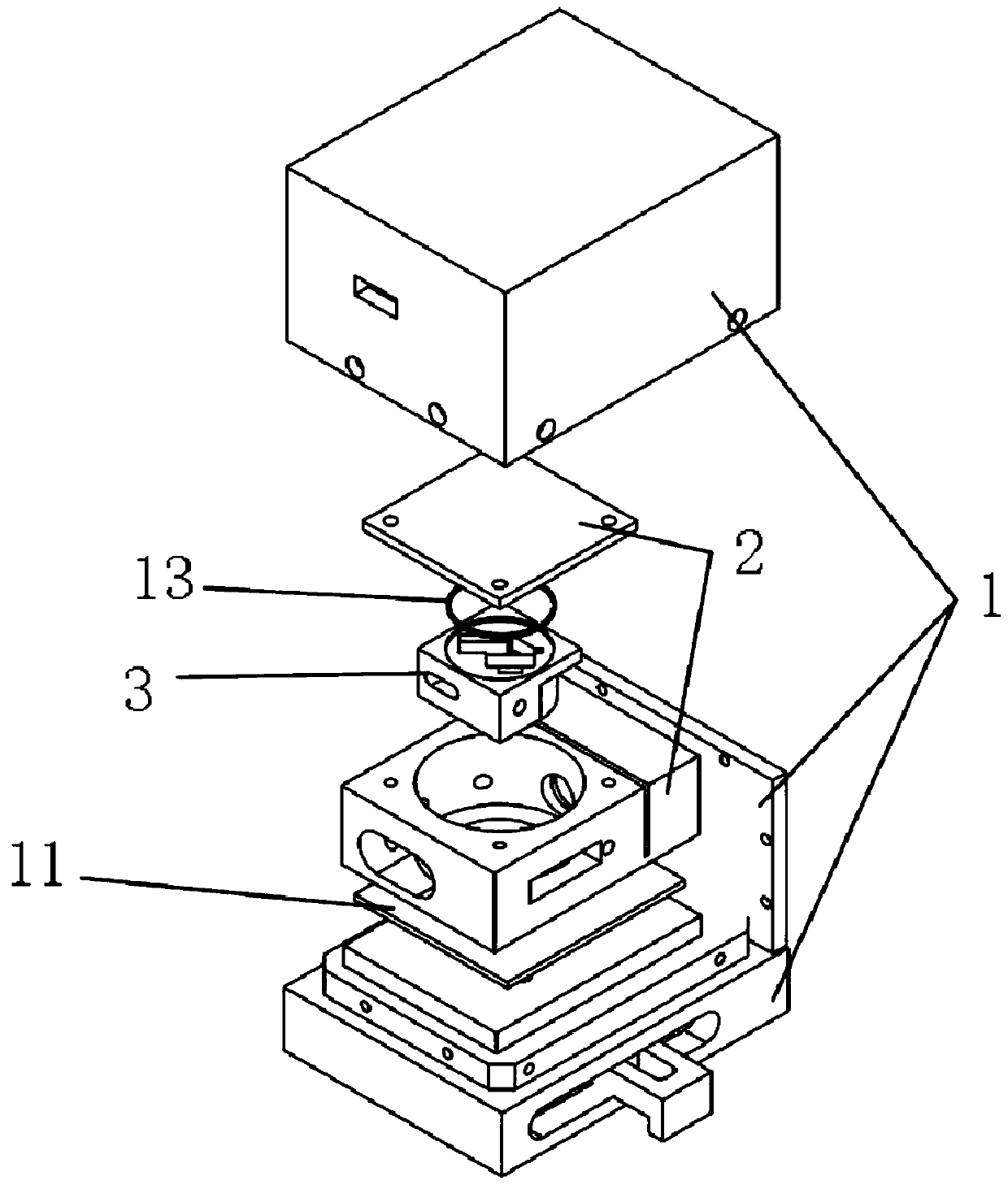

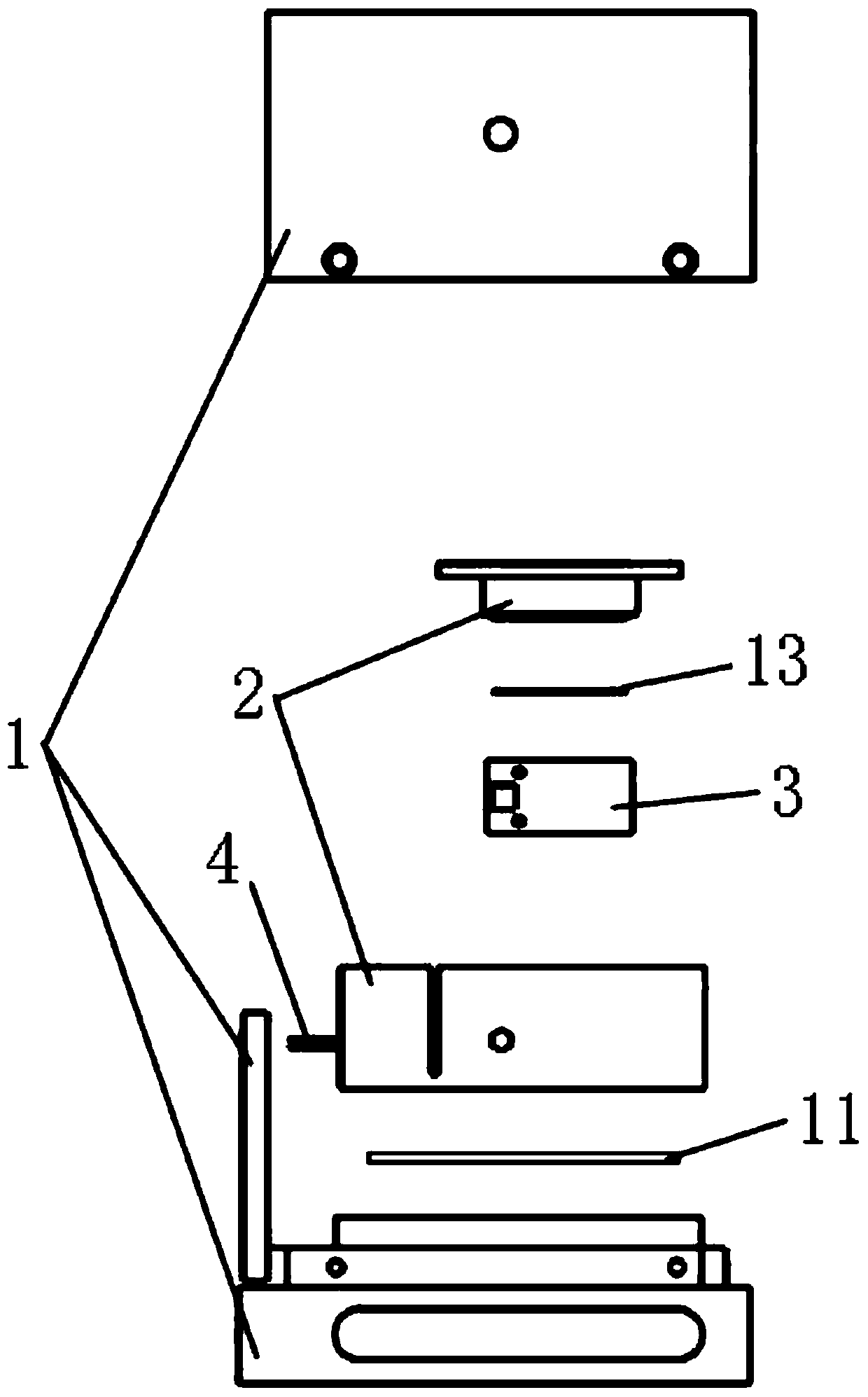

Grating external cavity feedback semiconductor laser and adjusting method thereof

ActiveCN109936047AFeedback control with increasedFrequency stabilityLaser detailsLaser optical resonator constructionState of artGrating

Owner:北京瓦科光电科技有限公司

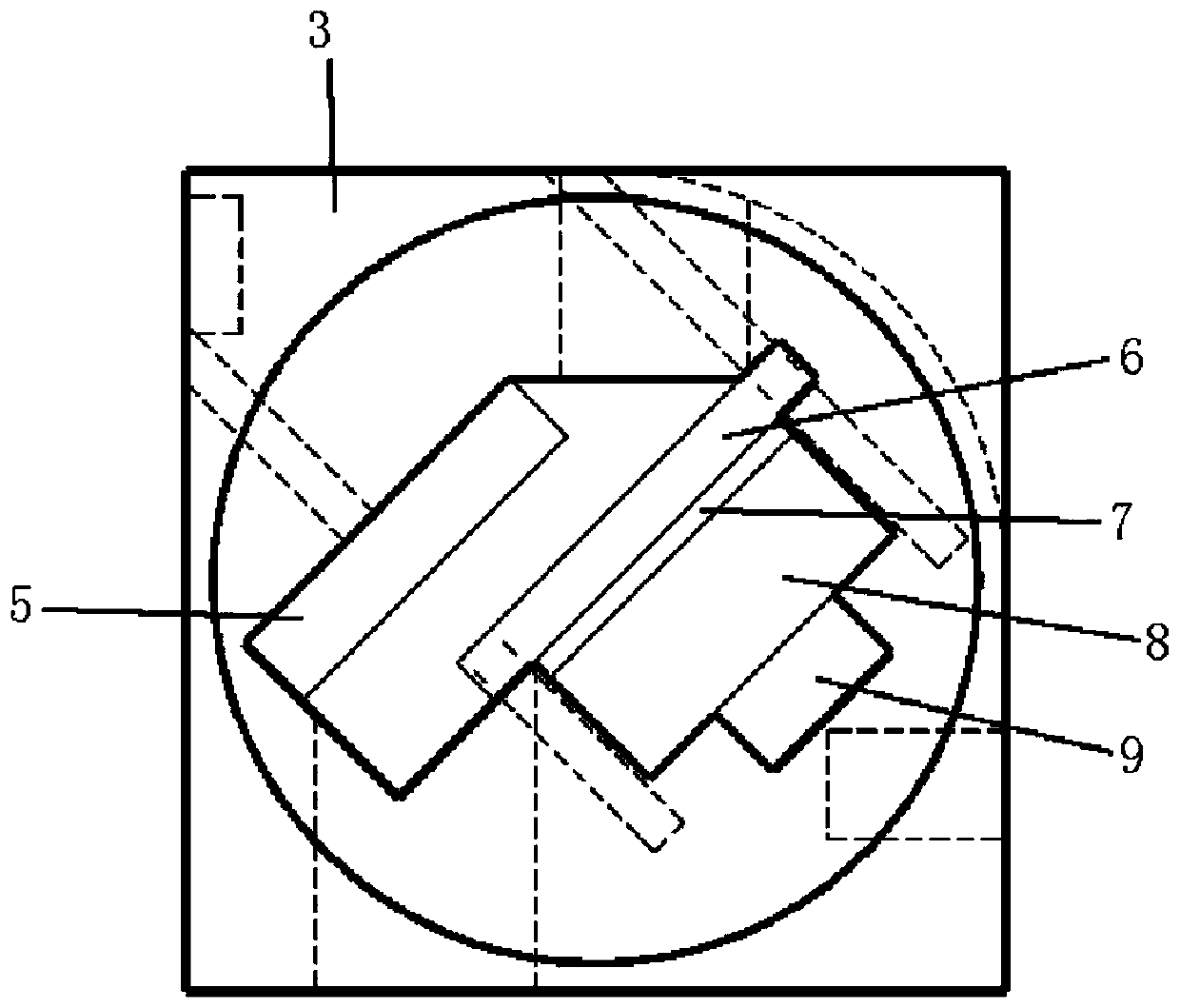

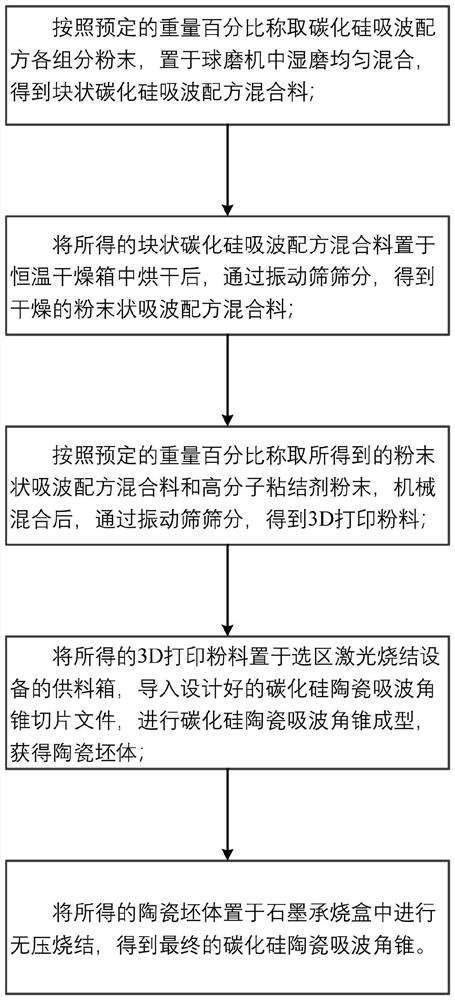

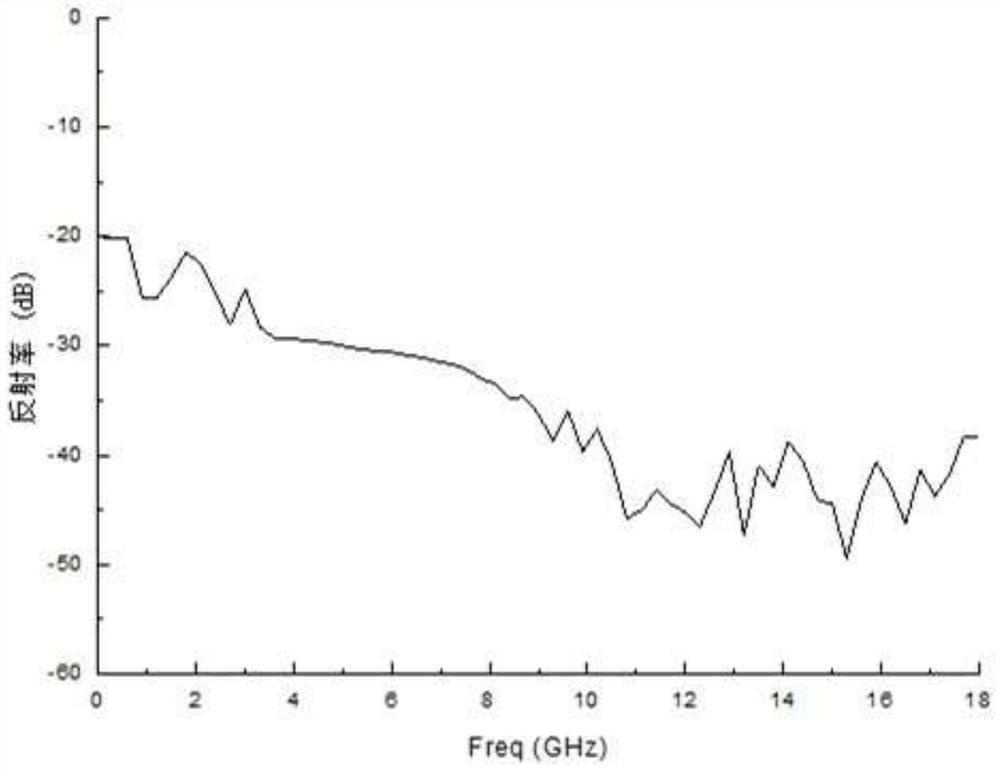

Silicon carbide ceramic wave-absorbing pyramid based on 3D printing and preparation method thereof

Owner:CHANGPING BEIJING ELECTROMAGNETIC PROTECTION

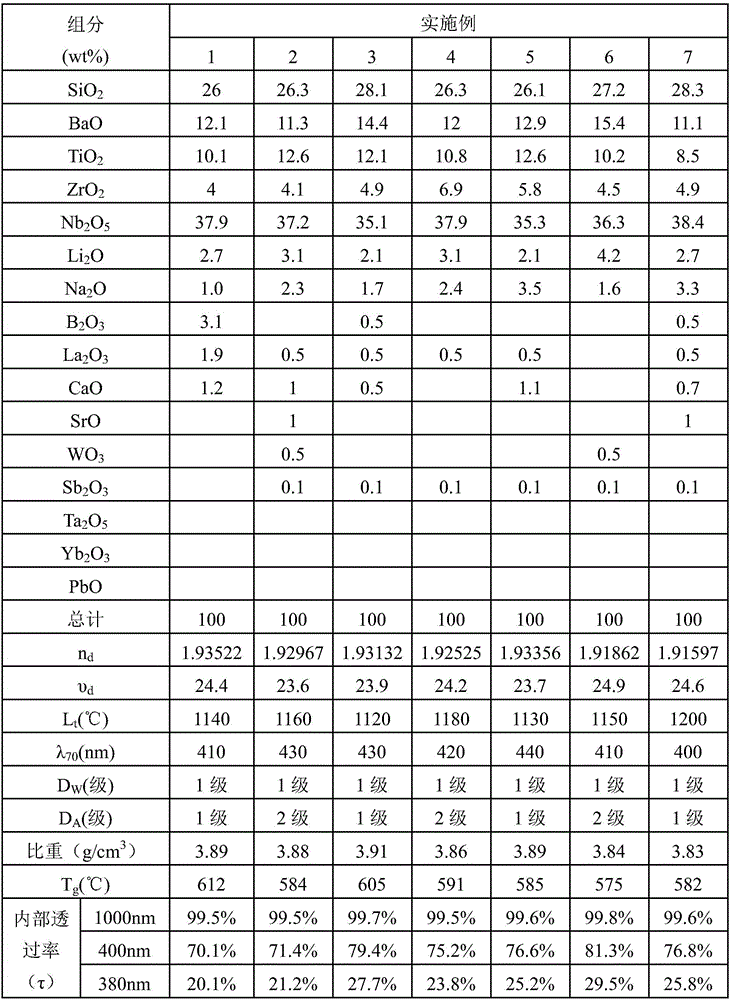

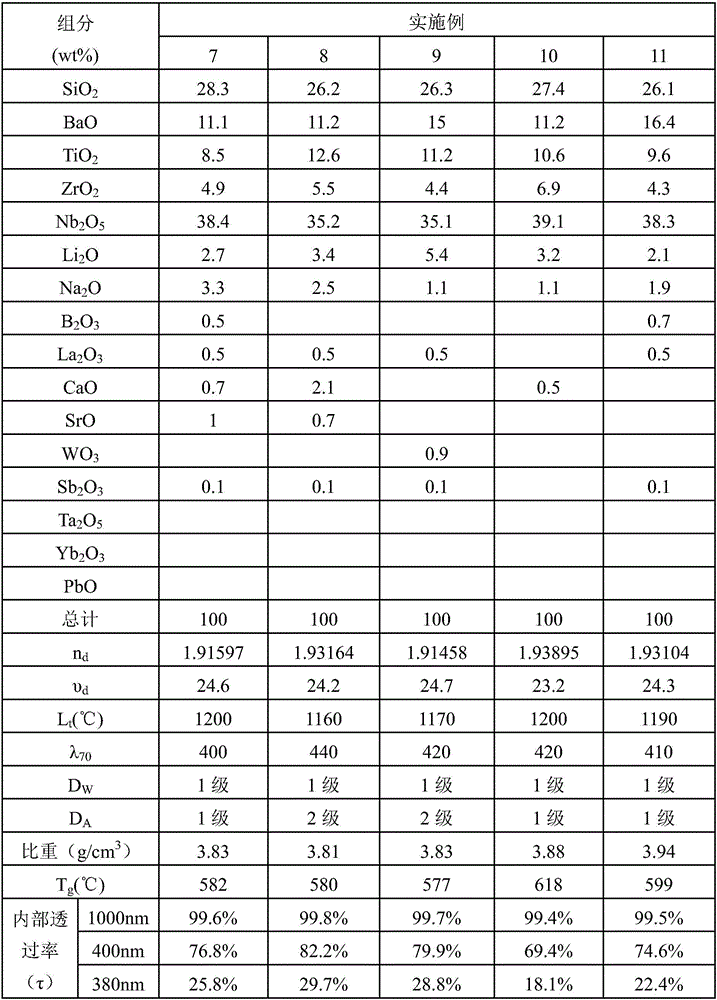

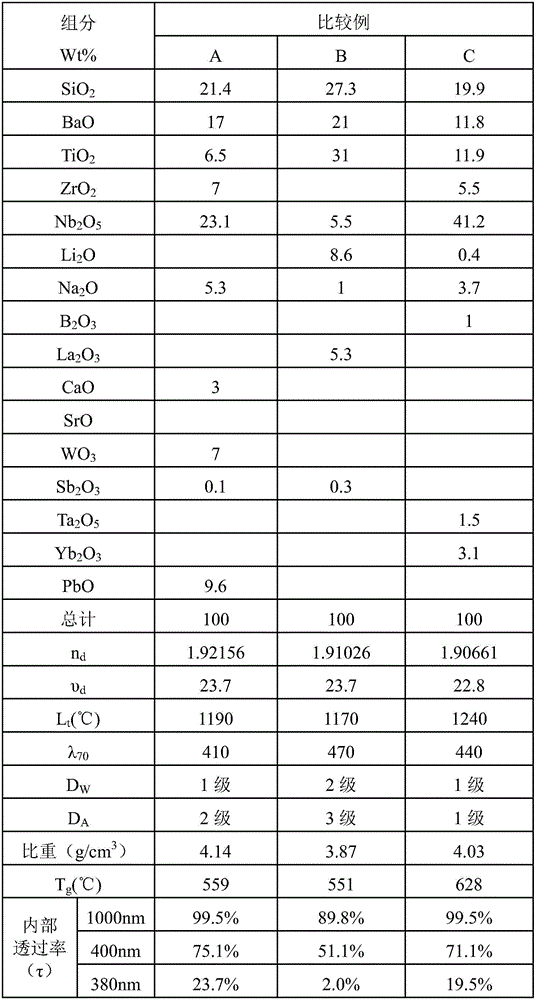

Optical glass, preparation method therefor and optical components thereof

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Antiemetic drug device for batch production

Owner:XINCHANG HAIGE SAISI TRADE

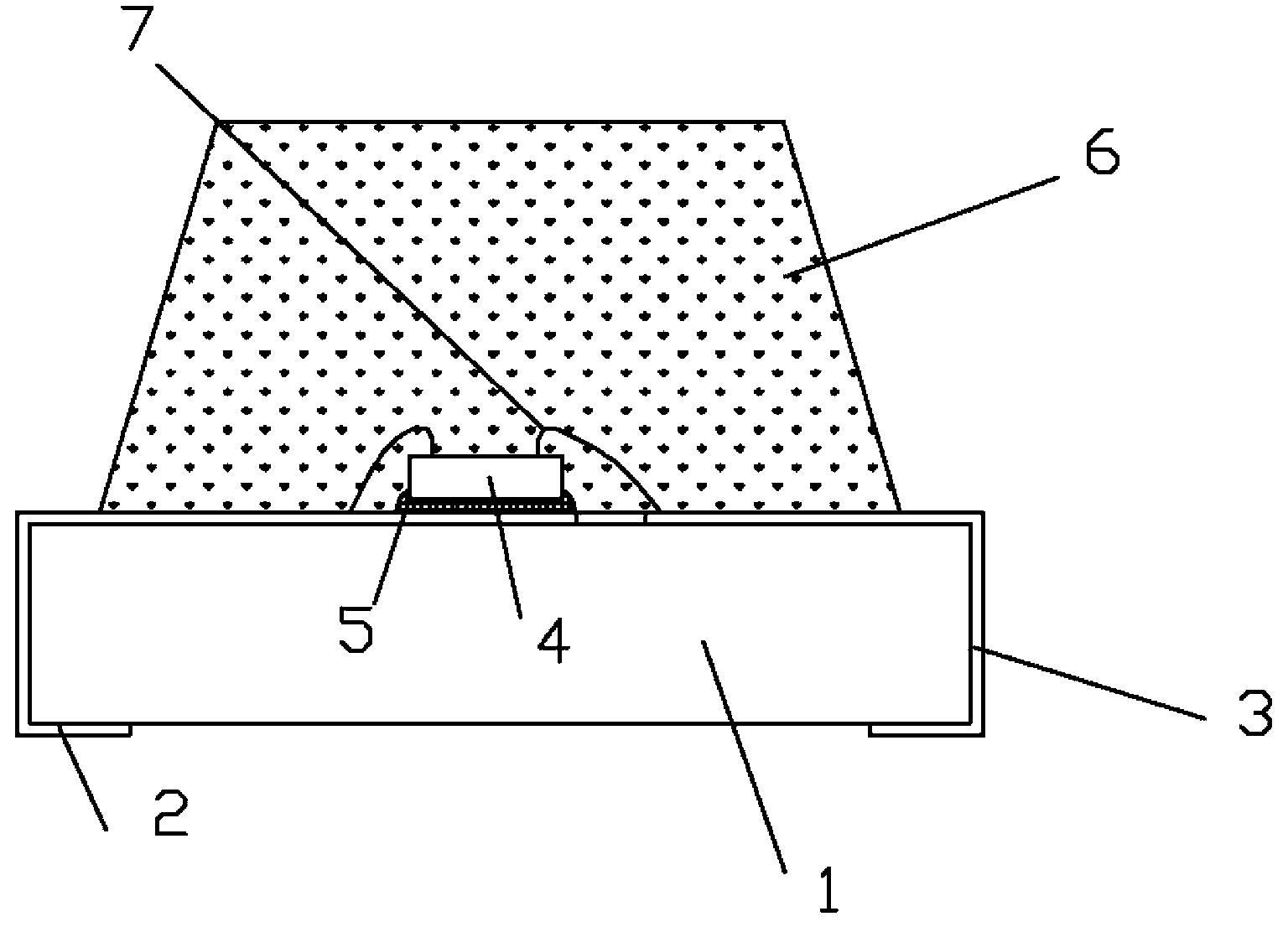

Integrated dual-polarization ceiling antenna

ActiveCN112467346AMeet the use requirementsReduce volumeParticular array feeding systemsRadiating elements structural formsHigh volume manufacturingFeeder line

The embodiment of the invention provides an integrated dual-polarization ceiling antenna, and relates to the technical field of mobile communication. The integrated dual-polarization ceiling antenna comprises a reflection plate, a horizontal polarization feeder line, a vertical polarization feeder line and a sheet-shaped radiator, the radiator is installed on the reflection plate, the radiator isprovided with a first hollow structure and a second hollow structure, the first hollow structure and the second hollow structure are orthogonally arranged and communicated, the radiator is electrically connected with a vertical polarization feeder line, and the second hollow structure is fed through a horizontal polarization feeder line. According to the integrated dual-polarization ceiling antenna provided by the invention, the vertical polarization part in the antenna is realized through the radiator and the reflection plate, and the horizontal polarization part in the antenna is realized through the hollow structure in the radiator, so that the dual-polarization antenna is realized, the requirement of a 5G frequency band can be met, and the existing 2G / 3G / 4G frequency band requirement can be compatible; and the full-band standing-wave ratio is kept at a low value, the size is small, the gain is high, the structure is simple, and large-batch production and manufacturing are easy.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

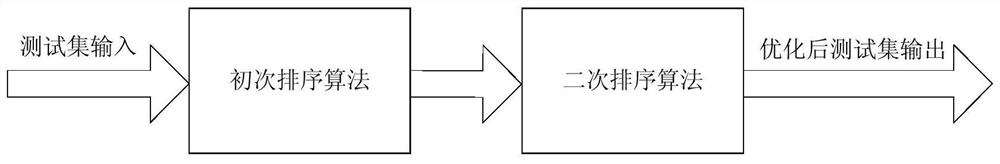

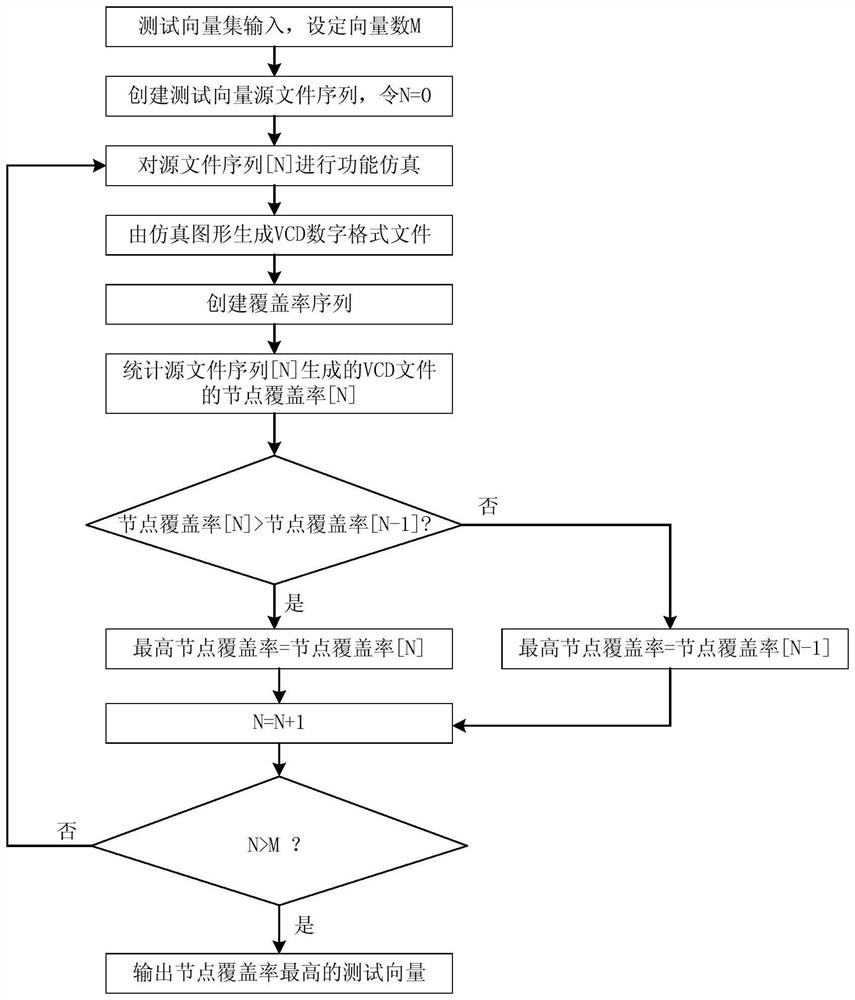

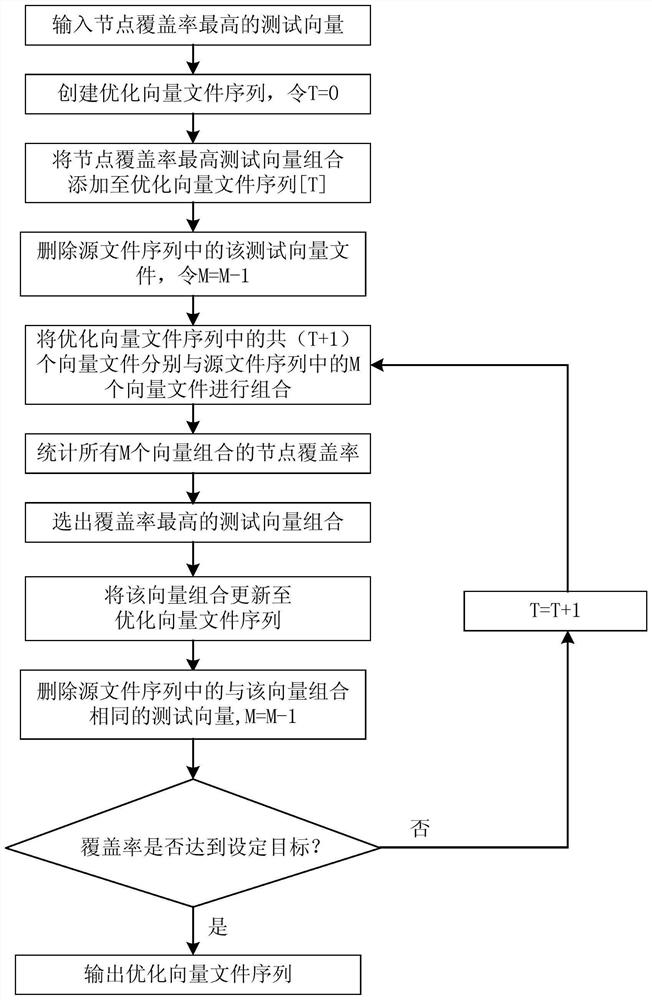

FPGA embedded PCIExpressIP core mass production test optimization method based on coverage rate sorting

Owner:BEIJING MXTRONICS CORP +1

Preparation method of carbon nanotube hollow sphere composite material and composite material

PendingCN112479182AStable structureGood heat insulationCarbon nanotubesMicrospherePolystyrene microsphere

The invention belongs to the technical field of carbon nanotube hollow sphere composite materials, and particularly relates to a preparation method of a carbon nanotube hollow sphere composite material and the composite material. The preparation method comprises the following steps: mixing carbon nanotubes, polystyrene microspheres, an amino surfactant, (CH2OH)2 and resin, stirring the componentsfor 30 minutes, and heating the mixture to form a gel state; screening the gel through a screen, and heating the gel in a vacuum oven at 80-150 DEG C; then adding the polystyrene microspheres and thehollow microspheres of carbon nanotubes again, mixing and dispersing the components, introducing carbon source gas, and carrying out high-temperature decomposition so that the decomposed carbon sourcegas bridges the adjacent carbon nanotubes to form a carbon atom-bridged hollow mesh-woven composite structure. The preparation process is simpler, the cost is lower, batch production can be achieved,and the composite material is better in heat insulation, sound insulation and stability.

Owner:ZHONGBAO (XIAN) TECH GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap