Sheet micro-forming method and device

A micro-forming and thin-plate technology, applied in the field of micro-forming, can solve the problems of not involving the replication of micro-features, the internal pressure is not easy to control, and the production cost is increased, so as to achieve low-cost mass production, saving processes, and simple tooling and molds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

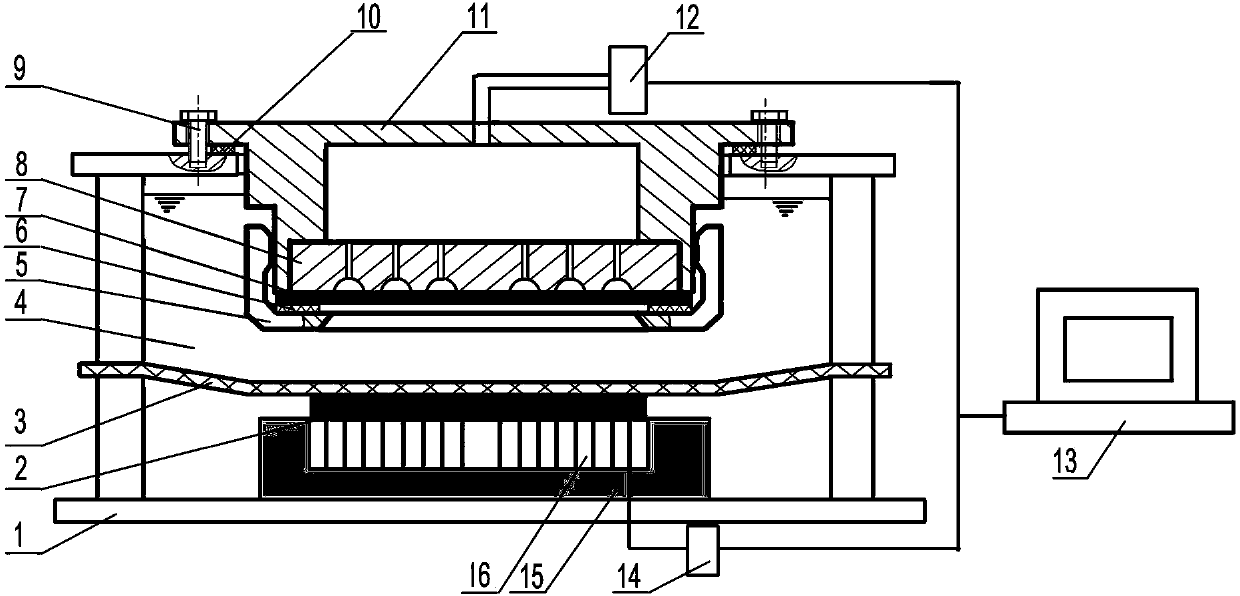

[0024] Such as figure 1 Shown, a kind of thin plate microforming method comprises the following steps:

[0025] Step 1: The computer 13 pumps the upper cavity of the micro-mold 8 and the pit of the micro-mold 8 into a vacuum state by controlling the air extraction device 12;

[0026] Step 2: The computer 13 discharges the electromagnetic coil 16 by adjusting the controller 14, and the electromagnetic force generated after the discharge drives the metal plate 2, and drives the elastic medium 4 above the metal plate 2 to move upward together;

[0027] Step 3: an incompressible liquid medium 4 is sealed above the elastic medium 4, the upwardly moving elastic medium 3 squeezes the liquid medium 4, and the workpiece 7 is squeezed between the liquid medium 4 and the micro-mold 8, causing the workpiece 7 to undergo plastic deformation, Cooperating with the micro-mold 8, the shape of the micro-mold 8 can be copied to realize the rapid and precise forming of the workpiece 7;

[0028] St

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap