Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Positioning devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bending machine

ActiveCN104646460AReduce the number of repositioning workpiecesEasy to achieve U-shapeMetal-working feeding devicesStripping-off devicesEngineeringRapid prototyping

Owner:OMS MASCH CO LTD

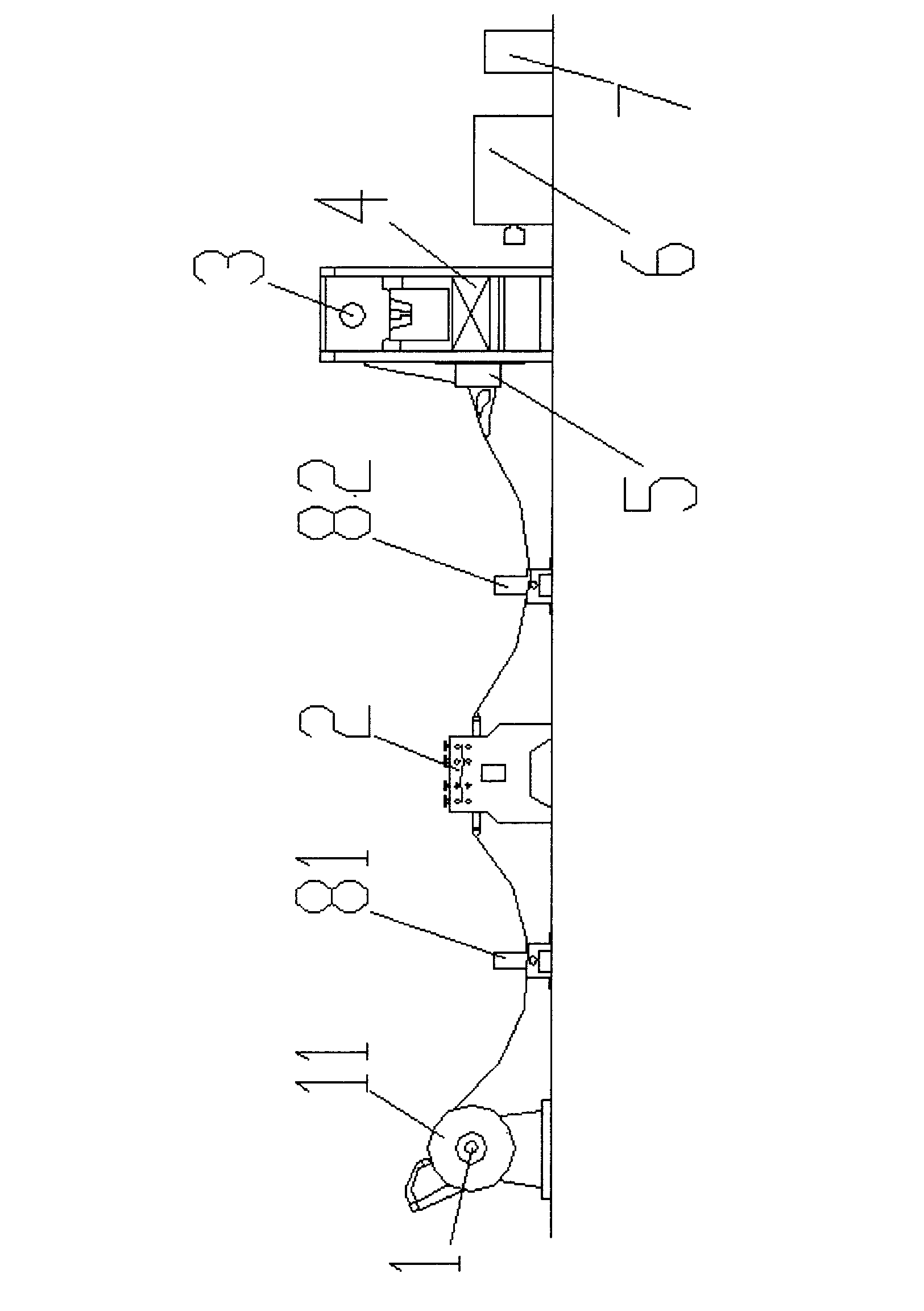

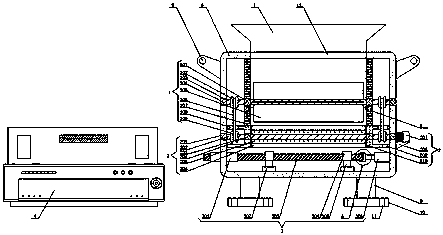

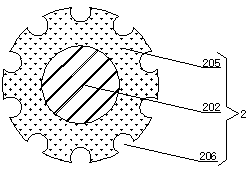

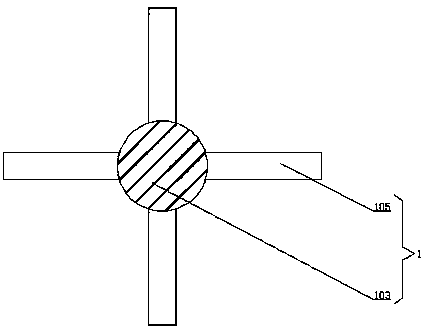

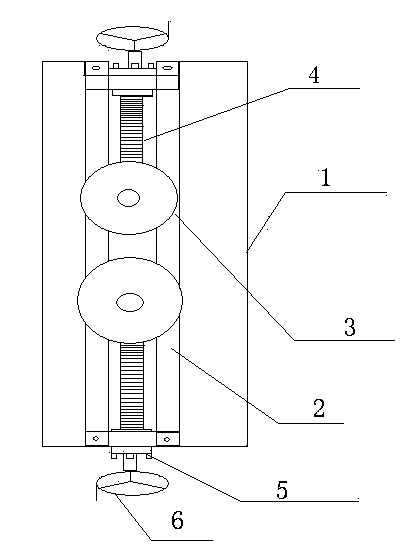

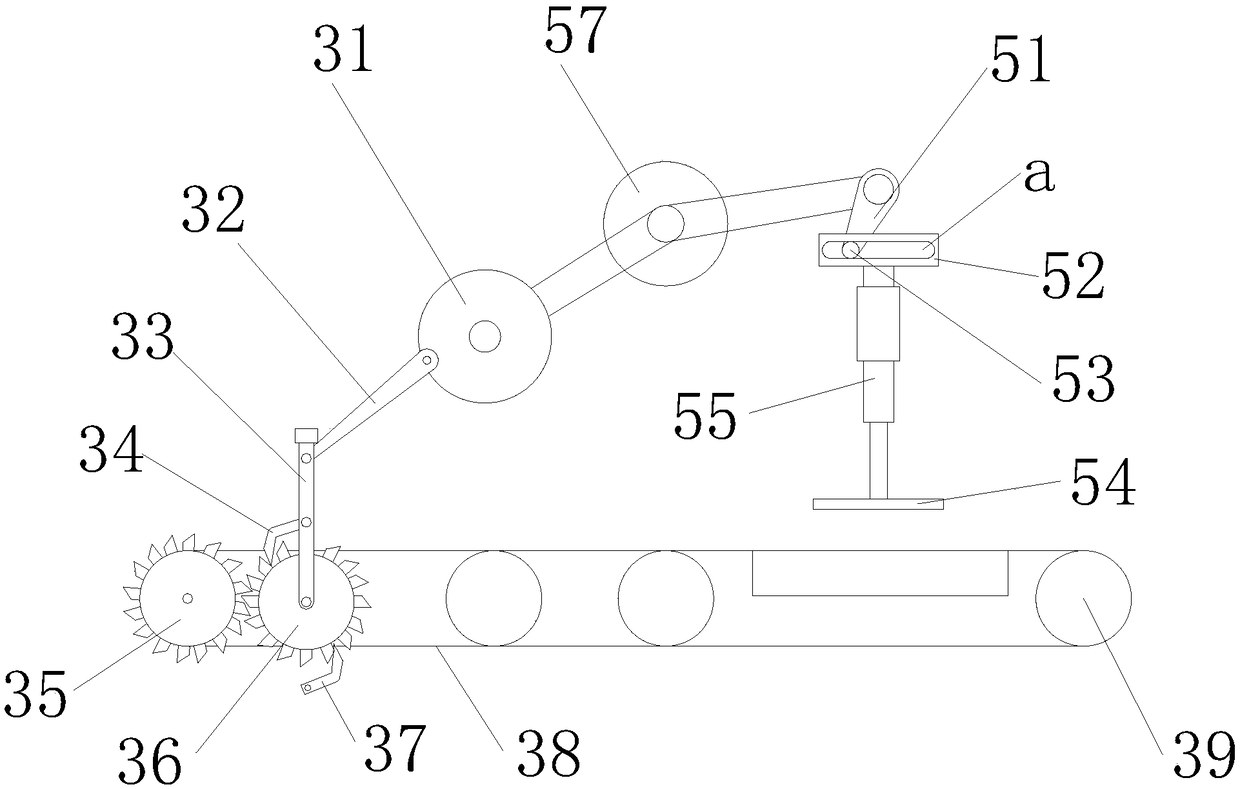

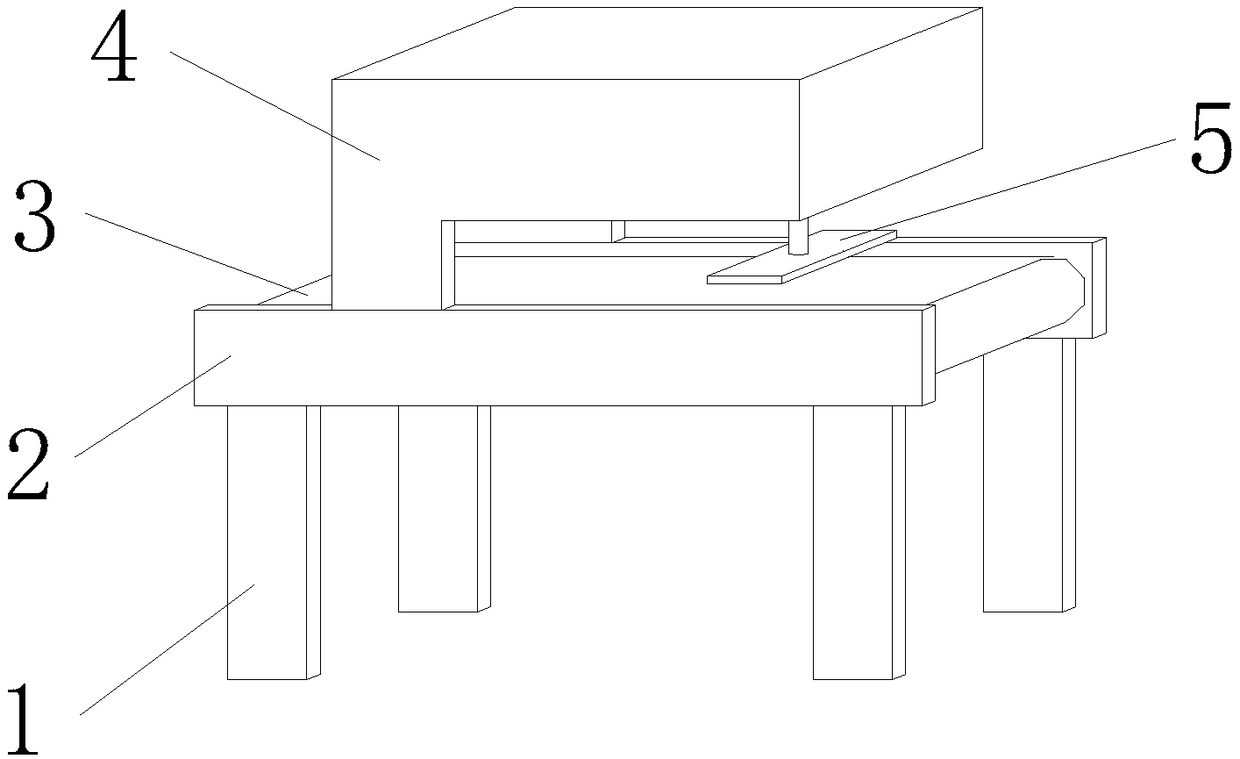

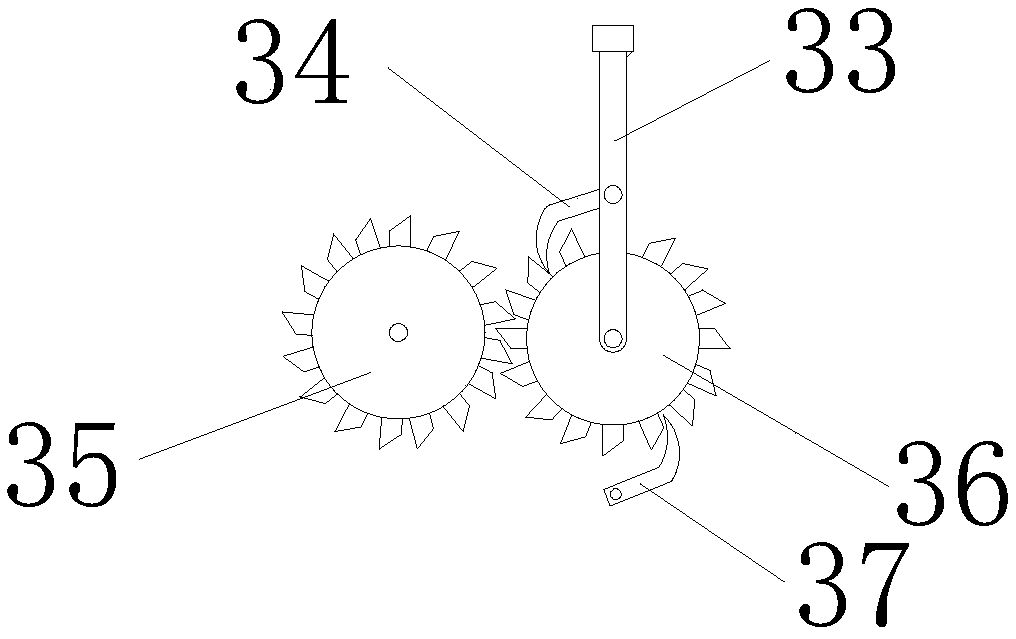

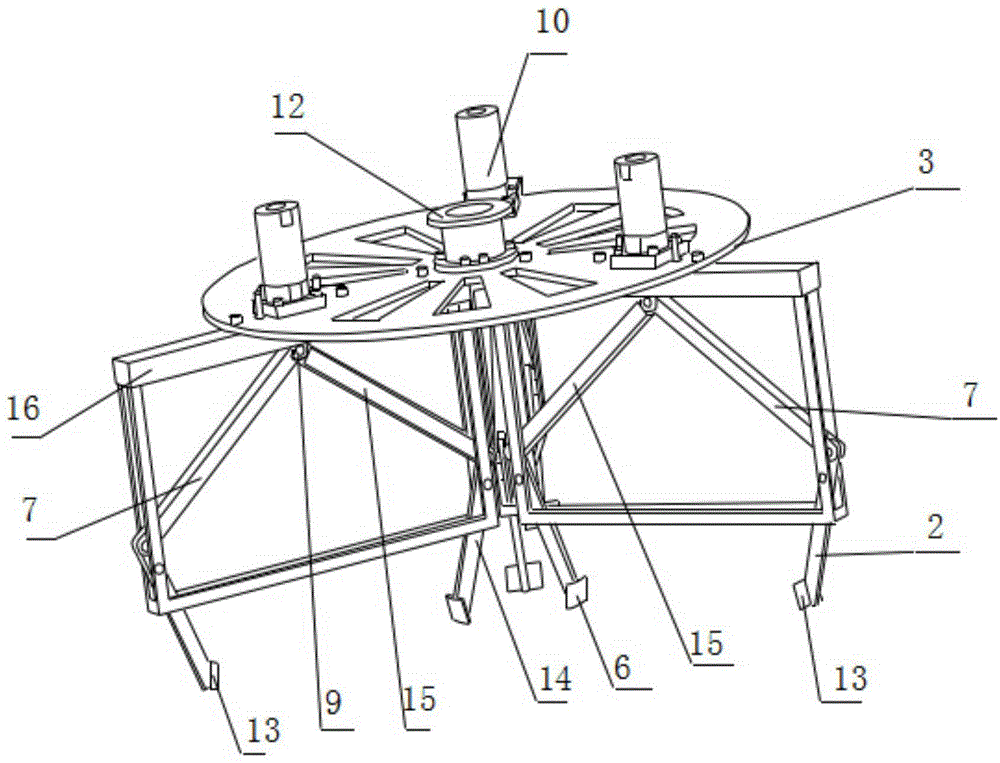

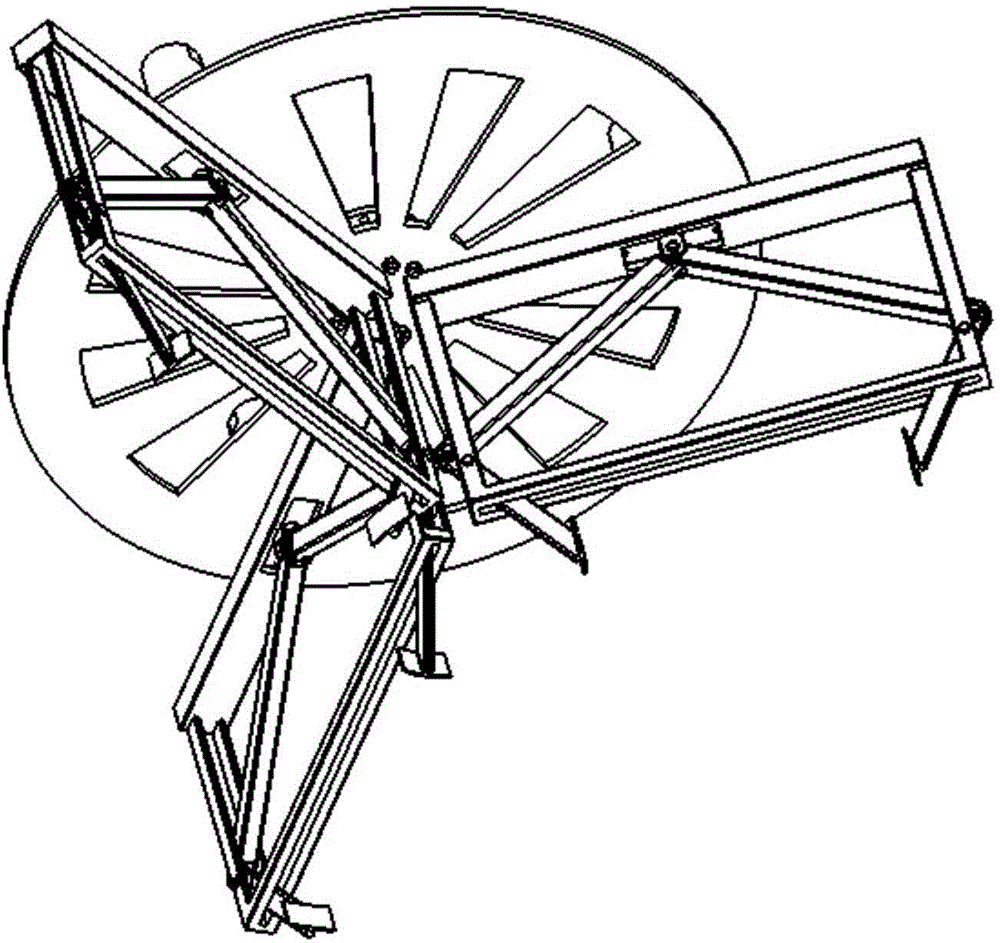

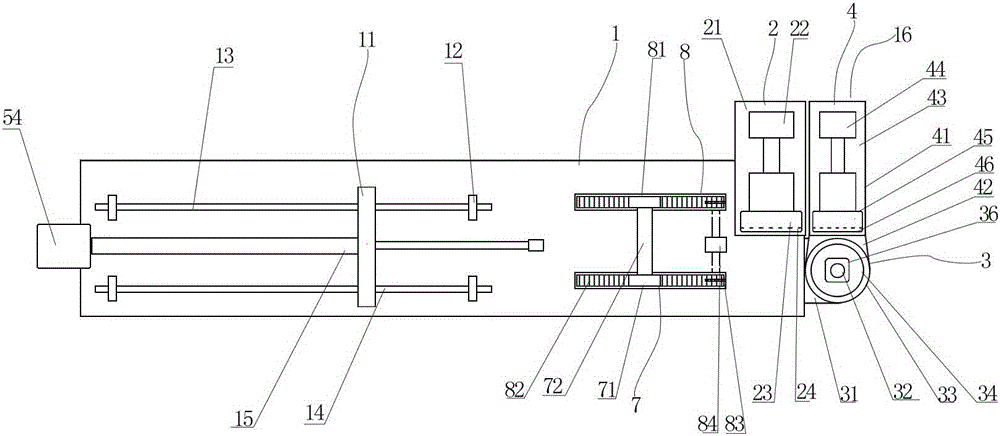

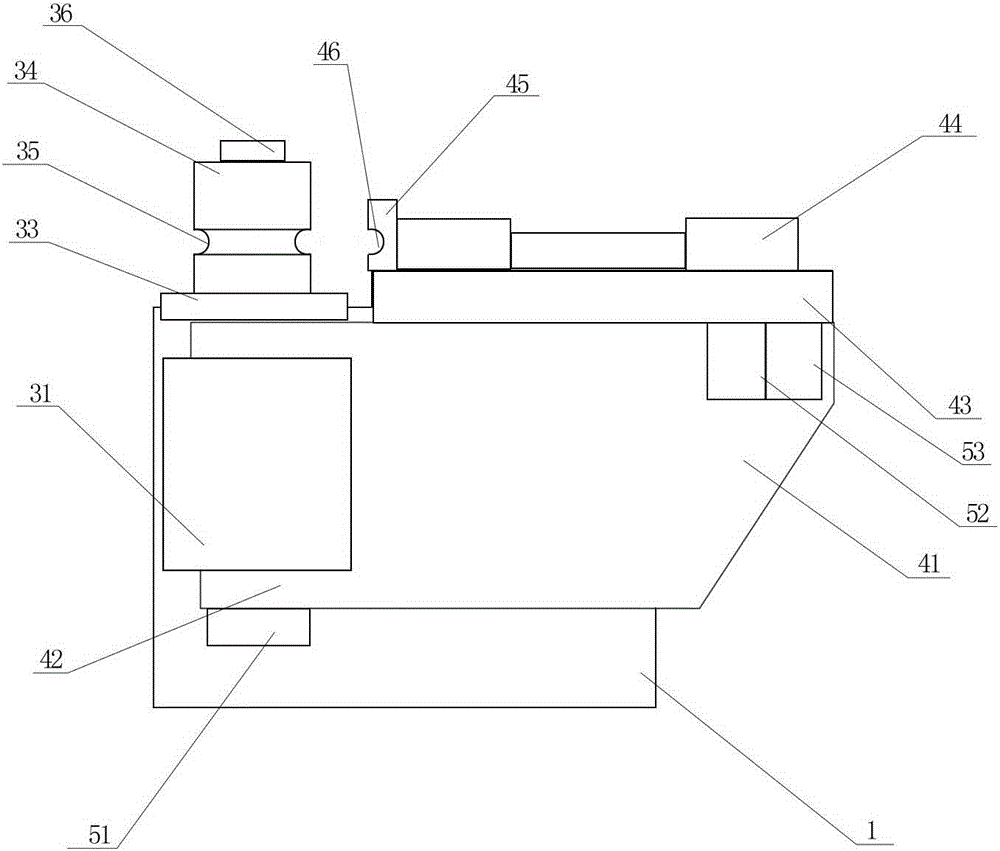

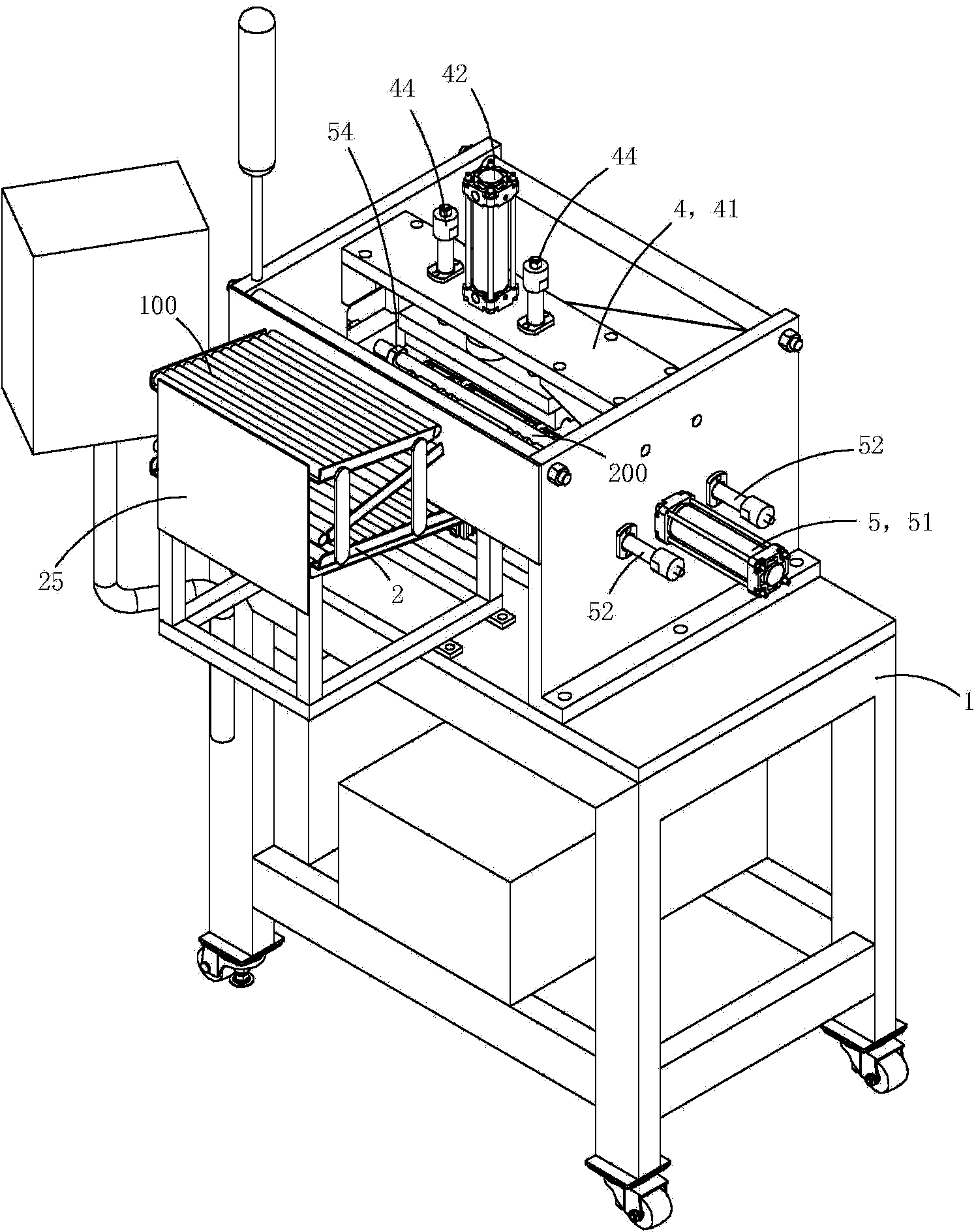

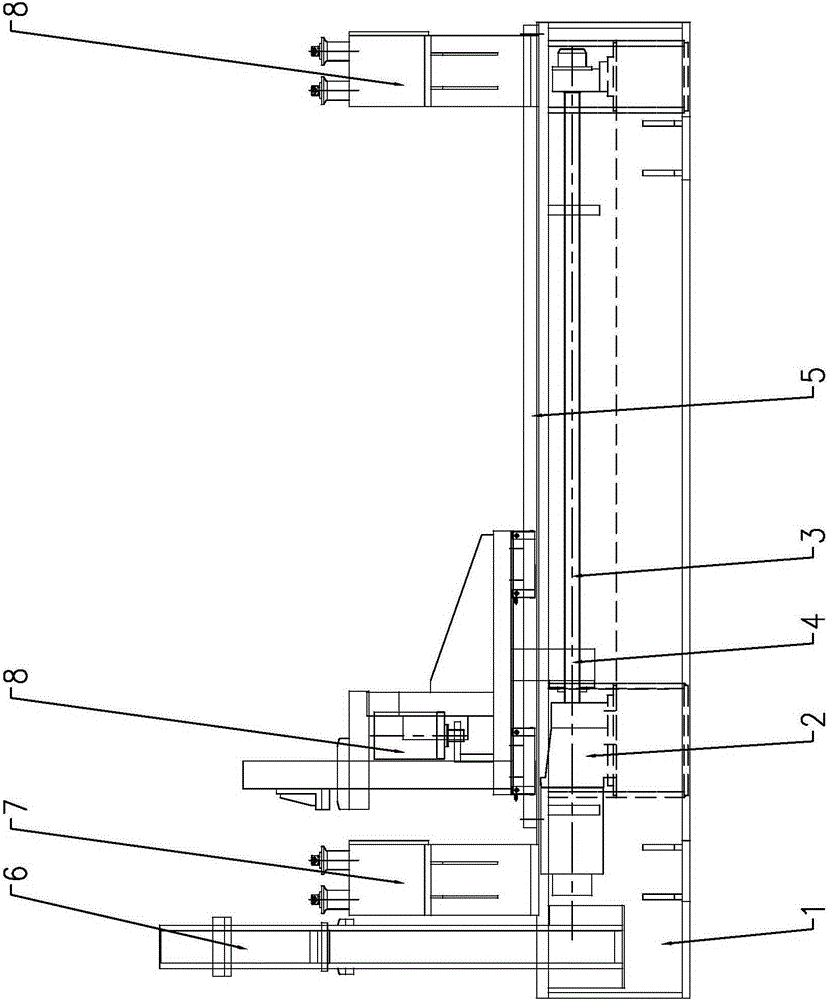

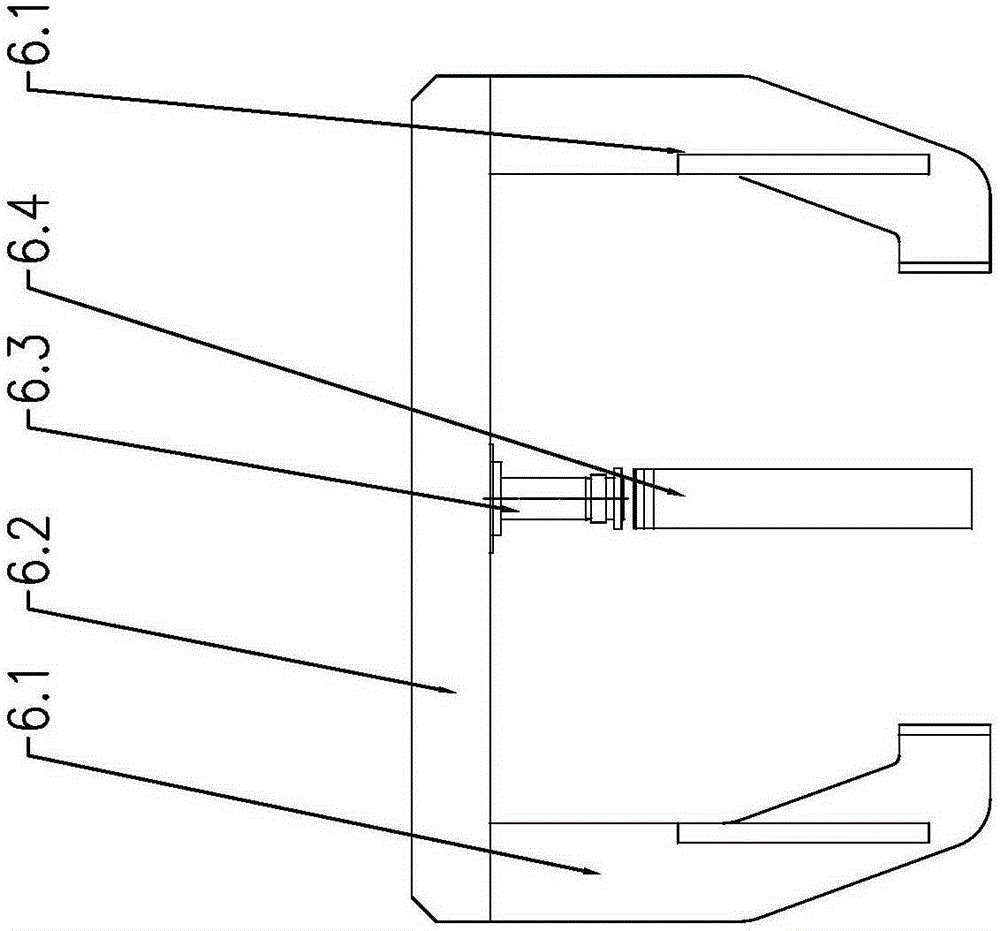

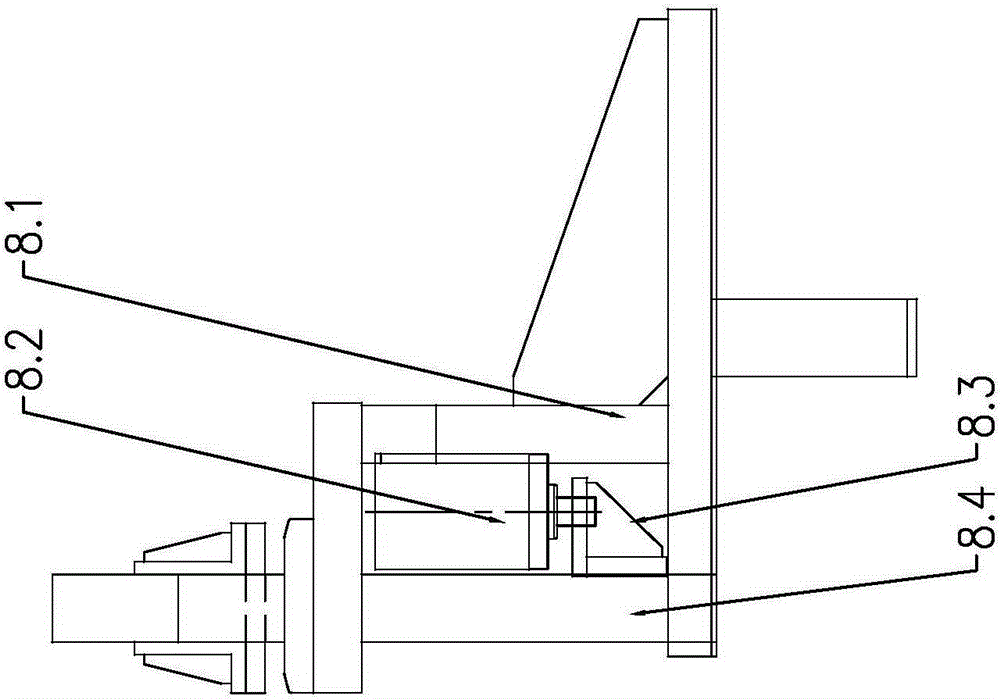

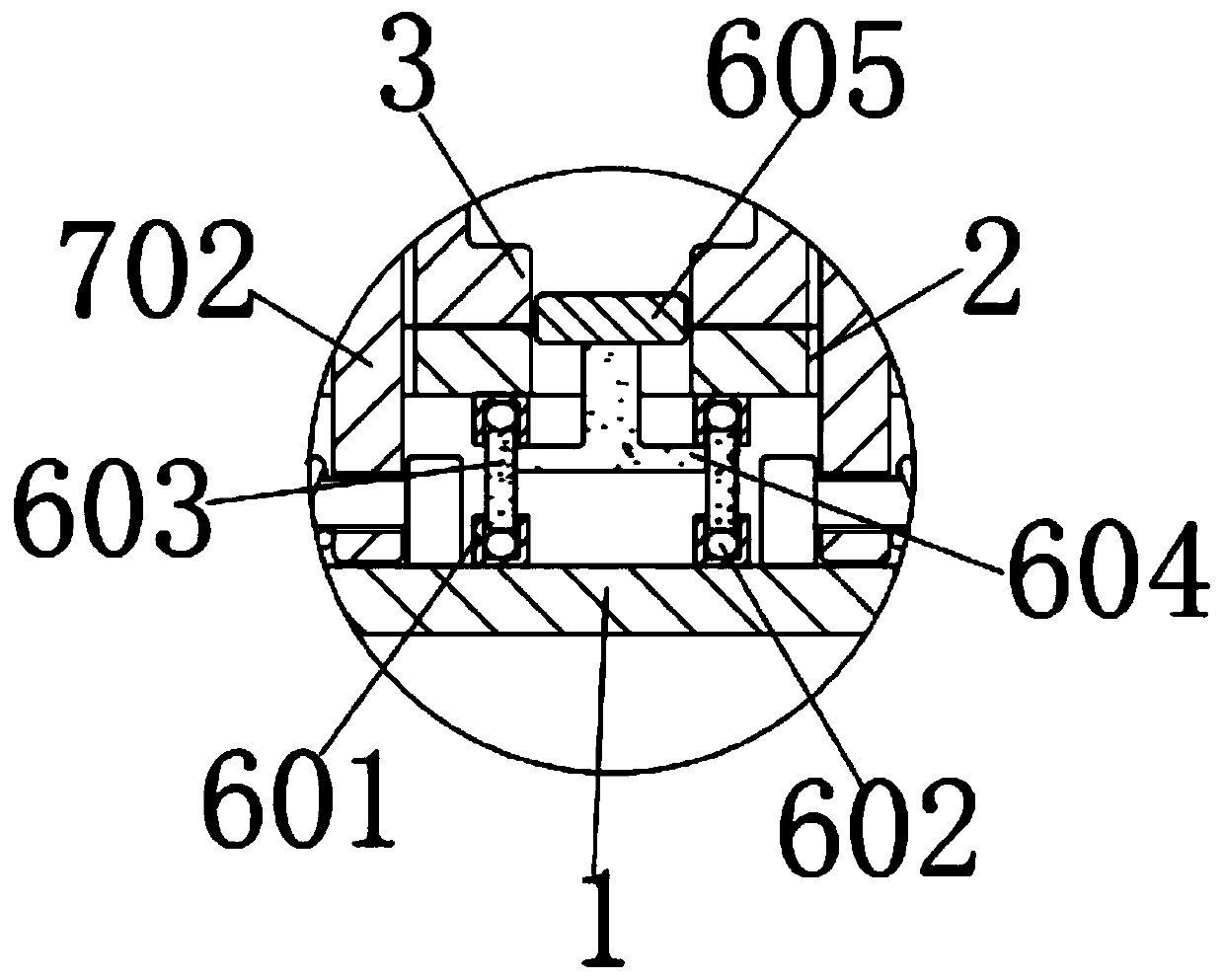

Numerical control machining device for key bit tooth punching

InactiveCN107262625AThe delivery path is reasonableEasy to controlMetal-working feeding devicesKeysNumerical controlPunching

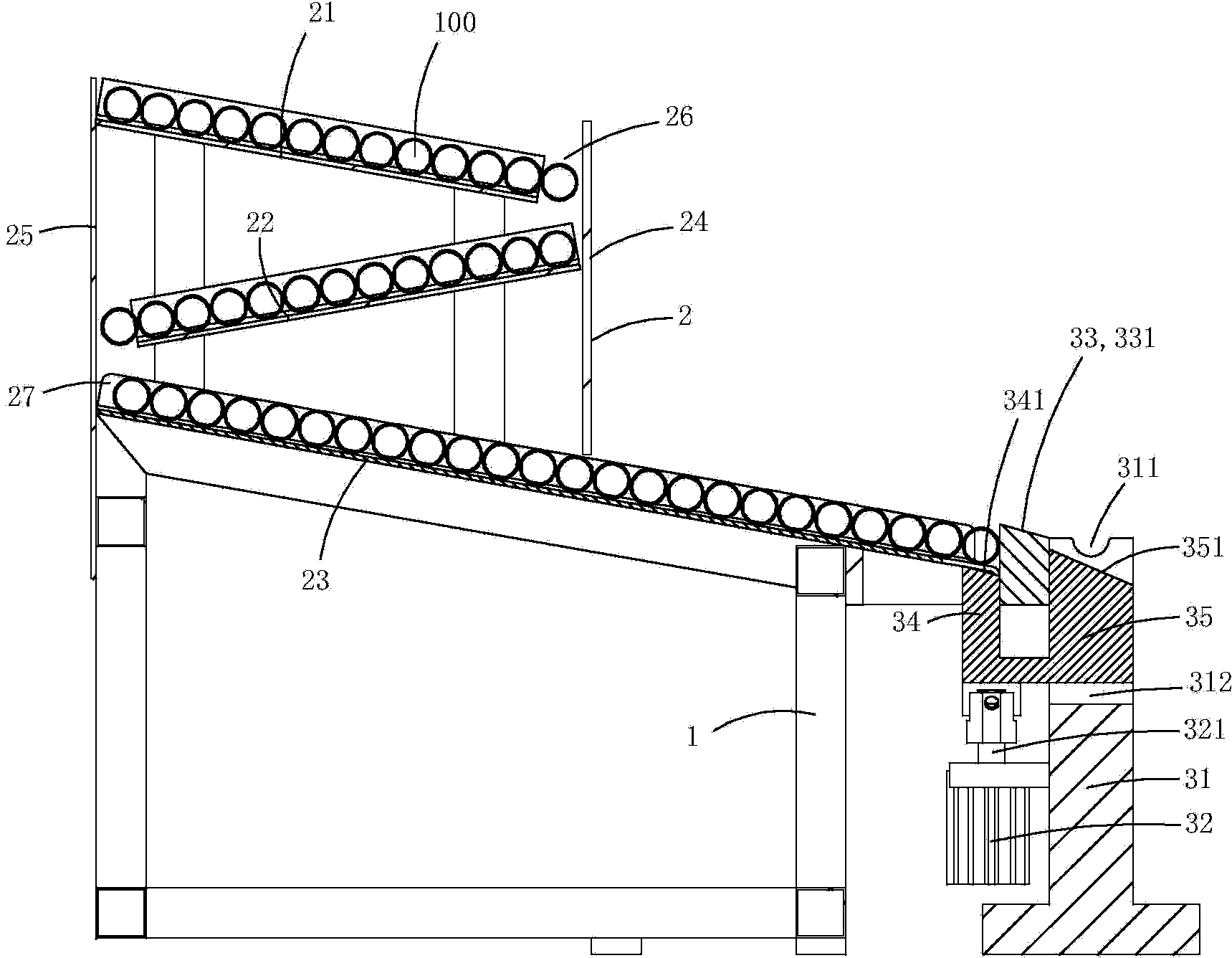

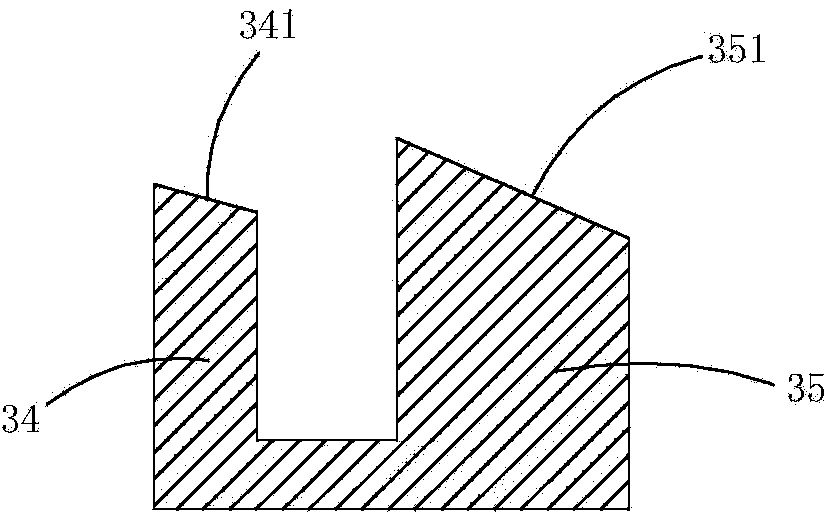

The invention discloses a numerical control machining device for key bit tooth punching. The numerical control machining device for key bit tooth punching comprises a rack which is provided with a feeding mechanism, a clamping mechanism, a tooth punching mechanism, a discharging mechanism, a ring stringing mechanism and a numerical control unit; the clamping mechanism is fixed behind the feeding mechanism which conveys a key to the clamping mechanism to be clamped; the tooth punching mechanism is arranged behind the clamping mechanism, and is used for punching teeth of the key clamped by the clamping mechanism; the discharging mechanism is connected with the feeding mechanism and the ring stringing mechanism, and is used for conveying the key subject to tooth punching to the ring stringing mechanism from the clamping mechanism; and the numerical control unit is connected with the feeding mechanism, the clamping mechanism, the tooth punching mechanism, the discharging mechanism and the ring stringing mechanism, and is used for controlling overall running of the device. According to the numerical control machining device for key bit tooth punching, the conveying path in the key tooth punching process is optimized, the whole tooth punching process of the key is smoother, machined tooth bits are more accurate, the work efficiency is improved, and the control cost is reduced.

Owner:ZHEJIANG XINGYU MASCH TECH CO LTD

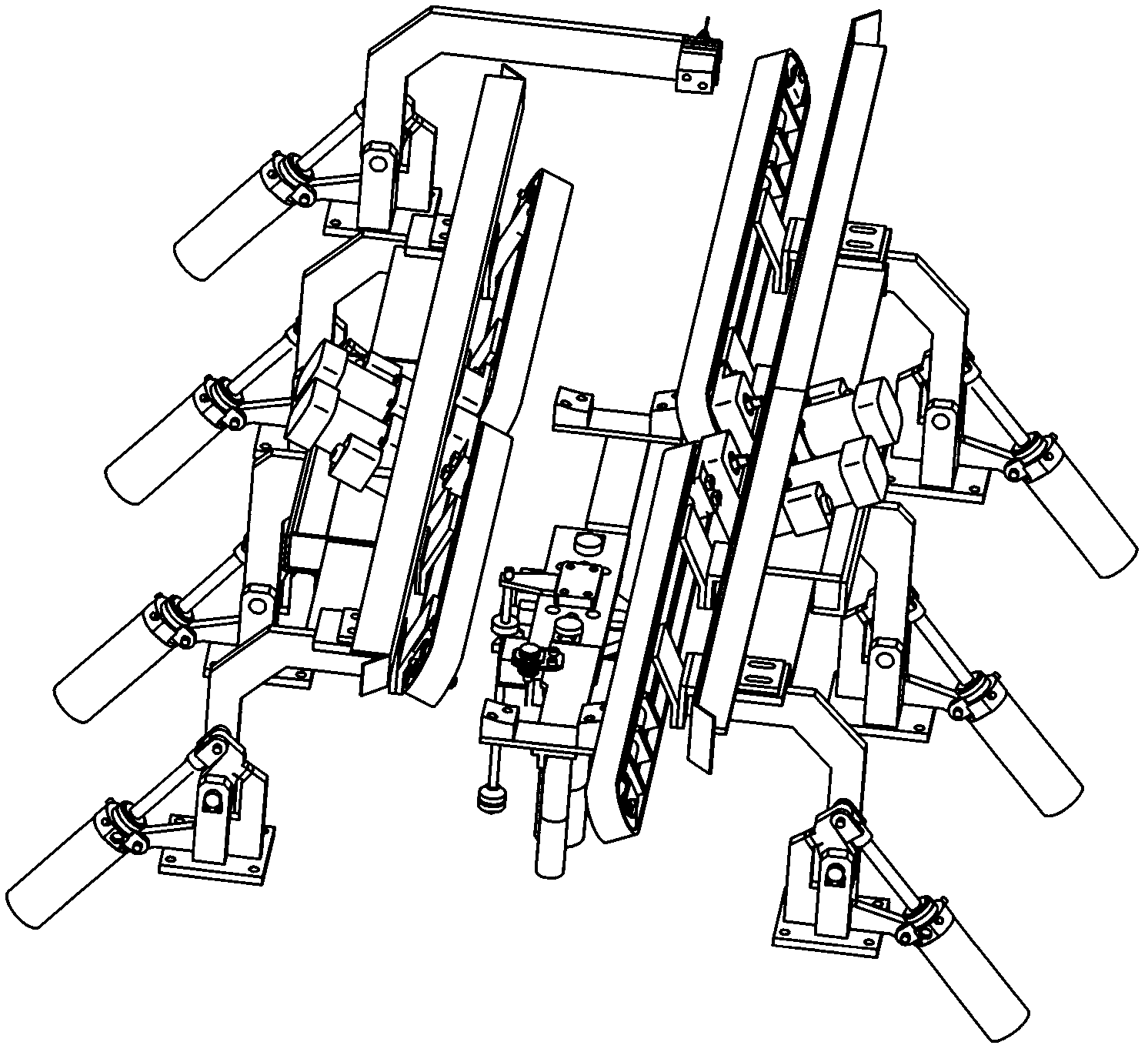

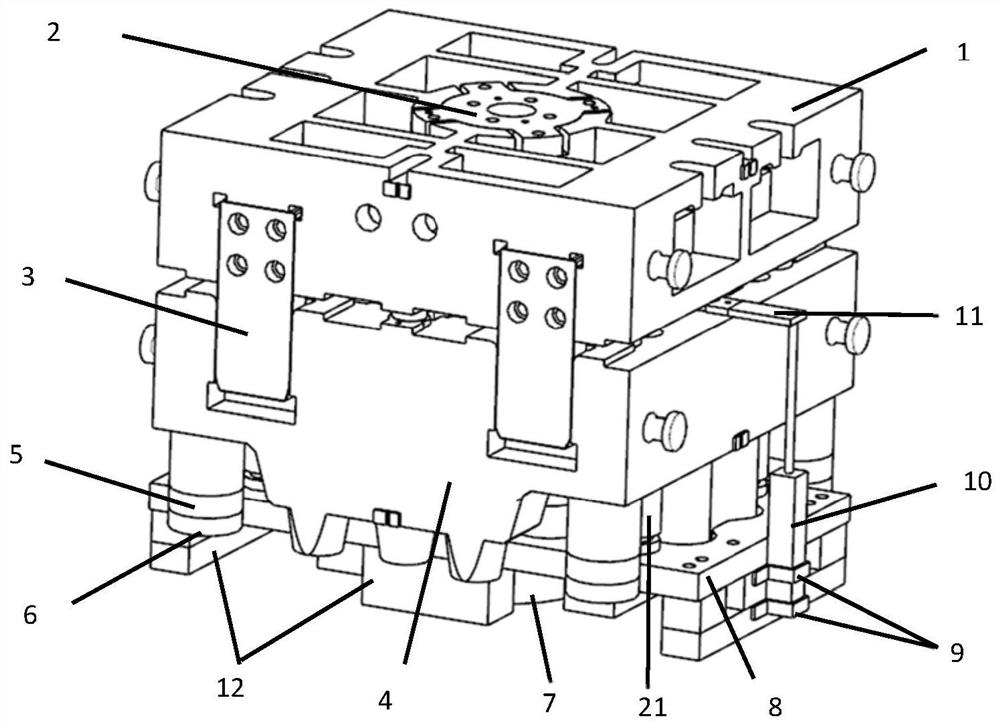

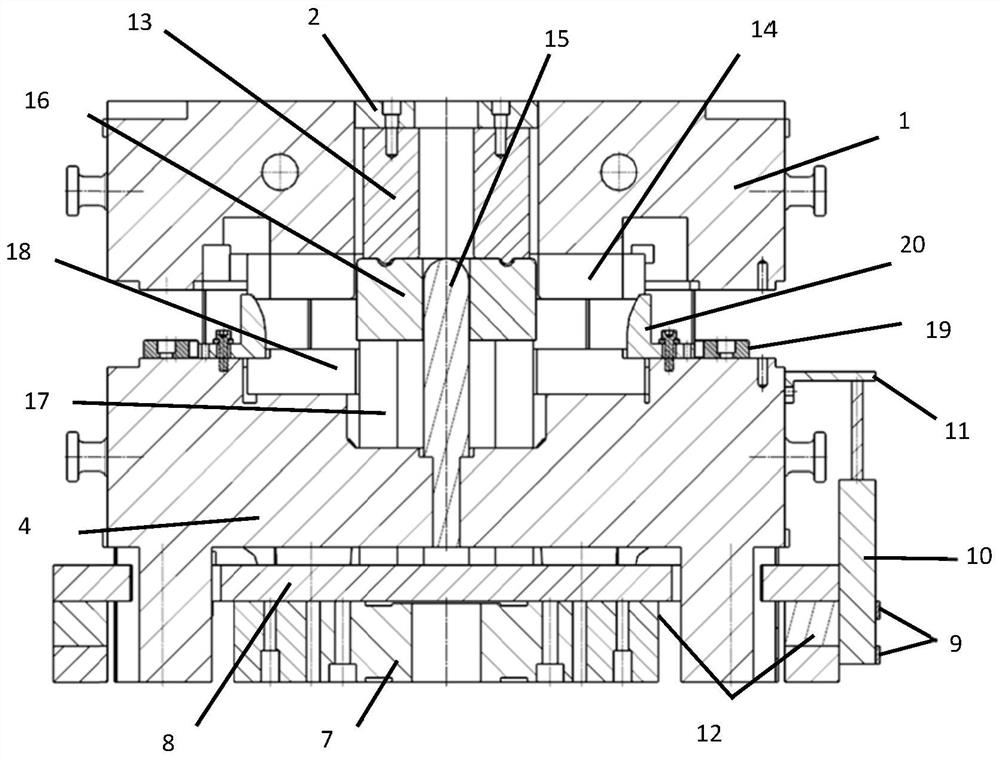

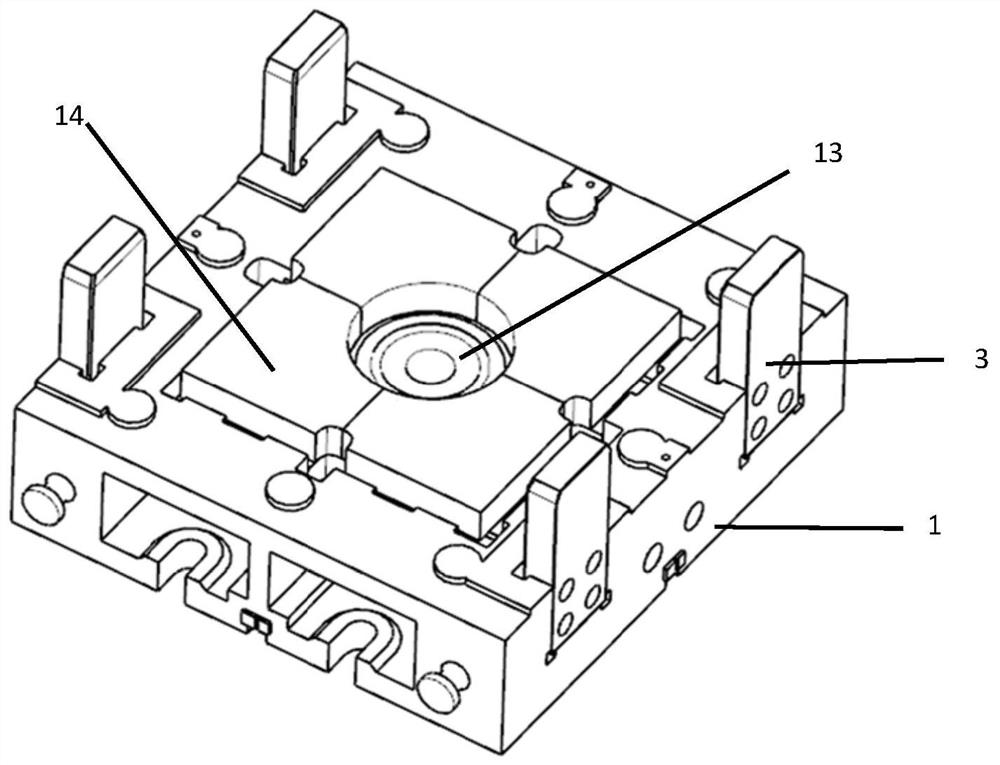

Automatic wire press mold workpiece transfer and positioning device

Owner:SHANDONG WEIFANG FOTON MOLD

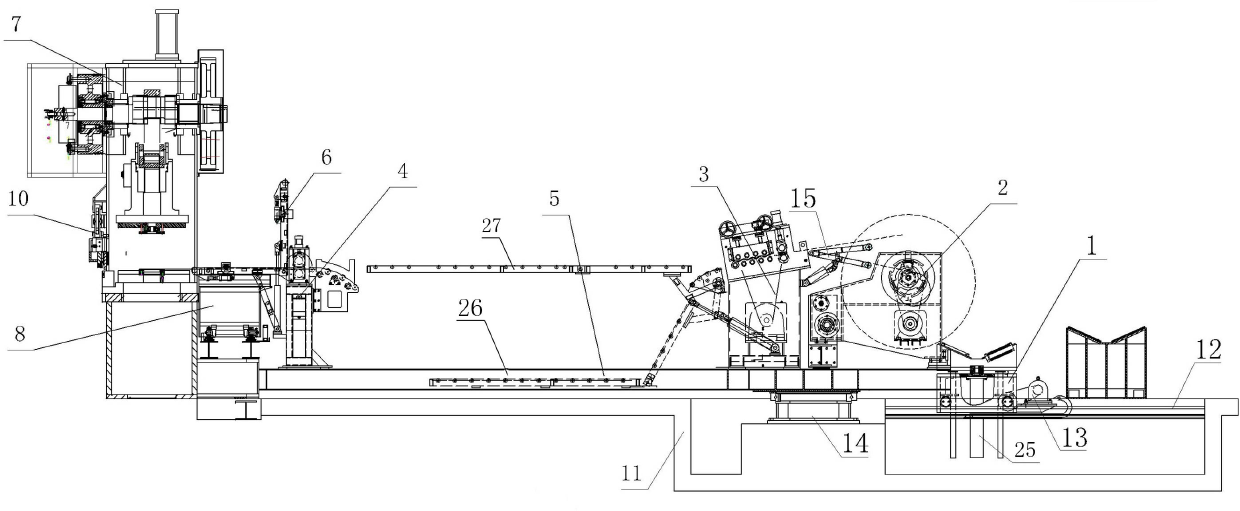

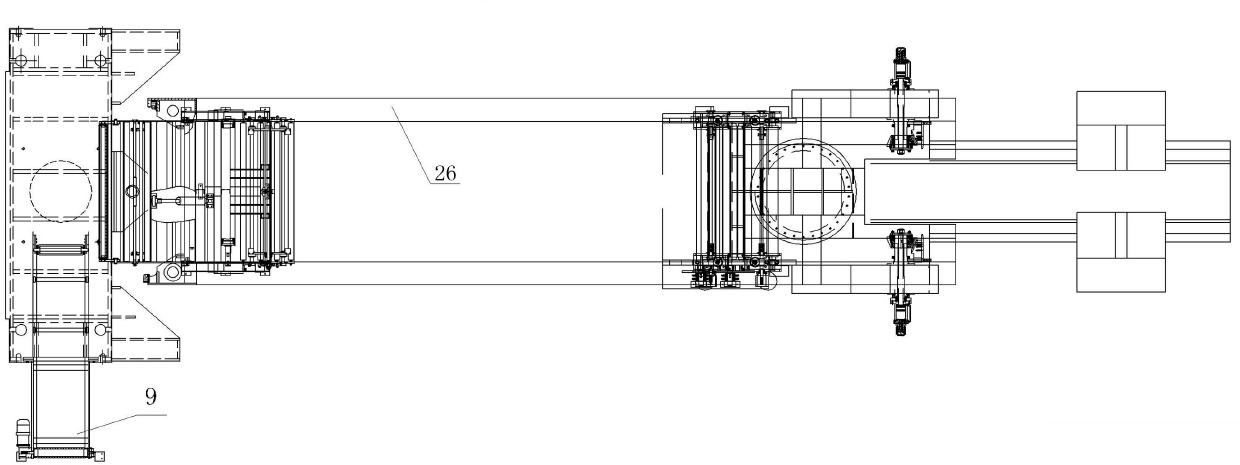

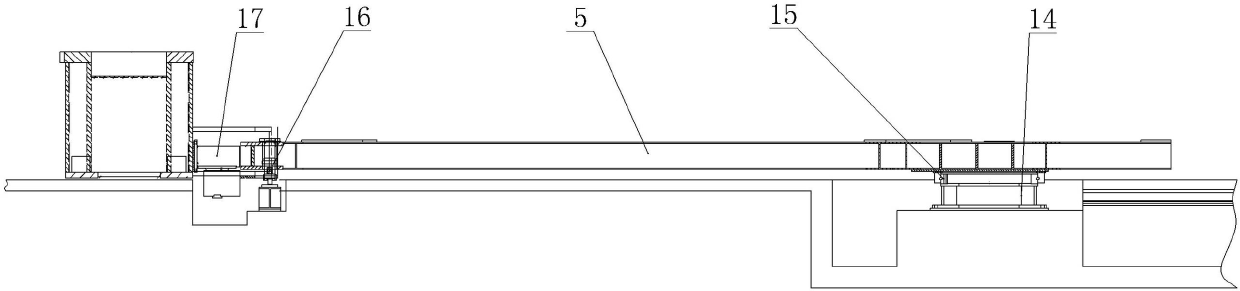

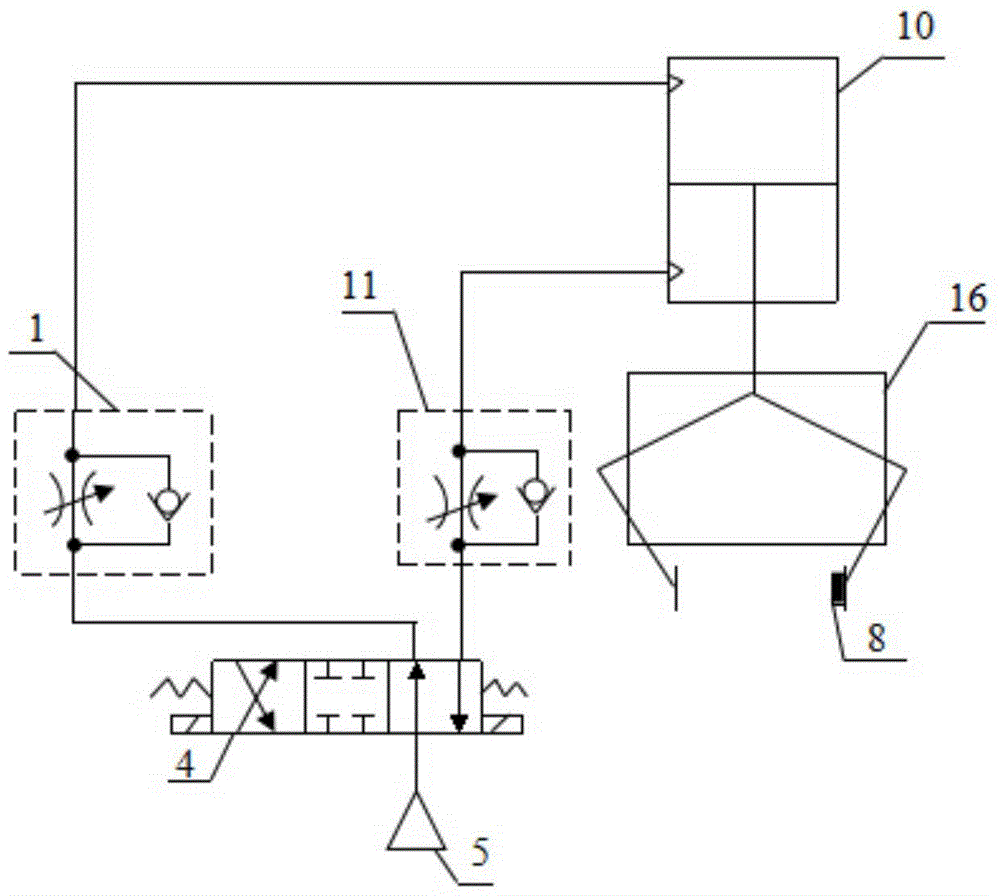

Feeding process and feeding device for straightening machine

InactiveCN101797613ACenter and bite wellSuperiorMetal-working feeding devicesPositioning devicesDevice form

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Wafer blanking production equipment and processing method

Owner:江苏华工蓝天智能科技有限公司

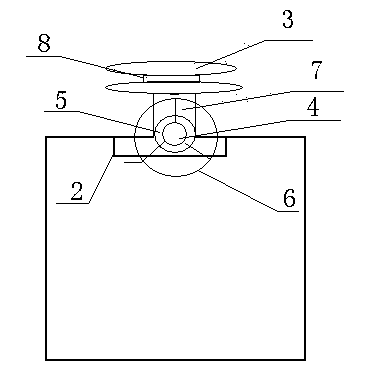

Pipe bending machine

InactiveCN104841738AAvoid damageMetal-working feeding devicesPositioning devicesPipe fittingEngineering

The invention relates to a pipe bending machine. The pipe bending machine is characterized in that a pipe conveying mechanism, a heater and a pipe bending mechanism are sequentially arranged on a base from left to right, wherein the pipe conveying mechanism comprises a stepping motor and a guide wheel; the heater is arranged between the pipe conveying mechanism and the pipe bending mechanism; the pipe bending mechanism comprises a compression roller and a power mechanism; and the compression roller is provided with a peripheral groove matched with a pipe fitting. According to the pipe bending machine, the heater is arranged between the pipe conveying mechanism and the pipe bending mechanism and the pipe fitting is heated before being bent, so that the damages to the pipe fitting in a bending process can be reduced.

Owner:XINCHANG HUAXIONG MACHINERY

Stamping production equipment and stamping production technology

Owner:NINGBO HAIHONG RADIATOR

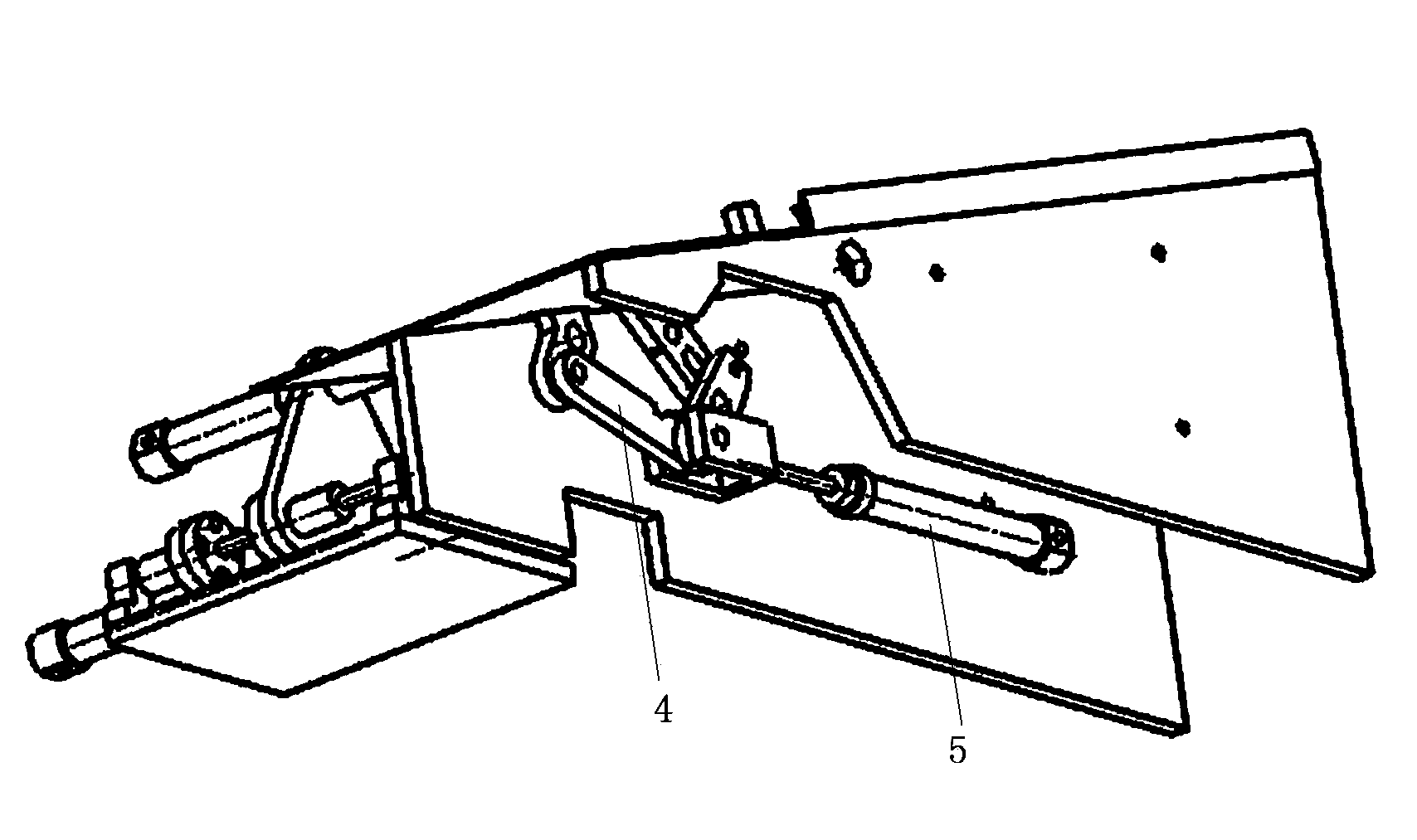

Steel bending equipment for steel machining

InactiveCN112139303AAvoid scratchesAvoid damageShaping toolsMetal-working feeding devicesStructural engineeringContact position

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

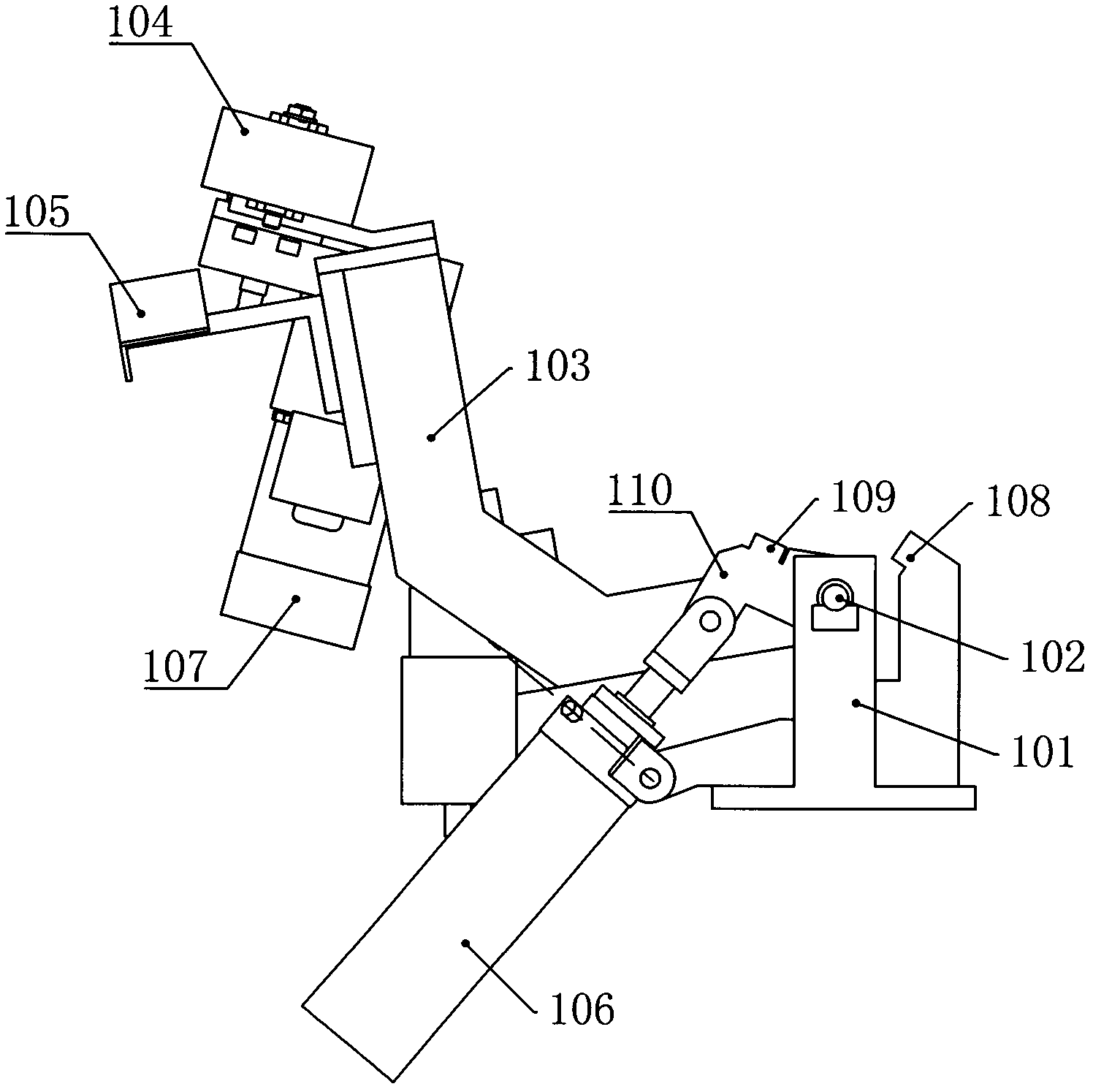

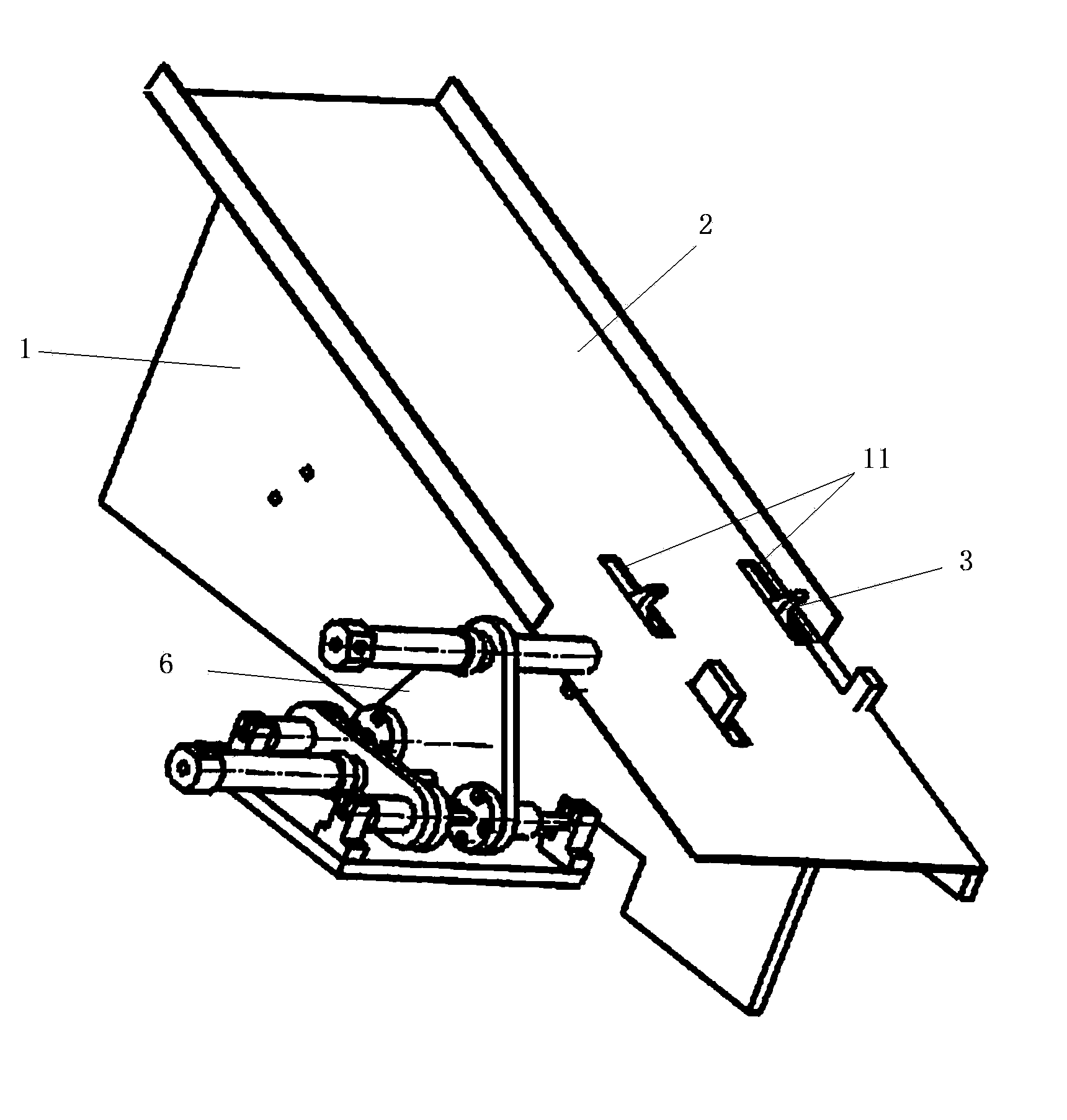

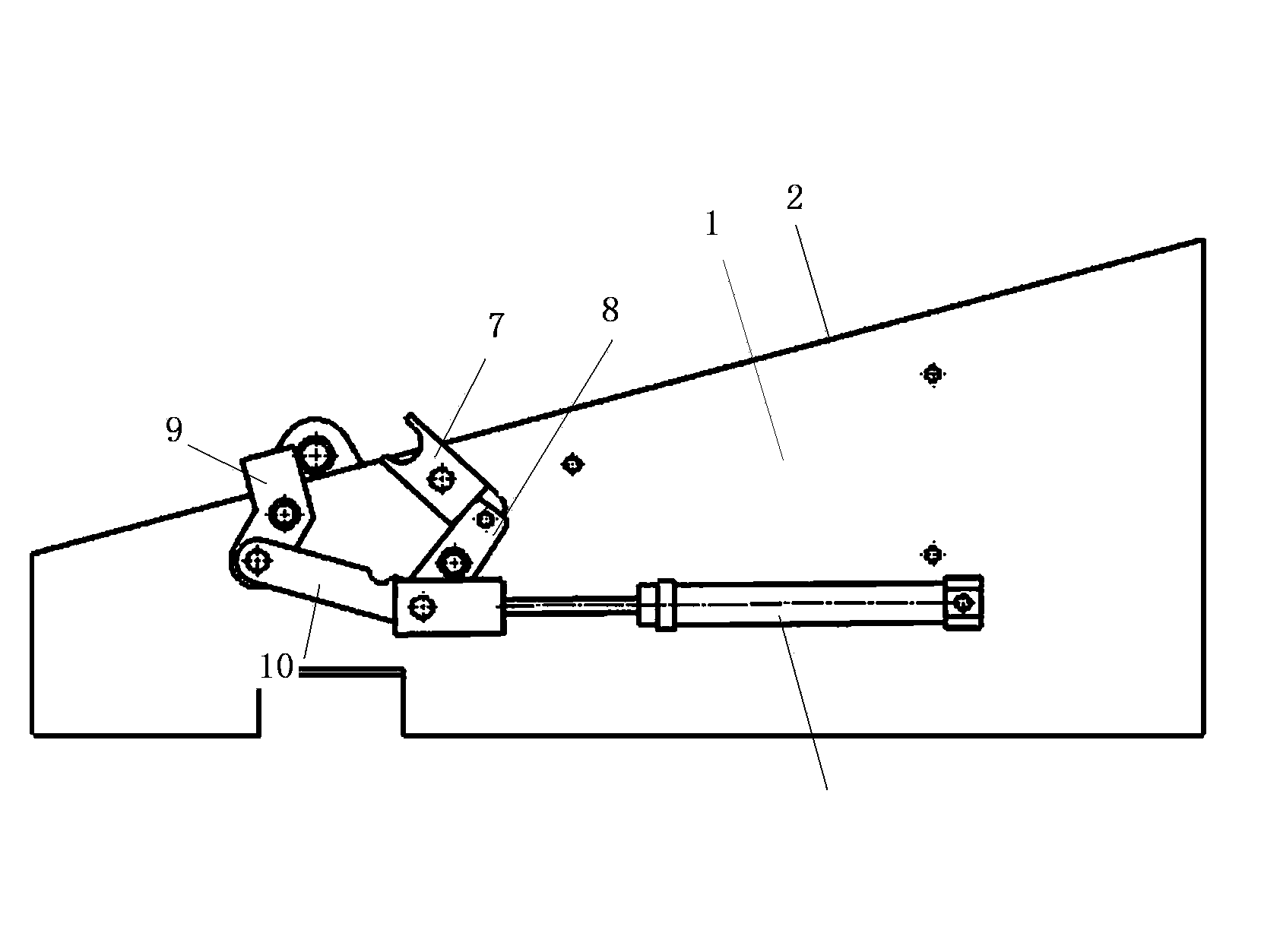

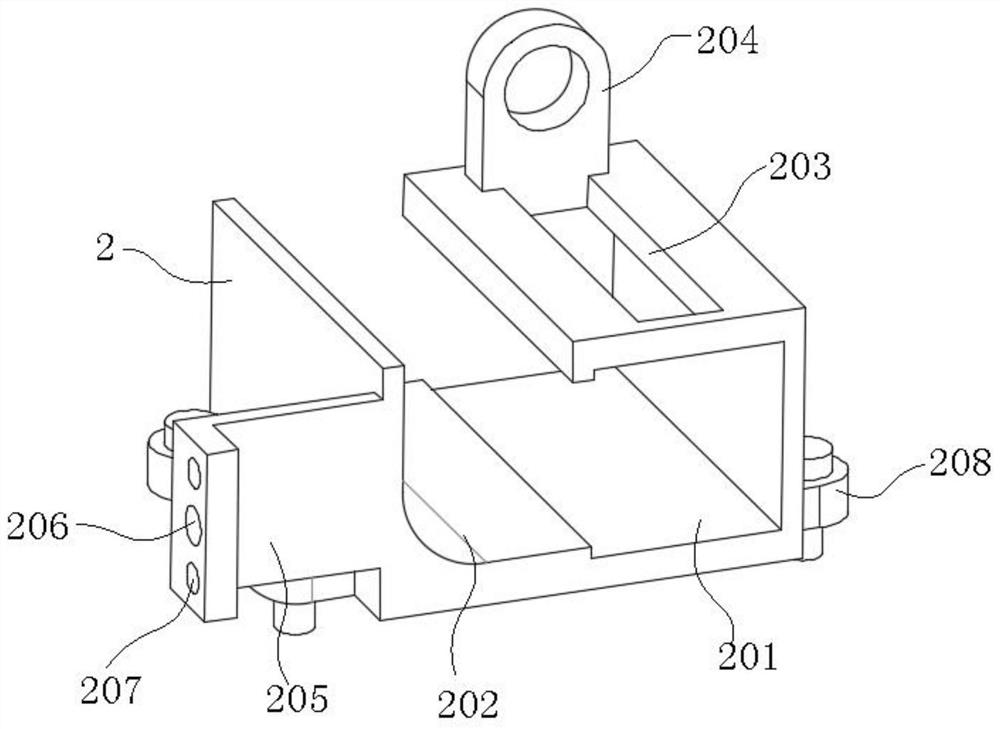

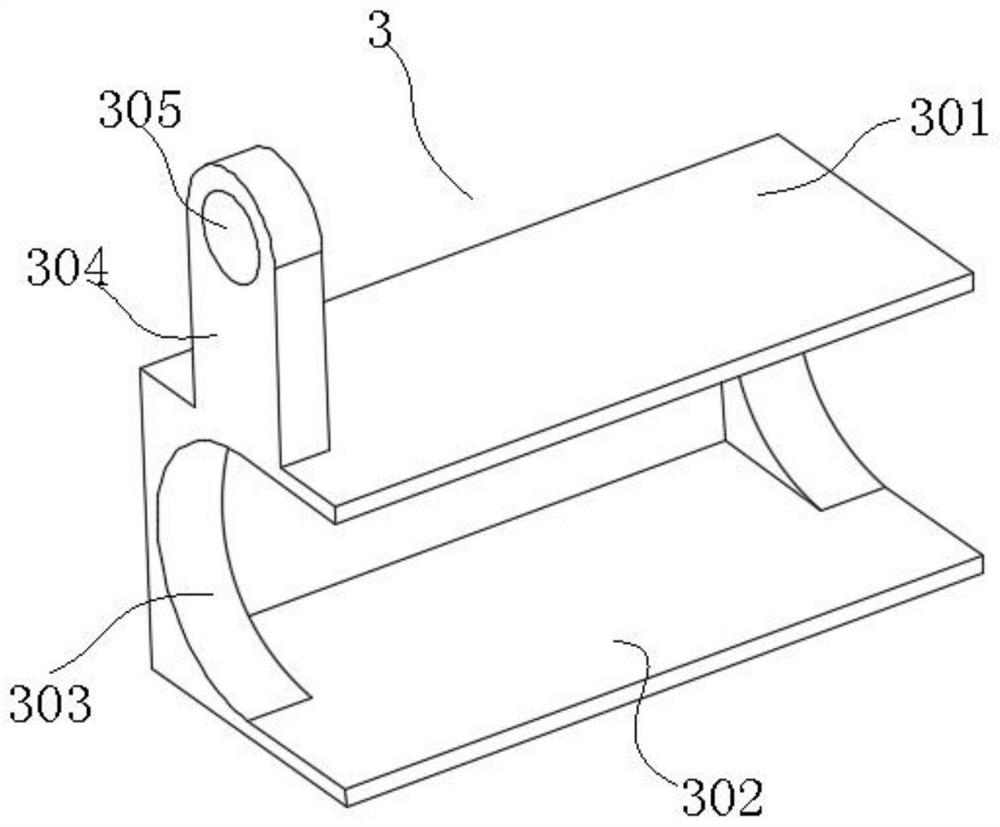

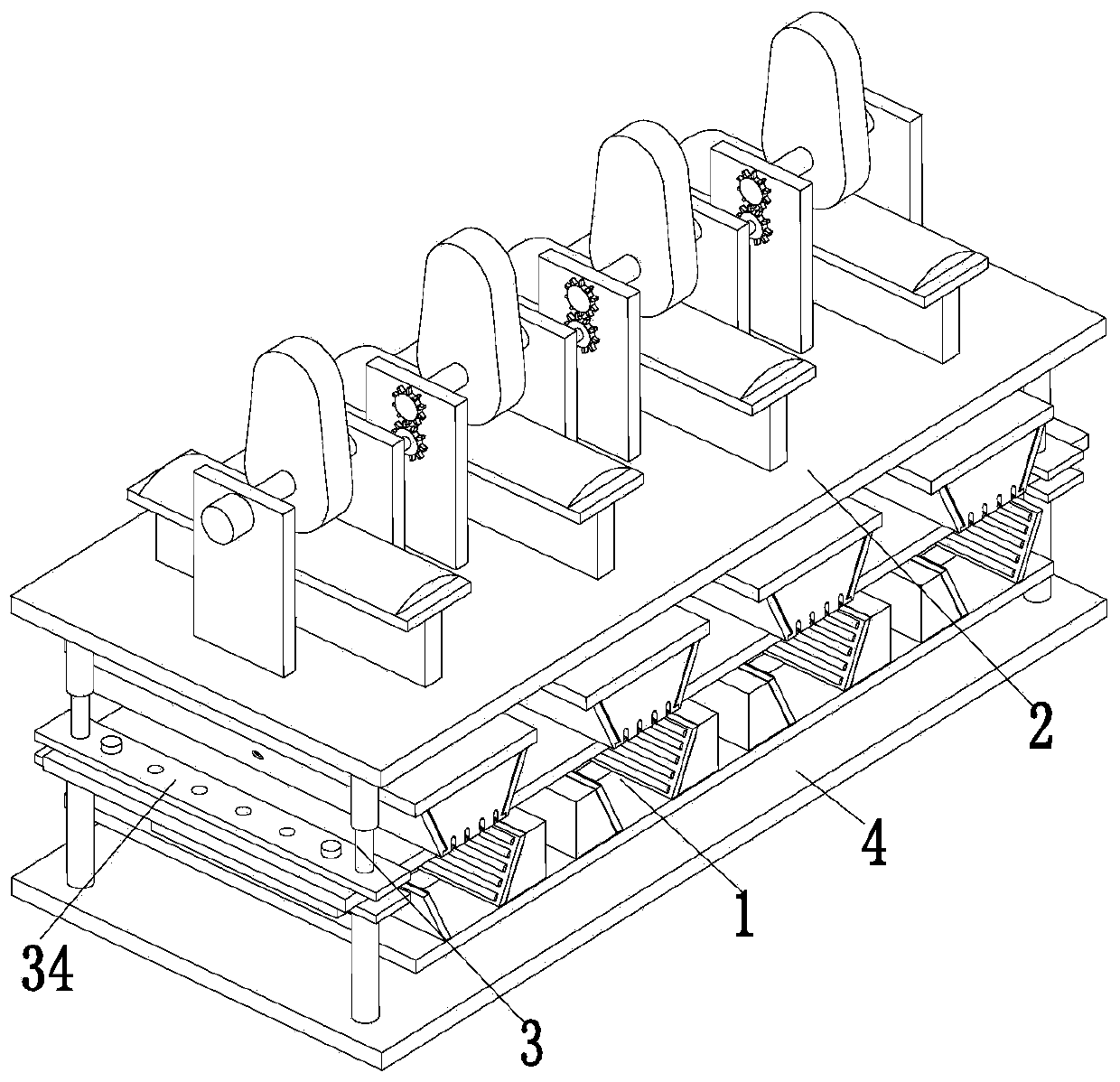

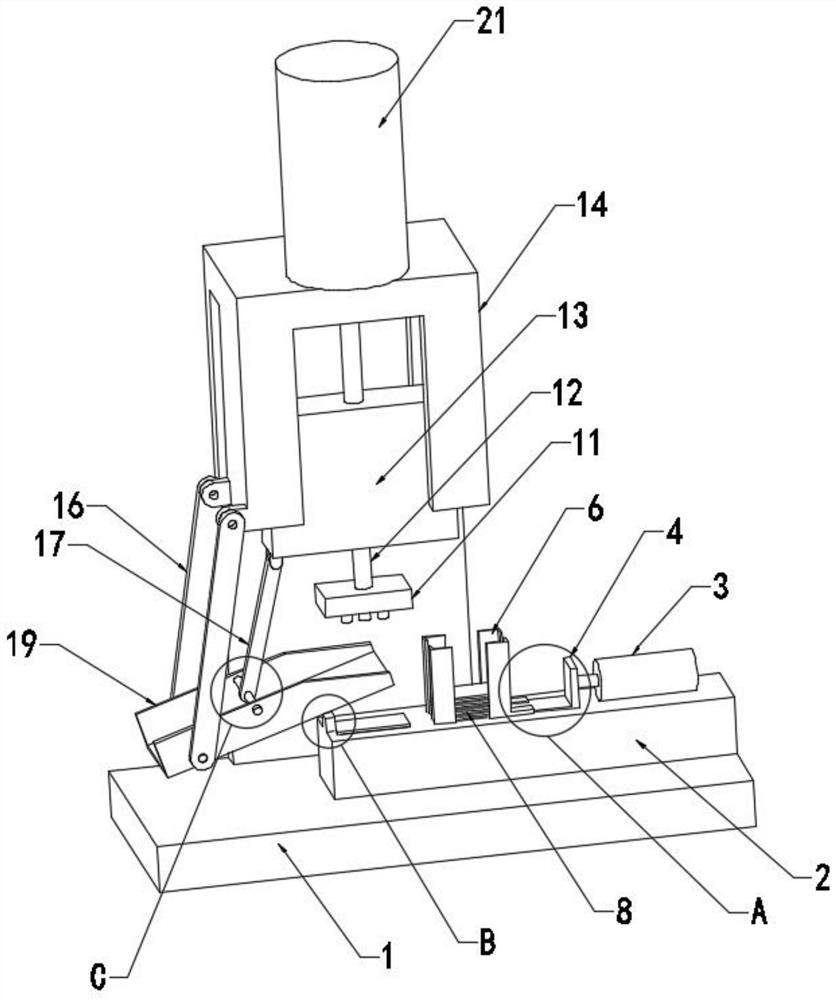

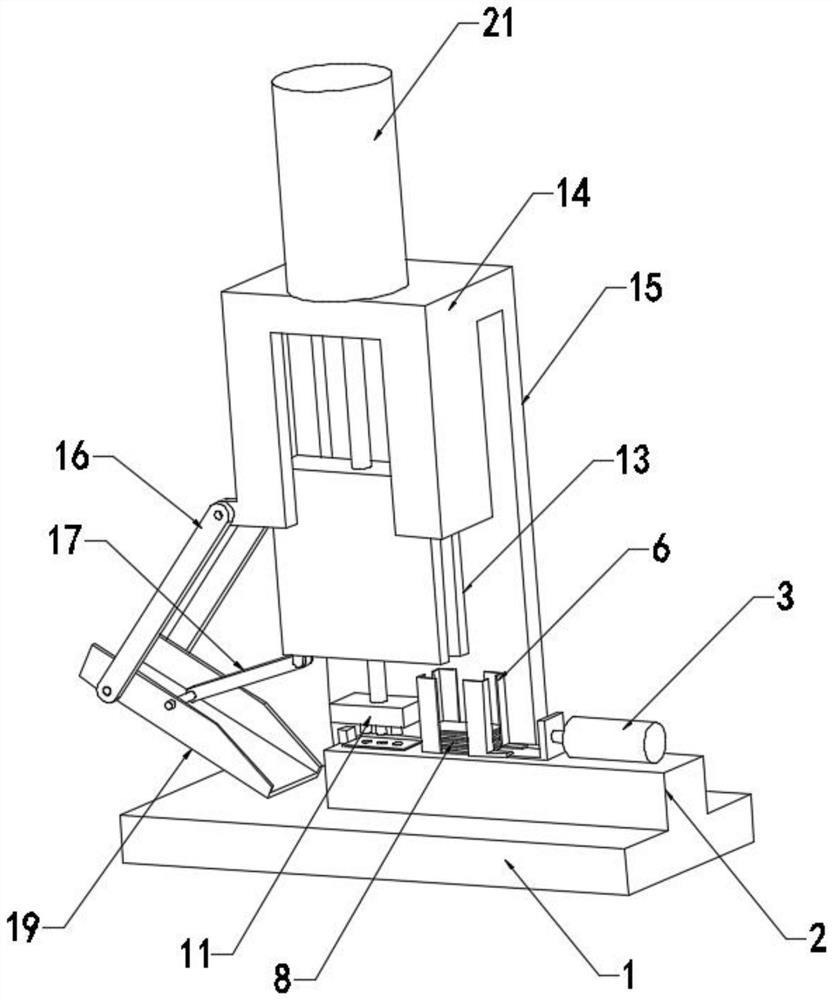

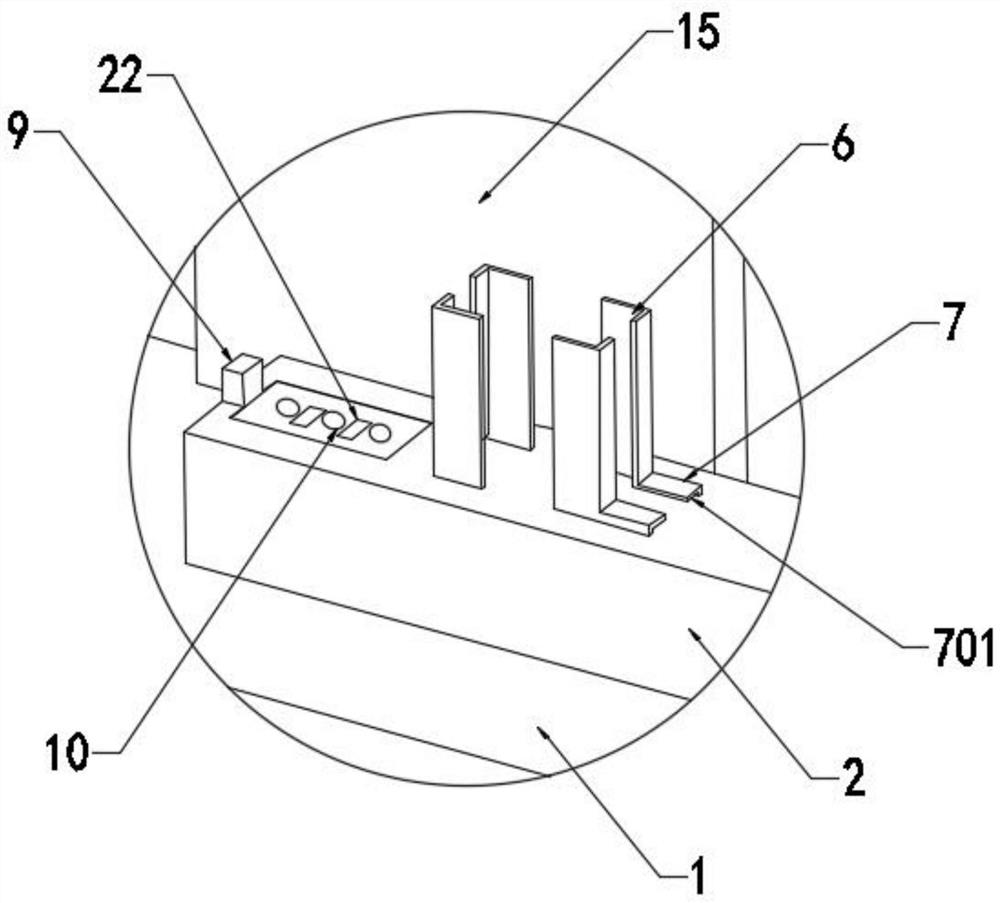

Punch line and material pushing and positioning device thereof

InactiveCN104722669AImprove connection convenienceMetal-working feeding devicesPositioning devicesButt jointEngineering

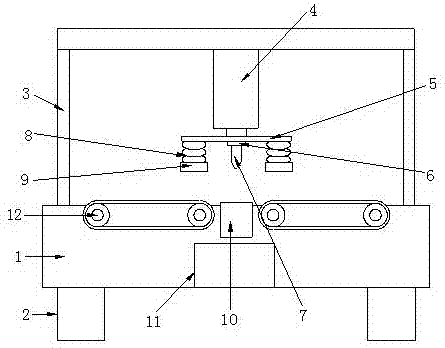

The invention discloses a punch line and a material pushing and positioning device thereof. The material pushing and positioning device comprises an installation seat, a material pushing seat, a material pushing plate, a straight connecting rod, a bent connecting rod, a telescopic cylinder connecting rod and a telescopic cylinder, wherein one end of the installation seat is rotationally connected with the material pushing seat, and the other end of the installation seat is connected with a fixed part of the telescopic cylinder; the material pushing plate in butt joint with a blank is installed at the upper end of the material pushing seat, the lower end of the material pushing seat is rotationally connected with a first end of the straight connecting rod, and a second end of the straight connecting rod is rotationally connected with the lower end of the bent connecting rod; the corner of the bent connecting rod is rotationally connected with the installation seat, the upper end of the bent connecting rod is rotationally connected with the upper end of the telescopic cylinder connecting rod, and the lower end of the telescopic cylinder connecting rod is fixedly connected with a telescopic part of the telescopic cylinder; all rotary shafts are parallel. In this way, the material pushing and positioning device can realize automatic feeding and positioning of blank materials, thereby improving the efficiency of punching production and the automation degree of the punch line, relieving the labor intensity of workers, and guaranteeing the production safety of workers.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Auxiliary material feeding device used for electro-hydraulic numerical control bending machine

Owner:南京郎顿机床制造有限公司

Adjusting device for feeding frame of bridge plate flatting machine

Owner:江苏天成电器设备有限公司

Automatic pipe feeding mechanism

ActiveCN103567314AImprove product qualityFast processingMetal-working feeding devicesPositioning devicesIndustrial AccidentEngineering

Owner:上海汽车空调配件股份有限公司

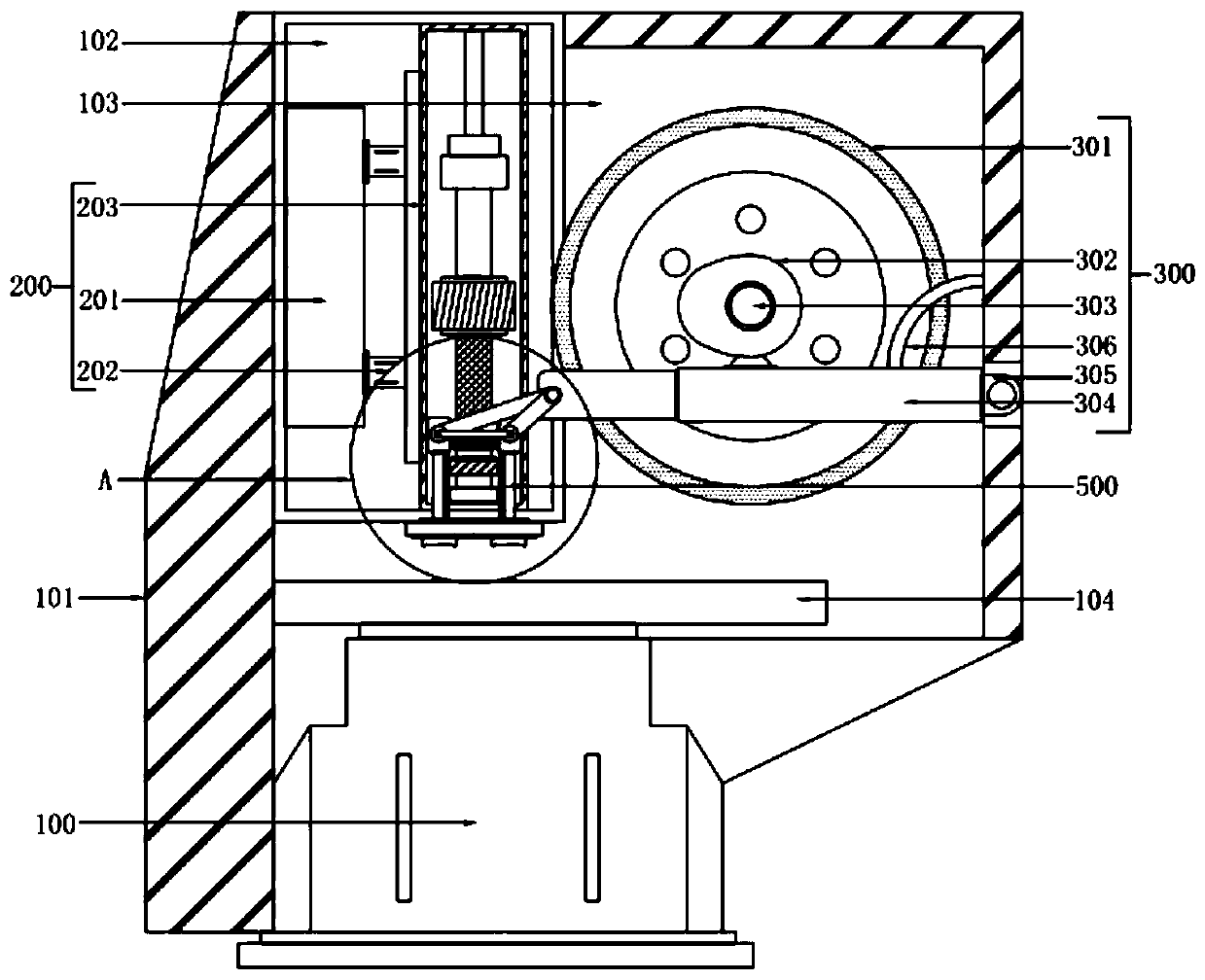

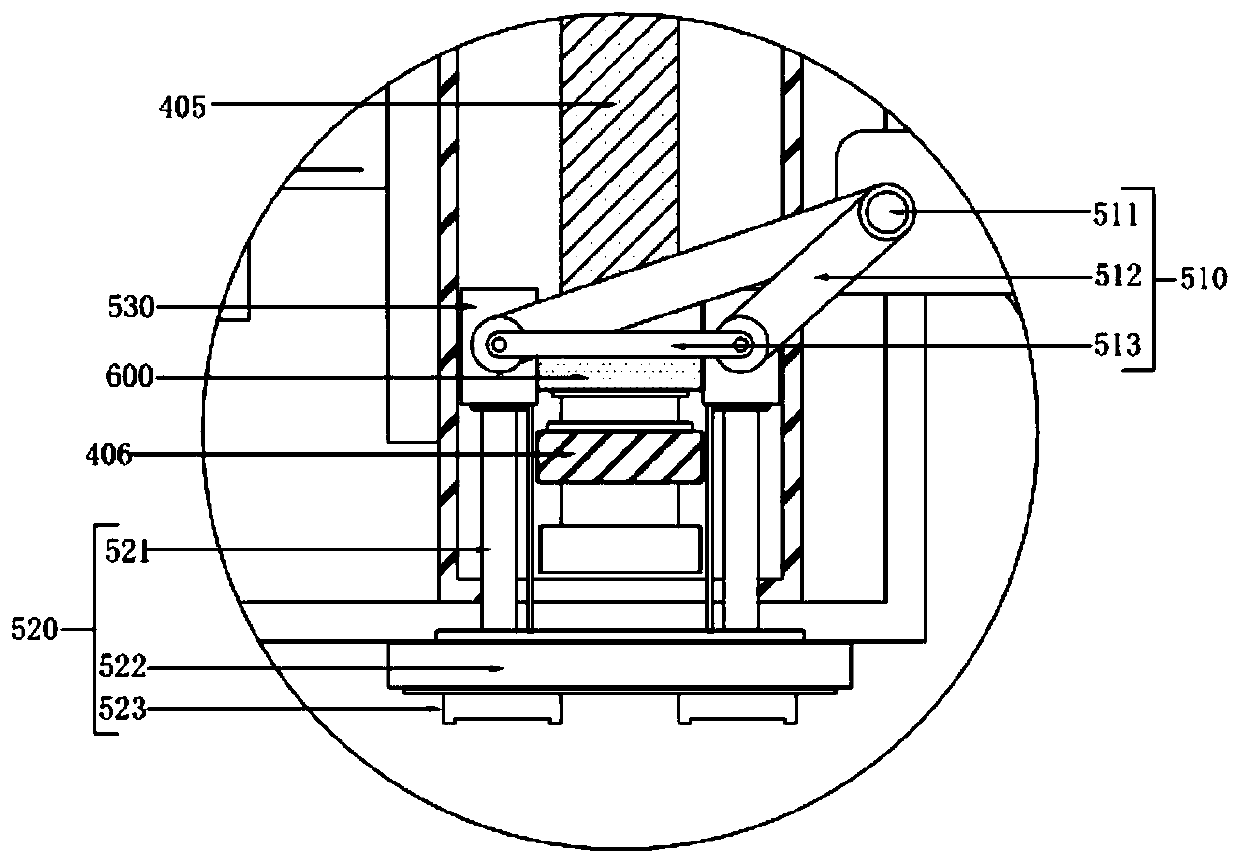

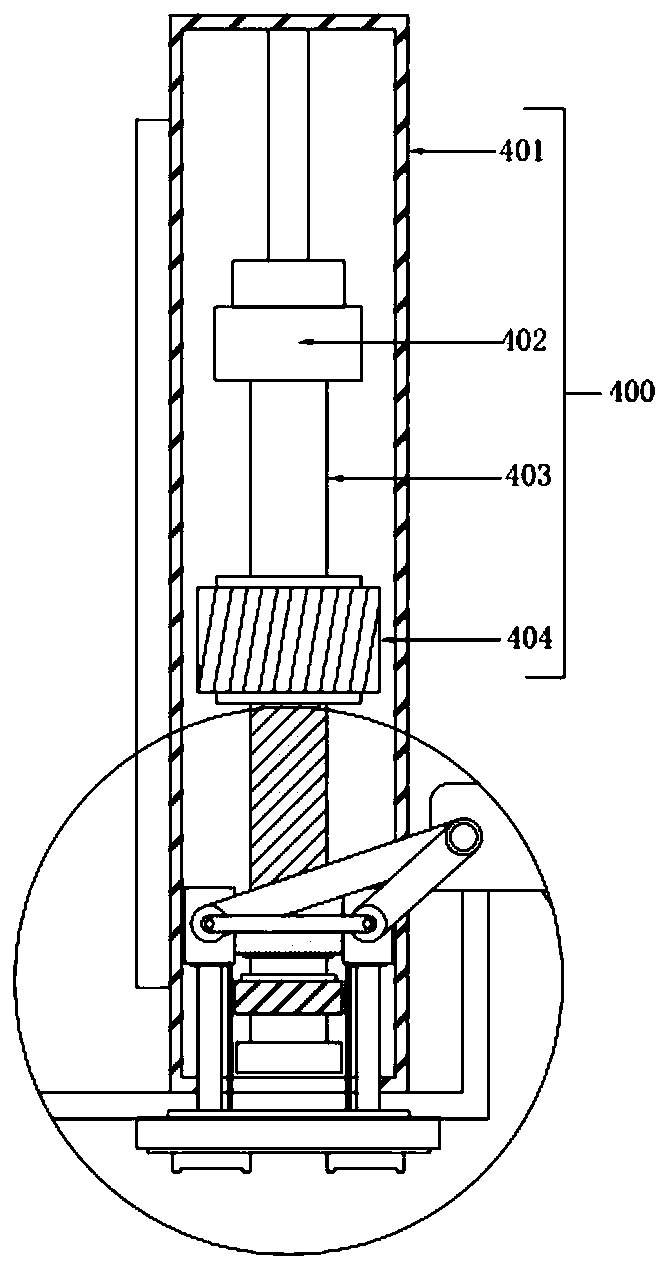

Cam push rod type material pressing device with numerical control punch press frame and method

InactiveCN111545656AImprove stabilityImprove work efficiencyMetal-working feeding devicesPositioning devicesNumerical controlPunch press

Owner:新昌县羽林街道全利机械厂

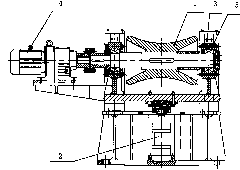

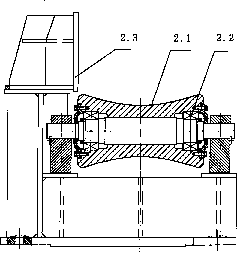

Double alloy steel rail distortion correction device

ActiveCN104801584AImprove efficiencyHigh precisionMetal-working feeding devicesPositioning devicesMetallurgyTorsion spring

The invention discloses a double alloy steel rail distortion correction device which is characterized by being provided with a horizontal C-shaped body, wherein a clamping mechanism and a torsion mechanism are arranged at different axial positions in a C-shaped cavity, and a groove opening of the C-shaped cavity faces upwards; the clamping mechanism pushes clamping sliding blocks arranged at opposite positions by utilizing clamping oil cylinders to clamp the alloy steel rail in an encircling manner; the torsion mechanism pushes torsion clamping sliding blocks arranged at opposite positions by utilizing torsion clamping oil cylinders to clamp the alloy steel rail in an encircling manner, the torsion clamping sliding blocks are arranged in shaft end sliding chutes of a torsion hollow shaft, gear teeth which form a torsion gear are arranged on the periphery of the torsion hollow shaft, a torsion loading oil cylinder drives a rack to stretch and contract, and the rack is meshed with the torsion gear to drive the alloy steel rail to reverse. The double alloy steel rail distortion correction device achieves distortion correction for the alloy steel rail, corrects the distortion repeatedly in a segmental distortion correction mode, and can acquire high distortion correction efficiency and accuracy.

Owner:HEFEI UNIV OF TECH

Continuous feeding and stamping apparatus for bottle cap production

InactiveCN109127940AHighly corporatedImprove stamping effectMetal-working feeding devicesClosure capsDrive shaftEngineering

Owner:安徽省潜山县包装制品有限公司

Electronic element stamping raw material feeding clamping mechanical hand and clamping method thereof

Owner:WUHU ANPU ROBOT IND TECH RES INST

Adjustable copper pipe bending machine

InactiveCN105312374AMeet the needs of angle bendingEasy to operateMetal-working feeding devicesPositioning devicesEngineeringRotating disc

Owner:苏州沃尔非自动化设备有限公司

Punching device capable of achieving conveying

InactiveCN107344197AImprove stabilitySimple and fast operationPerforating toolsMetal-working feeding devicesHydraulic cylinderPunching

Owner:SUZHOU HONGQIRUI AUTOMATION

Feeding device for electric power copper pipe flaring machine

InactiveCN104056973AImprove processing efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:STATE GRID CORP OF CHINA +1

Drawing die for sheet metal part of automobile shock absorber

InactiveCN106001276AQuality assuranceAchieve drawing formingShaping toolsMetal-working feeding devicesWrinkle skinEngineering

Owner:SHAZHOU PROFESSIONAL INST OF TECH

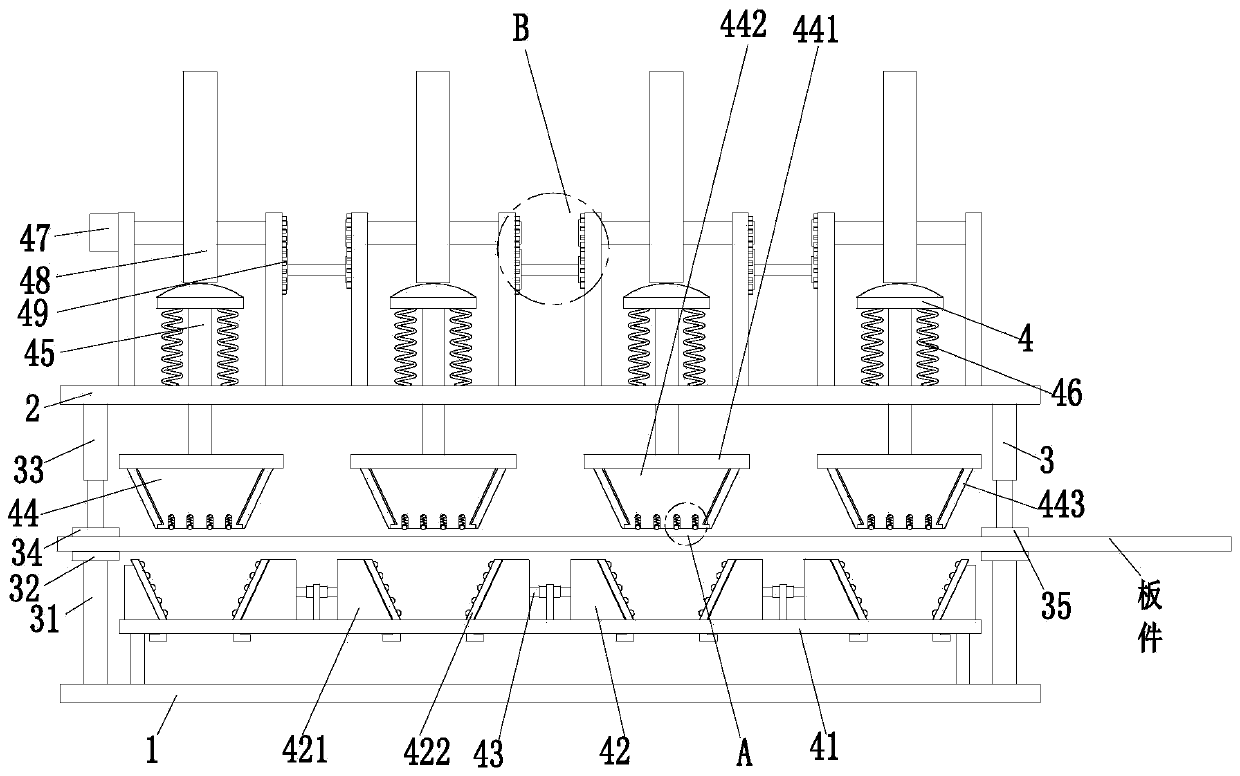

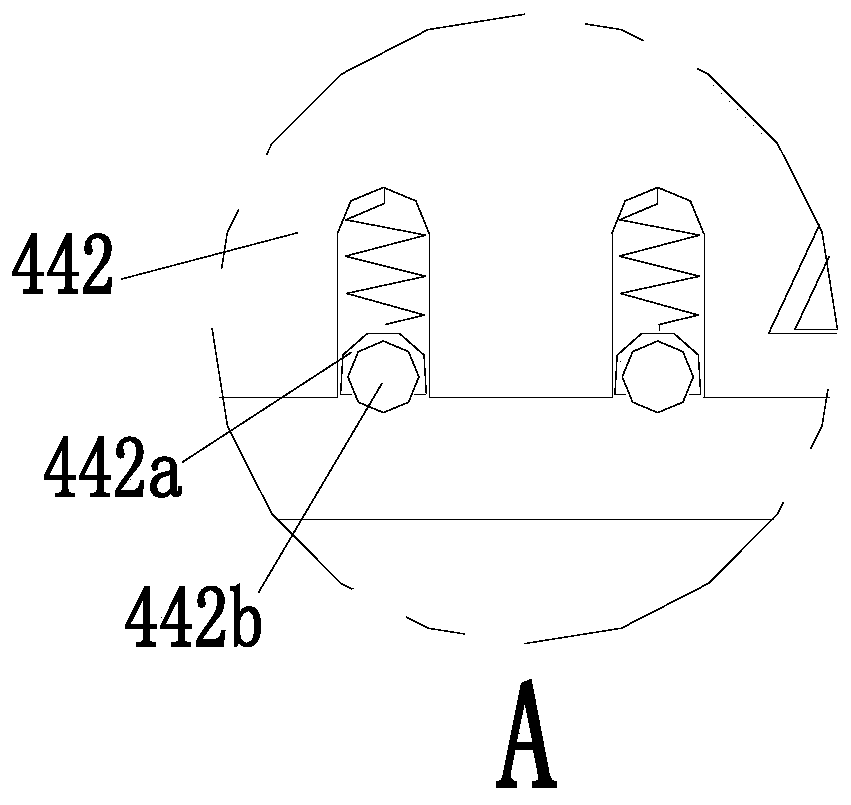

Flexible roll bending numerical control plate bending machine

PendingCN113458197AEasy to move up and downAvoid deformationMetal-working feeding devicesPositioning devicesNumerical controlHydraulic cylinder

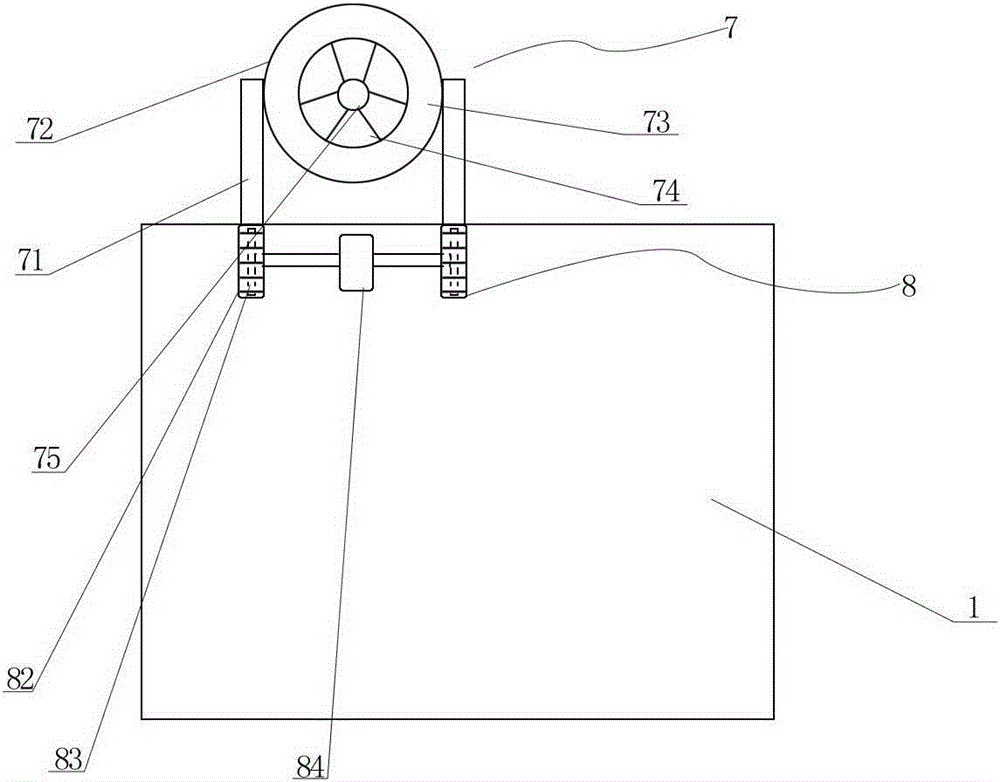

The invention relates to the technical field of plate bending machines, in particular to a flexible roll bending numerical control plate bending machine. The machine comprises a base. A feeding box body and supporting columns are fixedly connected to the outer surface of the upper end of the base, the supporting columns are distributed behind the feeding box body in a bilateral symmetry manner, a driving roller and a driven roller are arranged between the two supporting columns, and the driving roller is located over the driven roller, and first hydraulic cylinders are fixedly connected to the outer surfaces of the upper ends of the supporting columns correspondingly. Plates with different diameters in the bending treatment process are lifted up through supporting blocks, the situation that the plates hang down and deform under the influence of gravity is avoided, the application range is widened, meanwhile, when the plates are fed, the plates with different widths are clamped and limited through limiting rollers on the two sides, the bending effect is prevented from being affected by position deviation generated during manual feeding, feeding is assisted through feeding rollers, the friction force is reduced, the pushing force of a worker for pushing a plate is conveniently reduced, and the overall working efficiency is improved.

Owner:汪新纪

Multi-caliber pipe bending device for steel pipe machining

InactiveCN112024663AAvoid bendingImprove general performanceMetal-working feeding devicesPositioning devicesPipeScrew thread

Owner:合肥巨步机械科技有限公司

Corrugated pipe forming device

ActiveCN112958671AEasy to holdStable clampingShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

Owner:江苏新汇烽塑胶有限公司

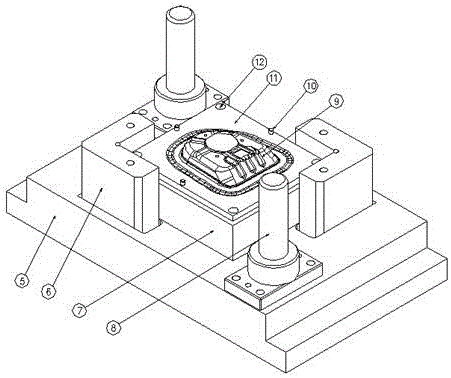

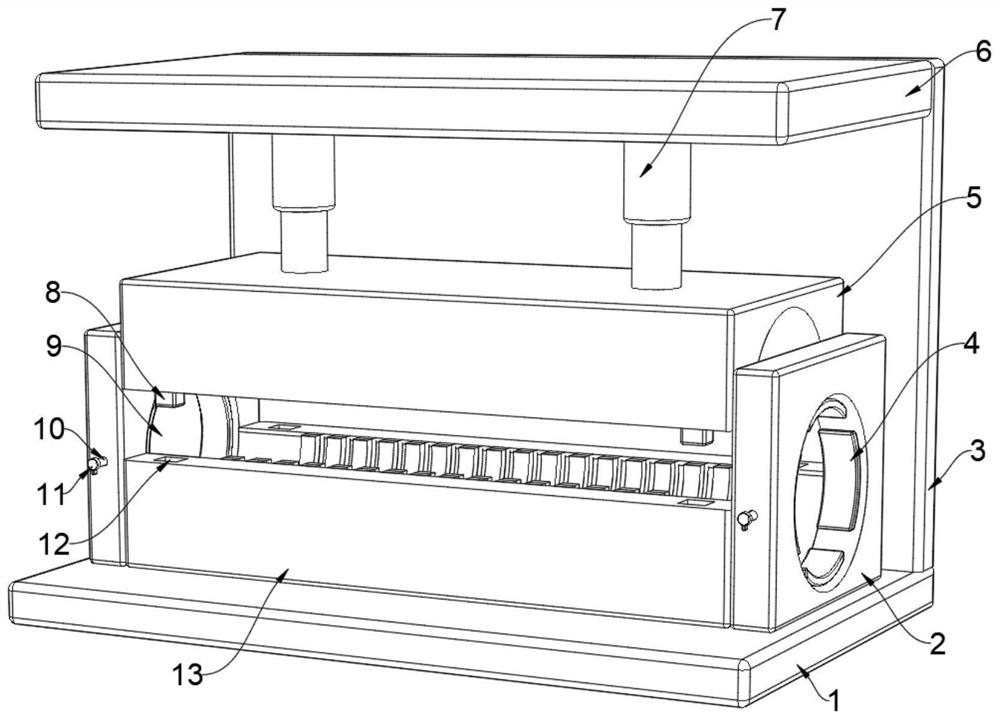

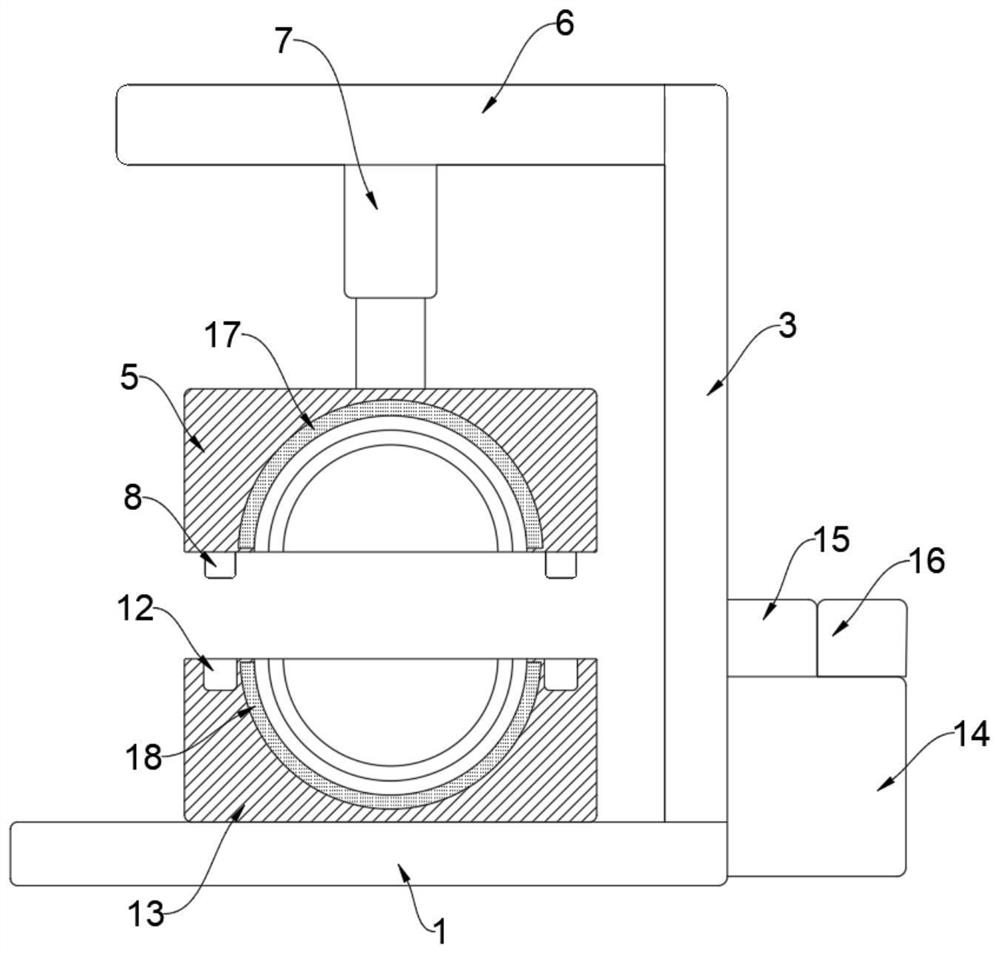

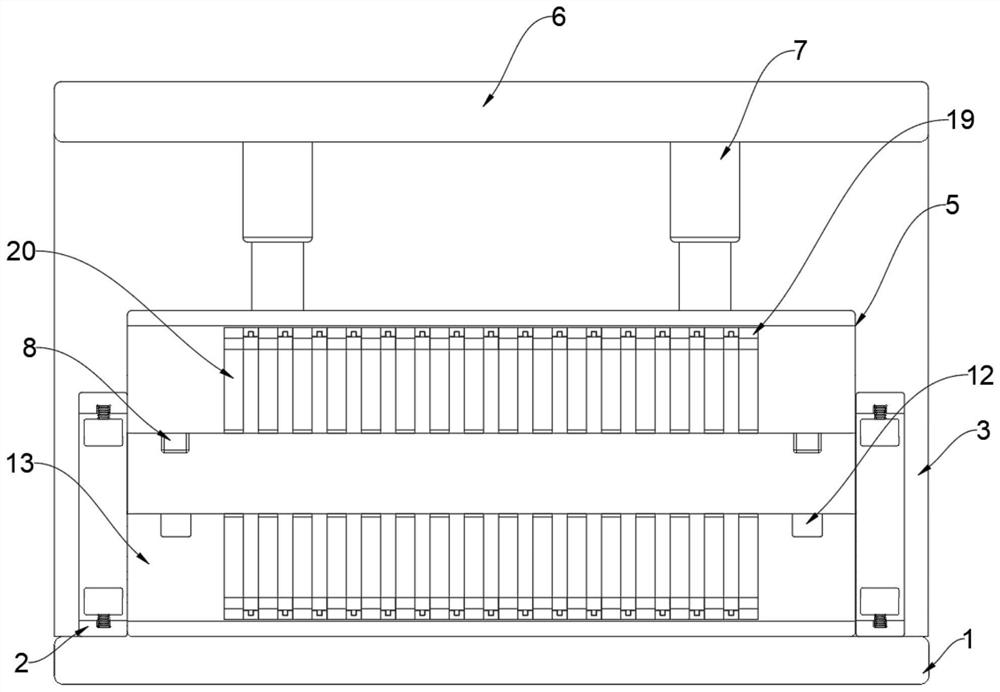

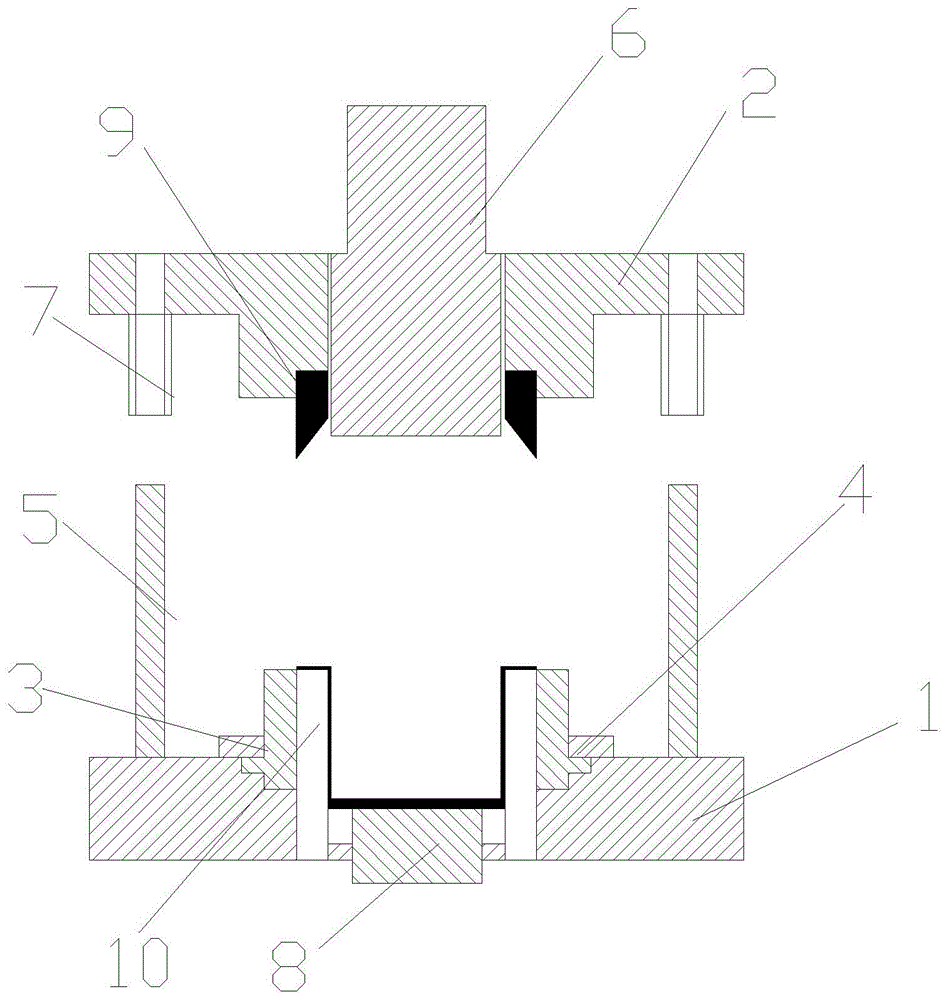

Die structure for plate drawing and bulging performance experiments

ActiveCN112045052AAvoid wastingGuaranteed accuracyShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

Owner:HUNAN UNIV +1

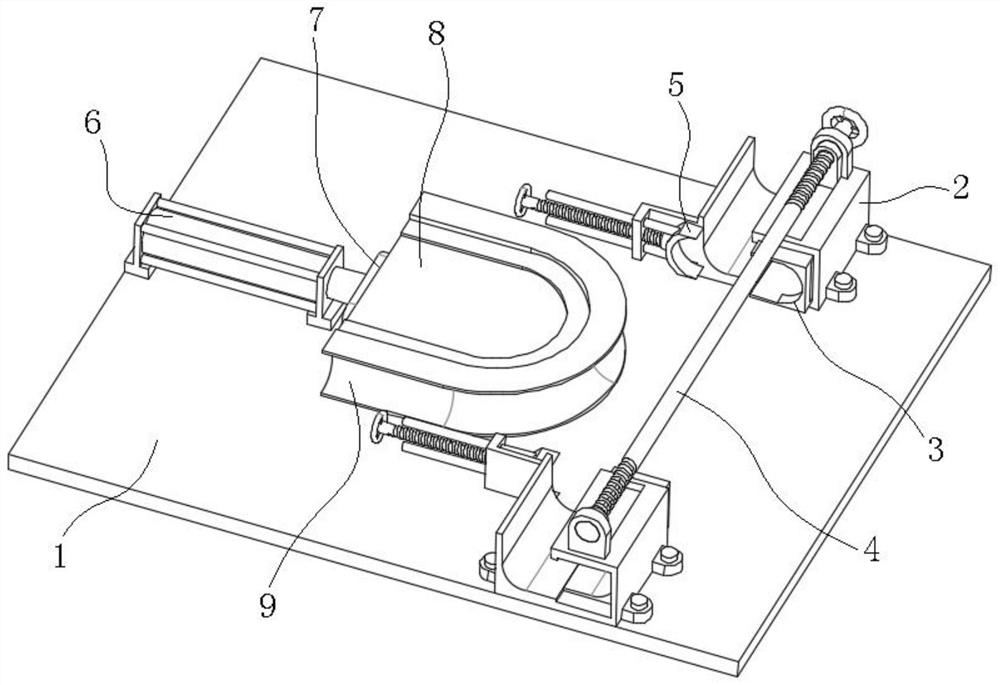

Punching forming clamp

InactiveCN104438879AGuaranteed stabilityImprove pass rateShaping toolsMetal-working feeding devicesPunchingEngineering

Owner:SUZHOU SONGSHUN HARDWARE

Fully-automatic numerical control feeding device

Owner:无锡锡锻机床有限公司

Machining machine for environmental-protection sand preventing and dust suppressing net

ActiveCN111036748AReduce processing costsGuaranteed stamping effectMetal-working feeding devicesPositioning devicesMolding machineElectric machinery

Owner:泉州芳盟科技有限公司

Rebound prevention hardware stamping die

InactiveCN111151653AScientific and reasonable structureEasy to useShaping toolsMetal-working feeding devicesComputer hardwareEngineering

Owner:杨士强

Punching device applied to field of automobile manufacturing

PendingCN112845819AEasy to operateImprove work efficiencyPerforating toolsMetal-working feeding devicesHydraulic cylinderPunching

Owner:ANHUI WEIWEI RUBBER PARTS GRP

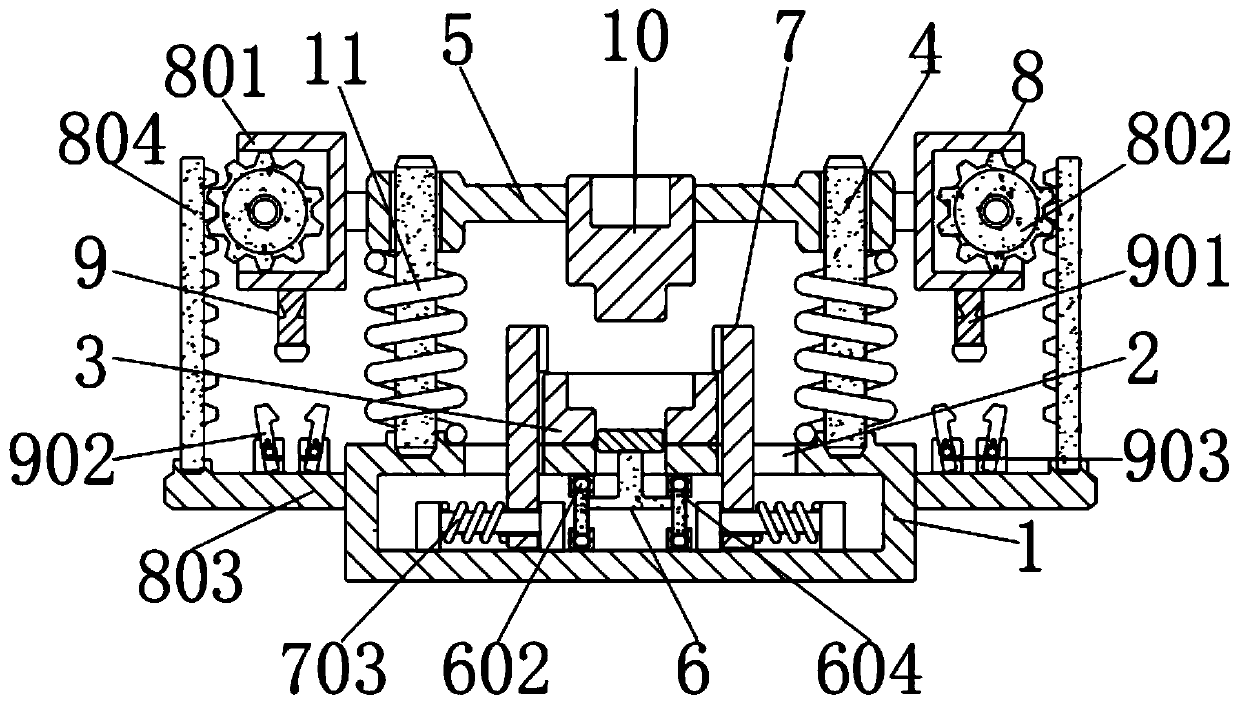

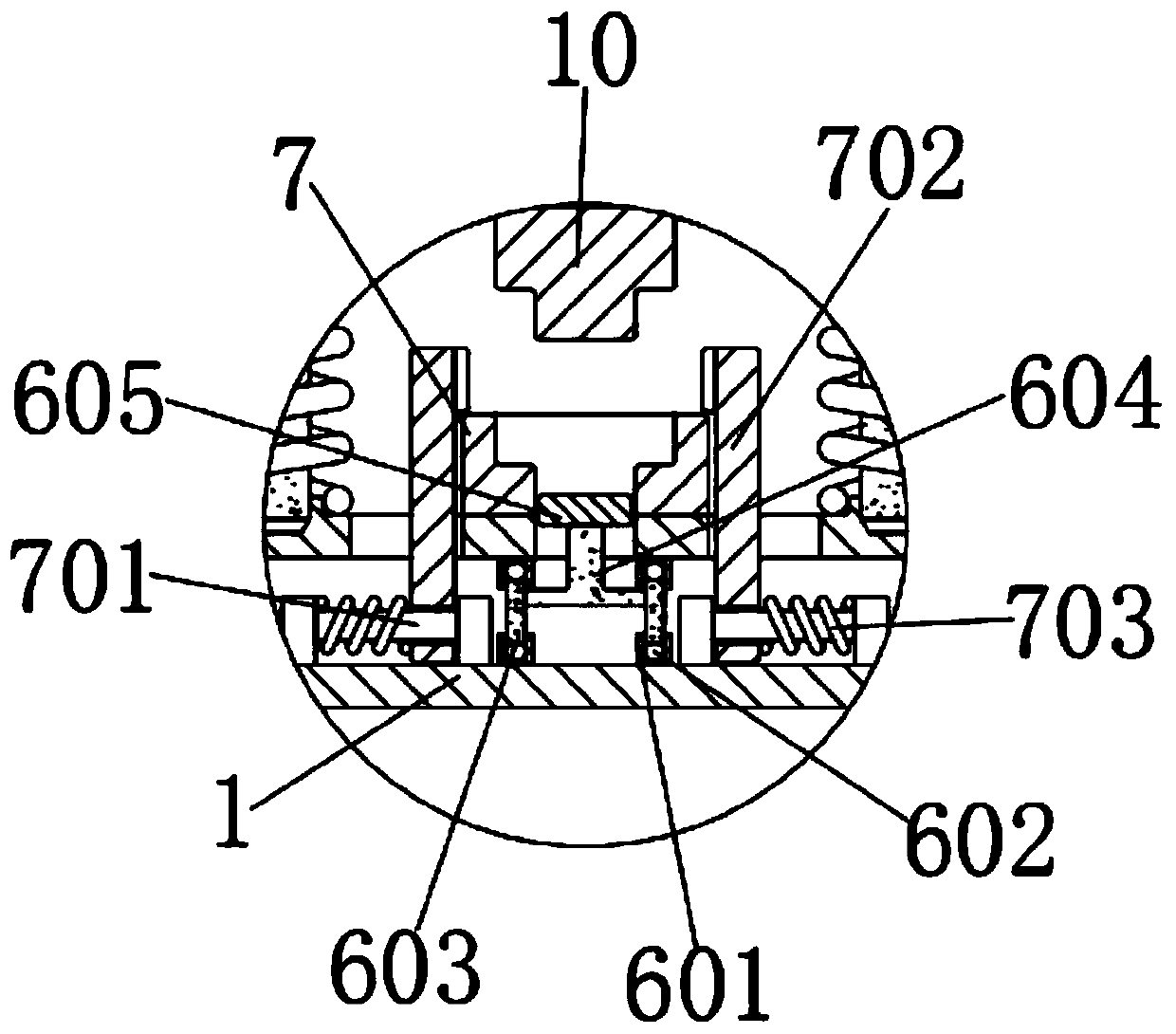

Automatic machining line equipment for check ring with lug

ActiveCN112355135AEffective and stable grippingConsistent structurePerforating toolsMetal-working feeding devicesPunchingMachining

The invention discloses automatic machining line equipment for a check ring with a lug. The automatic machining line equipment comprises a stamping die, a feeding device and a discharging device, wherein the stamping die comprises an upper die and a lower die; the feeding device is used for conveying a to-be-stamped piece to the stamping die; the discharging device is used for discharging a stamped piece machined by the stamping die; and a punching station for punching an inner ring of the check ring with the lug, a punching station for punching a lug hole in the check ring with the lug and aclamping jaw mechanism for clamping the to-be-stamped piece or the stamped piece to move between different stations are arranged in the stamping die. The automatic machining line equipment for the check ring with the lug has multiple stations, standardized and integrally formed production can be carried out, the working efficiency is high, manufacturing procedures are reduced, the manufacturing cost is saved, and the material utilization rate is increased.

Owner:DONGFENG AUTO PARTS (GRP) CO LTD GENERAL CASTING & FORGING BRANCH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap