Stamping production equipment and stamping production technology

A technology for production equipment and stamping dies, which is applied in the fields of stamping production equipment and stamping technology, can solve the problems of difficult operation control, many potential safety hazards, and difficult quality assurance, so as to reduce labor costs, facilitate large-scale promotion, and improve quality products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

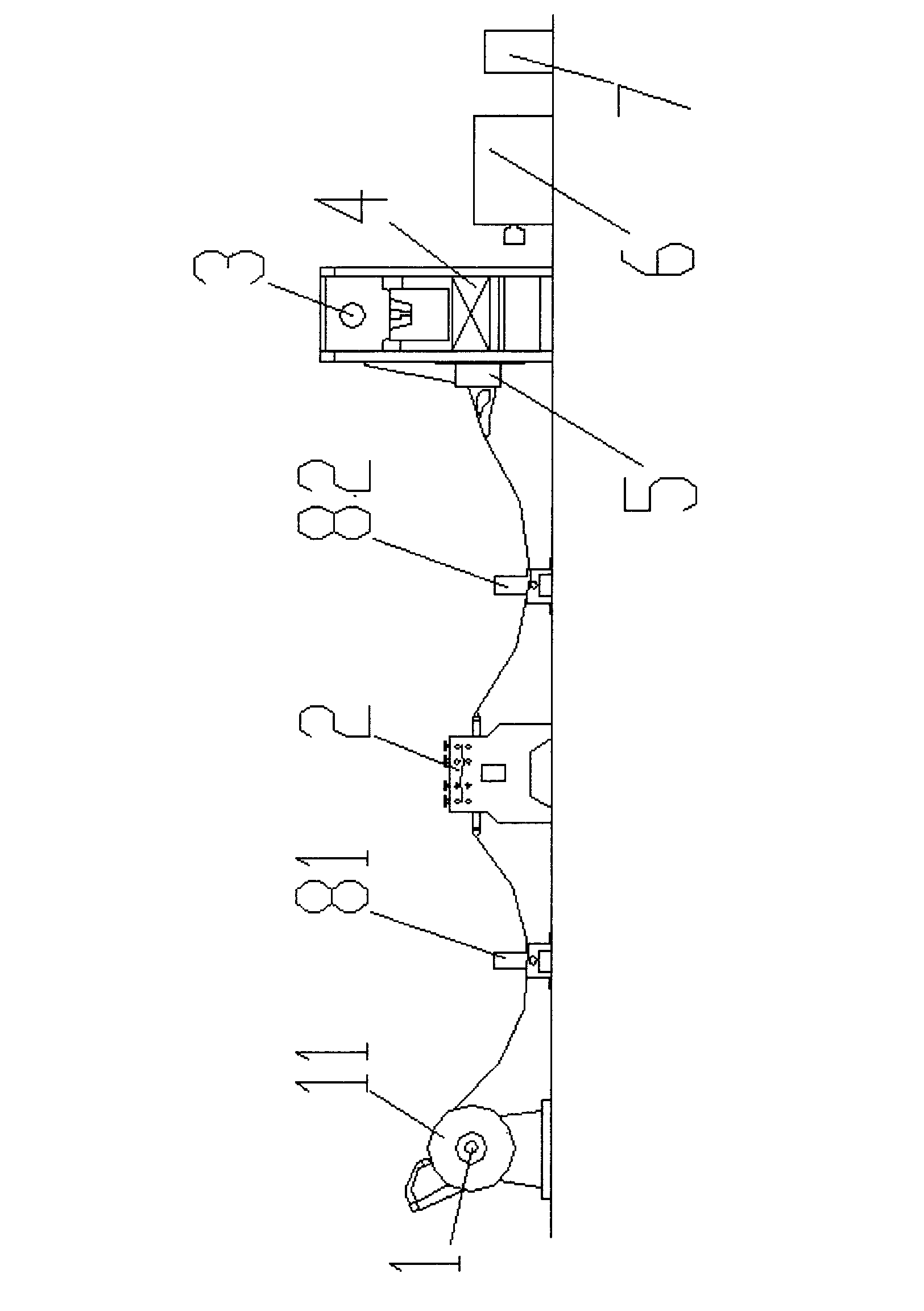

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0020] Such as figure 1 The technical problem to be solved by the present invention is to overcome existing defects and provide a stamping production equipment and a stamping production process.

[0021] In order to solve the problems of the technologies described above, the present invention provides the following technical solutions:

[0022] A kind of stamping production equipment, comprising a material transport frame 1, a smoothing machine 2, a punch press 3, a stamping die 4, a feeder 5, a stacker 6, a control cabinet 7 and an inductor, and a steel plate is fixed on the material transport frame 1 Coil 11; the leveler 2 is located behind the transport frame 1; th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap