Steel bridge deck pavement structure with reinforced construction

A steel bridge deck and pavement technology, applied in bridges, bridge parts, bridge construction, etc., can solve the difficulties in the design of the steel bridge deck pavement structure, the decrease in the construction efficiency of the steel bridge deck pavement, and the increase in the thickness of the steel bridge pavement layer. Large and other problems, to achieve the effect of alleviating the bottom shear stress, light weight, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following specific examples.

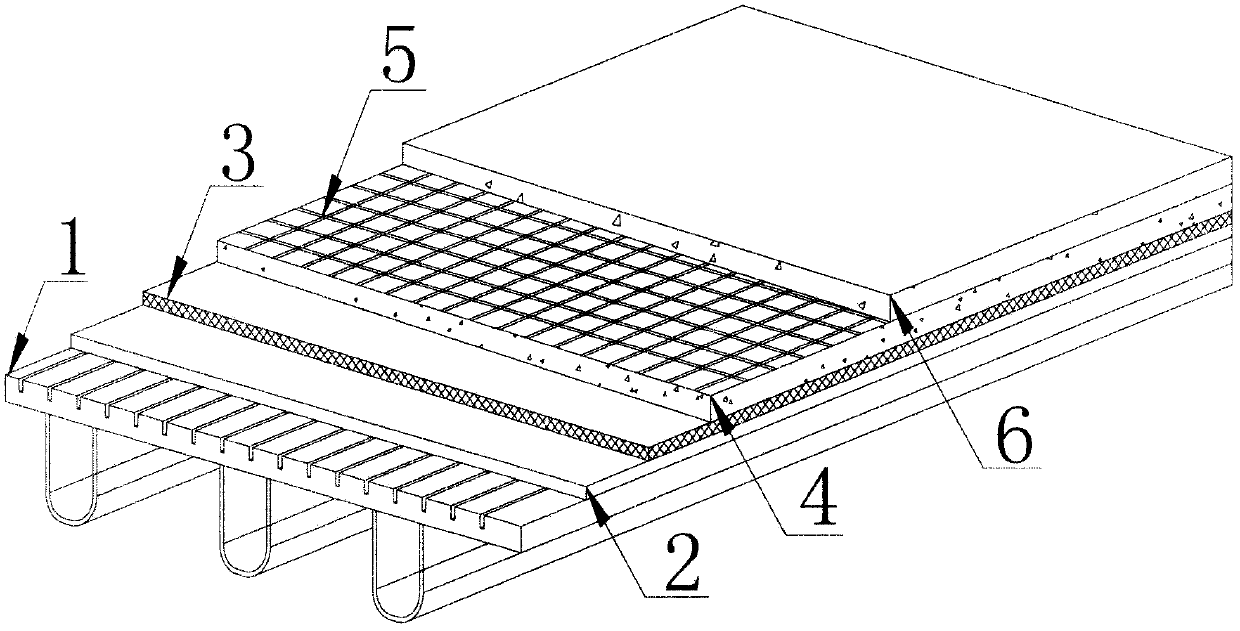

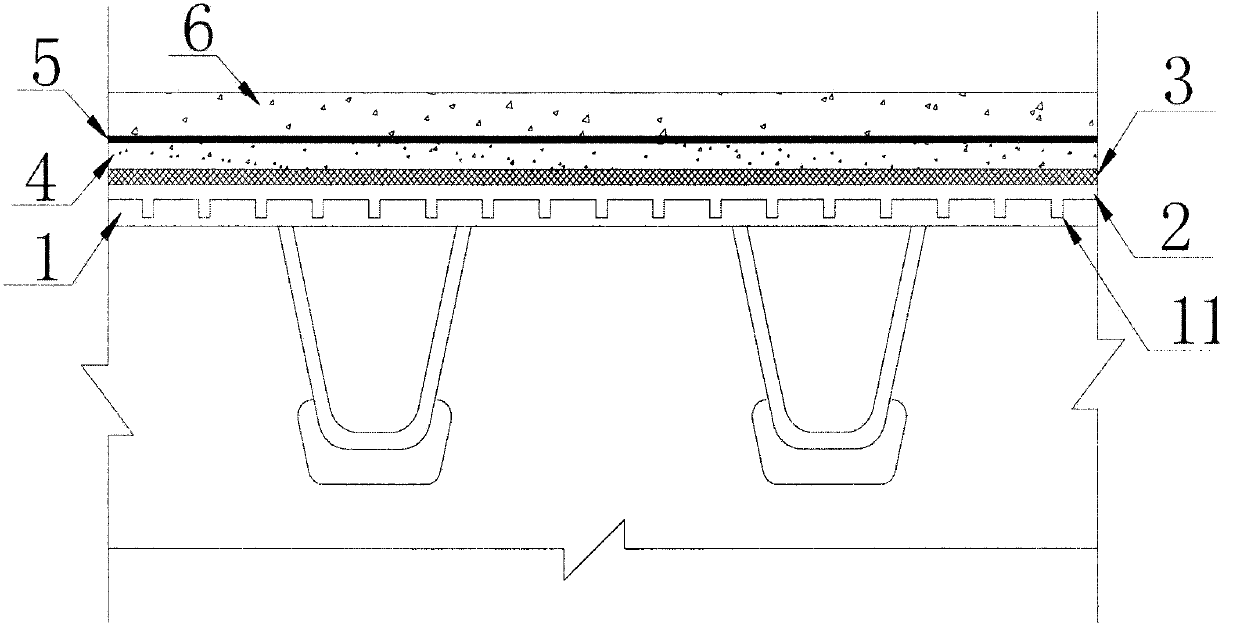

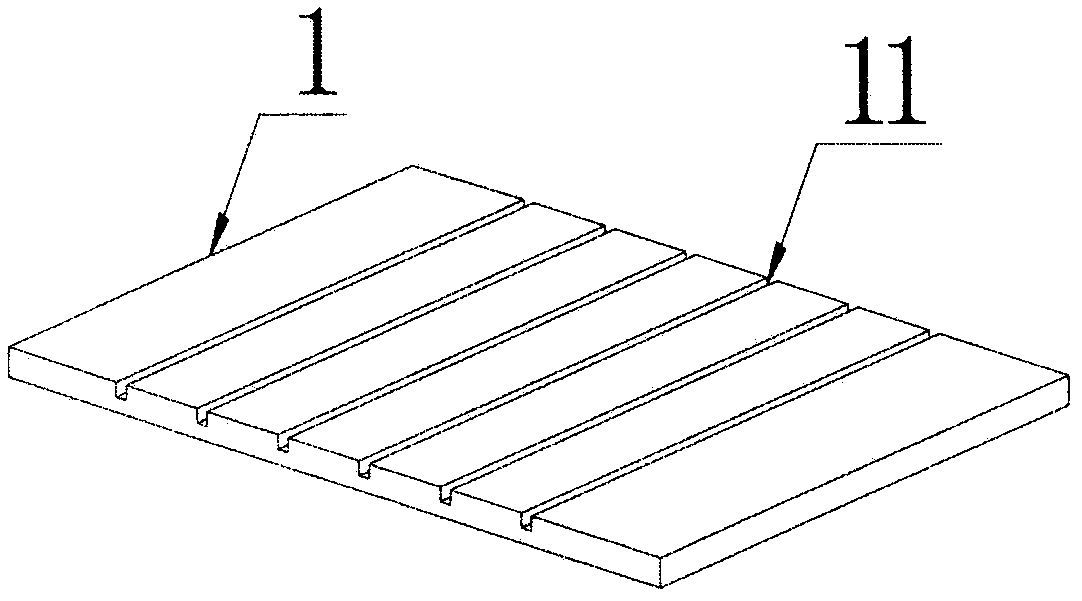

[0037] Such as Figure 1 to Figure 16 As shown, a steel bridge deck pavement structure with reinforced structure is composed of prefabricated reinforced steel plate 1, anti-corrosion layer 2, waterproof layer 3, lower layer 4, fiber mesh 5 and upper layer 6 from bottom to top. It is characterized in that the top surface of the prefabricated reinforced steel plate 1 is provided with a rectangular groove 11, an inverted triangular groove 12, an inverted trapezoidal groove 13, a semi-arc groove 14, a U-shaped groove 15, a point protrusion 16, a pattern The reinforced structure of type protrusion 17 or rib type protrusion 18, fiber grid 5 is forme

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap