Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, quenching is the rapid cooling of a workpiece in water, oil or air to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness.

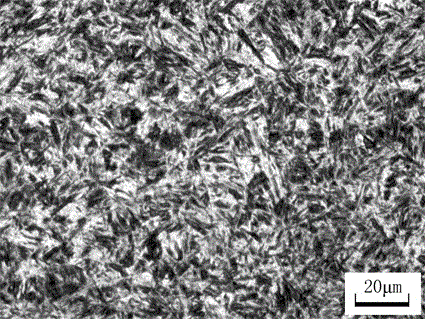

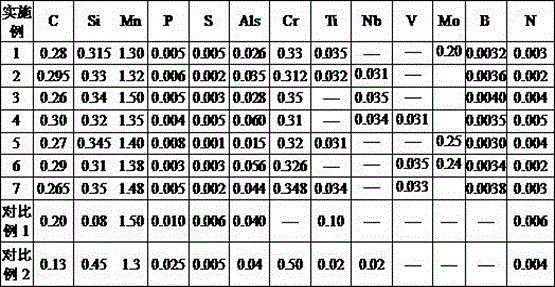

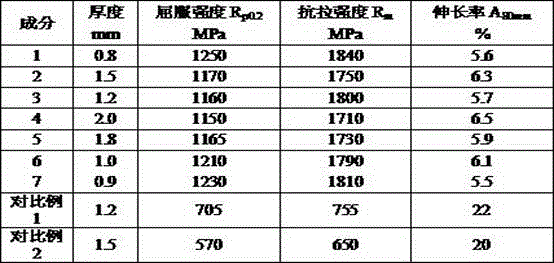

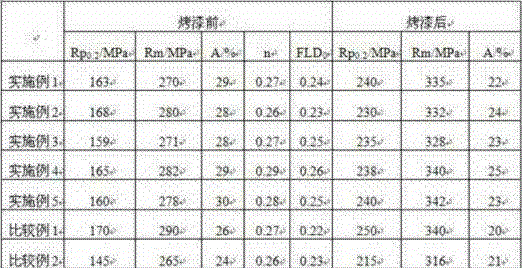

High-strength steel plate and manufacturing method thereof

Owner:BAOSHAN IRON & STEEL CO LTD

Heat treatment method for aluminum alloy

InactiveCN101463453ASolution treatment5005 aluminium alloy

A heat treatment method of aluminium alloy comprises the steps: the aluminium alloy is sequentially treated by solid solution, quenching, cold rolling and ageing, wherein, the cold rolling treatment is ultralow temperature cold rolling treatment carried out at the ultralow temperature of 170 DEG C below zero to 200 DEG C below zero; and the method comprises that low temperature annealing treatment is carried out after the cold rolling treatment and before the ageing treatment. The heat treatment method of the aluminium alloy provided by the invention not only can improve the elongation percentage of the aluminium alloy, namely, breaking elongation, but also can greatly enhance the strength of the aluminium alloy.

Owner:JIANGSU HAIYU MACHINERY

Manufacture method of slip sheet of air conditioner compressor

InactiveCN102251166AImprove the lubrication effectImprove wear resistanceFoundry mouldsSolid state diffusion coatingCarbideSlip sheet

Owner:乐金电子(秦皇岛)有限公司 +1

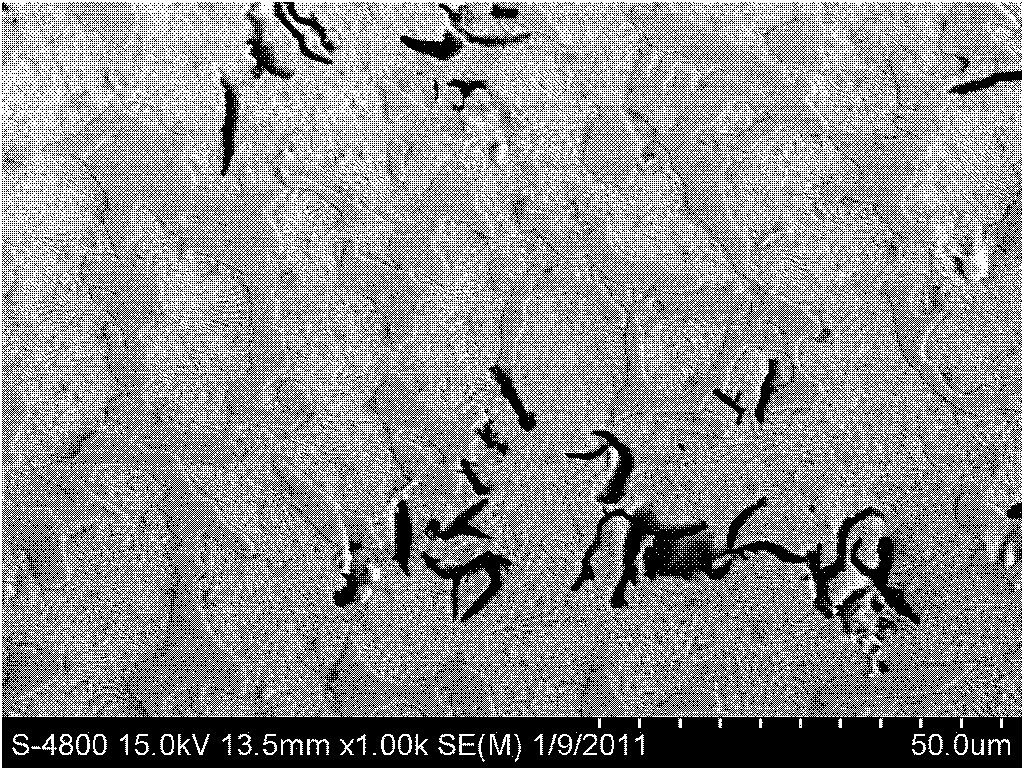

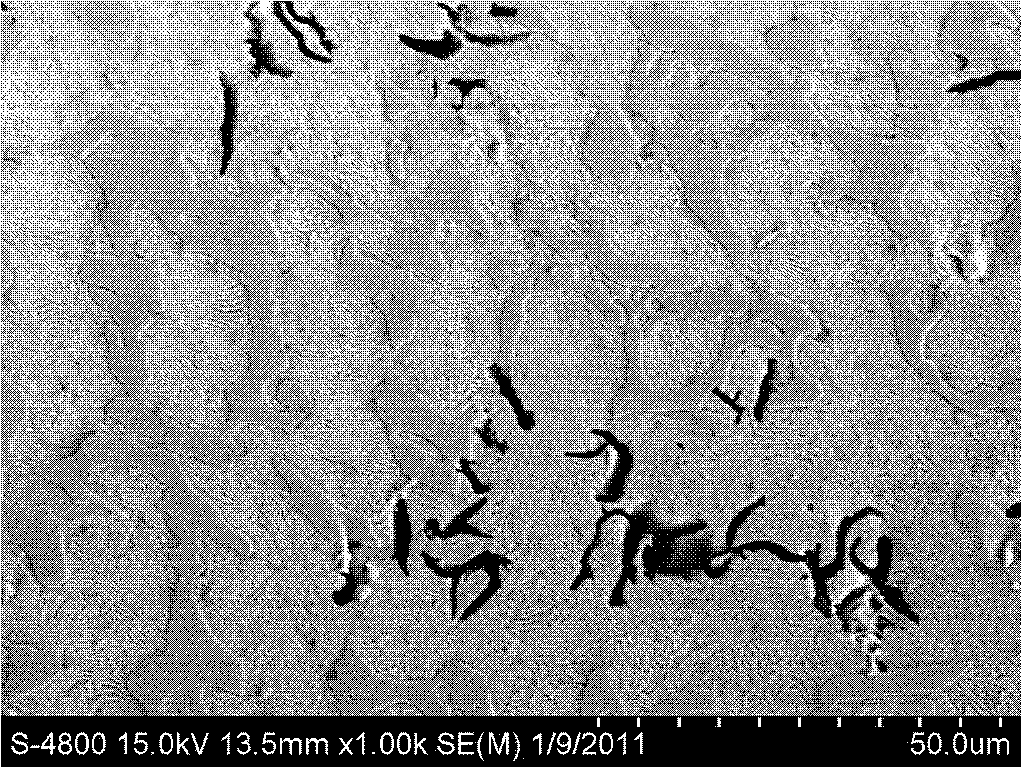

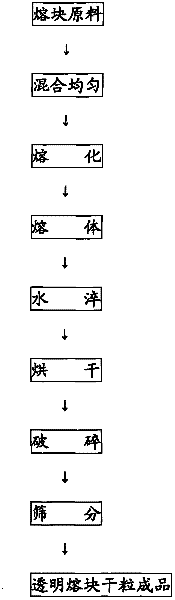

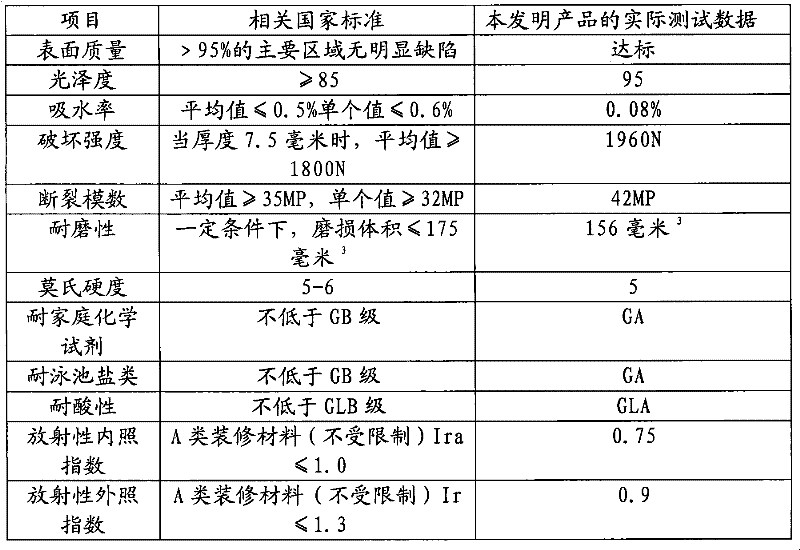

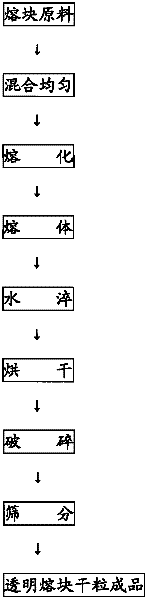

Method for producing transparent clinker capable of being compounded with colored glaze ceramic blank

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

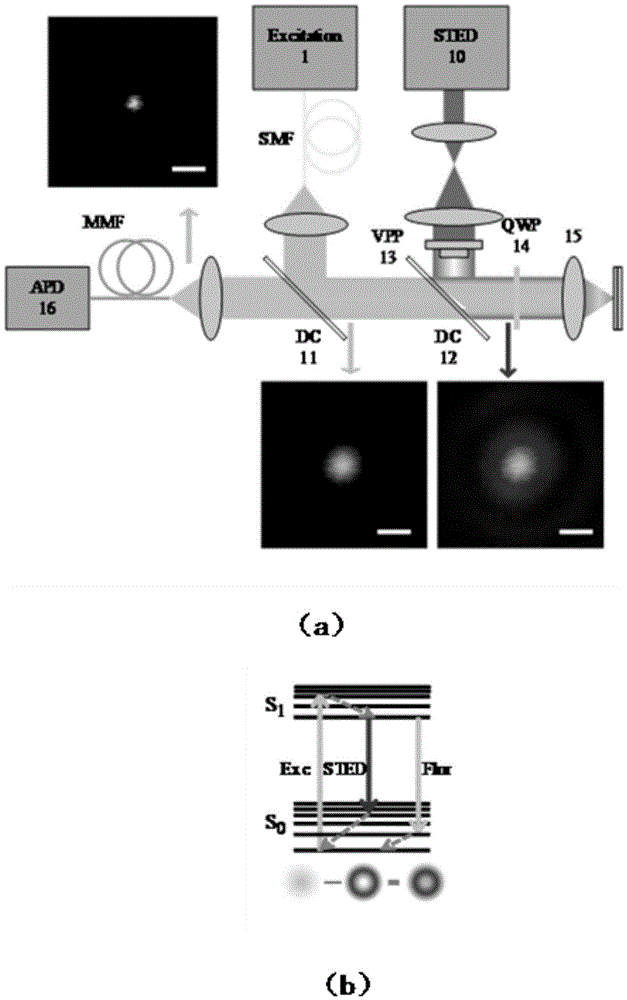

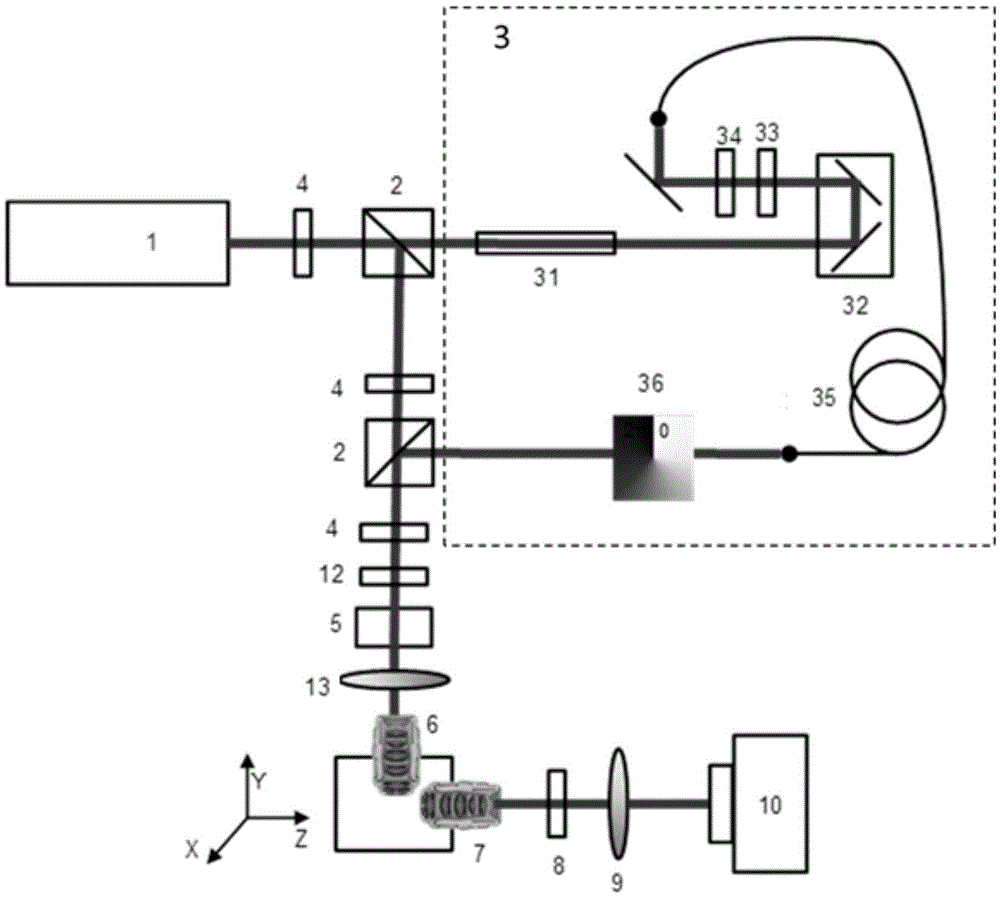

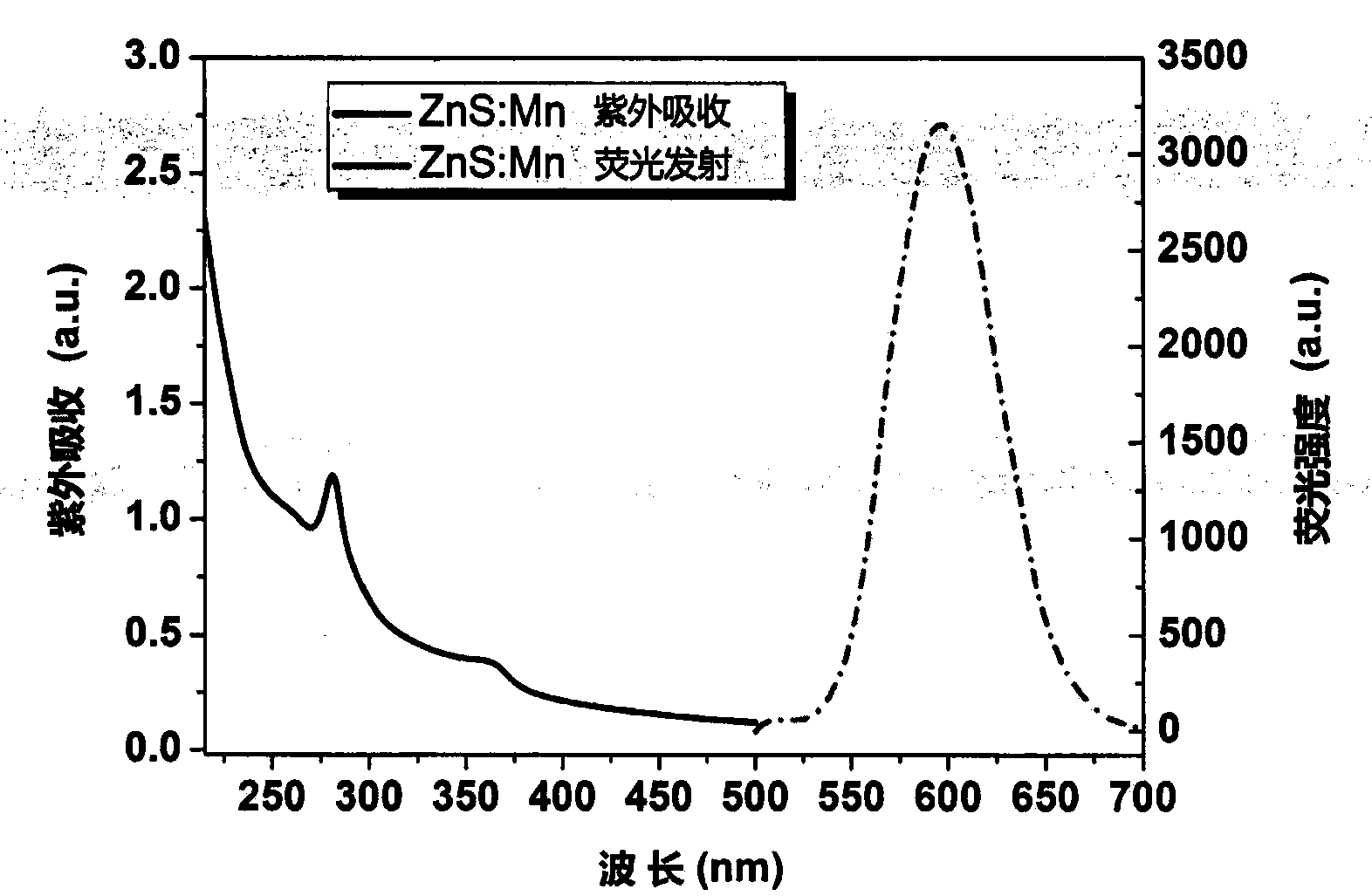

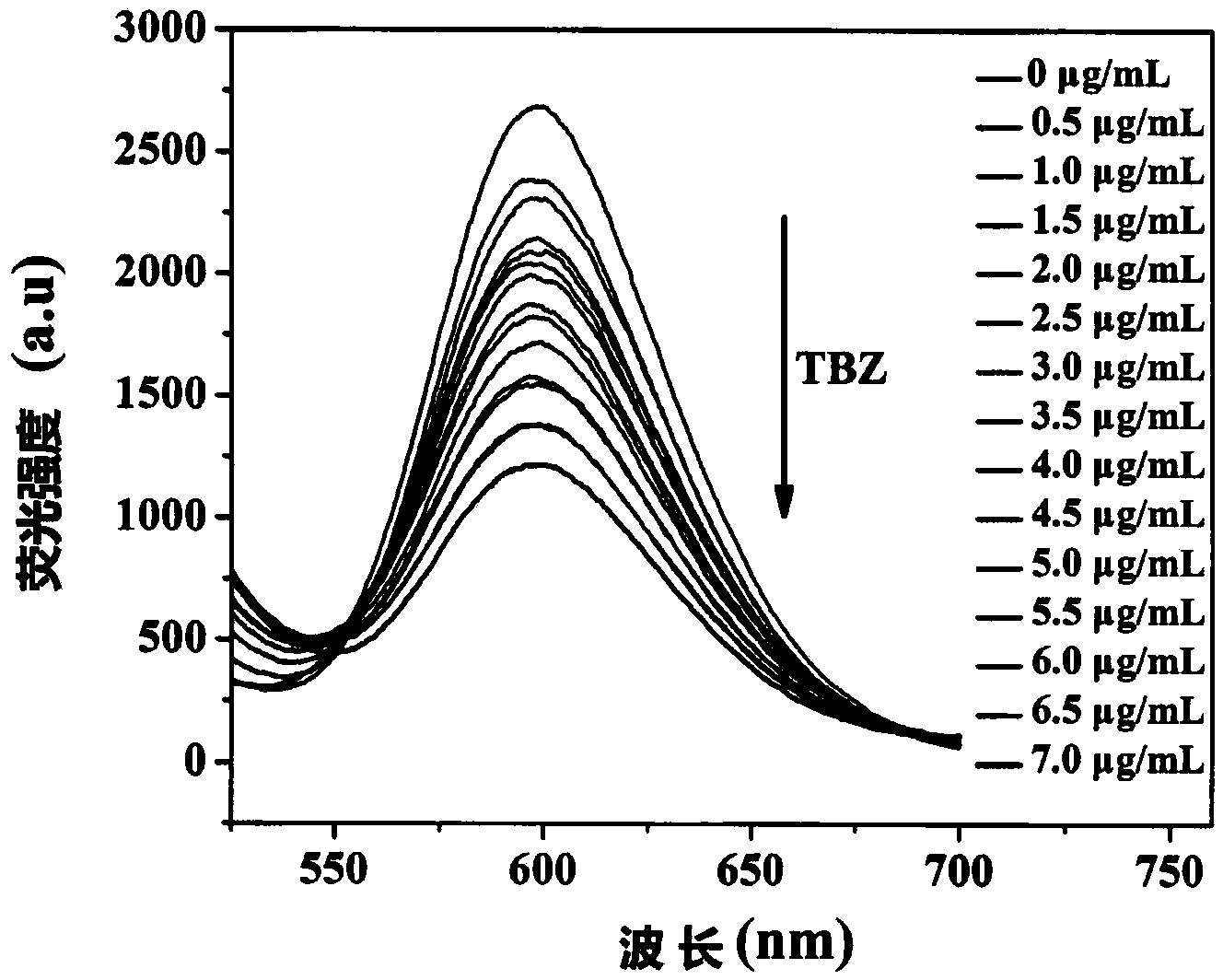

Building method of molecularly imprinted fluorescent probe, and application thereof in benzimidazole detection

InactiveCN103709433AHigh sensitivityImprove featuresFluorescence/phosphorescenceMicrosphereQuenching

Owner:TIANJIN POLYTECHNIC UNIV

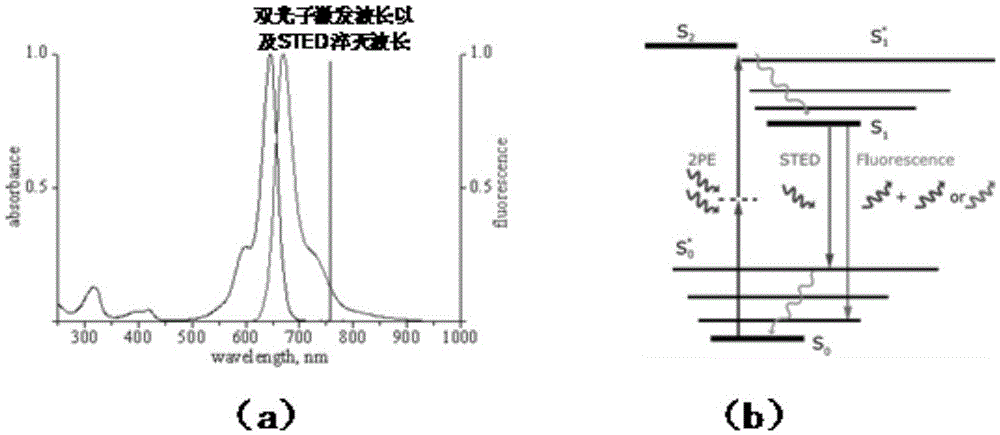

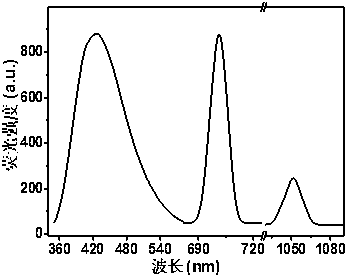

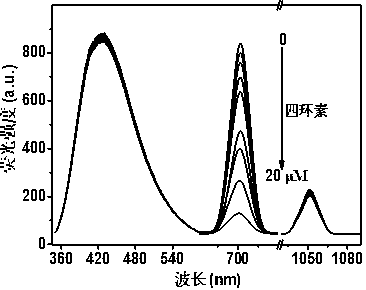

Preparation of fluorogold nano-clusters and application of fluorogold nano-clusters to tetracycline and copper fluorescent probes

PendingCN108760700AFluorescence intensity does not affectReduce distractionsMaterial nanotechnologyTransportation and packagingUltravioletQuenching

Owner:云南健牛环境监测有限公司

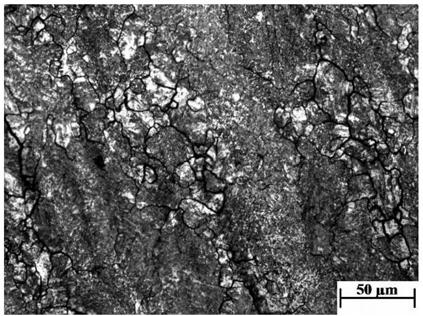

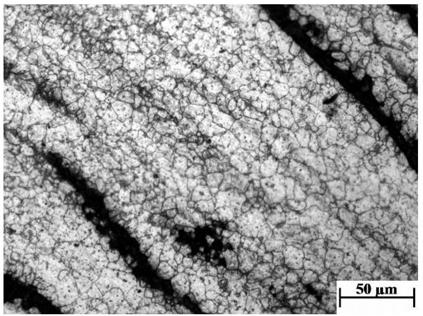

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

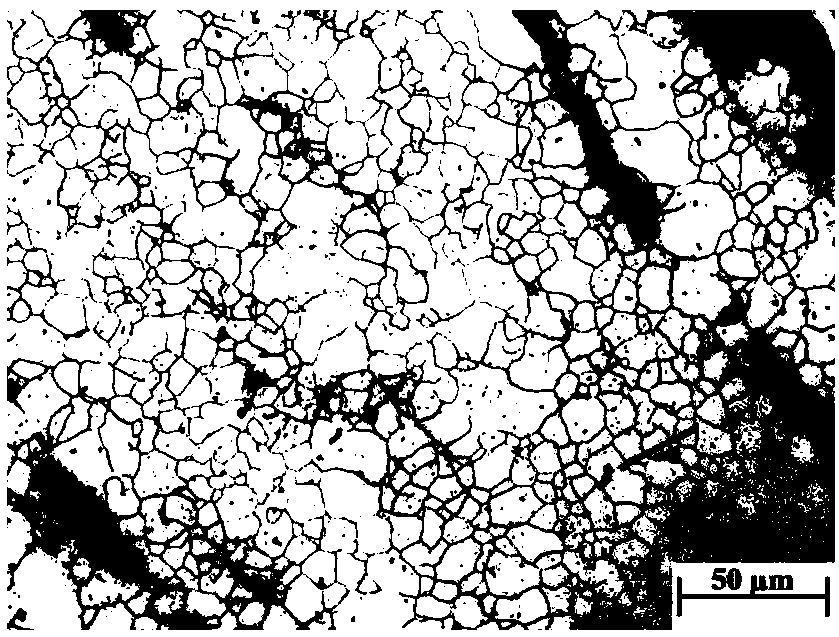

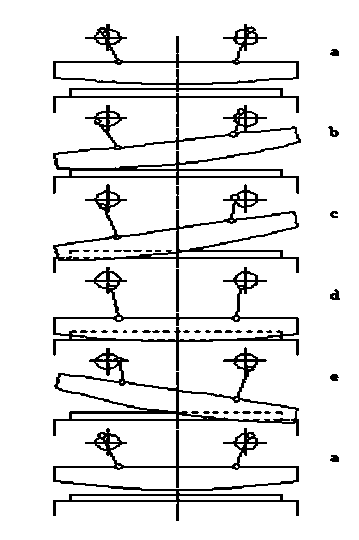

Special-steel-material flexible wheel of harmonic reducer, and cyclic heat treatment method thereof

InactiveCN109280851AImprove fatigue lifeImprove stabilityFurnace typesHeat treatment furnacesAustenite grainReduction drive

Owner:XINING SPECIAL STEEL +1

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

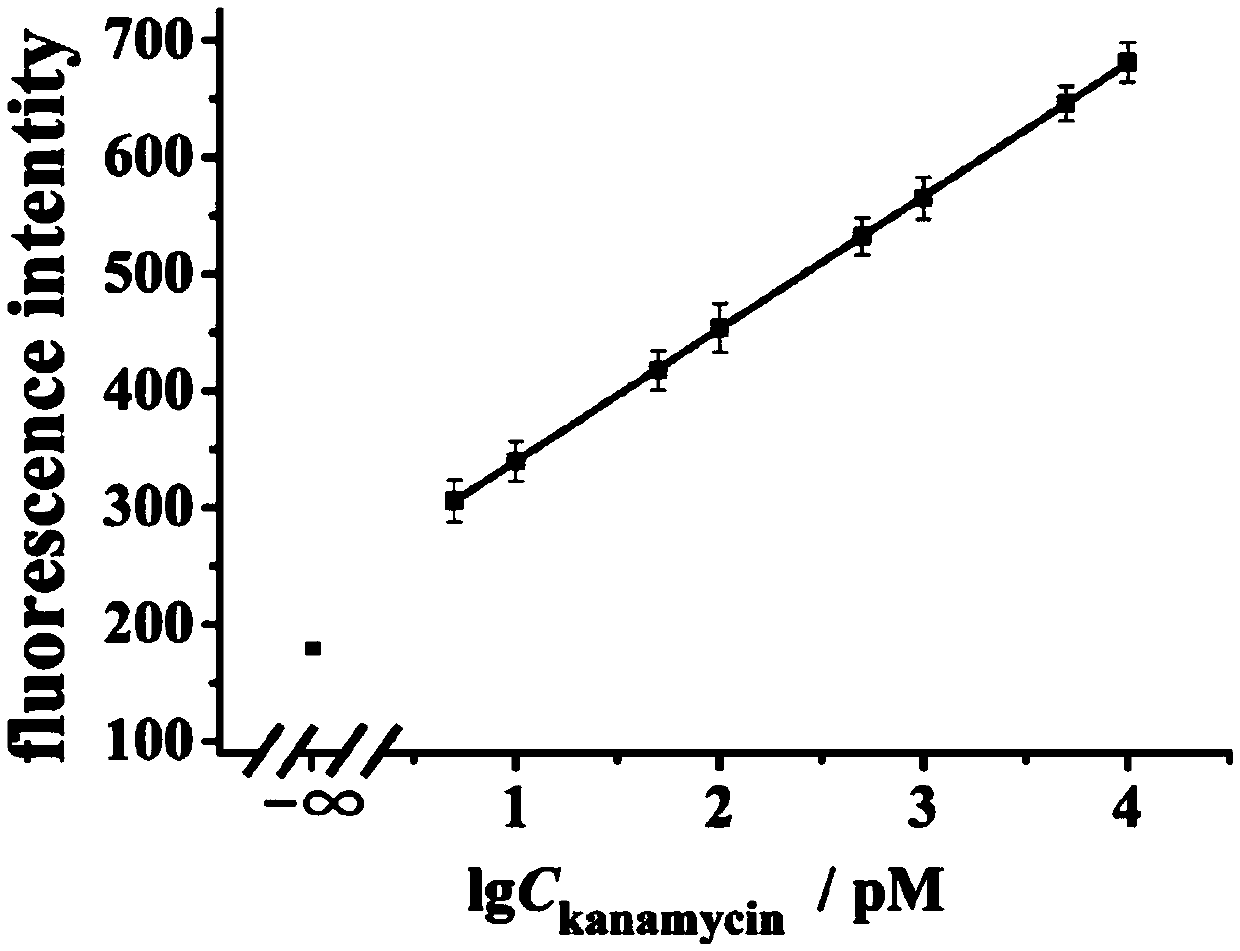

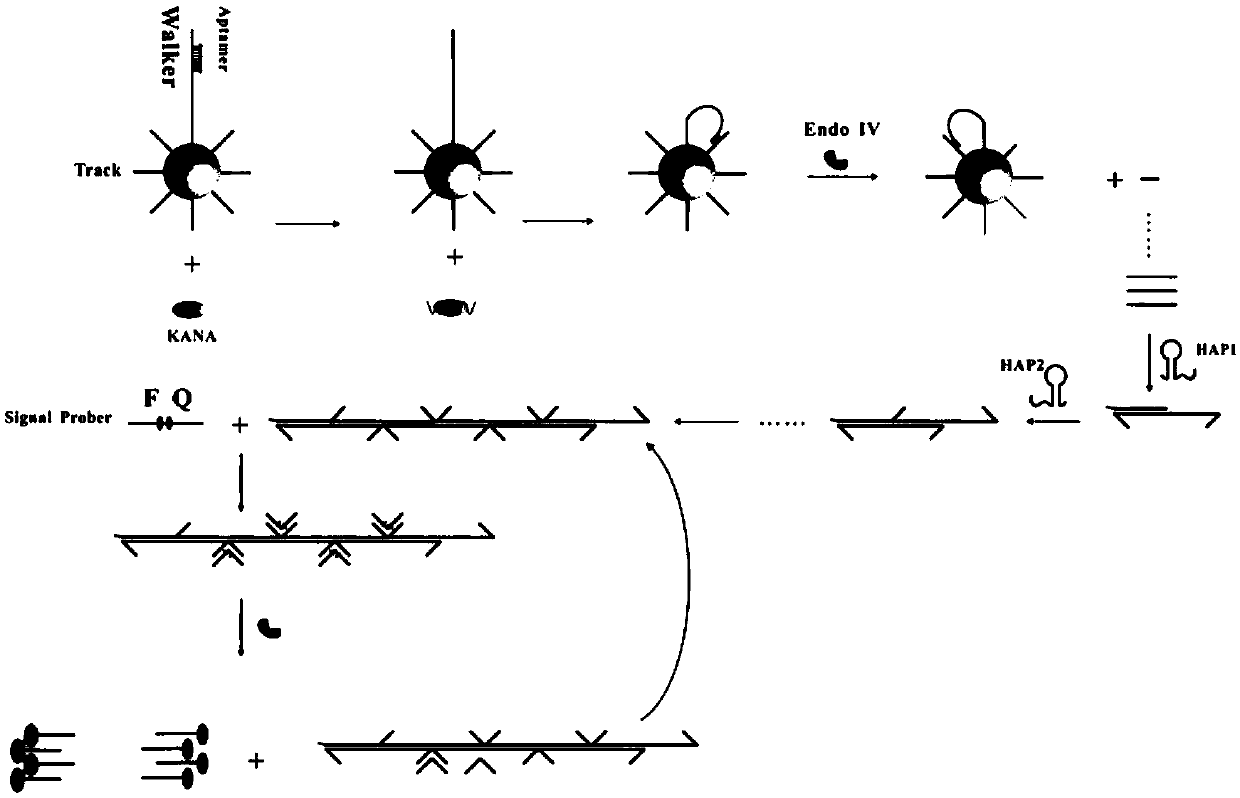

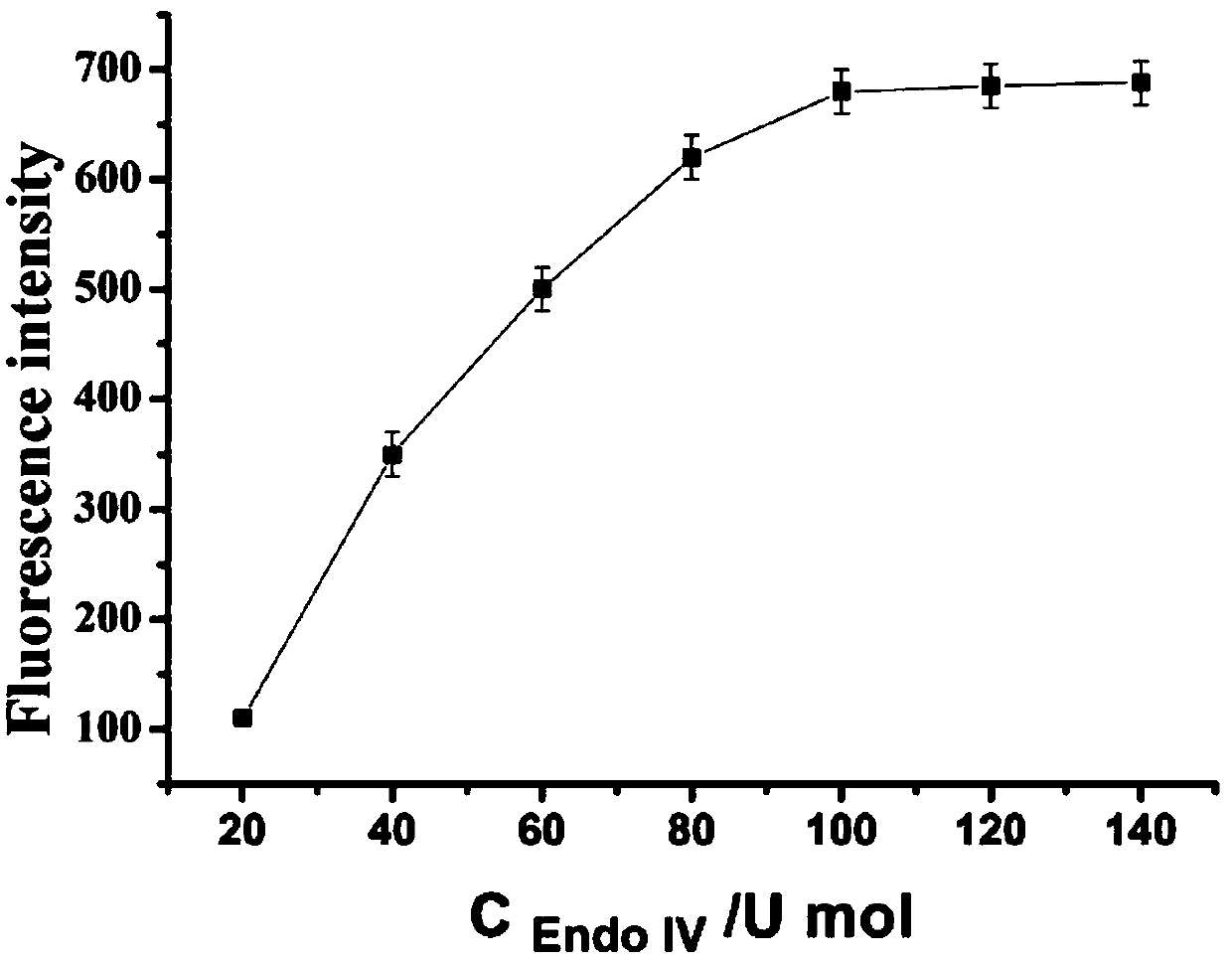

Fluorescent biosensor for detecting kanamycin and preparation method and application thereof

ActiveCN109540860ARealize highly sensitive detectionAchieve signal amplificationFluorescence/phosphorescenceKanamycinFluorophore

Owner:UNIV OF JINAN

Low-cost high-strength steel plate for engineering machinery, and production method thereof

Owner:HEBEI IRON AND STEEL

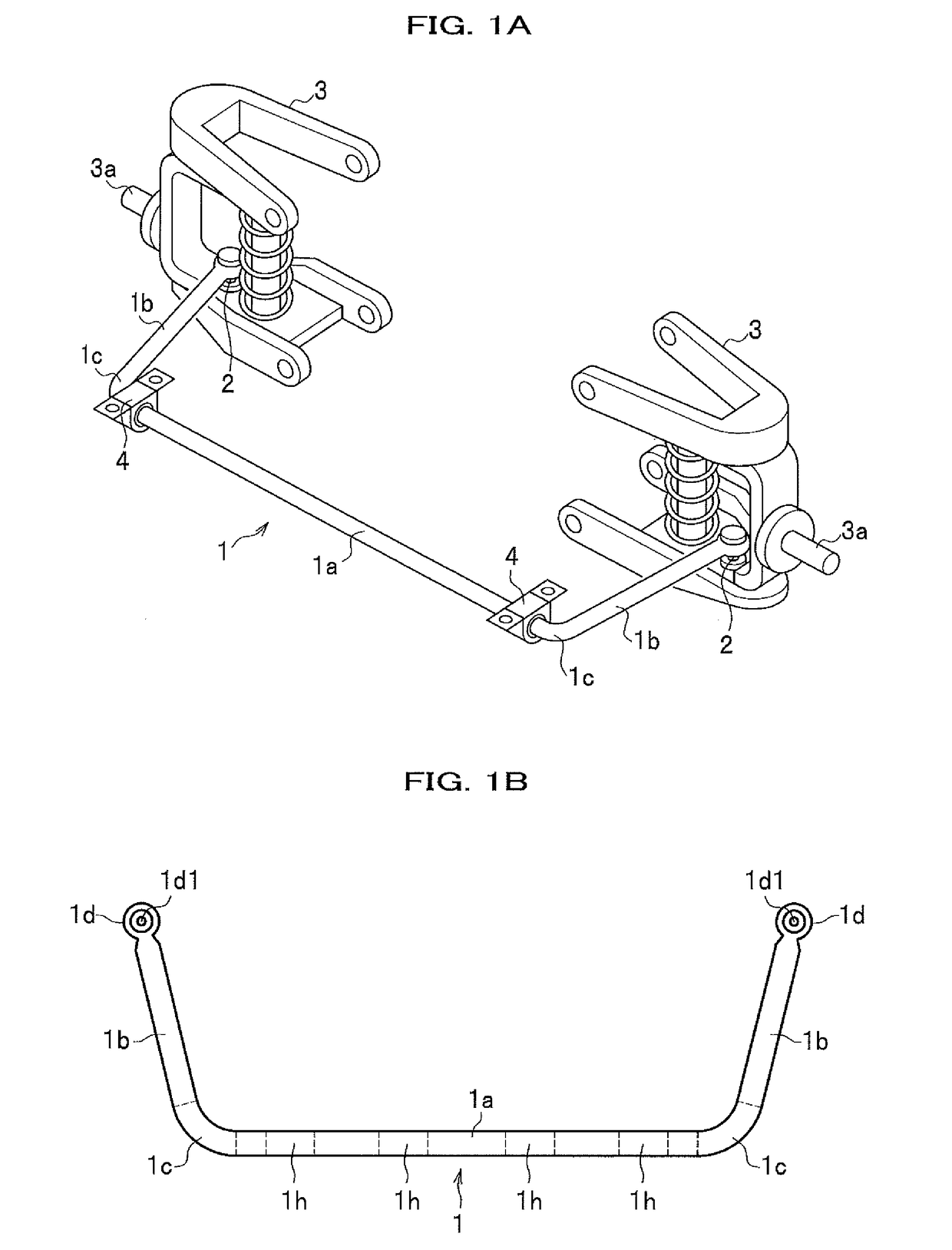

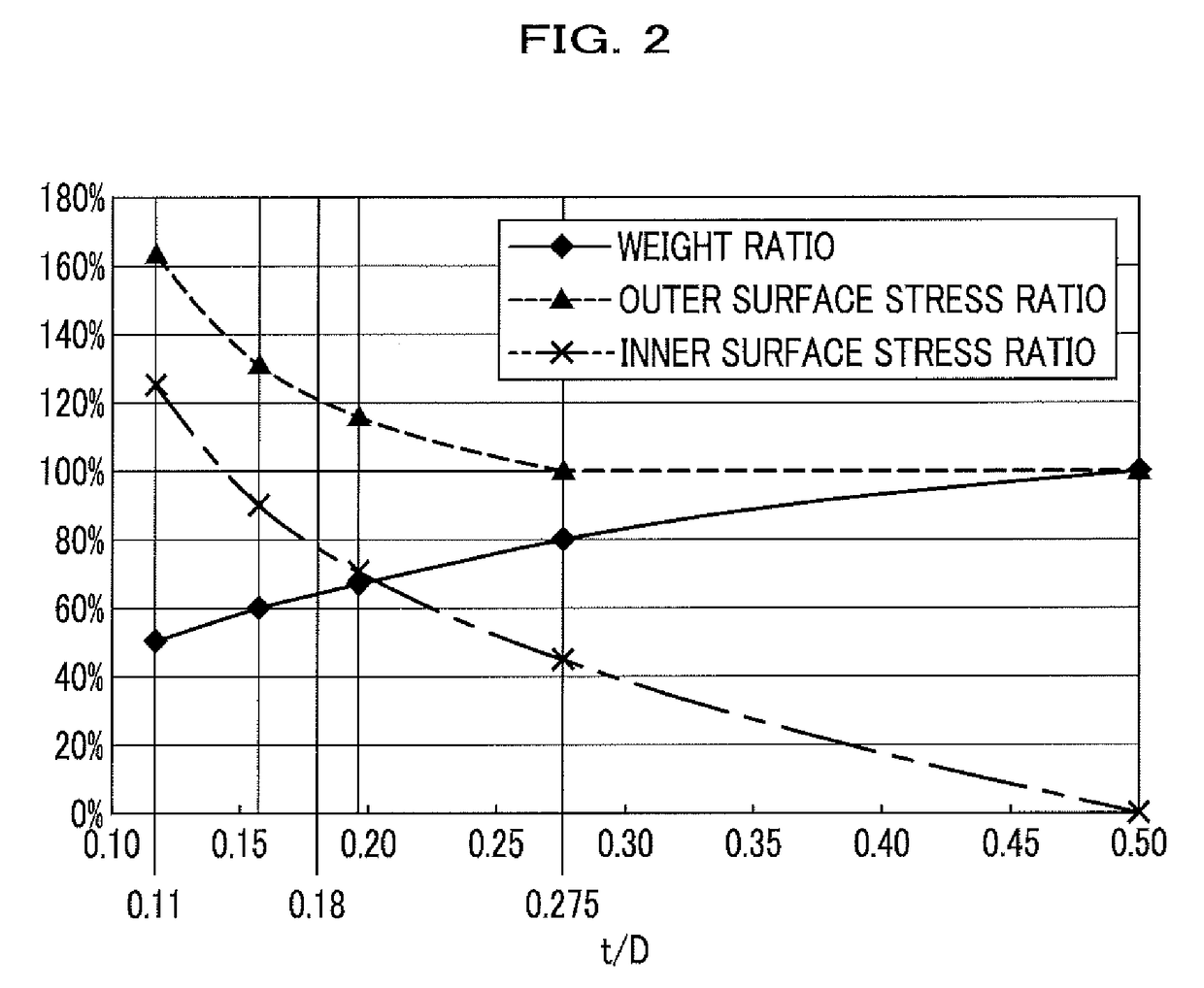

Method for producing hollow stabilizer

ActiveUS20180073096A1Good quenching hardnessHigh hardnessFurnace typesSolid state diffusion coatingQuenchingCoolant

Owner:NHK SPRING CO LTD

Rolling-cut type bilateral scissors and manufacturing method thereof

ActiveCN104233101AMeet normal cutting needsFurnace typesHeat treatment furnacesThick plateIngot casting

Owner:TAIER HEAVY IND

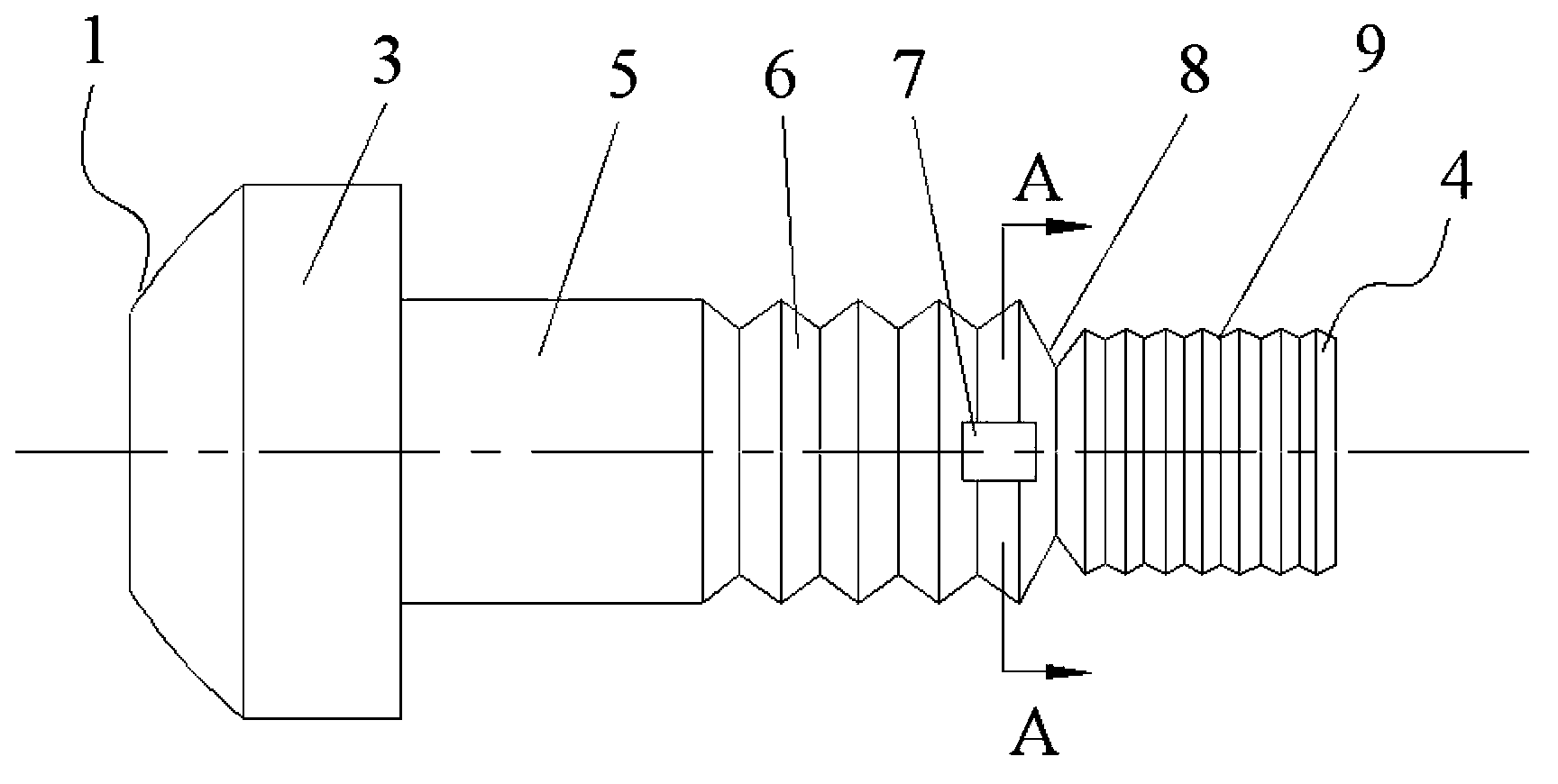

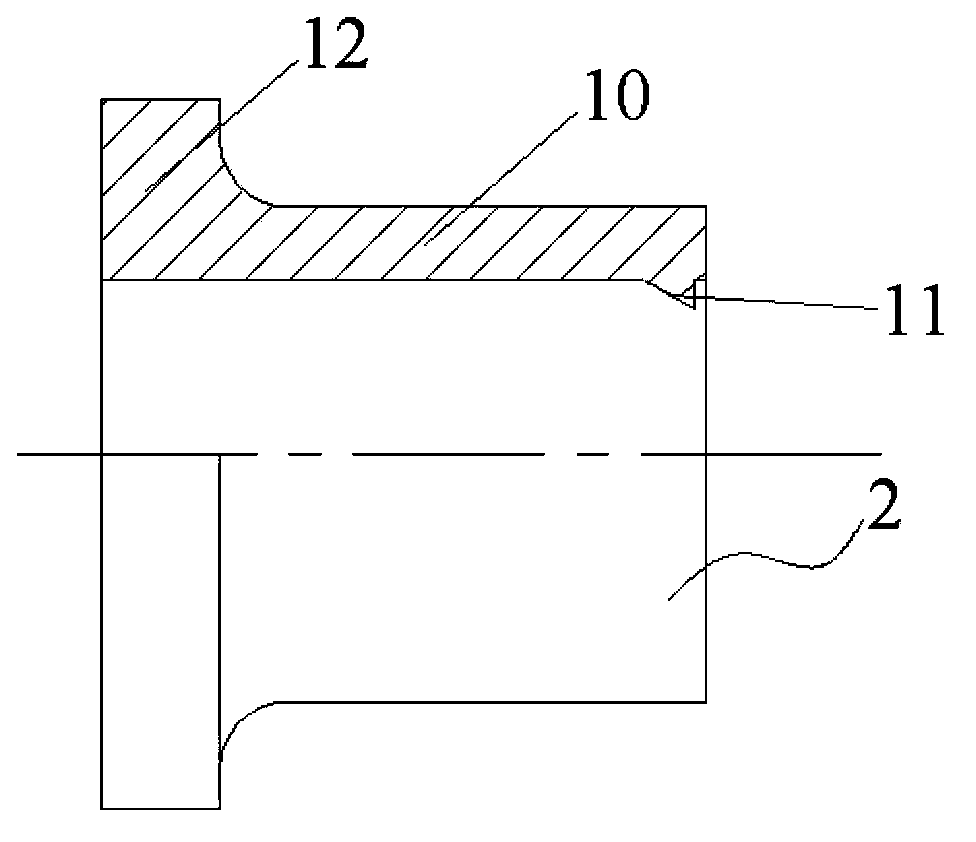

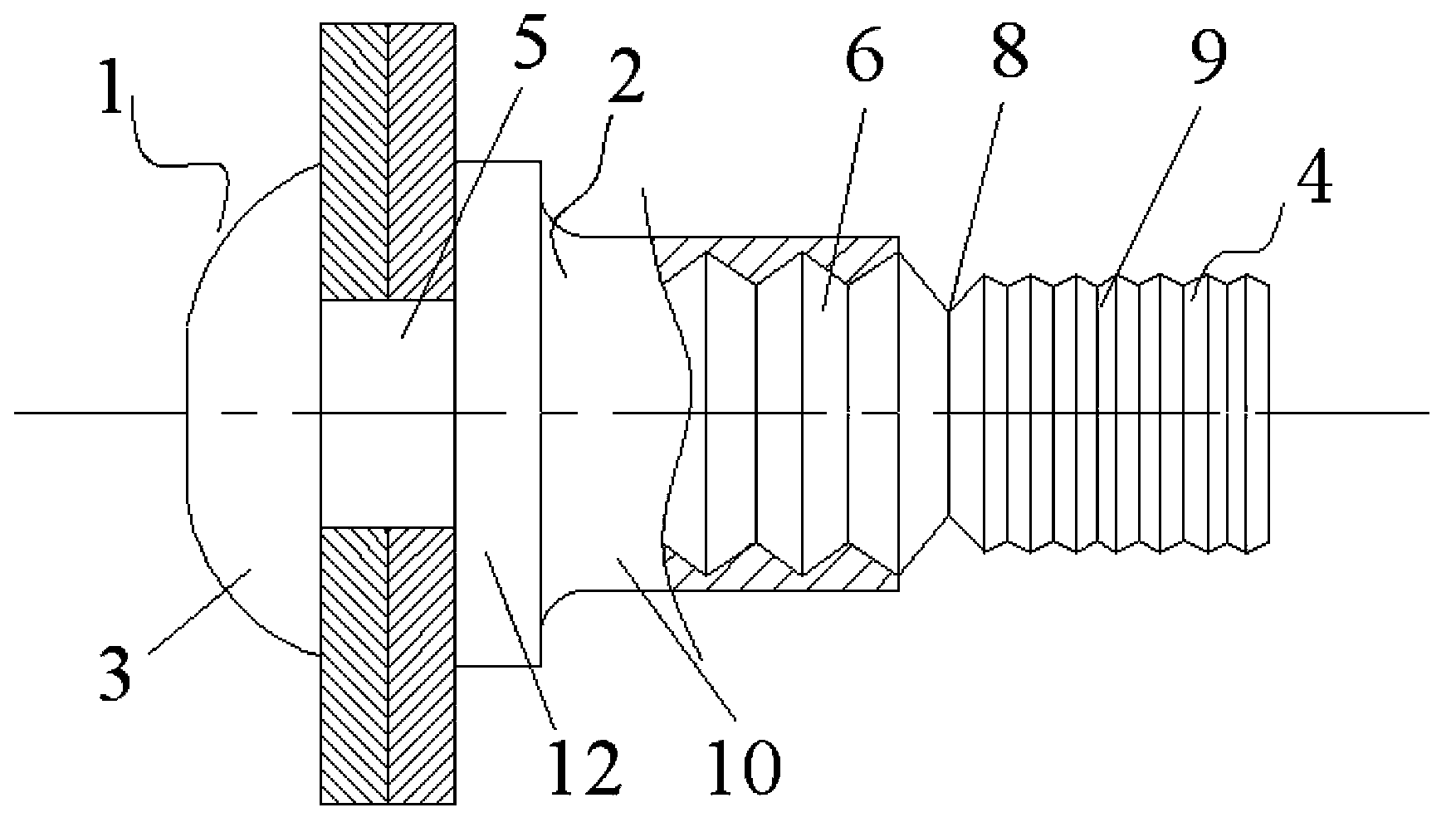

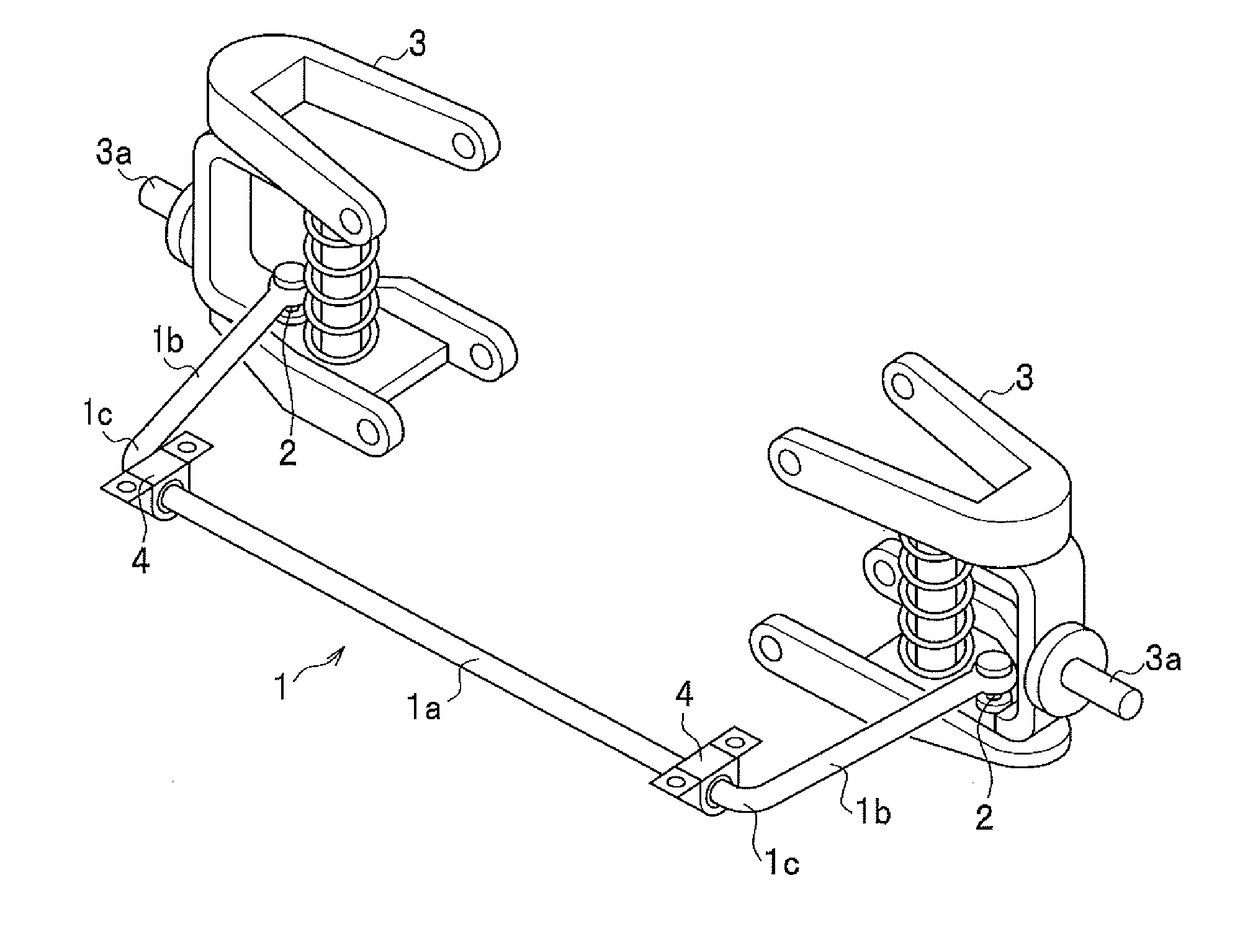

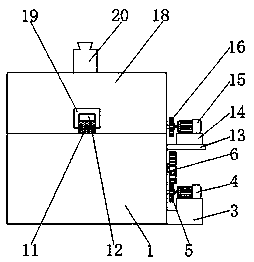

Quenching anti-deformation clamping device for series connection type brake disc

Owner:南京中盛铁路车辆配件有限公司 +1

Self-peelable protective coating for cogging and forging process of pure titanium or titanium alloy and production process of self-peelable protective coating

InactiveCN104371385ASimple coating processGood molding effectAlkali metal silicate coatingsProduction rateTitanium

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV

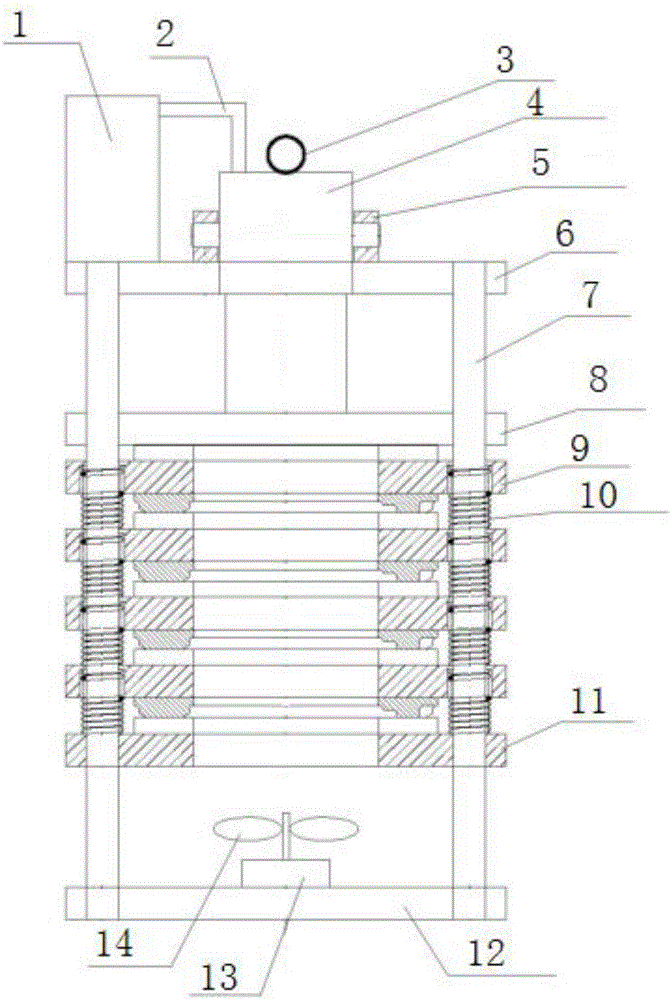

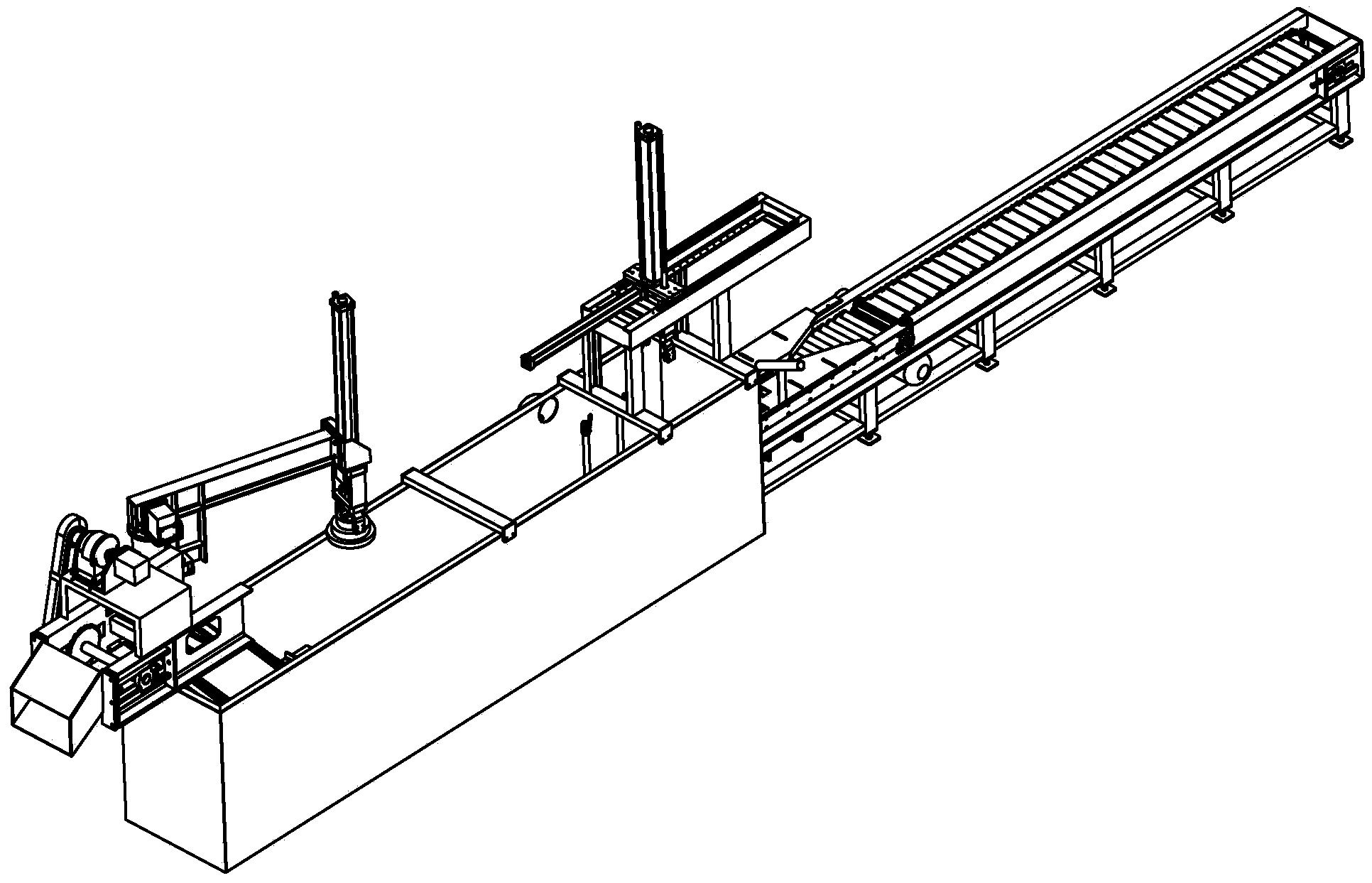

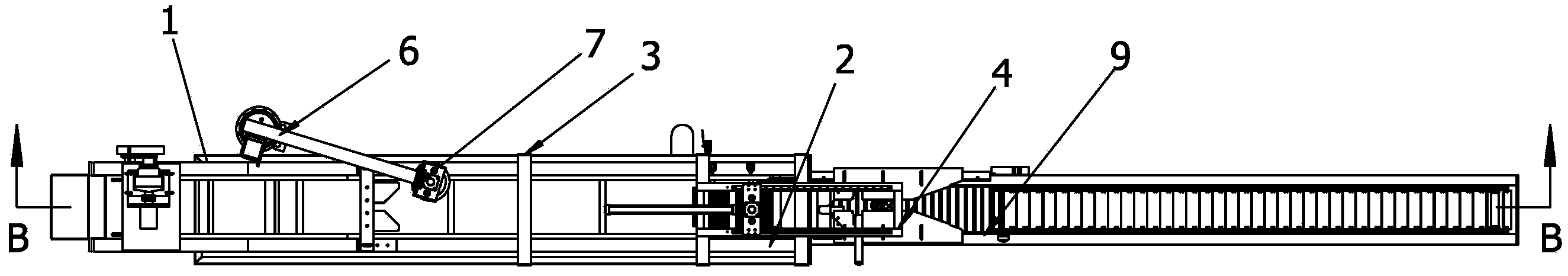

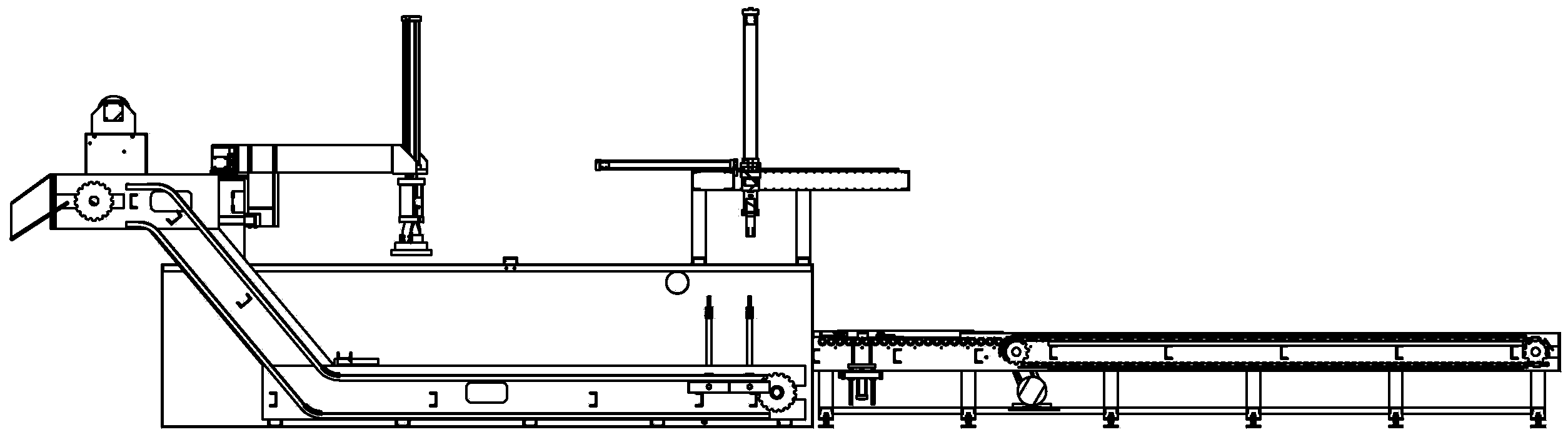

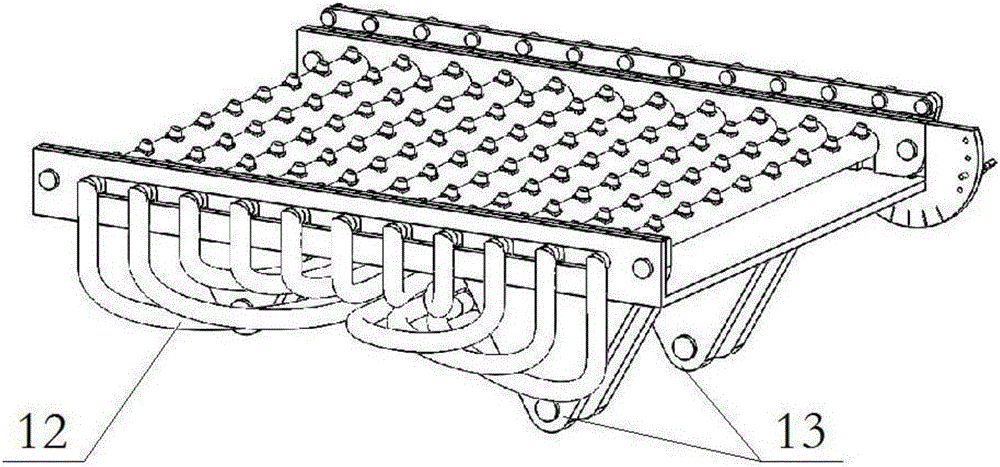

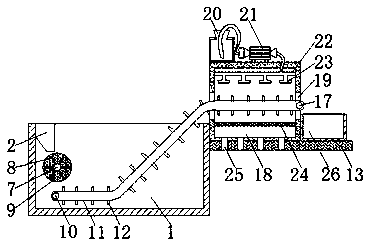

Forged piece waste heat quenching machining tool

ActiveCN103667636AImprove production efficiency and control accuracyIncrease productivityQuenching devicesAutomatic controlQuenching

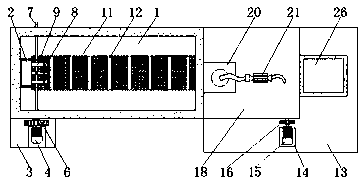

The invention discloses a forged piece waste heat quenching machining tool which comprises a forged piece input unit (9) formed by a track shoe through combining with chains and chain wheels, wherein a temperature probe (10) is arranged at the tail end of the input unit (9); the temperature probe (10) is positioned at the initial end where a forged piece is held by a manipulator transferring unit; the manipulator transferring unit is used for holding the forged piece and used for conveying the forced piece to a quenching tank at the tail end; the quenching tank is filled with a quenching liquid; and an output unit for outputting the quenched forged piece is also arranged inside the quenching tank. The equipment for performing thermal treatment by utilizing the waste heat of the forged piece adopts numerical full-automatic control, so that the production efficiency and the control precision are greatly improved, and the pass percent of thermal treatment is controlled to be greater than 99%.

Owner:DALIAN SHENGLONG MACHINERY

Machining method for bearing steel balls

InactiveCN107186447AWire rodSteel ball

Owner:WUHU YUHENG SPECIAL STEEL BALL

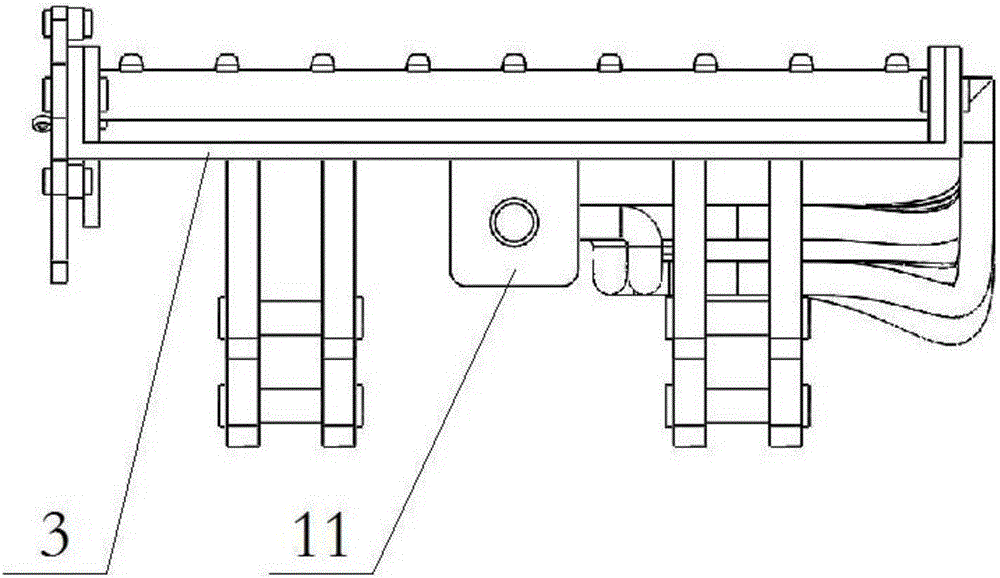

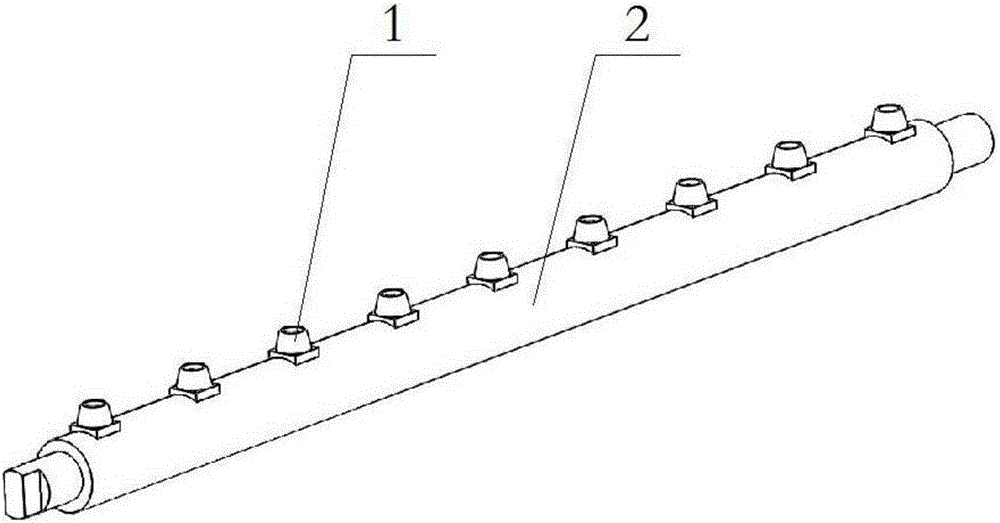

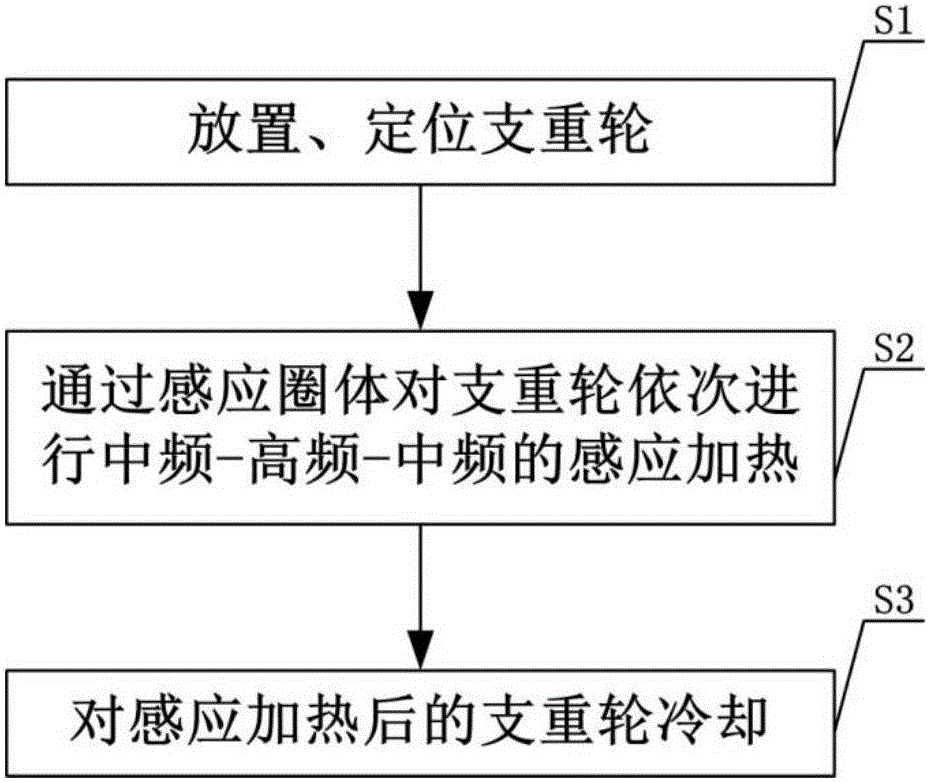

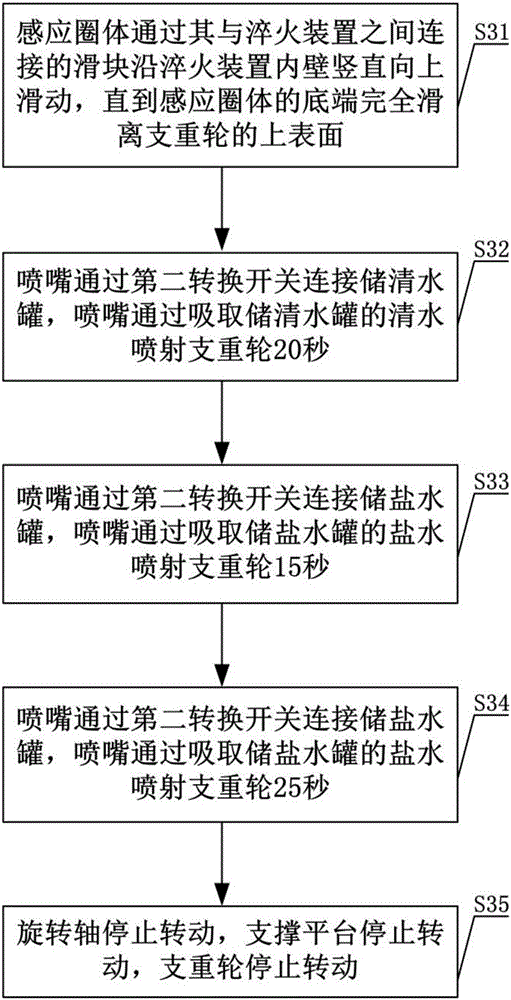

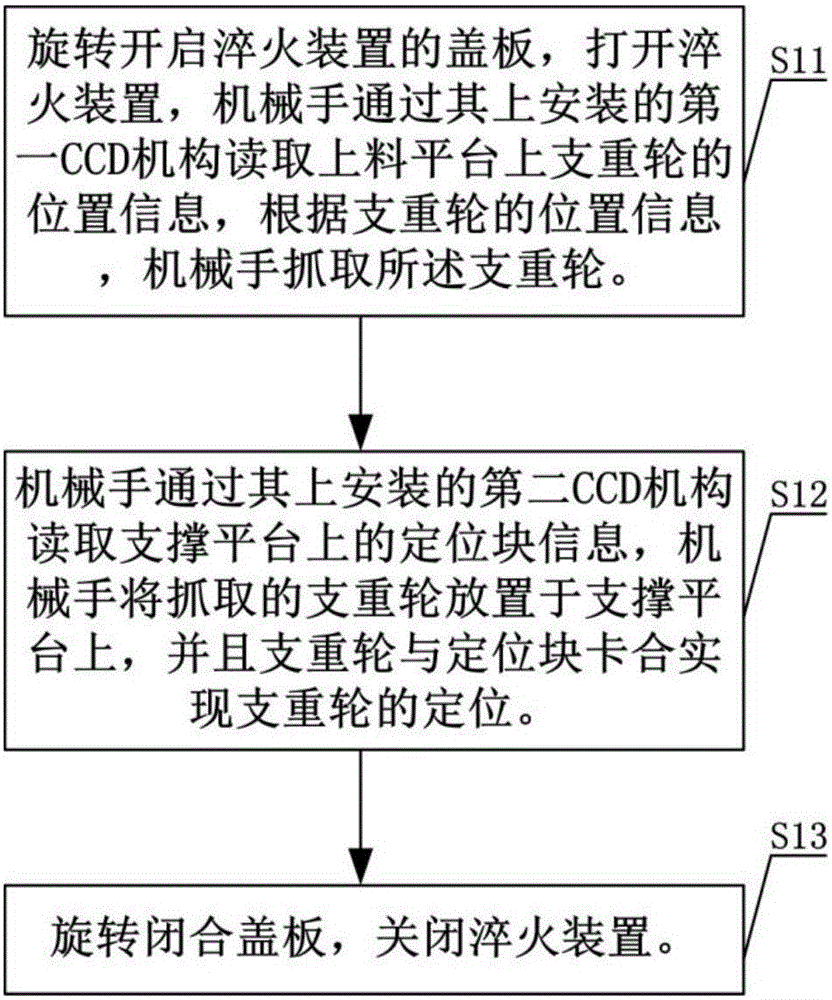

Segmented heating and cooling quenching process for wheel body of thrust wheel

ActiveCN105821195ASolve the speed problemSolve cracking and deformationFurnace typesIncreasing energy efficiencySaline waterIntermediate frequency

Owner:KUSN KENSETABU BUHIN

Heat treatment method of aluminum alloy for automotive body

Owner:重庆金亚模具制造有限公司

Quench cleaning device for bearing ring assembly

Owner:HEFEI YUANDA BEARING FORGING

Online quenching oil filtering device for thermal treatment furnace

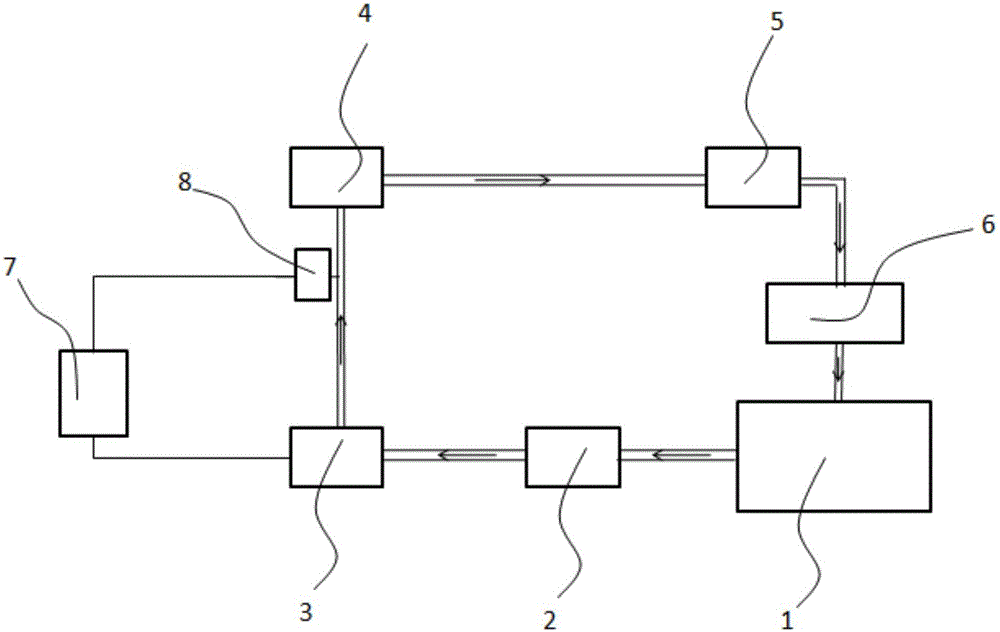

InactiveCN105920914AOnline filtering implementationGuaranteed cooling effectFiltration circuitsQuenching devicesSuspended particlesOil sludge

Owner:JIANGSU FENGDONG HEAT TREATMENT & SURFACE MODIFICATION ENG & TECH RES CO LTD

Heat processing technology method of austenitic ductile iron wear-resistant casting

Owner:NINGGUO HUAFENG WEAR RESISTANT MATERIAL

Heat treatment quenching technology for high-carbon chromium-molybdenum-vanadium powder hubbing steel precise parts

The invention discloses a heat treatment quenching technology for high-carbon chromium-molybdenum-vanadium powder hubbing steel precise parts. The technology comprises the following steps that 1, workpieces with the average thickness being 32 mm are put into a quenching furnace to be preheated twice to reach the temperature being 150 DEG C; 2, heating is conducted in the quenching furnace in two stages to reach the quenching temperature being 1,018 DEG C, and heat preservation is conducted; 3, the workpieces are subjected to discharge and air cooling till the temperature is 65 DEG C; 4, the workpieces are put into a tempering furnace twice, heat preservation and tempering are conducted at 510 DEG C, and discharge and air cooling are conducted. The workpieces with the average thickness being 32 mm are put into the quenching furnace to be preheated twice, for the first time, the temperature is raised to 100 DEG C at the heating speed smaller than 75 DEG C / hour, and for the second time, the temperature is raised to 150 DEG C at the heating speed smaller than 115 DEG C / hour. Accordingly, the excellent performances such as the extremely high abrasive wear resistance and high pressure resistance strength, good toughness and good size stability of heat treatment of the precise parts are reliably guaranteed, and the use requirements of the precise parts are met.

Owner:HUBEI ENG INST

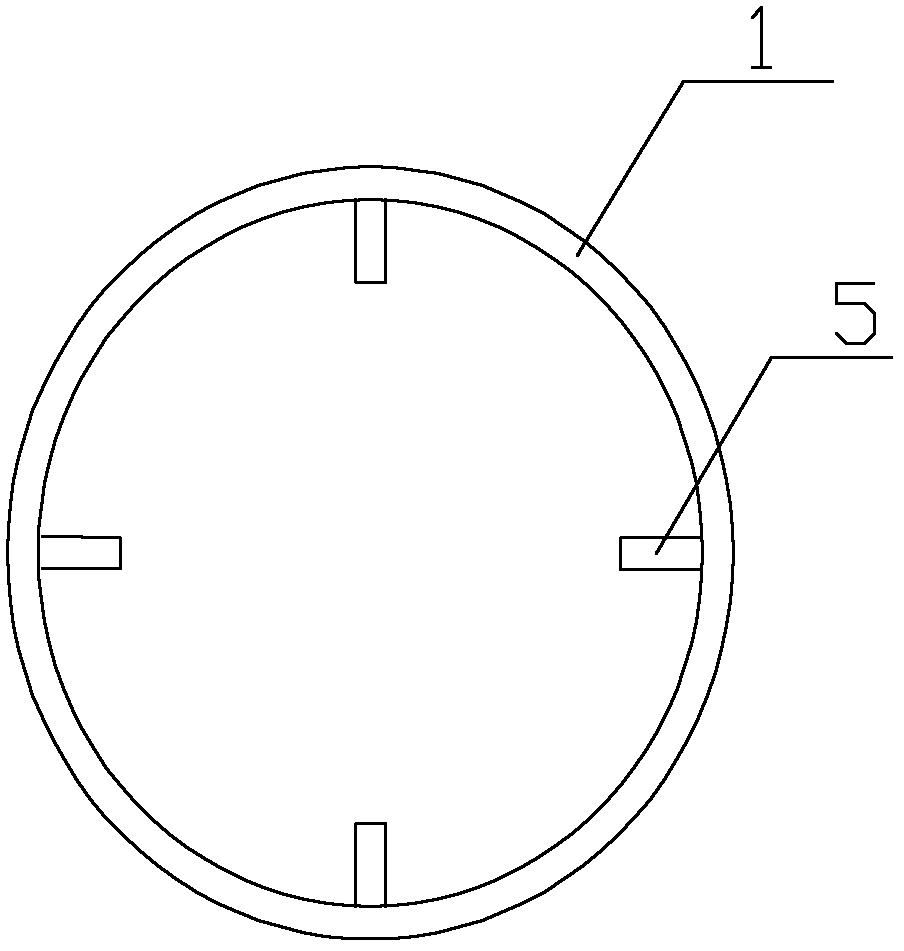

Steel plate type circular thin-walled quenching roller

InactiveCN103184328ANo deformationGuaranteed aestheticsQuenching devicesInterference fitSoldering

Owner:刘平祥

Hardened and toughened nut

The invention includes a screw body, a screw stem, screw stem threads and a screw top. The screw body or the partial screw body is made of Cr10 or Cr20 manganese-titanium steels, or Cr20 or Cr40 steels, and is three-quarter hard finished by the quenching or the cementation quenching process in the heat treatment. If the cementation quenching process is adopted, the screw body containing low carbon steel in the cemented depth is hardened to 46 deg. or above 46 deg. / 60 kilogram pressure hardness.

Owner:徐尚仁

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap