Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Oil cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil cooling is the use of engine oil as a coolant, typically to remove surplus heat from an internal combustion engine. The hot engine transfers heat to the oil which then usually passes through a heat-exchanger, typically a type of radiator known as an oil cooler. The cooled oil flows back into the hot object to cool it continuously.

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

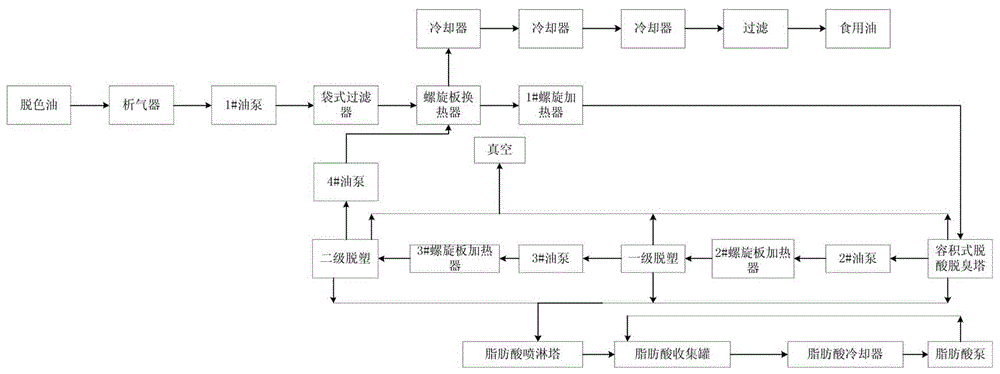

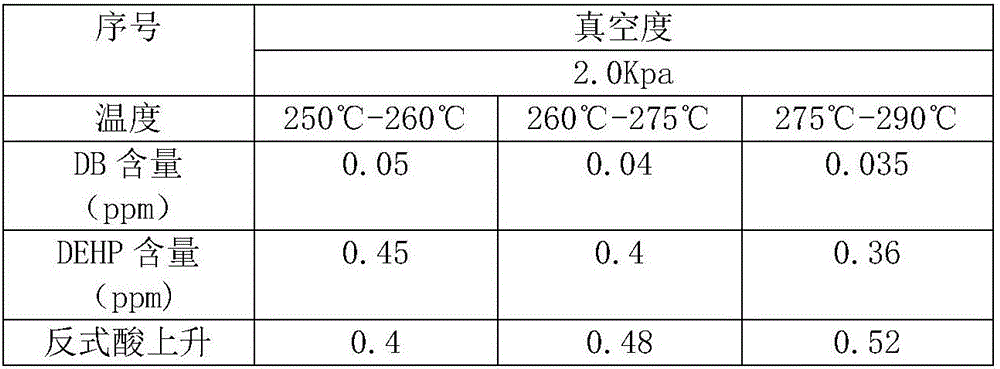

Edible-oil processing technology for decreasing content of trans-fatty acid and removing plasticizer

ActiveCN105925371AEfficient removalSolve the problem of serious exceeding the standardFatty-oils/fats refiningPlasticizerNational standard

Owner:HEBEI JIAFENG PLANT OILS

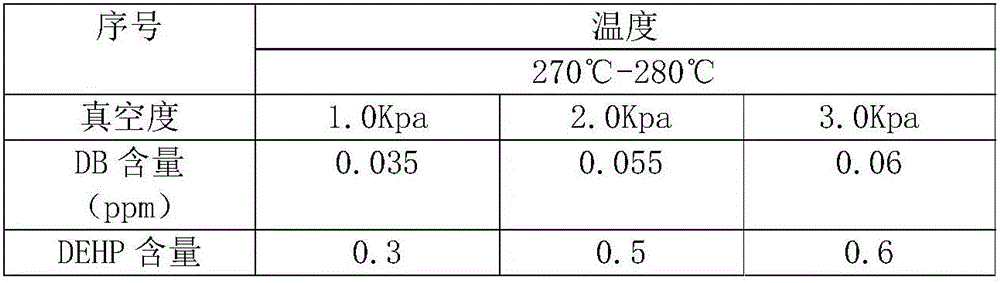

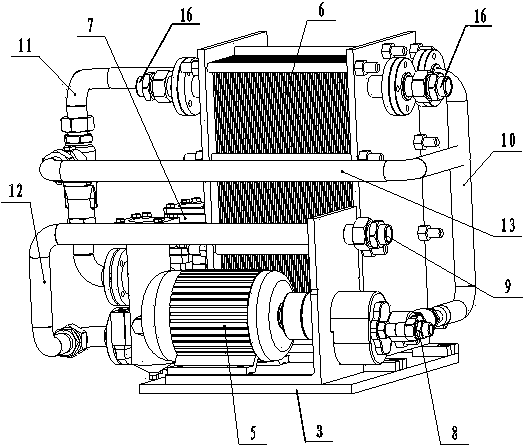

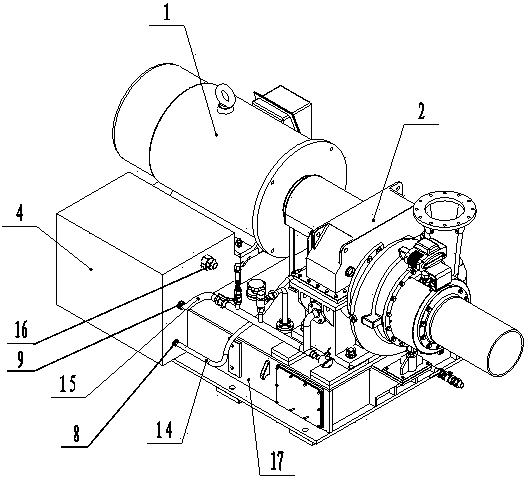

Lubricating oil cooling and filtering integrated device for single-stage high-speed centrifugal blower

Owner:SHANXI JULONG FAN & BLOWERS

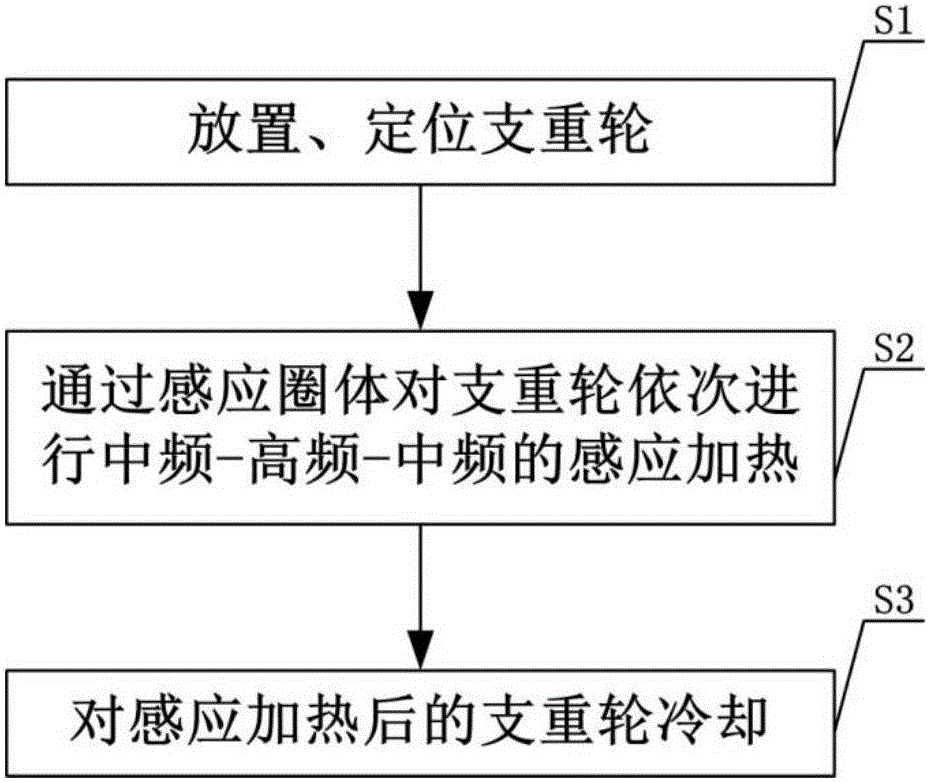

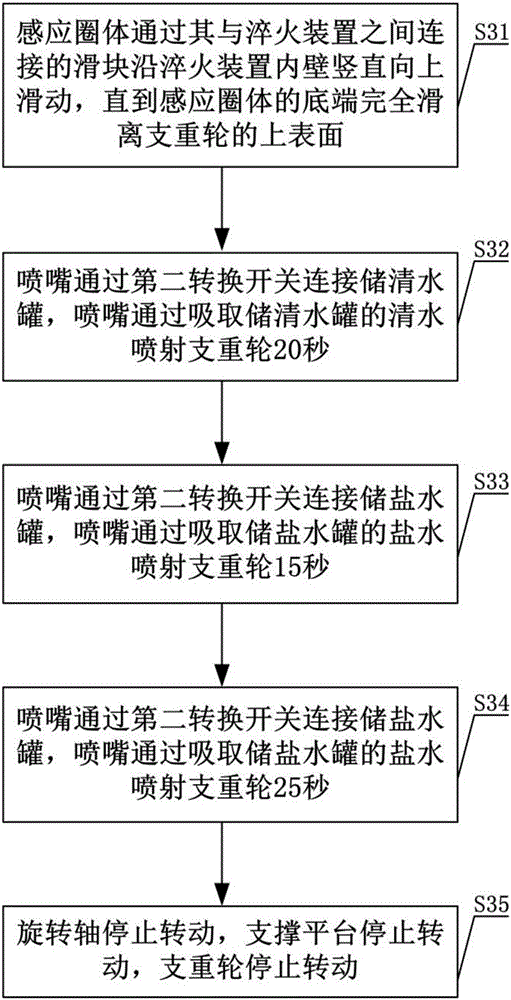

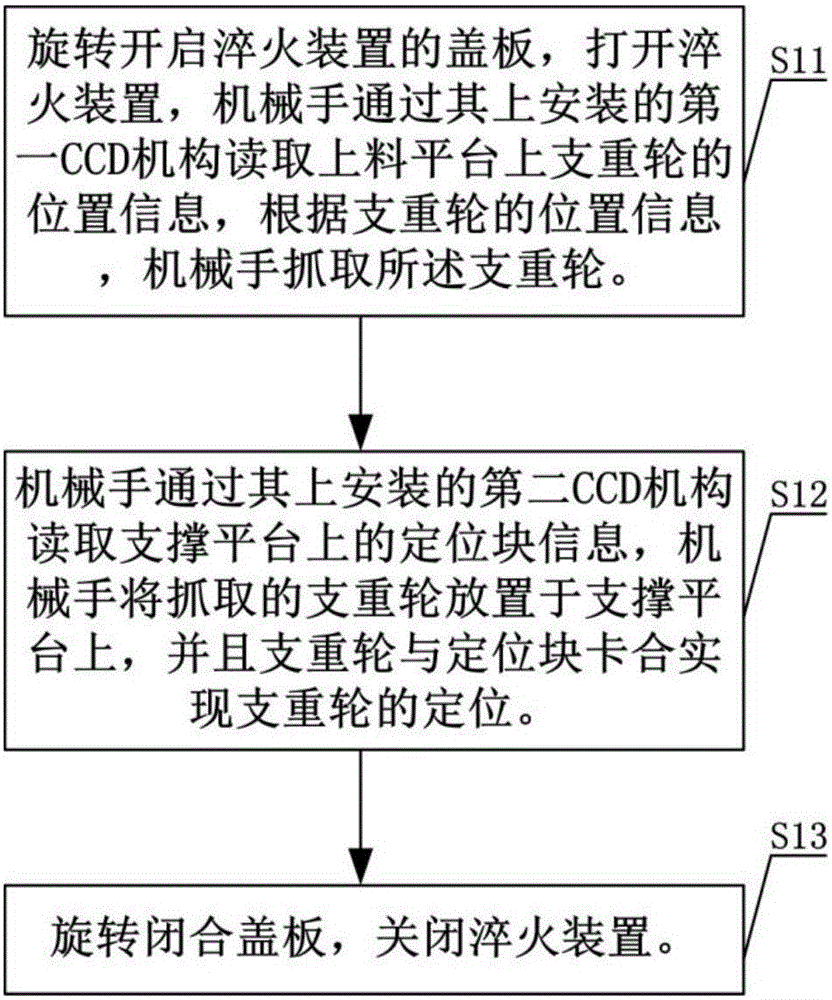

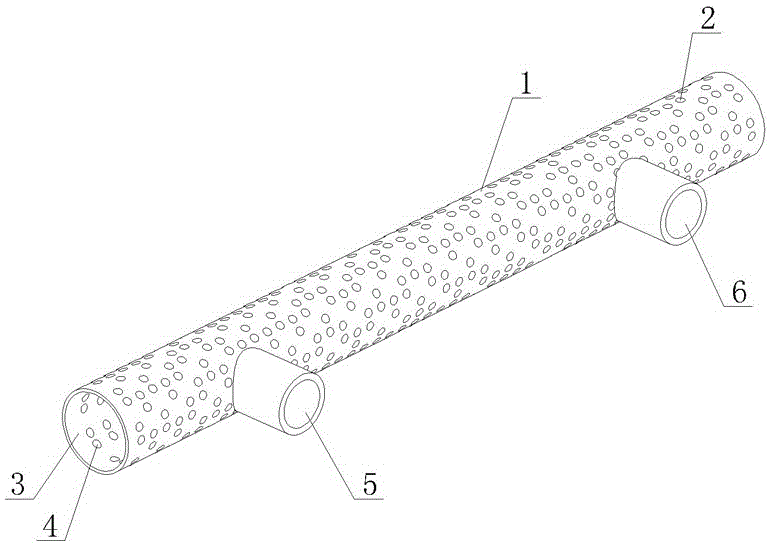

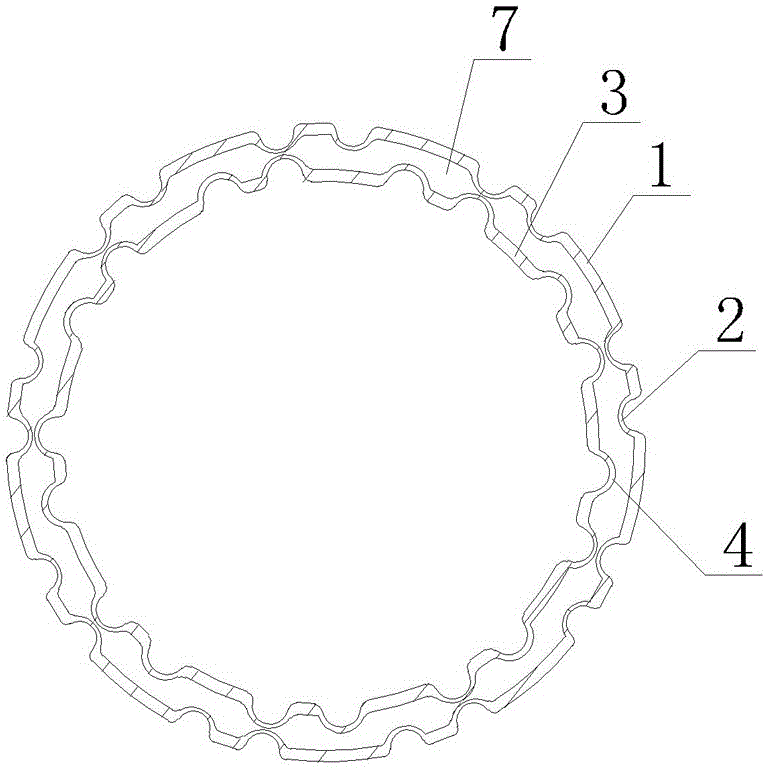

Segmented heating and cooling quenching process for wheel body of thrust wheel

ActiveCN105821195ASolve the speed problemSolve cracking and deformationFurnace typesIncreasing energy efficiencySaline waterIntermediate frequency

Owner:KUSN KENSETABU BUHIN

5CrNiMo tempering process

InactiveCN105755240ALow experience requirementEasy to operateFurnace typesHeat treatment furnacesRoom temperatureHardness

Owner:CHONGQING HUANDE TECH CO LTD

Automobile oil cooler

InactiveCN106439469ALubrication elementsMotor oilOil cooling

Owner:RUIAN XINHAI AUTO PARTS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap