Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98 results about "Manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

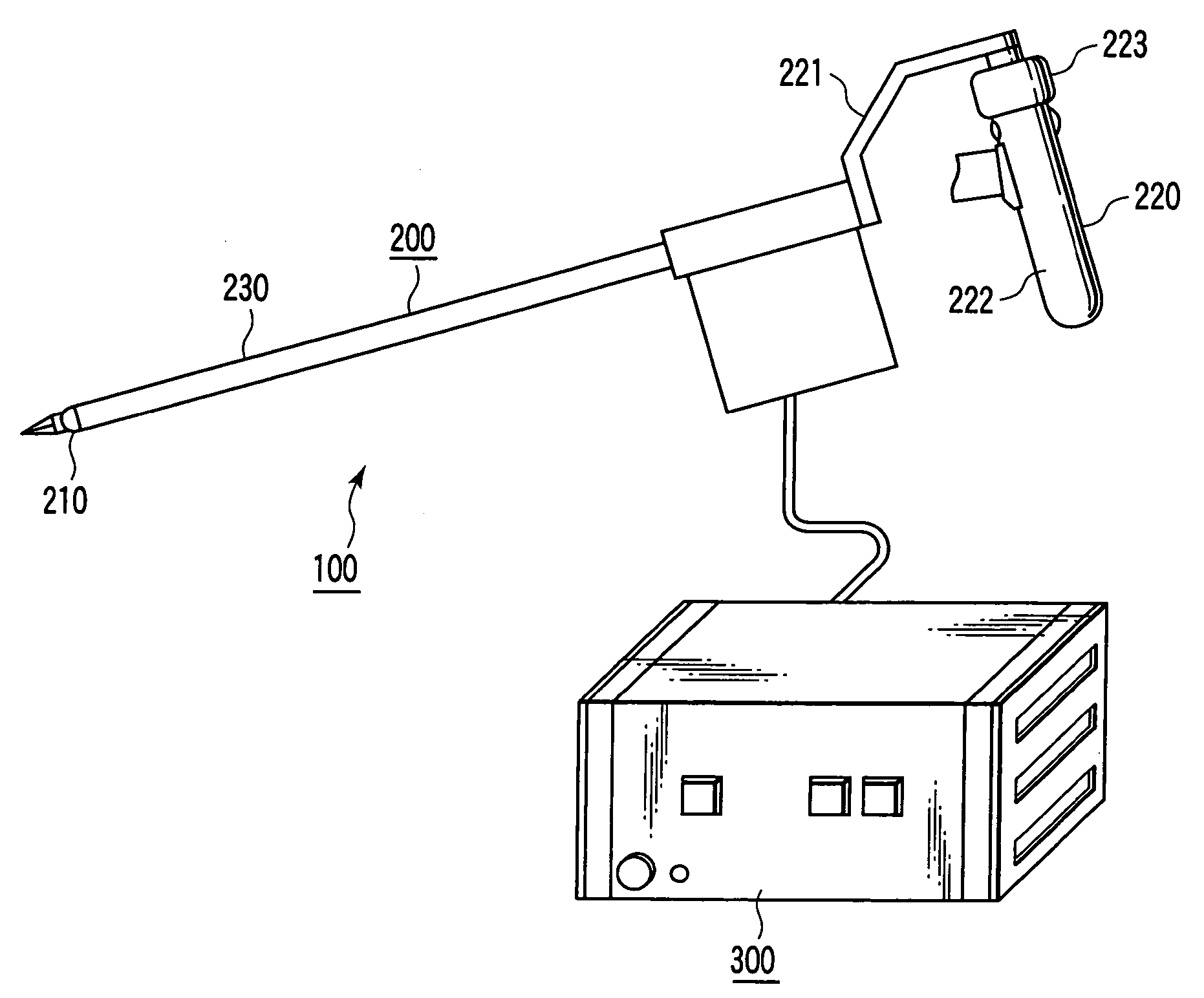

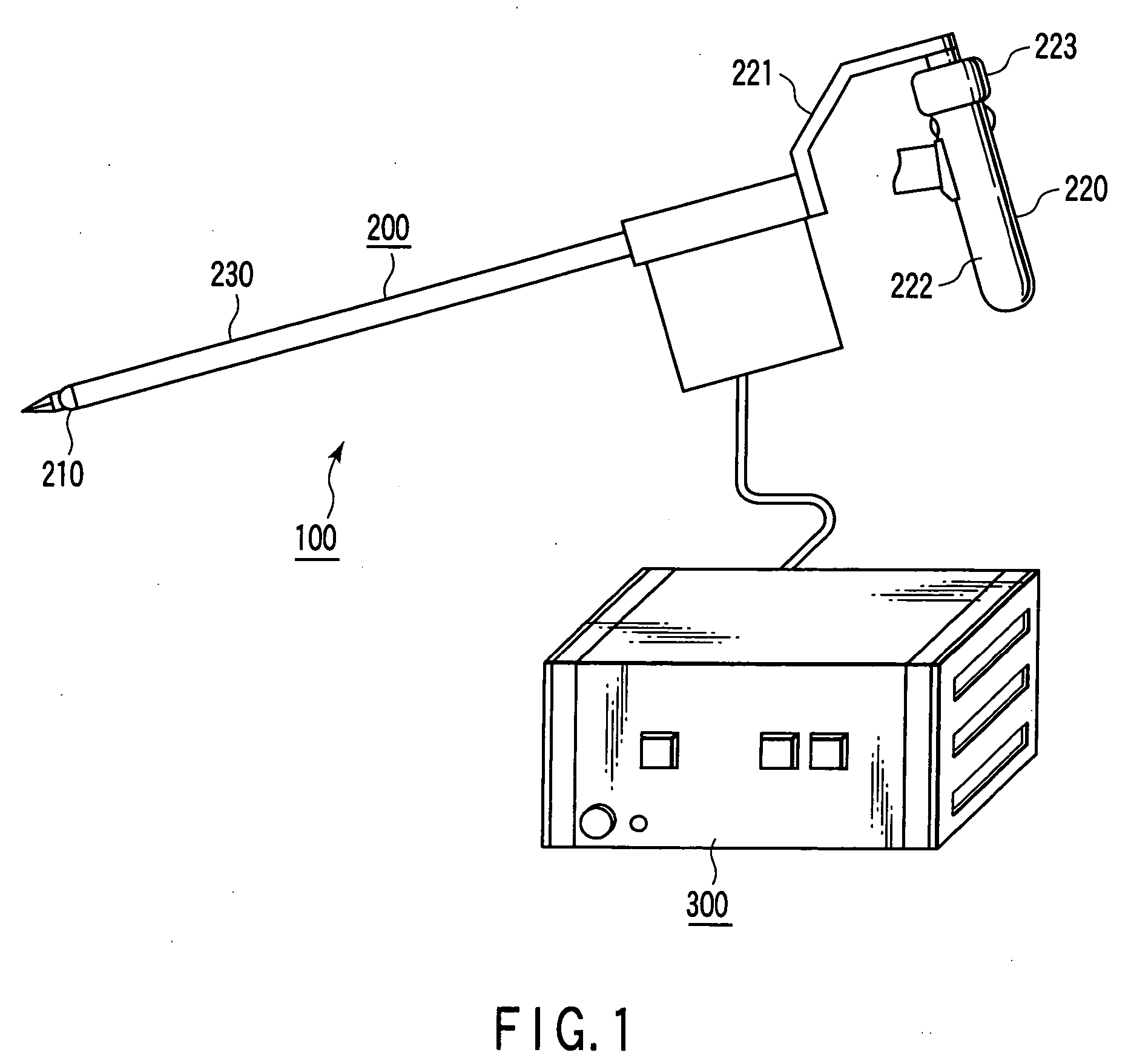

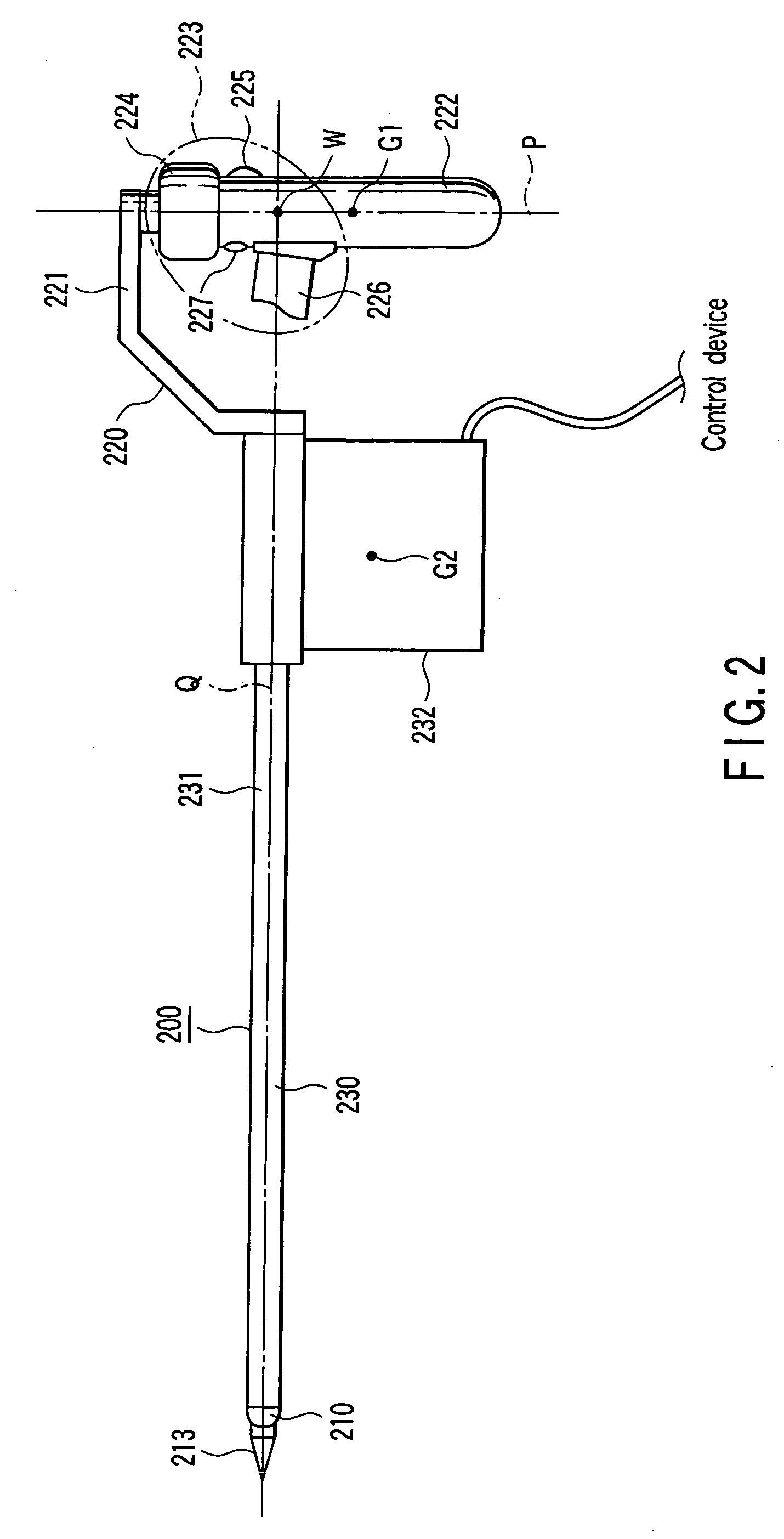

Manipulator apparatus

InactiveUS20050222587A1Minimizing affectionHigh manipulationDiagnosticsSurgical manipulatorsManipulatorEngineering

Owner:TERUMO KK

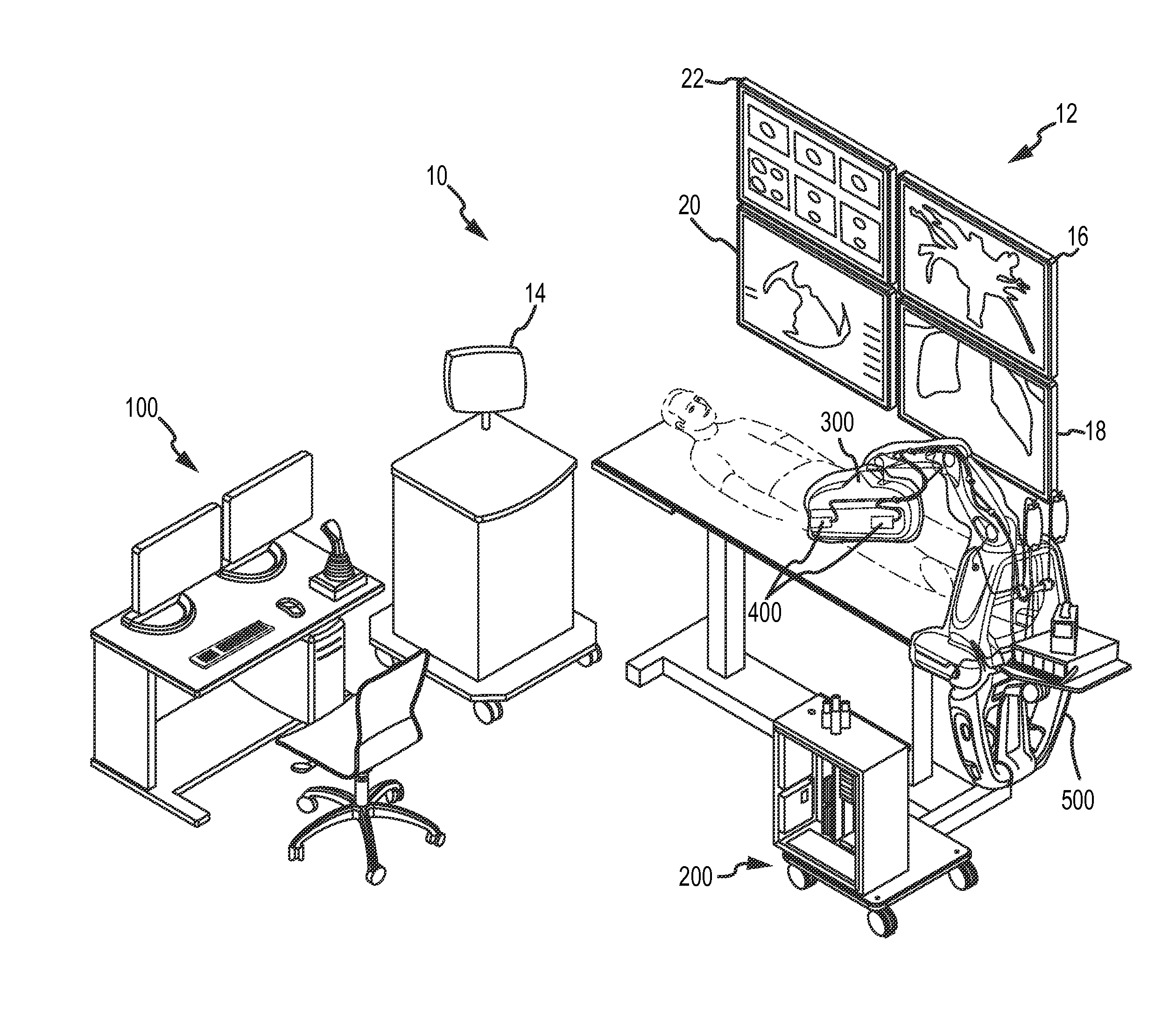

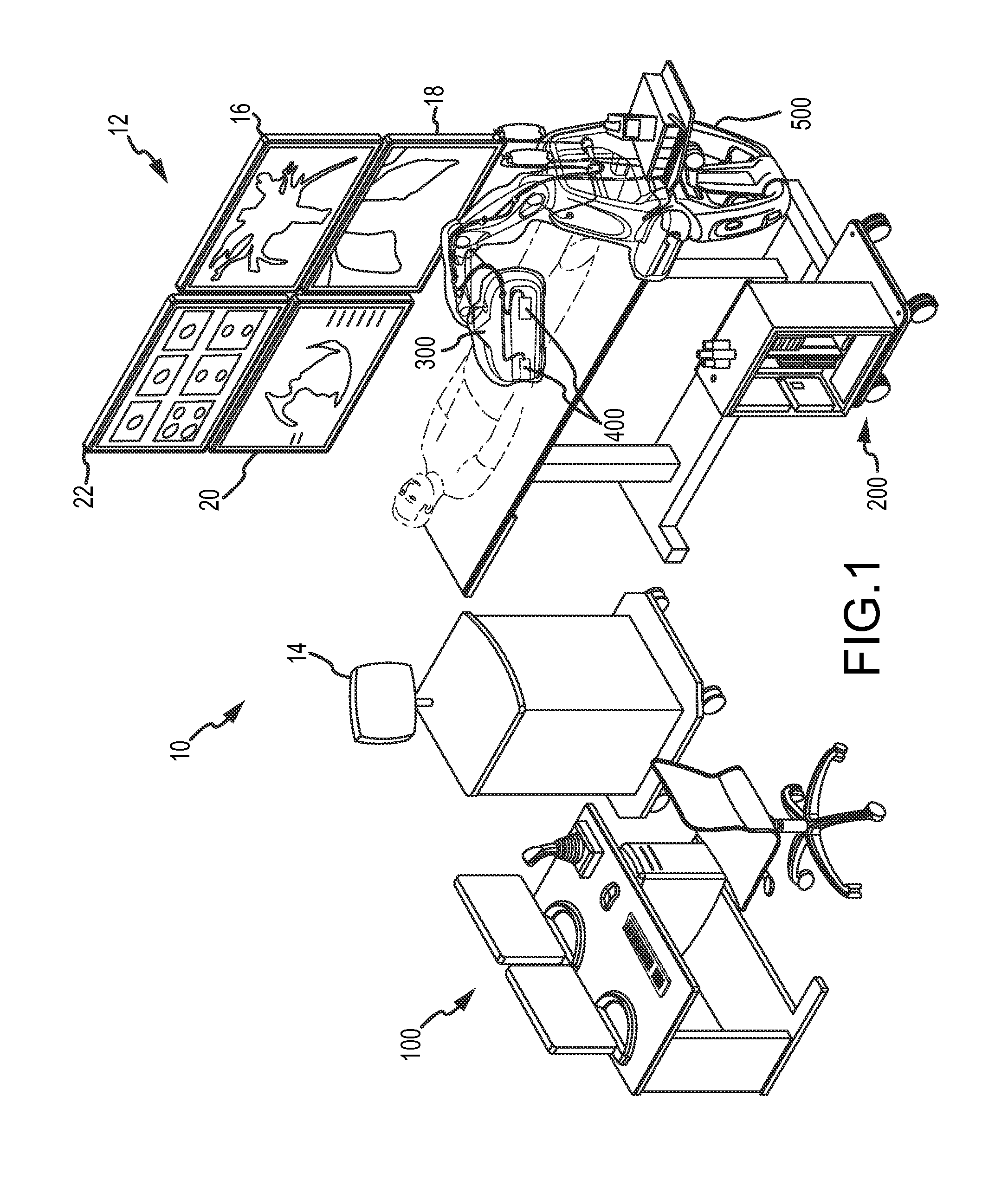

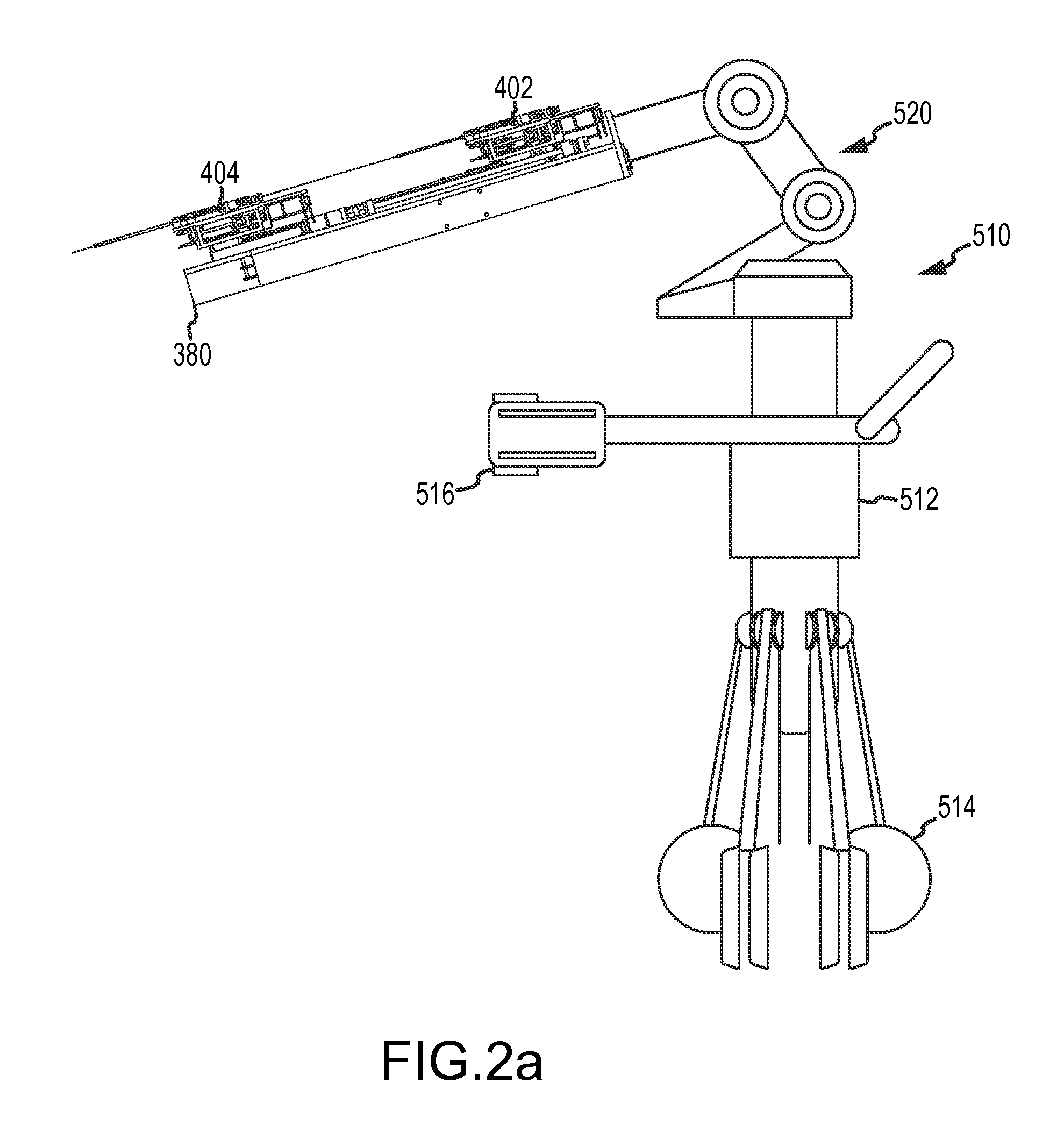

Robotic catheter system

ActiveUS20100256558A1Surgical navigation systemsSurgical systems user interfaceRobotic systemsUser input

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

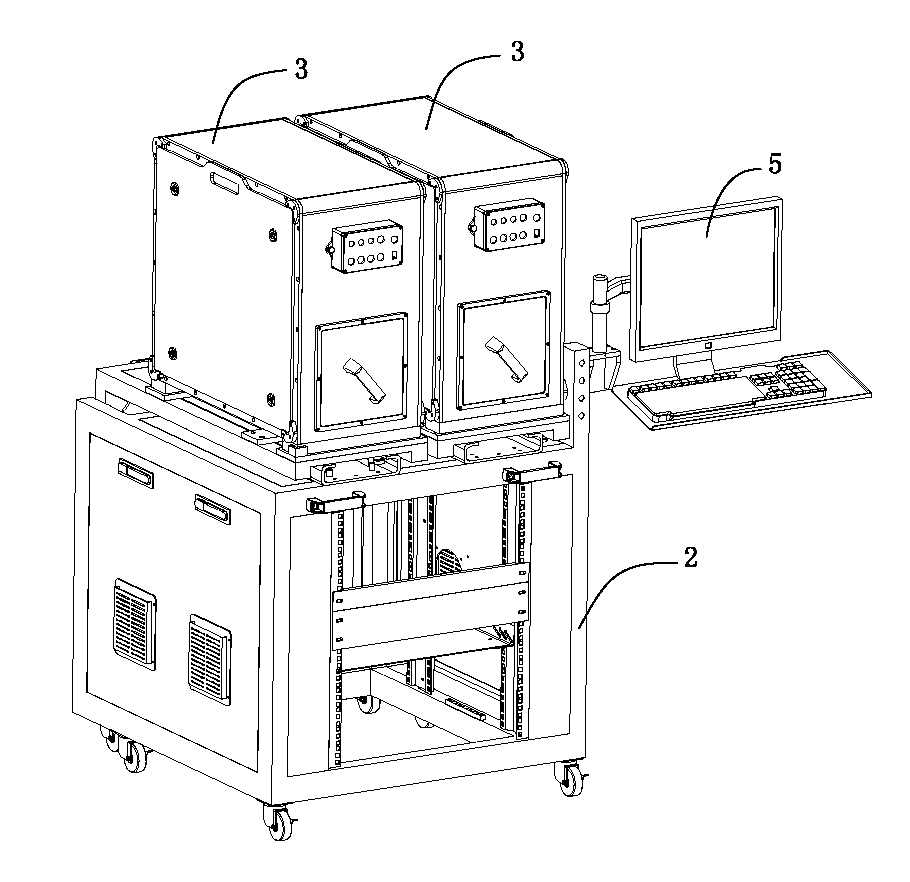

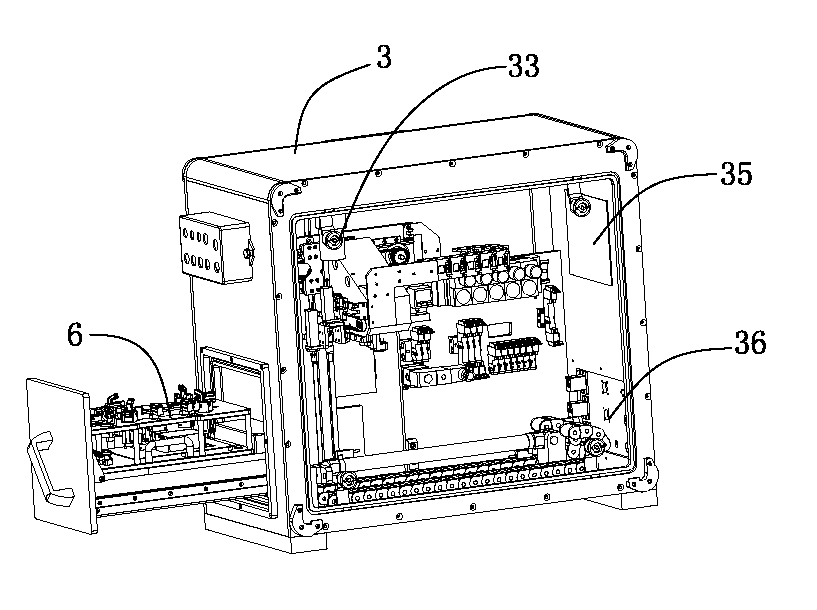

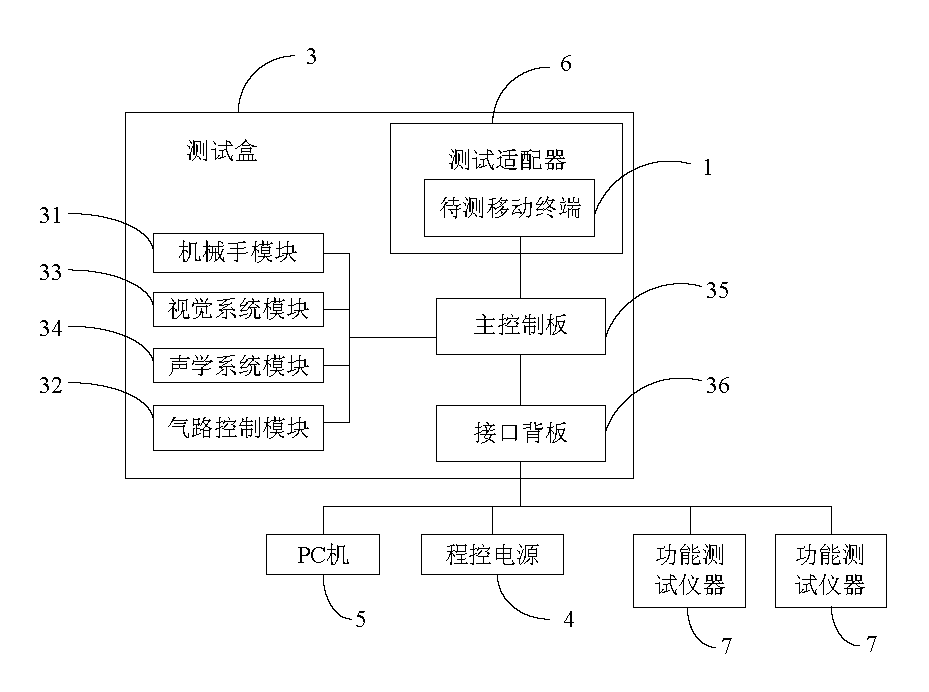

Testing system for mobile terminal and testing method thereof

Owner:广东每通测控科技股份有限公司

Tissue Manipulator

Owner:ETHICON ENDO SURGERY INC

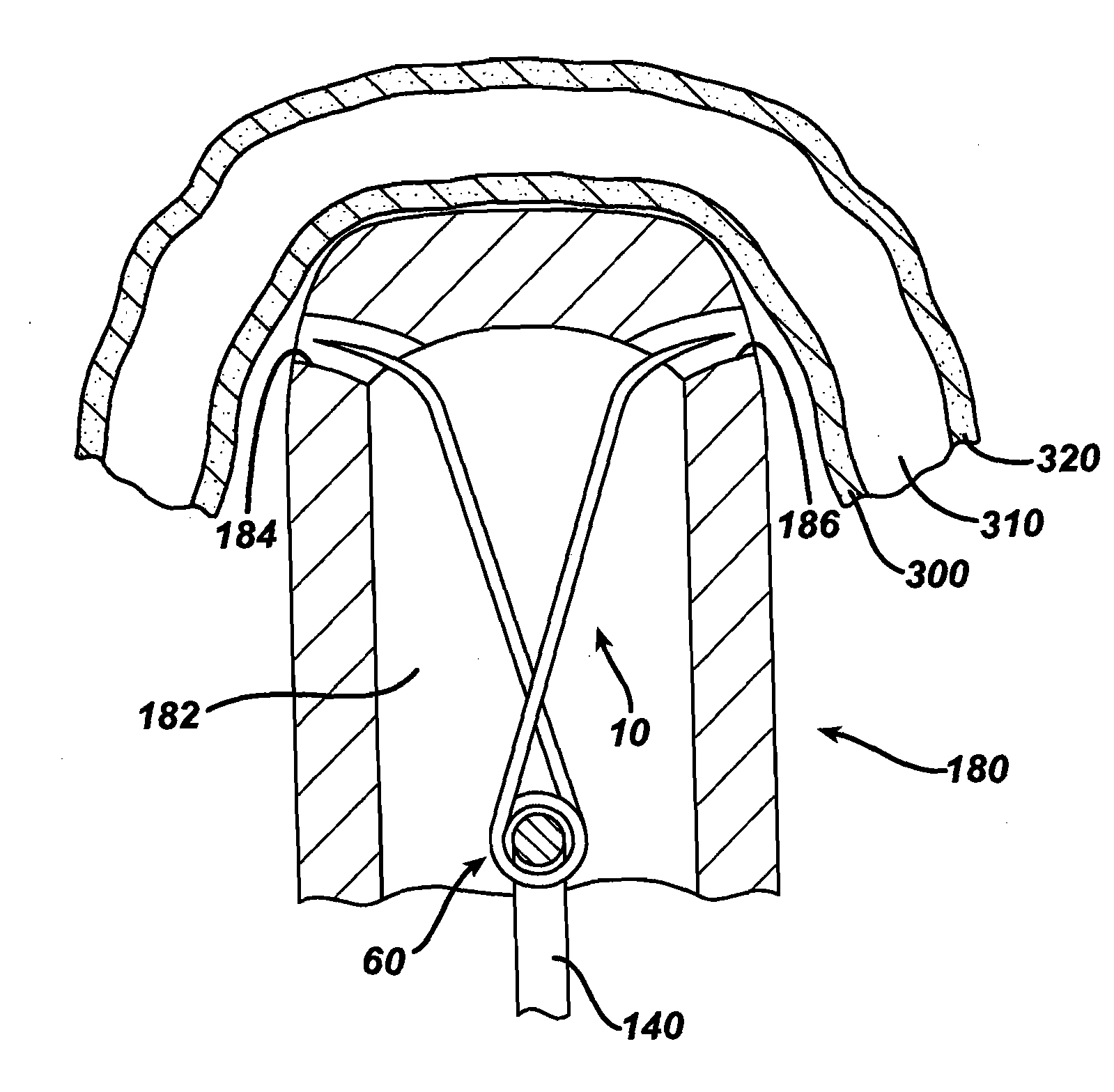

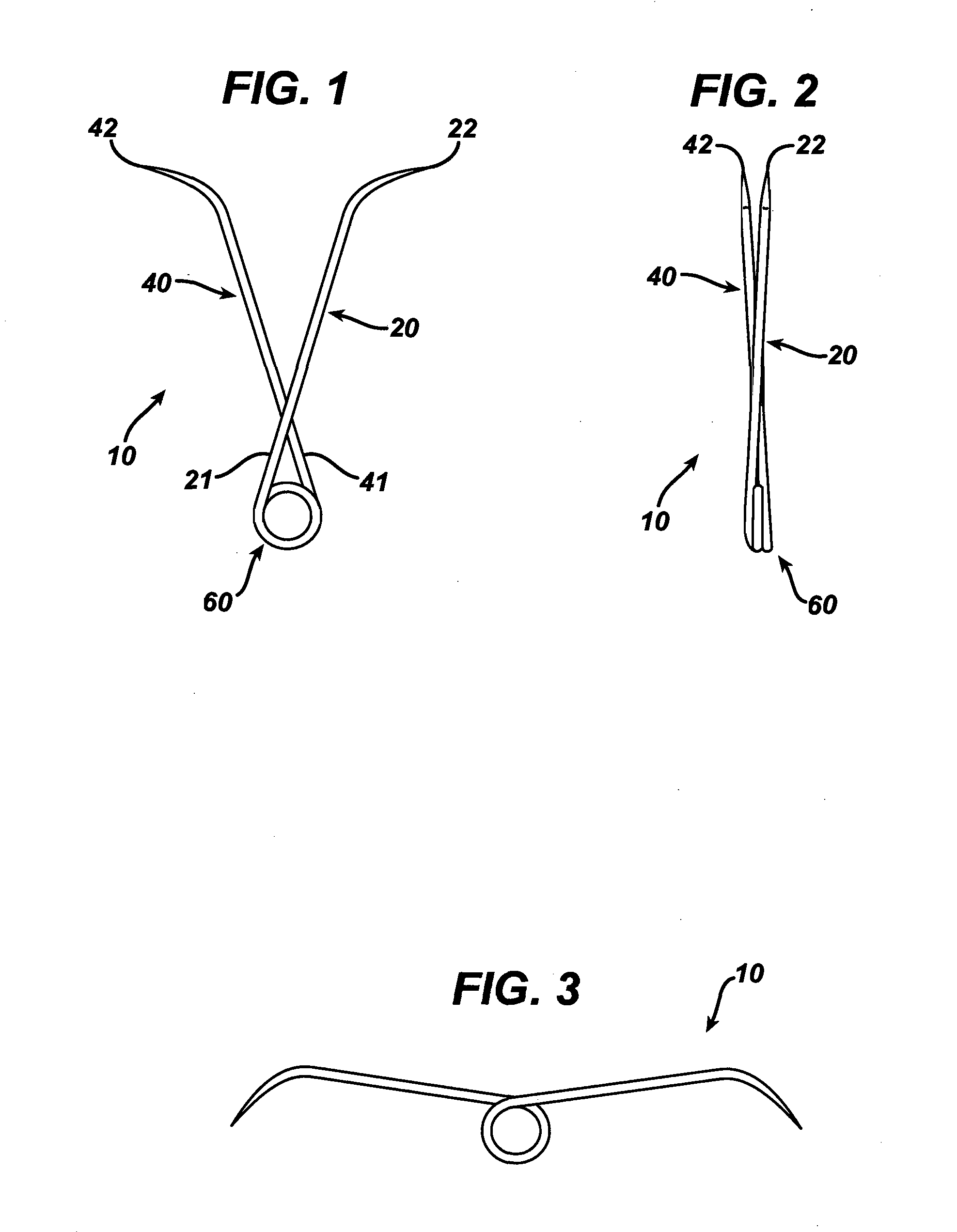

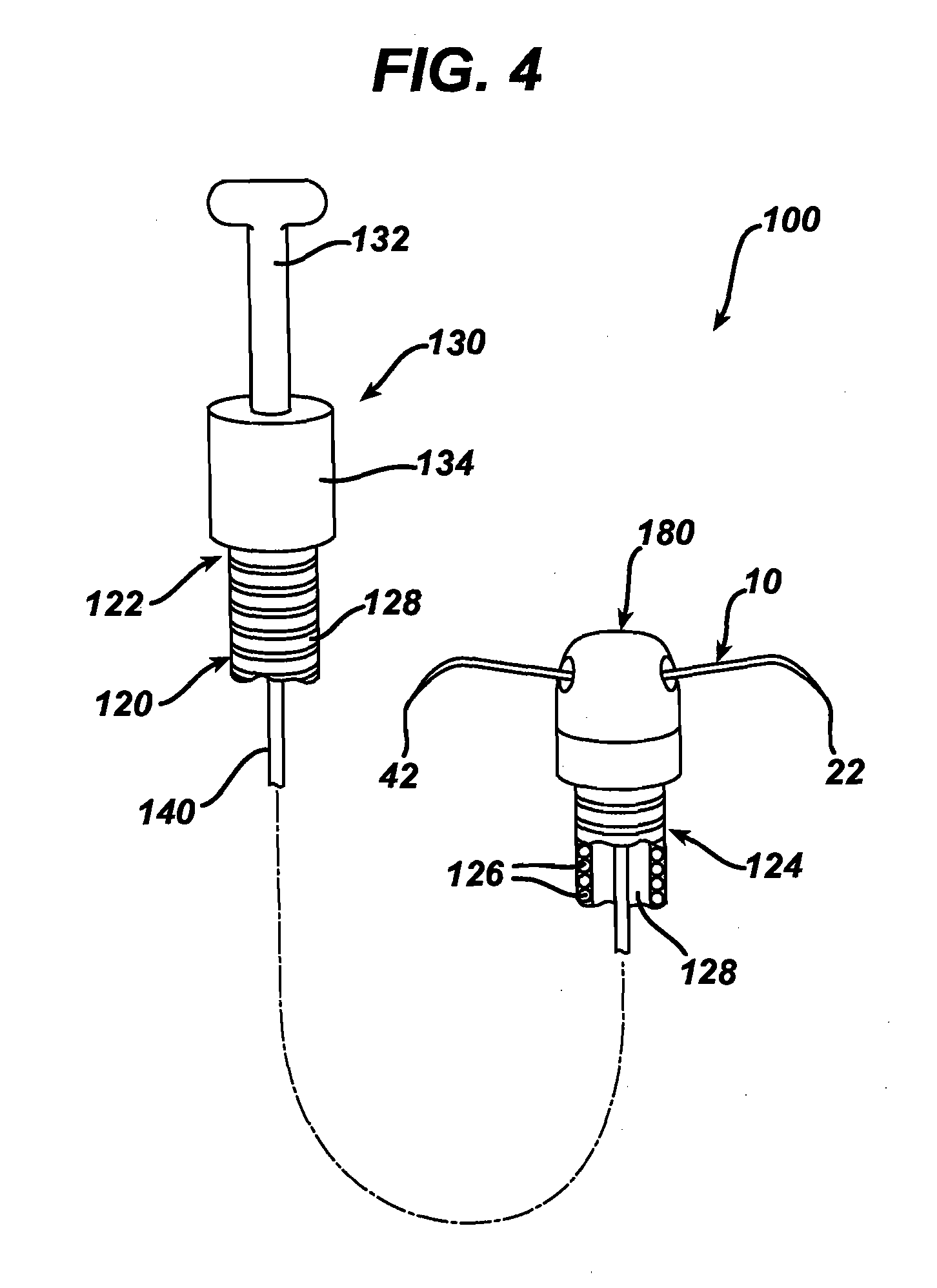

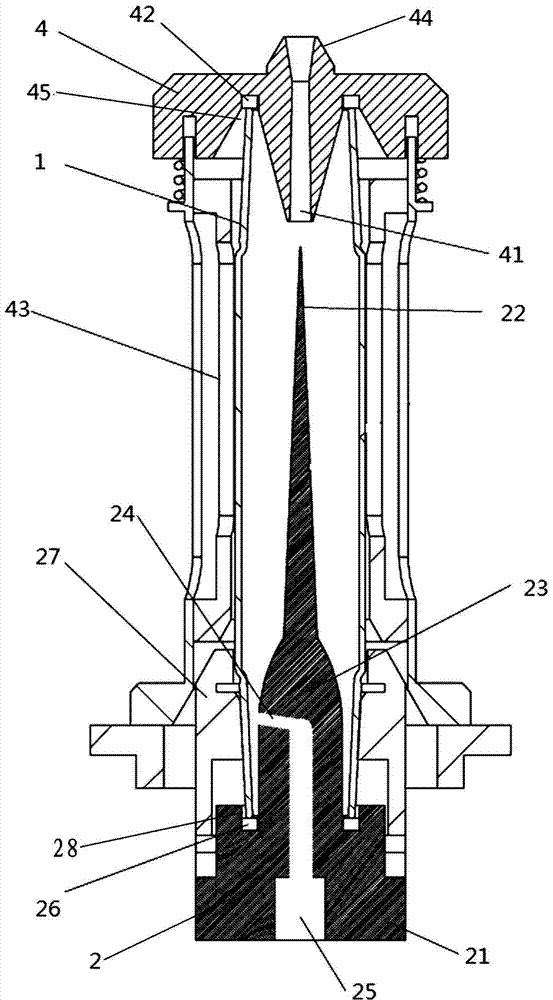

Expandable blade device for stabilizing long bone fractures

InactiveUS20080221575A1Improve stabilityLower the volumeDilatorsExcision instrumentsDistal portionLONG BONE FRACTURE

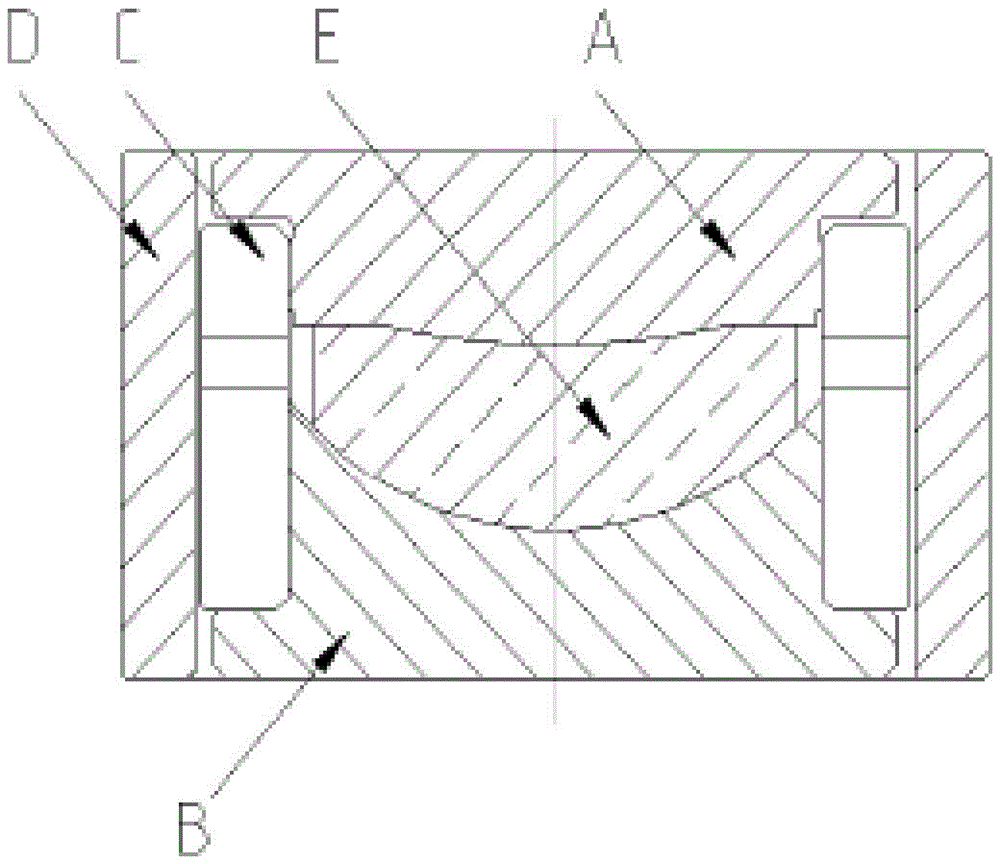

The present invention relates generally to medical devices and medical methods, in particular, devices and methods useful for stabilizing fractures of long bones. In one embodiment, the present invention is a device comprising a housing having a lumen; a plunger having a proximal portion and a distal portion, where the plunger is disposed within the lumen and is movable relative to the housing; a plurality of blades, where the blades can expand radially from the axis of the housing; and a manipulator functionally connected to the plunger, wherein the manipulator is operable to: move the plunger relative to the housing; expand the blades radially from the axis of the housing; and move the blades about the axis of the plunger.

Owner:BETTS ANDRES

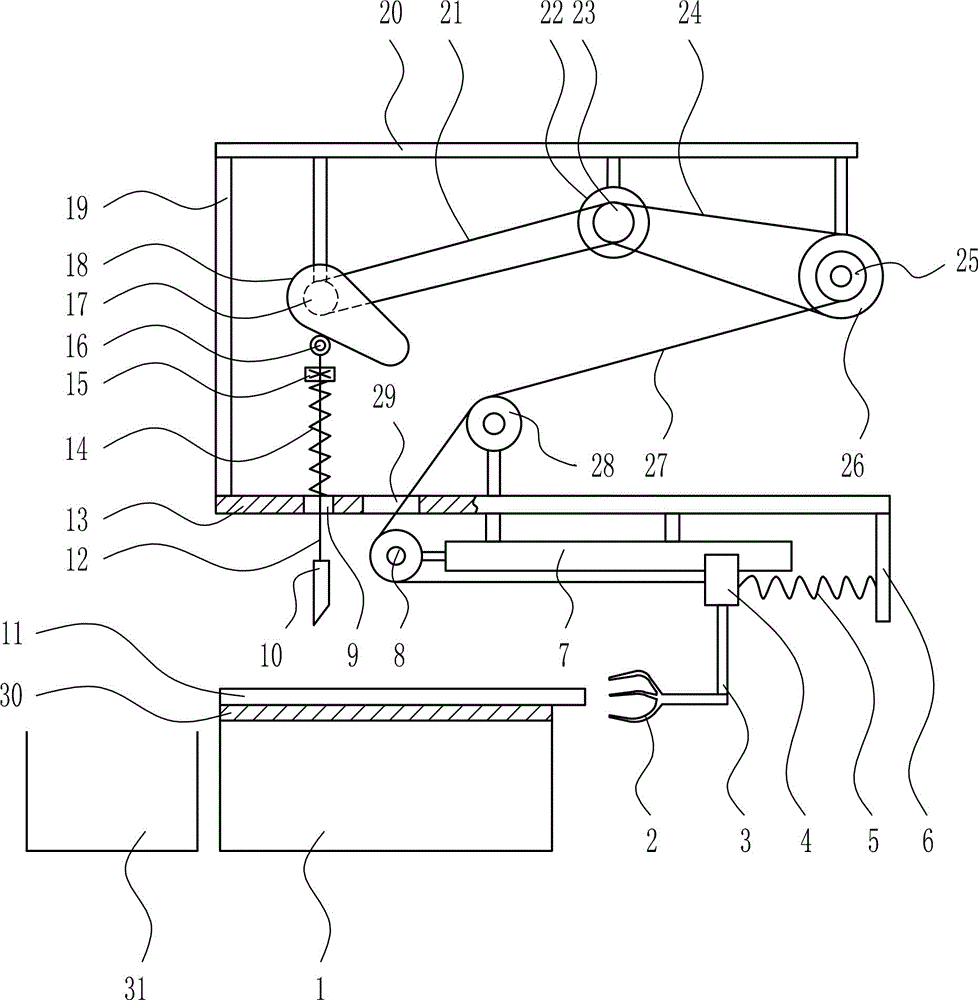

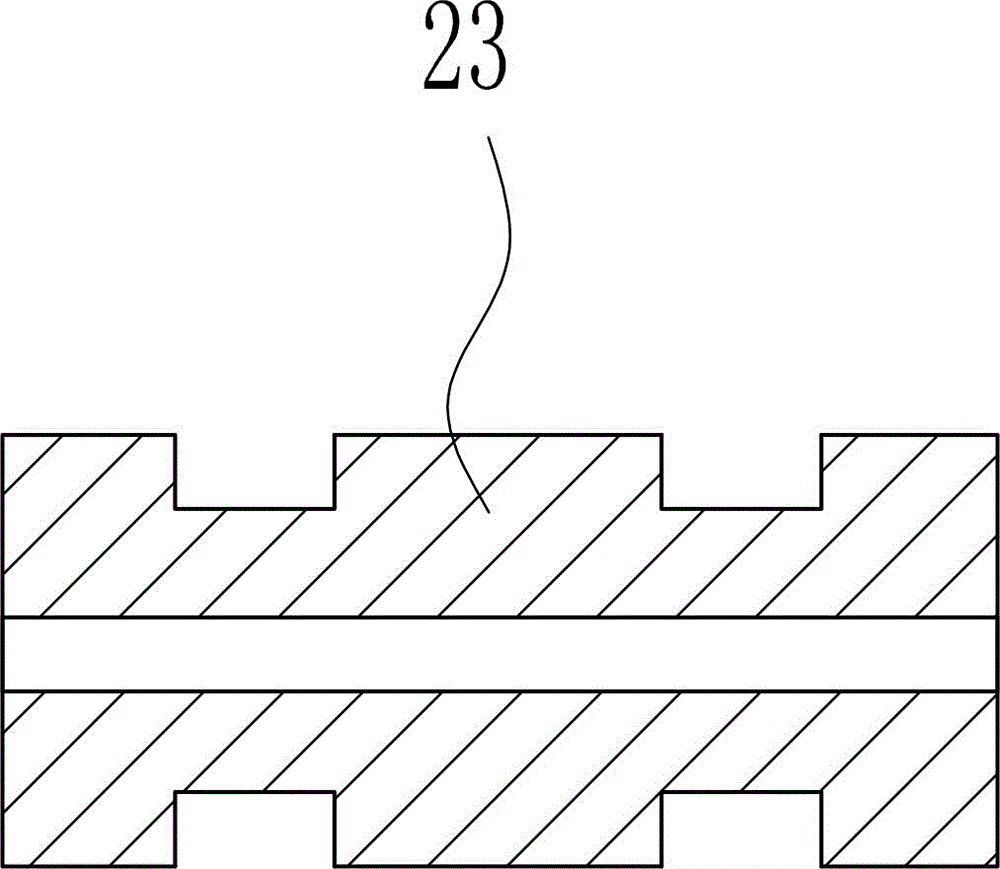

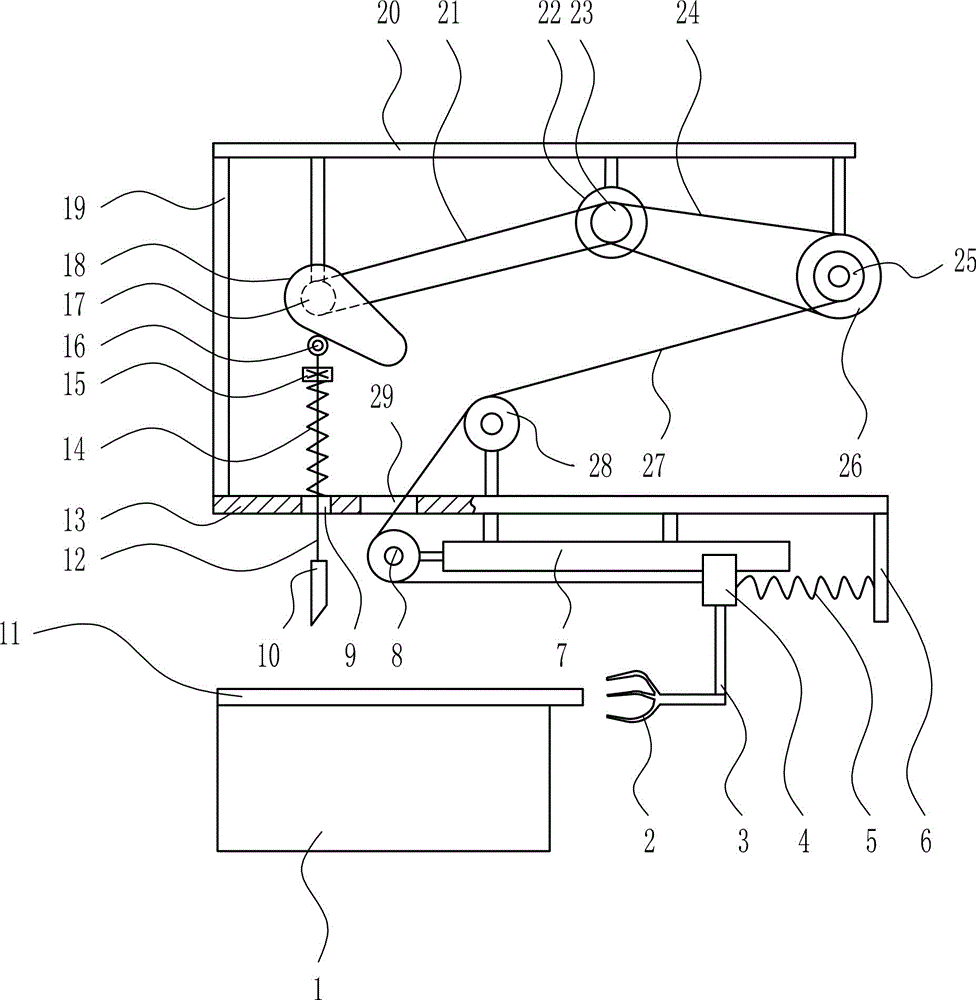

Efficient cutting device of hardware steel pipe

ActiveCN106180867AHigh hardnessAnti-crackTube shearing machinesDriving apparatusEconomic benefitsEngineering

Owner:开平力蒲卫浴有限公司

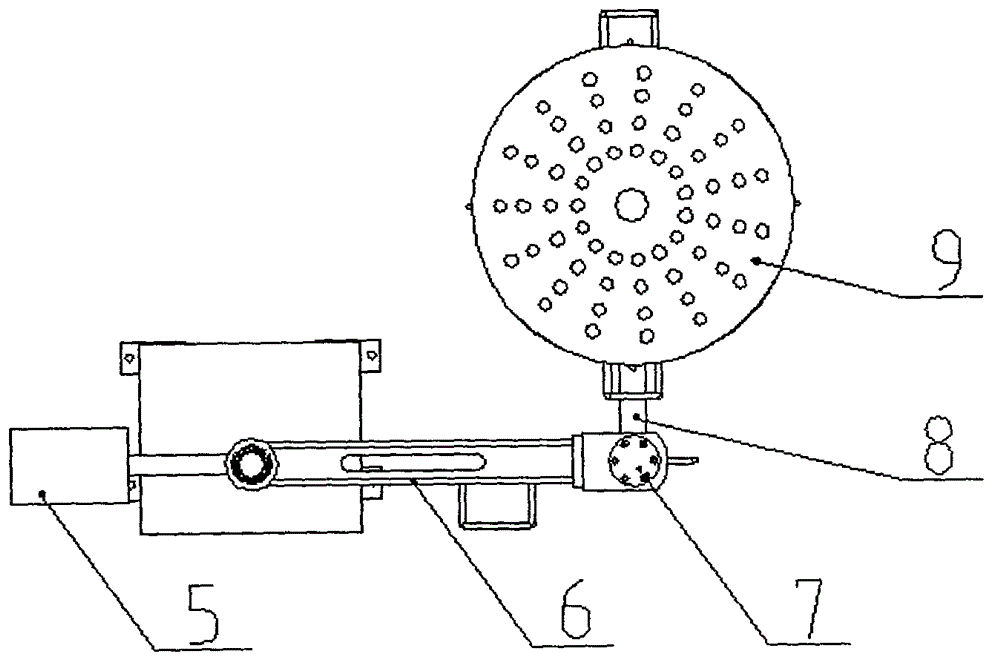

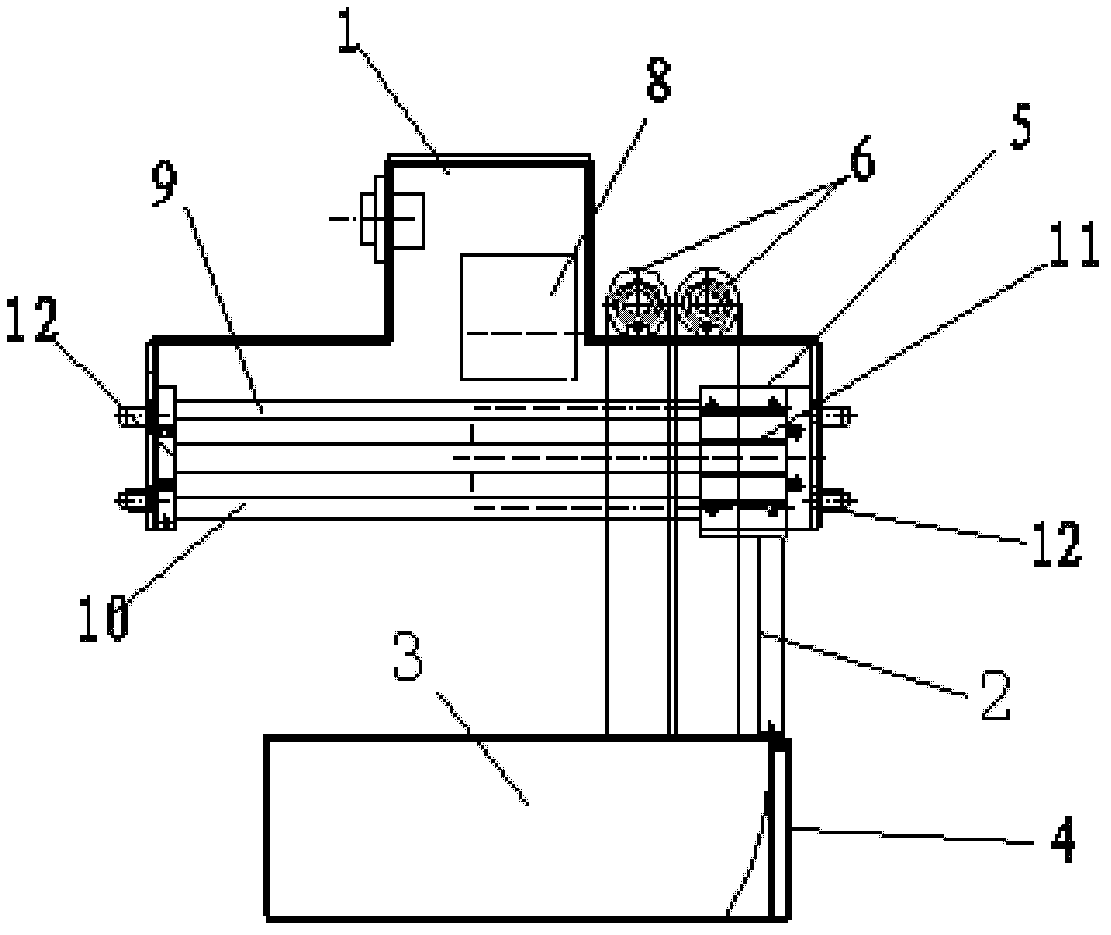

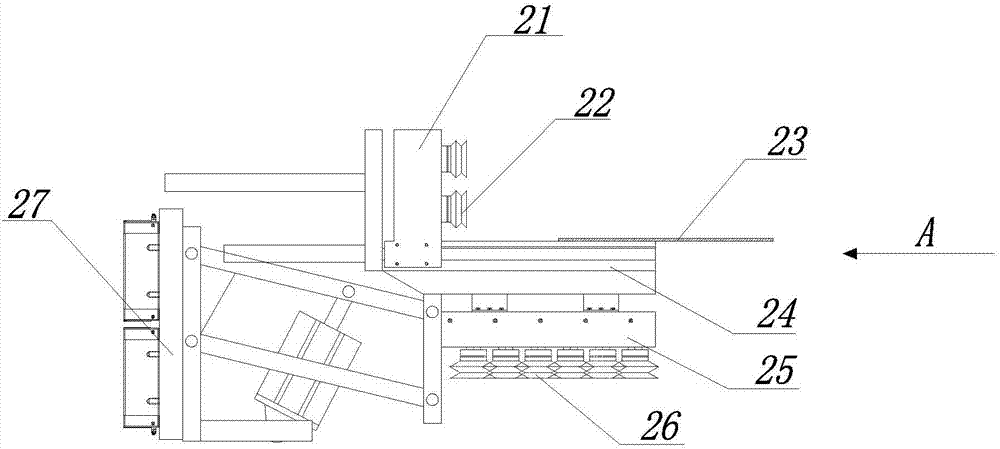

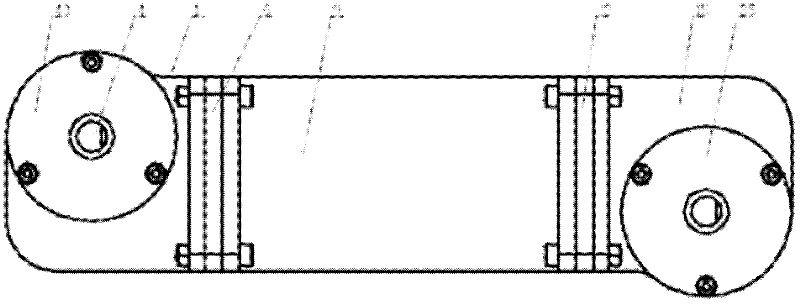

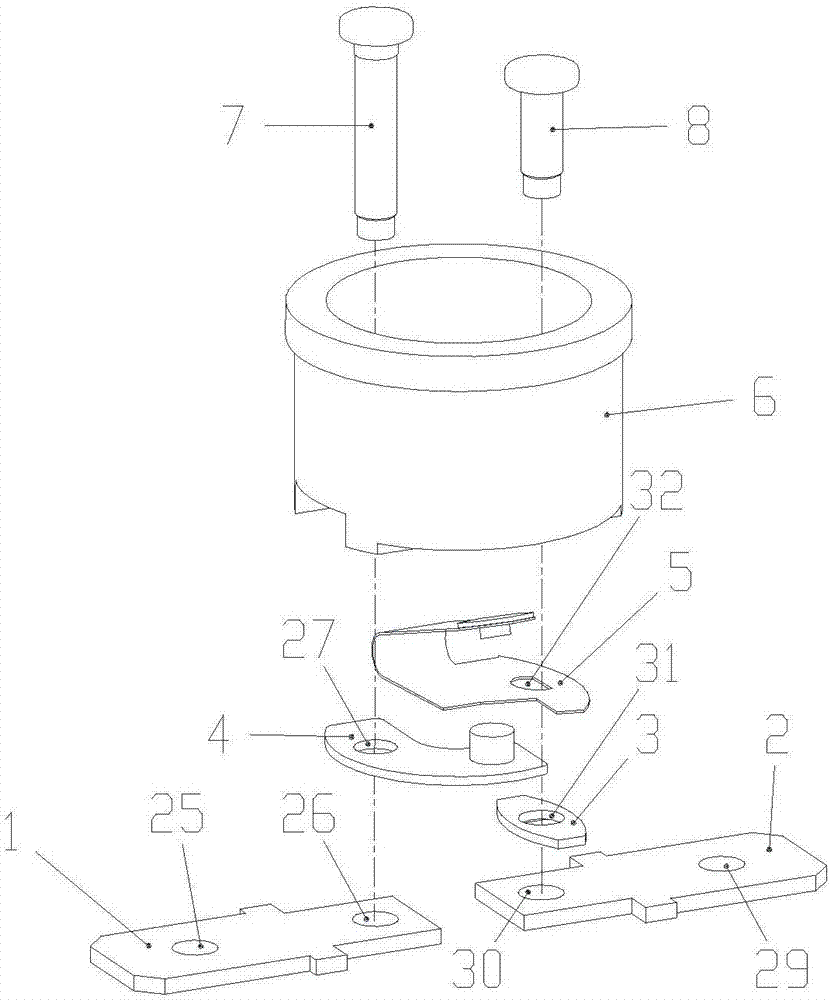

High-universality feeding device of pipe end-facing machine and feeding method

ActiveCN104907879AImprove processing qualityEasy to correctMetal working apparatusEngineeringScrew thread

The invention discloses a high-universality feeding device of a pipe end-facing machine and a feeding method. The feeding device of the pipe end-facing machine comprises a feeding mechanism and a manipulator, wherein the feeding mechanism comprises a feeding rack, a chain conveying mechanism and a plurality of pipe end-facing feeding supporting plates; each pipe end-facing feeding supporting plate comprises a supporting plate body, a main supporting block and a first auxiliary supporting block, wherein a first adjustment through hole is further formed in one side of the supporting plate body; the first auxiliary supporting block comprises a first adjustment block, a supporting screw rod, a first locking screw and a first locking nut; the supporting screw rod comprises a screw rod part and a screw rod fork part; a plurality of threaded holes are formed in the first adjustment block; the first locking screw penetrates through the first adjustment through hole in the supporting plate body and is screwed into one threaded hole of the first adjustment block; the screw rod part of the supporting screw rod penetrates through the first locking nut, is screwed into another threaded hole in the first adjustment block and then is locked through the first locking nut; a main fork part is formed on the main supporting block; the pipe is supported by the main fork part and the screw rod fork part. According to the invention, the processing quality is improved.

Owner:GUANGDONG GLORY METAL PROD CO LTD

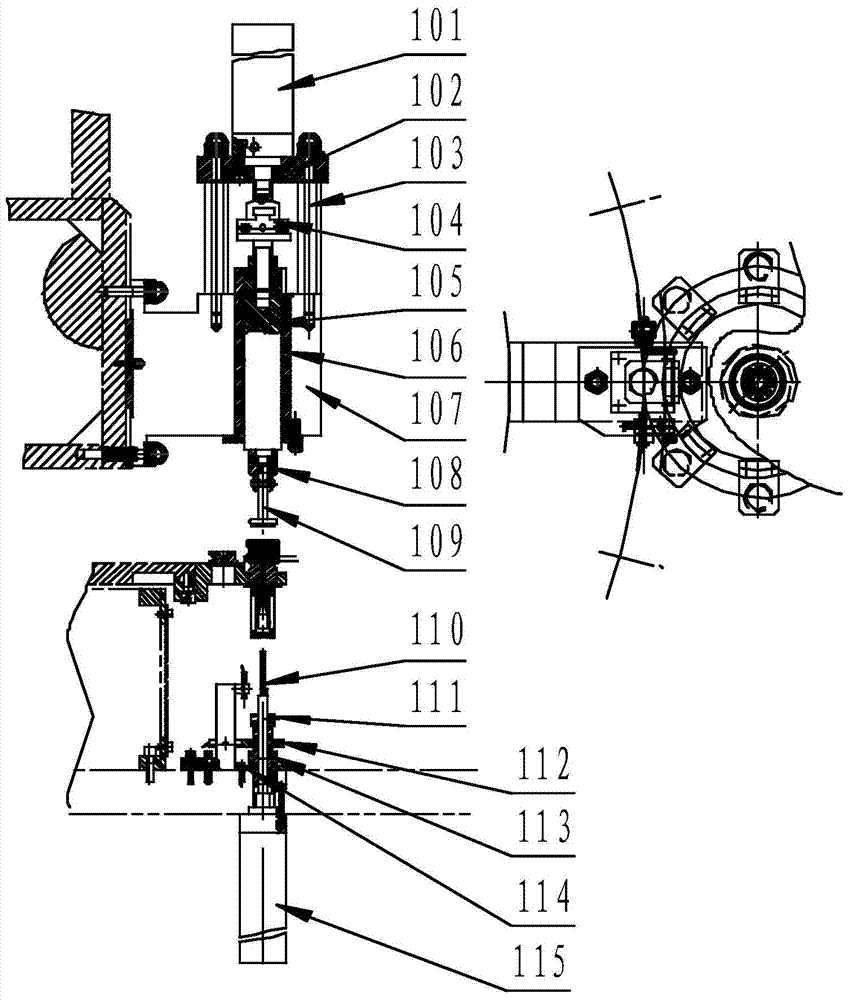

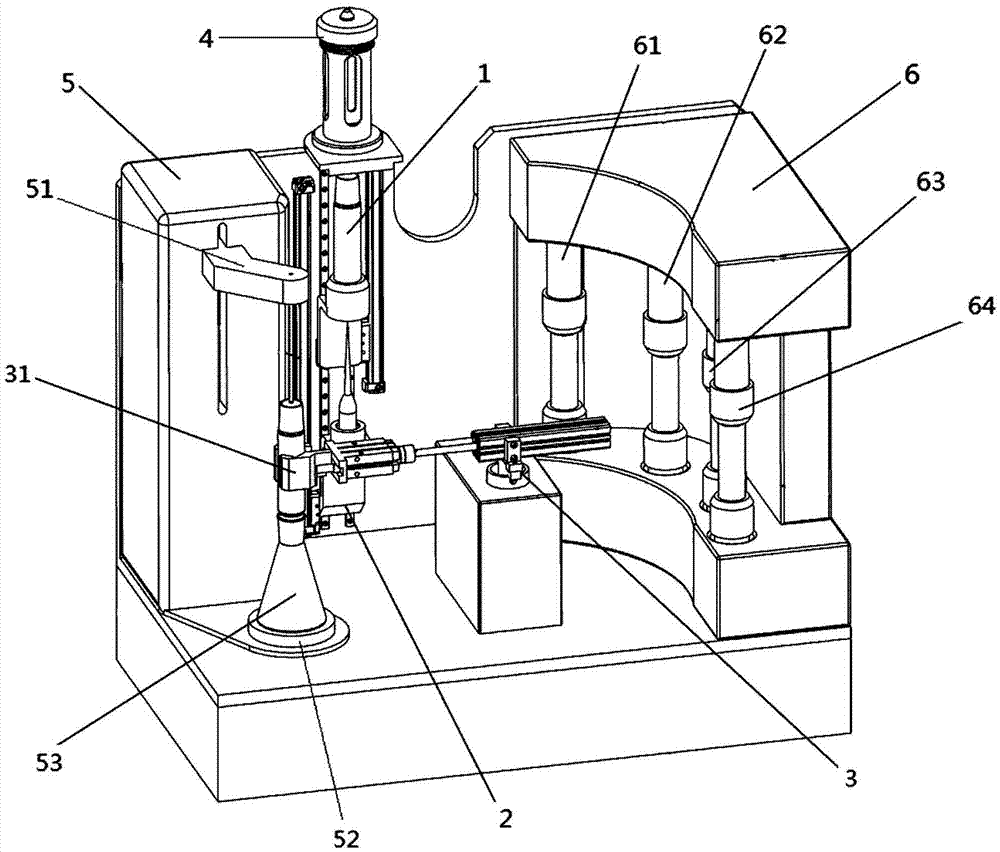

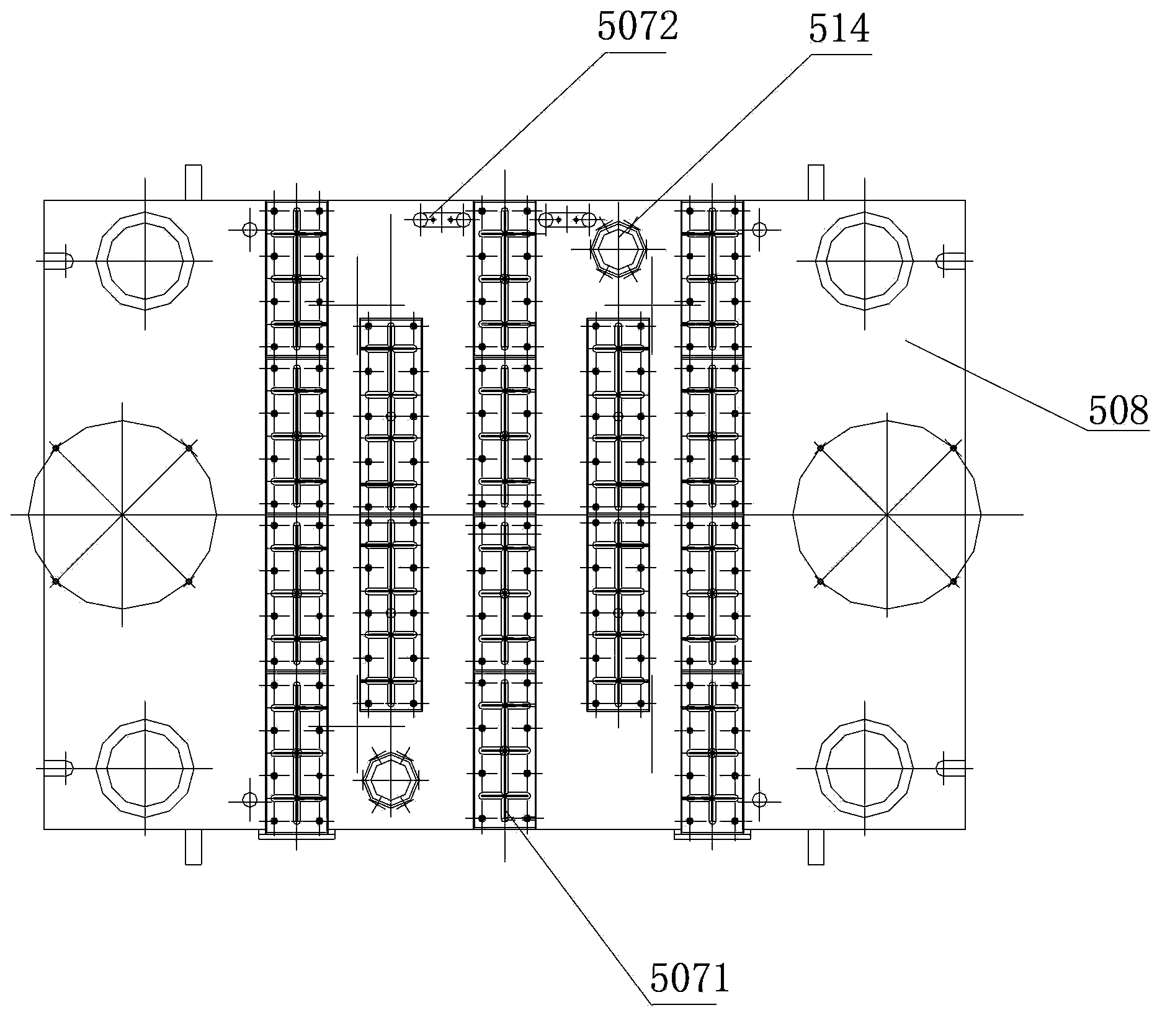

Double-disk detonator automatic assembling machine buckling assembling pressing device

Owner:北方特种能源集团有限公司西安庆华公司

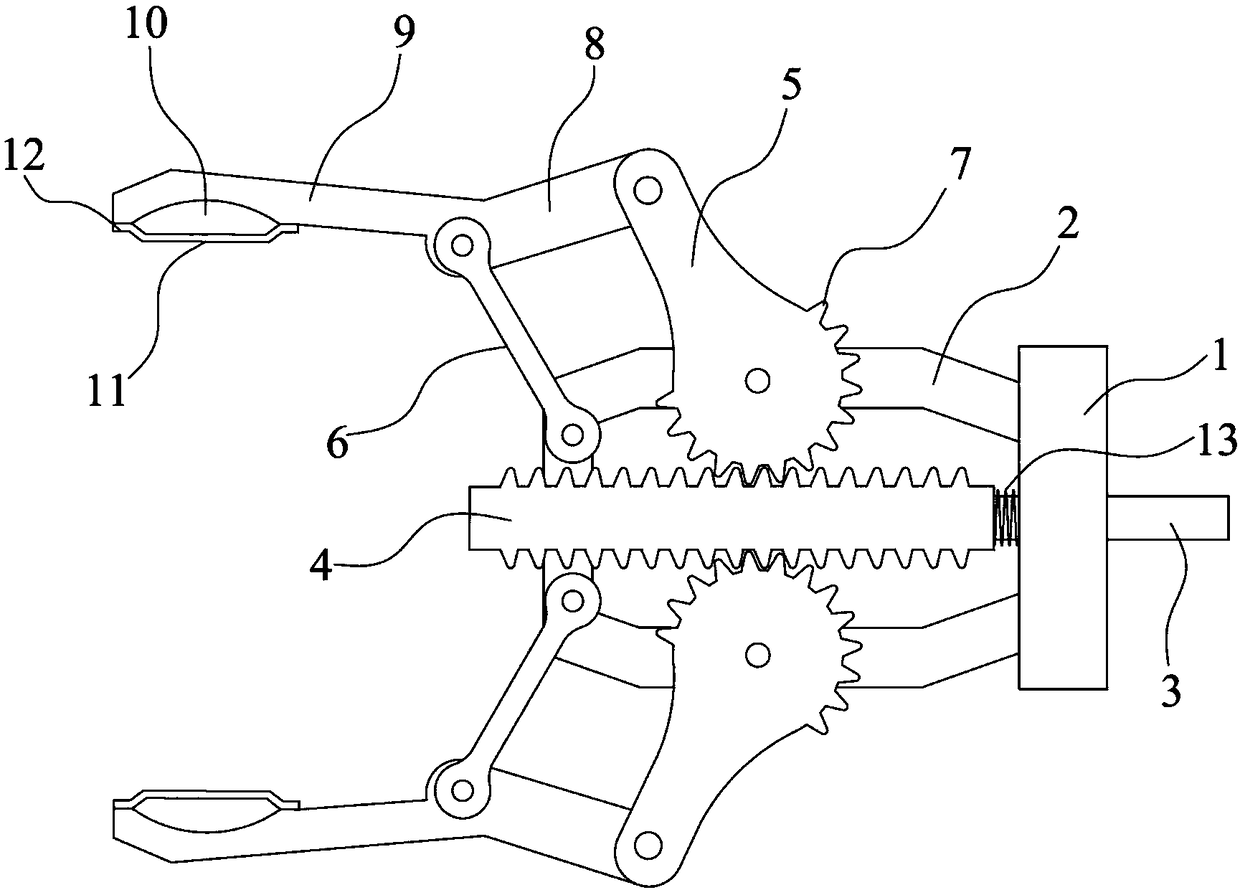

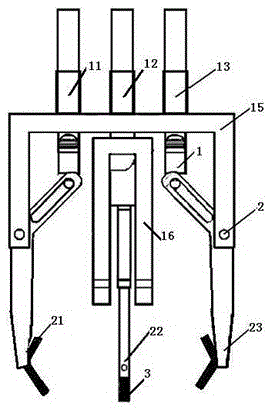

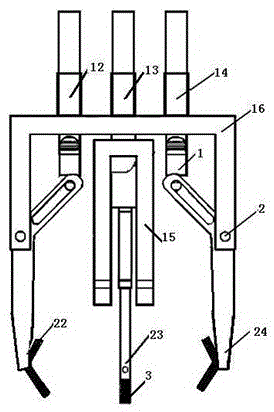

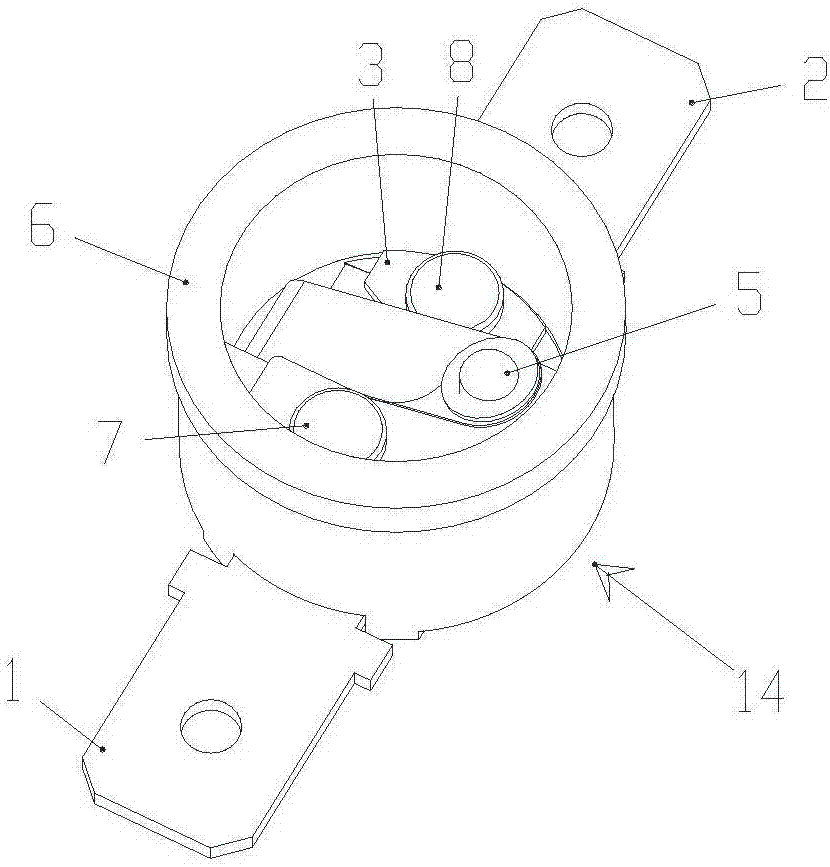

Large-opening-and-closing-angle manipulator

InactiveCN108544522ALarge opening and closing angleAvoid being scratchedGripping headsEngineeringManipulator

Owner:东阳市天齐科技有限公司

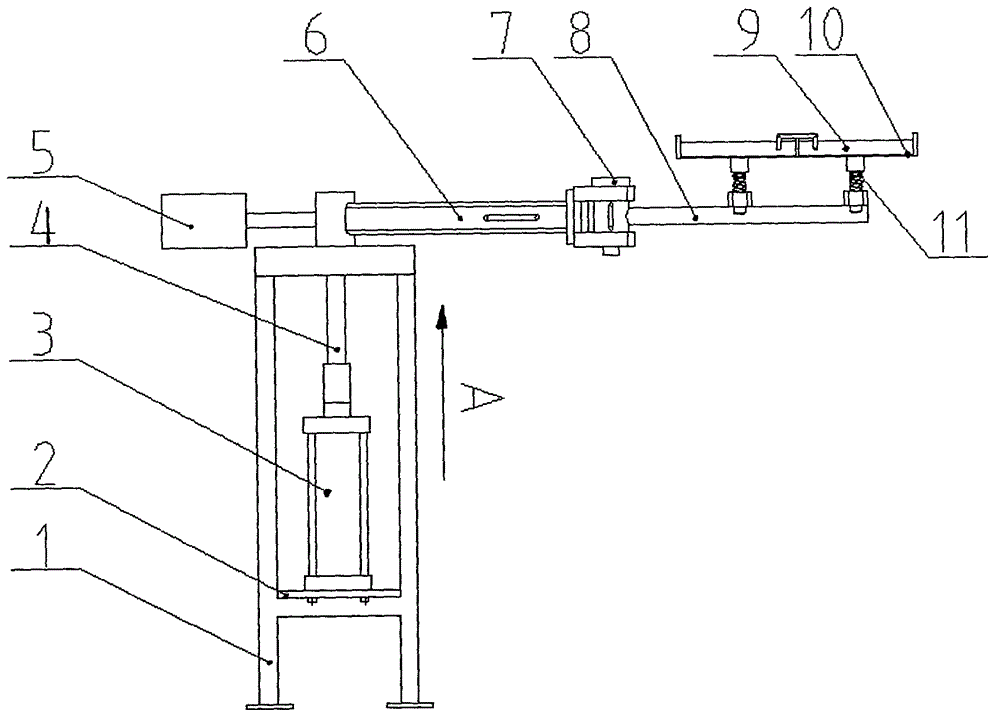

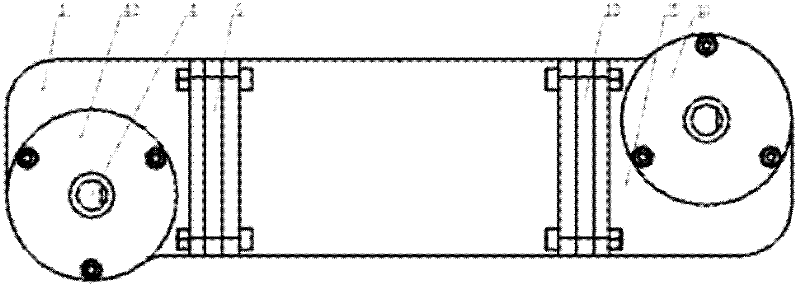

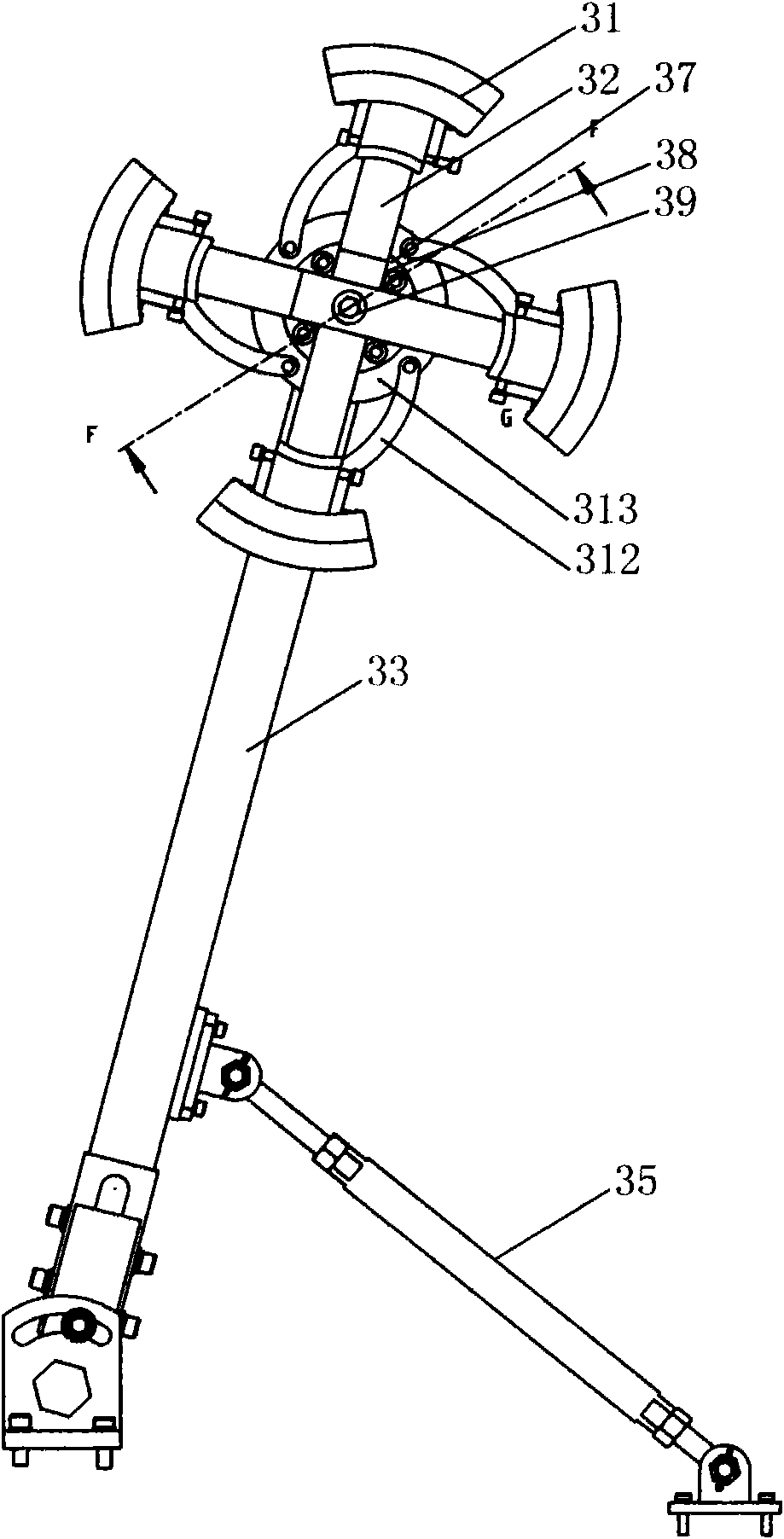

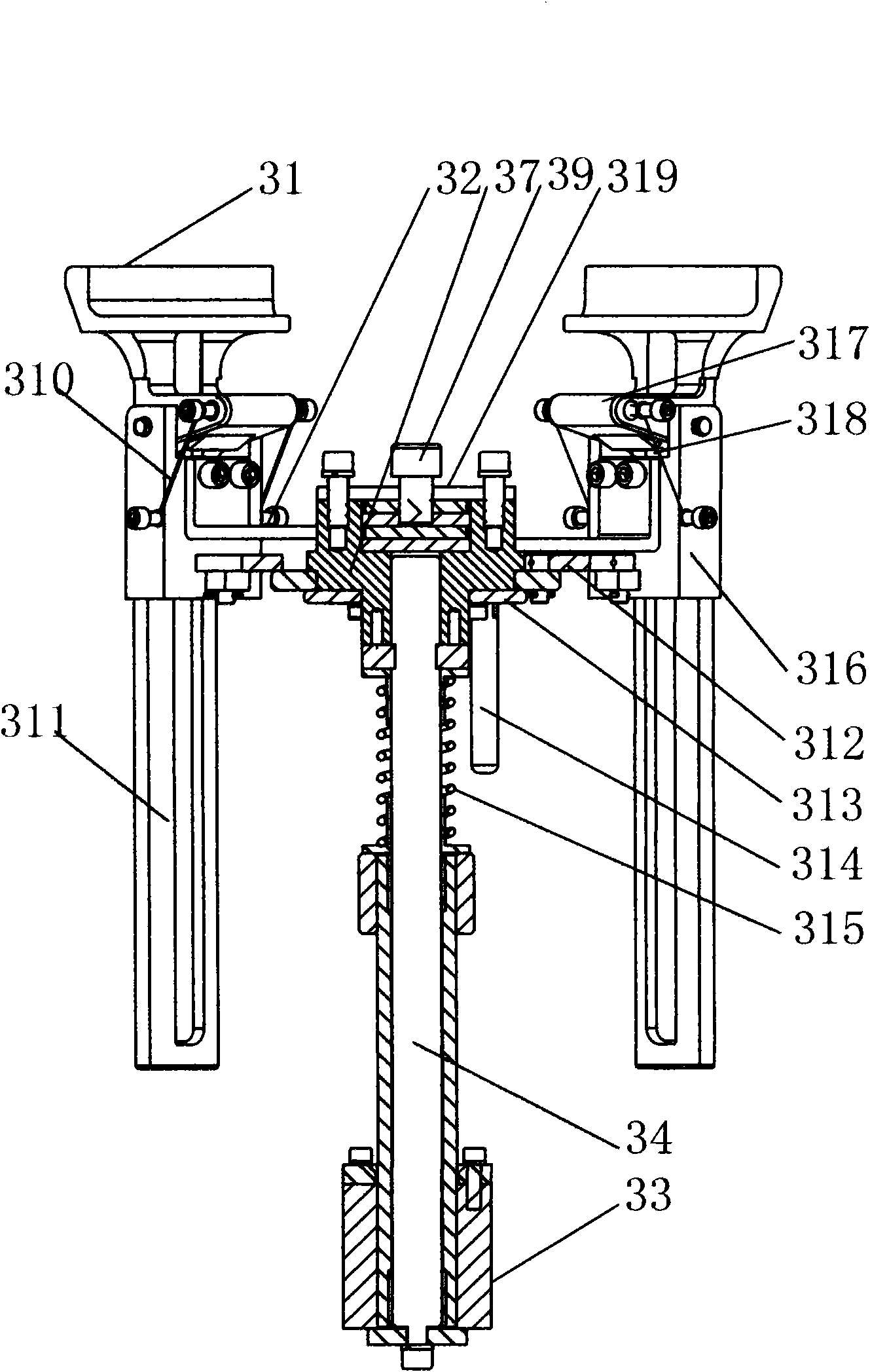

Automatic cast receiving method for rollover casting machine and receiving mechanical arm thereof

InactiveCN102873314AEasy to install and debugReduce manufacturing costProgramme-controlled manipulatorRotational axisManipulator

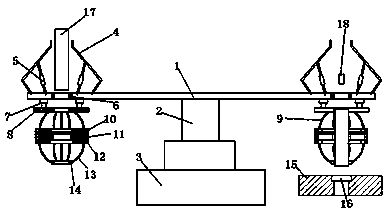

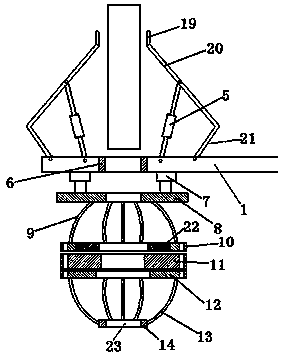

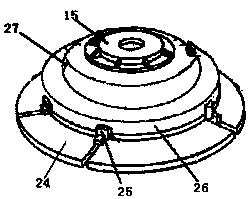

The invention relates to an automatic cast receiving method for a rollover casting machine. The method comprises the following steps of: after casting and mold opening of the casting machine, firstly rotating a mechanical arm comprising a main arm and an auxiliary arm to extend into the interior of the rollover casting machine, and aligning a disc on the auxiliary arm with a cast in position; then controlling a driving device to drive the mechanical arm to automatically rise and receiving the cast by the disc, and then controlling the driving device to drive the mechanical arm to automatically fall, and rotating the mechanical arm outward to automatically take out the cast. The adopted mechanical arm is characterized in that the driving device is mounted on a base; the driving device is connected with the main arm by a transmission rod; one end of the main arm is connected with a balancing block, and the other end is connected with the auxiliary arm by a rotating shaft; and a tray is mounted to the tail end of the auxiliary arm. The automatic cast receiving method for the rollover casting machine provided by the invention has the beneficial effect that installation and debugging are convenient, the manufacturing cost is low, the production efficiency is obviously improved, the labor intensity is effectively lowered, and potential safety hazard is eliminated.

Owner:WENZHOU RUIMING IND

Automated flue gas collection device and analysis method

ActiveCN103674629AWithdrawing sample devicesWeighing by absorbing componentManipulatorProcess engineering

Owner:SHANGHAI TOBACCO GRP CO LTD +1

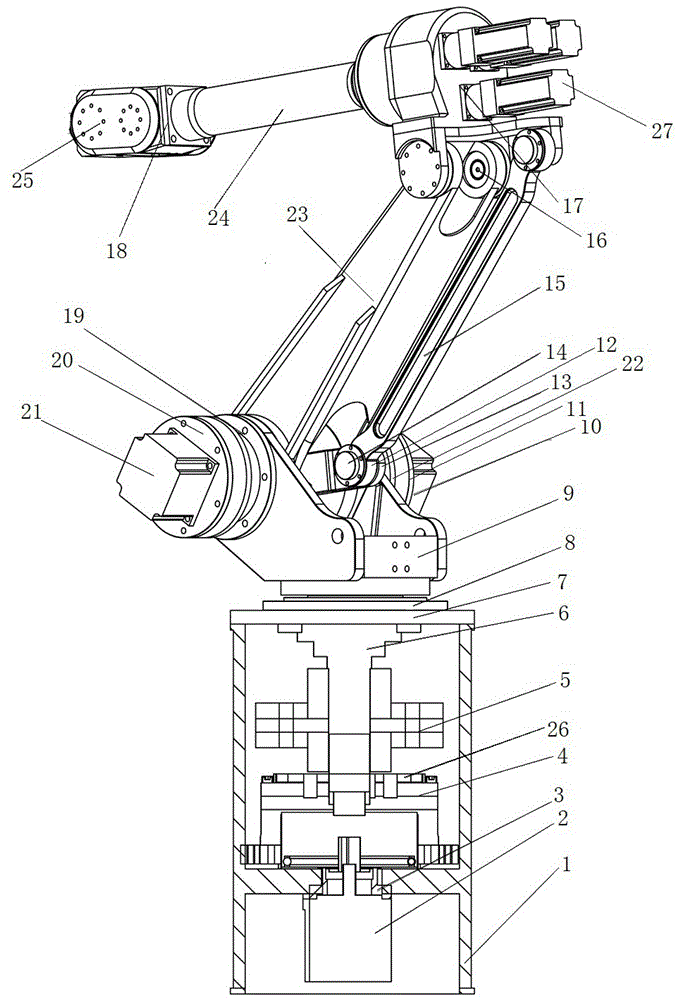

Six-degree-of-freedom mechanical arm device of block press dedicated for optical element, and picking and placing method thereof

PendingCN106607878ATroubleshoot pipeline layout issuesSmall radius of rotationProgramme-controlled manipulatorGripping headsCouplingReducer

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Silicon slice conveying device

ActiveCN103199044ASemiconductor/solid-state device manufacturingConveyor partsManipulatorConnection control

Owner:北京京仪仪器仪表研究总院有限公司

Mechanical arm capable of relatively stably and conveniently grasping spherical part

Owner:SUZHOU BEITELUO INTELLIGENT TECH CO LTD

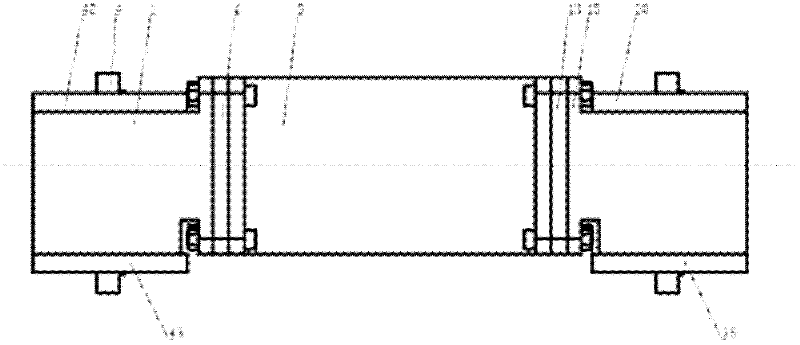

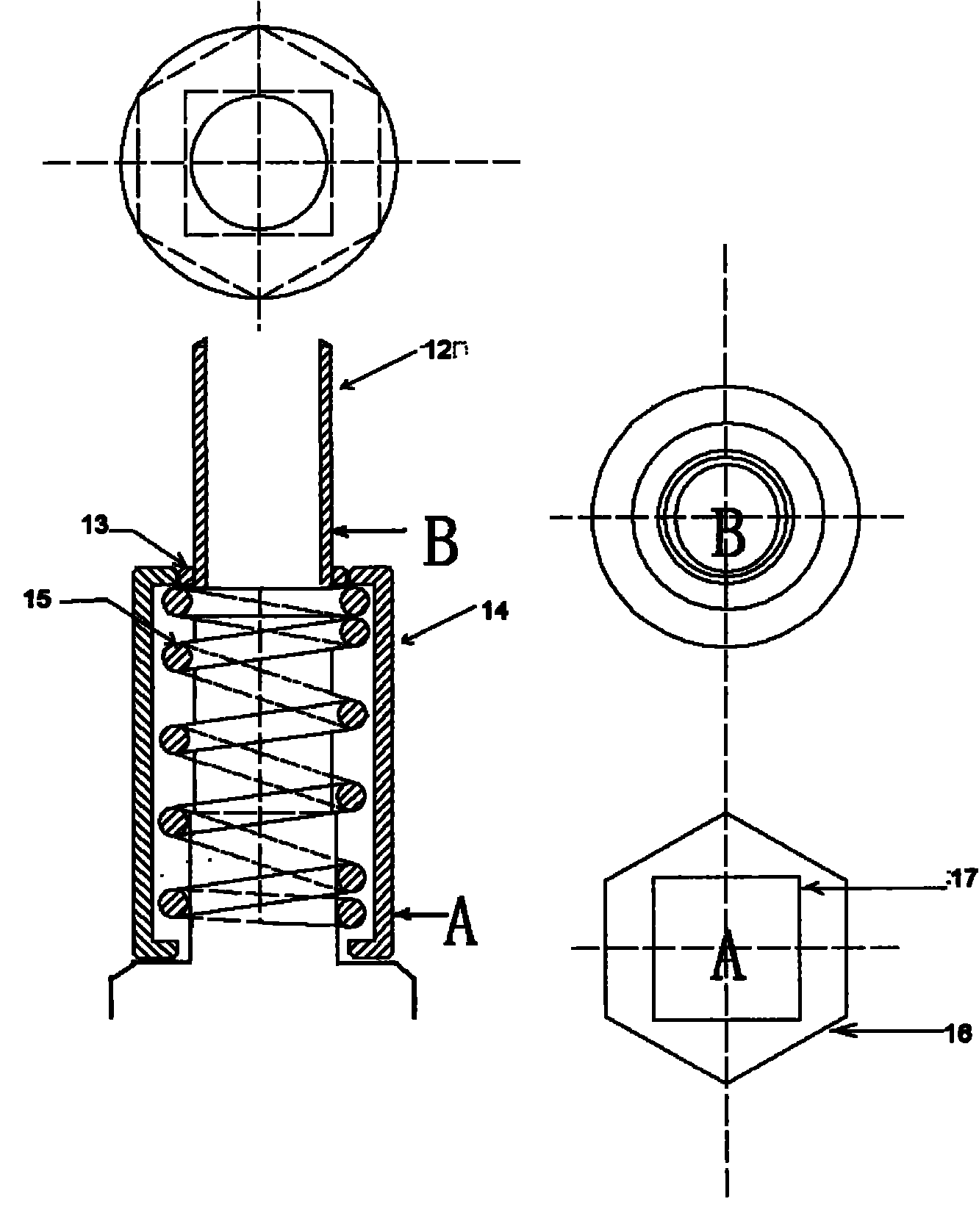

Transmission of manipulator for dredging slag from liquid zinc of zinc pot

InactiveCN102528012AExpand the scope of slag removalContinuous slag unloadingHot-dipping/immersion processesCharge manipulationSlagEngineering

Owner:WUHAN IRON & STEEL (GROUP) CORP

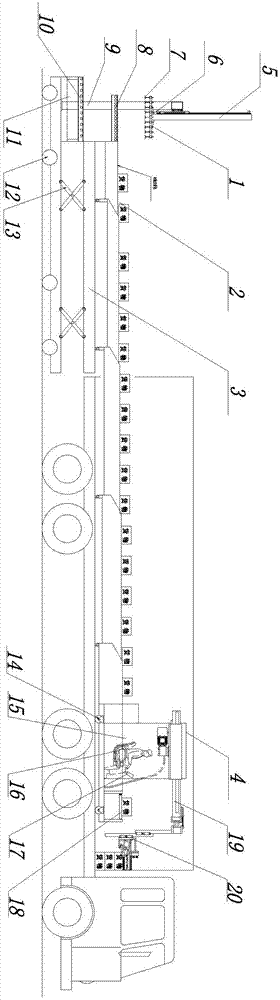

Full-automatic pressing production line for large turbine blade

Owner:TIANJIN TIANDUAN PRESS CO LTD

Fully-automatic five-axis manipulator

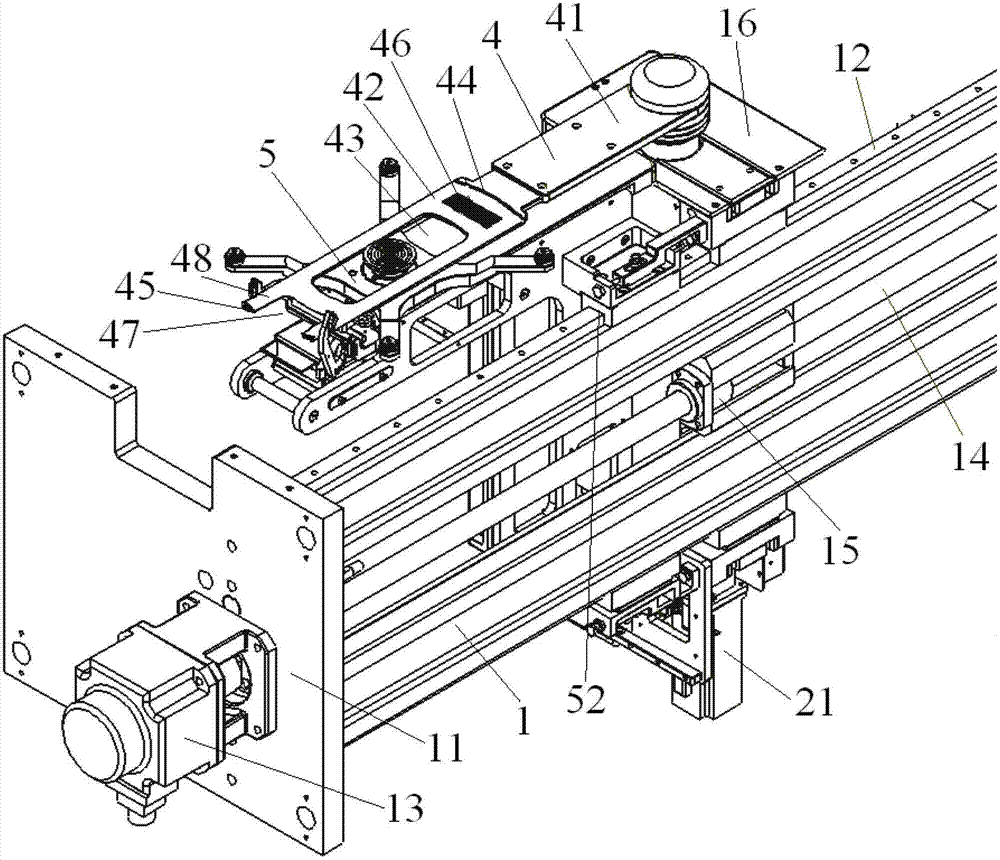

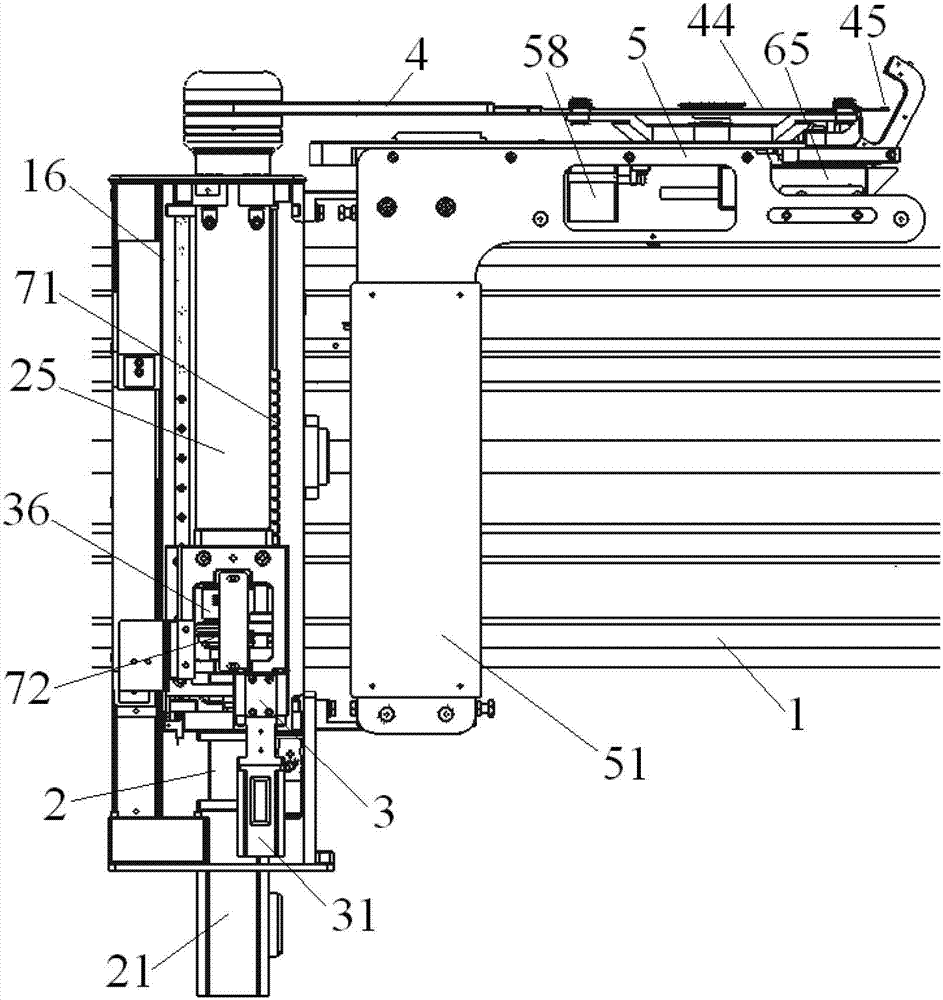

ActiveCN104647369ACompact structureImprove stabilityProgramme-controlled manipulatorOriginal equipment manufacturerDual beam

The invention relates to a dual-system immunity analyzer, in particular to a fully-automatic five-axis manipulator applied to the dual-system immunity analyzer. The manipulator can move on the X axis, Y axis and Z axis and can rotate around the Z axis, and grabbing action at any angle in the X-Y plane is realized. Compared with the prior art, the fully-automatic five-axis manipulator has the advantages that due to the fact that a combined beam substitutes a dual-beam structure, the structure is compact, and the stability is high; due to the fact that the manipulator and a grabbing claw are buckled, grabbing claws with different specifications can be convenient to replace; the fully-automatic five-axis manipulator is applied to various experiments and facilitates OEM (original equipment manufacturer) production; a five-axis design is adopted and a shielding cable is adopted to filter external electromagnetic interference, so that electric control stability is improved.

Owner:JIAXING KERUIDI MEDICAL EQUIP CO LTD

Automatic truck loading stacker crane

PendingCN106915636ASave human effortImprove palletizing efficiencyLoading/unloadingEngineeringManipulator

Owner:天津君晟科技发展有限公司

Secondary oscillating joint structure of underwater electric manipulator

InactiveCN102229145ALarge transmission ratioPlay a role in boostingJointsMechanical energy handlingStructure of the EarthElectric machine

Owner:HARBIN ENG UNIV

Mop water twisting device

Owner:陈志中

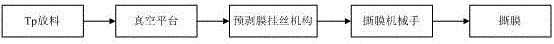

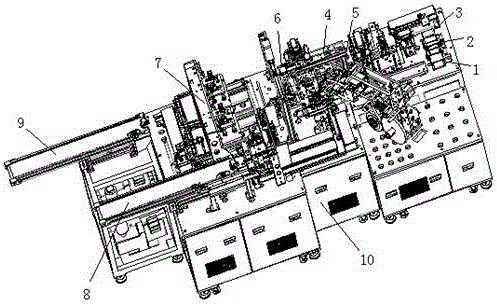

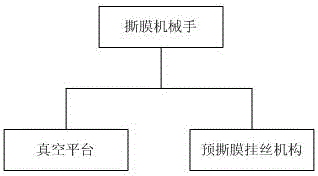

Pre-tearing film laminating device

InactiveCN106003999AFully automatedReduce difficultyLamination ancillary operationsLaminationManipulatorAlloy steel

Owner:SHENZHEN DEEP HON HAI AUTOMATION EQUIP CO LTD

Automatic lamination, detection and boxing production line of stator and rotor

PendingCN108526375AReduce in quantityReduce labor intensityManufacturing stator/rotor bodiesSortingProduction lineMechanical equipment

Owner:浙江钜丰科技有限公司

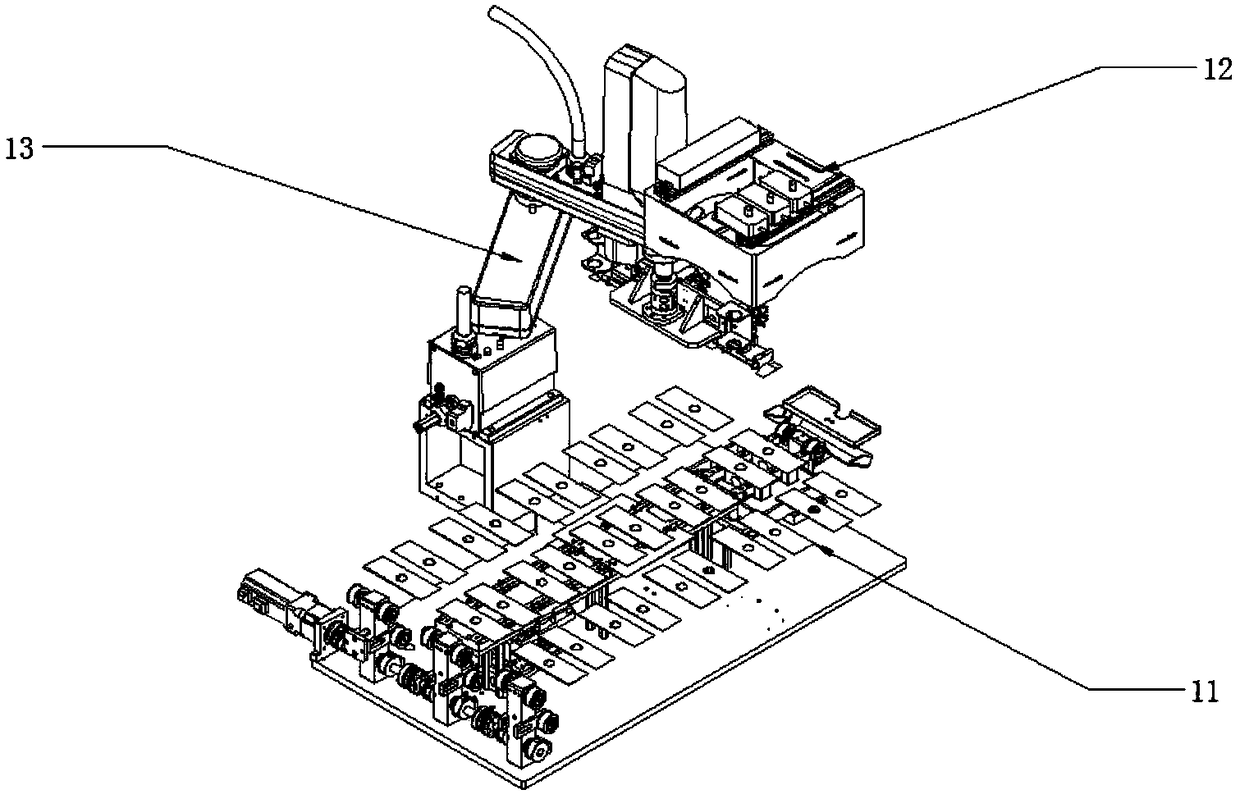

High-speed photovoltaic module production device and high-speed photovoltaic module production method

InactiveCN108161328AWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryManipulator

Owner:SUZHOU CHENZHENG SOLAR ENERGY EQUIP CO LTD

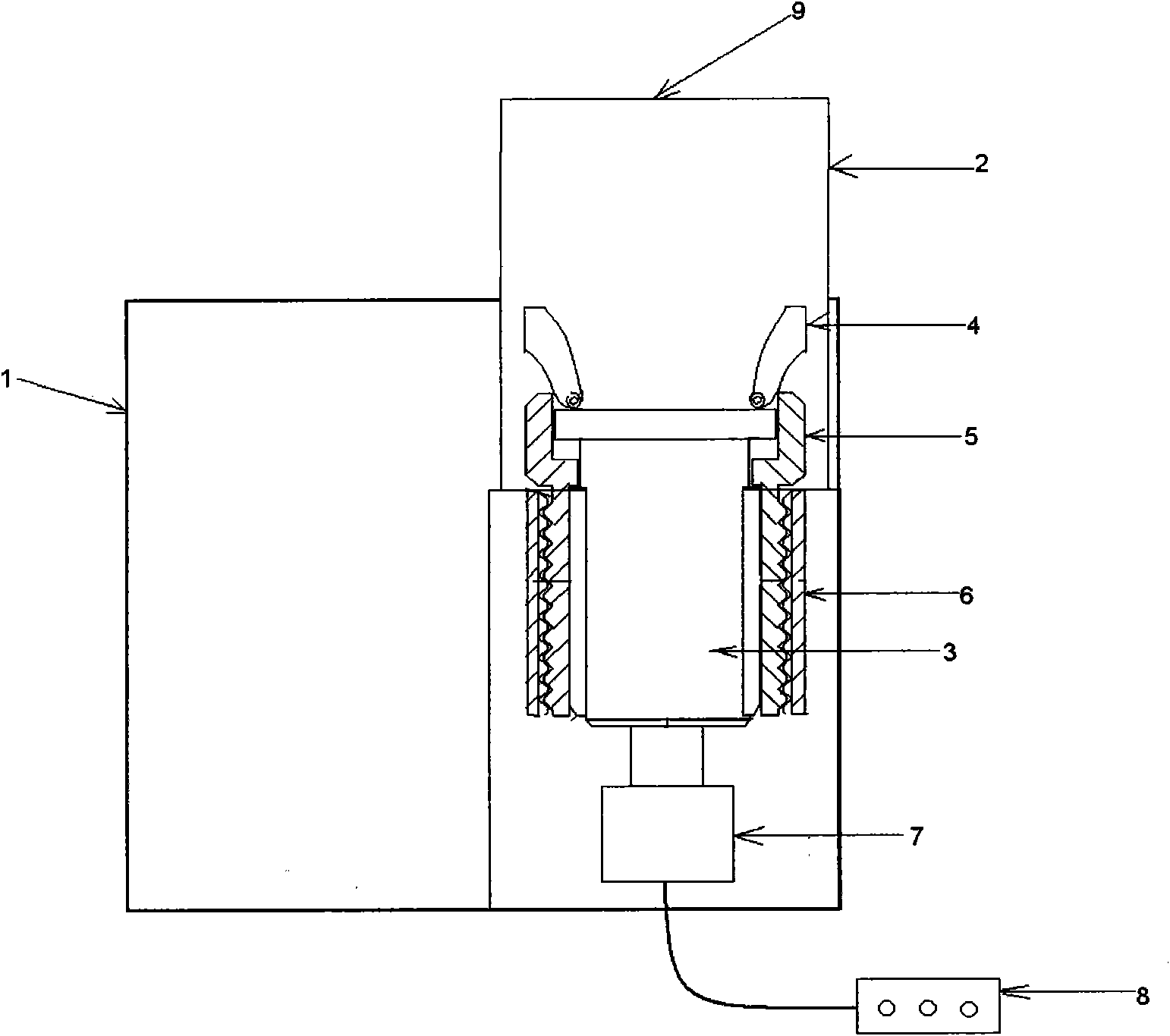

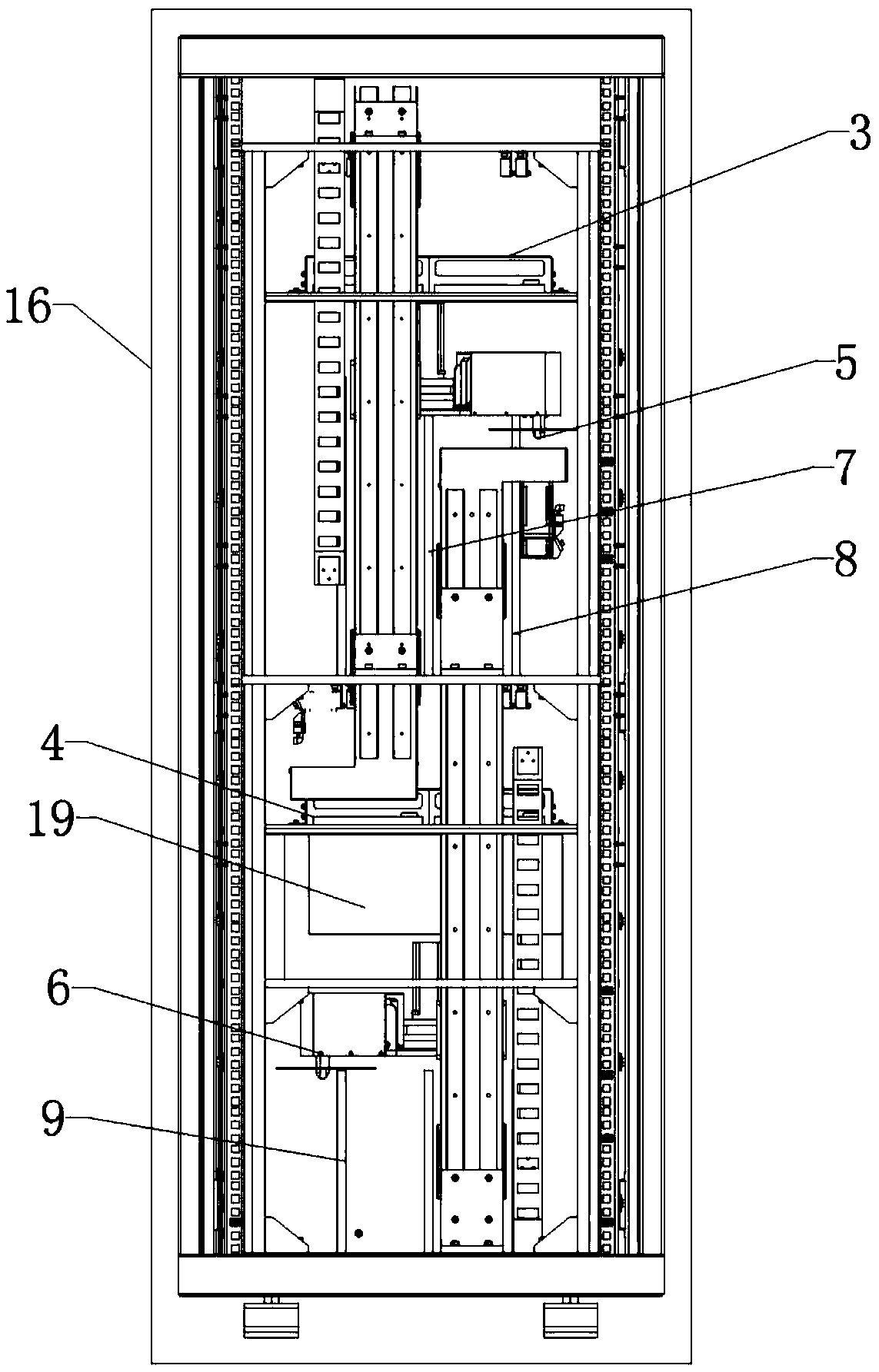

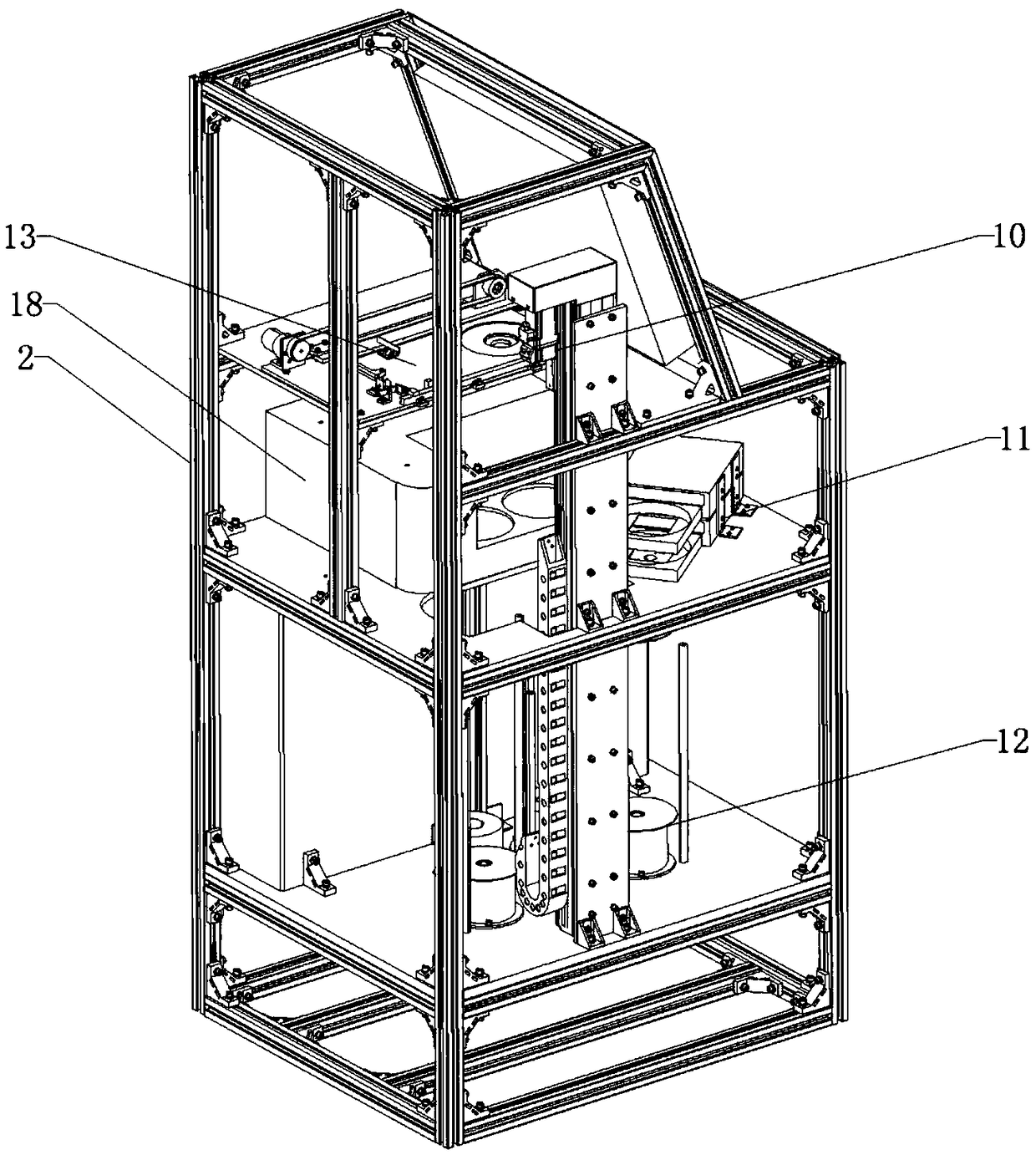

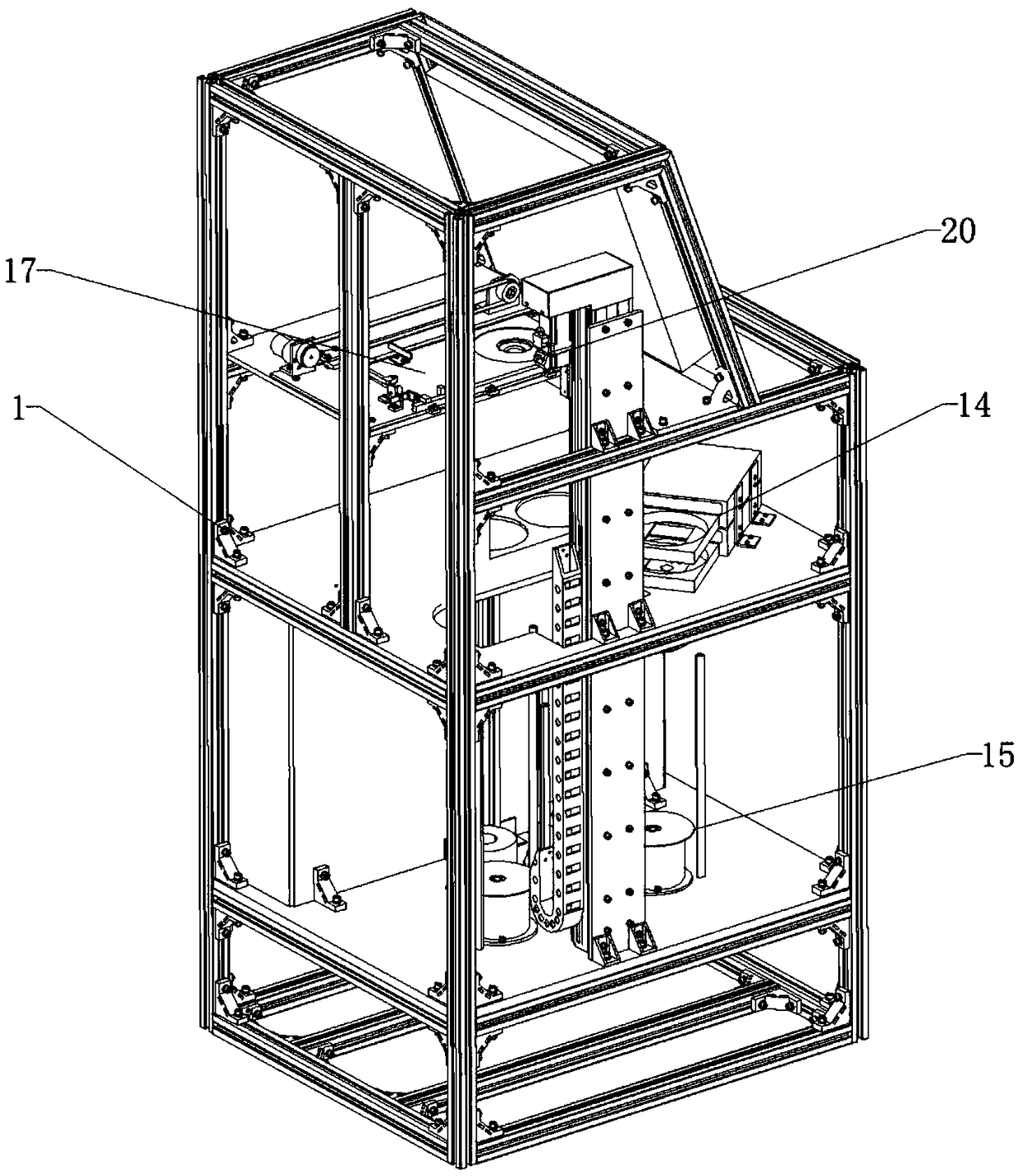

Data exchange device between internal network and external network

PendingCN108766469ATwo-way data interaction is efficientEasy to manage centrallyRecord information storageDigital data authenticationData transmissionManipulator

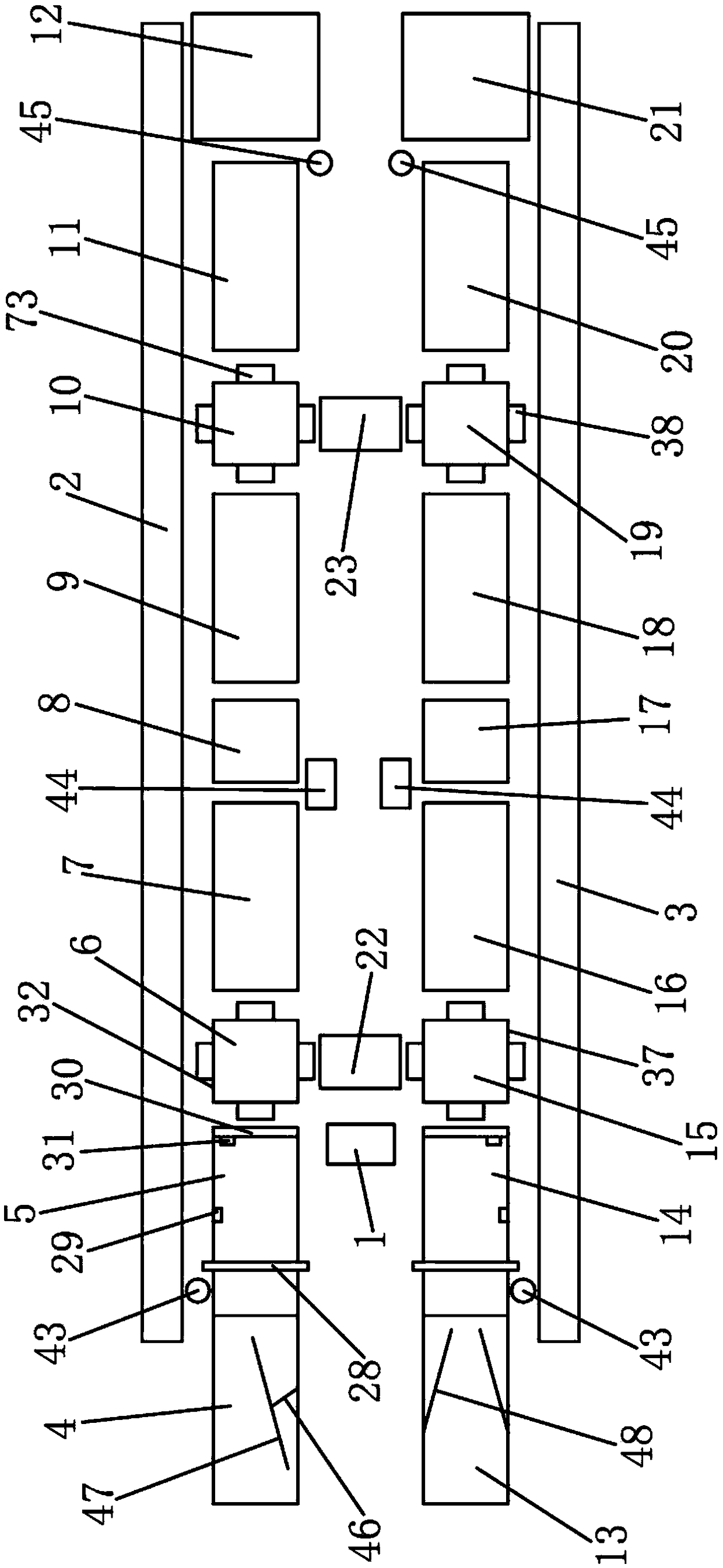

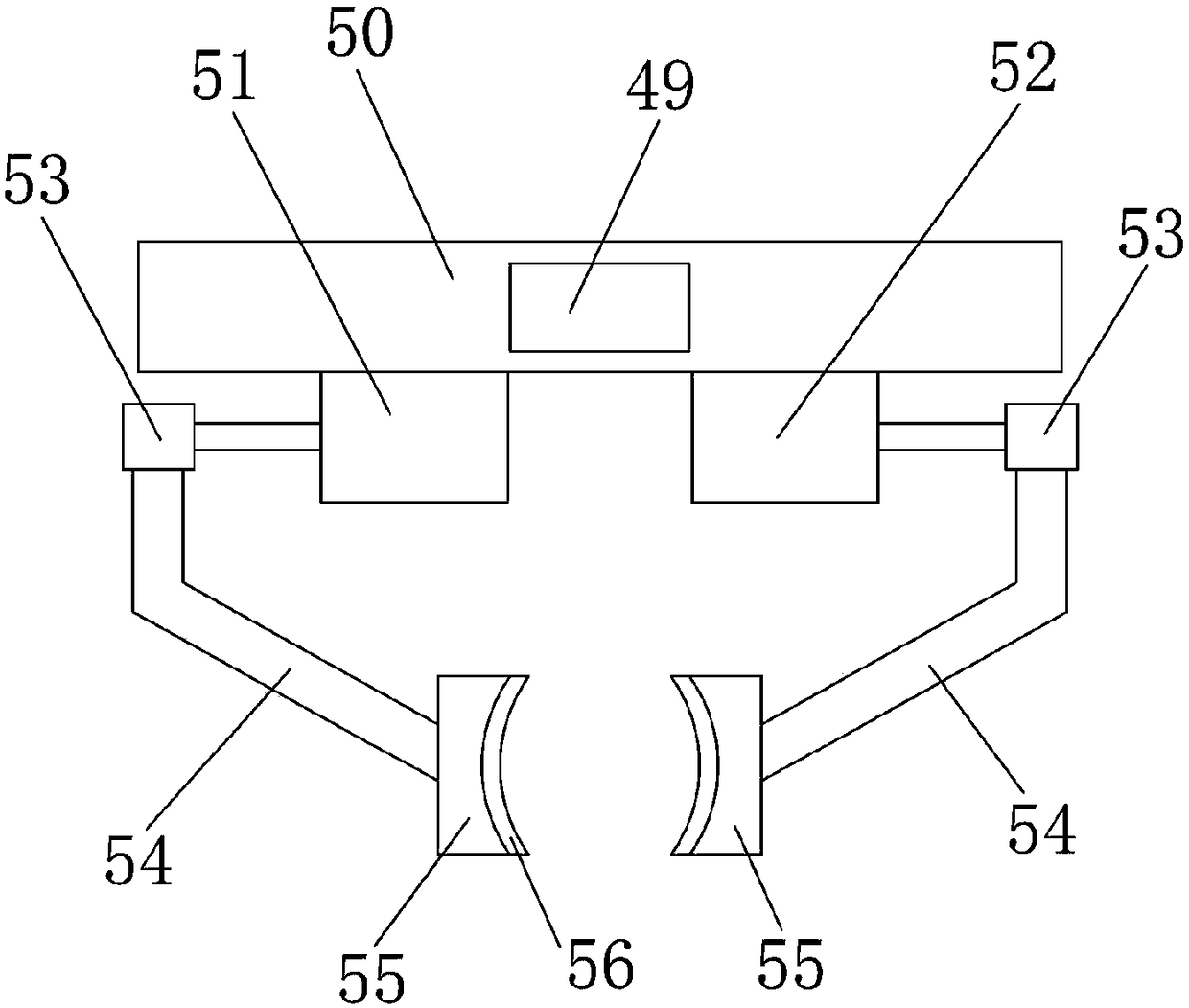

The invention provides a data exchange device between an internal network and an external network, comprising an input terminal, a ferry device and an output terminal, wherein the ferry device comprises an intermediate server, a transfer server, a record optical drive, a read-only optical drive, an intermediate manipulator, a transfer manipulator, a first disc warehouse, a second disc warehouse, athird disc warehouse, and a controller; the output terminal comprises an output manipulator, an output record optical drive, a fourth optical disc warehouse, an output controller, and an output disctray; the input terminal comprises an input manipulator, an input disc tray, an input read-only optical drive, an input controller, and a fifth disc warehouse; the input terminal and the intermediateserver are connected by a network cable, the relay server is connected to the internal network for data transmission, the internal network is connected to the output terminal for data transmission, and the intermediate server is provided with a virus killing module. The invention enables a real "physical isolation" between the external network and the internal network.

Owner:山东格数数据技术股份有限公司

Track suspension type multifunctional orchard mechanical device

PendingCN113228866AIncrease economic benefitsReduce labor intensityWatering devicesCultivating equipmentsFruit treeAgricultural science

Owner:SOUTH CHINA AGRI UNIV

Top following tool magazine tool changing device and method thereof

Owner:JIANGSU HENGLI MACHINE TOOL +1

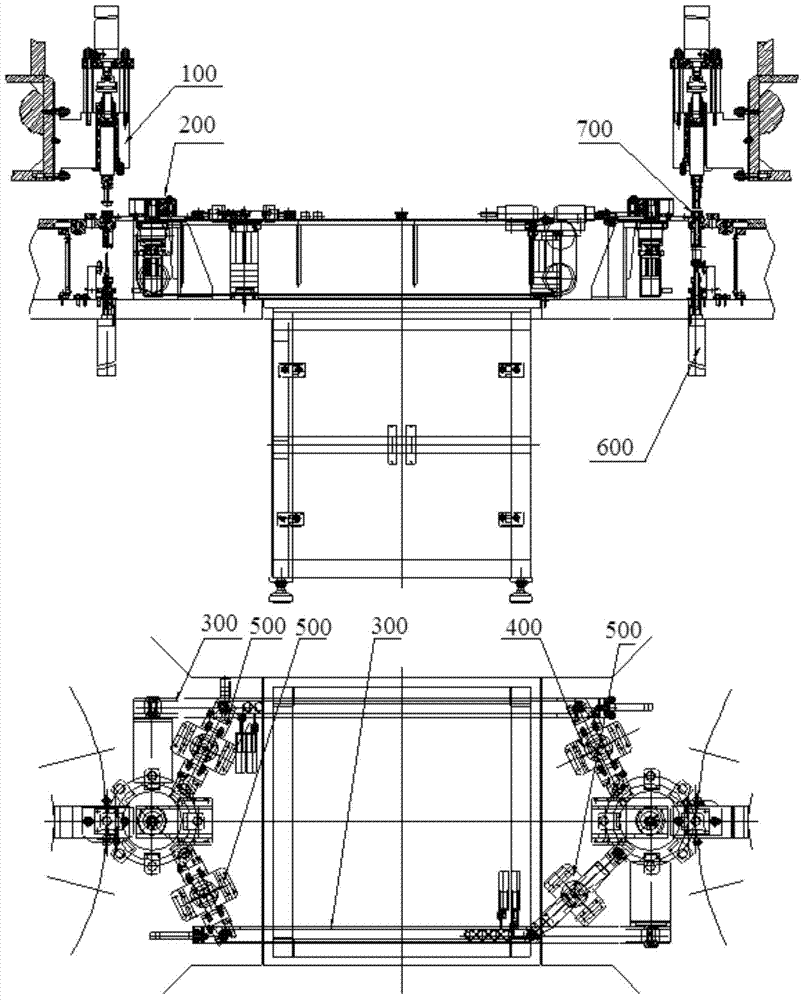

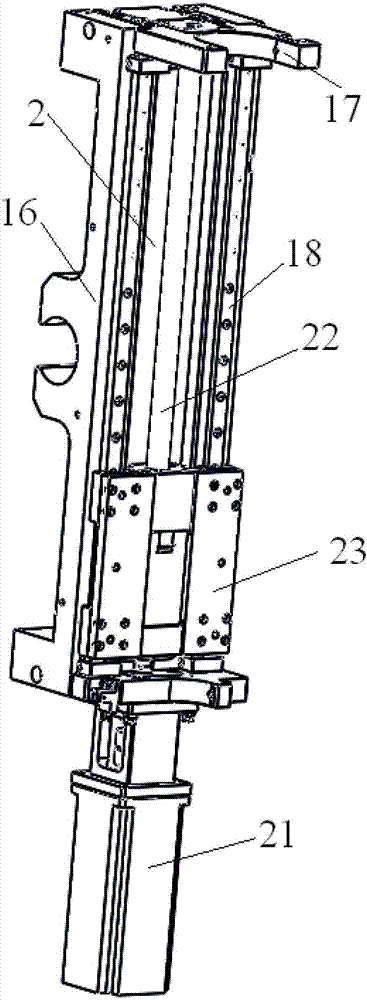

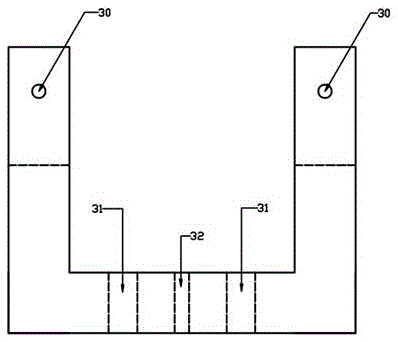

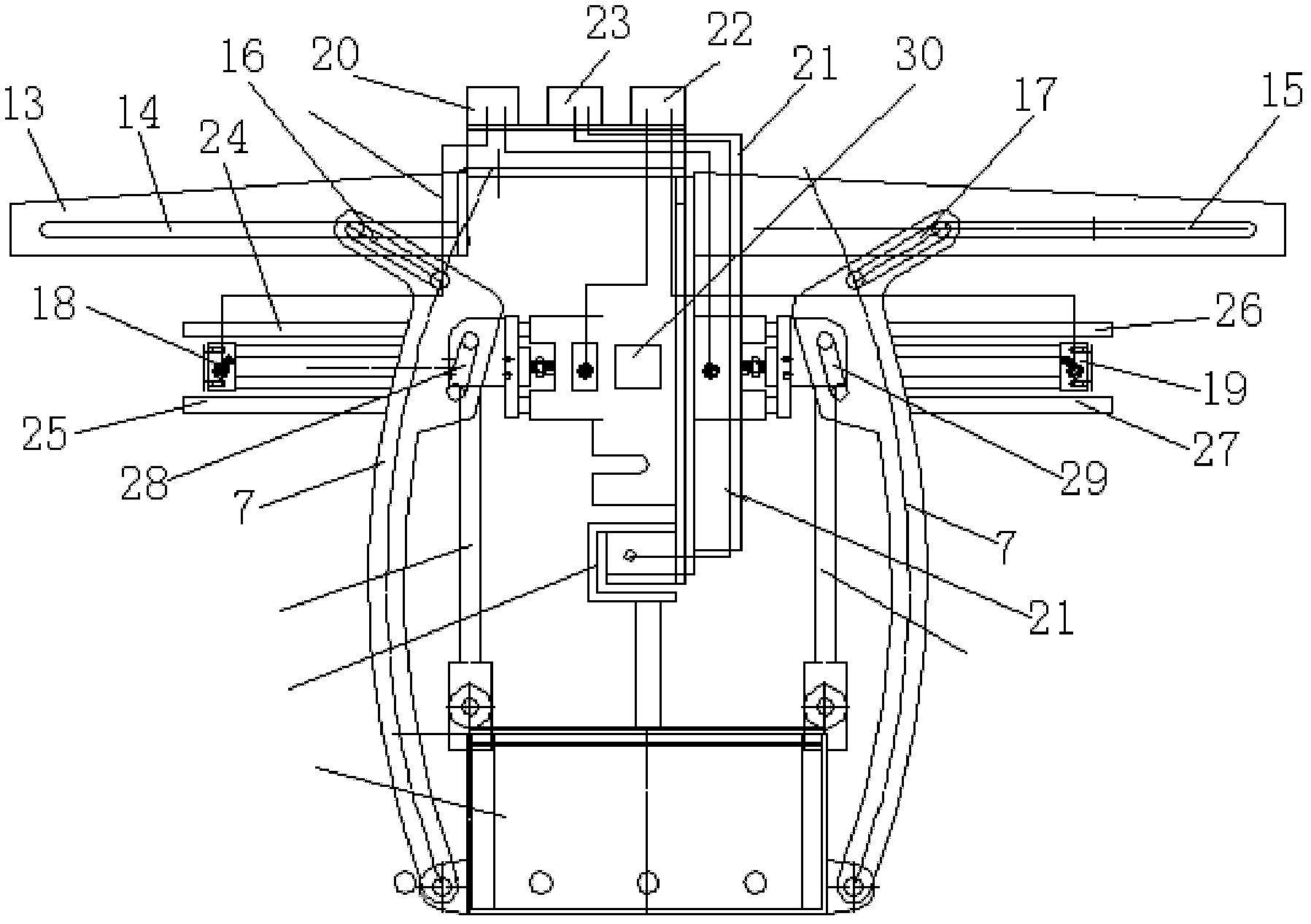

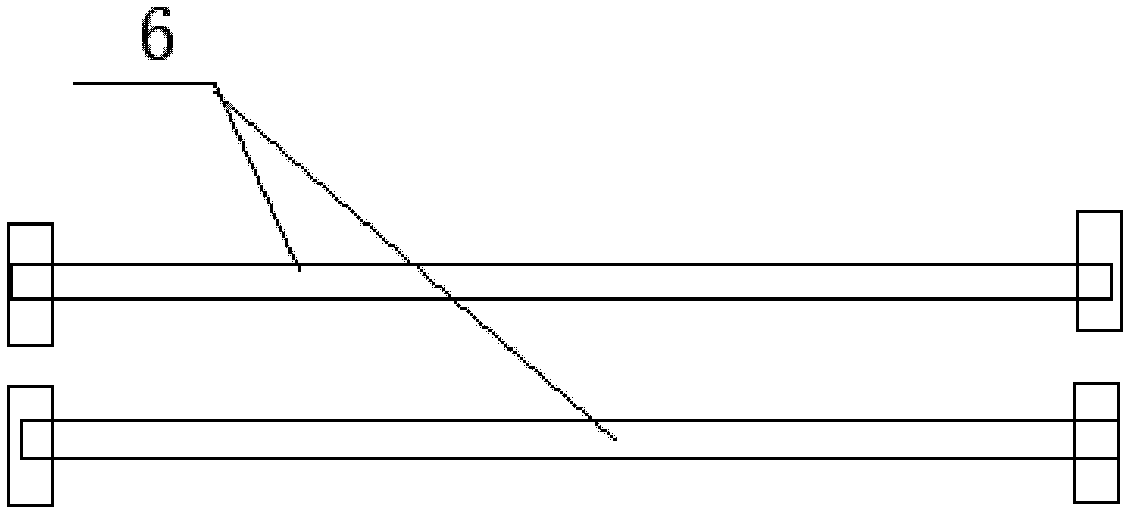

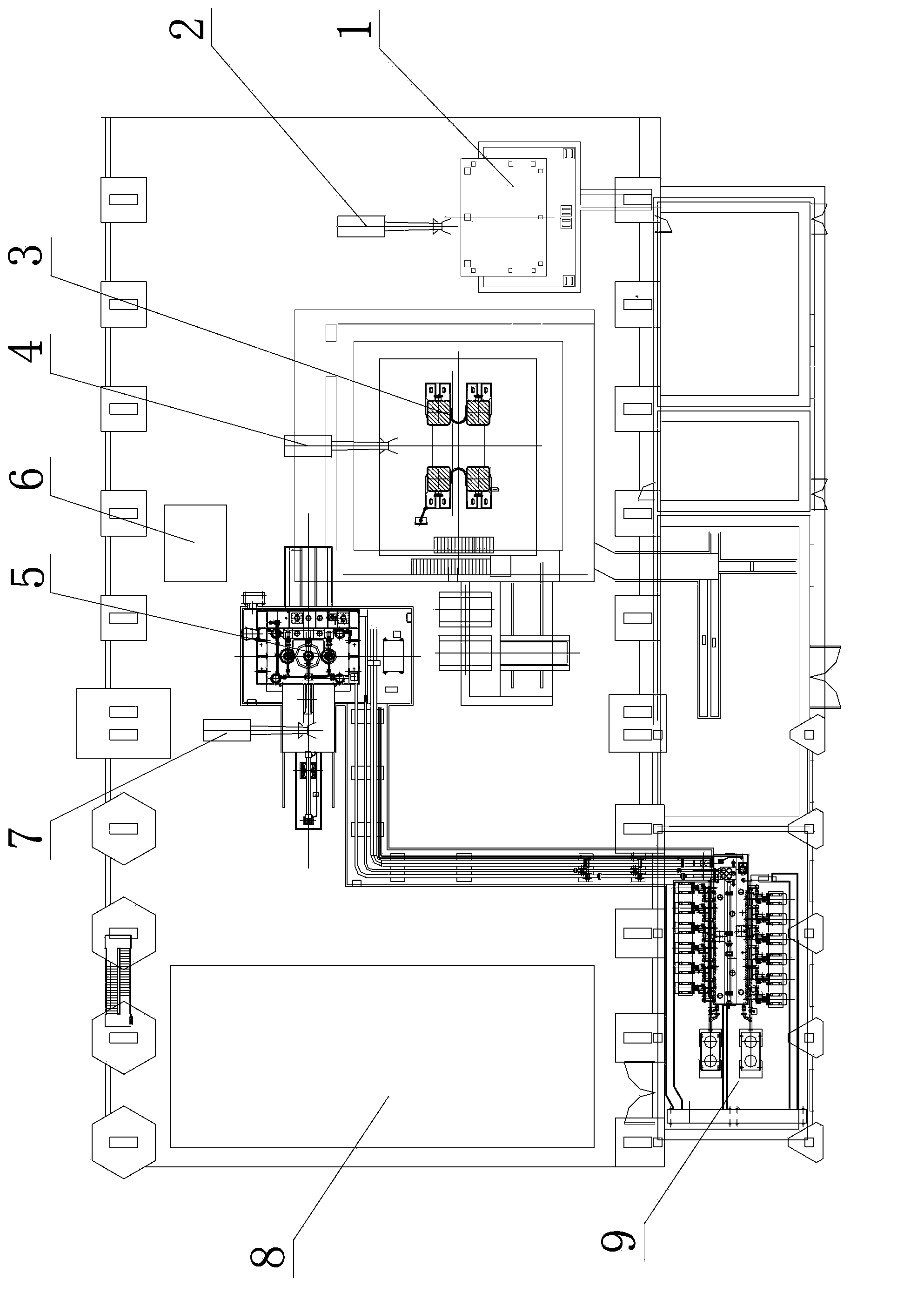

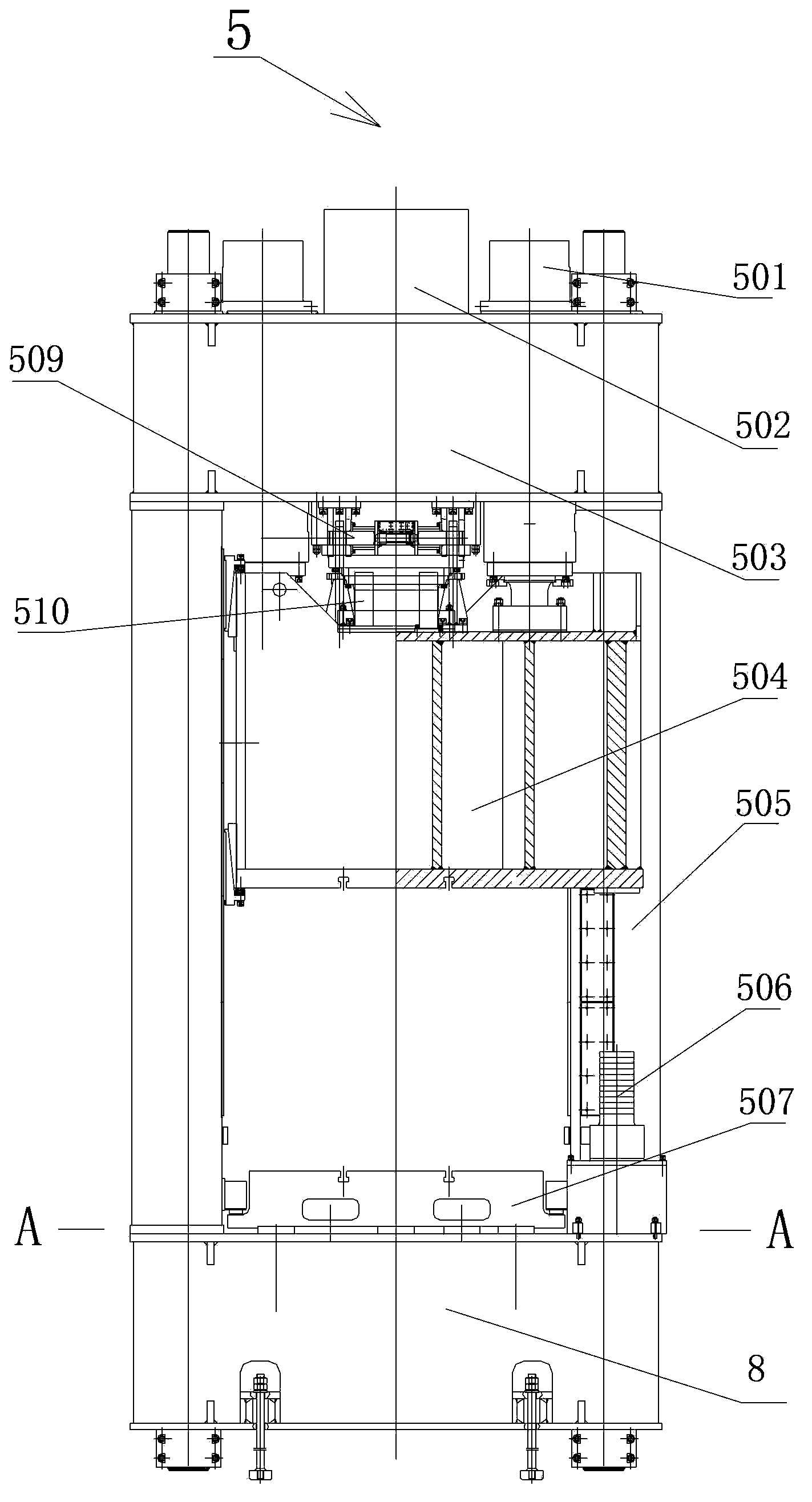

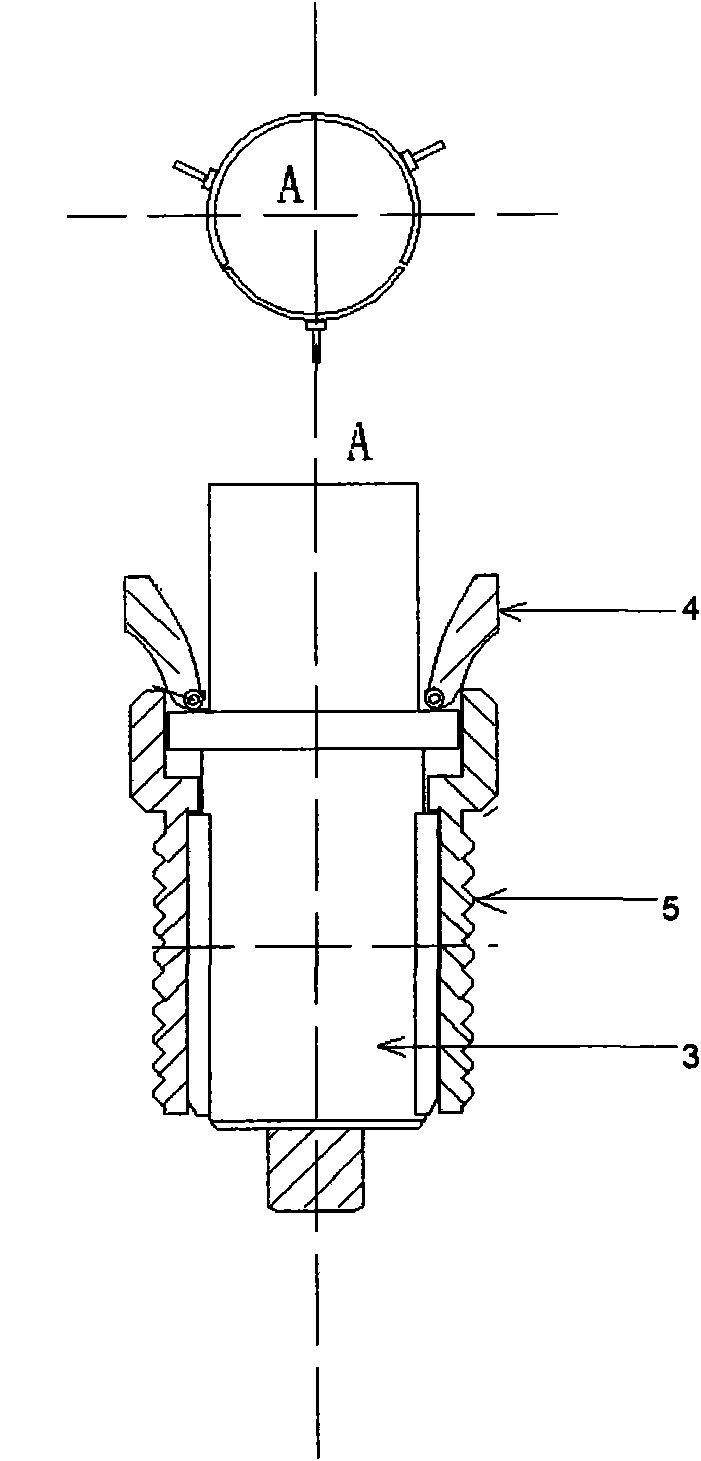

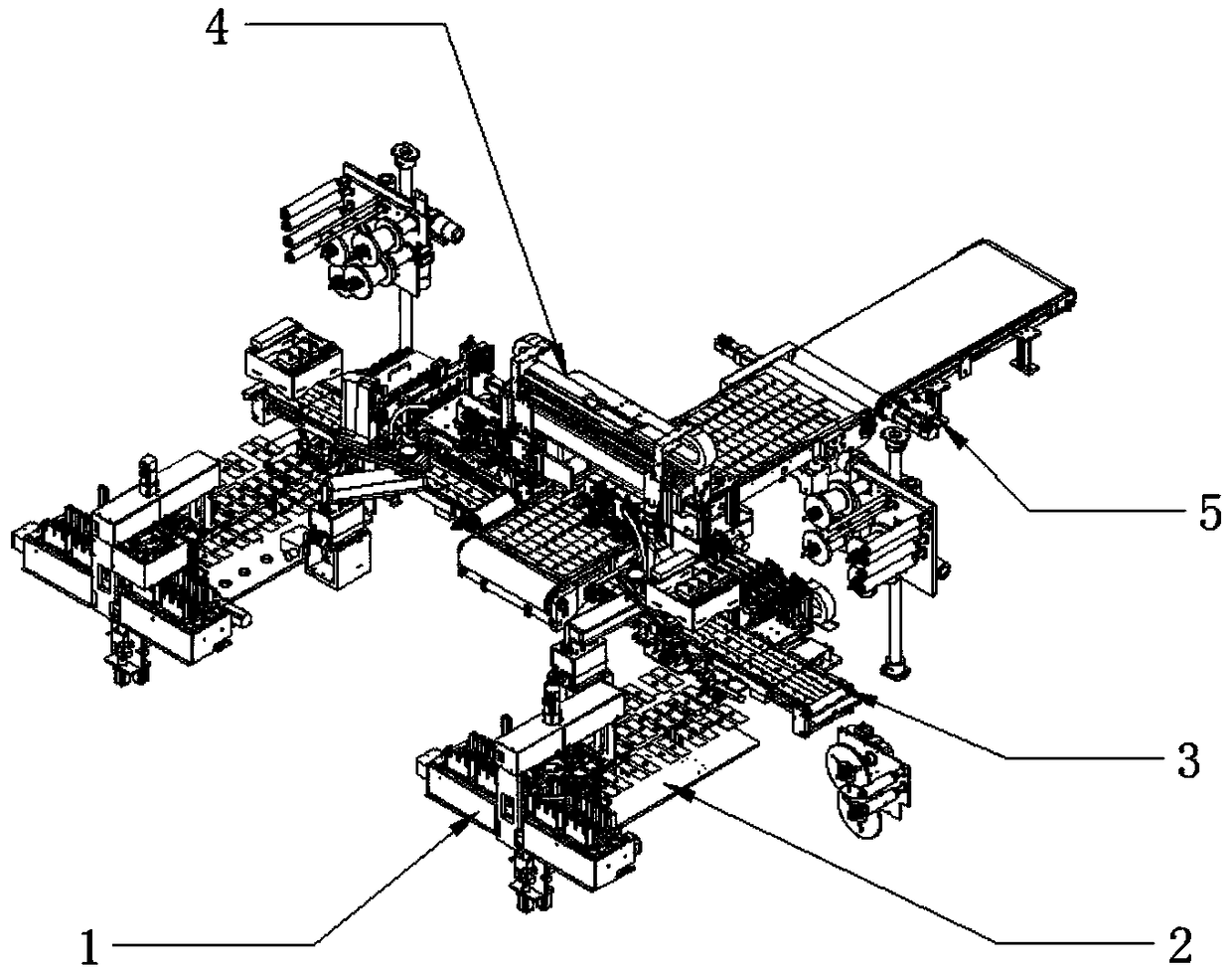

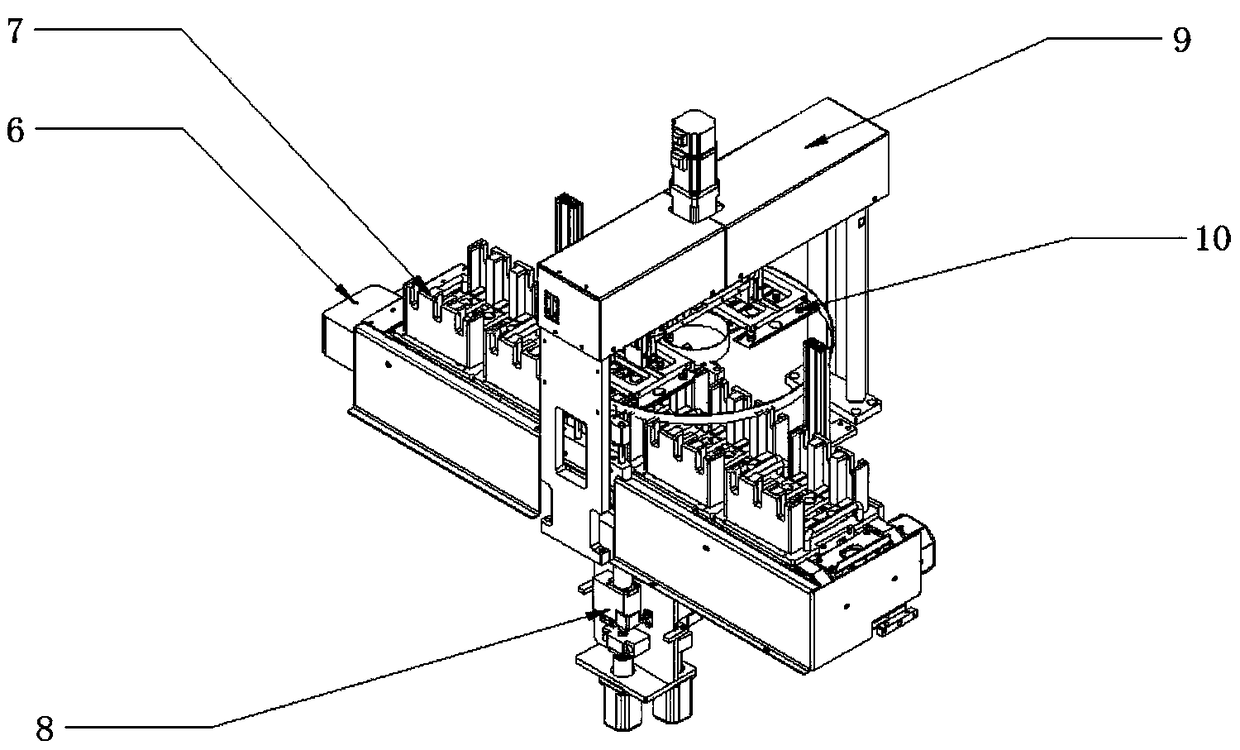

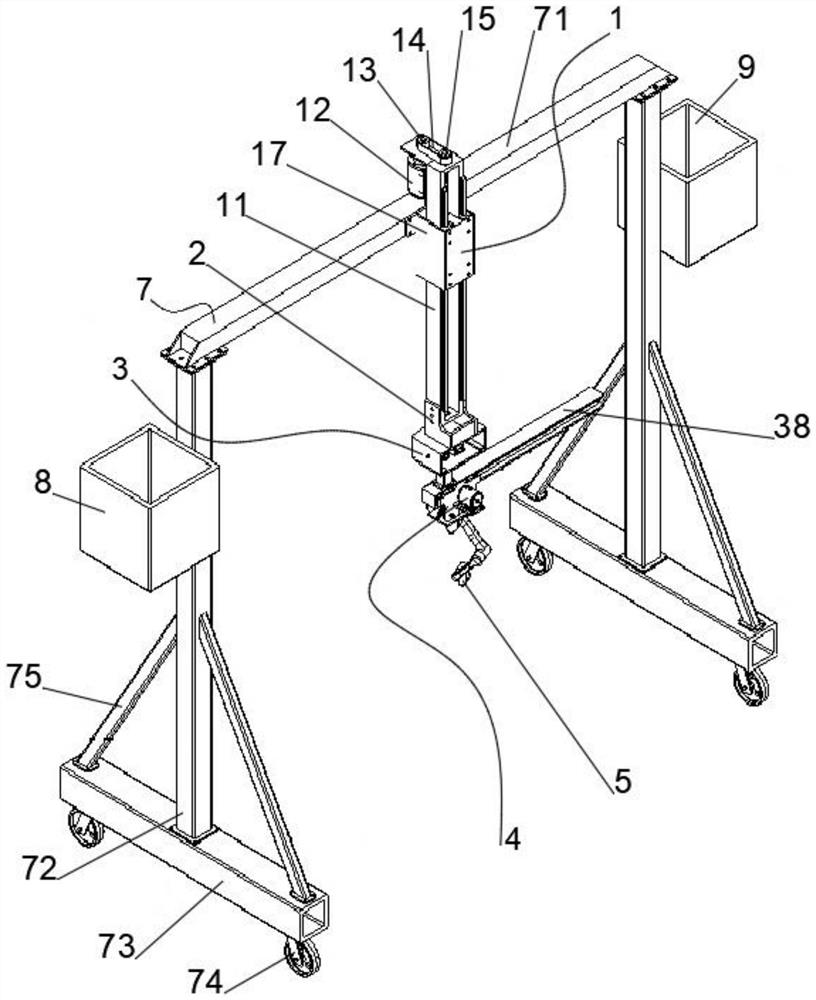

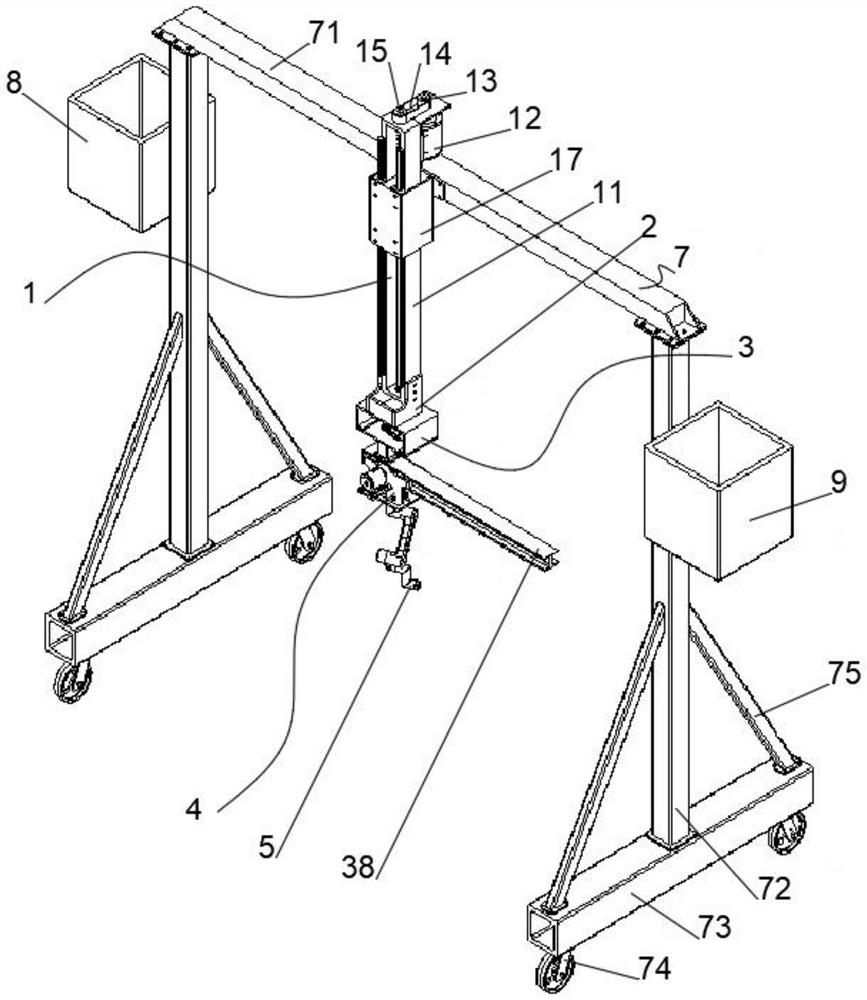

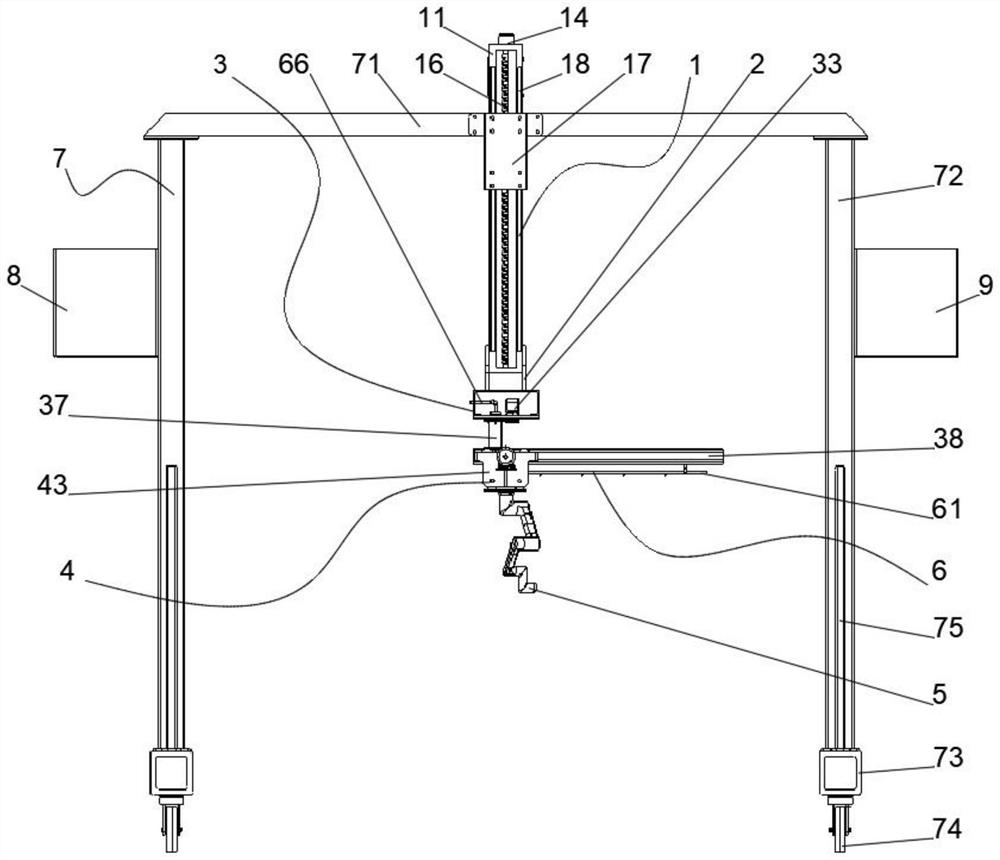

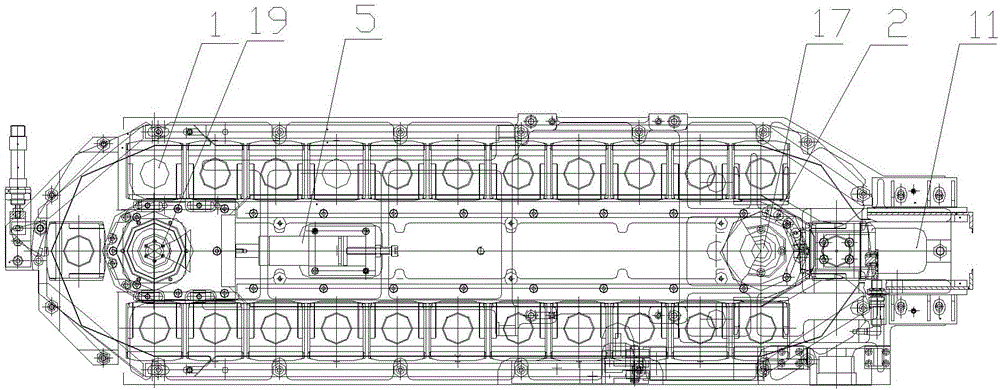

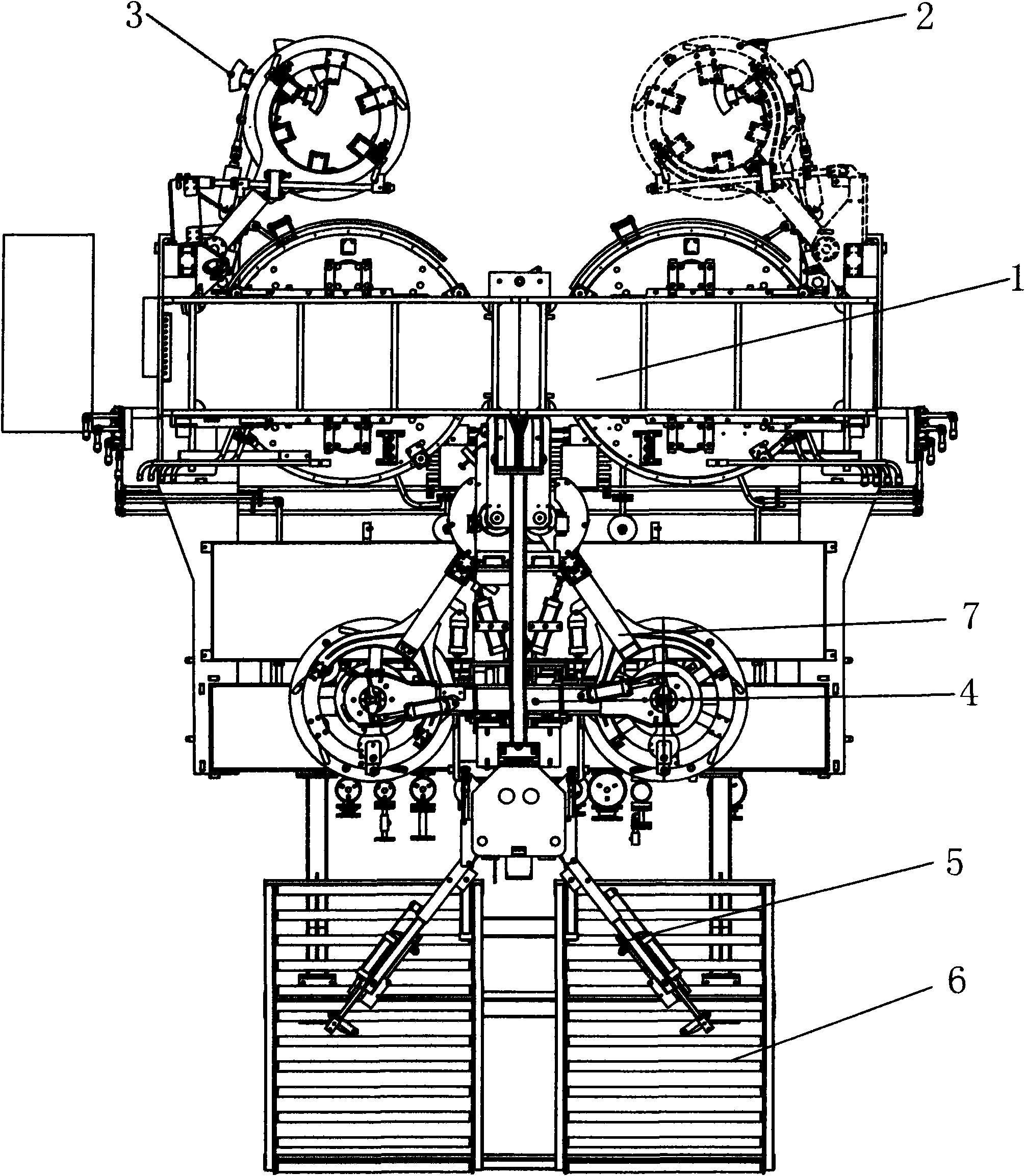

Assembling manipulator for electric locomotive wheel driving unit

The invention relates to the technical field of electric locomotives, and provides an assembling manipulator for an electric locomotive wheel driving unit. The electric locomotive wheel driving unit comprises main tracks, a cross beam, a slide carriage, a transverse walking mechanism, a lifting mechanism, and a picking mechanism, wherein the cross beam is movably arranged on the main tracks, and comprises cross beam tracks; the extending directions of the main tracks are perpendicular to the extending directions of the cross beam tracks; the slide carriage is arranged on the cross beam tracks;the transverse walking mechanism is connected with the slide carriage and is movably arranged relative to the cross beam tracks to drive the slide carriage to move along the cross beam tracks; the lifting mechanism is connected with the slide carriage and comprises a ram; the ram is movably arranged relative to the slide carriage in the vertical direction; the picking mechanism is connected withthe ram and comprises a clamping jaw part used for clamping a workpiece; the clamping jaw part is arranged adjustably relative to the position of the ram.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

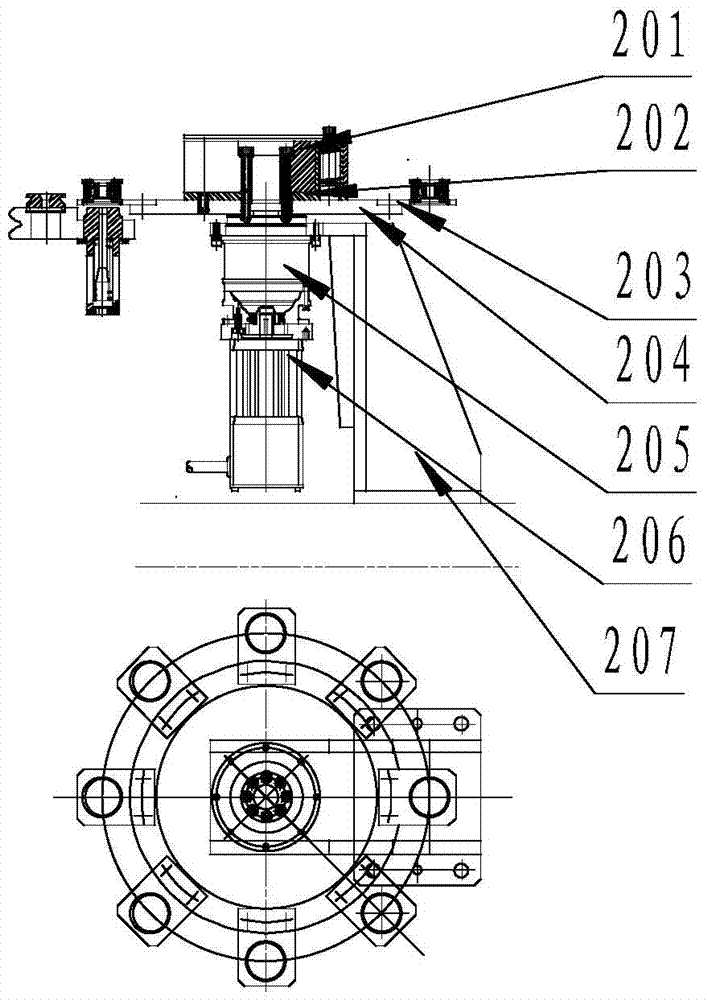

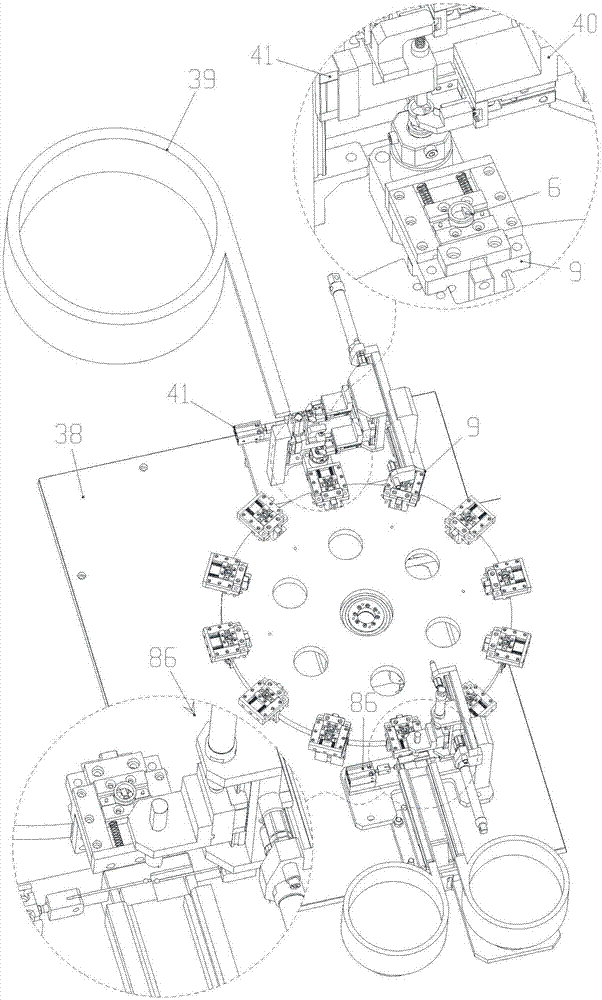

High-performance radial tire intelligent vulcanizing machine

Owner:双星东风轮胎有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap