High-speed photovoltaic module production device and high-speed photovoltaic module production method

A photovoltaic module and production equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of slow speed, low production capacity of production equipment, hindering the large-scale promotion and application of photovoltaic modules, etc., to improve the preparation efficiency, The effect of increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

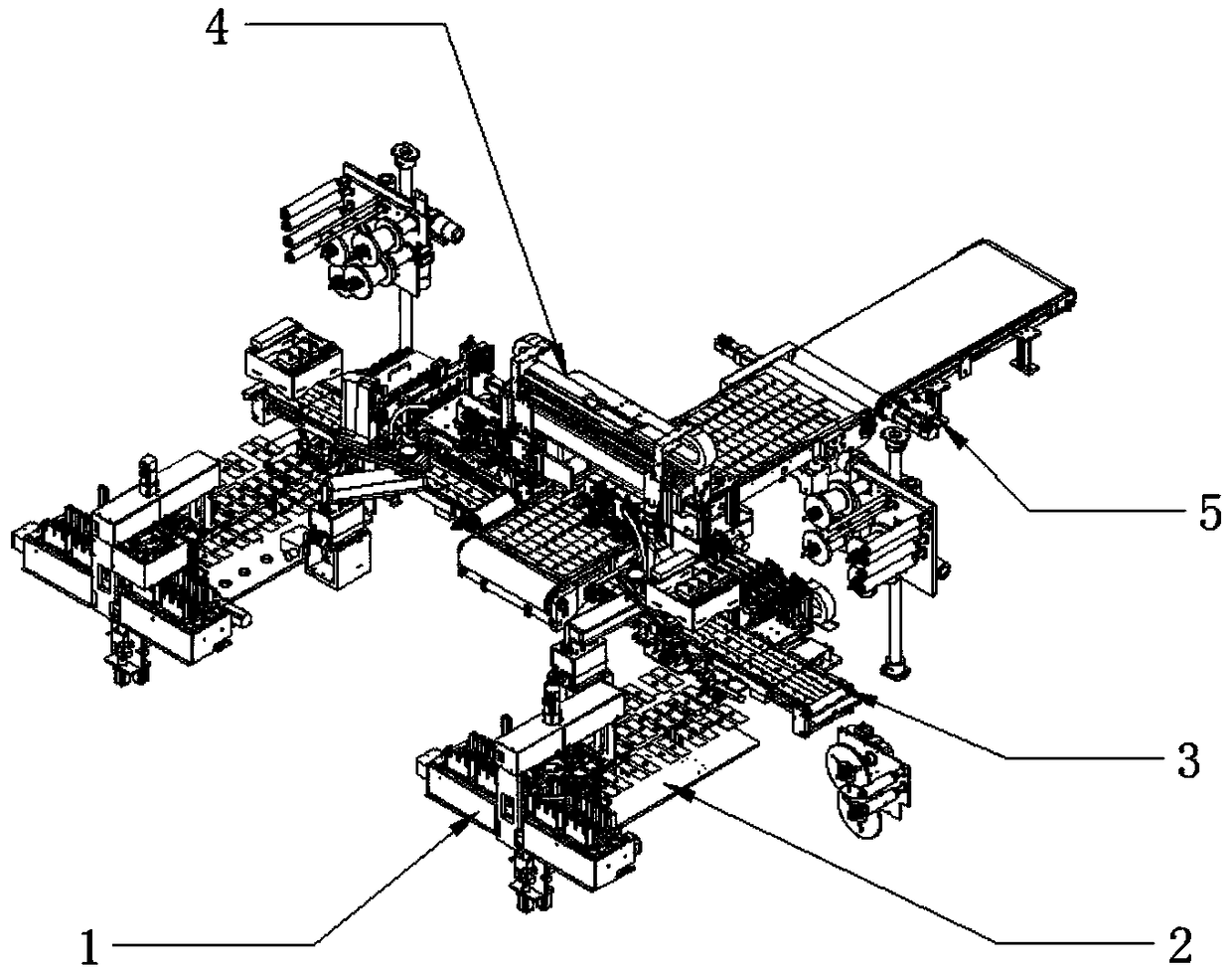

[0032] refer to Figure 1-6 , this embodiment shows a high-speed photovoltaic module production equipment, including:

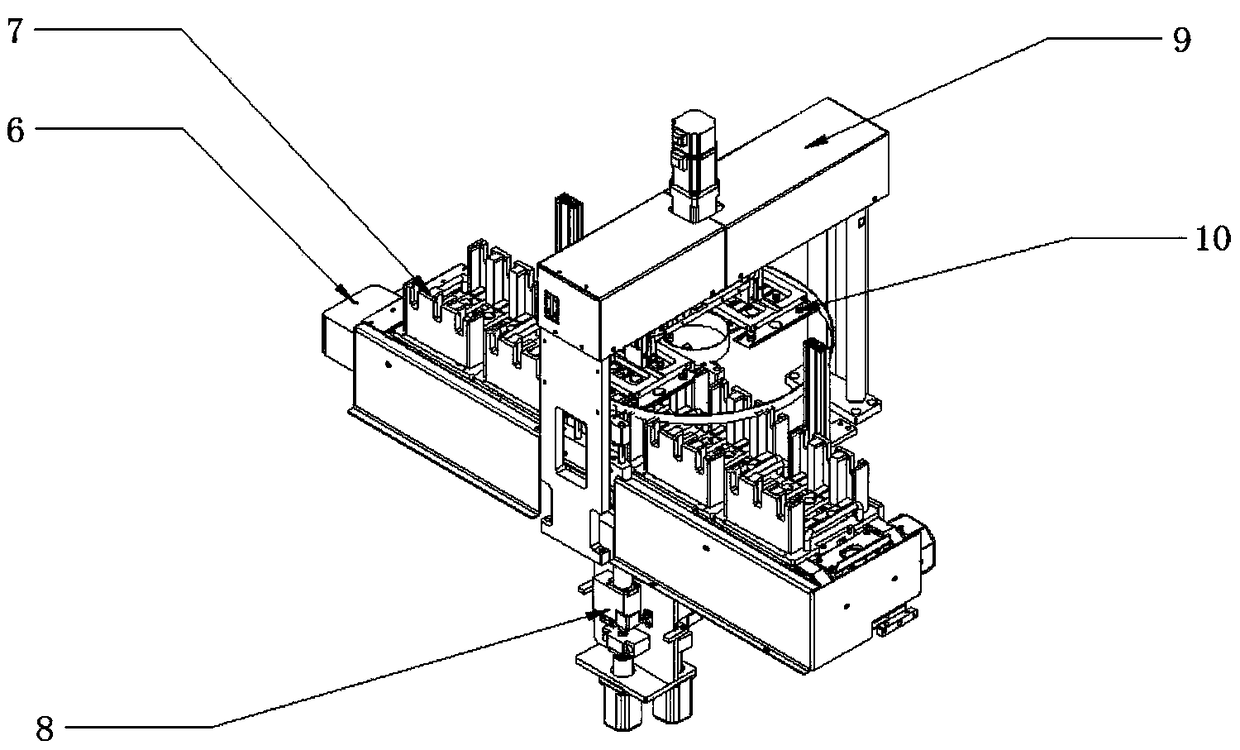

[0033] Automatic feeding mechanism 1:

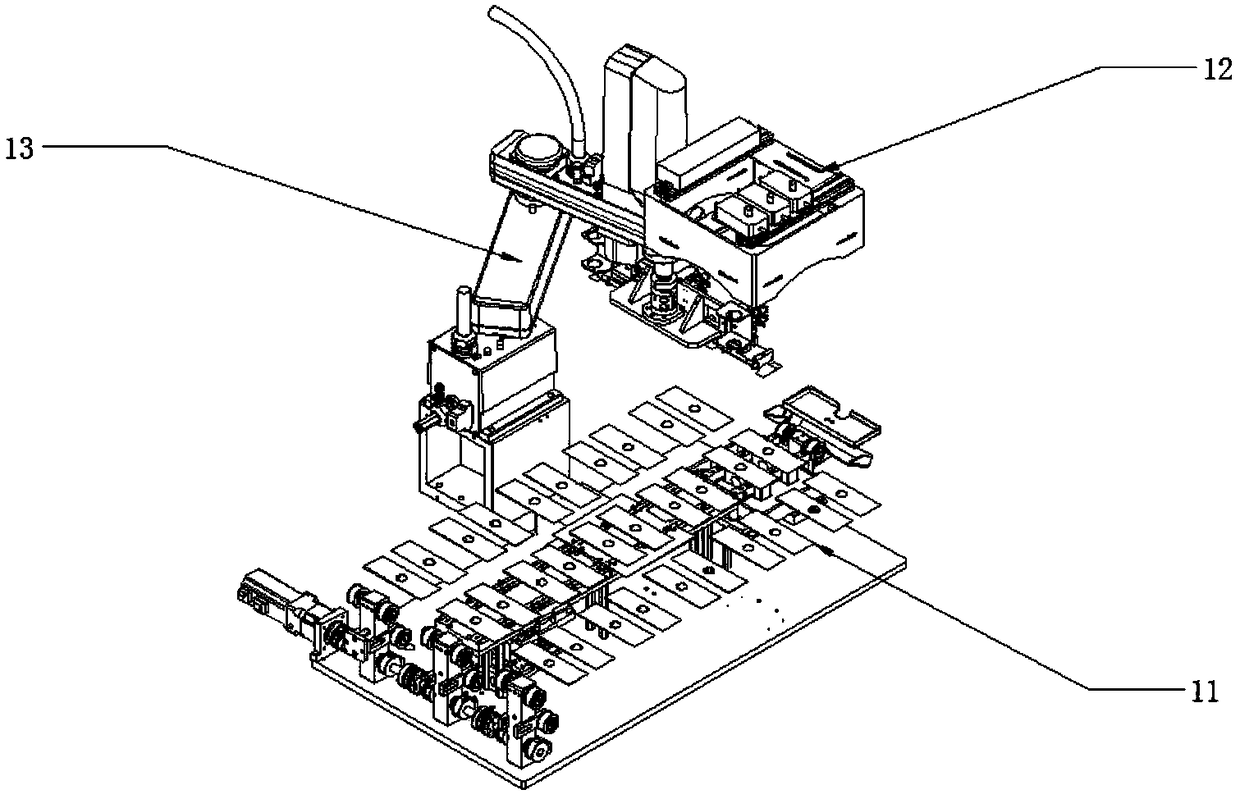

[0034] The automatic feeding mechanism 1 includes a battery sheet material box conveyor belt 6, a battery sheet material box 7, a battery sheet ejecting mechanism 8, a battery sheet handling mechanism 9, and a battery sheet 10; the box conveyor belt 6 can transfer the battery sheet material box 7 to Cell ejector mechanism 8, cell ejector mechanism 8 can lift the cells 10 one by one to the bottom of the cell transport mechanism 9, the cell transport mechanism 9 places the cells 10 one by one to the cell transport Institution 11 on;

[0035] The automatic feeding mechanism 1 is provided with 3 sets of battery slices to be fed simultaneously, so that the battery plate plate welding mechanism 5 can simultaneously weld 3 sets of battery slices 10 together.

[0036] Cell transmission camera mechanism 2:

[0037] The cell tra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap