Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Welding/soldering/cutting articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

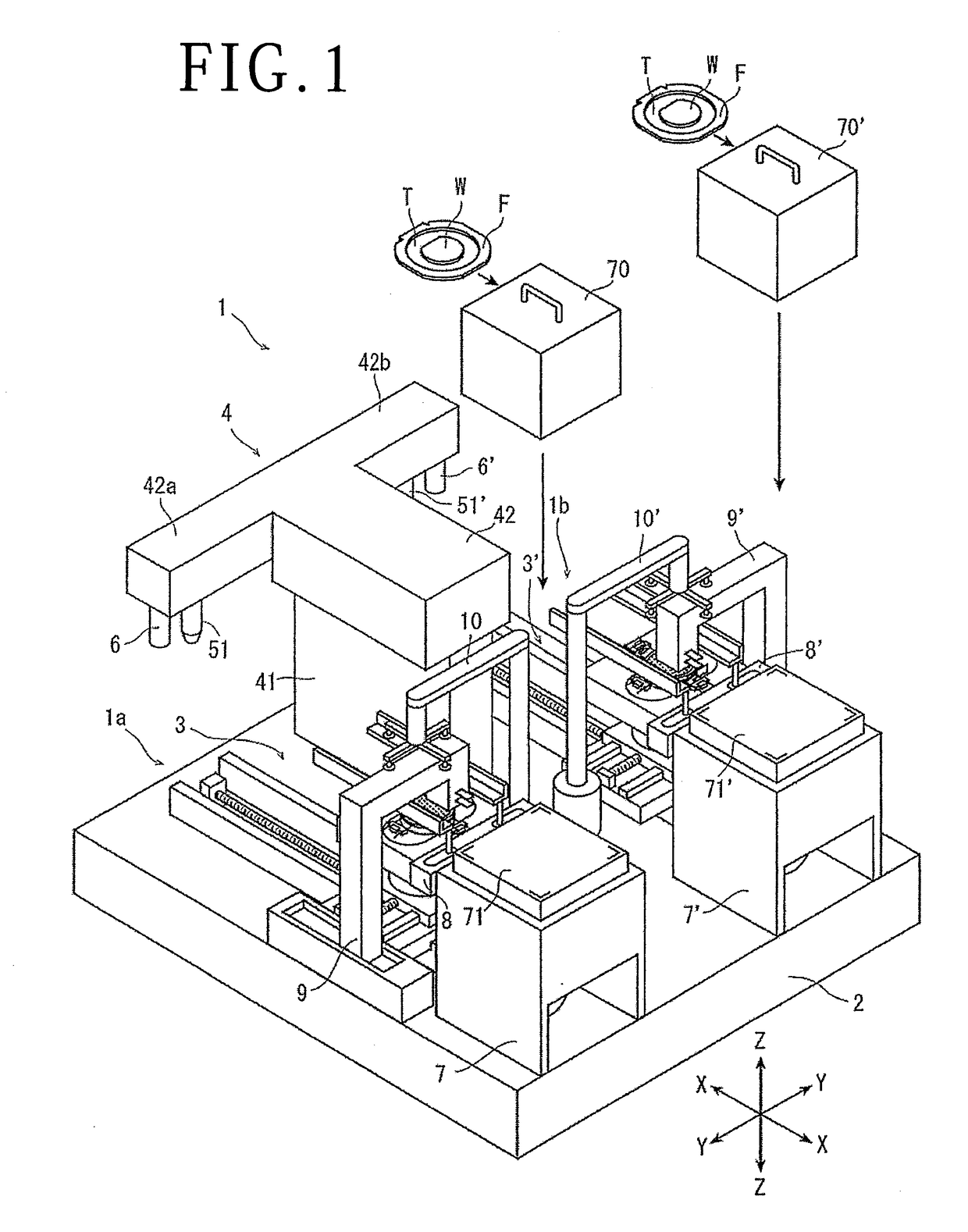

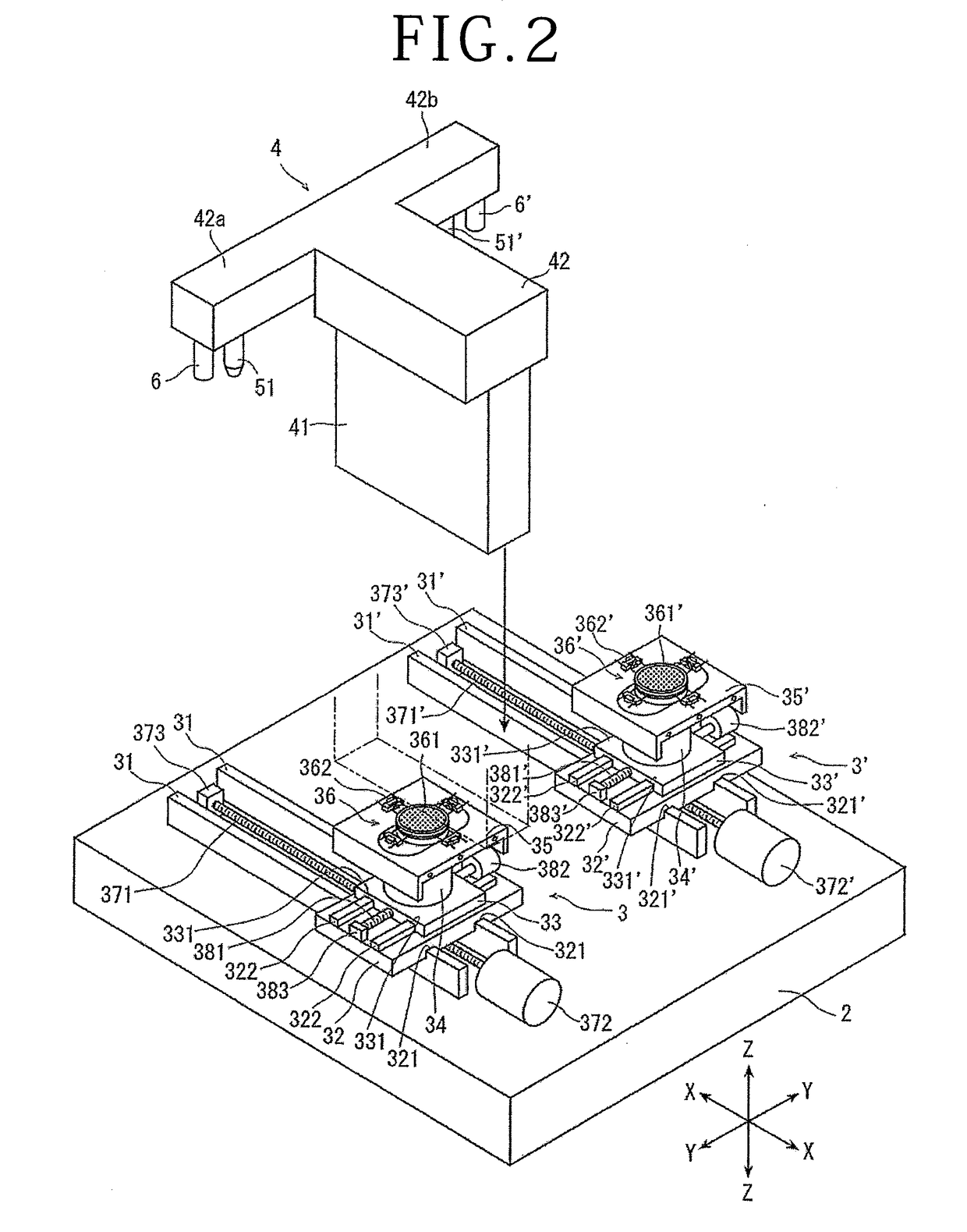

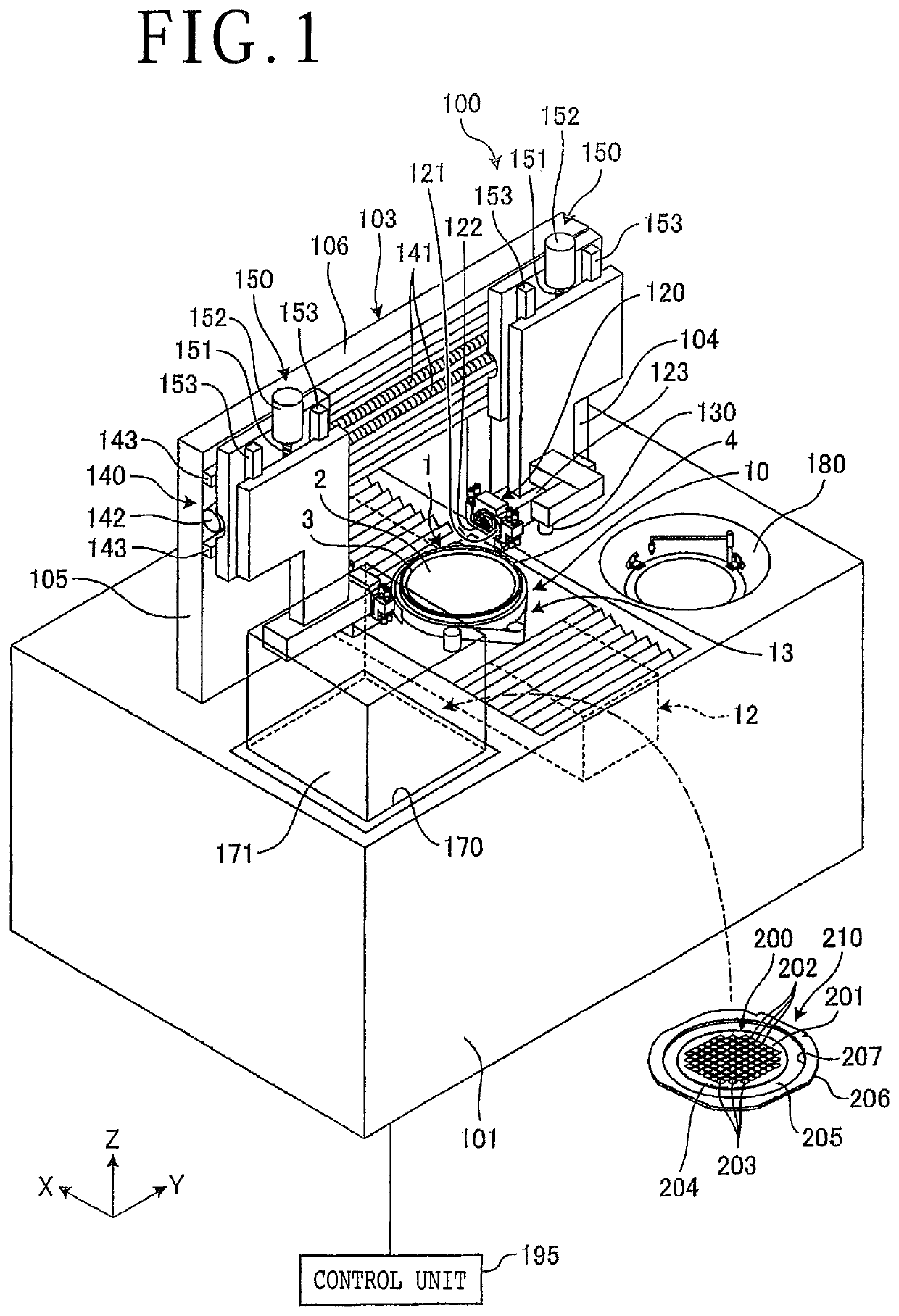

Laser processing apparatus

ActiveUS20130334185A1Welding/soldering/cutting articlesLaser beam welding apparatusOptical pathOptoelectronics

Owner:DISCO CORP

Laser etched trim

Owner:ADIENT LUXEMBOURG HLDG SARL

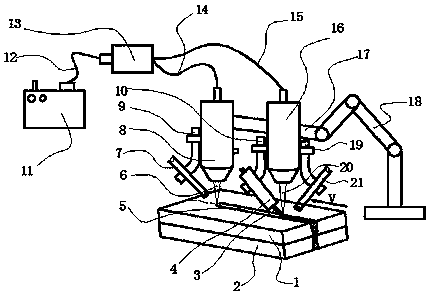

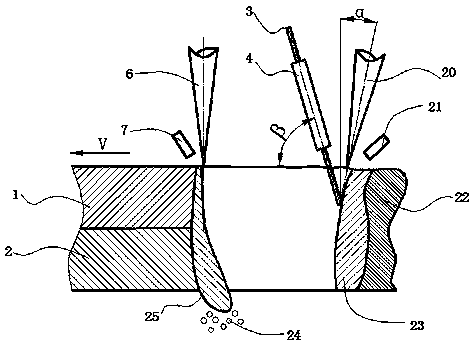

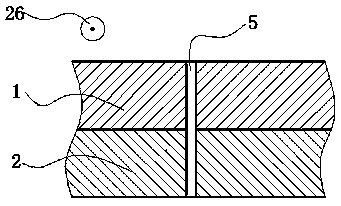

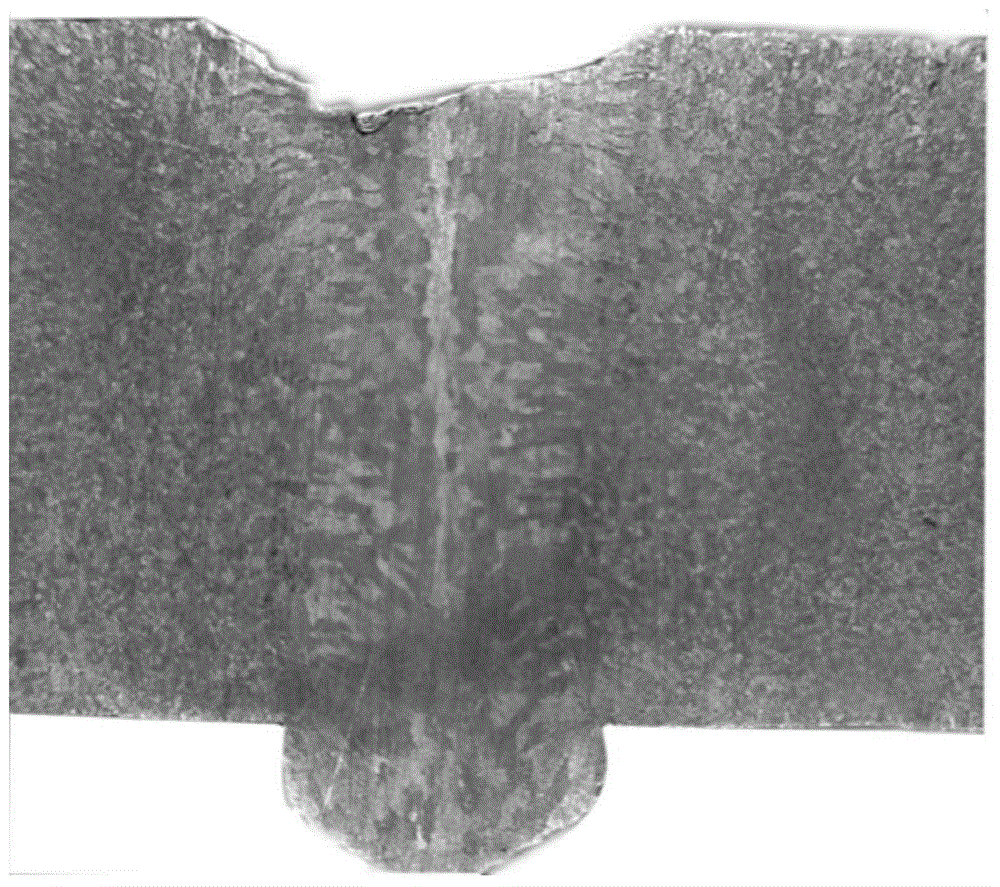

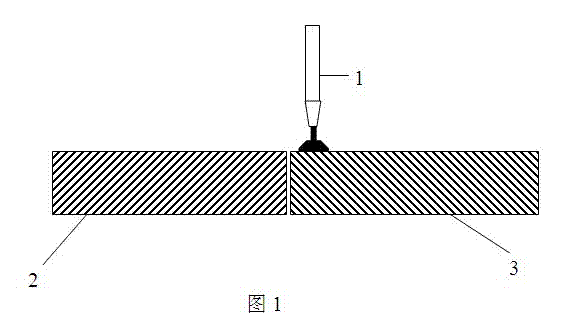

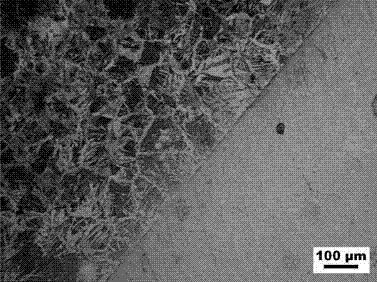

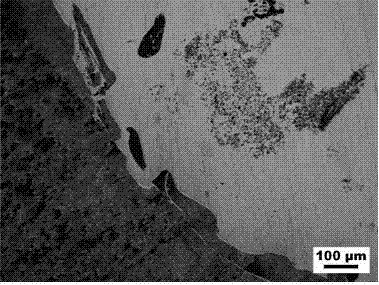

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Avoiding hot cracks during laser welding of a workpiece stack-up assembly of aluminum alloy workpieces

ActiveUS20180243861A1Vehicle componentsWelding/soldering/cutting articlesIntermediate stageOptoelectronics

A method of laser welding a workpiece stack-up that includes two or more overlapping aluminum alloy workpieces is disclosed. The method involves controlling the power level of the laser beam during at least one of an initial stage or a final stage of advancing the laser beam along a weld path so as to limit a line energy of the laser beam during such stage or stages to being no greater than 10% above a line energy of the laser beam during an intermediate stage of laser beam advancement that is performed between the initial and final stages. By limiting the line energy during the initial and / or final stages of laser beam advancement along the weld path, excessive fusion of the workpiece stack-up assembly can be avoided in those locations to help protect against hot-cracking in the resultant laser weld joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for welding thick copper plate by fiber laser

ActiveCN104646825ARadiation-absorbing paintsWelding/soldering/cutting articlesSpecific gravityLaser fiber

Owner:WUHAN HGLASER ENG CO LTD

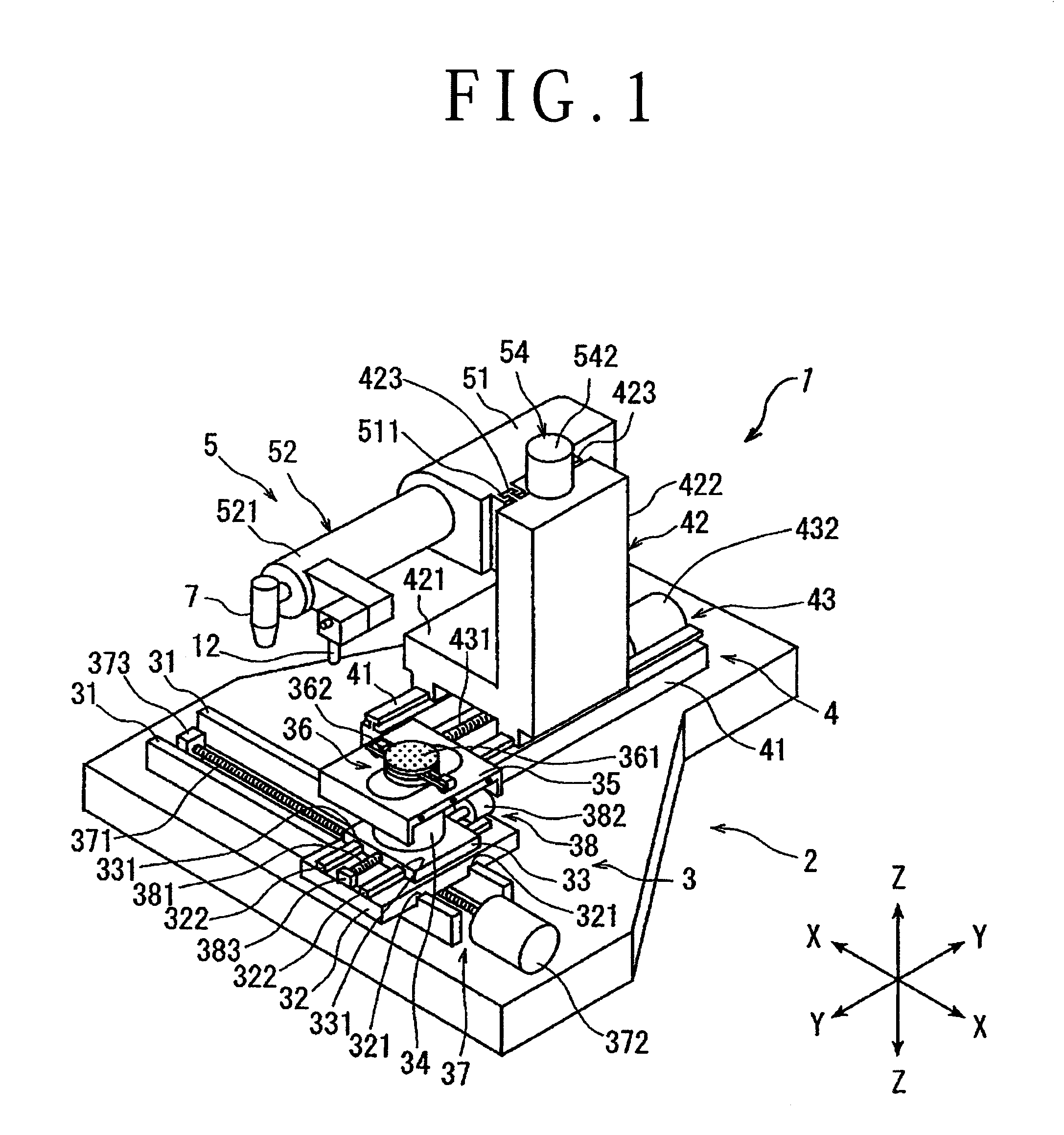

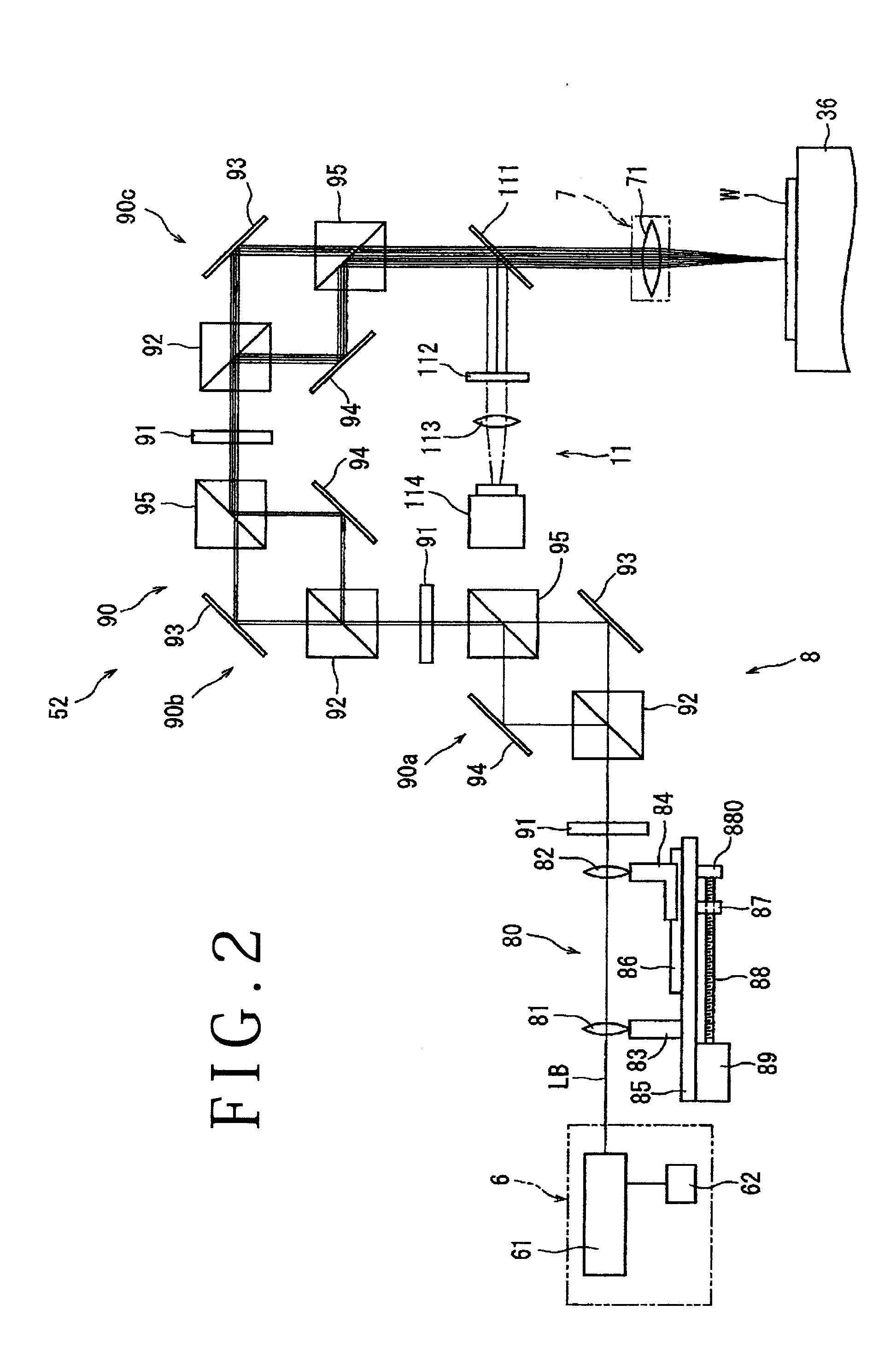

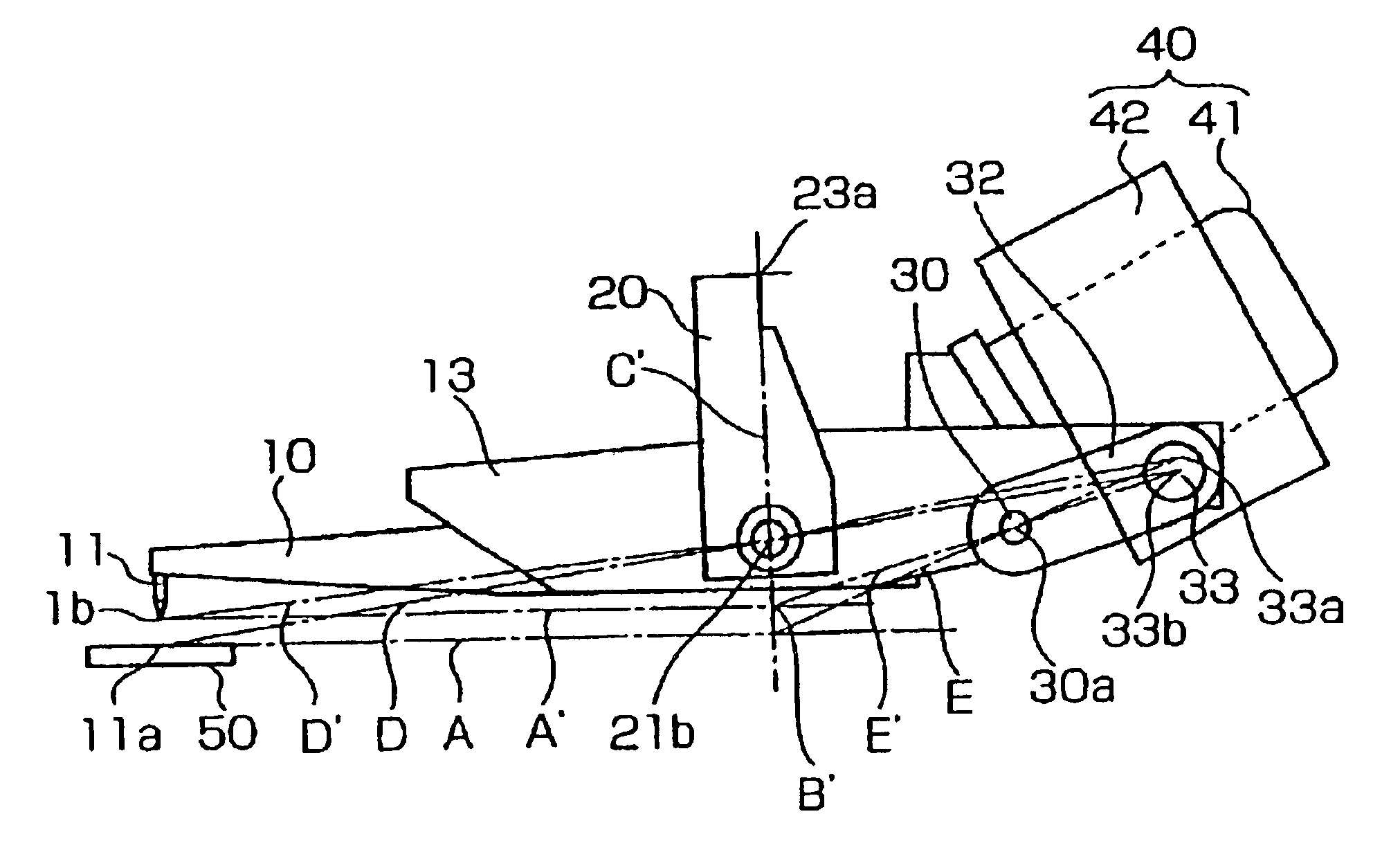

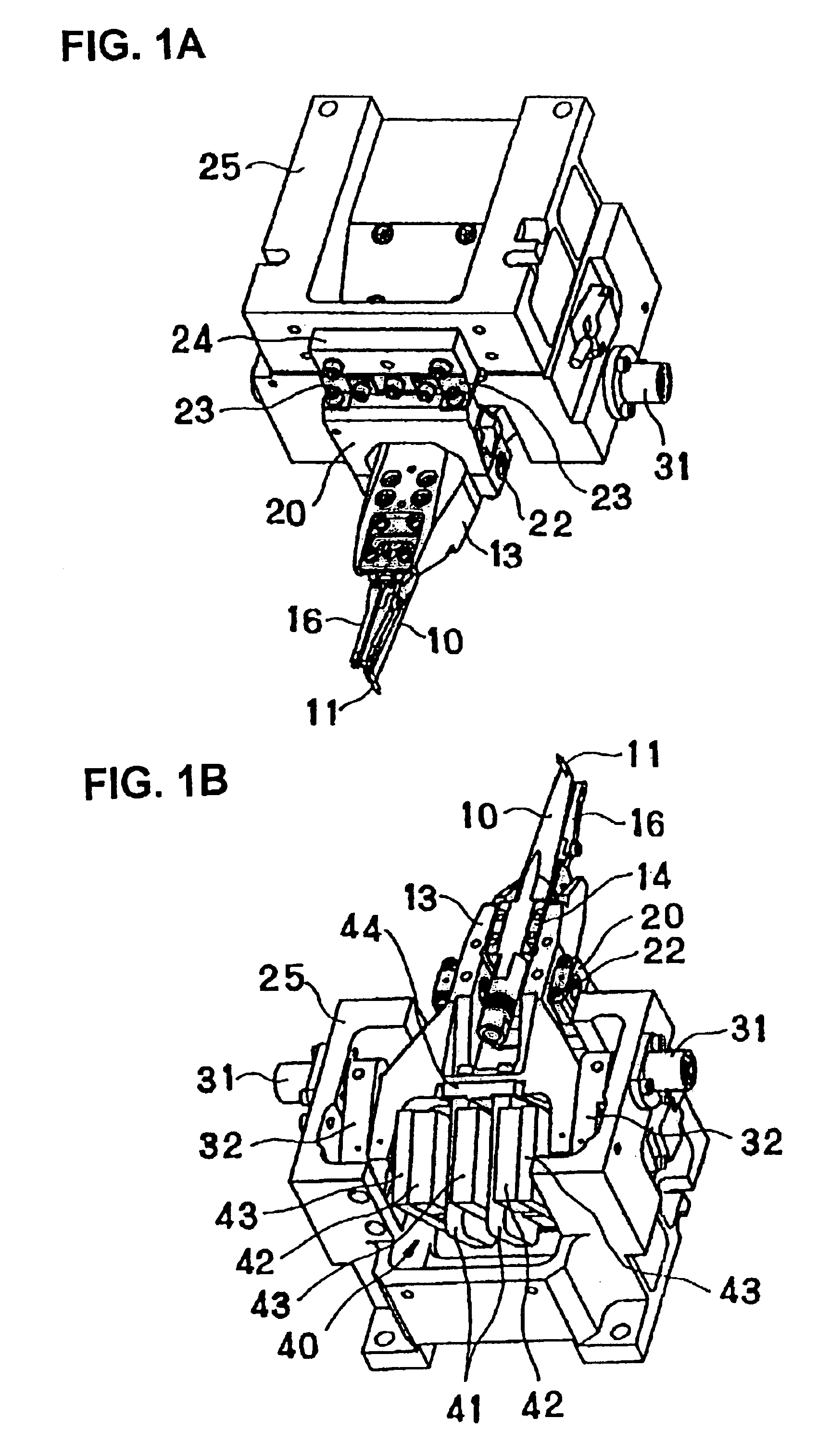

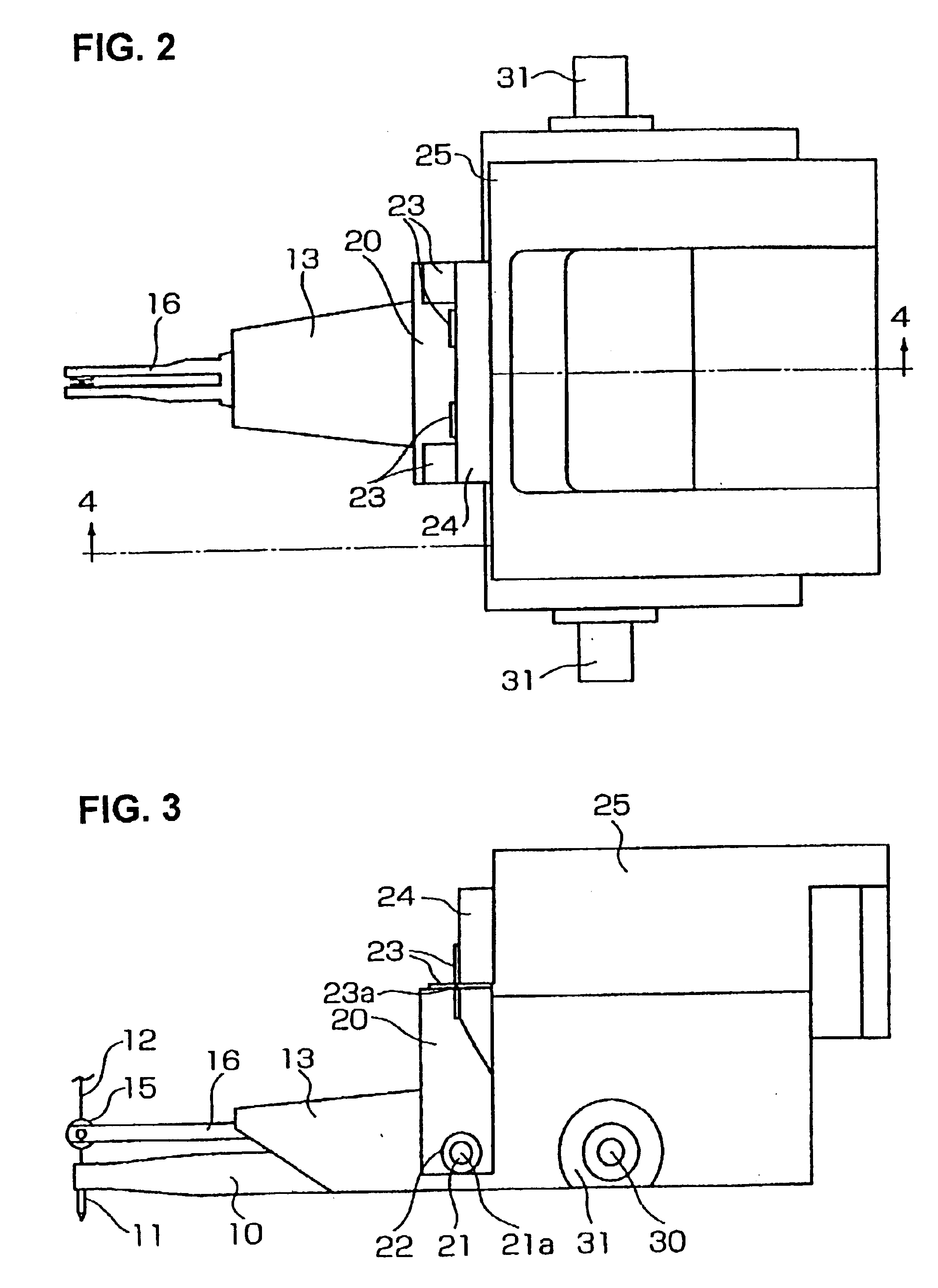

Bonding apparatus

InactiveUS6863206B2Increase bonding areaSolid-state devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

Owner:SHINKAWA CO LTD

Flow adjuster and processing devices

InactiveCN1406707ALow priceImprove reliabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTraffic volume

This invention provides a flow amount adjustment apparatus able to adjust flow amount with high reliability at a low cost without being oversized. The flow amount adjustment apparatus has a plurality of orifices having different bore diameter for a predetermined flow amount, respectively, the orifices being opened and closed by an open-close member, respectively; a primary piping connected to each of the orifices for supplying gas adjusted to a prescribed pressure; and a secondary piping connected to each of the orifices for gathering gas passed through an opened orifice or a plurality of opened orifices, wherein one orifice or a plurality of orifices capable of satisfying a prescribed flow amount are selected and opened.

Owner:KOIKE SANSO KOGYO CO LTD

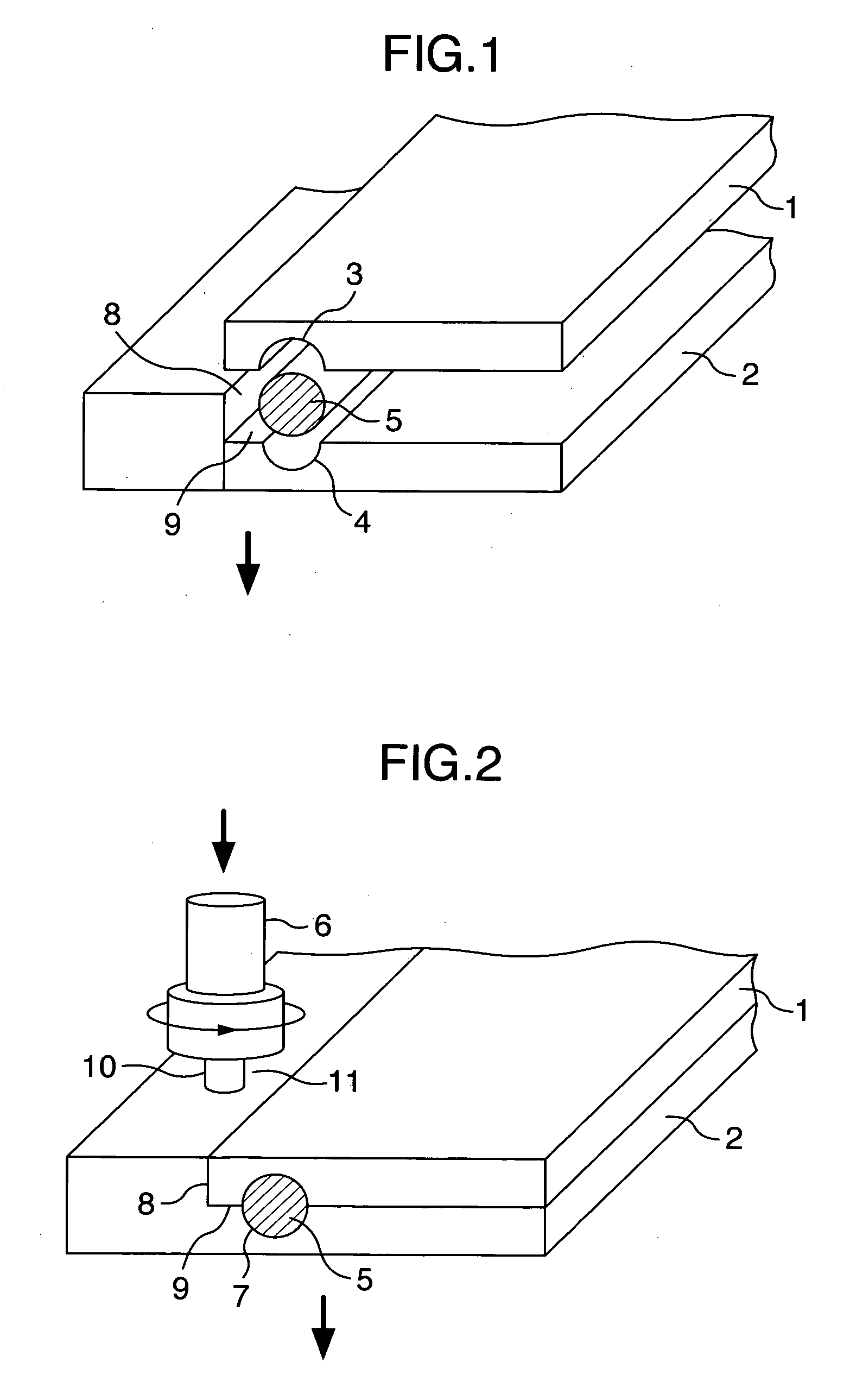

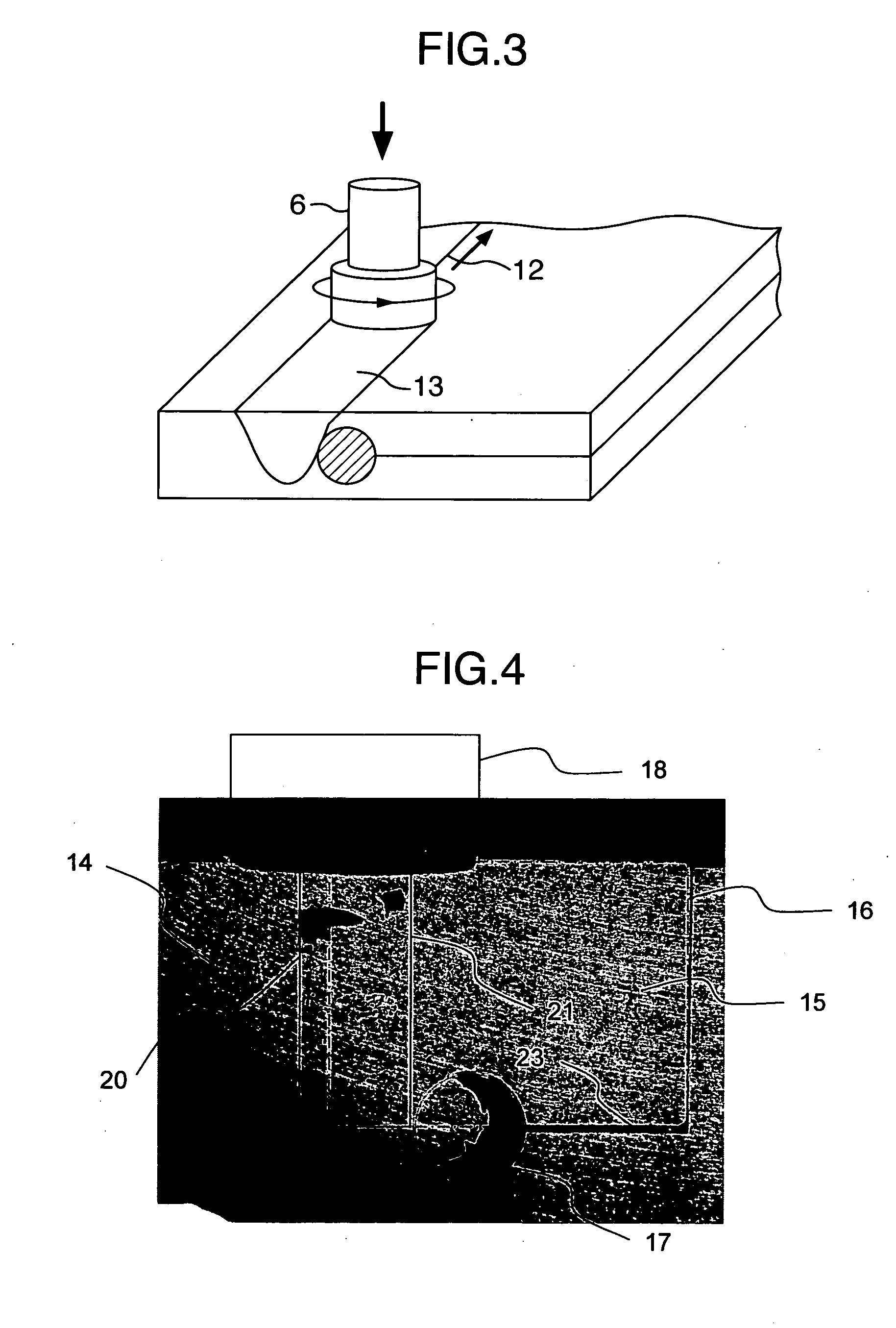

Method of resistance spot welding aluminum alloy workpieces

ActiveUS20140076859A1Easy to moveEliminate contaminationVehicle componentsWelding/cutting media/materialsSurface roughnessSpot welding

A method of resistance spot welding aluminum alloy workpieces together includes several steps. In one step a welding electrode is provided. The welding electrode has a weld face. In another step, the weld face of the welding electrode is shaped to have a desired radius of curvature. The shaped weld face is then textured to a desired surface roughness, and resistance spot welding using the welding electrode is performed to the aluminum alloy workpieces. In yet another step, the weld face is dressed to an extent sufficient to remove contamination build-up that may have accumulated on the weld face from the aluminum alloy workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

Friction stir welding method

InactiveUS20070181649A1Excellent fatigue propertiesSimple structureCooking-vessel materialsWelding/cutting auxillary devicesEngineeringMechanical engineering

Owner:HITACHI LTD

Method for conductively connecting a component on a transparent substrate

InactiveUS20120266461A1Avoid cleaningFast solderingPrinted circuit assemblingLight absorption dielectricsEnergy supplyLength wave

The invention relates to a method to conductively connect an electrical component with at least one conductive layer, whereby the conductive layer is applied to a substrate which is essentially transparent in the visible wavelength zone of light, comprising the following steps: the electrical component or the conductive layer is provided with a soldering material in the area where the component is to be connected to the conductive layer; the soldering material is provided with energy supplied by an energy source, such that the soldering material melts and a non-detachable, material-bonded conductive connection between the electrical component and the conductive layer is established.

Owner:SCHOTT AG

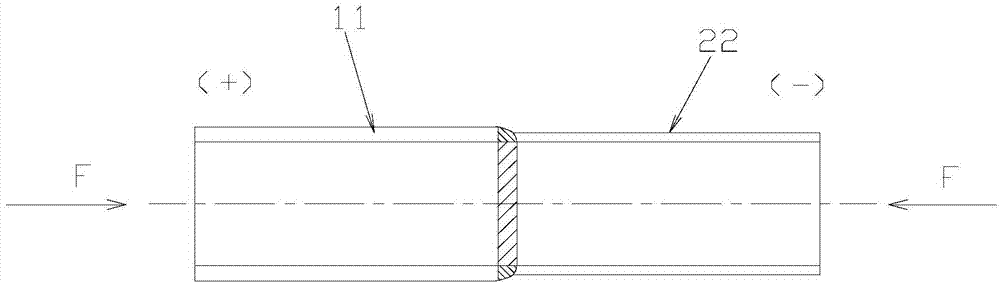

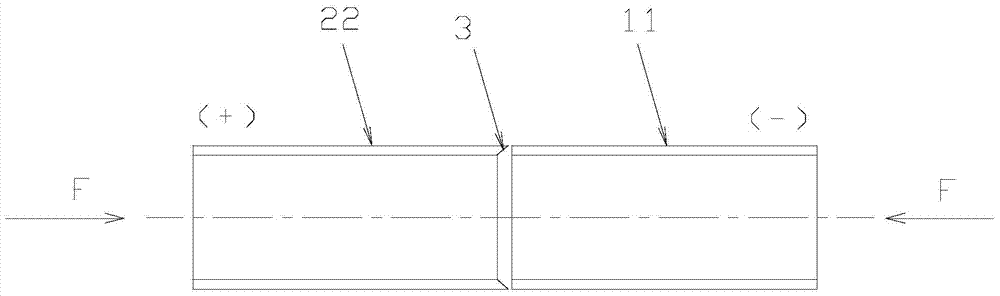

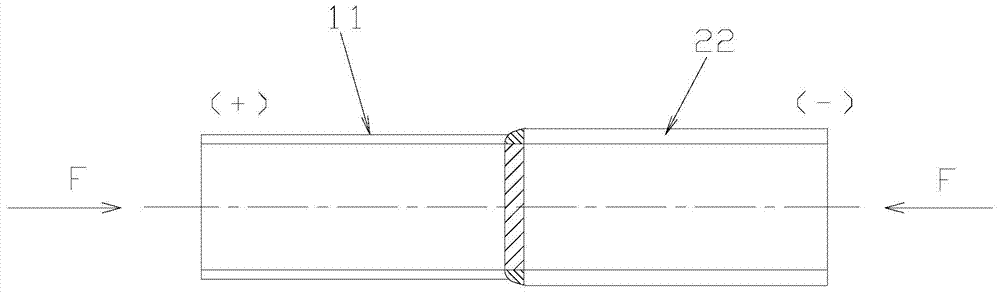

Flash welding method for dissimilar metal

InactiveCN103692073AWelding/soldering/cutting articlesResistance welding apparatusDissimilar metalMelting point

Owner:ZHUJI SIBEIDA MACHINERY CO LTD

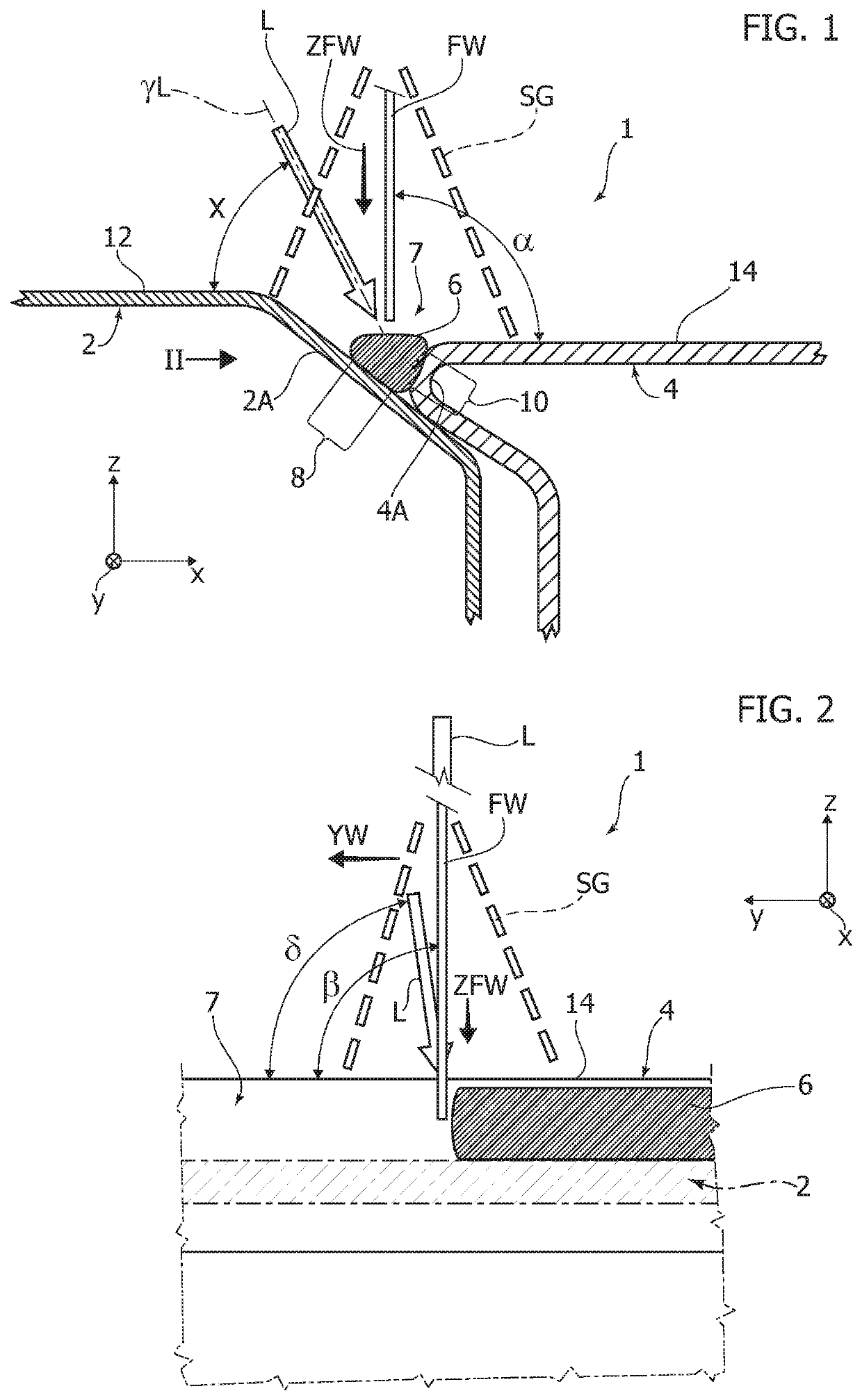

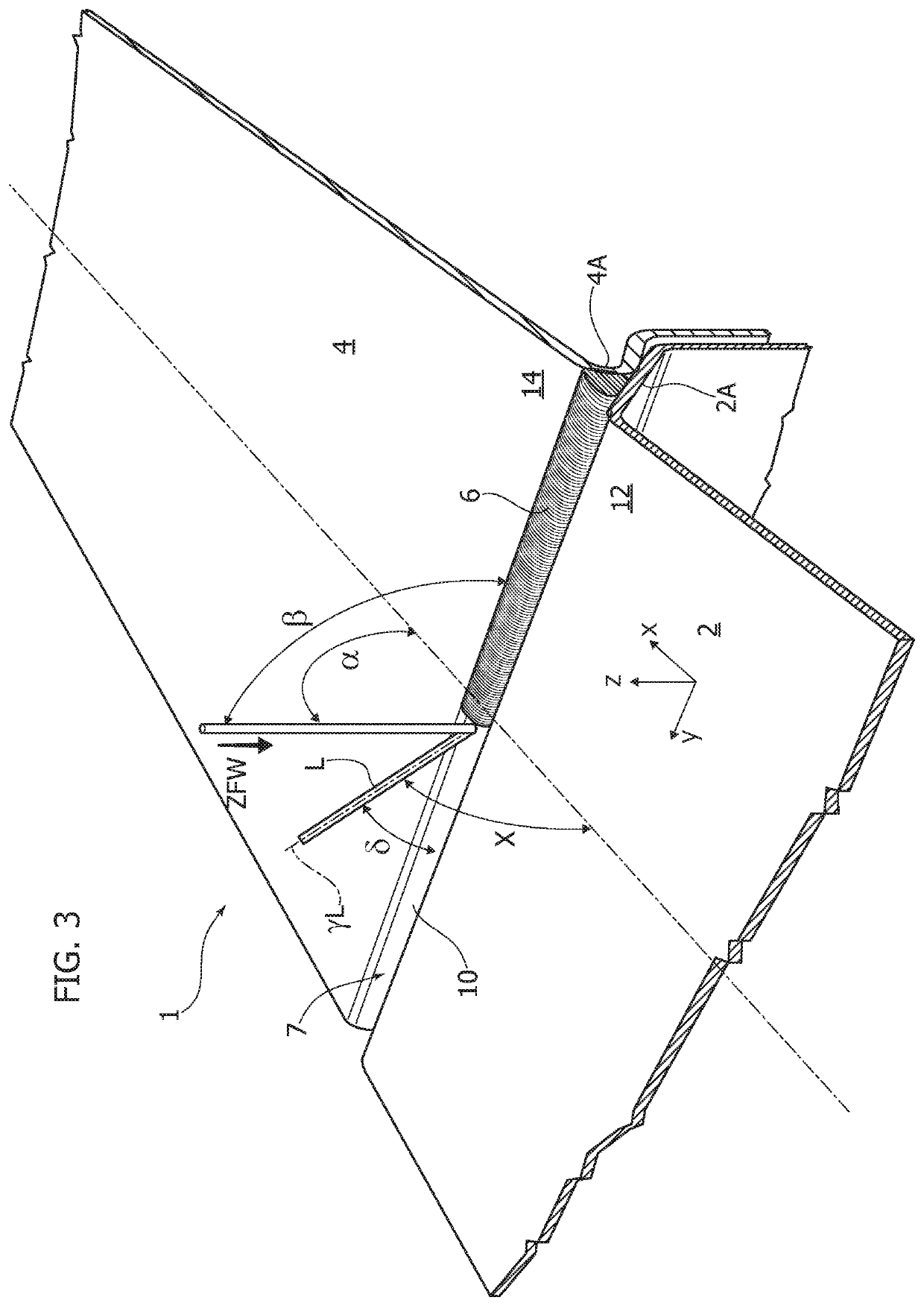

Laser welding apparatus and method of laser welding

ActiveCN102196879AAvoid meltingInhibitionWelding/cutting auxillary devicesAuxillary welding devicesThick wallLaser beams

Owner:MITSUBISHI SHIPBUILDING CO LTD

Manufacturing method of semiconductor device

InactiveCN102468153AEfficient reorganizationIncrease etch ratePolycrystalline material growthAfter-treatment detailsPulsed laser beamCrystalline silicon

In a manufacturing method of a semiconductor device, a substrate including single crystalline silicon is prepared, a reformed layer that continuously extends is formed in the substrate, and the reformed layer is removed by etching. The forming the reformed layer includes polycrystallizing a portion of the single crystalline silicon by irradiating the substrate with a pulsed laser beam while moving a focal point of the laser beam in the substrate.

Owner:DENSO CORP

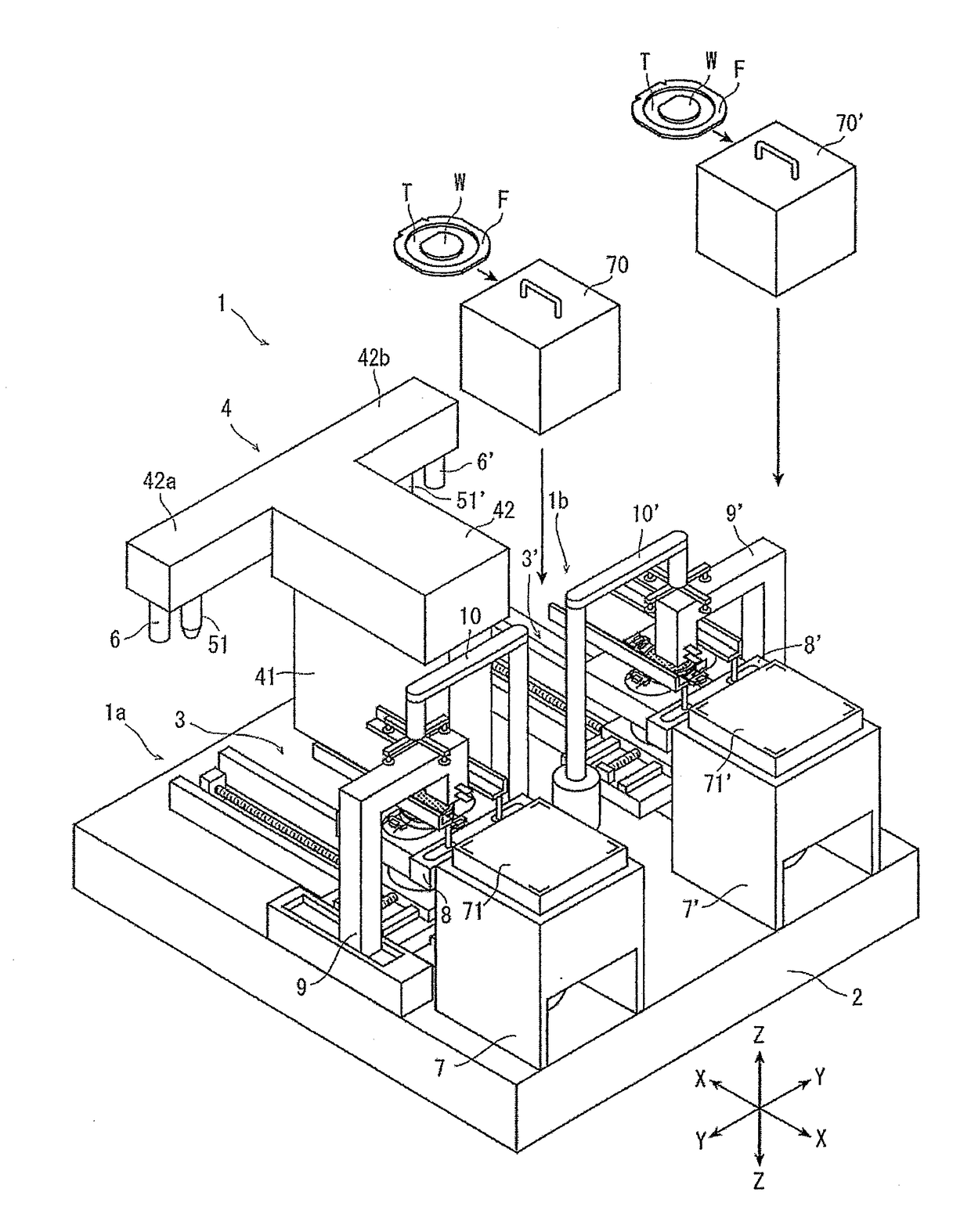

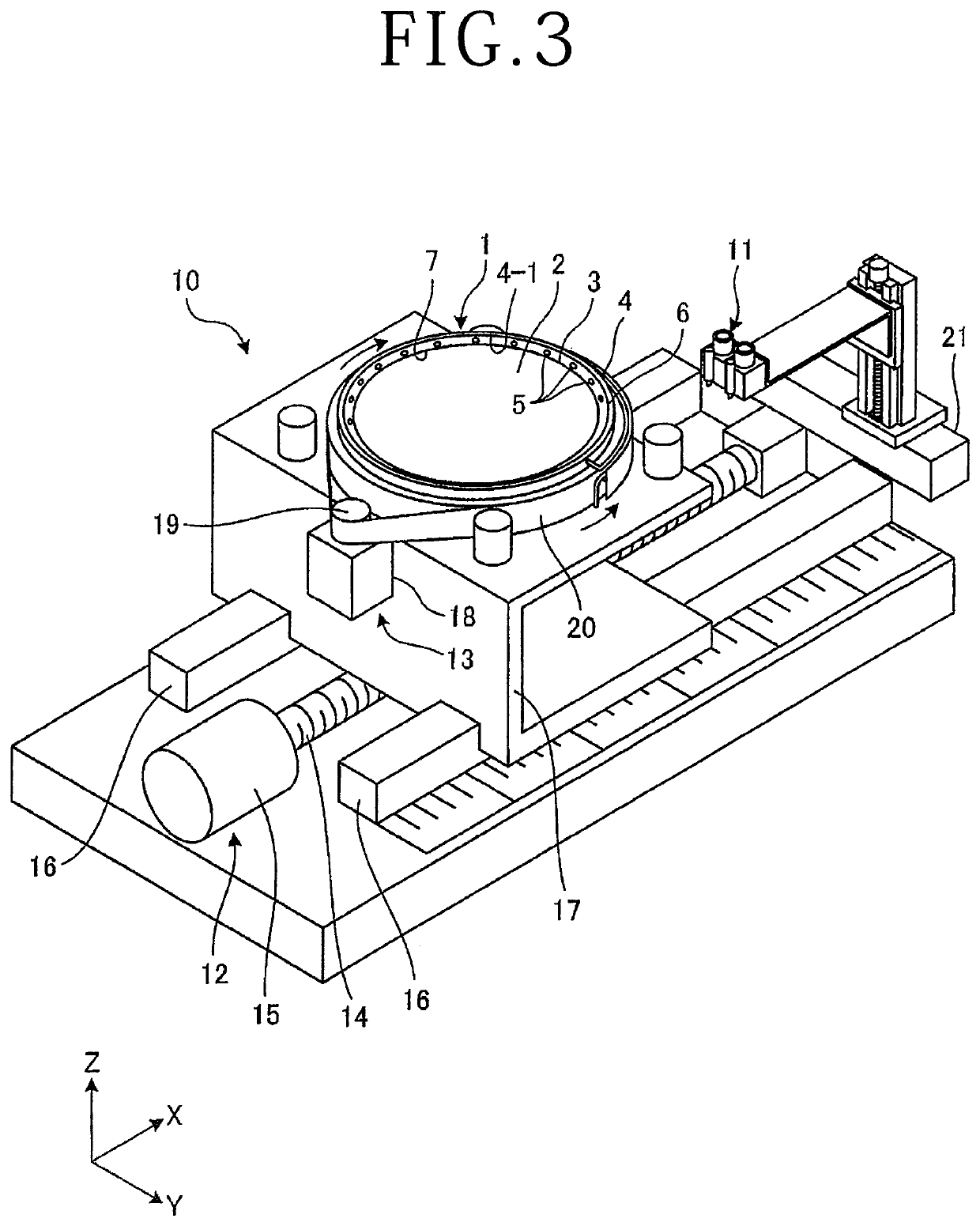

Laser processing apparatus

ActiveUS20170087671A1Improve economyLow costSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingOptoelectronics

Owner:DISCO CORP

Wafer spot heating with beam width modulation

ActiveUS20190371631A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLight beamHeat treated

Embodiments of the present disclosure provide a thermal process chamber that includes a substrate support, a first plurality of heating elements disposed over or below the substrate support, and a spot heating module disposed over the substrate support. The spot heating module is utilized to provide local heating of regions on a substrate disposed on the substrate support during processing. Localized heating of the substrate alters temperature profile. The shape of the beam spot produced by the spot heating module can be modified without making changes to the optics of the spot heating module.

Owner:APPLIED MATERIALS INC

High-strength silver-free copper-based brazing filler metal

InactiveCN104889598ALow melting pointHigh tensile strengthWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalCopper

The invention discloses a high-strength silver-free copper-based brazing filler metal which is composed of P, Sn, Ni and Cu. The high-strength silver-free copper-based brazing filler metal is low in cost, safe, environmentally friendly and good in welding effect; through the adding of Sn and Ni, the melting point of brazing filler metal alloy is reduced, and the tensile strength and wettability of the brazing filler metal alloy are enhanced.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

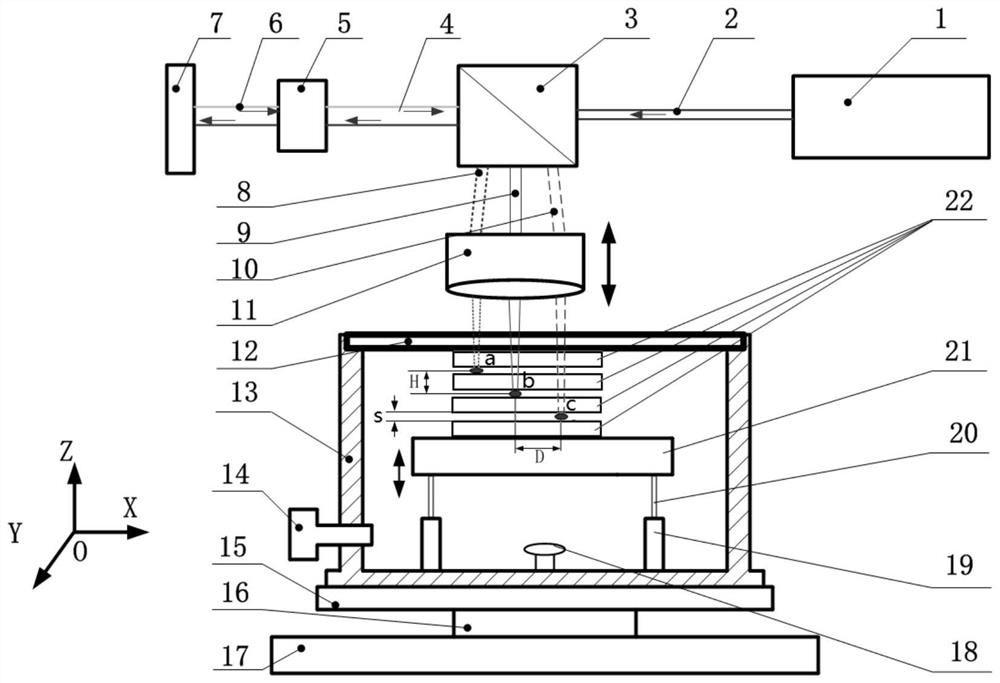

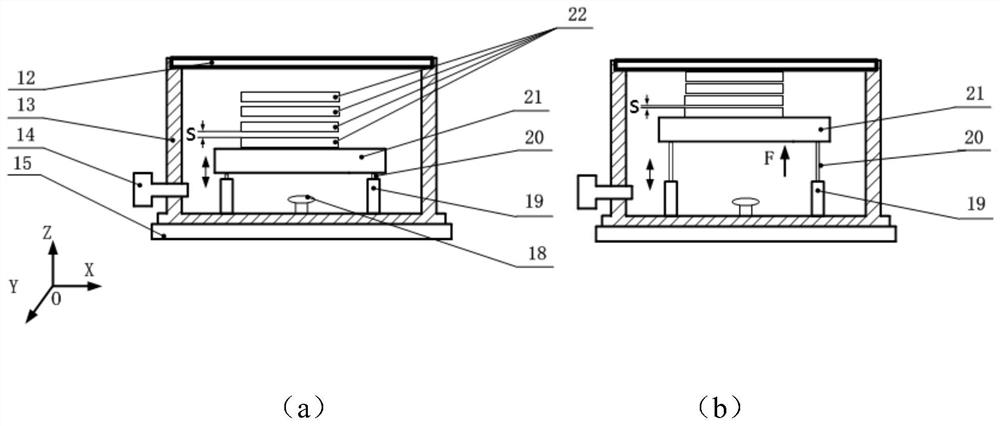

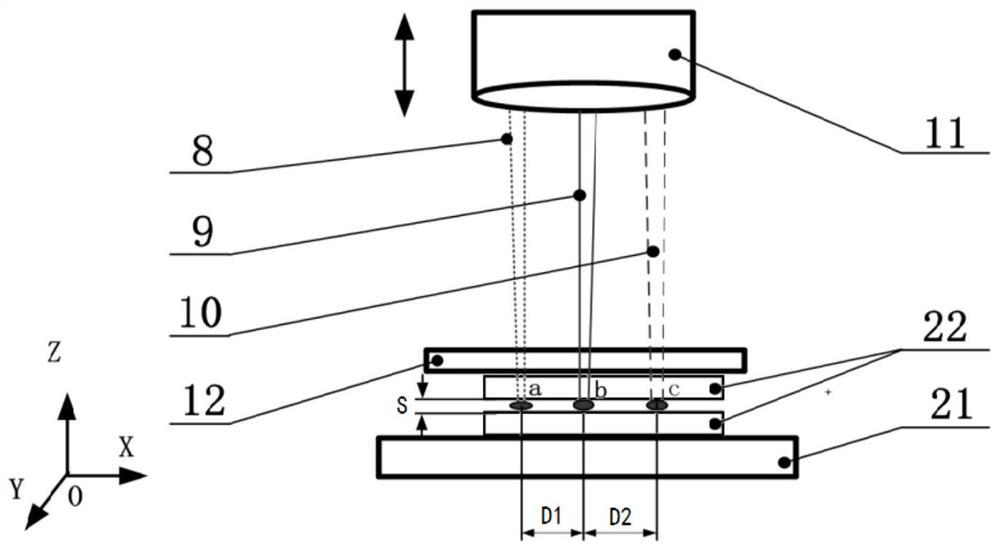

Glass material ultrafast laser precision welding system and method

ActiveCN112171055AWelding/soldering/cutting articlesLaser beam welding apparatusPhysicsWeld strength

Owner:西安中科光凝科技有限公司

Welding wire of steel-copper dissimilar metal submerged-arc welding and welding method of welding wirethereof

InactiveCN102873467AImprove mechanical propertiesBeautiful shapeArc welding apparatusWelding/cutting media/materialsManganeseSpot welding

Owner:SHENYANG POLYTECHNIC UNIV +1

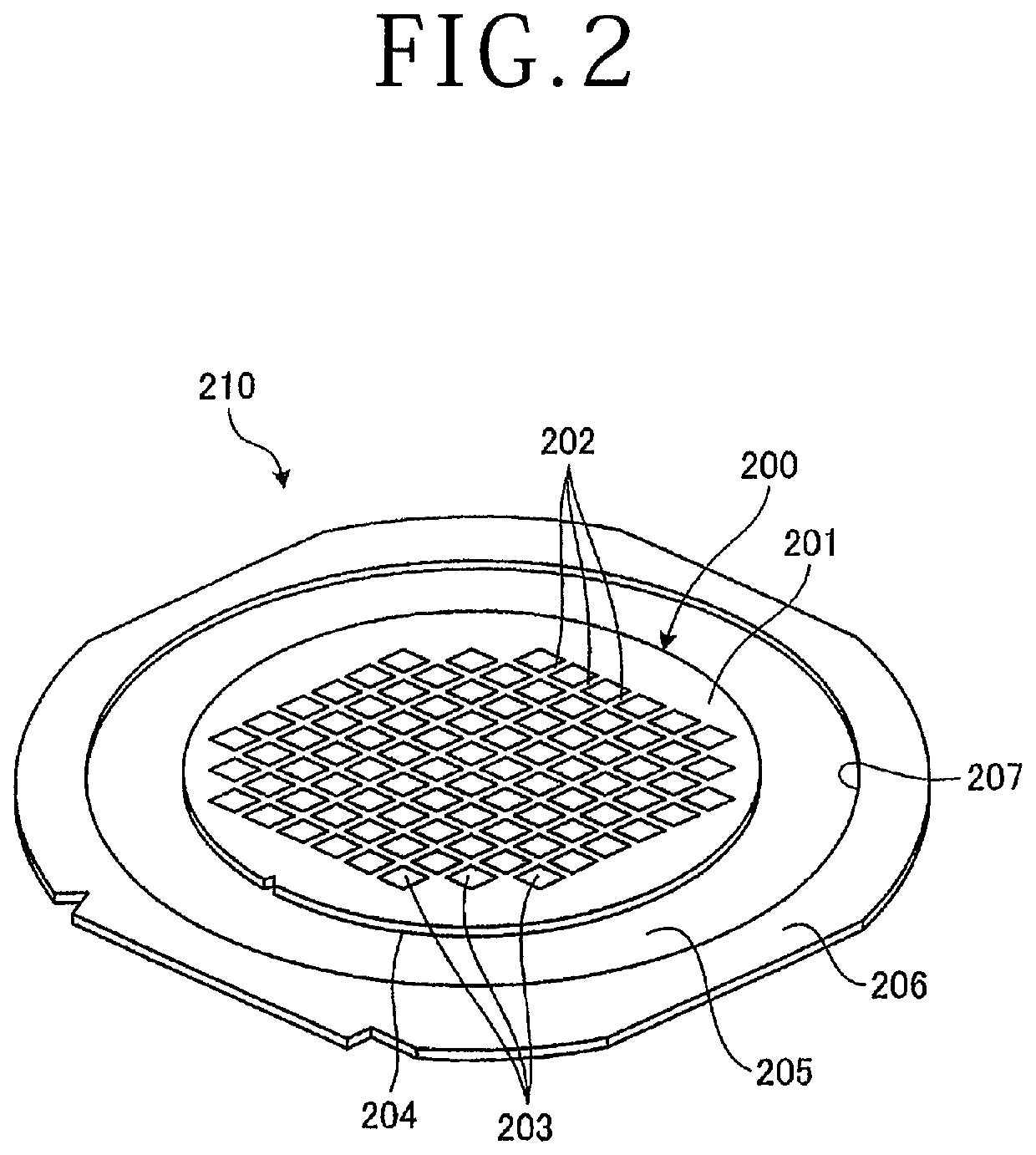

Chuck table and inspection apparatus

ActiveUS20200266091A1Eliminate needSemiconductor/solid-state device testing/measurementWelding/cutting auxillary devicesSuction forceAdhesive belt

Owner:DISCO CORP

Method for fabricating radiating pipes of water tank in car heat exchanger made from aluminum alloy, and dedicated device

InactiveCN101092000AOvercoming Pollution DefectsRealize green industrial productionLiquid surface applicatorsWelding/cutting media/materialsEngineeringMachining process

The invention relates to a machining method and special device for vehicle aluminum alloy heat exchange water tank radiator pipe. It puts the machining radiator pipe between two rollers of special device, which has flux on the surface. The flux would coat equally onto the surface of radiator pipe. The special device includes upper roller and down roller. The down part of driving upper roller drainage wheel and down roller is dipped in stock solution slot containing flux solution. The invention decreases a machining process, shortens machining time, improves producing efficiency, and decreases pollution to environment. The defective fraction of using the method could be under 0.3%. And the surface of the product is smoothing and bright.

Owner:林世东

Two-piece compactor wheel tip

A compactor tip (10) assembly for a landfill or soil compactor comprises a base (200) and a tip that are formed from dissimilar materials. The tip (100) may be formed from high carbon steel for wear resistance, while the base (200) may be formed from low carbon steel for easy welding. The compactor tip assembly is attached to the compactor wheel by welding the base to the wheel. The tip and the base each have ground engaging surfaces (101, 201) which may be complementary to one another. A hollow pocket (11) may be formed through the base and in the tip.

Owner:CATERPILLAR INC

4d printing method for in-situ regulation of functional properties of nickel-titanium alloy and use thereof

PendingUS20210394269A1Easy to prepareBroaden applicationAdditive manufacturing apparatusTransportation and packagingNiti alloyManufacturing technology

Owner:SOUTH CHINA UNIV OF TECH +2

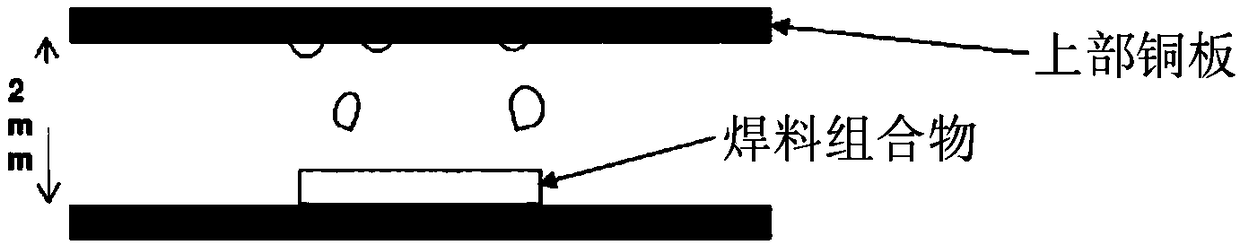

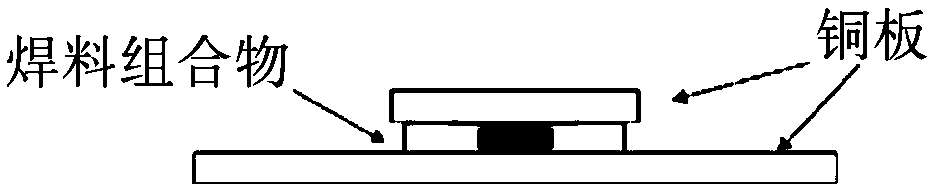

Solder composition

PendingCN109414787ASuppression of scatteringWelding/cutting media/materialsWelding/soldering/cutting articlesSilicone oilSilicon

Owner:KOKI

Machine tool, its manufacture method and welding plate therefor

InactiveCN100415434CContains inhomogeneityTool workpiece connectionReaming toolsVolumetric Mass DensityThermal expansion

The invention relates to a machine tool with a tool shank (10) and a cutting head (12) made from different materials, which are joined to each other on opposite joint surfaces (14,16) in a positive material fit by means of a joint layer (18') made of a ductile solder material. According to the invention, in order to obtain a solder connection which is substantially stress-free, powder particles (31) made of a temperature-resistant material with a thermal expansion coefficient which is lower than the solder material (30) are embedded into the joint layer (18') and the density of the powder particles (31) varies along the entire thickness of the joint layer (18').

Owner:KOMET GROUP GMBH

Method for providing a welded joint between dissimilar materials

PendingUS20200246896A1Improve mechanical propertiesWelding/cutting media/materialsWelding/soldering/cutting articlesMetallurgySolder material

Owner:CENT RICERCHE FIAT SCPA

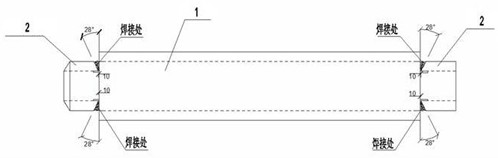

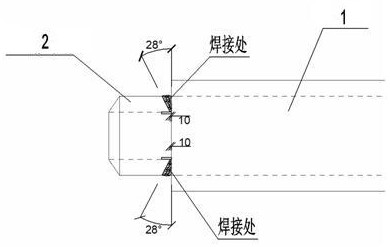

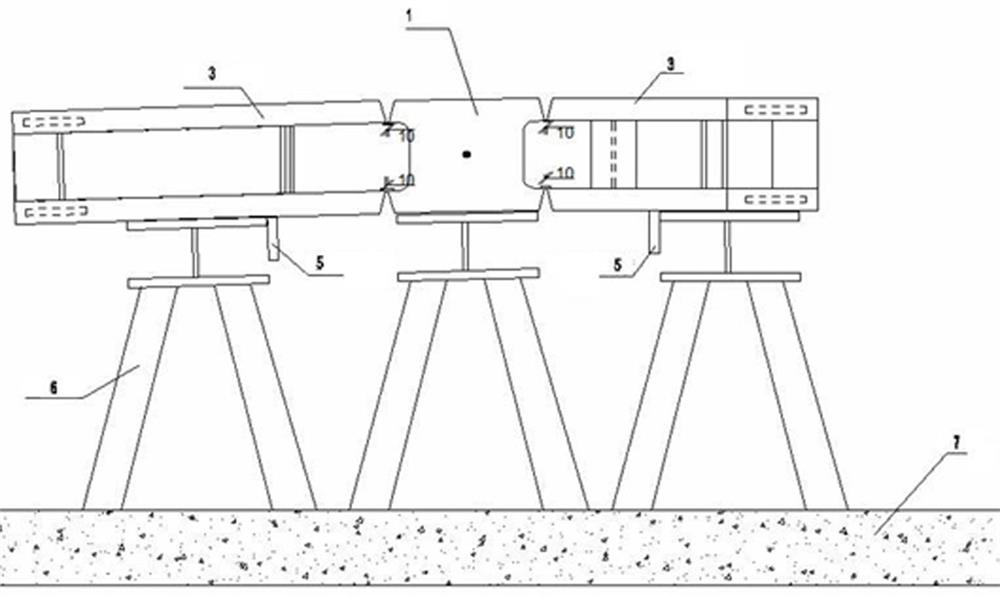

Assembling and welding method for truss layer corner column

PendingCN114515917AImprove securityReduce the amount of weldingFurnace typesWelding/soldering/cutting articlesStructural engineeringWeld seam

Owner:中冶(上海)钢结构科技有限公司

Copper surface treating agent and surface treatment method

InactiveCN101668883ASoldering apparatusMetallic material coating processesHeat resistanceSolderability

Disclosed is a copper surface treating agent satisfying both heat resistance and solderability. Also disclosed is a surface treatment method. Specifically disclosed is a copper surface treating agentcontaining an acid, a benzimidazole compound and water, which is characterized in that at least a first benzimidazole compound and a second benzimidazole compound having a melting point lower than that of the first benzimidazole compound by 70 DEG C or more are contained as the benzimidazole compound.

Owner:MEC CO LTD

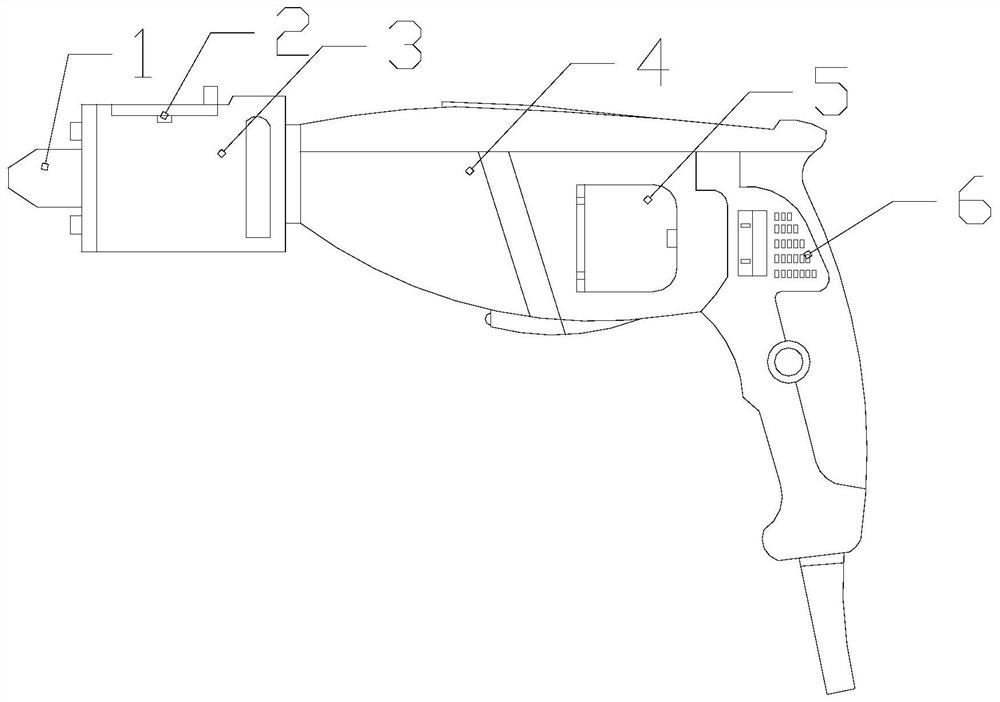

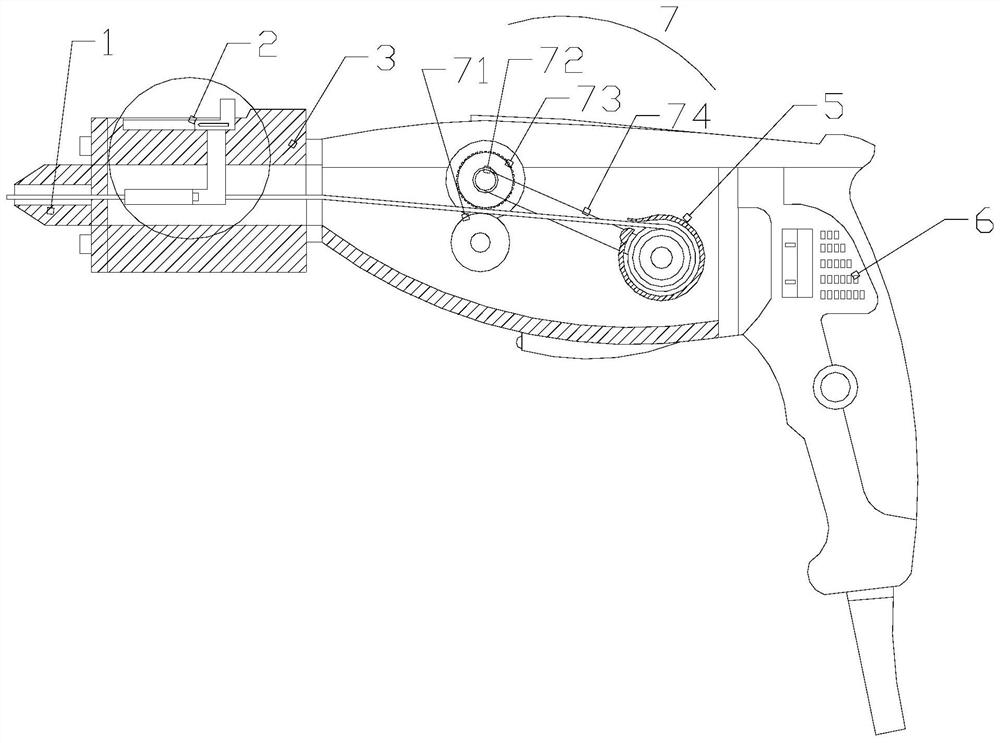

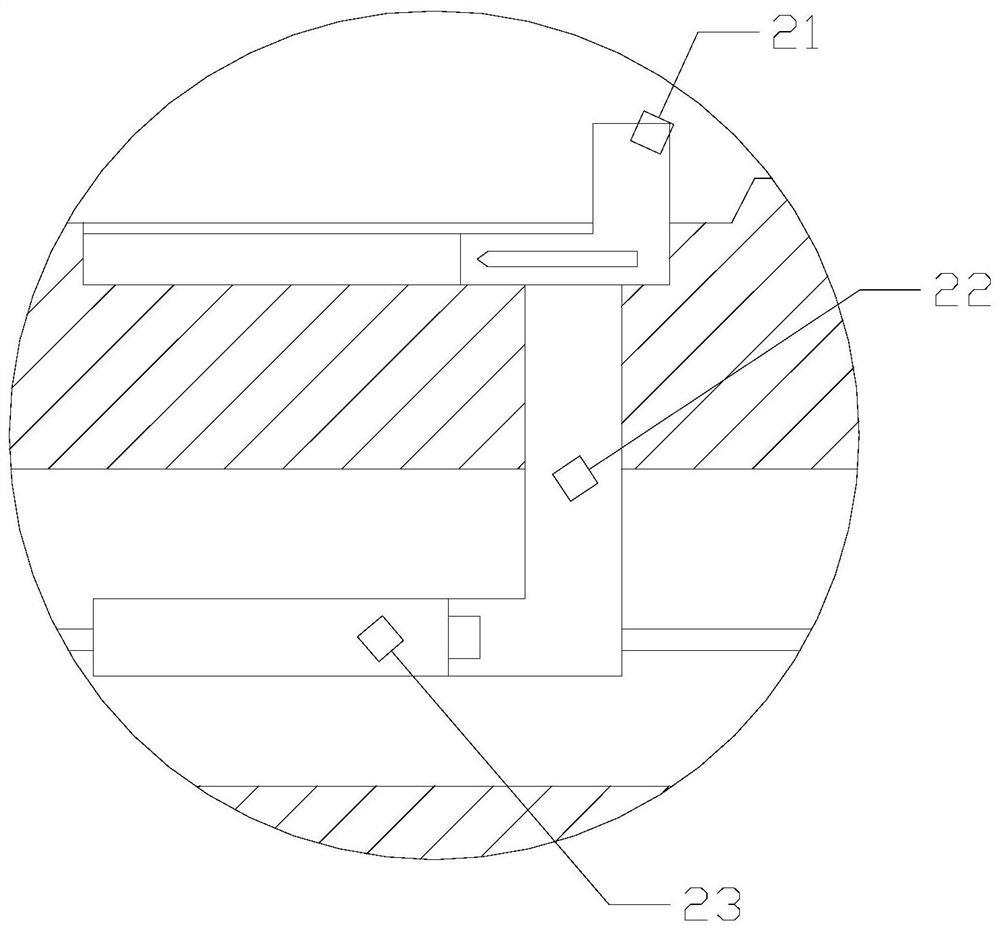

Circuit board welding gun achieving automatic feeding

InactiveCN111745248AWelding/soldering/cutting articlesMetal working apparatusElectrical and Electronics engineeringSoldering gun

Owner:蔡彪

Method for ultrasonic welding of copper thin plate and nickel thin plate

ActiveCN111843169AGood dispersionNot easily oxidizedWelding/soldering/cutting articlesNon-electric welding apparatusPower batteryElectrical resistance and conductance

The invention discloses a method for ultrasonic welding of a copper thin plate and a nickel thin plate. The method comprises the steps that the portion between the to-be-welded copper thin plate and the to-be-welded nickel thin plate is coated with nano nickel formate particles to form a middle layer with the thickness of 15-45 microns; before the middle layer is coated, the copper thin plate andthe nickel thin plate are immersed in a dilute hydrochloric acid solution with the concentration of 4.5%-8.8% to be washed for 5-10 minutes, and then the middle layer is cleaned with pure alcohol andair-dried; and the copper thin plate and the nickel thin plate coated with the nano nickel formate particles as the middle layer are subjected to ultrasonic welding for 0.20-0.75 seconds at the welding pressure of 30-60 psi, wherein the welding amplitude is 25-55 microns. According to the method, the nano nickel formate particles are used as the middle layer to assist ultrasonic welding of the copper thin plate and the nickel thin plate, the maximum shearing strength can reach 2898 N, the joint resistance is less than 102 microhm, the mechanical property and conductive performance of a joint are improved, and the requirement of the automobile power battery industry for ultrasonic welding of copper / nickel joints can be met.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

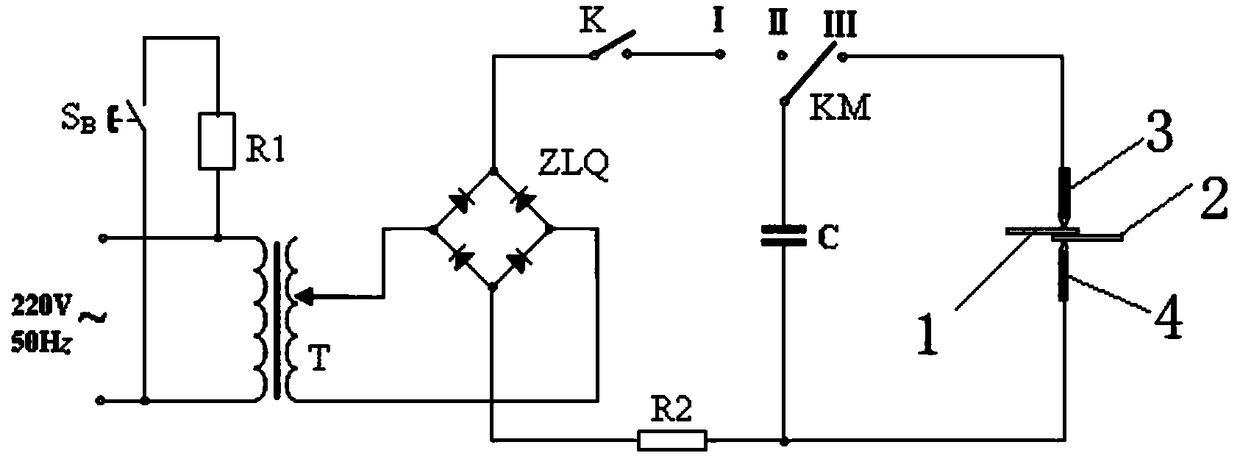

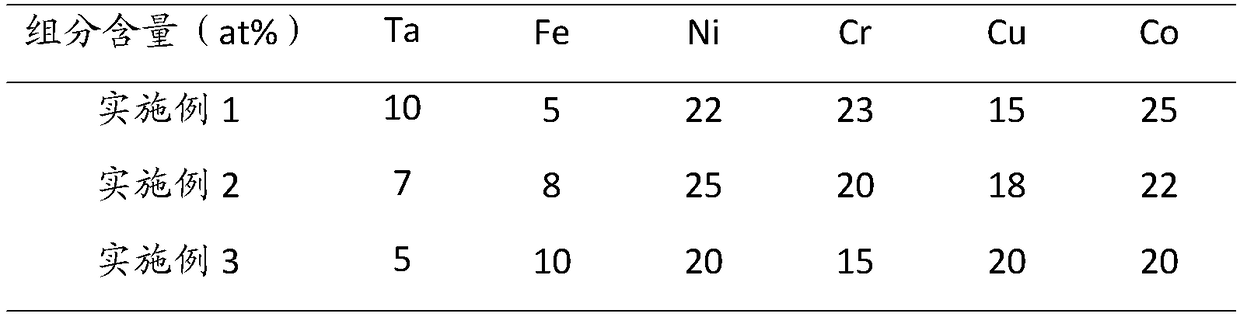

Intermediate layer alloy applied to resistance spot-welding of tantalum Ta1 and Q235 and preparation method thereof

ActiveCN109202244AImprove matchImproved comprehensive mechanical properties of jointsWelding/cutting media/materialsWelding/soldering/cutting articlesElectrical resistance and conductanceSpot welding

Owner:XIAN UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap