Bonding apparatus

a technology of bonding apparatus and bonding surface, which is applied in the direction of soldering apparatus, auxillary welding devices, manufacturing tools, etc., can solve the problems of large inertia and special difficulty in bonding small balls, and achieve the effect of large bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

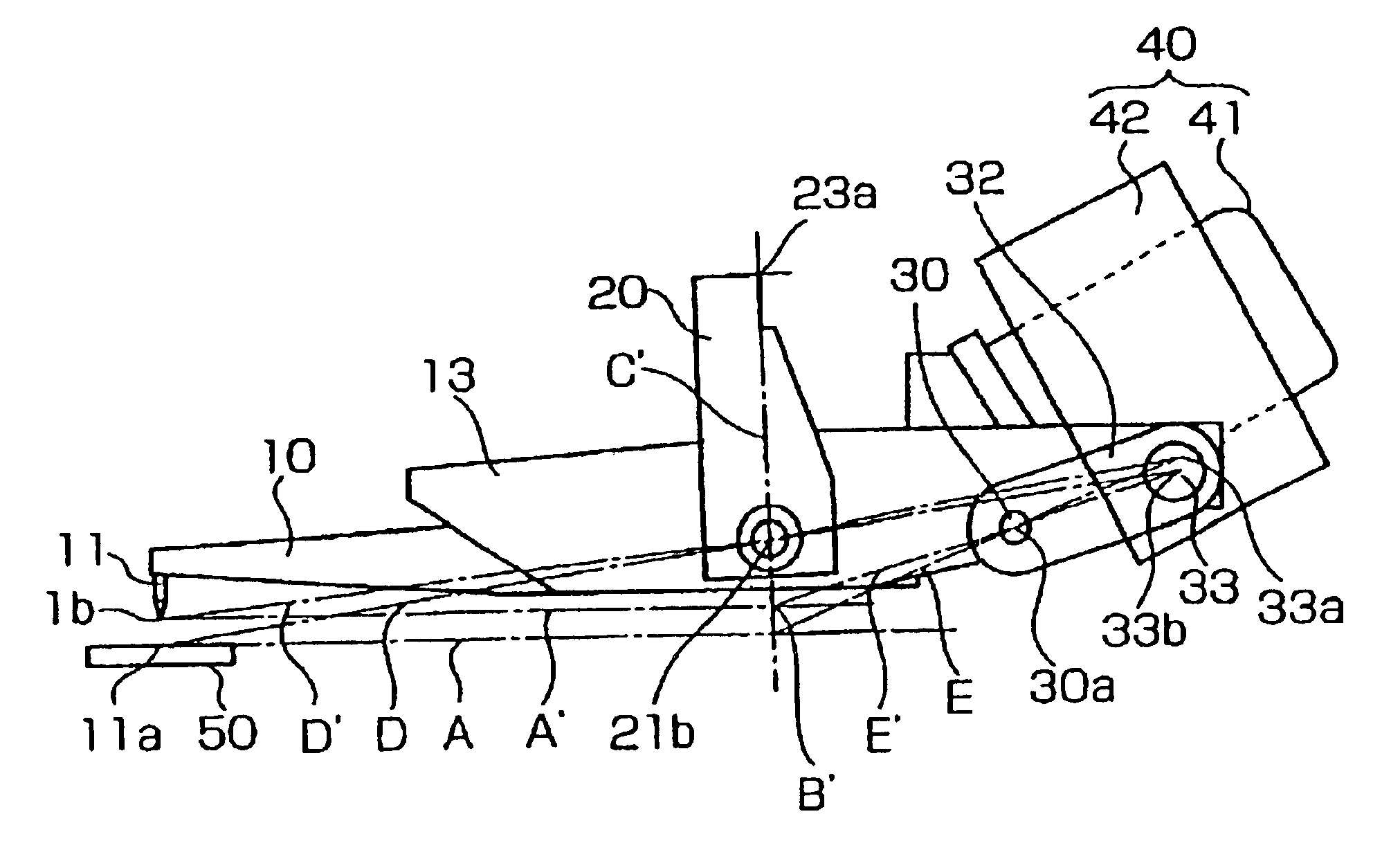

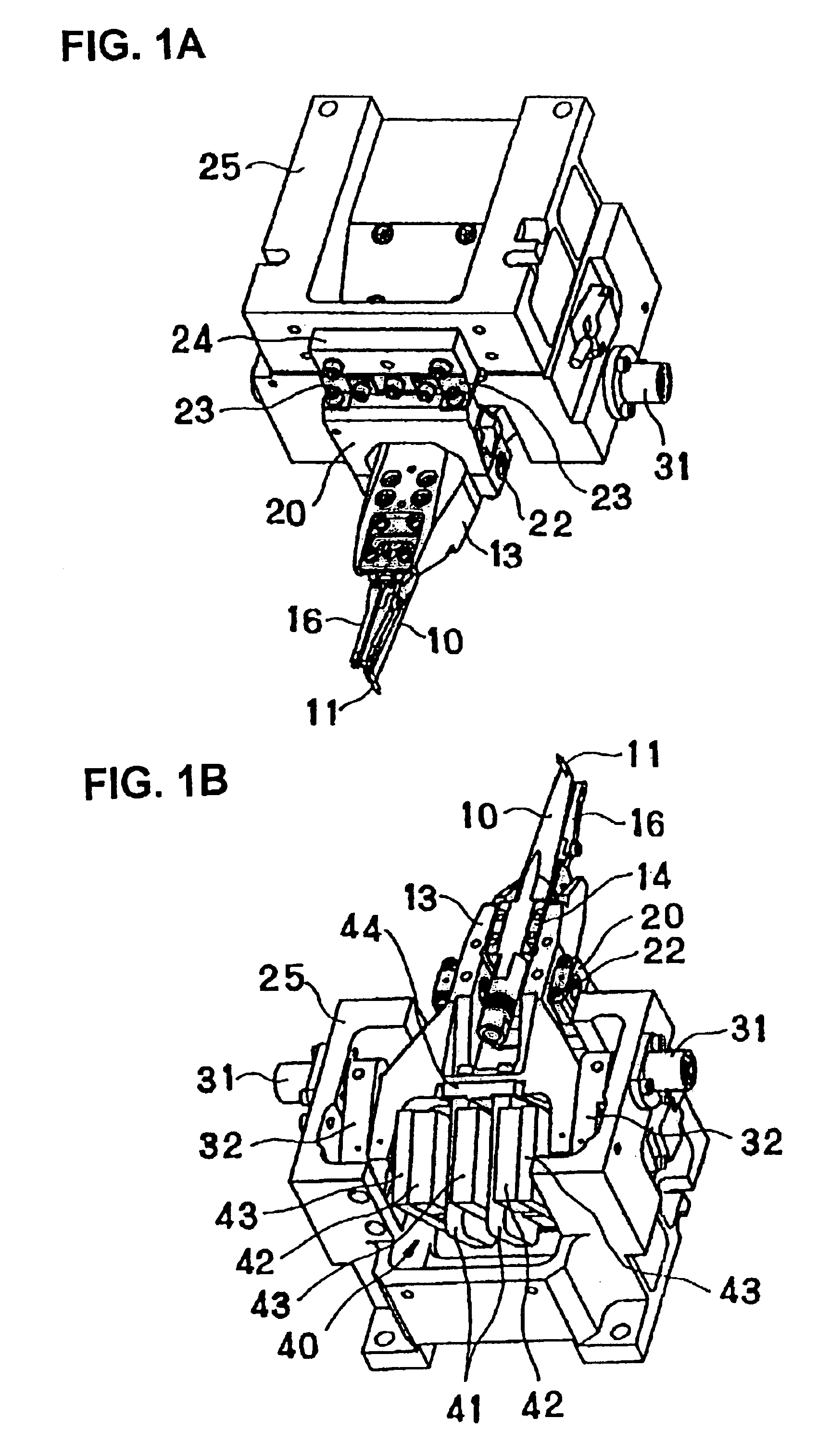

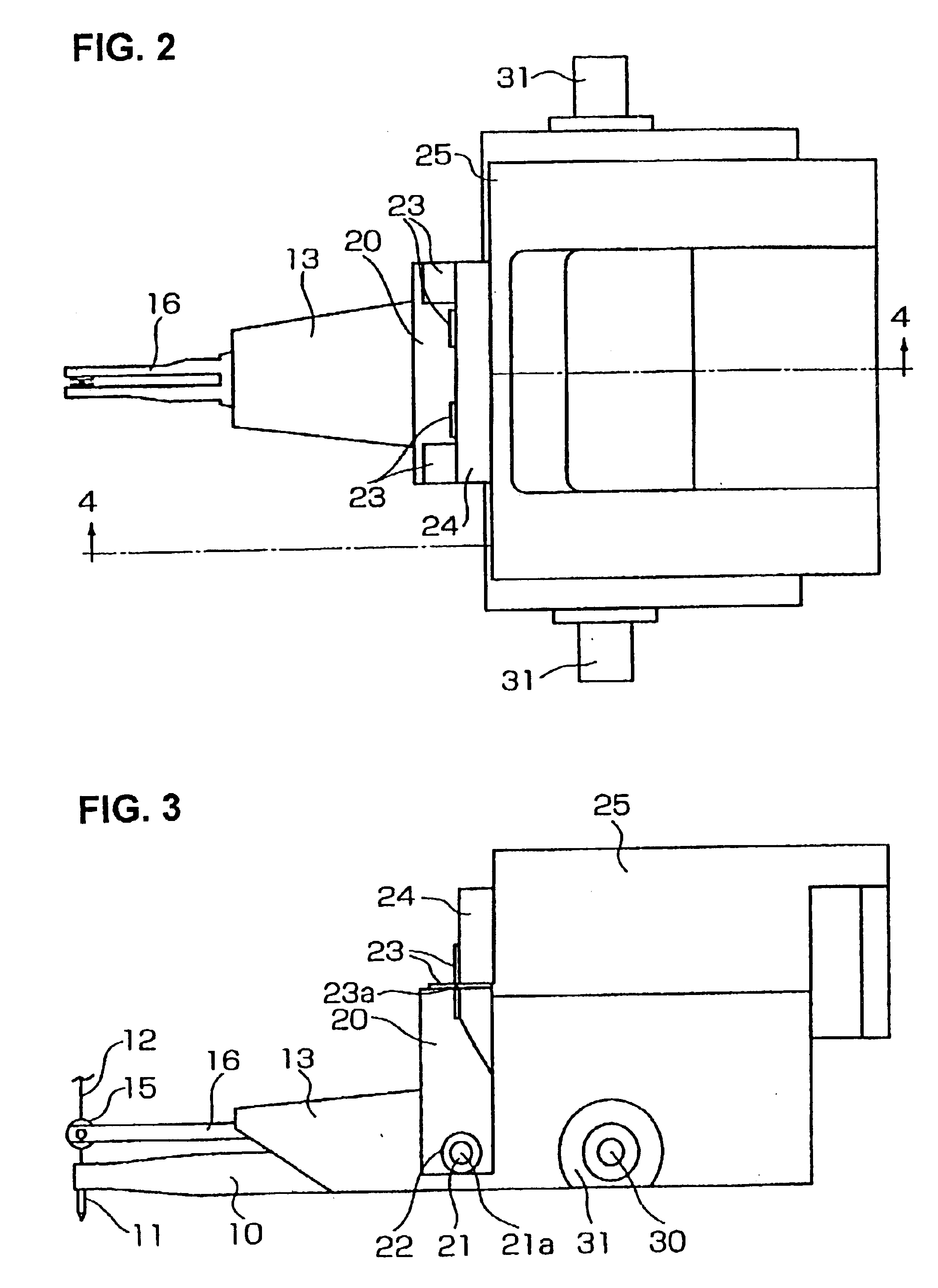

Embodiments of the bonding apparatus of the present invention will be described below with reference to the accompanying drawings.

As shown in FIG. 1 and FIGS. 3 through 5, a capillary 11 is fastened to the tip end portion of an ultrasonic horn 10, and a wire 12 which is wound on a wire spool (not shown) passes through the capillary 11. The ultrasonic horn 10 is disposed in a recess formed in the undersurface of a horn holder 13 and is fastened to the horn holder 13 via a connecting plate 14 which has a node part 14a that constitutes a node of vibration of the ultrasonic horn 10. Furthermore, a clamping arm 16 which has a wire damper 15 that holds the wire 12 is disposed above the ultrasonic horn 10, and this clamping arm 16 is fastened to the horn holder 13.

The horn holder 13 is disposed inside the bifurcate shape of a swing arm 20 which is open at the bottom, and horn holder supporting shafts 21 which are fastened to both side surfaces of the horn holder 13 are supported on the swing

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap