Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about "Auxillary welding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

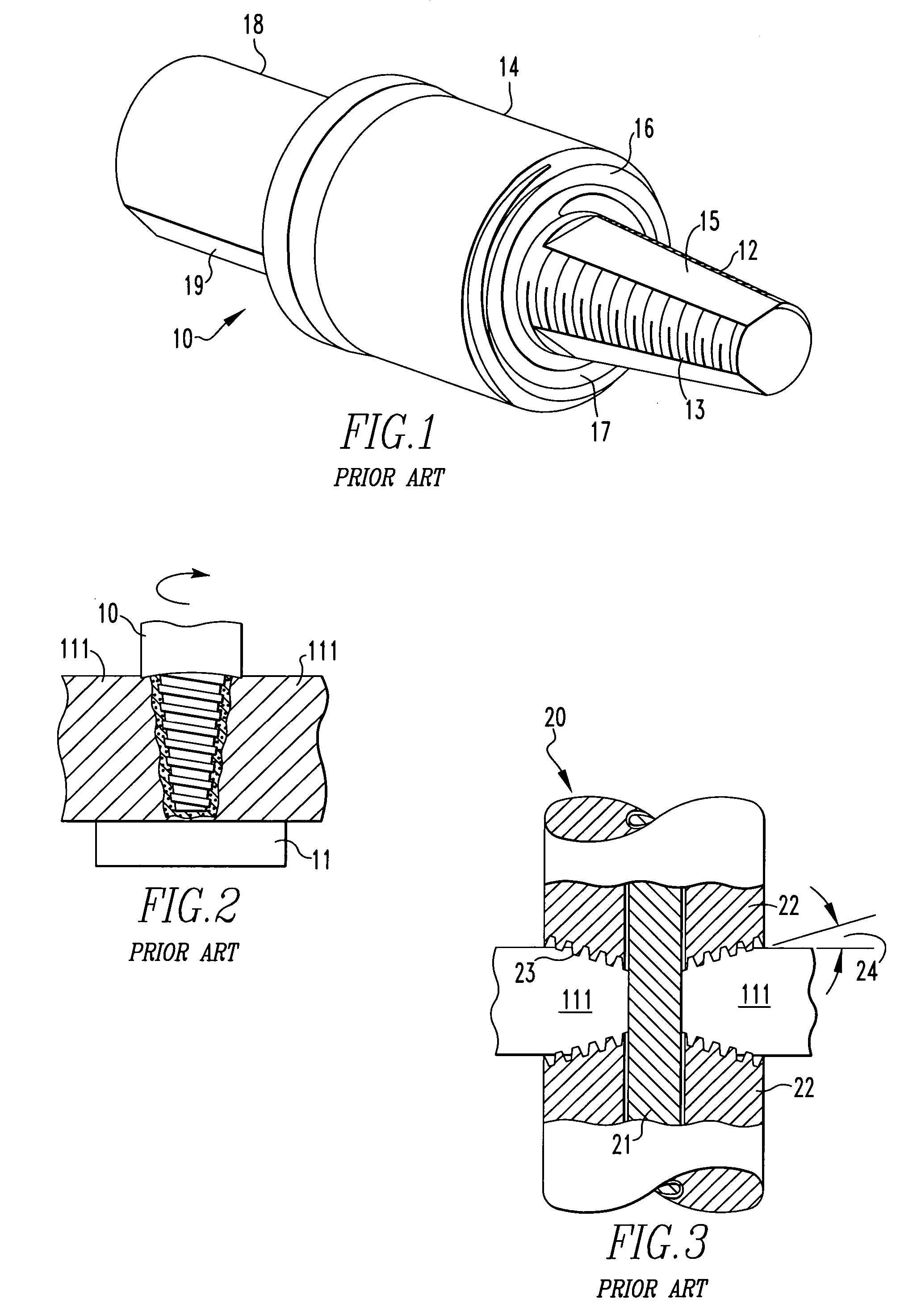

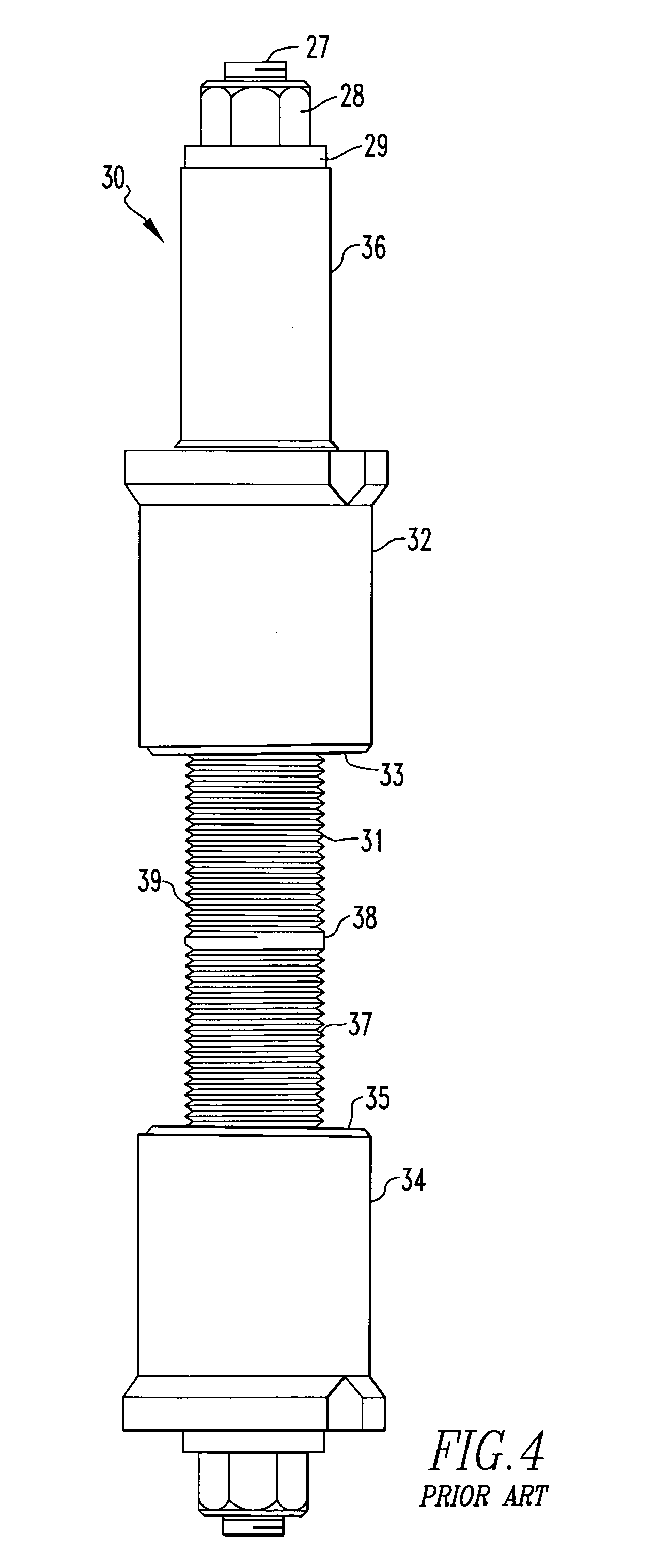

Multi-shouldered fixed bobbin tools for simultaneous friction stir welding of multiple parallel walls between parts

Owner:ARCONIC INC

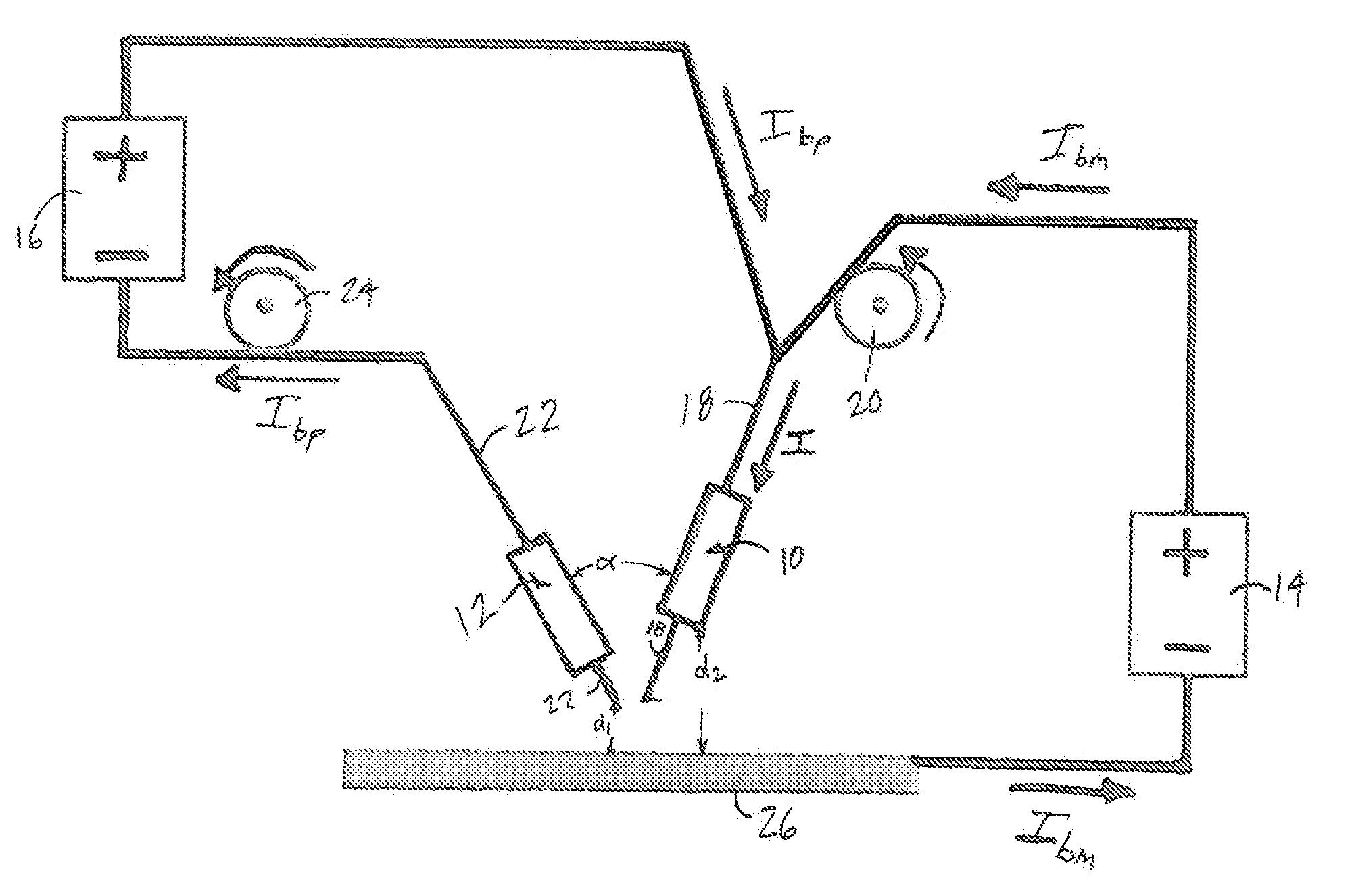

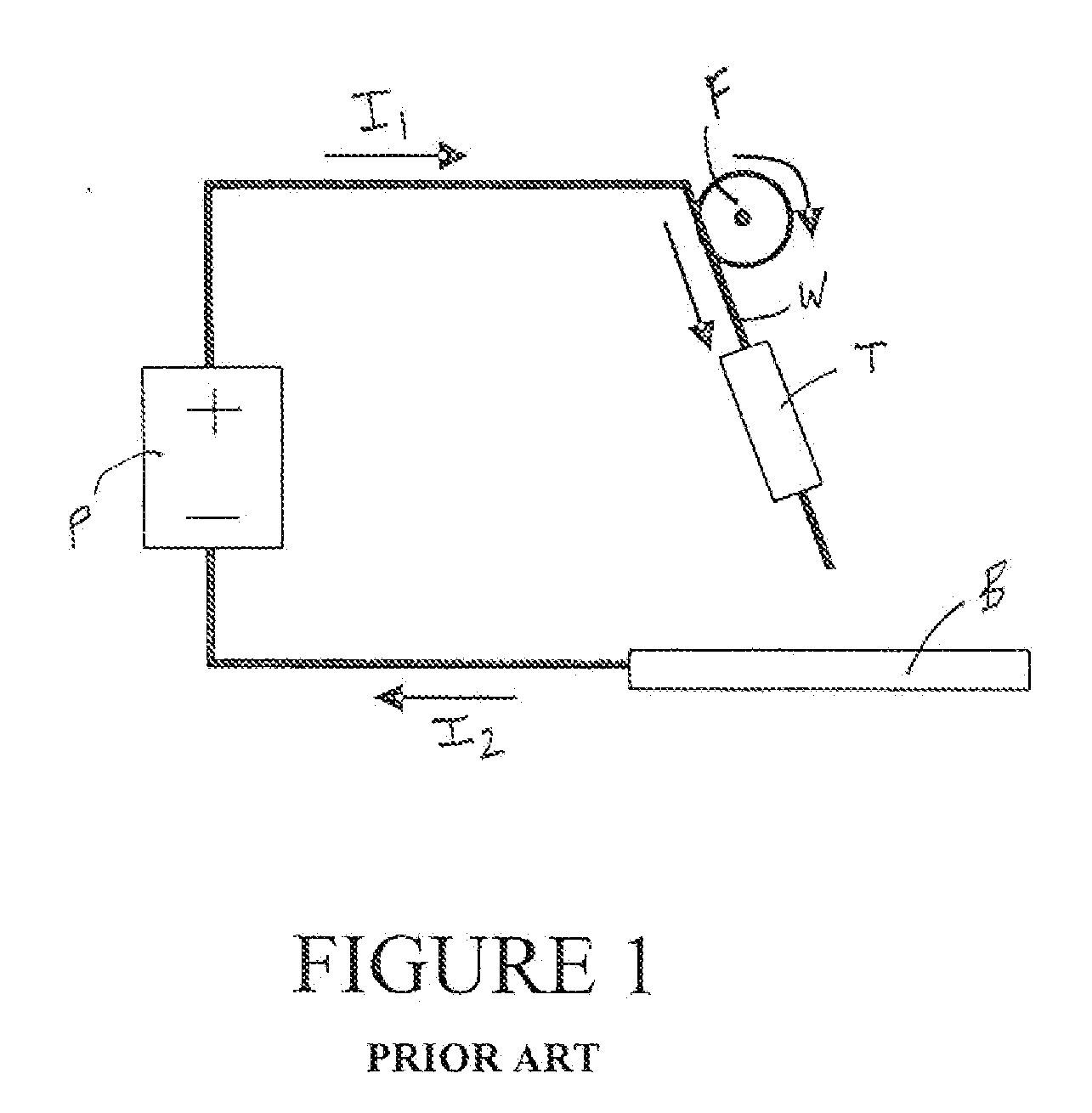

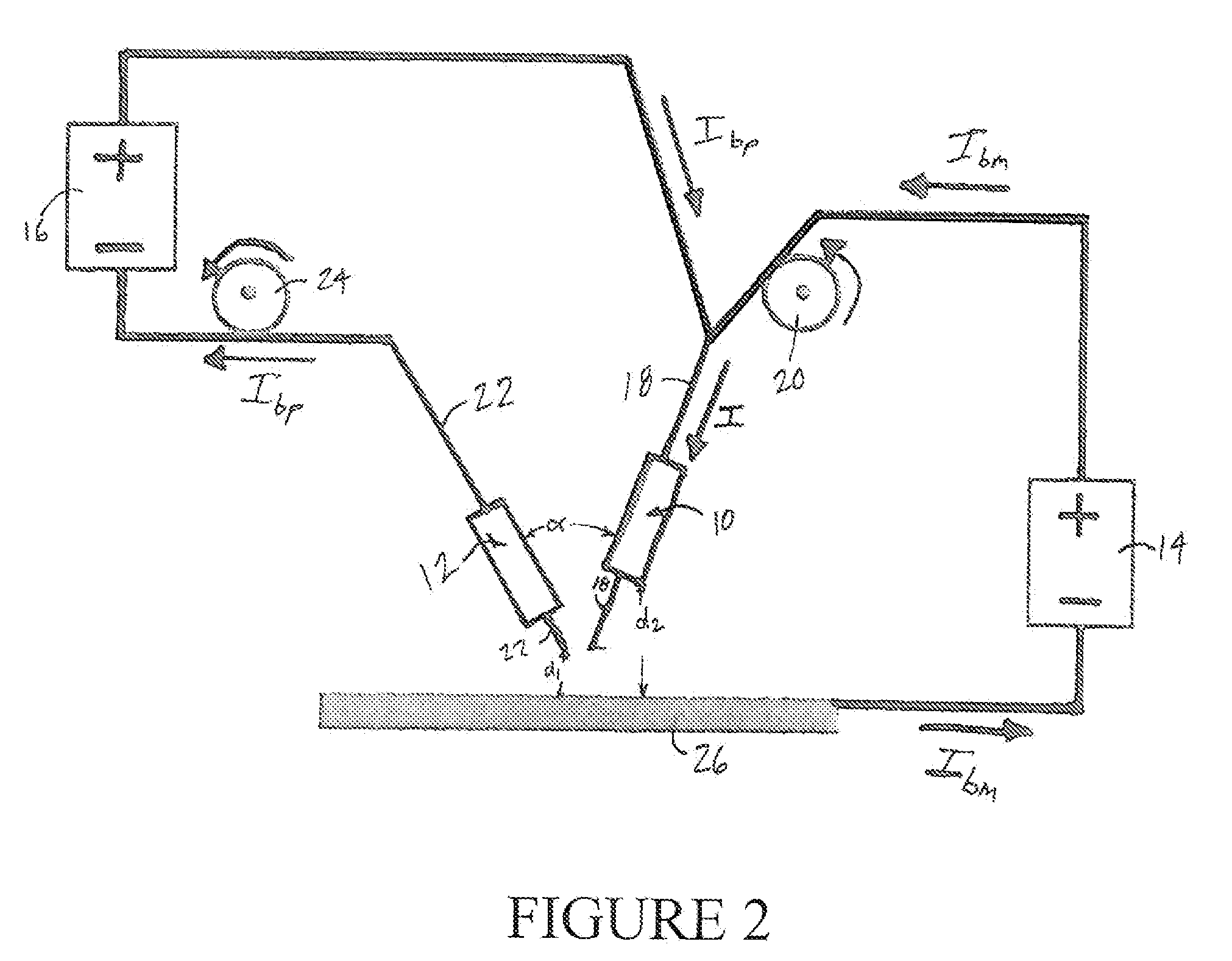

Arc Welder and Related System

ActiveUS20080190900A1Welding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

Owner:ZHANG YU MING

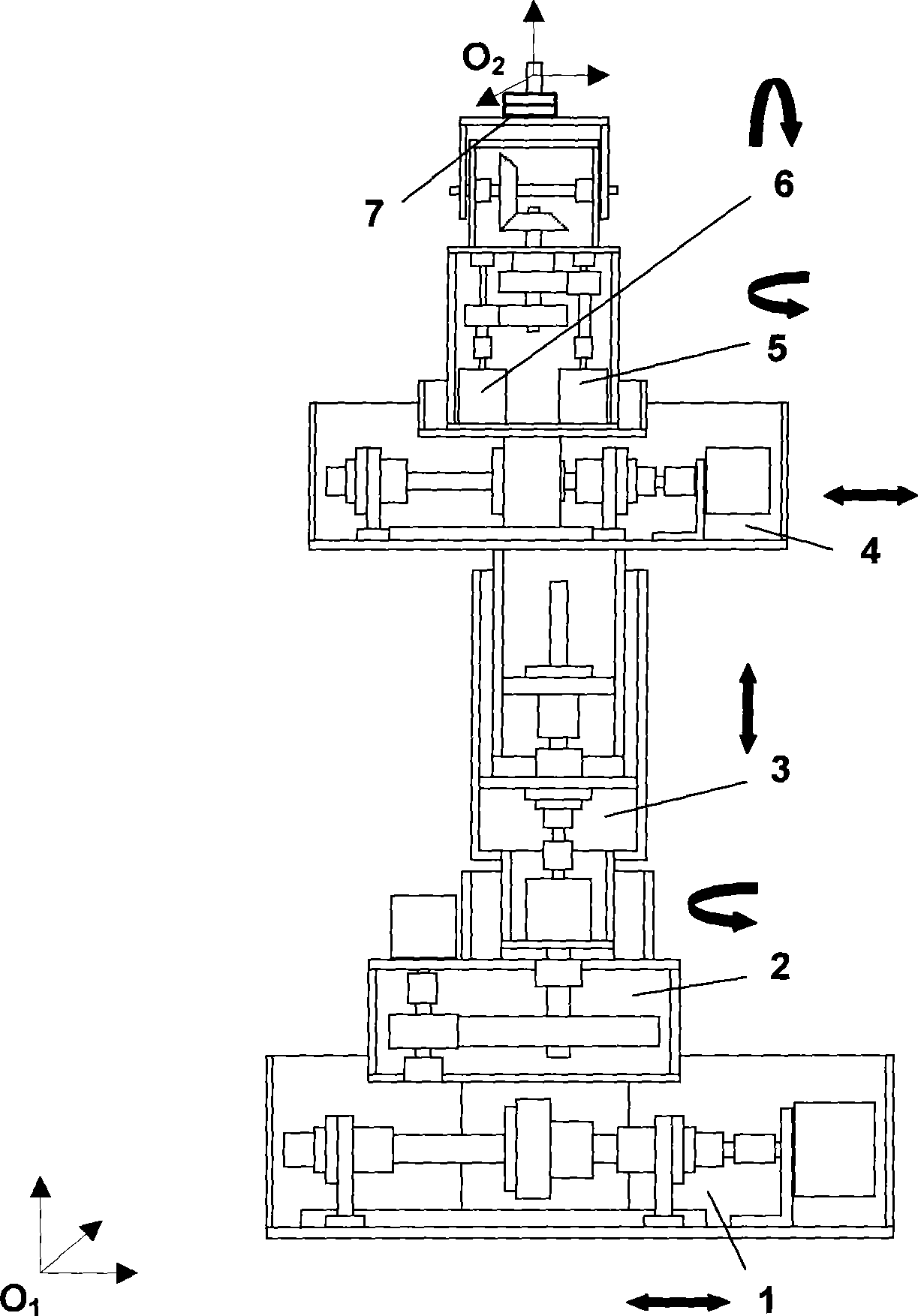

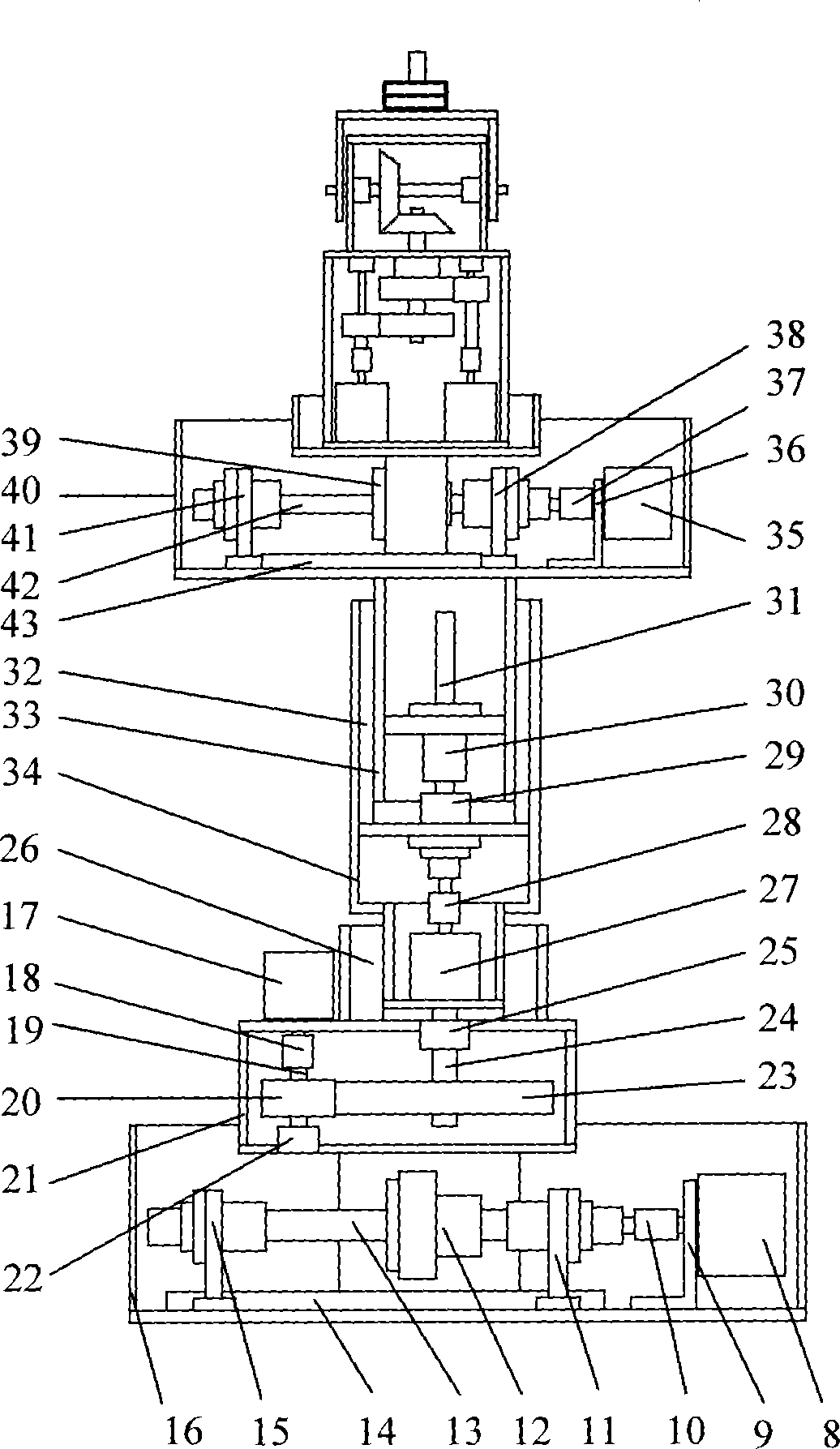

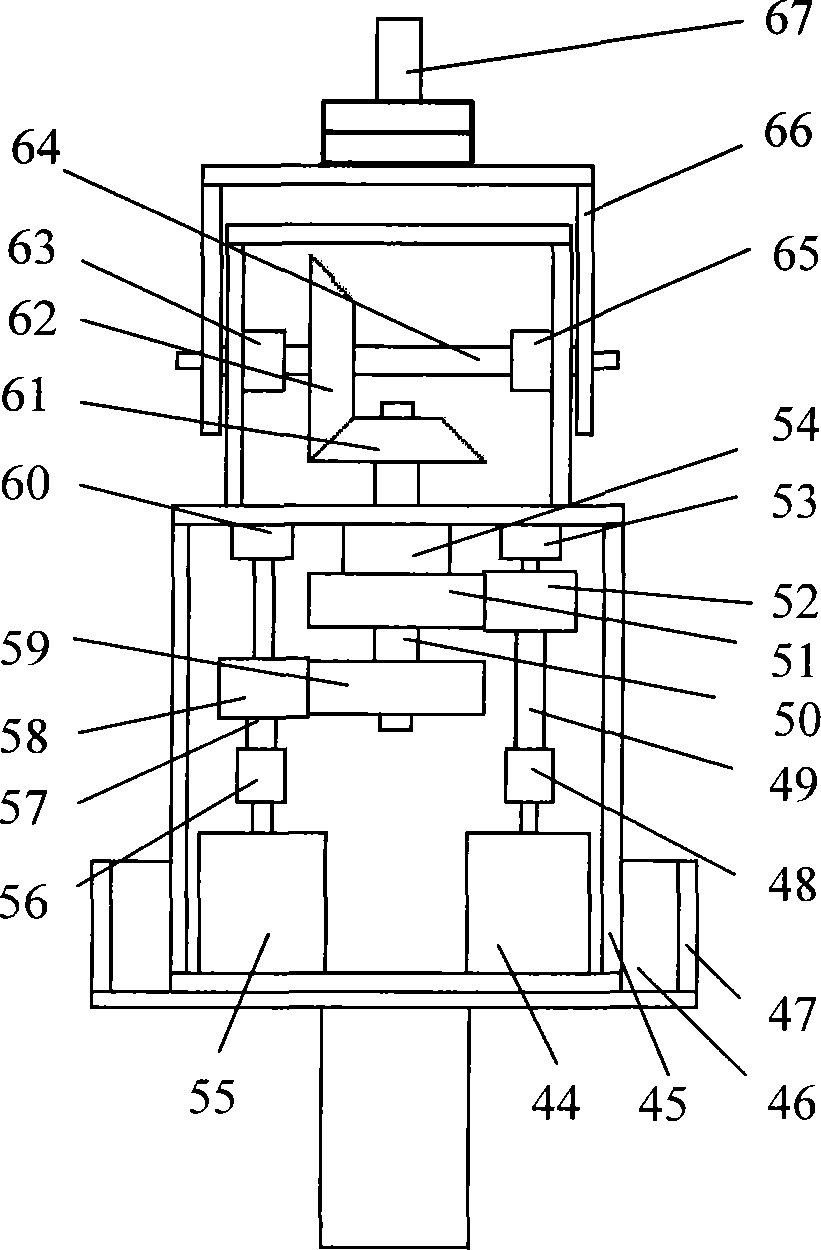

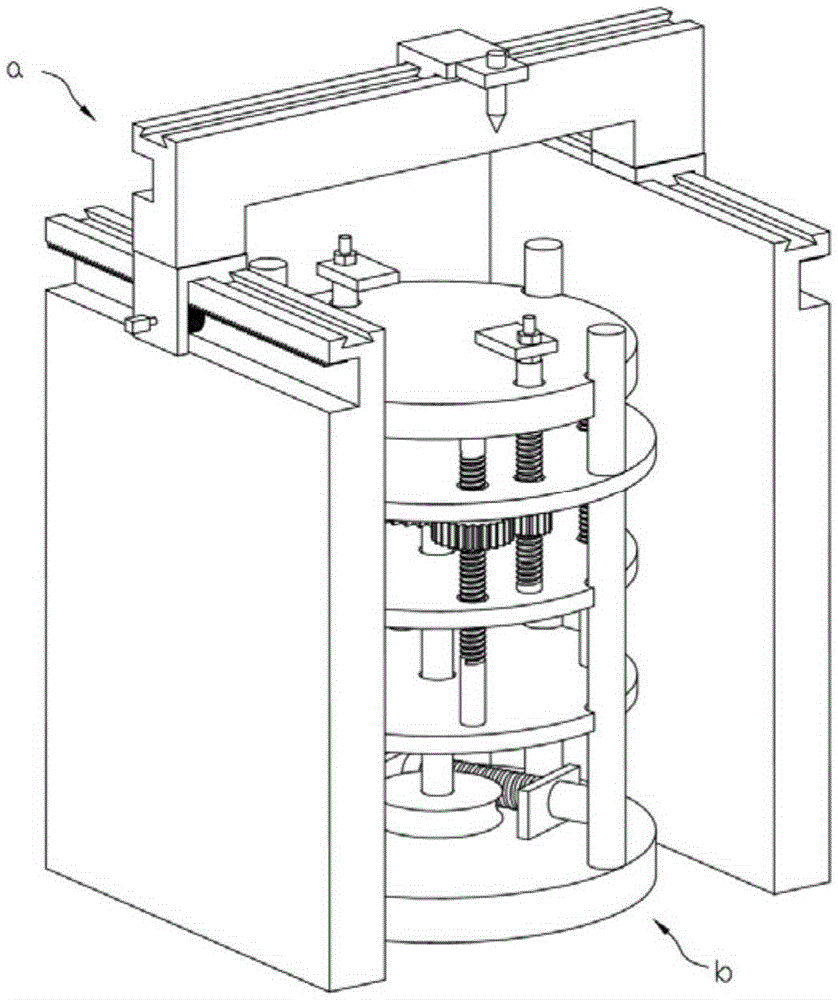

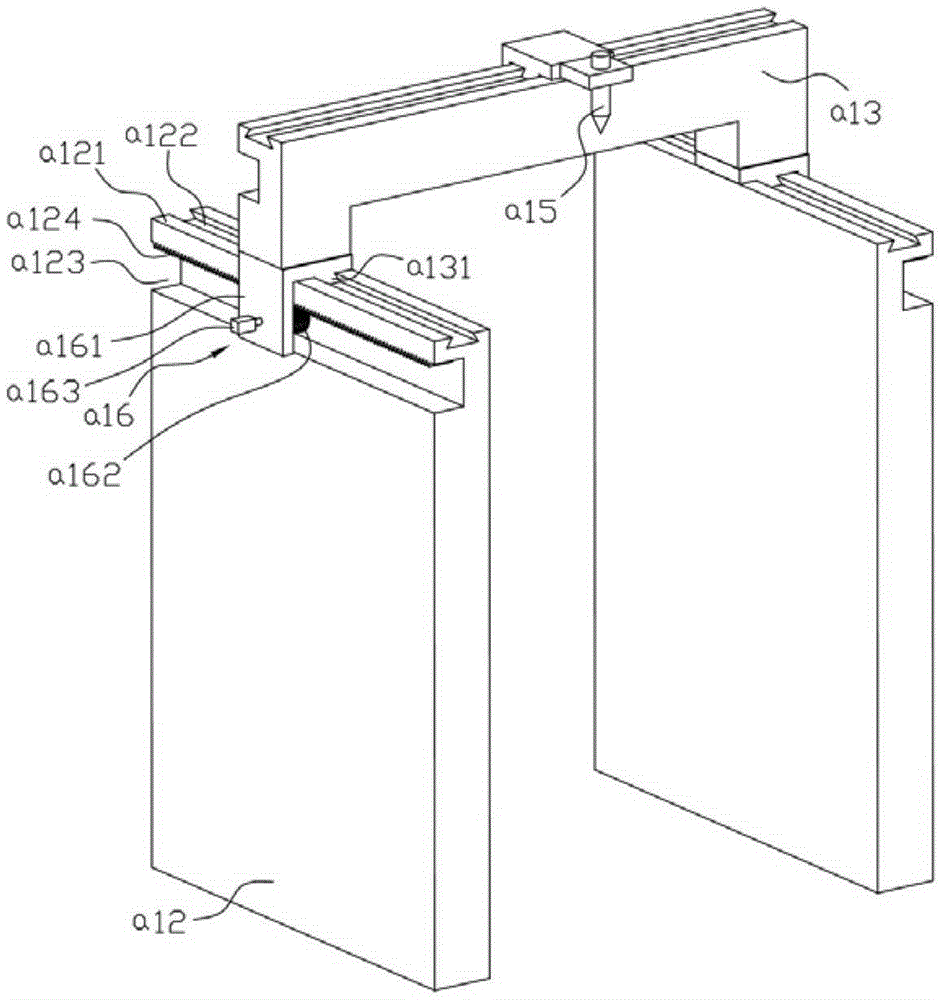

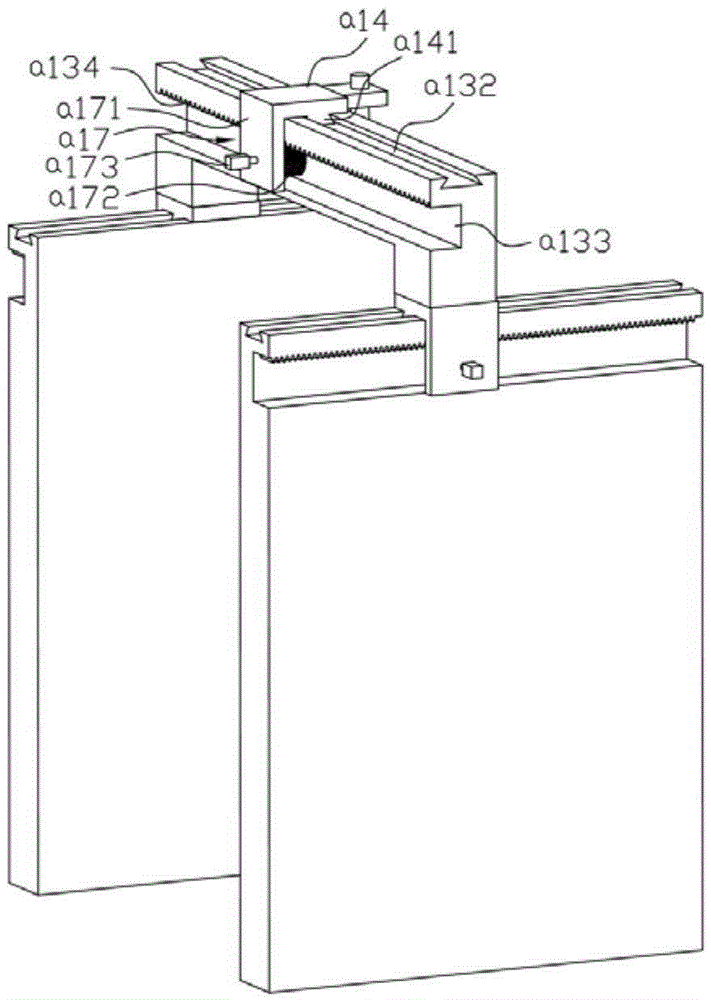

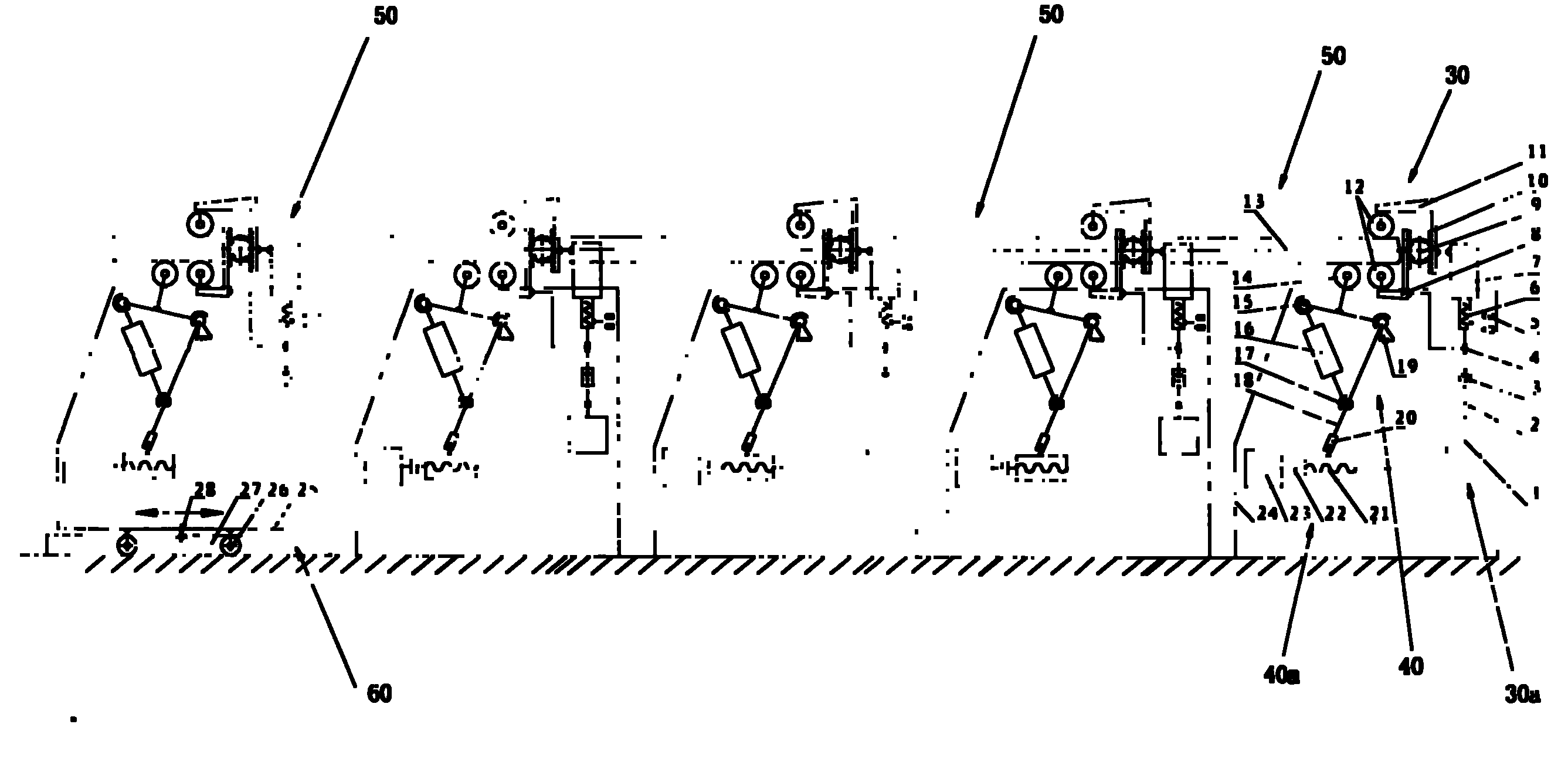

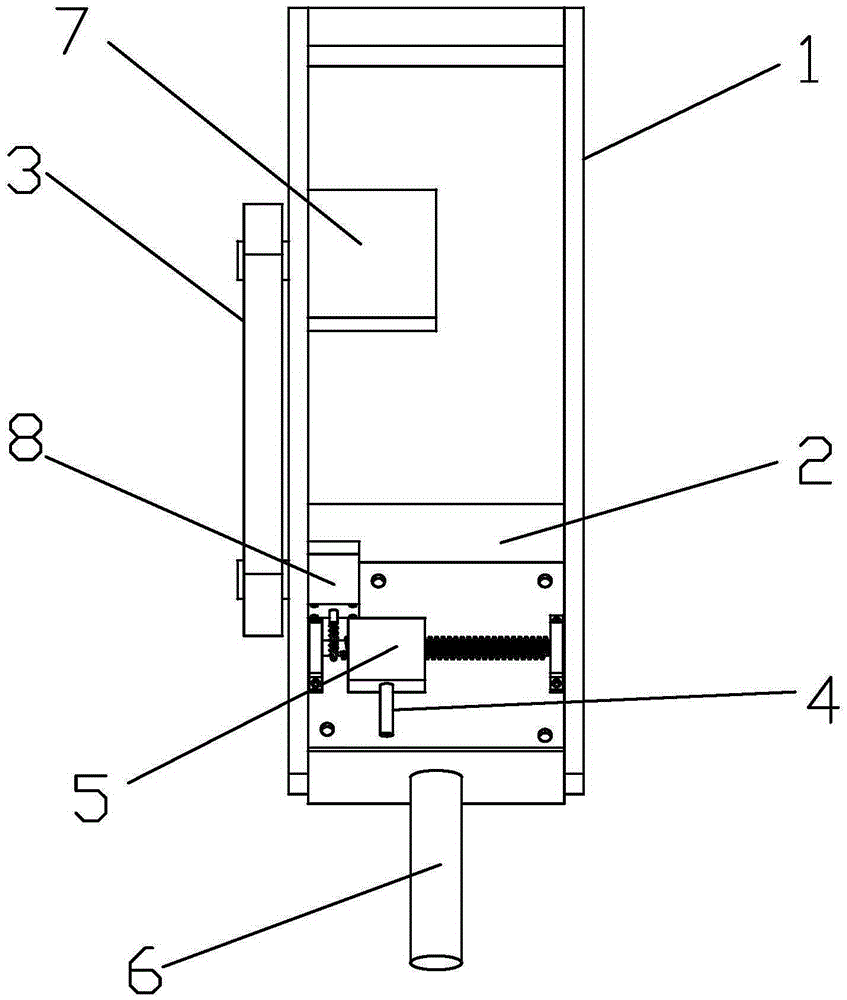

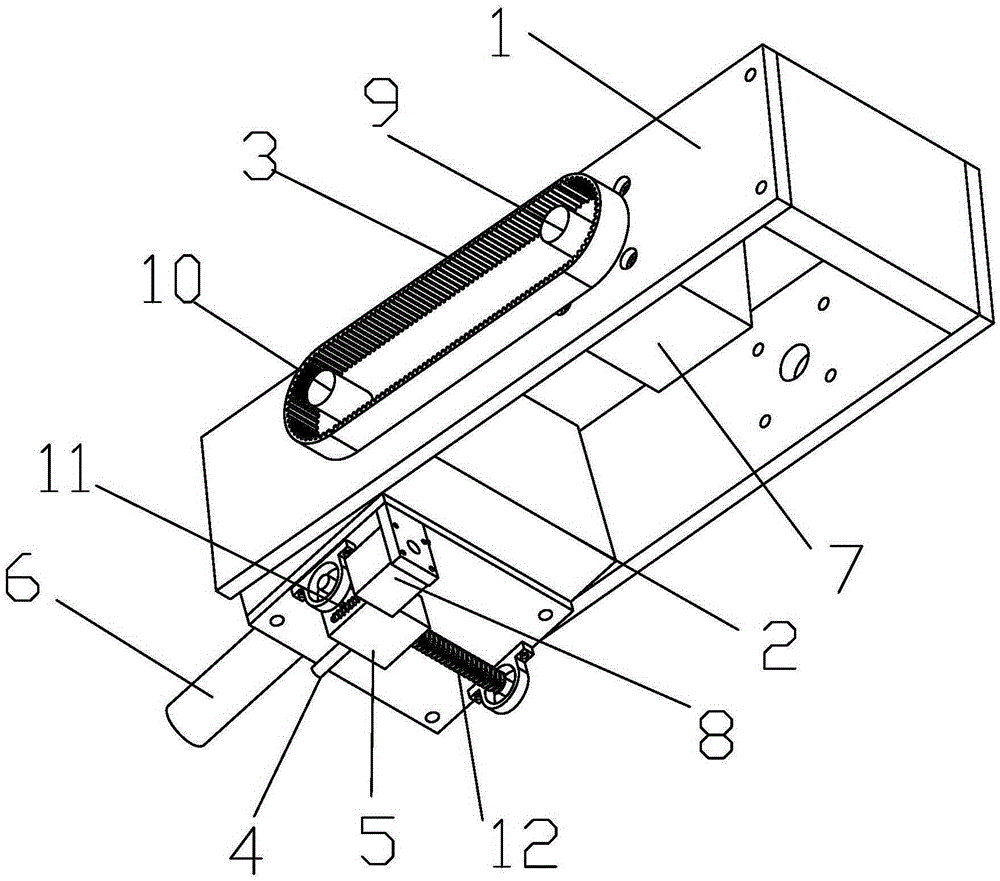

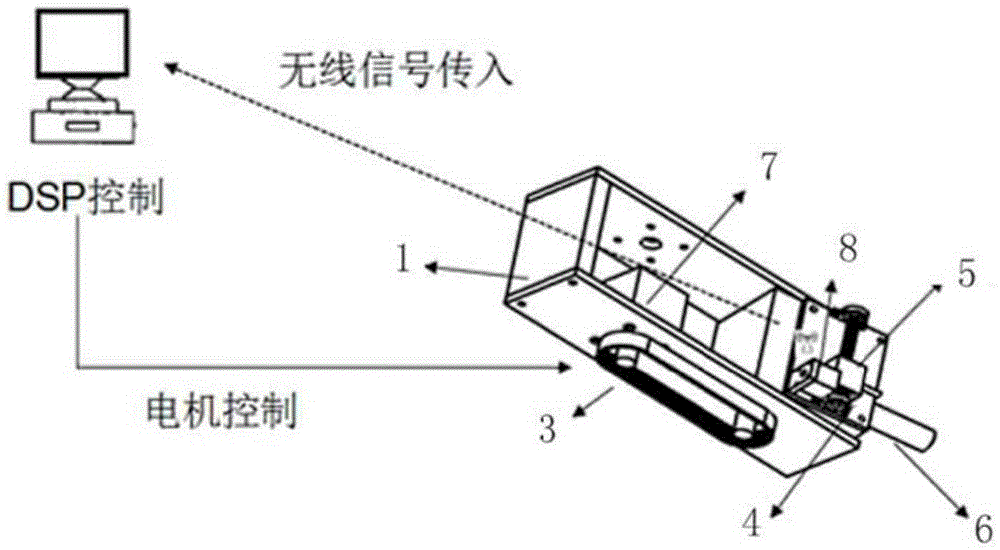

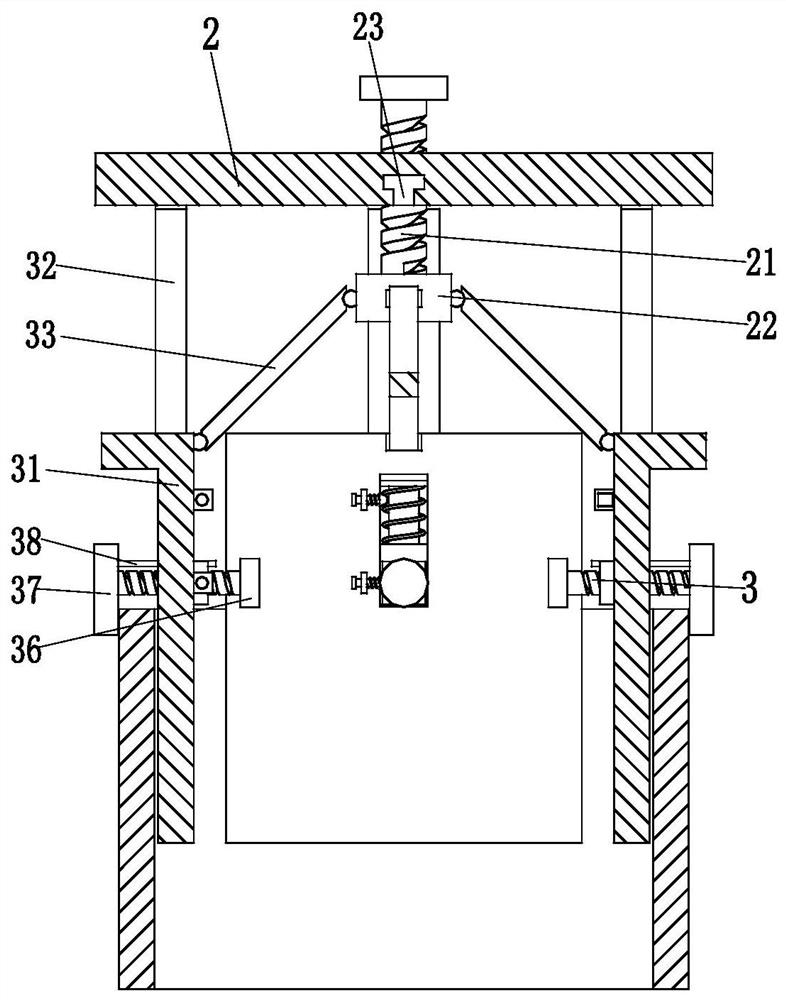

Flexible locating cramping apparatus controlled by servo

InactiveCN101249597AWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMultiple degrees of freedom

Owner:柳州远翅塑料有限公司

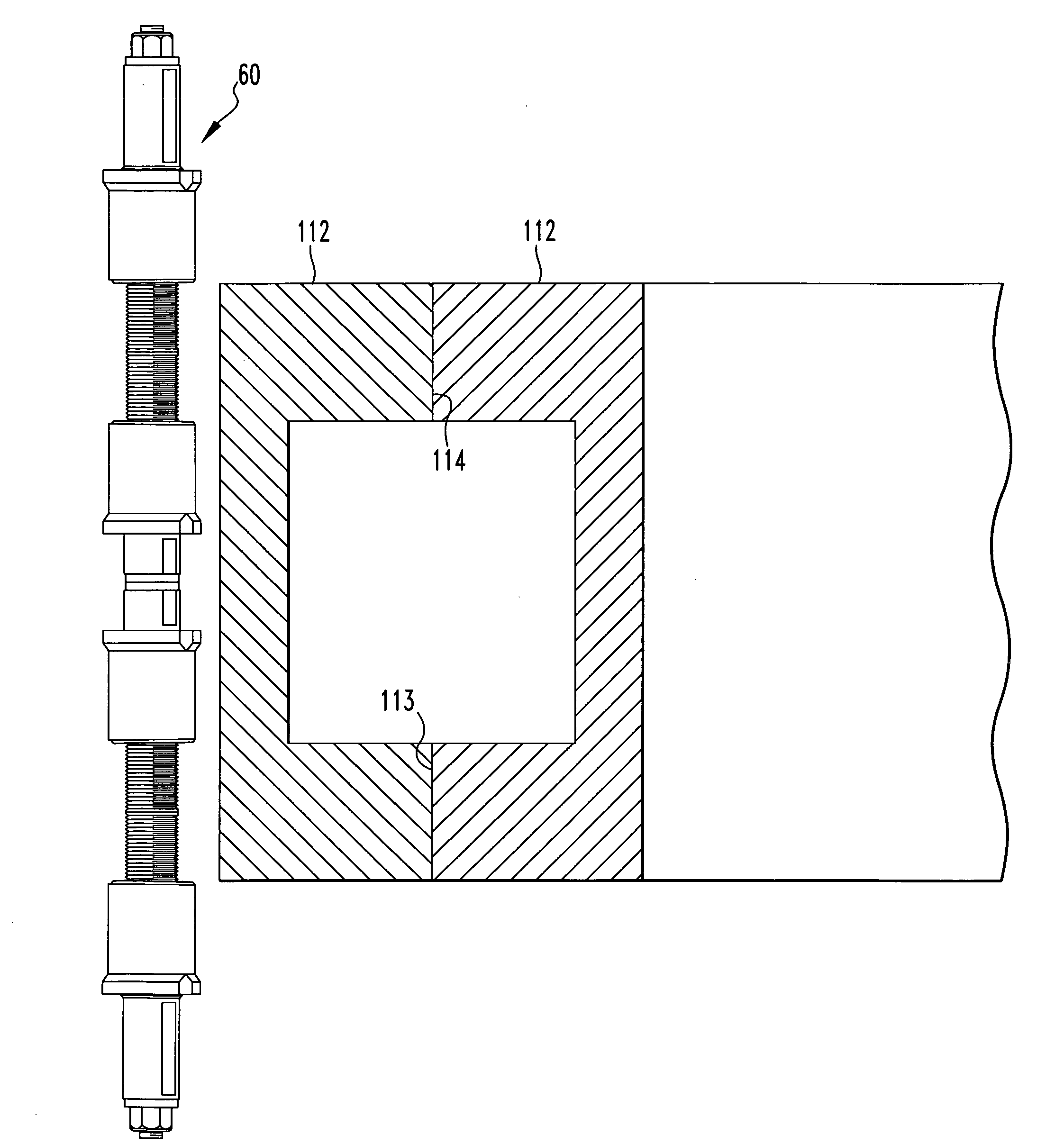

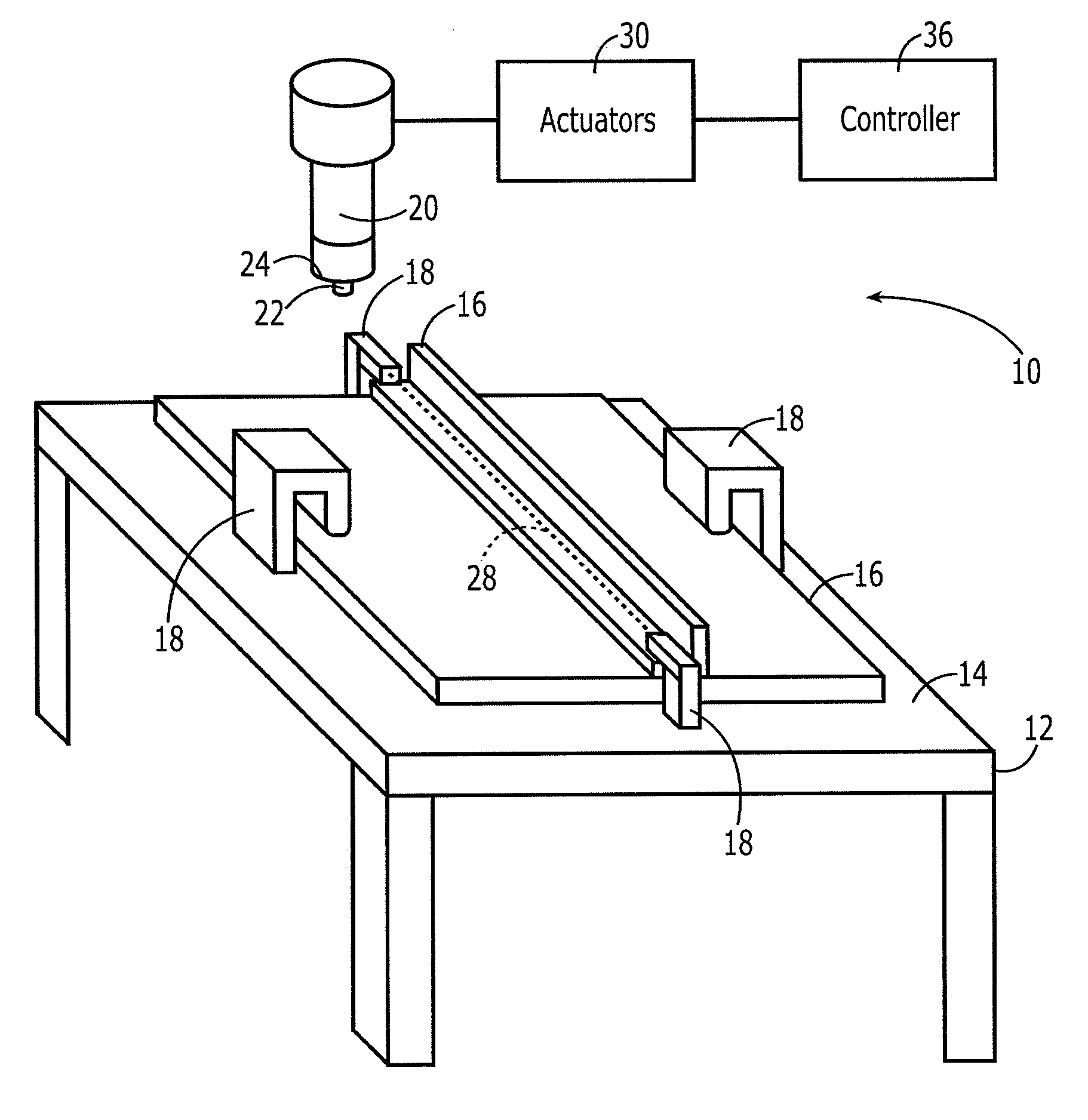

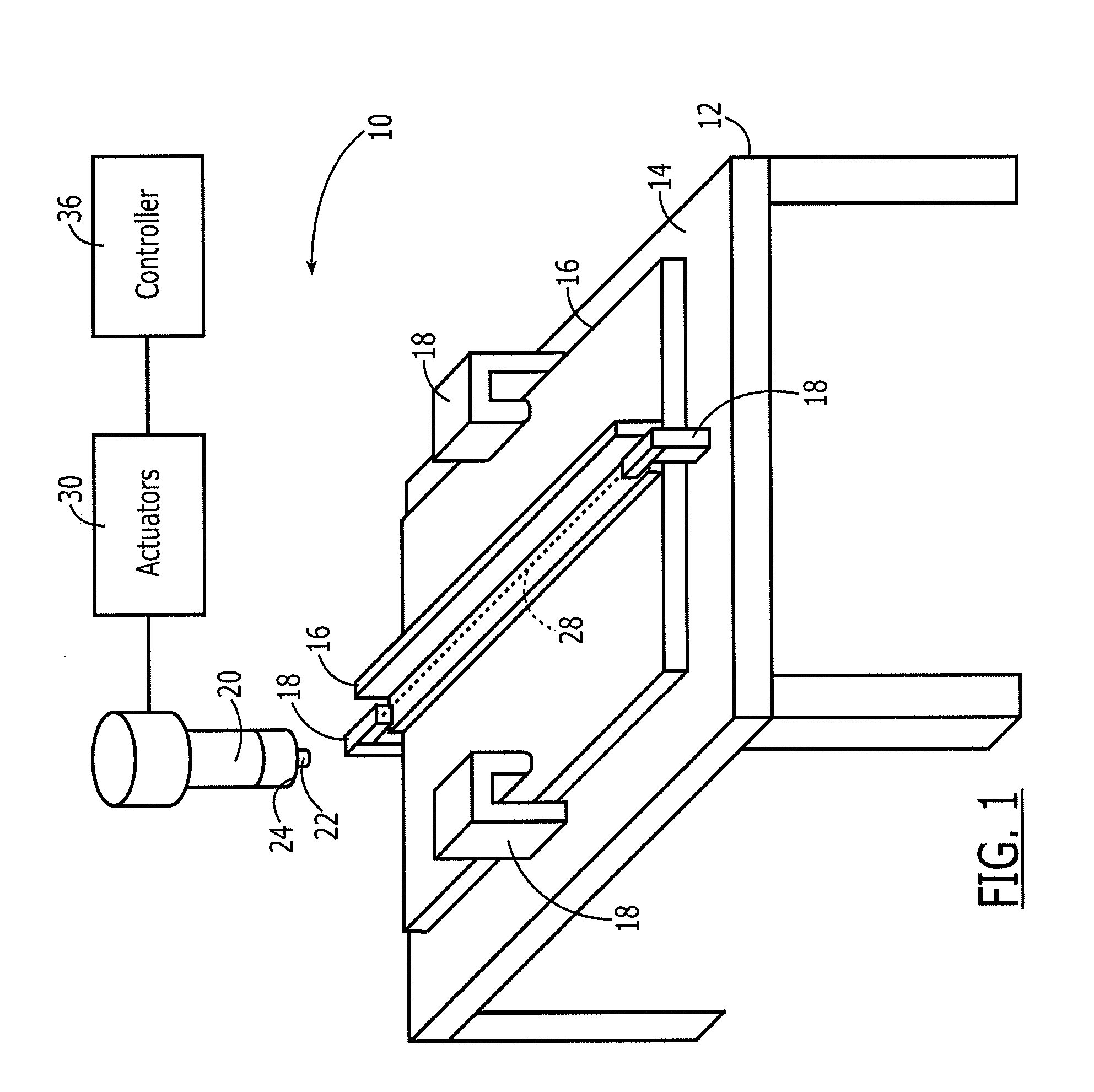

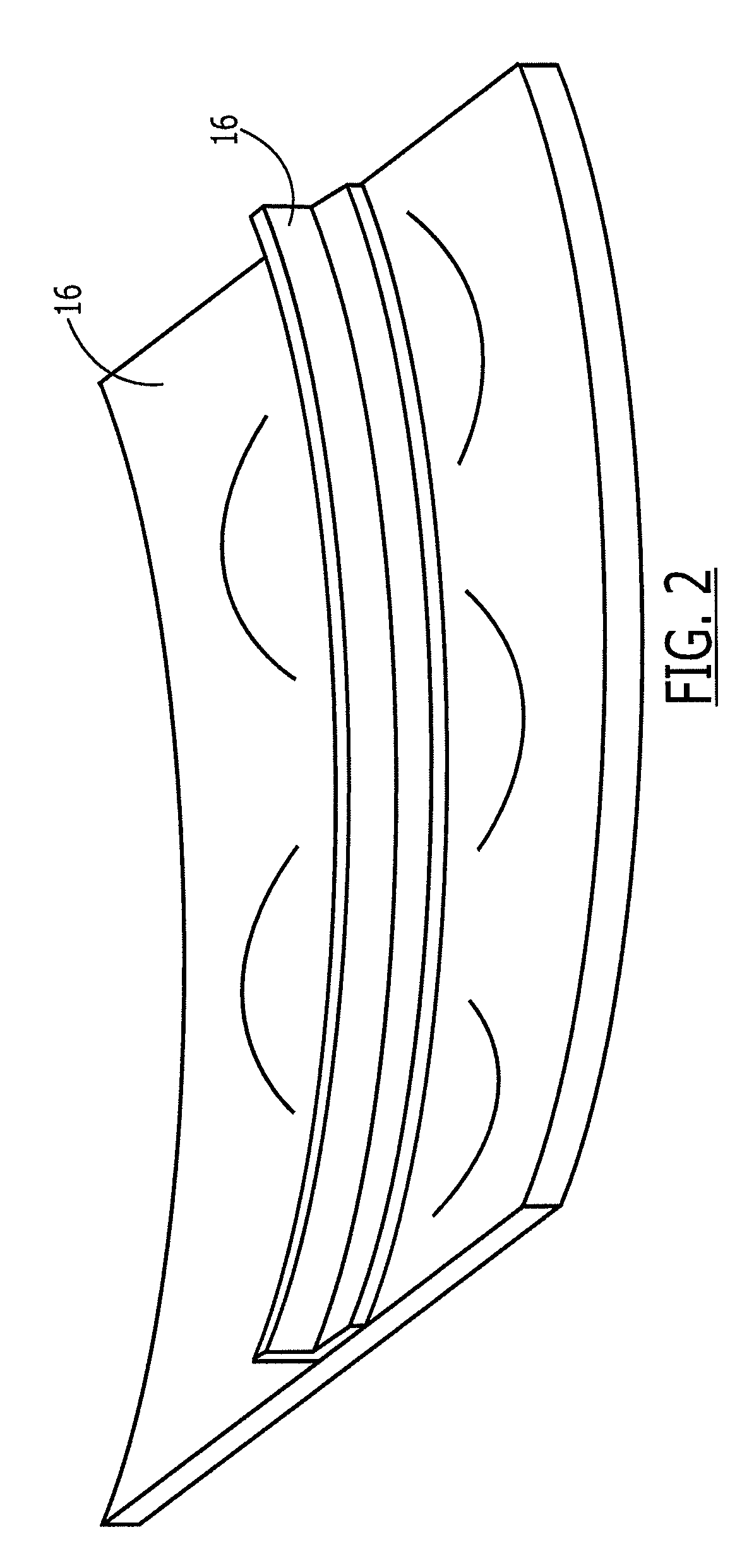

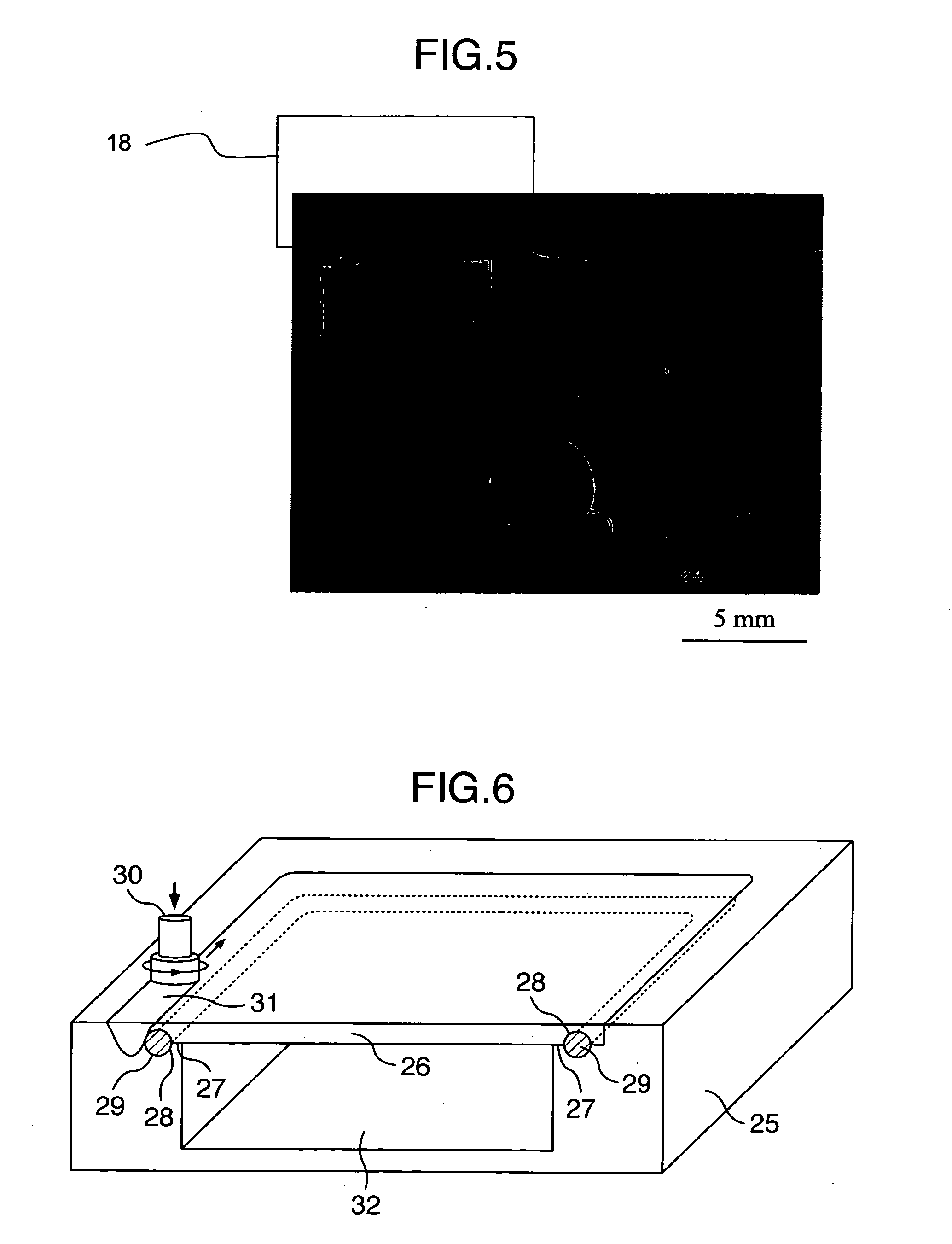

Friction Stir Weld Assembly And Associated Method For Mitigating Distortion In A Friction Stir Weld Joint

InactiveUS20110068150A1Reduce out-of-plane bowingReduce complex bucklingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDistortion

Owner:THE BOEING CO

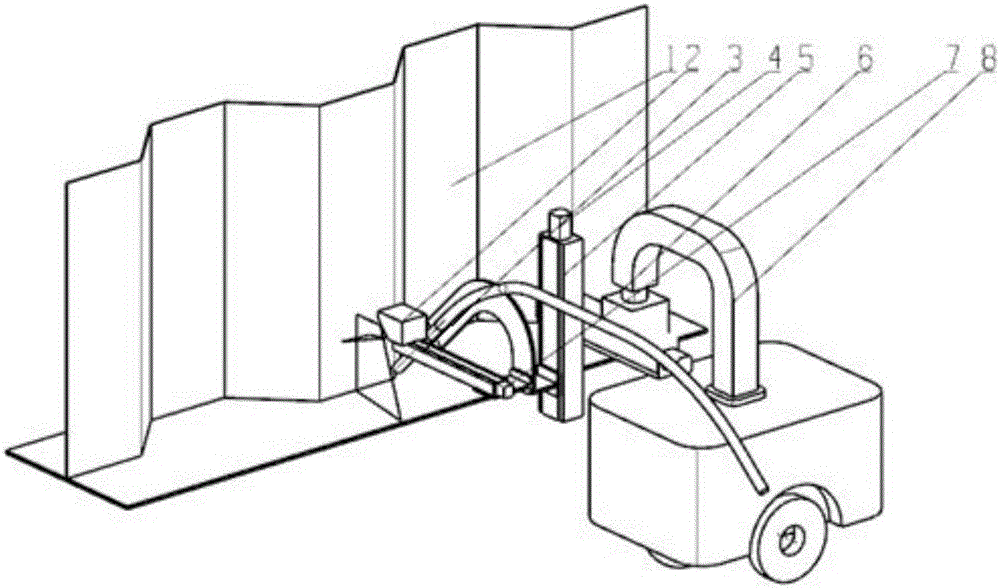

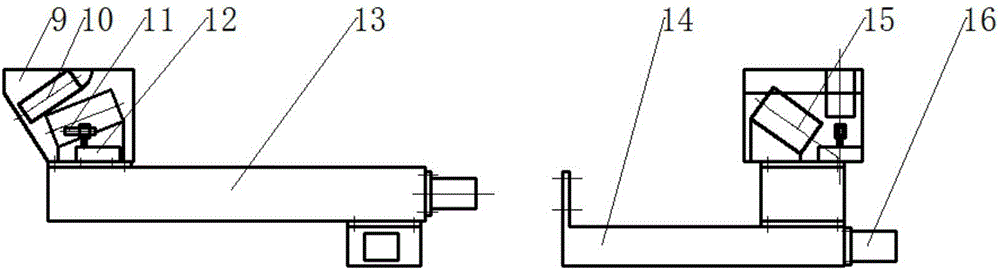

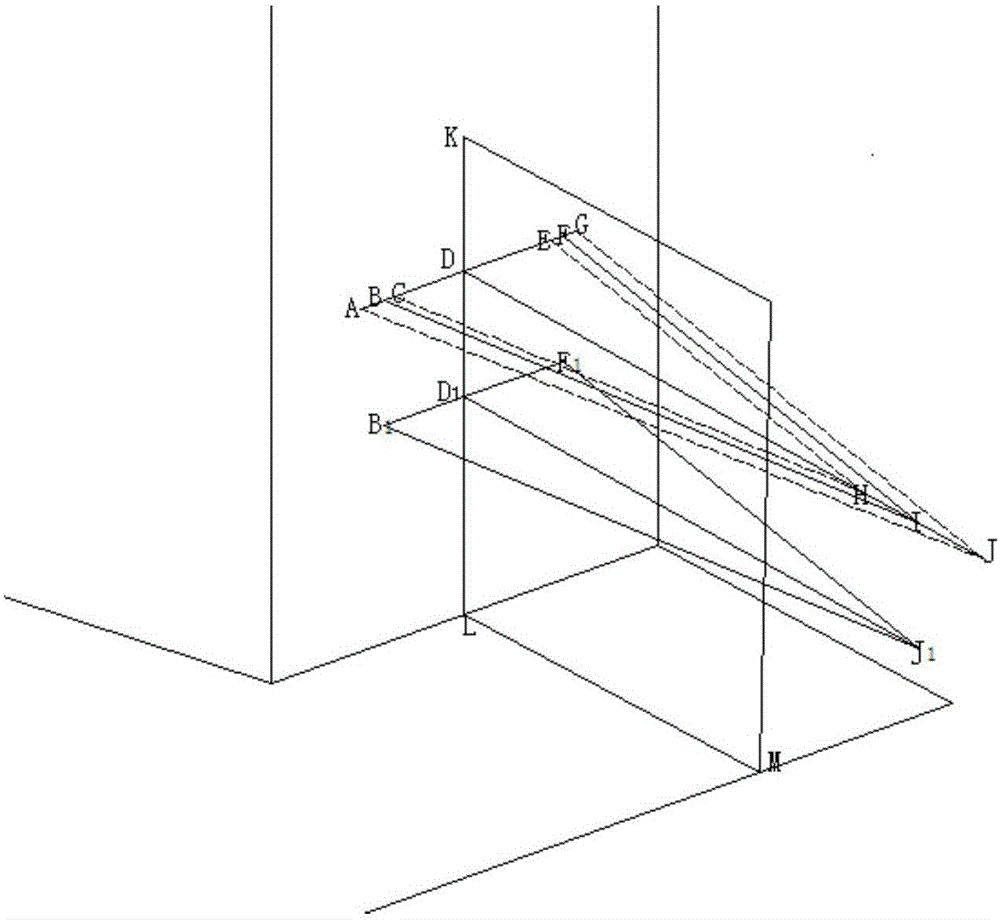

Monocular self-adaption cross laser visual corrugated plate welding line tracking sensor

ActiveCN106002022AWelding/cutting auxillary devicesAuxillary welding devicesSelf adaptiveTransfer mechanism

Owner:湖南艾克机器人有限公司

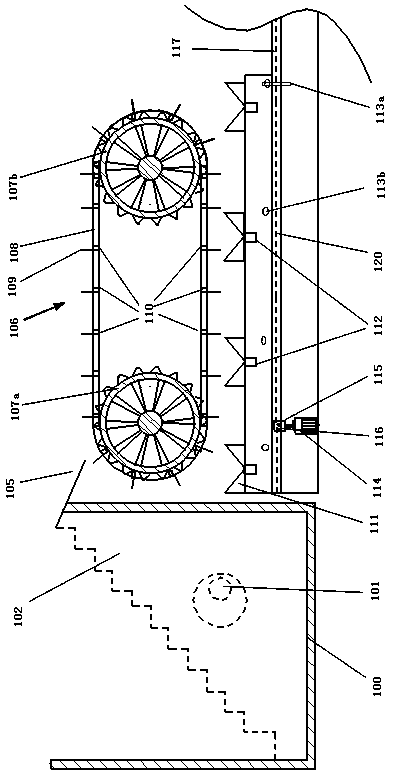

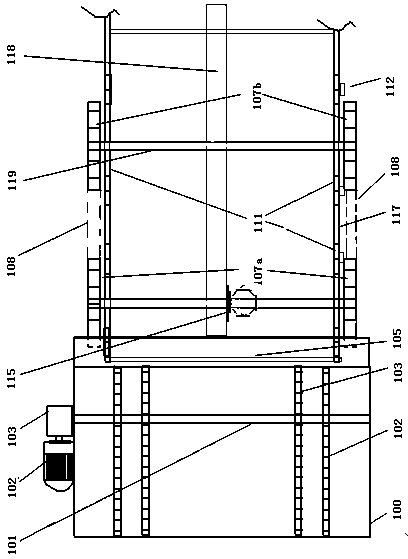

Longitudinal short rib feeding and distributing device and method used during welding of steel bar meshes

ActiveCN110480221APreventing difficulties in the smooth supply of steel barsAccurate transferWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

Owner:河南省鼎鼎实业有限公司

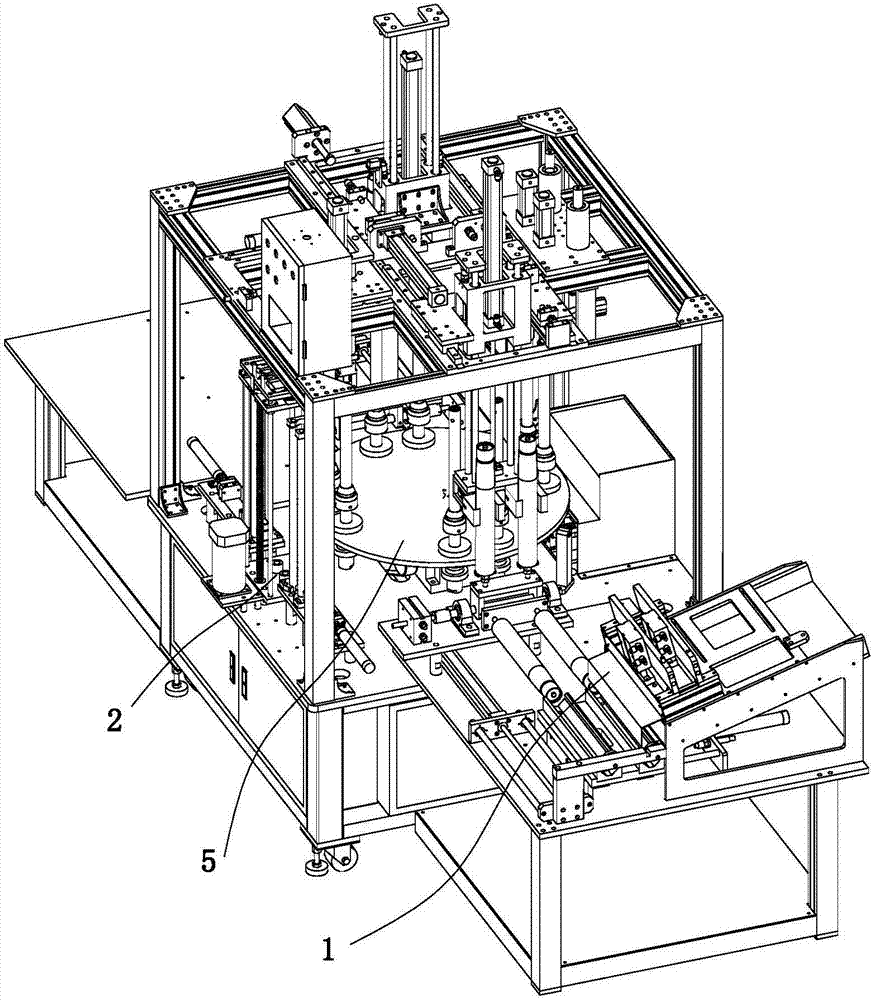

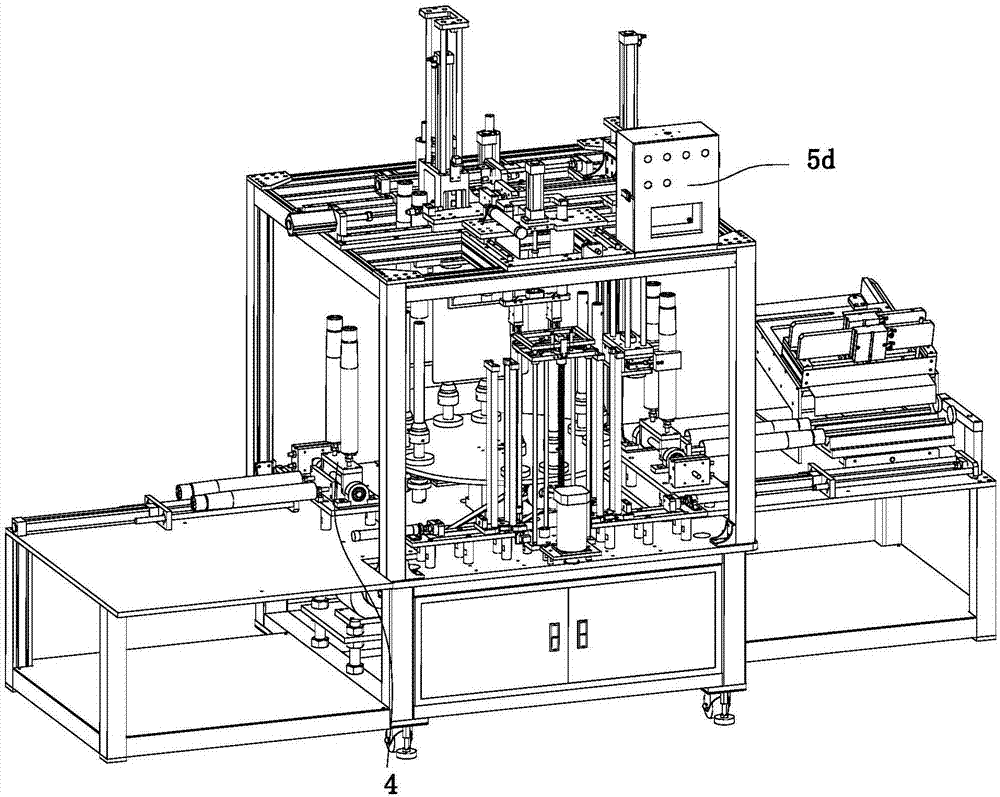

Full-automatic welding machine

ActiveCN107378321APrecise feedingWay accurateWelding/cutting auxillary devicesAuxillary welding devicesVolumetric Mass DensityEngineering

Owner:安徽荣盛精密科技有限责任公司

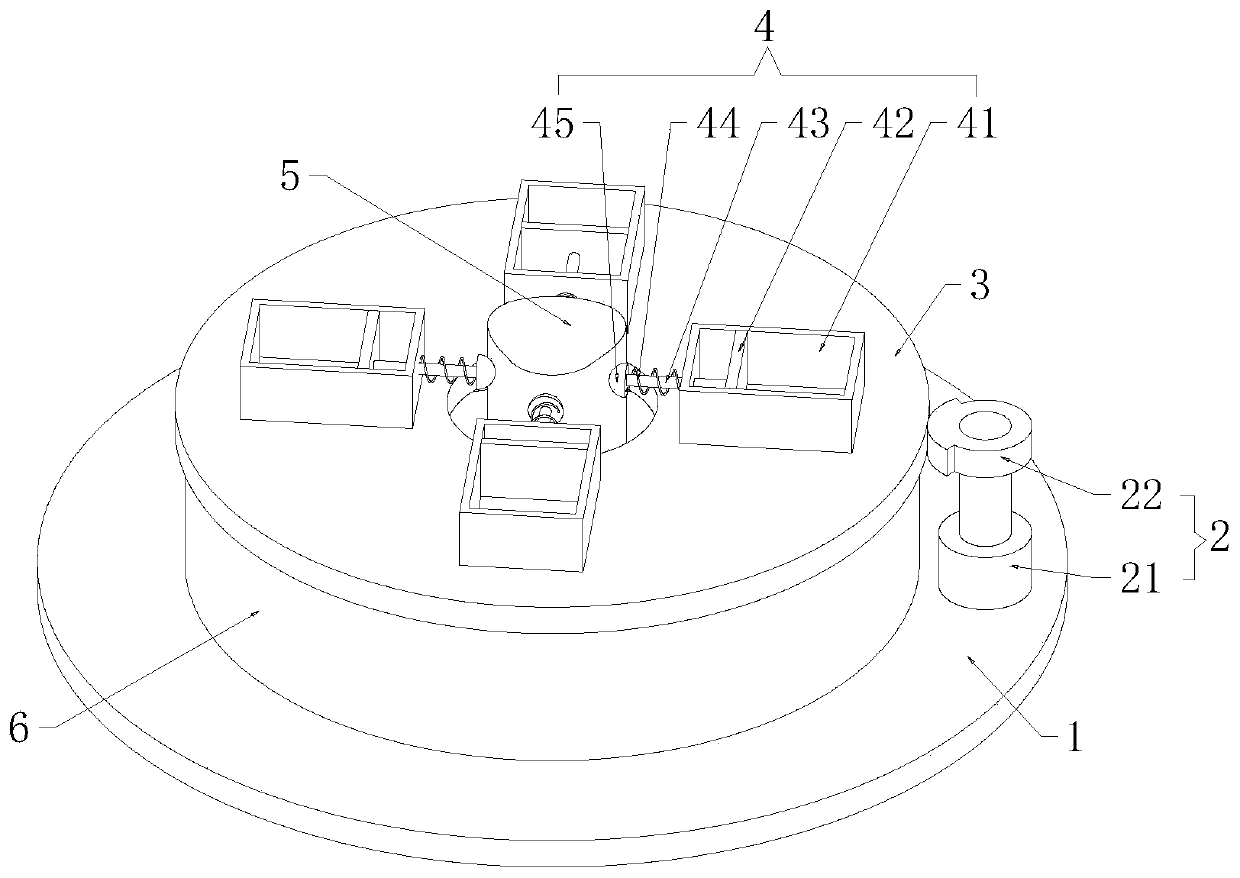

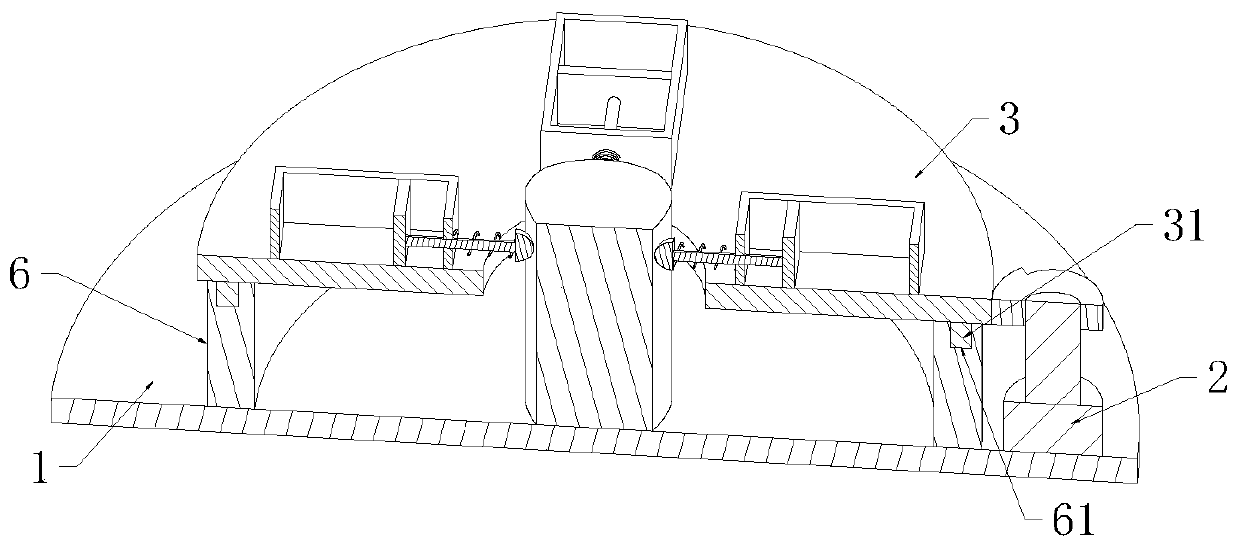

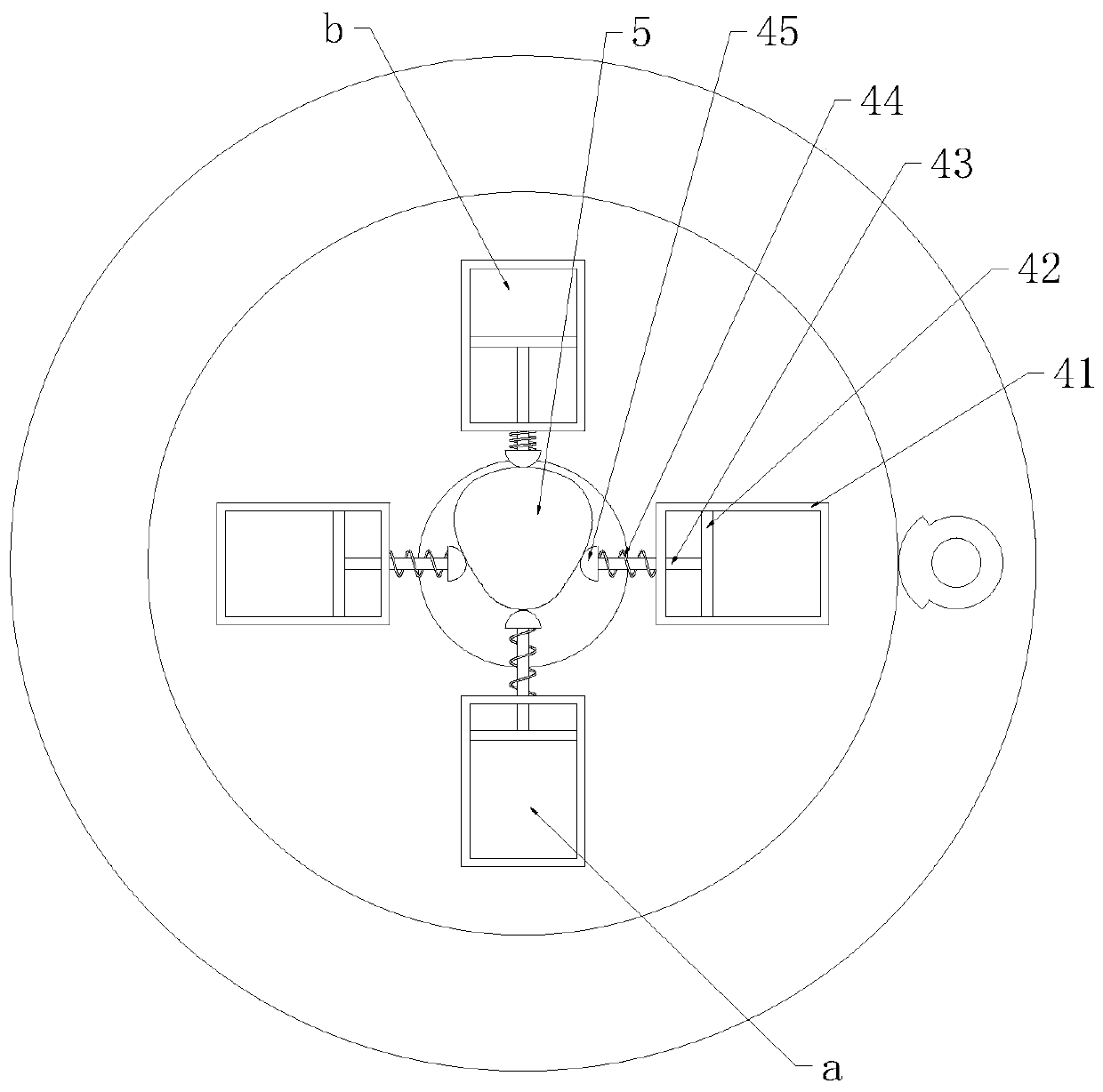

Semi-automatic spot welding machine device locating clamp

InactiveCN110977305AEasy to take outEasy to placeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCam

The invention provides a semi-automatic spot welding machine device locating clamp comprises a bottom plate. A transmission gear is rotationally installed at the upper end of the bottom plate througha support ring. At least two holding assemblies are evenly fixed to the upper end of the transmission gear and are arranged annularly. A cam is fixed to the middle of the upper end of the bottom plate, penetrates through the support ring and the transmission gear and extends to the upper end of the transmission gear. Cam arc-shaped outer ends are evenly installed on the at least two holding assemblies. A driving structure is fixed to the side end of the transmission gear and is fixed to the upper end of the bottom plate. The semi-automatic spot welding machine device locating clamp is reasonable in structure, the structure is simplified, cost is lowered, and the use effect is good.

Owner:荣旗工业科技(苏州)股份有限公司

Bonding apparatus

InactiveUS6863206B2Increase bonding areaSolid-state devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

Owner:SHINKAWA CO LTD

Flow adjuster and processing devices

InactiveCN1406707ALow priceImprove reliabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTraffic volume

This invention provides a flow amount adjustment apparatus able to adjust flow amount with high reliability at a low cost without being oversized. The flow amount adjustment apparatus has a plurality of orifices having different bore diameter for a predetermined flow amount, respectively, the orifices being opened and closed by an open-close member, respectively; a primary piping connected to each of the orifices for supplying gas adjusted to a prescribed pressure; and a secondary piping connected to each of the orifices for gathering gas passed through an opened orifice or a plurality of opened orifices, wherein one orifice or a plurality of orifices capable of satisfying a prescribed flow amount are selected and opened.

Owner:KOIKE SANSO KOGYO CO LTD

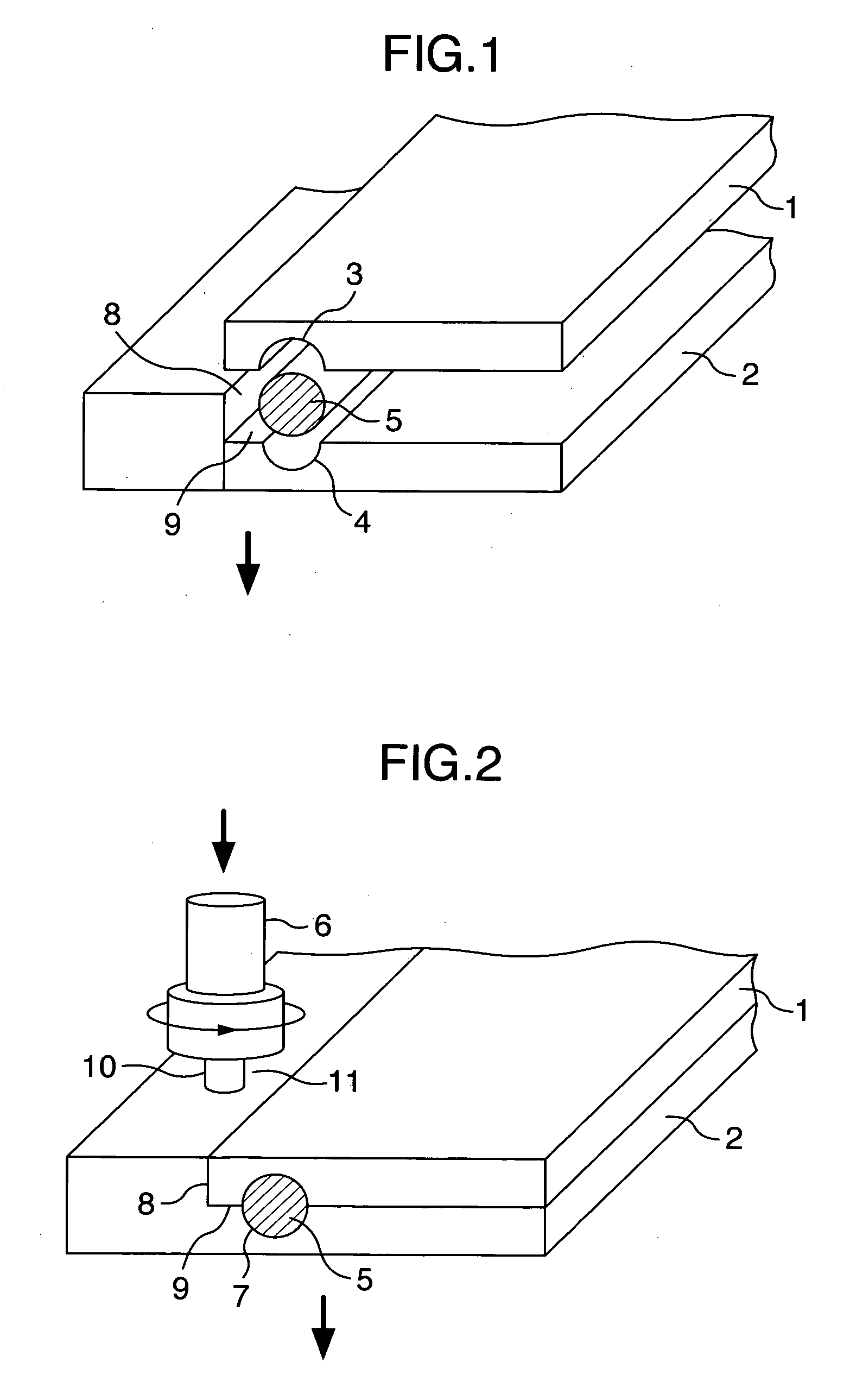

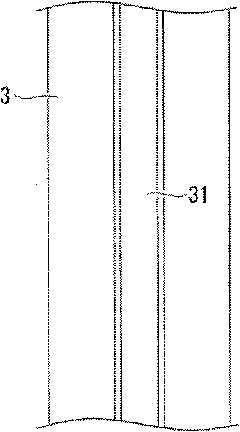

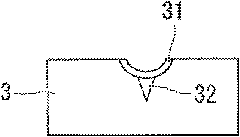

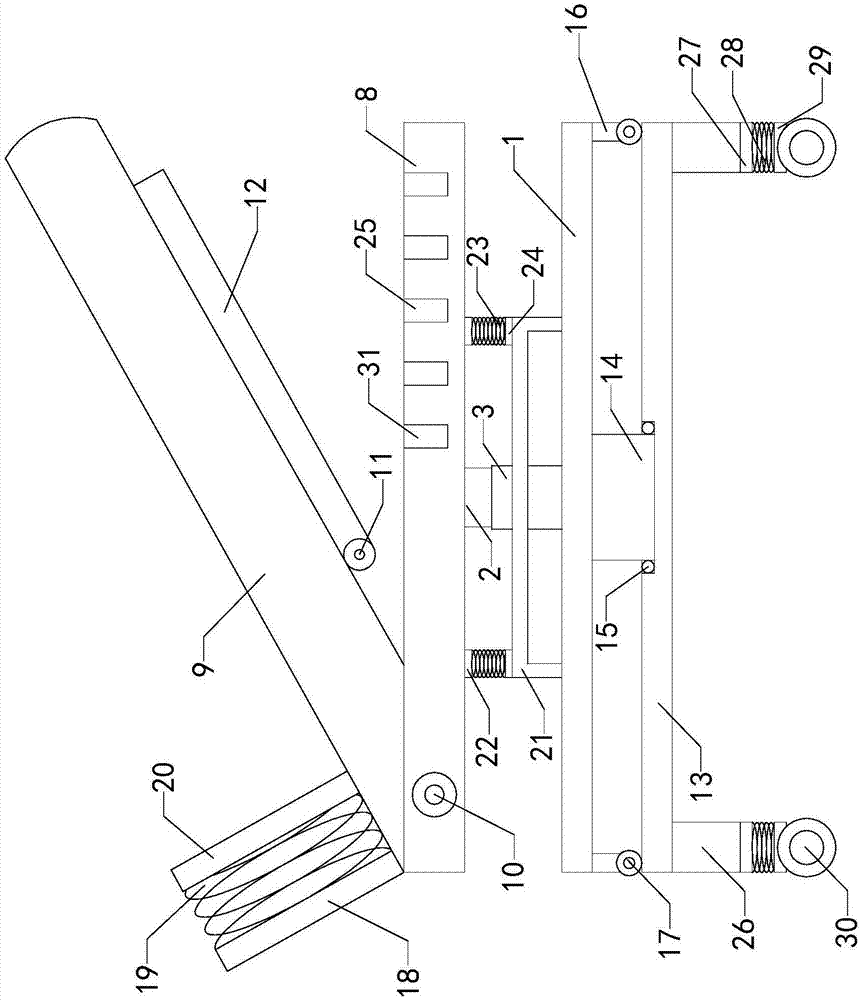

Laminated plate and end treatment method of the laminated plate

ActiveUS20100021675A1Welding/cutting auxillary devicesHollow wall articlesEngineeringMechanical engineering

A manufacturing method of a laminated plate (19) includes: a first step of supporting, by a support member (9), a thermoplastic resin-made laminated material (1) in which a pair of plate-like members (3, 4) are laminated to each other while interposing a longitudinal wall portion (2b) so that a peripheral edge portion (1a) of the laminated material (1) can be exposed, and heating and softening the peripheral edge portion (1a) by blowing a hot air to the peripheral edge portion (1a); and a second step of pressing the plate-like member (4) as one of the pair of plate-like members (3, 4) against other plate-like member (3) by thrusting a cutting blade (17a) of a cutting die (17) against the heated and softened peripheral edge portion (1a), thereby bringing the pair of plate-like members (3, 4) into contact with each other and welding the plate-like members (3, 4) to each other, and then cutting the laminated plate (19) out of the laminated material (1).

Owner:MEIWA IND CO LTD

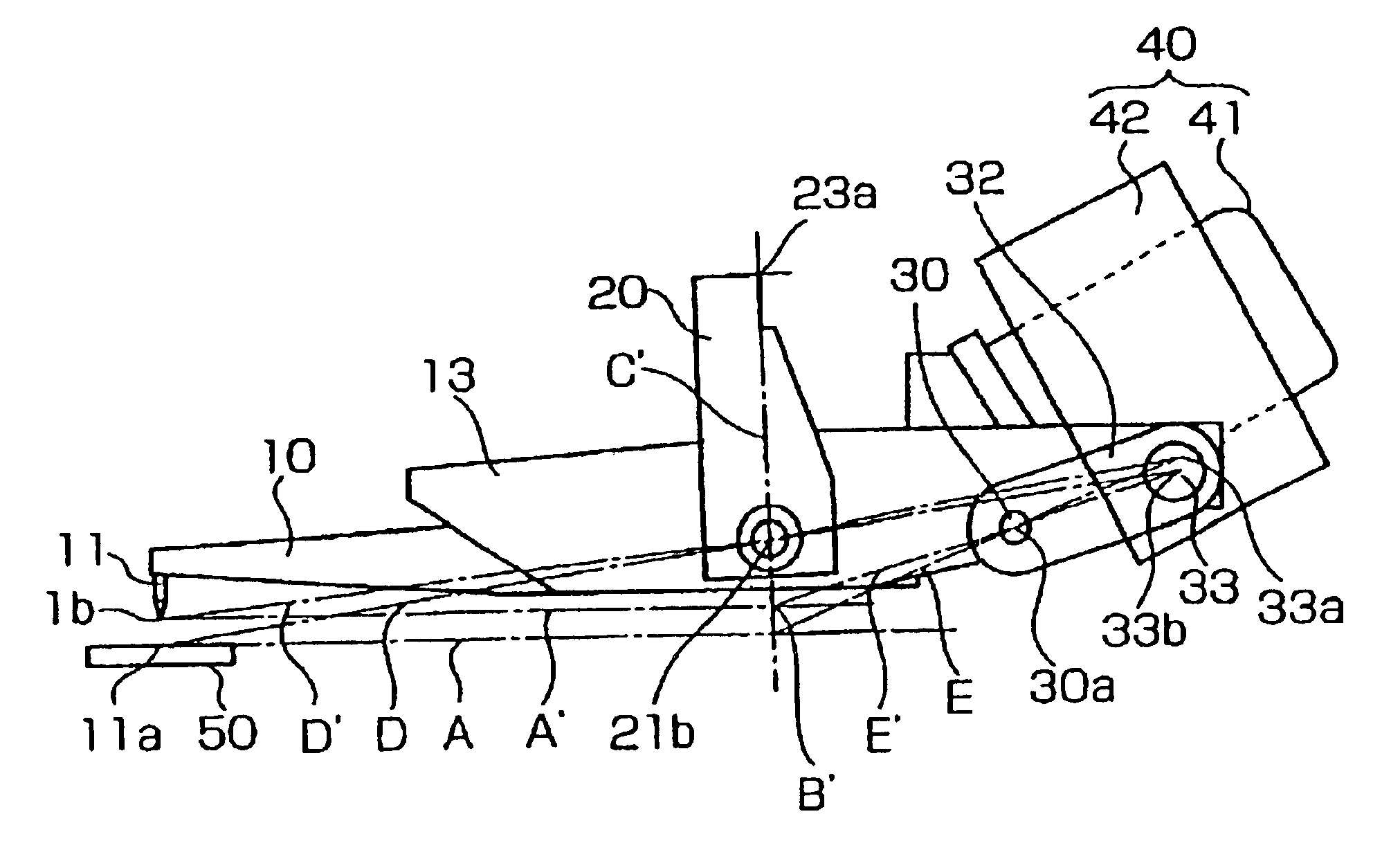

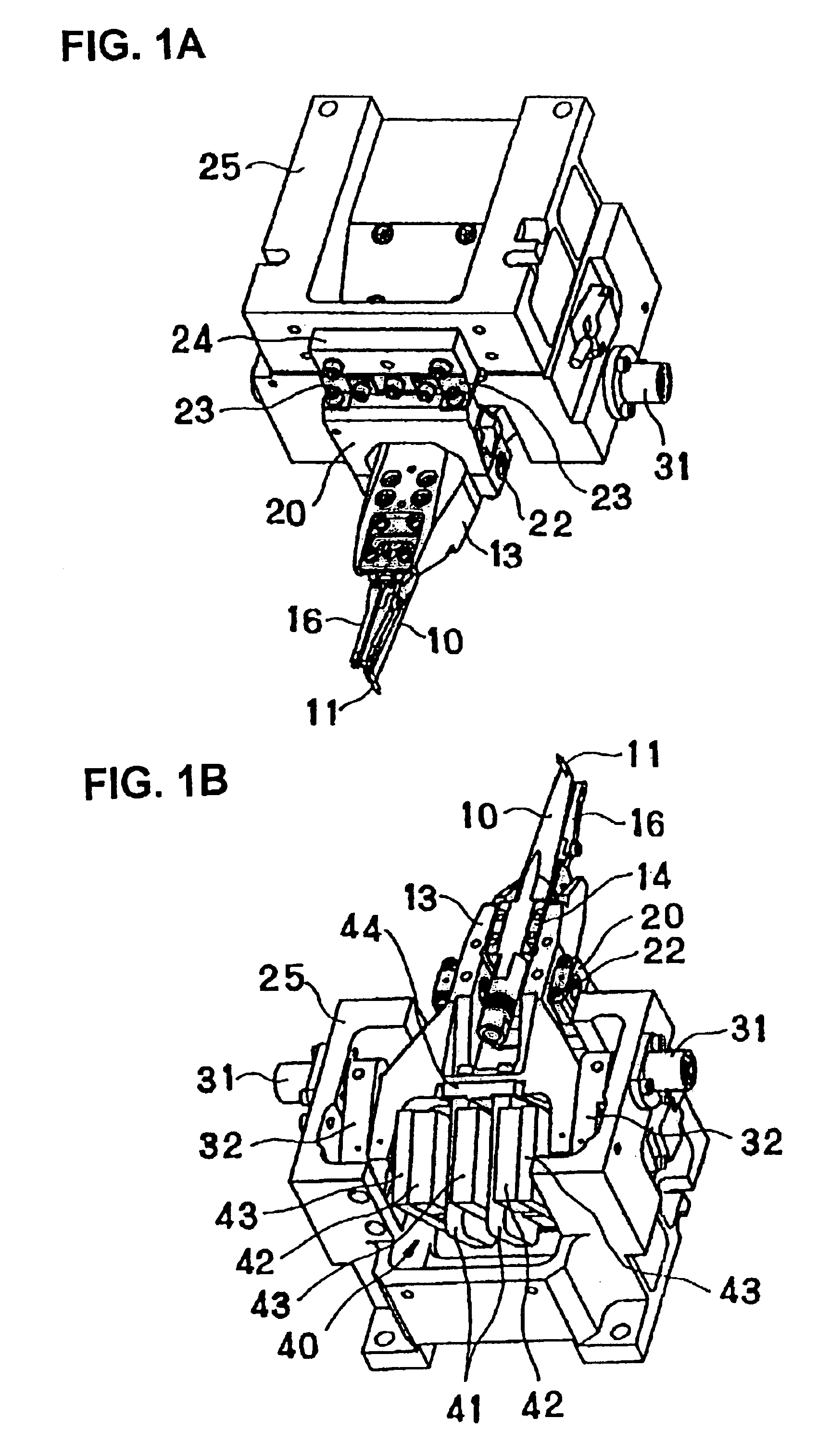

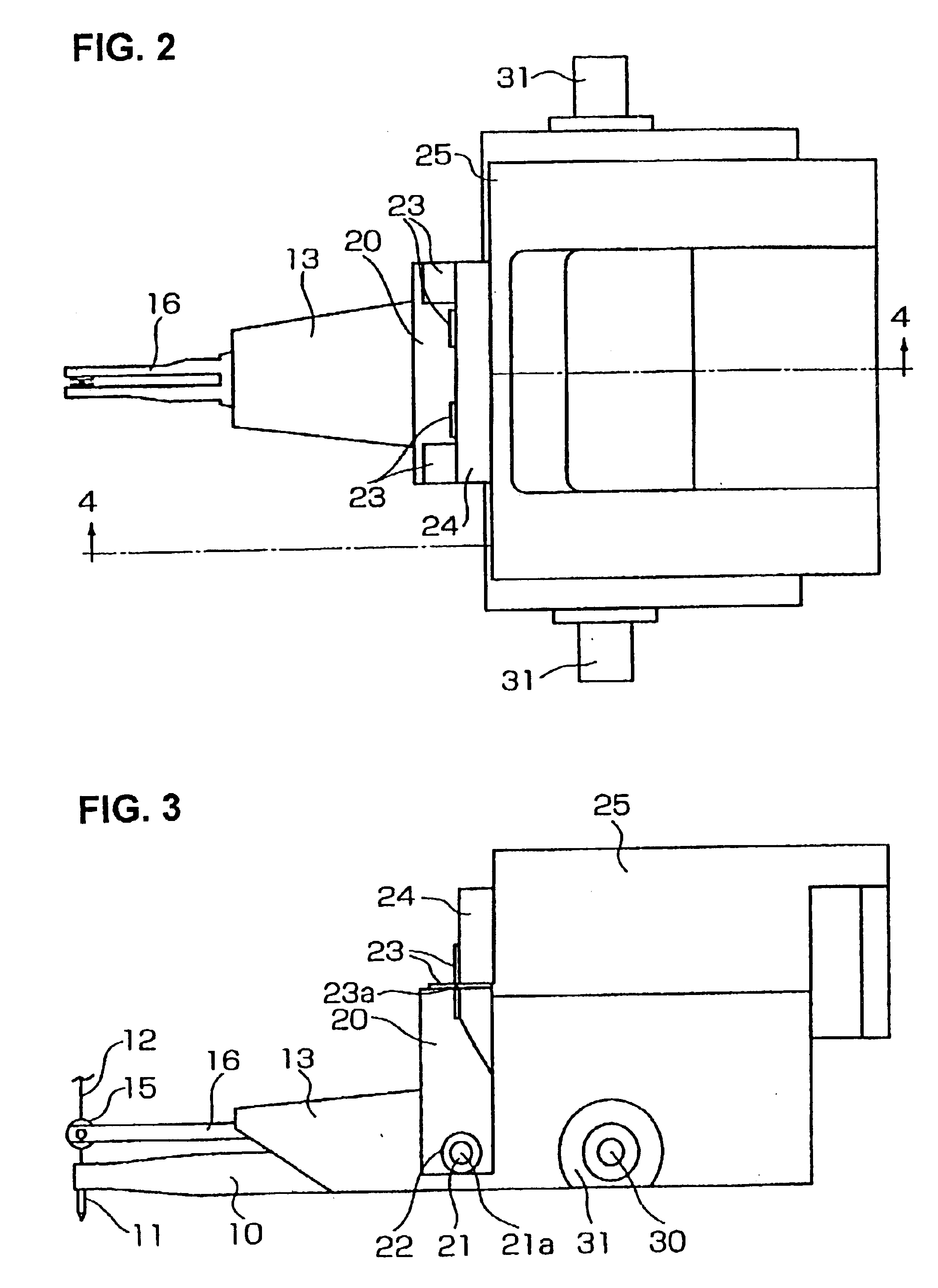

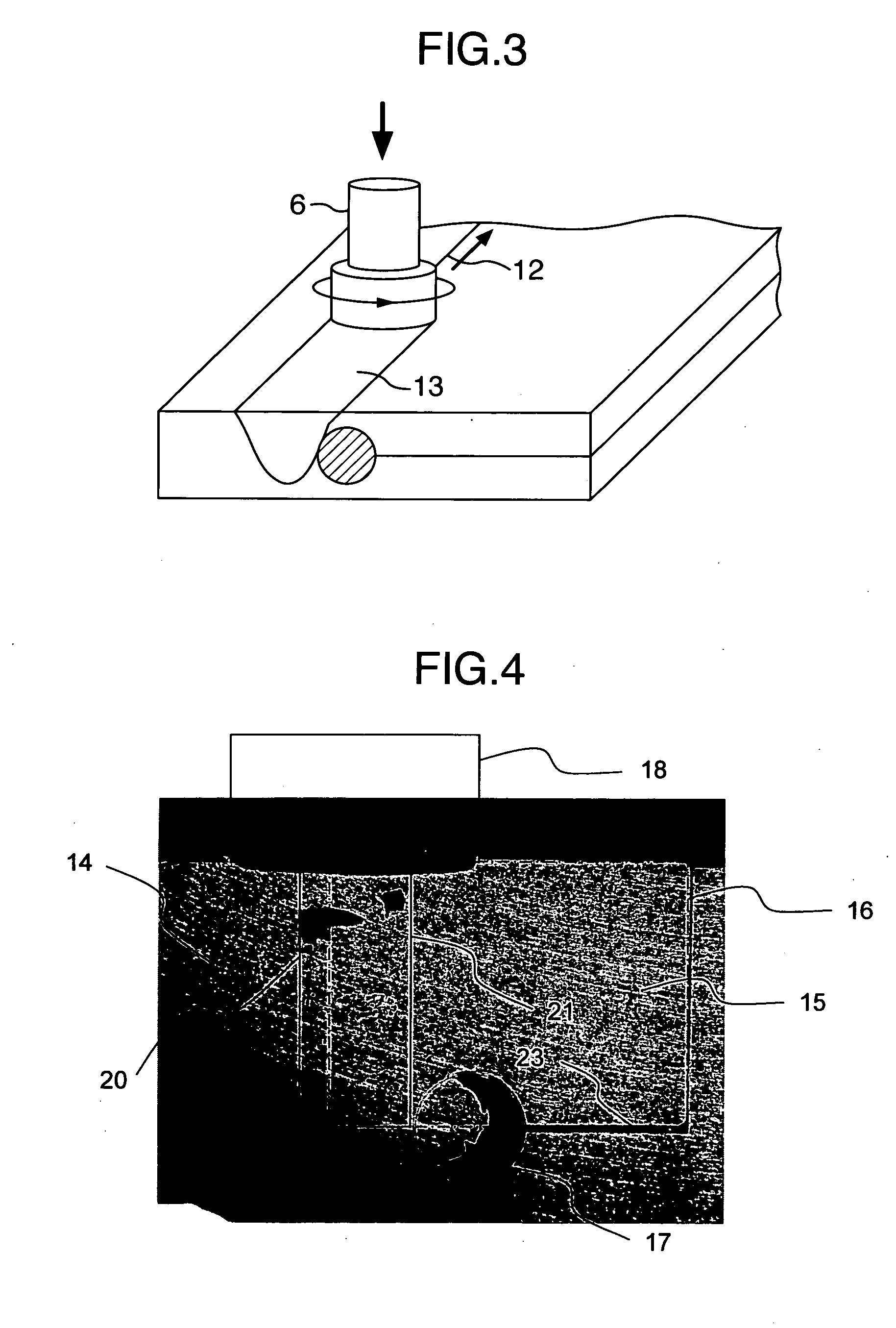

Friction stir welding method

InactiveUS20070181649A1Excellent fatigue propertiesSimple structureCooking-vessel materialsWelding/cutting auxillary devicesEngineeringMechanical engineering

Owner:HITACHI LTD

Template laser cutting equipment provided with template fixture

InactiveCN105414750AWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingLaser beams

Owner:DONGGUAN QINZHI IND DESIGN CO LTD

Welding method, welding system and welding jig

InactiveUS20060151572A1Reduce impactAvoid crackingElectric heatingWelding/cutting auxillary devicesFuel tankThermal deformation

A plurality of attachments having springs hold the outer plate of a fuel tank, and an inner jig positions the inner plate. The attachments are attached to clamp arms which are opened / closed by cylinders. When the overlap portion between the outer and inner plates is welded, the thermal deformation caused by welding is accommodated by the springs. The attachments are spaced from the fuel tank in the order in which the welding point is approached.

Owner:HONDA MOTOR CO LTD

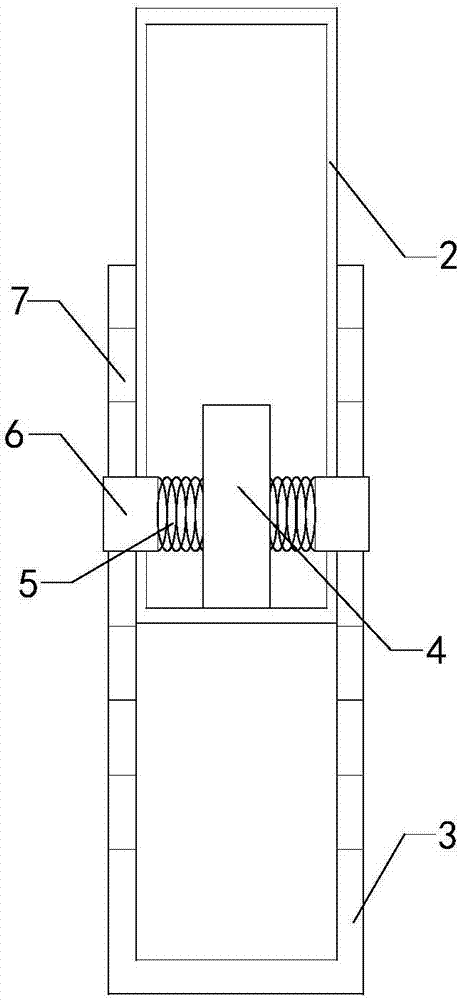

Welding and radiating turntable

ActiveCN102717214AImprove cooling effectEasy to grasp the rotation angleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringComputer fan

The invention relates to a welding and radiating turntable, which comprises a rotation platform and a platform base plate, wherein the rotation platform is in a disc shape; the center of the rotation platform is connected and fixed with a rotating shaft; the rotating shaft is arranged on the platform base plate; a bearing is arranged between the rotating shaft and the platform base plate; a cross-shaped groove is arranged on the rotation platform; the center of the cross-shaped groove is arranged in the center of the rotation platform; the rotation platform is divided into four equal sectors through the cross-shaped groove; and an air vent is arranged in the central position of each sector. The welding and radiating turntable has the beneficial effects that the bearing is arranged between the rotation platform and the platform base plate, and the position of the platform base plate is fixed, so that the rotation platform can be rotated manually; the cross-shaped groove and the air vents are arranged on the rotation platform, so that the heat of the rotation platform can be radiated conveniently, and particularly, the radiating effect can be further improved through a radiating fan on the platform base plate; and through circumferential scales on the surface of the rotation platform, an operator can grasp the rotation angle conveniently, and can operate flexibly and accurately.

Owner:WUXI UNITE ENERGY TECH CO LTD

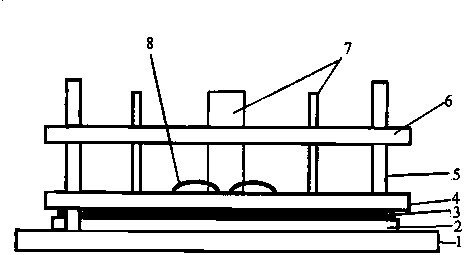

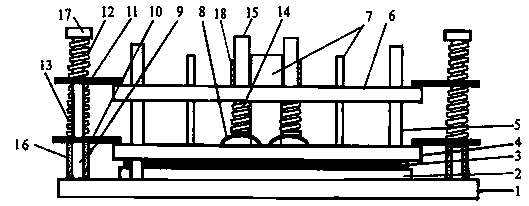

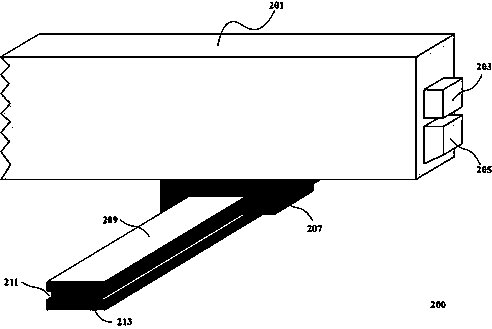

Improved welding mold for welding semiconductor power module

ActiveCN104191063ASimple structural designPractical structural designWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSemiconductor

Owner:XUZHOU HANTONG ELECTRONICS TECH CO LTD

Floating regulating and clamping device for center of a welding tube

ActiveCN101774104ASuppression of shaking phenomenonExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:SHANGHAI ZHUGUANG MACHINERY +1

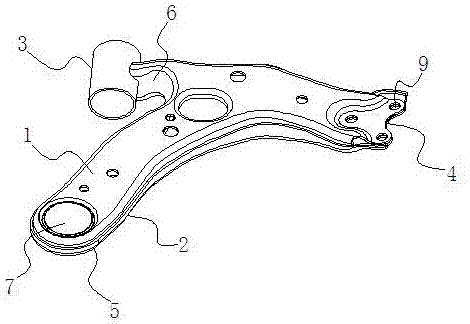

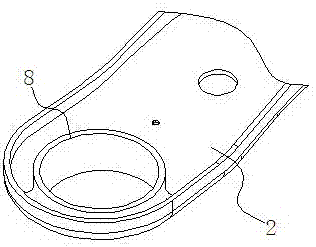

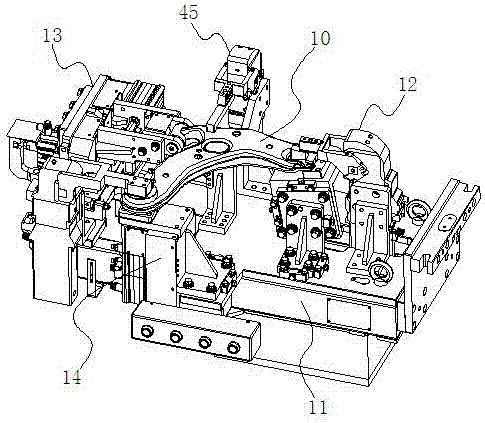

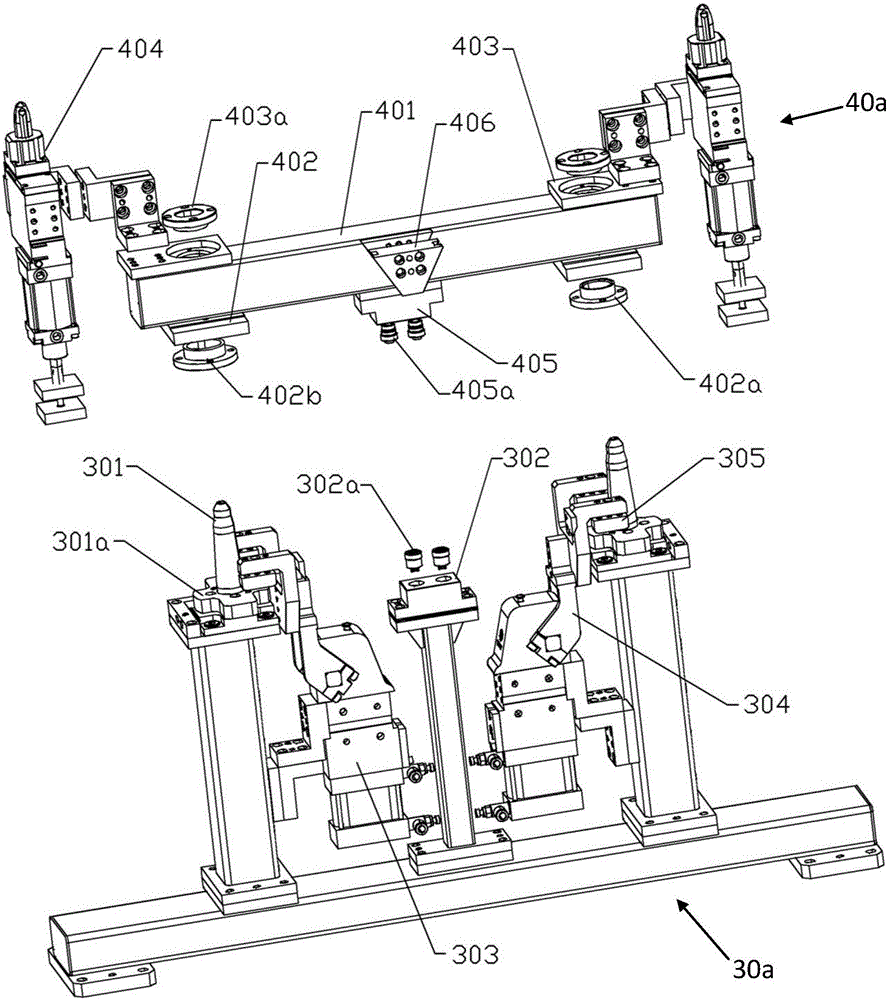

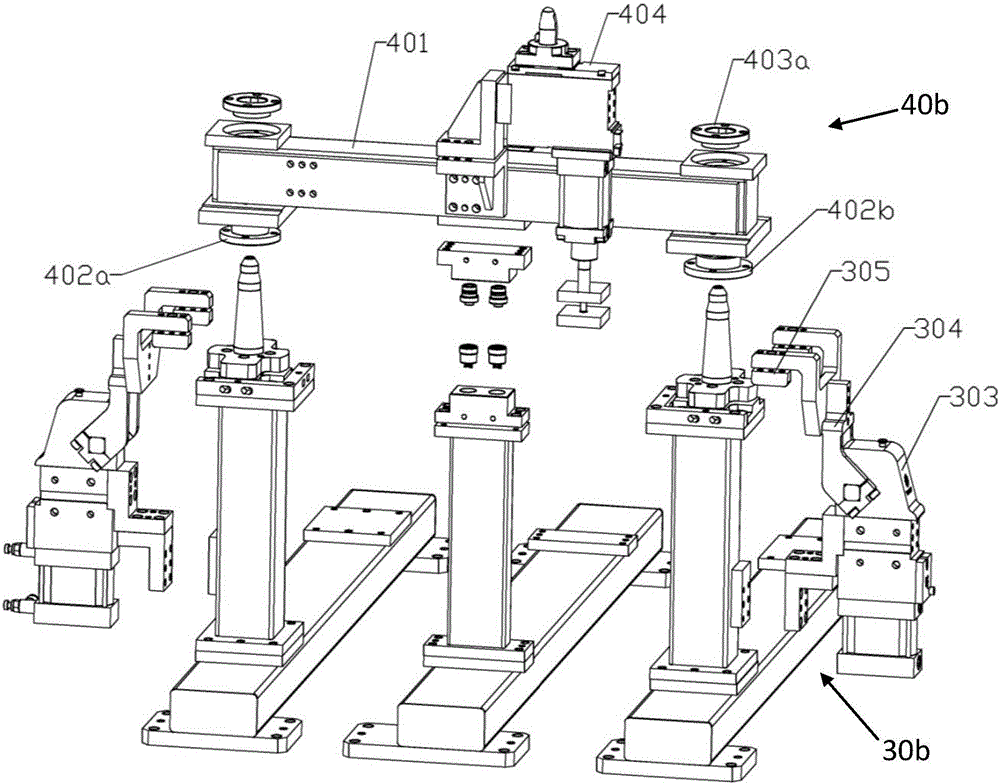

Welding clamping method for automotive suspension control arm

ActiveCN107971676AImprove processing efficiencyGuaranteed machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a welding clamping method for an automotive suspension control arm. The welding method comprises the steps that a ball head connecting end clamping mechanism, a sleeve connecting end clamping mechanism and a ball head pin mounting end clamping mechanism are arranged on a working platform; before welding, firstly, a top cover and a bottom cover are clamped together through the ball head connecting end clamping mechanism and the ball head pin mounting end clamping mechanism, wherein the top cover and the bottom cover are located at a ball head connecting end and a ball head pin mounting end; then, a sleeve is tightly pressed onto a sleeve connecting end through the sleeve connecting end clamping mechanism; and then, welding is conducted. By means of the welding clamping method, machining precision of the automotive suspension control arm can be guaranteed; the operation is convenient and fast to conduct; and machining efficiency is improved.

Owner:ZHUZHOU KAIFENG IND

Automatic tracking system for welding robot welding seam

Owner:NANJING UNIV OF TECH +1

Laser welding apparatus and method of laser welding

ActiveCN102196879AAvoid meltingInhibitionWelding/cutting auxillary devicesAuxillary welding devicesThick wallLaser beams

Owner:MITSUBISHI SHIPBUILDING CO LTD

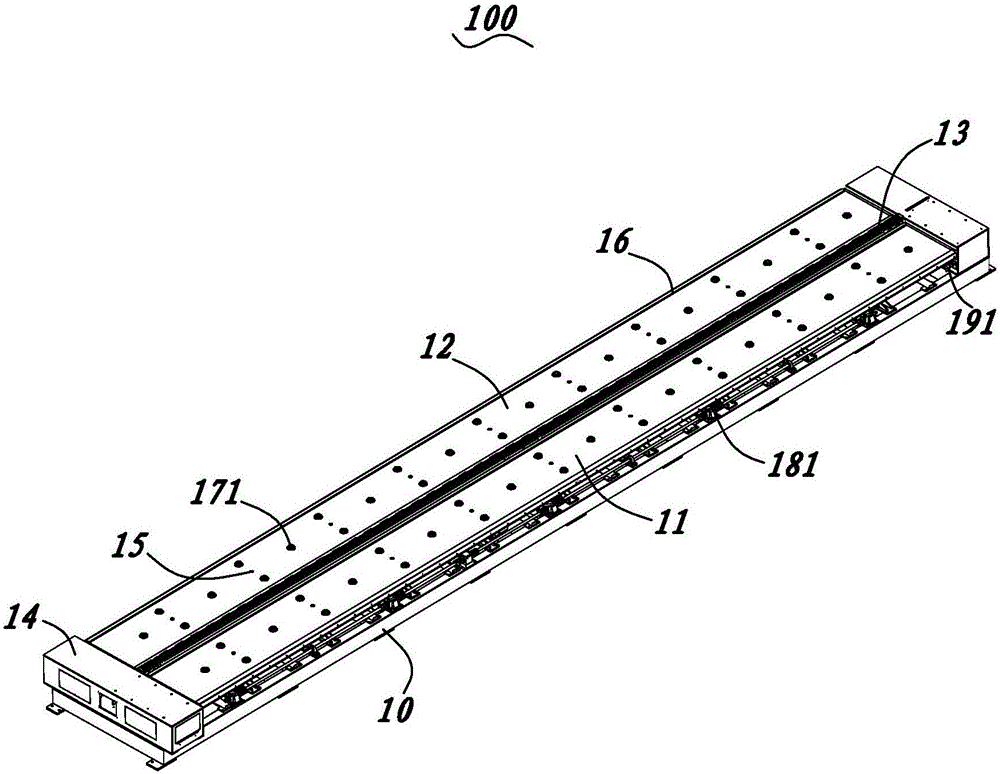

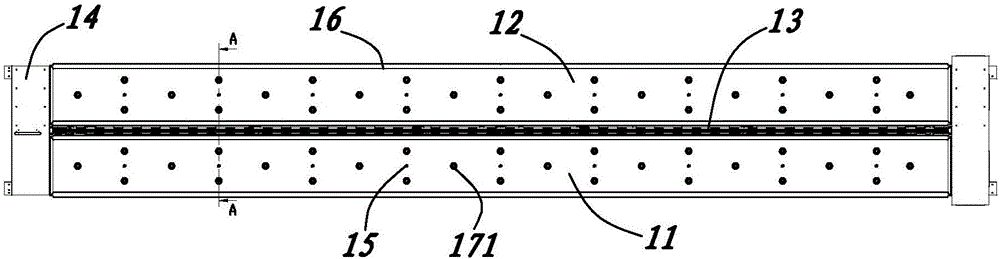

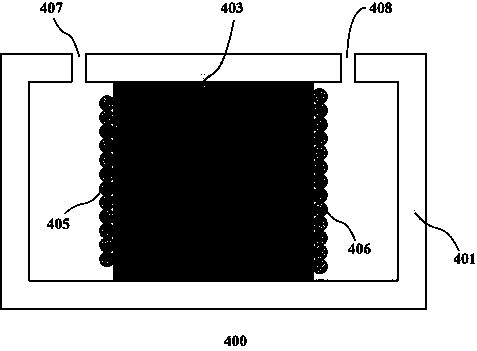

Vacuum adsorption welding device for plate splicing in submerged-arc welding

ActiveCN106077918AFast adsorption fixationEasy to operateWelding/cutting auxillary devicesArc welding apparatusEngineeringPlate fixation

Owner:HUAHENG WELDING

Portable fixing support equipment for gas protection welding furnace

InactiveCN107350668AEasy to move verticallyAchieve a fixed effectWelding/cutting auxillary devicesAuxillary welding devicesBall bearingArchitectural engineering

Owner:JIANGSU KANGJIE MACHINERY

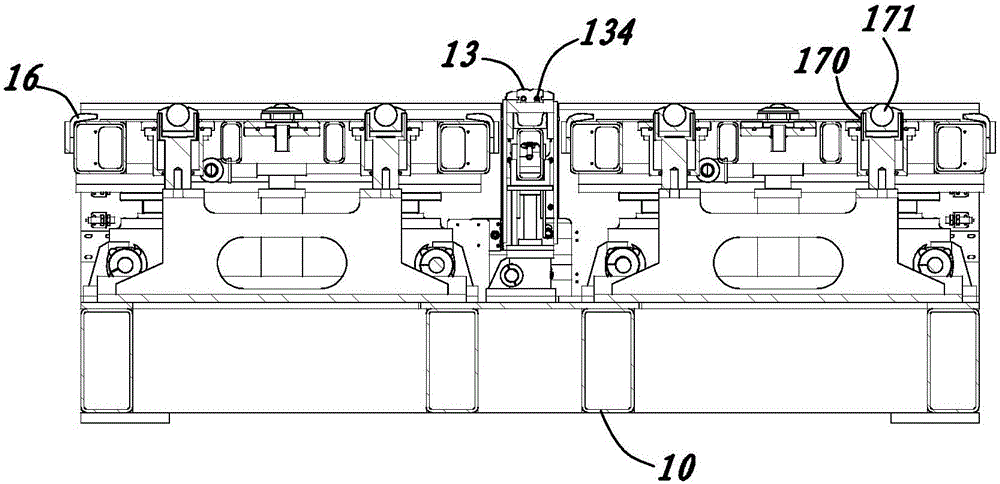

Automotive chassis support positioning mechanism and offline detection platform

ActiveCN106078051ASimple structureSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesElectrical and Electronics engineeringRolling chassis

Owner:SHANGHAI SINYLON AUTO EQUIPMENT MANUFACTURE CO LTD

Interactive automatic welding system based on three-dimensional vision

InactiveCN112958974ALower programming skill requirementsHigh degree of automationProgramme-controlled manipulatorWelding/cutting auxillary devicesRemote controlSoftware engineering

The invention discloses an interactive automatic welding method based on three-dimensional vision. The interactive automatic welding method comprises the following steps that an interactive automatic welding system based on the three-dimensional vision is built; a three-dimensional model of a to-be-welded workpiece is obtained; a workpiece coordinate system and a robot coordinate system are aligned by using three-dimensional vision; to-be-welded features are selected in an interactive interface, and a welding track is generated; and welding is performed using a robot. According to the interactive automatic welding method, three-dimensional vision is combined with an interaction system, and the online programming or on-site teaching process is changed into an automatic welding system based on image interaction. Compared with traditional online programming and field teaching schemes, the automation degree is higher, labor is saved, and efficiency is improved; meanwhile, the programming skill requirement on front-line operators is also effectively reduced; and in addition, remote control can be achieved through the method, or one worker can control multiple devices, and unmanned flexible welding can be achieved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

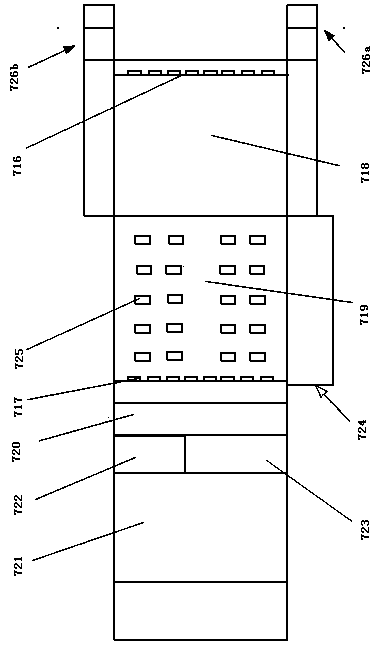

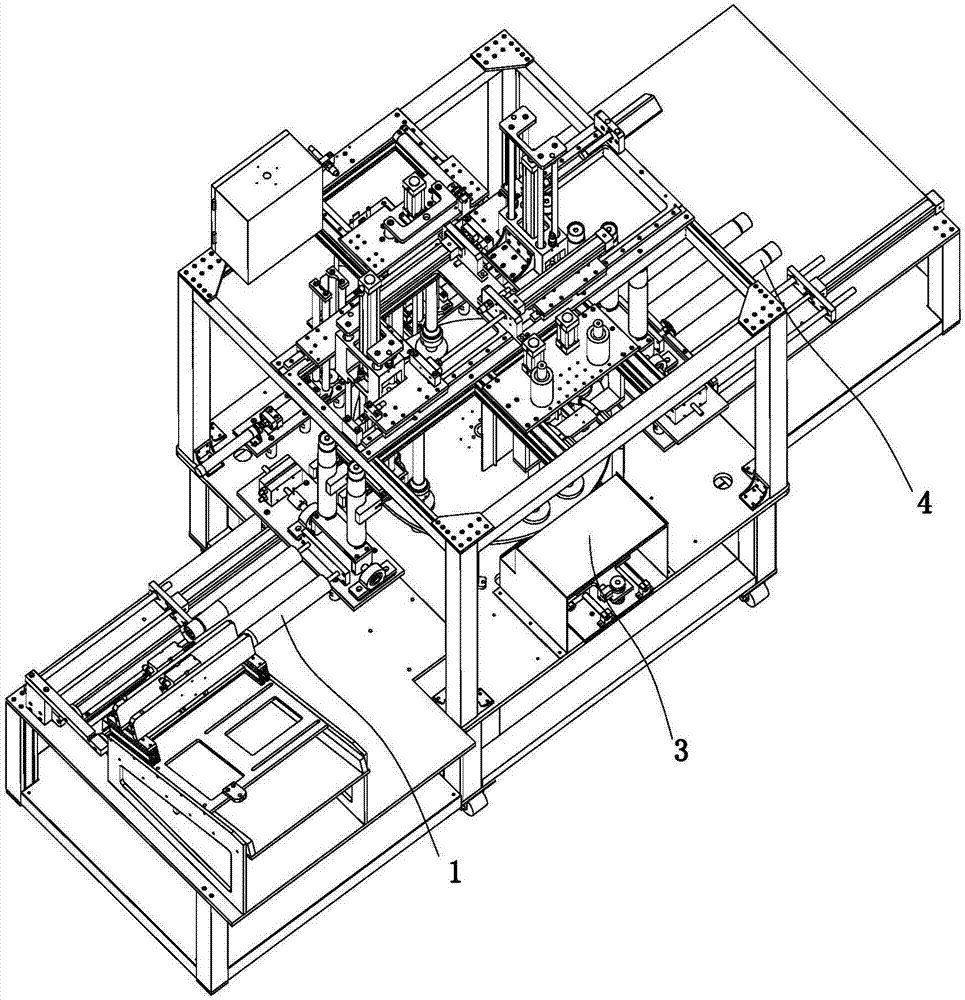

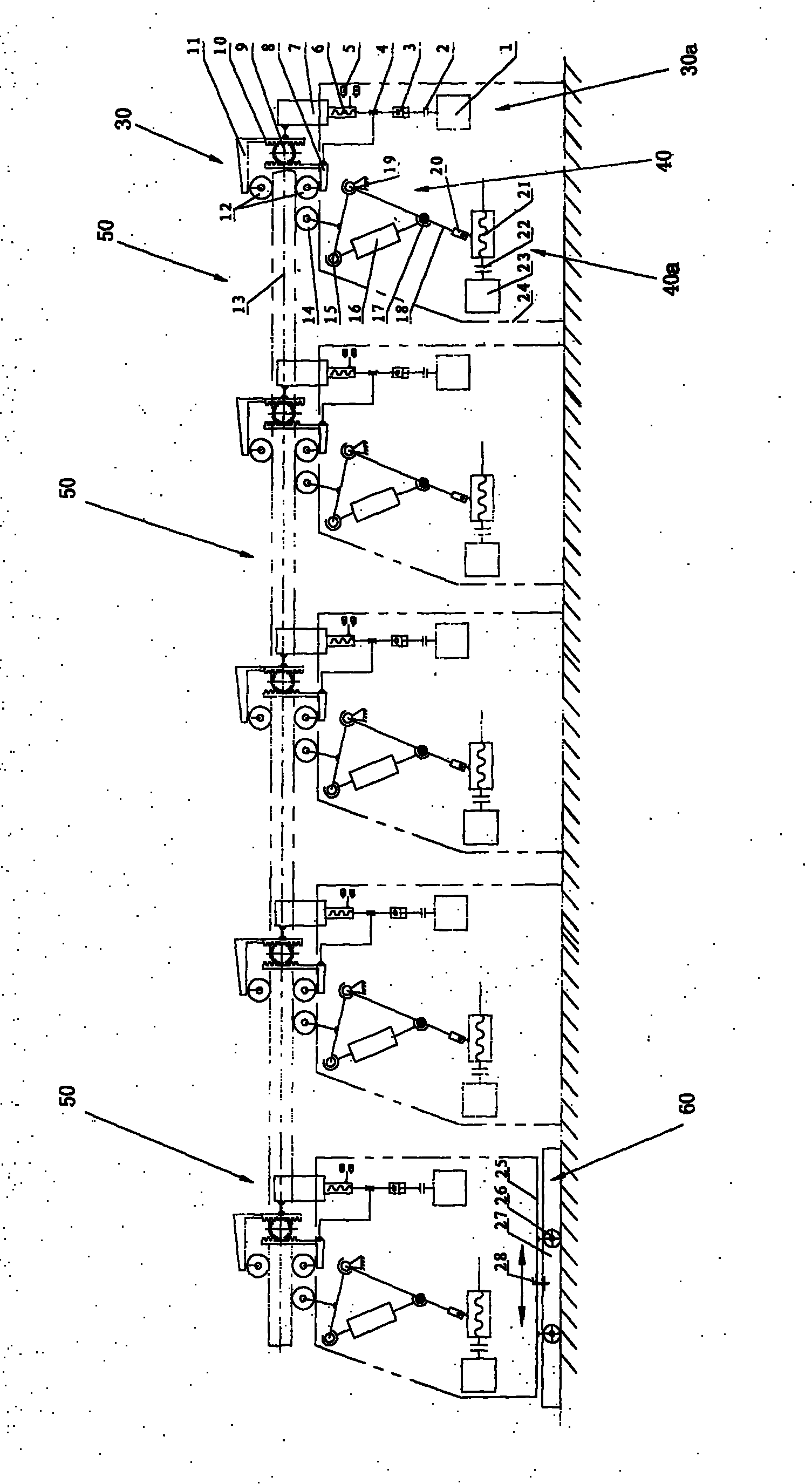

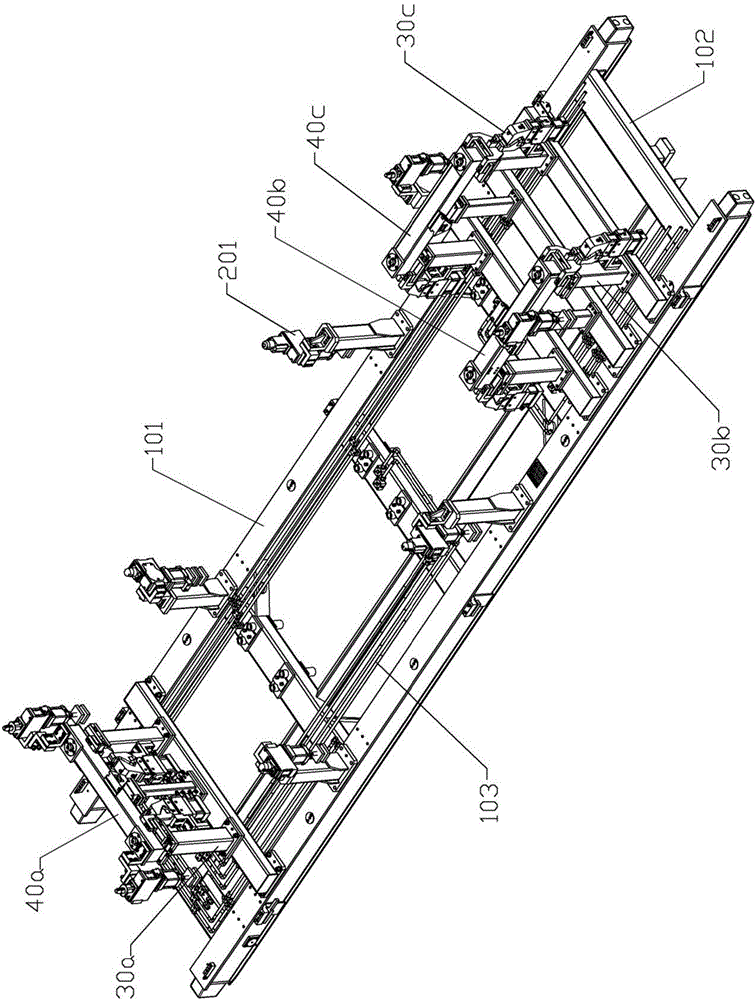

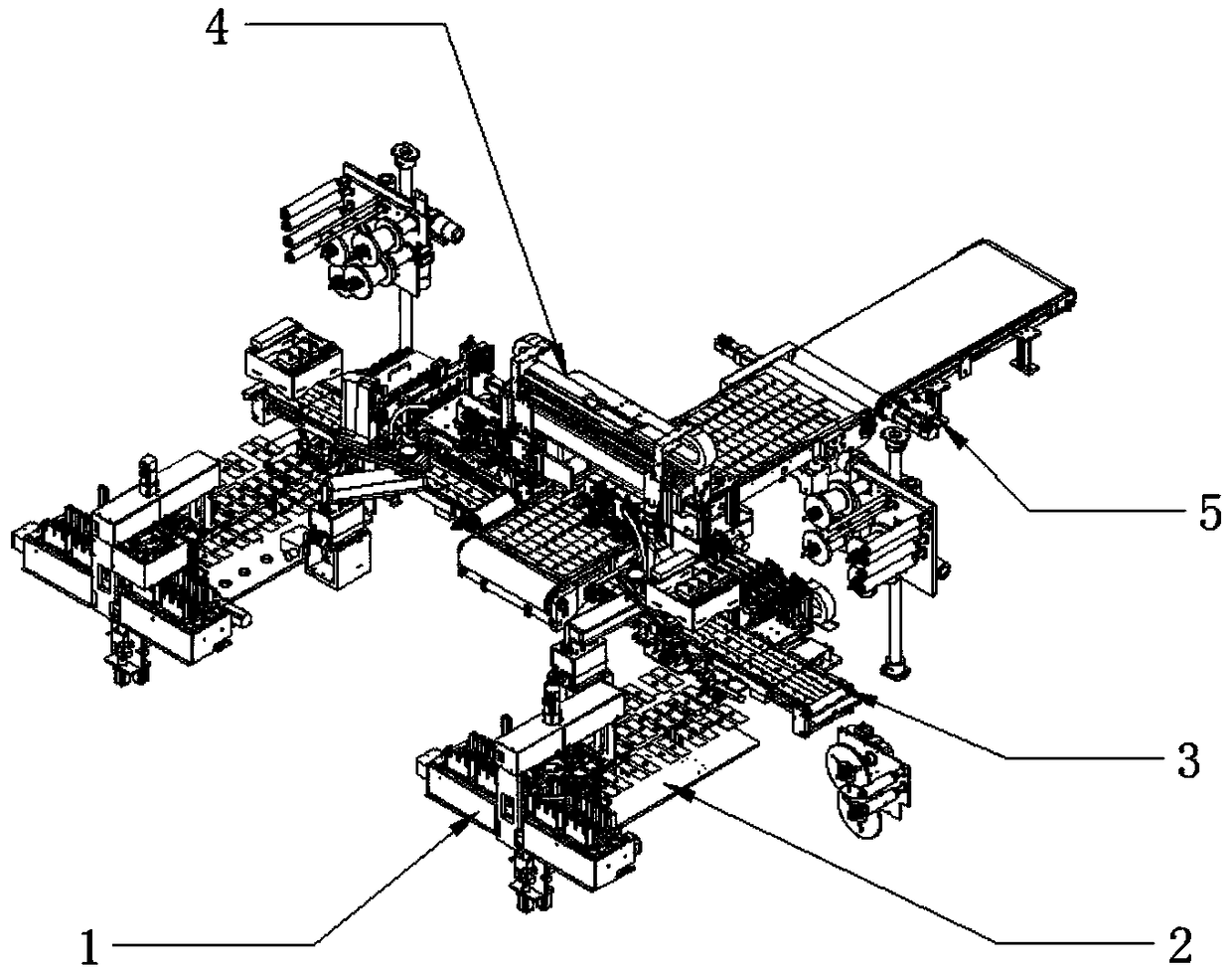

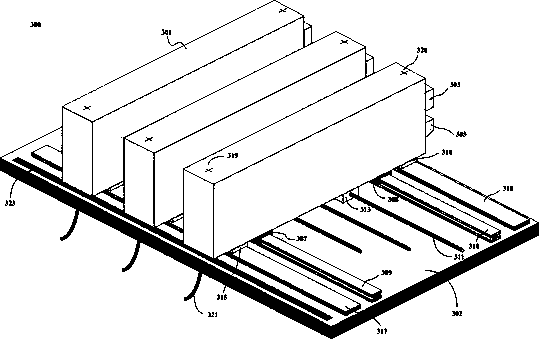

Automatic production line of laminated board and automatic production method of laminated board

ActiveCN109928209ARealize automated productionNo manual operationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineFixed frame

The invention provides an automatic production line of a laminated board and an automatic production method of the laminated board. The automatic production line comprises a double-head spot welding machine, a feeding mechanical arm, a discharging device and a conveying line; the discharging device comprises a machine frame, an overturning mechanism, a clamping mechanism, a clamping and positioning mechanism, a lifting discharging mechanism and a pushing mechanism, wherein the machine frame is arranged on the front side of a positioning mold, and the overturning mechanism is erected between the machine frame and the positioning mold; the overturning mechanism comprises a bearing seat, a swinging shaft, two overturning arms, a swinging driving part and a fixing frame, wherein the bearing seat and the swinging driving part are oppositely arranged, one end of the swing shaft is rotationally arranged on the bearing block, and the other end of the swing shaft is arranged on the swing driving part, the fixing frame is fixedly connected to the swing shaft, one ends of the two overturning arms are arranged on the fixing frame in a spaced mode through the clamping mechanism, the clamping and positioning mechanism is arranged at the extending end of each overturning arm, and the lifting discharging mechanism is arranged on the machine frame and is positioned between the two overturning arms. According to the automatic production line, the automatic production of the laminated board can be realized, and the working efficiency is improved.

Owner:HONORFAITH FURNITURE

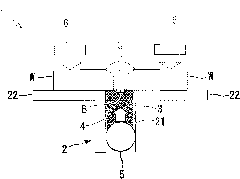

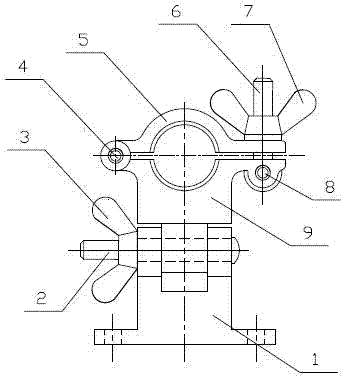

Hydraulic external line-up clamp for steel gas pipeline

InactiveCN111112935AGood adjustment functionEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the technical field of welding auxiliary tools, in particular to a hydraulic external line-up clamp for a steel gas pipeline. The hydraulic external line-up clamp comprises apositioning plate, a central positioning element, lateral positioning elements and a synchronous feeding mechanism, wherein the central positioning element comprises two symmetric middle half rings and a first hydraulic cylinder; the two middle half rings are hinged; the articulated shafts of the two middle half rings are arranged on the upper surface of the positioning plate; the first hydrauliccylinder can drive the two middle half rings to be tightly abutted; the two lateral positioning elements are symmetrically arranged on two sides of an axial line direction of each middle half ring; the positioning plate is fixedly provided with spacing rods; the two spacing rods are independently positioned on two sides of the central positioning element and are positioned on lateral sides of theaxial line direction of lateral half rings; and the synchronous feeding mechanism can drive the two lateral positioning elements to synchronously move to a direction near or far away from the centralpositioning element relative to the positioning plate. According to the hydraulic external line-up clamp, a function that a worker can conveniently regulate a welding line between two pipelines is realized.

Owner:SHANGHAI ANHONG CONSTR ENG CO LTD

Fixing device of welding cable of welding robot

InactiveCN103498966ALarge clamping forceWork reliablyPipe supportsWelding/cutting auxillary devicesPower cableEngineering

Owner:JISHOU WOHUADE ROBOT SCI & TECH

High-speed photovoltaic module production device and high-speed photovoltaic module production method

InactiveCN108161328AWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryManipulator

Owner:SUZHOU CHENZHENG SOLAR ENERGY EQUIP CO LTD

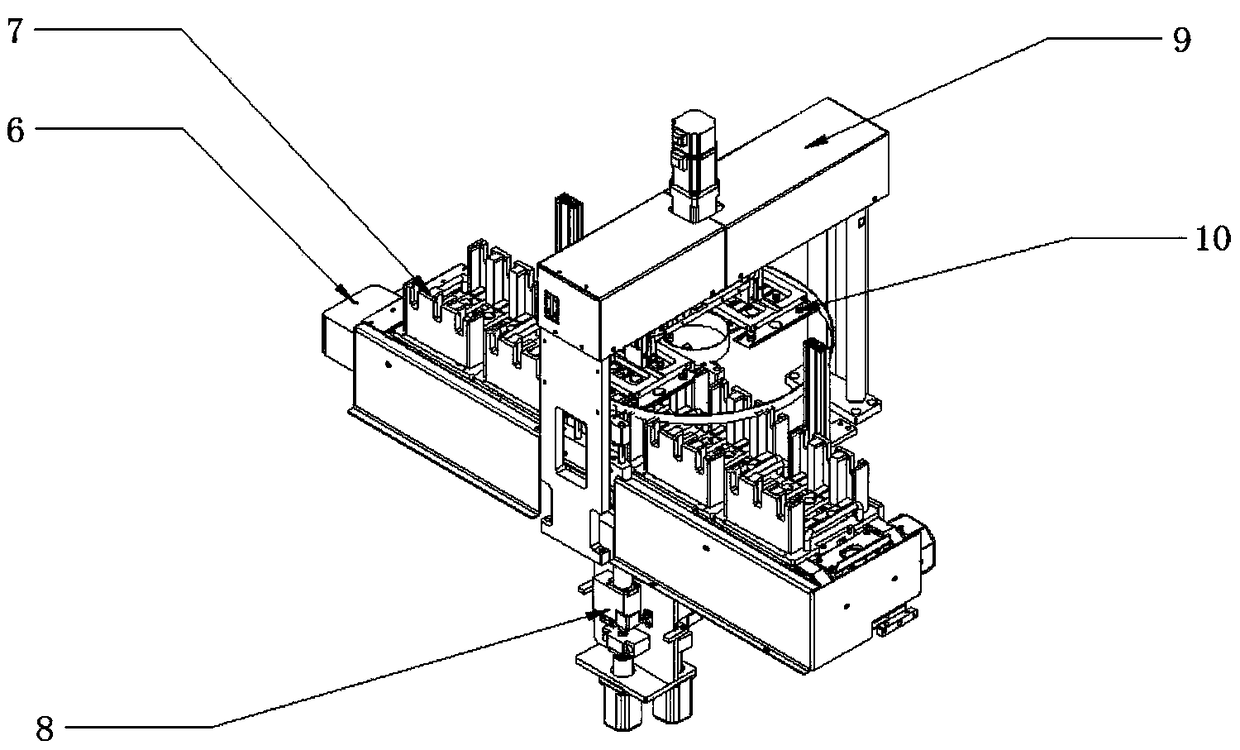

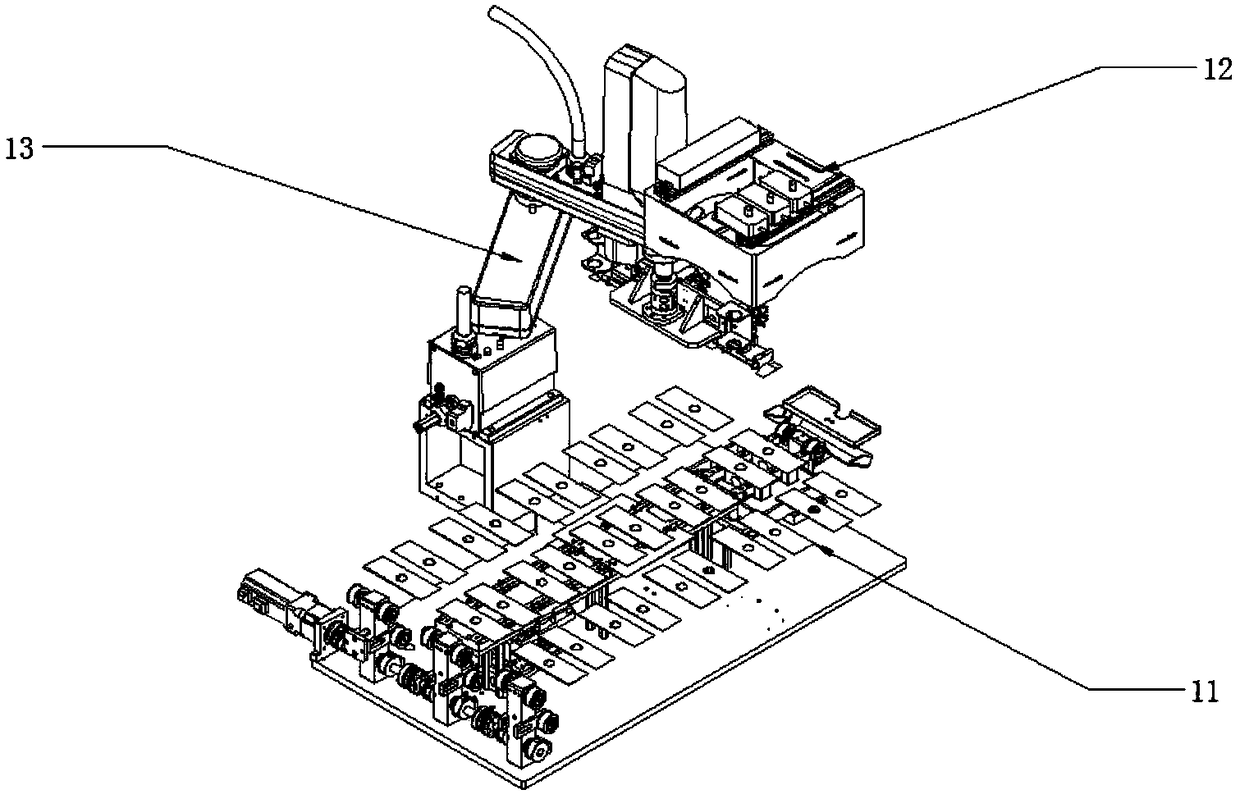

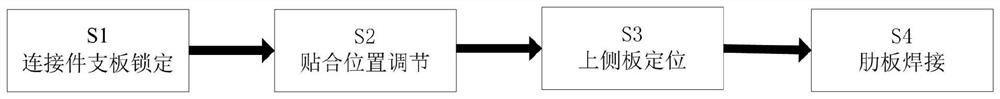

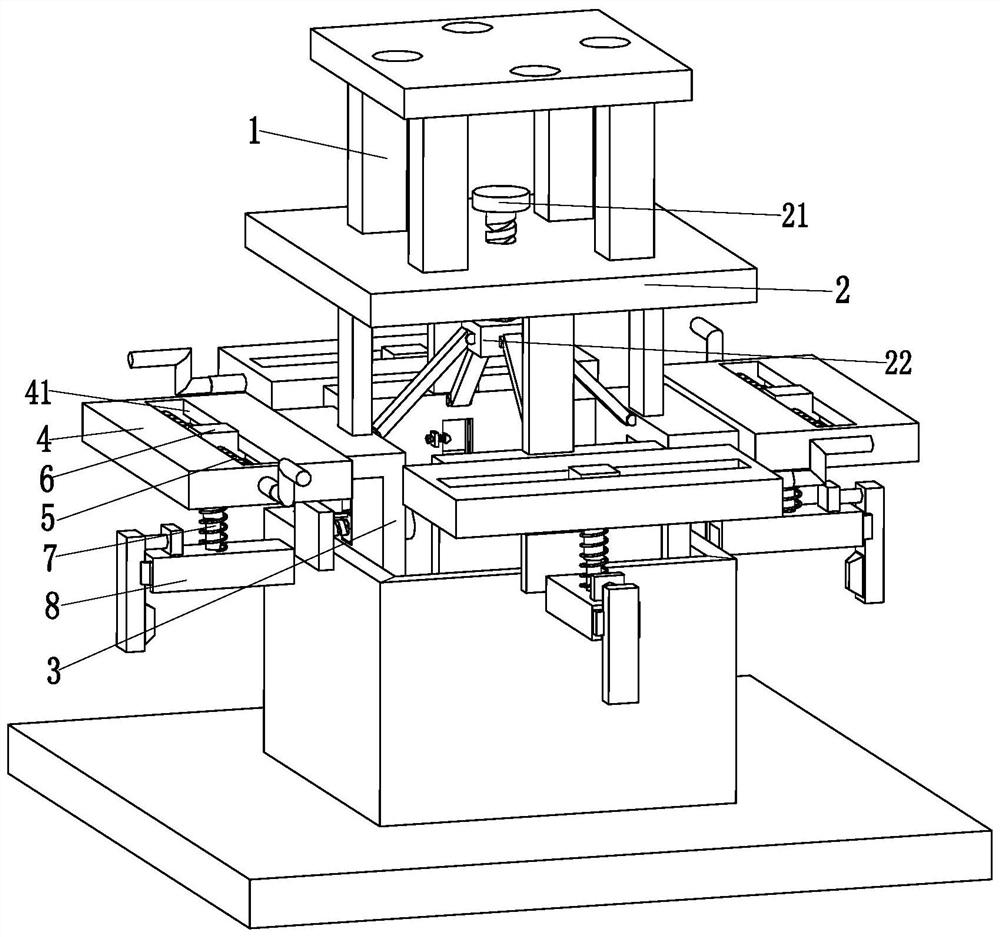

Forming process of support connecting piece of bridge steel structure foundation

ActiveCN111822930AWelding/cutting auxillary devicesAuxillary welding devicesEngineeringForming processes

Owner:GUANGZHOU JISHI CONSTR GRP +1

Structural design and use method of net tensioning equipment

PendingCN111112884AHigh precisionEliminate displacementVacuum evaporation coatingWelding/cutting auxillary devicesControl cellStructural engineering

Owner:SUZHOU JINGLAI OPTO CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap