Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Gas pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

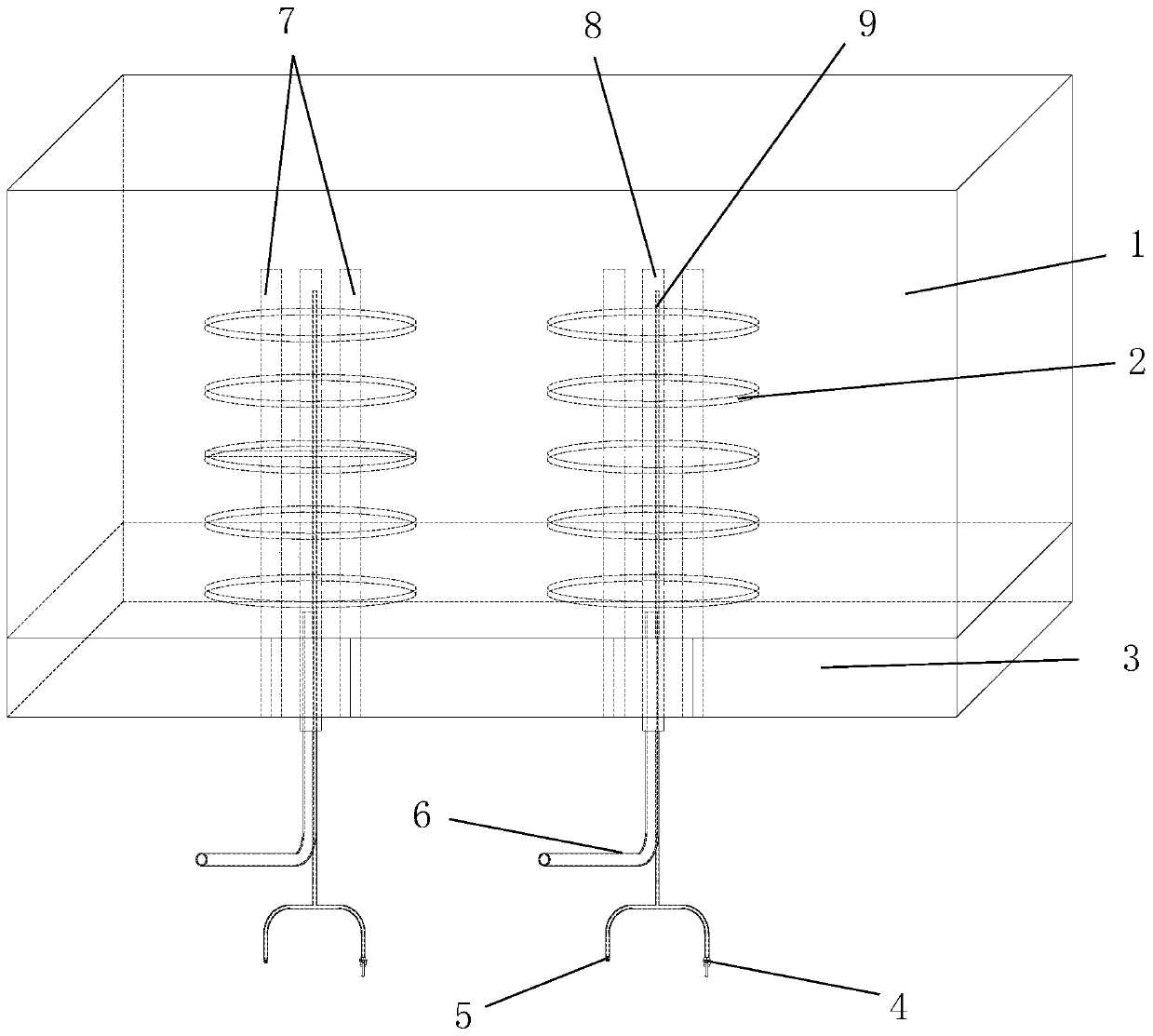

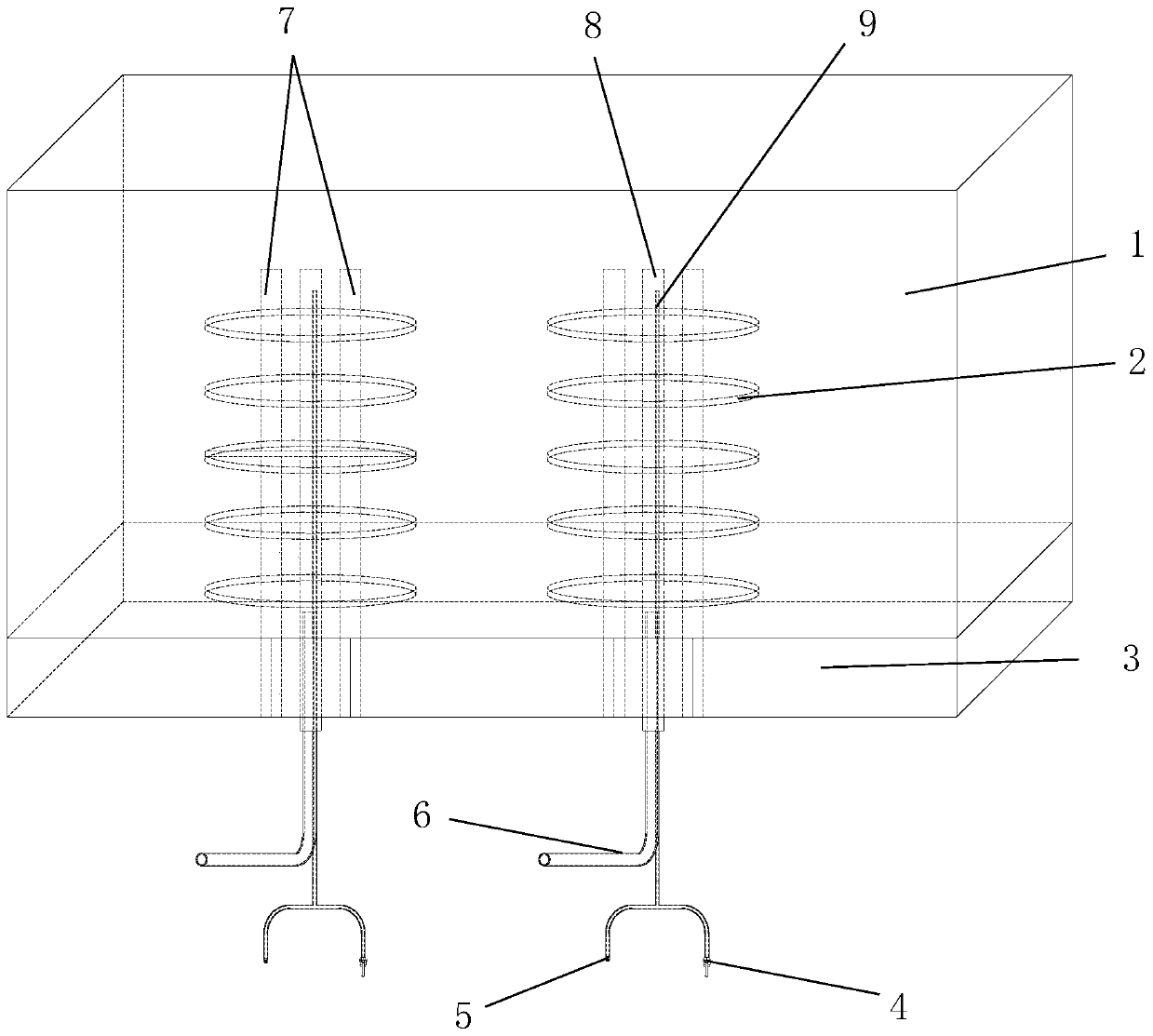

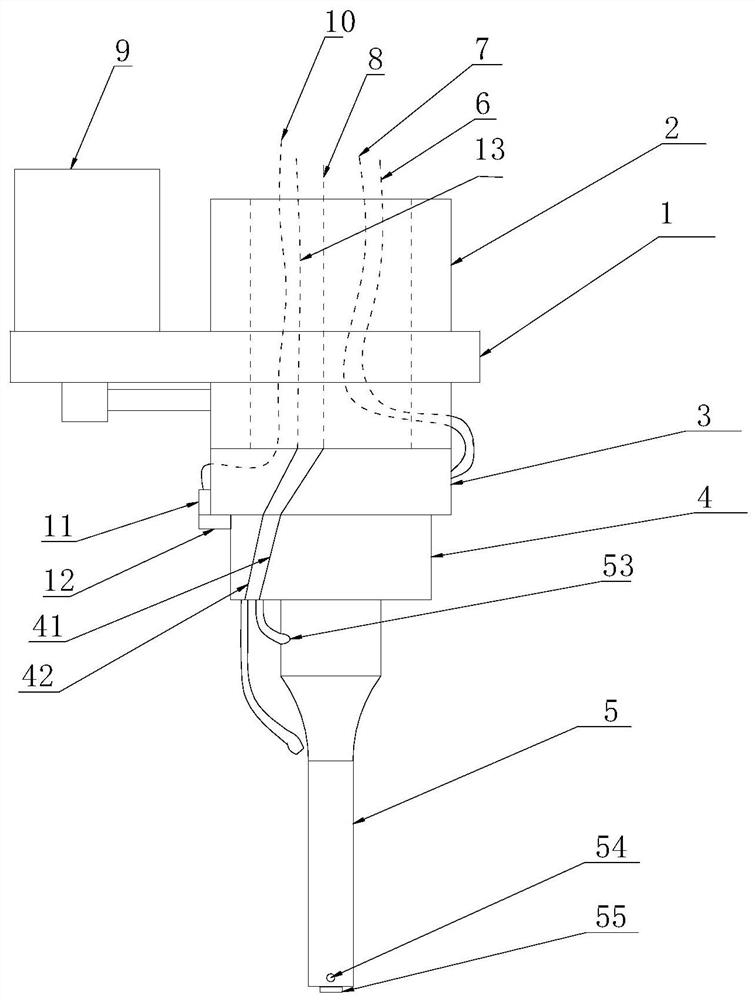

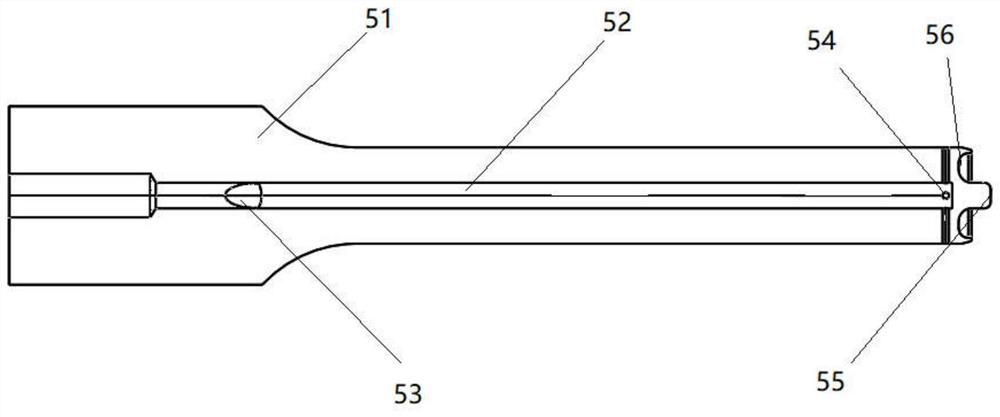

Coal seam anti-reflection method for circular damage by using cold shock of liquid nitrogen and phase change gas

ActiveCN111119829AGood cracking and anti-reflection effectFast injectionDrilling rodsFluid removalEngineeringNitrogen gas

Owner:CHINA UNIV OF MINING & TECH

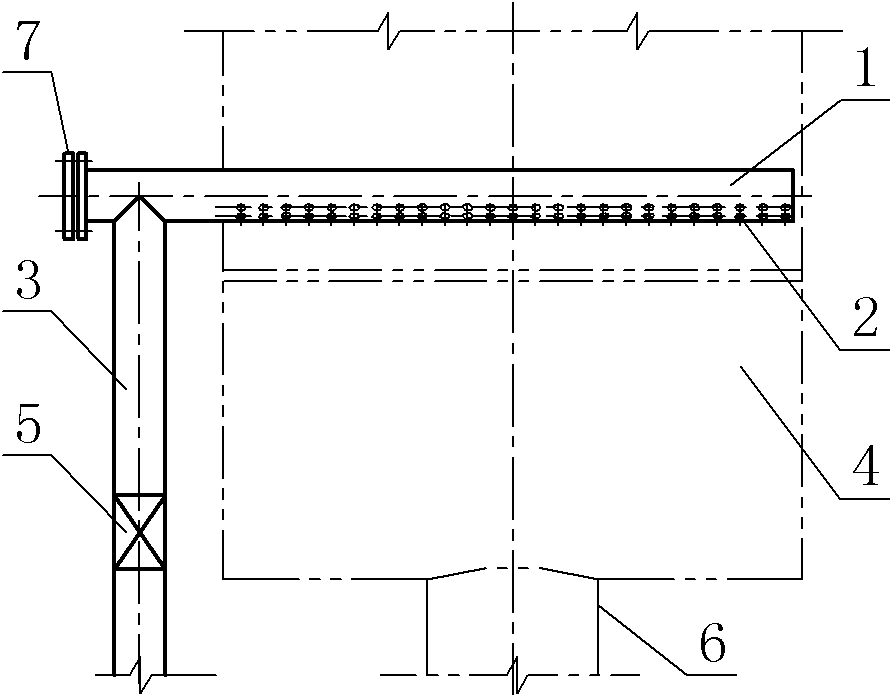

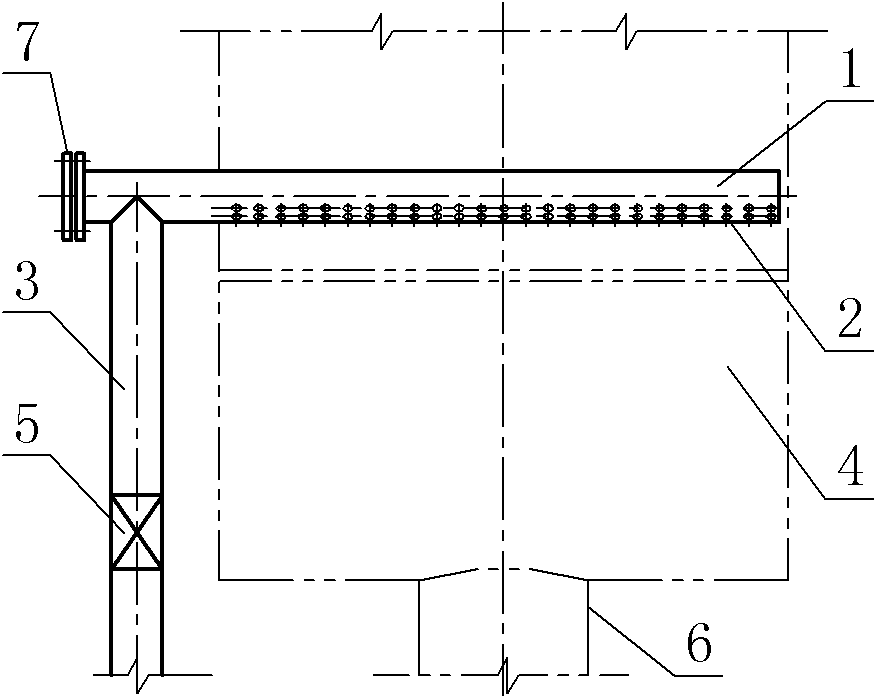

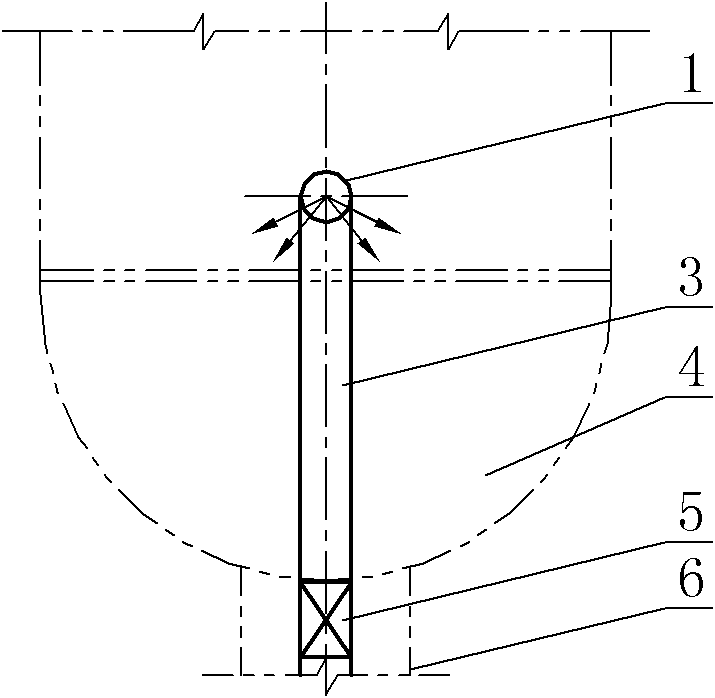

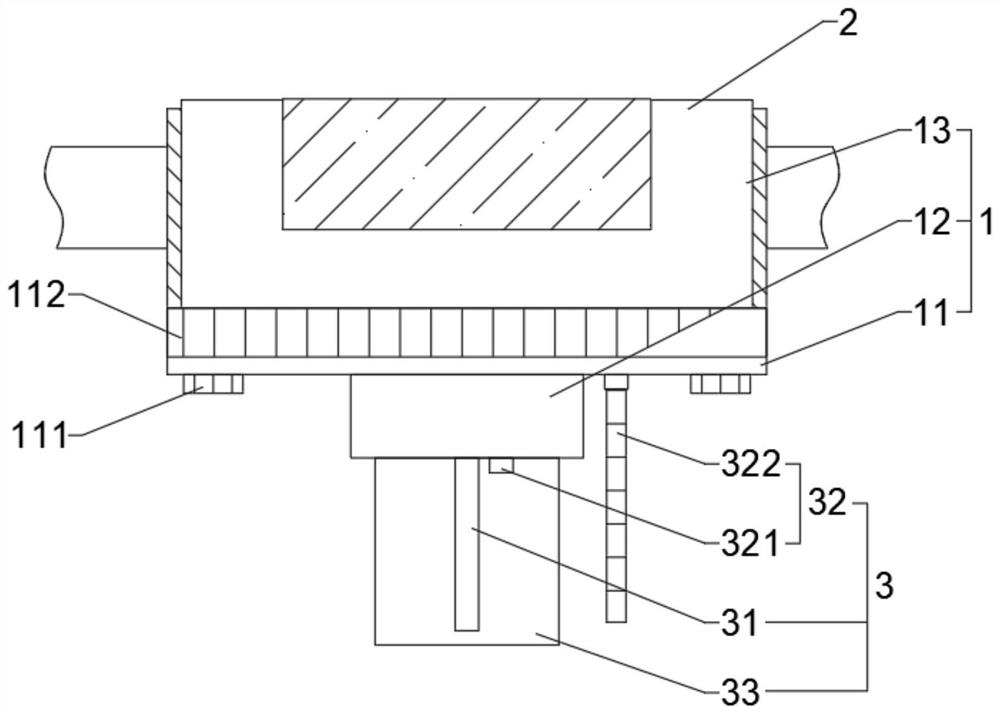

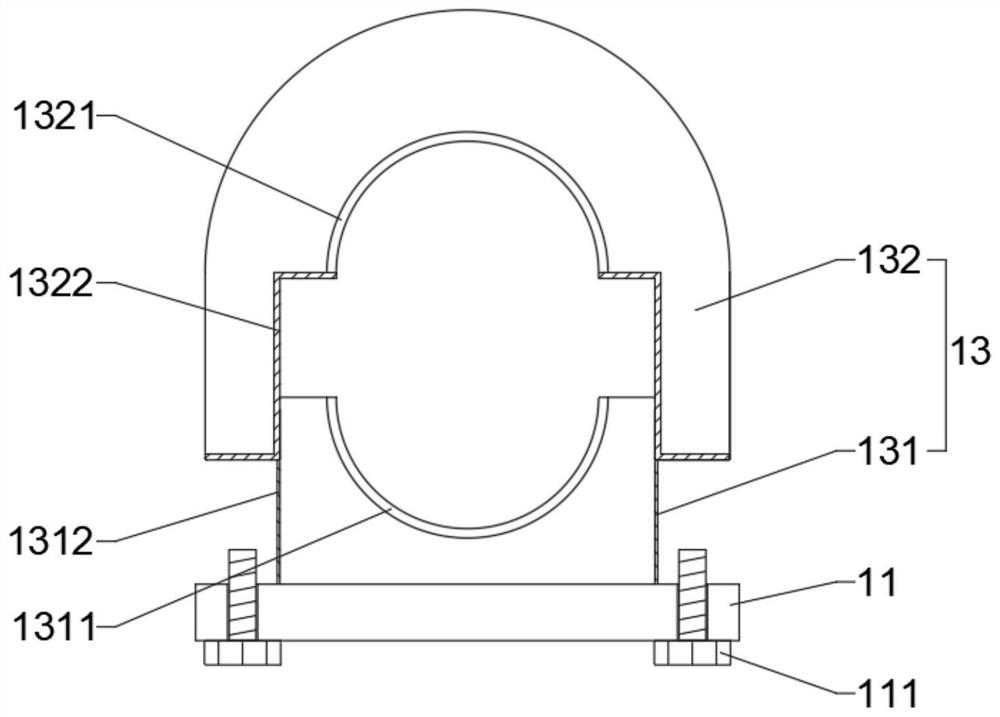

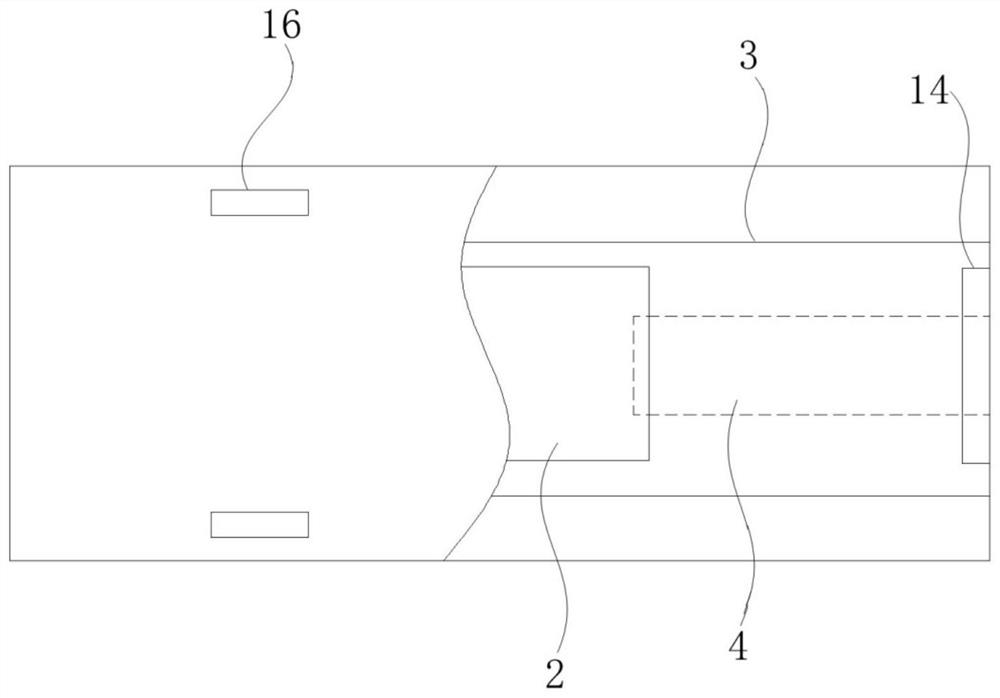

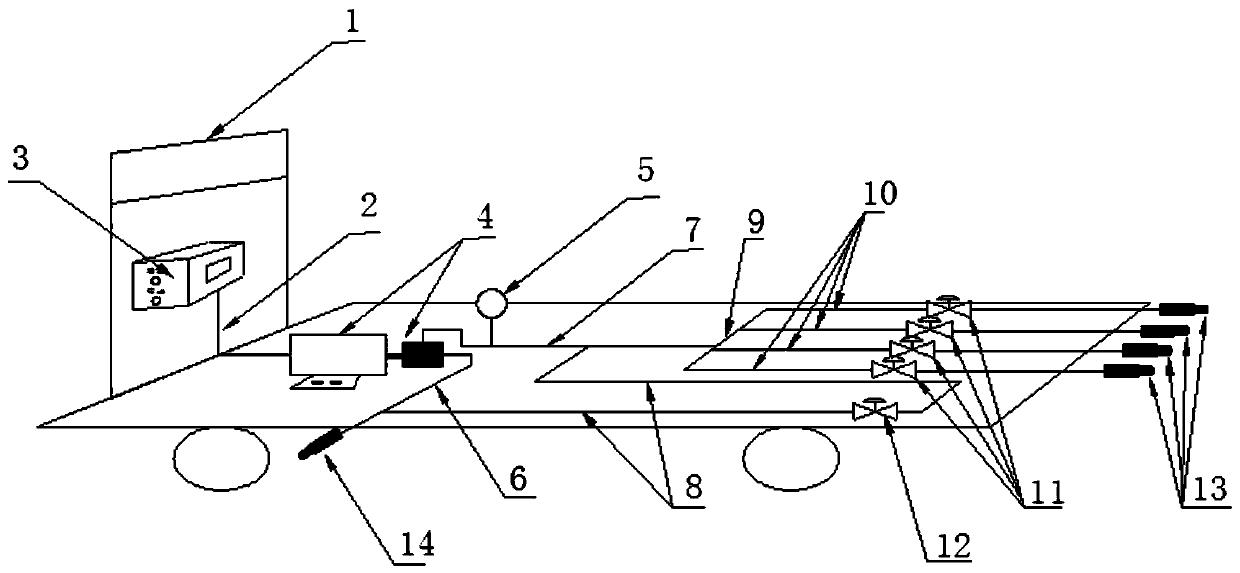

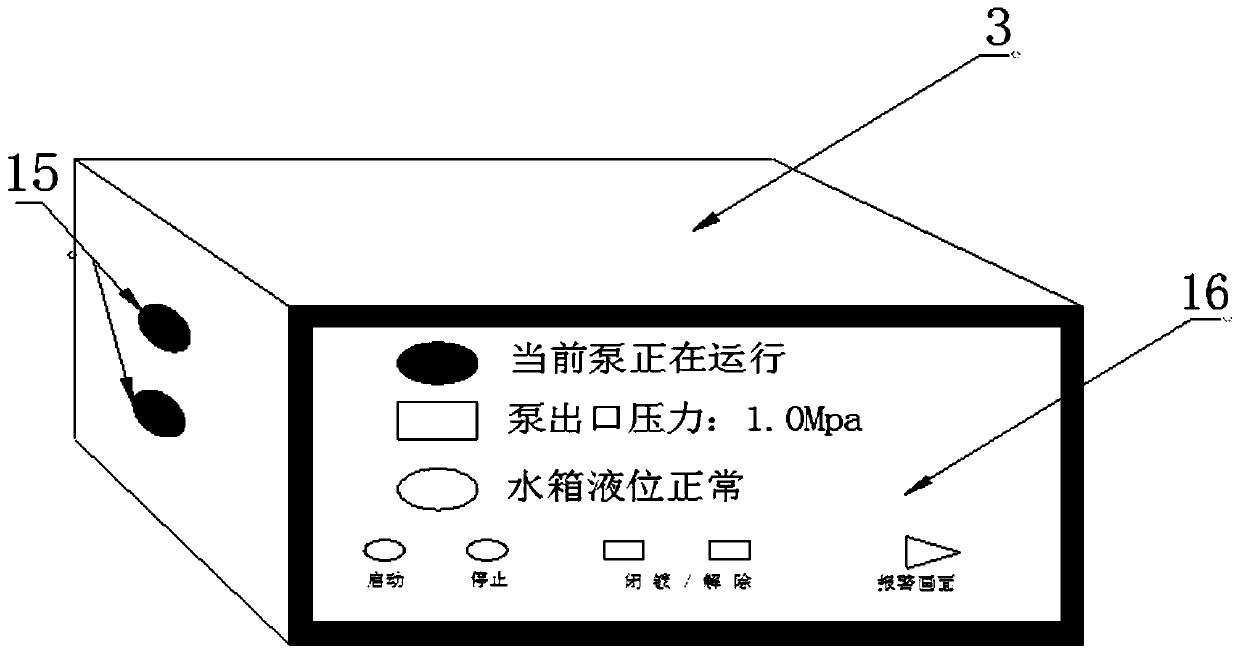

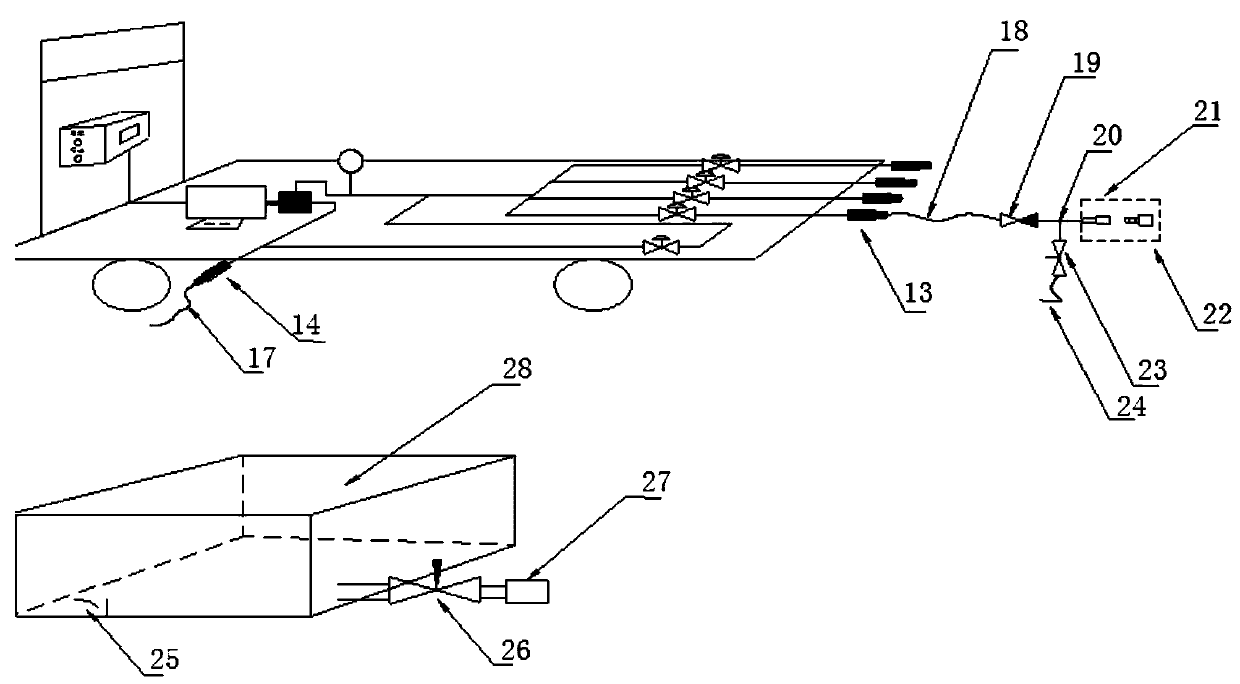

Hydraulic external line-up clamp for steel gas pipeline

InactiveCN111112935AGood adjustment functionEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the technical field of welding auxiliary tools, in particular to a hydraulic external line-up clamp for a steel gas pipeline. The hydraulic external line-up clamp comprises apositioning plate, a central positioning element, lateral positioning elements and a synchronous feeding mechanism, wherein the central positioning element comprises two symmetric middle half rings and a first hydraulic cylinder; the two middle half rings are hinged; the articulated shafts of the two middle half rings are arranged on the upper surface of the positioning plate; the first hydrauliccylinder can drive the two middle half rings to be tightly abutted; the two lateral positioning elements are symmetrically arranged on two sides of an axial line direction of each middle half ring; the positioning plate is fixedly provided with spacing rods; the two spacing rods are independently positioned on two sides of the central positioning element and are positioned on lateral sides of theaxial line direction of lateral half rings; and the synchronous feeding mechanism can drive the two lateral positioning elements to synchronously move to a direction near or far away from the centralpositioning element relative to the positioning plate. According to the hydraulic external line-up clamp, a function that a worker can conveniently regulate a welding line between two pipelines is realized.

Owner:SHANGHAI ANHONG CONSTR ENG CO LTD

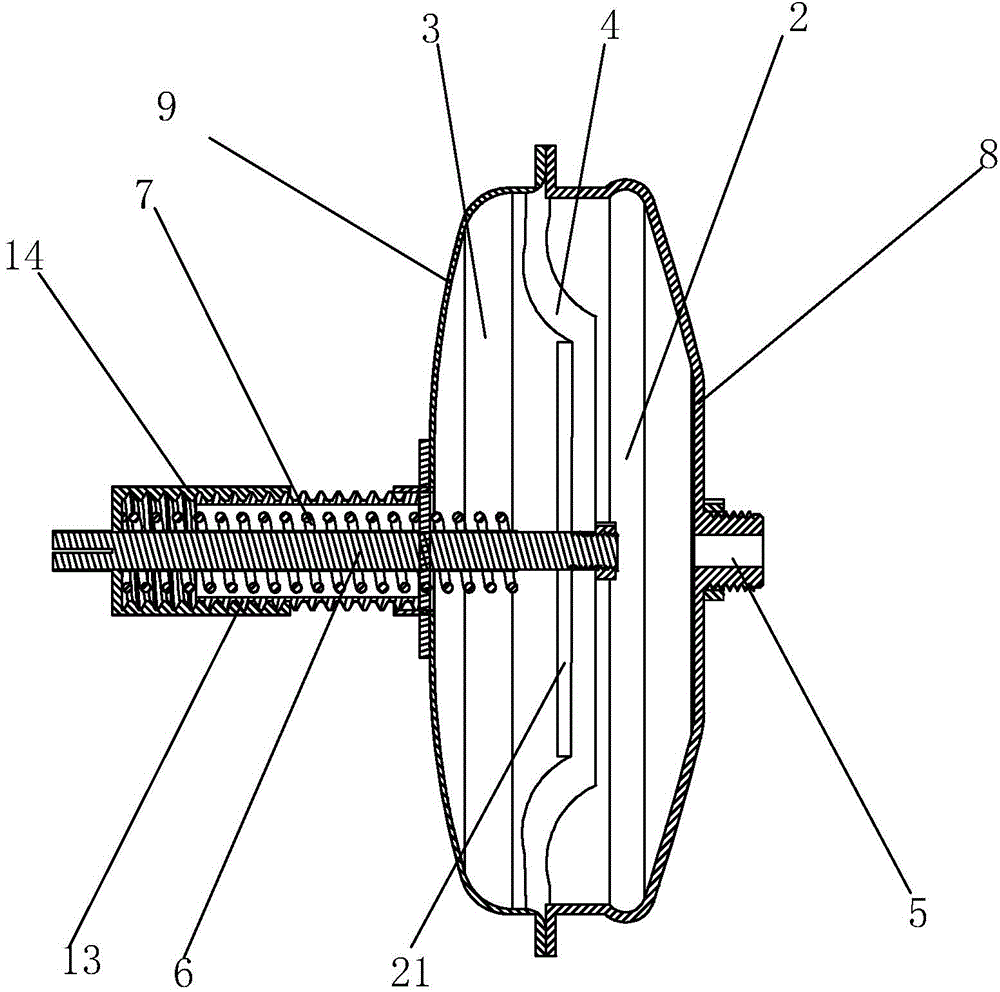

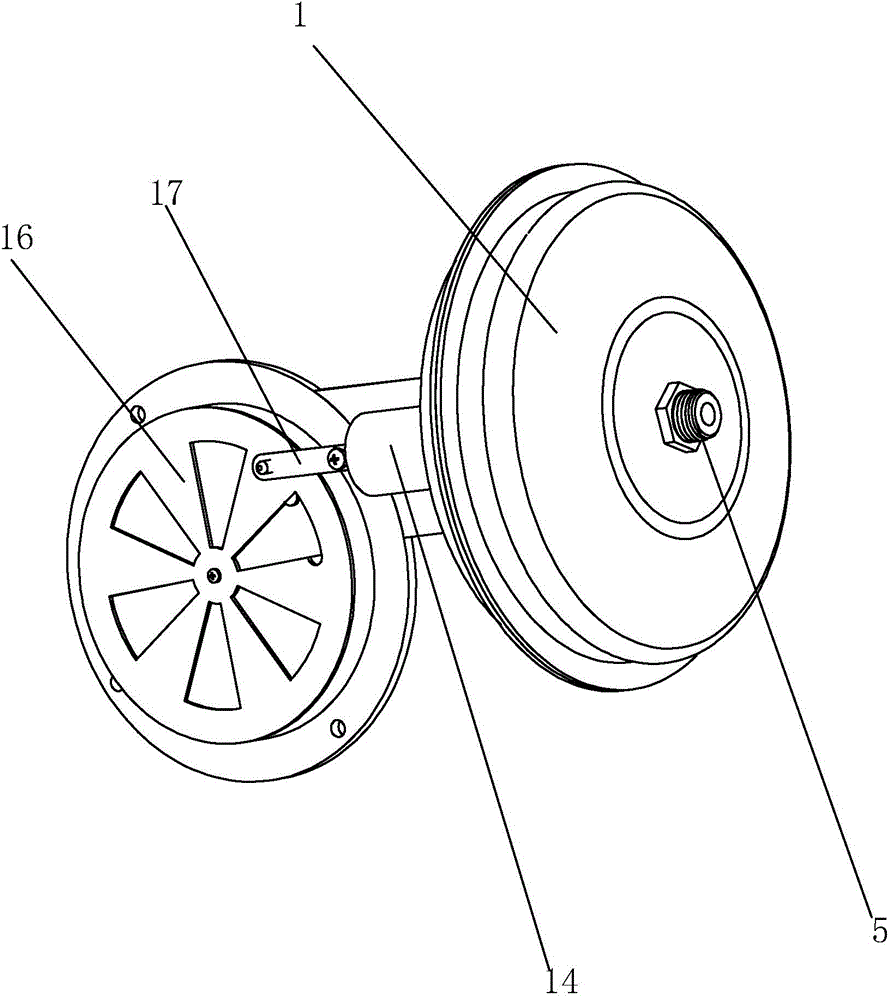

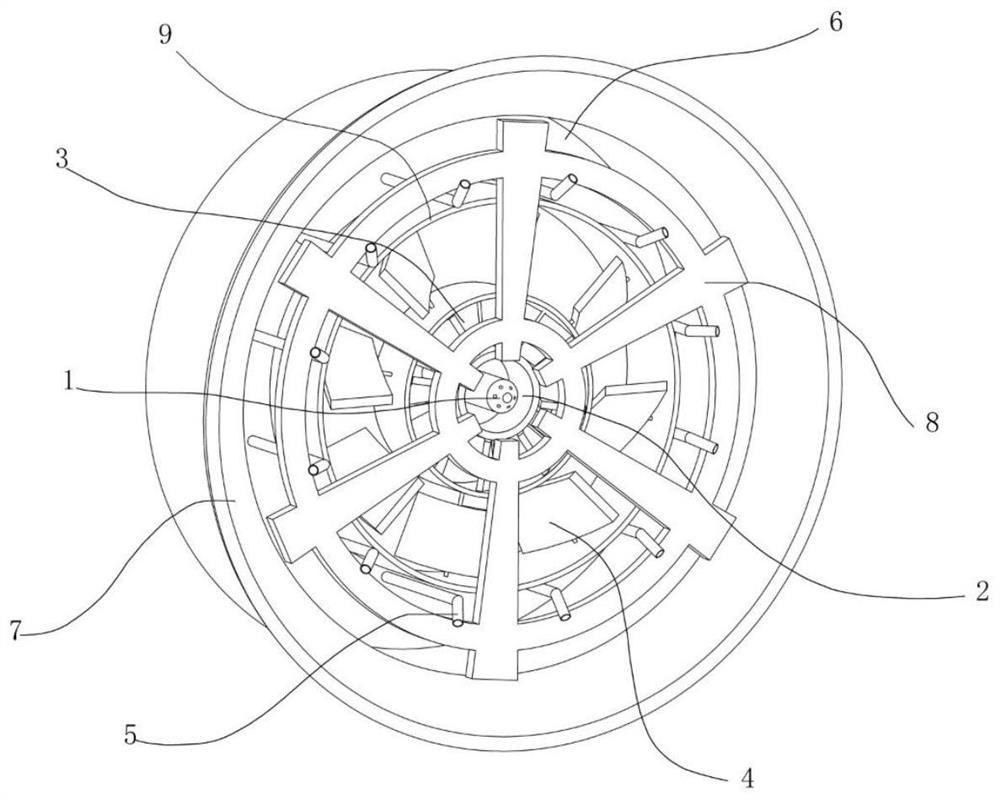

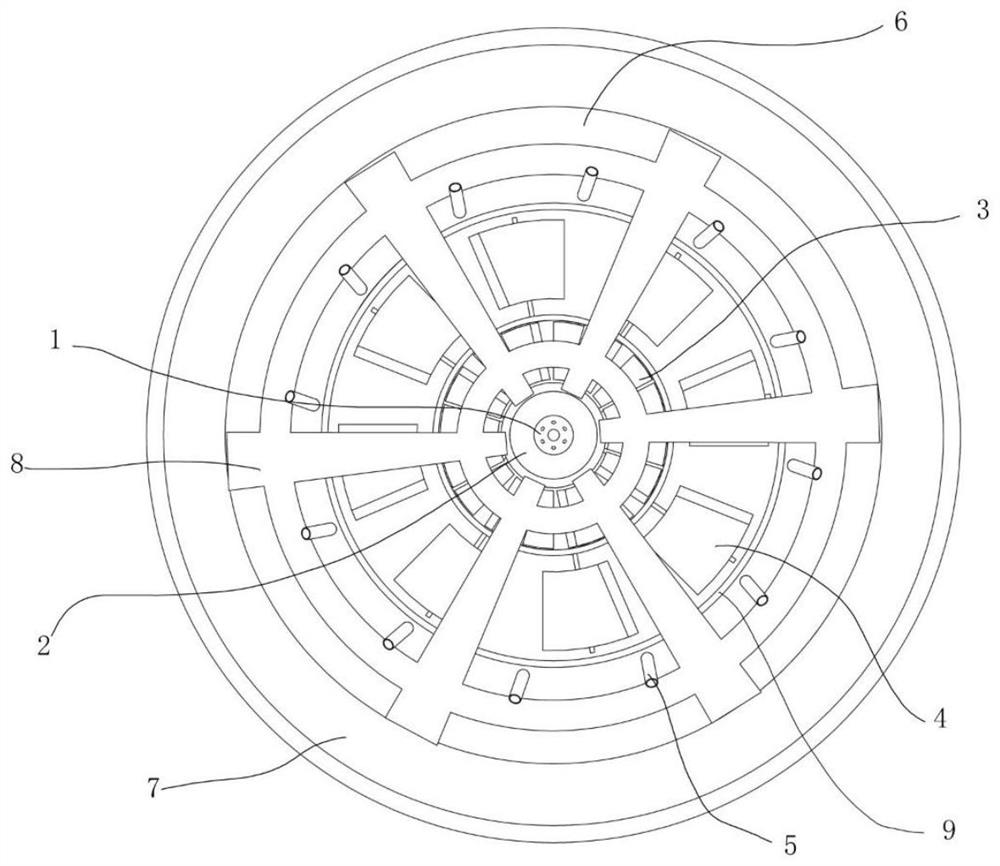

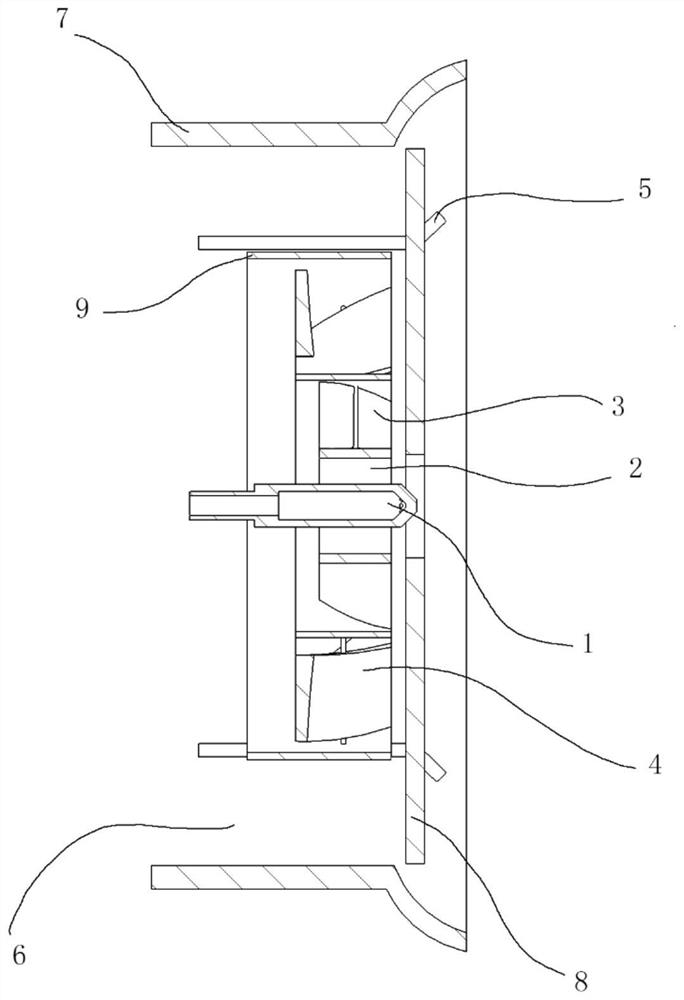

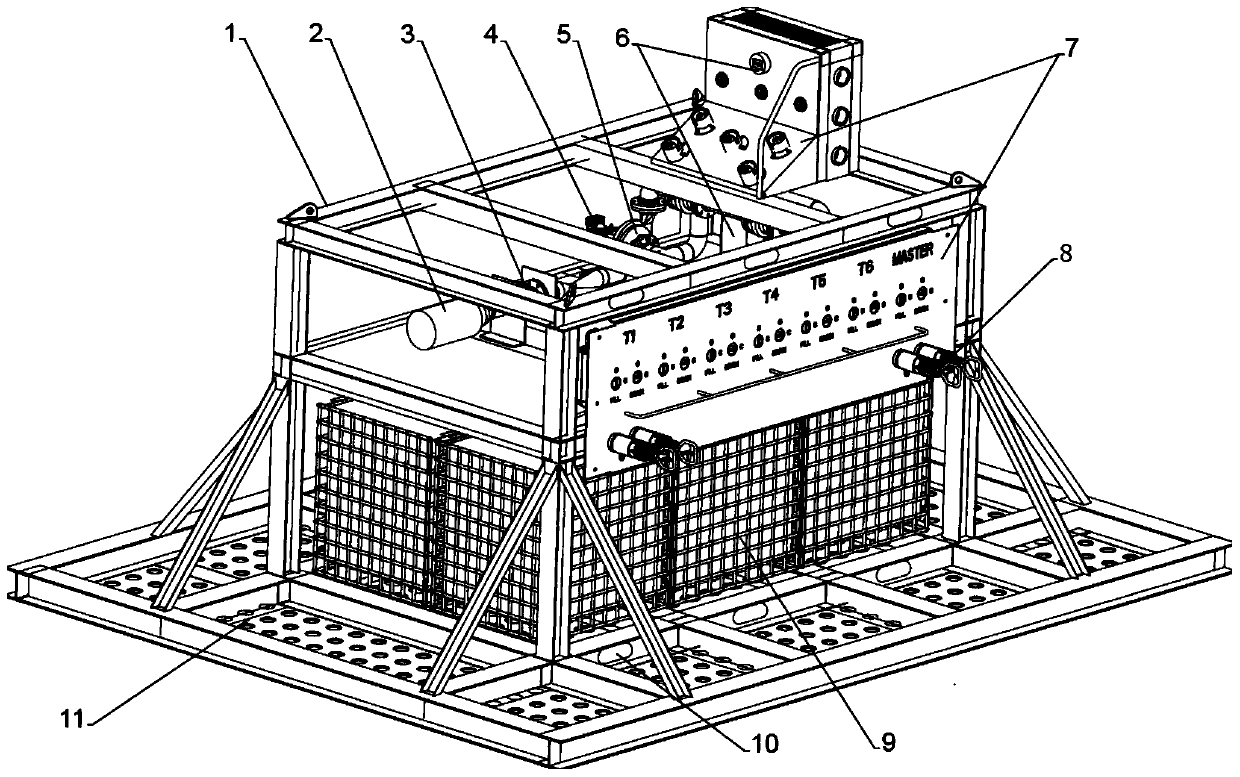

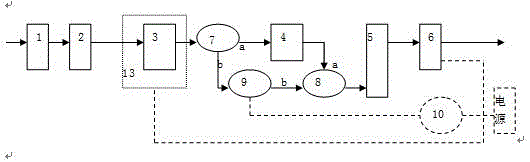

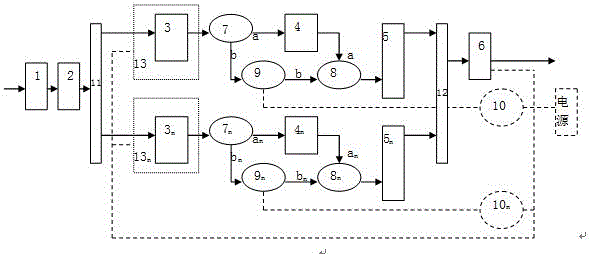

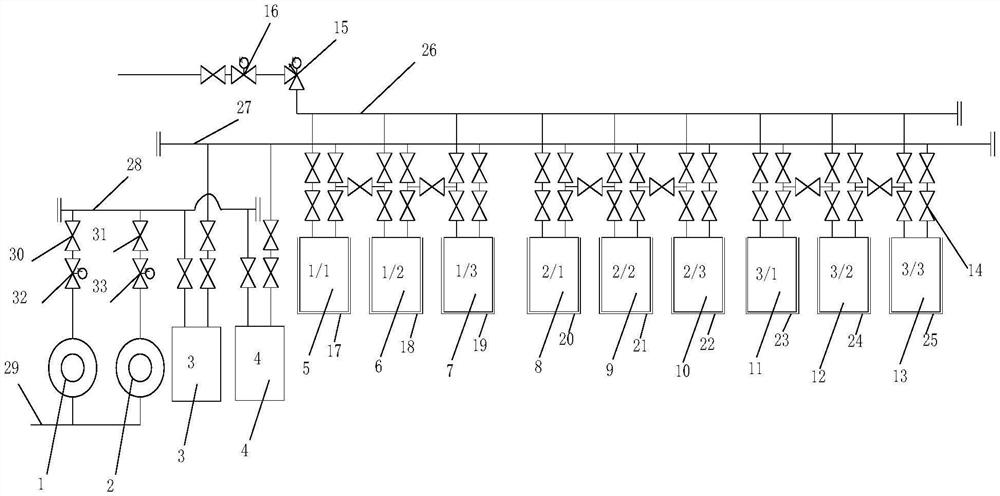

Natural gas differential pressure energy recovery unit device

InactiveCN105757455AQuick meshEasy to separatePipeline systemsSteam engine plantsElectricityDifferential pressure

The invention provides a natural gas differential pressure energy recovery unit device which is arranged between a natural gas inlet pipeline and a natural gas low pressure equipment pipeline.The device comprises a turbo expander, a gas inlet pipeline of the turbo expander is connected with the natural gas inlet pipeline, an exhaust pipeline of the turbo expander is connected with the equipment pipeline in need of natural gas, the turbo expander is further connected with a clutch, an output shaft of a motor is coaxially connected with a compressor, and the other end of the motor is coaxially connected with the turbo expander through the clutch.Compared with the prior art, the turbo expander of the natural gas differential pressure energy recovery unit device and a pressure regulator subcircuit are arranged in parallel, when the turbo expander breaks down and the clutch separates quickly, a gas circuit can be switched to the pressure regulator subcircuit rapidly, and normal operation of a system is not influenced.Through arrangement of the turbo expander, a pressure regulator can be effectively replaced to achieve the function of lowering the pressure, meanwhile, action is conducted outward, the compressor is driven to run, self-consumed electricity is effectively reduced, and full utilization of energy is achieved.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

Gas cooker pipeline machining device

InactiveCN107971783AFast processingImprove processing efficiencyPositioning apparatusMaintainance and safety accessoriesEngineeringCooker

The invention relates to the technical field of gas cooker part machining, and discloses a gas cooker pipeline machining device which comprises a base and a supporting frame. The supporting frame is fixedly connected to the upper surface of the base, two electric push rods are fixedly connected to the top of the inner side of the supporting frame, and a bearing plate is fixedly connected to the tail ends of the two electric push rods. By means of mutual cooperation of the base, the supporting frame, the electric push rods, the bearing plate and a driving device, the problem that an existing gas cooker pipeline machining device is low in machining efficiency is solved. By means of mutual cooperation of an installation plate, the driving device and a clamp device, the problem that an existing gas cooker pipeline machining device cannot rapidly and effectively position gas pipelines is solved. By means of mutual cooperation of the installation plate, the driving device, the clamp device and a cleaning device, the problem that fragment stacking produced in the using process of an existing gas cooker pipeline machining device affects machining precision is solved.

Owner:XINCHANG CHANGCHENG AIR-CONDITIONER COMPONENTS INC

Air and gas synchronous controller

Owner:NINGBO XIANGYING KITCHEN EQUIP ENG

Ammonia low-nitrogen multi-stage rotational-flow burner

ActiveCN112963833AWell mixedUniform heat loadAir supply regulationGaseous fuel burnerCombustorThermal radiation

Owner:XI AN JIAOTONG UNIV

Liquid feed distributor for lamella heat exchanger

Owner:GANSU LANPEC TECH +3

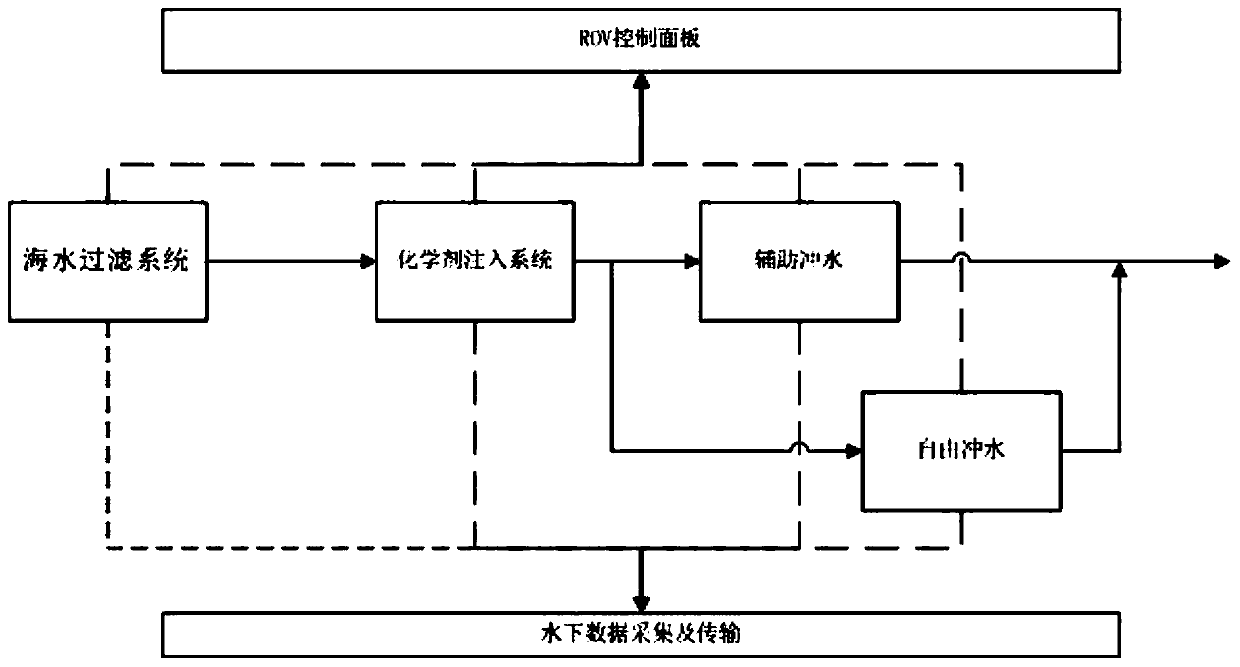

Device applicable to pipe washing work of deep sea oil and gas pipeline

InactiveCN110252750AOvercome stressOvercoming resistance along the wayHollow article cleaningPiggingPore water pressure

Owner:OFFSHORE OIL ENG +1

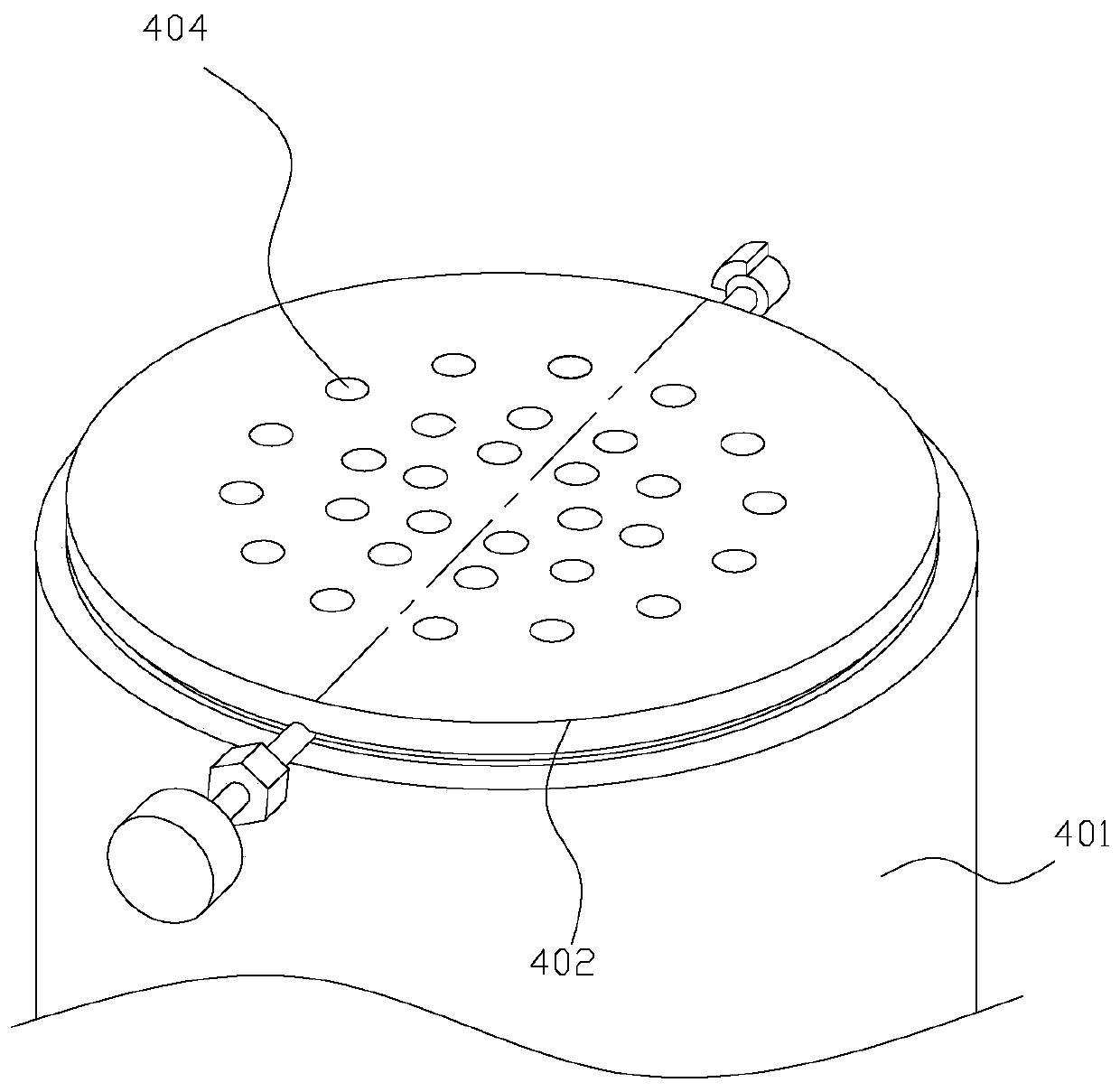

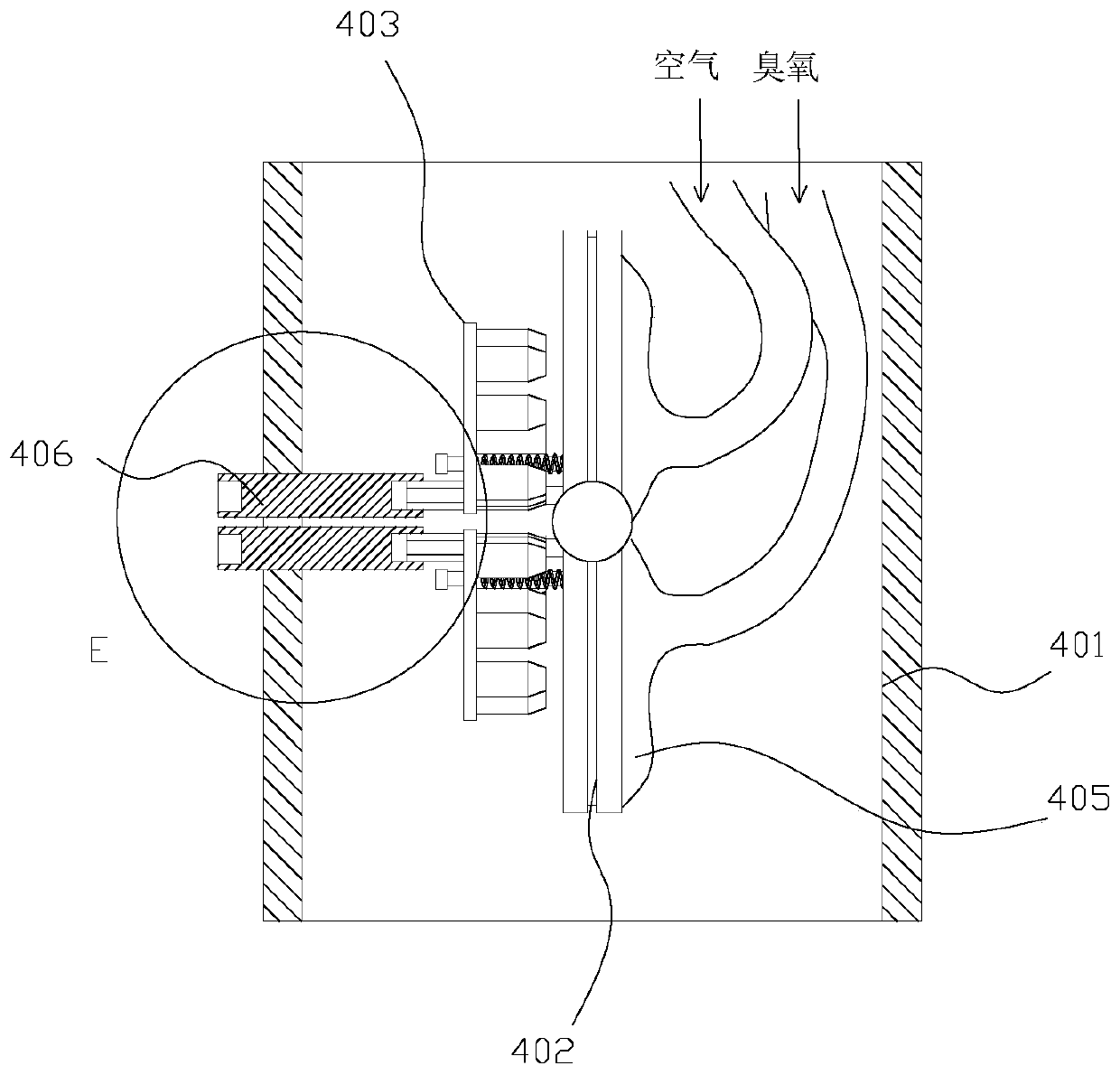

High-voltage electro-catalysis discharge reactor

ActiveCN106475029ALow operating costImprove efficiencyDispersed particle separationEnergy based chemical/physical/physico-chemical processesNitric oxideHigh voltage

The invention discloses a high-voltage electro-catalysis discharge reactor which comprises a positive polar discharge reactor and a negative polar discharge reactor which are connected through a gas pipeline, wherein the positive polar discharge reactor comprises at least one discharge structure unit I; each discharge structure unit I comprises at least one group of discharge assemblies I; each discharge assembly I comprises a PCB I uniformly equipped with discharge needles, two discharge reactors I fitted to two sides of the PCB I and two module insulation plates I fitted to the outer sides of the discharge reactors I; and catalytic agent carriers are further embedded into the discharge reactors I. The high-voltage electro-catalysis discharge reactor can efficiently decompose oxysulphide, nitric oxide and carbon dioxide under the reducing atmosphere and can remove various heavy metal pollutions and volatile organic compounds under the oxidizing atmosphere.

Owner:QIDONG HUIHUA HEALTH TECH CO LTD

Removal method of outdoor hanging steps

InactiveCN112727147AReduce demandNo drop phenomenonBuilding repairsBridge strengtheningArchitectural engineeringCrusher

Owner:ZHEJIANG YIJIAN CONSTR GROUP

Cecropin antibacterial peptide fermentation sterilization equipment and sterilization method thereof

Owner:LINZHOU SINAGRI YINGTAI BIOLOGICAL PEPTIDES CO LTD

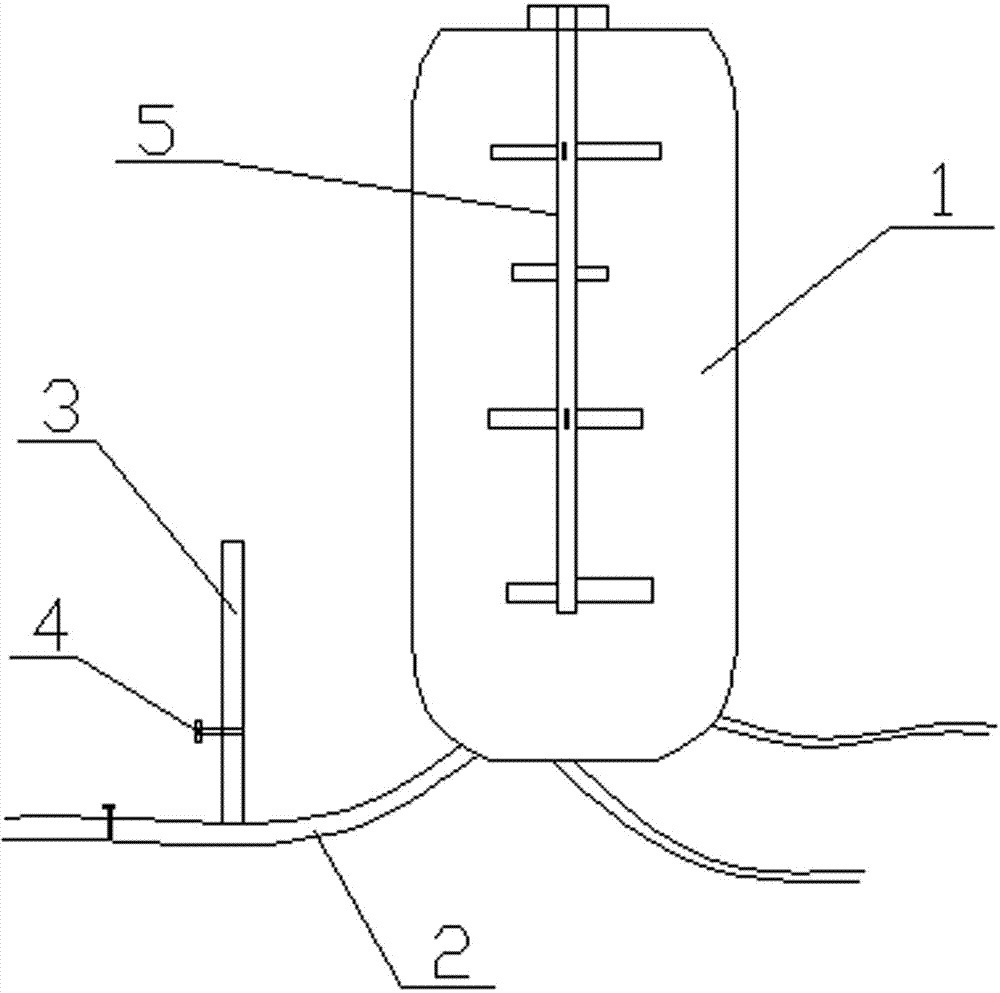

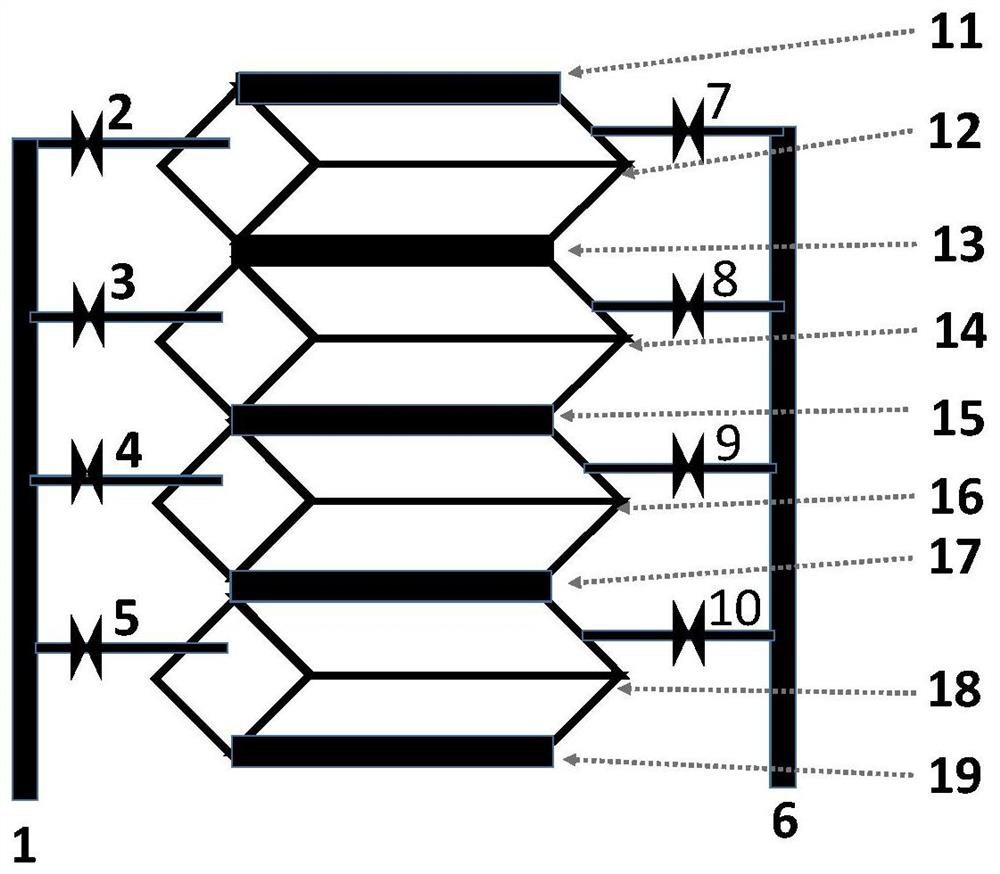

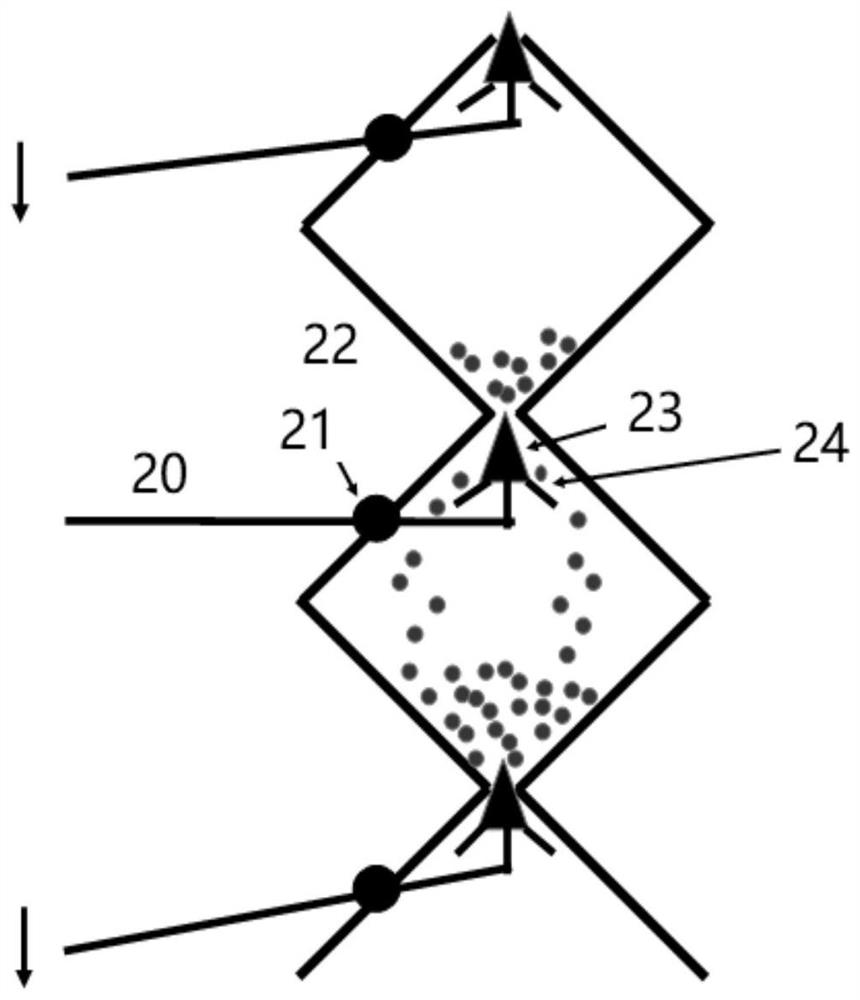

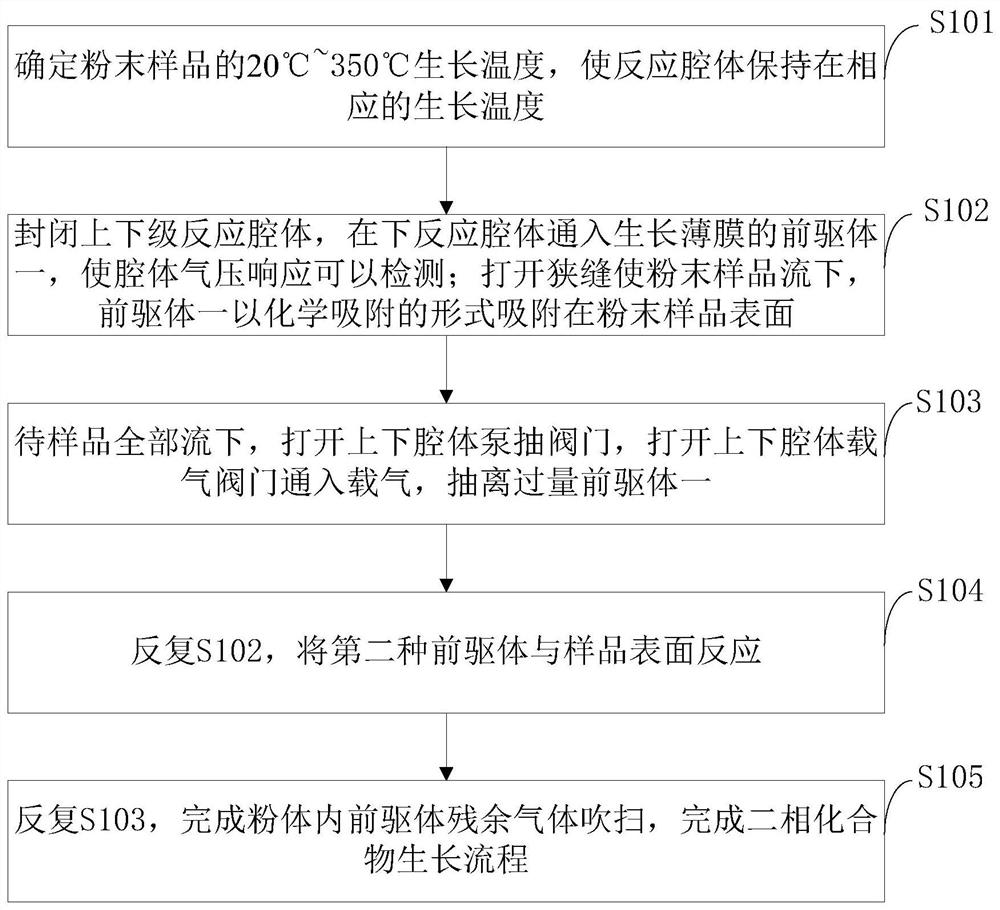

Gravity-driven spatial resolution powder atomic layer deposition equipment, method and application

Owner:NANKAI UNIV

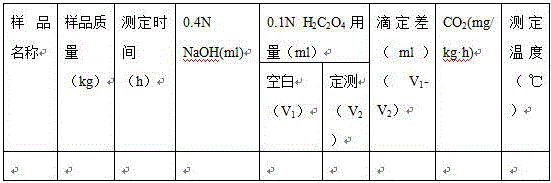

Conjoined determining device for respiration intensity of agricultural products and use method

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Gas flow regulating device

Owner:JIANGSU SUYUN MEDICAL MATERIALS

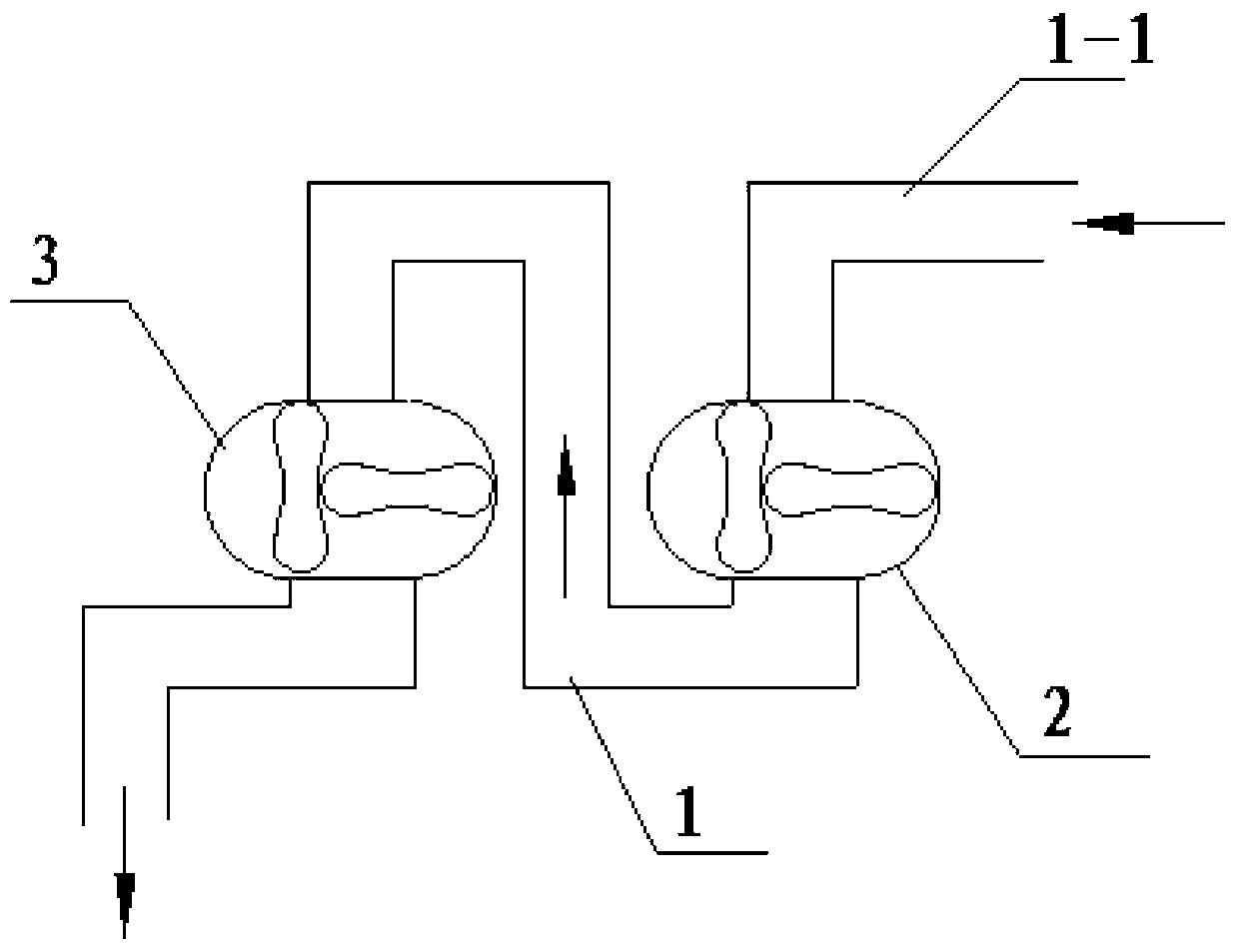

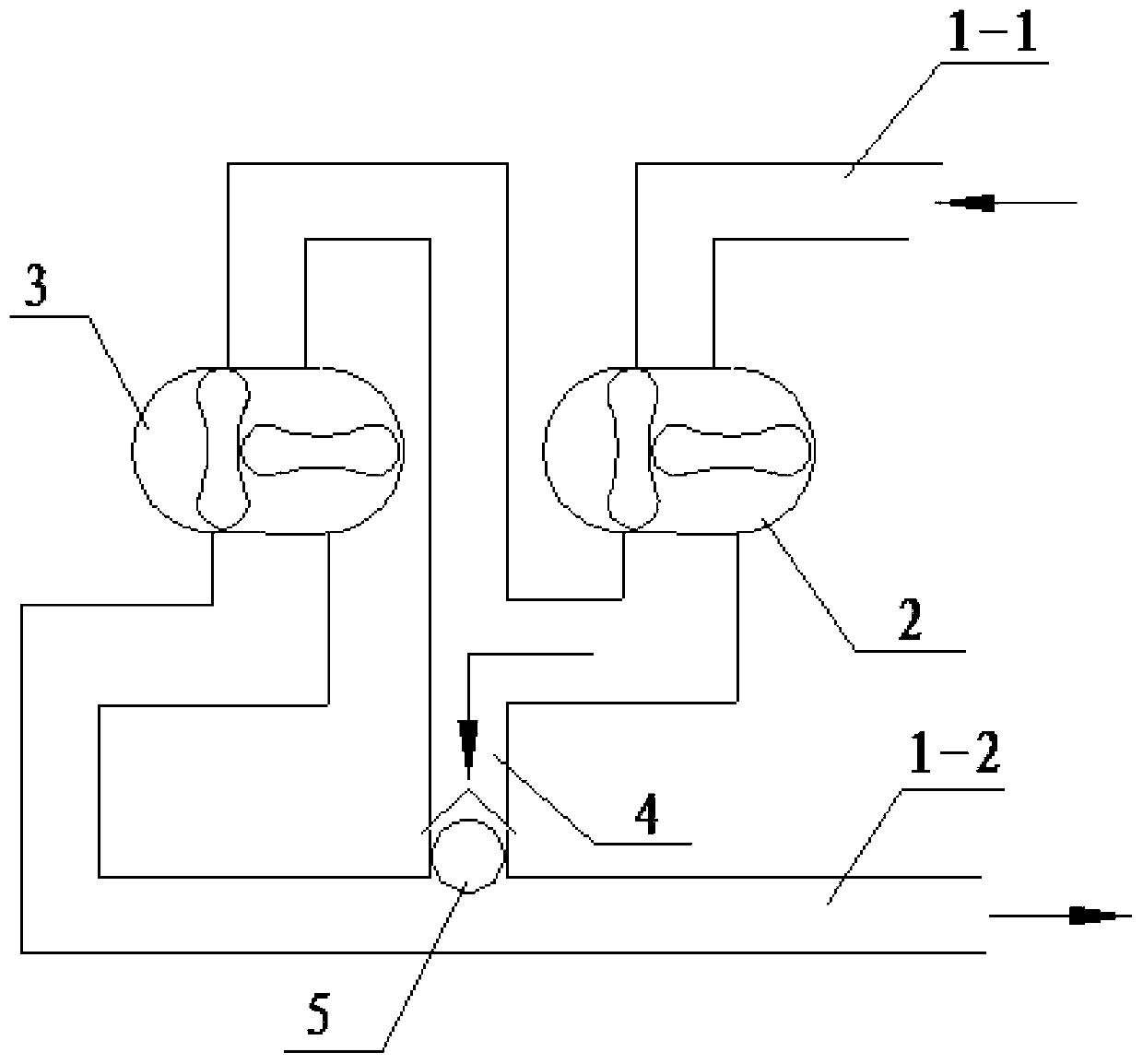

Suction power unit for industrial vacuum sweeper

InactiveCN103277287ACapable of continuous operationThe industrial vacuum truck equipped with a set of series vacuum pumps has the ability of continuous operationPump installationsPositive-displacement liquid enginesEngineeringPower unit

Owner:BAOSTEEL DEV CO LTD

R-axis optimized ultrasonic welding device

Owner:广东富强科技股份有限公司

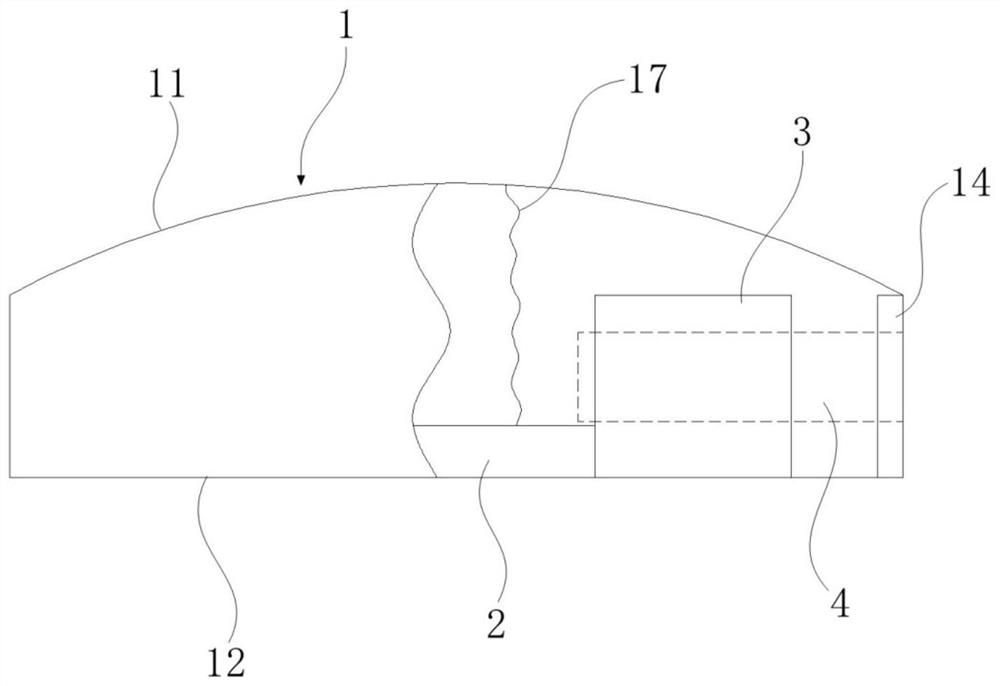

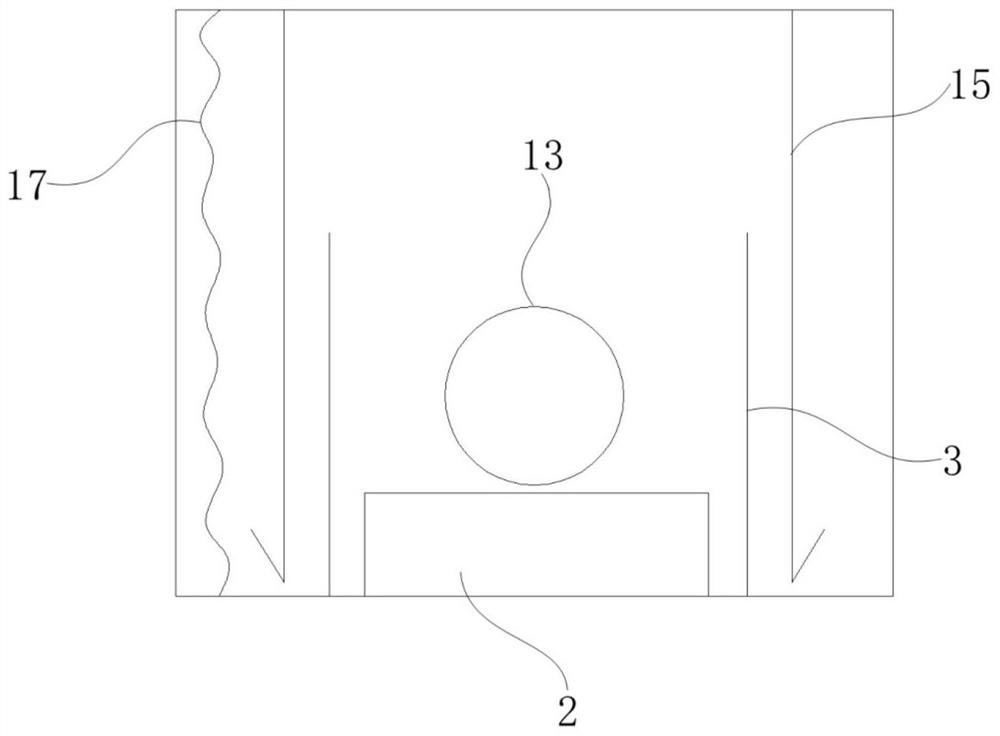

Carbon doping device and carbon doping method for growing semi-insulating gallium arsenide single crystal

ActiveCN113136616AAchieving C deposition amountEasy to controlPolycrystalline material growthFrom frozen solutionsSemiconductor materialsGallium arsenate

The invention discloses a carbon doping device and a carbon doping method for growing semi-insulating gallium arsenide single crystals, and relates to the technical field of semiconductor materials. The device comprises a quartz tube and a PBN crucible set, the PBN crucible set is arranged in the quartz tube, and sealing chucks are installed at the two ends of the quartz tube; pipelines are respectively arranged at two ends of the quartz tube, namely an inflation pipeline and an exhaust pipeline; a third on-off valve is arranged on the gas filling pipeline, two branch gas pipelines which are connected in parallel are arranged on the upstream of the gas filling pipeline and are respectively called an oxygen filling pipeline and a carbon filling pipeline, the oxygen filling pipeline is connected with an oxygen source, and the carbon filling pipeline is connected with a carbon gas source, wherein the on-off of the oxygen source or the carbon gas source is controlled through the valves; the downstream of the exhaust pipeline is provided with two branch air pipelines which are connected in parallel and are respectively called a deflation pipeline and a vacuumizing pipeline, the deflation pipeline is provided with a valve, and the vacuumizing pipeline is connected with a vacuumizing device. According to the invention, an oxygenating baking process and a C deposition process can be respectively implemented, and the two processes are sequentially carried out on the same equipment, so that the equipment is simplified, and the heat energy loss is reduced.

Owner:ITE SEMICON MATERIAL CO LTD

Unit bromine trifluoride treatment material taking device

InactiveCN112629081AEnsure safetyImprove continuityMechanical apparatusInter-halogen compoundsEngineeringBromine trifluoride

Owner:SICHUAN HONGHUA IND

Leak detection device of semiconductor special gas conveying pipeline

PendingCN114295295AWill not affect test resultsIncrease concentrationDetection of fluid at leakage pointGas leakMechanical engineering

Owner:理纯(上海)洁净技术有限公司

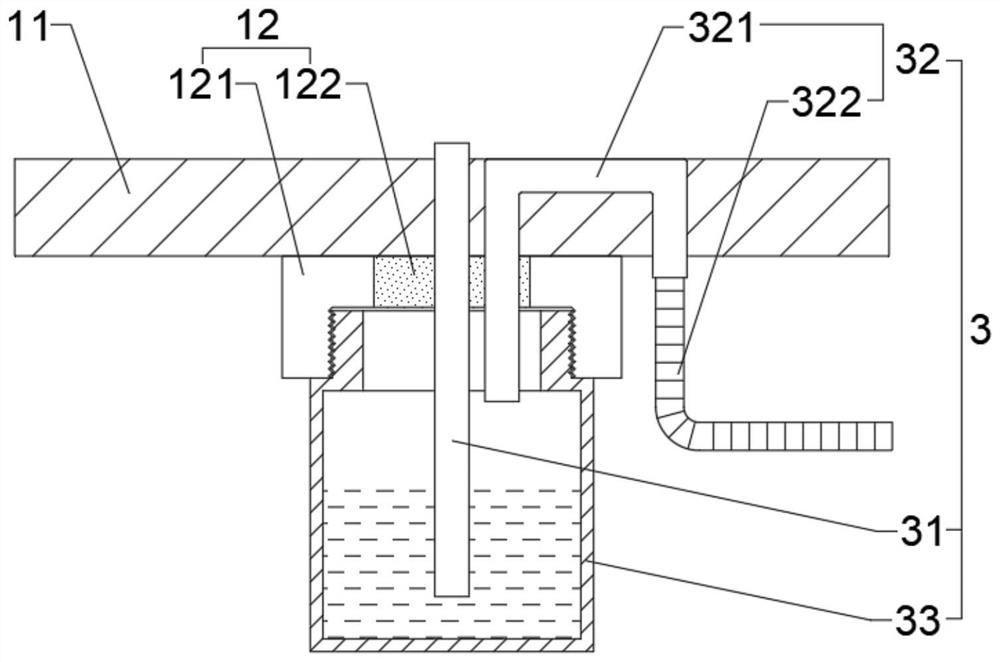

Gas pipeline tracing line connector device

Owner:GUANGZHOU GAS

Recycling type multi-direction pneumatic redundant material flushing device and method

ActiveCN114682551ARealize positive and negative repeated washingImprove efficiencyCleaning using liquidsLiquid storage tankGas holder

The invention relates to a recycling type multi-direction pneumatic redundant material flushing device and method, and the recycling type multi-direction pneumatic redundant material flushing device comprises a first liquid storage tank, a second liquid storage tank, a gas storage tank, a first flushing pipeline and a second flushing pipeline, the gas storage tank is connected with a first gas inlet in the top of the first liquid storage tank and a second gas inlet in the top of the second liquid storage tank through gas pipelines. Two ends of the first flushing pipeline are respectively connected with a first liquid inlet of the first liquid storage tank and a second liquid inlet of the second liquid storage tank, and two ends of the second flushing pipeline are respectively connected with a first liquid outlet of the first liquid storage tank and a second liquid outlet of the second liquid storage tank; a to-be-flushed product is connected to the first flushing pipeline in series, the two ends of the first connecting pipeline are connected with an upstream pipe section and a downstream pipe section of the first flushing pipeline respectively, and the two ends of the second connecting pipeline are connected with a first opening of the to-be-flushed product and the second flushing pipeline respectively. Two ends of the third connecting pipeline are respectively connected with the second opening of the to-be-flushed product and the second flushing pipeline.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Hotspot backwash device for instrument pipes of main pipelines of nuclear power stations

Owner:JIANGSU NUCLEAR POWER CORP

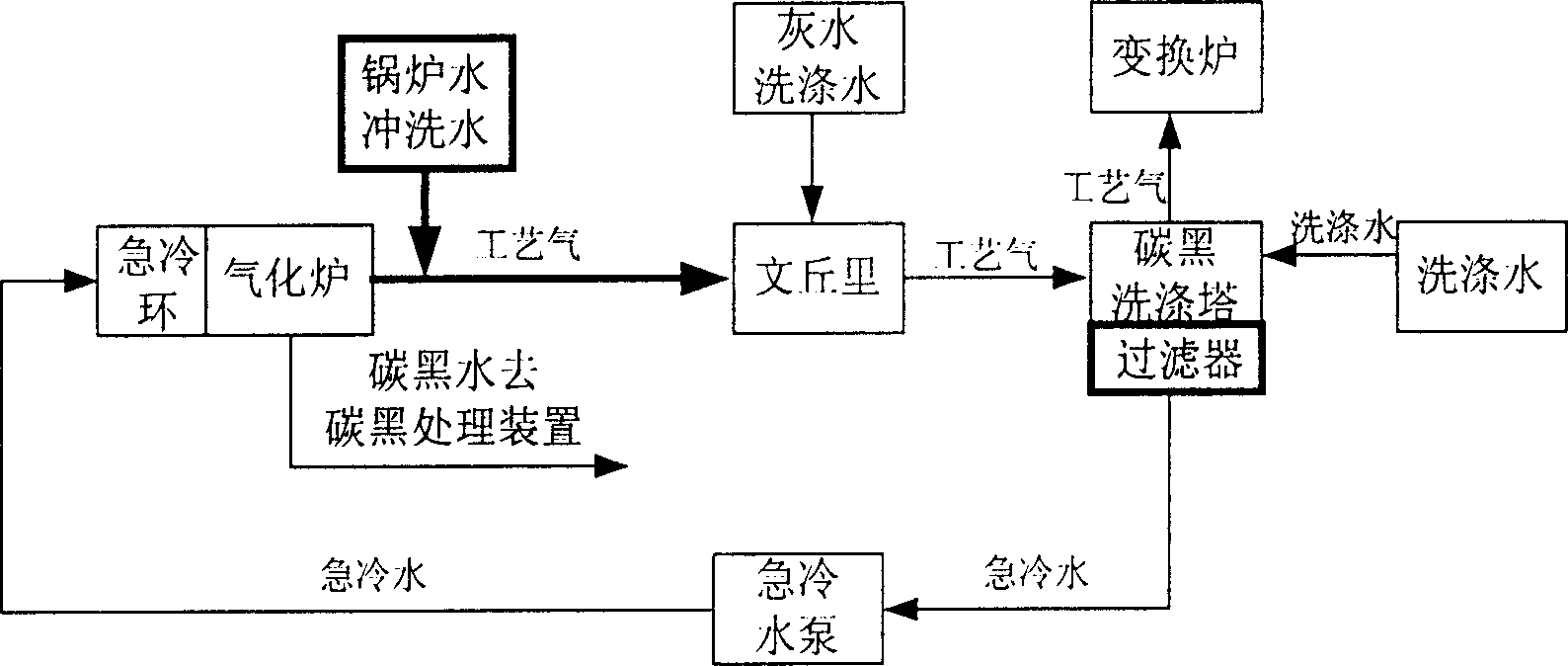

Method for preventing quench water flow reduction for gasifying furnace and its special device

ActiveCN1277767CLarge storage capacitySlow down the fouling rateScale removal and water softeningMultistage water/sewage treatmentWater flowTower

Owner:中国石油化工股份有限公司镇海炼化分公司

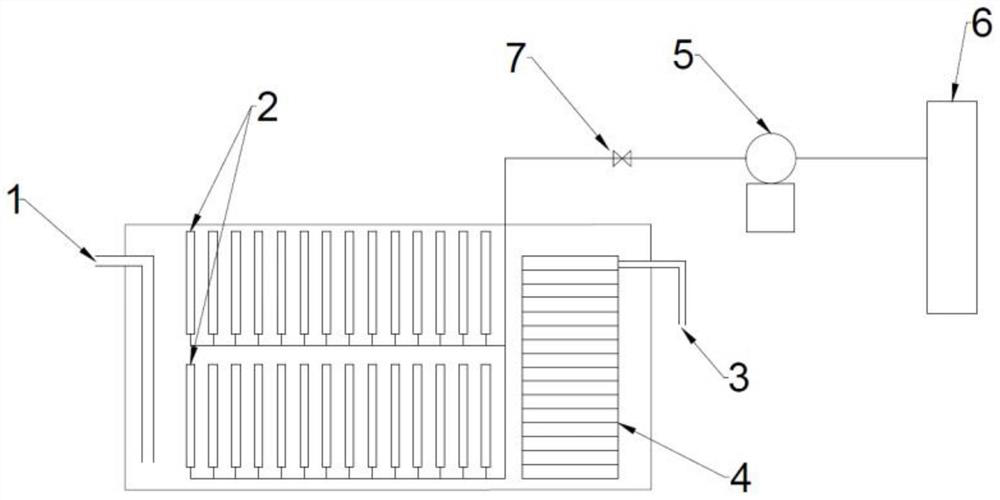

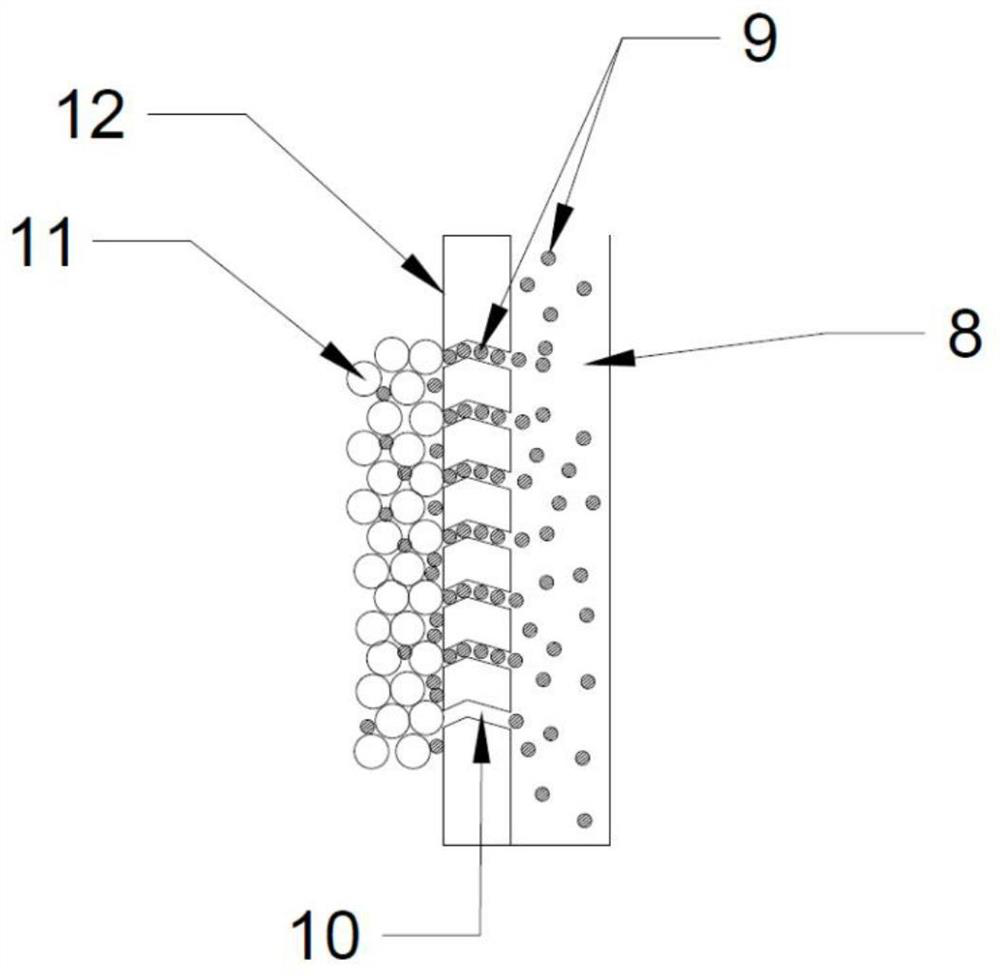

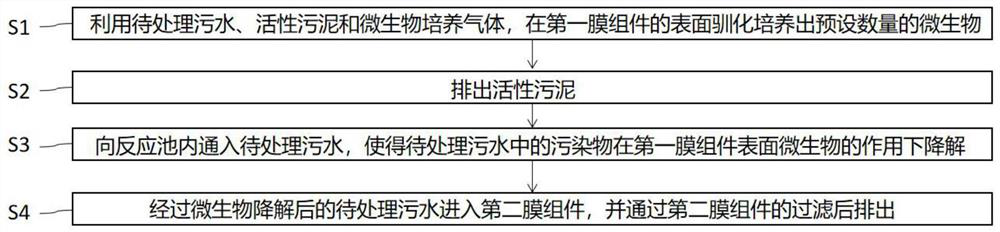

Ceramic membrane sewage treatment equipment and method based on domestication of active microorganisms

ActiveCN112174306AGrow fastBioreactor/fermenter combinationsBiological substance pretreatmentsActivated sludgeBiofilm

Owner:SHENZHEN ZHONGQING ENVIRONMENTAL TECH +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap