Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about "Positive-displacement liquid engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

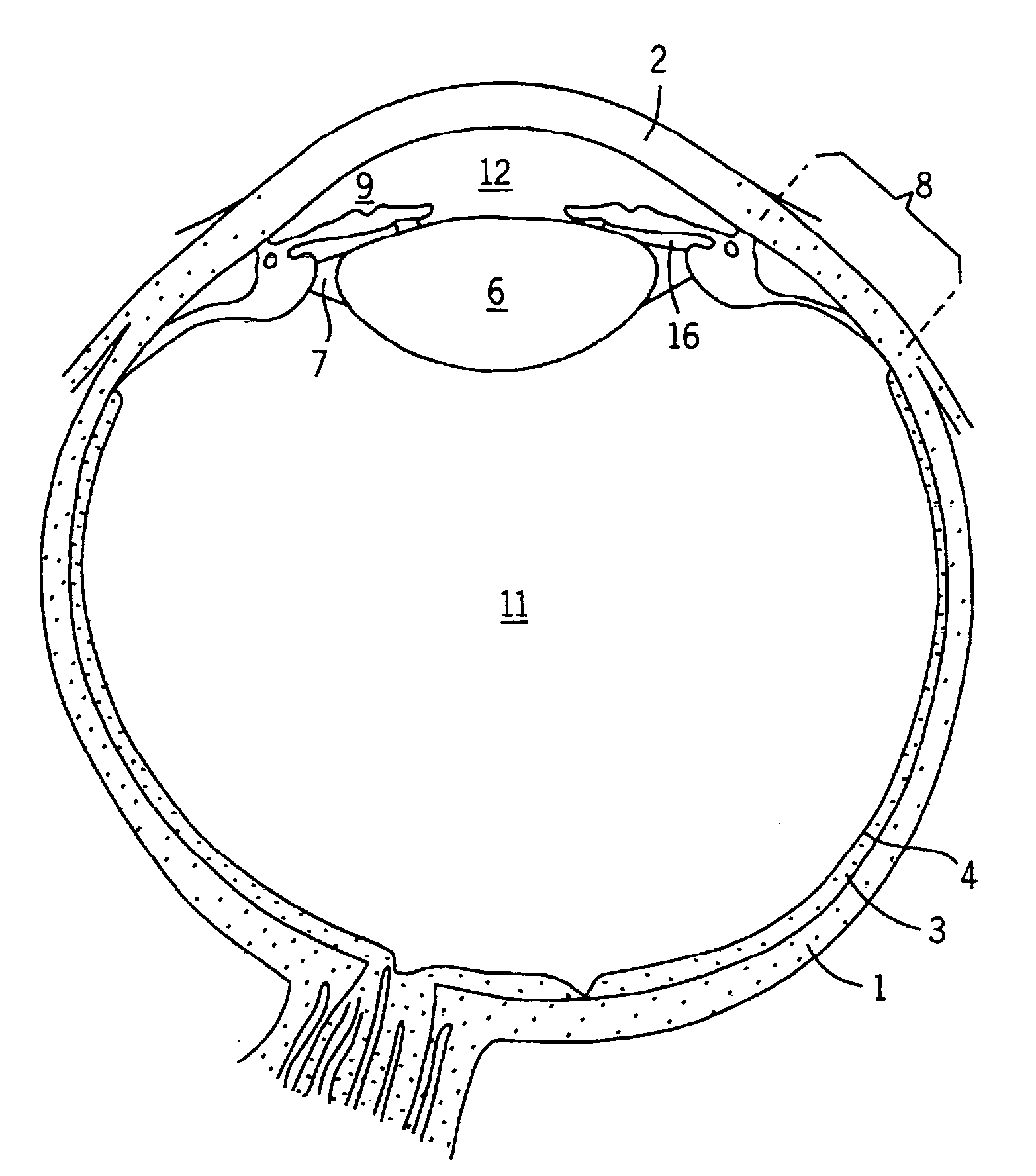

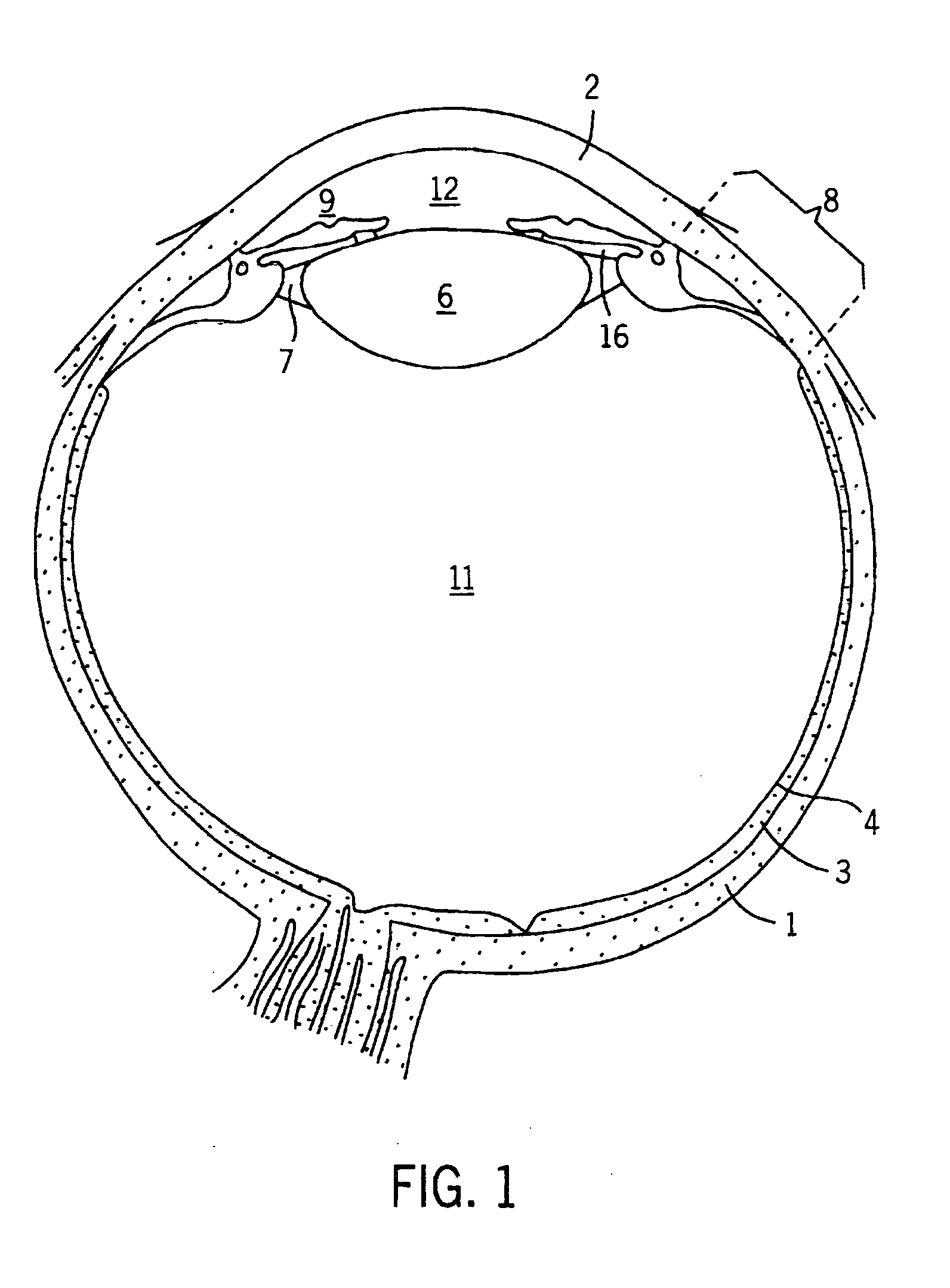

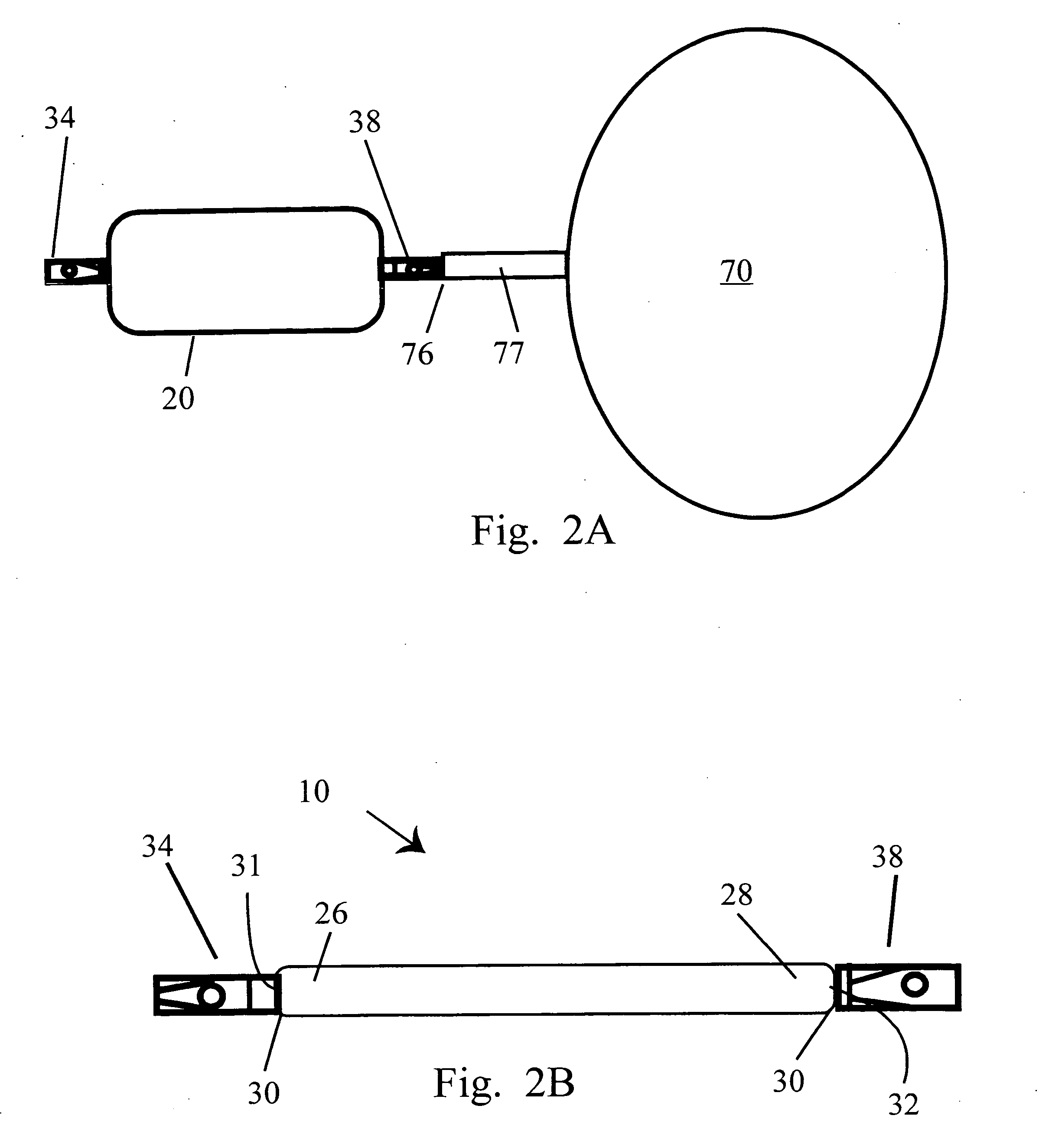

Implantable pump apparatuses

InactiveUS20070106199A1Harvesting energyControl flowEye surgeryFlexible member pumpsDynamic motionEngineering

Owner:SOLTANPOUR DAVID P

Micropumps with passive check valves

Owner:WATERS TECH CORP

Low profile inlet for an implantable blood pump

InactiveUS7338521B2Improve pumping capacityImprove pumping efficiencyPump componentsMedical devicesBlood pumpCatheter

Owner:WORLD HEART

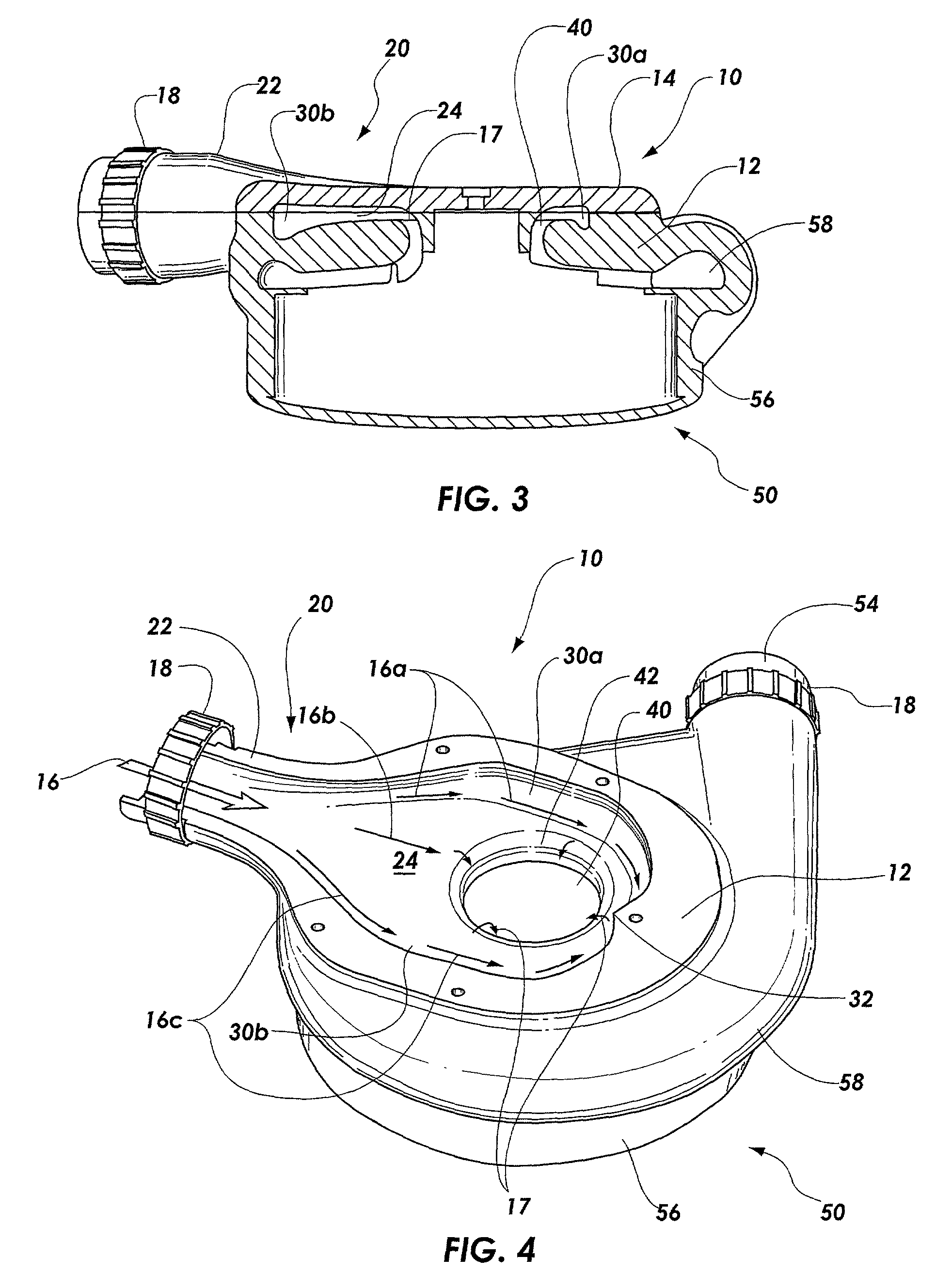

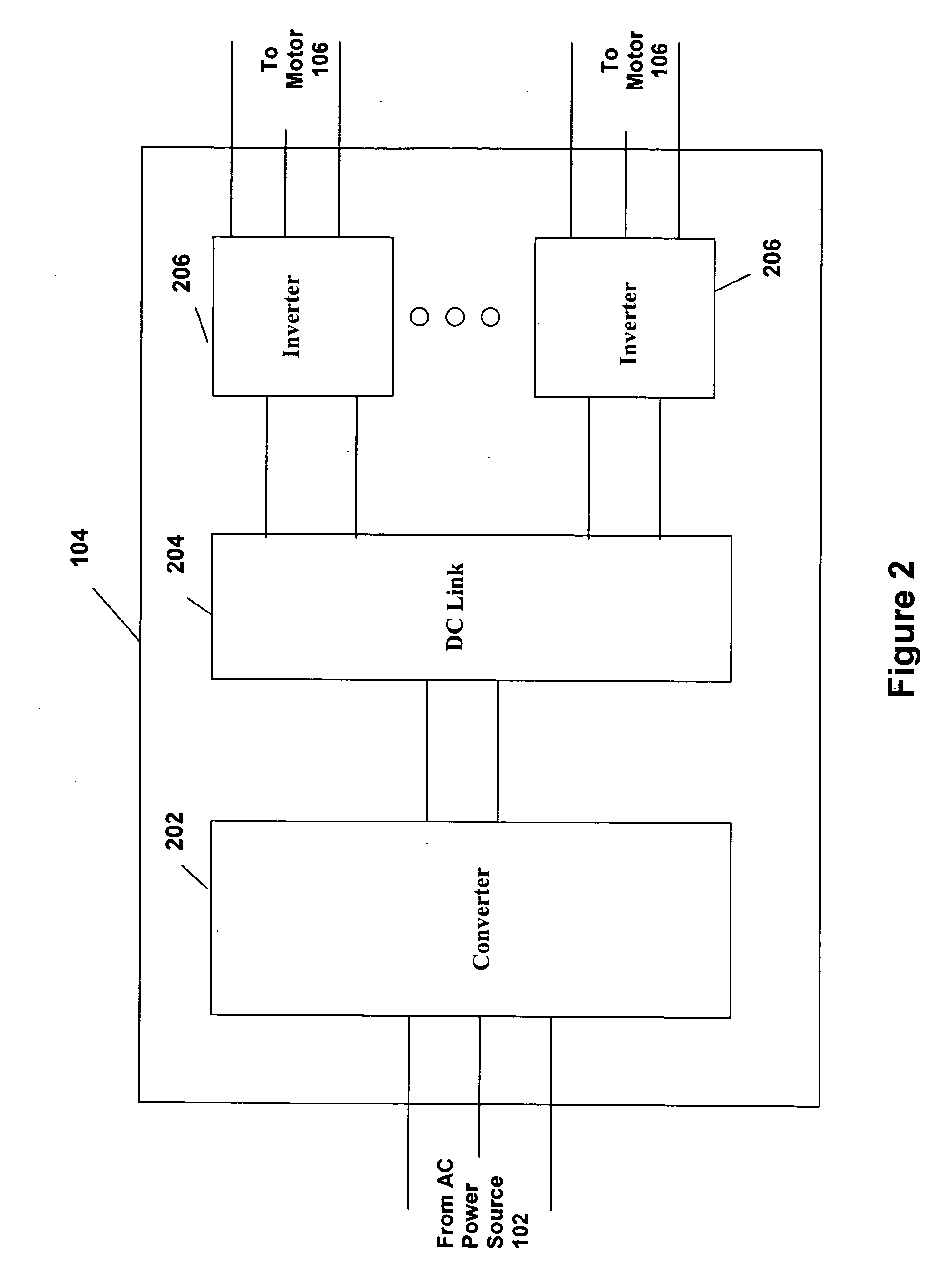

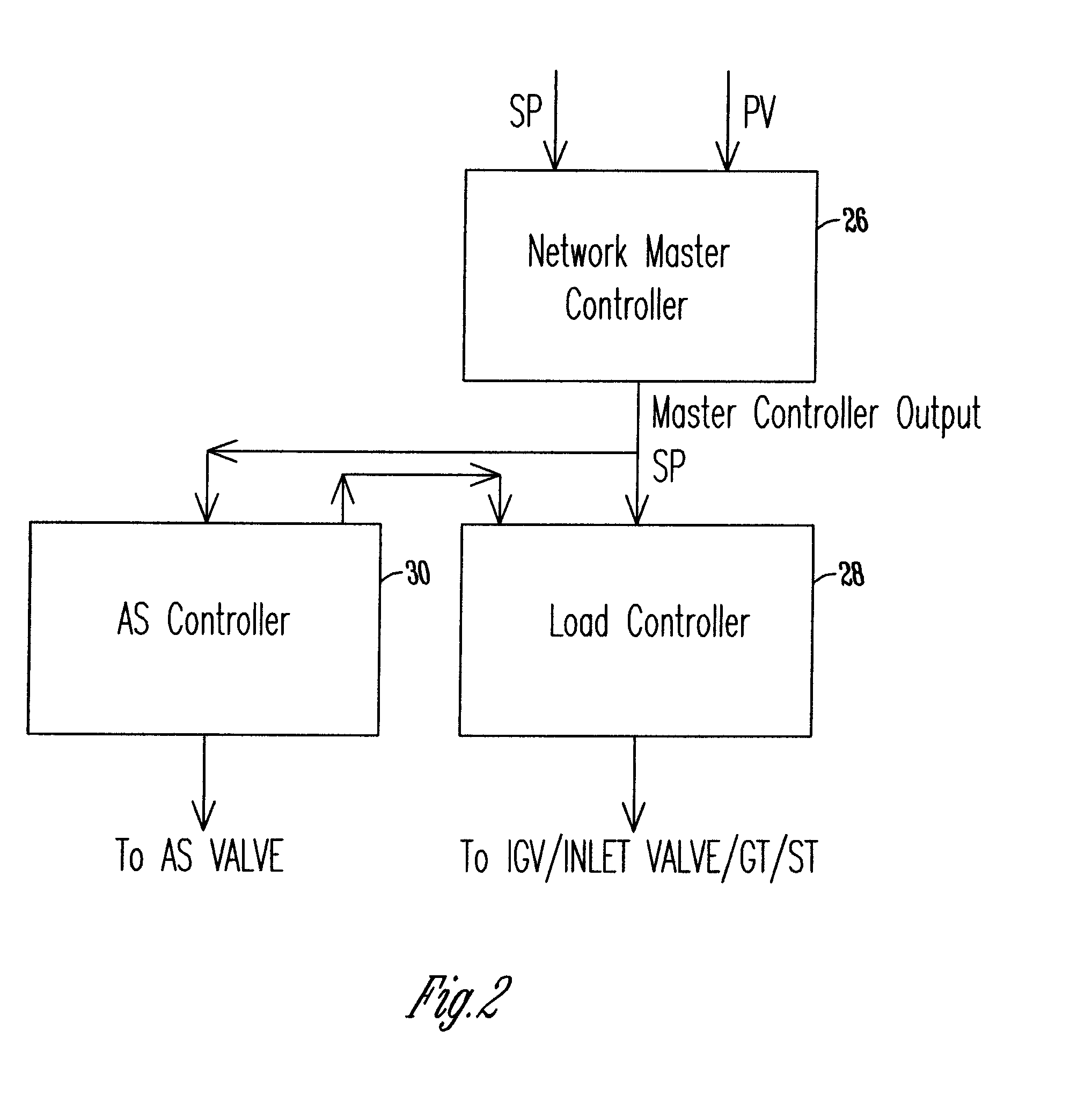

System and method for capacity control in a multiple compressor chiller system

ActiveUS20050223724A1Easy to controlImprove system efficiencyCompression machines with non-reversible cycleEfficient regulation technologiesLiquid temperatureControl theory

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

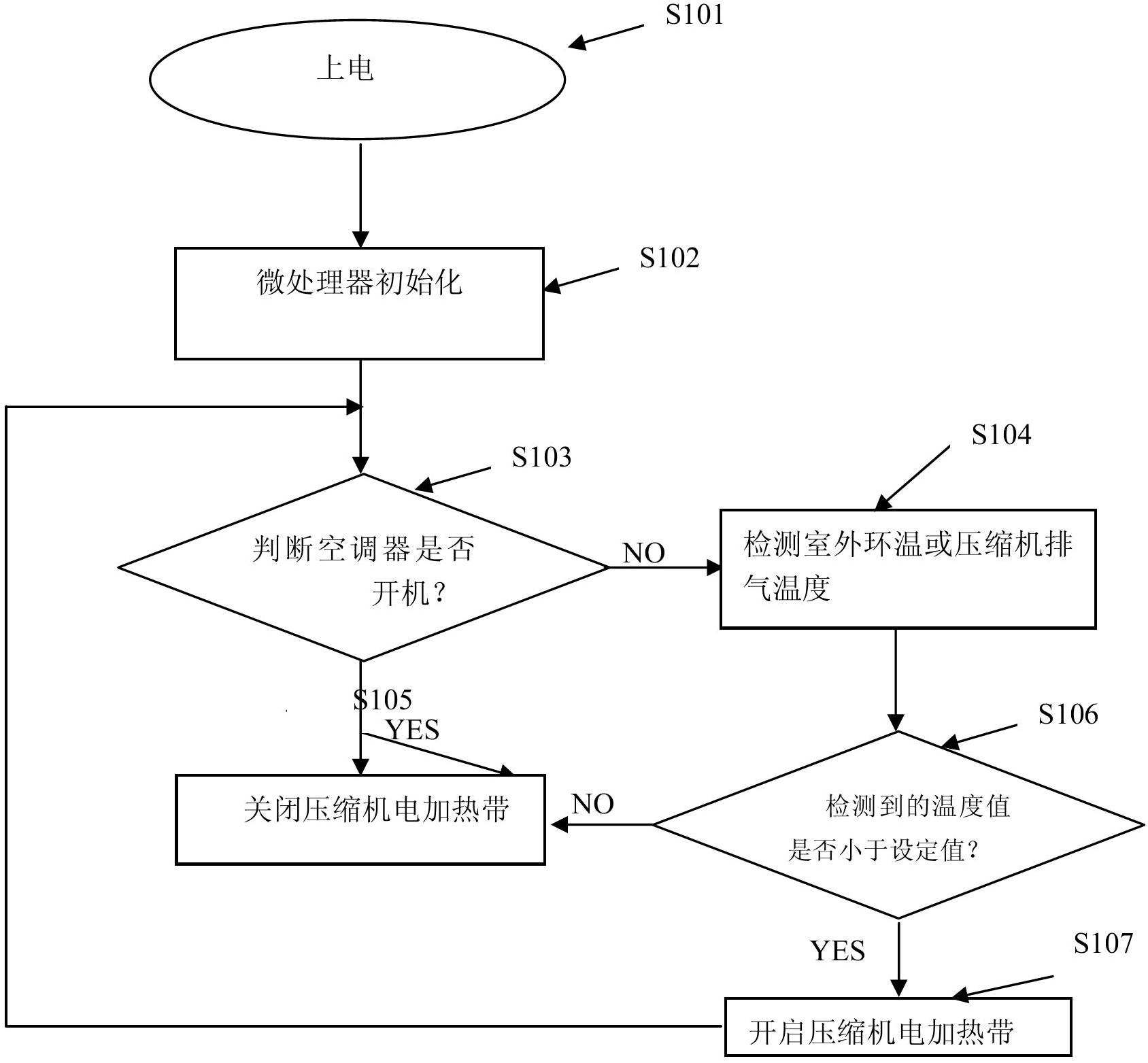

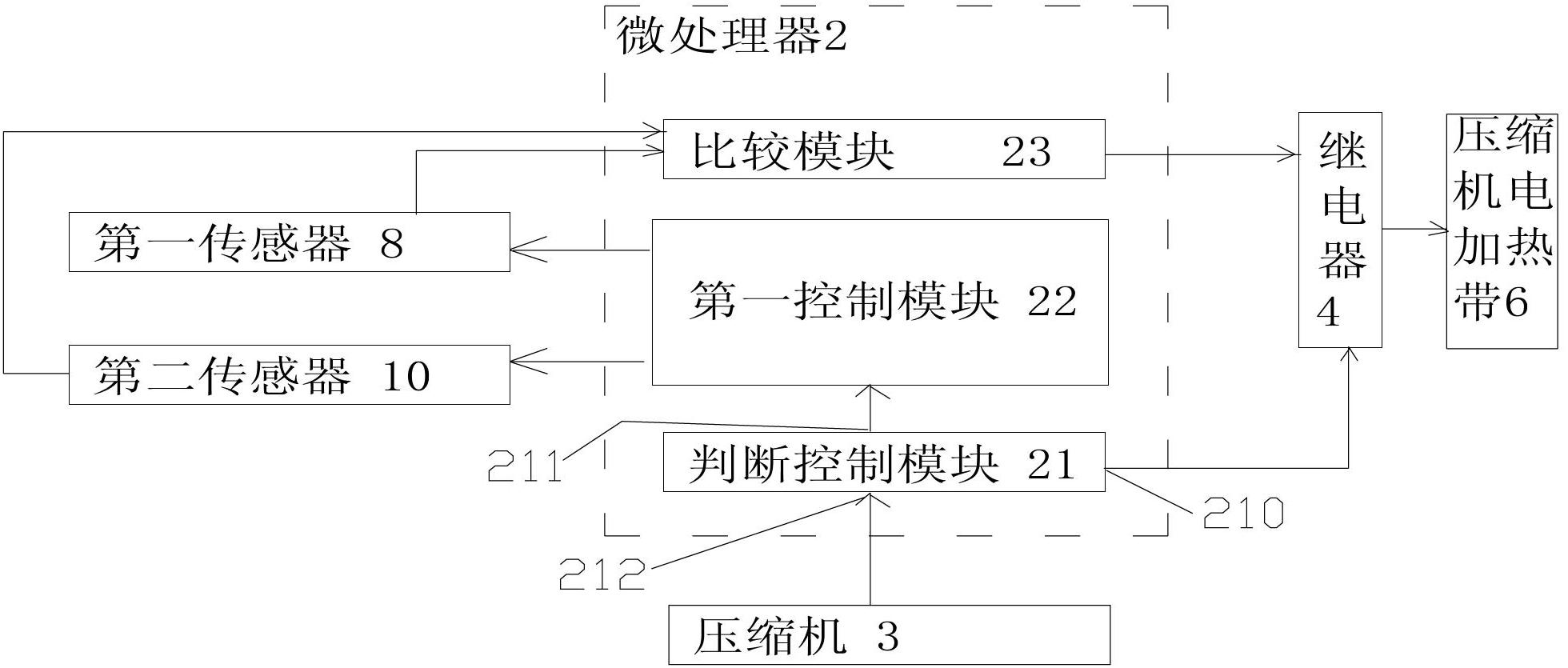

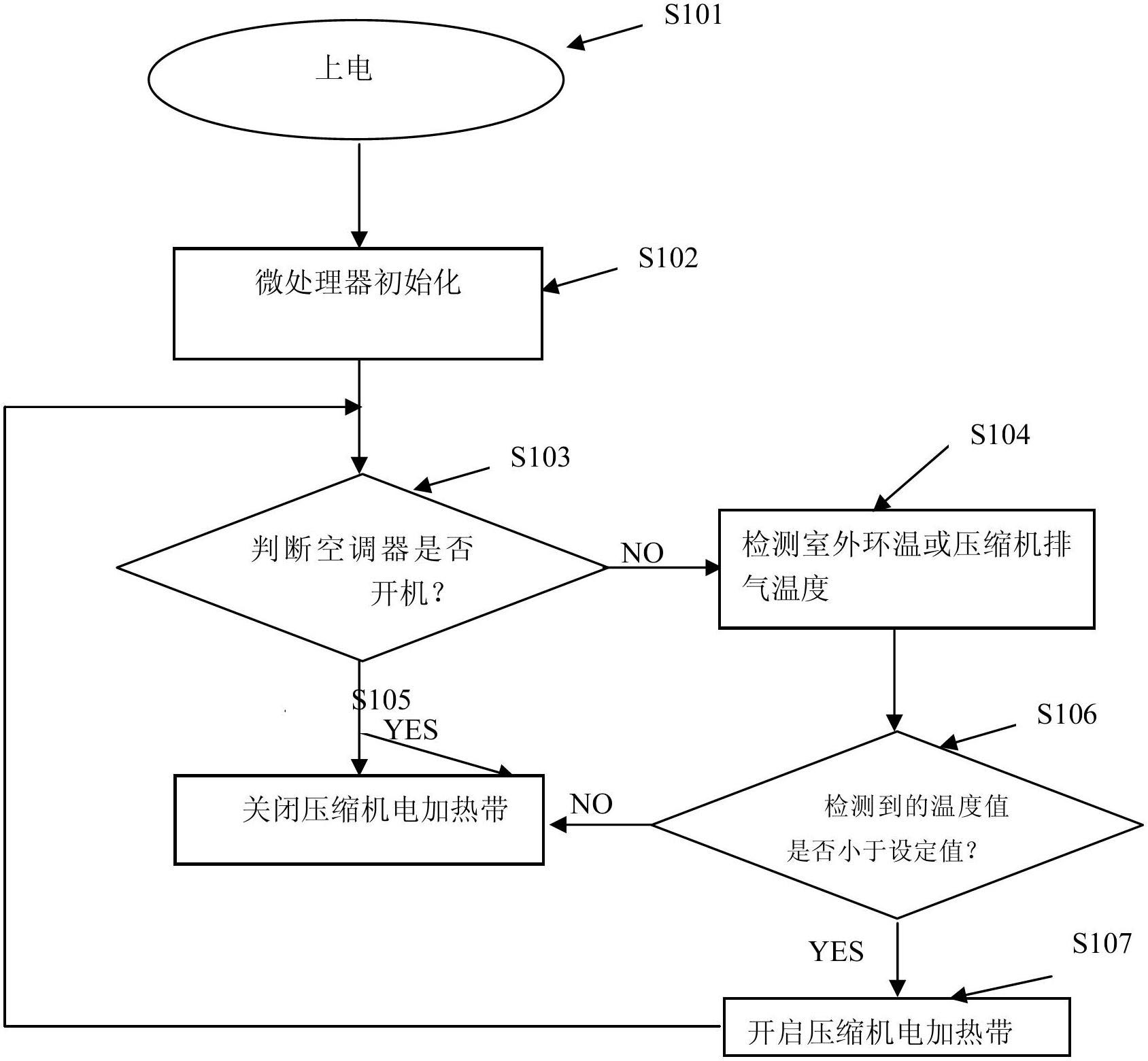

Control method and system of compressor electric heating band in air conditioner

InactiveCN102661267AReduce standby power consumptionLow costPositive displacement pump componentsPump controlElectricityControl system

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Motor

InactiveUS20050035670A1Reduce noiseExtended service lifePump componentsMagnetic circuitPhysicsMagnetic structure

Owner:DELTA ELECTRONICS INC

Combined sight oil level gage and ultrasonic sensor

InactiveUS20080173088A1Pump testingPositive displacement pump componentsUltrasonic sensorEngineering

The invention provides a combined fluid level sight gage and ultrasonic sensor featuring a fluid level sight gage having a housing for containing a fluid and having a sight glass for viewing the level of the fluid therein, and an ultrasonic sensor coupled to the housing, responsive to the level of fluid in the housing, for providing an ultrasonic sensor signal containing information about the level of fluid in the housing. In operation, the sight glass provides a visual verification that the ultrasonic sensor is working correctly in relation to the fluid visible in the sight glass. The ultrasonic sensor signal may be used to automatically annunciate alarms or warnings either locally at the equipment or by wired or wireless electronic means. In some embodiments according to the present invention, the housing has a centerline for indicating a normal fluid level therein. The ultrasonic sensor may be arranged in the housing on the centerline, or slightly below the centerline, or slightly above the centerline.

Owner:GERBER LIONEL +1

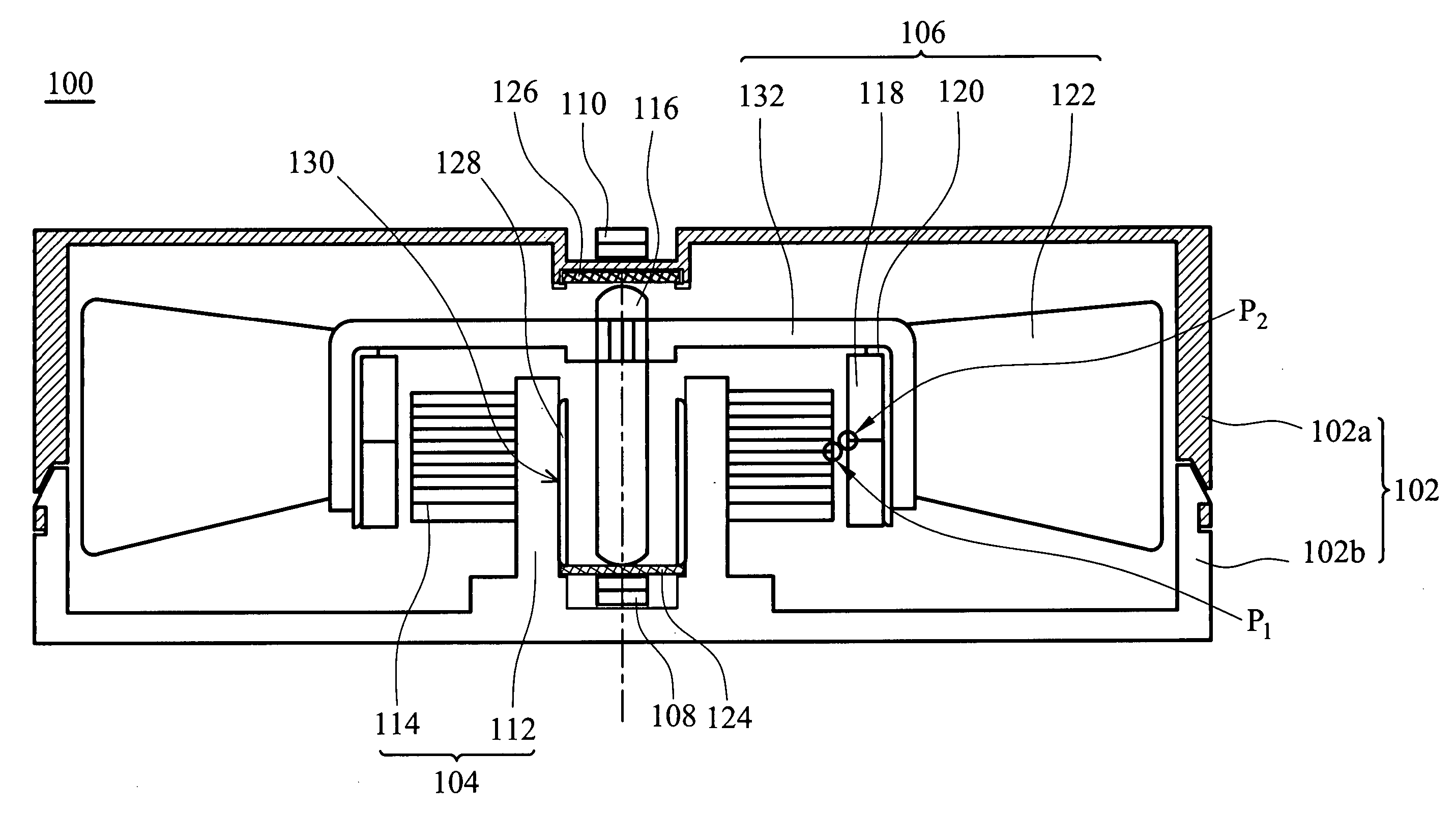

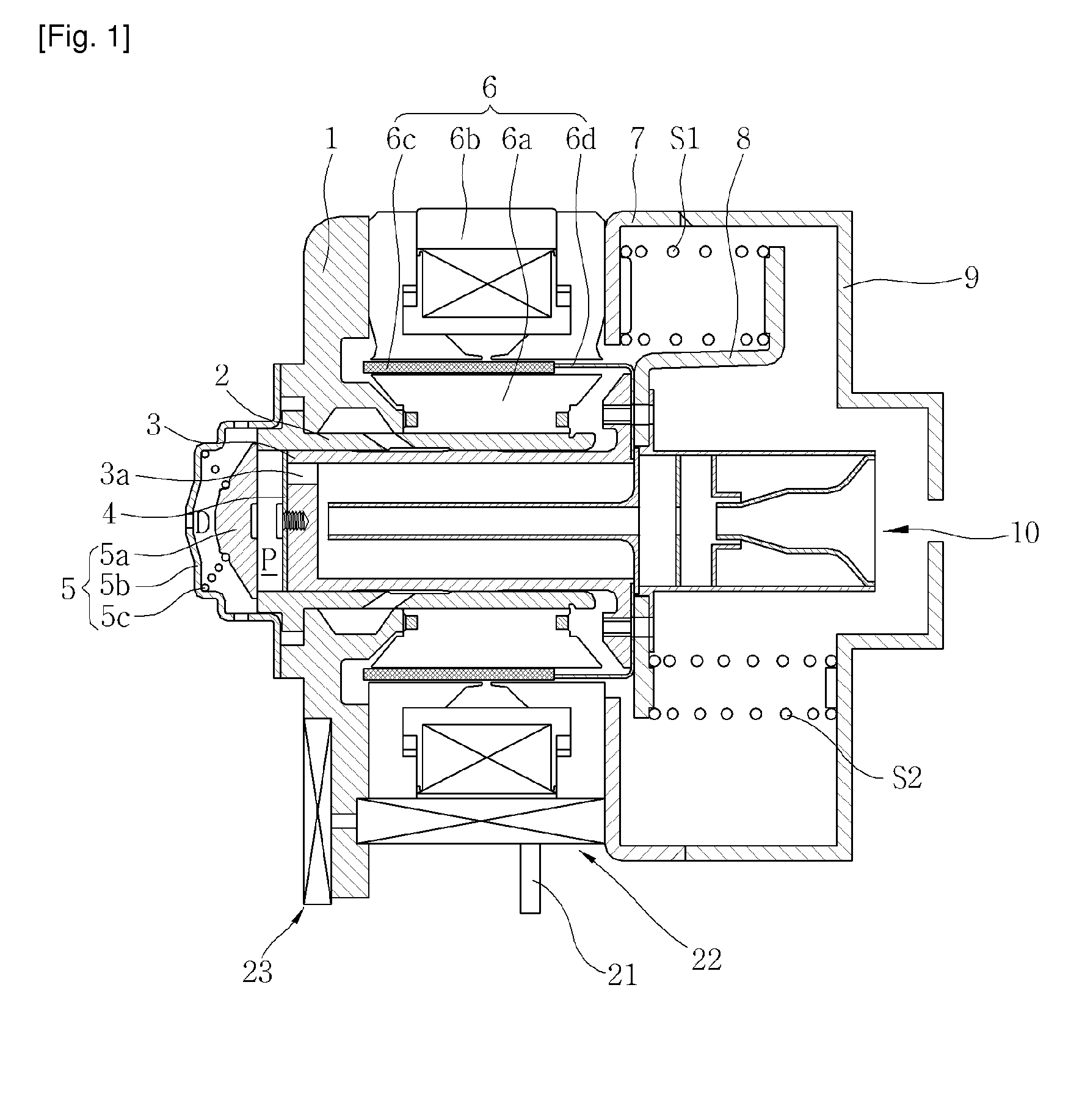

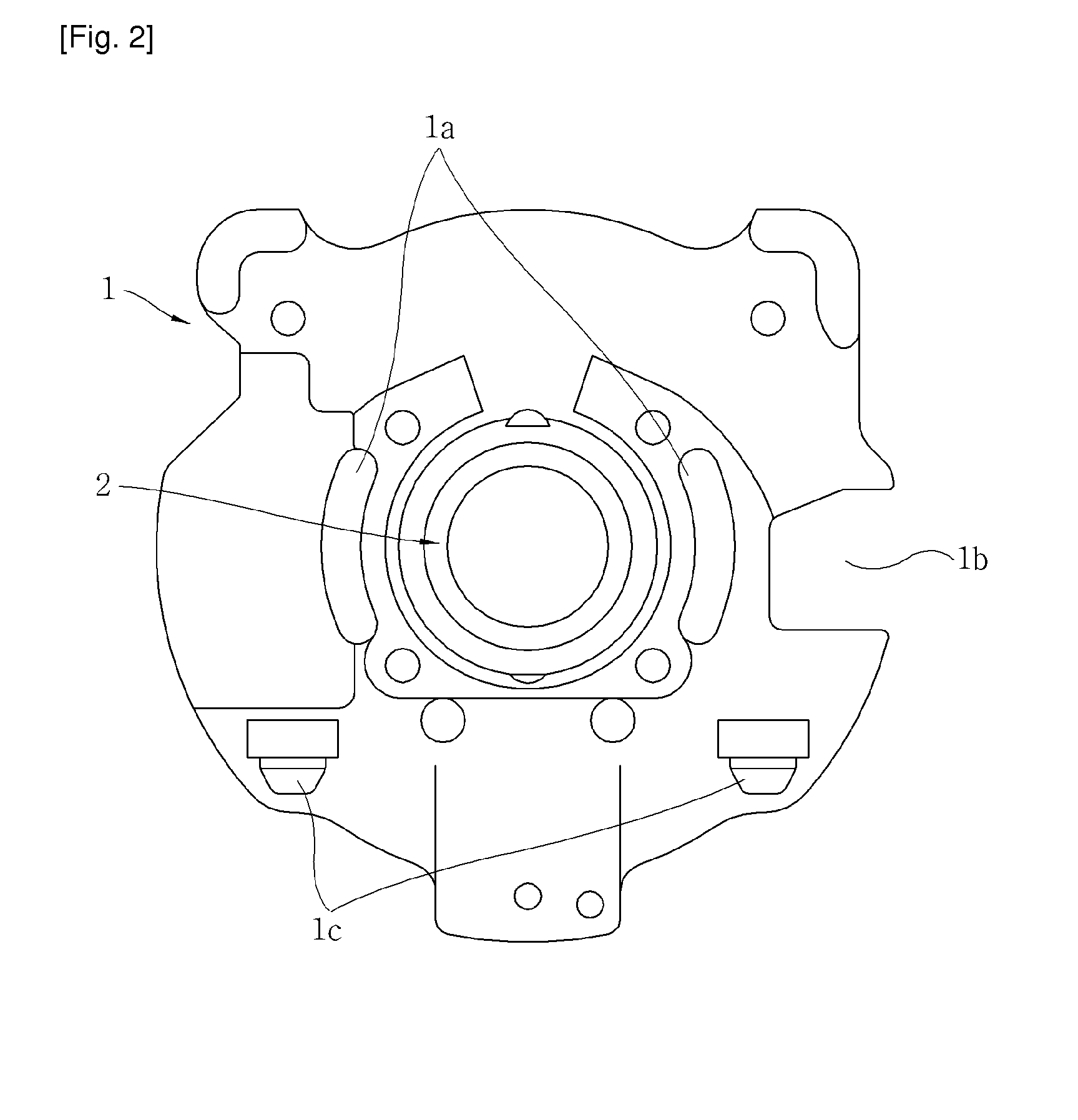

Linear compressor

ActiveUS20100260628A1Operational reliability is increasedSmall frame sizePositive displacement pump componentsPiston pumpsReciprocating motionLinear compressor

Owner:LG ELECTRONICS INC

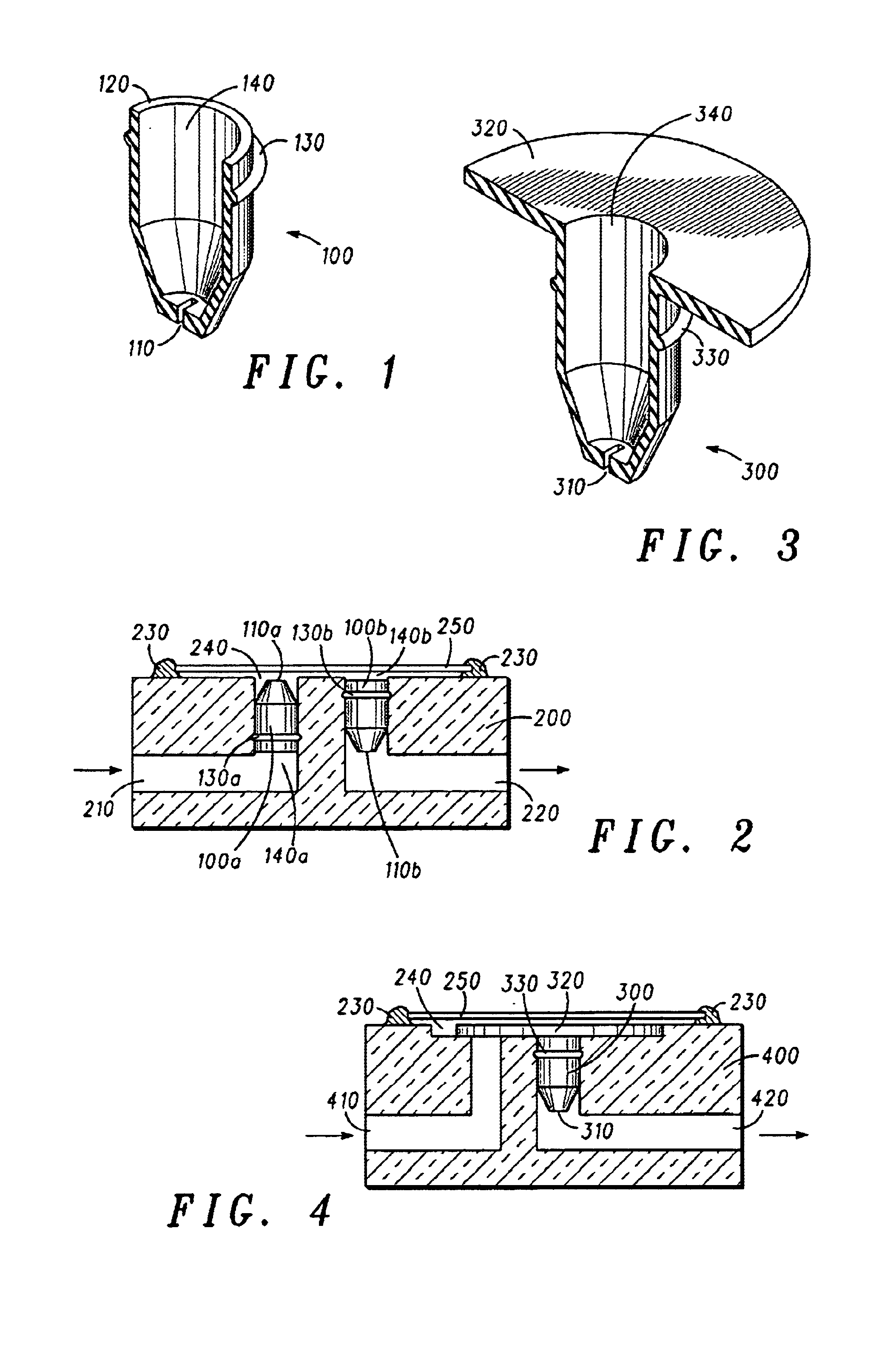

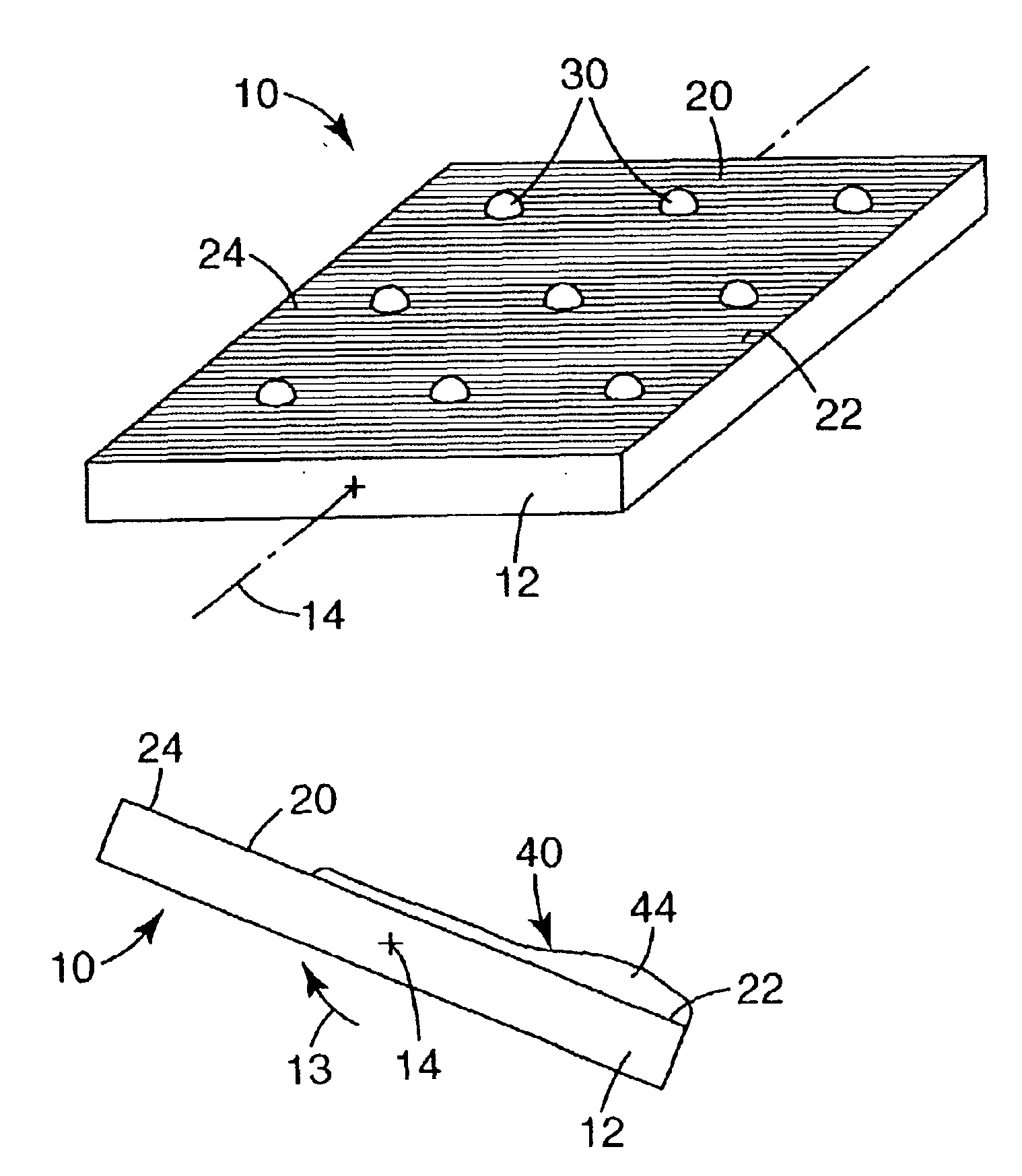

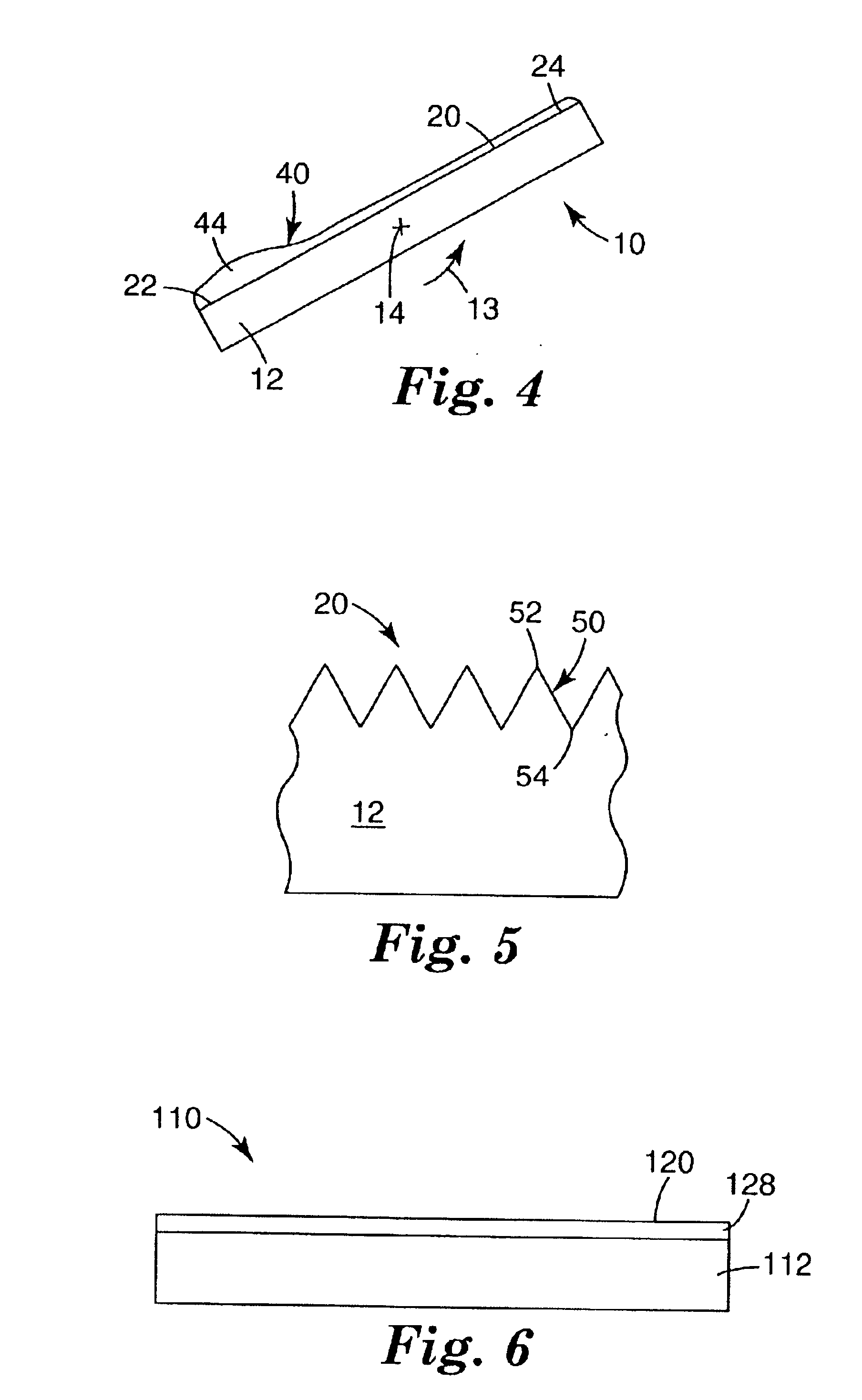

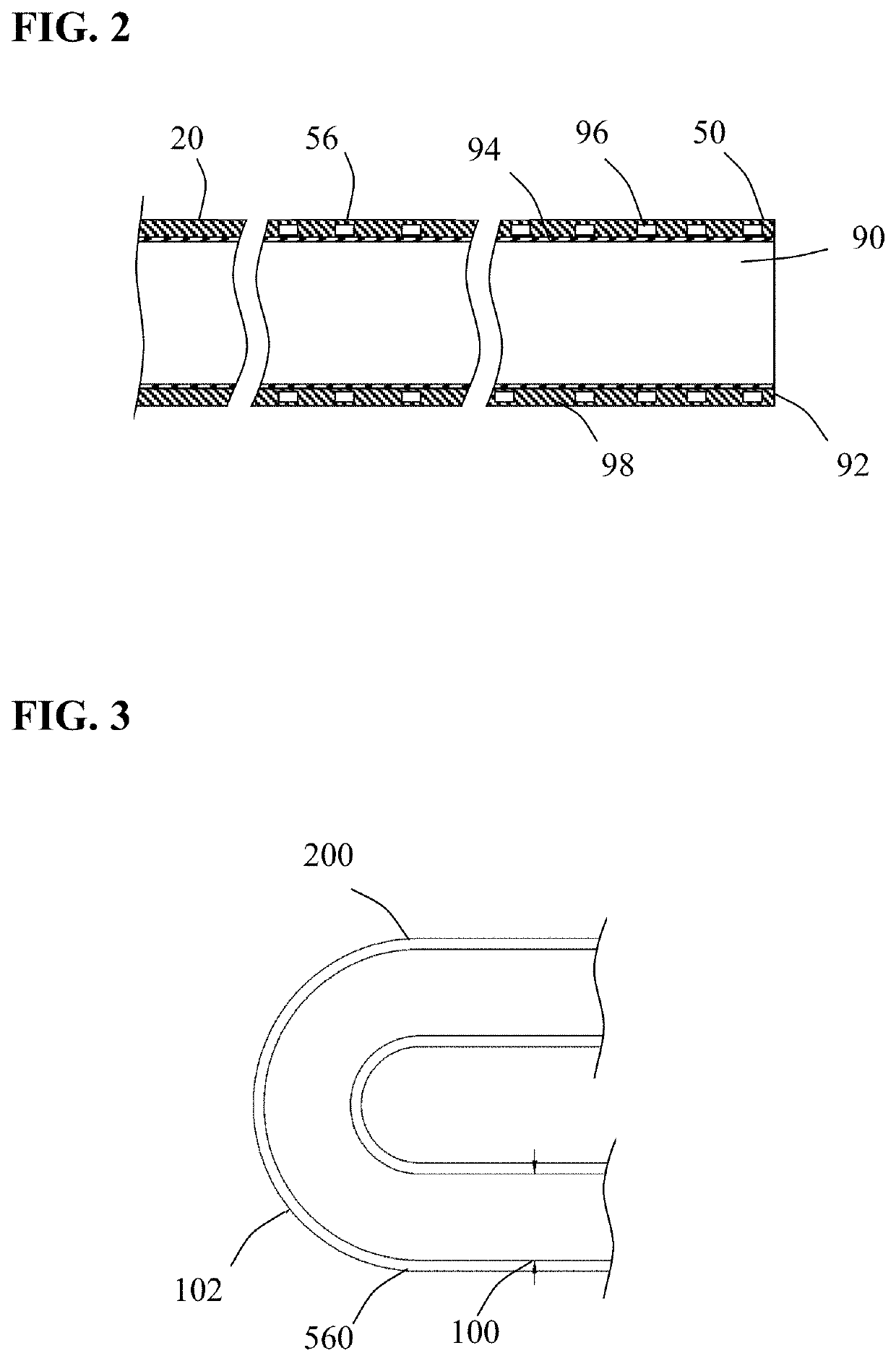

Devices, methods and systems for low volume microarray processing

InactiveUS6913931B2Reduction and elimination of liquid retention interfaceAvoid the needMaterial nanotechnologyAnalysis using chemical indicatorsAnalyteFluorescence

Owner:3M INNOVATIVE PROPERTIES CO

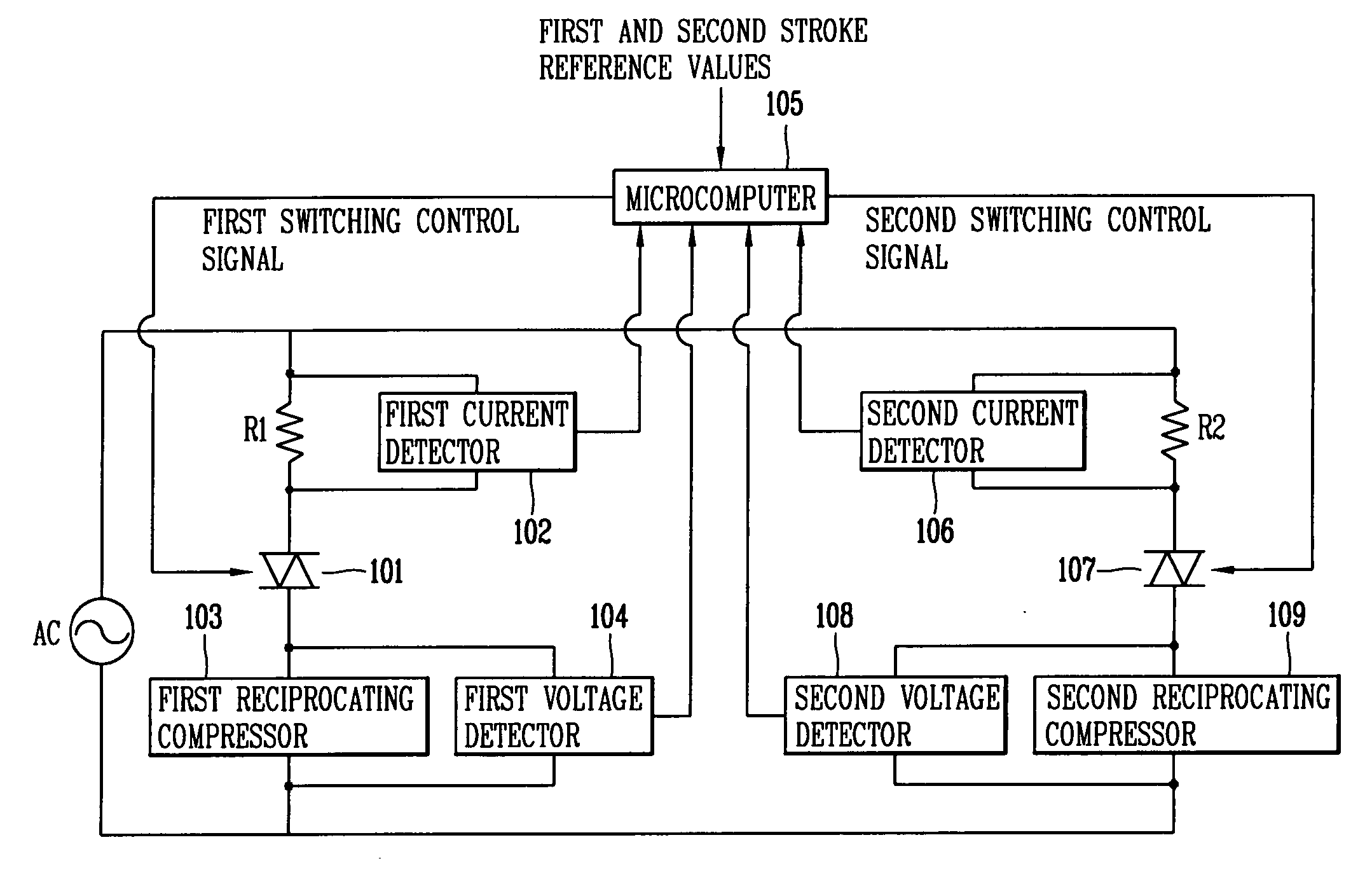

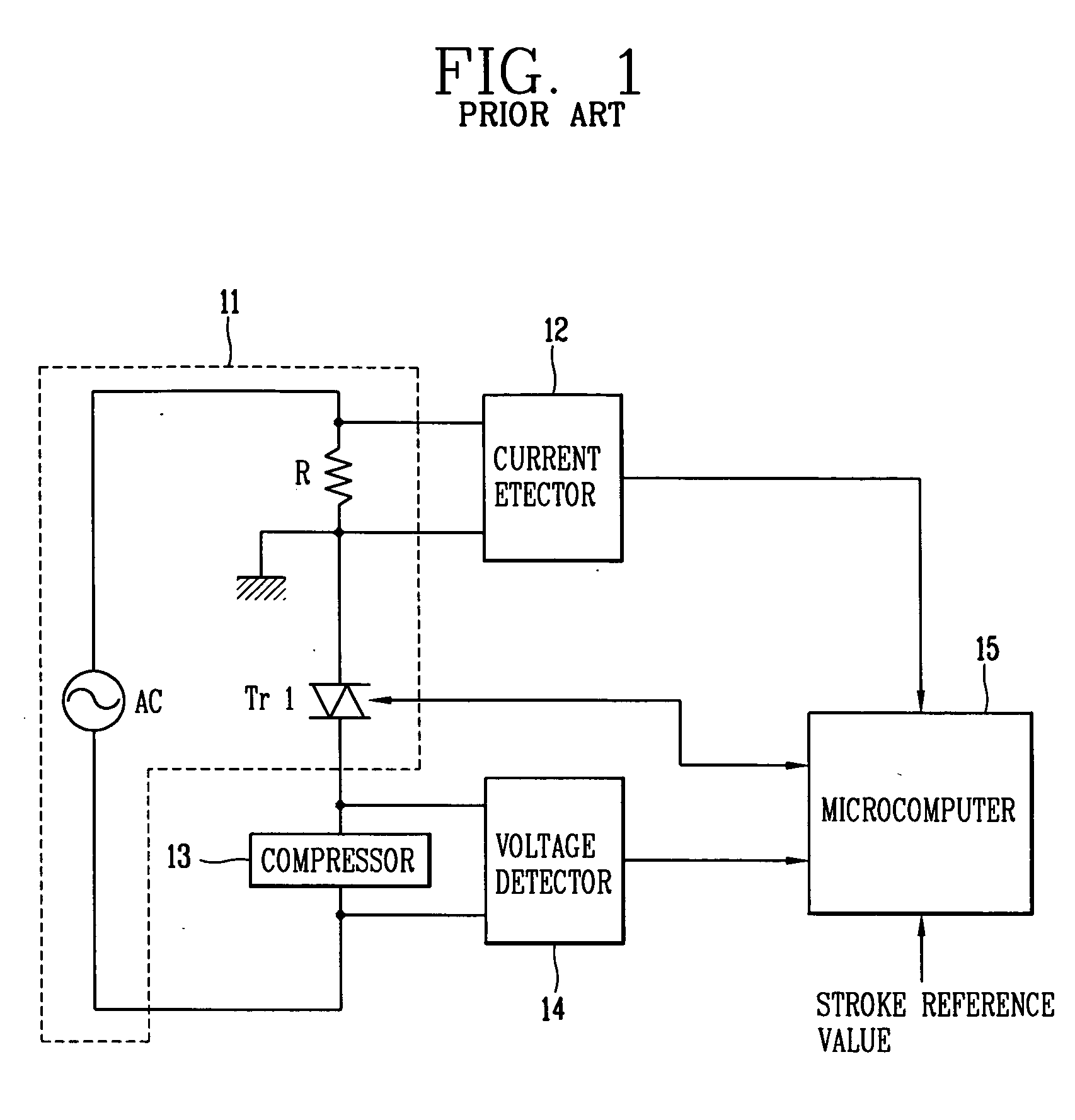

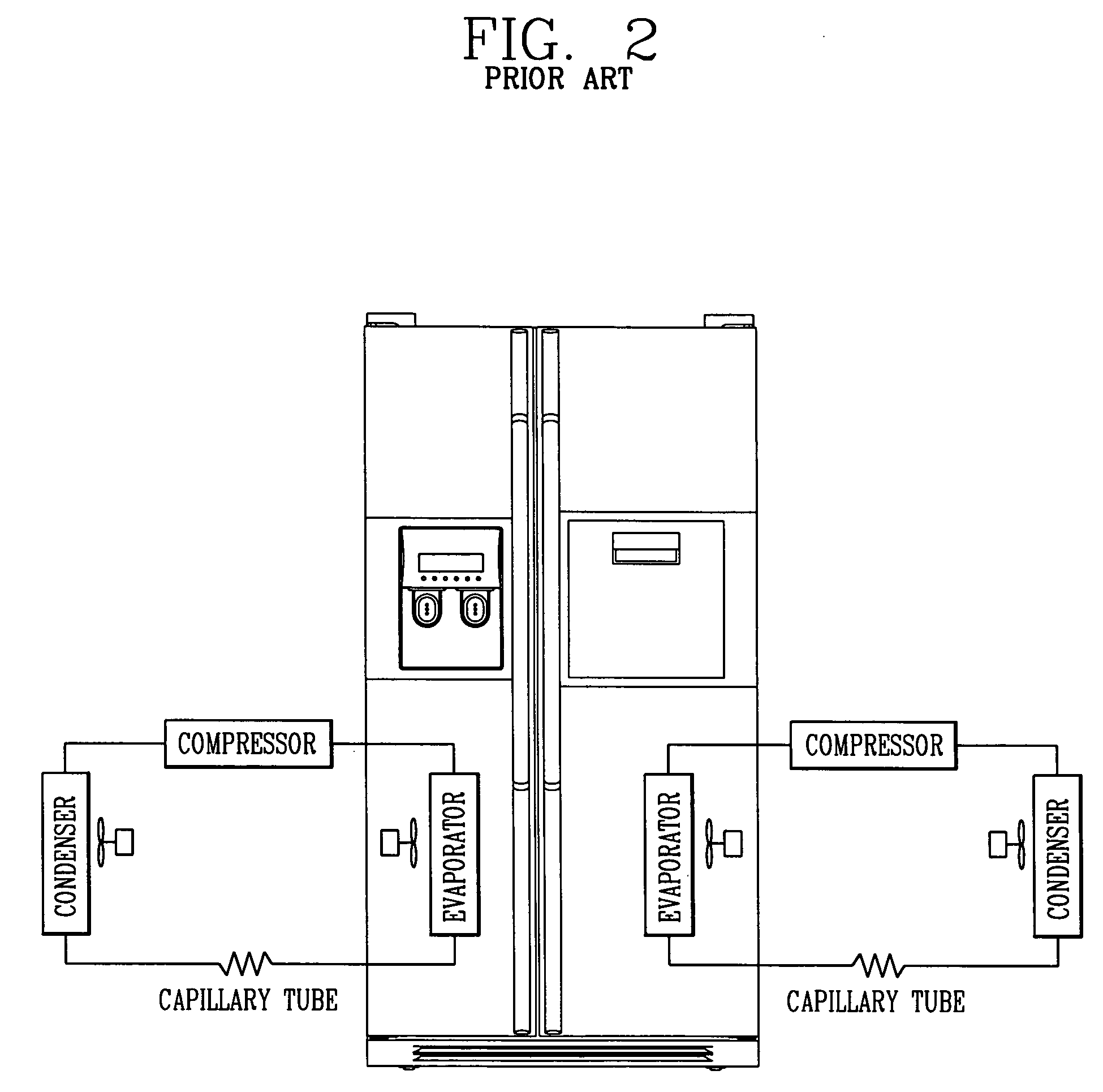

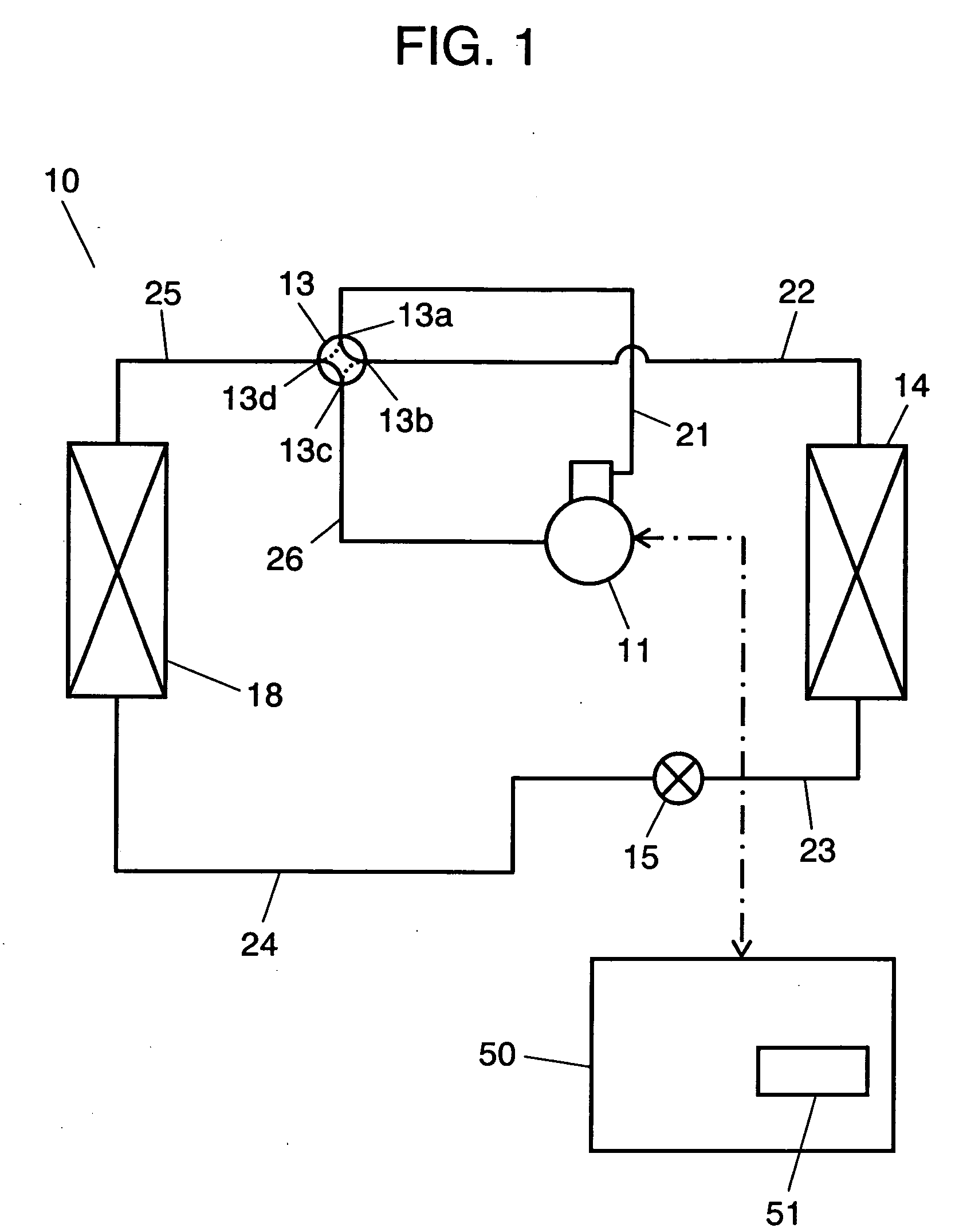

Apparatus for controlling operation of compressors

InactiveUS20060228221A1Low costReduce power consumptionCompressorMotor parameterMicrocomputerControl signal

Owner:LG ELECTRONICS INC

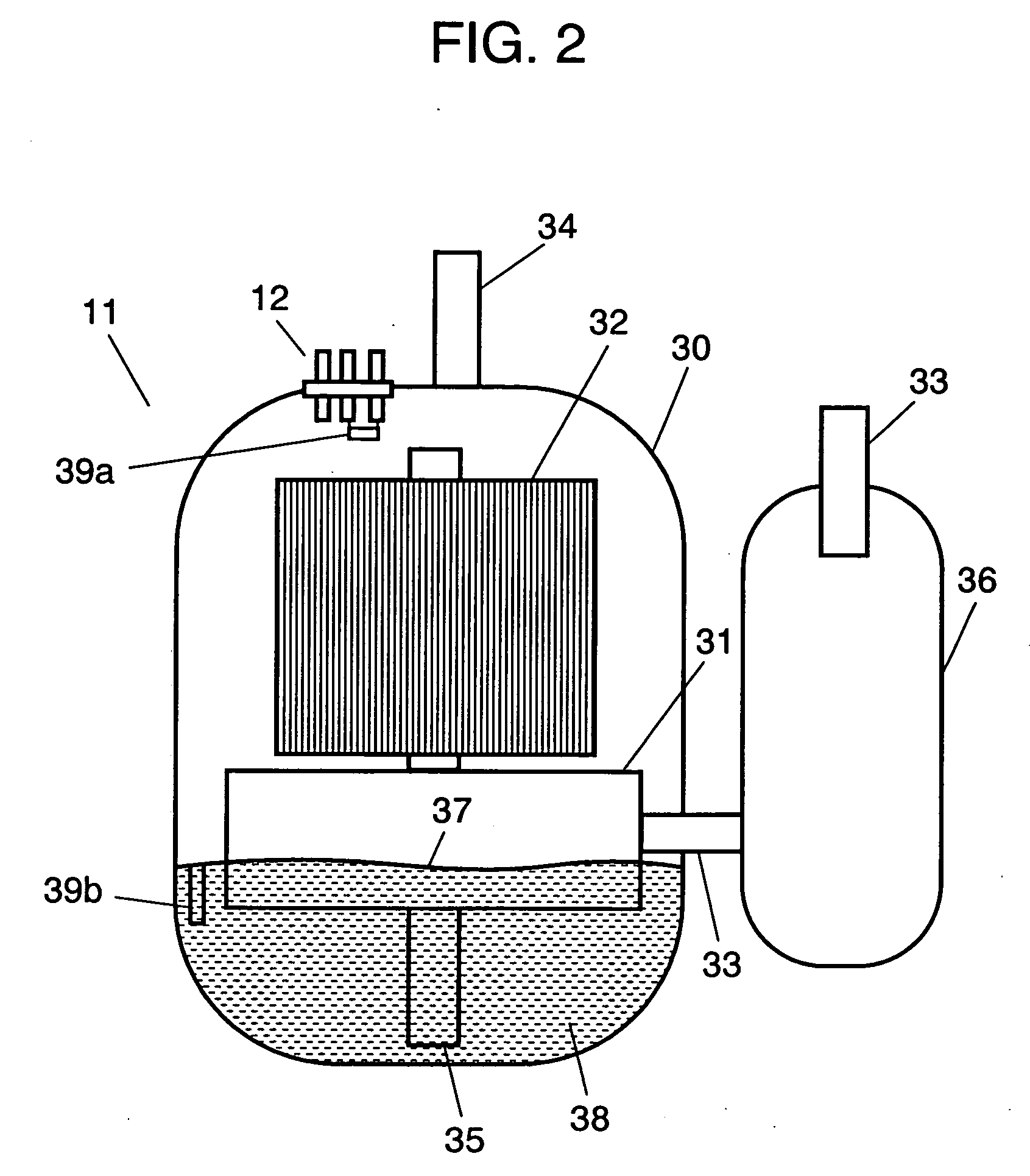

Hermetic compressor and refrigeration unit

InactiveUS20050254977A1Improve reliabilitySimple structurePositive displacement pump componentsPump controlEngineeringRefrigerant

Owner:PANASONIC CORP

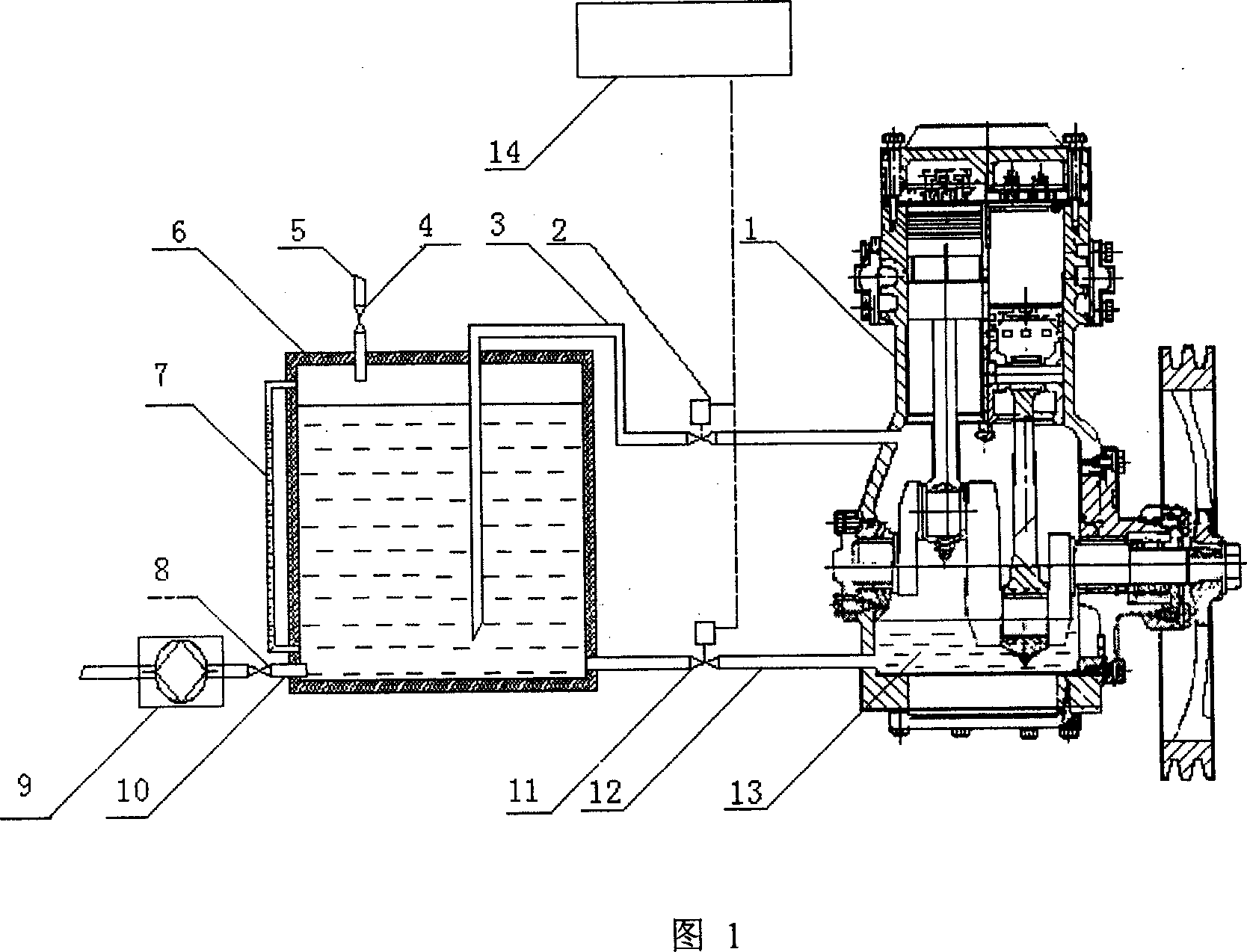

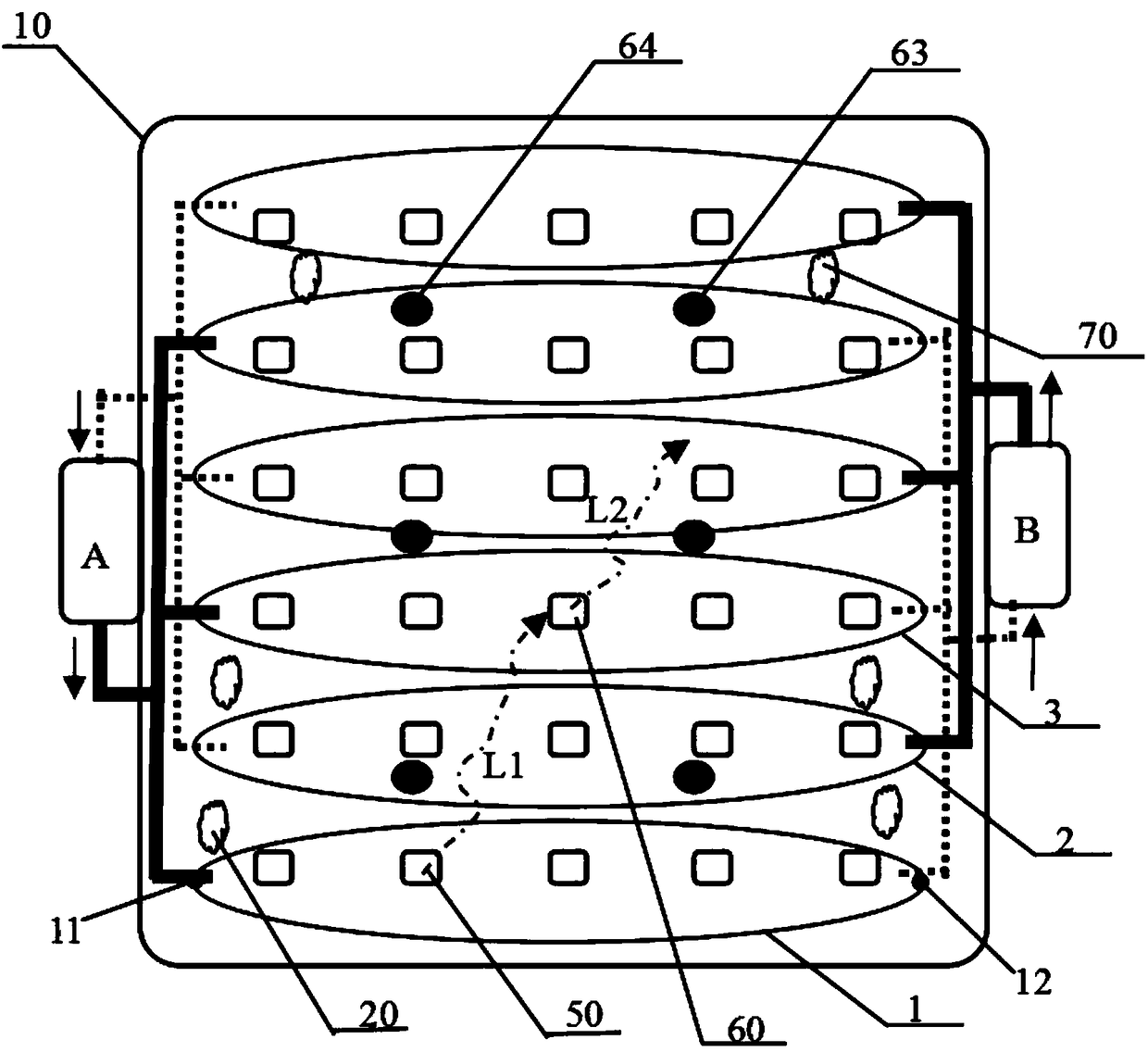

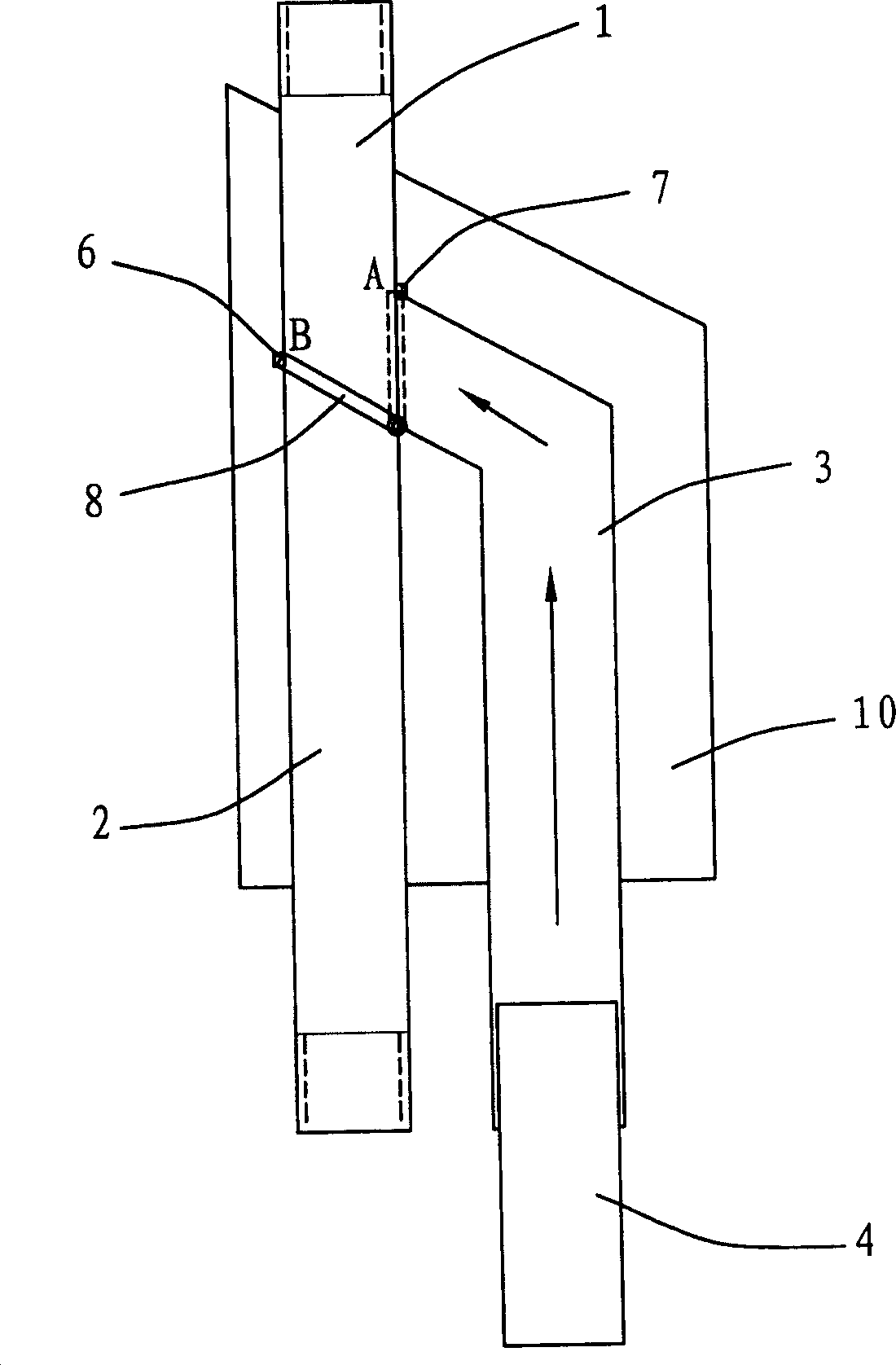

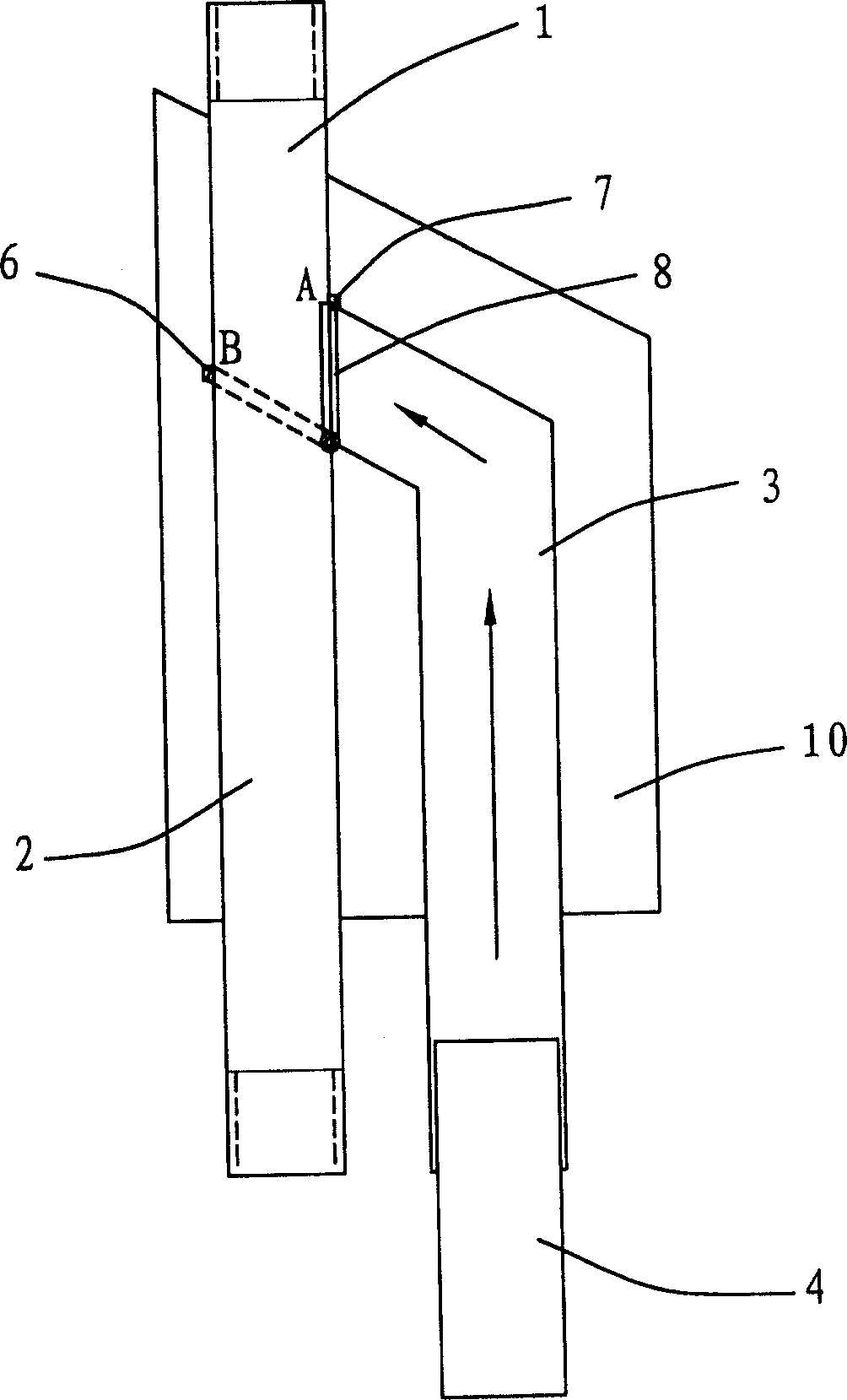

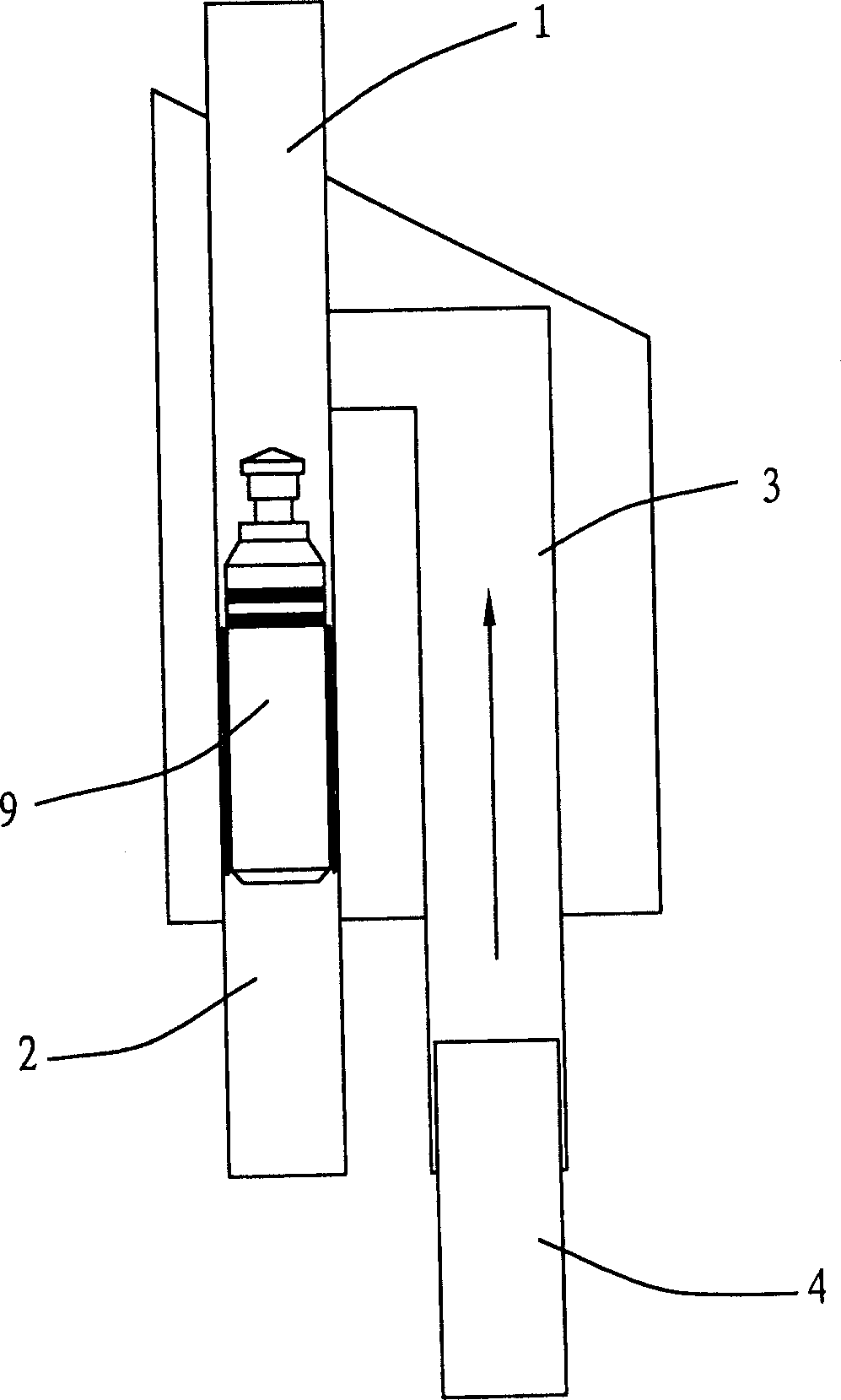

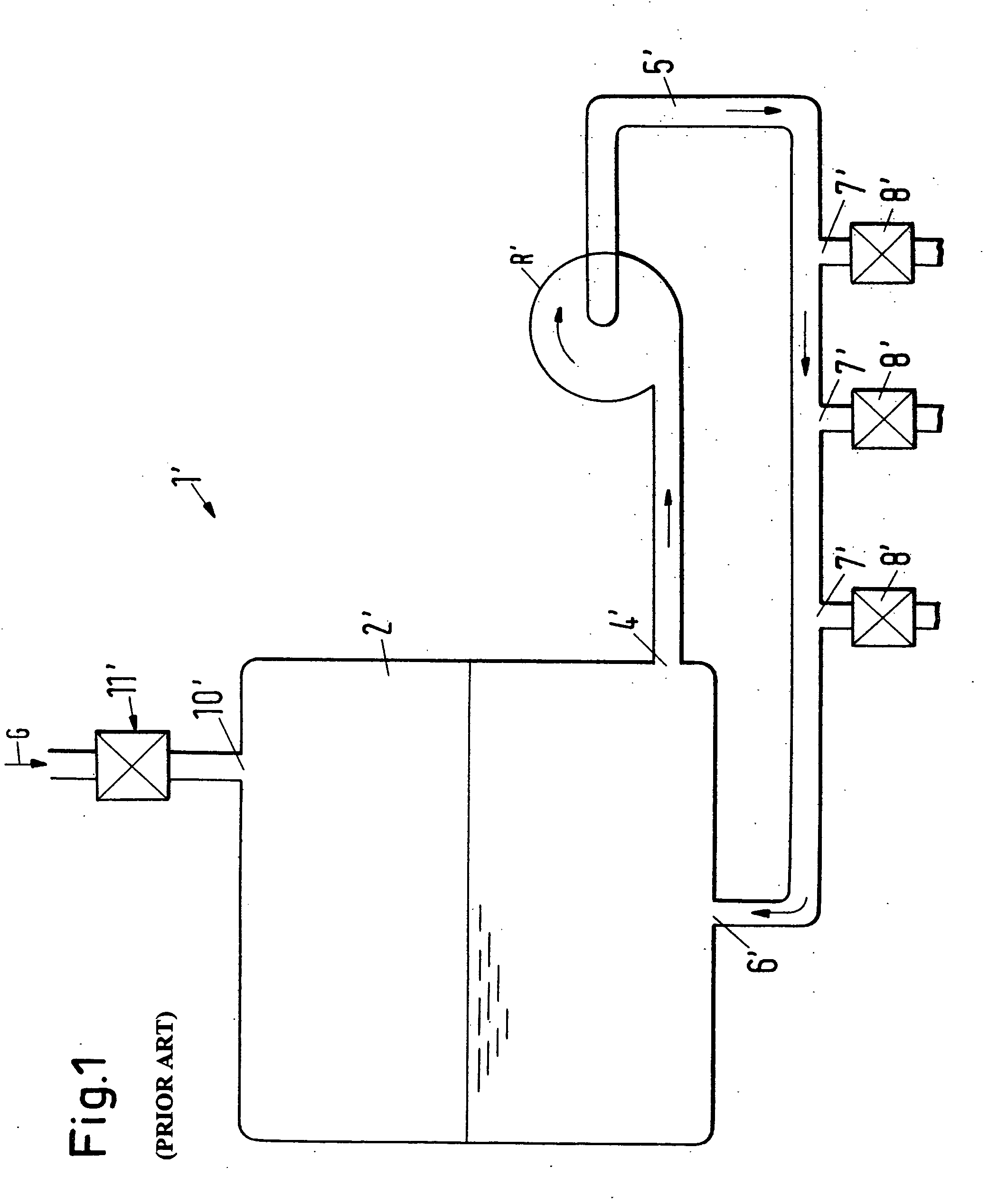

Automatic balance and compensating device for refrigeration compressor oil level

InactiveCN1945014APositive displacement pump componentsPositive-displacement liquid enginesLevel lineFuel tank

Owner:SOUTHEAST UNIV

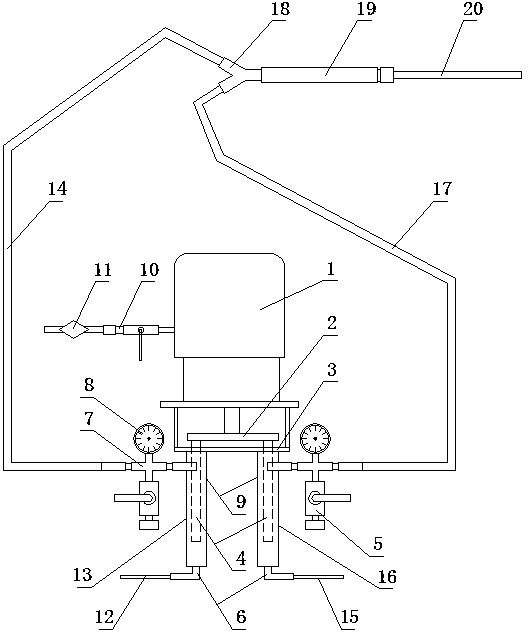

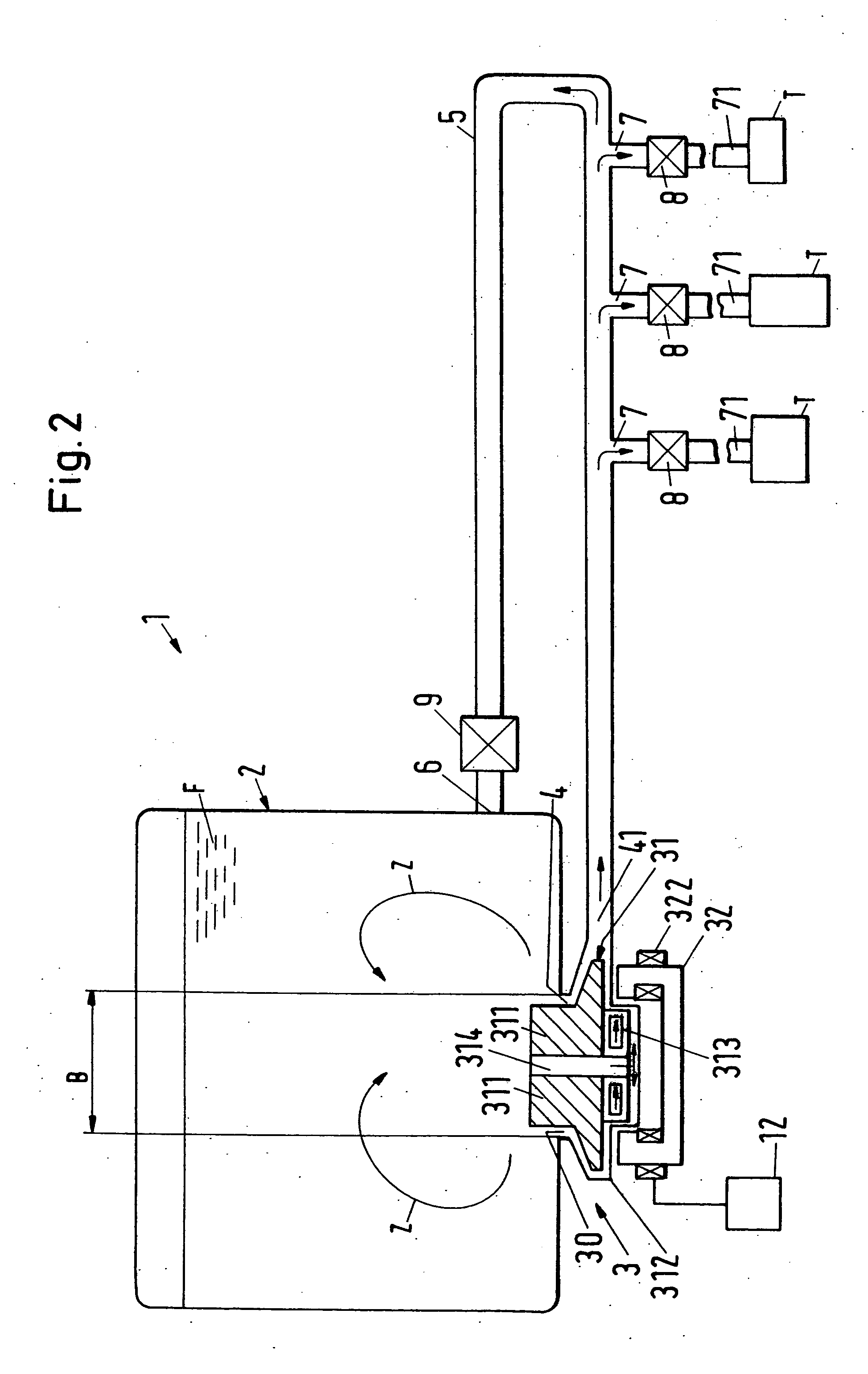

Hydraulic pressure generation unit with pneumatic actuation

InactiveUS20160230786A1Servomotor componentsAccumulator installationsEngineeringMechanical engineering

A “HYDRAULIC PRESSURE GENERATION UNIT WITH PNEUMATIC ACTUATION” in particular a multifunction unit activated by low pressure air, consisting of at least one pump (1), preferably two pumps (1 and 2), which are pneumatically automated, comprising a pneumatic cylinder (5) with a medial plunger (7), in addition to two symmetrical and opposite hydraulic plungers (8 and 9) limiting an upper hydraulic chamber (1 A and 2 A) and another lower hydraulic chamber (1 B and 2 B) having different volumes, wherein since they work in parallel and out-of-phase a reduced oil volume is required and the pulsating movement thereof is removed.

Owner:NEMA ERCIO MIGUEL

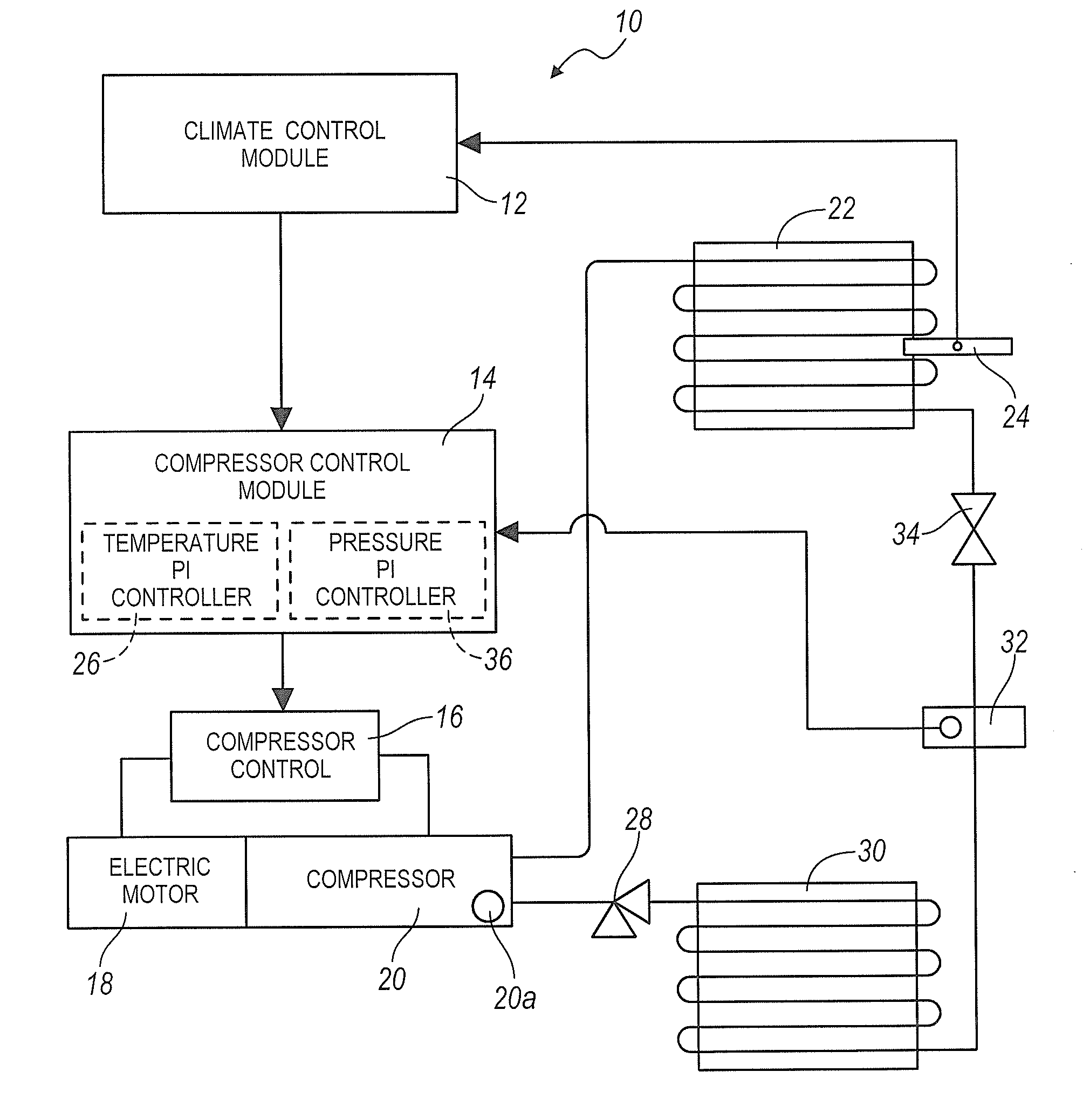

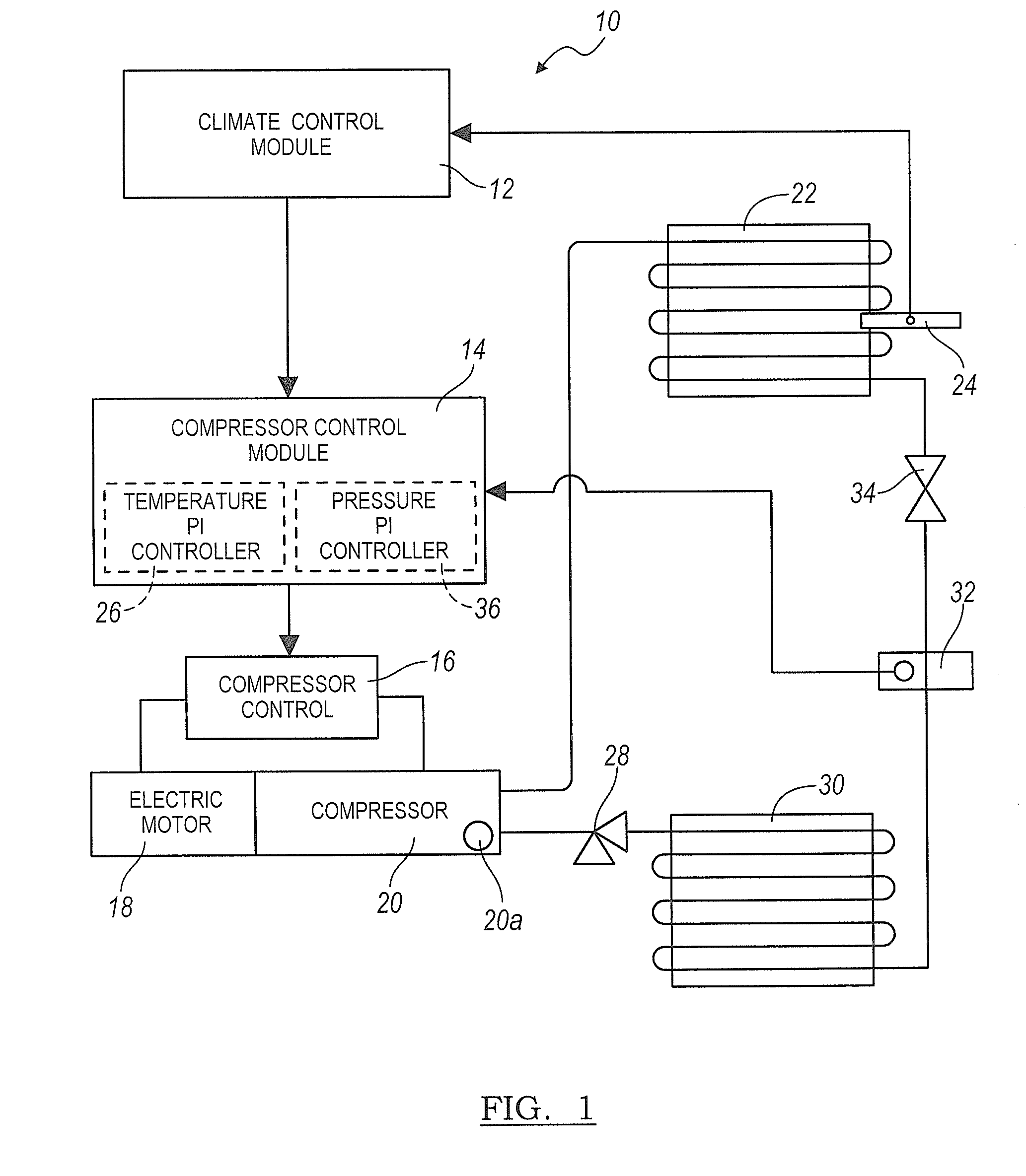

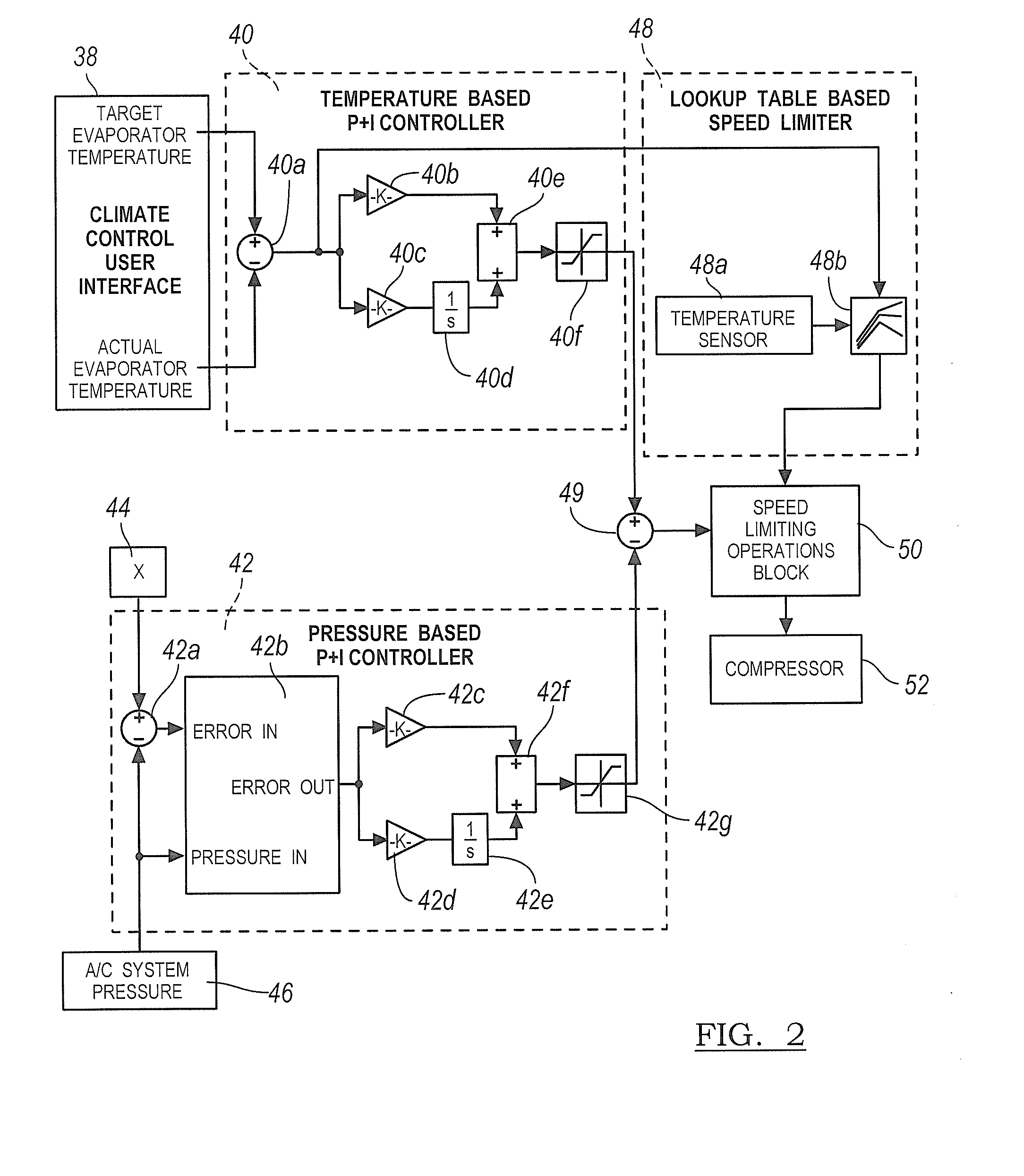

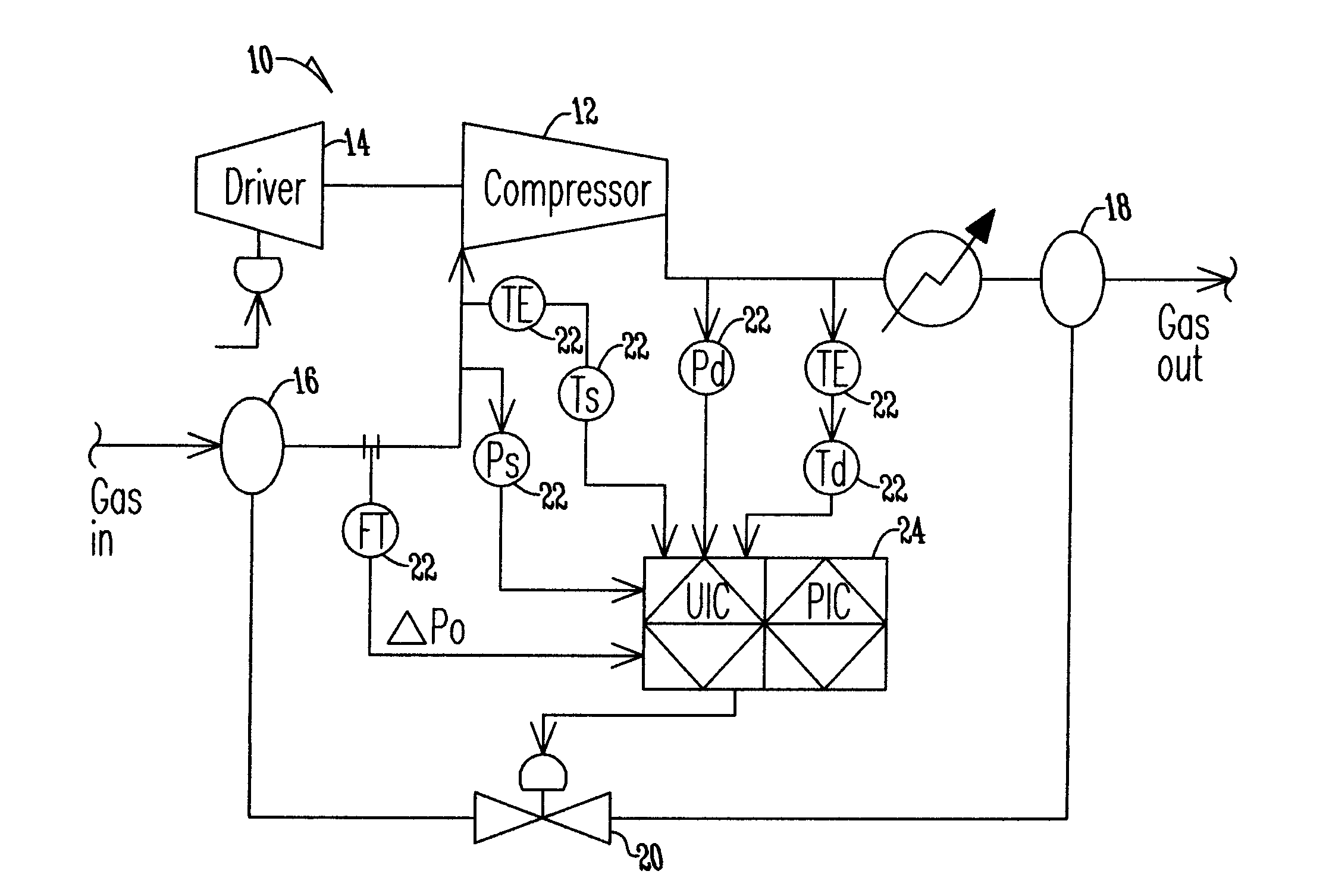

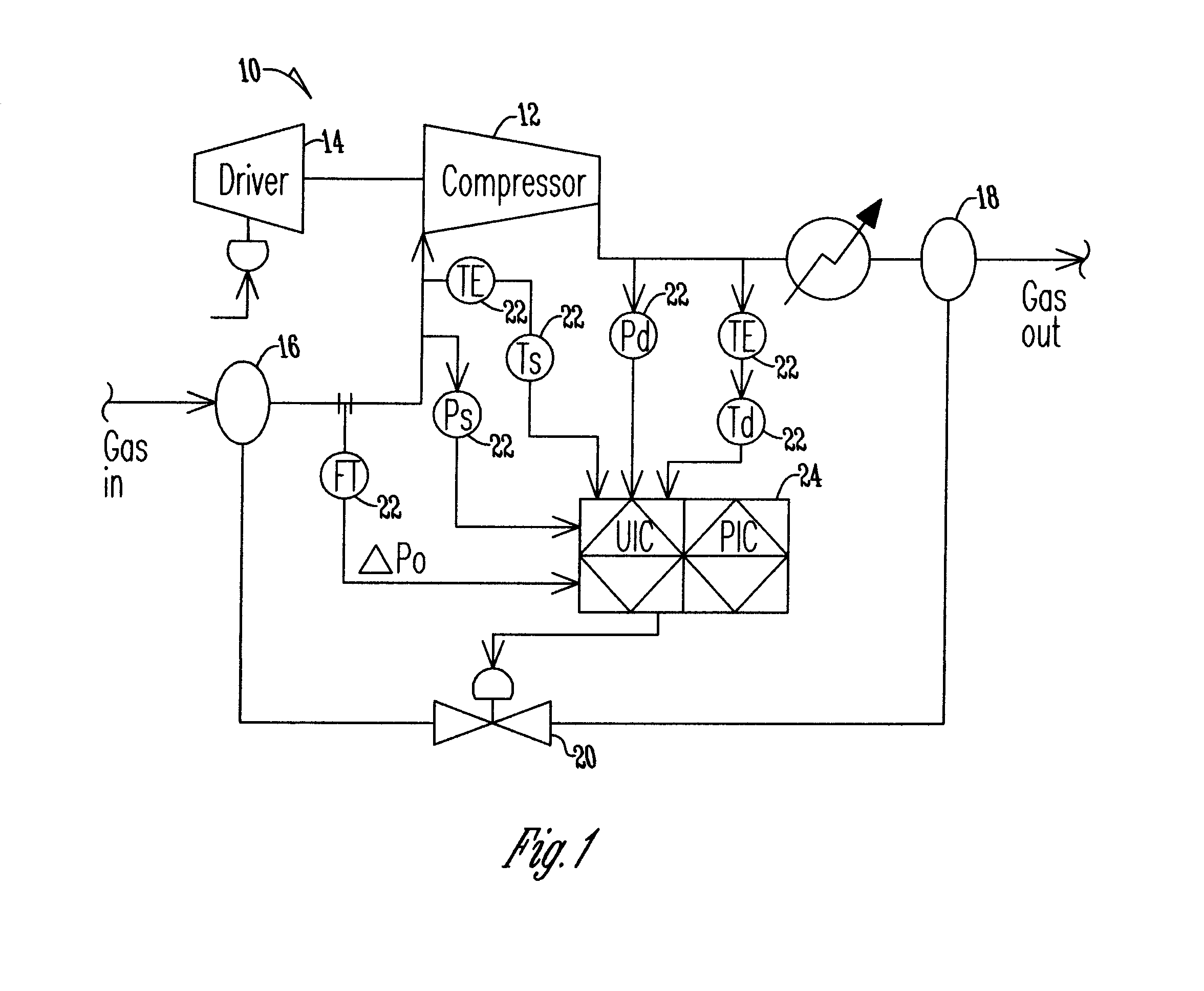

System and method for controlling a compressor

ActiveUS20080307811A1Increase speedCompression machines with non-reversible cycleVehicle heating/cooling devicesControl systemEngineering

Owner:FORD GLOBAL TECH LLC

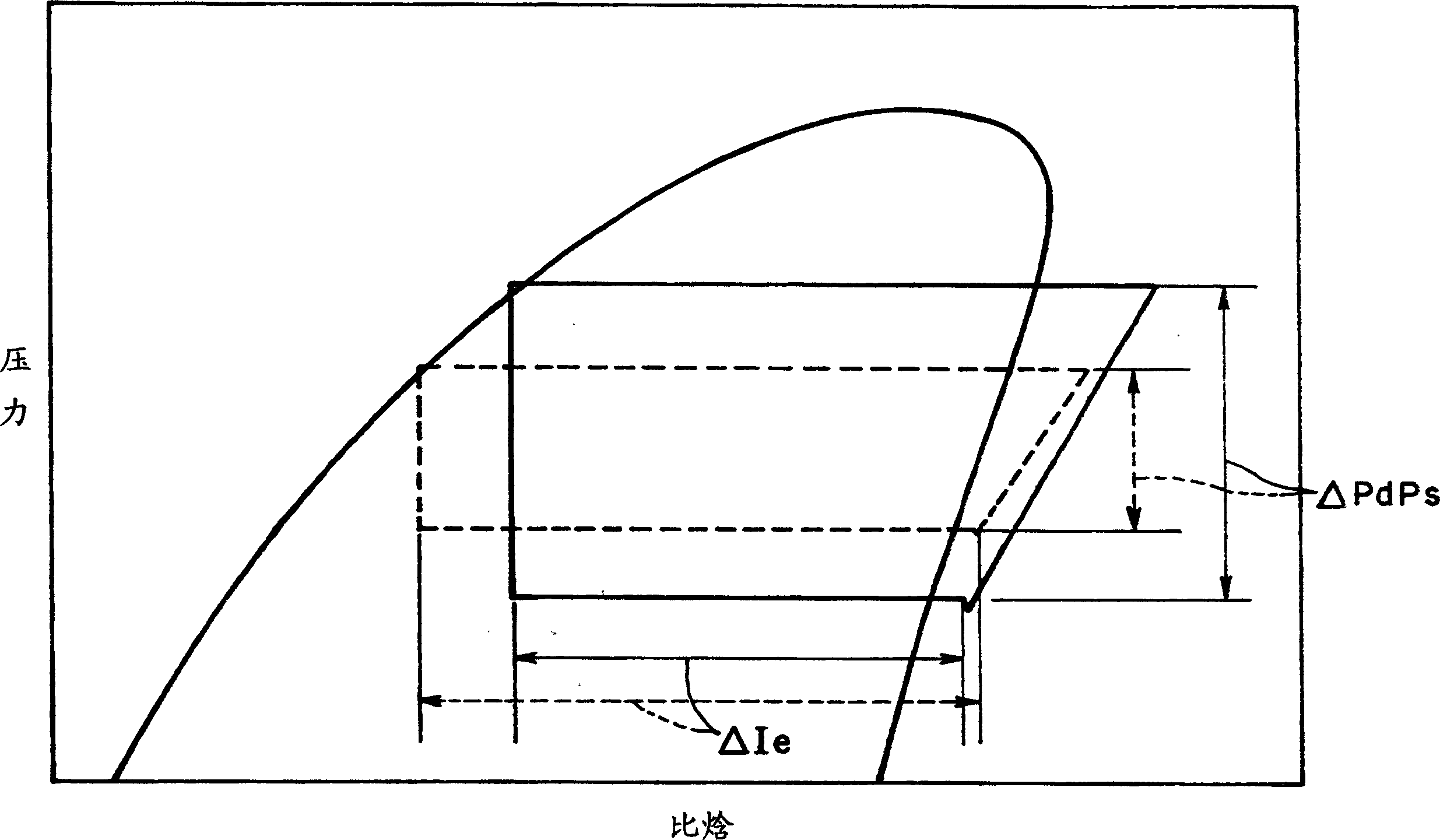

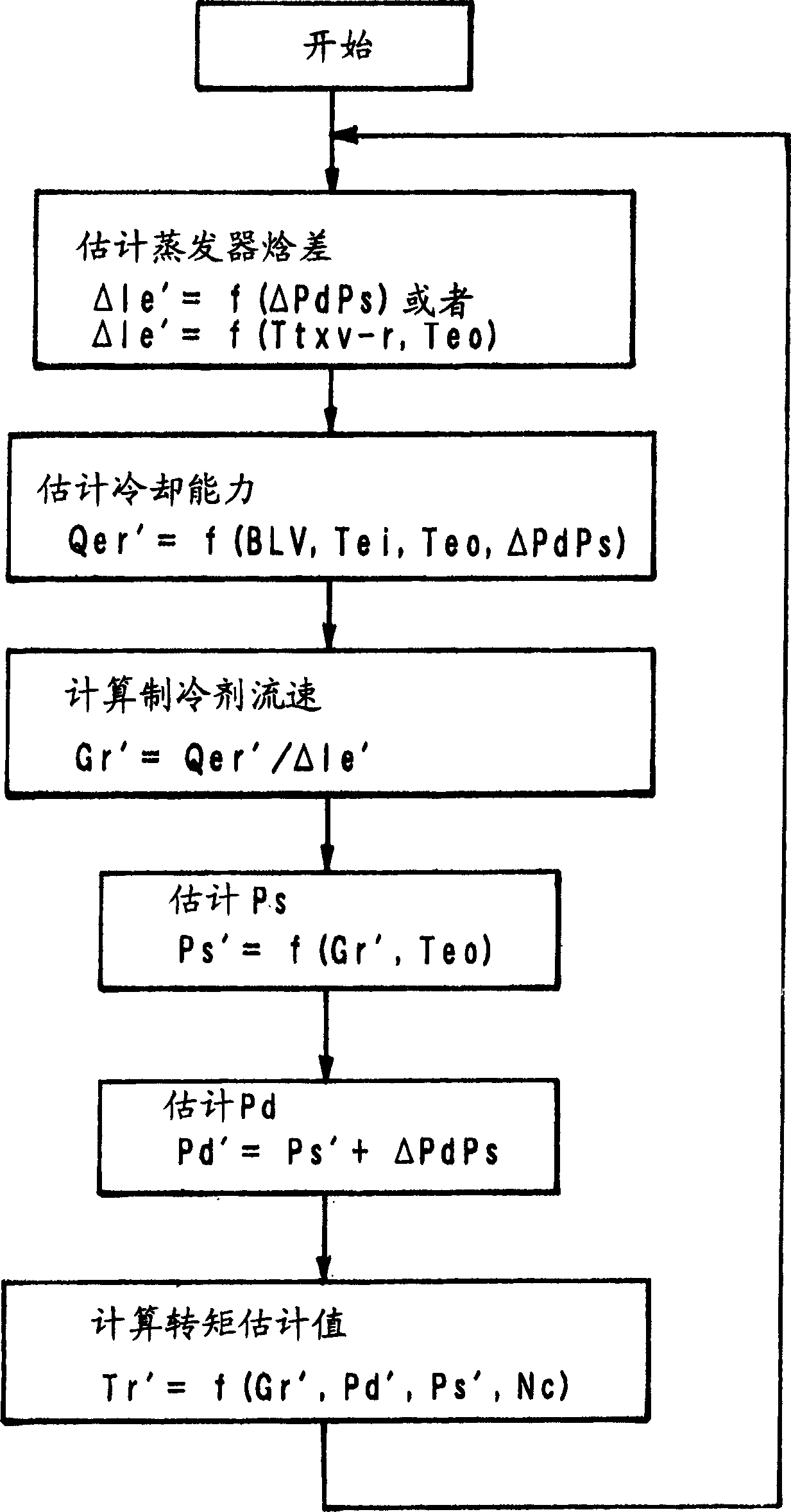

Control system

ActiveCN104220822APump componentsCompression machines with non-reversible cycleControl systemControl theory

A control system controls the output capacity of a compressor to avoid surge conditions in the compressor. The control system determines a capacity control output for the compressor and then modifies the capacity control output in view of any output limiters or overrides as determined by system operating parameters and to maintain a minimum frequency of operation for the compressor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

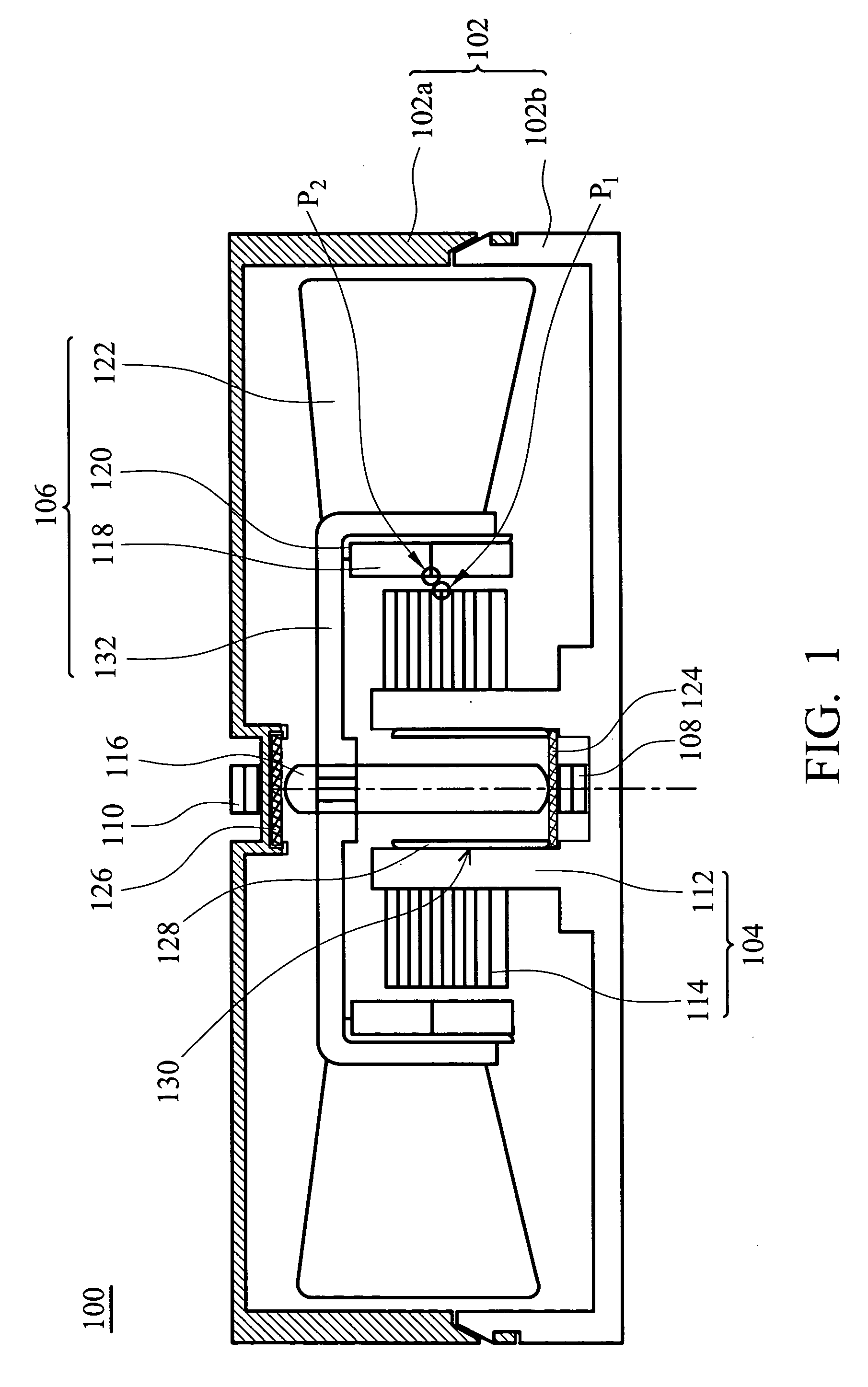

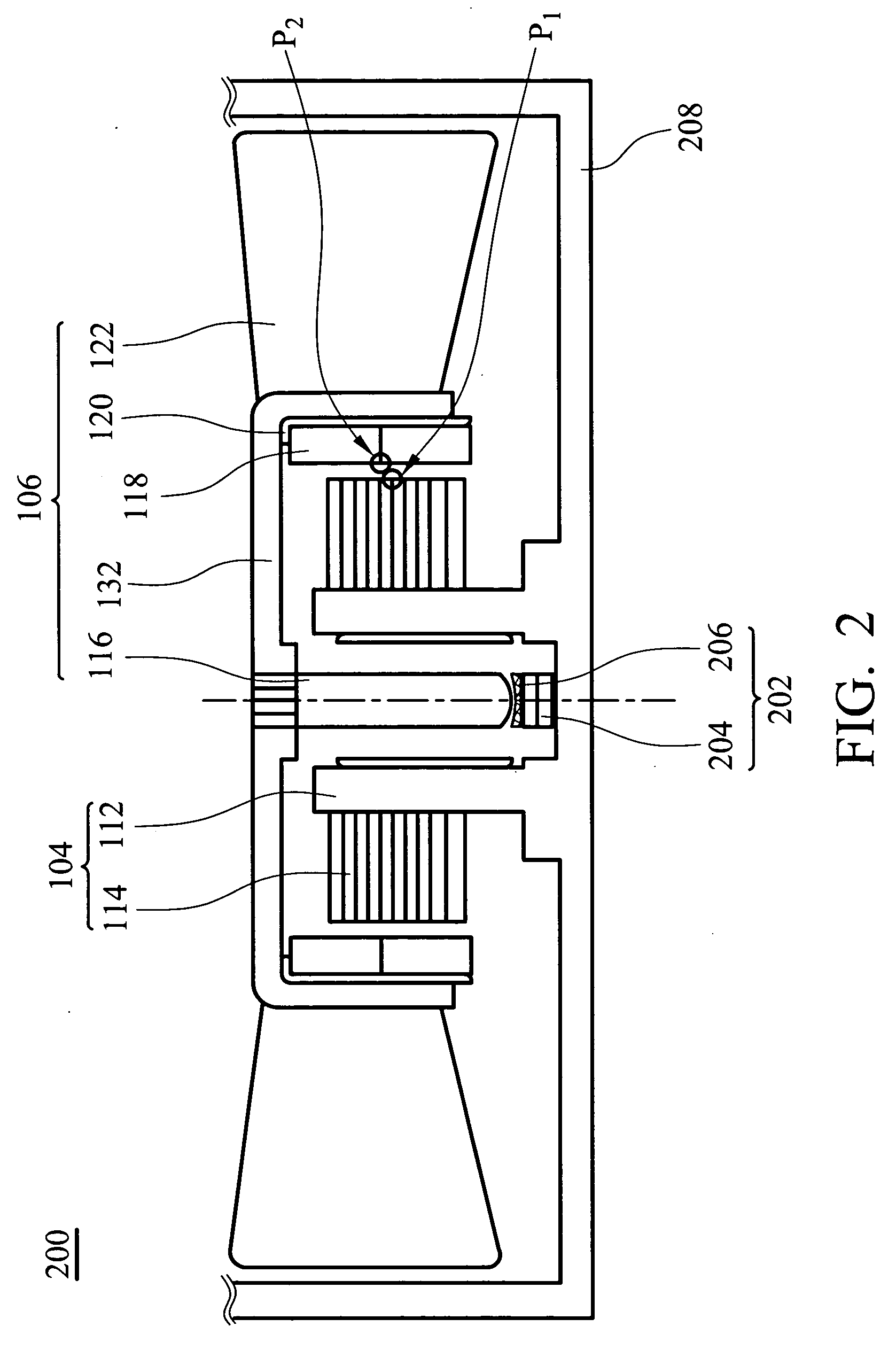

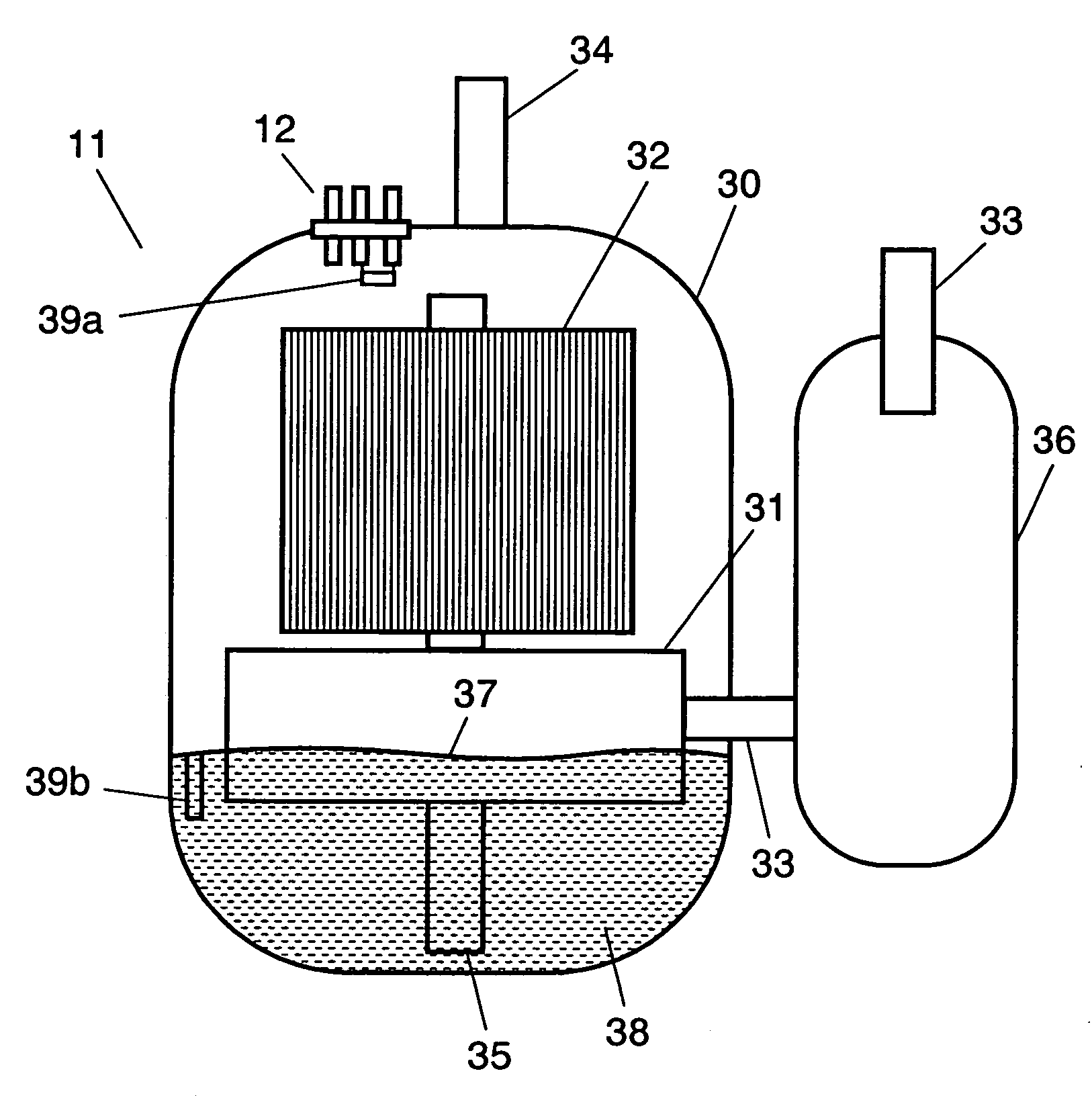

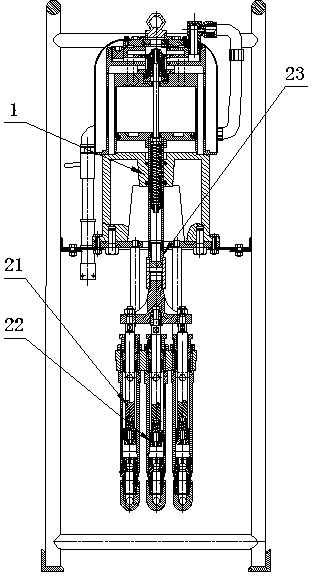

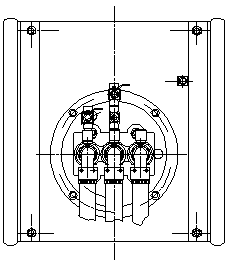

Linear compressor and lubricating oil pump thereof

InactiveUS20060257275A1Reduce frictionIncreased durabilityPositive displacement pump componentsWorking fluid for enginesLinear compressorReciprocating motion

Disclosed herein are a linear compressor and a lubricating oil pump thereof. The lubricating oil pump comprises a lubricating oil cylinder integrally formed in a frame that supports a compression unit, a lubricating oil piston mounted to be reciprocated inside the lubricating oil cylinder to resonate with the compression unit, and a lubricating oil cylinder protector to prevent generation of friction between the lubricating oil cylinder and the lubricating oil piston. With this configuration, it is possible to improve the durability of the lubricating oil cylinder and to simplify or omit additional processing of the lubricating oil piston.

Owner:LG ELECTRONICS INC

High-pressure plunger pump with energy recycling function

InactiveCN105526051AReduce deliveryImprove recycling efficiencyPositive displacement pump componentsPositive-displacement liquid enginesHigh concentrationReverse osmosis

The invention discloses a high-pressure plunger pump with an energy recycling function and relates to the technical field of hydraulic energy recycling. The problem that many energy transmission links exist in the energy recycling process is solved. The high-pressure plunger pump with the energy recycling function comprises an outer shell and a cylinder body, wherein the outer shell comprises two end covers and a shell body with a through hole; the cylinder body is arranged in the through hole of the shell body; a swash plate is arranged between the cylinder body and one of the end covers; cylinder holes are formed in the cylinder body in a circumferential array; a plunger and sliding shoe assembly is arranged in each cylinder hole; the outer shell is provided with a fluid inlet and a fluid outlet which communicate with the cylinder holes; a fluid channel is arranged on the cylinder body; a hydraulic cavity is formed between each plunger and sliding shoe assembly and the inner wall of the corresponding cylinder hole and communicates with the fluid channel; the outer shell is provided with a recycling inlet and a recycling outlet which communicate with the fluid channel. The high-pressure plunger pump with the energy recycling function is mainly applied to high-pressure fluid equipment for industrial production to achieve the functions like recycling energy of waste high-concentration sea water in reverse-osmosis seawater.

Owner:WOER TECH

Automatic identifying method for frequency-conversion and constant-speed compressor and refrigerator

ActiveCN103343743AReduce typesReduce power consumptionPump testingDomestic cooling apparatusGas compressorFrequency conversion

The invention discloses an automatic identifying method for a frequency-conversion and constant-speed compressor and a refrigerator. A detection circuit is arranged on a main control board and is divided. A circuit on a frequency conversion board is used for conducting switch-on control on the detection circuit. Consequently, whether the frequency conversion board is plugged on the main control board can be judged through judging whether a signal circuit of the detection circuit is switched on or not, so that whether a selected compressor is a frequency-conversion compressor can be further judged, and the purpose that the main control board automatically identifies the frequency-conversion and constant-speed compressor is achieved. According to the identified type of the compressor, the main control board can selectively start a drive circuit used for driving compressors of different types to operate, so that whole machine power consumption is remarkably reduced, and the design purposes of saving energy and reducing consumption are further achieved. Meanwhile, the main control board can properly configure refrigerating reference in a compressor control procedure according to the automatically-identified compressor types, so that the optimization of compressor refrigerating efficiency can be achieved.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Compressor output calculation unit and control unit using the same

Owner:SANDEN CORP

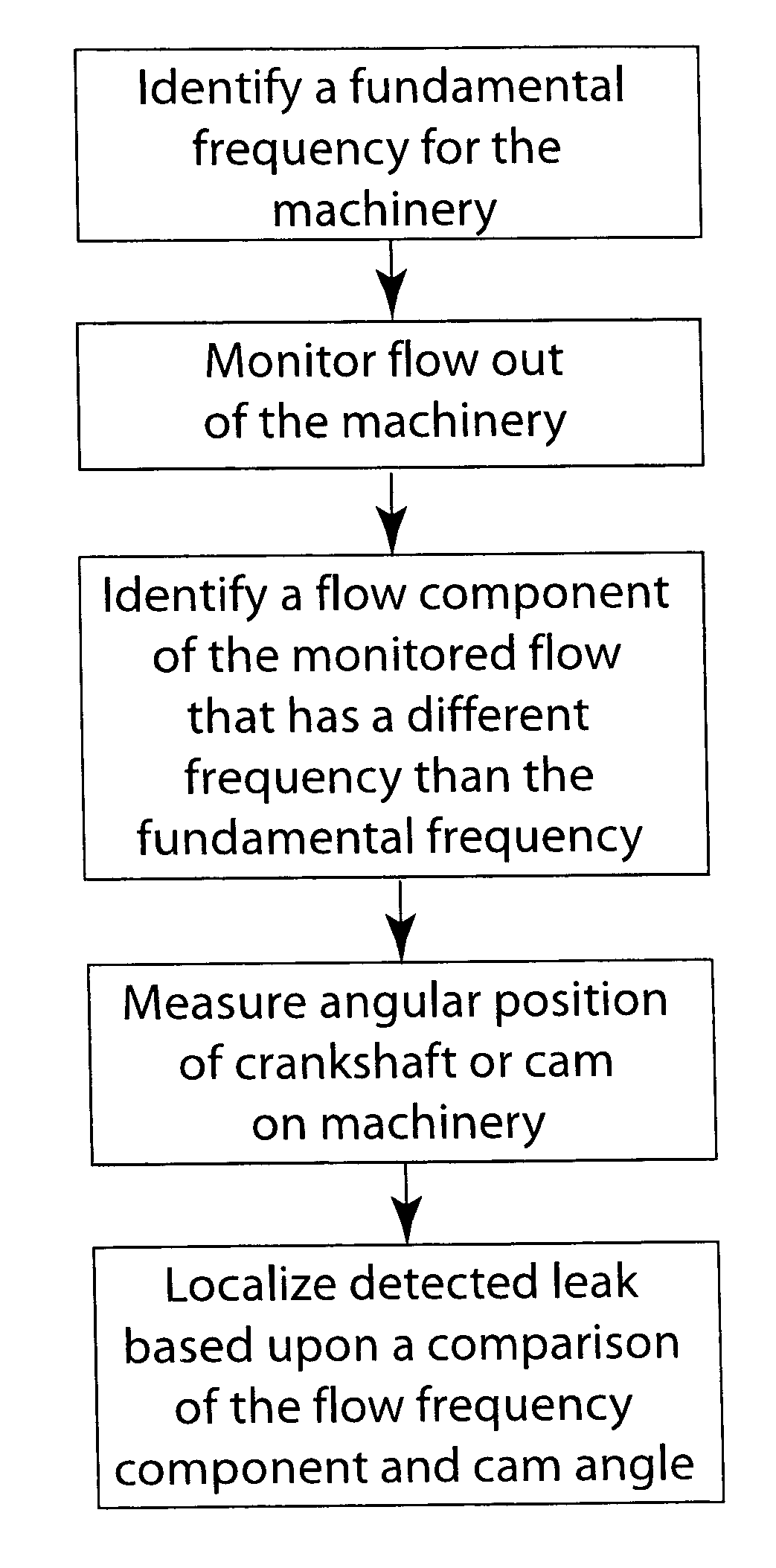

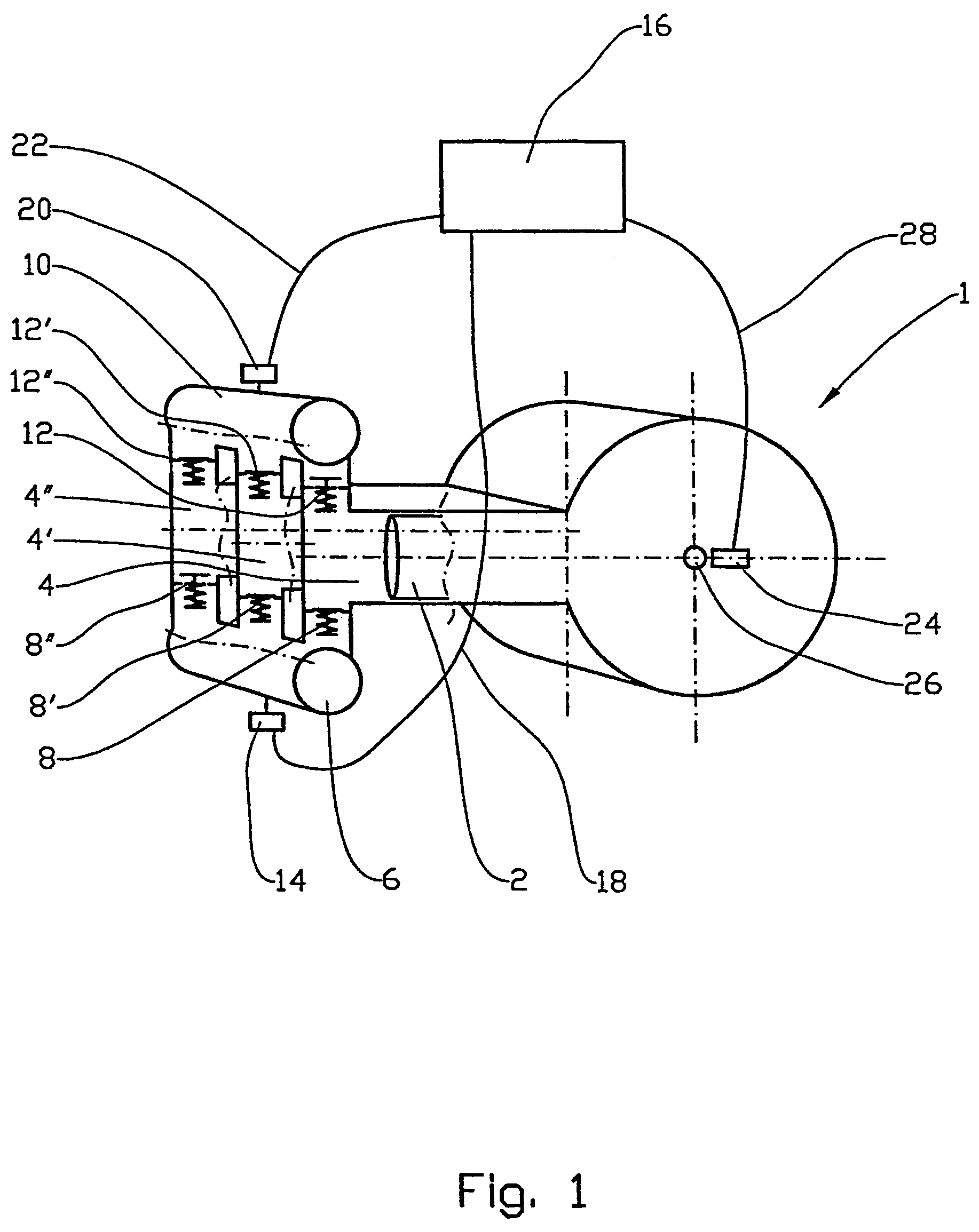

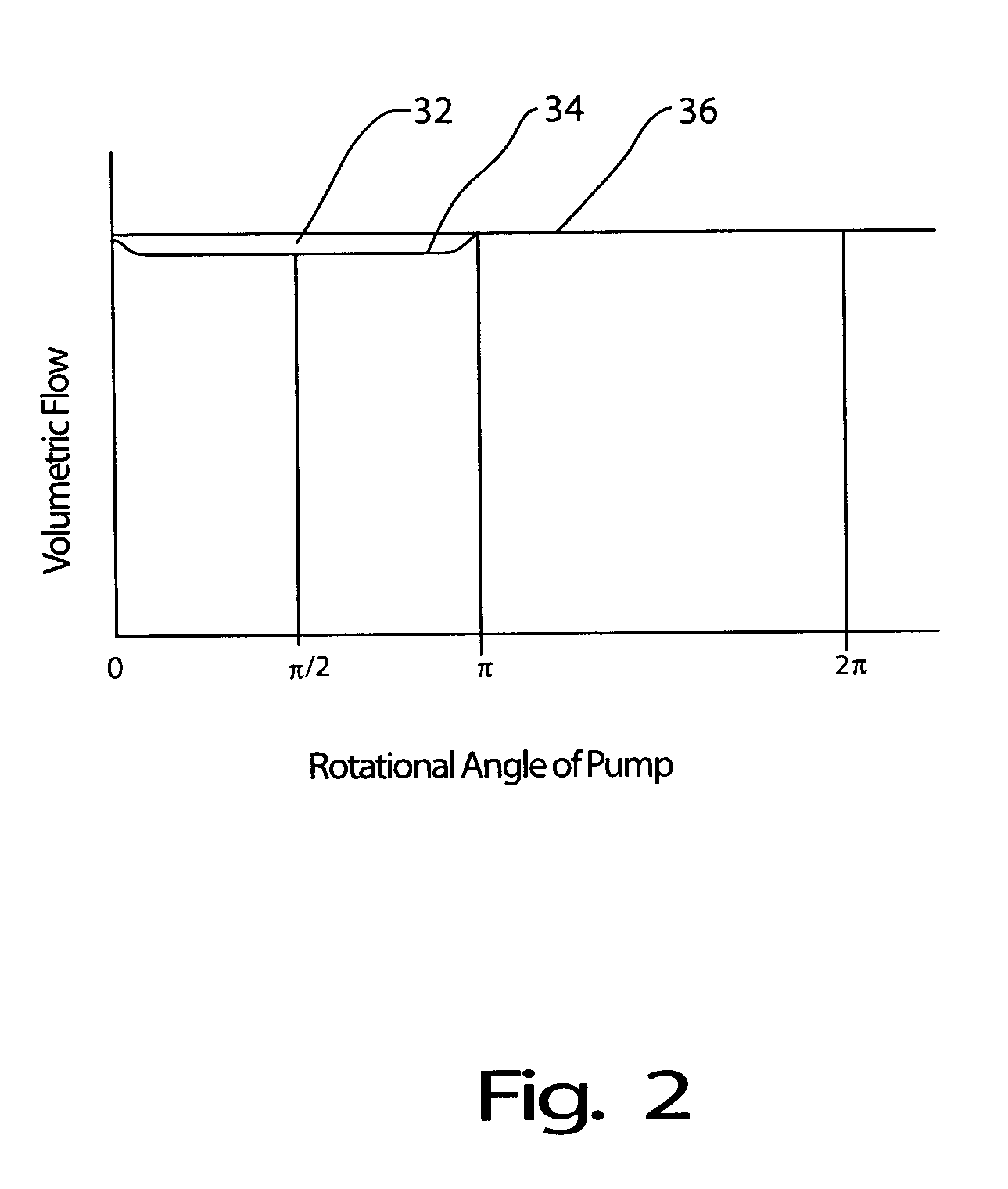

Method and device for detecting leaks in reciprocating machinery

InactiveUS7130751B2Spectral/fourier analysisDetection of fluid at leakage pointEngineeringFundamental frequency

Owner:NAT OILWELL VARCO NORMAY AS

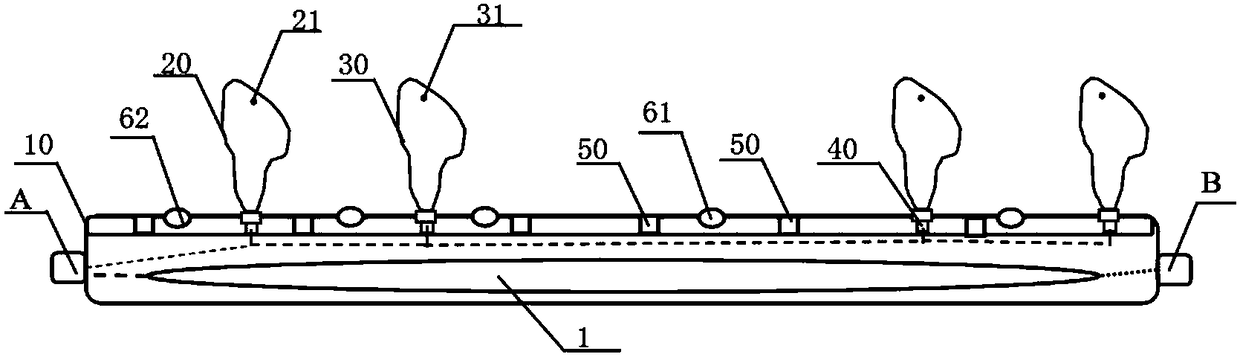

Pneumatic two-fluid grouting pump

InactiveCN103410696AReduce purchasing costsFirmly connectedPiston pumpsPositive-displacement liquid enginesHigh pressurePlunger pump

Owner:SHANDONG XINGYUAN MINING EQUIP GRP

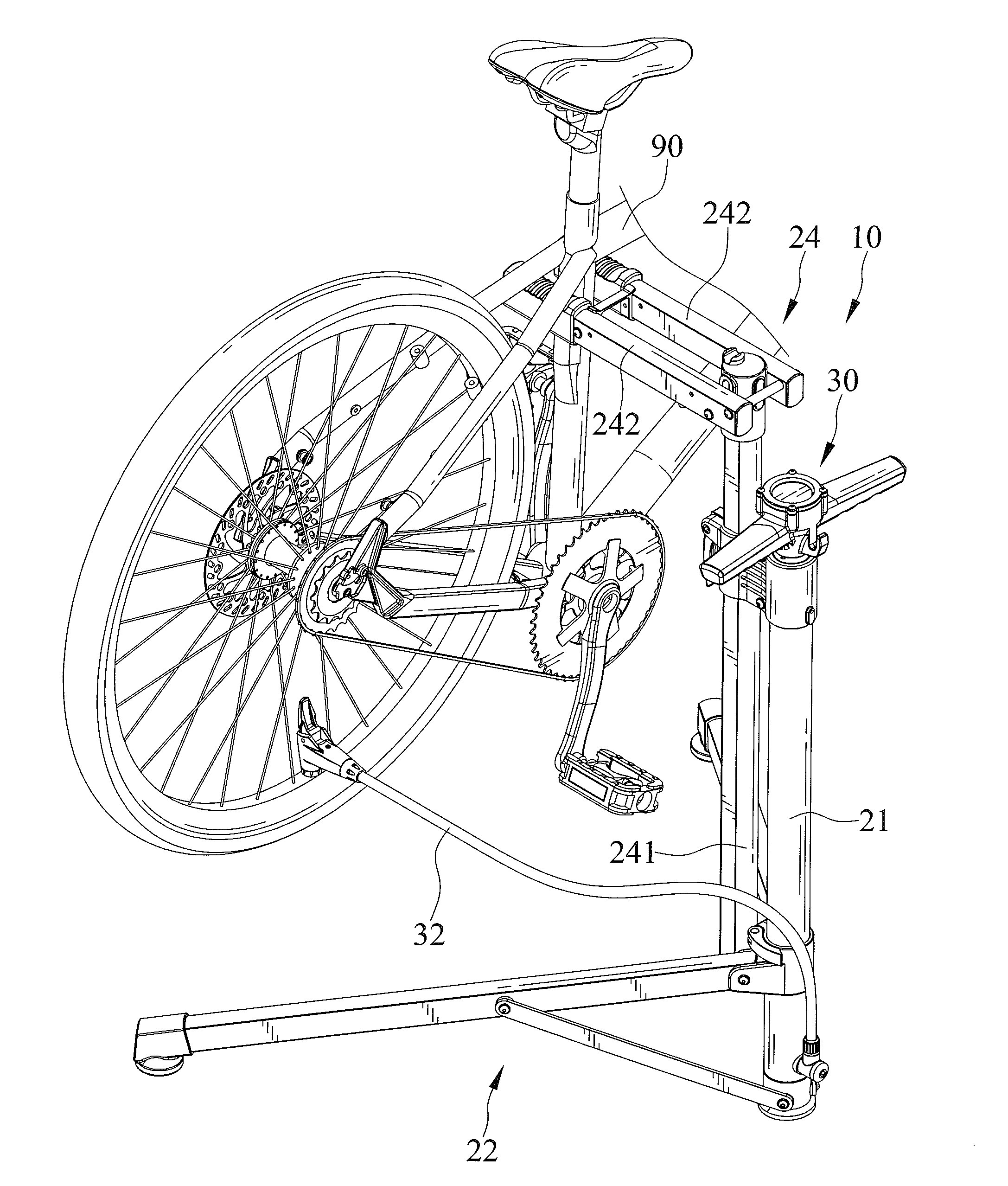

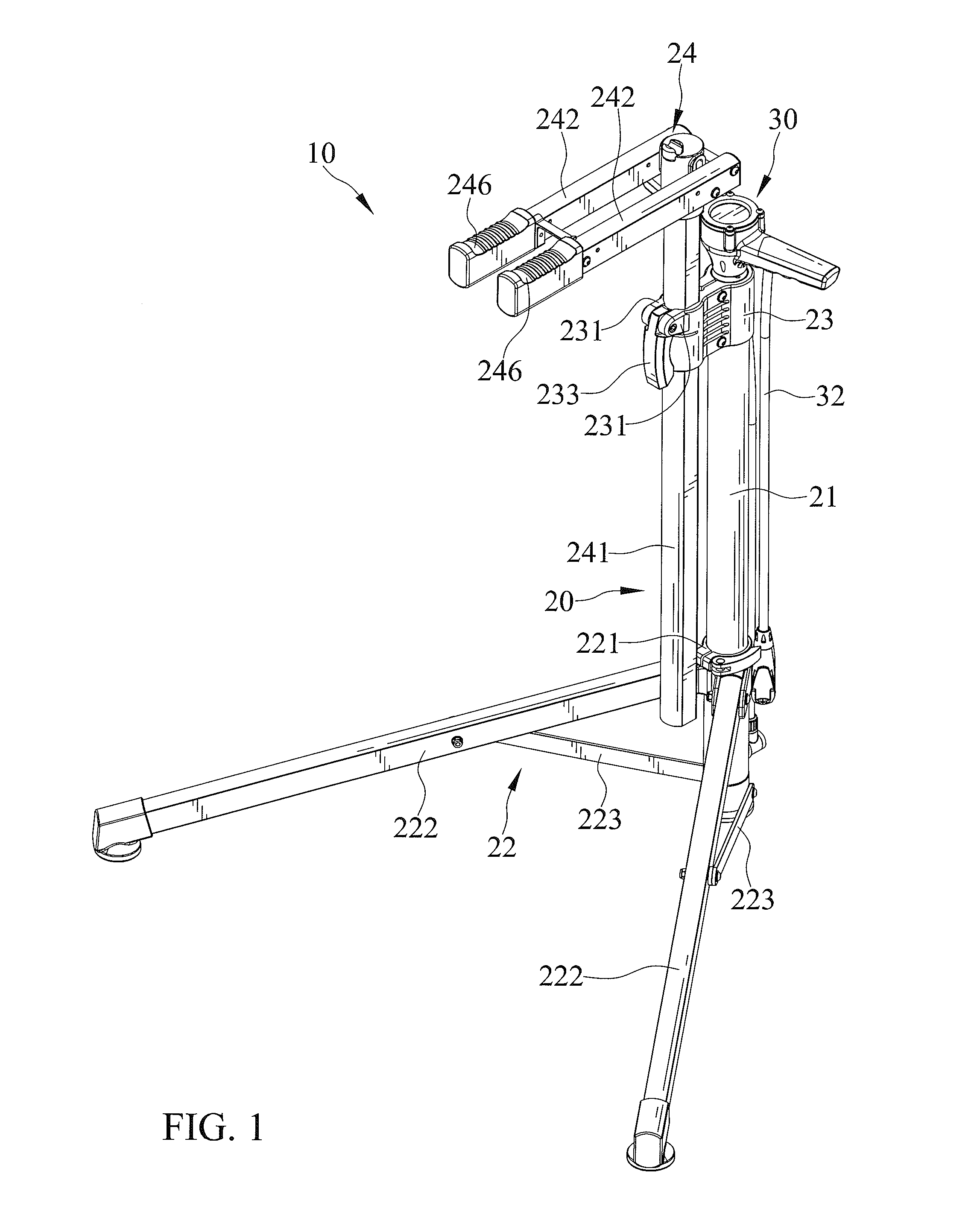

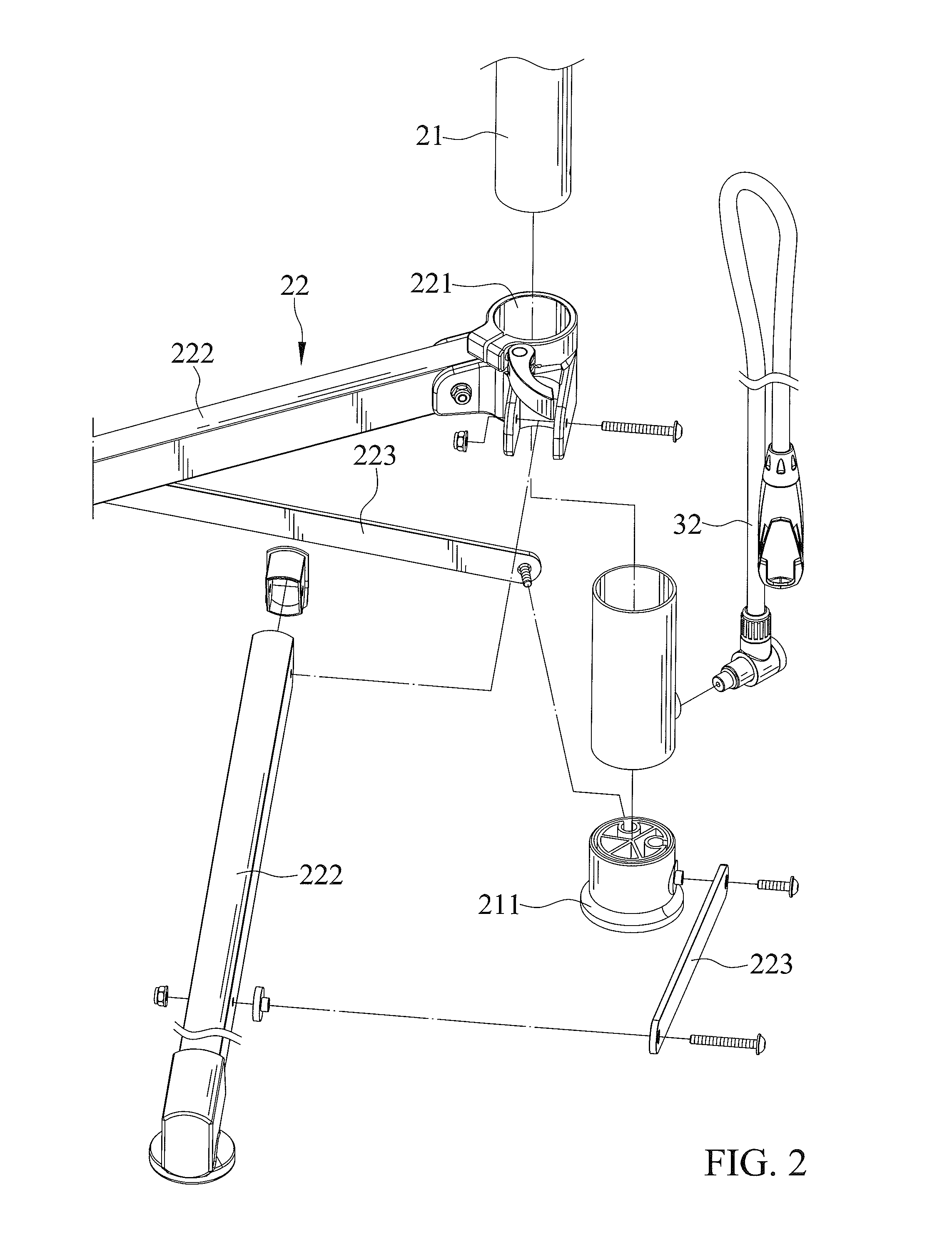

Bike Repair Stand

InactiveUS20160297063A1Positive displacement pump componentsCycle standsLeg mechanismMechanical engineering

Owner:CHUANG LOUIS

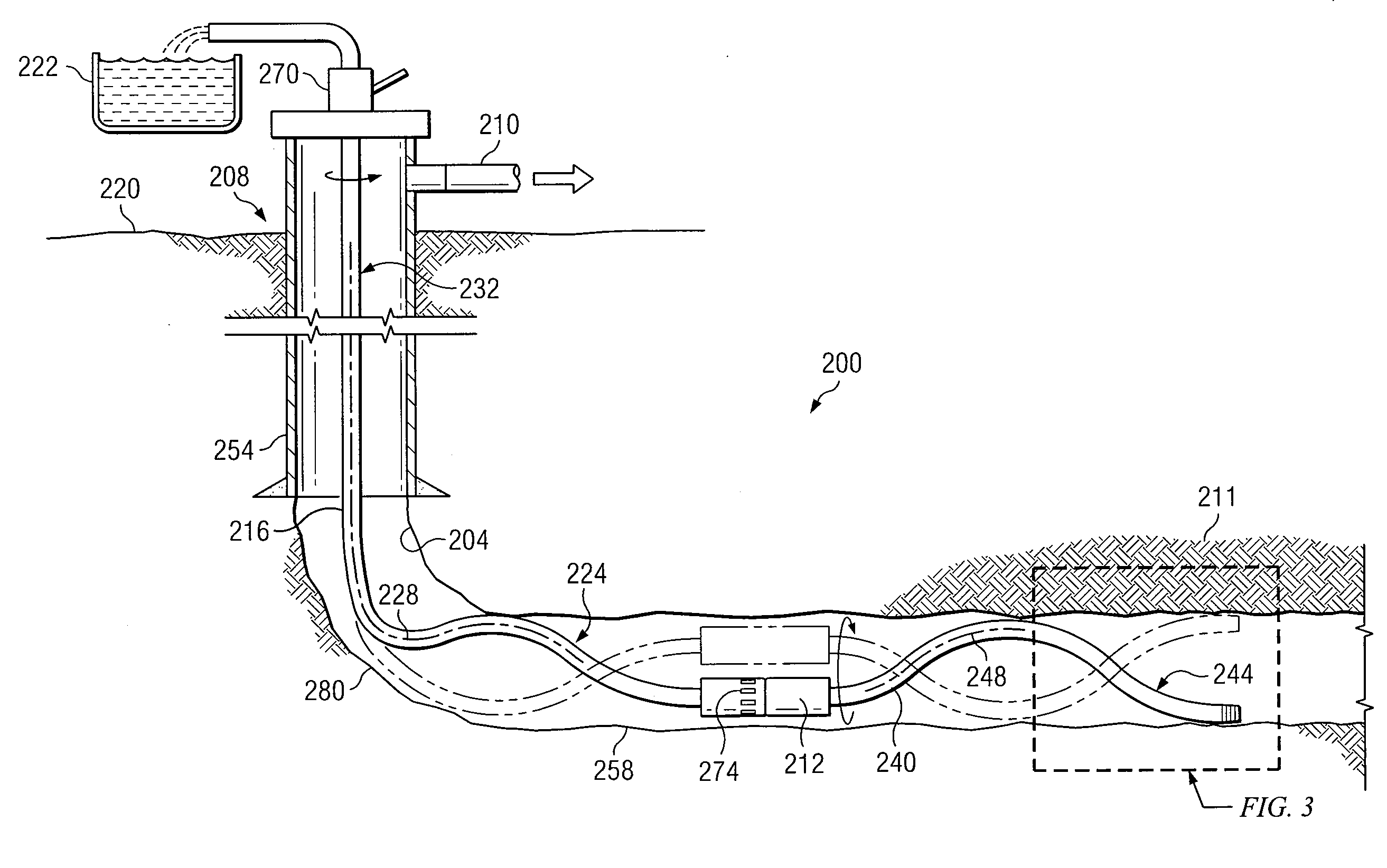

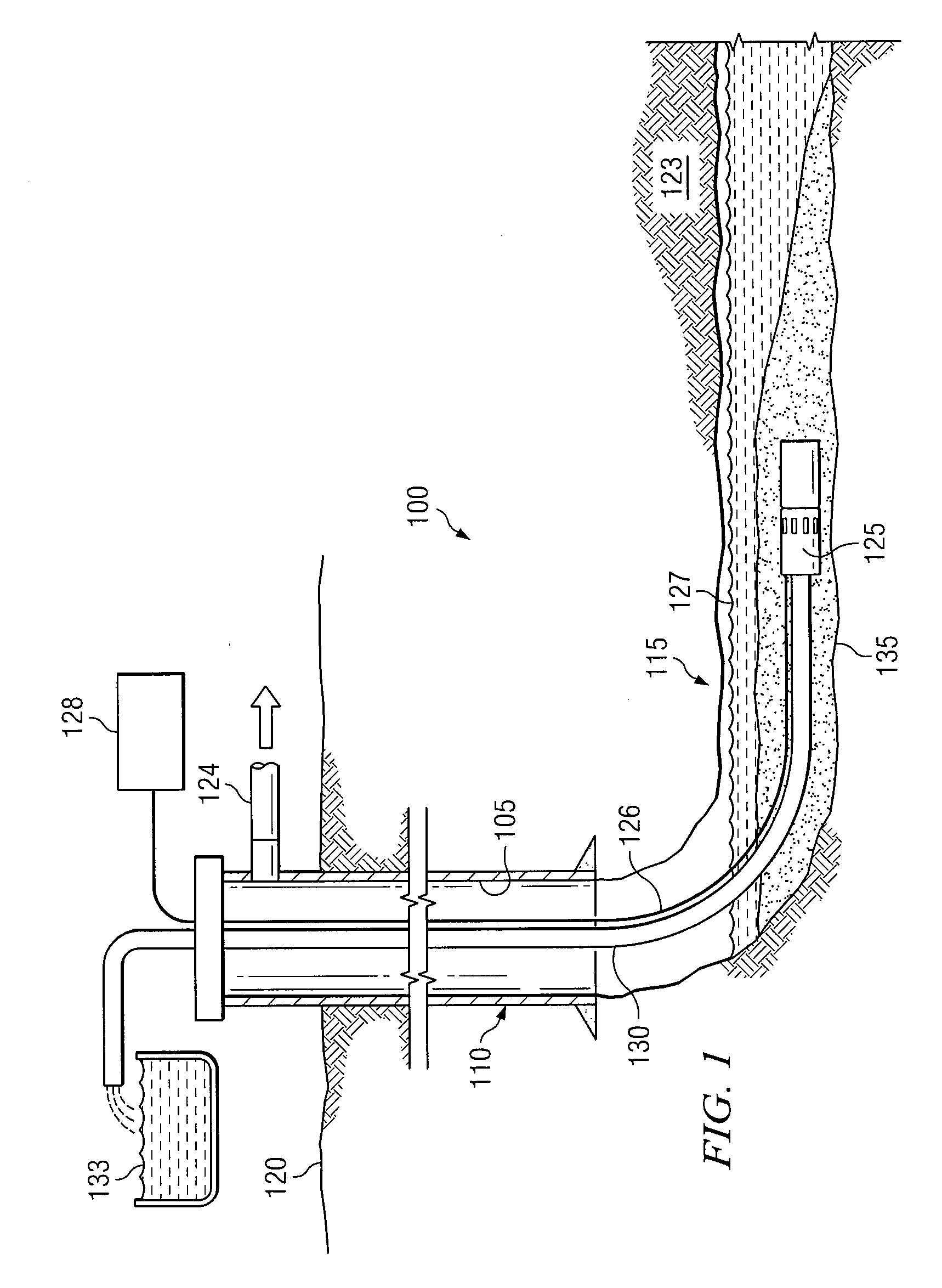

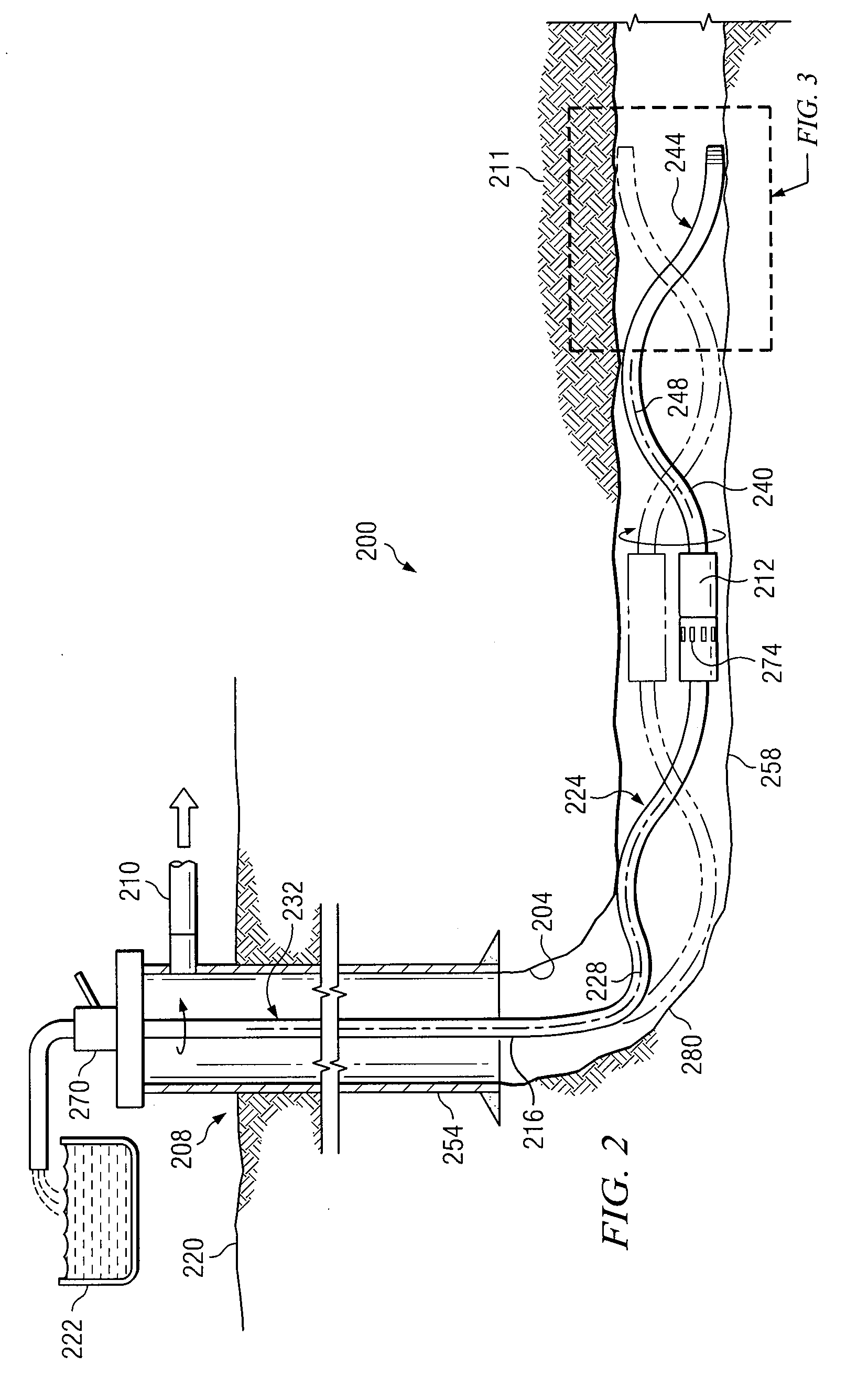

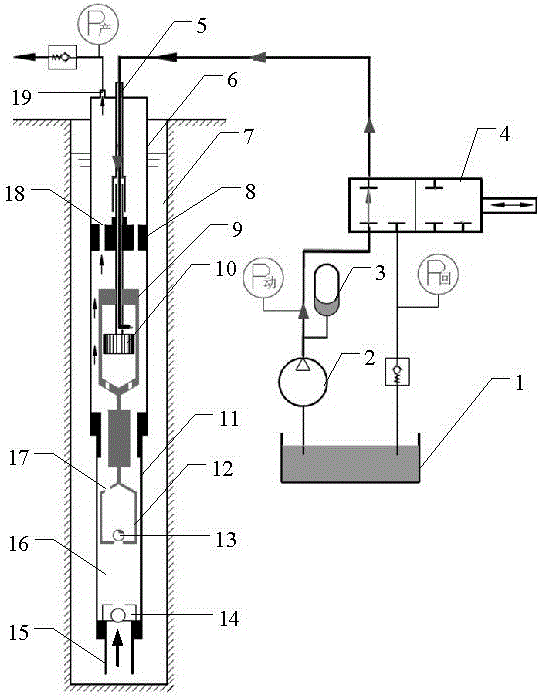

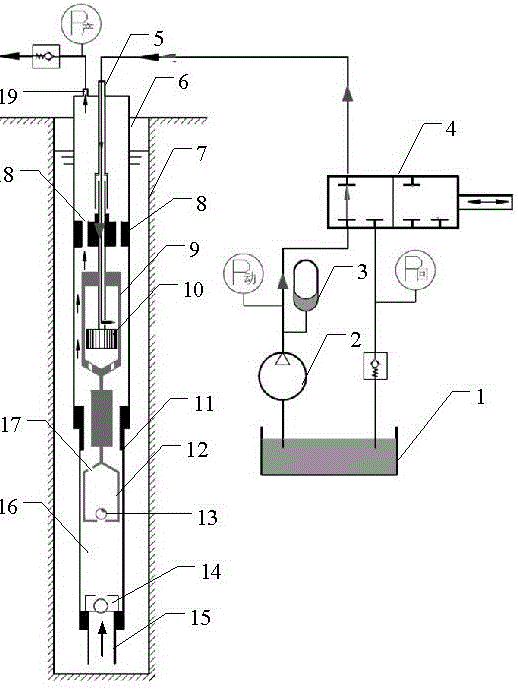

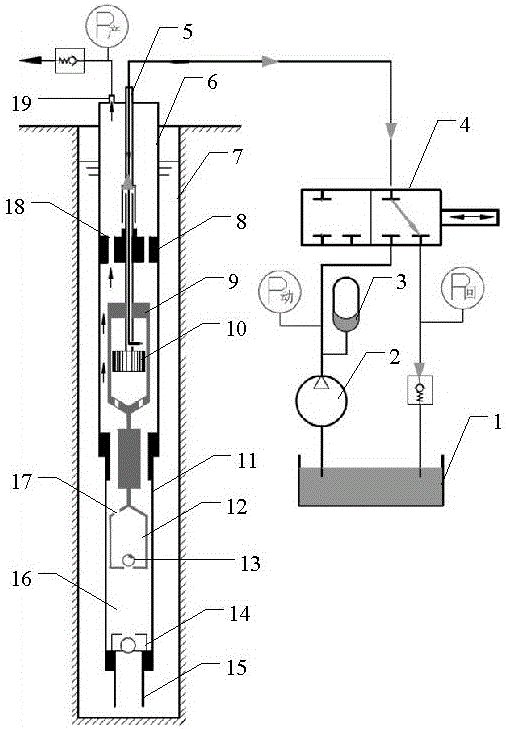

System and method for controlling solids in a down-hole fluid pumping system

InactiveUS20090090511A1Reduce congestionEarth drilling toolsPositive displacement pump componentsEngineeringMechanical engineering

Owner:PINE TREE GAS

Method of surge protection for a dynamic compressor using a surge parameter

Owner:ENERGY CONTROL TECH

Novel anti-eccentric wear hydraulic oil extraction device

InactiveCN105041629ANo loadShort schedule of activitiesOperating means/releasing devices for valvesFlexible member pumpsLiquid storage tankPower equipment

Owner:盐城市佳鑫石化机械制造有限公司

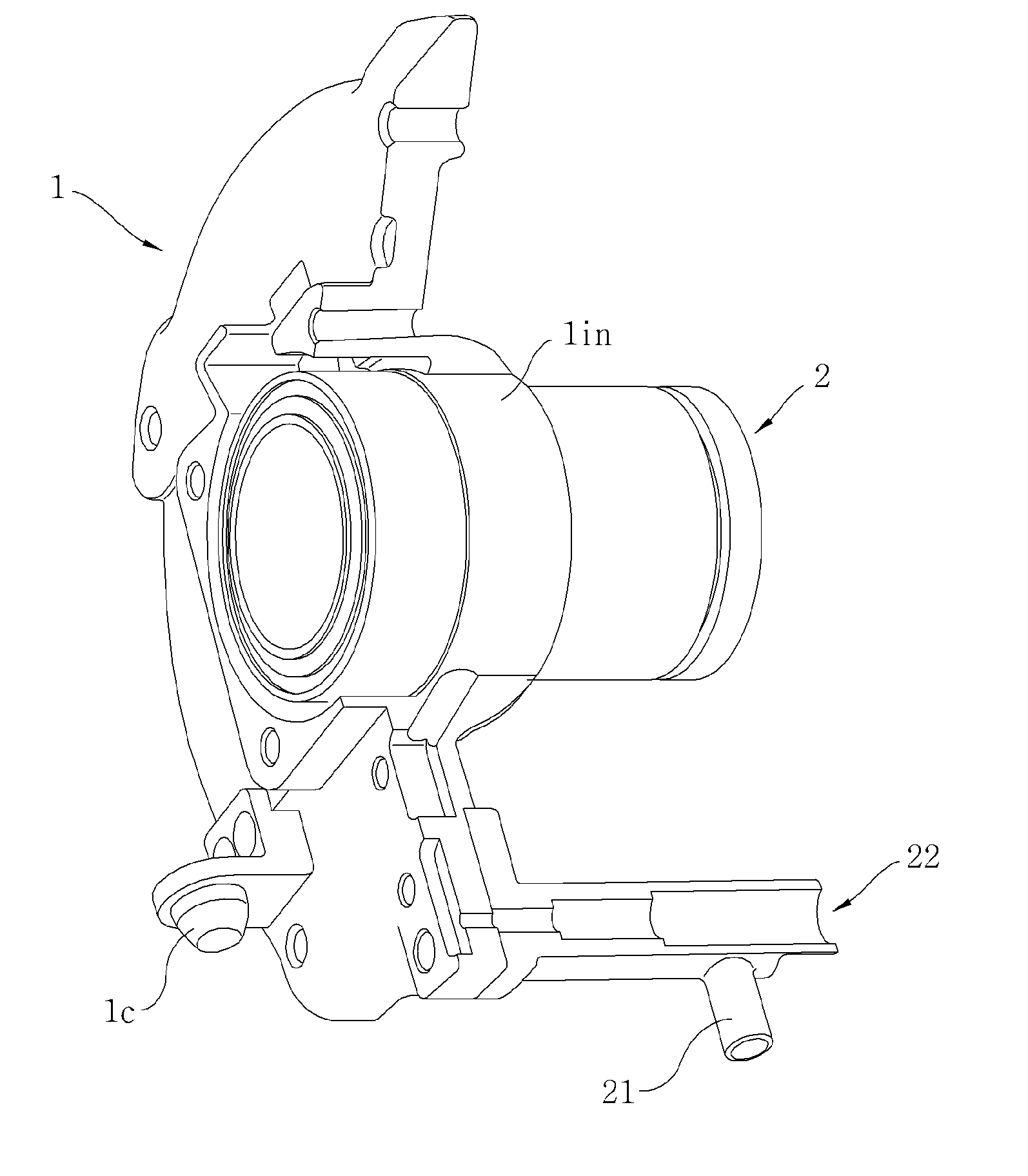

Collet adapter for a motor shroud

ActiveUS20090053080A1Easy to installMeet precise requirementsPump componentsFluid removalEngineeringSubmersible pump

An electrical submersible pump assembly (ESP) includes a pump section, a motor section, and a seal section. In one embodiment, an exterior of the pump section defines a gripping indentation above the pump intake. Alternatively, a clamp member may be provided that surrounds the pump, wherein the clamp member defines the gripping indentation. A collet adapter is affixed to an upper end of a shroud. The collet adapter has gripping members that engage the gripping indentation for attaching the shroud to the electrical submersible pump assembly. The collet adapter is provided to ease installation of the motor shroud onto the ESP as well as to ease removal of the motor shroud from the ESP. The collet adapter of the present invention eliminates precise alignment and bolt-on requirements of typical motor shroud mounting techniques.

Owner:BAKER HUGHES HLDG LLC

Spring type Y-shaped well joint

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

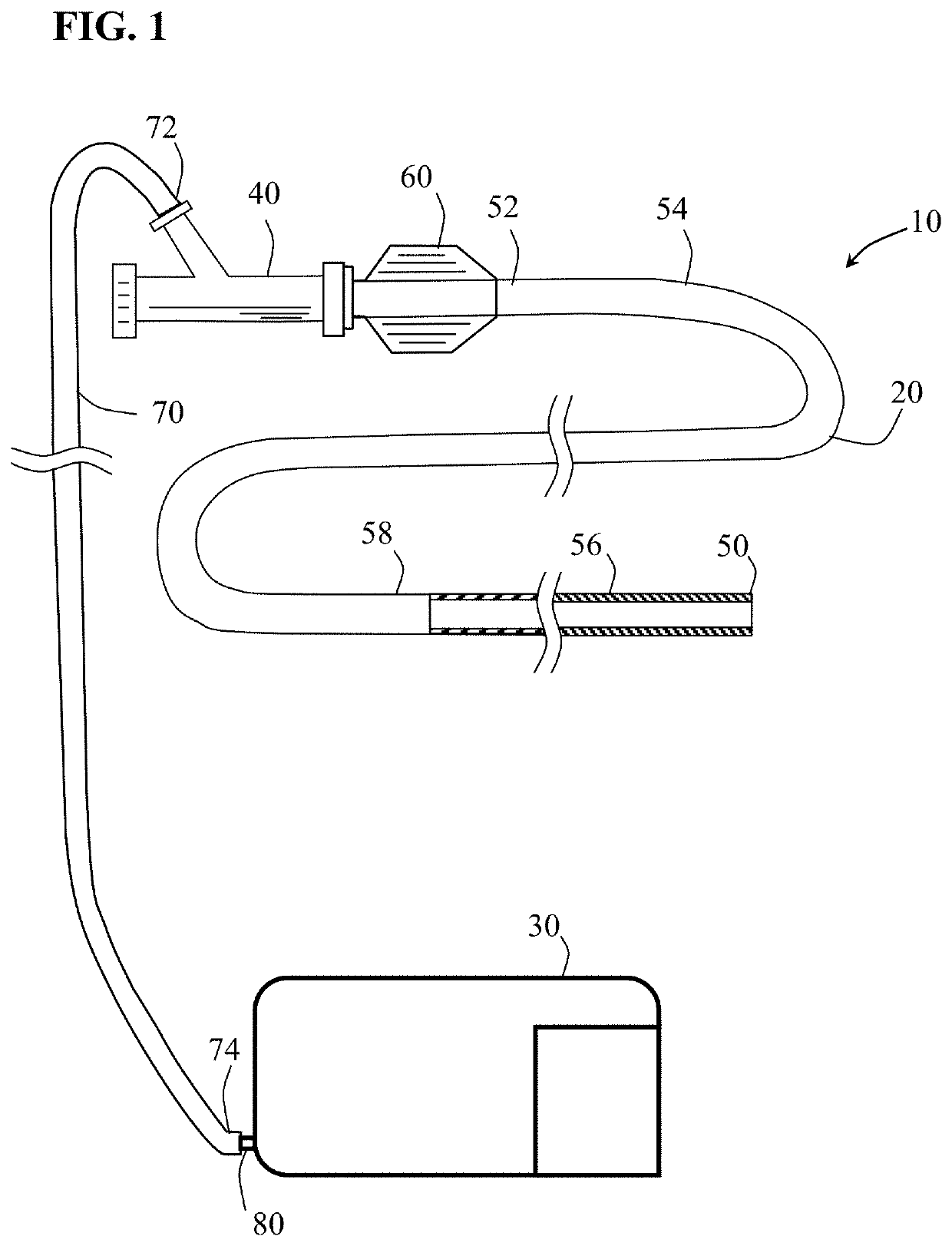

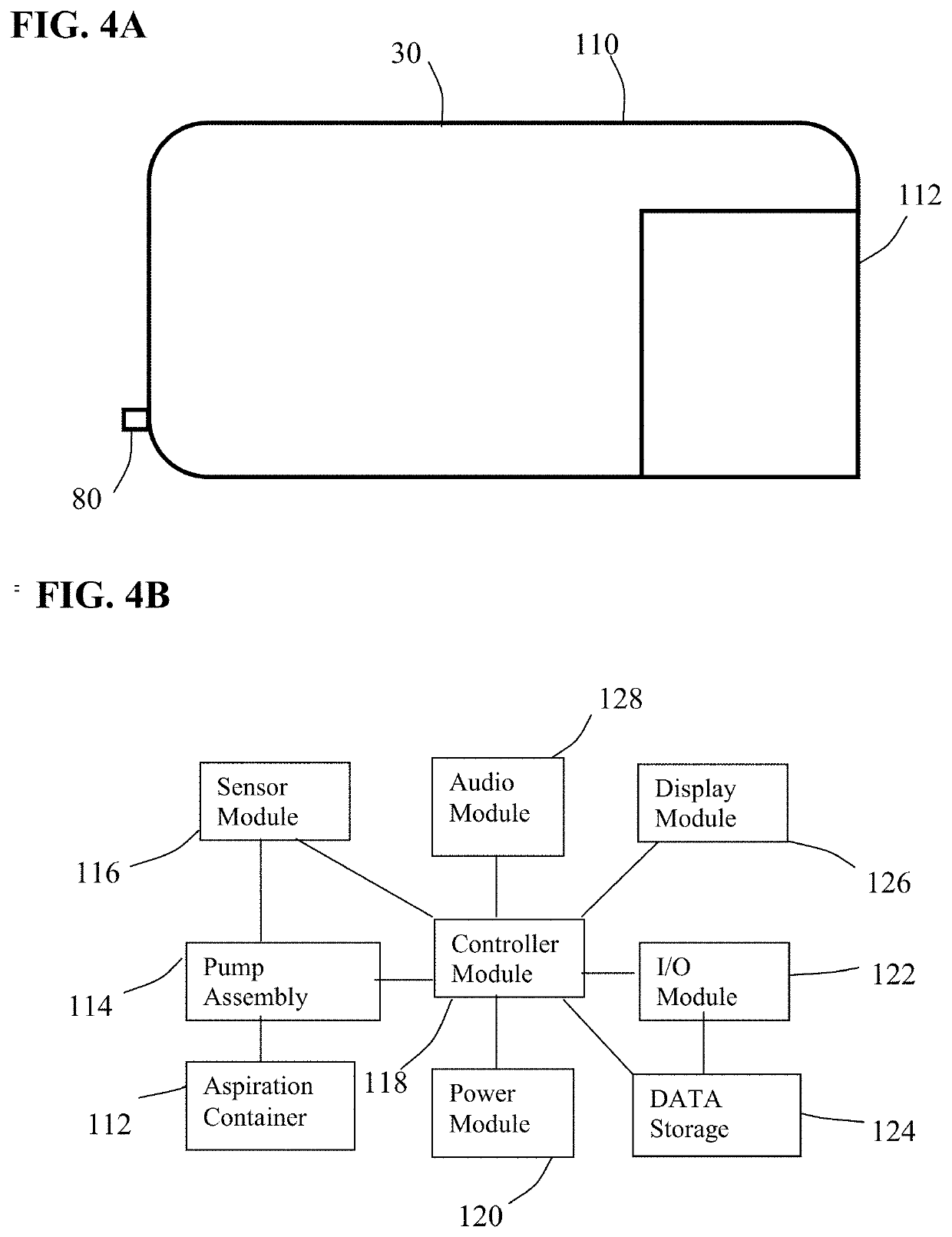

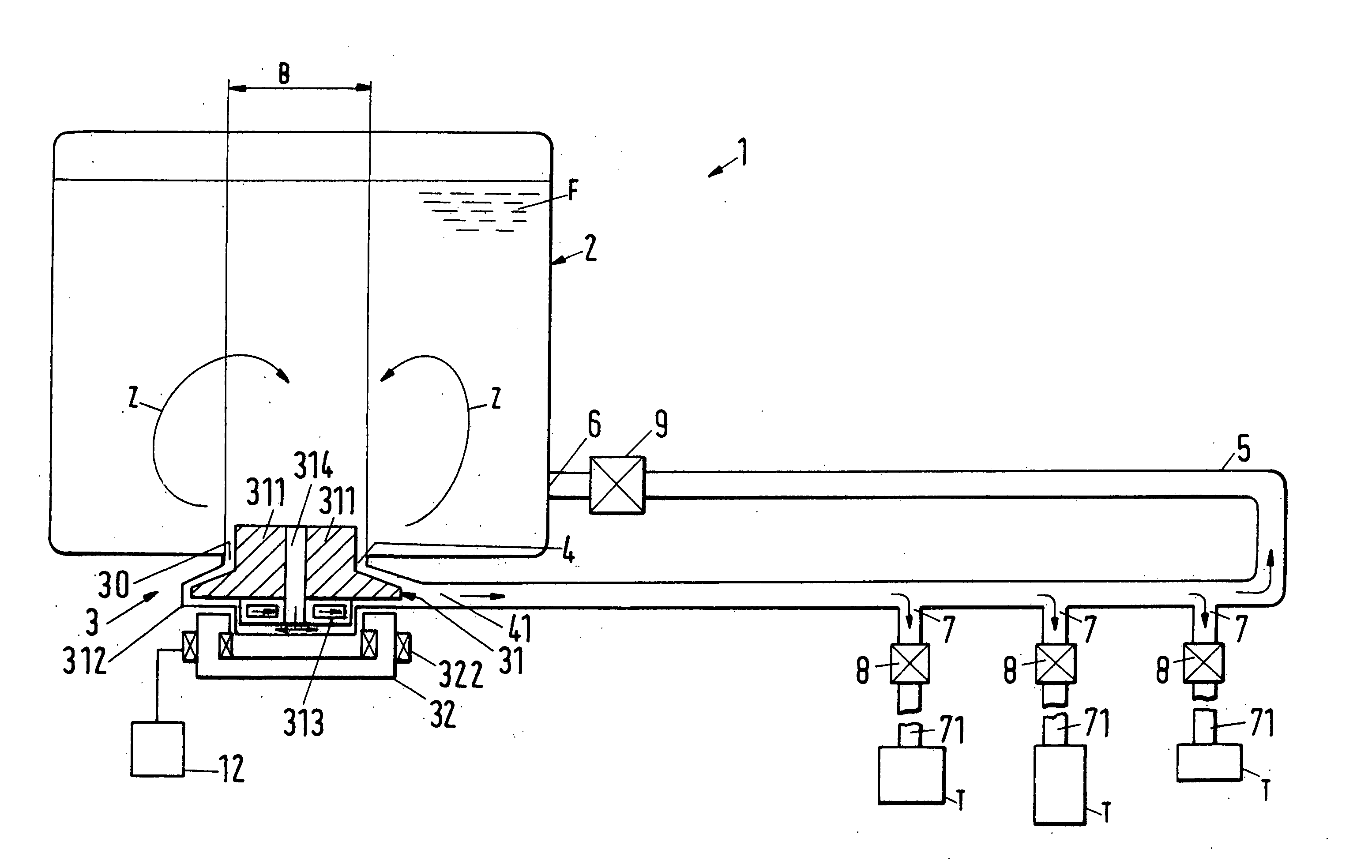

Aspiration systems, devices and methods for treating ischemic stroke

PendingUS20220168000A1Mitigates pressure dampening of pressureMinimize dampening of pressure signalDiagnosticsFlexible member pumpsBlood flowThrombus

Owner:POSEYDON MEDICAL LLC

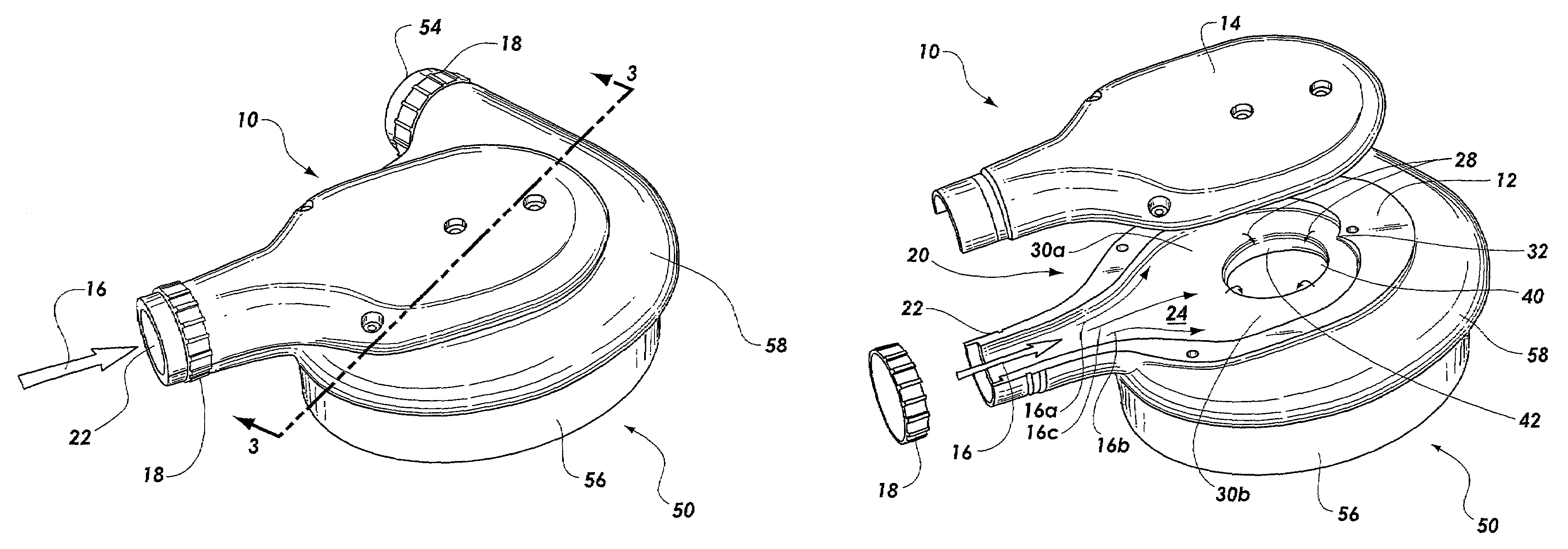

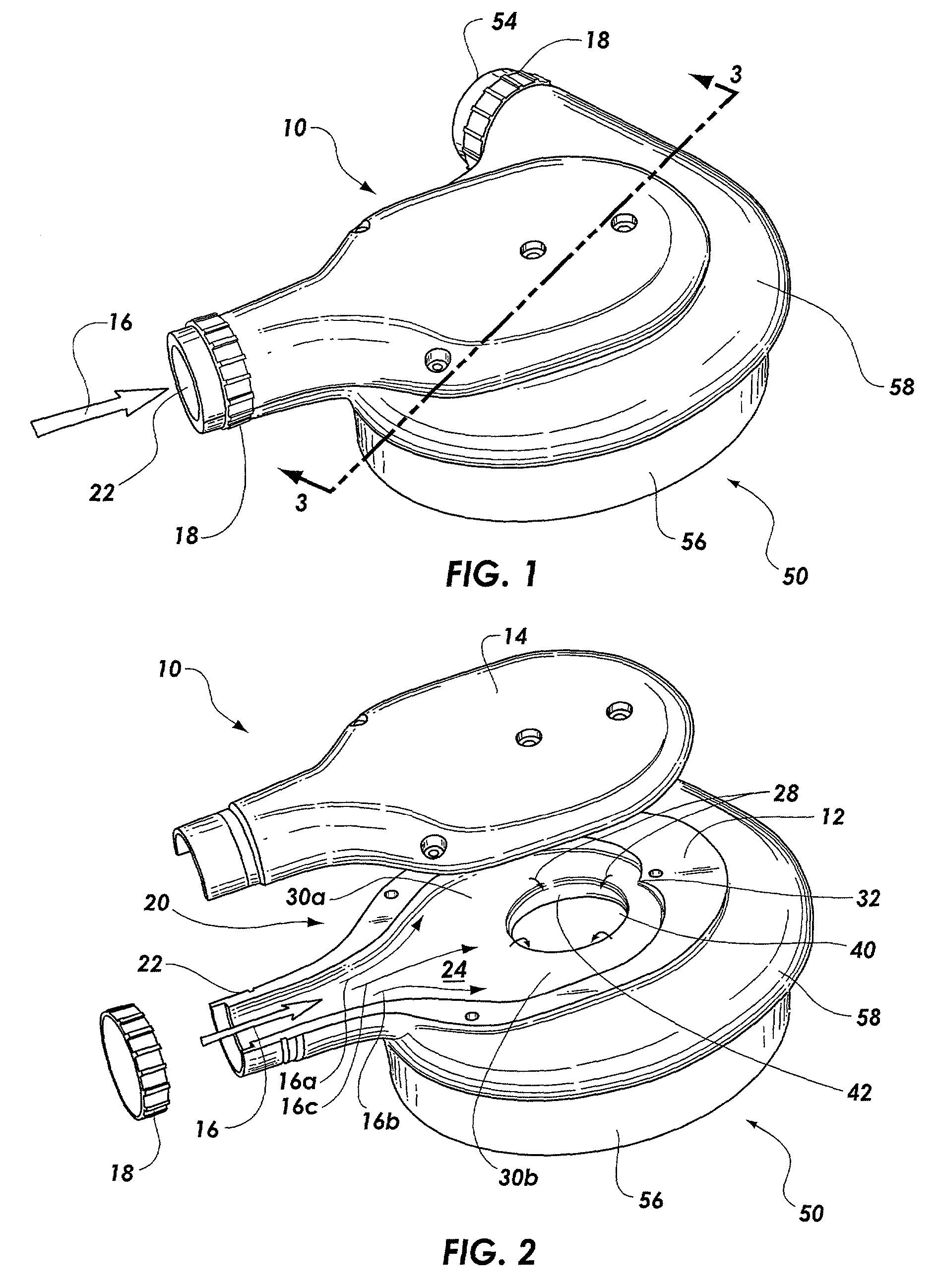

Dispensing apparatus for a fluid

InactiveUS20050226746A1Simple wayWell mixedLapping machinesPiston pumpsRotary pump

Owner:LEVITRONIX

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap