Automatic balance and compensating device for refrigeration compressor oil level

A refrigeration compressor and automatic balancing technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., to achieve the effects of stable oil level, avoiding severe wear, and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

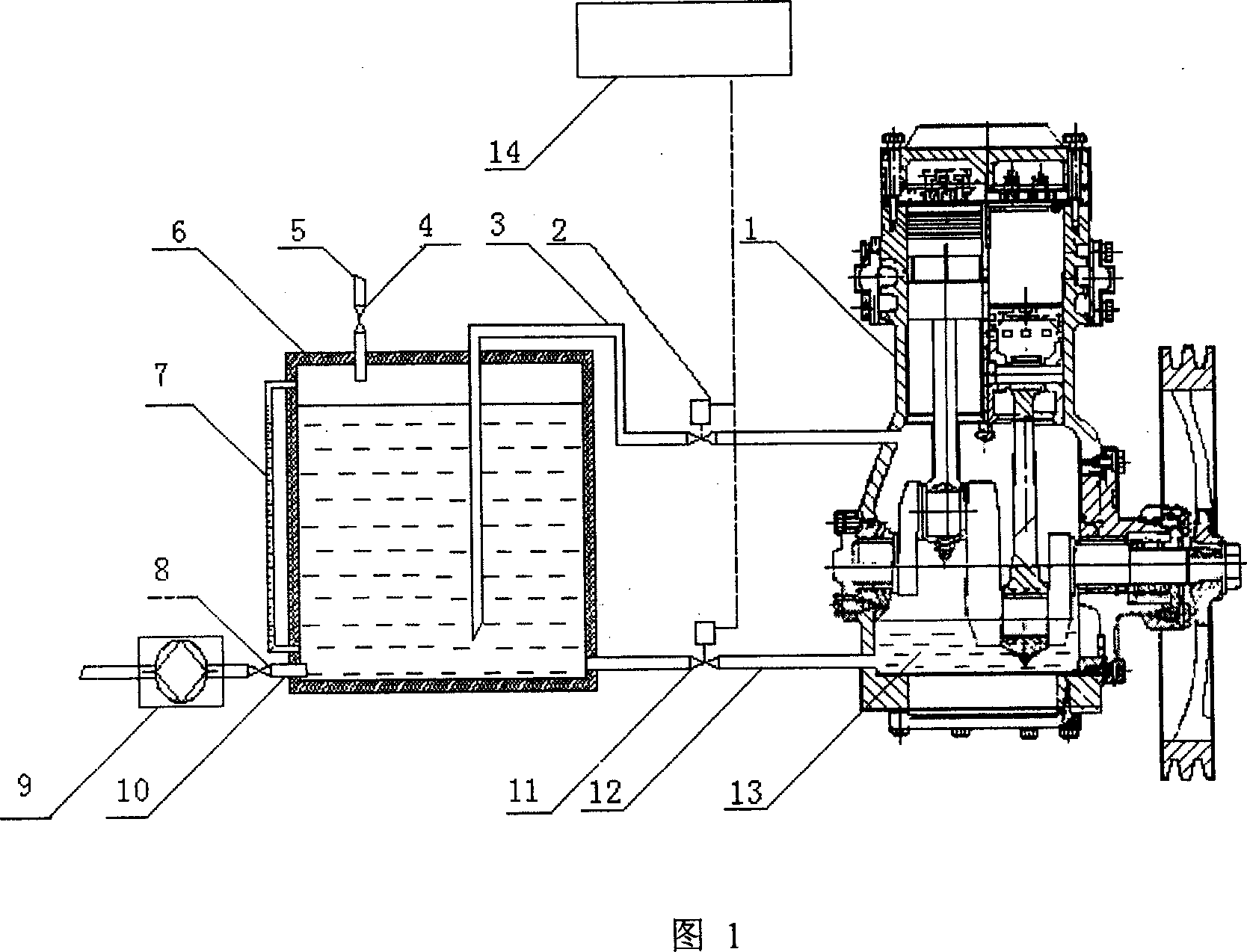

[0009] The device of the present invention takes the supplementary oil tank 6 as the main body, and the bottom of the supplementary oil tank 6 is respectively provided with a supplementary oil pipe 10 and a second solenoid valve 11, and the second solenoid valve 11 is connected to the bottom of the crankcase 13 in the compressor 1 through a communication oil pipe 12 , the upper part of the supplementary oil tank 6 is respectively provided with a communication air pipe 3 and an exhaust valve 4, the outer end of the communication air pipe 3 is connected to the upper part of the crankcase 13 in the compressor 1, and is above the oil level line of the crankcase 13, and the communication air pipe 3 The inner port of the pump extends into the bottom of the supplementary oil tank 6, wherein the absolute height of the lower port of the connecting air pipe 3 in the supplementary oil tank 6 is the absolute height of the oil level in the crankcase 13, therefore, according to the normal oil le

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap