Orbital Sign Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

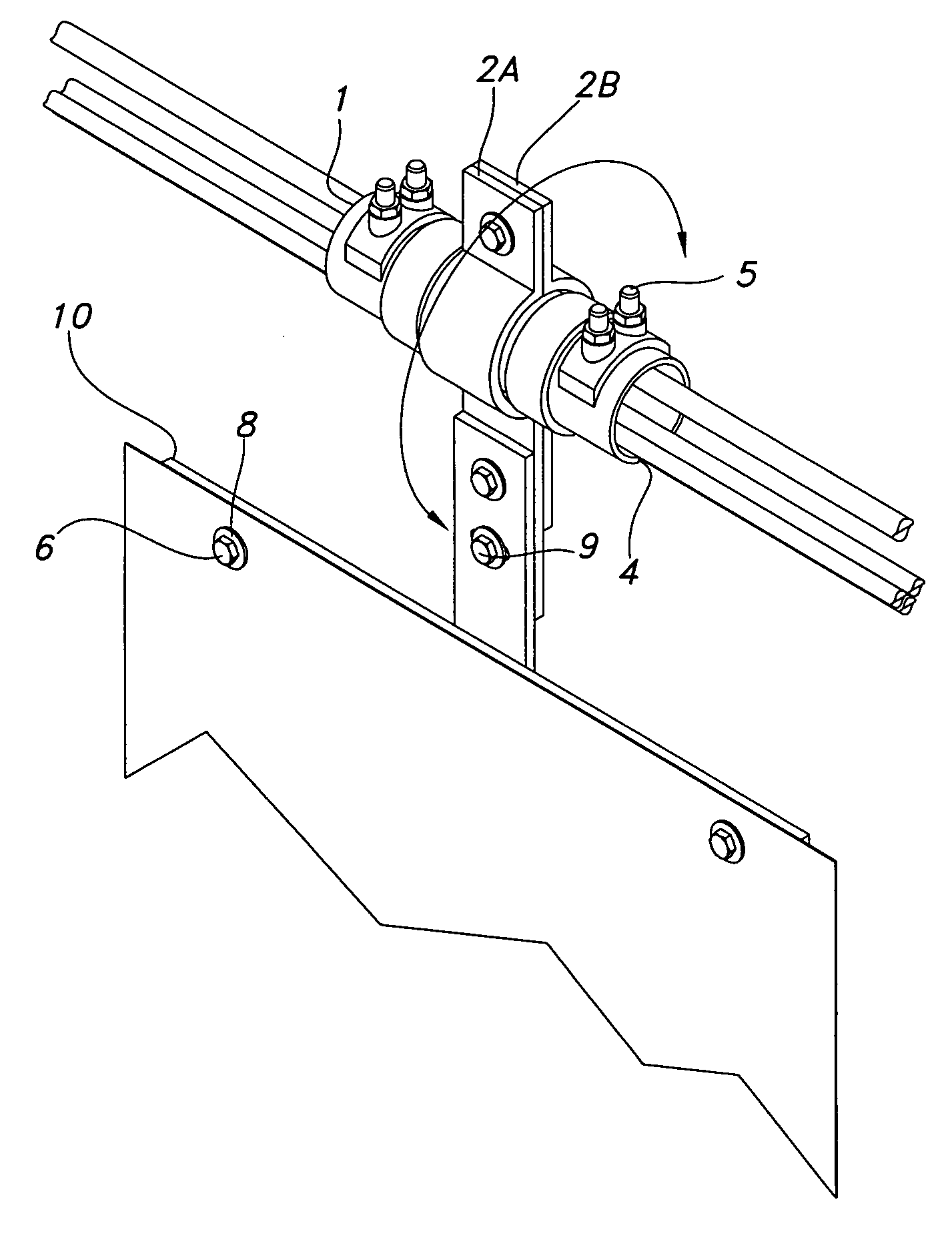

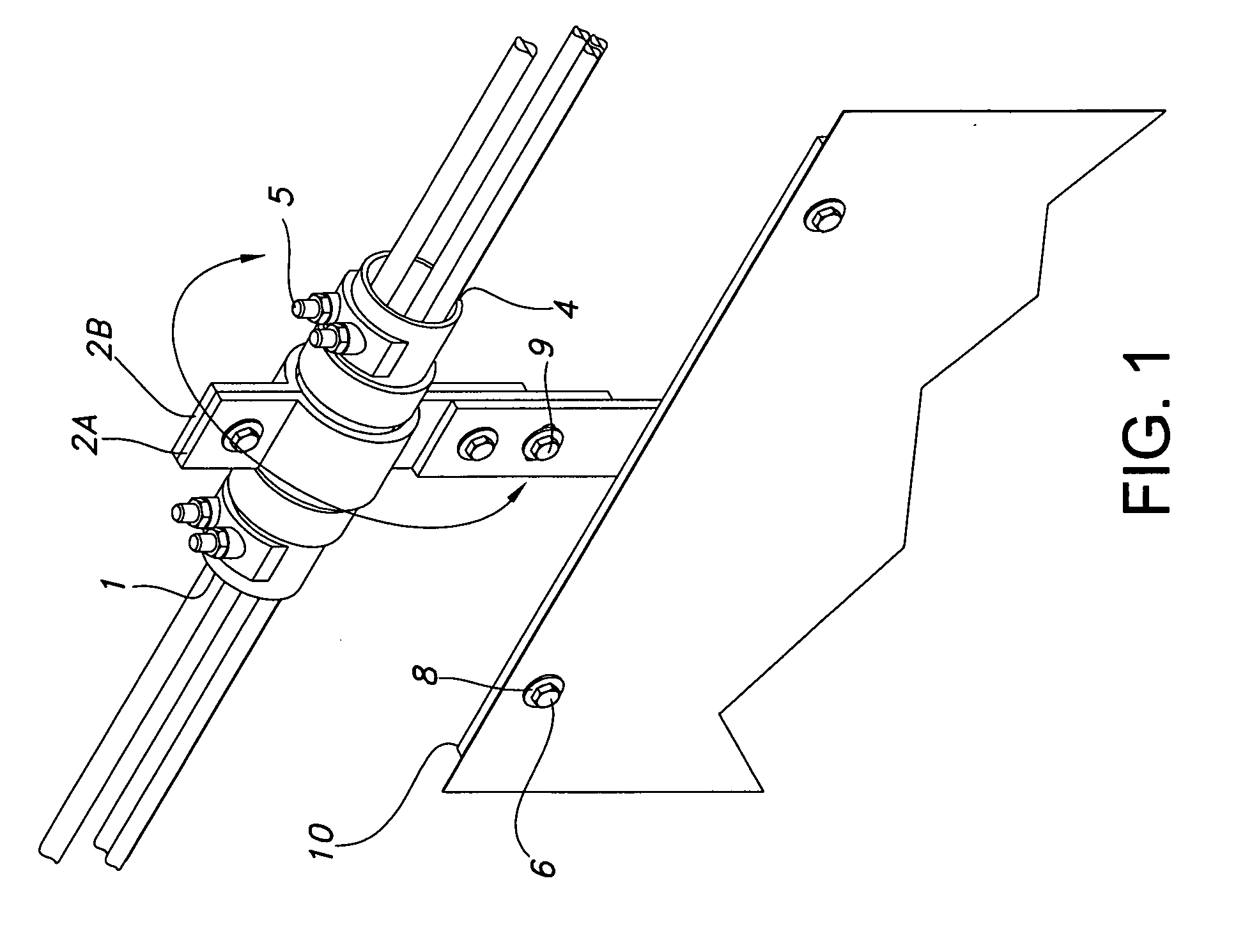

[0024]FIG. 1 shows a perspective view of the preferred embodiment of the orbital sign assembly. The orbital sign assembly includes mainly a cable saddle 1, a pivot attachment 2, and a sign bracket 10. The cable saddle is cylindrical in shape and acts as a bearing or chassis to which the pivot attachment attaches. The pivot attachment 2 is comprised of two pieces 2a and 2b which are joined together at top and bottom. The pivot attachment 2 has two semicircle sections that when joined form a circular opening that allows for the cable saddle 1 to be enclosed about. The pivot attachment 2 has two ends. At one end there is the above mentioned circular opening and at the other an attachment point for the sign bracket 10.

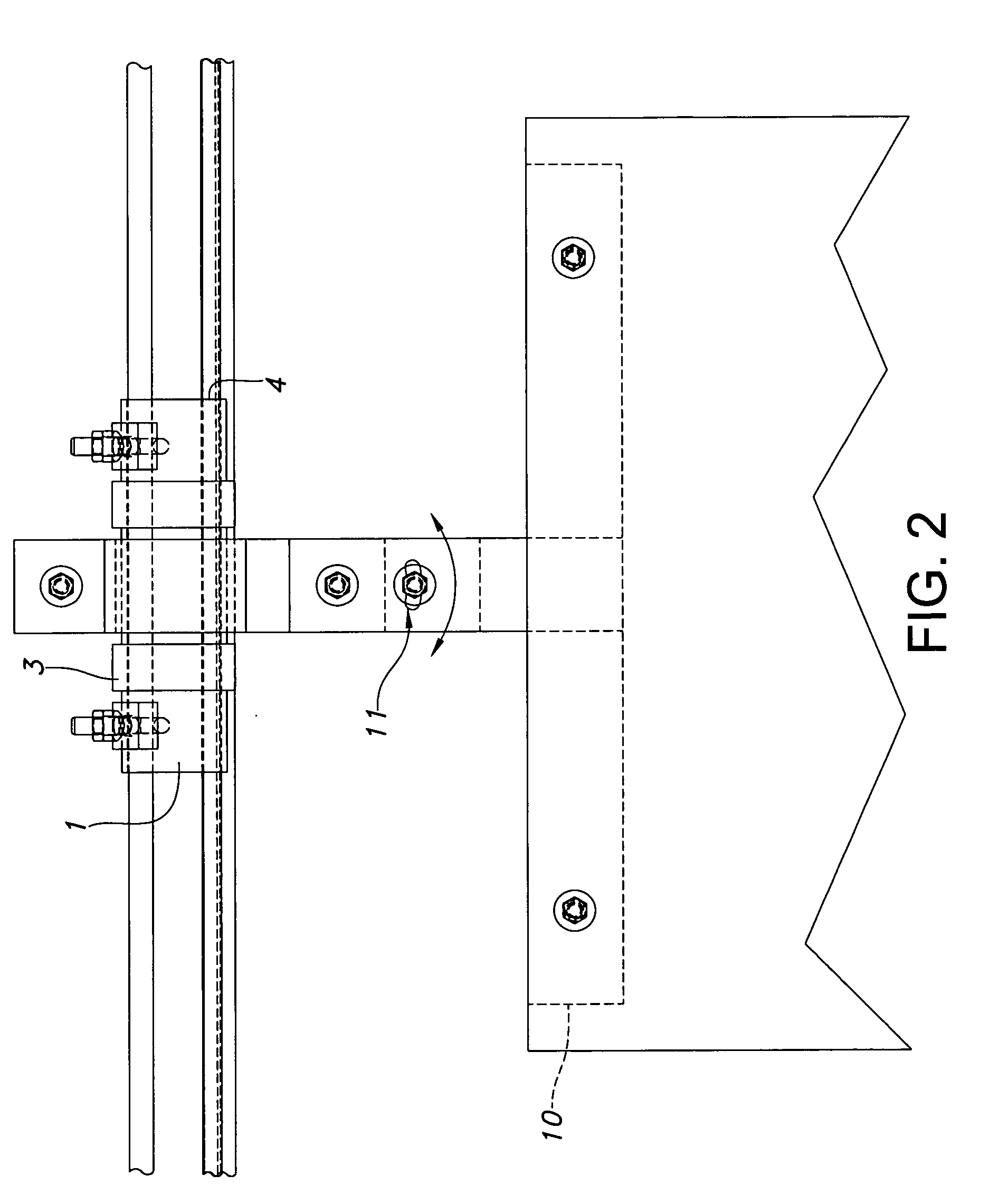

[0025]The cable saddle 1 (FIG. 1) as previously stated, is cylindrical in shape and includes two rings, guides, or pivot attachment rails 3 (FIG. 2). The pivot attachment rails 3 are raised above the contour of the cable saddle and spaced appropriately to accommodate the pivo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap