Temperature control method for dual-clutch transmission

A temperature control method and dual-clutch transmission technology, applied in the direction of temperature control without auxiliary power supply, clutches, transmission parts, etc., can solve the problems of poor clutch over-temperature protection effect, inability to immediately reduce clutch temperature, etc., and reduce the possibility of achieving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

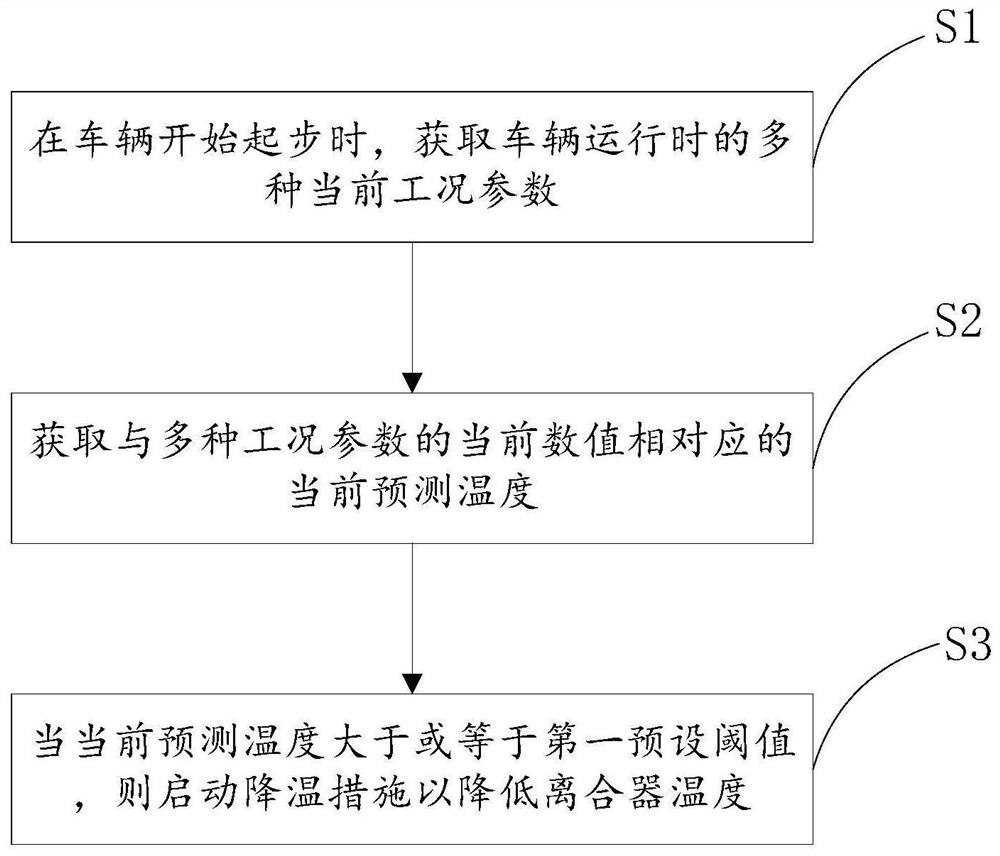

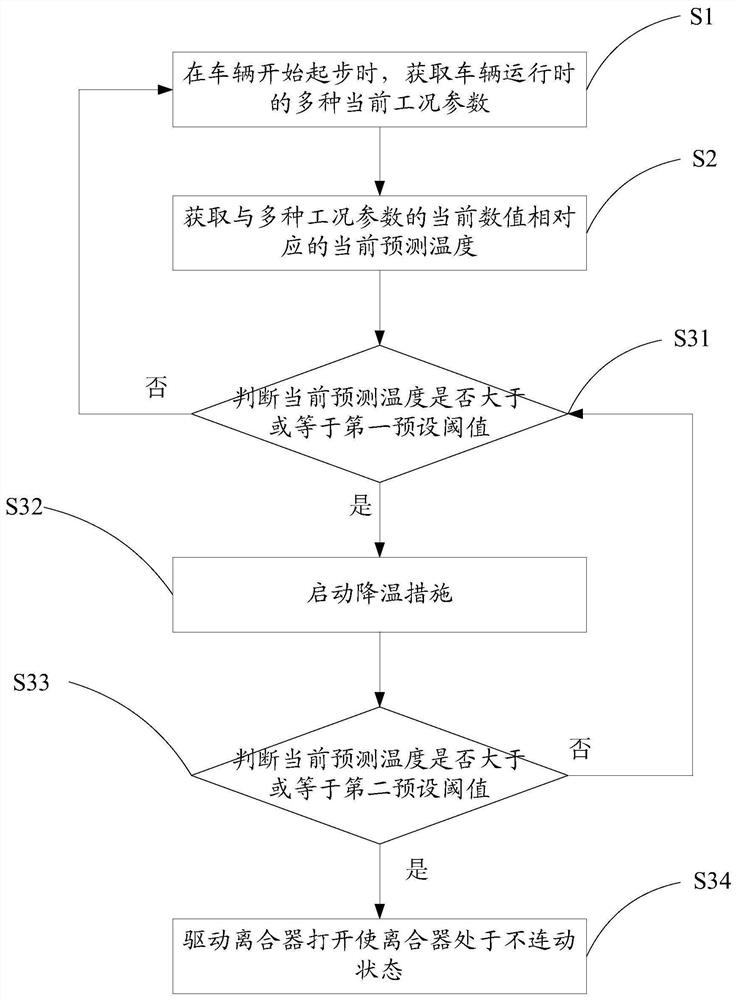

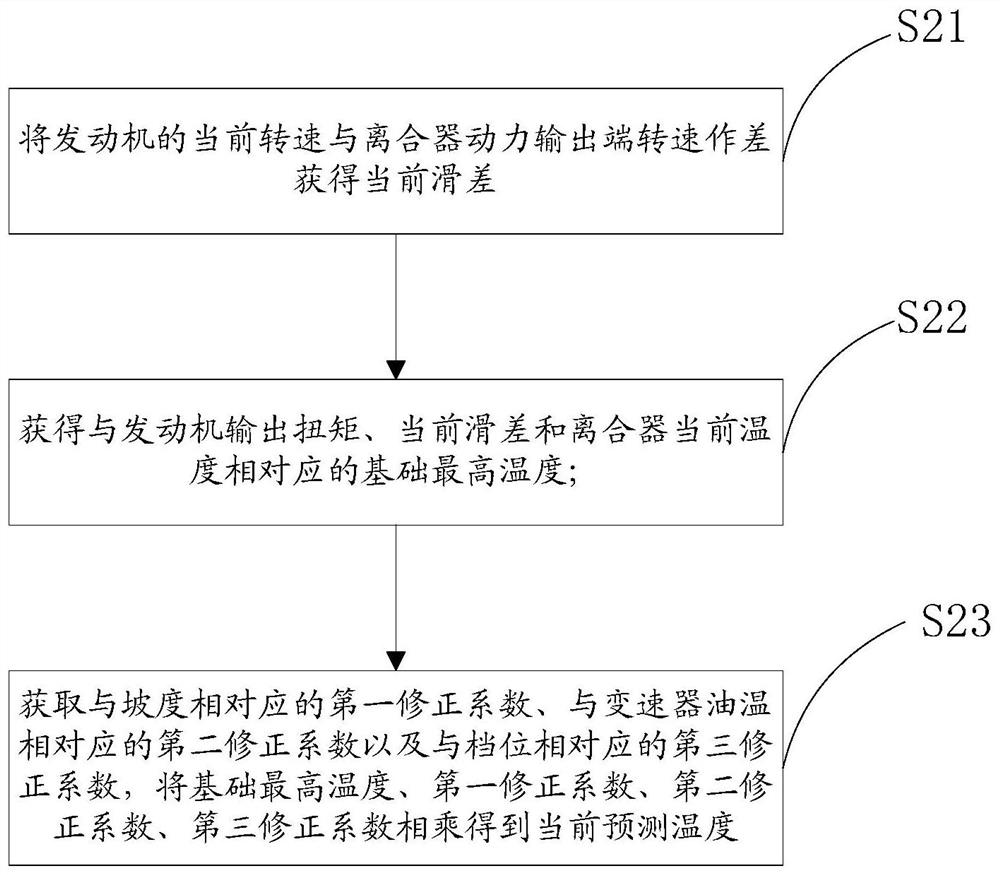

[0028] Such as figure 1 Distance figure 1 A flow chart showing a temperature control method of a double clutch transmission. This temperature control method includes the following steps:

[0029] S1: When the vehicle starts to start, a plurality of current working condition parameters at the time of the vehicle are obtained, and the process proceeds to step S2;

[0030] Vehicles include dual clutch transmission, engine, water-cooled heat dissipation system, and cooling fans. Double clutch transmission includes clutches and transmission. The clutch includes a power output and a power input. The power output of the clutch is connected to the transmission. The power input of the clutch is connected to the engine of the car. The clutch can pass the torque of the engine to the transmission when closed, and drive the transmission.

[0031] The water-cooled heat dissipation system is coupled to the double clutch transmission, the water-cooled heat dissipation system utilizes the heat of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap