Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about "Layered products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

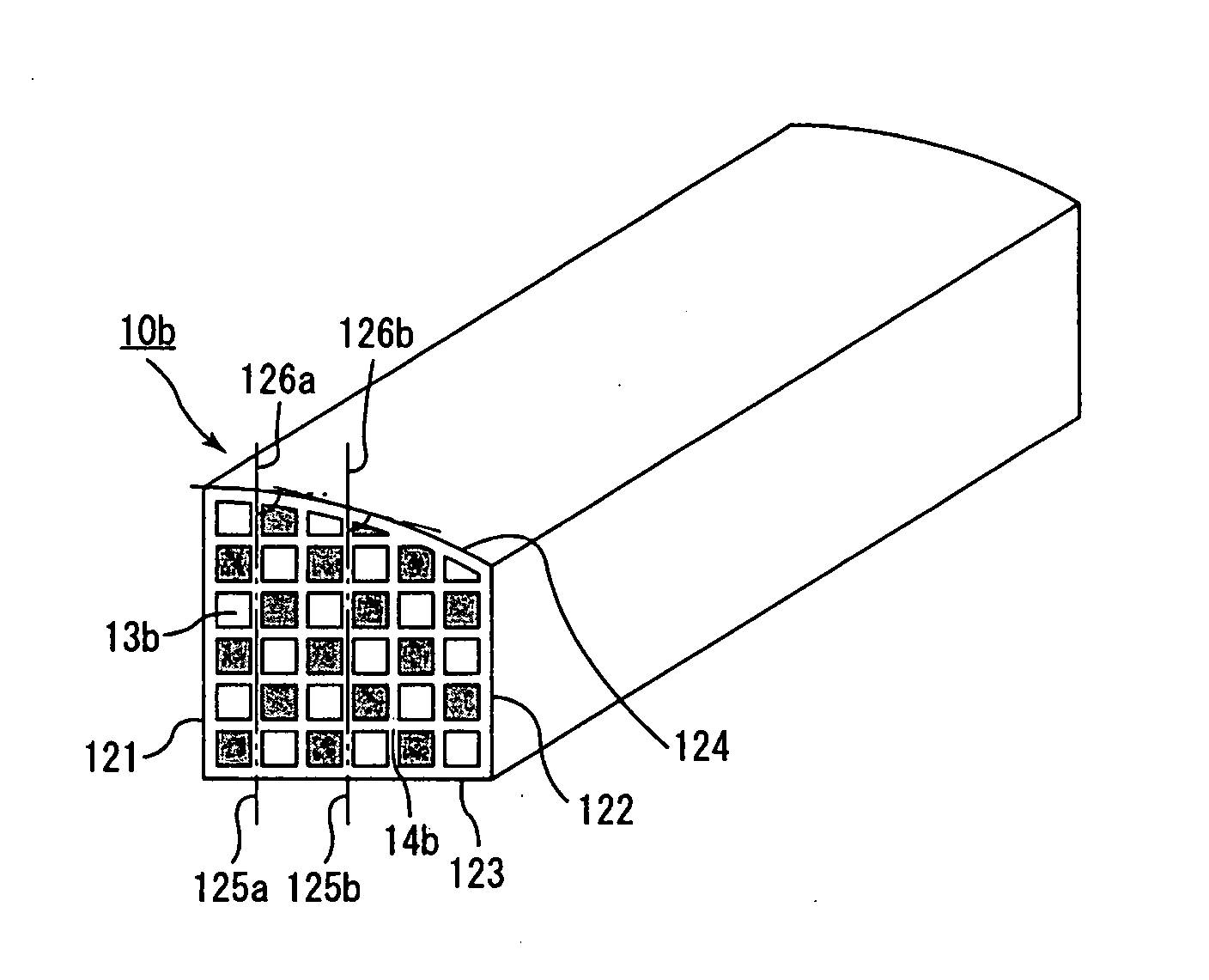

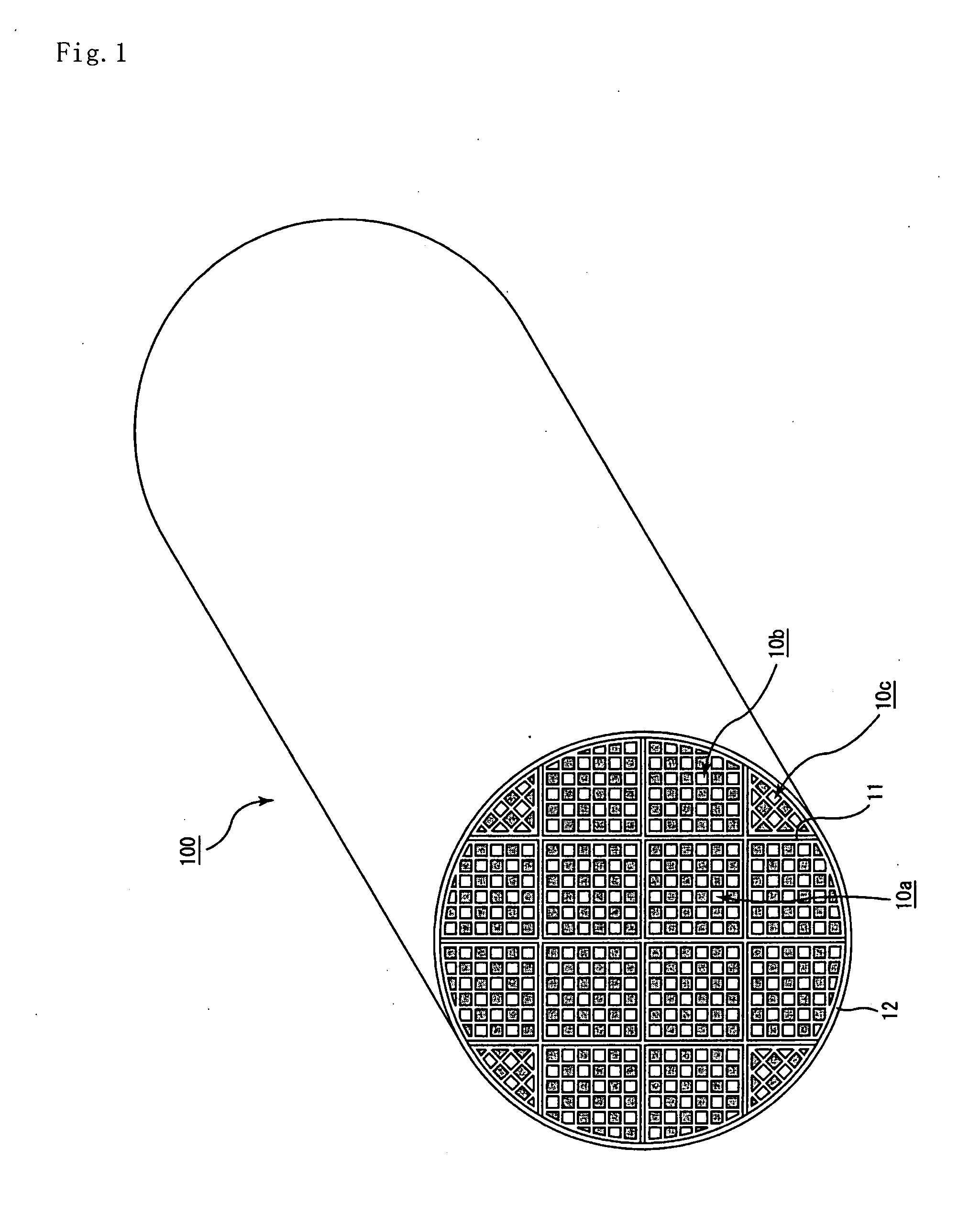

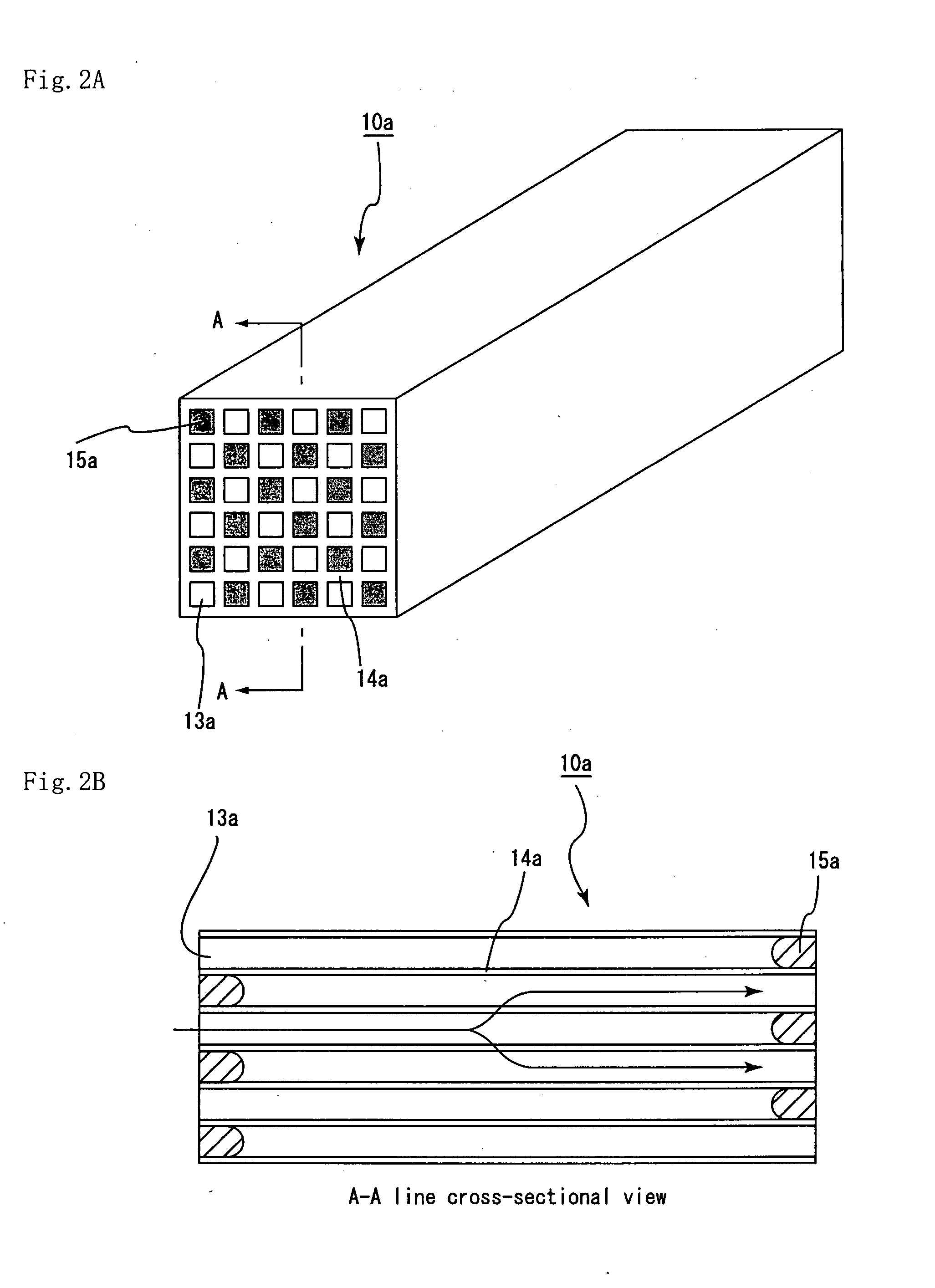

Honeycomb structured body

InactiveUS20070212517A1Dispersed particle filtrationLayered productsHoneycomb structureHoneycomb like

Owner:IBIDEN CO LTD

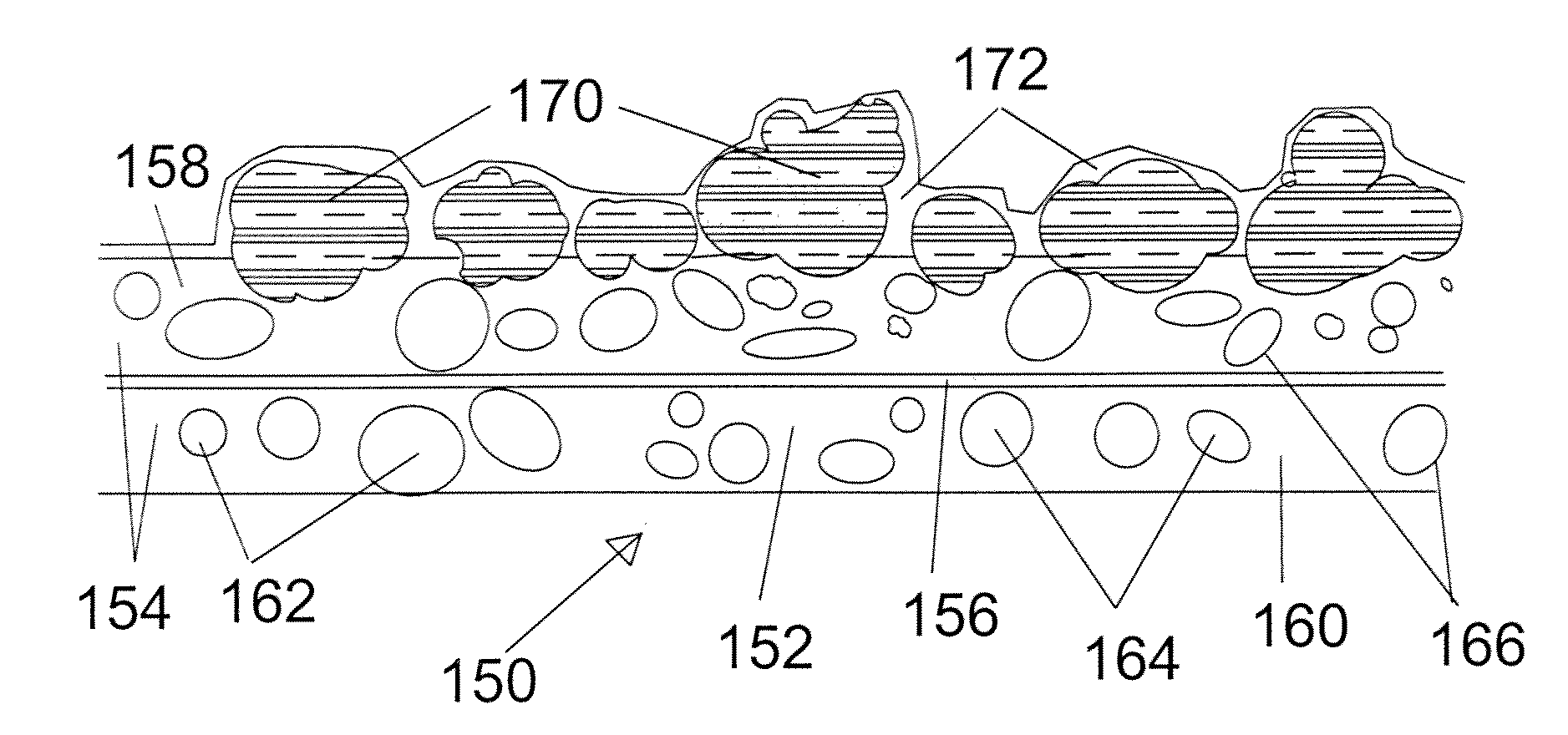

Roofing Products Containing Phase Change Materials

InactiveUS20080008858A1Improve the immunityAttractive appearanceRoof covering using tiles/slatesHeat storage plantsDegree CelsiusPhase change

Owner:CERTAINTEED CORP

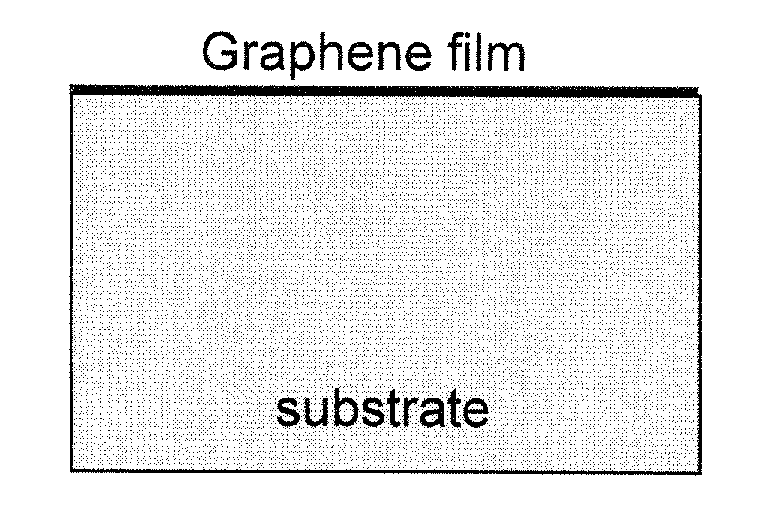

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

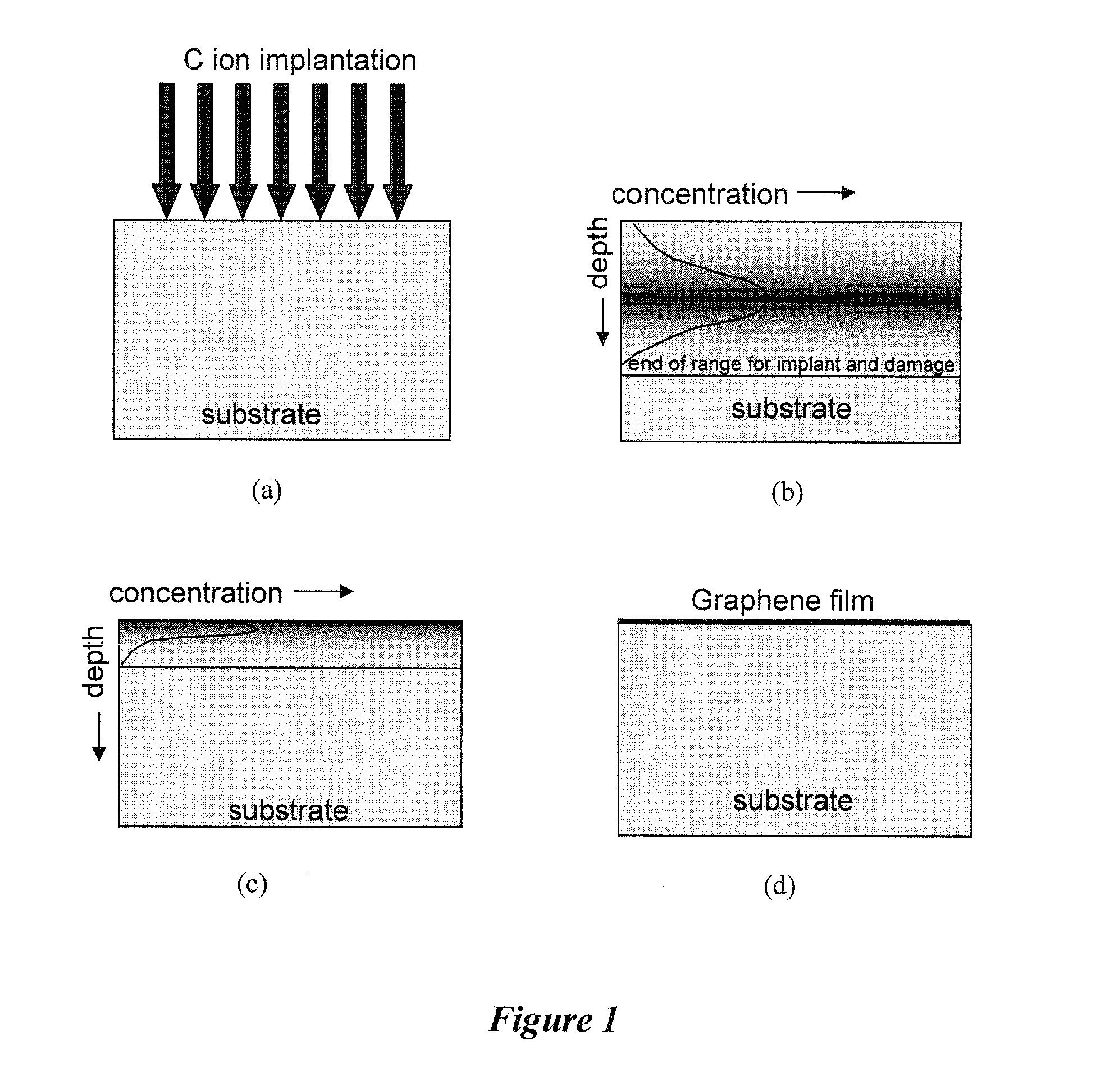

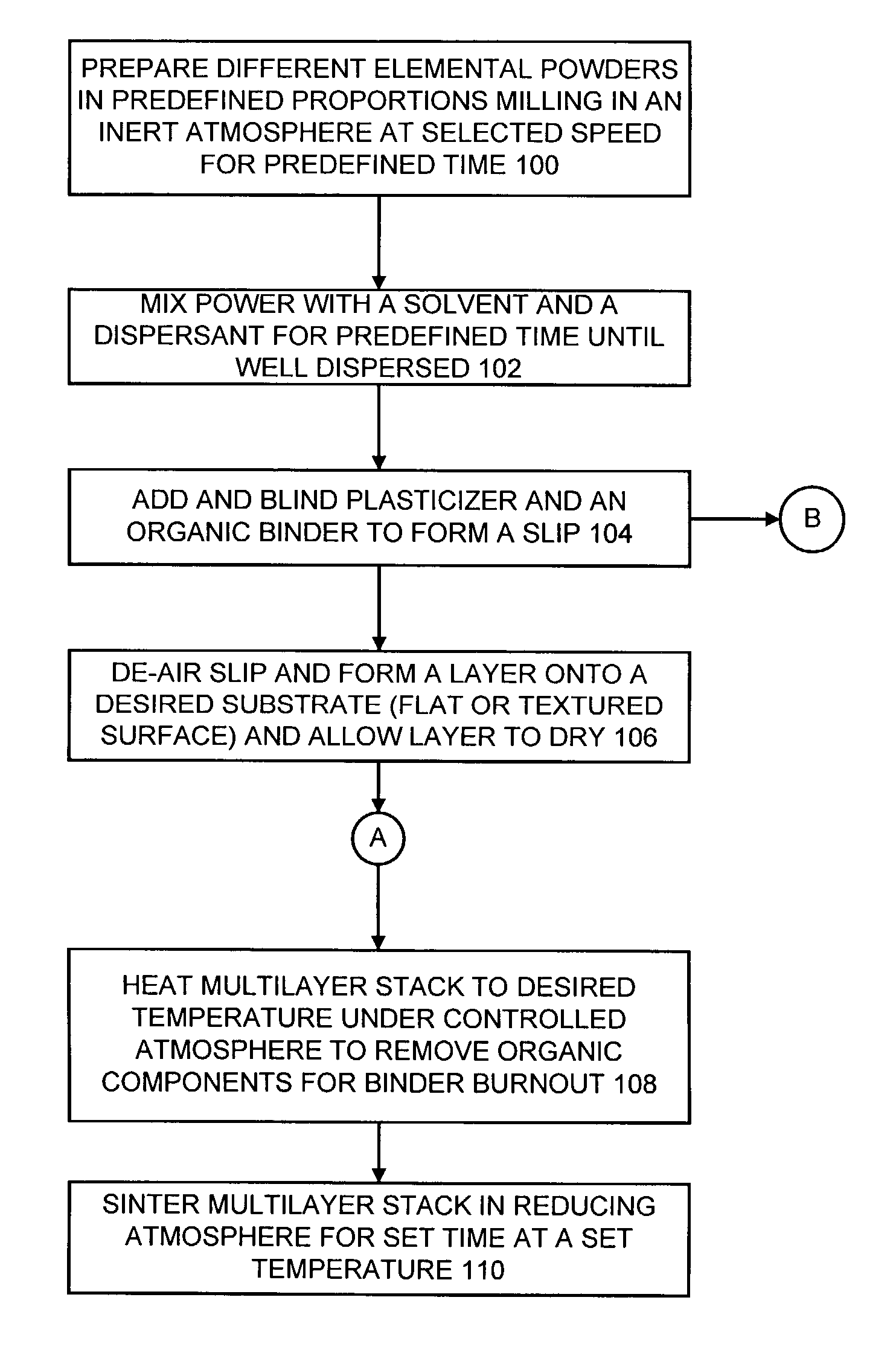

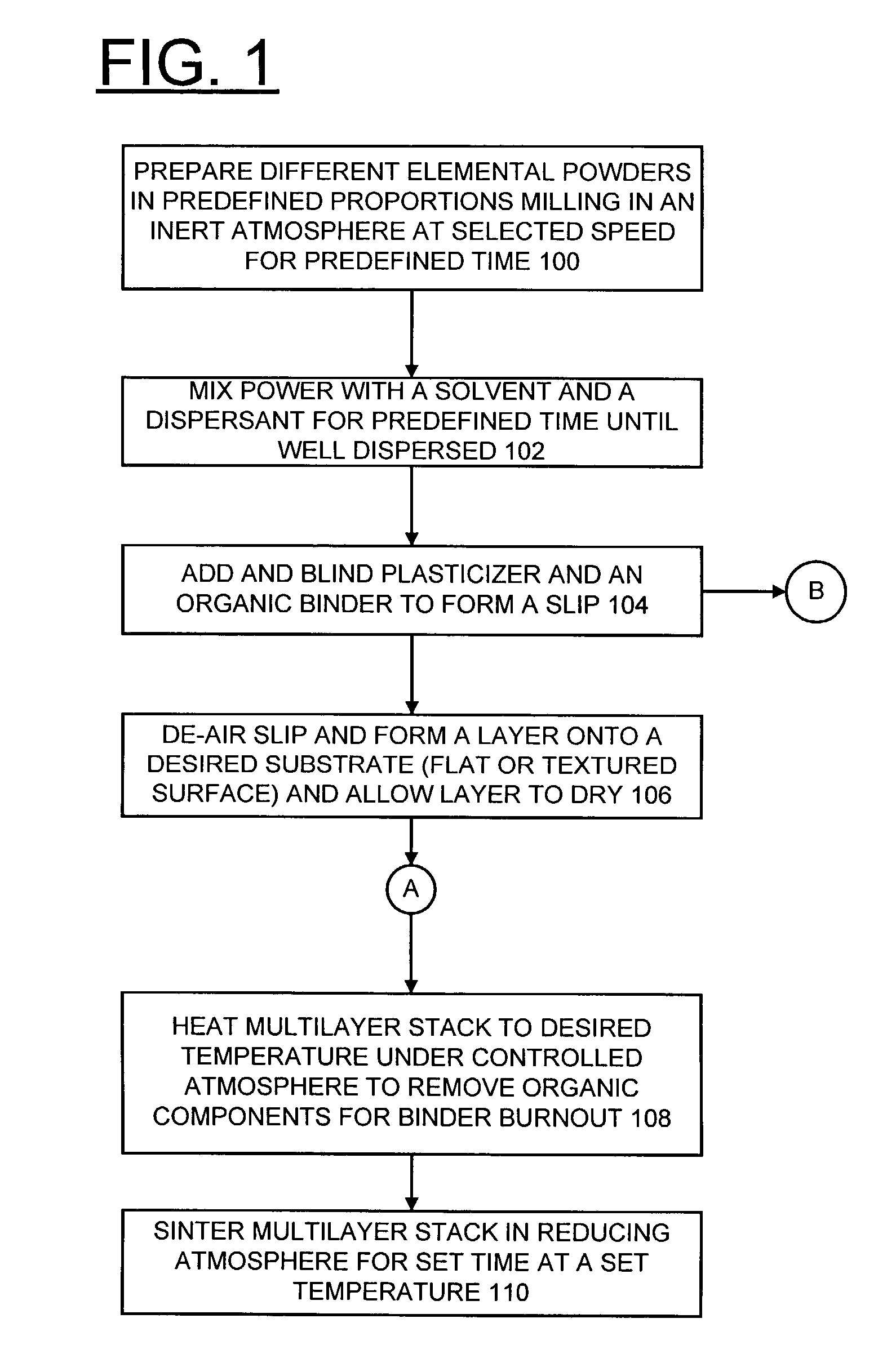

Compositionally graded metallic plates for planar solid oxide fuel cells

Owner:UCHICAGO ARGONNE LLC +1

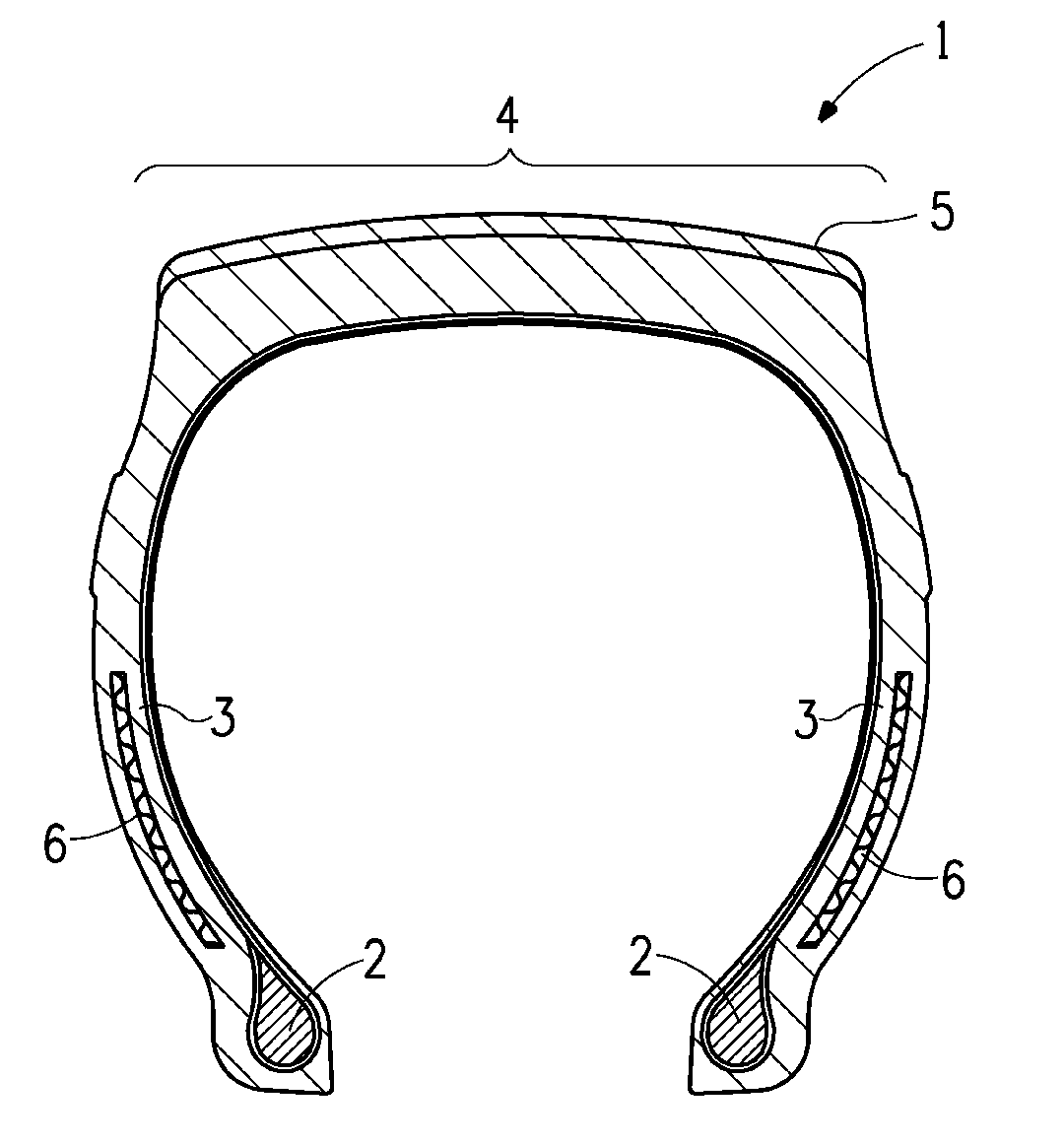

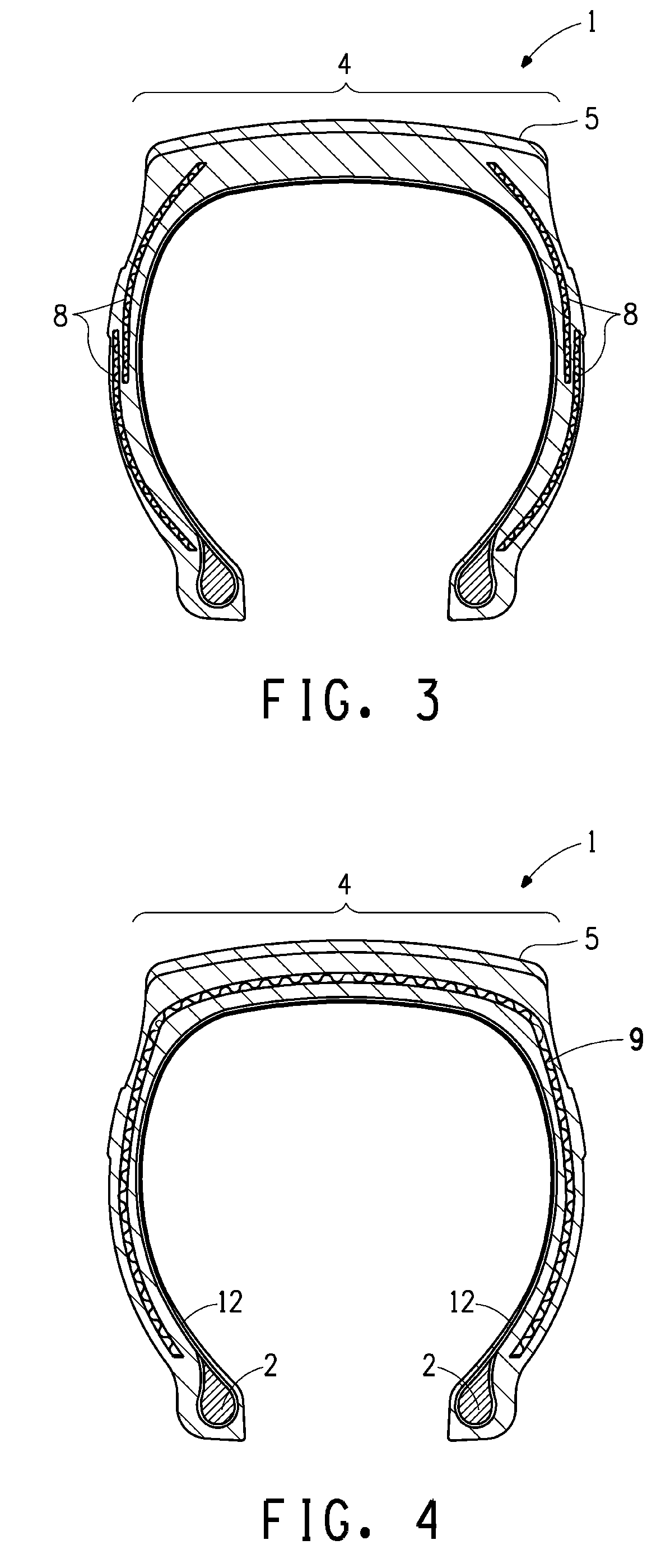

Soft convex adhesive wafer

InactiveUS20030171737A1Improve sealingShort molding timeLayered productsNon-surgical orthopedic devicesWaferingMedicine

An adhesive wafer for attaching an ostomy appliance to a peristomal skin surface surrounding a stoma has an integrally molded adhesive layer made of a skin barrier material, a distal surface covered by a flexible backing layer, and a proximal bodyside surface contoured so the adhesive layer has a thin peripheral portion and thick central portion surrounding a stoma-receiving aperture. A set of at least two wafers is provided in one embodiment, wherein individual wafers have differing central portion surface topography, and different stoma receiving apertures. To produce a closely fitting wafer for a given stoma, a method of producing wafers includes providing a representation of the topography of the peristomal surface and the stoma, and, using the representation, manufacturing a mold having a surface configuration substantially matching the topography of the peristomal surface and stoma.

Owner:HOLLISTER INCORPORAED

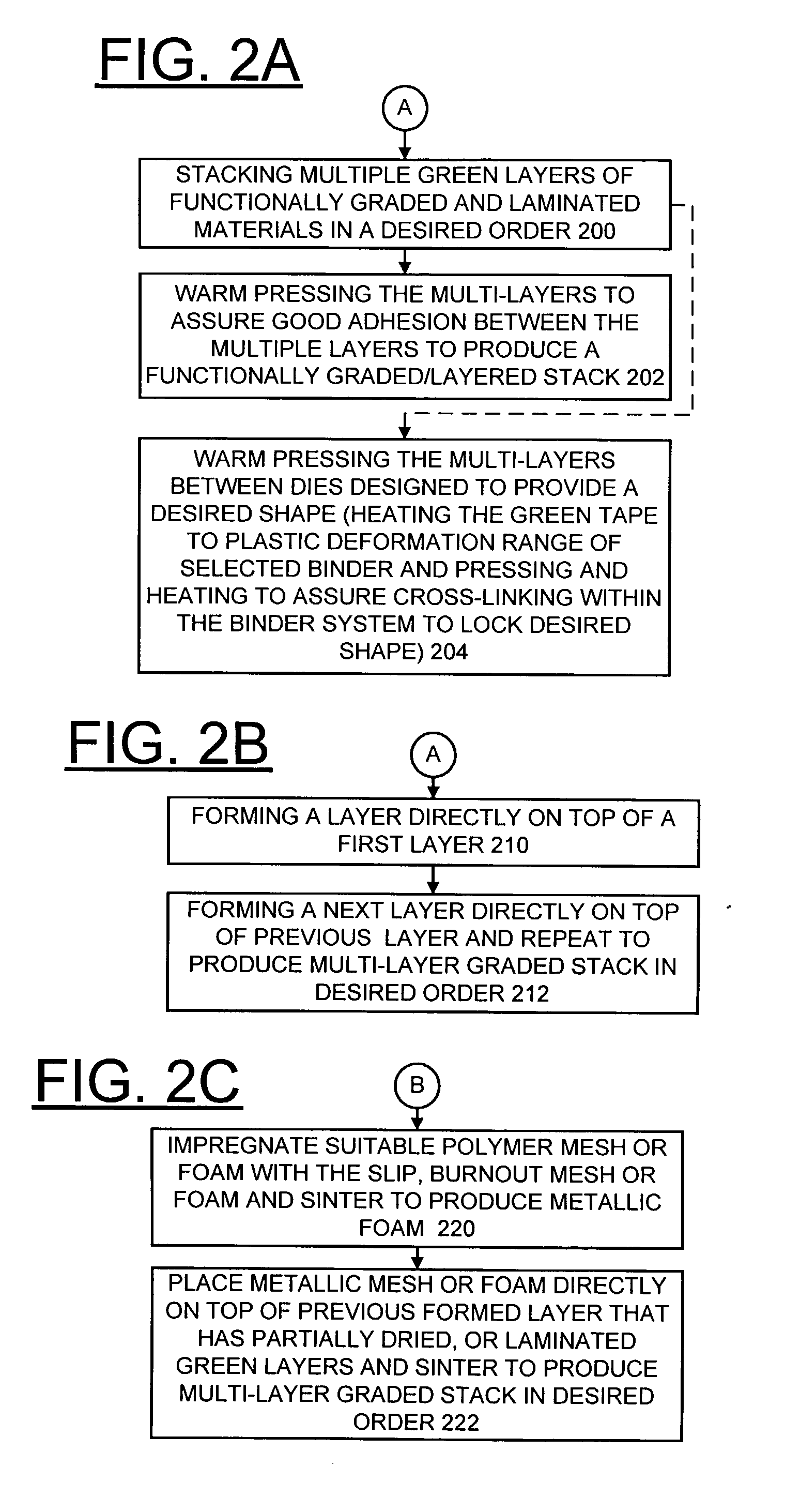

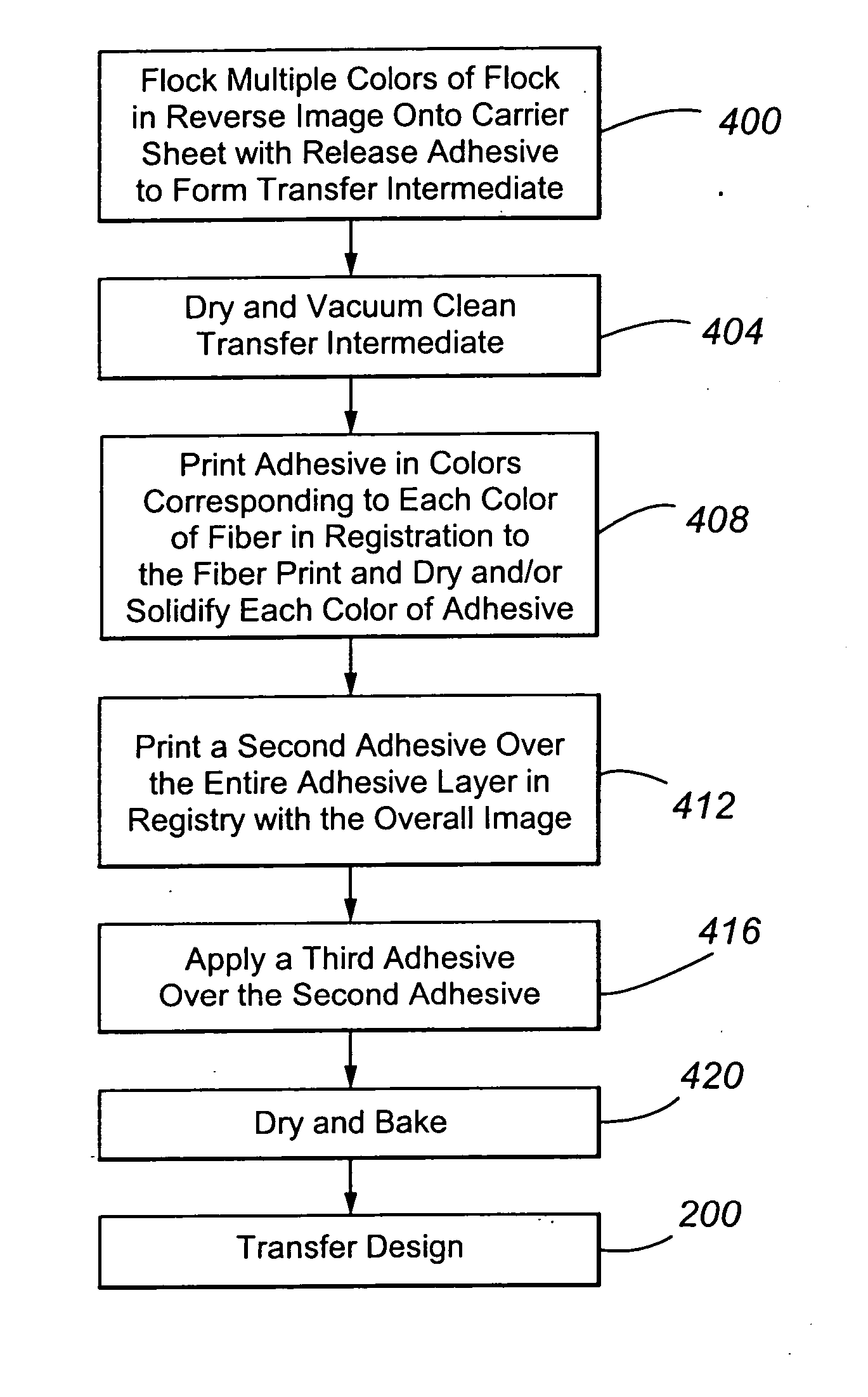

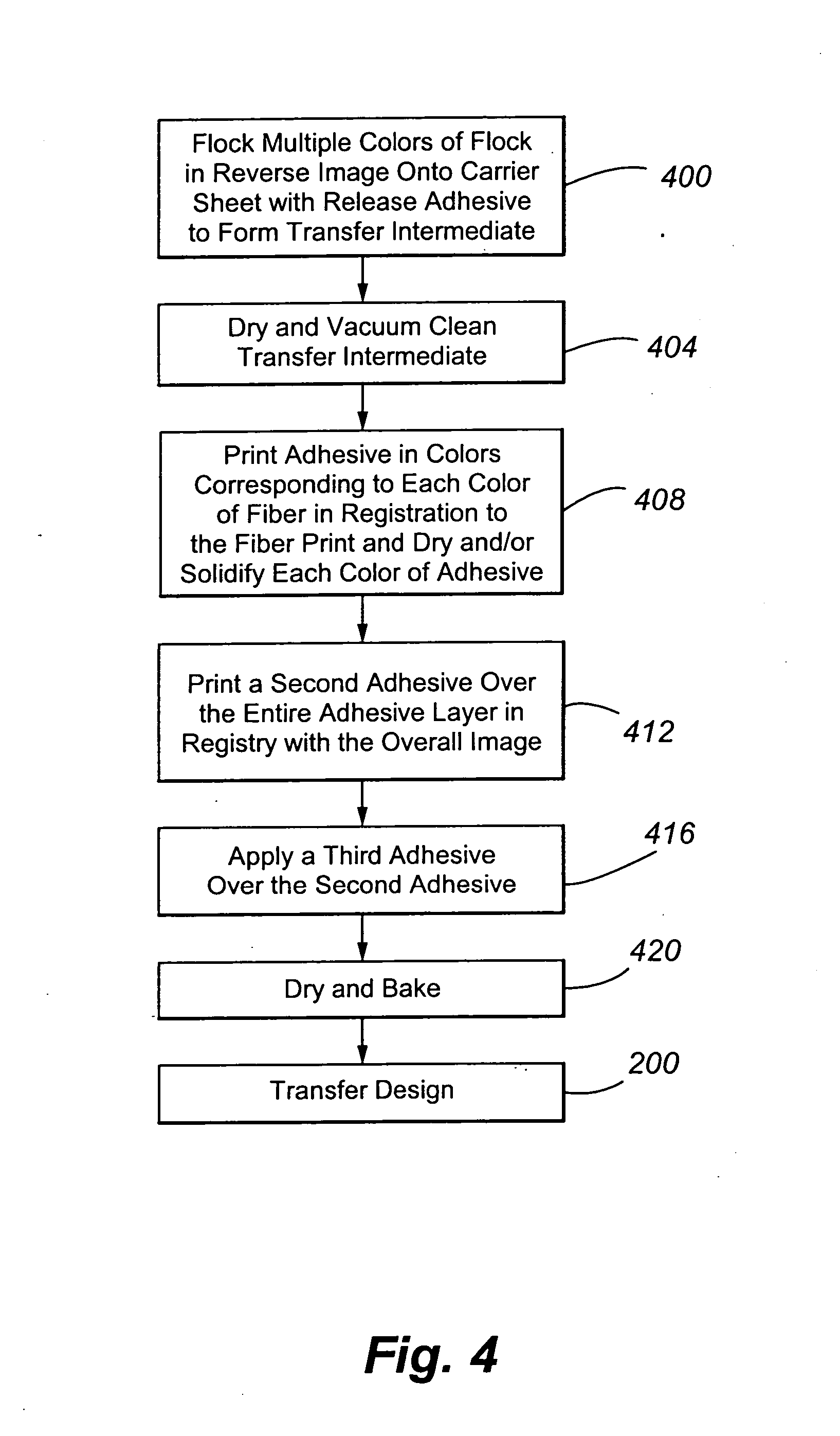

Flocked multi-colored adhesive article with bright lustered flock and methods for making the same

InactiveUS20060251852A1Reduce shadowing effectFlock densityLayered productsOrnamental structuresFiberEngineering

Owner:HIGH VOLTAGE GRAPHICS

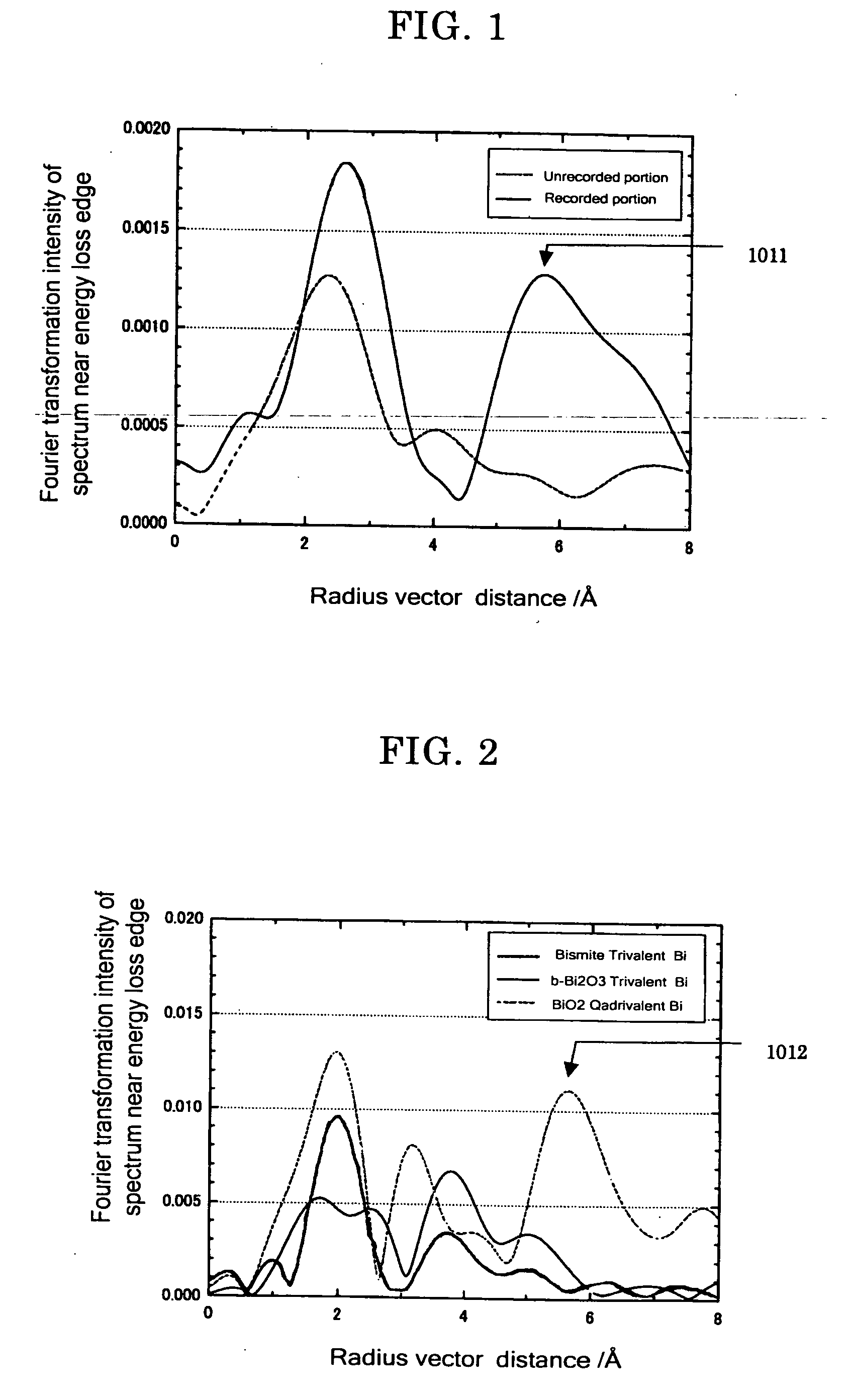

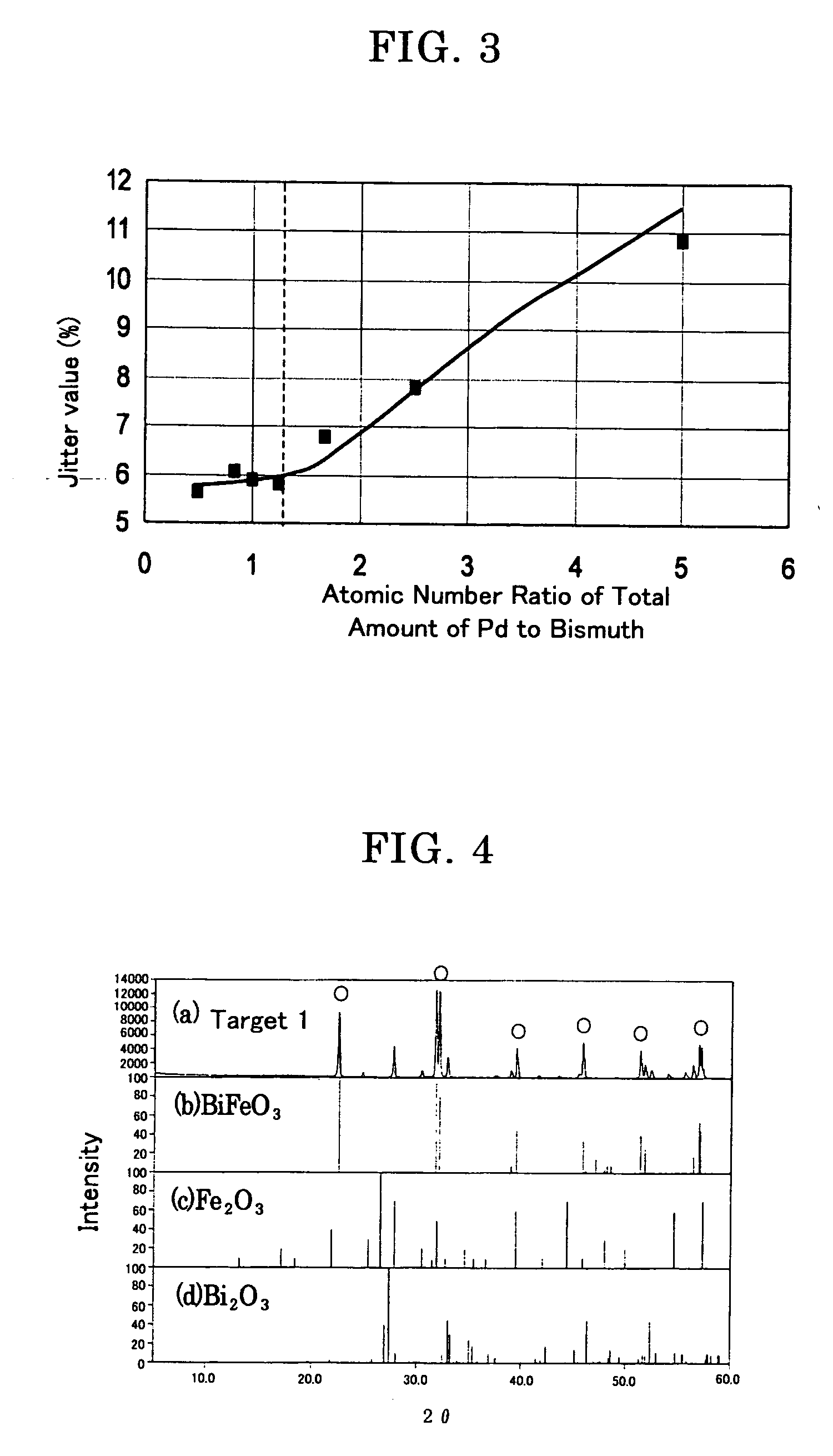

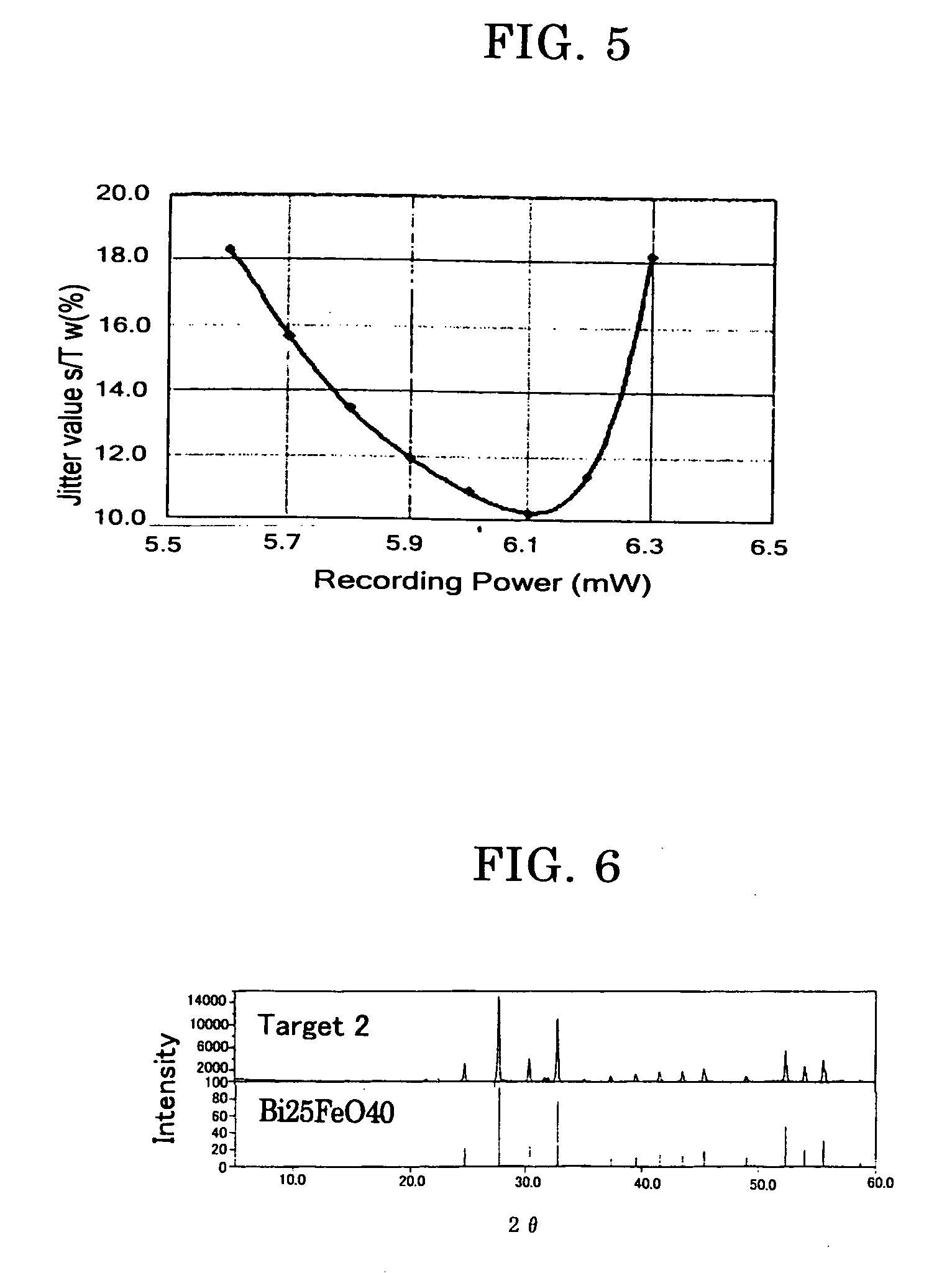

Write-onece-read-many optical recording medium, sputtering target and the production method thereof

InactiveUS20060222810A1High density recordingLayered productsVacuum evaporation coatingHigh densityOxygen

Owner:RICOH KK

Temporary image receptor and means for chemical modification of release surfaces on a temporary image receptor

InactiveUS6194106B1Fine surfaceGood release effectLayered productsRecord information storageDielectric substratePhotochemistry

Owner:3M CO

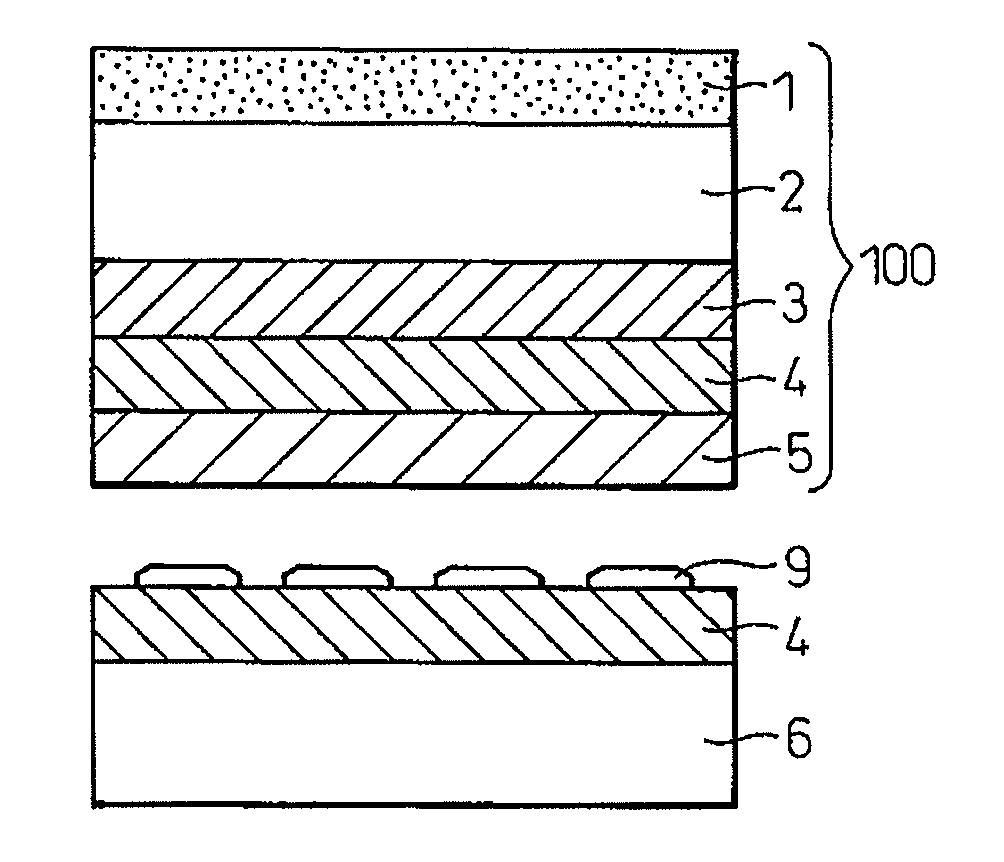

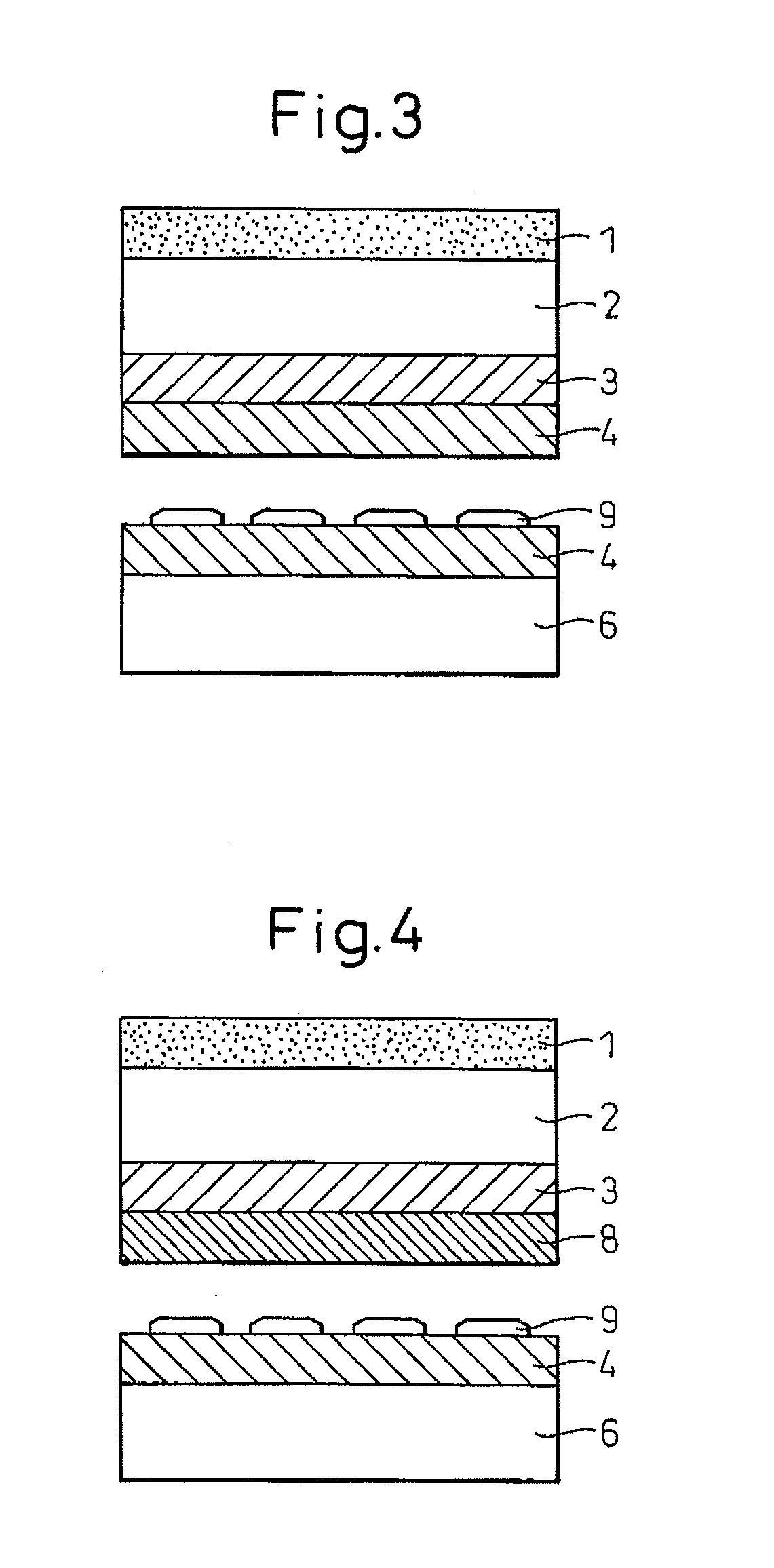

Transparent electroconductive laminate and transparent touch panel

InactiveUS20100260986A1Improved writing durabilityLayered productsThin material handlingTouch panelMetal alkoxide

Owner:TEIJIN LTD

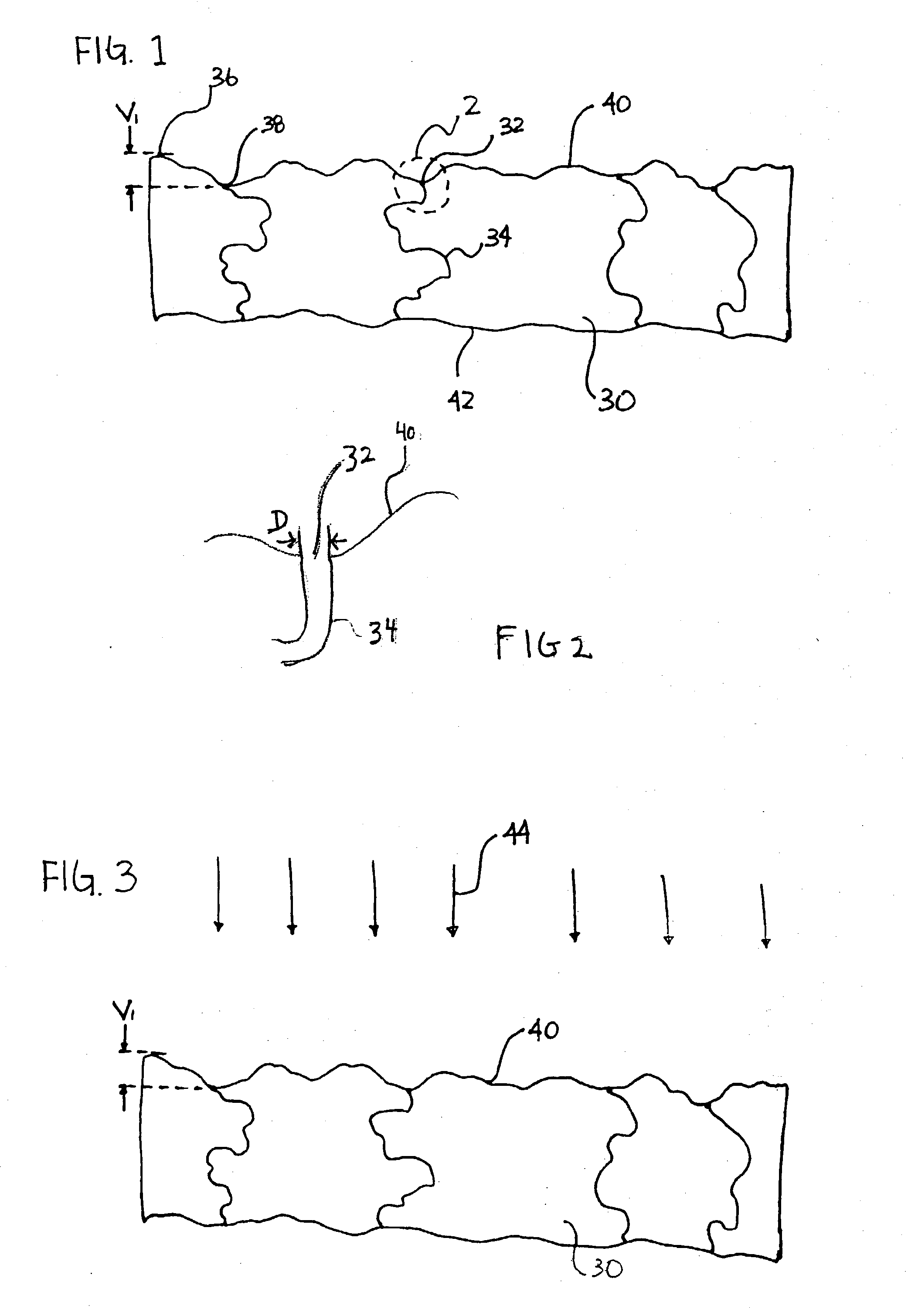

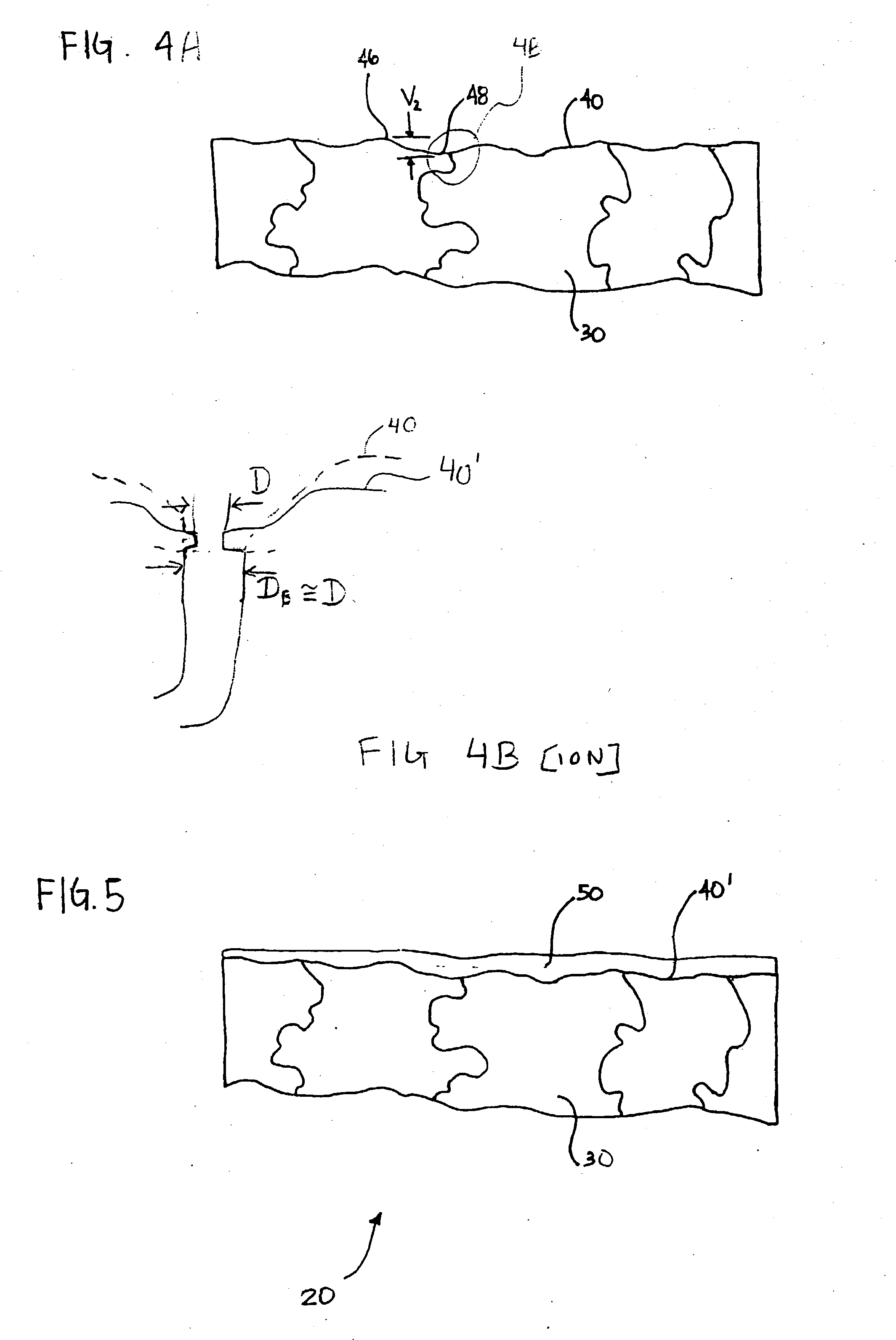

Building blocks

InactiveUS20140106108A1Reducing local tensionImprove connectivityWallsLayered productsEngineeringInterconnection

A building block comprising a panel member having a forward panel surface and a rearward panel surface, and a peripheral skirt extending rearward from the rearward panel surface and defining a receptacle; wherein an interconnection means adapted for making sidewise locked interconnection with an adjacent building block having a complementary or counterpart interconnection means is formed on the peripheral shirt, the interconnection means being a female connection member or a male connection member complementary to the female member; wherein the female member is shaped or adapted to permit a male connection member of the adjacent building block to enter into sidewise locked interconnection by entering at the free end of the peripheral skirt which is distal from the panel member, to move towards the forward panel surface, and to stop before reaching the forward panel surface.

Owner:LIN TSZ CHUNG

Reversibly adhesive thermal interface material

Owner:IBM CORP

Yoga mat with support and traction

ActiveUS20140342118A1Low compressibilityImprove compression performanceLayered productsFloor coveringsMechanical engineeringLayered structure

Owner:SEQUENCE

Carbon nanotube filled polycarbonate Anti-curl back coating with improved electrical and mechanical properties

Transparent or semi-transparent, electrically conductive anti-curl back coating composite for electrophotographic imaging member comprising a carbon nanotube complex and a polycarbonate binder are described along with processes for preparing them.

Owner:XEROX CORP

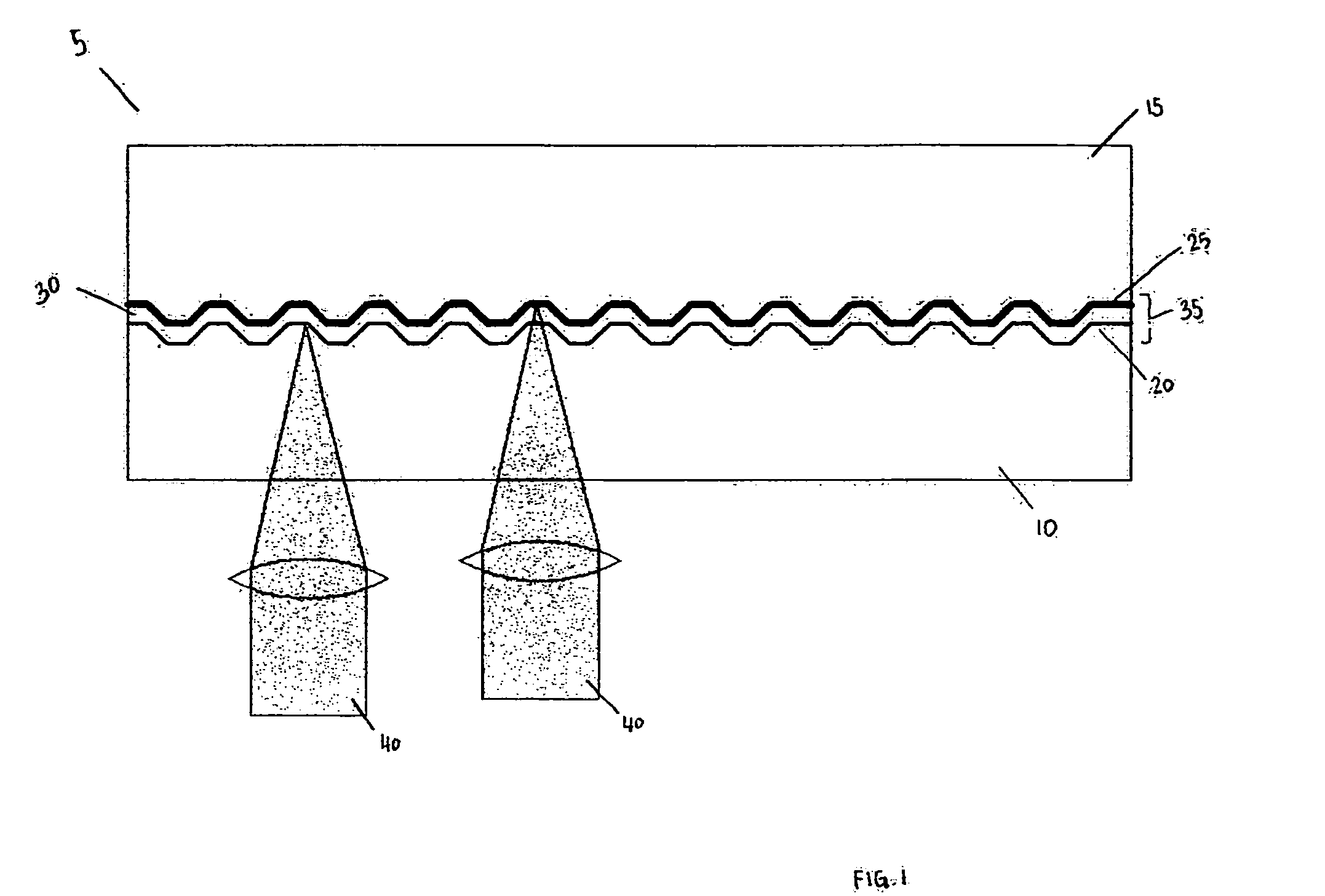

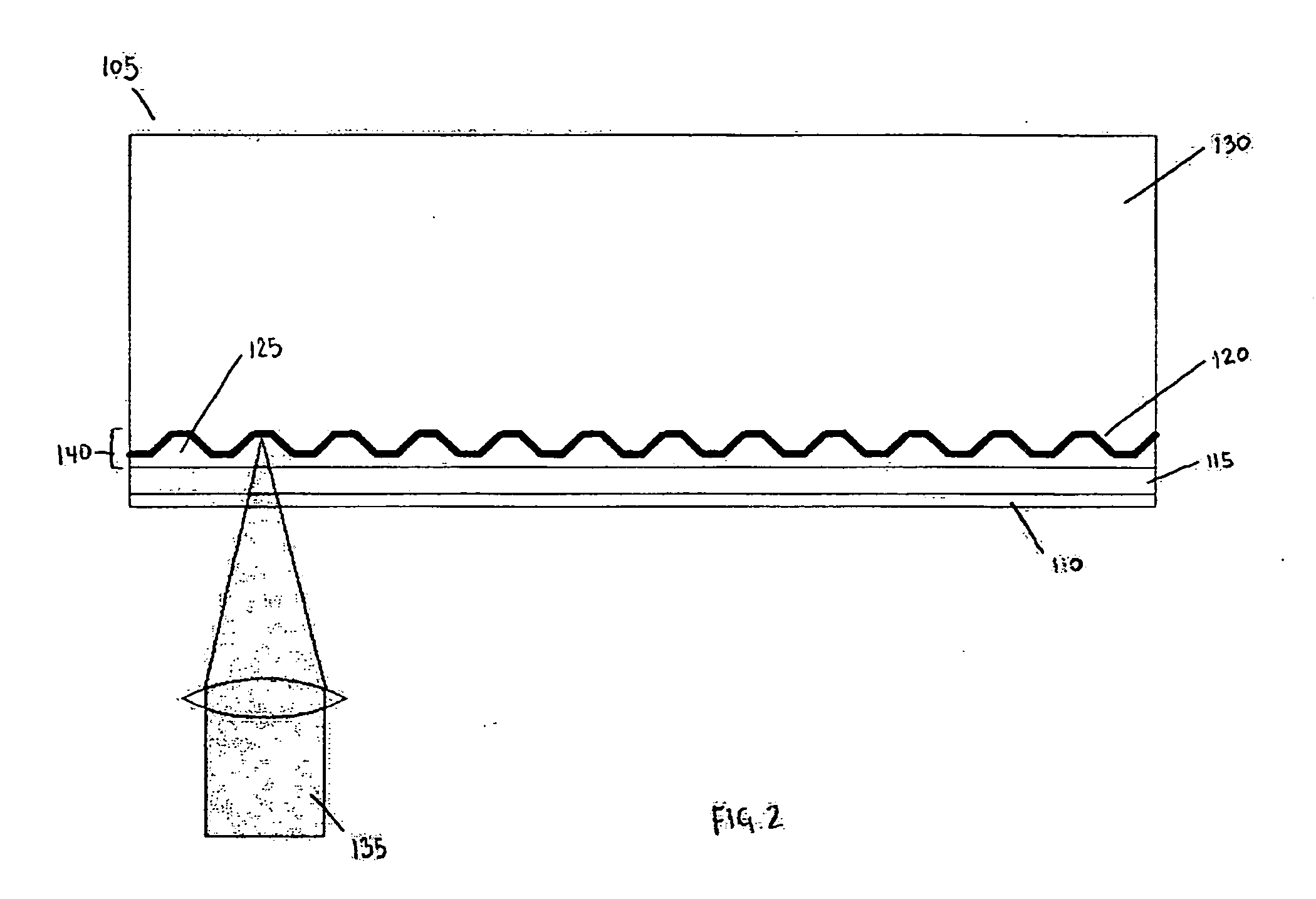

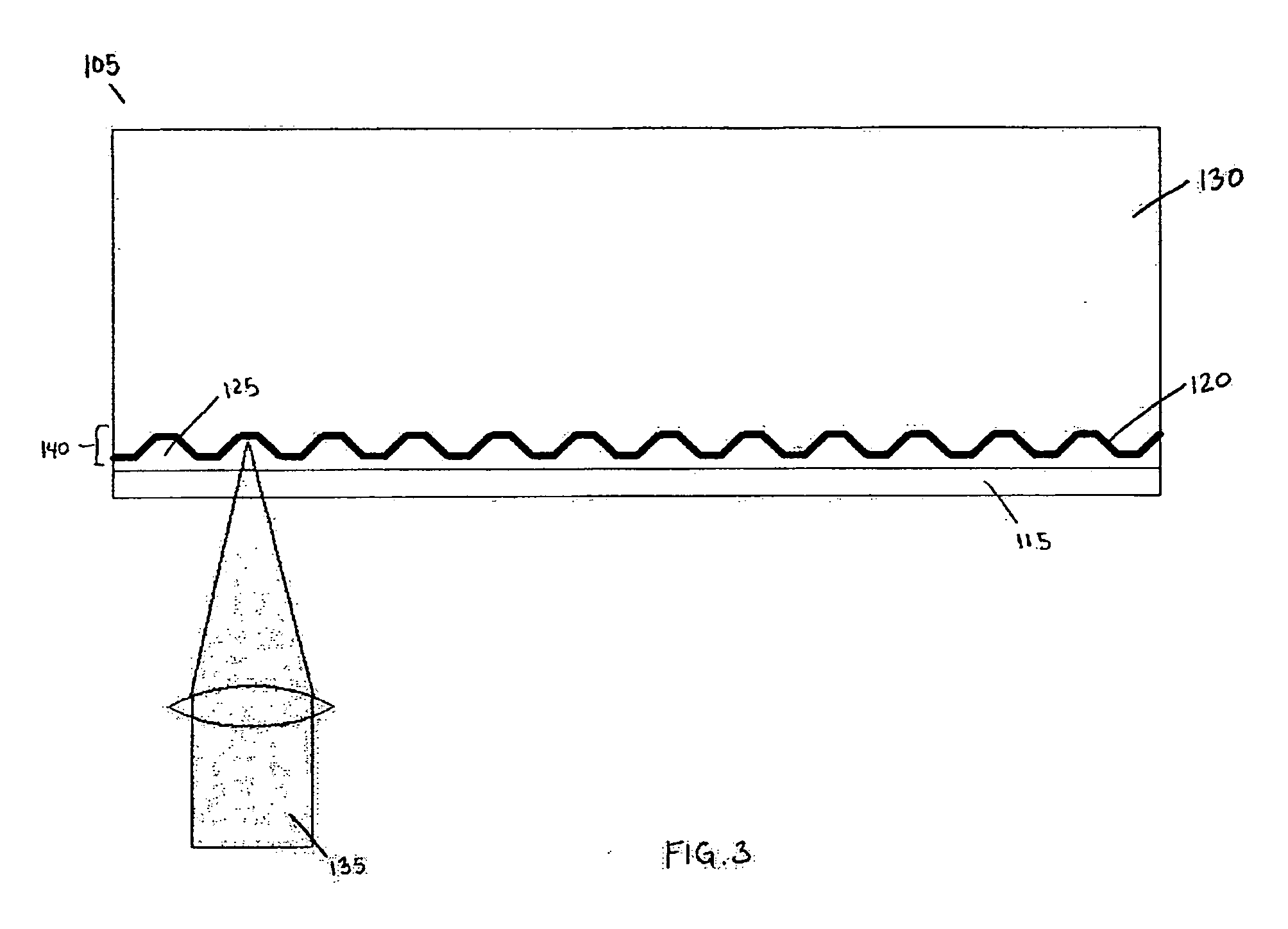

Light-emitting apparatus and method for forming the same

InactiveUS7071617B2Increase brightnessAvoid specular reflectionsDischarge tube luminescnet screensLayered productsPeak valueLength wave

In a light-emitting apparatus, a face of a substrate on which a light-emitting device is formed is an uneven surface having a plurality of asperities. The mean spacing Sm of adjacent asperities or the mean spacing S of peaks of adjacent projections of the asperities is no less than three times the longest wavelength of light generated by a light-emitting layer and no more than two hundred times the longest wavelength. The arithmetic mean slope Δa of the uneven surface is in a range between 4° and 30°, inclusive. Therefore, the apparatus emits substantially a greater amount of light from a light extraction side and has less brightness unevenness than a light-emitting apparatus with no uneven surface.

Owner:TOYOTA IND CORP

Extensible non-load bearing cut resistant tire side-wall component cotaining elastomeric filament, tire containing said component, and processes for making same

InactiveUS20100108218A1Improved adhesion of fabricLayered productsPneumatic tyre reinforcementsYarnFiber

Owner:EI DU PONT DE NEMOURS & CO +1

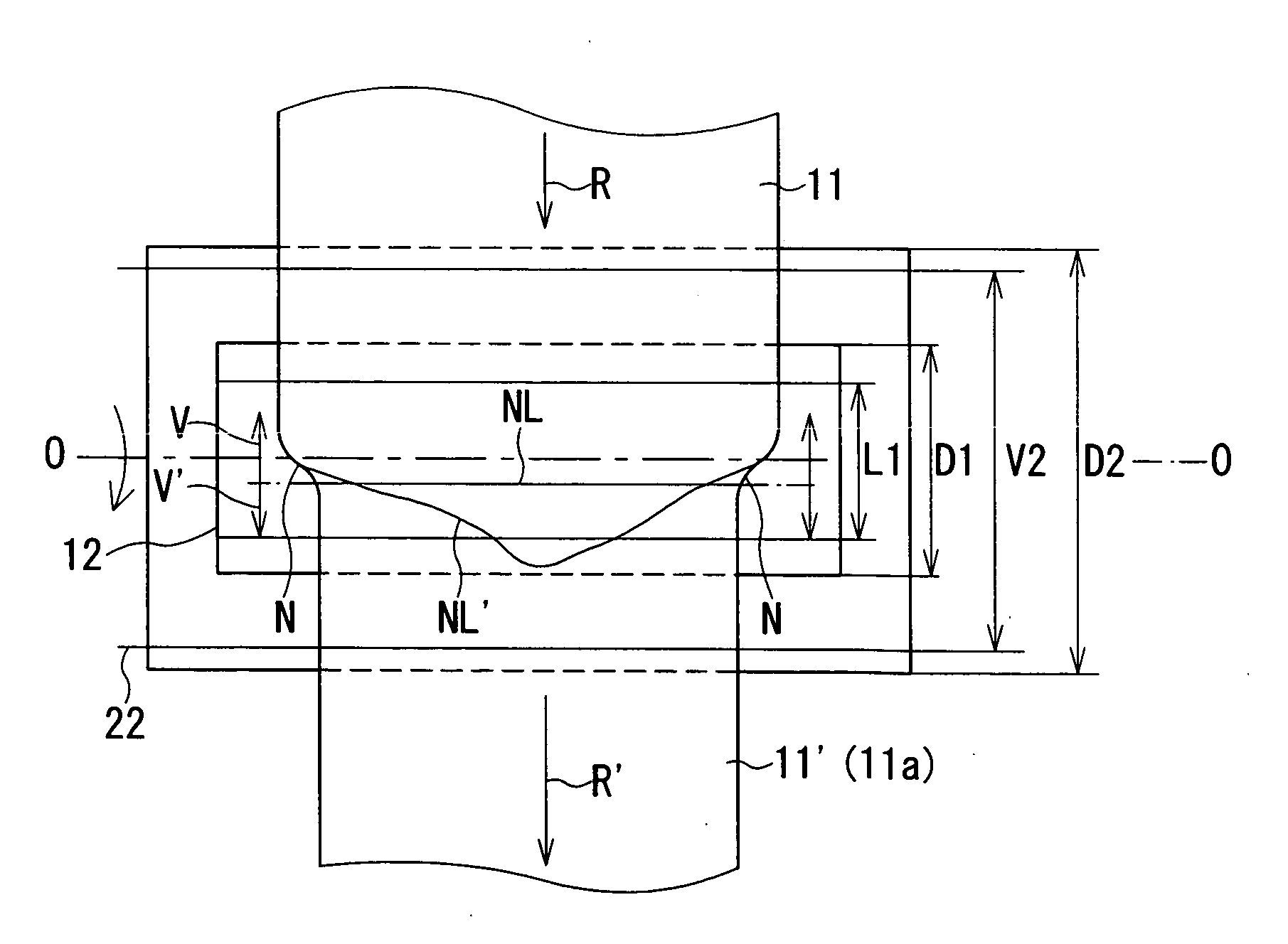

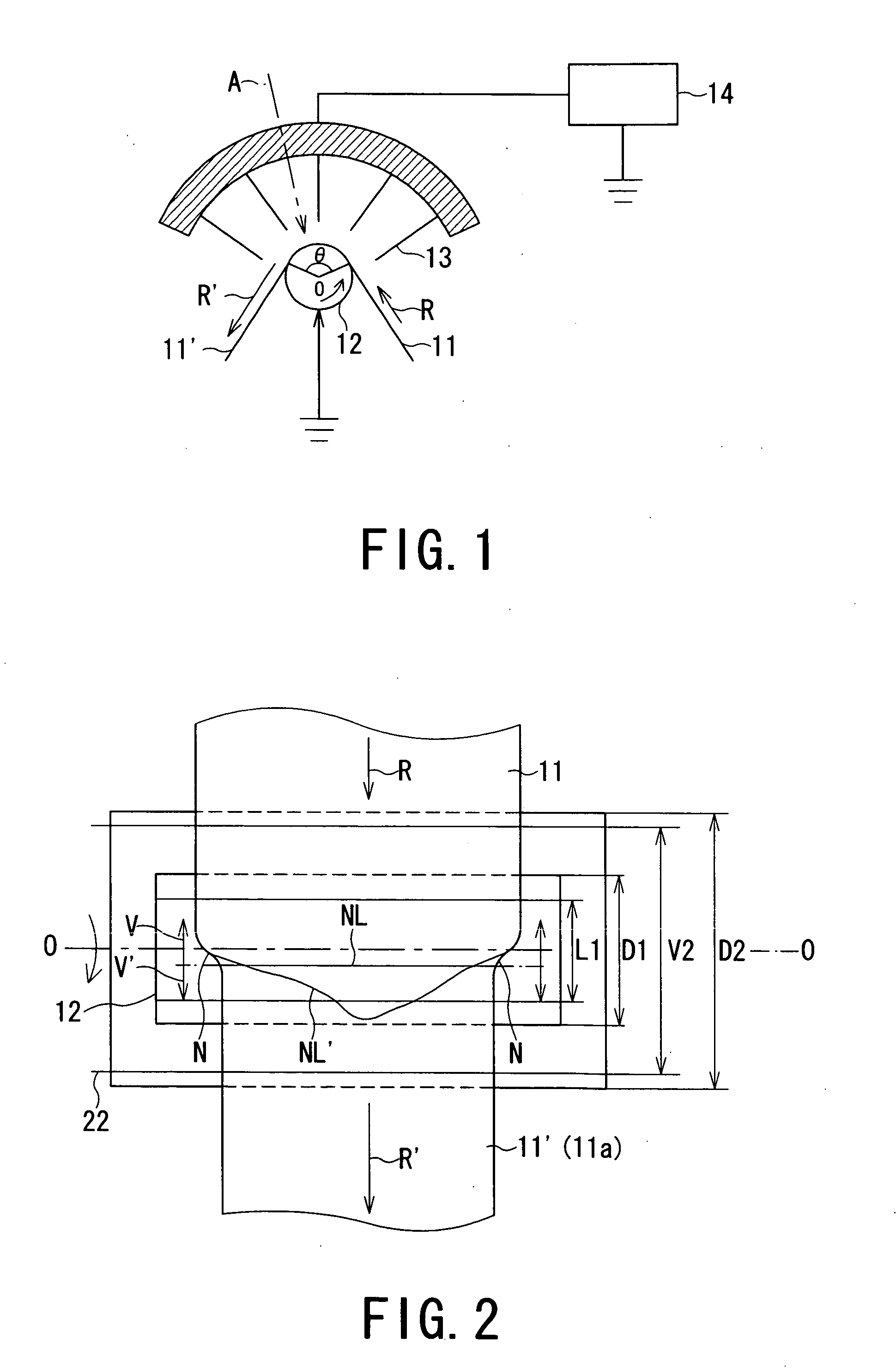

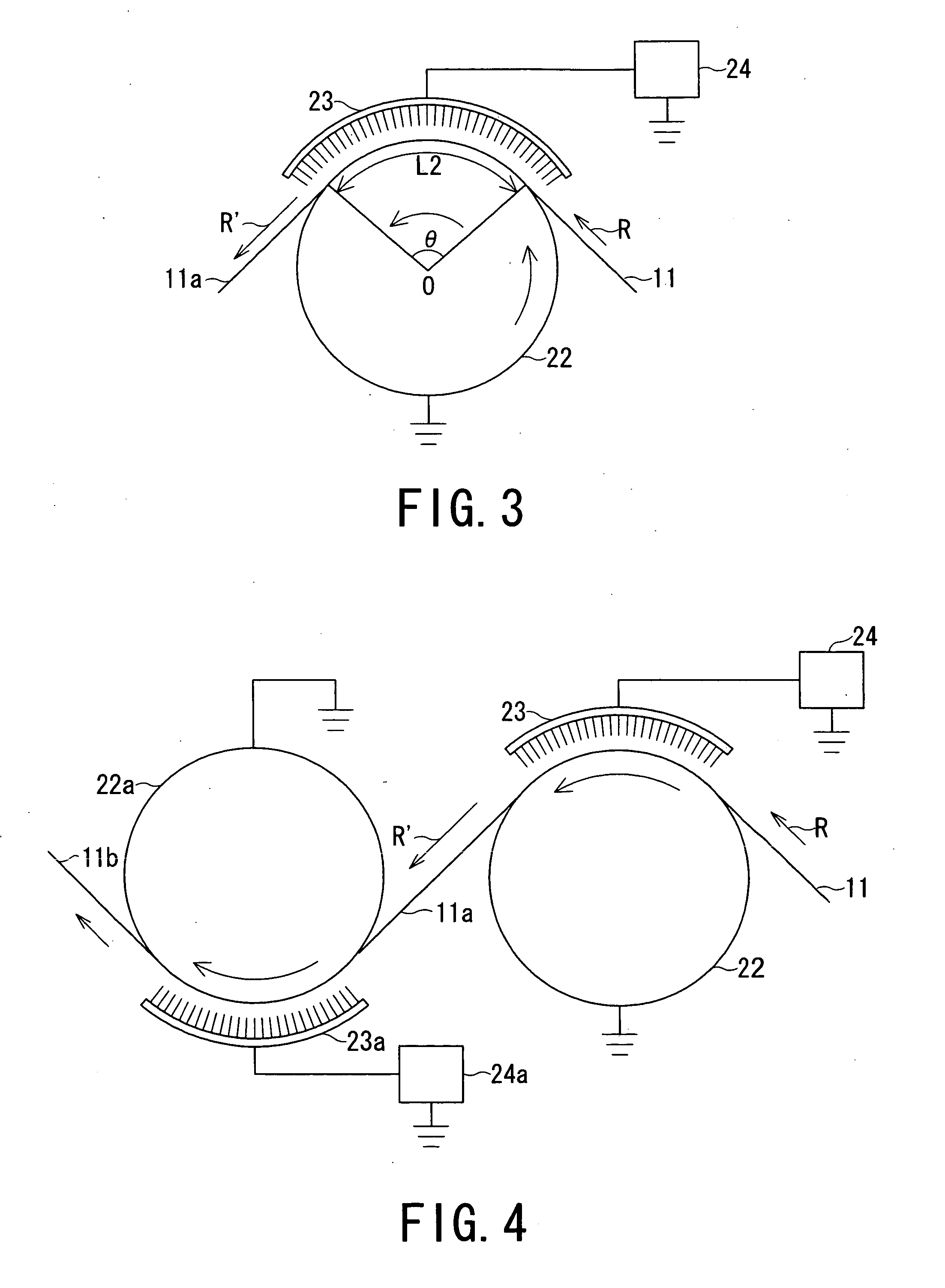

Method for manufacturing polymeric piezoelectric film and polymeric piezoelectric film

ActiveUS20100068460A1Stable productionImprove piezoelectric performancePiezoelectric/electrostrictive device manufacture/assemblyLayered productsRelative displacementPeak value

Owner:KUREHA KAGAKU KOGYO KK

Optical media, read inhibiting agents and methods of making and using same

InactiveUS20060105134A1Layered productsRecord information storageChemical substanceCompound (substance)

Owner:FLEXPLAY TECH INC

Packaging film and method for manufacturing packaging film

ActiveCN102751445AExtended service lifeReduce adhesionLayered productsSolid-state devicesNano structuringEngineering

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

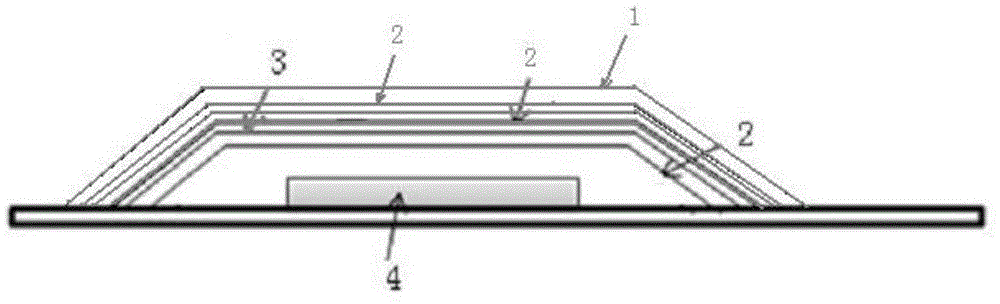

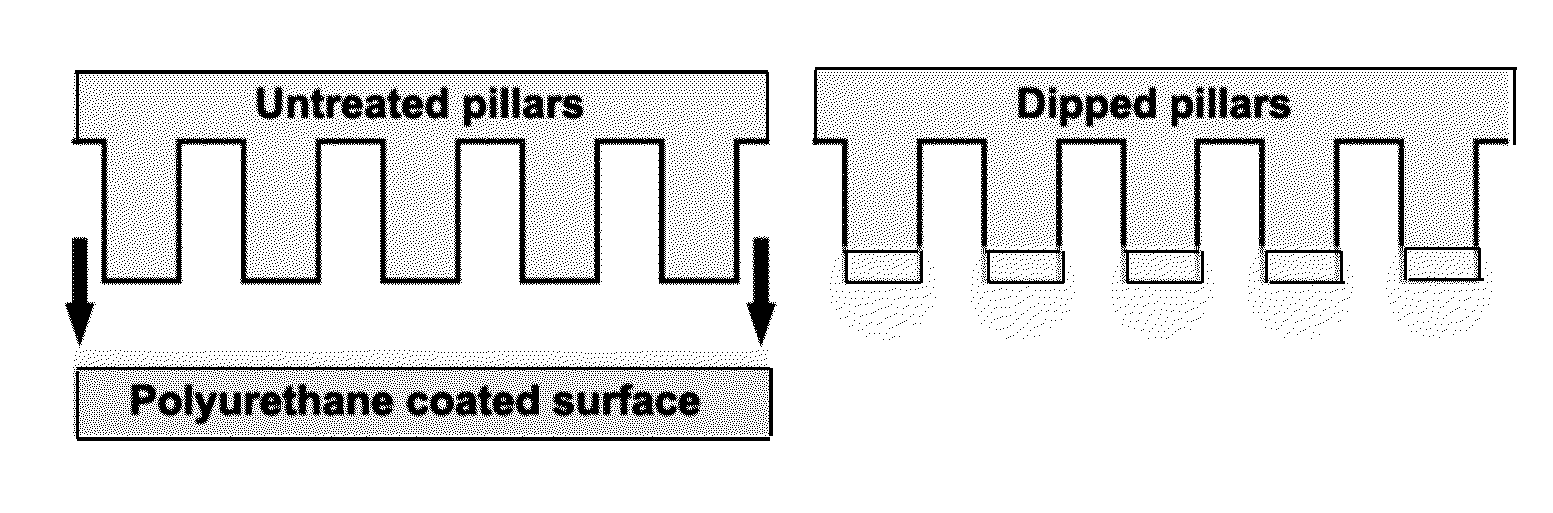

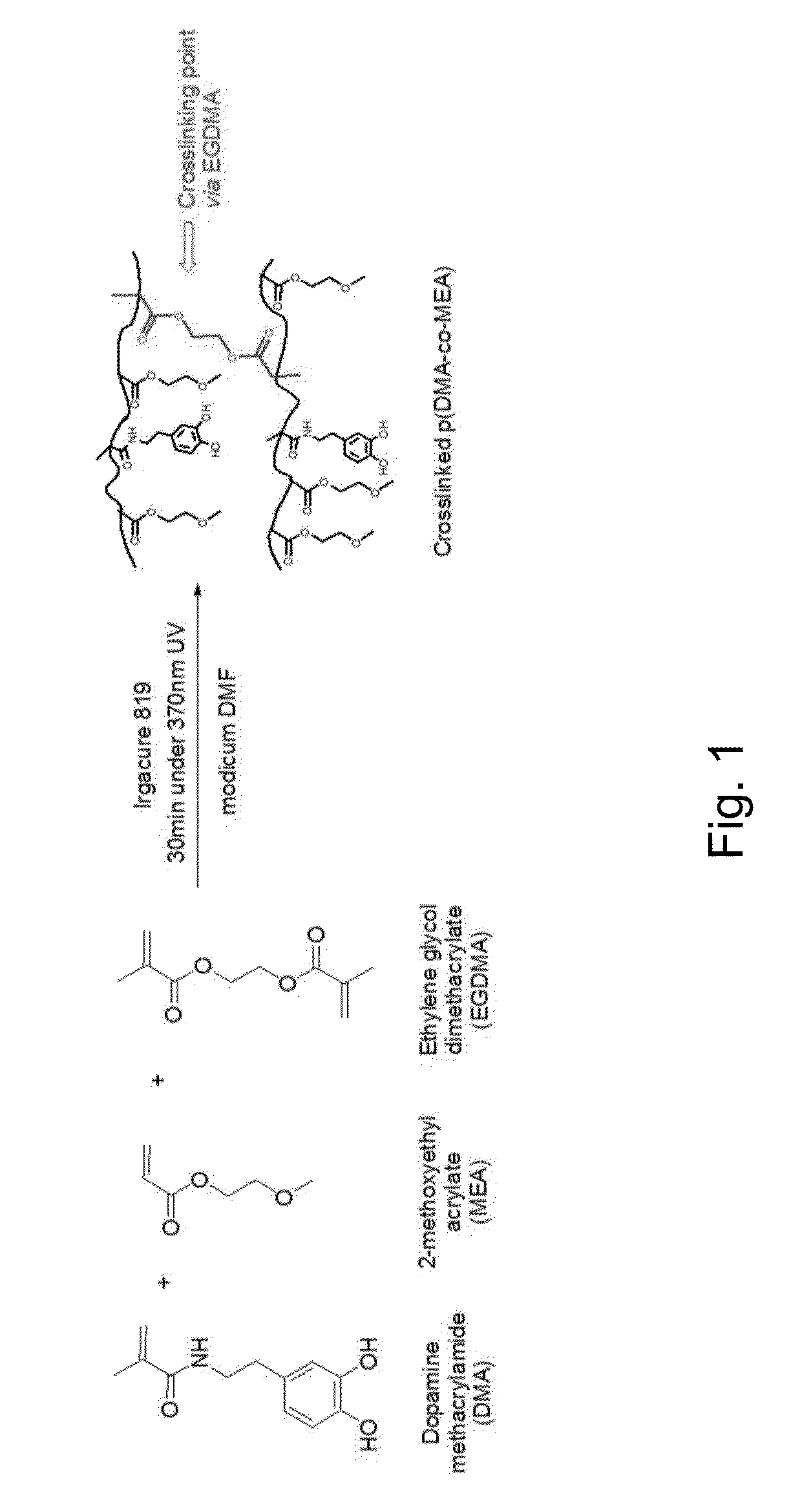

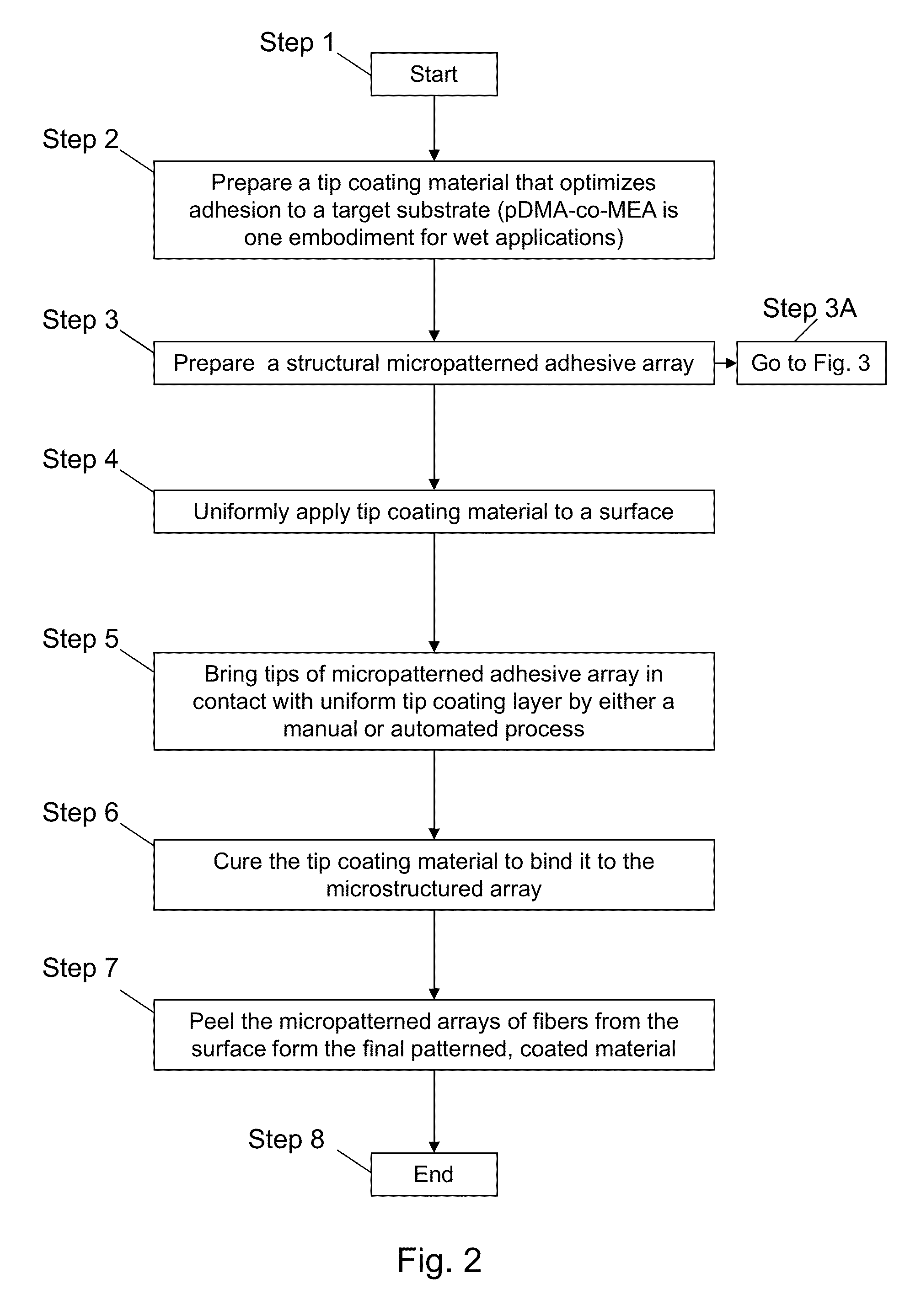

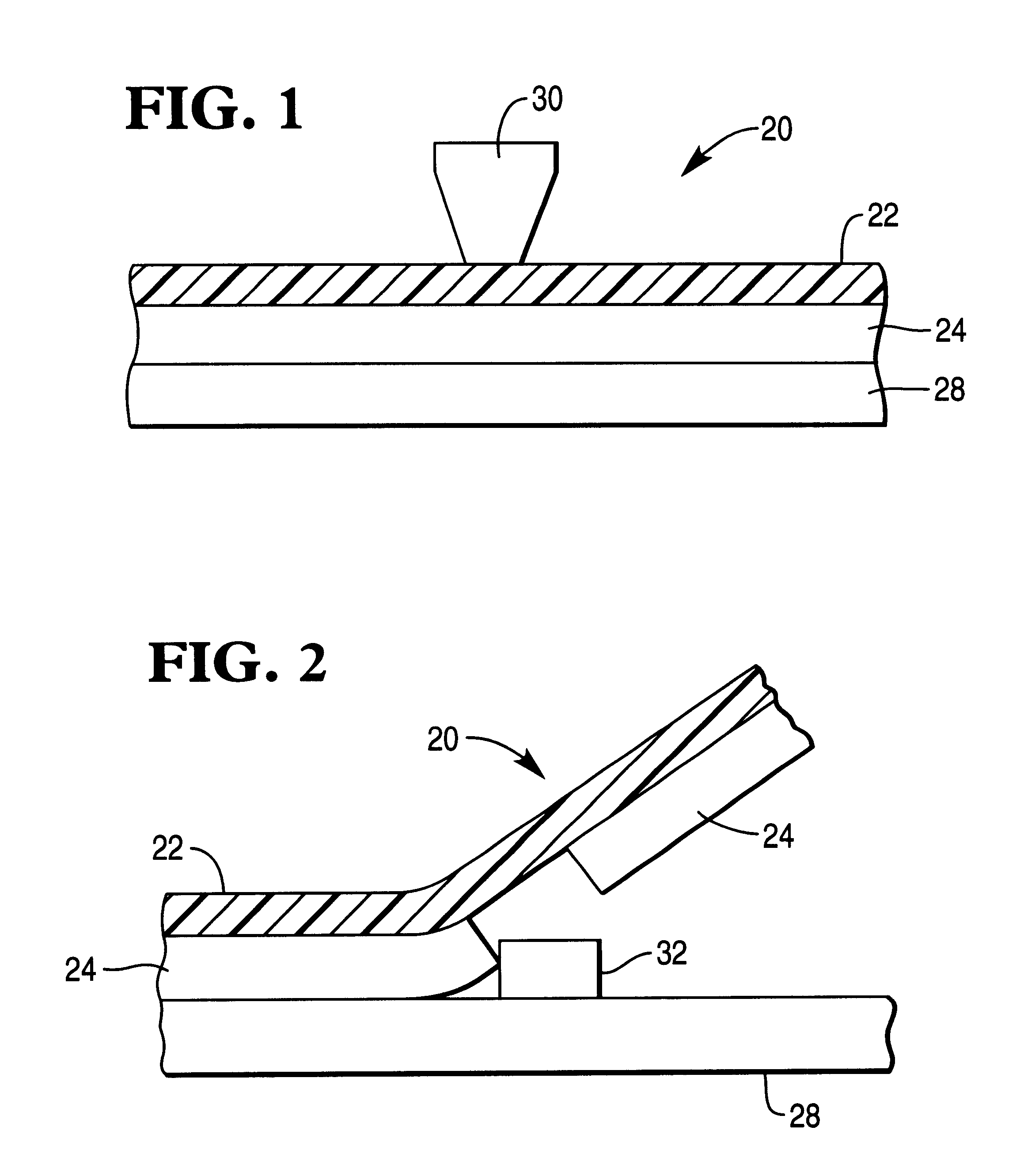

Micro-fiber arrays with tip coating and transfer method for preparing same

ActiveUS20130183481A1Performance deteriorationLayered productsPretreated surfacesMicron scaleElastomer

Owner:CARNEGIE MELLON UNIV CENT FOR TECH TRANSFER & ENTERPRISE CREATION

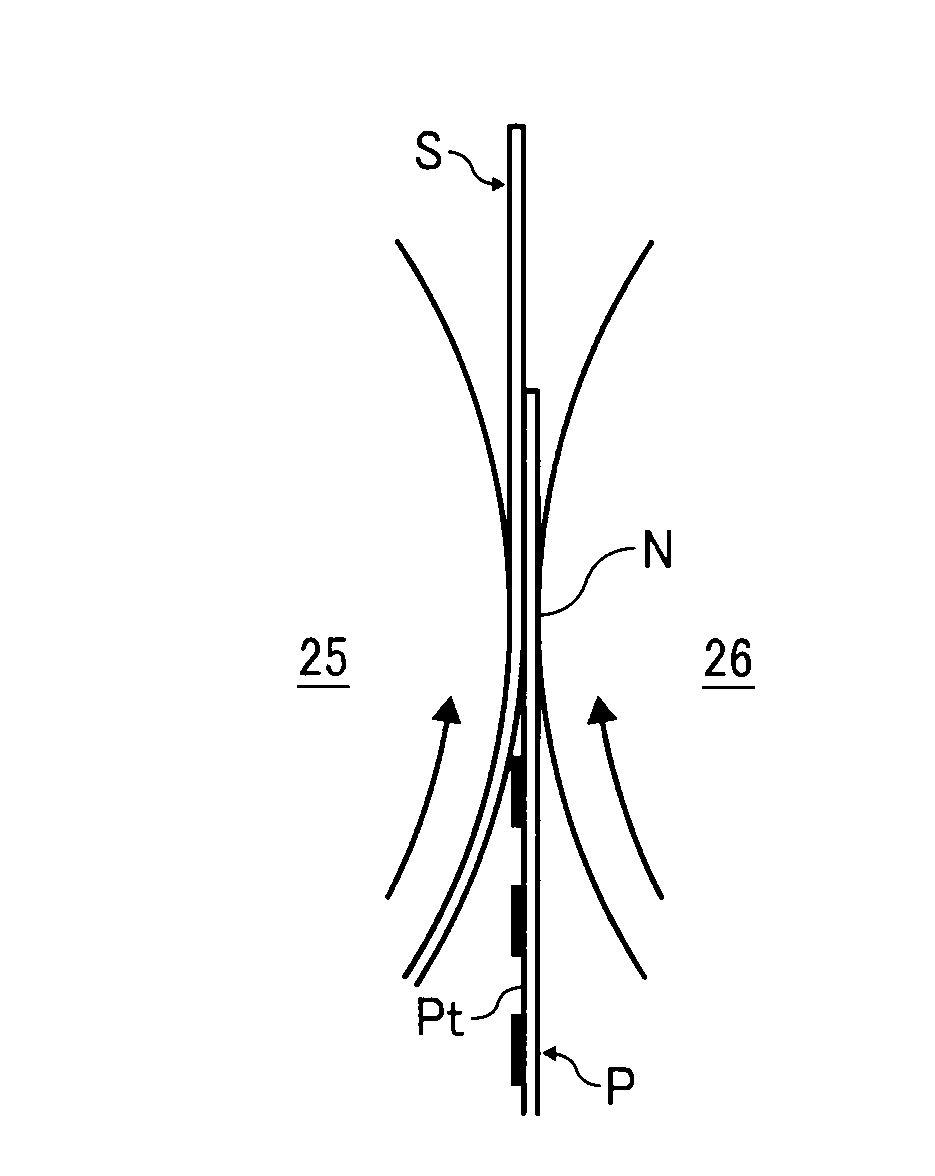

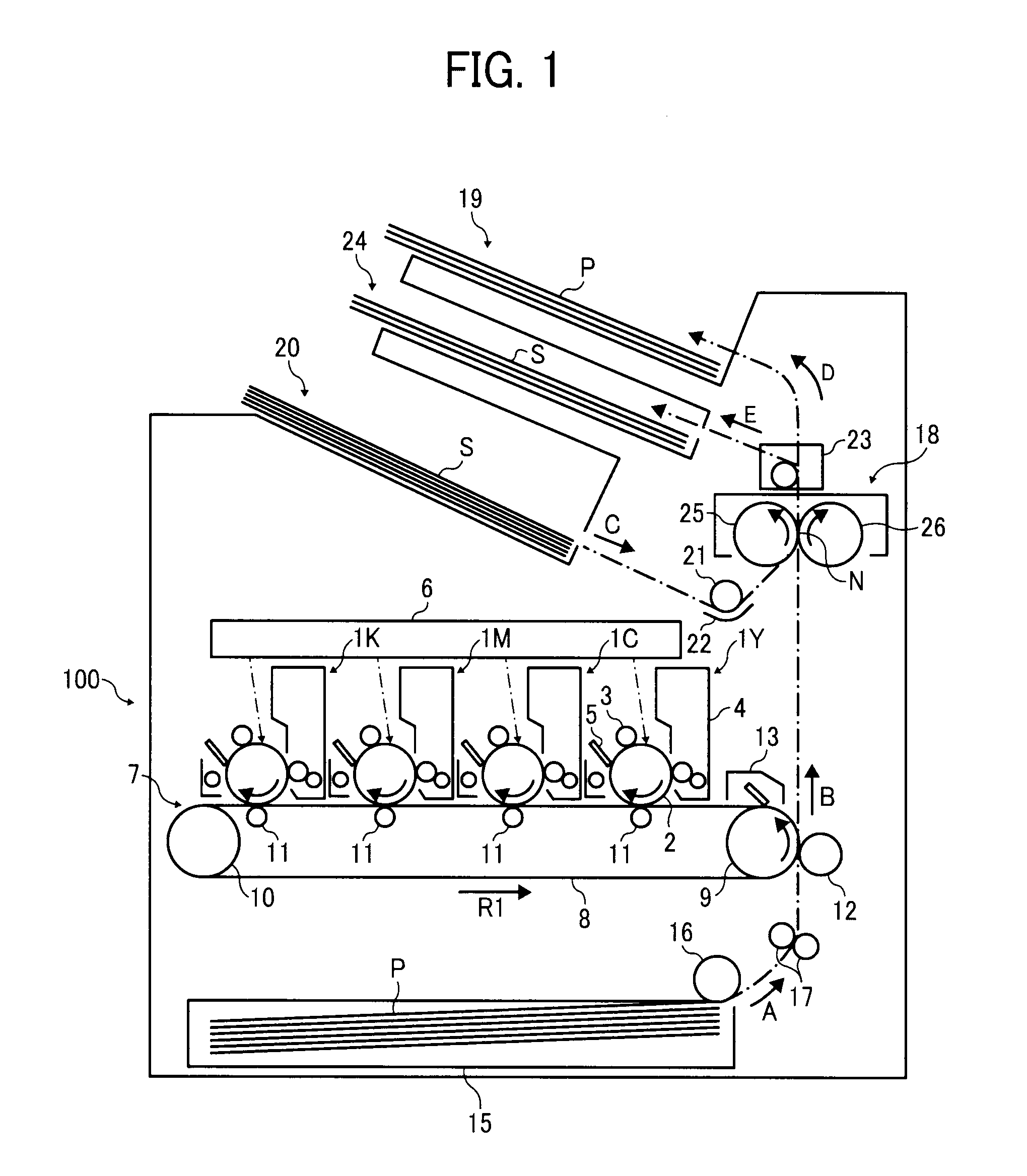

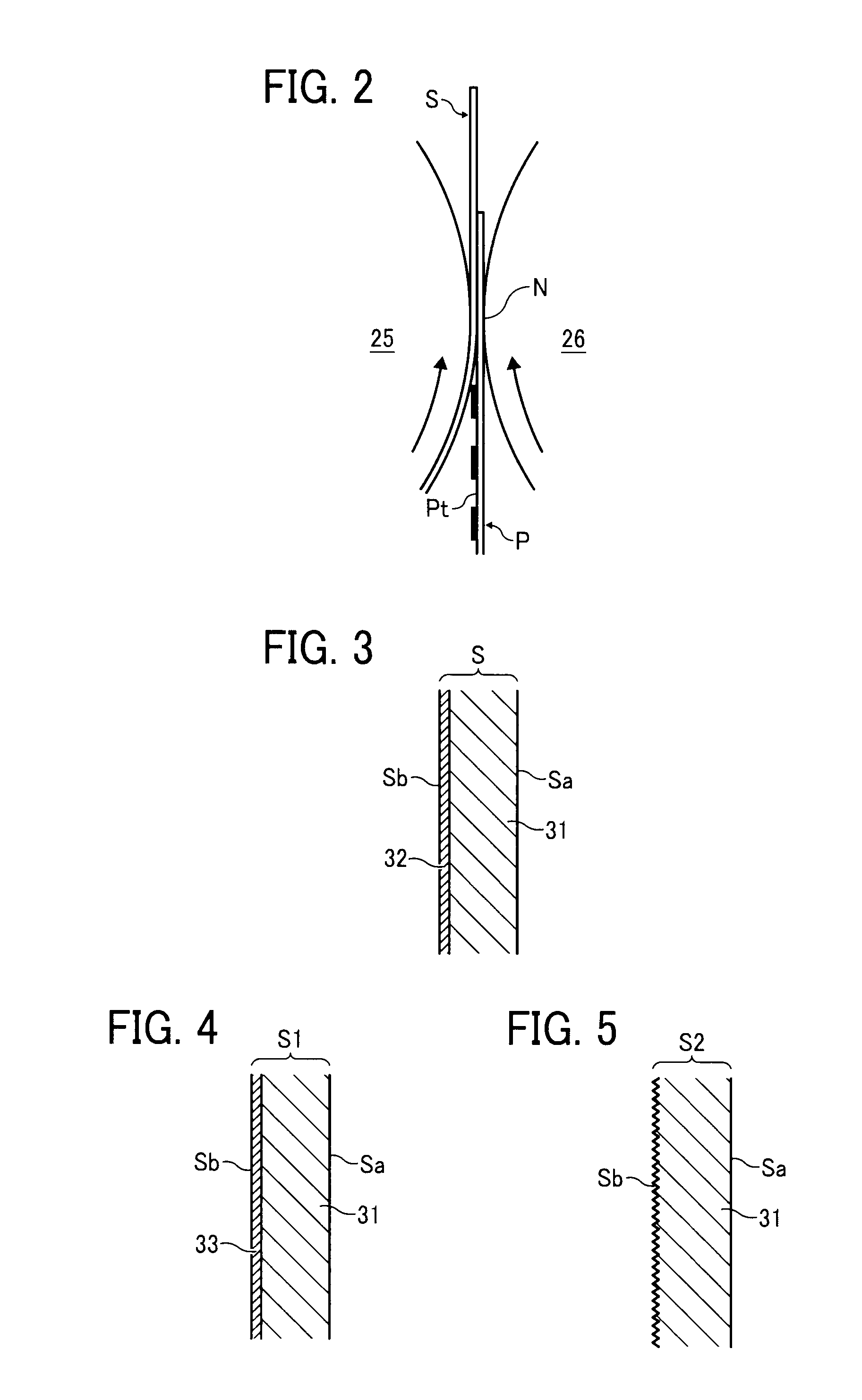

Printing superimposed layers

An apparatus and method for making a panel with superimposed layers of marking material in substantially exact registration is provided. An assembly includes a stencil layer sandwiched between a substrate and a transparent coating. The stencil includes a release surface. The coating tends to secure the stencil layer to the substrate, e.g., for storage and / or transport, and may protect the stencil layer from marking materials that might otherwise penetrate the stencil layer. A design and background layers are then printed onto the coating. A force is then applied to remove the background layer, design layer, and coating that are disposed on the stencil layer, leaving the remainder of the background layer, design layer, and coating adhered to the substrate in substantially exact registration within portions of the substrate that are devoid of the stencil layer. The design layer is right-reading visible through the substrates.

Owner:CONTRA VISION

Surface modification of porous metal substrates

Owner:INTELLIGENT ENERGY INC

Foams and methods for making the same

InactiveUS20040001942A1Low compression setReduce loadLayered productsThin material handlingPolymer chemistryCopolymer

A foam profile prepared by a process comprising the steps of foaming a thermoplastic vulcanizate, where the thermoplastic vulcanizate is prepared by a process comprising the step of dynamically vulcanizing a rubber within a mixture that includes from about 15 to about 95 percent by weight of the rubber and from about 5 to about 85 percent by weight of a thermoplastic component based upon the total weight the rubber and thermoplastic component combined, where the thermoplastic component includes from about 65 to about 90 percent by weight of a conventional thermoplastic resin and from about 10 to about 35 percent by weight of a random propylene copolymer based upon the total weight of the thermoplastic component.

Owner:ADVANCED ELASTOMER SYST LP

Expanded nanoclays and method of producing such expanded nanoclays

A method of producing nanoclays comprising the steps of preparing a first intercalant alkali salt of a carboxylic acid, adding the first intercalant to a swelled clay at a temperature of at least 50° C. so that the metal ions on the clay surface forms a complex with the carboxyl group that enlarges the space between the two galleries of clay. The method further comprises the step of adding an organic acid as a second intercalant to the clay modified by the first intercalant to form a clay / organic salt / organic acid complex. The clay / organic salt / organic acid complex may be post processed by precipitating, homogenizing with a solution comprising of water and alcohol, filtering, drying, milling, and sieving to produce the desired nanoclay.

Owner:ISIK KIVANC

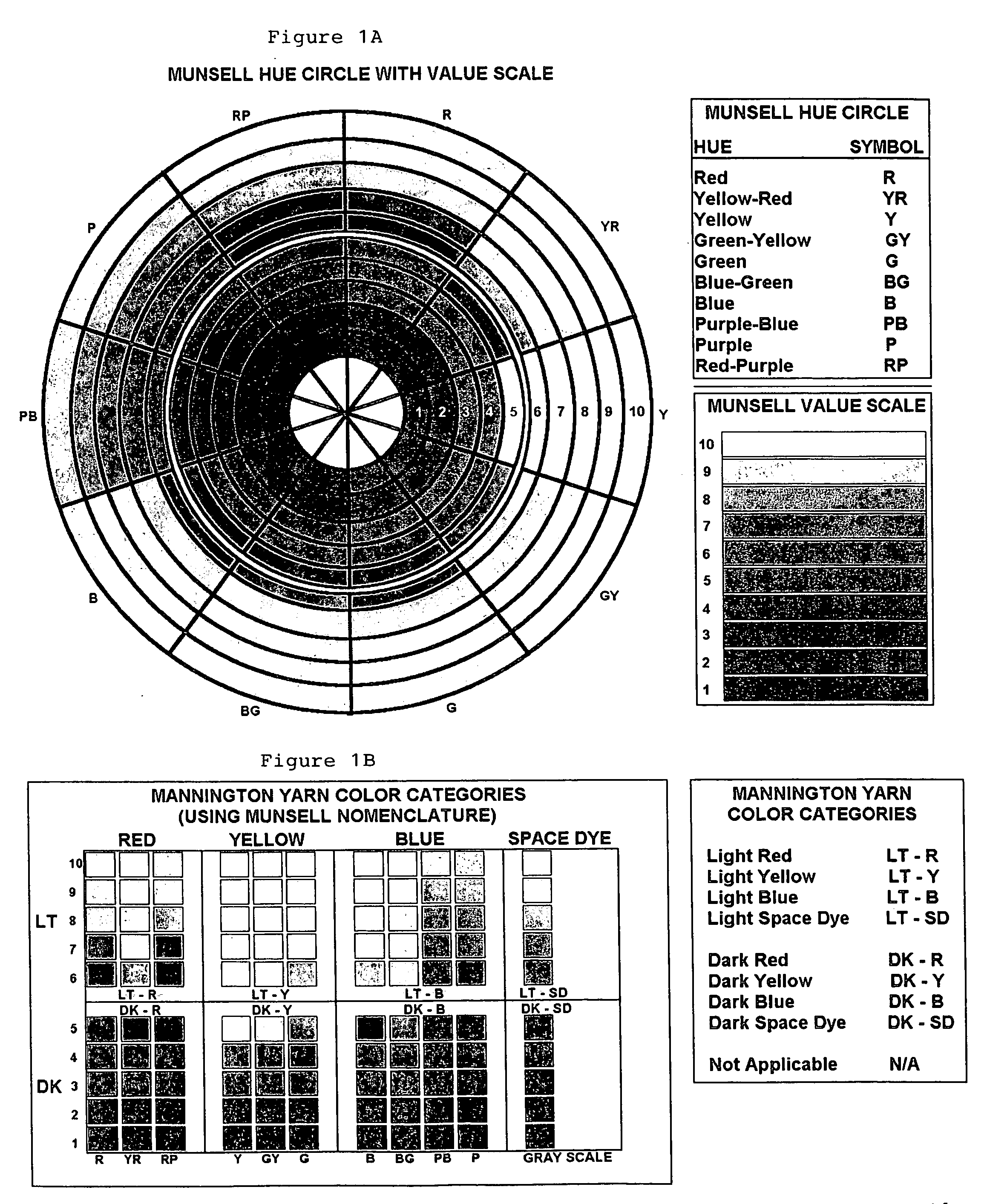

Carpet using using unused yarn

Owner:MANNINGTON MILLS

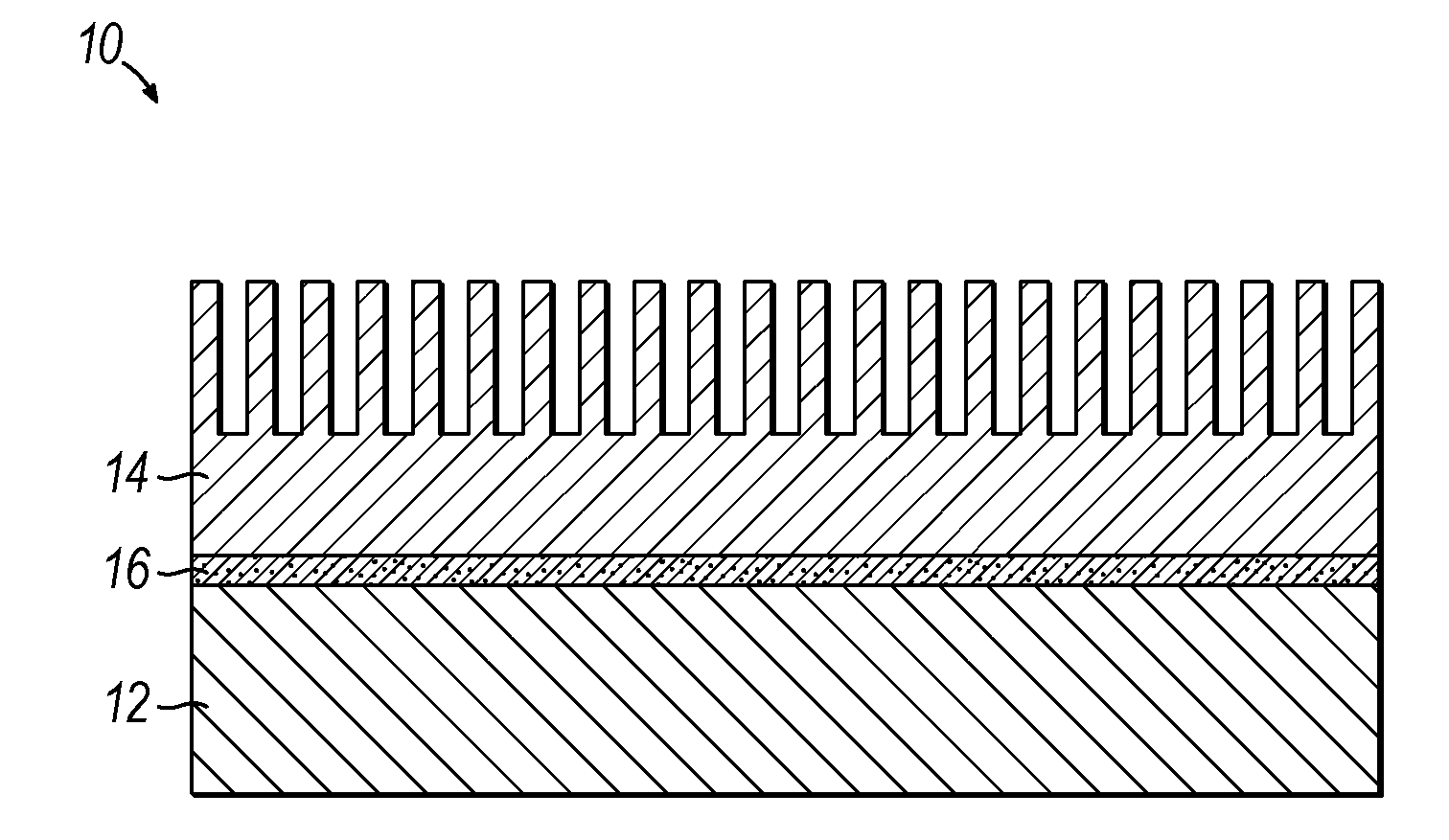

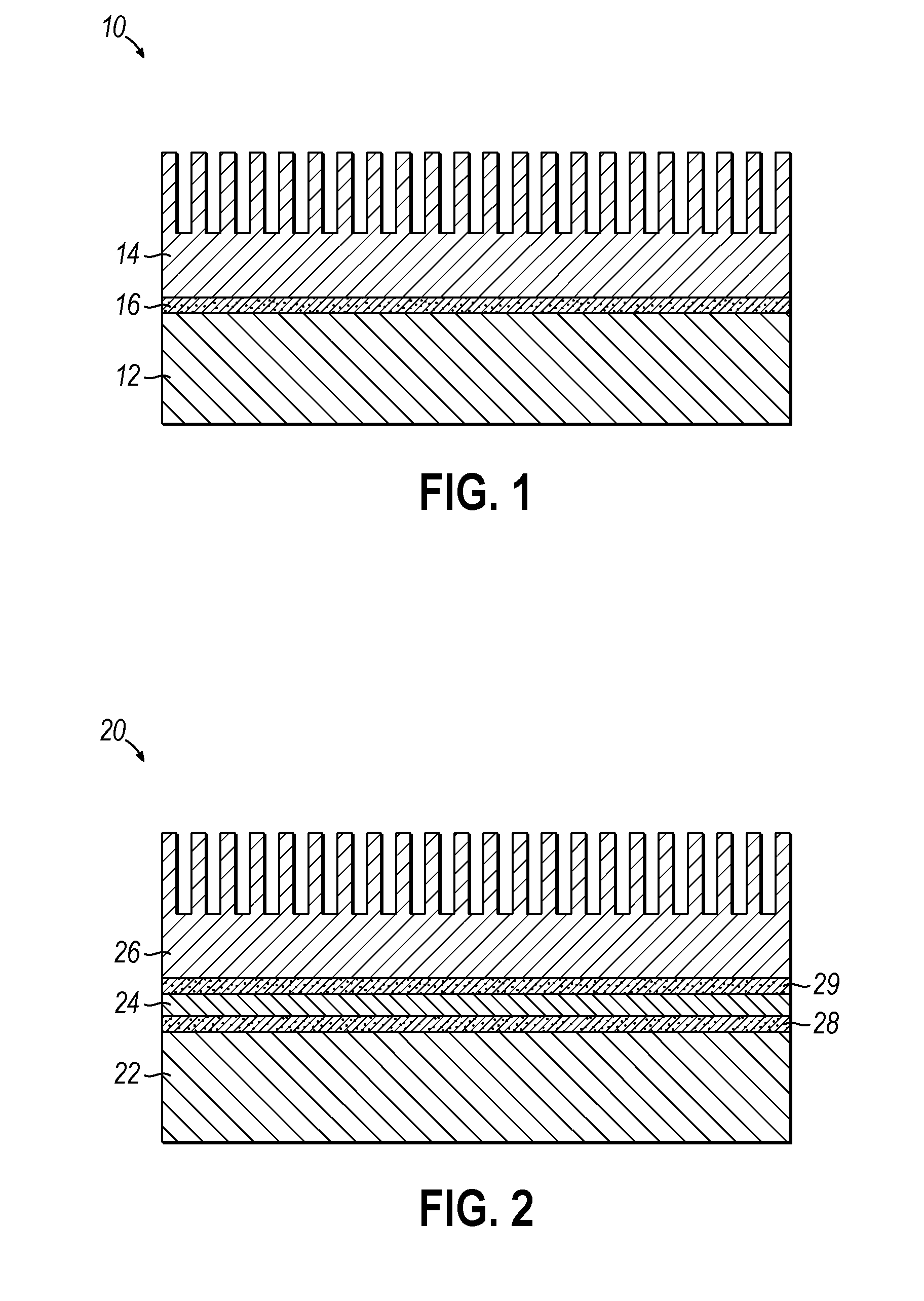

Substrate layer adapted to carry sensors, actuators or electrical components

ActiveUS20110069459A1Improve throughputImprove reliabilityThermometer detailsPrinted circuit assemblingEngineeringActuator

This invention relates to a substrate layer structure adapted to carry electronic device, or components, or electro-mechanical, or electro-chemical sensors, or a combination thereof, and adapted to be attached to a surface of a human or animal body or biological species. The surface of the flexible substrate layer structure is a patterned structure of pre-fixed geometry-formed by one or more slits, but this geometry being selected such that the stretchability of the substrate layer structure becomes adapted to the geometry of the body surface under it.

Owner:KONINK PHILIPS ELECTRONICS NV

Production of silver sulfate grains using inorganic additives

ActiveUS20080241511A1Reduce cakingReadily dispersed dryCosmetic preparationsLayered productsInorganic sulfateIon

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble inorganic additive compound containing a cation capable of forming a sulfate salt that is less soluble than silver sulfate or a halide anion or an oxyanion capable of forming a silver salt that is less soluble than silver sulfate, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain-size of less than 70 micrometers.

Owner:EASTMAN KODAK CO

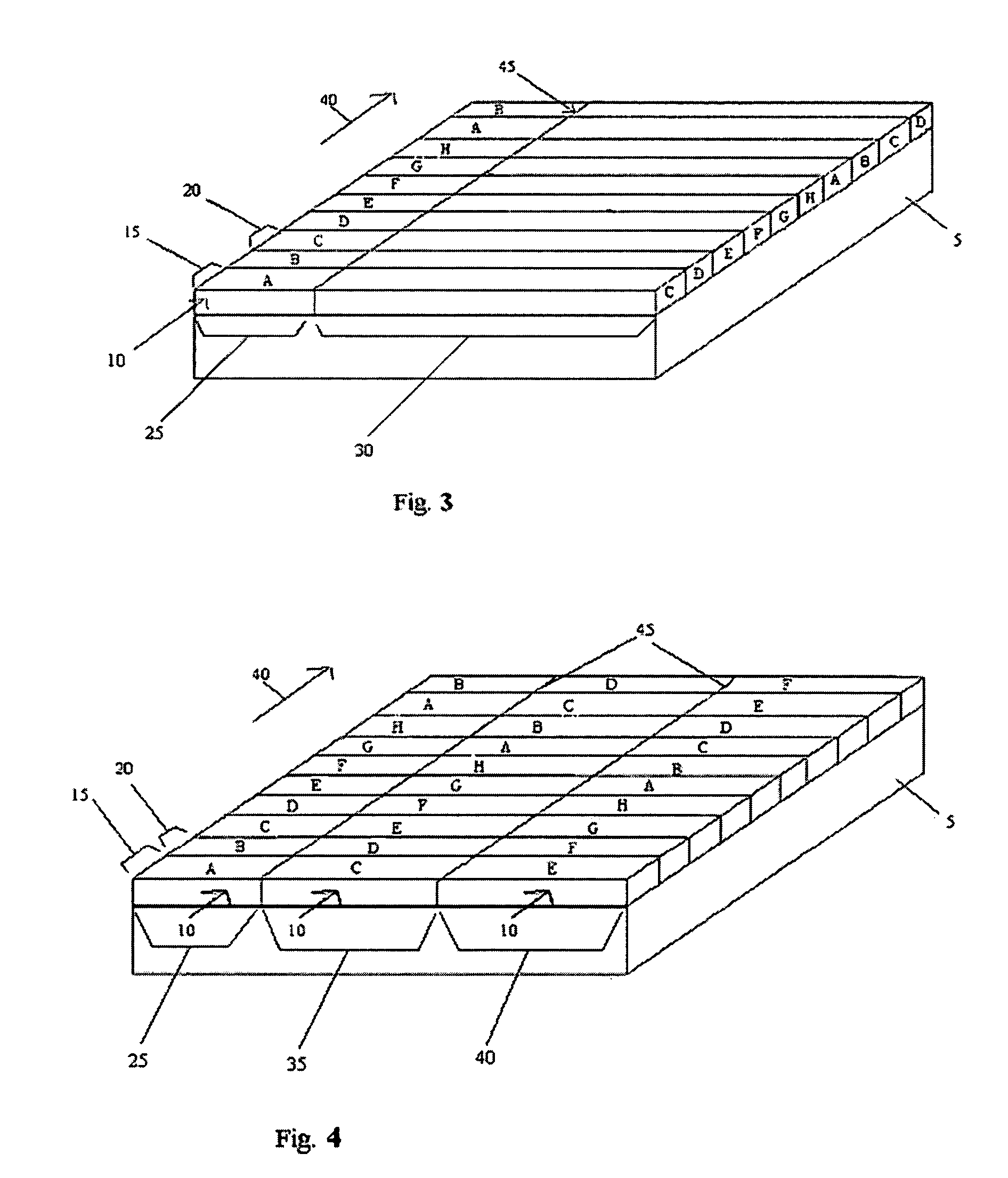

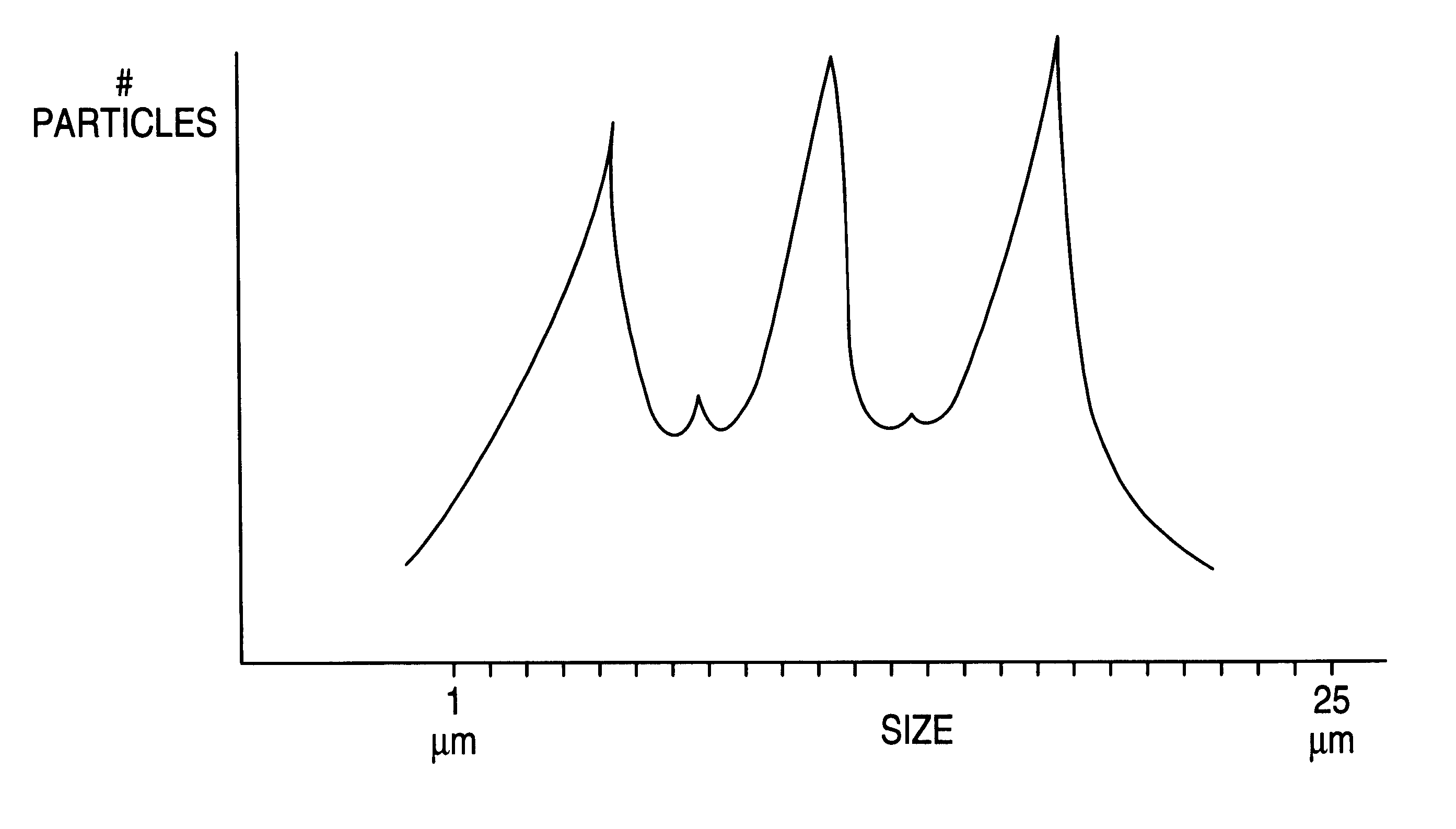

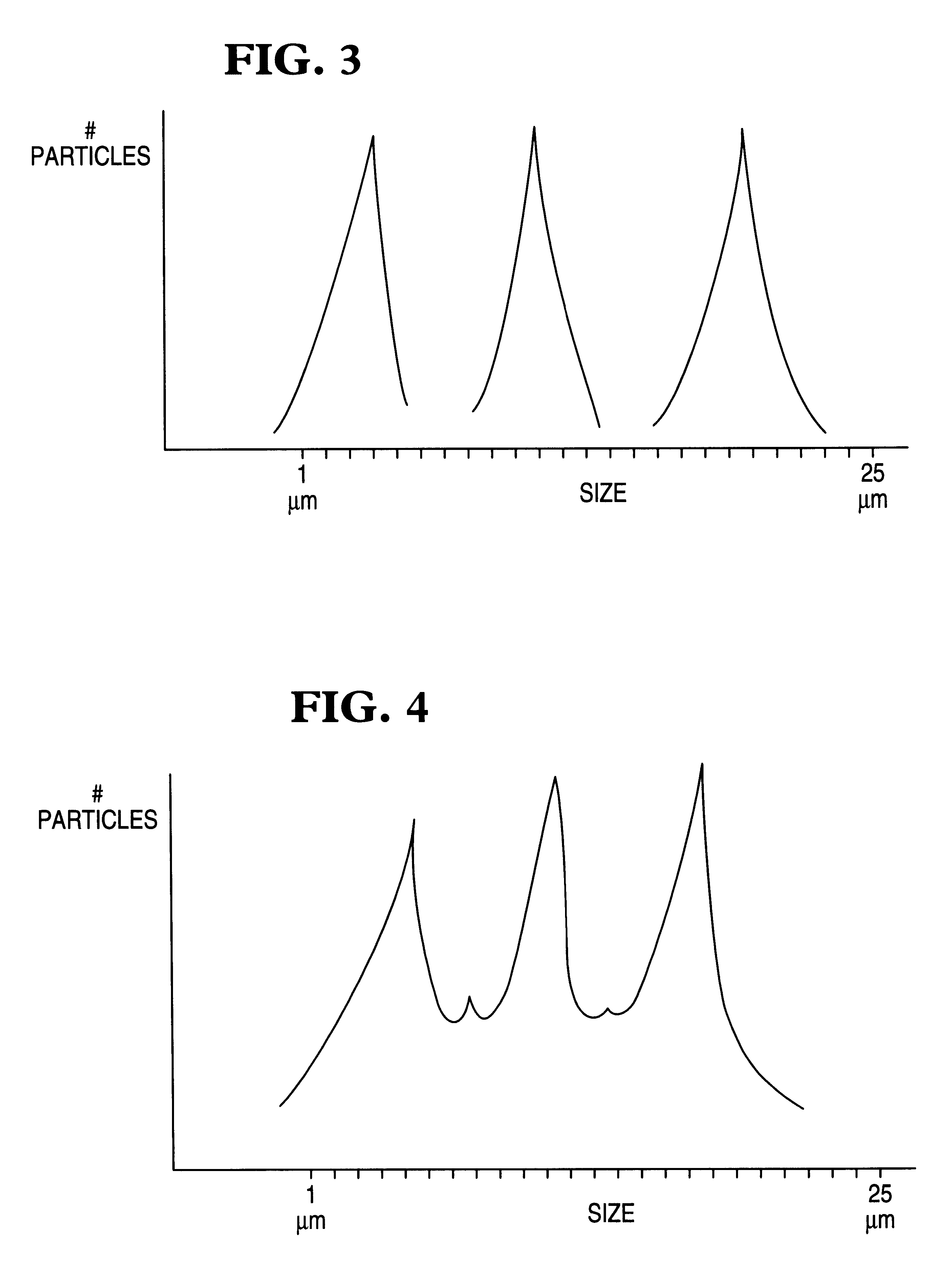

Thermal transfer media with a mixture of non-melting solid particles of distinct sizes

InactiveUS6171690B1Maintaining and reducing melt viscosityHigh densityLayered productsDomestic articlesHigh densitySolid particle

Owner:ICONEX LLC

Multi additive multifunctional composite for use in a non-metallic fuel conveyance system

A multifunctional composite material may include a polymer matrix, at least one nano-additive, micro-additive, and / or a spherical nano-additive. The non-metallic composite material may be used to make non-metallic parts for fuel conveyance systems for use in aircraft.

Owner:EATON INTELLIGENT POWER LTD

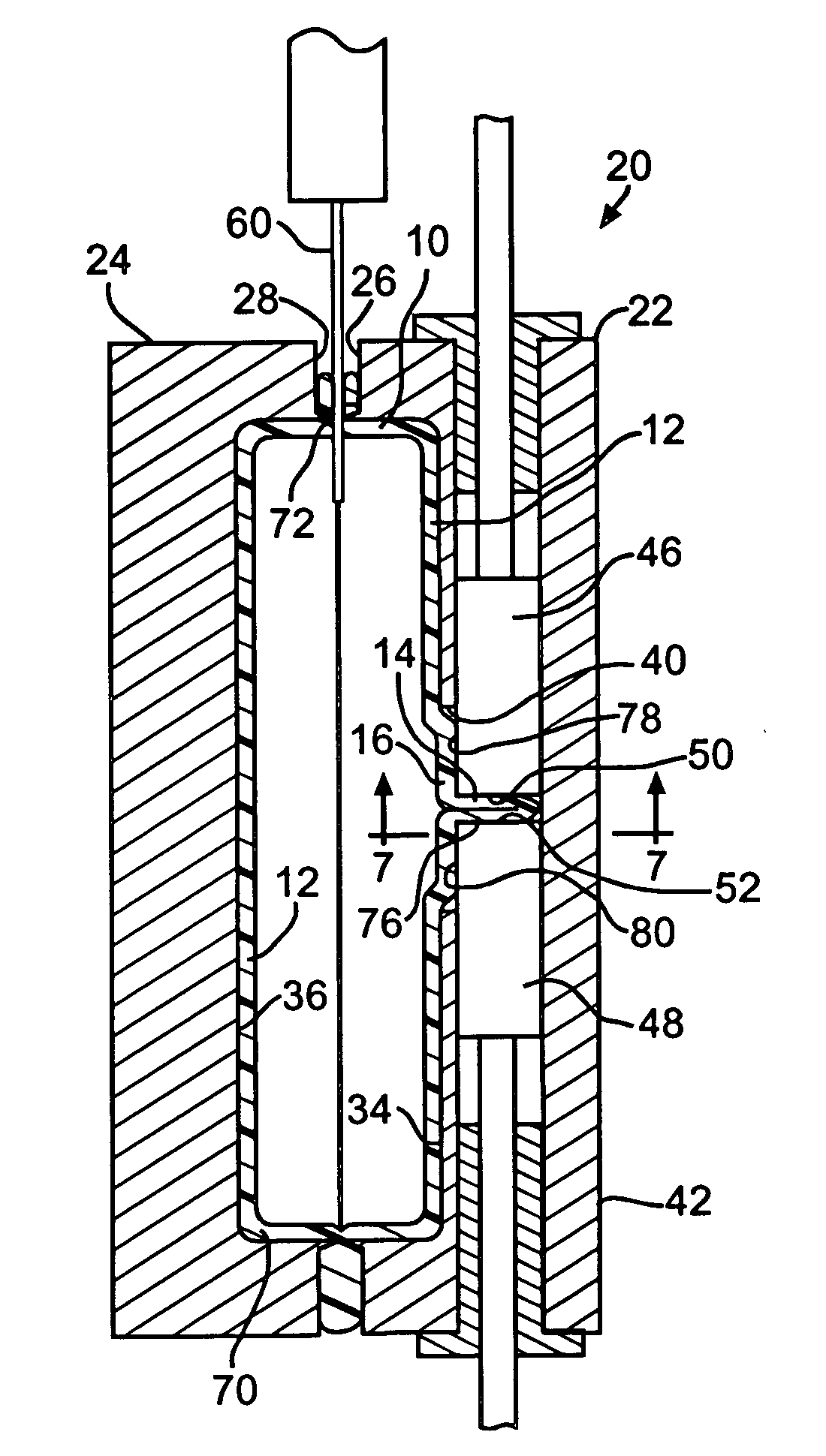

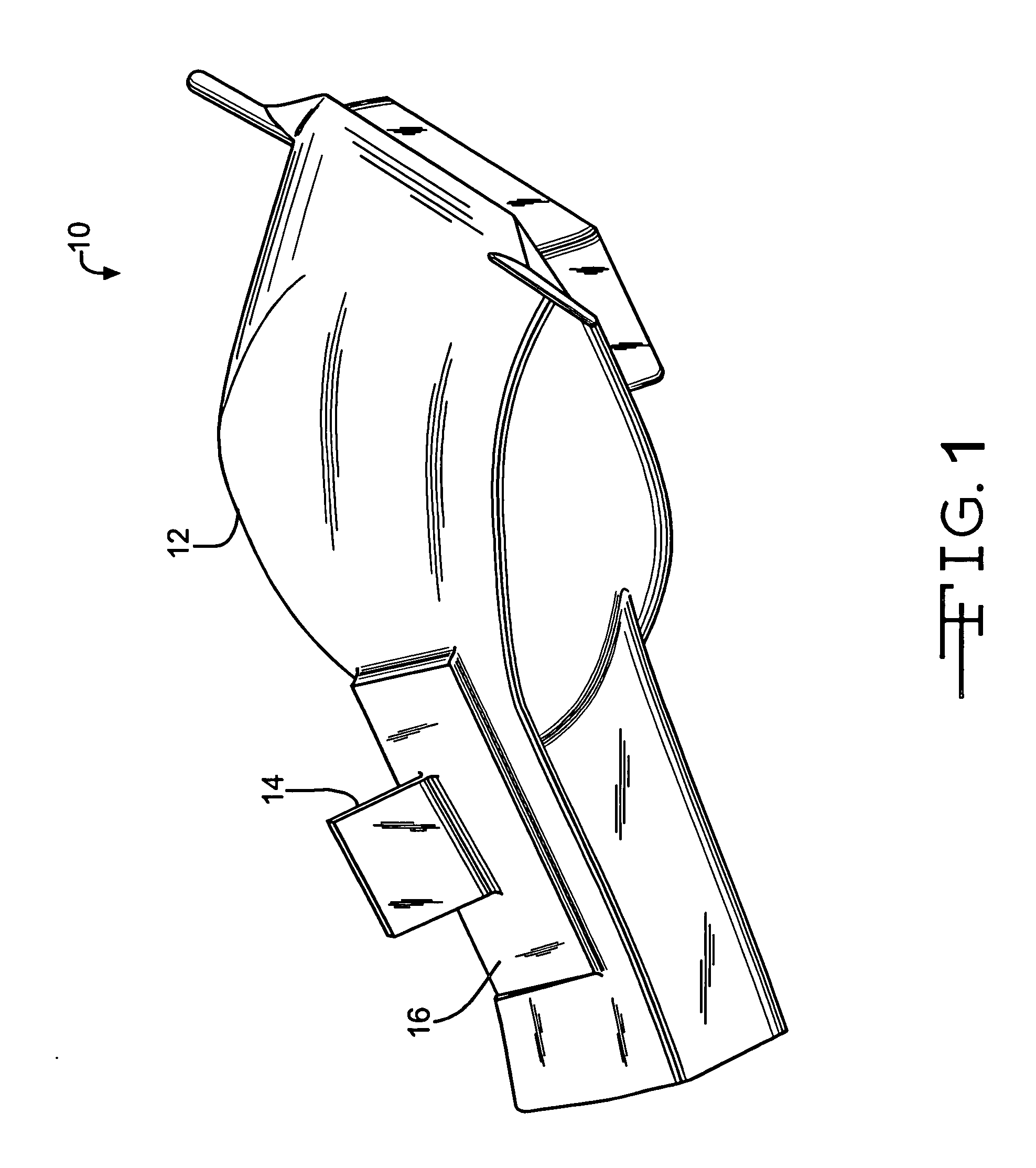

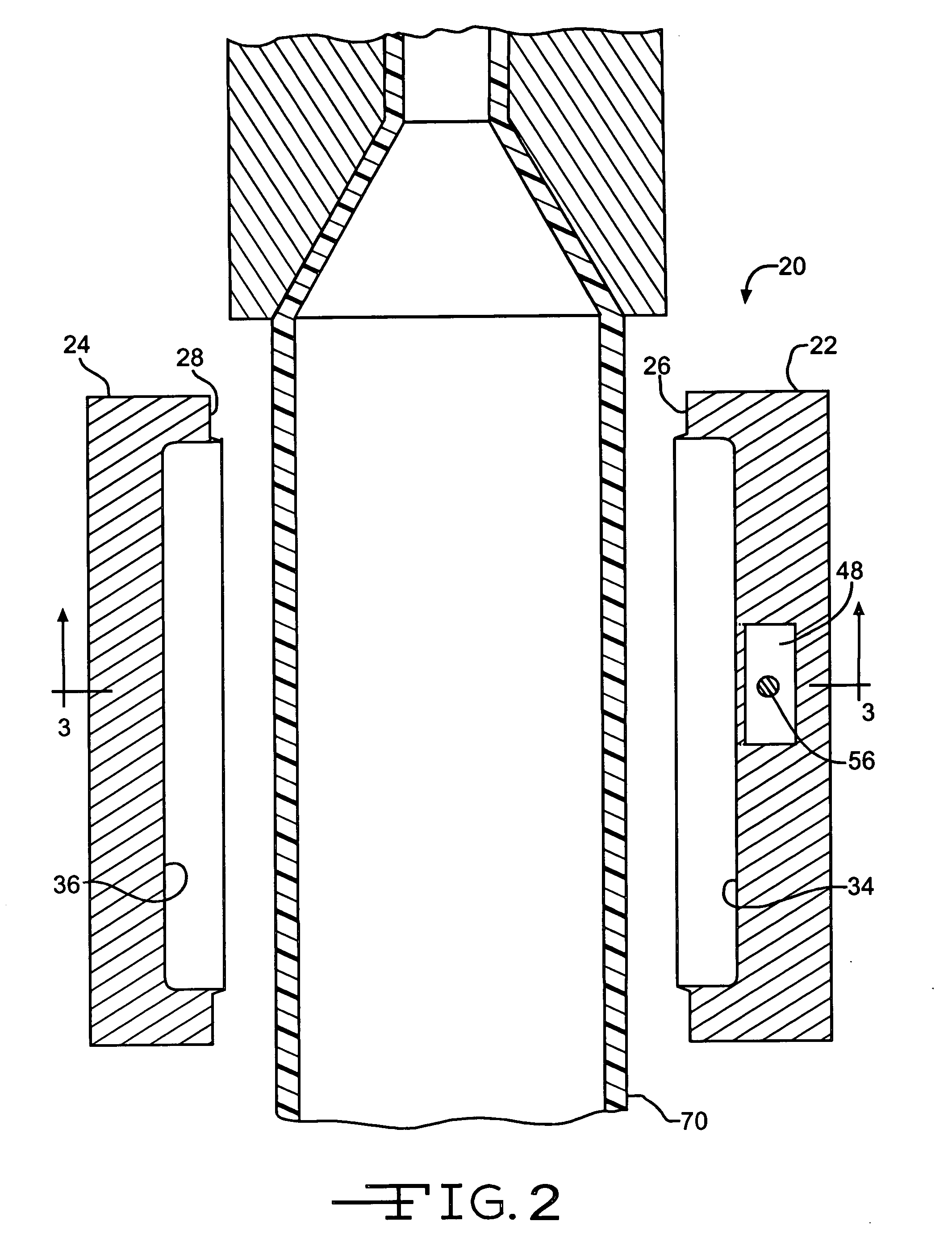

Process for forming a part having an integral feature, a part produced thereby and apparatus therefor

Owner:TOLEDO MOLDING & DIE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap