Reversibly adhesive thermal interface material

a technology of thermal interface material and adhesive, which is applied in the direction of electrical apparatus construction details, semiconductor/solid-state device details, transportation and packaging, etc., can solve the problems of voids at the interface, excessive heat generation during device operation, and degrade device performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

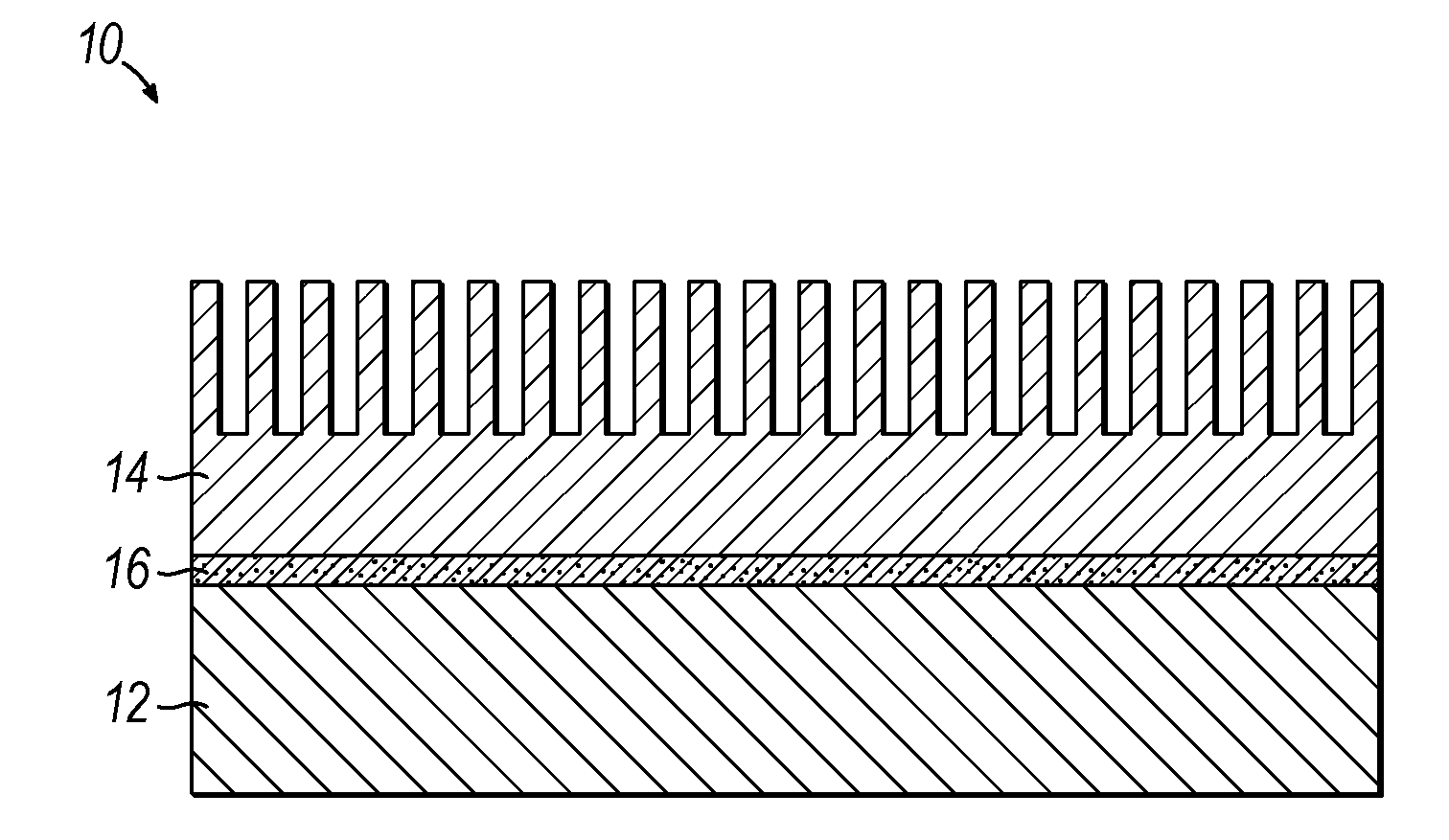

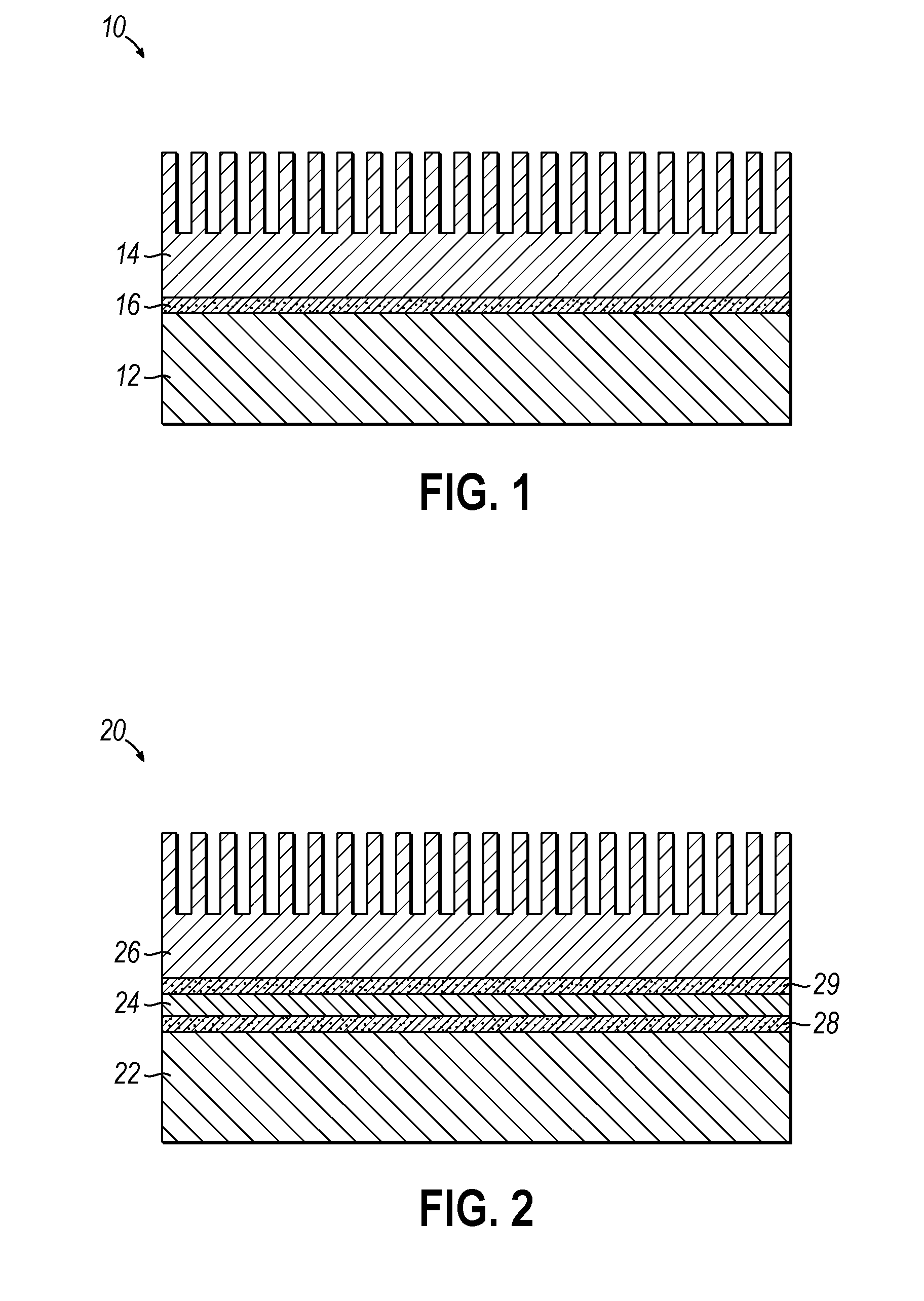

[0016]Embodiments of the present invention relate to an electronic assembly that includes a first element configured to generate heat during operation, a second element configured to transfer away the heat generated by the first element; and a layer of a thermal interface material situated between the first element and the second element. As shown in FIG. 1, an electronic chip module 10 includes an electronic chip 12, a heat sink 14, and a layer of thermal interface material 16 situated between and in intimate contact with both the electronic chip 12 and the heat sink 14. The configuration represented in FIG. 1 is known in the art as TIM 1. With reference to FIG. 2, another configuration for an electronic chip module 20 includes an electronic chip 22, a heat spreader 24, and a heat sink 26. A first layer of thermal interface material 28 is situated between and in intimate contact with both the electronic chip 22 and the heat spreader 24, and a second layer of thermal interface material

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap