Leak proof self securing container from single sheet

a self-sealing, container technology, applied in special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of lack of additional wall strength, lack of lateral sidewall stability, prior art did not disclose the option of manufacturers or users using elastic cords, etc., to achieve convenient assembly, cost-effective manufacturing, and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

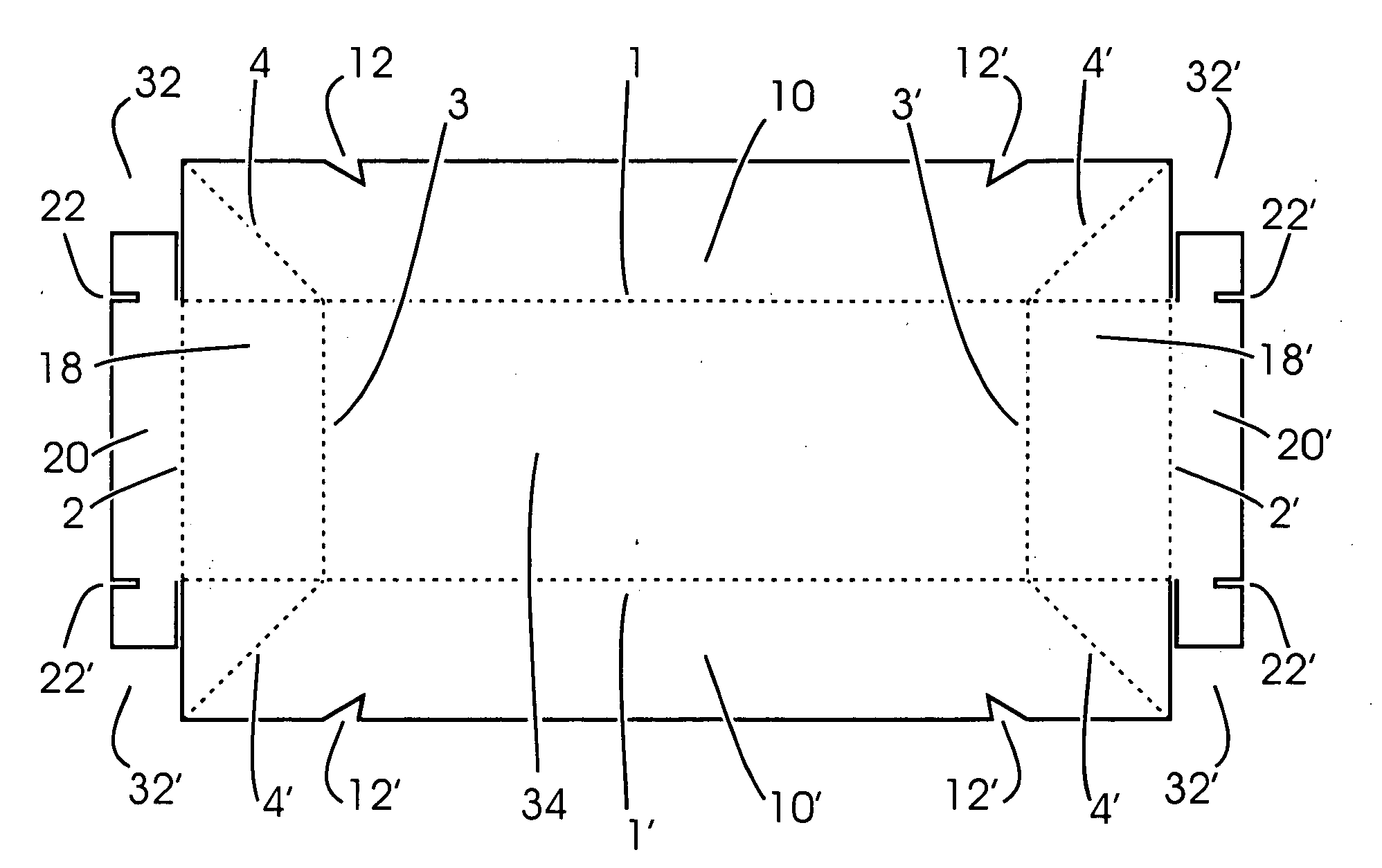

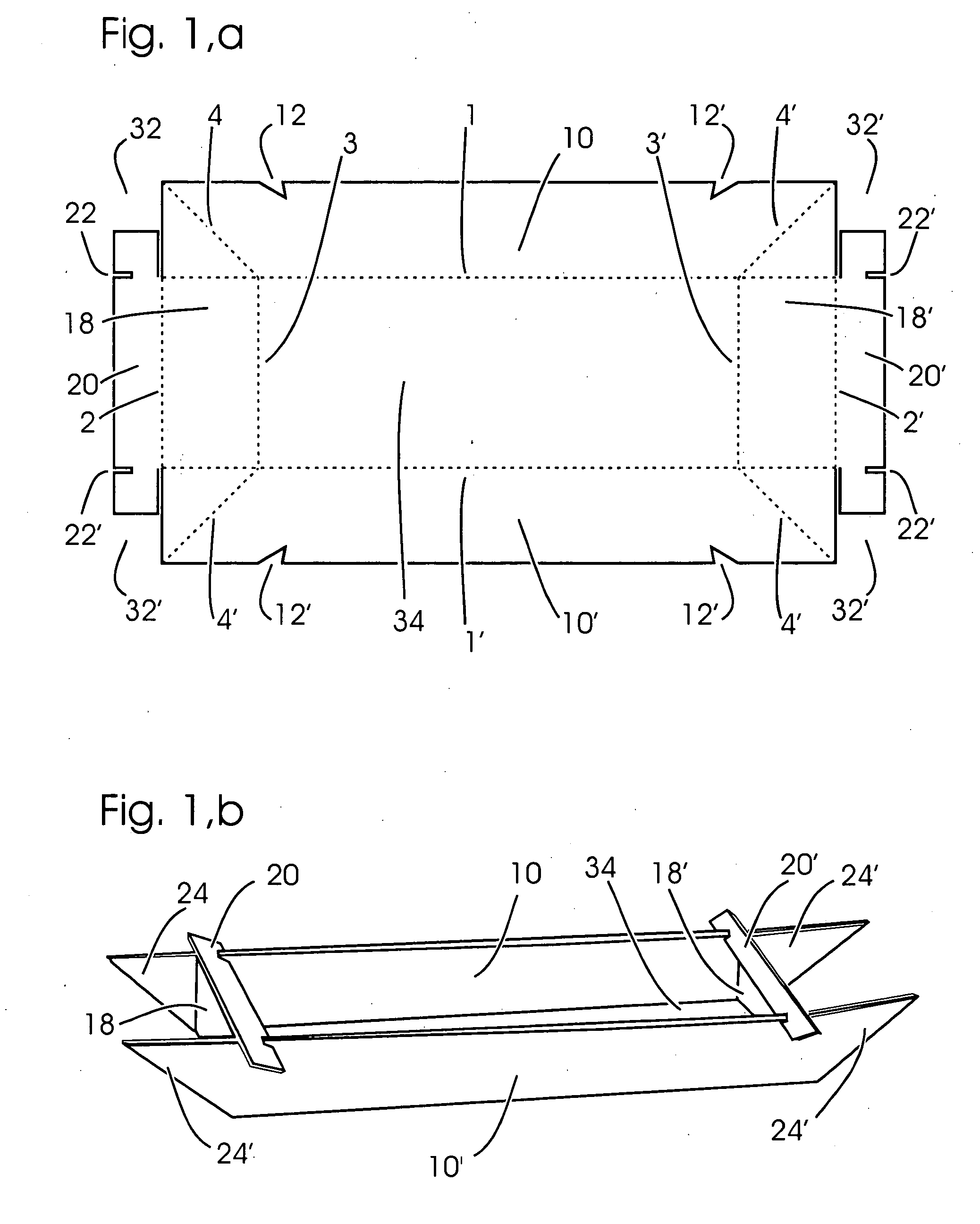

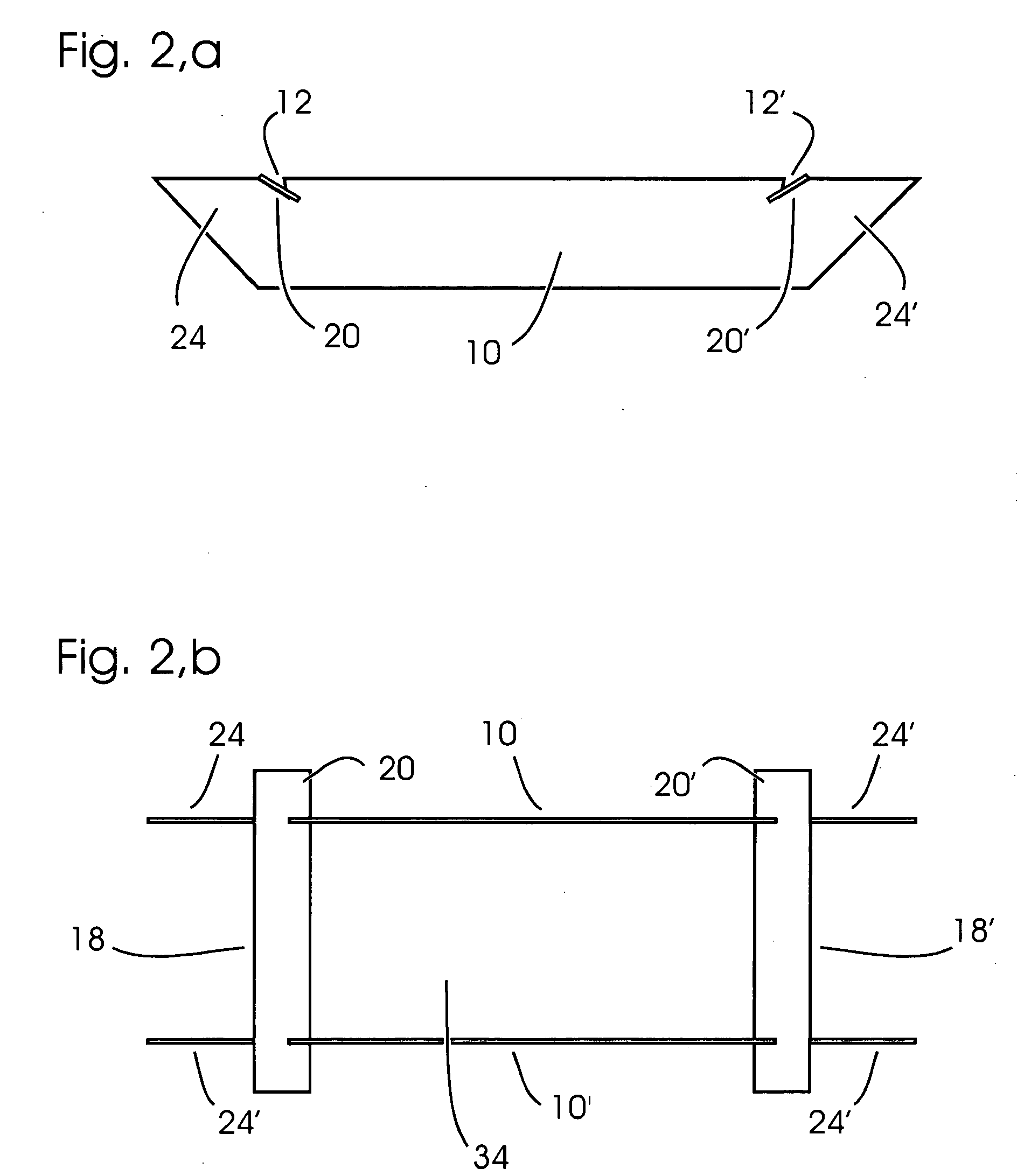

[0186]Shown in FIG. 1,a; is a plan view of the preferred embodiment in a flat and unassembled state, and comprising a plurality of bend lines with the substrates interior portion, and notched or cut away areas (32) within the perimeter edges of the body. A first portions of bend lines (1) parallel the substrate's longest length, and are spaced inwardly to determine a side walls height. A second portions of bend lines (2) parallel the substrate's shortest length and are distanced inwardly from the substrates perimeter edge to define two interlocking flaps (20) which are hingedly connected to the end walls (18). A third portions of bend lines (3) define the end walls (18) height and are parallel with and located further inwardly than the second portions (2) to perpendicularly nearly abut or abut to conjoin the first portions (1). A fourth portions of bend lines (4) extend inwardly and angularly from approximate corner areas to locations where the first (1) and third portions (3) nearly a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap