Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1221 results about "Structural engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural engineering is a sub-discipline of civil engineering in which structural engineers are trained to design the 'bones and muscles' that create the form and shape of man made structures. Structural engineers need to understand and calculate the stability, strength and rigidity of built structures for buildings and nonbuilding structures. The structural designs are integrated with those of other designers such as architects and building services engineer and often supervise the construction of projects by contractors on site. They can also be involved in the design of machinery, medical equipment, and vehicles where structural integrity affects functioning and safety. See glossary of structural engineering.

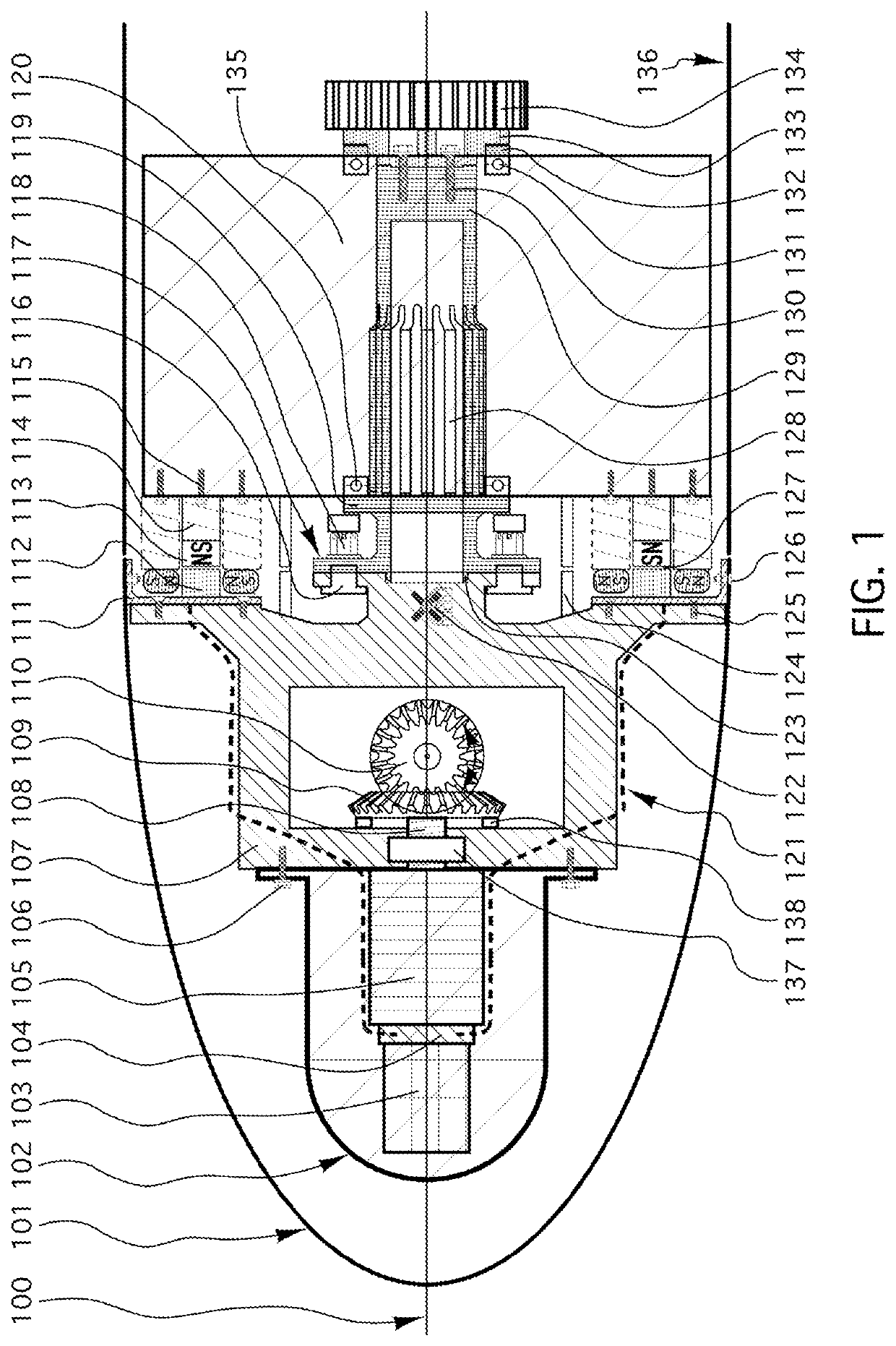

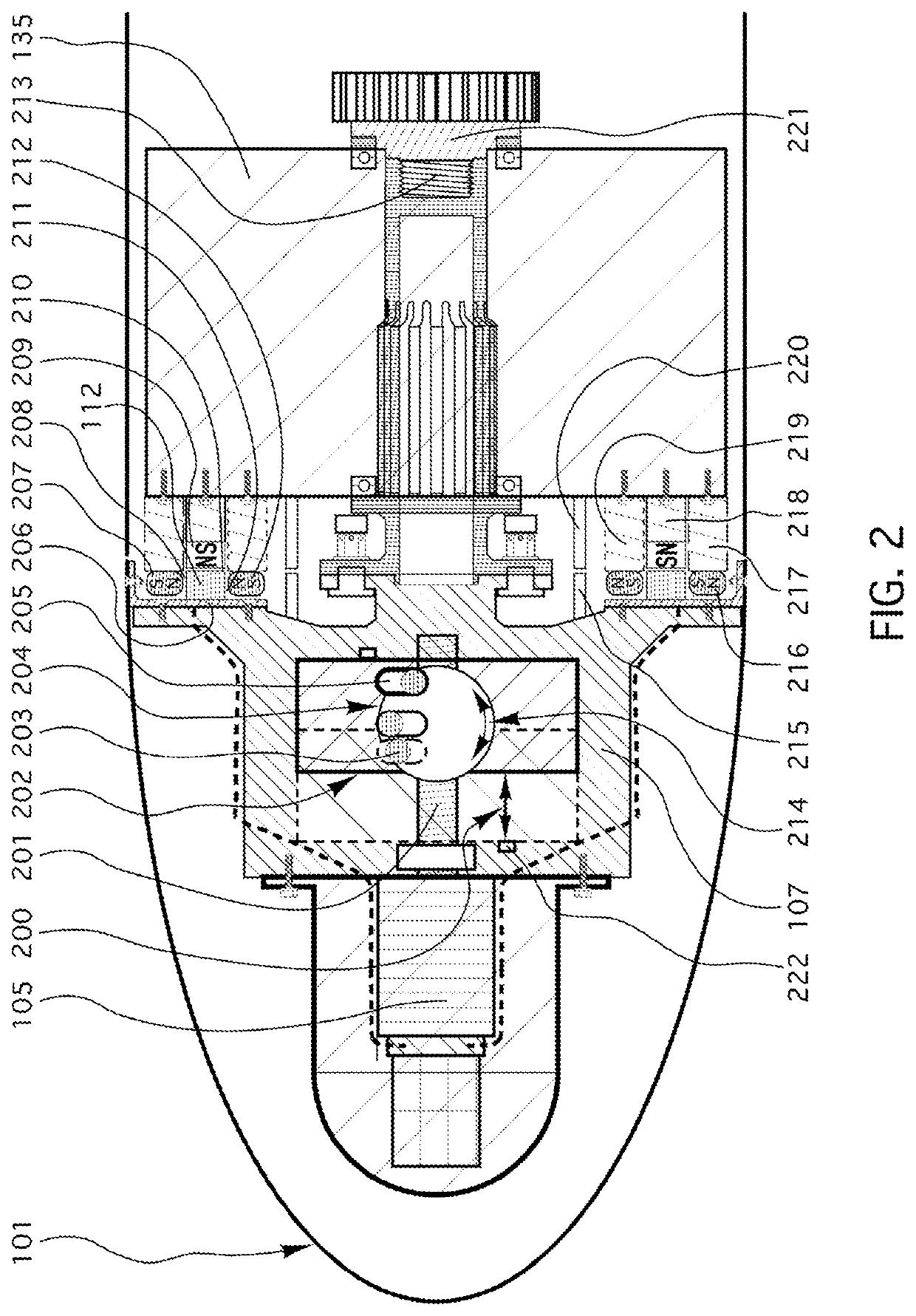

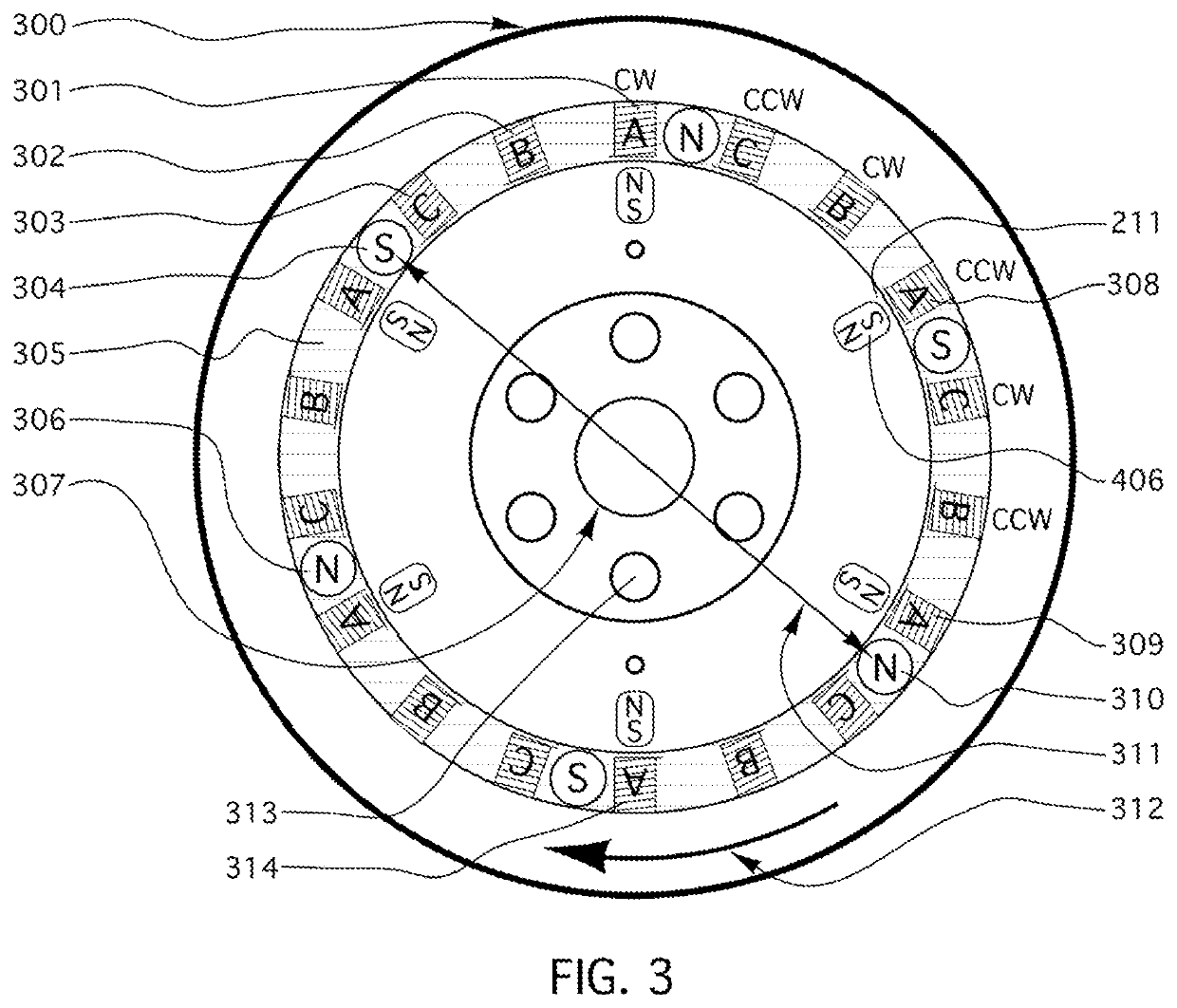

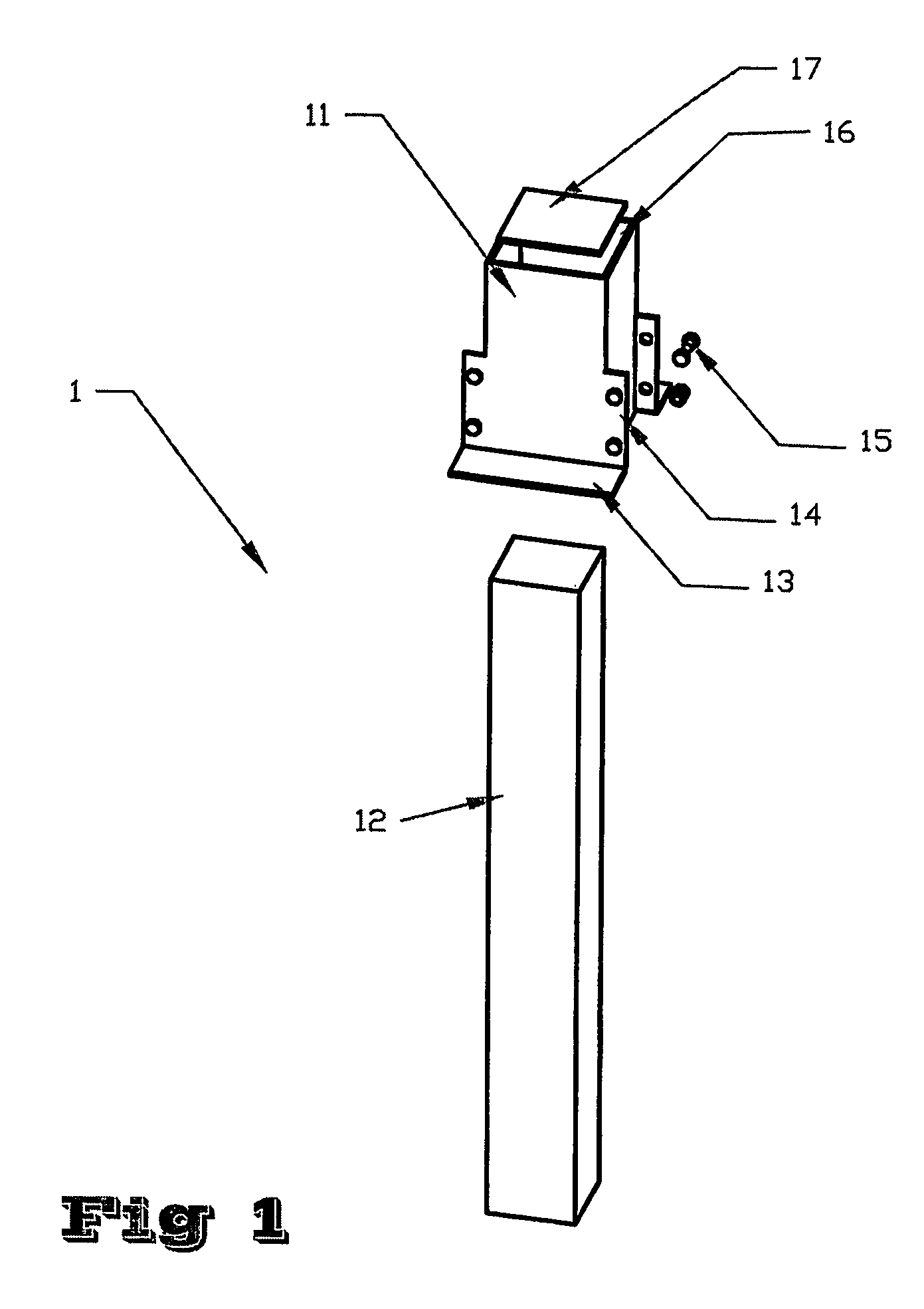

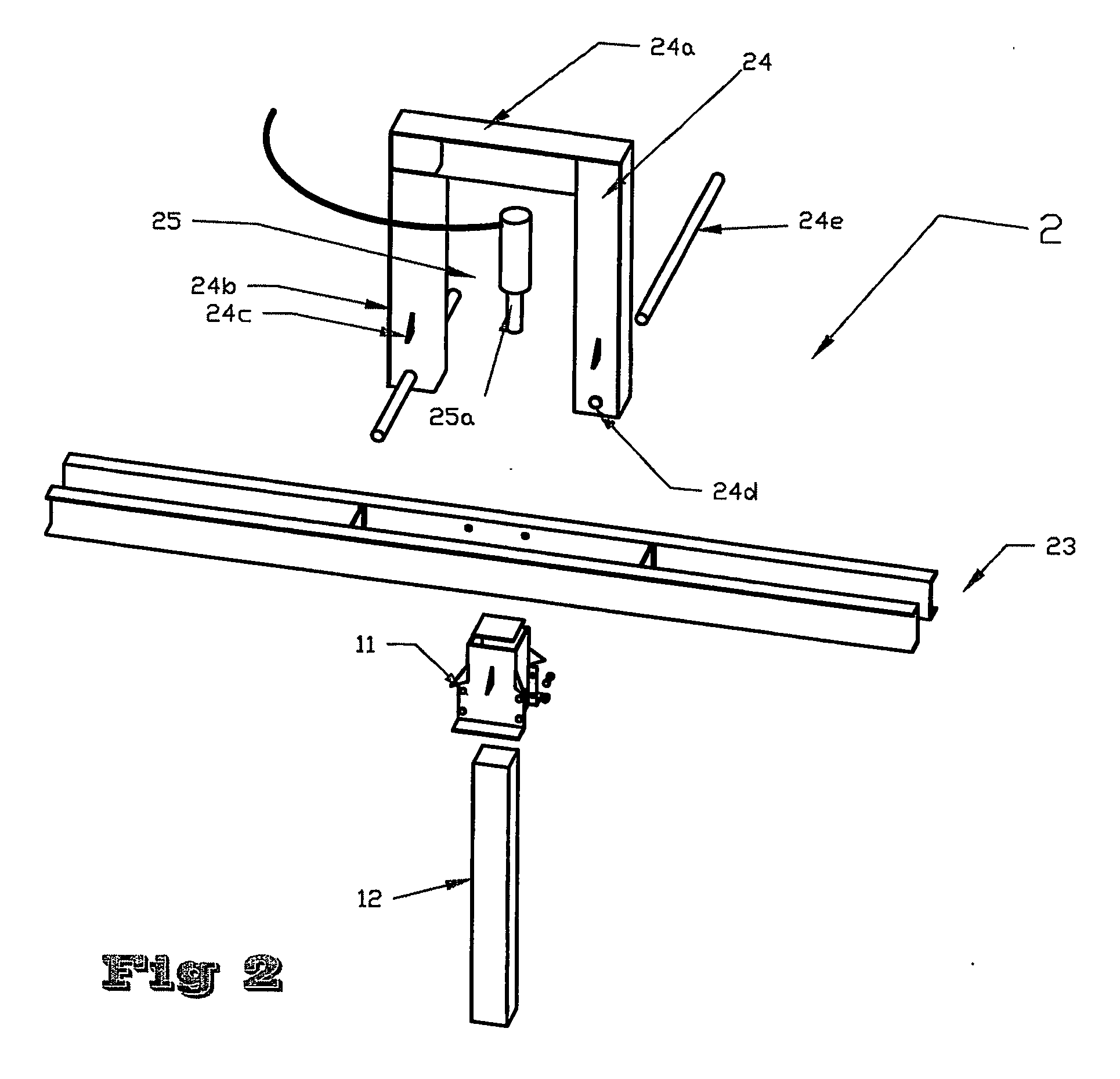

Electric, inductively-energized controllable-pitch propeller hub

ActiveUS11225318B1Quick installationQuick removalElectric power distributionPropellersElectrical batteryControl cell

Owner:SEELEY BRIEN AVEN

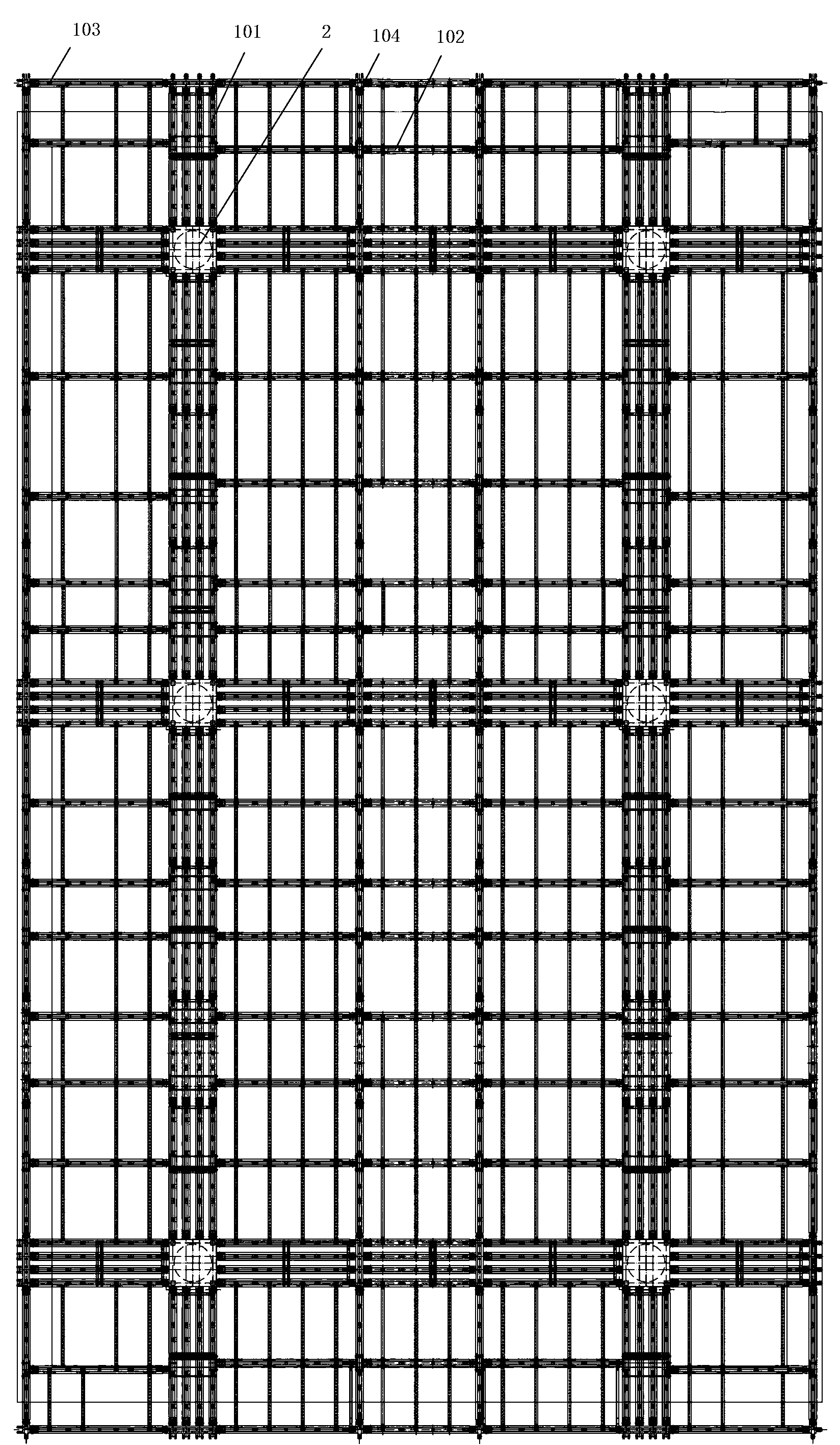

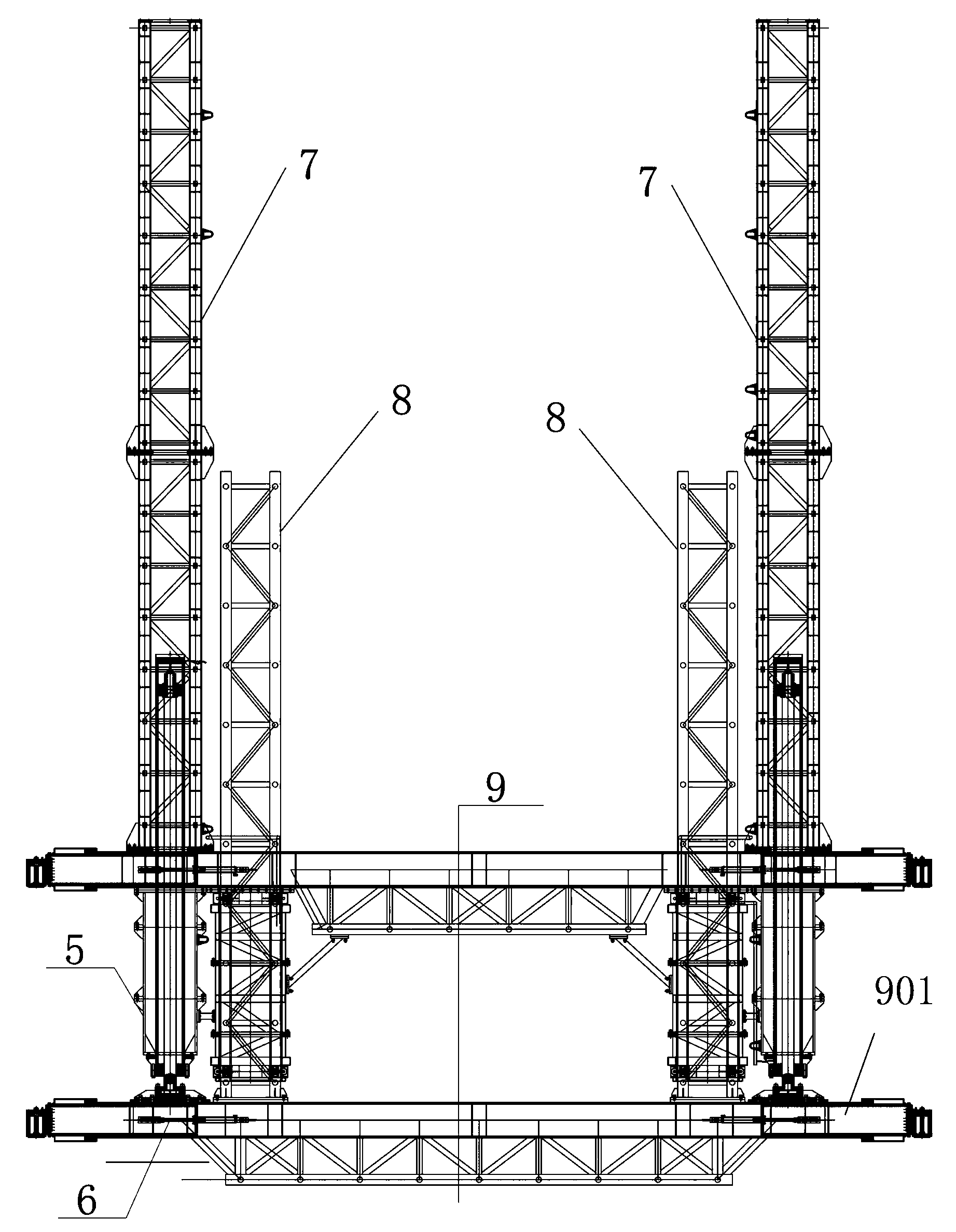

Automated warehouse system

ActiveUS20140212249A1Small footprintStorage devicesLoading/unloadingStructural engineeringStorage area

An automated warehouse system may require less space than conventional warehouse systems. The automated warehouse system is configured so that loads are stored in storage areas formed by vertically extending support pillars and horizontally extending beams. The loads are loaded into the storage areas, and the loads are unloaded from storage areas. The automated warehouse system comprises: vertical guide rails disposed on the support pillars; horizontal guide rails disposed on the beams; and a movable platform having a frame body and guide rollers, at least part of the frame body having the same rectangular shape as a shape of at least part of at least one of the storage areas and having vertical frame members and horizontal frame members, the guide rollers being disposed on the vertical frame members and engaging the vertical guide rails or disposed on the horizontal frame members and engaging the horizontal guide rails.

Owner:AMAZON TECH INC

Vehicular suspension arm

InactiveUS20090295113A1High strengthStrengthTractor-trailer combinationsResilient suspensionsSingle plateStructural engineering

A vehicular suspension arm is provided in which an arm main body (1) includes a main plate (2) press-formed as a main part of the arm main body and having a short cylindrical part (EB) provided integrally with one end by flanging, and a reinforcing plate (H) superimposed on one of upper and lower faces of the main plate (2) and reinforcing the main plate (2). The reinforcing plate (H) has an eye-shaped head part (Ha) formed in an annular shape and arranged coaxially with the short cylindrical part (EB), and a tail part (Hb) extending integrally from the eye-shaped head part (Ha) along the longitudinal direction of the main plate (2), is formed from a single plate material that is thicker than the main plate (2), and has at least the tail part (Hb) welded to the main plate (2). A bush press-fit portion (P1) is formed from an inner peripheral face of the eye-shaped head part (Ha) and an inner peripheral face of the short cylindrical part (EB). This ensures that the cross-sectional shape of a transition section from the bush press-fit portion to the plate-type arm main body is adequate, thus enabling the rigidity and strength required for the transition section to be easily guaranteed and, furthermore, it becomes possible to meet a requirement for increasing the strength of the arm without specially increasing the space around the outer periphery of the bush press-fit portion.

Owner:F TECH INC +1

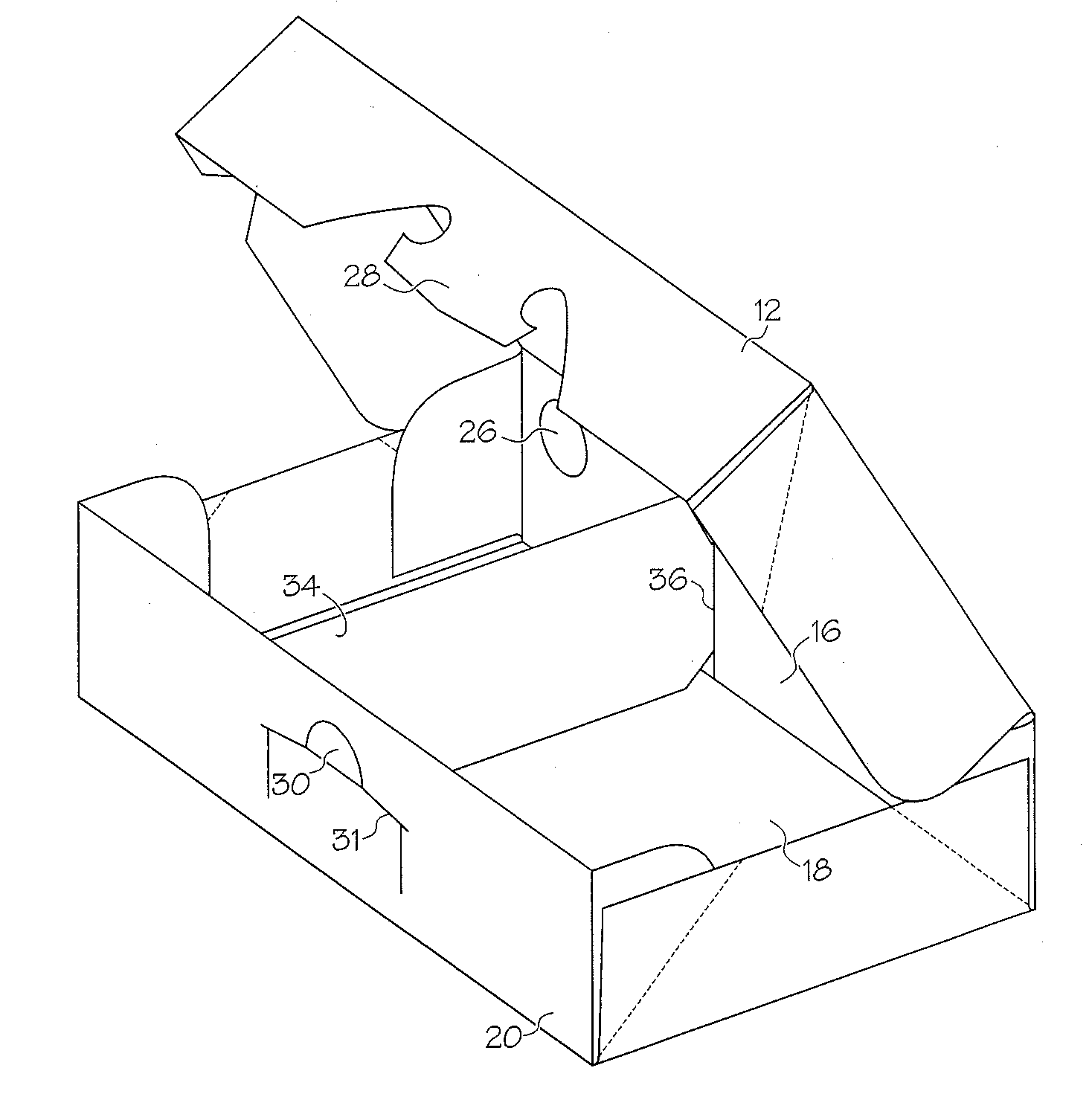

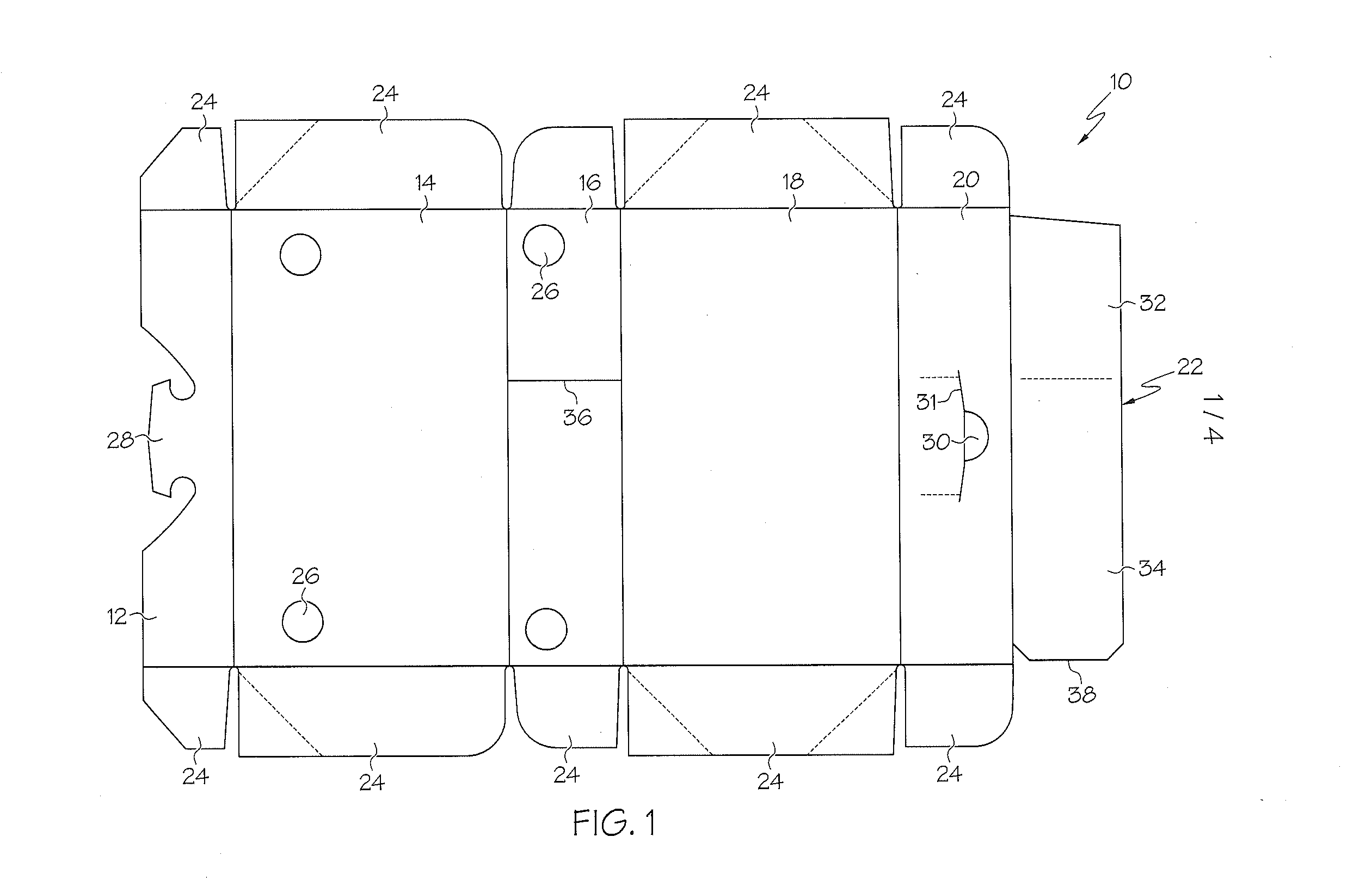

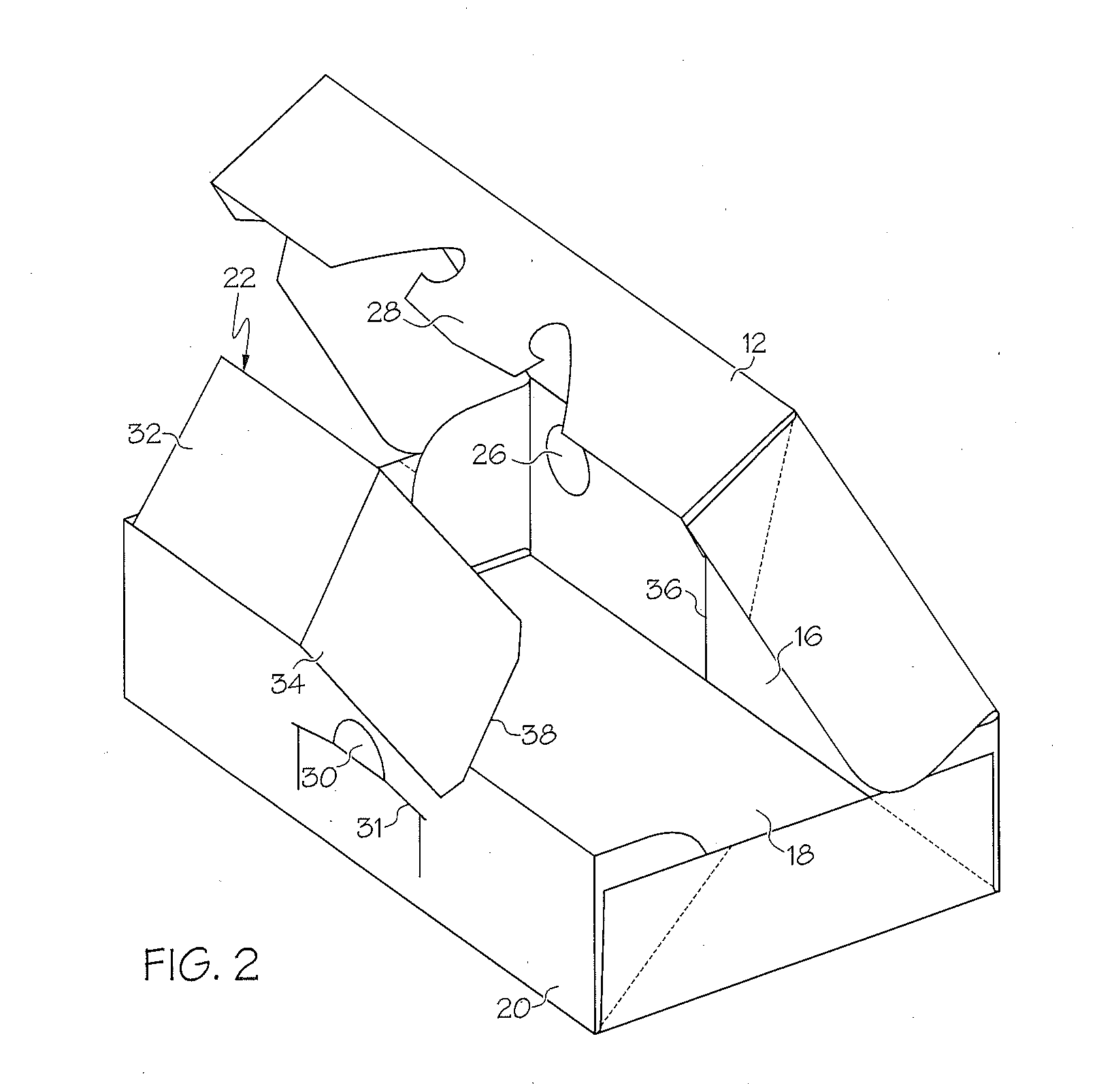

Carton with foldout partition

Owner:HUHTAMAKI INC

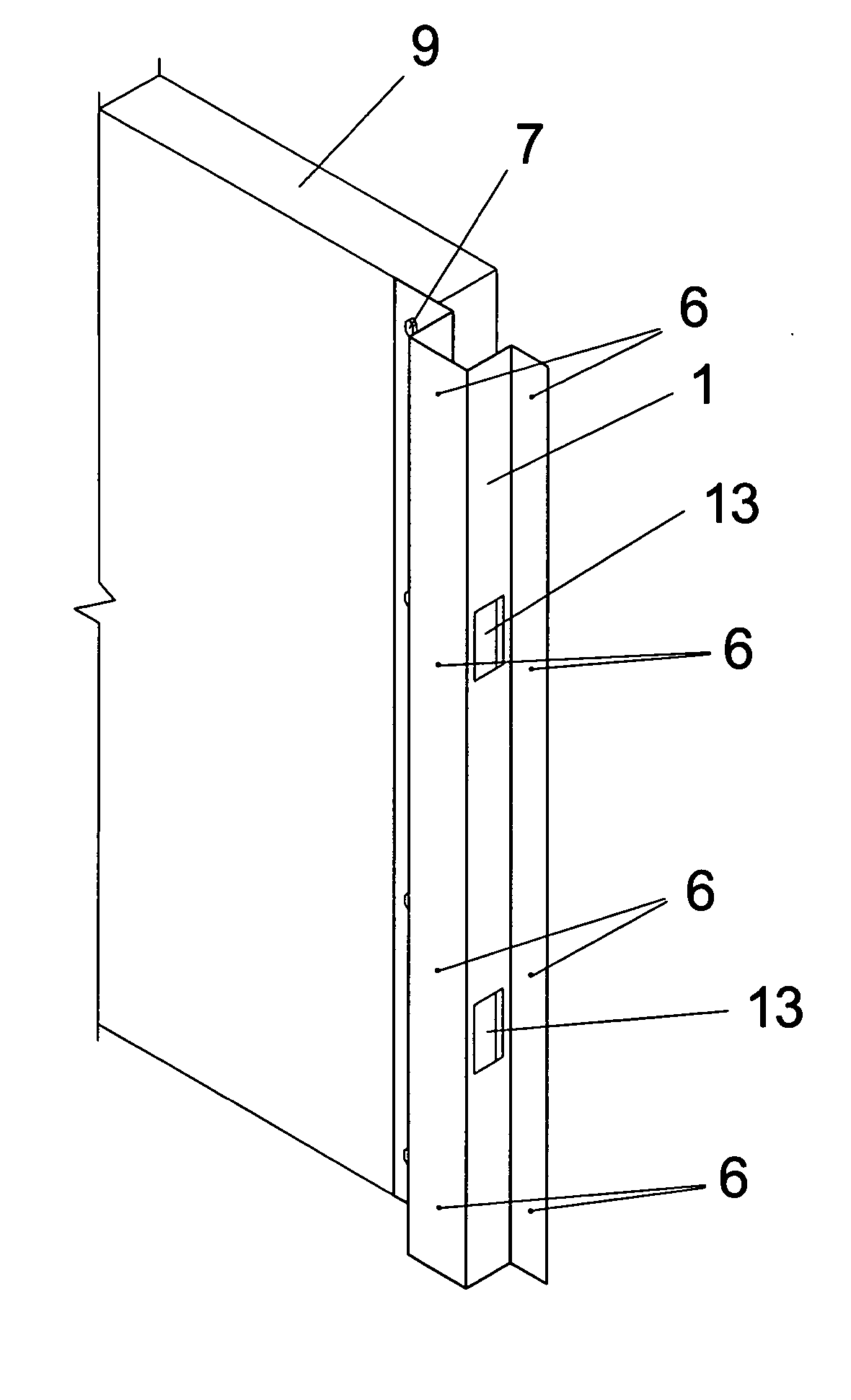

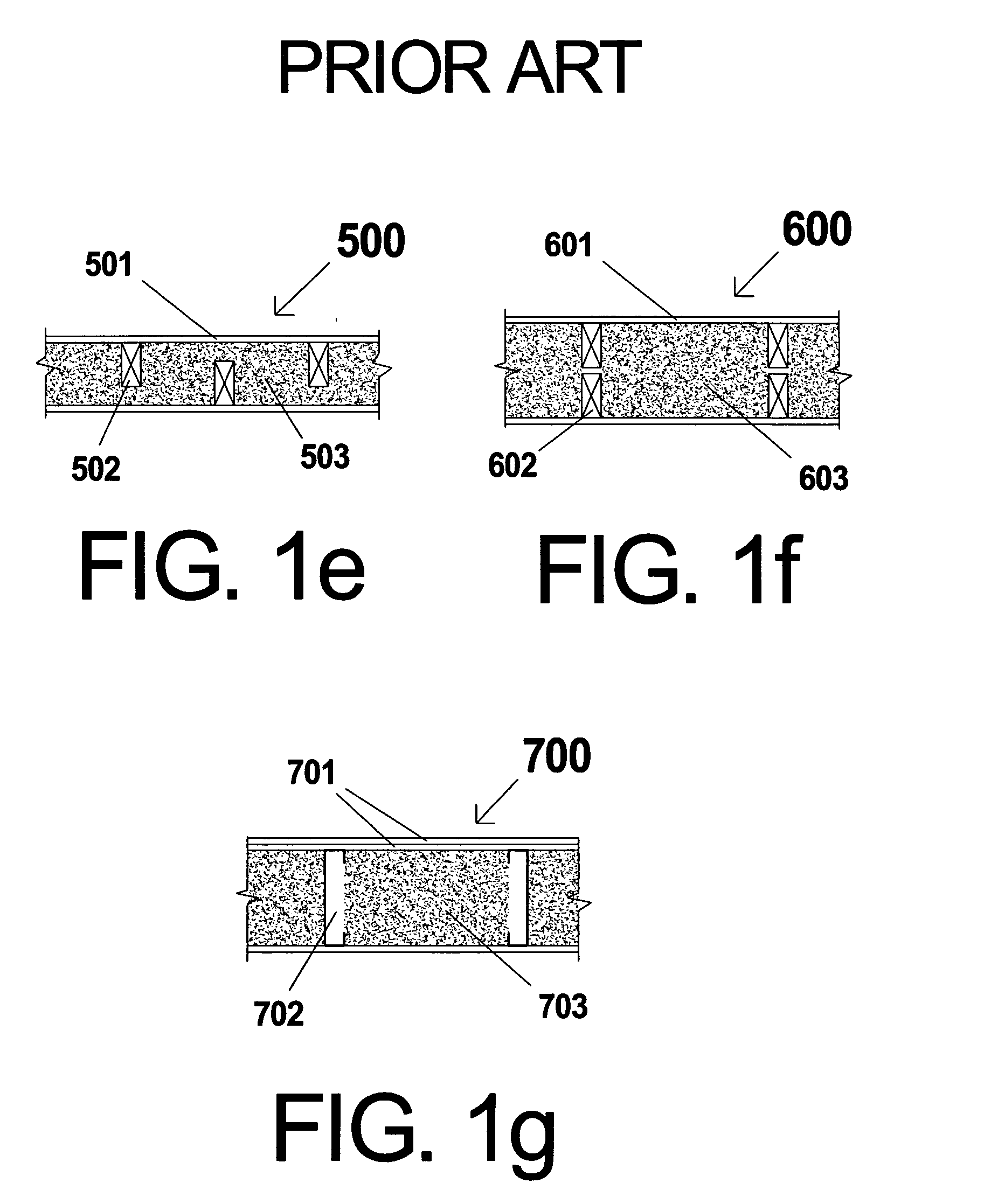

Wall and partition construction and method using hat-channel members

InactiveUS20050102969A1Easy re-routingLabor savingWallsElectrical apparatusTime efficientStructural engineering

Owner:STRAWMEN

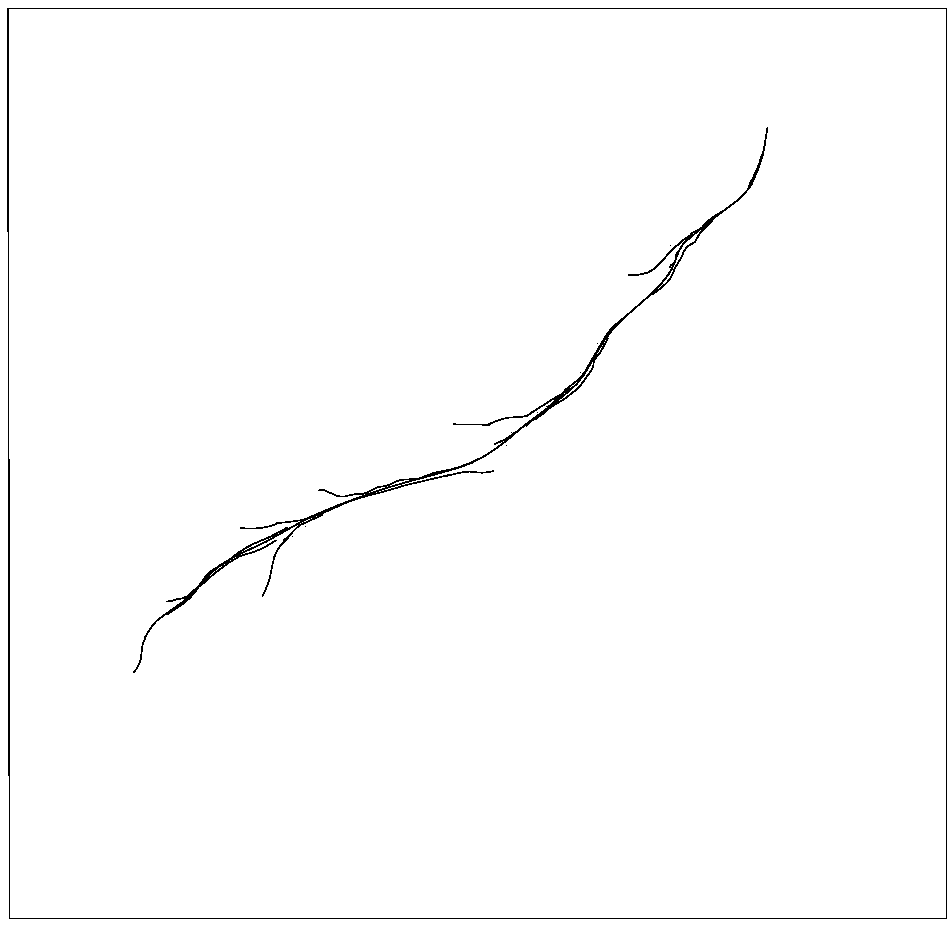

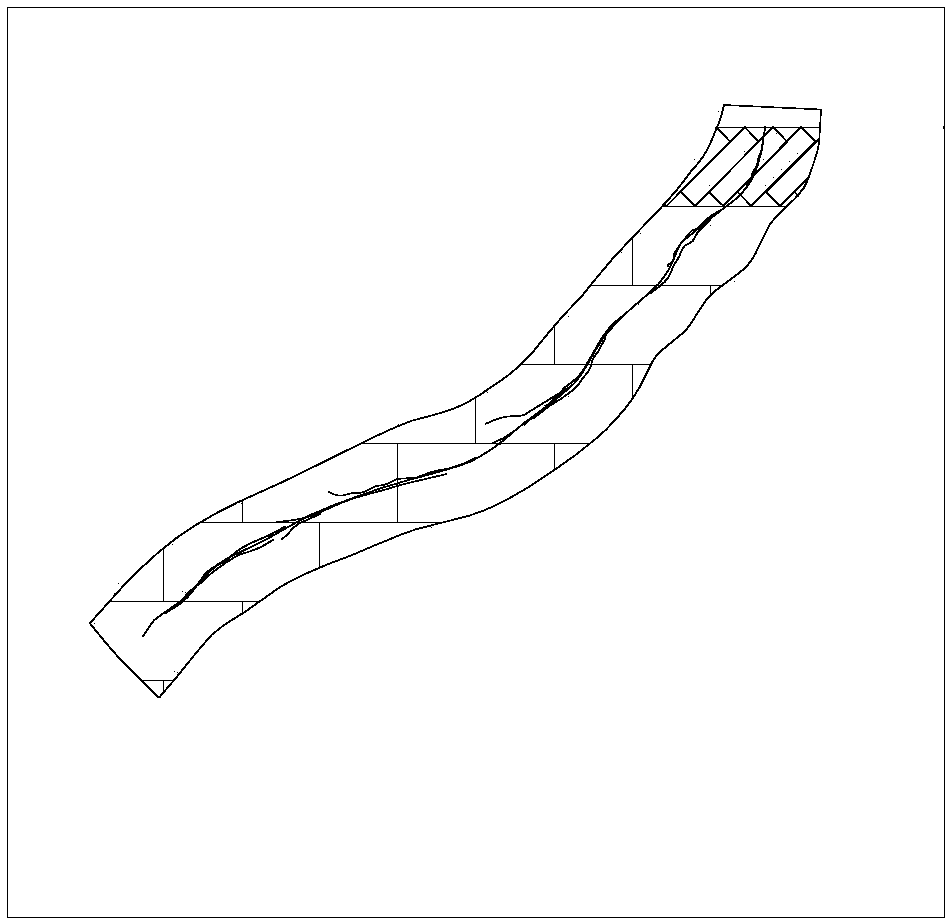

Detection device applied to bridge cracks

ActiveCN111007009ARealize no dead angle detectionReduce production and use costsOptically investigating flaws/contaminationEngineeringStructural engineering

Owner:济南工程职业技术学院

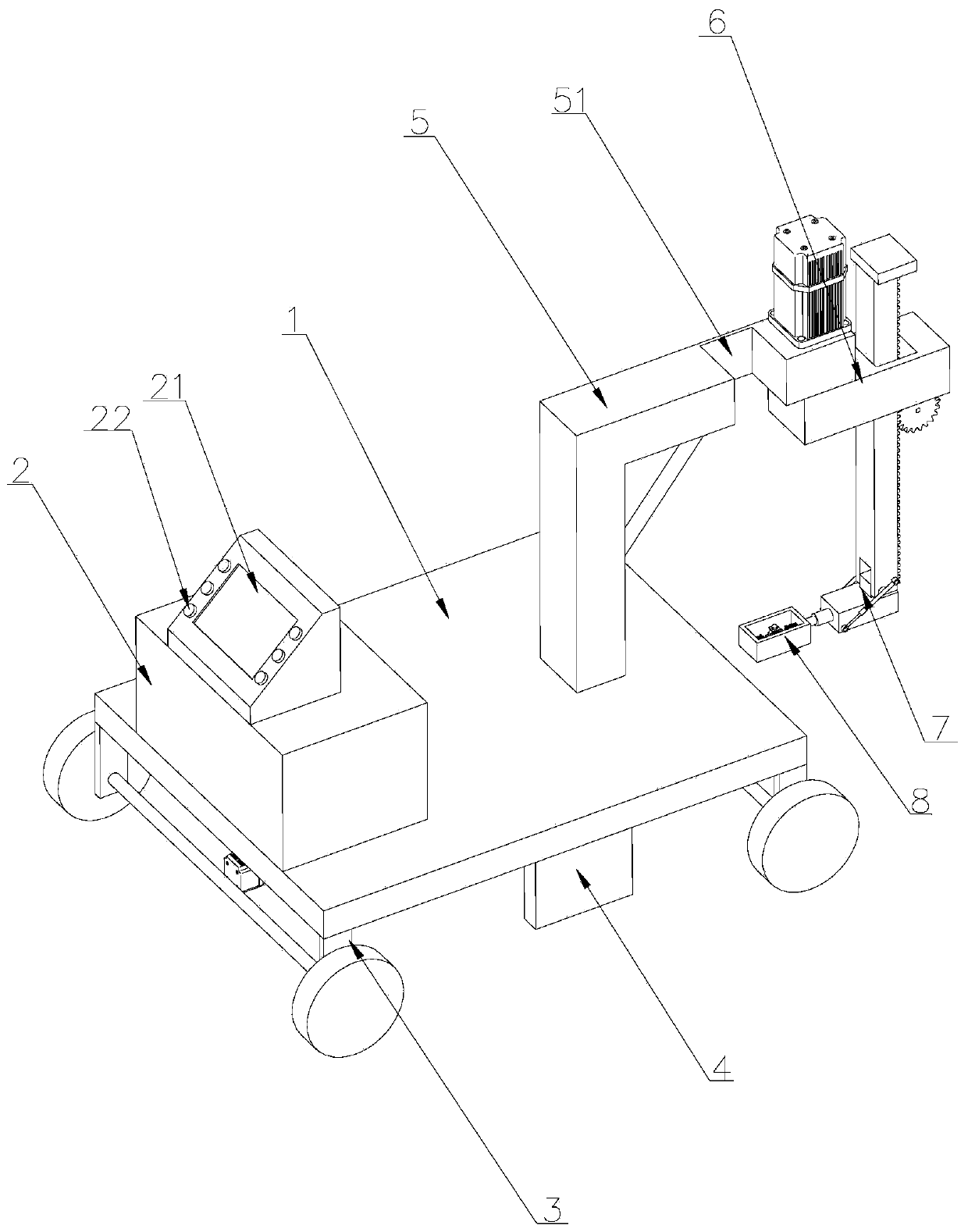

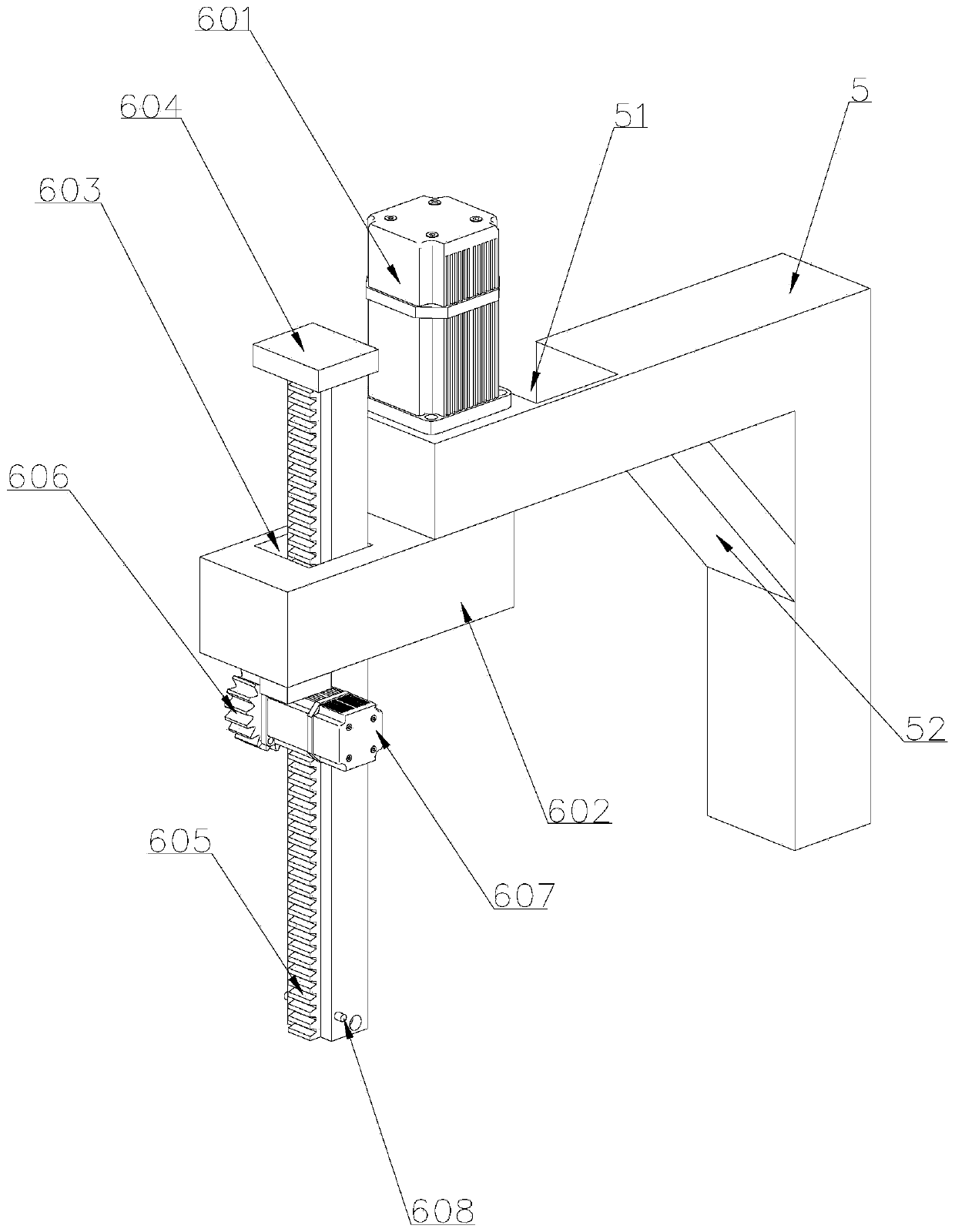

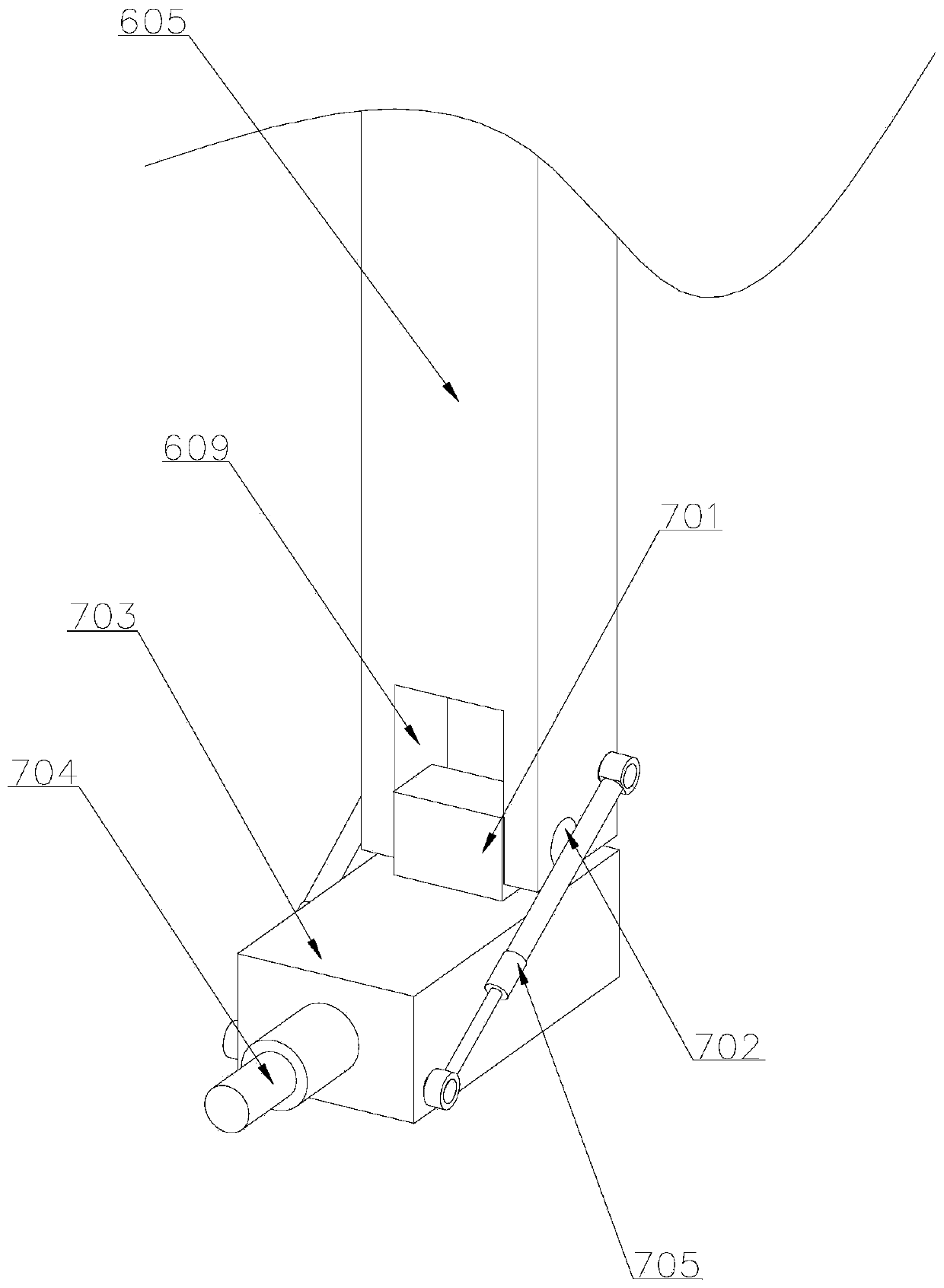

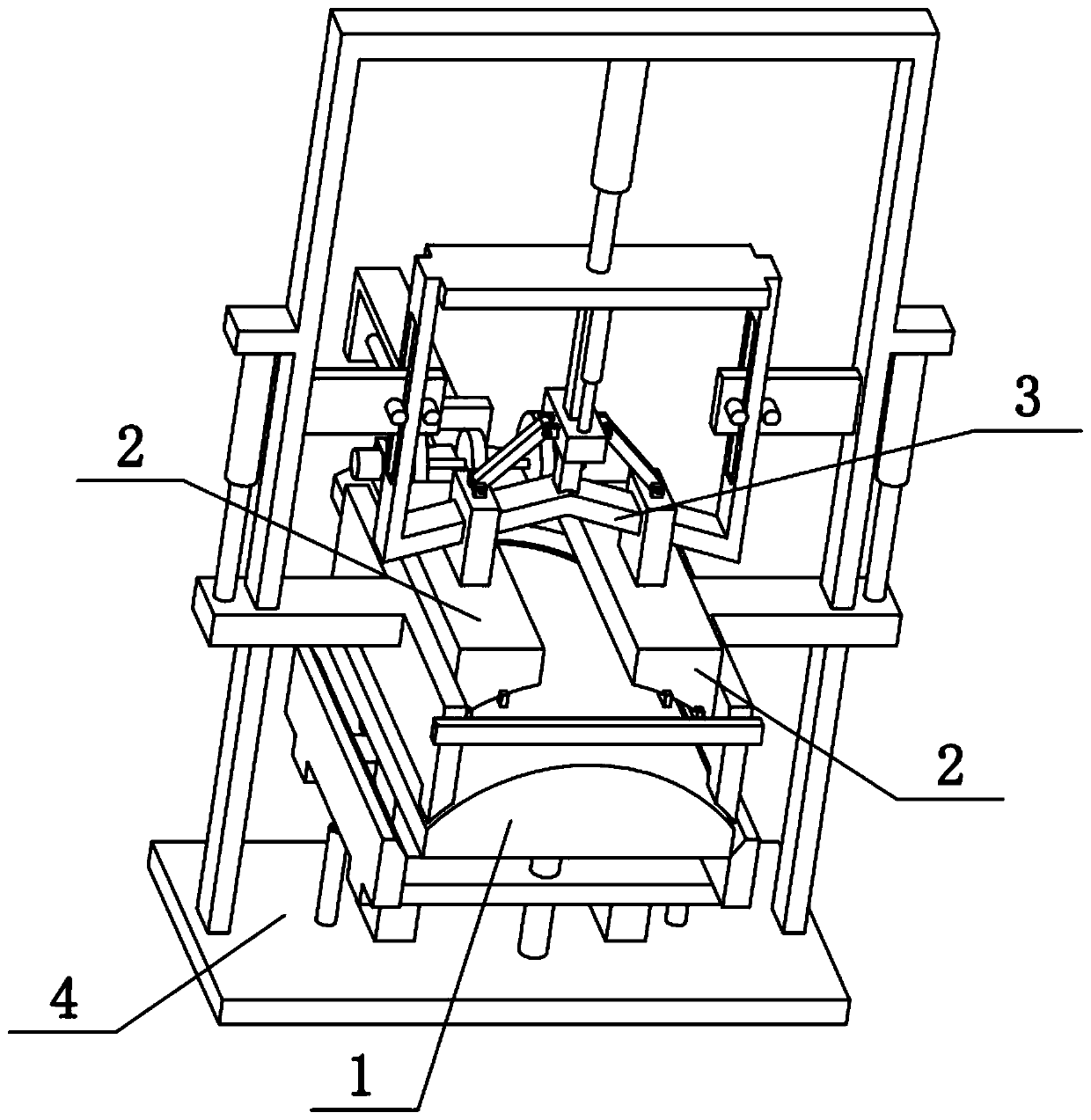

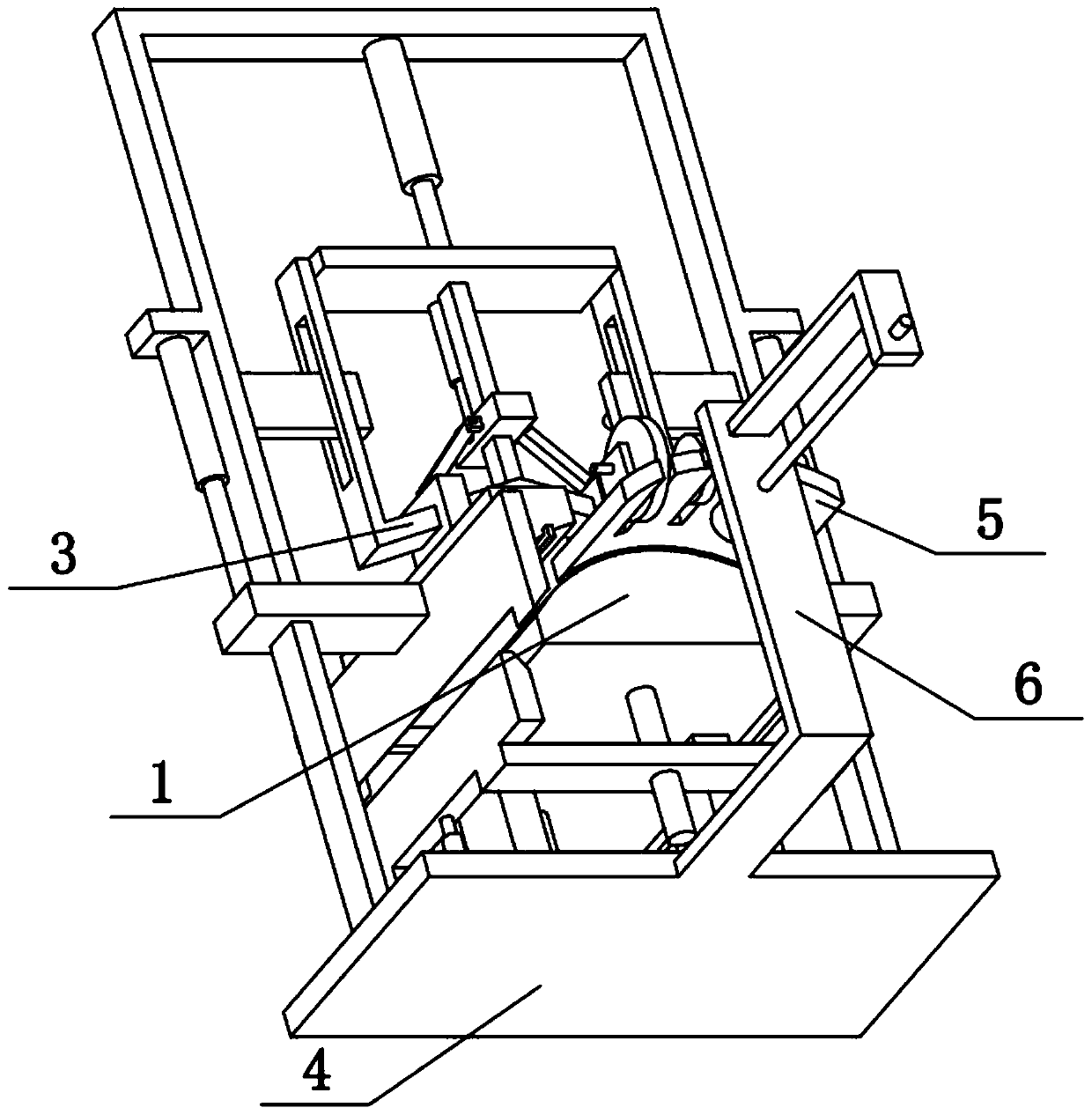

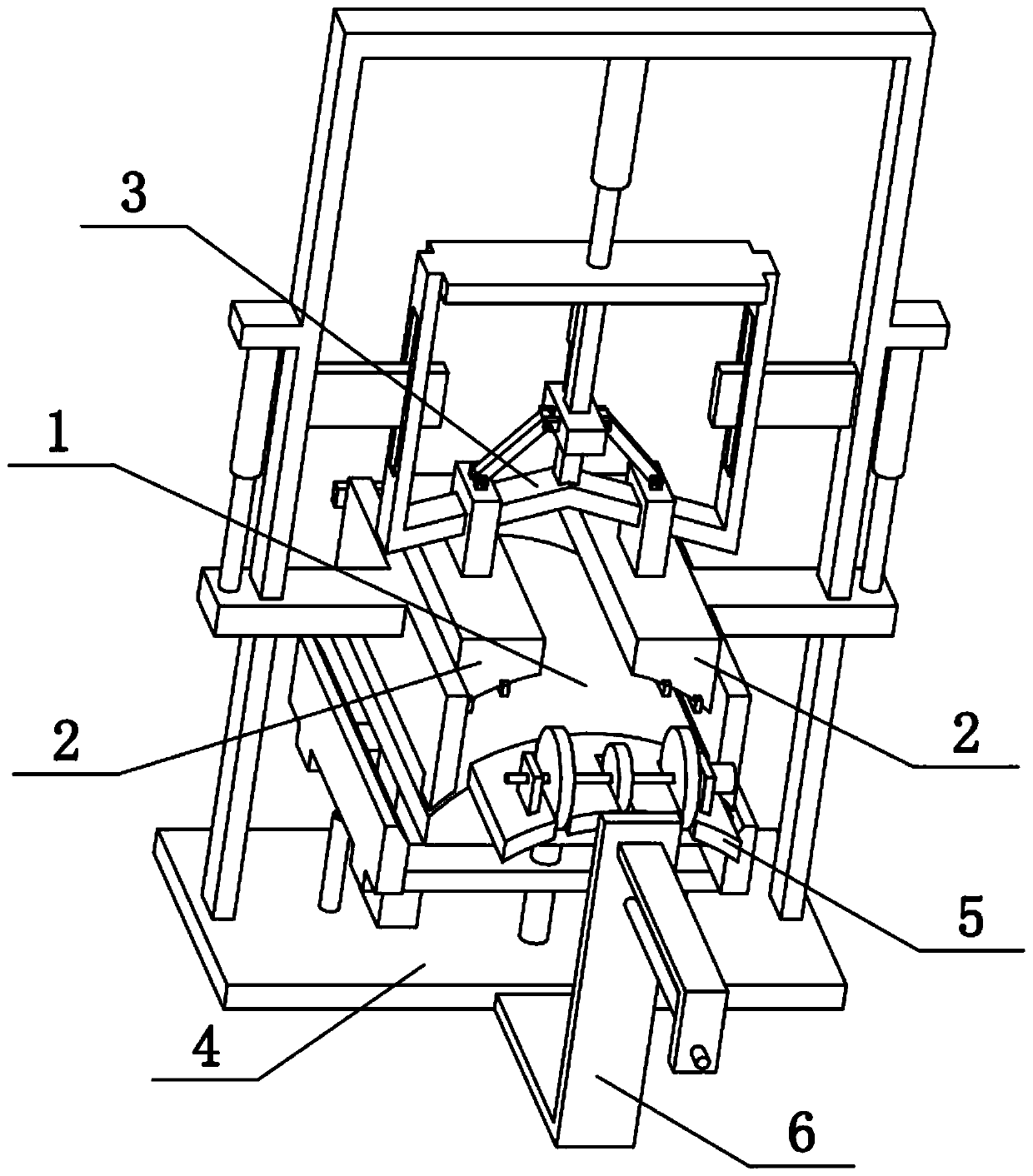

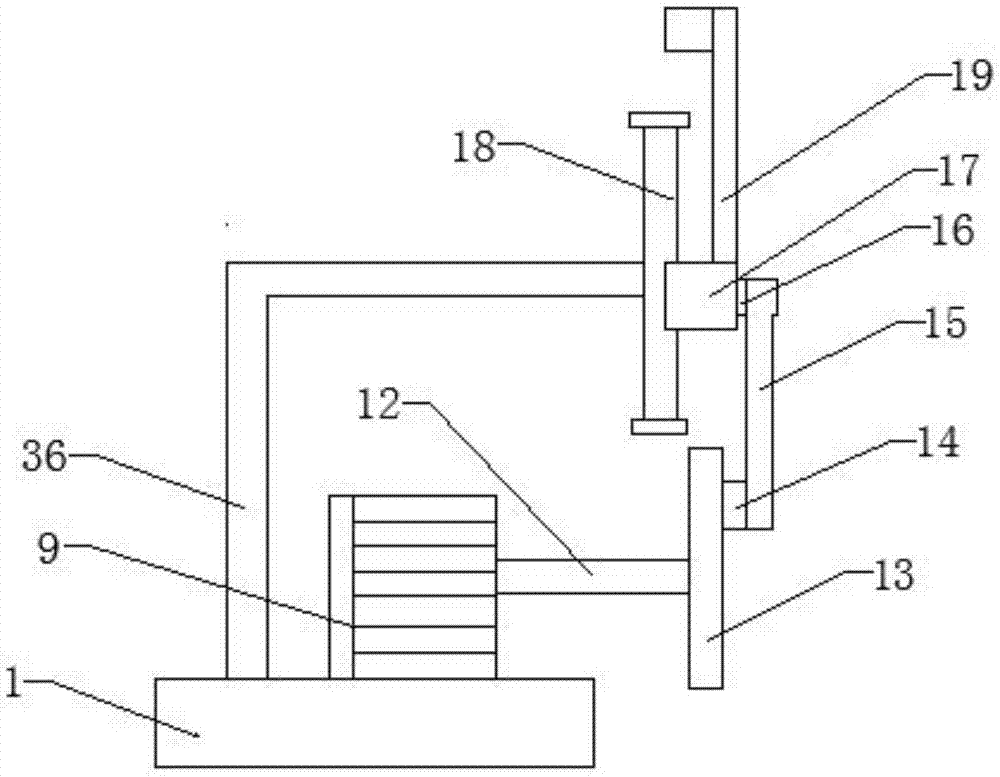

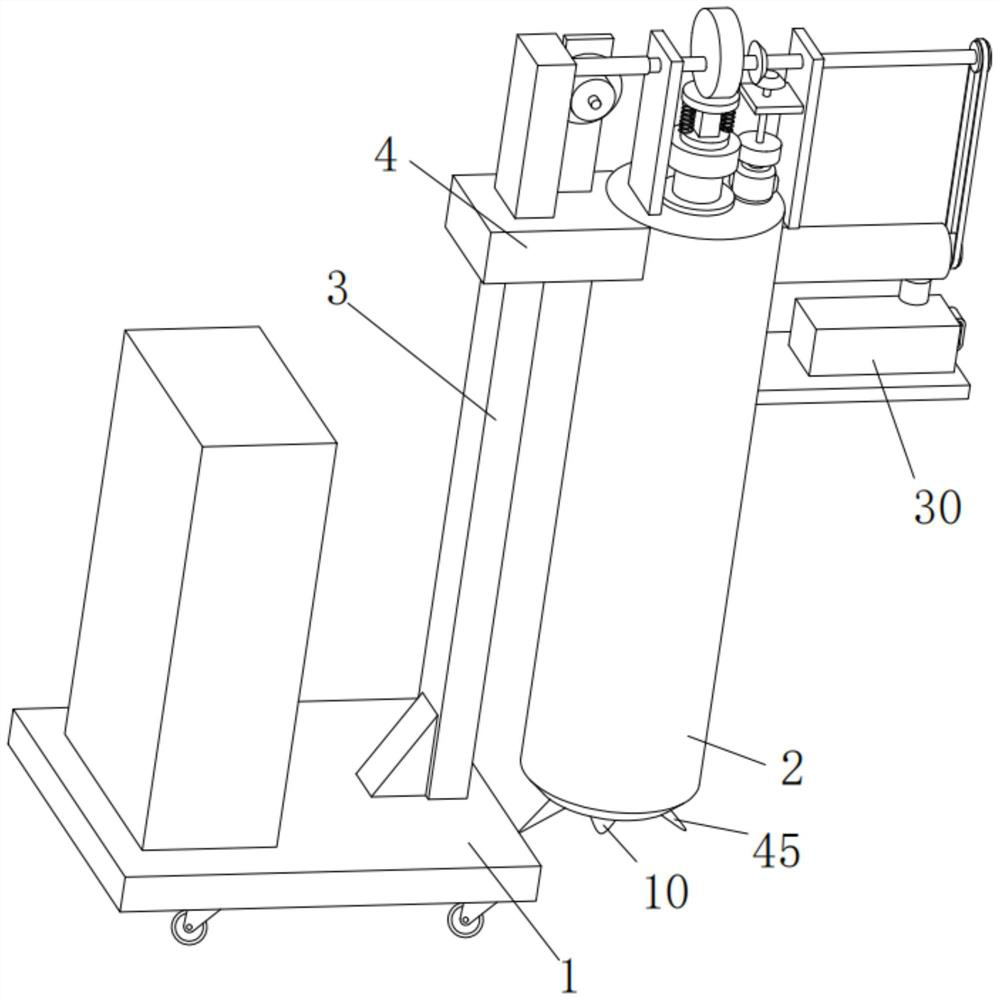

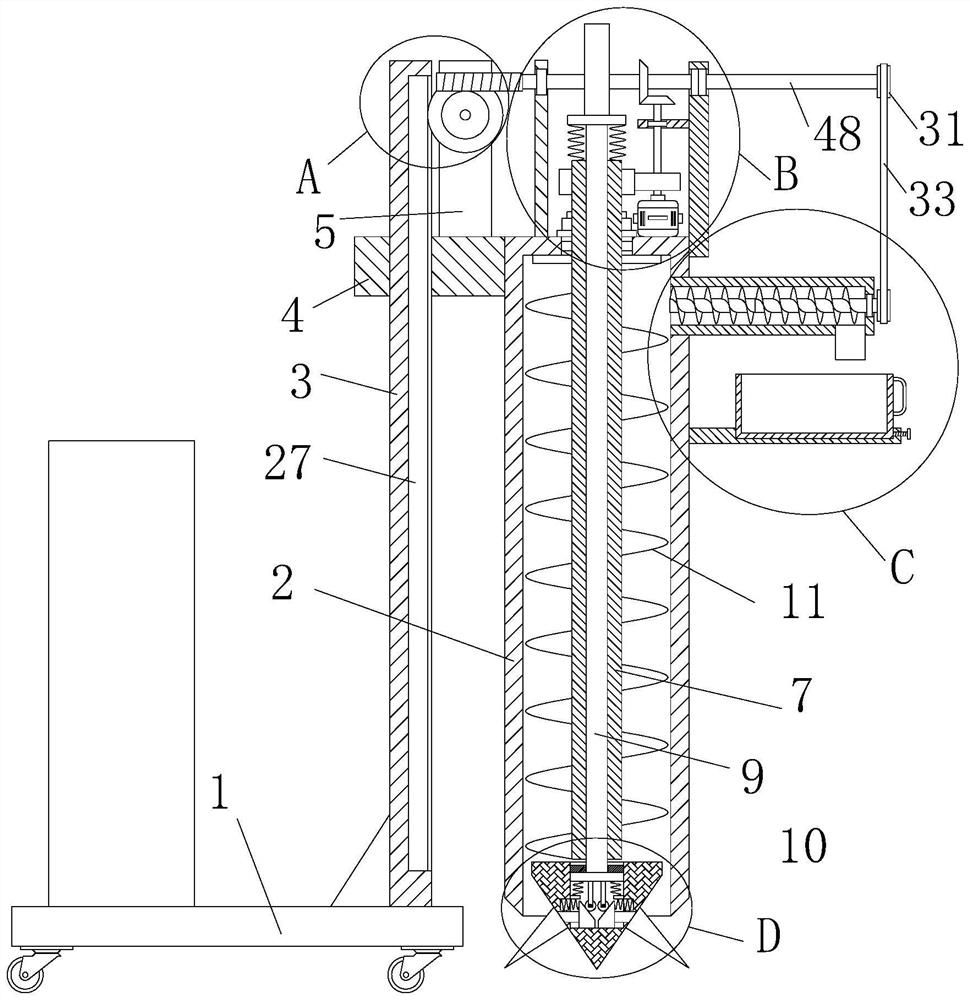

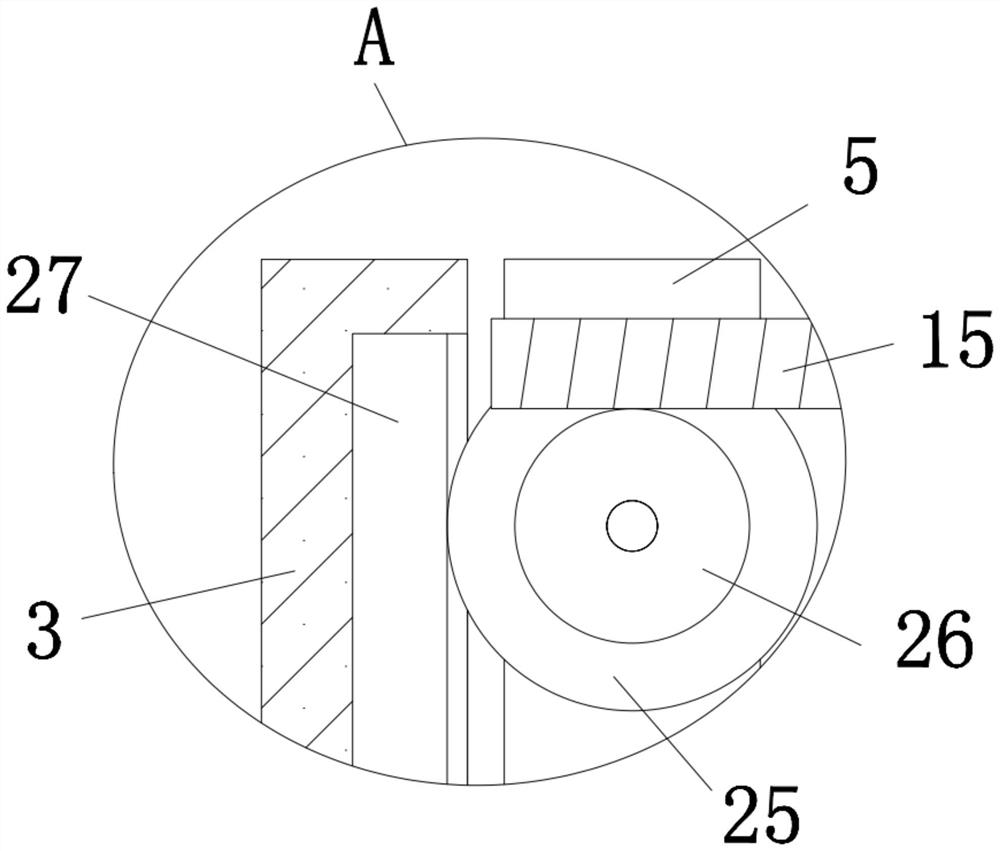

Bricklaying device and bricklaying robot

The invention discloses a bricklaying device and a bricklaying robot. The bricklaying device comprises a base, a brick transfer assembly, a brick feeding assembly and a plastering assembly. The bricktransfer assembly comprises a mechanical arm and a grabbing part. The mechanical arm is connected with the grabbing part to transfer bricks. The mechanical arm is movably arranged on the base and cando up-down lifting motion relative to the base. The brick feeding assembly comprises a bearing platform. The bearing platform is suitable for bearing the bricks. The bearing platform can do up-down lifting motion relative to the base, and the highest distance of the bearing platform relative to the base can be adjusted, so that the bricks are located within the grabbing range of the grabbing partall the time. The plastering assembly is arranged on the base and comprises a plastering head. The plastering head is used for plastering the bricks. The bricklaying device provided by the embodimentof the invention integrates brick transferring, brick plastering and bricklaying, can automatically complete the multiple working procedures, liberates manpower and accelerates the bricklaying progress; and shorter time required for brick taking is consumed, plastering and bricklaying can be quickly carried out after brick taking, the whole working procedure time is short, and the bricklaying efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

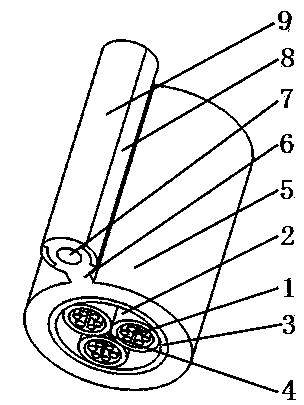

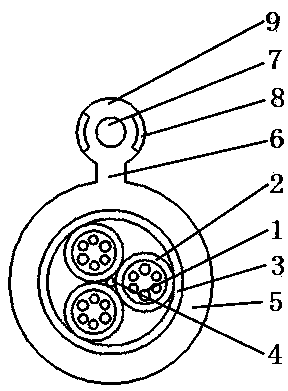

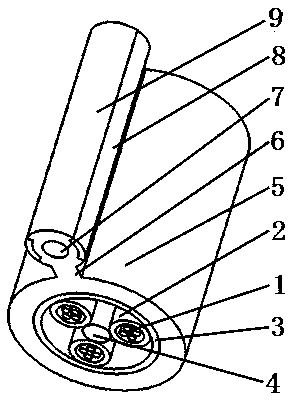

Aerial optical cable

ActiveCN103472553AEasy to identifyEasy maintenanceStampsOptical fibre/cable installationStructural engineeringMechanical engineering

Owner:STATE GRID CORP OF CHINA +3

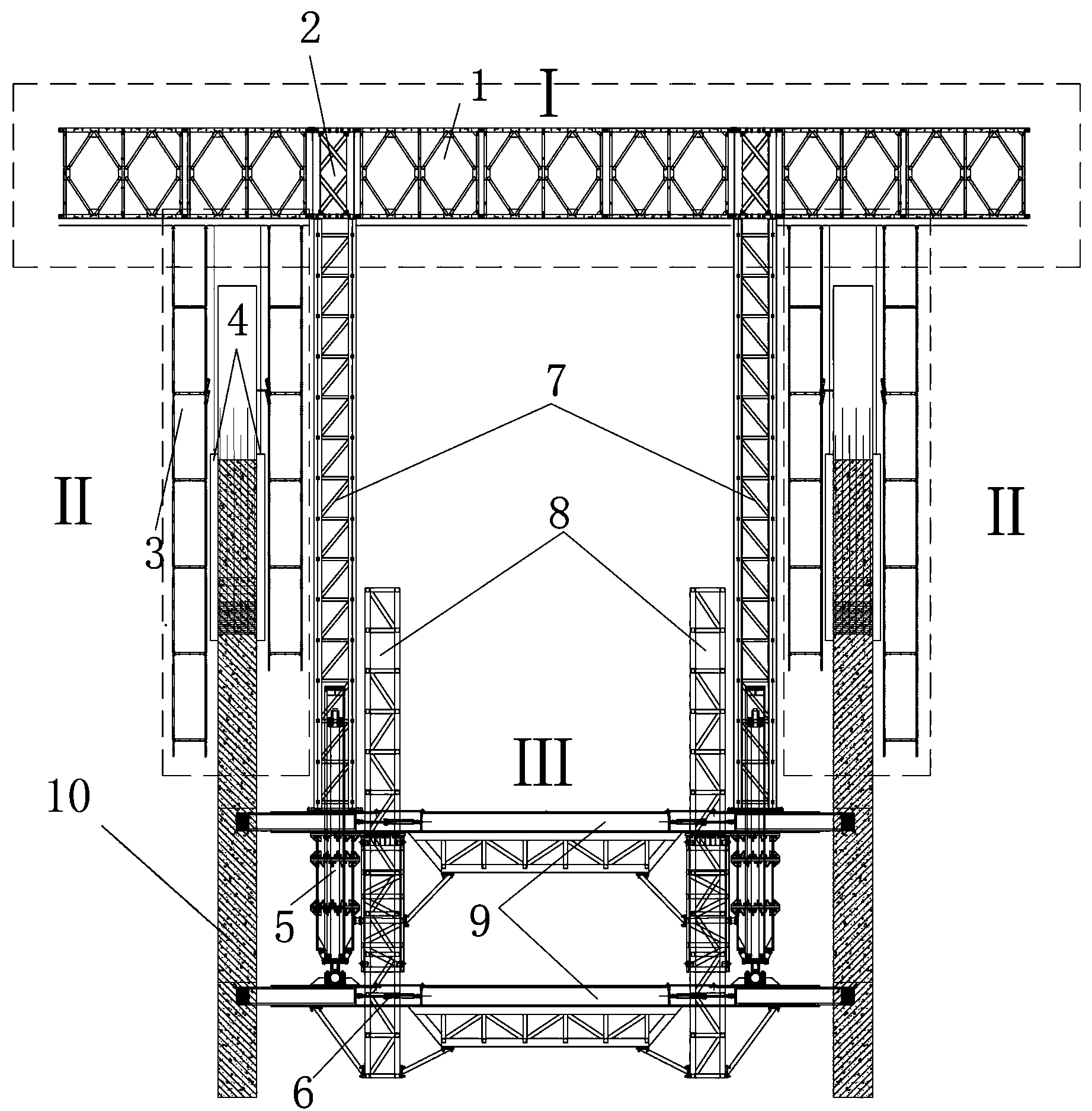

Standard Bailey truss assembling type jacking formwork system

ActiveCN103669832AForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel columnsStructural engineering

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

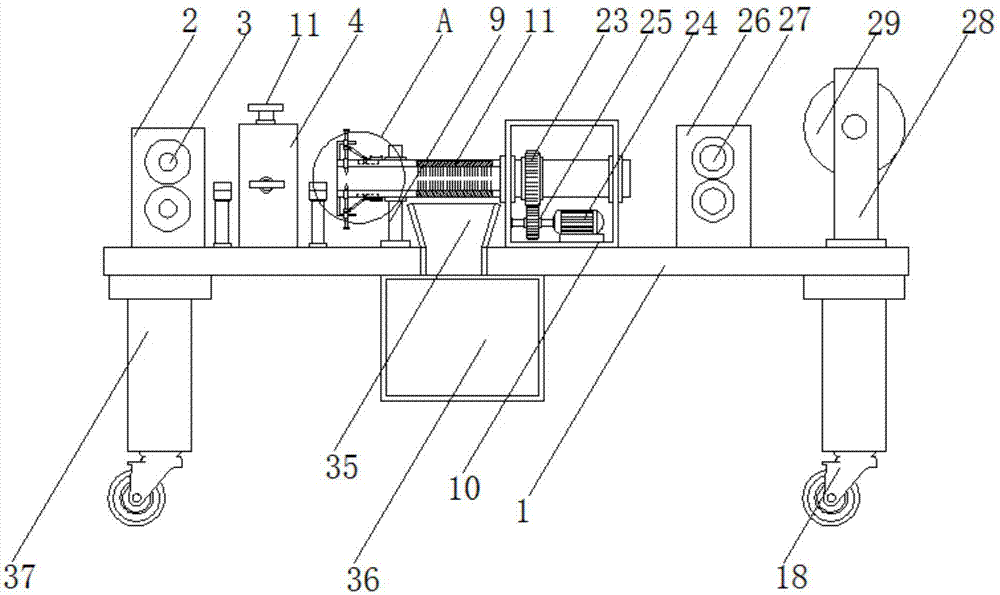

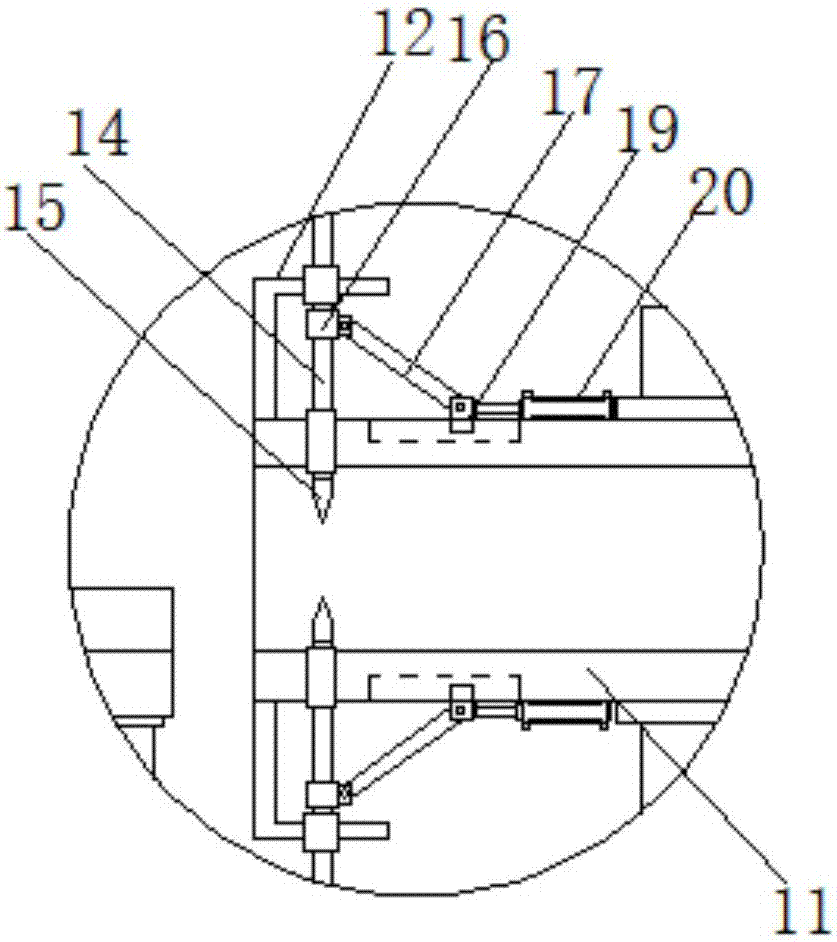

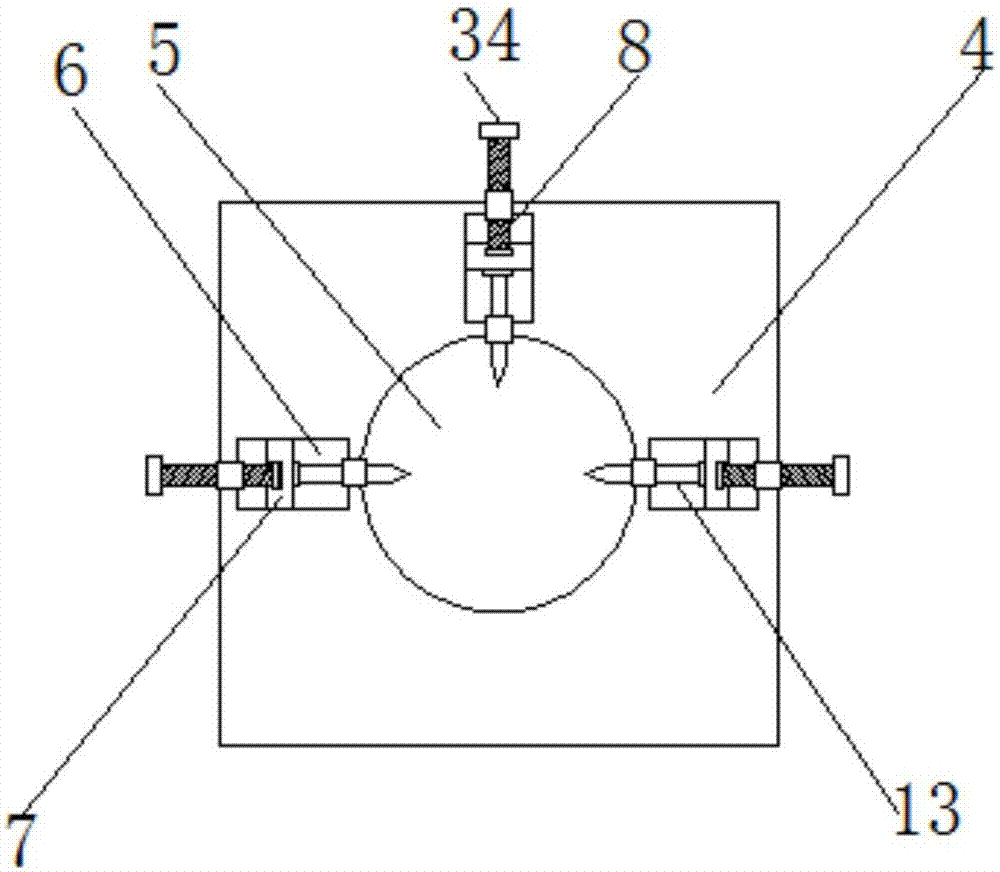

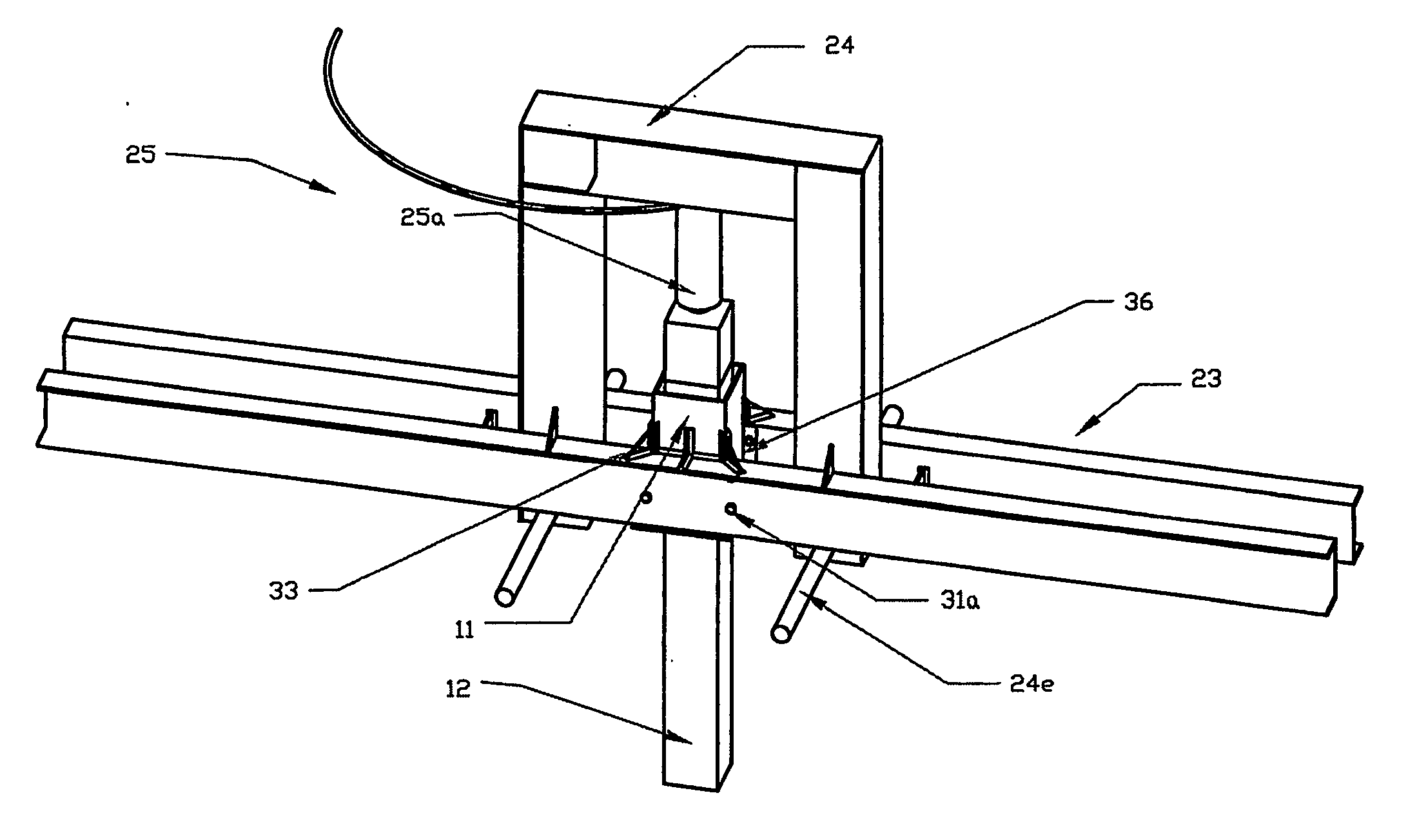

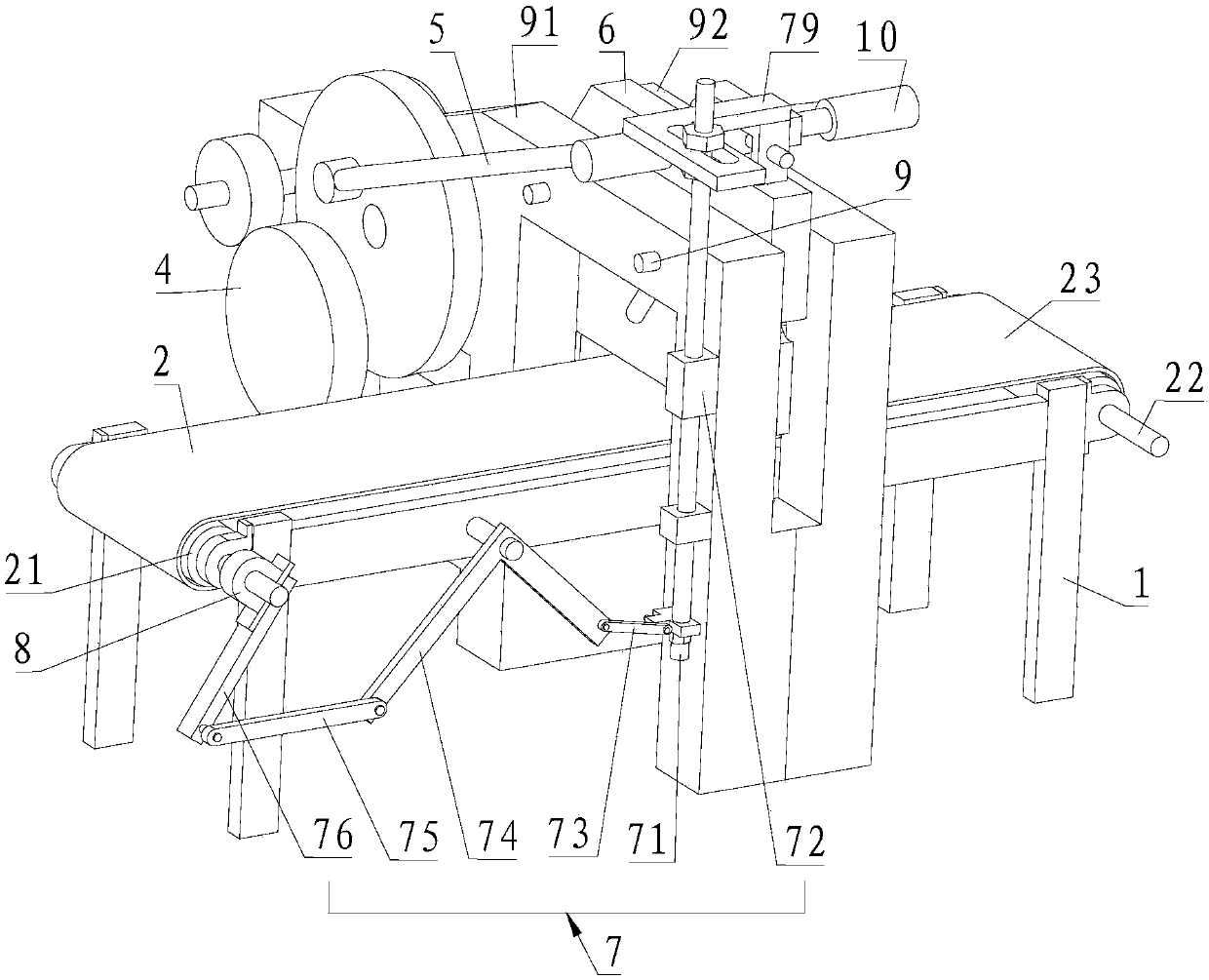

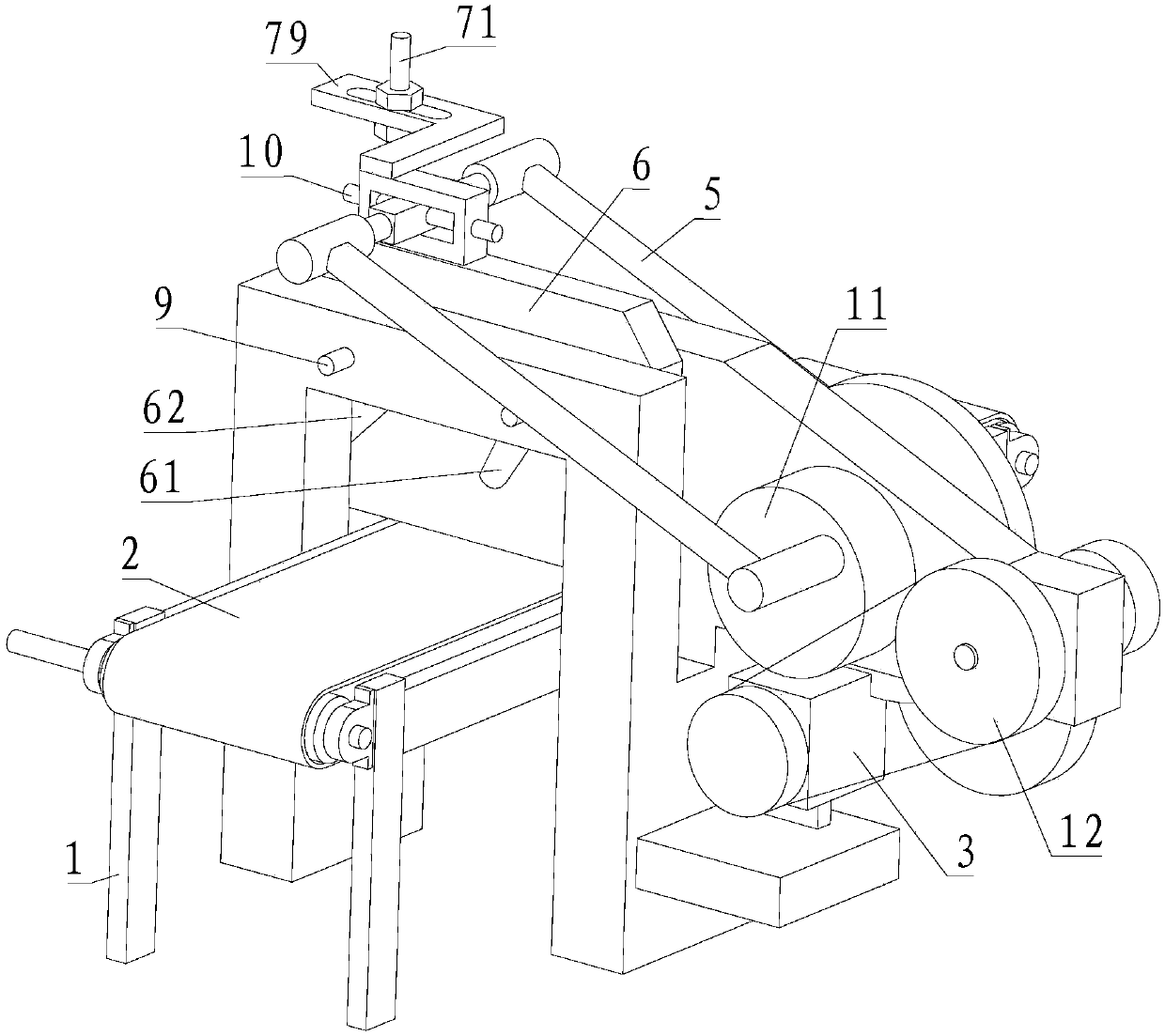

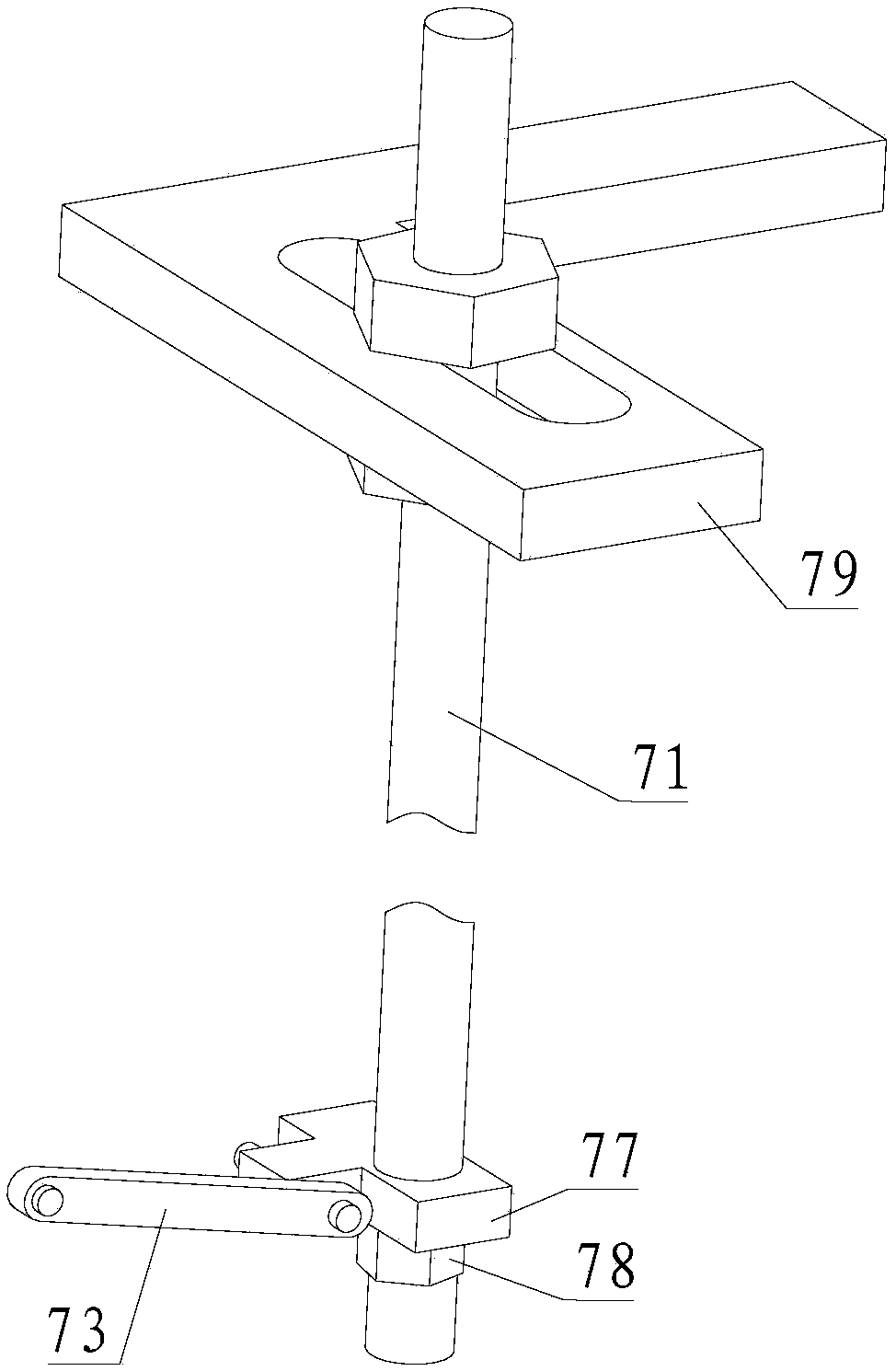

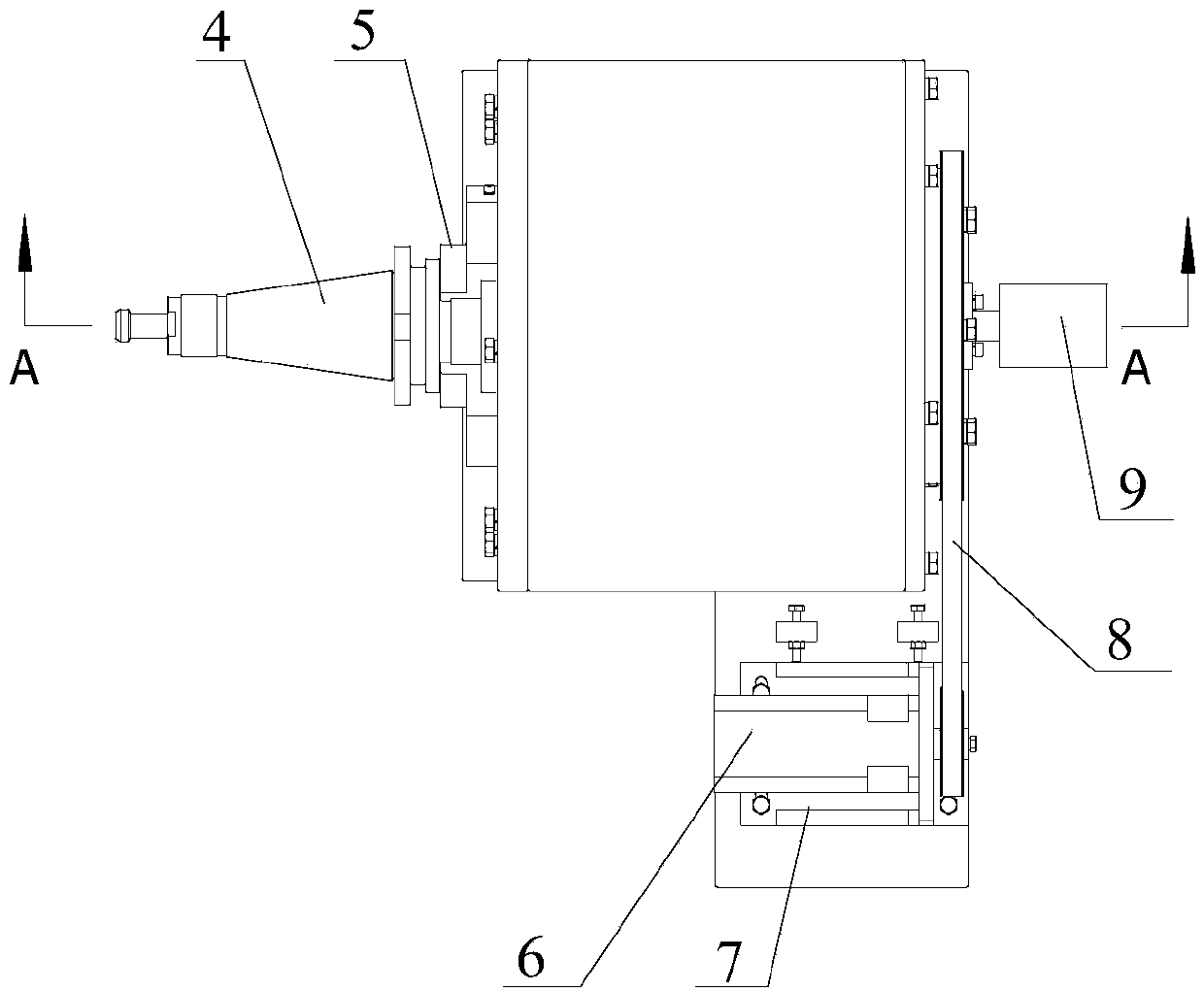

Horizontal sawing machine

ActiveCN107414182AIncrease profitReduce wasteMetal sawing devicesMetal sawing accessoriesStructural engineeringMechanical engineering

The invention discloses a horizontal sawing machine. The horizontal sawing machine comprises a machine frame, a feeding supporting device, a saw bite discharging clamping device, a small sliding table feeding clamping device, a big sliding table feeding clamping device, a sawing travelling device and a sawing cooling system. The machine frame is provided with a sawing position. The feeding supporting device is arranged on one side of the sawing position and comprises two slideway supporting blocks arranged on the machine frame in parallel, and a supporting assembly located on the slideway supporting blocks. A feeding guide rail is arranged on the upper surfaces of the slideway supporting blocks. The feeding guide rail extends from the feeding end of the machine frame to the sawing position. The saw bite discharging clamping device is located on the other side of the sawing position. The big sliding table feeding clamping device is slidably connected to the feeding guide rail. The small sliding table feeding clamping device can clamp and fix blanks and is slidably connected to the feeding guide rail. The sawing travelling device is arranged on the machine frame and comprises a saw blade. Through the horizontal sawing machine, tailing materials are reduced, the blank utilization rate is increased, and the blanks with different lengths can be machined continuously.

Owner:DALIAN JIACHENG RITA TECH DEV CO LTD

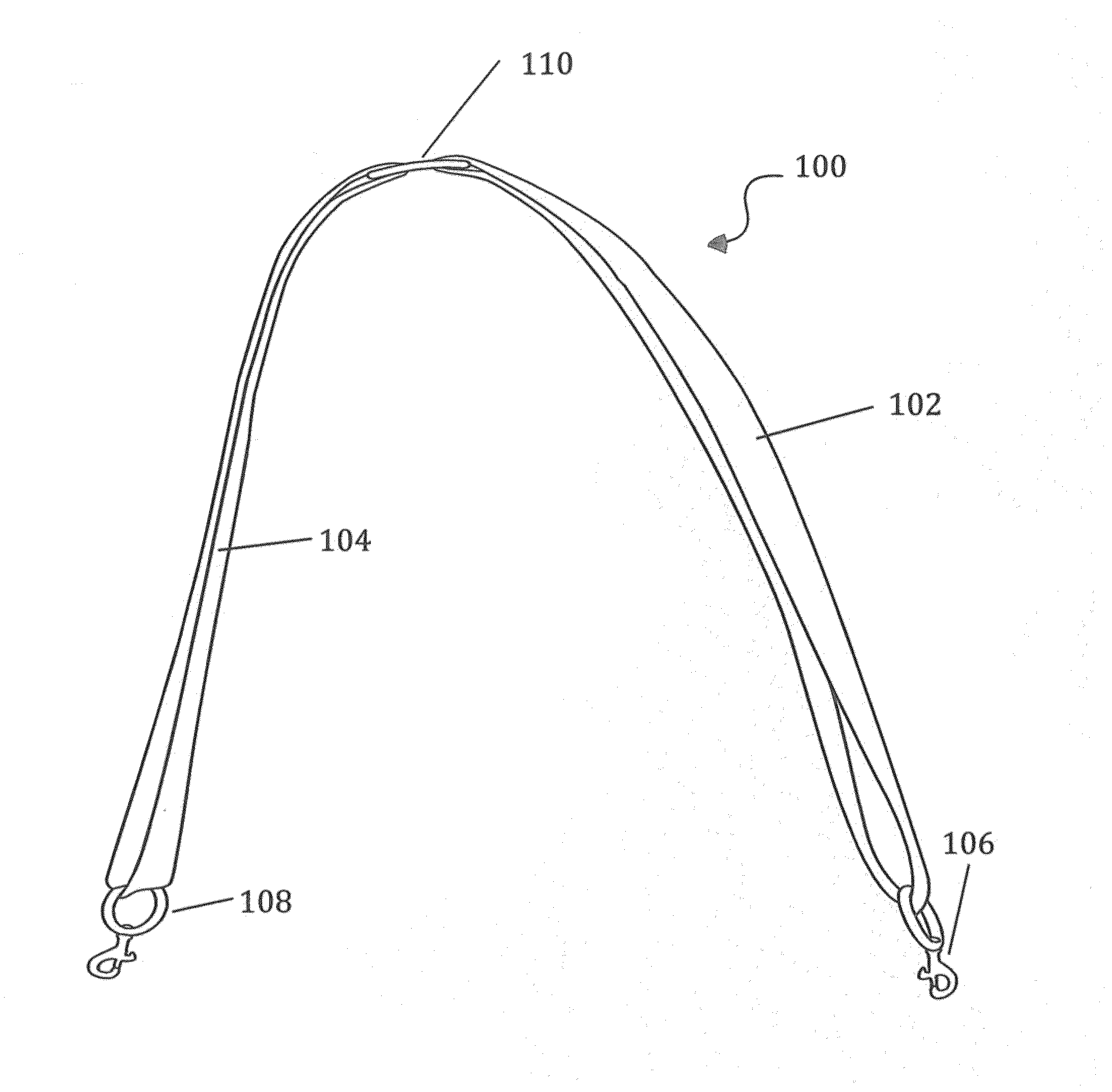

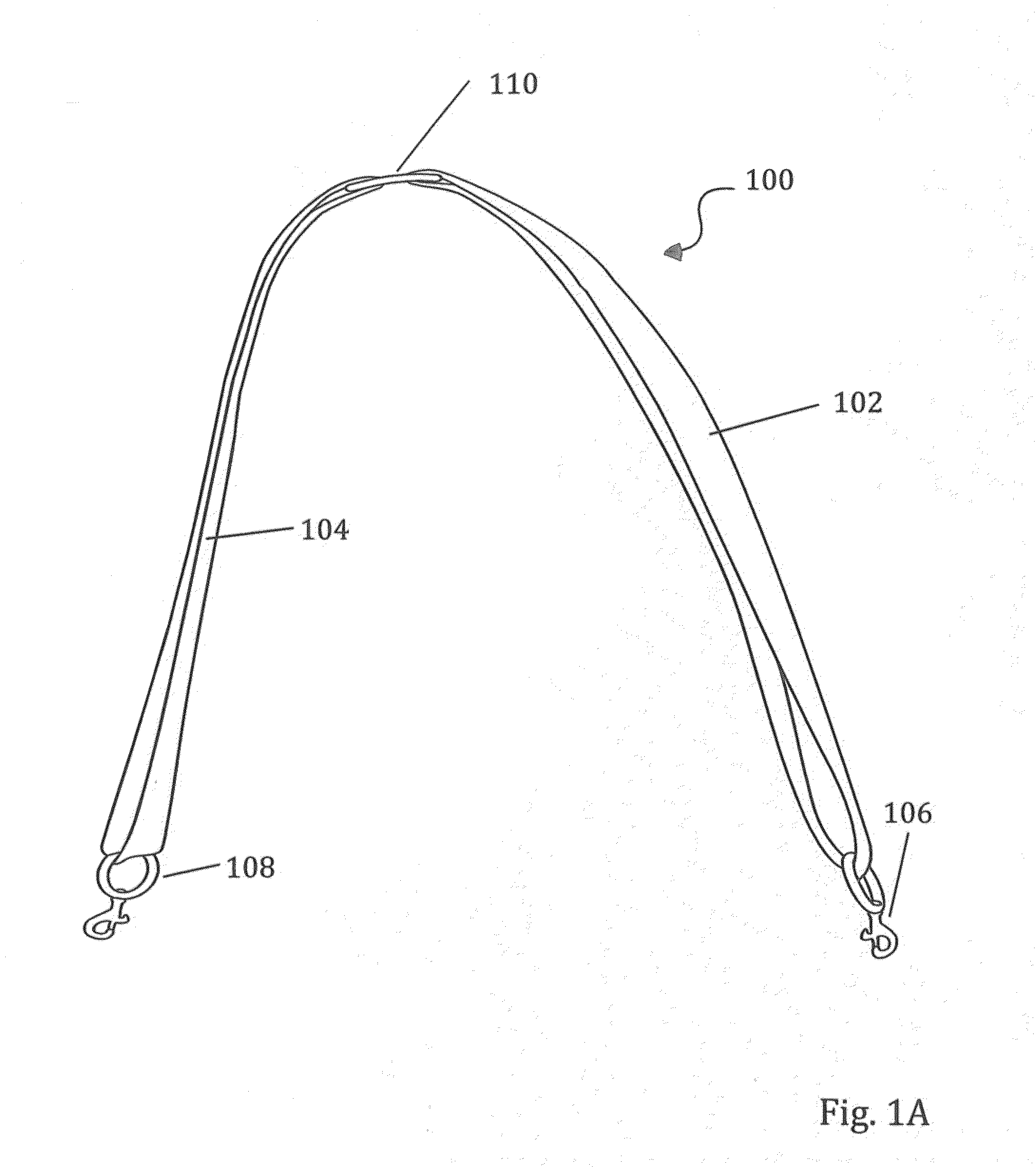

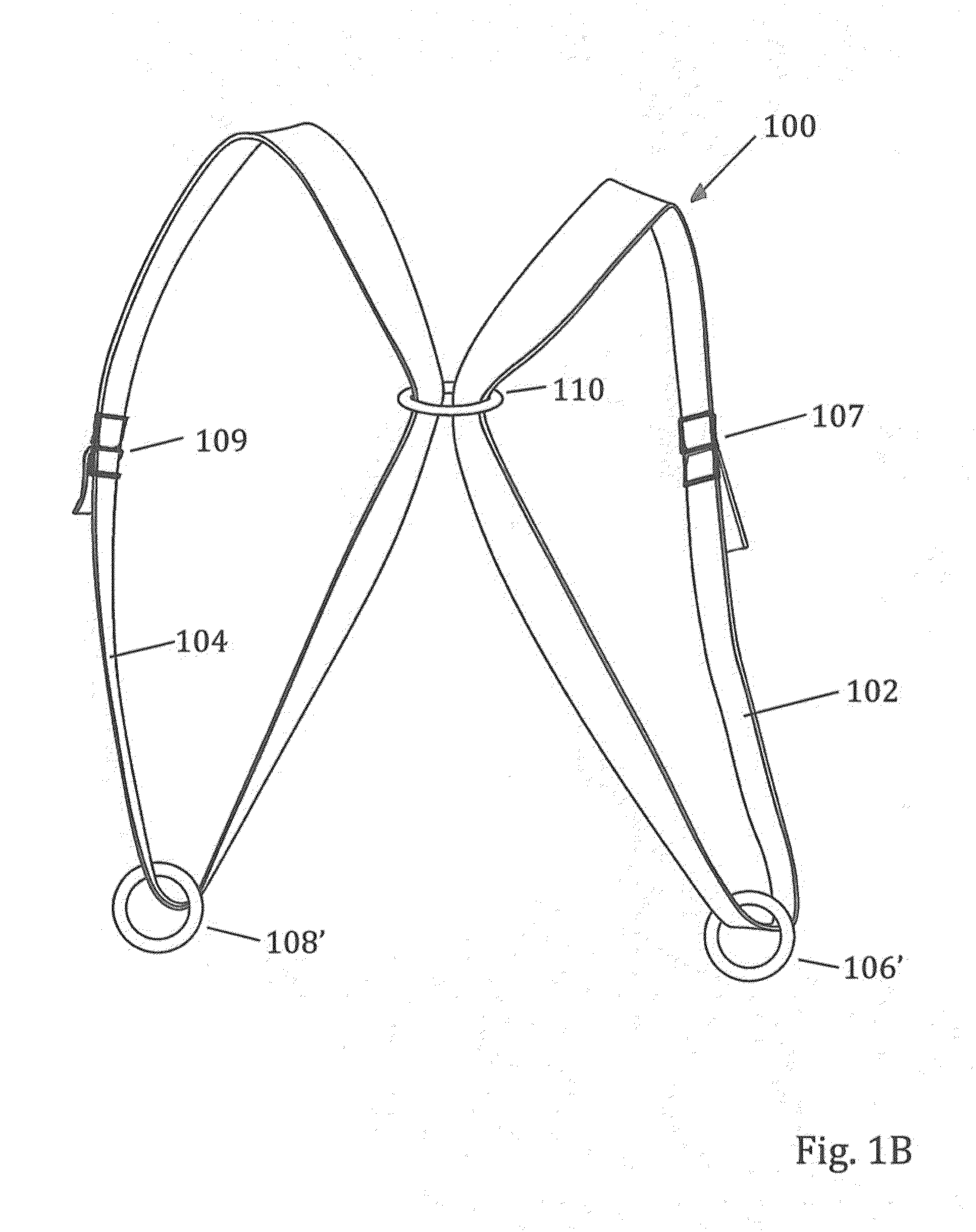

Convertible, self adjusting, multimodal strap system for carrying bags and packs

ActiveUS20160183666A1Comfortable and balanced and convenient positioningTravelling sacksPursesEngineeringSelf adjusting

A multi-mode strap system (100) is convertible between a single arm shoulder bag configuration, a two armed backpack configuration, and a single armed cross body configuration. The strap system (100) includes first and second straps (102 and 104), first and second attachment mechanisms (106 and 108) and a linkage assembly (110). The attachment mechanisms (106 and 108) and linkage assembly (110) allow the straps (102 and 104) to move or slide freely during transitions between the three configurations. The transitions can thus be accomplished without manipulating and straps or buckles and without having to remove the pack, and the pack remains upright during transitions.

Owner:WHITEHILL ANN

Hinge module for foldable type device

ActiveUS20200267856A1Simple componentsLow production costDigital data processing detailsCasings with display/control unitsDisplay deviceStructural engineering

The present invention relates to a hinge module of a foldable type device, which is connected to two casings for being relatively rotated for being in a folded status or in a unfolded status, each of the casings has a fixed outer casing and a moveable inner casing. The hinge module includes a base and two slide mechanisms. One end of a connection rod of each slide mechanism and one end of the linkage member are respectively pivoted to two pivotal parts at one end of the base; after each inner casing is driven to reversely displace, one end of each plate member is separated from each block part, so as to reversely swing and shift for forming an accommodation space allowing a bent central portion of a flexible monitor to be accommodated.

Owner:JARLLYTEC CO LTD

Cable peeling device

InactiveCN107300739AImprove work efficiencyReduce usageFibre mechanical structuresStructural engineeringMechanical engineering

Owner:陈杨平

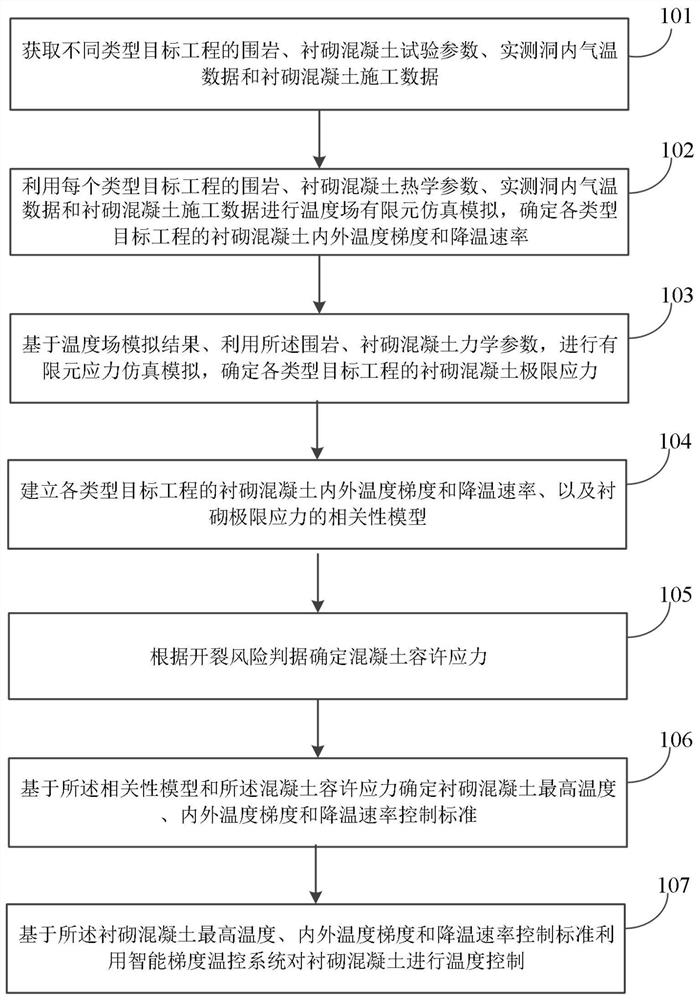

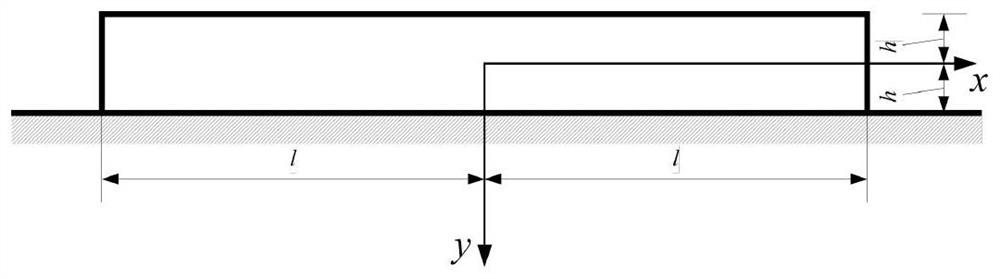

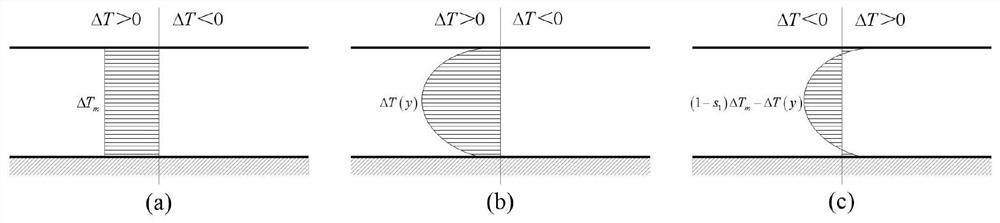

Intelligent gradient temperature control method, system and device and readable storage medium

ActiveCN112113875ARealize temperature control and crack preventionMaterial thermal analysisStrength propertiesStructural engineeringMechanics

The embodiment of the invention discloses an intelligent gradient temperature control method, system and device and a readable storage medium. The method comprises steps of temperature field finite element analogue simulation being conducted by means of surrounding rock, lining concrete thermal parameters, actually-measured in-tunnel temperature data and lining concrete construction data of each type of target engineering; carrying out finite element stress analogue simulation; establishing a correlation model of lining concrete internal and external temperature gradient and cooling rate of each type of target engineering and lining ultimate stress; determining concrete allowable stress according to the cracking risk criterion; determining the highest temperature, the internal and externaltemperature gradient and the cooling rate control standard of the lining concrete based on the correlation model and the concrete allowable stress; and performing temperature control on the lining concrete by utilizing an intelligent gradient temperature control system based on the maximum temperature of the lining concrete, the internal and external temperature gradient and the cooling rate control standard; and the temperature control anti-cracking of the lining concrete construction in the whole period being realized.

Owner:TSINGHUA UNIV +1

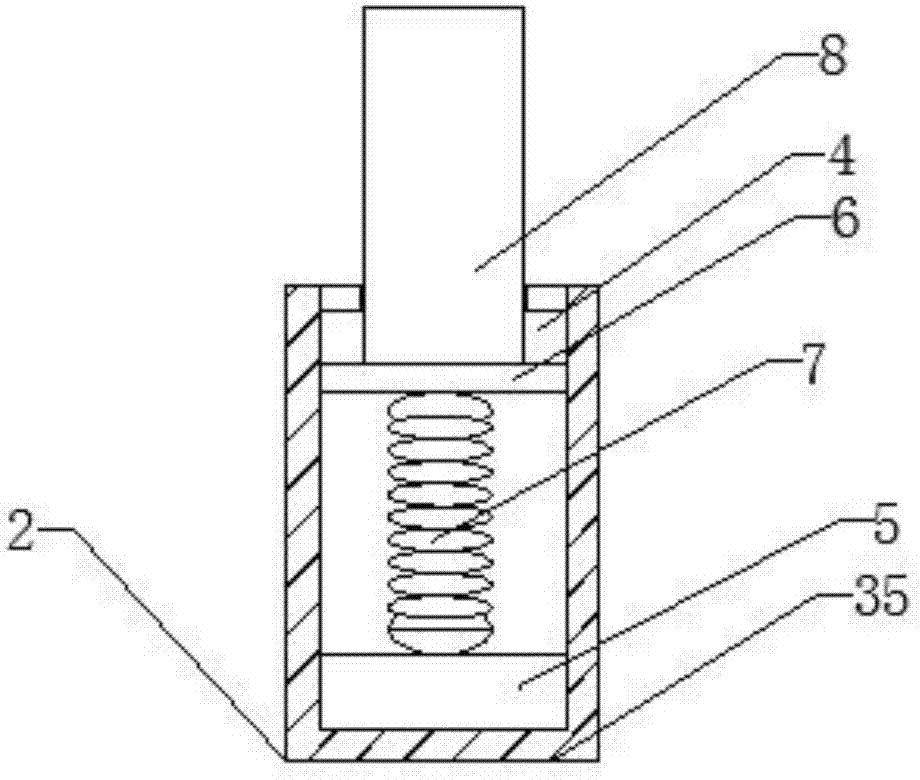

Pile anchor head for an underpinning pile and method of preloading the same

Owner:ONG CHIN CHAI

Metal plate forming mold and forming method thereof

Owner:浙江鑫正工贸有限公司

Girdling and stripping device for outer insulating sheath of cable

ActiveCN110994482AReliable cuttingHigh degree of automationApparatus for removing/armouring cablesWire cuttingStructural engineering

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Bituminous pavement track field evaluation method

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

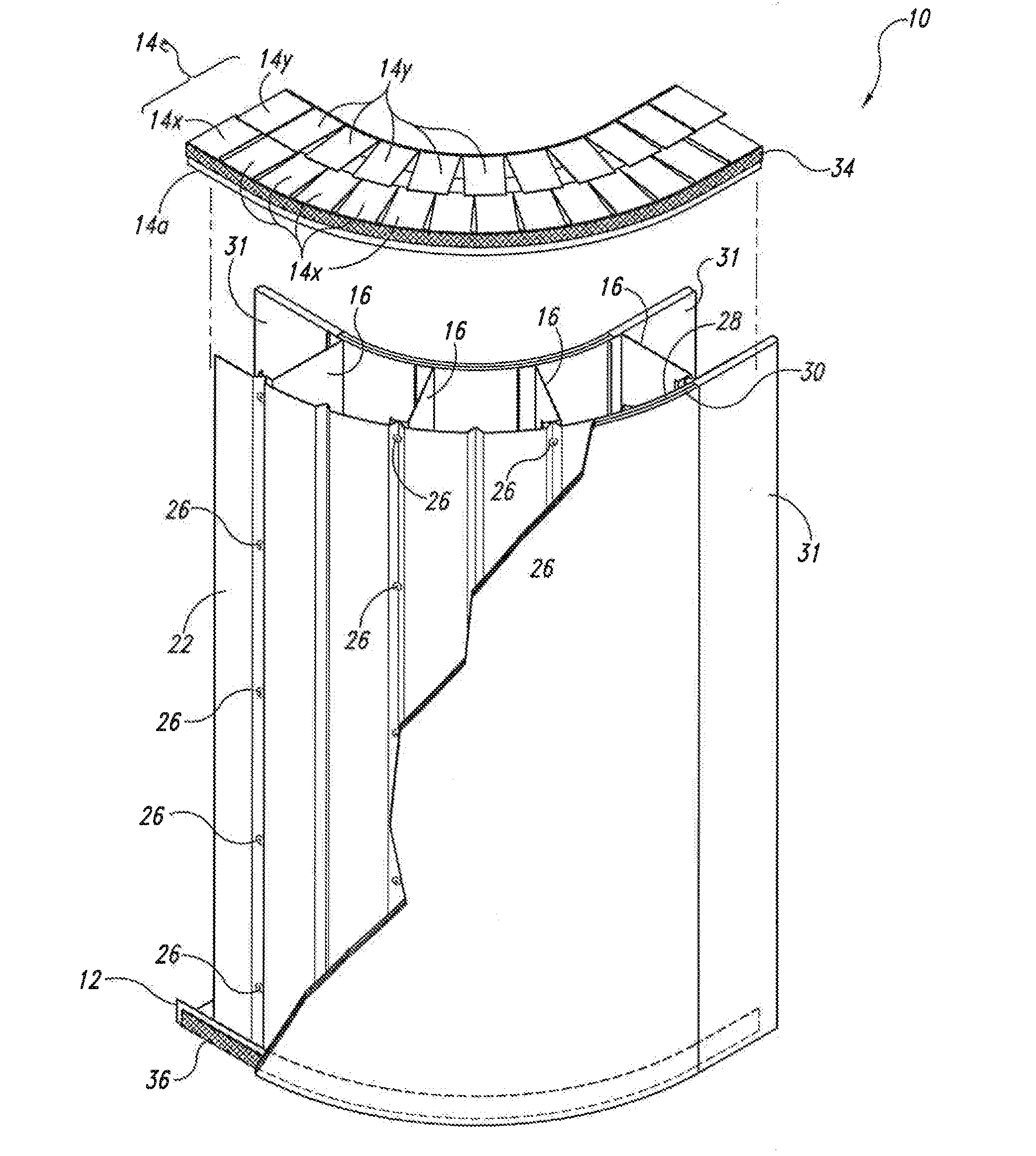

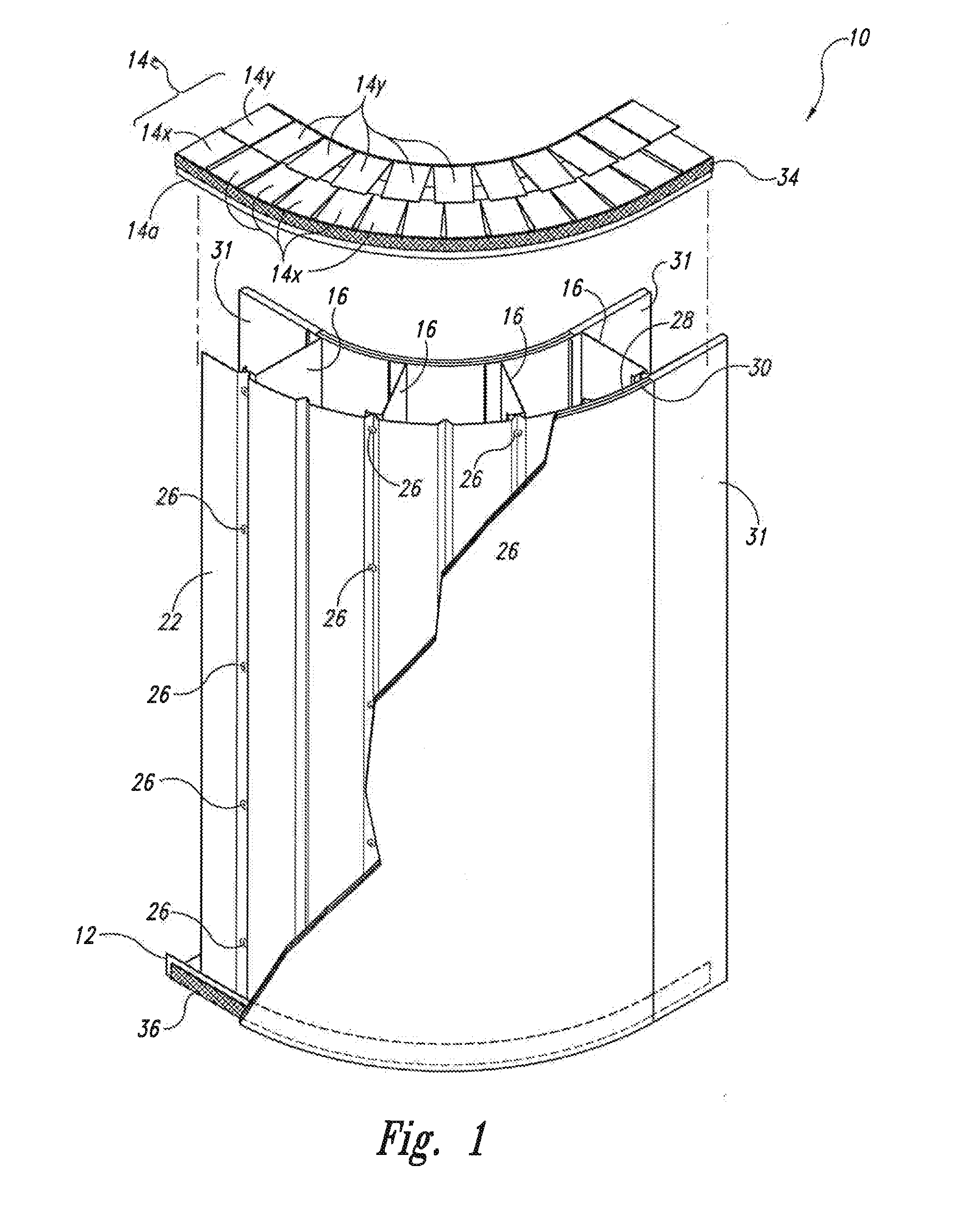

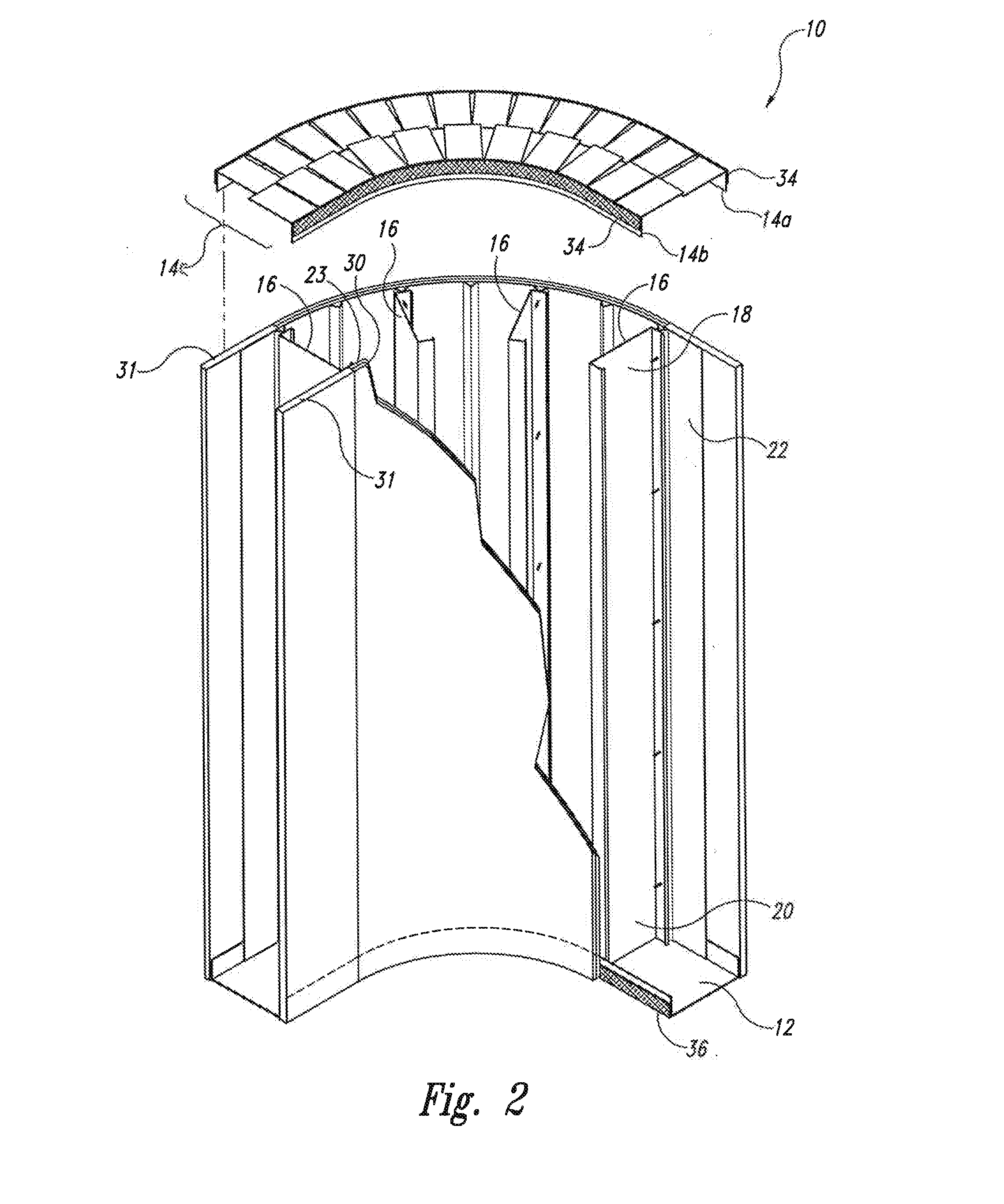

Fire rated radius wall structure

InactiveUS20130104474A1Easy to construct/installConstruction materialWallsEngineeringStructural engineering

Owner:KLEIN JAMES ALAN

Concrete curing device carried by secondary lining trolley and using method of concrete curing device

PendingCN107269296ANovel ideaSimple structureUnderground chambersTunnel liningWater storage tankStructural engineering

A concrete curing device carried by a secondary lining trolley and a using method of the concrete curing device are disclosed. The device comprises a water spraying system, the water spraying system comprises a water storage tank (1), a water spring pipeline and a water pump, the water spraying pipeline comprises a left arc-shaped water spraying pipeline (2) and a right arc-shaped water spraying pipeline (3), a plurality of spray heads (9) are arranged on the left arc-shaped water spraying pipeline (2) and the right arc-shaped water spraying pipeline (3) correspondingly, the left arc-shaped water spraying pipeline (2) is connected with the water storage tank (1), and the right arc-shaped water spraying pipeline (3) is connected with the water storage tank (1). The method comprises the steps of enabling a left arch ring (6) and a right arch ring (10) to rise above a top formwork of the secondary lining trolley, enabling the left arch ring (6) and the right arch ring (10) to cross edge formworks of the secondary lining trolley, adjusting the distance between each spray head (9) and secondary lining concrete, enabling the left arc-shaped water spraying pipeline (2) and the right arc-shaped water spraying pipeline (3) to spray water, and conducting water spraying curing on the concrete. According to the concrete curing device carried by the secondary lining trolley and the using method of the concrete curing device, the purpose that the concrete is cured timely after lining is subjected to formwork removing is achieved, and the problem that at present, concrete cannot be cured timely some time is solved.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

Core bar for steering wheels

A core bar includes upper and lower half shells, each having a boss portion including a boss-edge coupling part for coupling the shells along the edges, a shaft fixing part placed substantially in the center of the boss portion and mounted to a steering shaft, and a weak part placed between the boss-edge coupling part and the shaft fixing part and wherein the shells face each other without being coupled; and a rim portion including a rim-edge coupling part for coupling the shells along the edges and a rim hollow part defined between the shells. A spoke portion is interposed between the boss and the rim portions, and includes a spoke-edge coupling part for coupling the shells along the edges and a spoke hollow part defined between the shells.

Owner:NIHON PLAST CO LTD

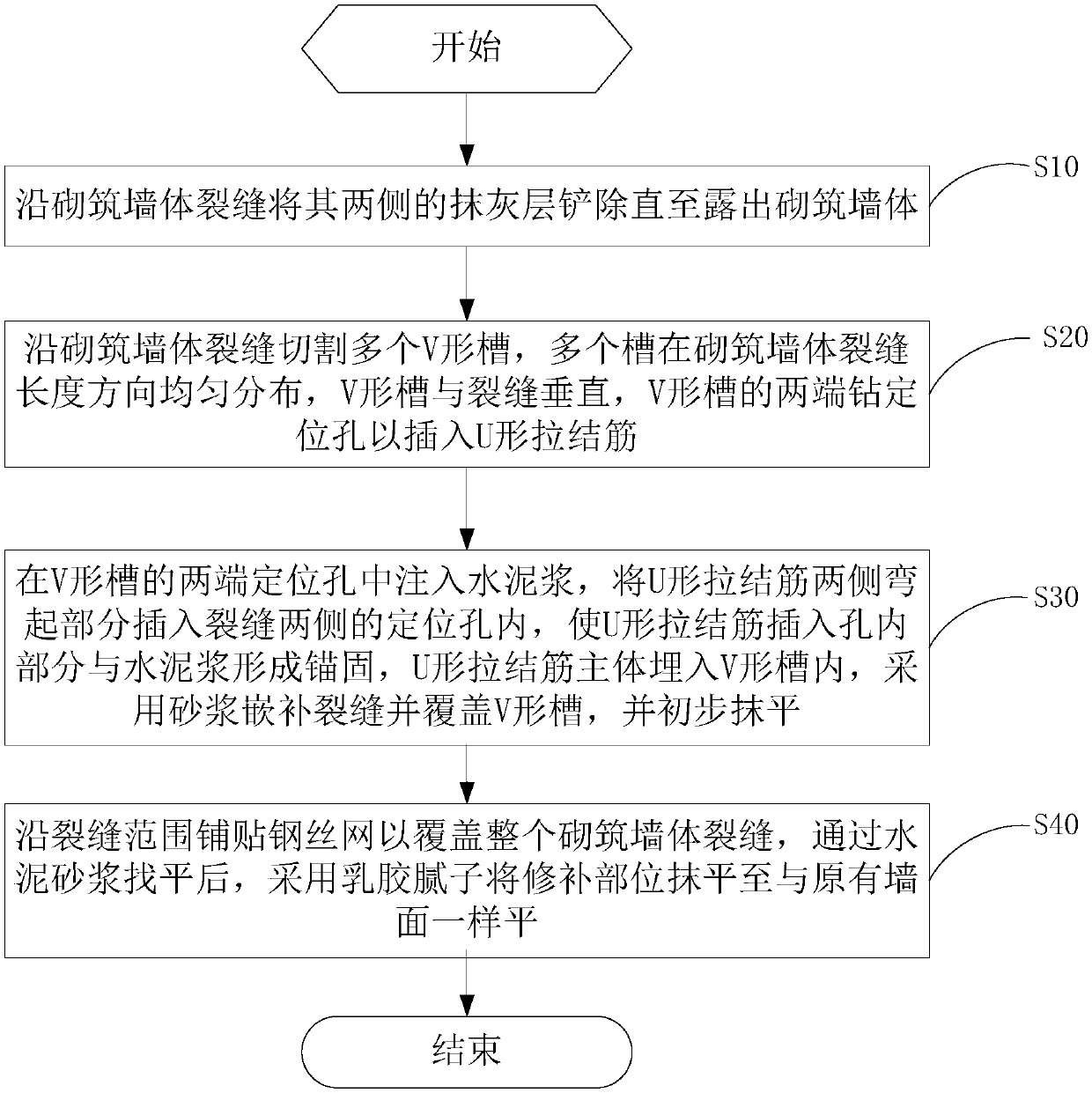

Processing method for masonry wall crack

Owner:CHINA FIRST METALLURGICAL GROUP

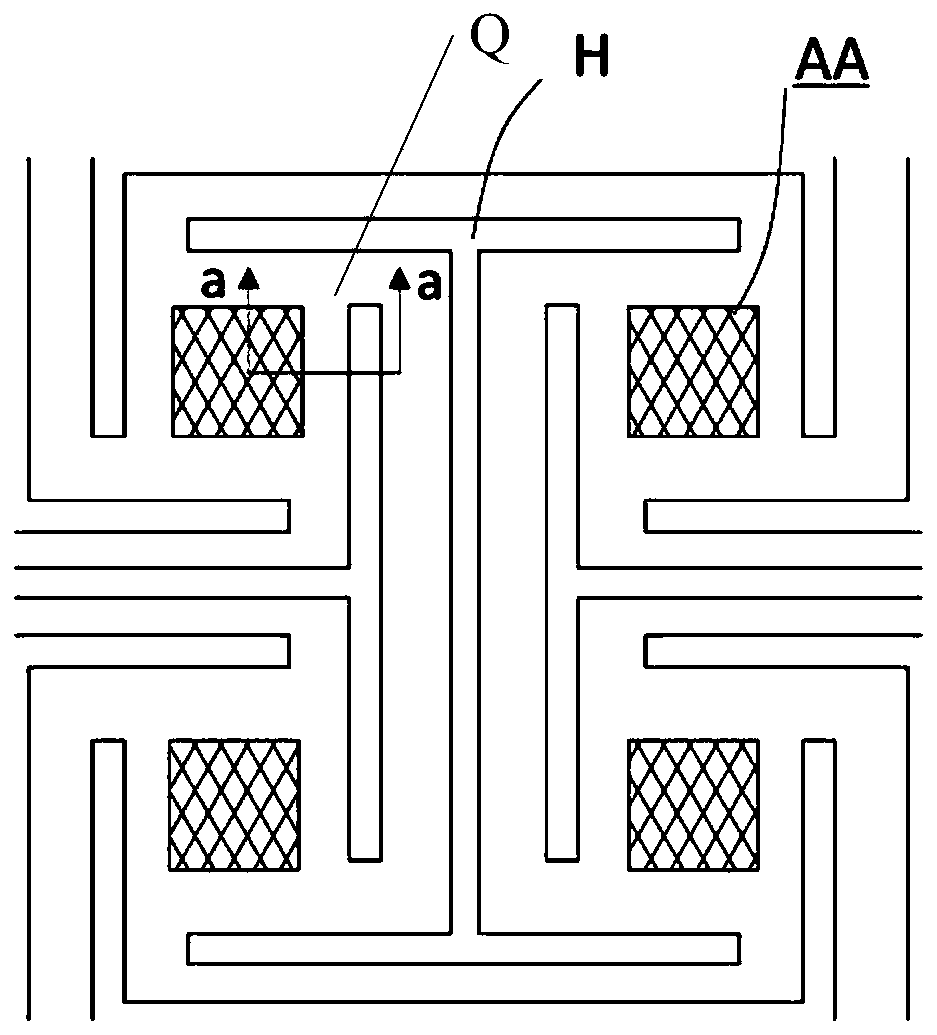

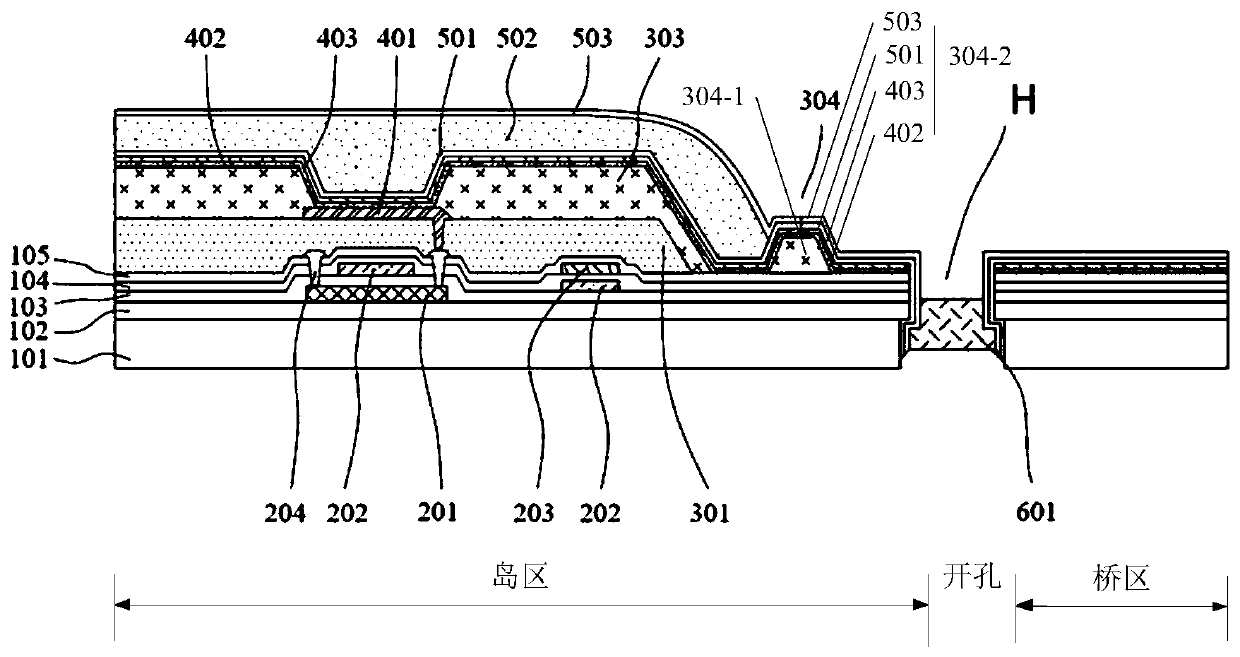

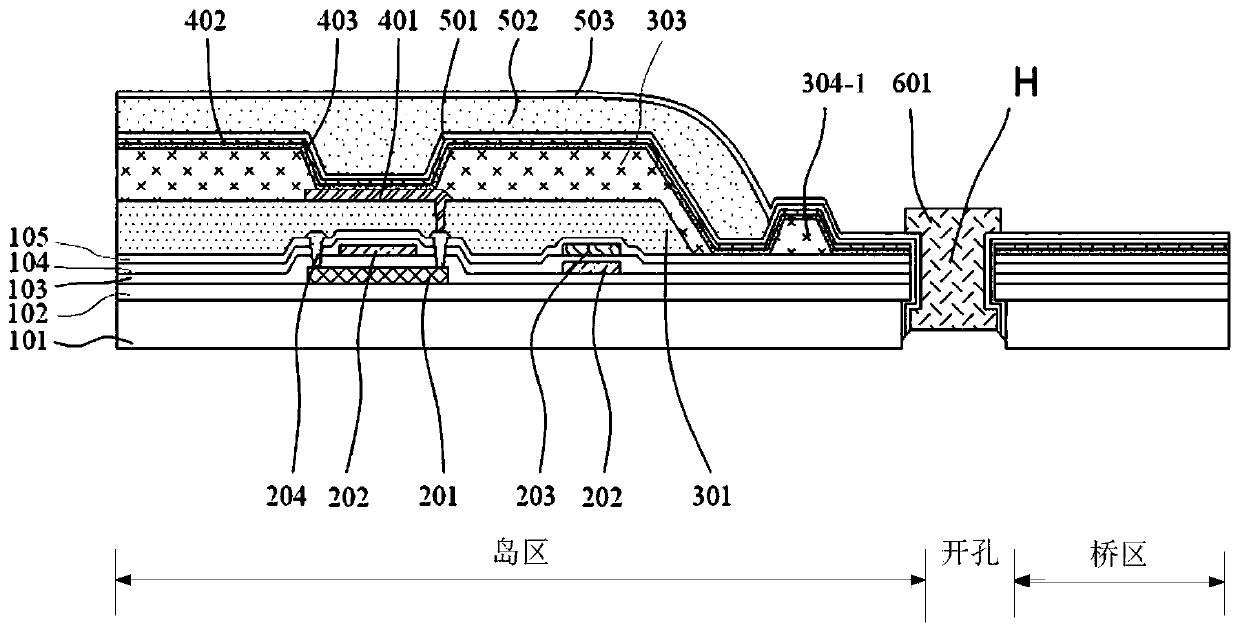

Display panel, display device and manufacturing method of display panel

PendingCN111341210AImprove package reliabilitySolve the ruptureIdentification meansStructural engineeringElectrical and Electronics engineering

The invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a substrate, a plurality of island areas, bridge areas and opening areas are arranged on the substrate, the island areas comprise pixel units, the adjacent island areas are connected through the bridge areas, and the opening areas penetrating through the substrateare distributed at preset positions between the island areas and the bridge areas; and the elastic filling layer is positioned in the opening area. According to the technical scheme provided by the embodiment of the invention, the elastic filling layer is arranged in the opening area, so that the problem that the packaging layer is easy to crack when the flexible display panel is stripped from theglass substrate can be solved, and the effect of improving the packaging reliability of the opening area is achieved.

Owner:BOE TECH GRP CO LTD

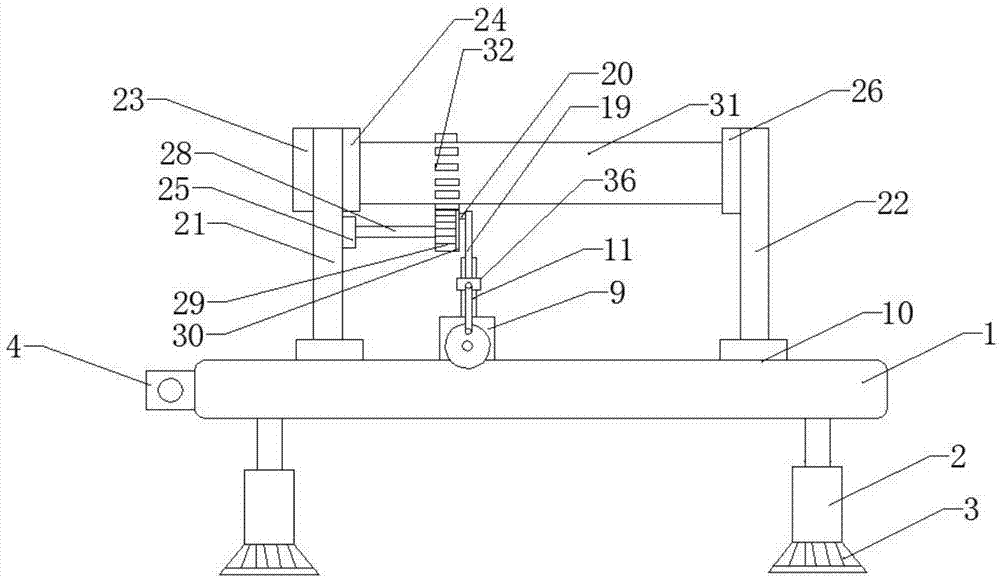

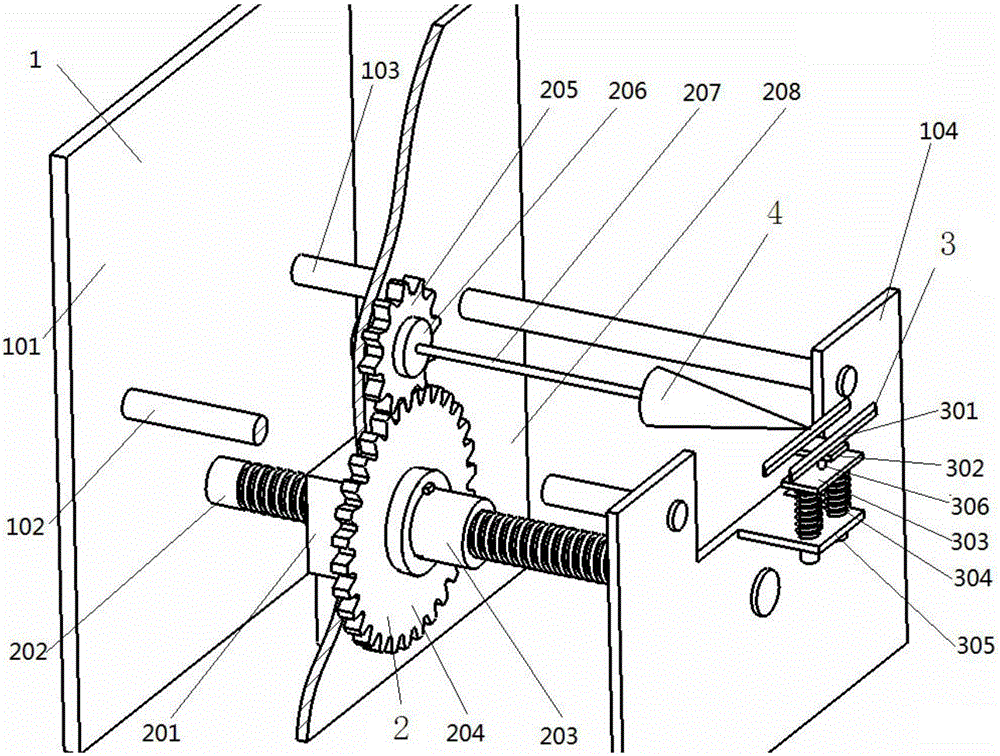

Film cutting device

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryEngineeringGear drive

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

Tea leaf drying equipment

PendingCN107514879AReduce the impactRealize rolling back and forthPre-extraction tea treatmentTea dryingElectric machineryStructural engineering

Owner:池州市华茂茶业有限公司

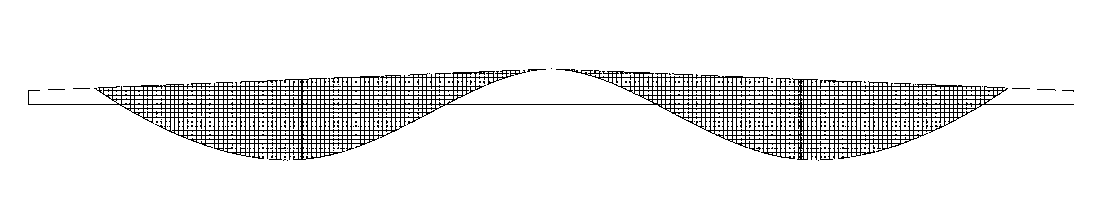

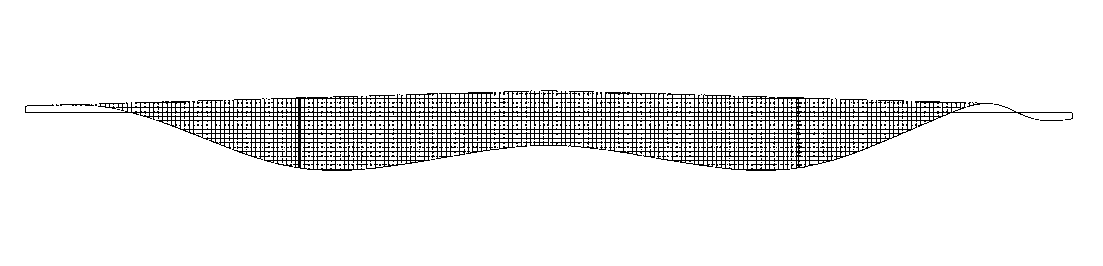

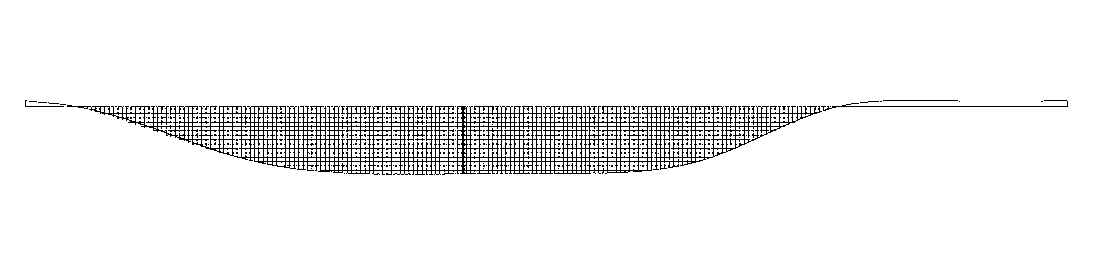

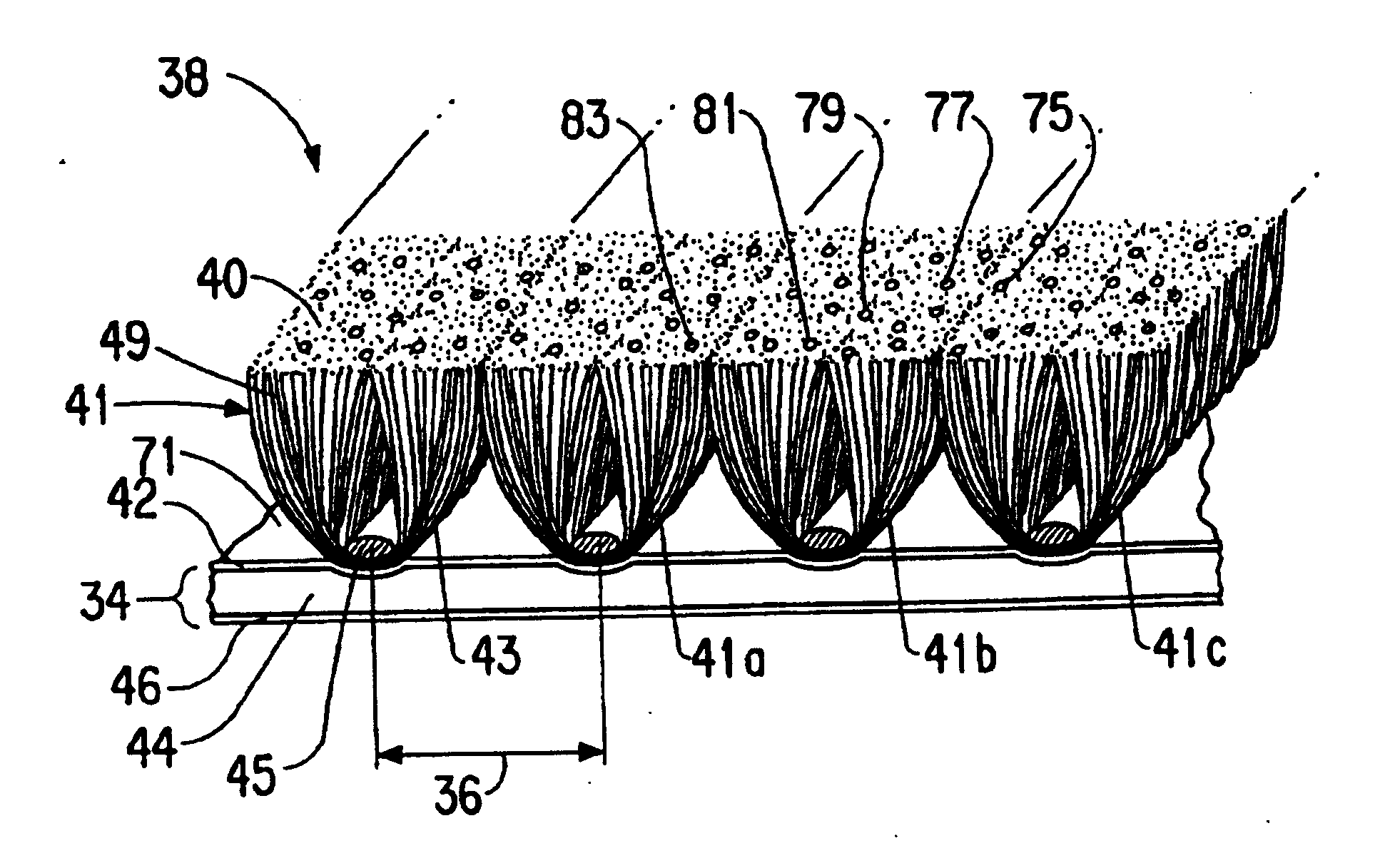

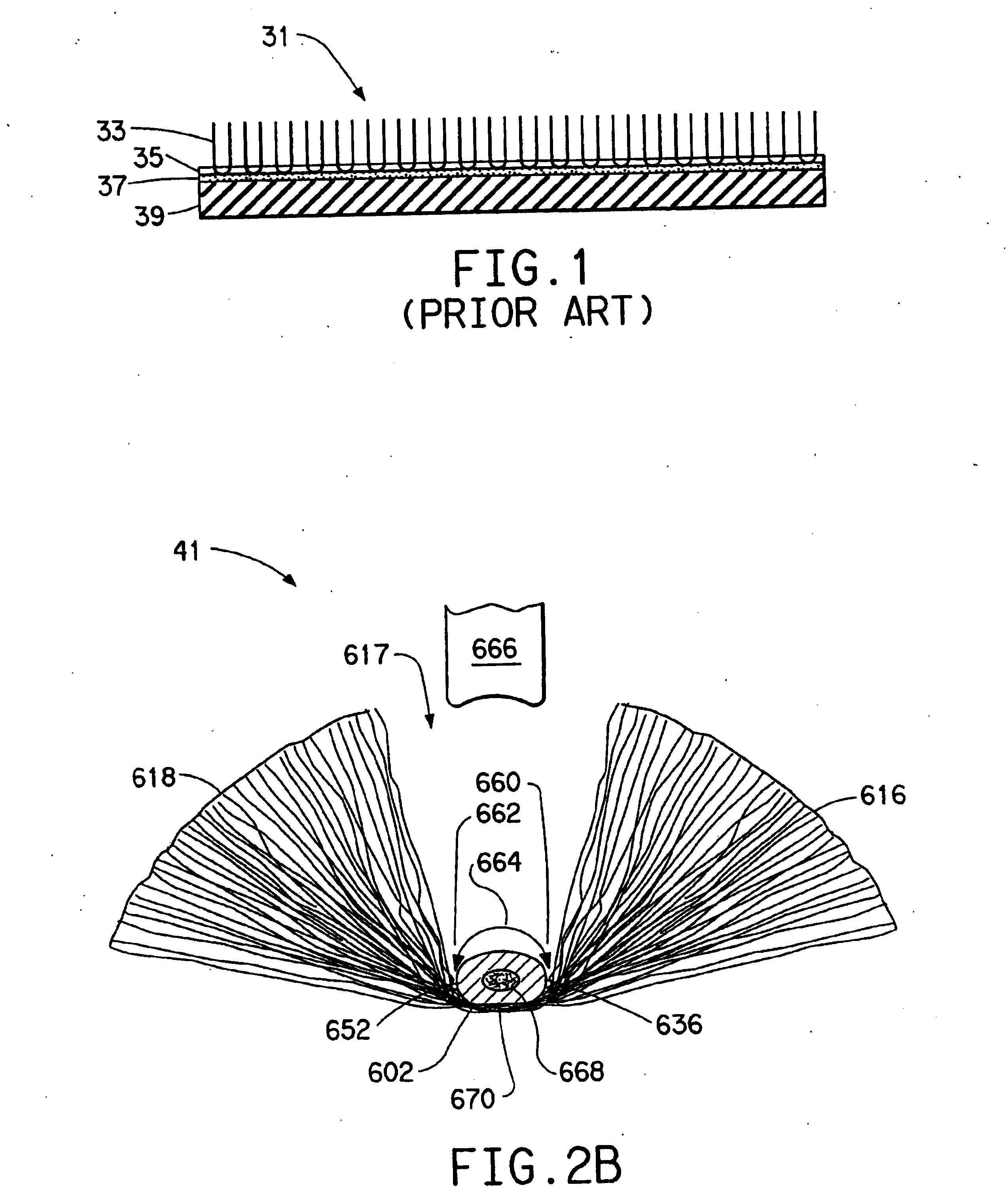

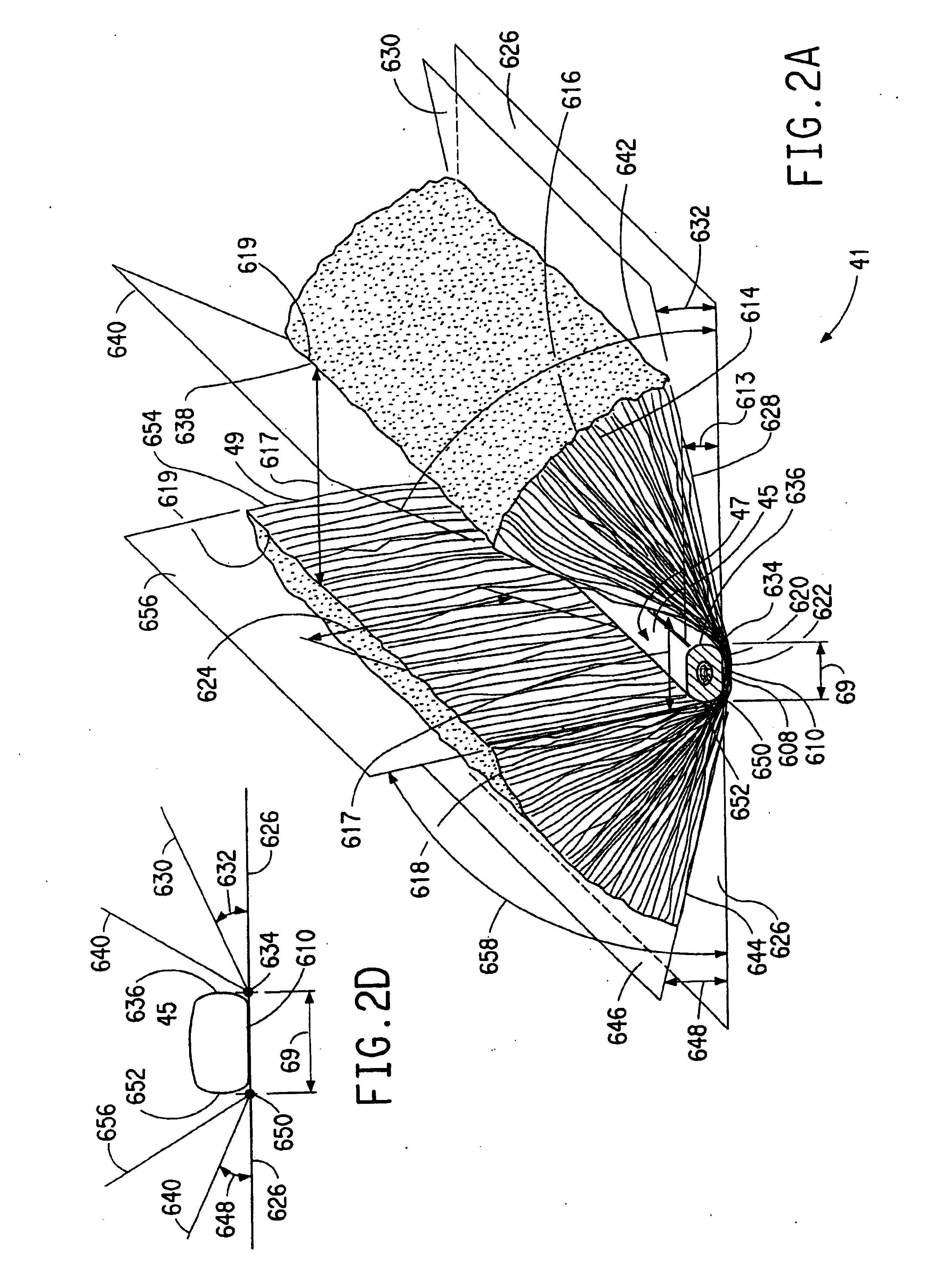

Velour-like pile articles and pile surface structures and methods of making

InactiveUS20050129905A1Convenient guidanceLittle torsional stabilityVehicle arrangementsSynthetic resin layered productsYarnStructural engineering

Owner:INVISTA NORTH AMERICA R L

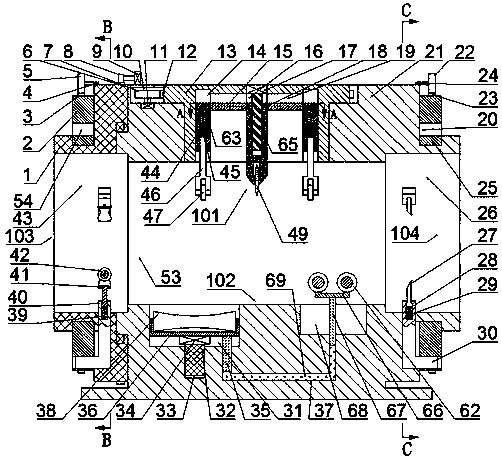

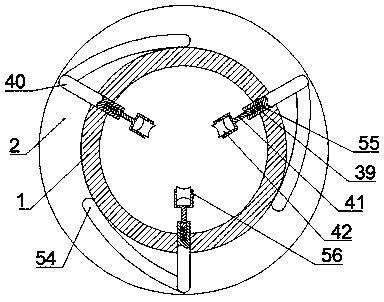

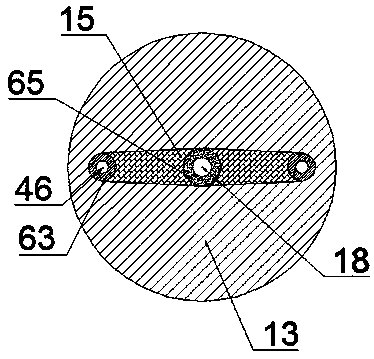

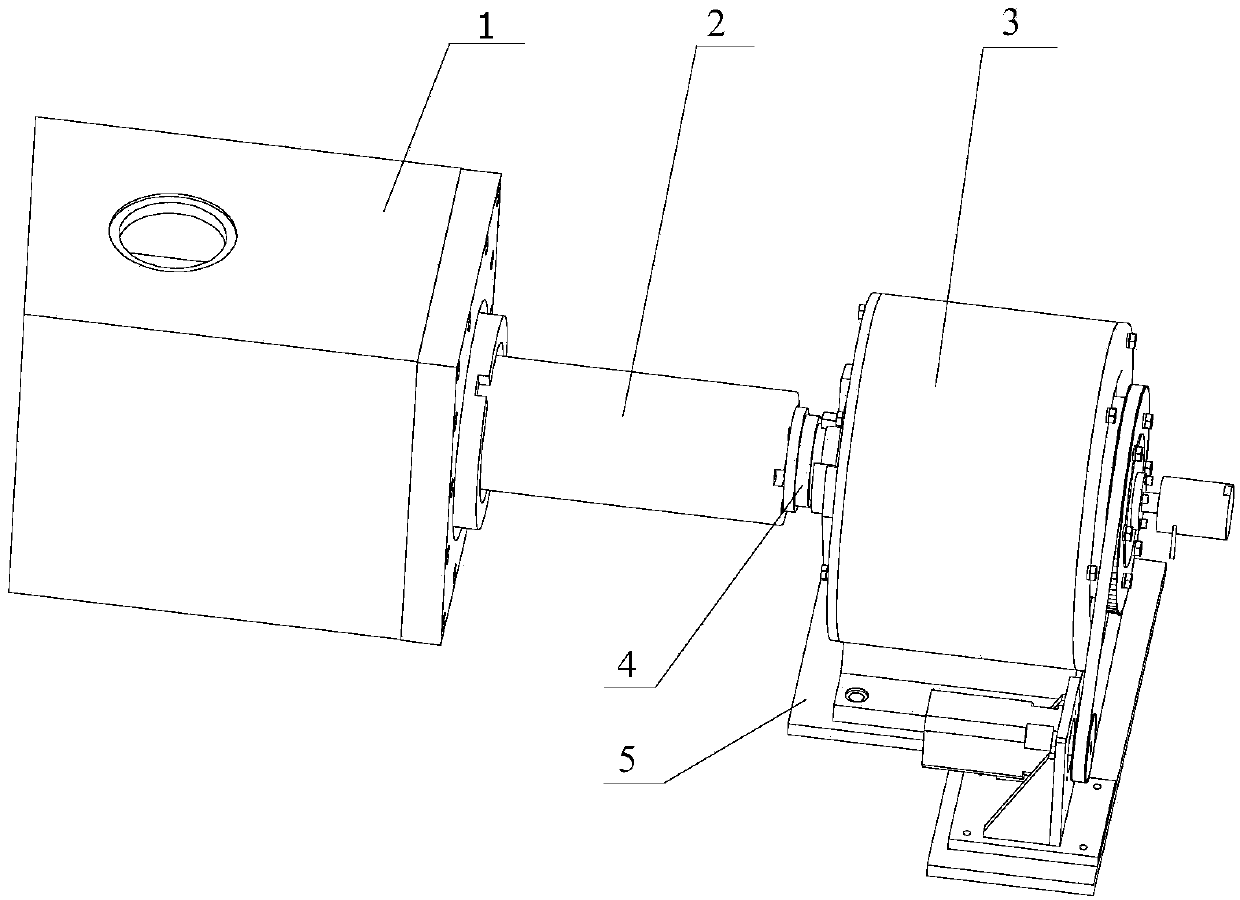

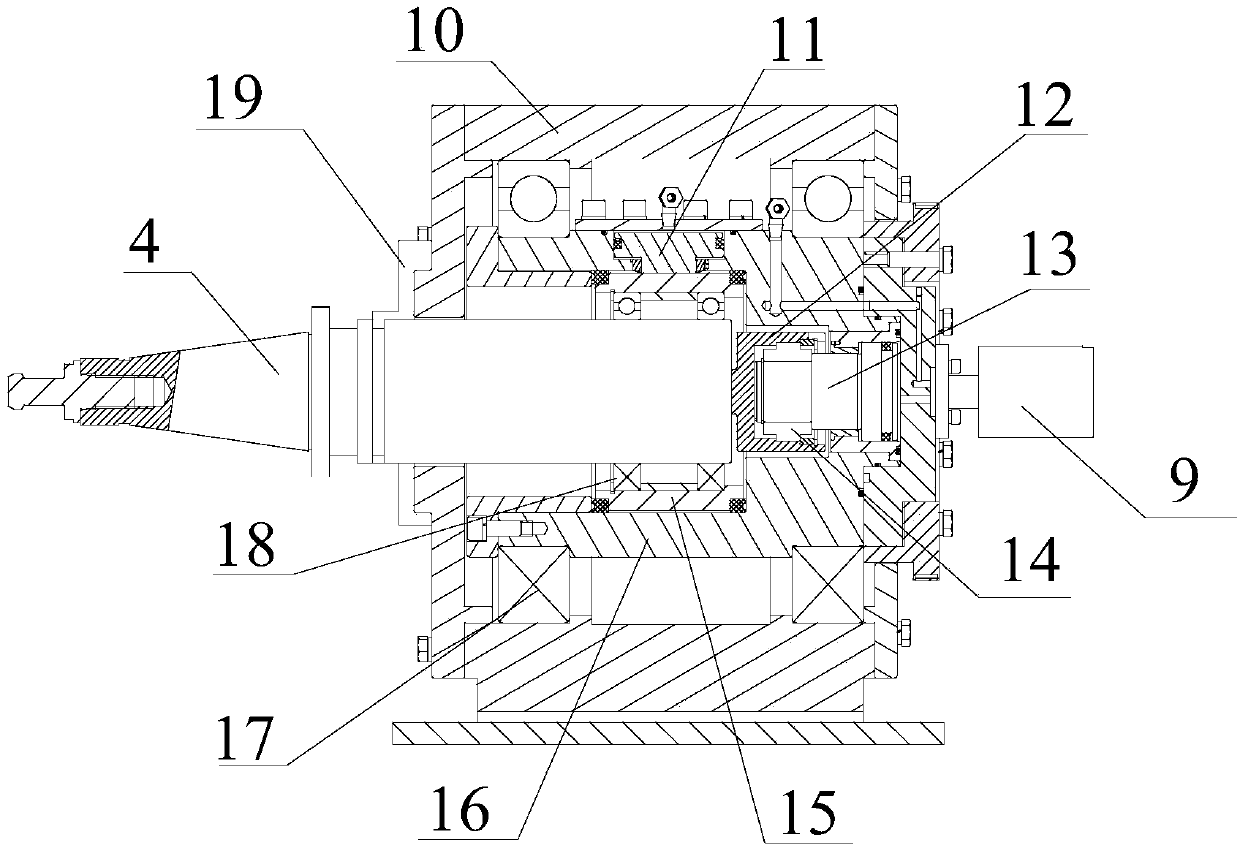

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

Soil sampling device for highway engineering road and use method thereof

PendingCN113404030AReduce manpower consumptionReduce difficultyIn situ soil foundationLow speedAgricultural engineering

Owner:谭小波

Shell stripping device and method for crushing shells of bamboo shoots

PendingCN105852162ACompact structureReduce volumeVegetable peelingReciprocating motionStructural engineering

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

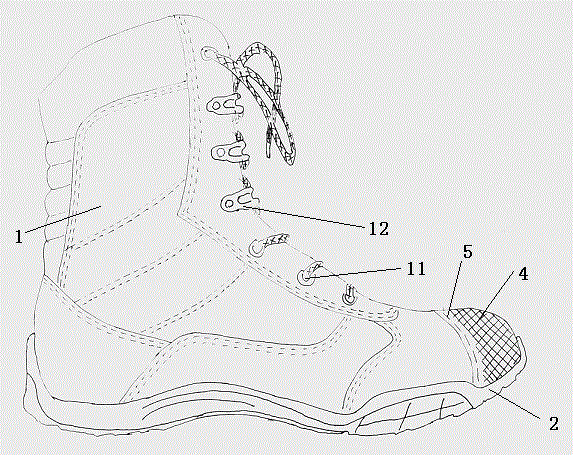

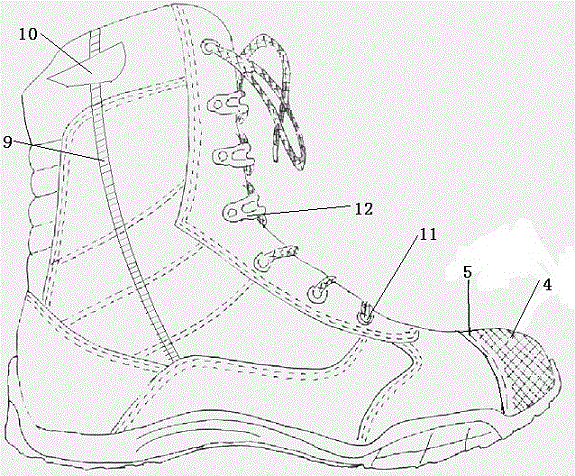

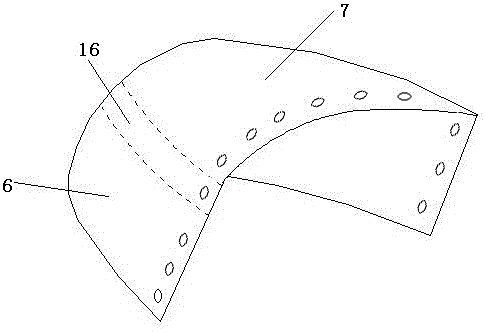

Safety shoe with external steel toe and production process of safety shoe

The invention discloses a safety shoe with an external steel toe and a production process of the safety shoe, and belongs to the technical field of labor protection appliances. The safety shoe comprises an upper, shoe sole, a tongue and the steel toe. The steel toe is arranged at the head portion of the upper. The safety shoe is characterized in that the steel toe is arranged on the outer layer of the surface skin of the upper, the inner side of the steel toe and the surface layer of the surface skin of the upper are connected in a glued mode, the bottom end of the steel toe is attached to the corresponding position of the edge of the bottom of the upper and fixedly connected with the shoe sole, the edges of the top face and the side face of the steel toe are evenly provided with a plurality of fixing holes, the positions, corresponding to the fixing holes, of the surface skin of the upper are provided with connecting holes, and mark threads penetrate through the fixing holes and the connecting holes so that the upper and the steel toe can be fixedly connected. The safety shoe is simple in structure and easy to produce and manufacture; the external steel toe is novel, fashionable and attractive, the comfort and safety are improved, and the safety shoe is durable in use and has wide market space.

Owner:江苏凯高鞋业有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap