Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Single plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicular suspension arm

InactiveUS20090295113A1High strengthStrengthTractor-trailer combinationsResilient suspensionsSingle plateStructural engineering

A vehicular suspension arm is provided in which an arm main body (1) includes a main plate (2) press-formed as a main part of the arm main body and having a short cylindrical part (EB) provided integrally with one end by flanging, and a reinforcing plate (H) superimposed on one of upper and lower faces of the main plate (2) and reinforcing the main plate (2). The reinforcing plate (H) has an eye-shaped head part (Ha) formed in an annular shape and arranged coaxially with the short cylindrical part (EB), and a tail part (Hb) extending integrally from the eye-shaped head part (Ha) along the longitudinal direction of the main plate (2), is formed from a single plate material that is thicker than the main plate (2), and has at least the tail part (Hb) welded to the main plate (2). A bush press-fit portion (P1) is formed from an inner peripheral face of the eye-shaped head part (Ha) and an inner peripheral face of the short cylindrical part (EB). This ensures that the cross-sectional shape of a transition section from the bush press-fit portion to the plate-type arm main body is adequate, thus enabling the rigidity and strength required for the transition section to be easily guaranteed and, furthermore, it becomes possible to meet a requirement for increasing the strength of the arm without specially increasing the space around the outer periphery of the bush press-fit portion.

Owner:F TECH INC +1

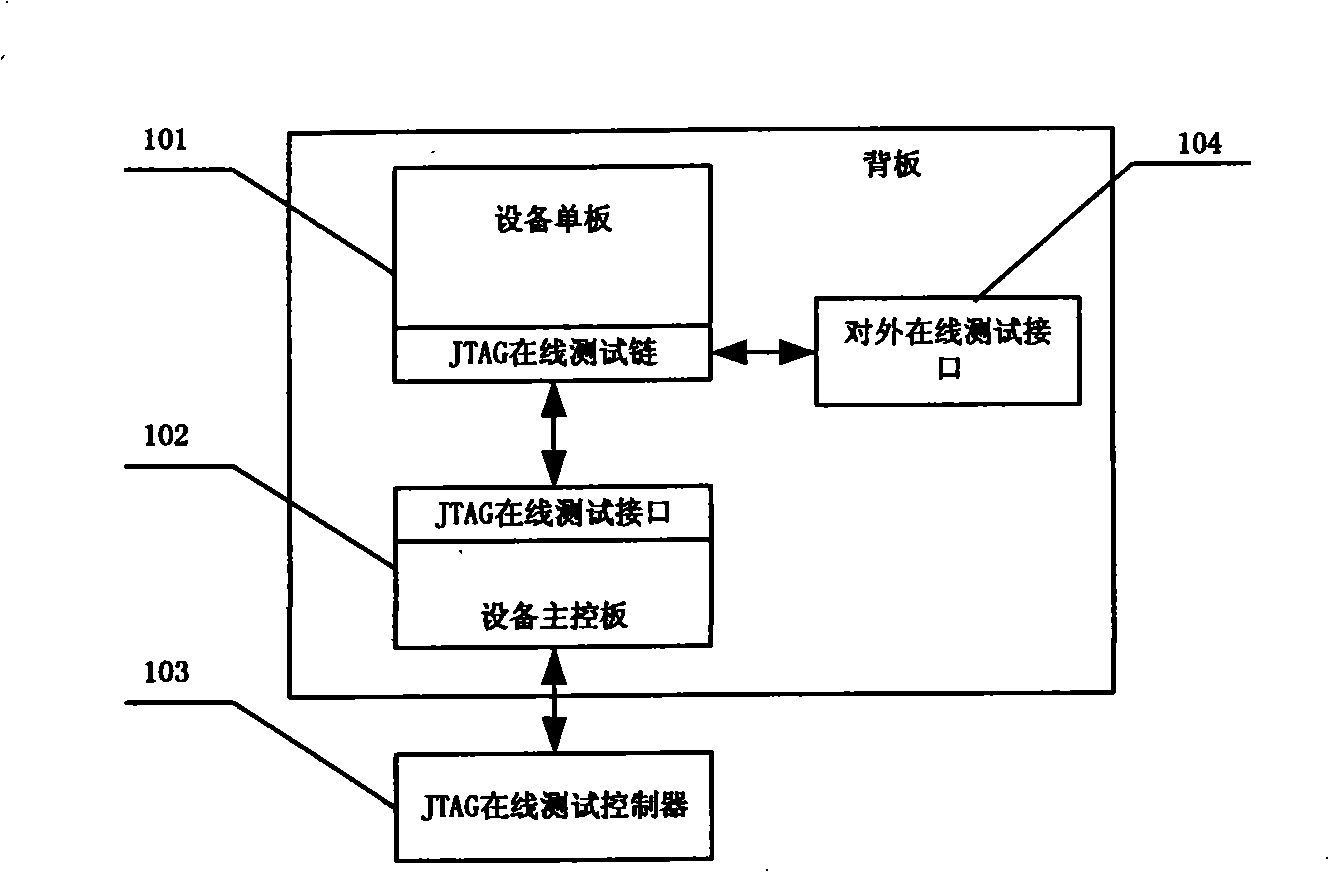

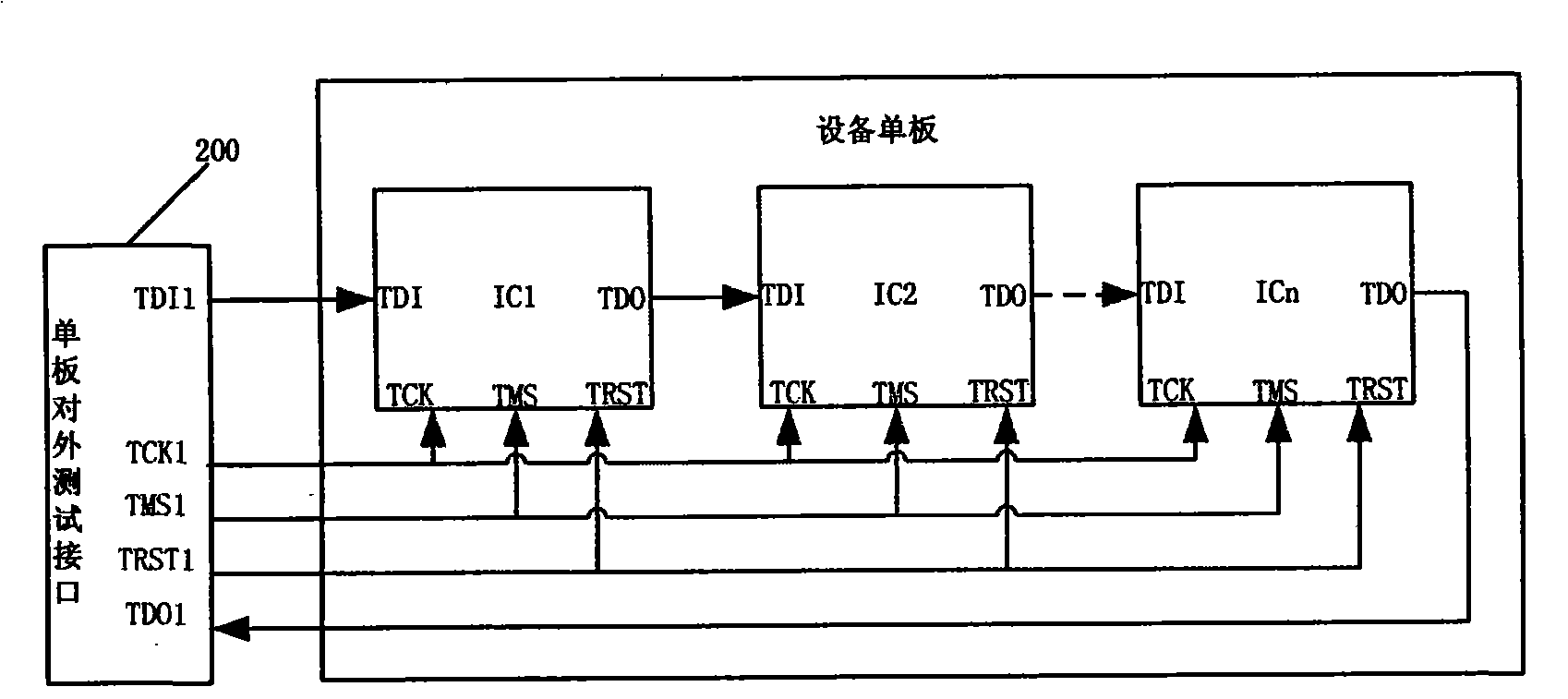

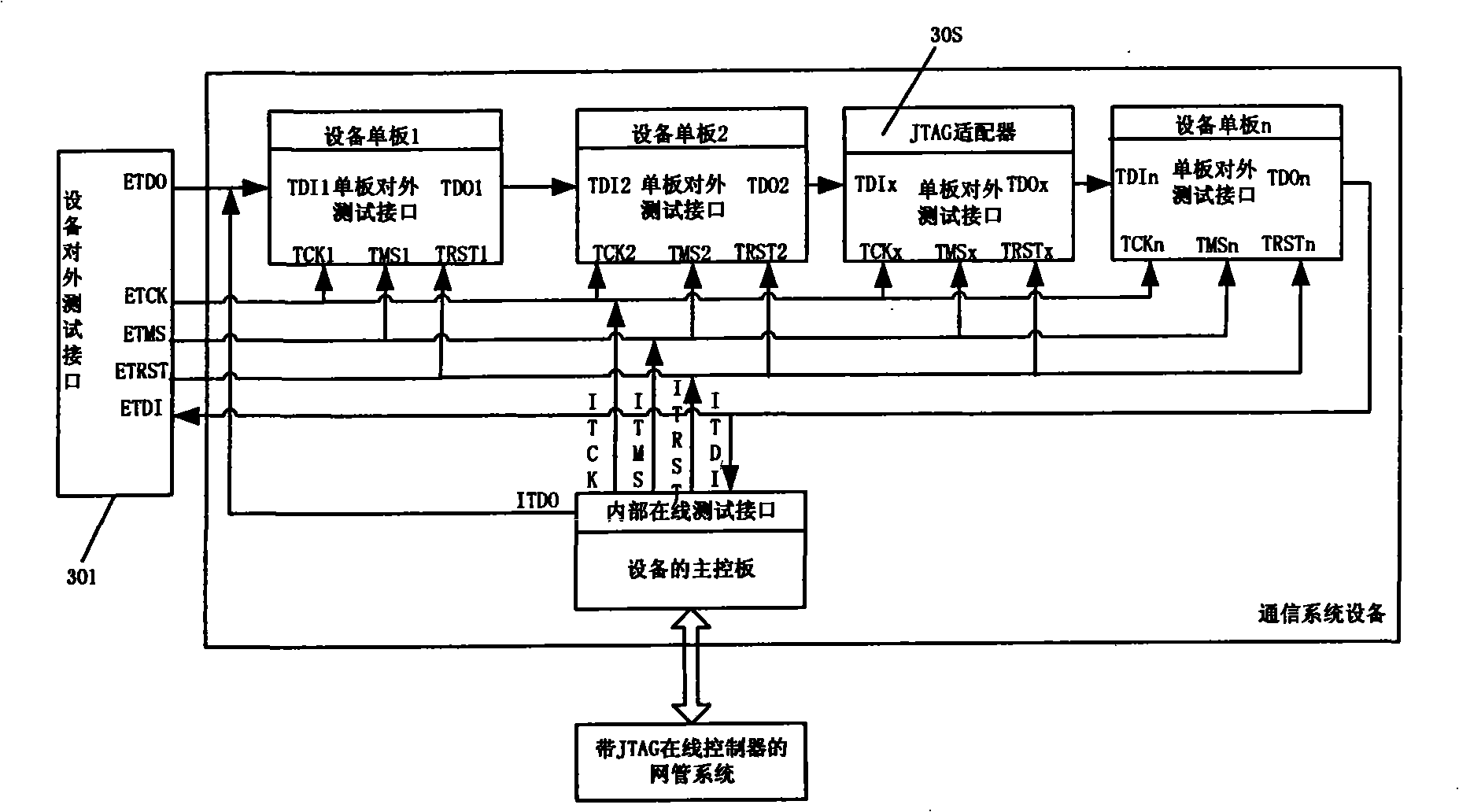

Communication system equipment and detection method thereof

InactiveCN101325517ARealize online automationRealize manual regular inspectionSupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsComputer hardwareCommunications system

Owner:ZTE CORP

Method for controlling single board to be safely started and method and device for upgrading software package

ActiveCN105117651AStartup does not affectImprove securityVersion controlPlatform integrity maintainanceElectricitySingle plate

The invention discloses a method for controlling a single board to be safely started. The method comprises the steps that after the single board is powered on, the resigned name of a software package to be loaded to the single board is acquired, the resigned name of the software package is obtained by using a single plate private key of the single board for resigning the software package, and is made after the original signature of the software package passes verification through a software package public key of the software package, and the original signature is obtained by signing the software package through a software package private key of the software package; the resigned name of the software package is verified through a single board public key paired with the single board private key; after the resigned name passes verification, the single board is started. According to the method for controlling the single board to be safely started, it can be guaranteed that the single board can still be safely started when the private key of the software package is leaked.

Owner:SHANGHAI HUAWEI TECH CO LTD

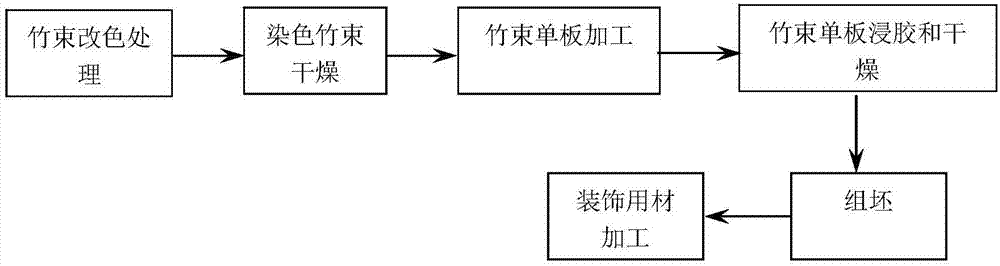

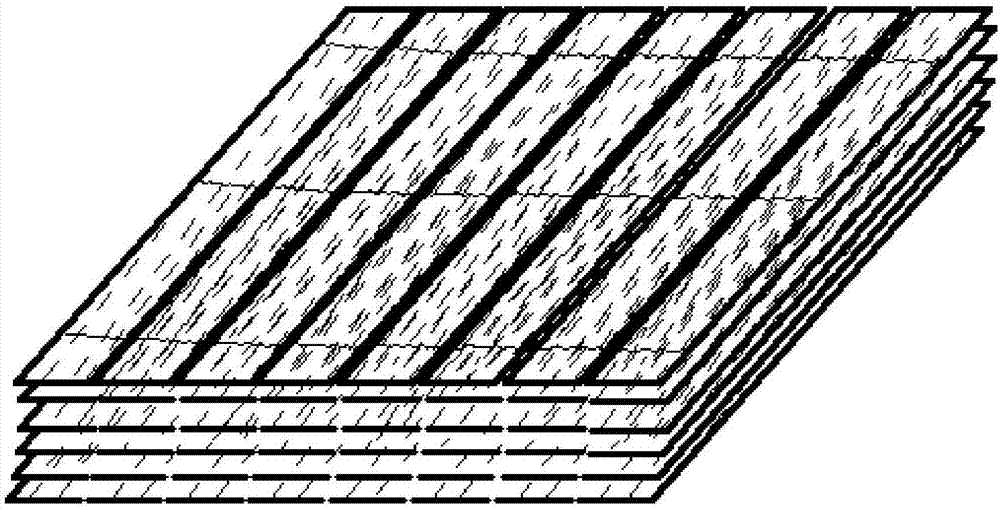

Manufacturing method of bamboo-based heterochromous laminated decorative plate

ActiveCN106926330AVariety of colorsFacilitate continuous productionOther plywood/veneer working apparatusWood treatment detailsChange colorSingle plate

Owner:国家林业局竹子研究开发中心

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

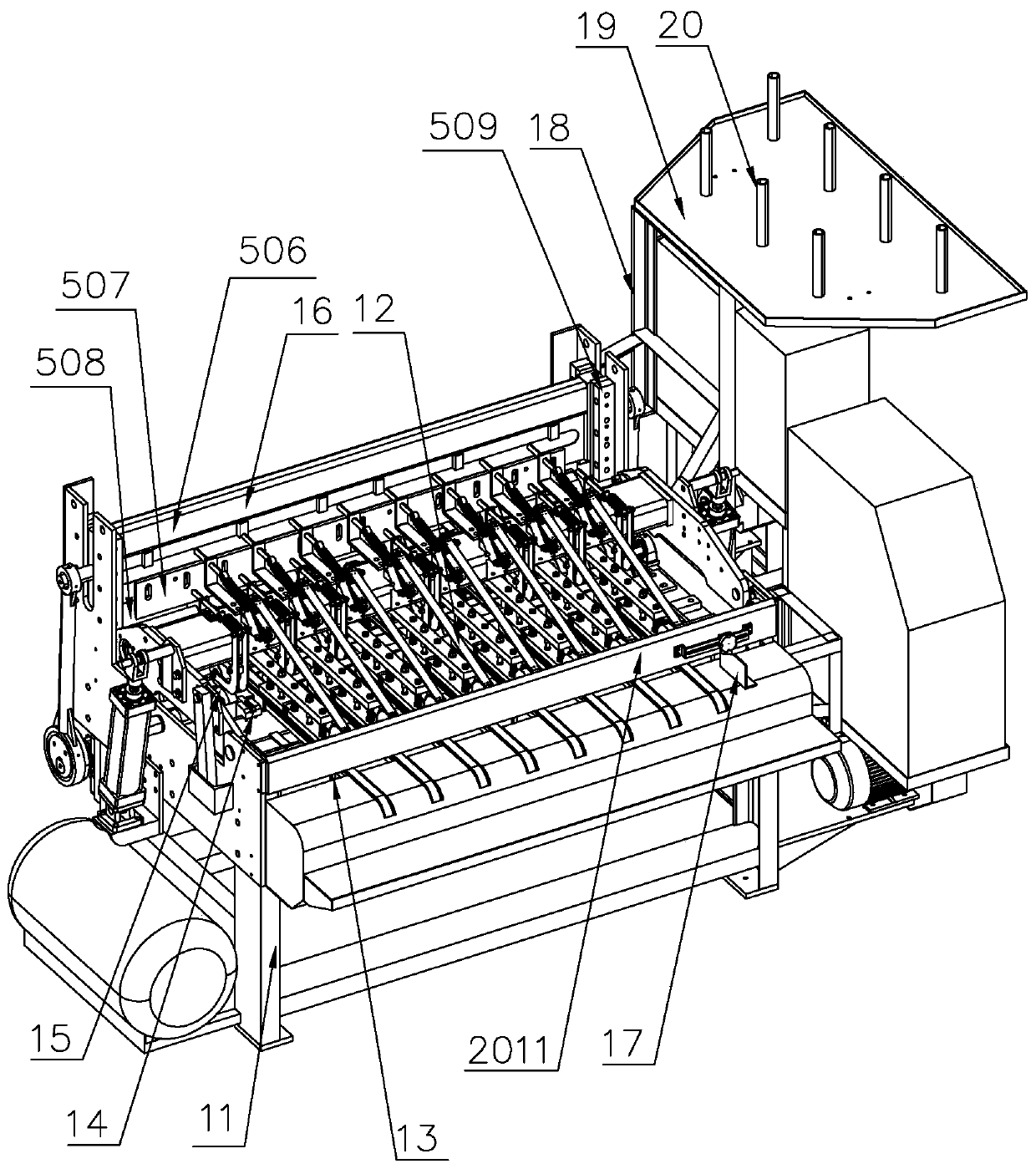

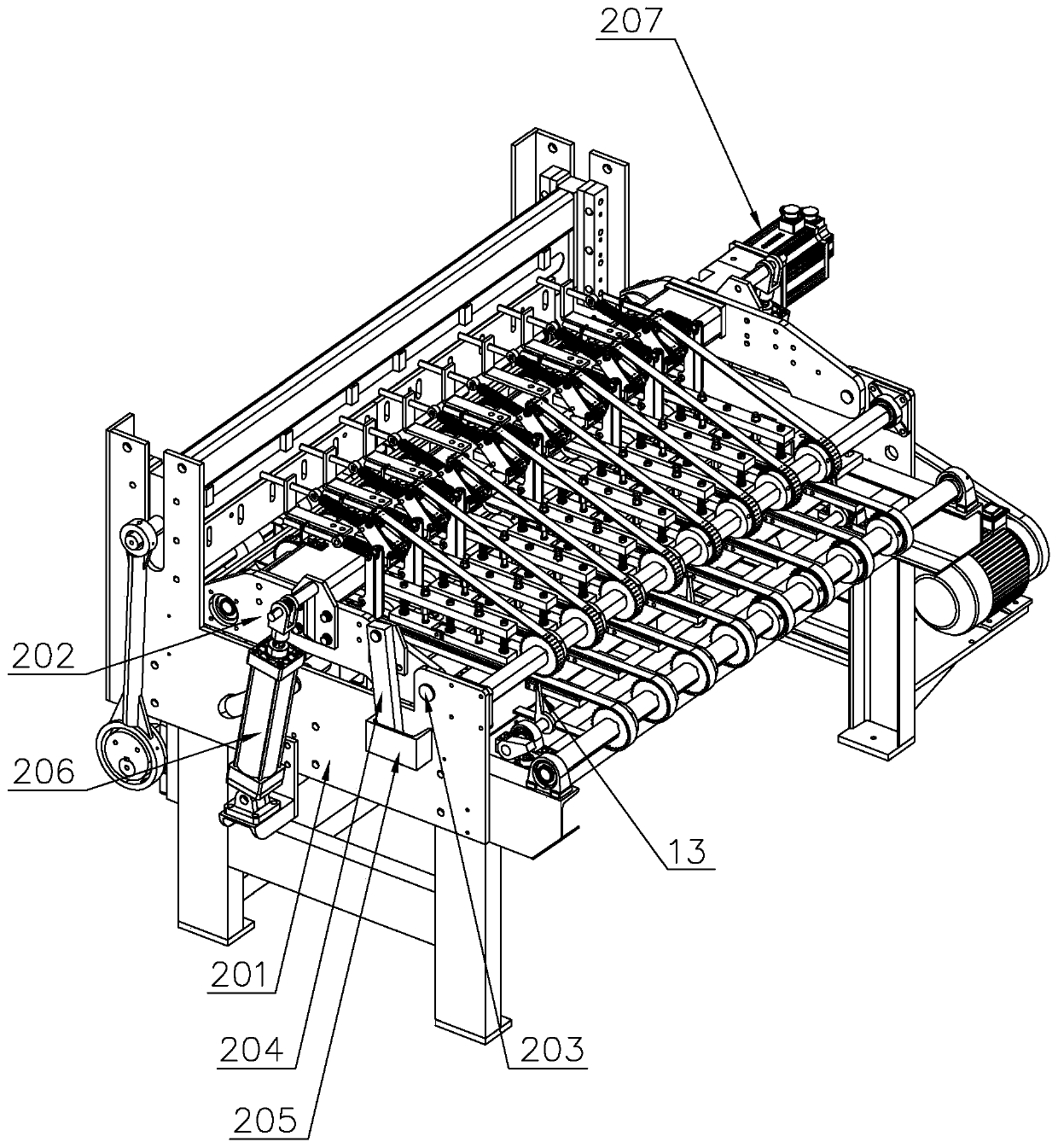

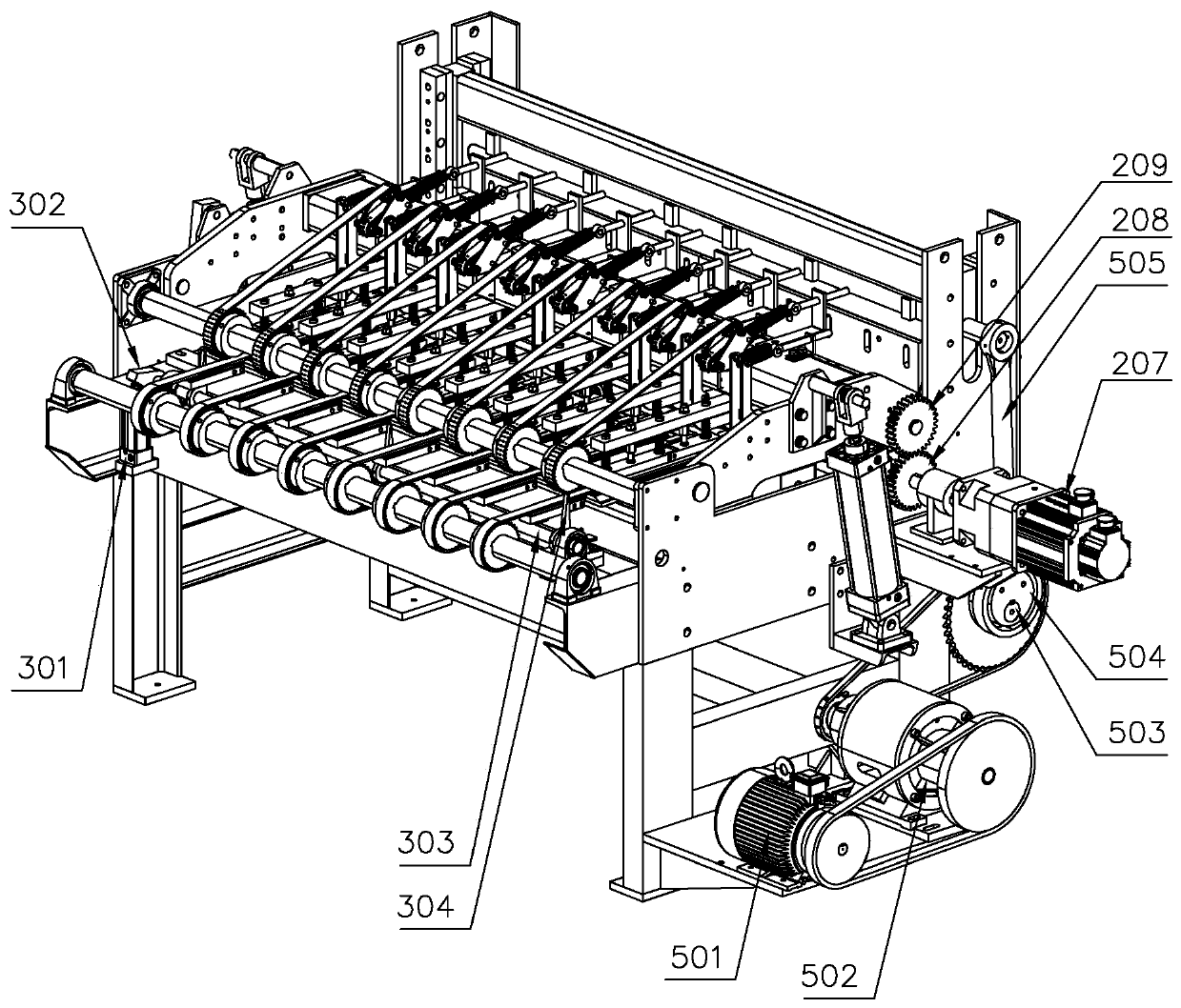

Full-automatic small strip splicing machine

PendingCN109940718AMake up for technical spaces that cannot be sewnImprove utilizationWood veneer joiningButt jointSingle plate

Owner:山东昶兴智能科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap