Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Increase elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Pallet with strength plates and related methods

A pallet includes a cargo layer and a base layer. The base layer includes a pair of spaced apart end deck boards, and a pair of spaced apart connector boards orthogonal to the pair of spaced apart end deck boards, with each connector board and each end deck board having respective ends. A strength plate is coupled to each respective end of the connector boards in the base layer. Spaced apart support blocks are between the base and cargo layers, and form a gap therebetween for receiving a lifting member. First fasteners couple the cargo layer to an upper surface of the support blocks. Second fasteners couple the base layer to a lower surface of the support blocks so that the ends of the connector boards and the corresponding strength plates are coupled to a first area of the lower surface of the support blocks, and so that the ends of the end deck boards are coupled to a second area of the lower surface of the support blocks.

Owner:CHEP TECH PTY LTD

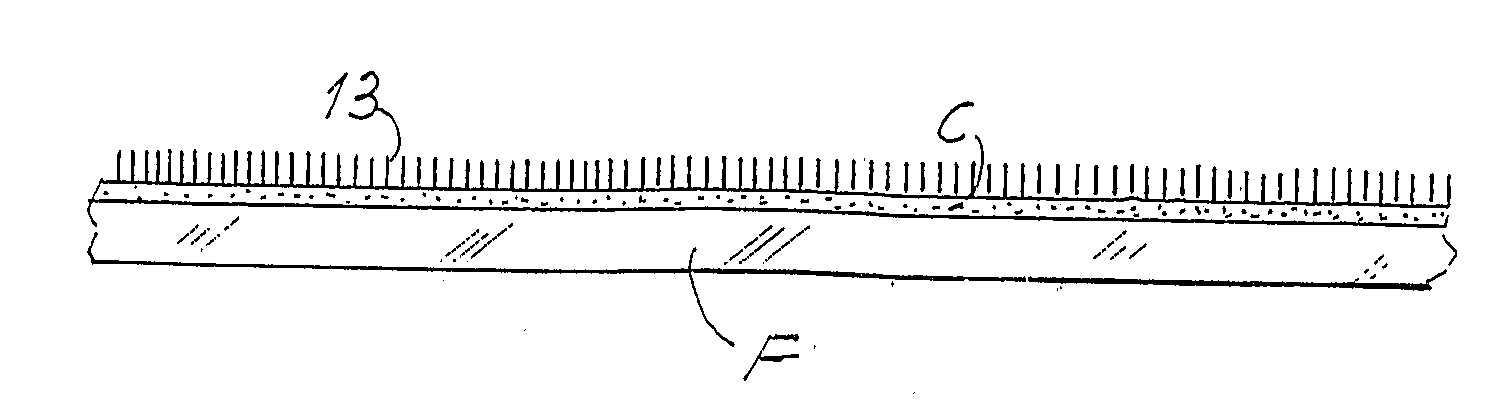

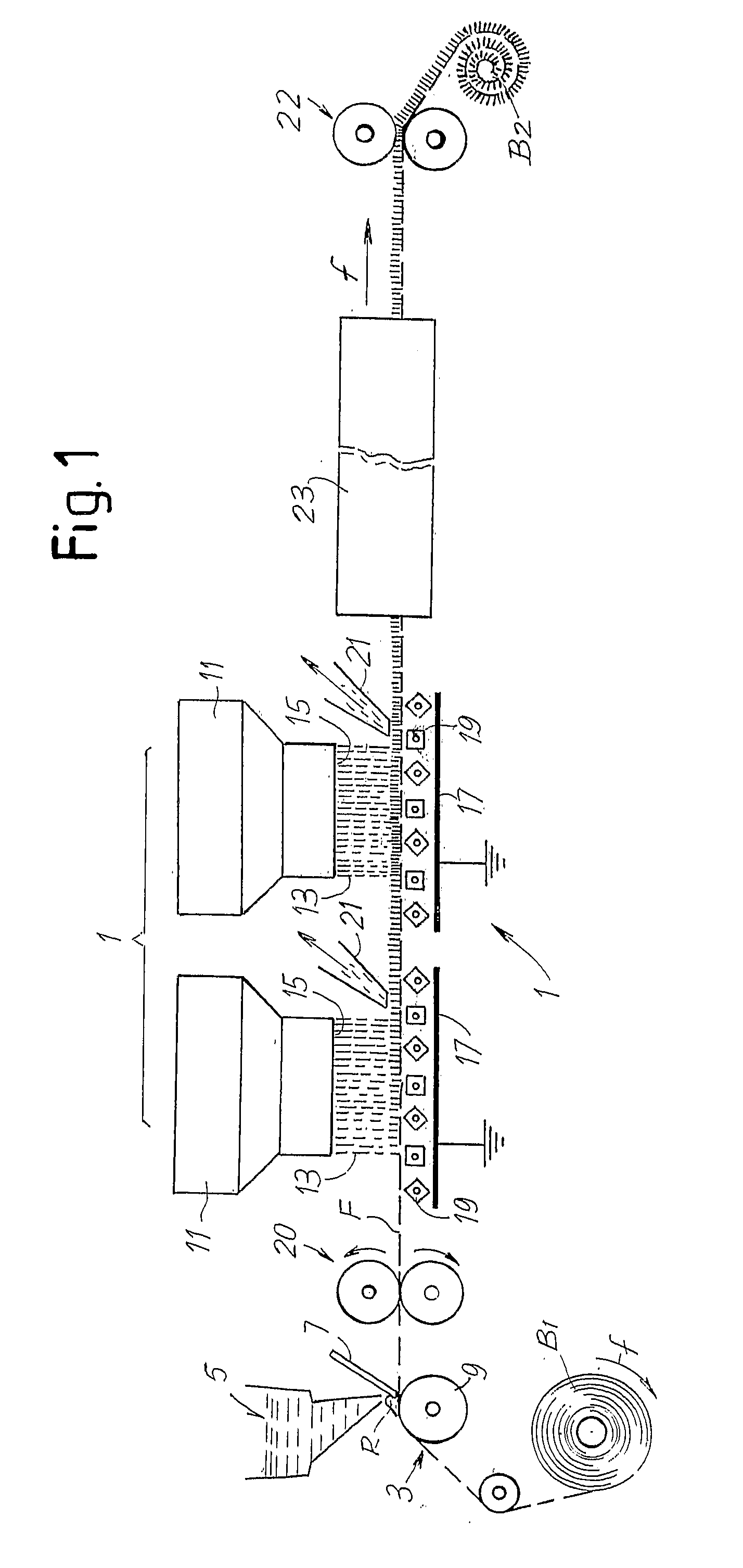

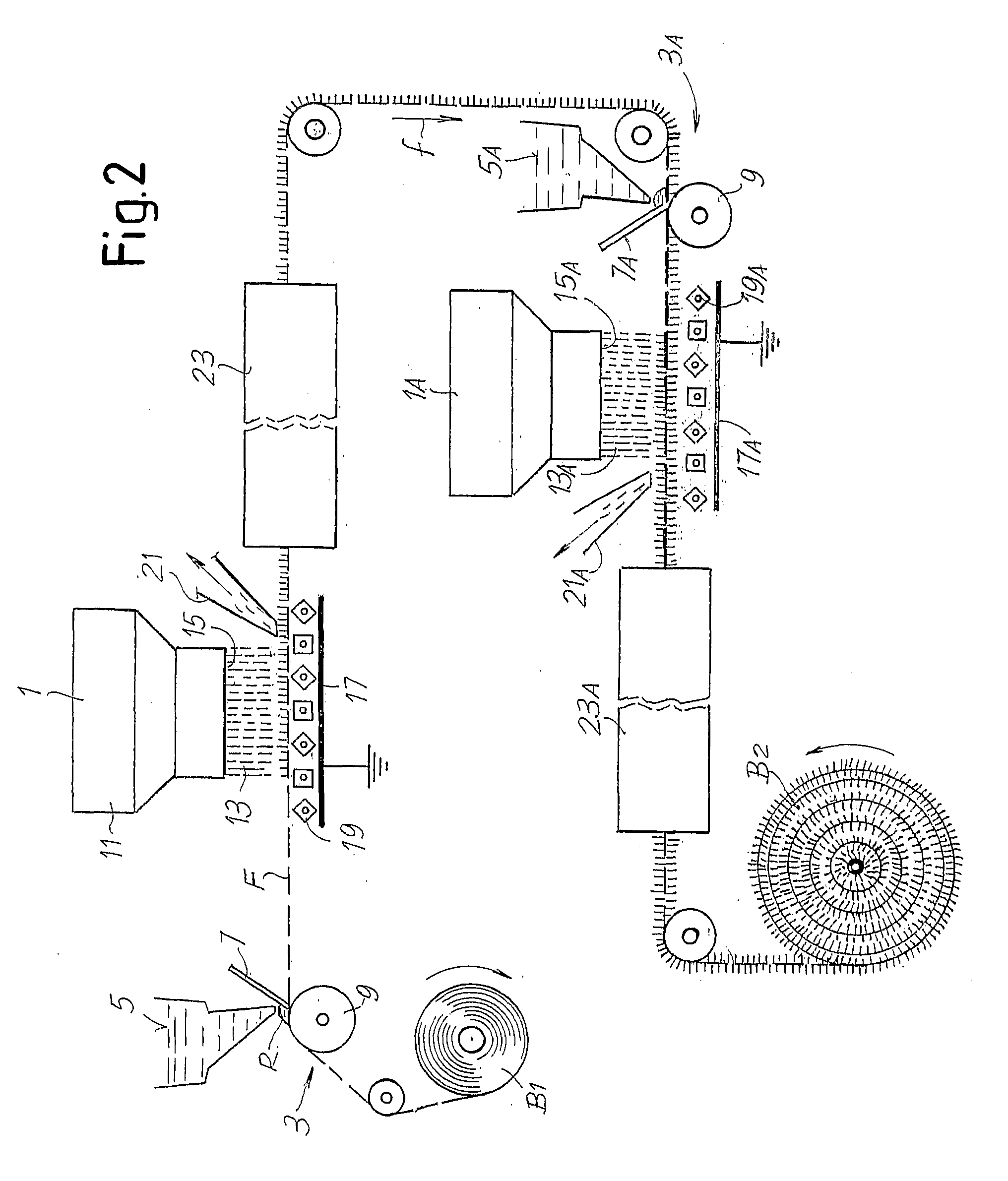

Elastic material coated in fibers, a diaper comprising said elastic material and a method for the production thereof

ActiveUS20090221982A1Modest deformationIncrease elasticityLiquid surface applicatorsLayered productsPolymer chemistryFiber

Owner:FINTEX & PARTNERS ITAL

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

InactiveCN109796825AAnti-rust and waterproof effect lasts for a long timeImprove UV protection effectAnti-corrosive paintsCelluloseUltraviolet

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

Wear resistant sole material

InactiveCN103483677ADoes not affect elasticityDoes not affect resilienceSolesEnvironmental resistanceFoaming agent

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:KUNSHAN CHUNBAI PRECISE HARDWARE CO LTD

Instant shrimp sausage and preparation method thereof

The invention relates to a process for producing an instant shrimp sausage, belonging to the technical field of food processing. The instant shrimp sausage comprises a main material and auxiliary materials, the main material comprises 50-60 parts by weight of shrimp meat and 17-19 parts by weight of ice water; an auxiliary material A comprises 3.5-3.7 parts by weight of protein isolate, 1.0-1.2 parts by weight of egg albumen powders, 3.0-3.2 parts by weight of onion, 4.8-5.0 parts by weight of corn starch, 9-10 parts by weight of soybean oil and 1.8-2 parts by weight of sodium lactate; an auxiliary material B comprises 1.0-1.2 parts by weight of edible salt, 0.7-0.9 part by weight of white sugar, 0.10-0.11 part by weight of pepper, 0.18 part by weight of sodium tripolyphosphate, 0.02 part by weight of sodium hexametaphosphate, 0.02 part by weight of sodium pyrophosphate, 0.1 part by weight of sodium citrate, 0.5 part by weight of carrageenan and 0.1 part by weight of D-sodium isoascorbate. The production process comprises the following thirteen steps: examination and acceptance of raw materials, defreezing, water controlling, cutting, vacuum mixing, filling / sealing, steaming, sterilizing, cooling, air curing, packaging, boxing and storage. The instant shrimp sausage prepared according to the method has compact flesh, long shelf life, is conveniently and instantly eaten, tastes good, and has less content of auxiliary materials and high nutrition value.

Owner:ZHANJIANG GUOLIAN AQUATIC PROD CO LTD

Flexible waterproof mortar and production method thereof

The invention discloses flexible waterproof mortar and a production method thereof. The method comprises a liquid material component and a powder material component. The liquid material component comprises styrene-acrylic emulsion, acetic acid emulsion, water, a defoaming agent, and a bactericide. The powder material component comprises quartz powder, wollastonite powder, ash concrete, a water-reducing agent, a dispersing agent, and a leveling thixotropic agent. The waterproof mortar is prepared from the liquid material and the powder material according to a ratio of 1:2. The waterproof mortar has good extensibility and high elasticity. With the mortar, slight cracks on a base layer can be resisted. During vertical surface construction, the waterproof mortar is prevented from flowing and dropping, and has good construction performance. After coating, the mortar surface is smooth as mirror. The mortar is suitable for underground space water prevention, seepage prevention, and moisture prevention. The mortar is especially suitable for water prevention of buildings with waterproof exposed underground. Soaking of underground condensed water and dew condensation to the building can be effectively resisted for a long time.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL +3

Crease-resistant wear-resistant fabric

InactiveCN109532130AGood warmth retentionImprove breathabilitySynthetic resin layered productsClothingsYarnWear resistant

The invention provides a crease-resistant wear-resistant fabric, which comprises a fabric body, wherein the fabric body is of an double-rib composite double-layer tissue structure compounded by changeplain stitch and tuck stitch; an inner layer fabric of the fabric body is woven by spandex composite yarns; an outer layer fabric of the fabric body is woven by chinlon composite yarns; the inner layer fabric and the outer layer fabric are connected in series through the tuck stitch. The fabric uses a double-rib air layer structure; the spandex composite yarns are used as the inner layer fabric;the chinlon composite yarns are used as the outer layer fabric; the problems of poor wear resistant performance, poor durability and easy crease occurrence of the existing fabric are solved.

Owner:SWOTO PROTECTION & TECH CO LTD +1

High-strength composite fiber non-woven cloth and preparation method thereof

ActiveCN106427147AFirmly connectedClosely connectedProtective equipmentSynthetic resin layered productsEpoxyAlcohol

The invention discloses high-strength composite fiber non-woven cloth and a preparation method thereof. Ultrahigh-strength high-modulus polyethylene fibers are used as base materials, the polyethylene fiber obtained after fiber placement is subjected to a series of homogenization, parallelization and straight and upright arrangement and placed in a modified epoxy resin solution for sizing treatment in an environment of 60-80 DEG C, then the formed polyethylene fiber layers are subjected to composite lamination, and the non-woven cloth is prepared, wherein the modified epoxy resin solution is prepared by adding and mixing an adhesion agent, a filling agent, an insulating filler, fire retardant, white carbon black and ethyl alcohol, the mass of hydroxyl chemigum accounts for 8-12% of the mass of the modified epoxy resin solution, and the content of vinyl cyanide accounts for 18-30% of the content of hydroxyl chemigum. The non-woven clothes with different thicknesses are prepared by lamination of the polyethylene fiber layers, an antiknock device can be made from different types of non-woven cloths according to explosion sites and use environment, and the non-woven cloths with different thicknesses are different in anti-explosion range so as to sufficiently withstand the impact of a bullet.

Owner:JIANGSU LINRY NEW MSTAR TECH

Improved anti-skid light running shoes

InactiveCN102871276AIncrease elasticityProtect healthBootlegsSolesAir cushionBiochemical engineering

Owner:NANTONG OERSTED SHOES

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AEnhance internal bondingImprove mechanical propertiesVulcanizationPolymer science

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Calcium sulfate whisker/styrene-butadiene latex composite foaming material and preparation method thereof

ActiveCN108841060AImprove performanceImprove mechanical propertiesMechanical propertyButadiene-styrene rubber

The invention discloses a calcium sulfate whisker / styrene-butadiene latex composite foaming material and a preparation method thereof. Raw materials preparing the calcium sulfate whisker / styrene-butadiene latex composite foaming material comprise, in parts by weight: 50 to 70 parts of styrene-butadiene latex, 8 to 20 parts of natural rubber latex, 5 to 20 parts of modified calcium sulfate whiskers, 0.5 to 4 parts of a modified glass fiber, 2 to 6 parts of talcum powder, 0.02 to 0.15 part of calcium chloride, 2 to 6 parts of zinc oxide, 3 to 8 parts of liquid soap and 0.5 to 3 parts of benzoylperoxide, wherein the solid content of the styrene-butadiene latex is 55 to 68 percent. The calcium sulfate whisker / styrene-butadiene latex composite foaming material prepared by the method is low indensity, light in weight, high in bearing capacity, excellent in mechanical property such as breaking elongation and toughness and high in resilience performance; furthermore, the preparation method is simple, and the preparation process is easy to operate; a product is high in size stability.

Owner:RUIAN SAIBAO LATEX TECH CO LTD

Preparation method and formula of aquatic feed

InactiveCN112753893AIncrease elasticityIncrease sweetnessFood processingClimate change adaptationHordeum vulgareHermetia illucens

The invention discloses a preparation method and a formula of an aquatic feed. The preparation method of the aquatic feed comprises the following steps of: S1, selecting the following raw materials in a weight ratio: dry flour of yellow mealworms, dry flour of barley pests, dry flour of black soldier flies, puffed soybean meal, pregelatinized starch, high-gluten flour, spirulina powder, blood worm powder, shrimp shell powder, beer yeast powder, bentonite powder, multivitamin for eels, glycerol monolaurate, choline chloride and calcium dihydrogen phosphate; S2, uniformly stirring the raw materials to form a mixed raw material; S3, adding water into the mixed raw material, continuing stirring, and then puffing the mixed raw material, wherein the water content in the mixed raw material is 17-20% by mass; and S4, after the puffing is completed, cooling and drying the granulated feed formed by puffing. The preparation method and the formula of the aquatic feed are applied to the technical field of aquatic feeds.

Owner:GUANGDONG LUJIN BIOTECHNOLOGY CO LTD

Polyurethane-nylon 6 block copolymer, preparation method thereof and polyurethane-nylon 6 elastic fiber

ActiveCN112127007AHigh mechanical strengthImprove wear resistanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides a polyurethane nylon 6 block copolymer, a preparation method thereof and a polyurethane nylon 6 elastic fiber. The polyurethane nylon 6elastic fiber is obtained by performing melt spinning on the polyurethane nylon 6 block copolymer. The polyurethane nylon 6 block copolymer is an ABA type block copolymer, wherein the block A is an amino-terminated polyamide chain segment, the block B is an isocyanate-terminated polyurethane chain segment, the mass content of the isocyanate-terminated polyurethane chain segment is 20-60wt%, and amino-terminated polyamide and isocyanate-terminated polyurethane are subjected to polymerization reaction according to a molar ratio of 1.2:1 to 1.3:1 by adopting a hydrolytic polymerization method. The molecular structure of the polyurethane-nylon 6 copolymer is designed, so that the copolymer has excellent properties of polyurethane and nylon, copolymer slices meeting melt spinning requirements are obtained, and the polyurethane-nylon 6copolymer elastic fiber with high strength and high resilience is obtained through melt spinning.

Owner:WUHAN TEXTILE UNIV

Foaming material with modifying filler

InactiveCN103613836AIncrease elasticityStrong sound insulationLinear low-density polyethylenePolyvinyl chloride

The invention discloses a foaming material with modifying filler. The foaming material is characterized by being prepared from the following raw materials in parts by weight: 80-90 parts of linear low density polyethylene, 12-16 parts of SG-5 polyvinyl chloride, 20-24 parts of calcium carbonate powder, 2-3 parts of stearic acid, 2-3 parts of zinc oxide, 4-5 parts of azodicarbonamide, 5-7 parts of chlorinated paraffin, 3-5 parts of polyethylene terephathalate, 4-6 parts of titanium dioxide powder, 2-3 parts of triphenyl phosphite and 6-8 parts of modifying filler. Due to addition of the modifying filler, the foaming material has excellent flame retardant effect, and is further endowed with excellent mechanical property, good rebound resilience and strong sound insulation performance. The polyvinyl chloride foaming material simultaneously has the characteristics of heat insulation, light weight, low water absorption and the like. The foaming material also has the advantages that the operation is simple, the raw materials are easily available, and the cost is low.

Owner:ANHUI AOLO DOOR & WINDOW SYST ENG CO LTD

Colored emulsified coating formula and manufacturing process

The invention relates to a colored emulsified coating formula and a manufacturing process. The invention relates to a surface cover layer of an urban road, particularly the surface cover layer of the urban road of an exclusive region such as a sidewalk for the blind, a cycle path, a sidewalk and an anti-skid path of a common motorway. The colored emulsified coating formula is realized by the following technical scheme: the colored emulsified coating formula comprises 0.1-4% of an emulsifier, 5-30% of a water-borne coloring agent: water-borne color paste and a colorless asphalt or decolored asphalt component: petroleum resin and mineral oil. The manufacturing process of the colored emulsified coating formula comprises the steps: uniformly emulsifying the colorless asphalt or decolored asphalt which is heated to 100-150 DEG C through a colloid mill with the emulsifier and water and the like to prepare an emulsifying coating; and uniformly stirring the emulsifying coating with the water-borne color paste to obtain the colored emulsified coating. Compared with other processes, the product lowers the cost and is simple in production process. Moreover, the product is simple in construction operation, bright in color, attractive, and good in anti-ageing and wear-resistant properties, and has the functions of improving the strength of pavement and roof, preventing water and isolating heat.

Owner:毛葵燕

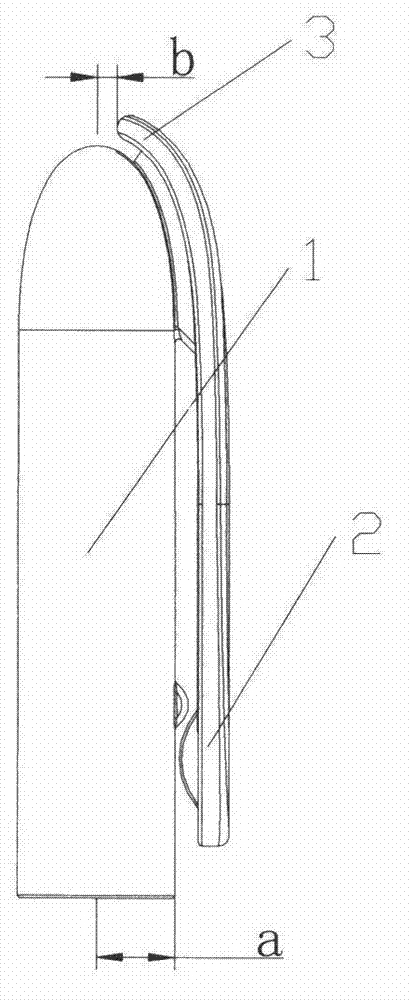

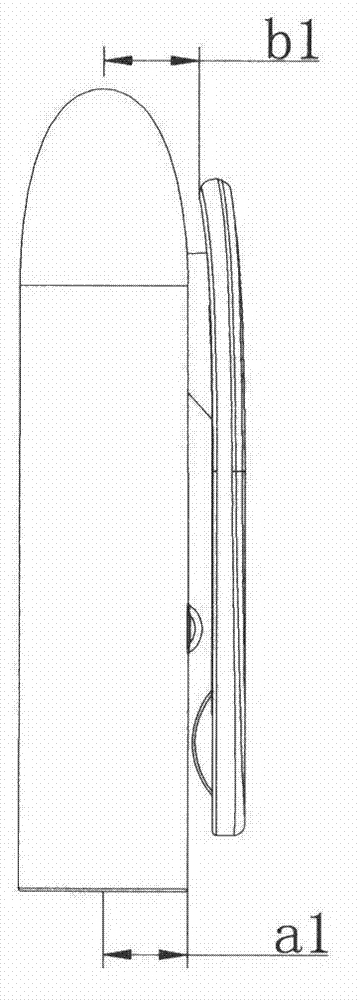

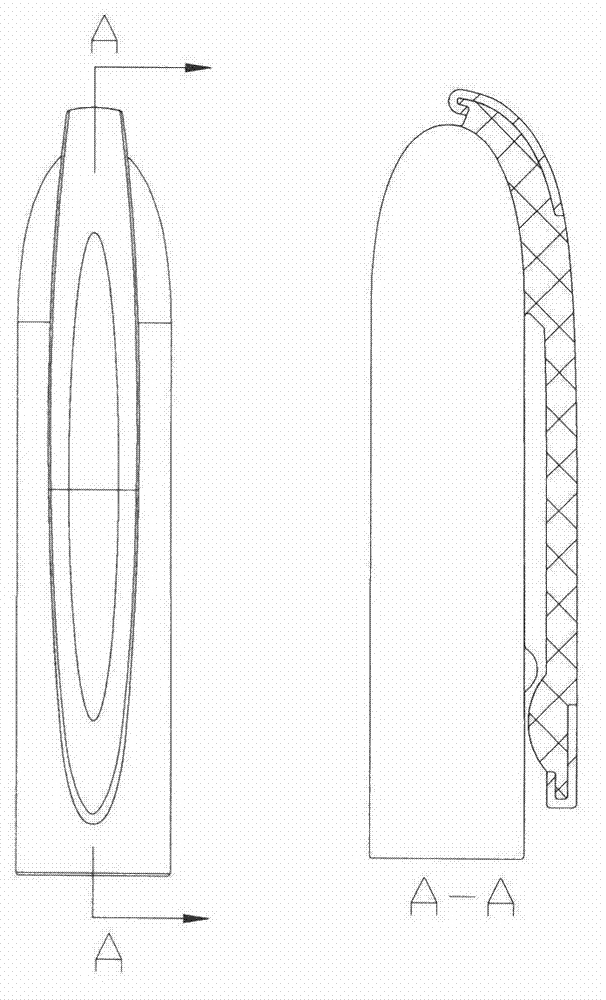

Novel pen cap, preparation method thereof and pen with novel pen cap

The invention discloses a novel pen cap which comprises a pen cap body and a pen clip which is installed on the pen cap by adopting a cantilever beam structure. The top portion of the pen clip is covered by a thermoplastic elastomer. The shortest radial distance between a region which is covered by the thermoplastic elastomer and the axle wire of the pen cap is smaller than or equal to the inner radius of the pen cap. The invention further discloses a pen cap preparation method. The pen clip with the cantilever beam structure is installed on the pen cap. The pen clip is formed by adopting a double-shot molding mode. The novel pen cap, the pen cap preparation method and the pen with the novel cap can not only provide comfortable touch when the pen cap is buckled or flipped, but also improve elasticity of the pen clip. Besides, when the pen clip is broken, the pen clip cannot fall off, and therefore the safety of the pen clip is improved. Even when the pen clip is used for clipping various smooth surfaces, the pen clip cannot easily slide. At the same time, if the function of friction is needed, multi-angle friction modes can be provided.

Owner:QINGDAO CHANGLONG STATIONERY

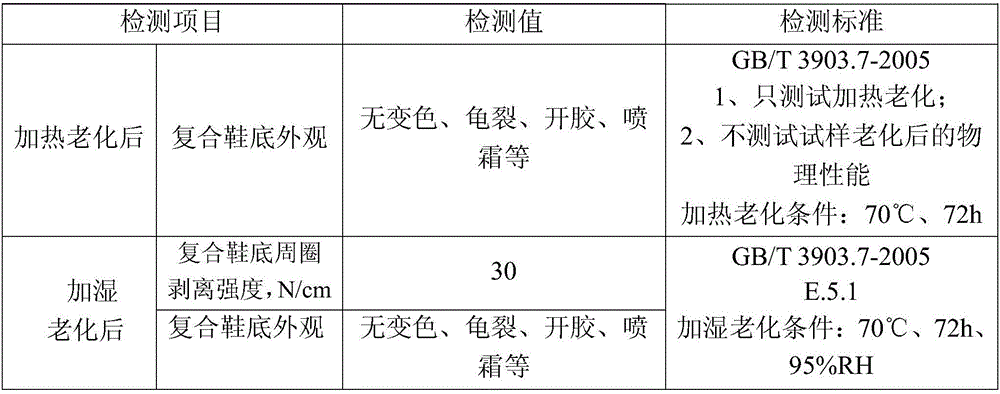

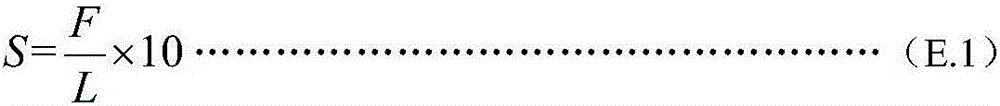

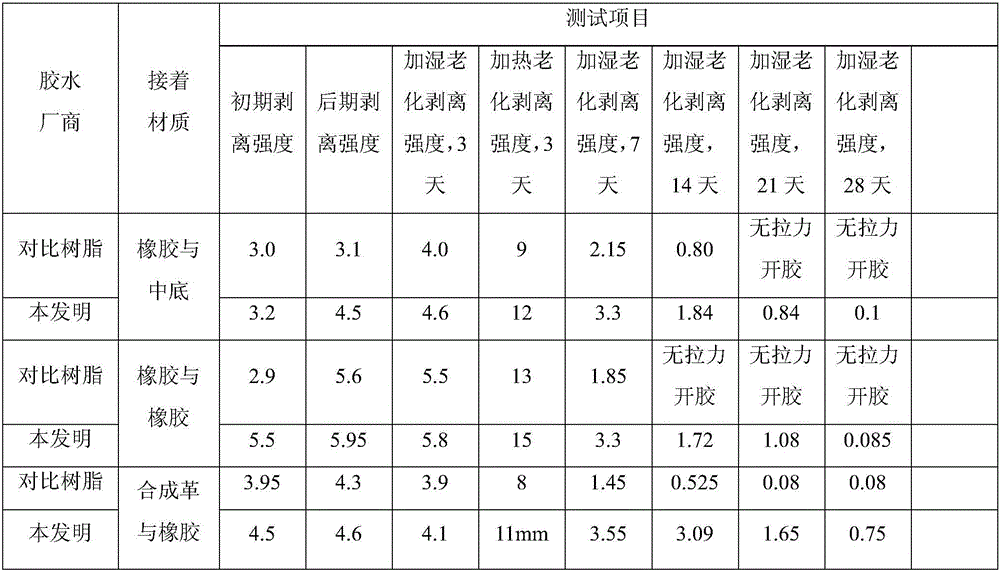

Shoe cellulose powder modified polyurethane adhesive and preparation method thereof

InactiveCN105925229AImprove fastness and hydrolysis resistanceImprove rigidityPolyureas/polyurethane adhesivesSolventIsocyanate compound

The invention discloses a shoe cellulose powder modified polyurethane adhesive and a preparation method thereof. The shoe cellulose powder modified polyurethane adhesive is prepared from the following components in parts by mass: 150 to 200 parts of diphenylmethane diisocyanate, 20 to 50 parts of isophorone diisocyanate, 200 to 400 parts of polyester glycol, 30 to 60 parts of chain extender, 1 to 10 parts of cellulose powder, and 2000 to 4000 parts of solvent. The preparation method has the advantages that under the synergistic action of two types of active isocyanate, by adopting different types of hydroxyl raw materials, the initial viscosity, hydrolysis resistance, wet and heat aging resistance and the like of products are improved; the technology implementing is good, and the environment-friendly and non-pollution effects are realized.

Owner:LI NING CHINA SPORTS GOODS +2

A cable wrapping intermediate joint and a manufacturing process thereof

PendingCN109245022AImprove electrical performanceGuaranteed uptimeCable junctionsApparatus for joining/termination cablesElectrical conductorButt joint

The invention provides a cable wrapping intermediate joint and a manufacturing process thereof, which are used for butt joint of two sections of three-core or single-core cables. The wrapping intermediate joint includes the connector wrapping connecting each single-phase cable, and the protective wrapping all the connectors; A tap wrap includes a pressure nozzle connected with a conductor core ofthat same-phase cable, a stress cone sleeved on the cable, a wound limiting step, a semi-conductive tape layer, an insulating tape layer, a tap shield layer, a copper mesh layer, a single-phase cablemetal shield tape, a PVC layer and a single-phase cable waterproof layer; The protective wrapping package comprises a binding layer, a cable metal shielding tape, a cable waterproof layer and a cablearmor layer from the inside to the outside. The winding intermediate joint of the invention can achieve the purposes of good connection, reliable insulation, good sealing performance, high mechanicalstrength, simple structure and convenient fabrication and installation of the conductor core of the cable, can ensure the safety and stability of the cable operation and obtain good economic benefits, and therefore has great popularization and application value.

Owner:SHANGHAI G&W ELECTRIC LTD

Steam-free hairdressing gel and preparation method thereof

The invention relates to a steam-free hairdressing gel and a preparation method thereof. The preparation method comprises the following steps of: heating and melting 2-8 parts by weight of cation conditioner; heating and melting 1-4 parts by weight of emulsifying agent, 1-5 parts by weight of mineral grease and 5-10 parts by weight of synthetic grease; sucking deionized water into an emulsification pot for heating; starting to mix when the temperature reaches 60-80 DEG C; adding 0.01-0.1 parts by weight of chelating agent, the melted cation conditioner, the melted emulsifying agent, the melted mineral grease and the melted synthetic grease into the mixture in sequence; cooling the mixture after the heat is preserved for 10-20min; adding 0.5-3 parts by weight of nutrient additives, 0.1-0.5 parts by weight of flavorings and 0.05-0.3 parts by weight of preservative when the temperature is cooled to 45-55 DEG C; and cooling the temperature to 30-45 DEG C. compared with the prior art, the steam-free hairdressing gel has the effects of deeply repairing and nourishing hair, strengthening, moisturizing and conditioning the hair, and keeping the hair smooth and bright.

Owner:SHANGHAI HUAYIN COMMODITY

Buffering device for trampoline and trampoline

InactiveCN108744389AFirmly connectedReduce breakageSpring boardsTrampolinesVibration amplitudeElastic component

The invention discloses a buffering device for a trampoline and the trampoline, aiming at improving the utilization safety of the trampoline. The trampoline comprises a plurality of edge frames; the buffering device comprises a connection component, a sleeve assembly and an elastic component, wherein any two adjacent edge frames are connected through the connection component; the sleeve assembly sleeves the connection component; the sleeve assembly is connected with the edge frames through the connection component to support the trampoline; the elastic component sleeves the connection component, is located in the sleeve assembly and is used for inhibiting the vibration amplitude of the trampoline. The trampoline disclosed by the invention comprises the buffering device. The buffering device disclosed by the invention is compact in structure and convenient and rapid to dismount; breaking and deformation, caused by the fact that a force on the edge frames is too great, are reduced through the elastic component and the elasticity of the trampoline also can be improved by utilizing a counter acting force of a compression spring, so that the utilization safety performance of the trampoline is improved.

Owner:刘运伟

Gel magnetic pillow and control method thereof

InactiveCN113143249AIncrease elasticityImproves breathability and comfortPillowsElectrotherapyCranial nervesClassical mechanics

The invention discloses a gel magnetic pillow and a control method thereof, and relates to the technical field of household bedding. The gel magnetic pillow comprises a gel magnetic pillow body, which is sequentially provided with a knitted eyelet fabric layer, a biomass gel layer, a rare earth particle layer, a memory cotton layer, an intelligent controller, a memory cotton cushion layer and a tencel and aloe knitted fabric layer from top to bottom; the knitted eyelet fabric layer is used for wrapping and protecting the biomass gel layer; the rare earth particle layer comprises a plurality of magnetic rare earth particles which are distributed in an array; and the intelligent controller is used for monitoring sleep and vital sign data and promoting the brain to release brain waves for improving the sleep quality by regulating human cranial nerves. The sleep and vital sign data are monitored through the intelligent controller, so that the effect of effectively improving the sleep quality is achieved; meanwhile, the effect of improving the softness and comfort of the gel magnetic pillow is achieved through the multi-layer fabric which is sequentially arranged from top to bottom.

Owner:HEYE HEALTH TECH CO LTD

Municipal road wetting dust-falling system

InactiveCN107675666AAvoid wastingRealize automatic moisteningFatty/oily/floating substances removal devicesSewerage structuresCell layerRoad surface

The invention discloses a wet dust suppression system for municipal roads, comprising: a water outlet unit, which includes a plurality of horizontally and vertically arranged water outlet holes, and the water outlet holes extend downward and run through the road; a water cavity unit, which has a closed cavity, and the water outlet The hole is connected to the closed cavity, and water is stored in the closed cavity, and the horizontal position of the closed cavity is lower than the water outlet hole; the pressure making unit includes a plurality of depressions and air intake holes, and the upper opening of the depression is oval or It is circular and has a diameter smaller than the width of the wheel. When it is rolled, the depression is gradually closed by the wheel to form an air cavity; the water supply unit is arranged on both sides of the road. The water supply unit has a water storage pool with a double-layer structure , the first layer is a clear water layer, the second layer is a sedimentation layer, the pool body is provided with pipes to connect the clear water layer with the closed cavity, the horizontal position of the pool body is higher than the closed cavity to automatically supply water to the closed cavity, And the horizontal position of the pool body is lower than the road surface of the road so that the water does not overflow the road surface.

Owner:蒋星

Emulsifying method of polyurethane micro-powder, polyurethane micro-powder emulsion, leather mending agent and application thereof

InactiveCN111072996AHigh strengthIncrease coagulation resistanceLeather surface finishingPolymer scienceEmulsion

The invention discloses an emulsifying method of polyurethane micro-powder, a polyurethane micro-powder emulsion, a leather mending agent and application of the leather mending agent, and the emulsifying method comprises the following steps: mixing nonionic surfactants with different HLB values to obtain a compound emulsifier; adding the polyurethane micro-powder into the composite emulsifier to obtain a polyurethane micro-powder suspension; dropwise adding deionized water into the polyurethane micro-powder suspension; dropwise adding a curing agent into the polyurethane micro-powder suspension, adjusting the pH value of the system to 7.5-9, and stirring to obtain the polyurethane micro-powder emulsion; according to the invention, the problem that in the prior art, polyurethane micro-powder is difficult to form a stable body in a water phase or a solvent phase is solved; the technical problem that the application of the polyurethane micro-powder emulsion in leather finishing is limitedin the prior art is solved, the polyurethane micro-powder emulsion is formed and applied to the leather mending agent, the performance of the leather mending agent is improved, and meanwhile, if theleather mending agent containing the polyurethane micro-powder is applied to the grain surface of crust leather, the mending effect can be remarkably improved.

Owner:XINGYE LEATHER TECH CO LTD

Special landscape architecture three-dimensional slope automatic planting regulation equipment

InactiveCN107187268AOperation diversificationEasy to operateSpecial ornamental structuresAgricultural engineeringSingle type

The invention relates to a special automatic planting and conditioning equipment for the three-dimensional slope of the garden landscape, which includes a mounting plate, a three-dimensional planting device is installed in the middle of the mounting plate, two mobile adjustment devices are installed on the installation plate, and the mobile adjustment device is located on the left side of the installation plate. A traction device is installed on the top, and a clamping device is installed on the mobile adjustment device on the right side of the mounting plate. The three-dimensional planting device, the mobile adjustment device, the traction device and the clamping device cooperate with each other to complete the technology of automatic conditioning and planting of the slope three-dimensional landscape. The invention can solve the problems existing in the planting process of the existing garden landscapes, such as limited plane planting, immature slope three-dimensional planting mode, insufficient utilization of planting space, poor plane and three-dimensional planting effect, single landscape types, requiring manual adjustment of landscape plants, and complicated operation , high labor intensity and low work efficiency, it can realize the function of automatic adjustment and planting of slope three-dimensional garden landscape.

Owner:吴慧

Simulated aircraft self-adhered skin emergency door and preparation method thereof

The invention discloses a simulated aircraft self-adhered skin emergency door which is prepared from the following raw materials in percentage by weight: 50-66% of polyether, 0.30-0.40% of A-33, 0.02-0.06% of A-1, 0.4-0.8% of silicone oil, 4-8% of a foaming agent, 4-8% of ethylene glycol and 20-40% of modified MDI, totaling 100%. The framework and self-adhered skin of the simulated aircraft self-adhered skin emergency door disclosed by the invention are processed at a time, and the two are firmly adhered. The self-adhered skin belongs to one kind of polyurethane, has excellent wear resistanceand rebound resilience, avoids the problems of crack, deformation and the like during repeated use, and is high in corrosion resistance and oxidation resistance, long in service life, light in weightand low in production cost.

Owner:杨凌平安汽车座椅有限公司

Damping material for dust collector motor

The invention discloses a damping material for a dust collector motor. The damping material is made of the following raw materials in parts by weight: 30-70 parts of butadiene styrene rubber, 30-70 parts of ethylene-propylene-diene-terpolymer rubber, 20-60 parts of styrene-butadiene-styrene segmented copolymer, 15-60 parts of a polypropylene thermal-plastic elastomer, 10-50 parts of a polyurethane elastomer, 10-60 parts of acrylic ester, 2-20 parts of nano silicon carbide powder, 1-20 parts of phosphate, 1-20 parts of nano magnesia powder, 2-20 parts of nano zirconium dioxide powder, 1-15 parts of carbon fiber powder, 1-15 parts of boron fiber powder, 1-15 parts of wollastonite powder, 1-25 parts of glass beads, 10-40 parts of methyl silicone oil, 5-40 parts of carboxymethyl starch, 5-40 parts of polyethylene wax, 5-30 parts of a coupling agent, 2-25 parts of a promoter, 2-25 parts of an initiator and 1-20 parts of an anti-aging agent. The damping material for the dust collector motor, which is disclosed by the invention, is excellent in damping property and wearing resistance.

Owner:SUZHOU HAIGE ELECTRICAL TECH CO LTD

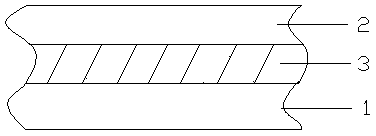

Mosquito-repelling and static-electricity-transferring shell fabric

The invention relates to a mosquito-repelling and static-electricity-transferring shell fabric. The mosquito-repelling and static-electricity-transferring shell fabric comprises a base fabric layer (1) and a shell fabric layer (2), wherein a mosquito-repelling sandwich layer (3) is arranged between the base fabric layer (1) and the shell fabric layer (2) and is made from a mosquito repellent, and the mosquito repellent is wrapped in a film and is arranged between the base fabric layer (1) and the shell fabric layer (2) in order; the base fabric layer comprises warps and wefts, conductive yarns are respectively wound into the warps and the wefts in a winding manner, and all the warps and all the wefts are woven together in a mutually sunk-floated and staggered manner. The mosquito-repelling and static-electricity-transferring shell fabric has the function of slowly releasing mosquito-repelling odor and can be used for persistently repelling mosquitoes, thereby protecting people from mosquito bites. The mosquito-repelling and static-electricity-transferring shell fabric can transfer static electricity.

Owner:JIANGSU BAILIDA

Environmentally-friendly plastic cement

Environmentally-friendly plastic cement is disclosed. The plastic cement is composed of the following ingredients (by weight): 28-32% of epoxidized soybean oil, 13-15% of polyol benzoate, 7-13% of polyethylene resin, 11-14% of polyepichlorohydrin, 2-7% of white carbon black, 3-5% of calcium oxide, 1-4% of amide, 3-6% of barium stearate and the balance rubber particles. The invention has the following beneficial effects: the prepared product is environmentally-friendly, harmless, odorless, has flat surface, high compressive strength, good elasticity and long service life, and is not easy to age.

Owner:TIANJIN KANG ENVIRONMENTAL PROTECTION EQUIP CO LTD

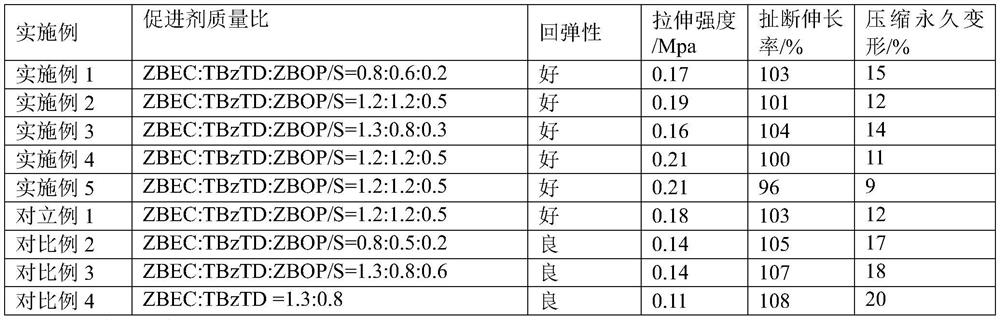

A kind of production method of environment-friendly latex sponge

ActiveCN112980008BReduce environmental pollutionReduces pungent odorsNatural rubber latexPotassium hydroxide

The invention relates to the field of latex, and aims at the problem that the preparation process of latex sponge is not environmentally friendly, and provides a production method of an environment-friendly latex sponge. Zinc oxide and potassium hydroxide are mixed, aged in a water bath, shaped with hot air, vulcanized in a steam box, and dried to obtain a latex sponge. The vulcanization package dispersion is composed of sulfur and an accelerator. Agent ZBOP / S. The present invention uses an environmentally friendly vulcanization accelerator with little environmental pollution, little irritating odor and no harm to the skin, uses natural latex and / or synthetic latex as main raw materials, and adopts methods such as mechanical blending and vulcanization to produce latex sponges, and the product performance meets the requirements. , the production process also achieves the purpose of green environmental protection.

Owner:宁波恩派新材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap