Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about "Lamination ancillary operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

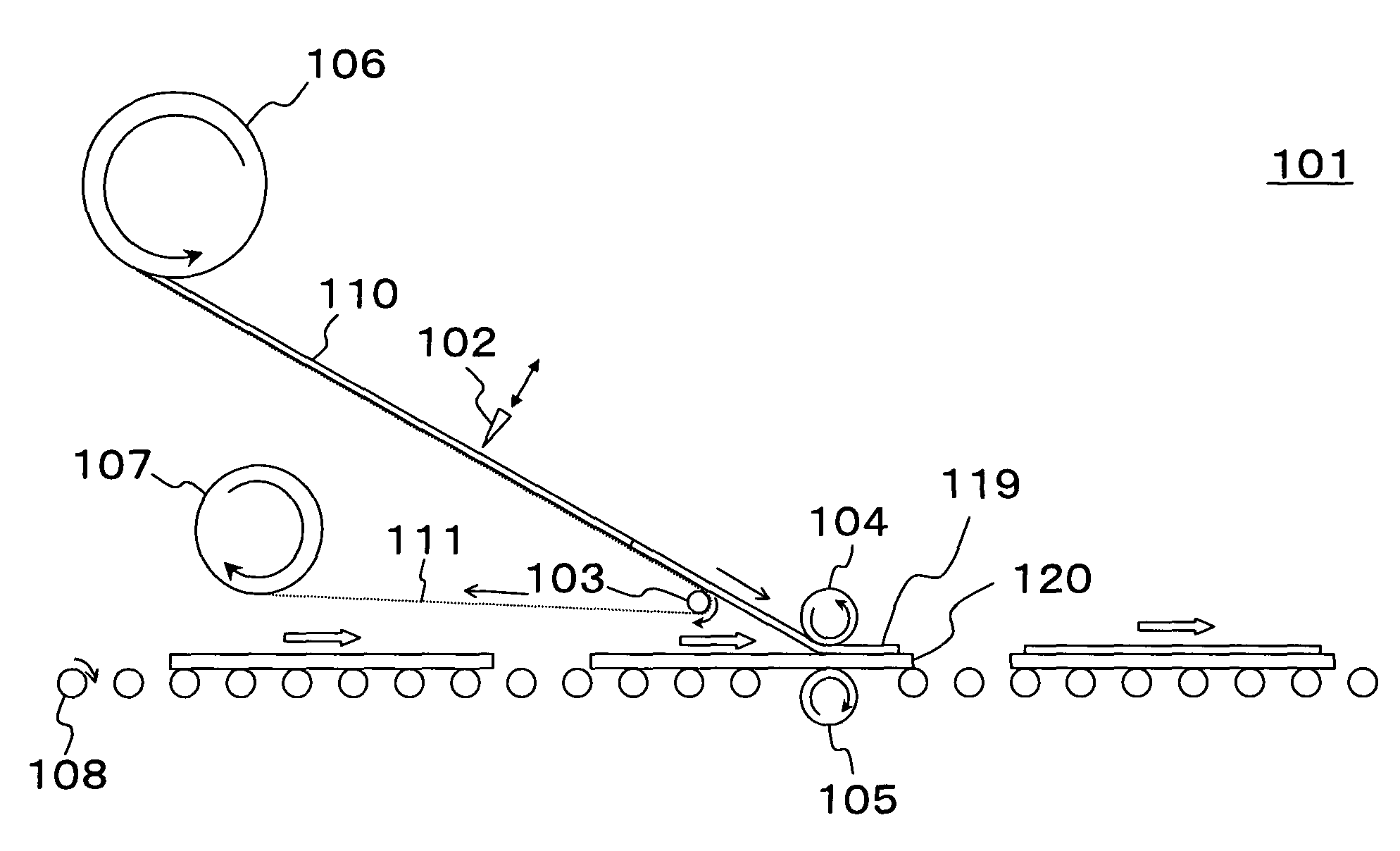

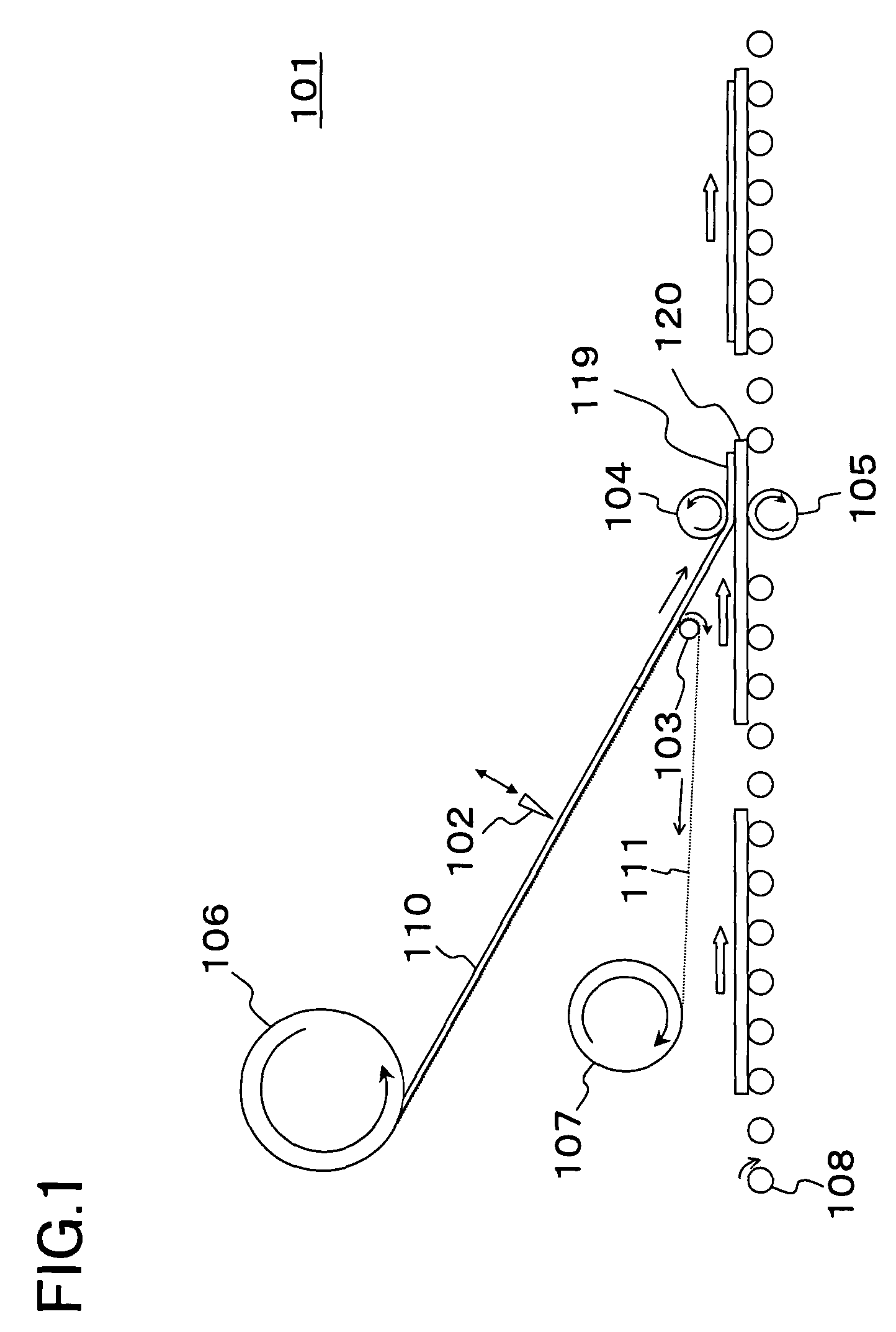

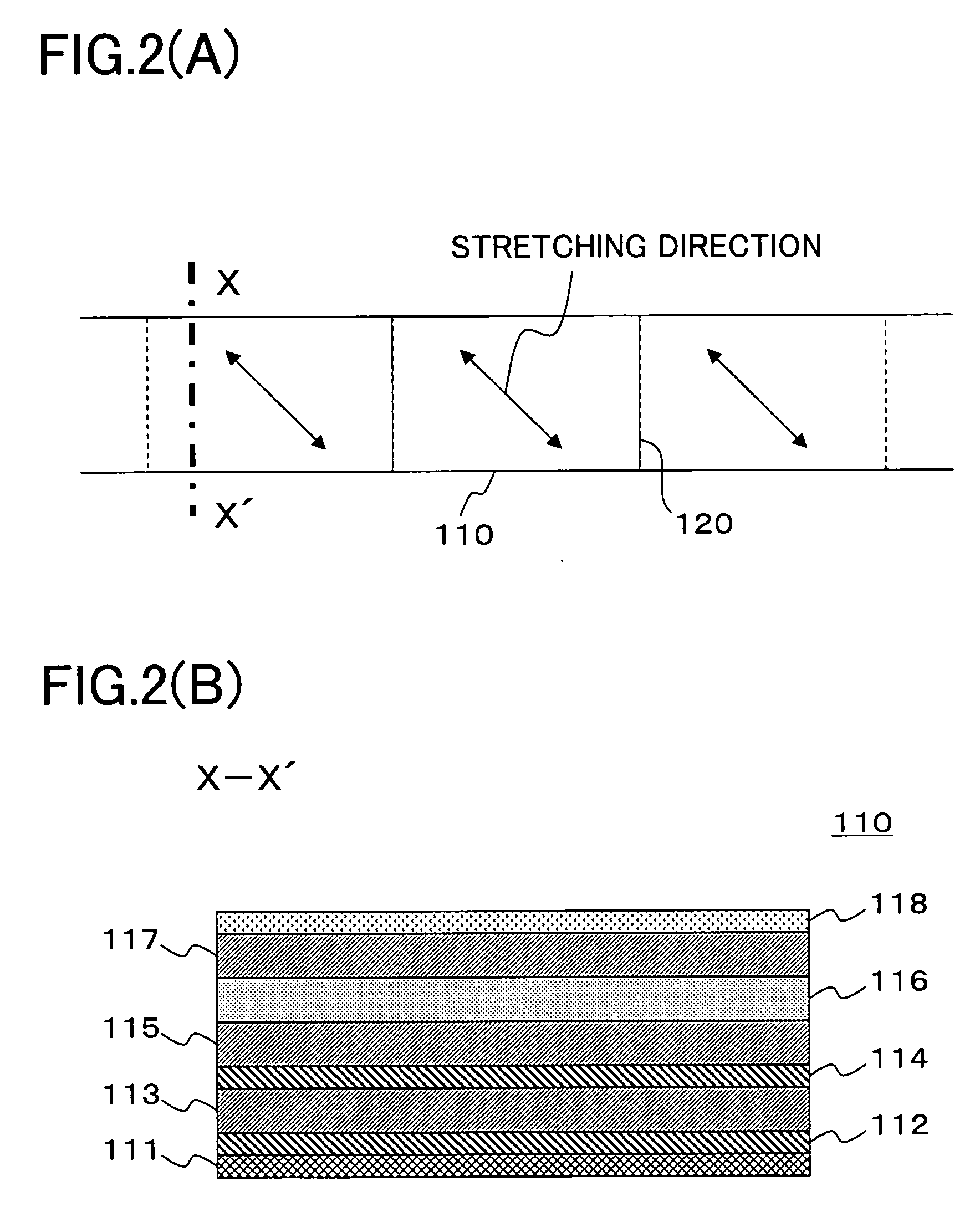

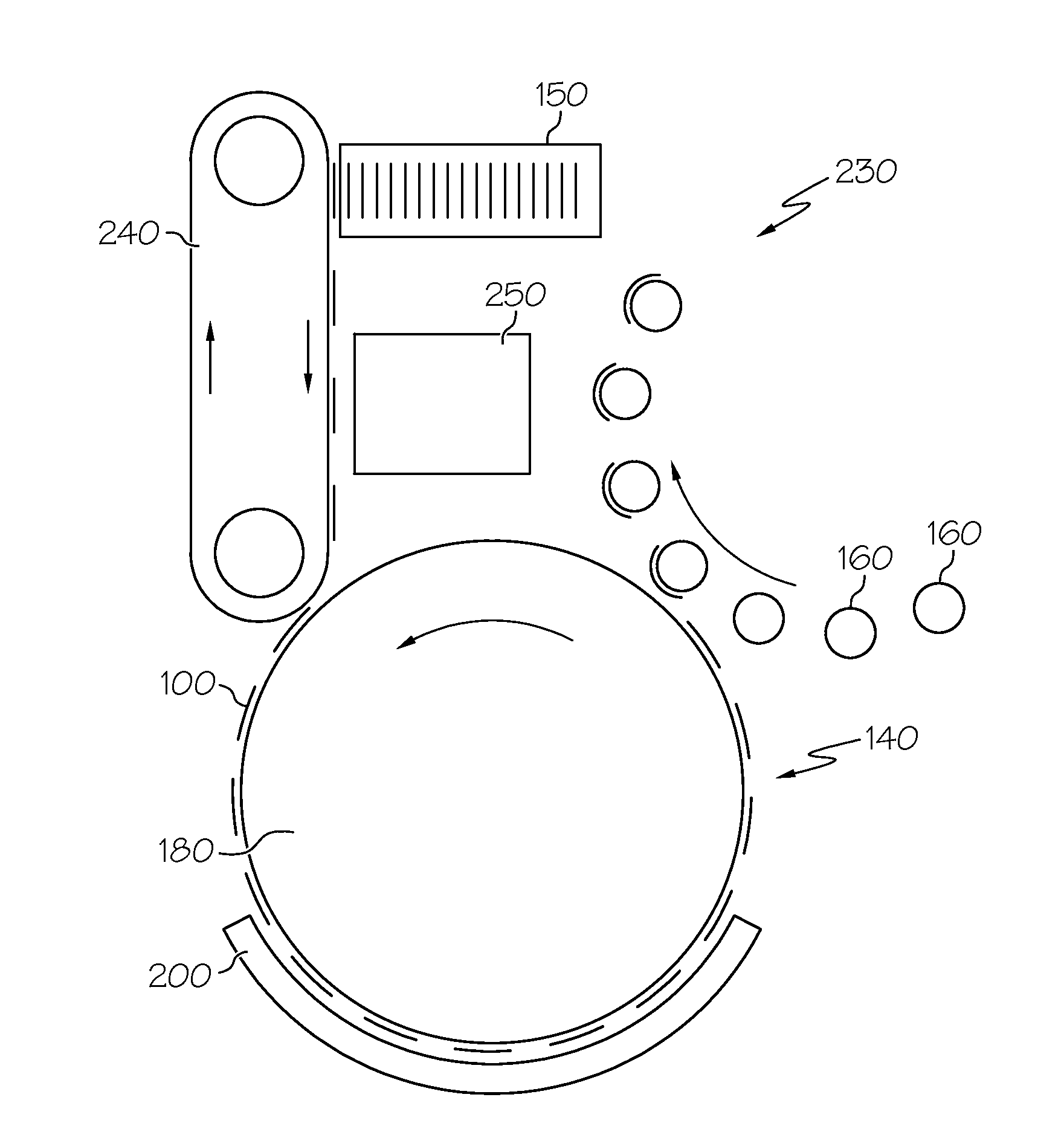

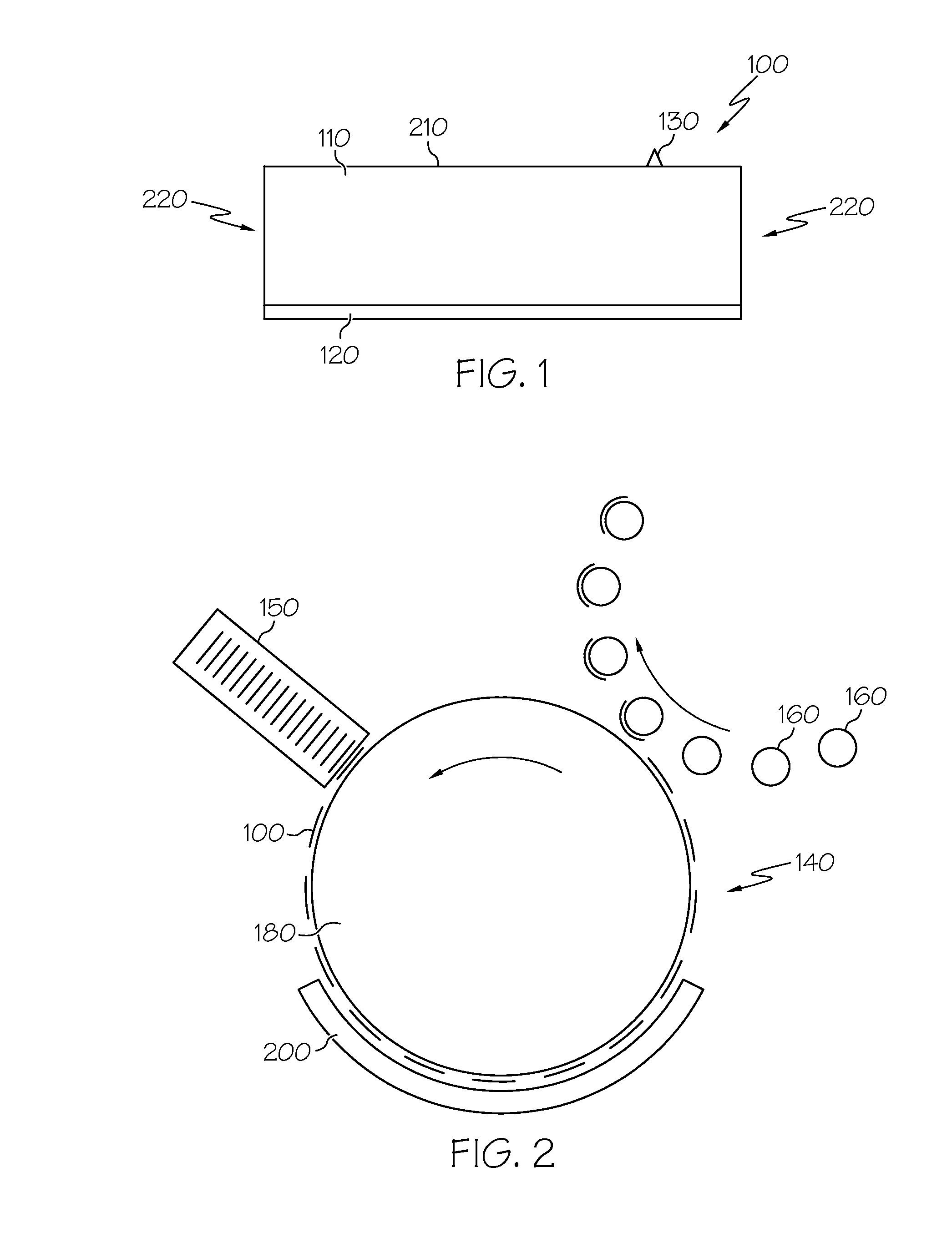

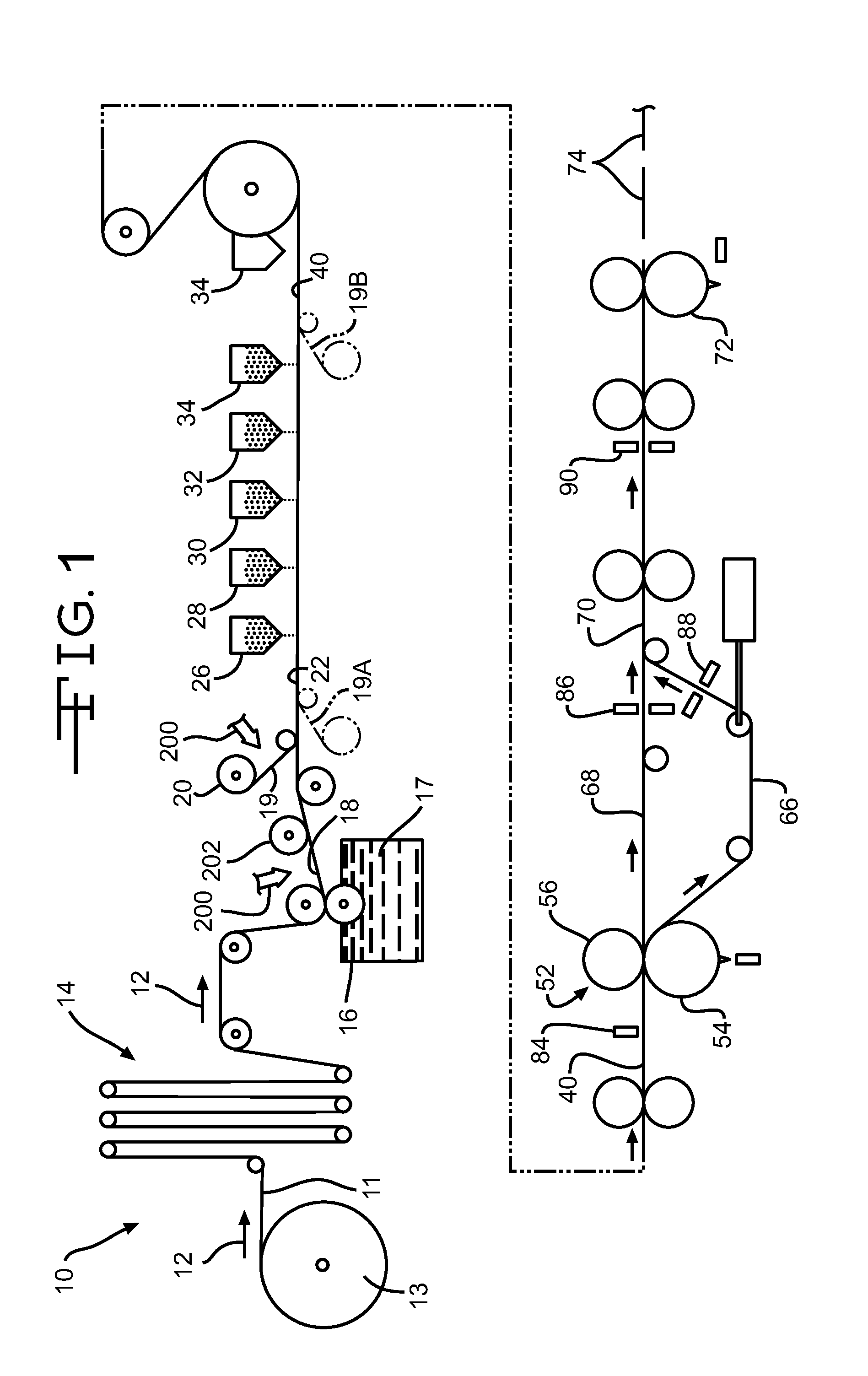

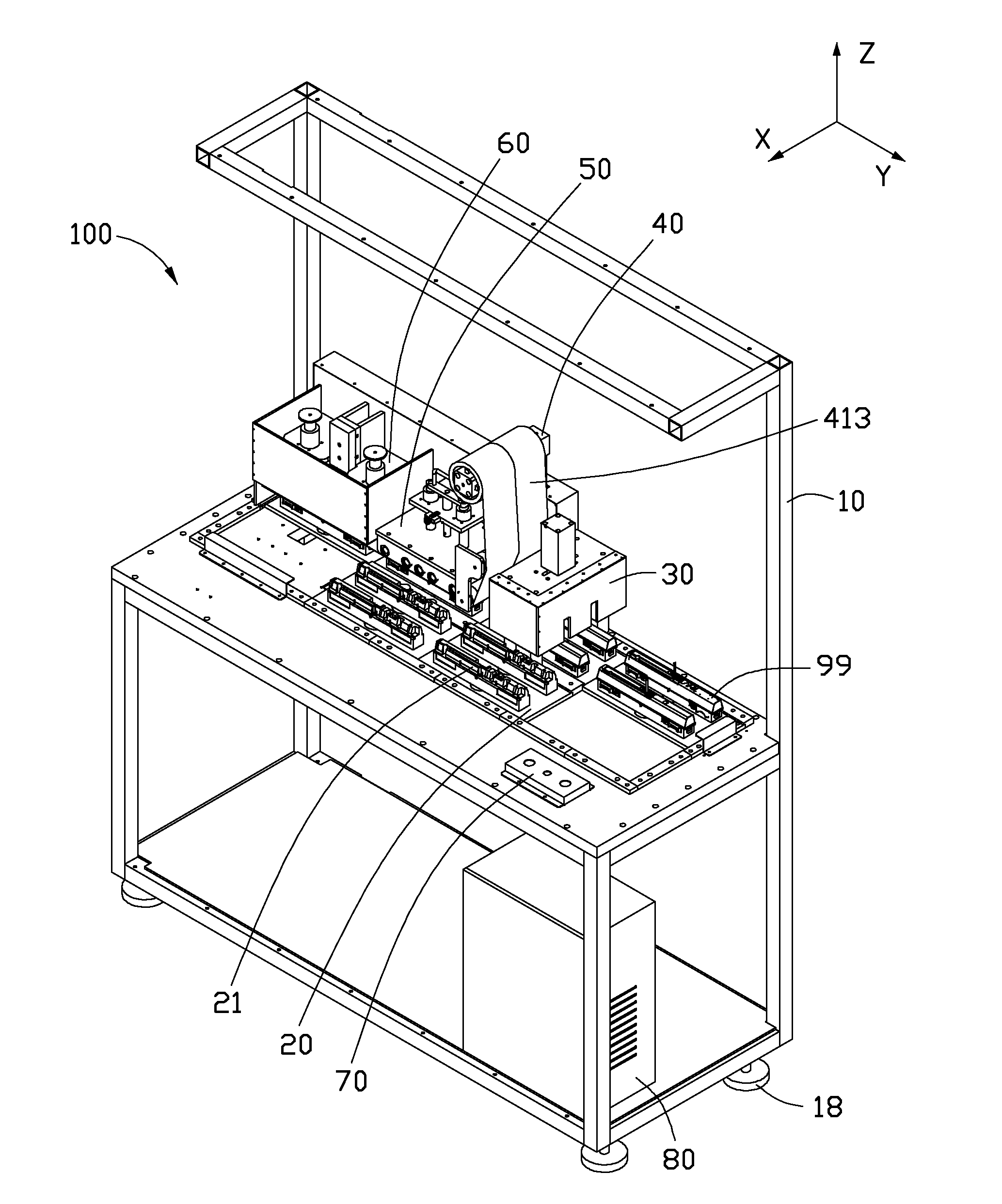

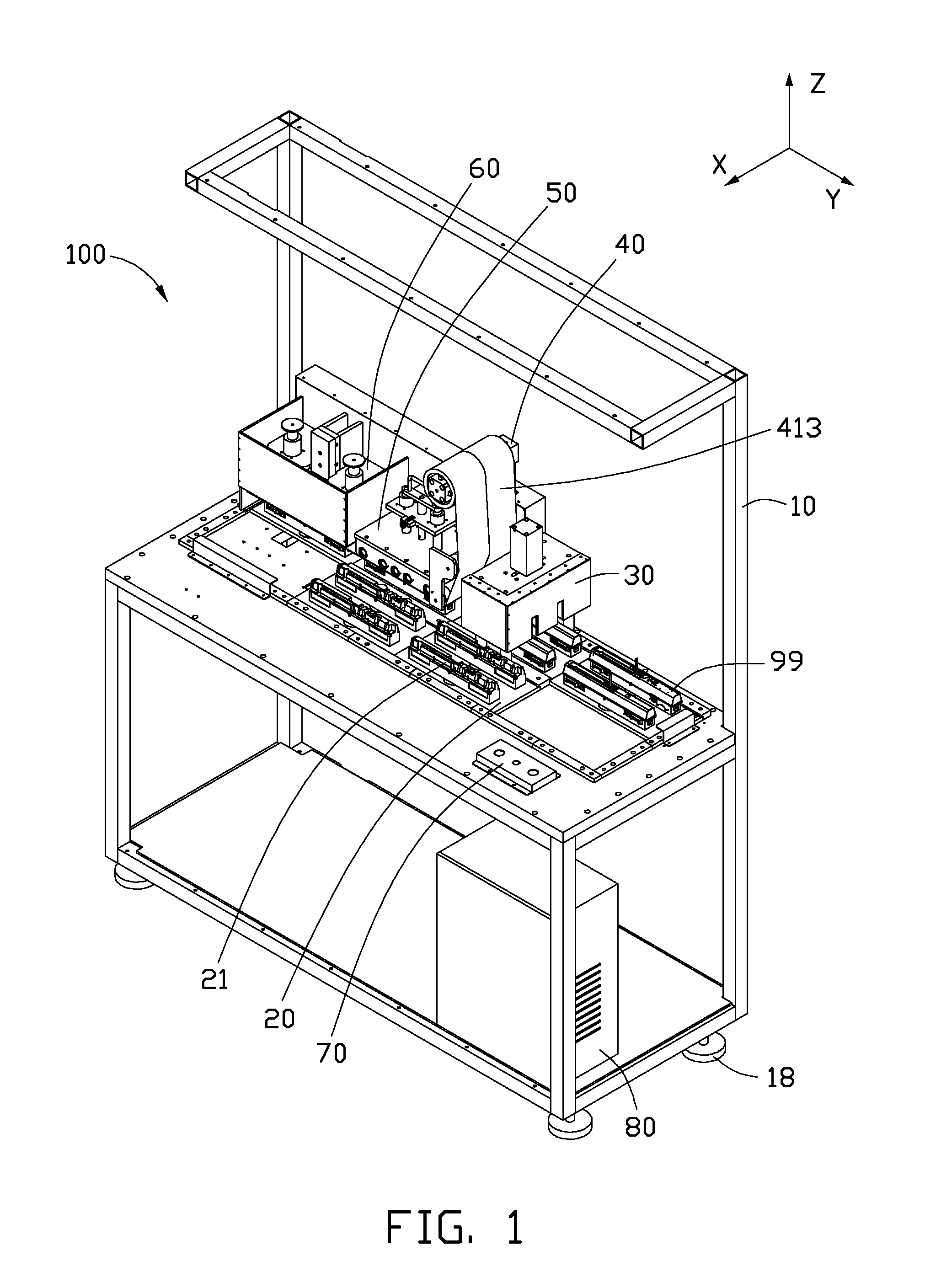

Method and apparatus for bonding polarizing plate

ActiveUS20050016670A1Easy to controlProhibit stop markLamination ancillary operationsDecorative surface effectsPolarizerEngineering

Owner:FUJIFILM CORP +1

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

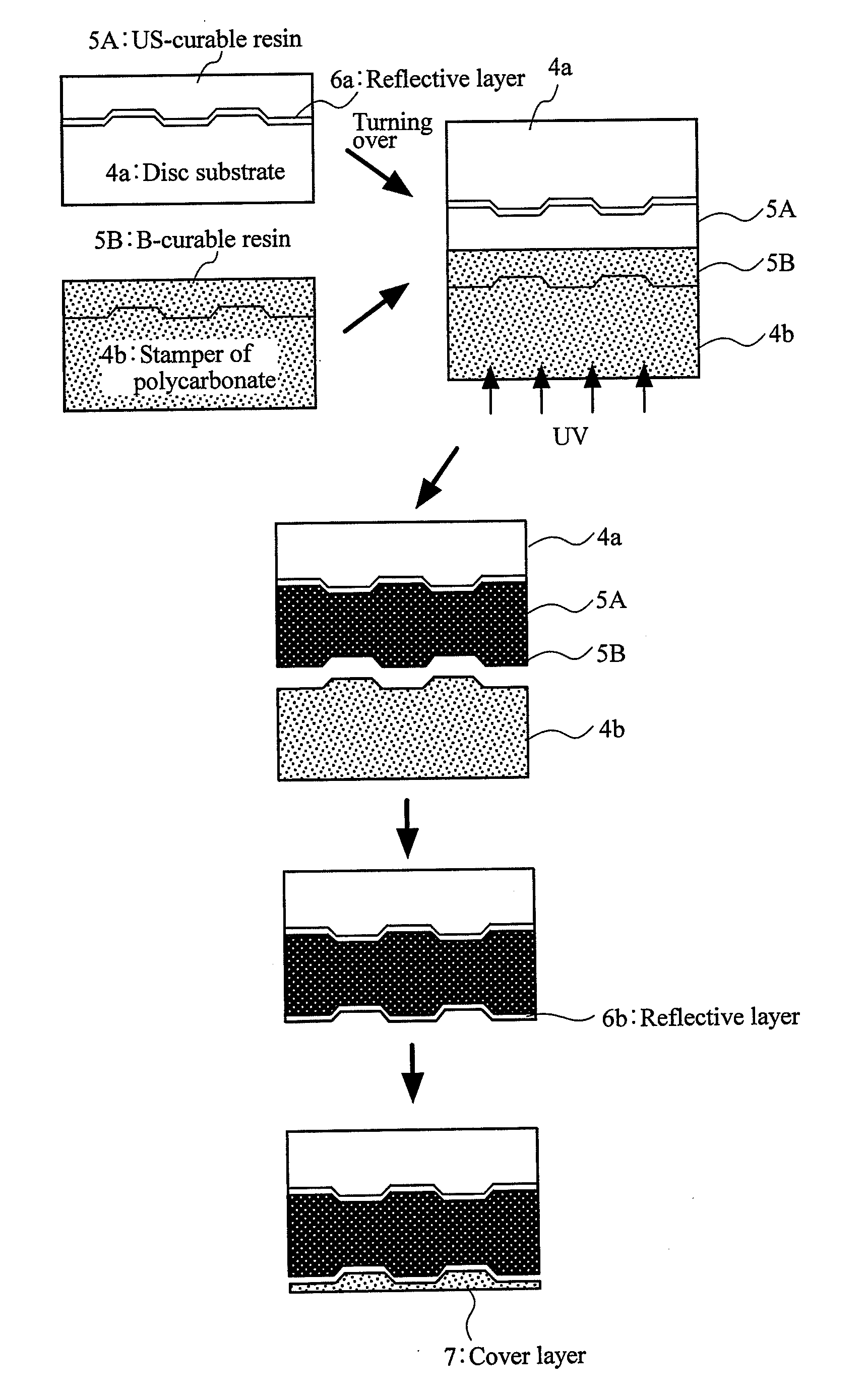

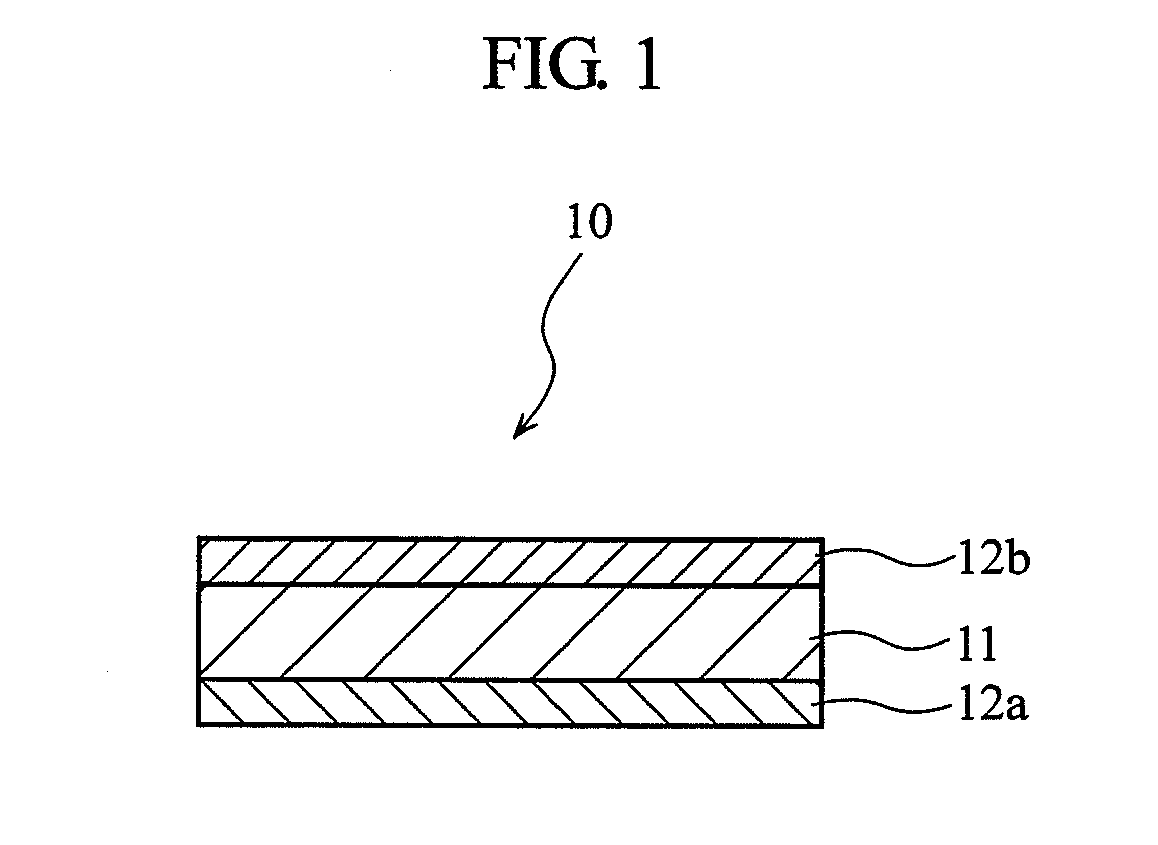

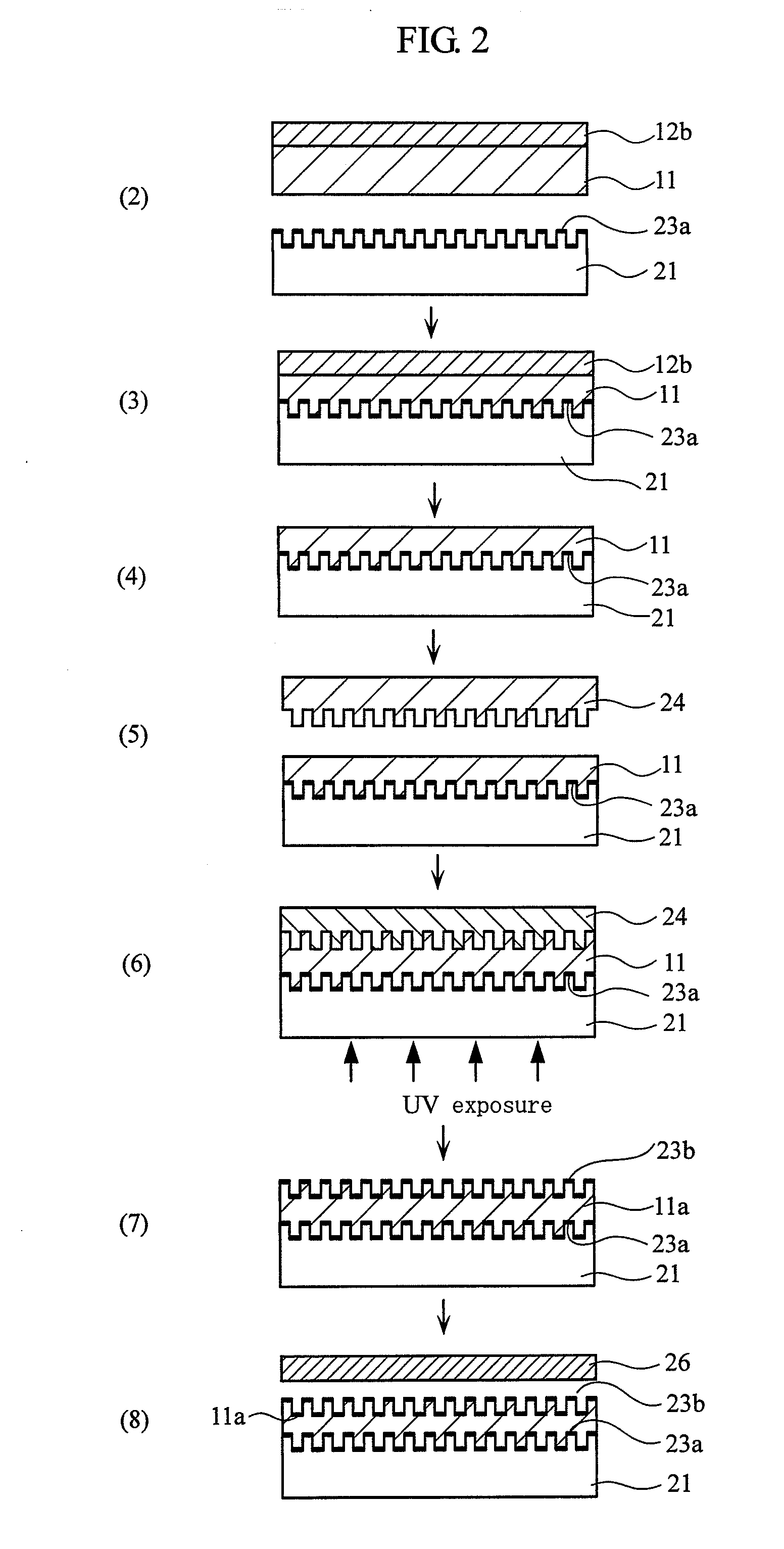

Photo-curable transfer sheet, process for the preparation of optical information recording medium using the sheet, and optical information recording medium

Owner:BRIDGESTONE CORP

Method for manufacturing copper clad laminated board adapted to leadless process

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

Activatable Adhesive, Labels, and Related Methods

InactiveUS20120216951A1Improve securityEasy to operateStampsNon-macromolecular adhesive additivesAdhesivePlasticizer

Owner:AVERY DENNISON CORP

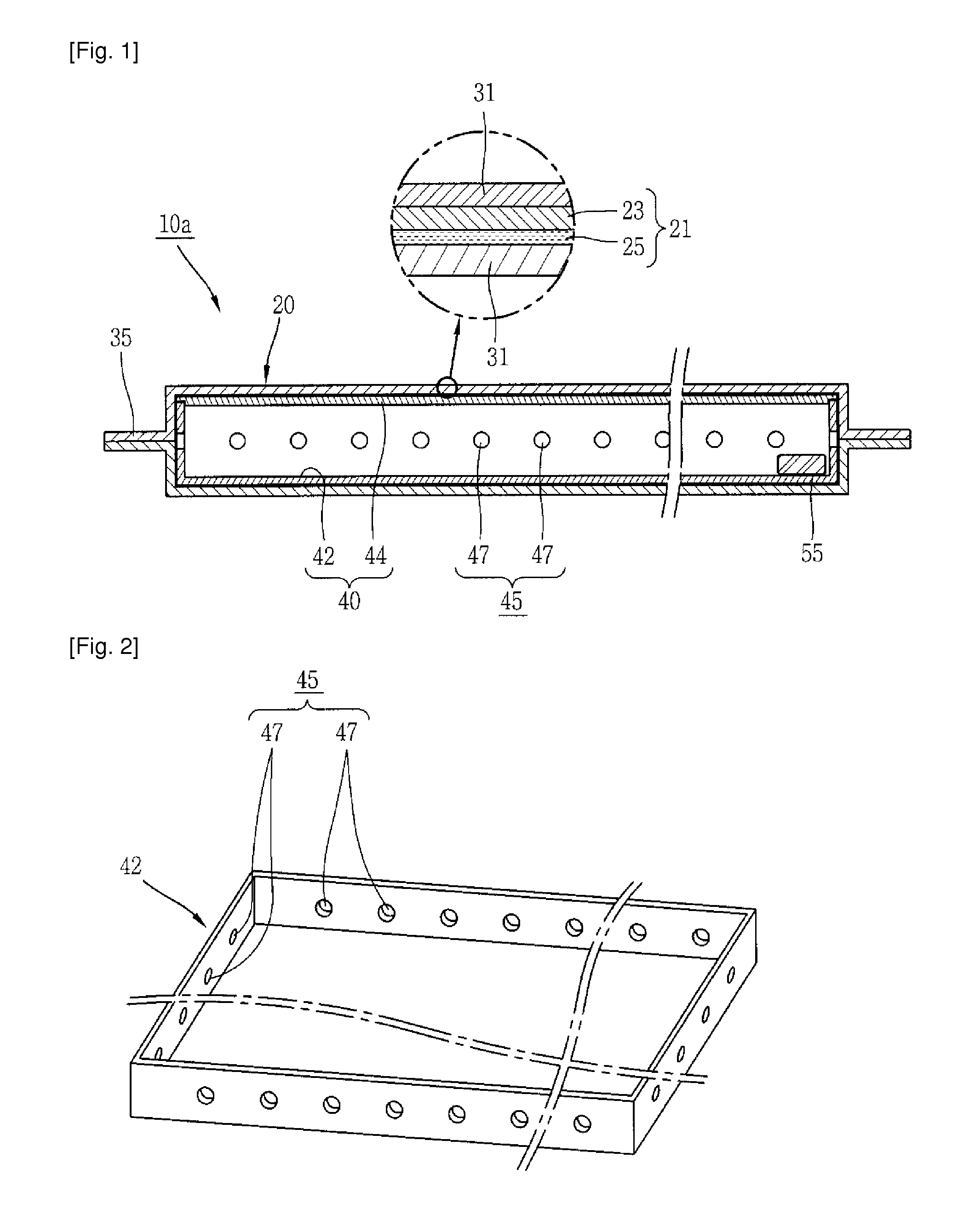

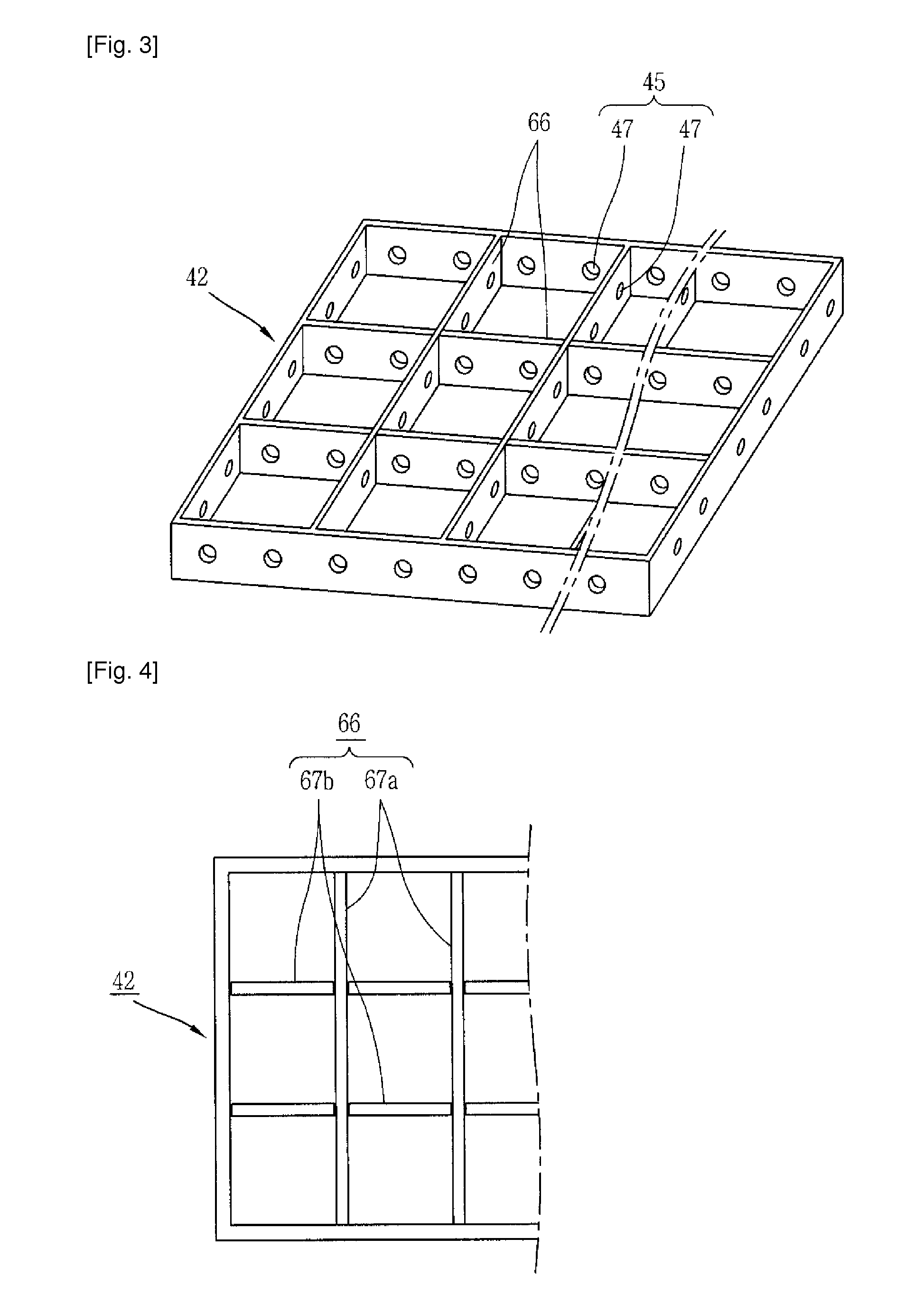

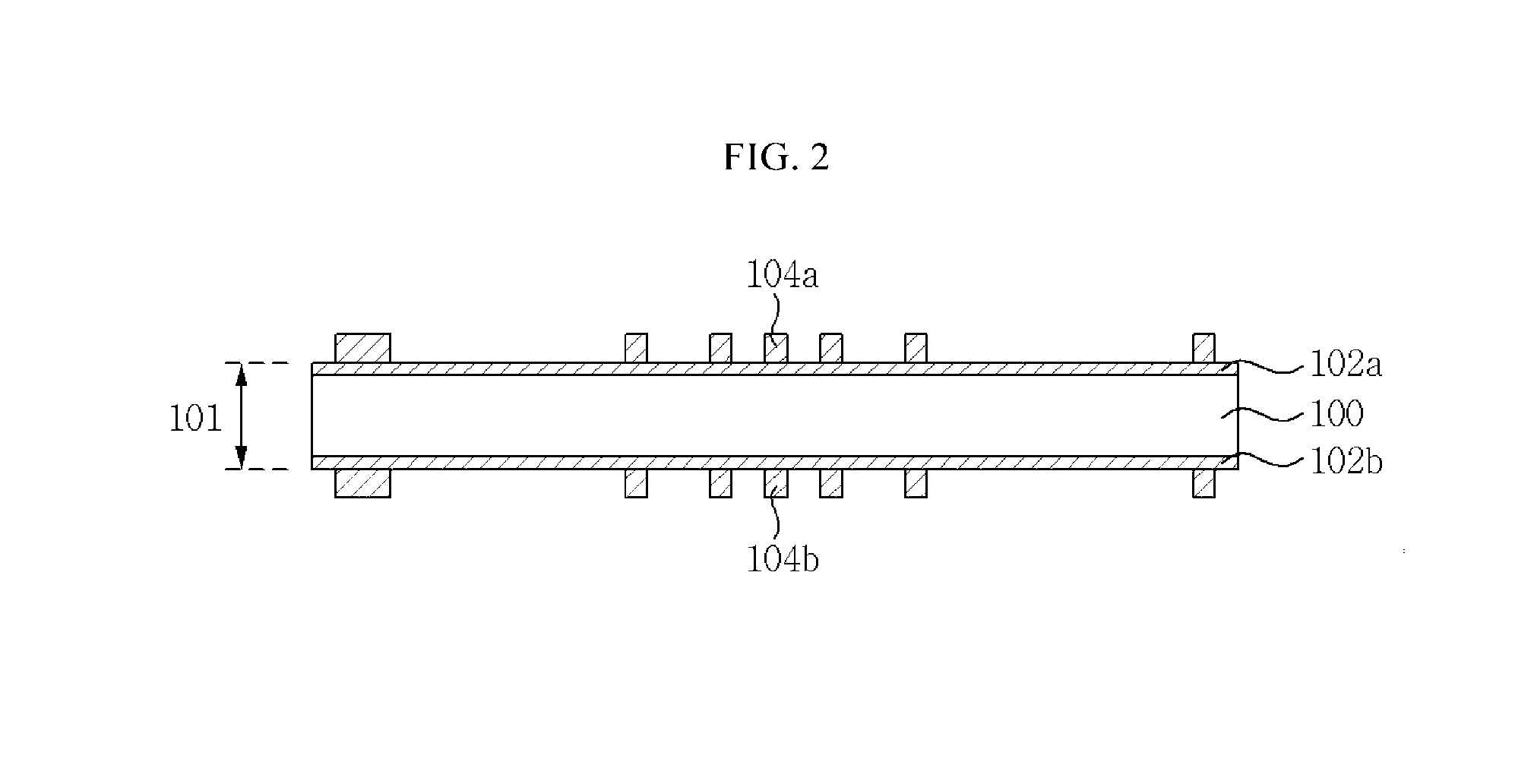

Vacuum insulation member, refrigerator having vacuum insulation member, and method for fabricating vacuum insulation member

ActiveUS20120125039A1Easy to manufactureReduce manufacturing costLamination ancillary operationsThermal insulationGlass fiberEngineering

Owner:LG ELECTRONICS INC

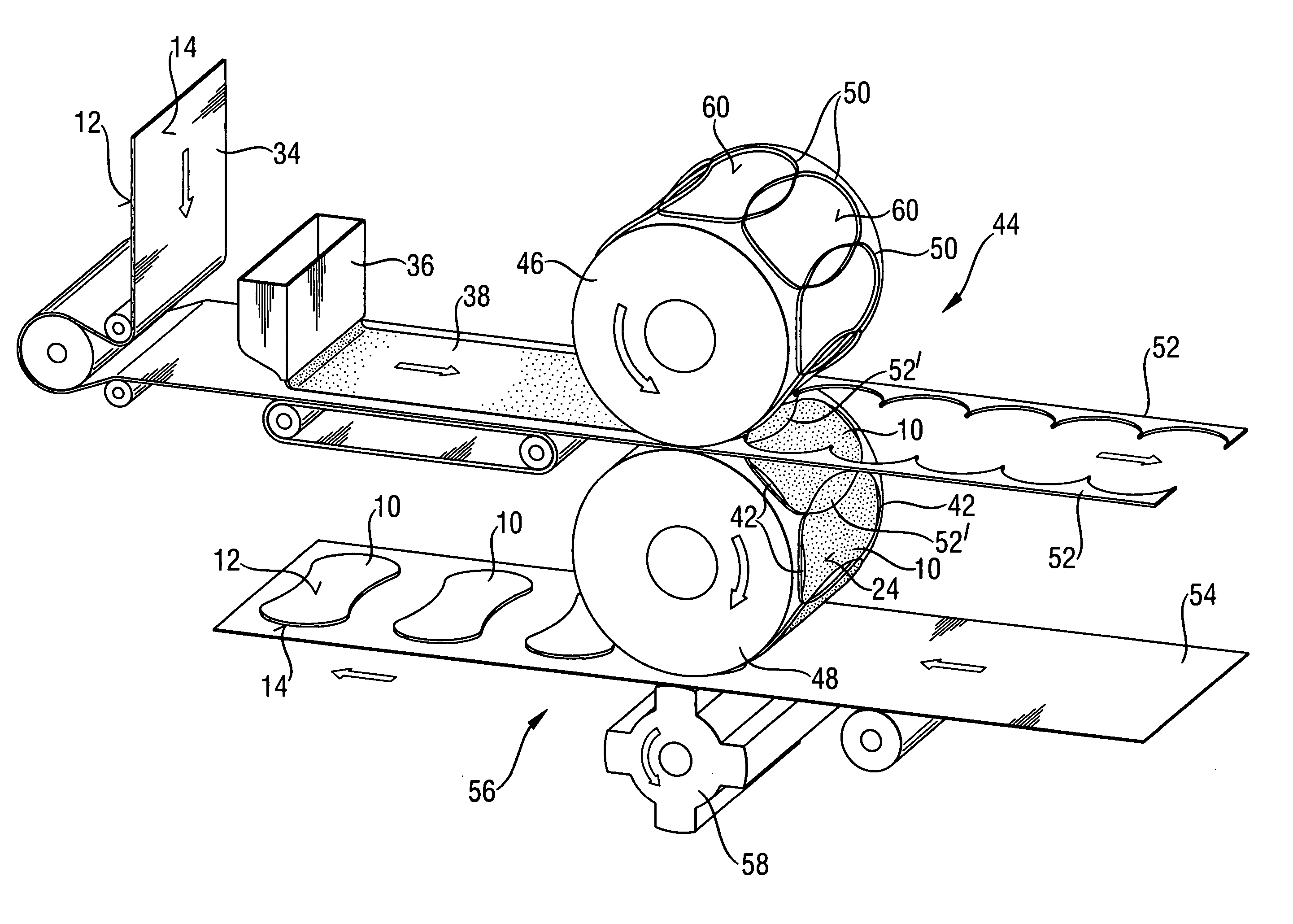

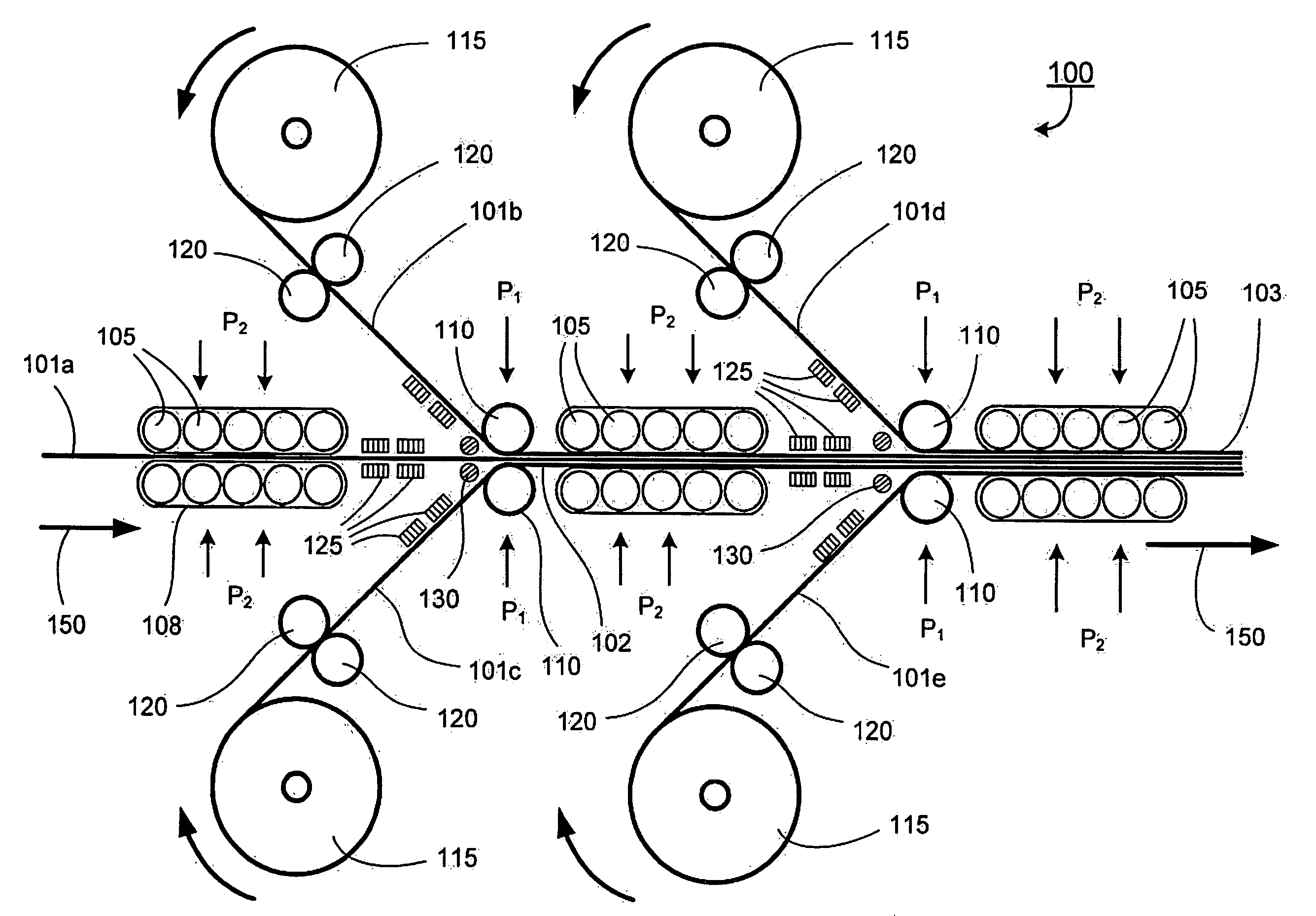

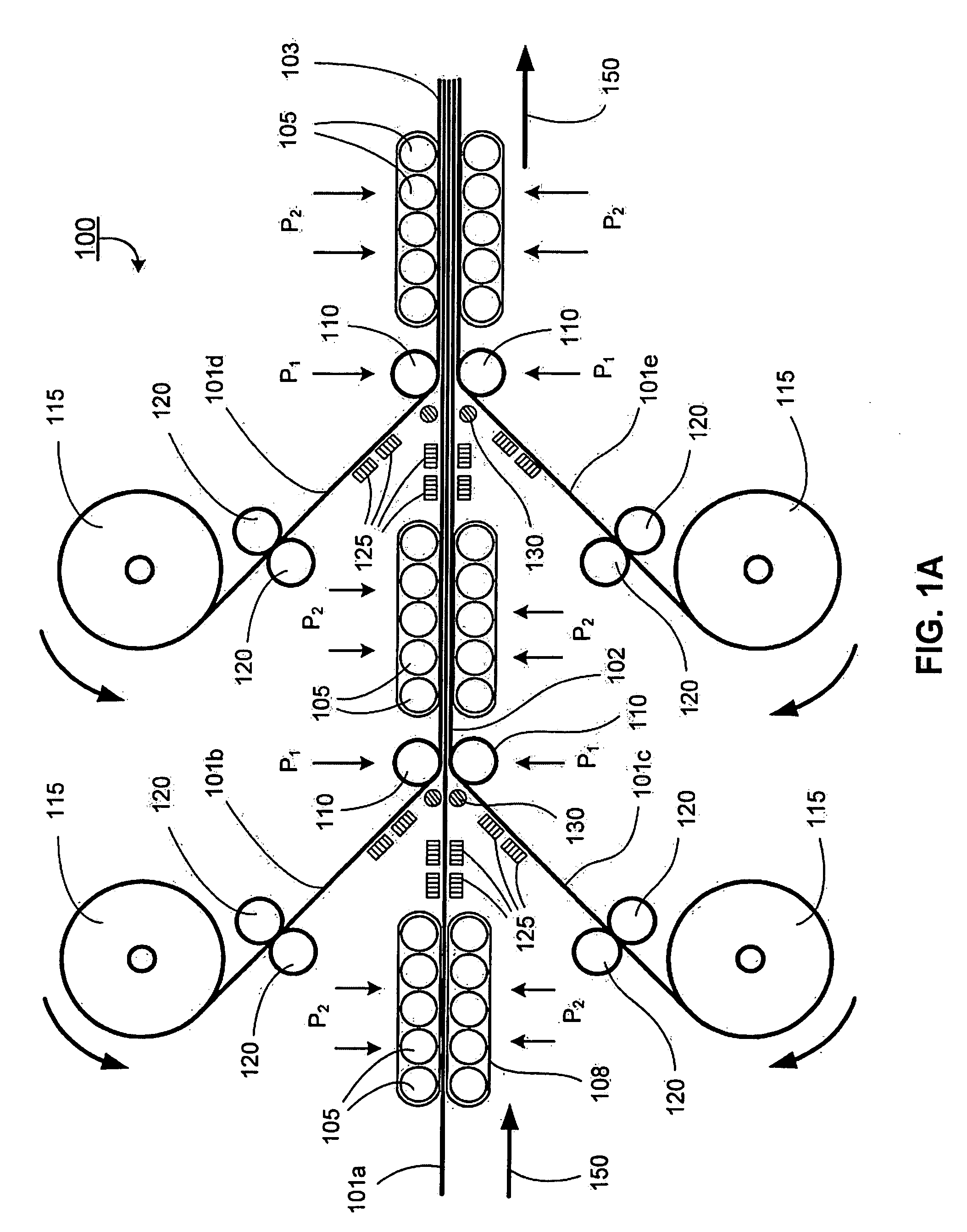

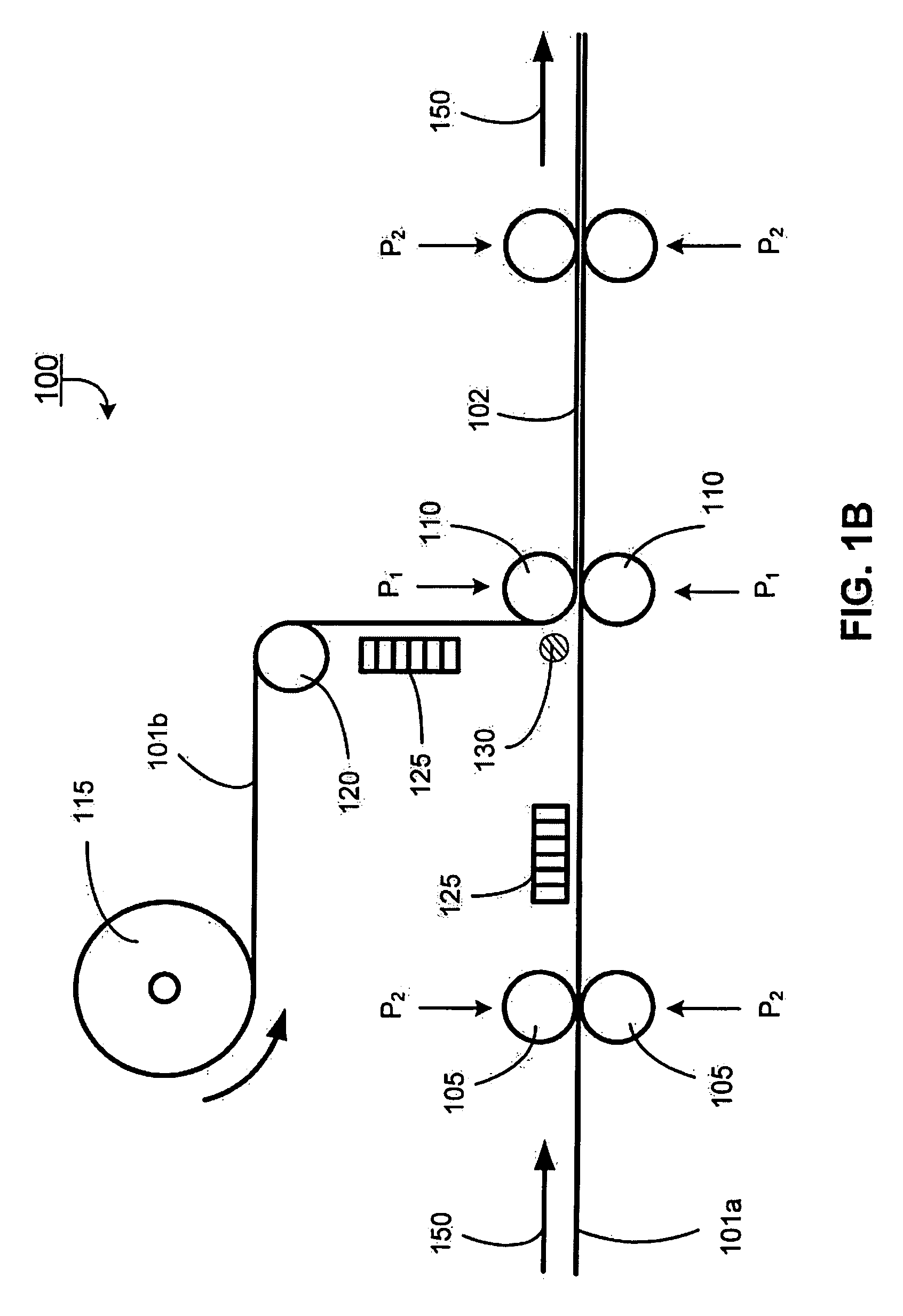

Process and apparatus for making individually packaged disposable absorbent articles

InactiveUS20050198931A1Lamination ancillary operationsWrapper folding/bending apparatusLayered structureAdhesive

Owner:THE PROCTER & GAMBLE COMPANY

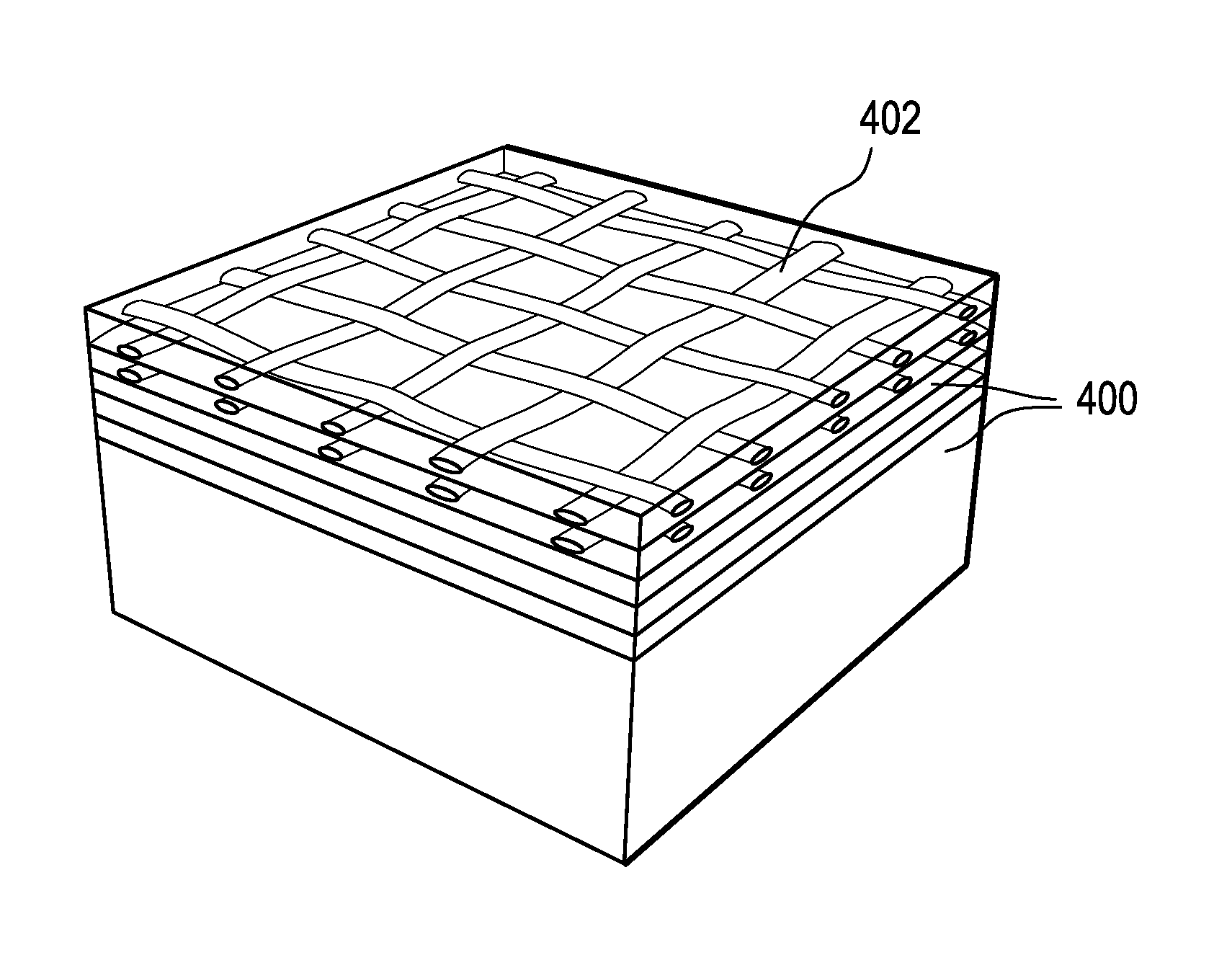

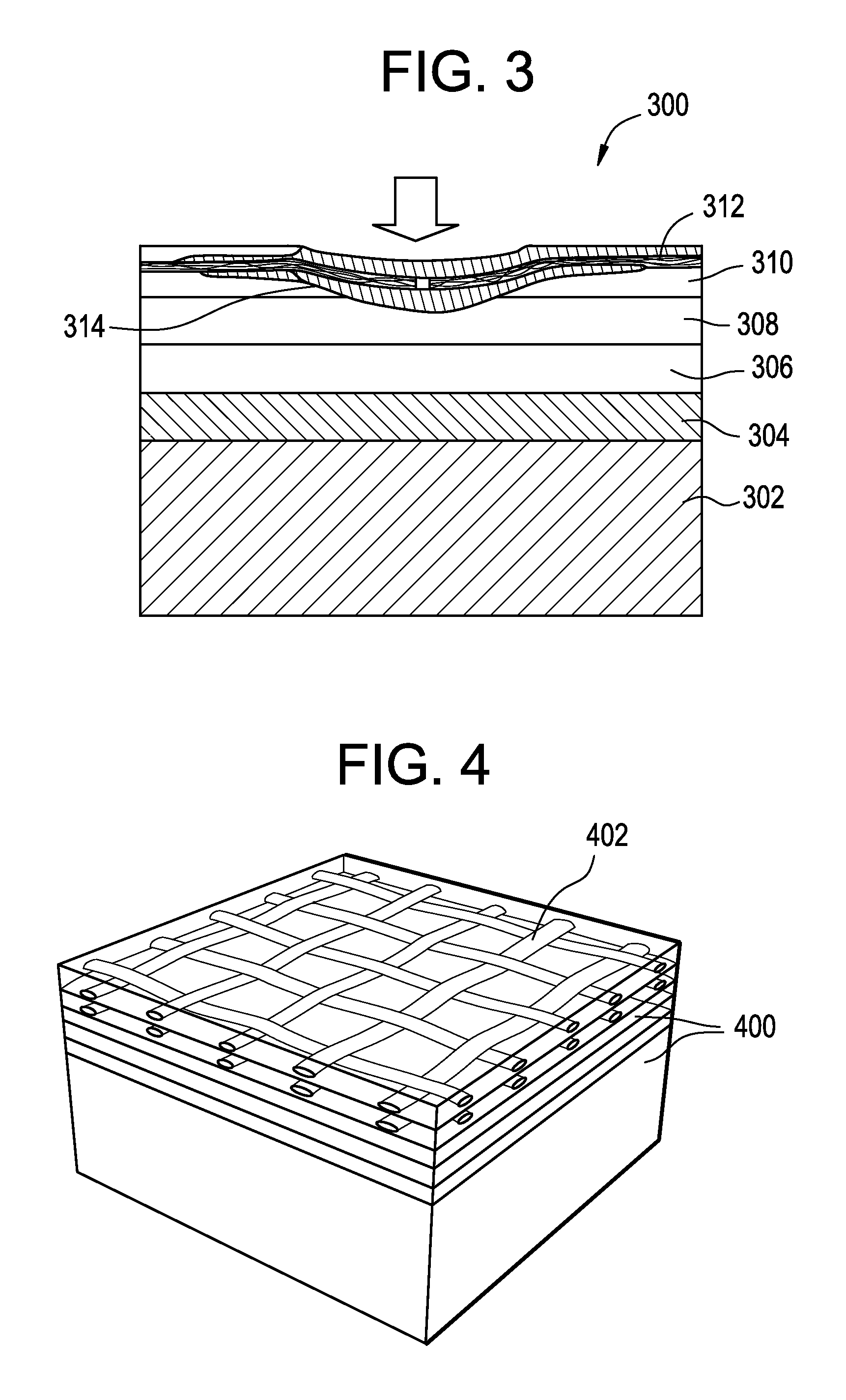

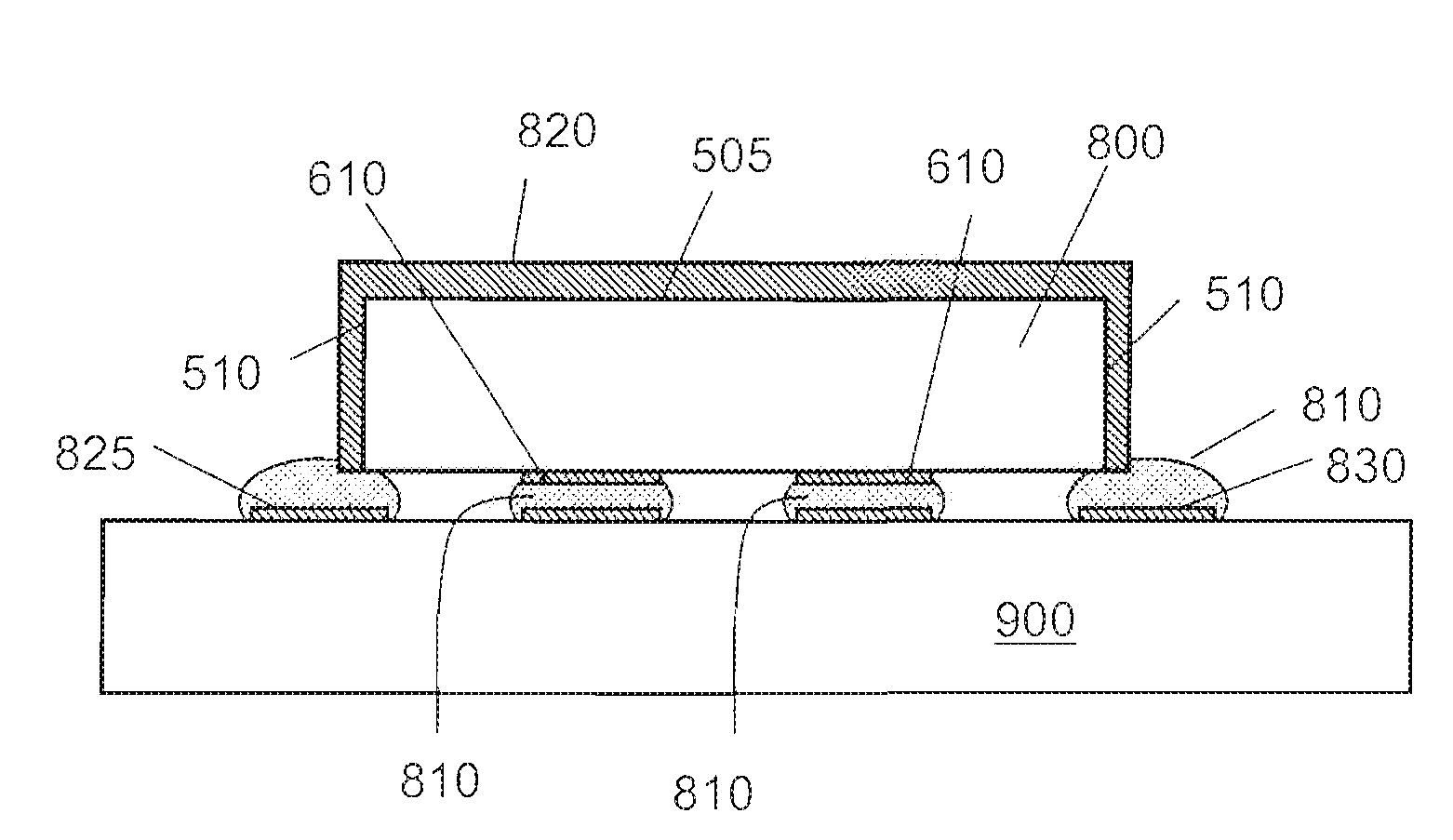

Embedded printed circuit board and method of manufacturing the same

InactiveUS20160174381A1Well formedSolid-state devicesElectrical connection printed elementsInsulation layerElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

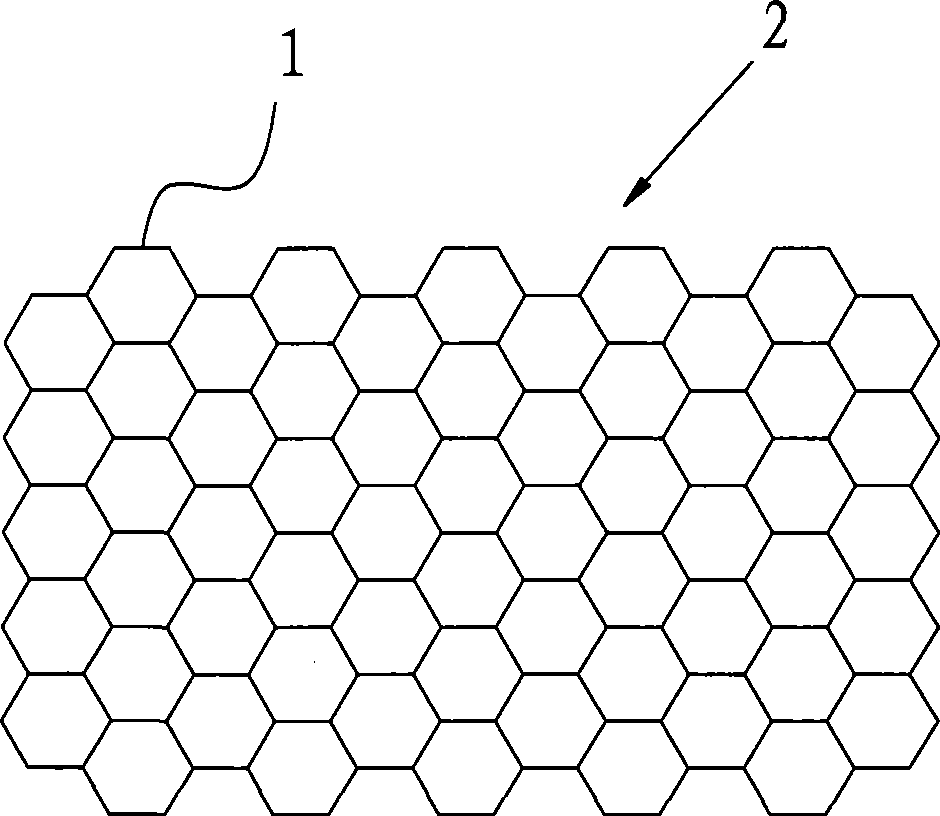

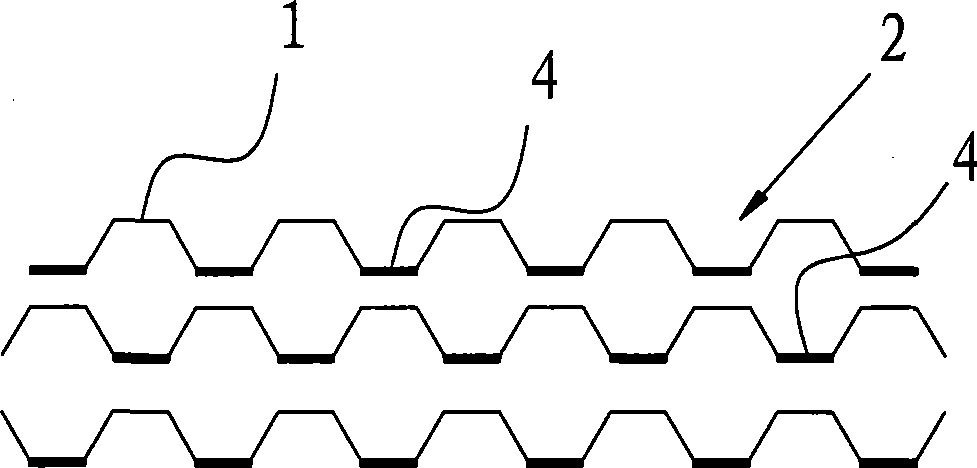

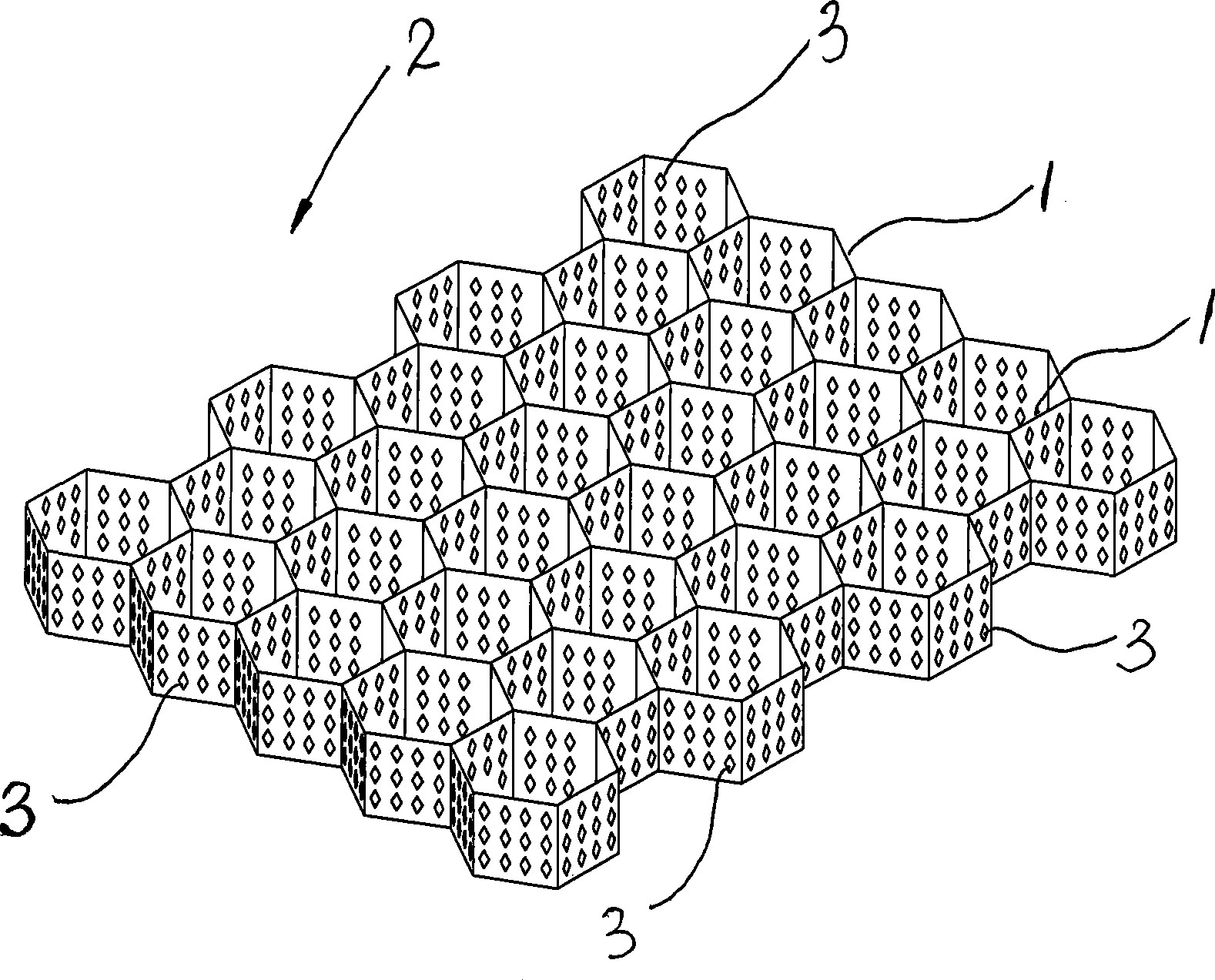

High intensity lightweight honeycomb core and production method thereof

Owner:苏州航通蜂窝科技有限公司

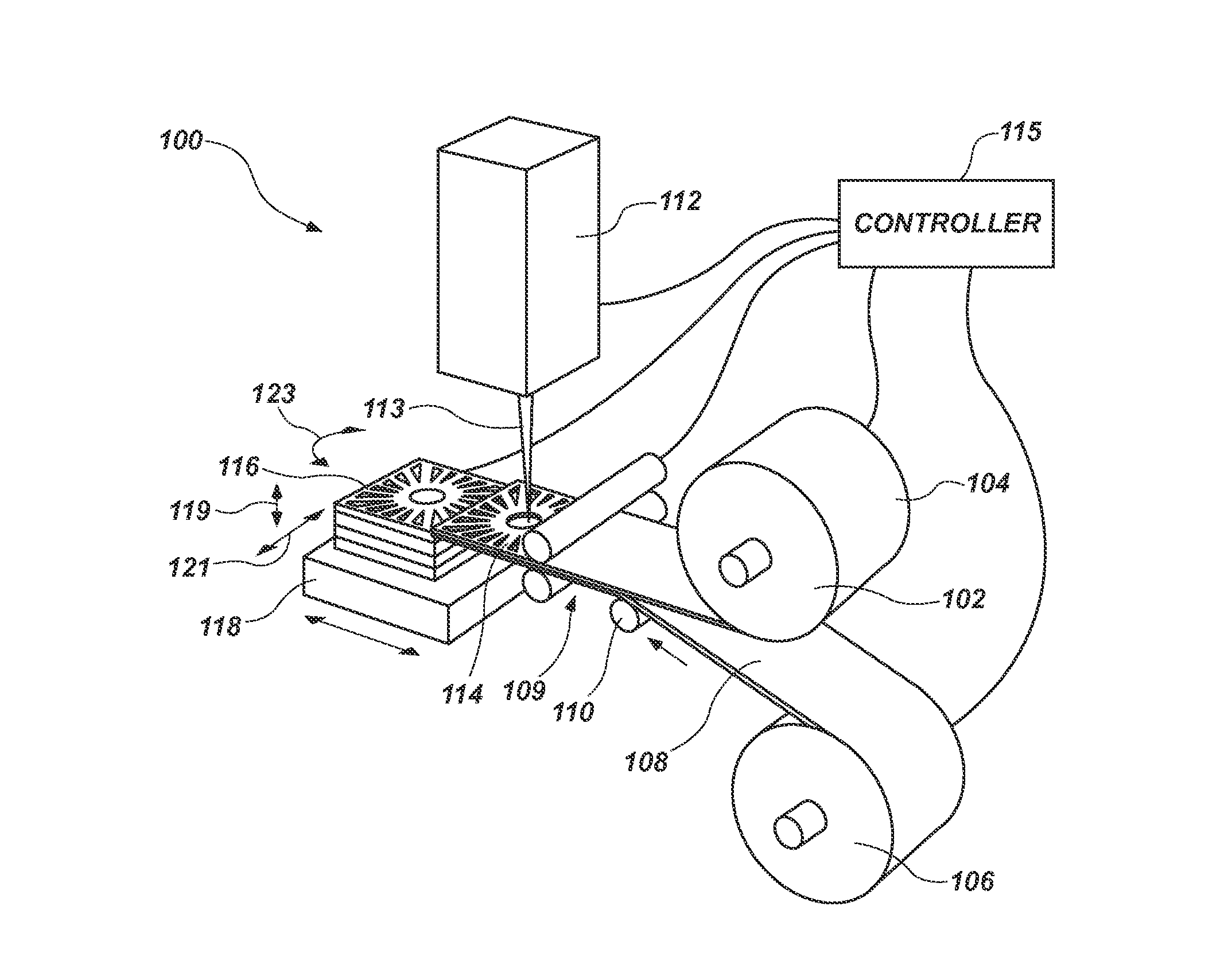

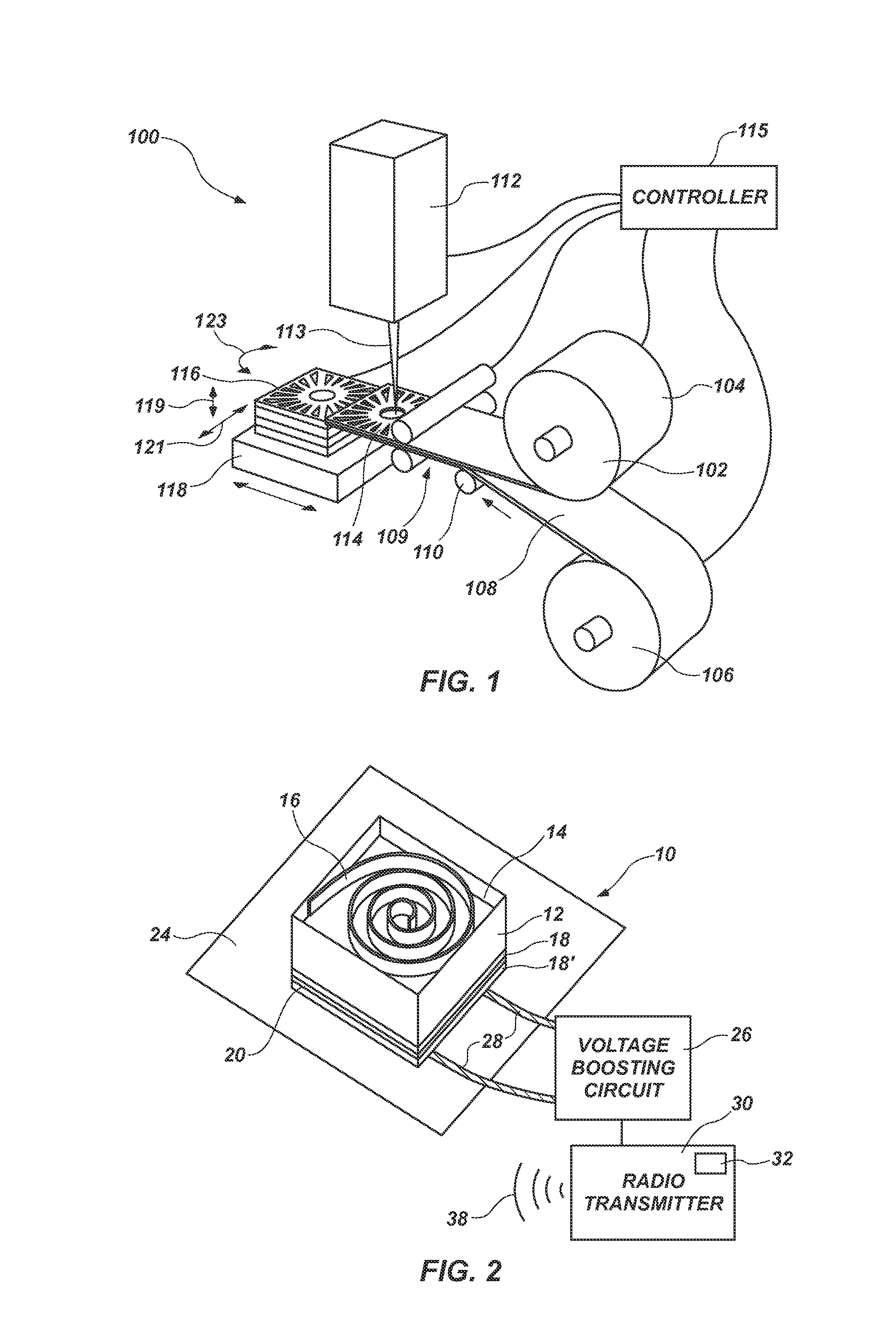

System and method for additive fabrication using laminated sheets

ActiveUS9550349B1Fast formingImprove developmentAdditive manufacturing apparatusLamination ancillary operationsComputer generationThermal energy harvesting

Owner:THE BOEING CO

Reinforced coatings and methods of making the same

Owner:GENERAL ELECTRIC CO

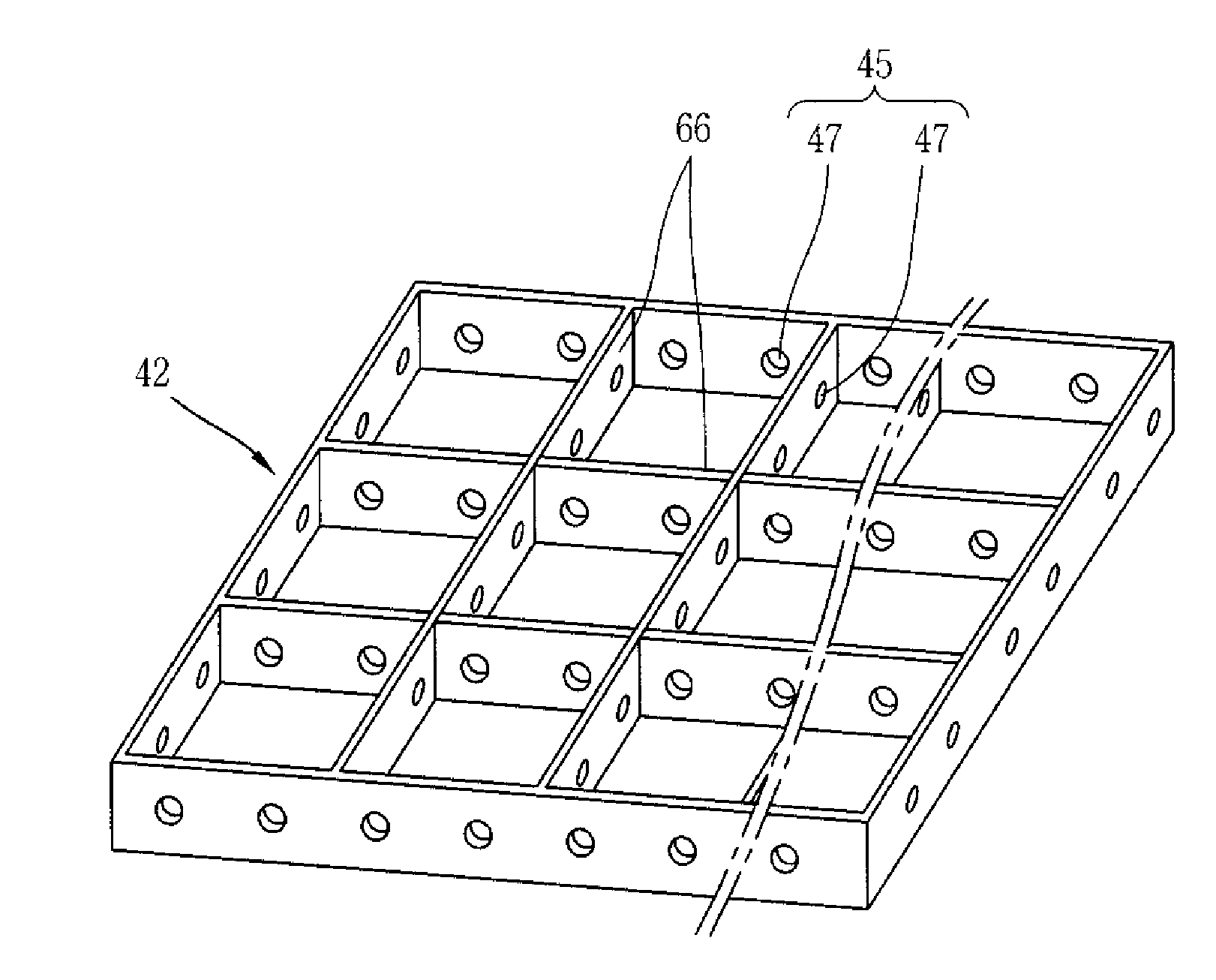

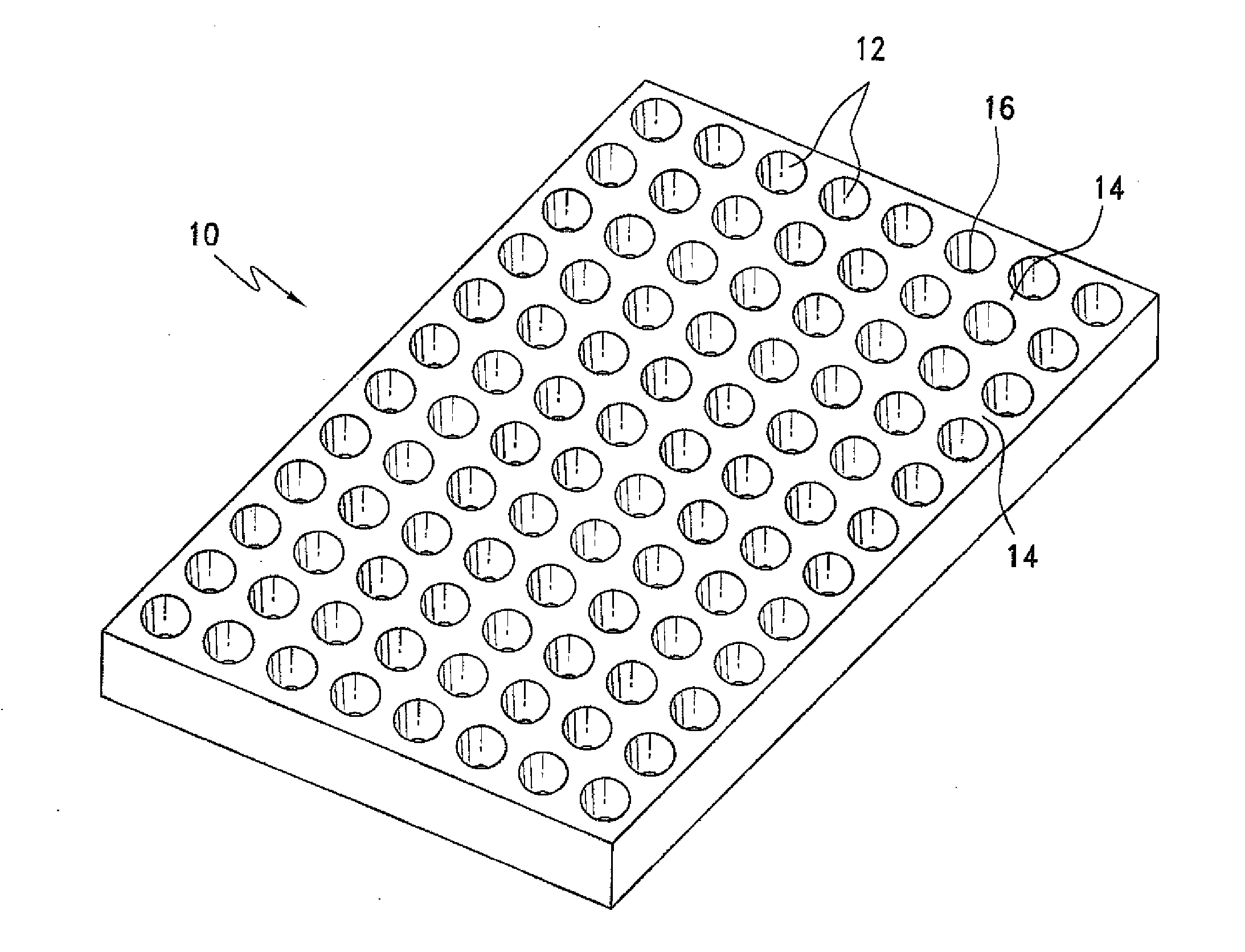

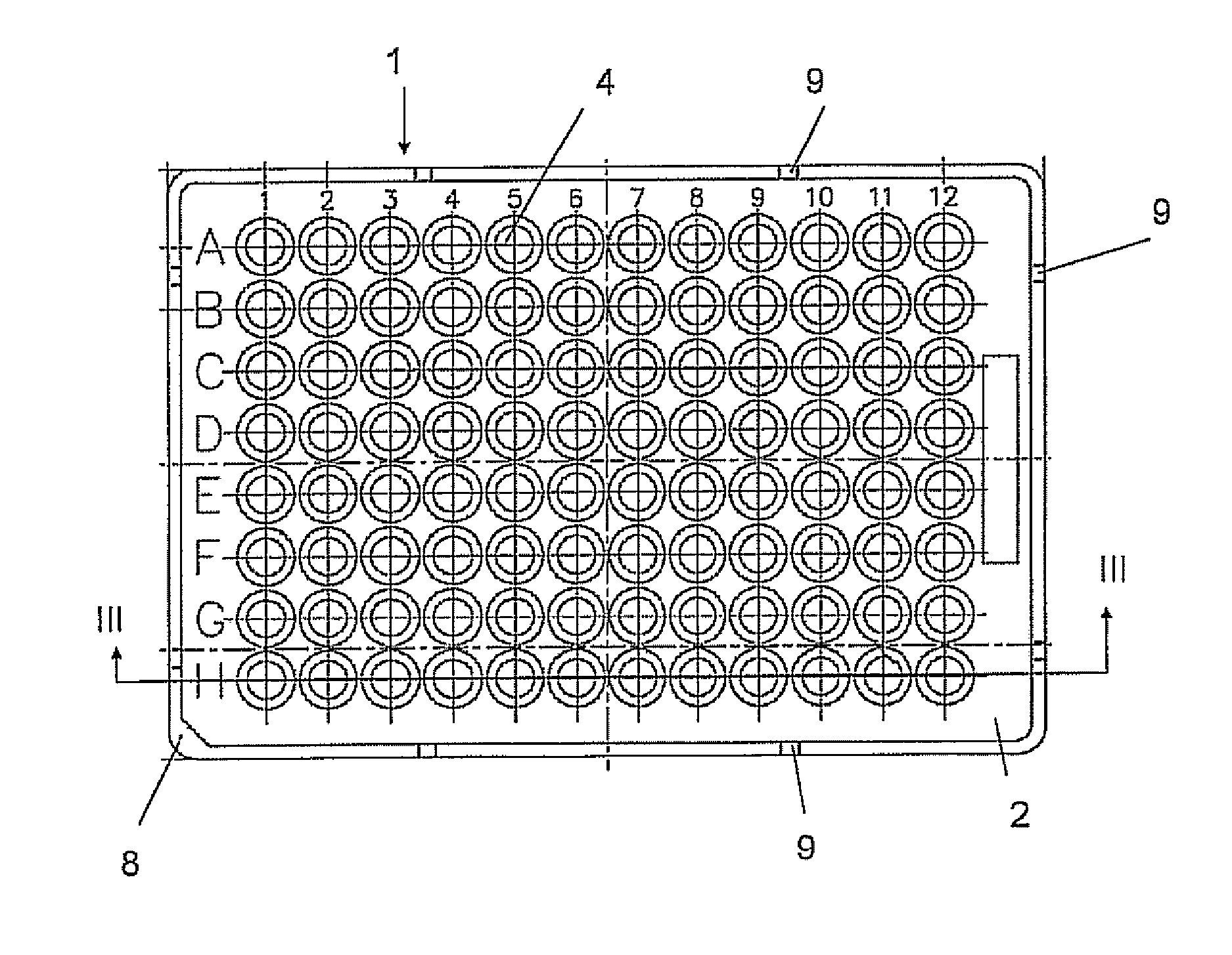

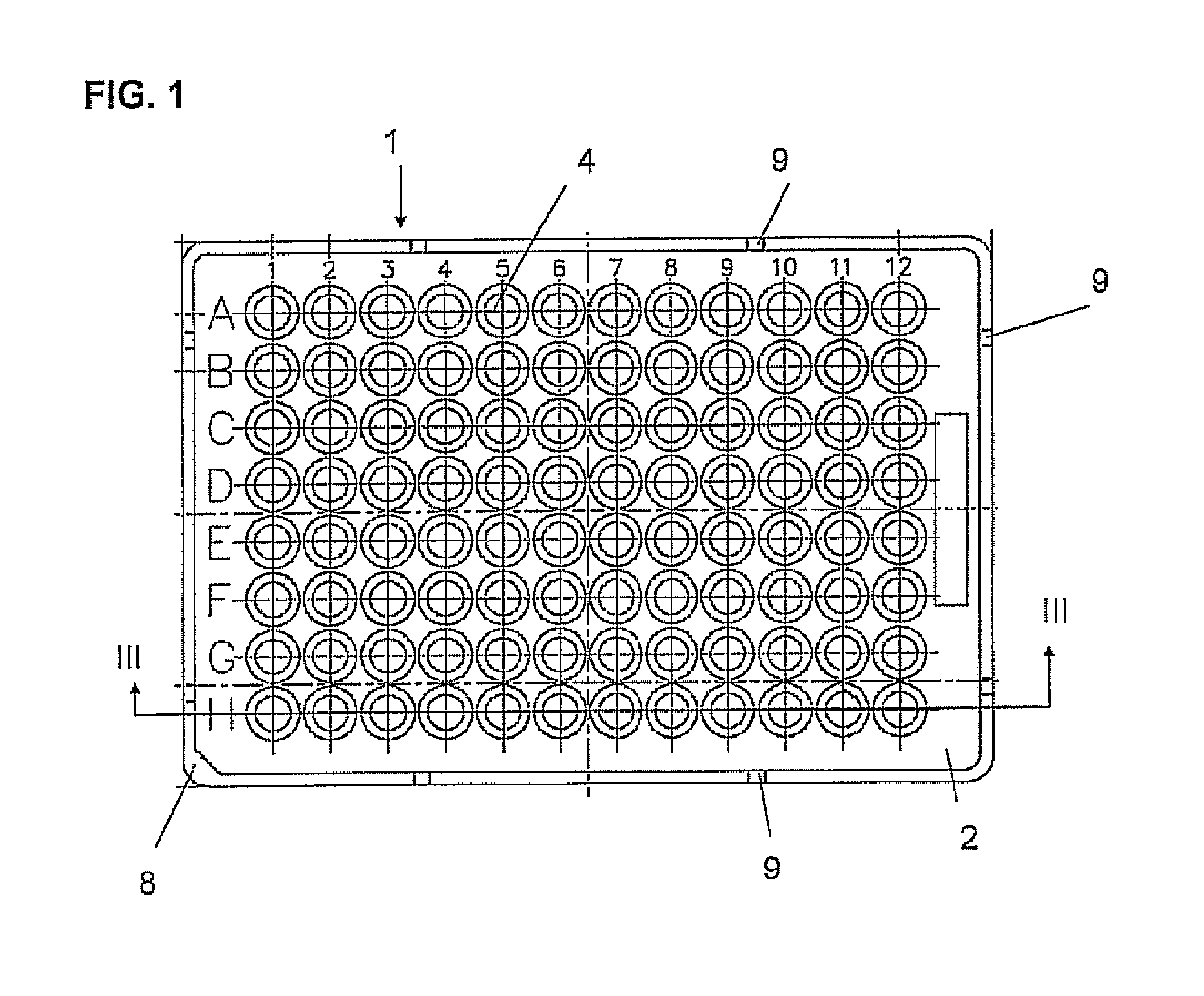

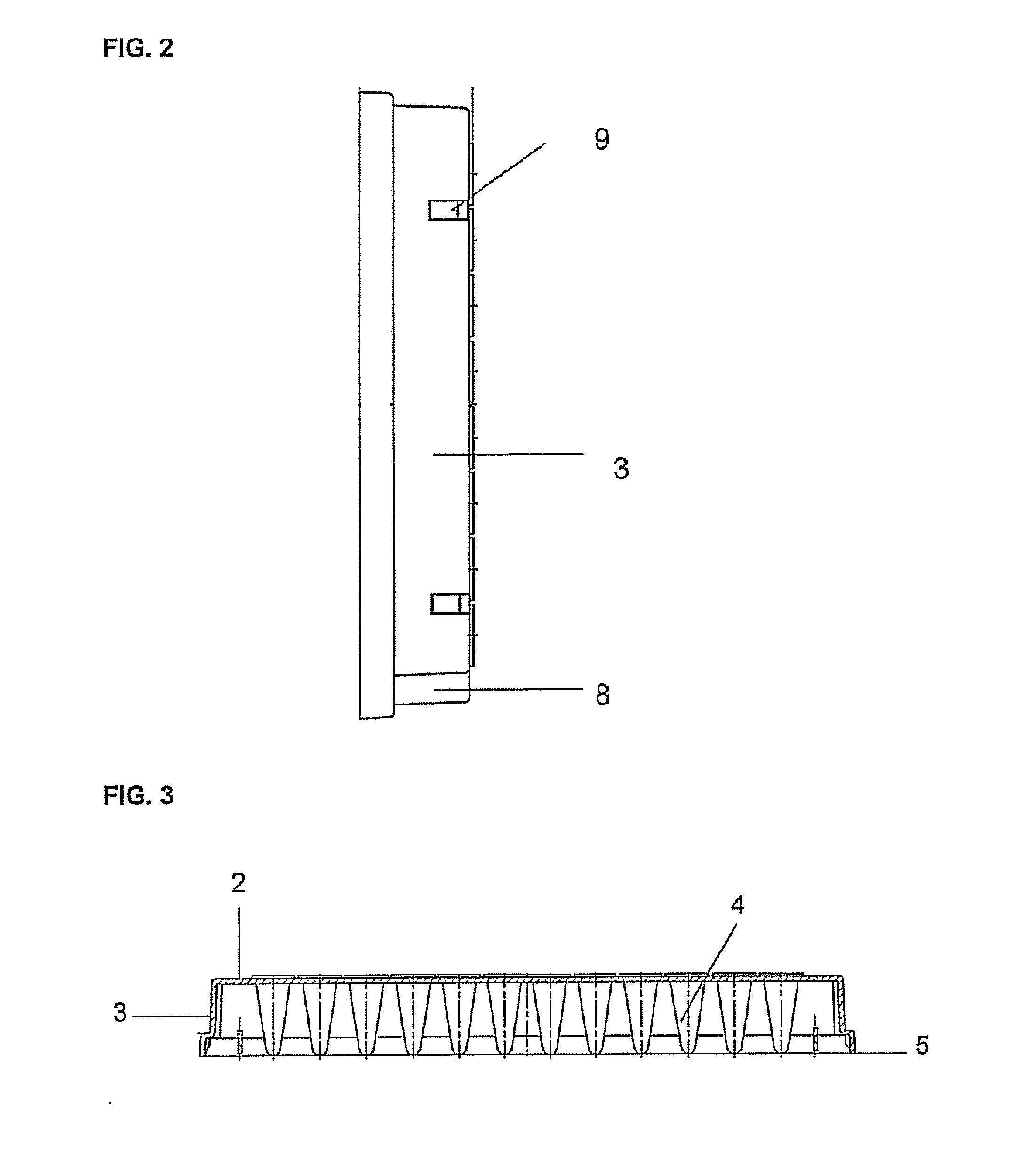

Pico liter well holding device and method of making the same

InactiveUS20100247386A1Reduce distortion problemsEngine sealsLamination ancillary operationsRefractive indexAqueous medium

Owner:SENG ENTERPRISES

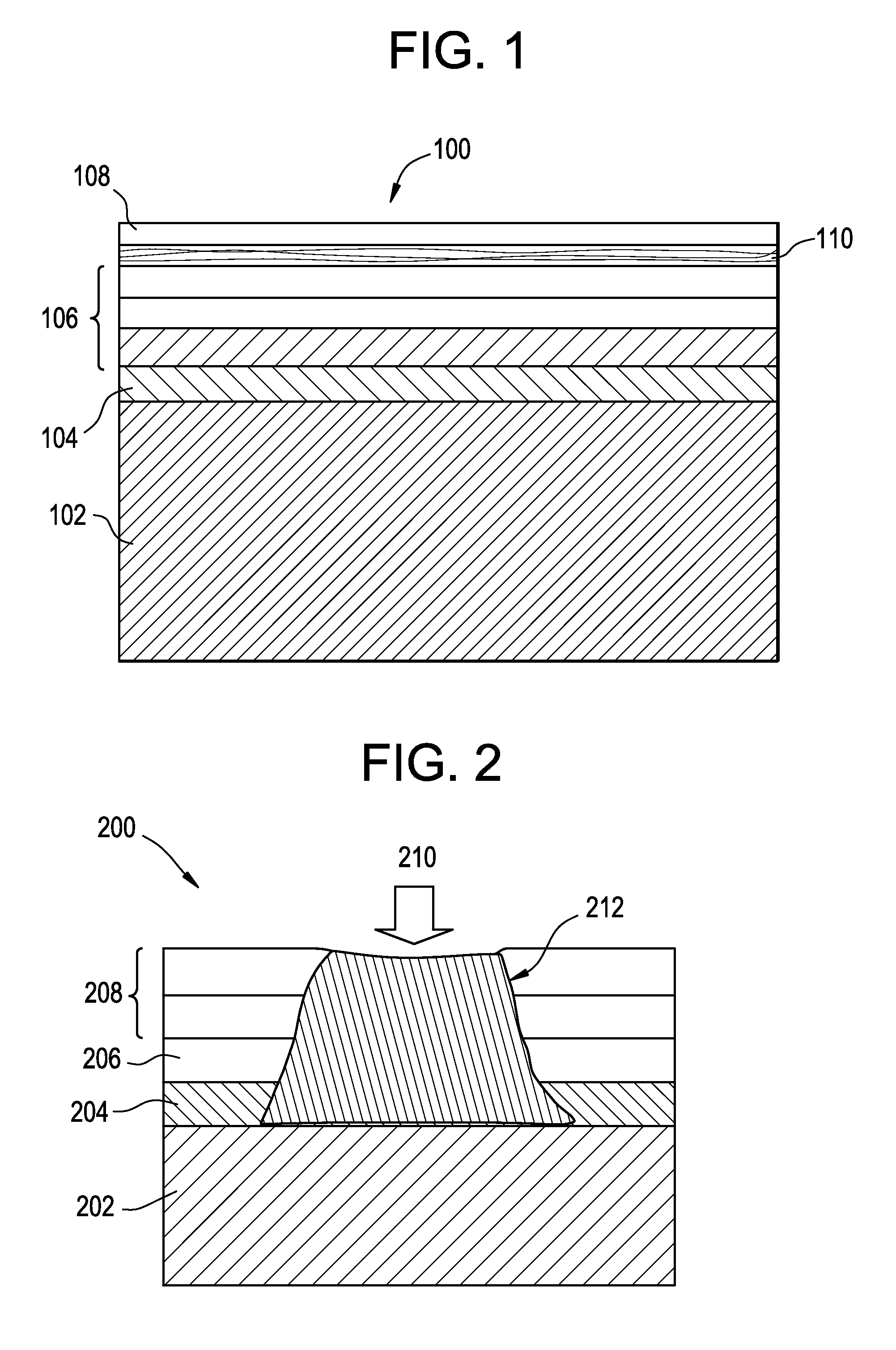

Systems and methods for manufacturing composite materials using thermoplastic polymers

InactiveUS20080254307A1Improve adhesionLamination ancillary operationsLayered product treatmentThermosetting polymerMelting point

Owner:HIGHPLEX

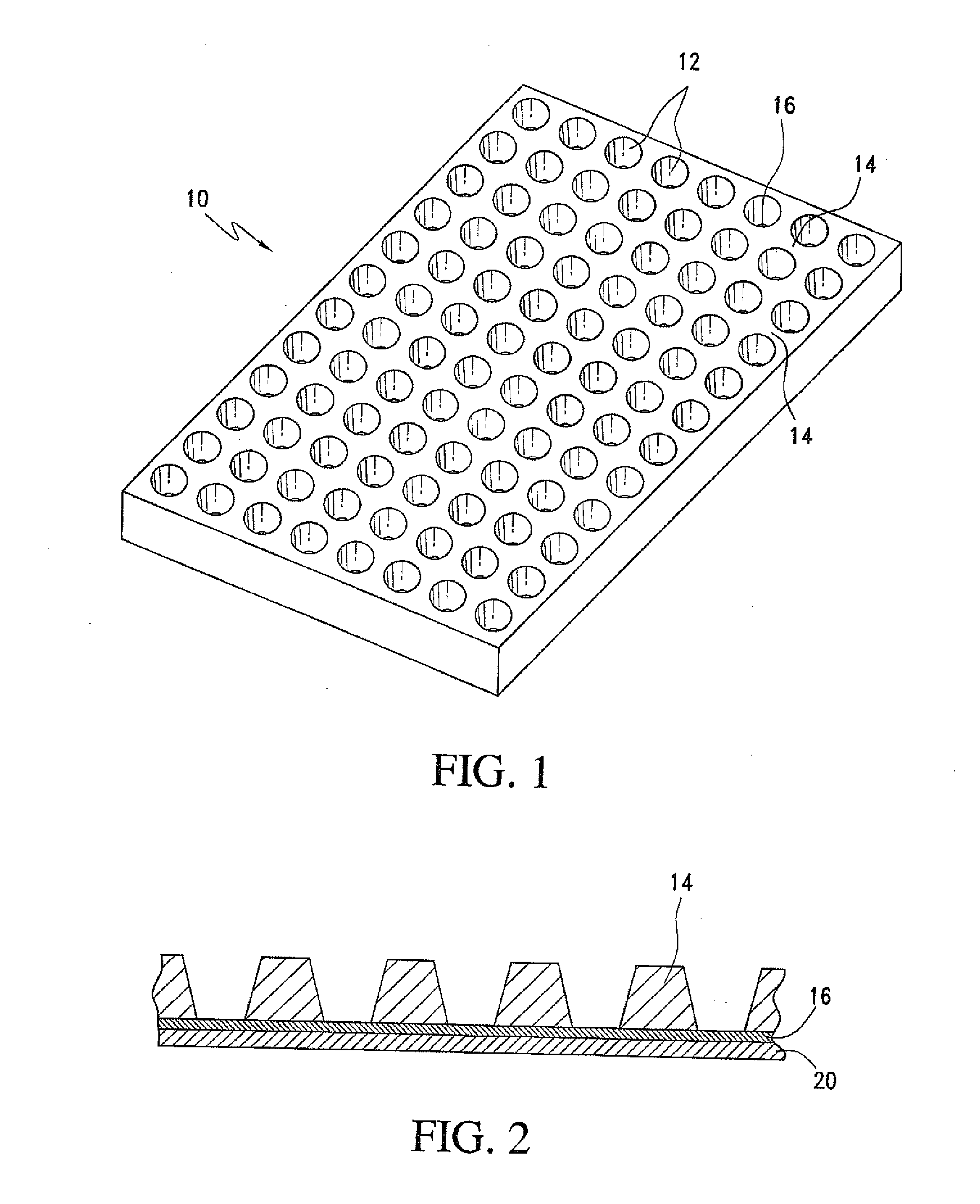

Sealing multiwell plates

InactiveUS20120058516A1Avoid pollutionLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:4TITUDE

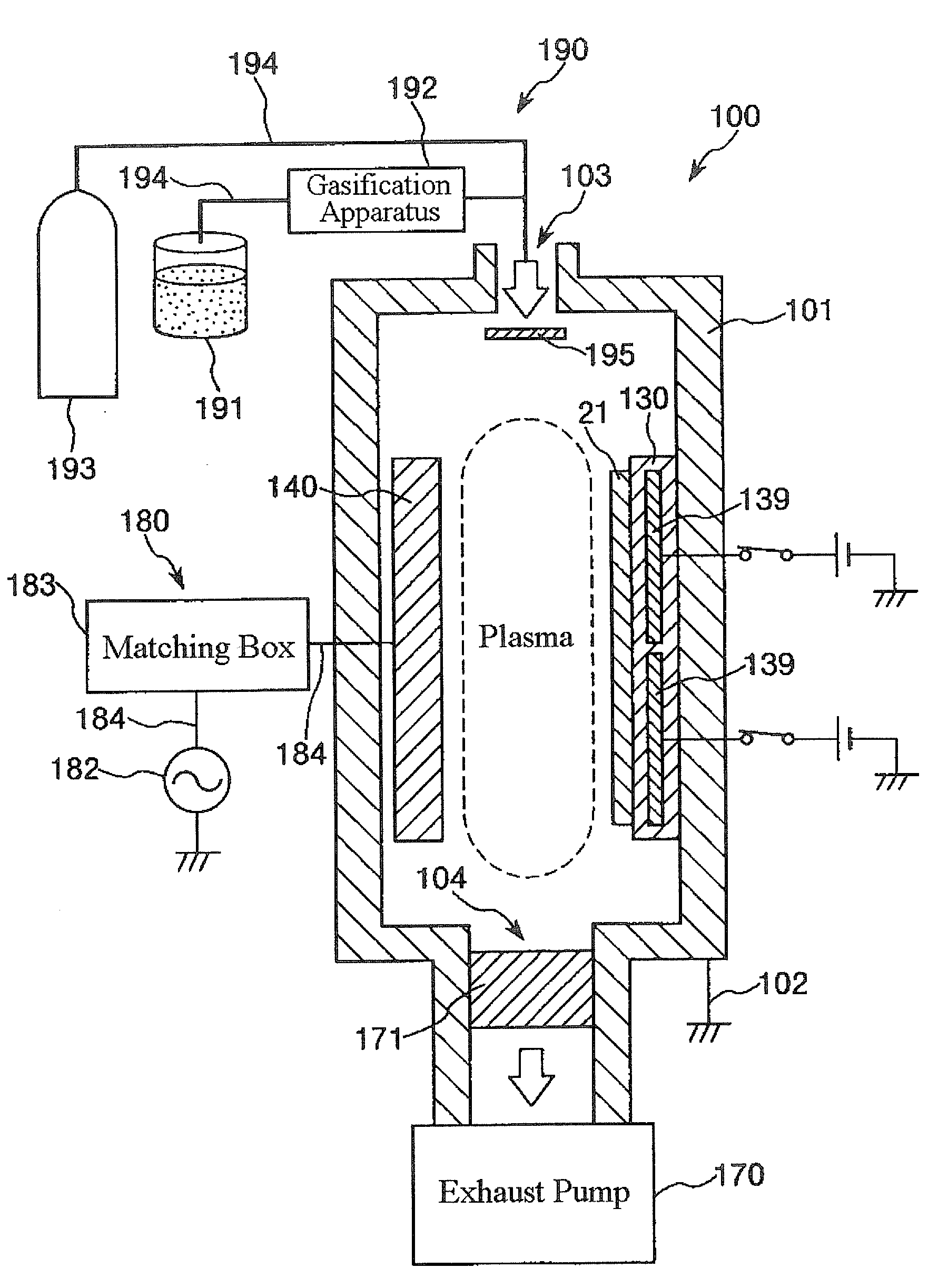

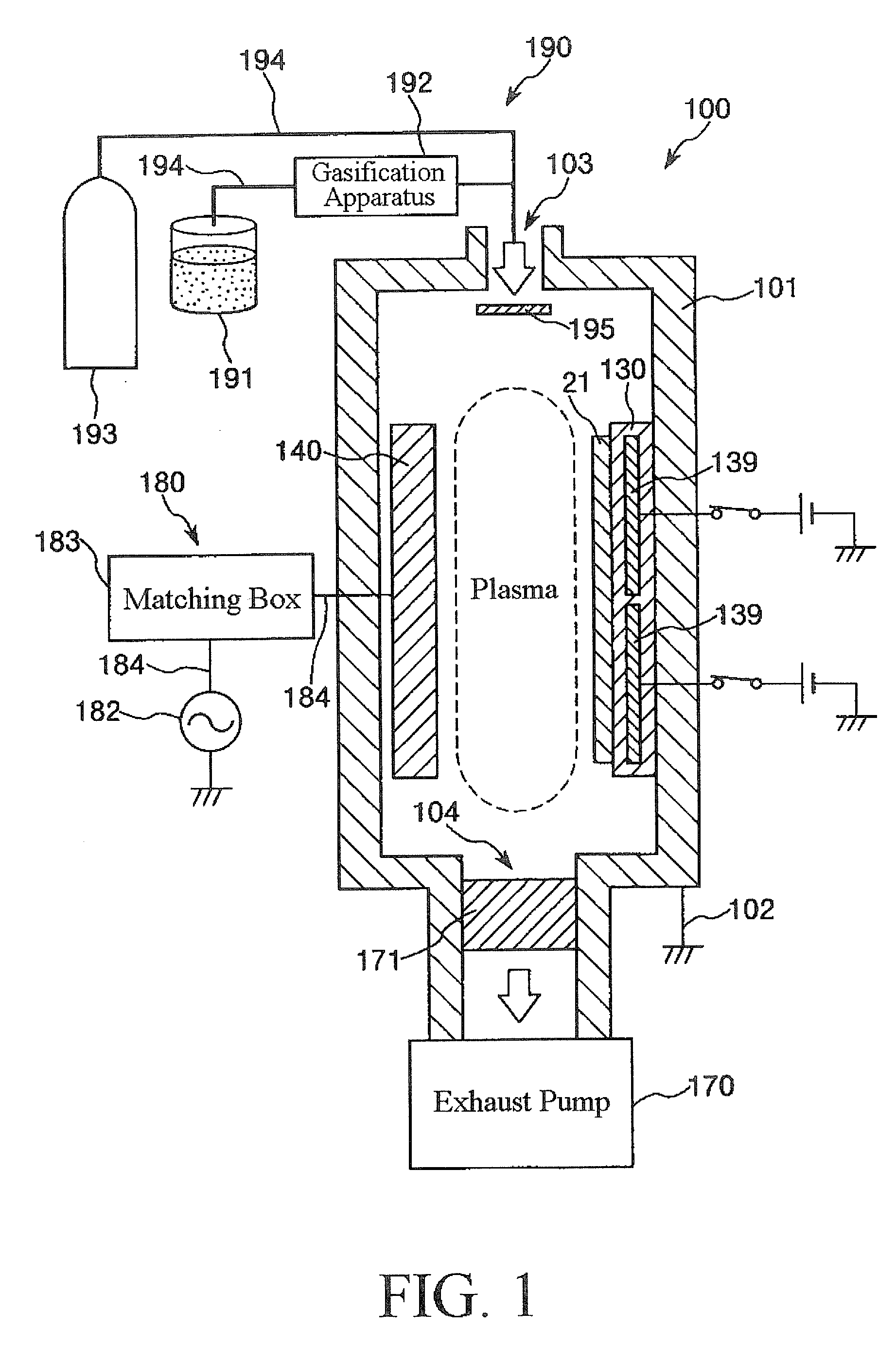

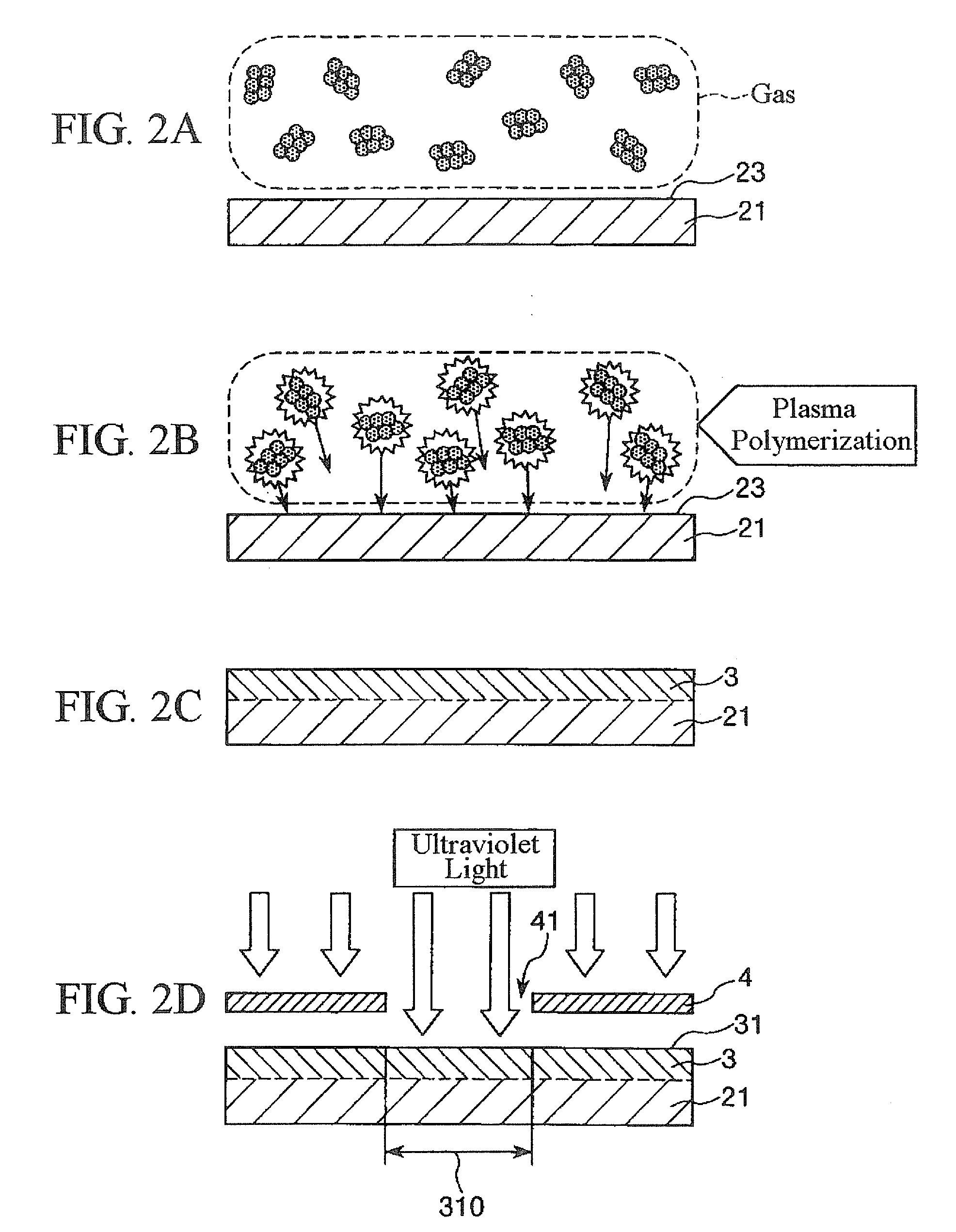

Bonding method, bonded body, droplet ejection head, and droplet ejection apparatus

InactiveUS20100193120A1Lamination ancillary operationsAdhesive processes with surface pretreatmentPlasma polymerizationMaterials science

Owner:SEIKO EPSON CORP

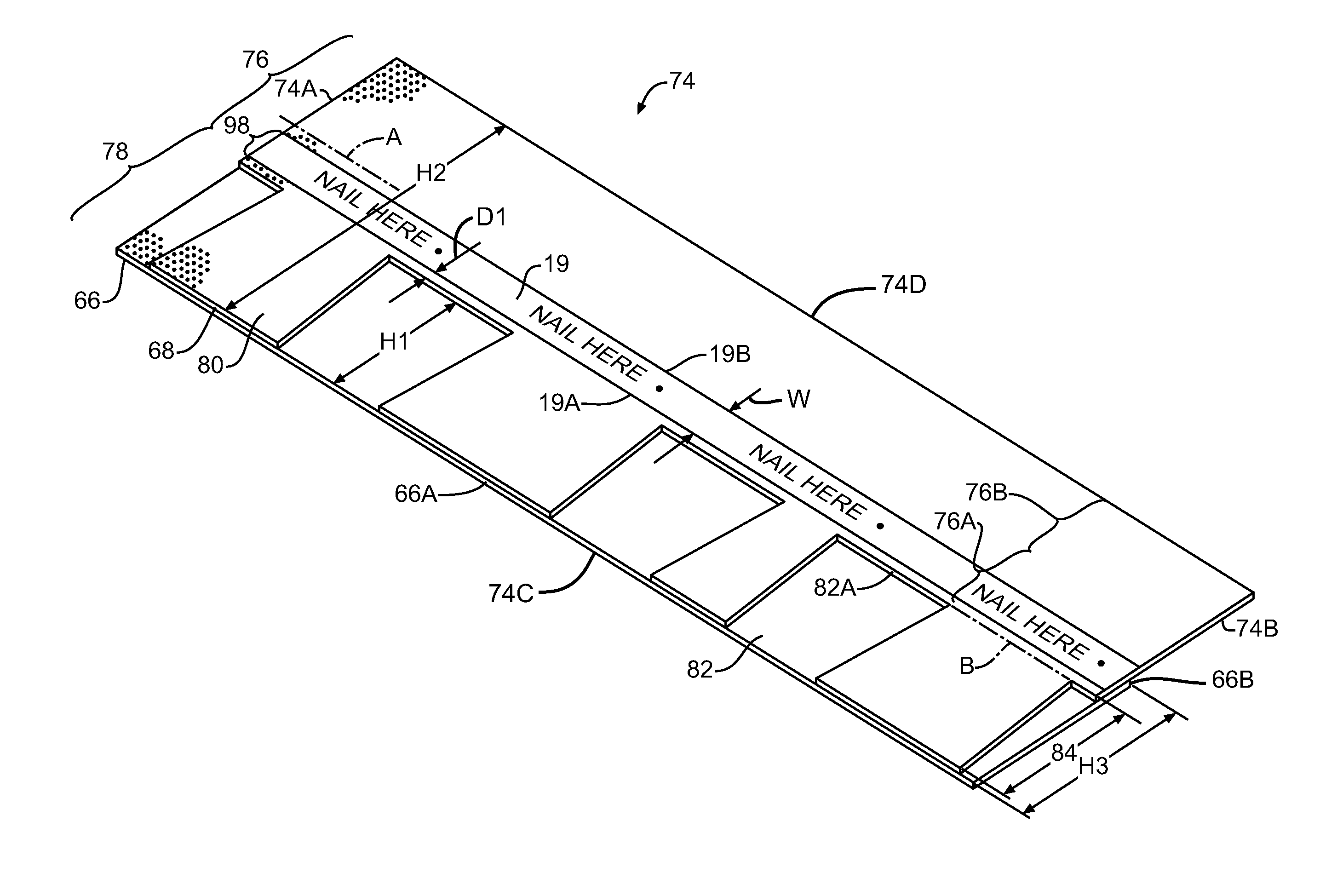

Method of manufacturing a shingle with reinforced nail zone

InactiveUS20130025771A1Amount be controlAdhesive processesLamination ancillary operationsAsphaltBiomedical engineering

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

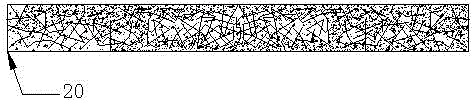

Laminated plate and end treatment method of the laminated plate

ActiveUS20100021675A1Welding/cutting auxillary devicesHollow wall articlesEngineeringMechanical engineering

A manufacturing method of a laminated plate (19) includes: a first step of supporting, by a support member (9), a thermoplastic resin-made laminated material (1) in which a pair of plate-like members (3, 4) are laminated to each other while interposing a longitudinal wall portion (2b) so that a peripheral edge portion (1a) of the laminated material (1) can be exposed, and heating and softening the peripheral edge portion (1a) by blowing a hot air to the peripheral edge portion (1a); and a second step of pressing the plate-like member (4) as one of the pair of plate-like members (3, 4) against other plate-like member (3) by thrusting a cutting blade (17a) of a cutting die (17) against the heated and softened peripheral edge portion (1a), thereby bringing the pair of plate-like members (3, 4) into contact with each other and welding the plate-like members (3, 4) to each other, and then cutting the laminated plate (19) out of the laminated material (1).

Owner:MEIWA IND CO LTD

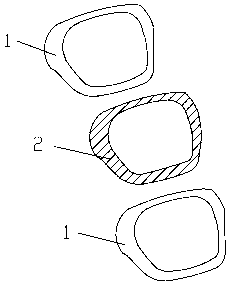

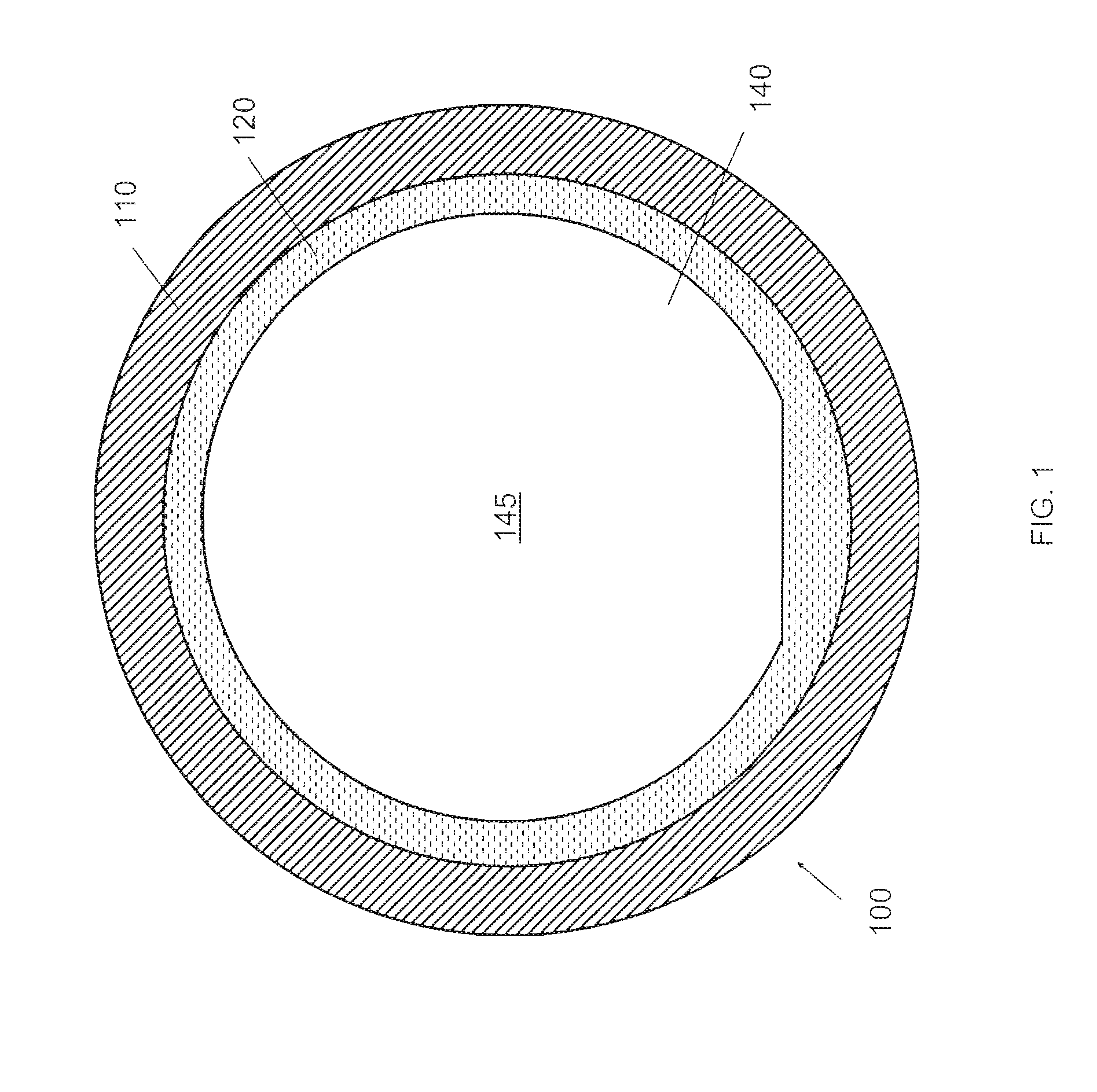

Novel spectacle material and production process thereof

InactiveCN103121322AHigh strengthImprove axial strengthLamination ancillary operationsLaminationSandwich likePunching

Owner:东莞炜创光学眼镜有限公司

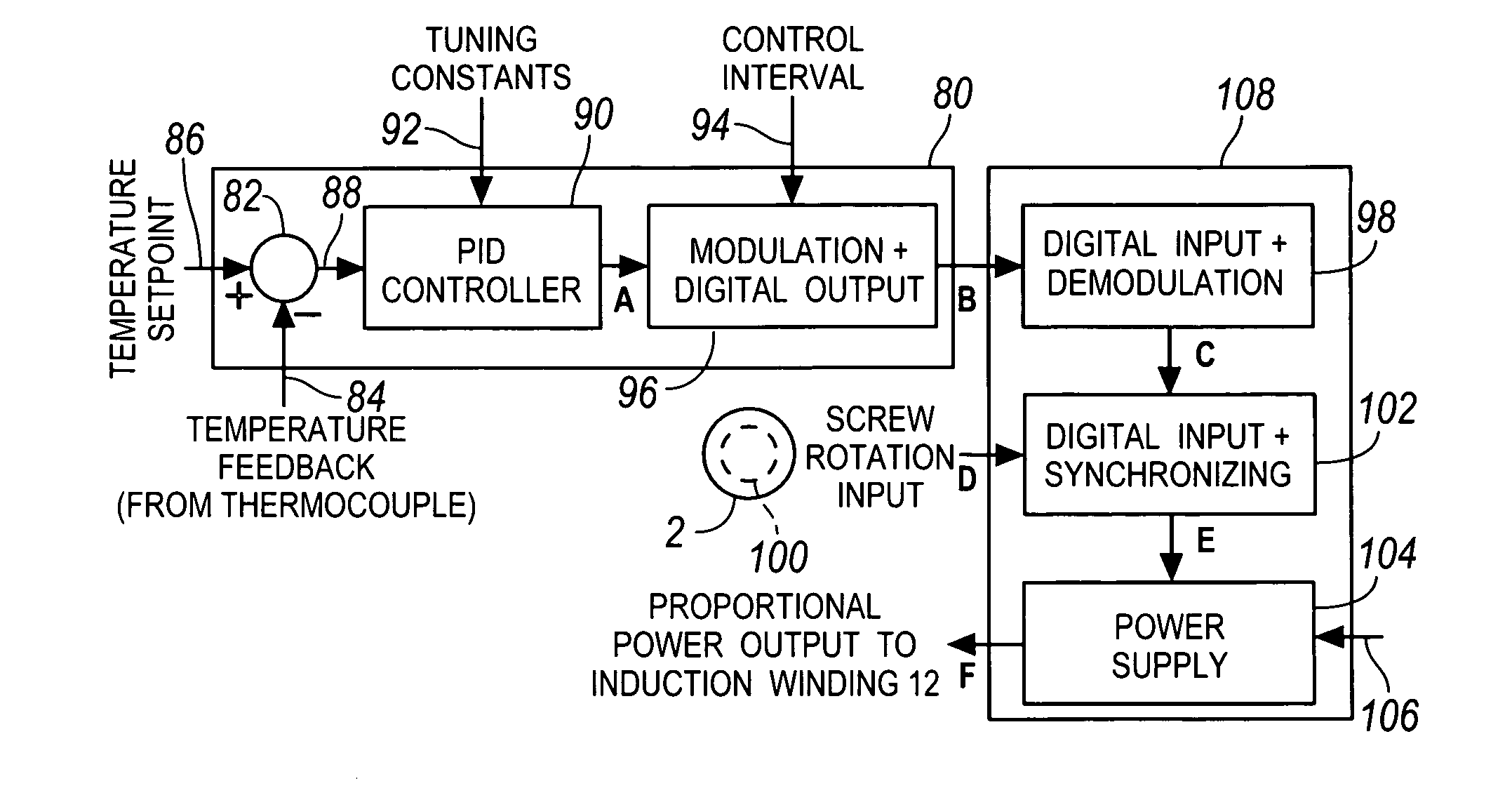

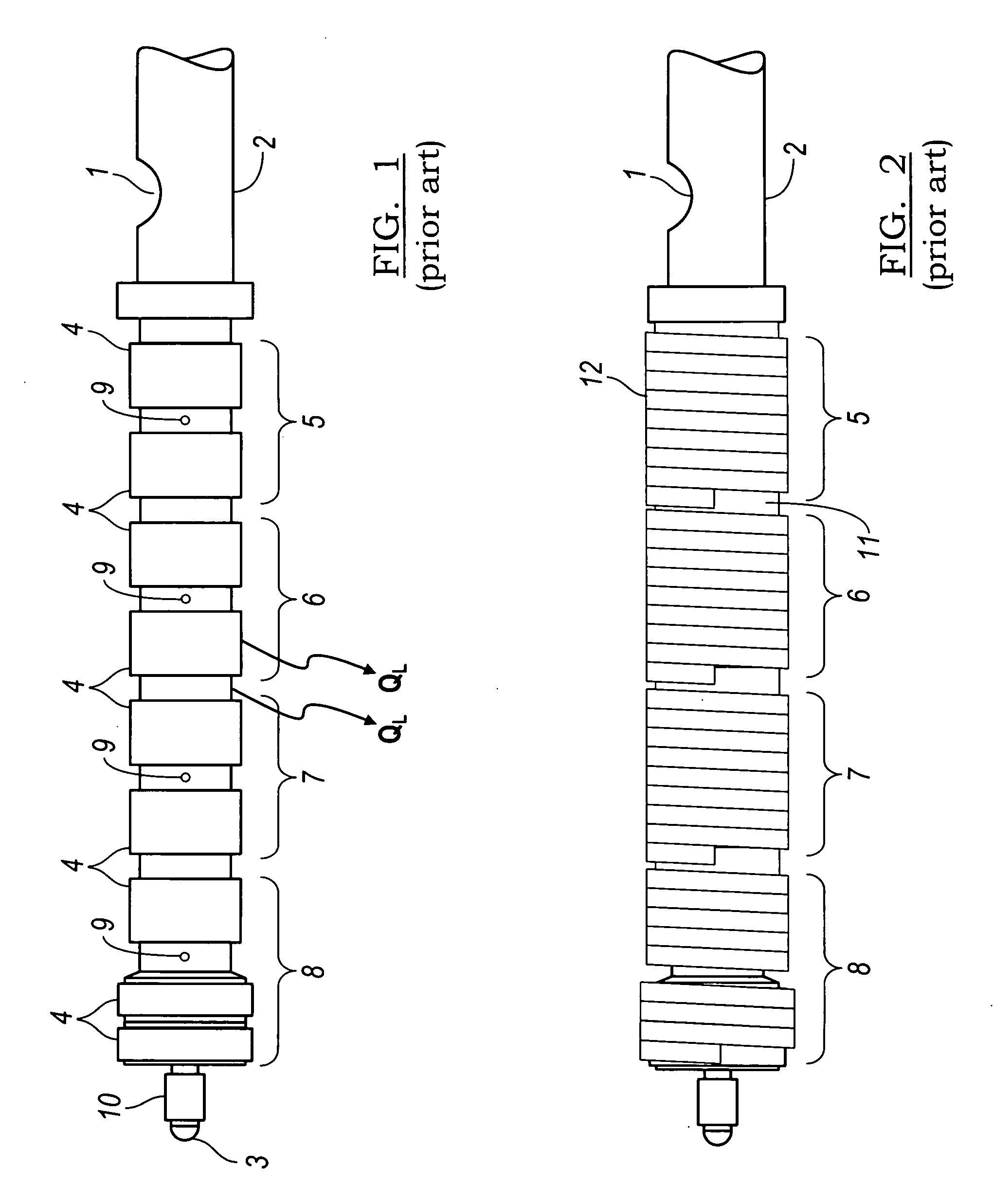

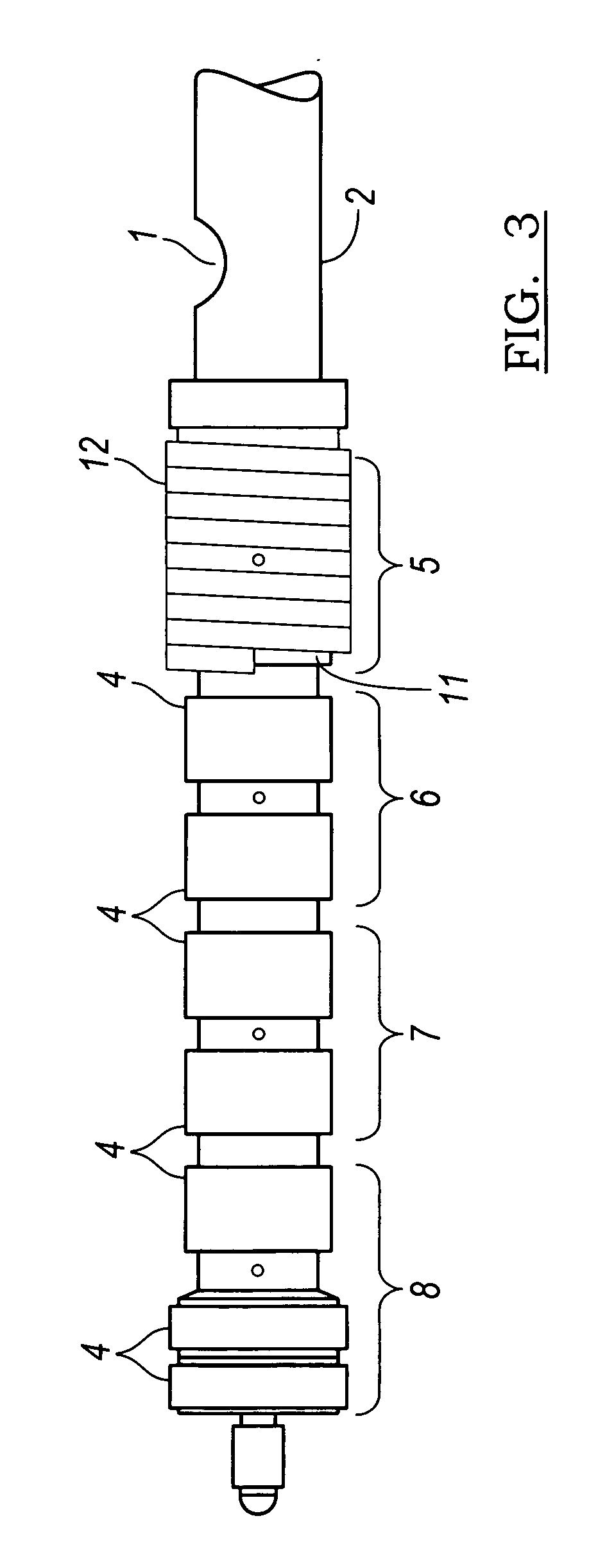

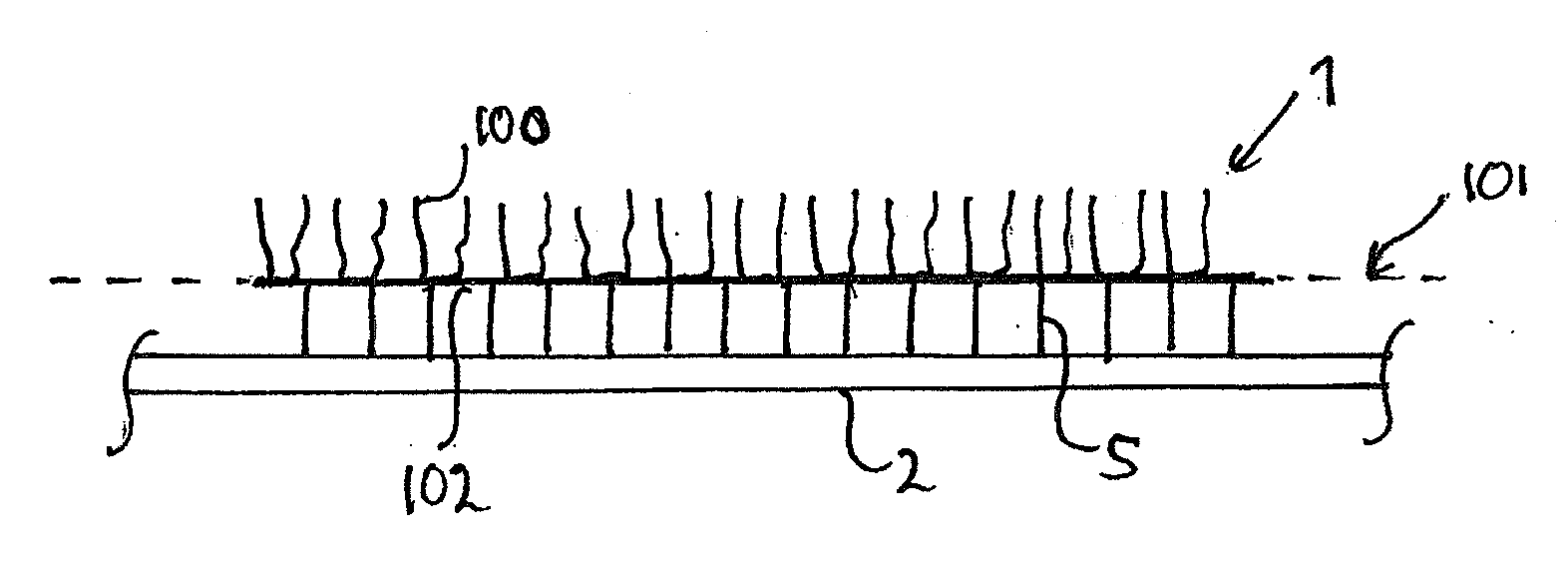

Synchronized temperature contol of plastic processing equipment

Owner:XALOY INCORPORATED

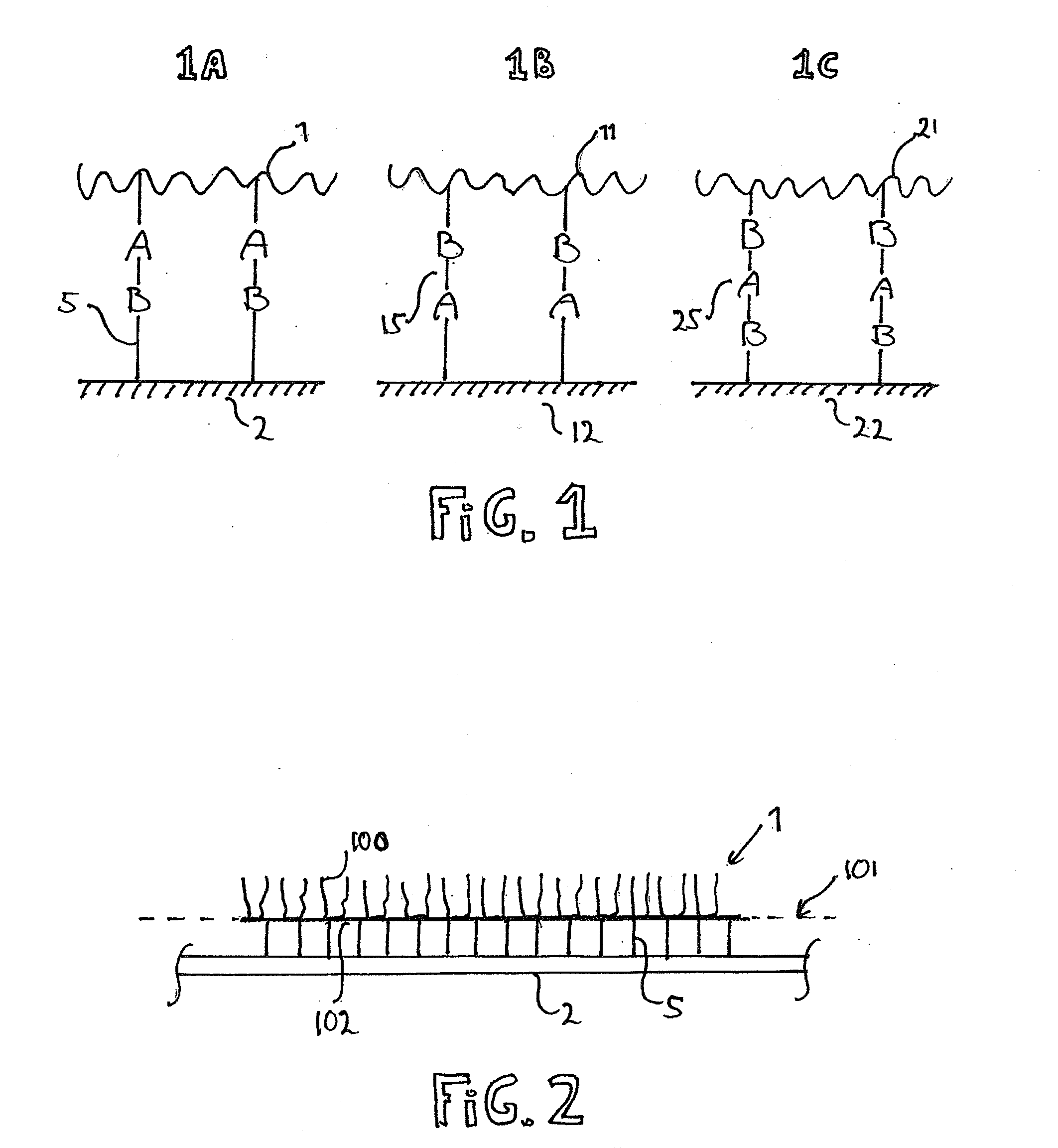

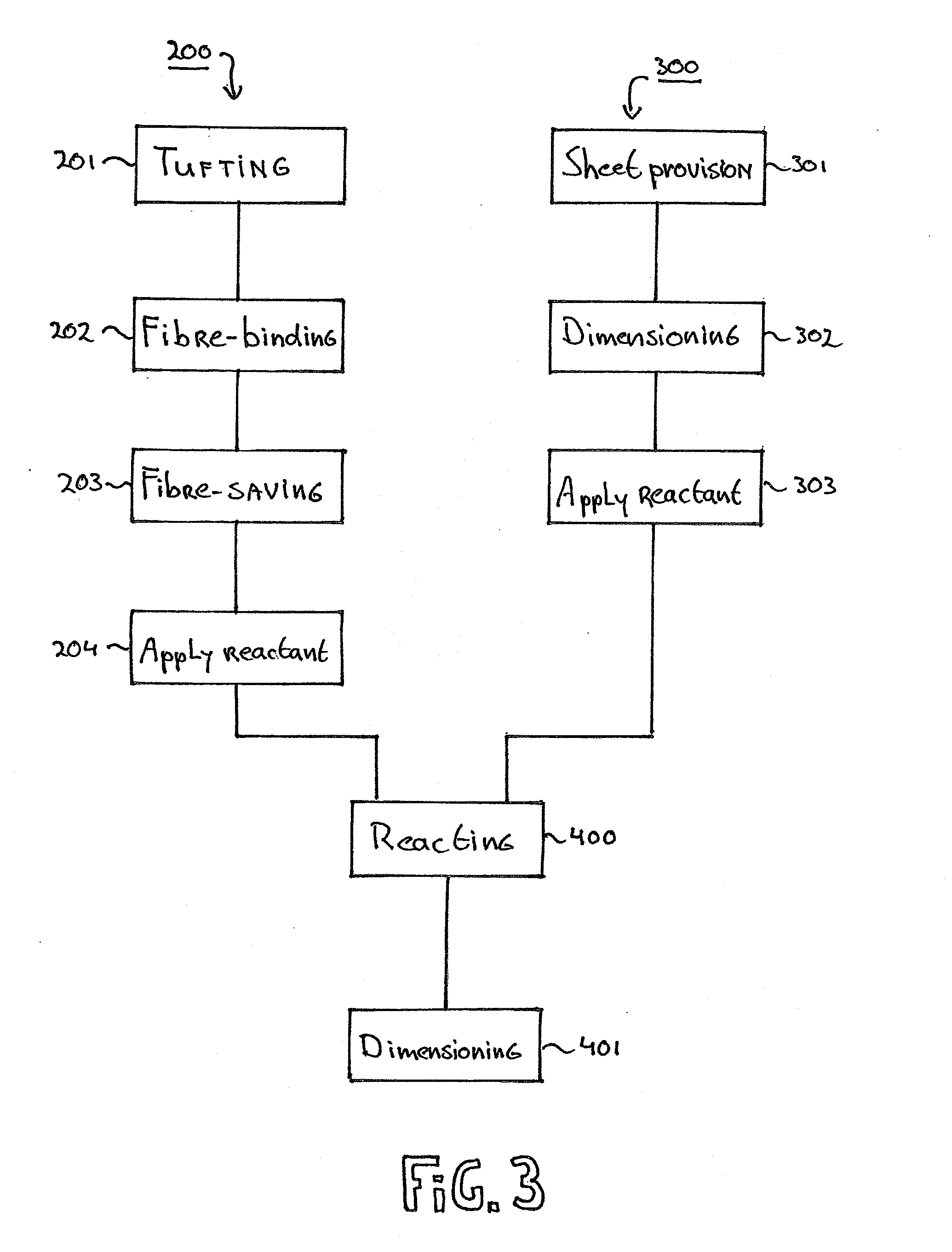

Method to Produce a Textile Product and a Textile Product Resulting from the Same

ActiveUS20130240117A1Reliable and easy connectionInexpensive materialsLiquid surface applicatorsLamination ancillary operationsYarnCovalent Interaction

Owner:COVESTRO NETHERLANDS BV

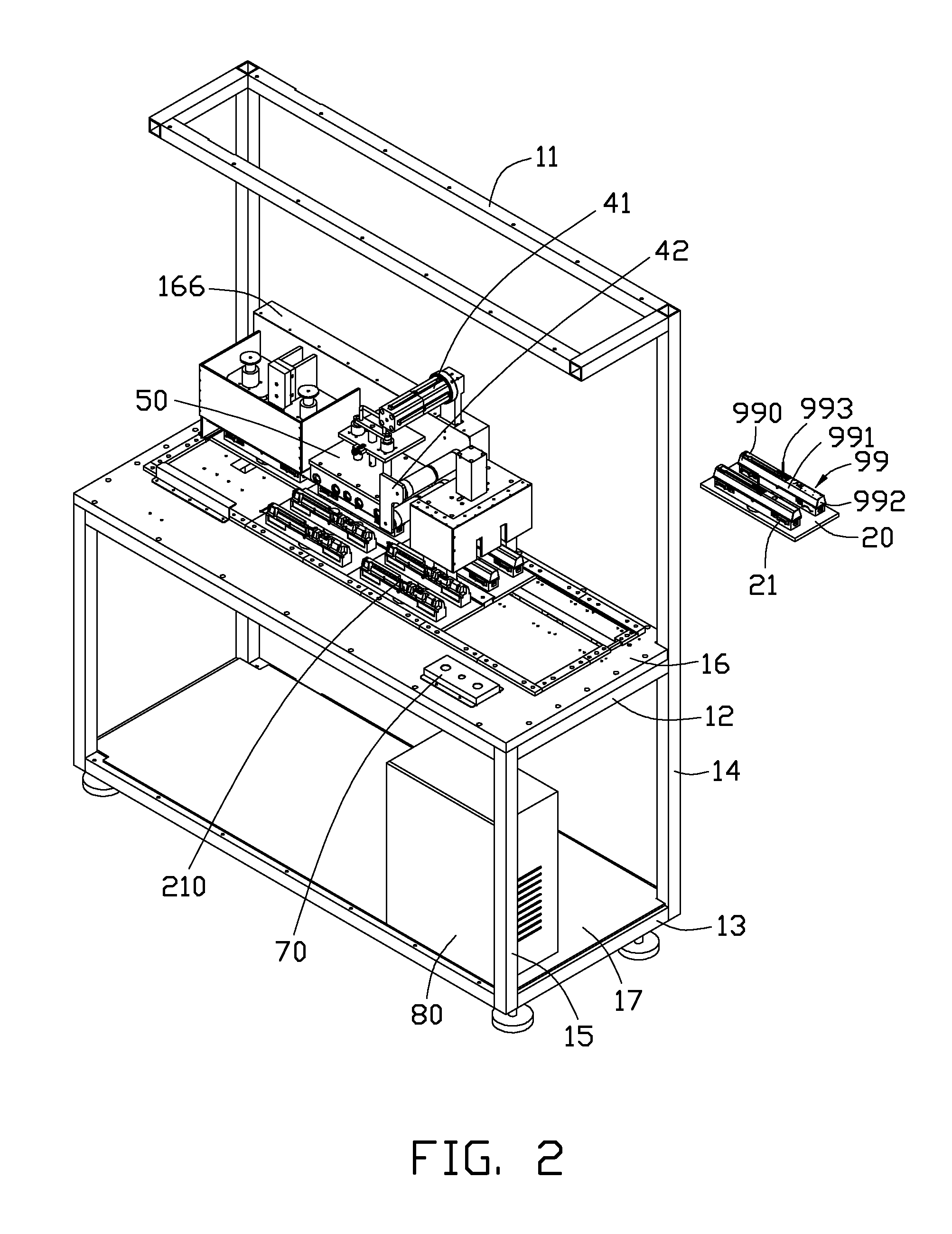

Machine for cutting object and sticking film

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

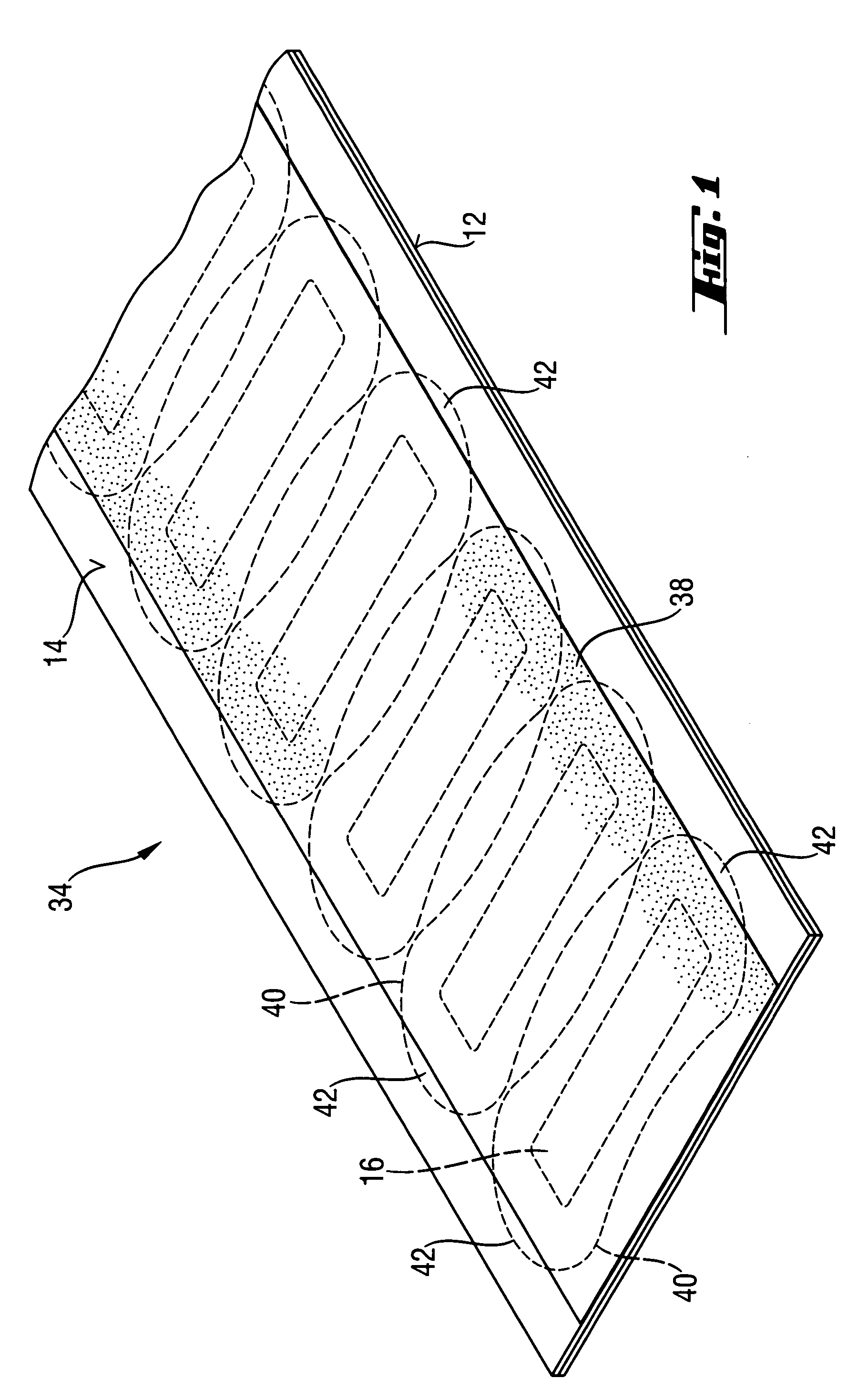

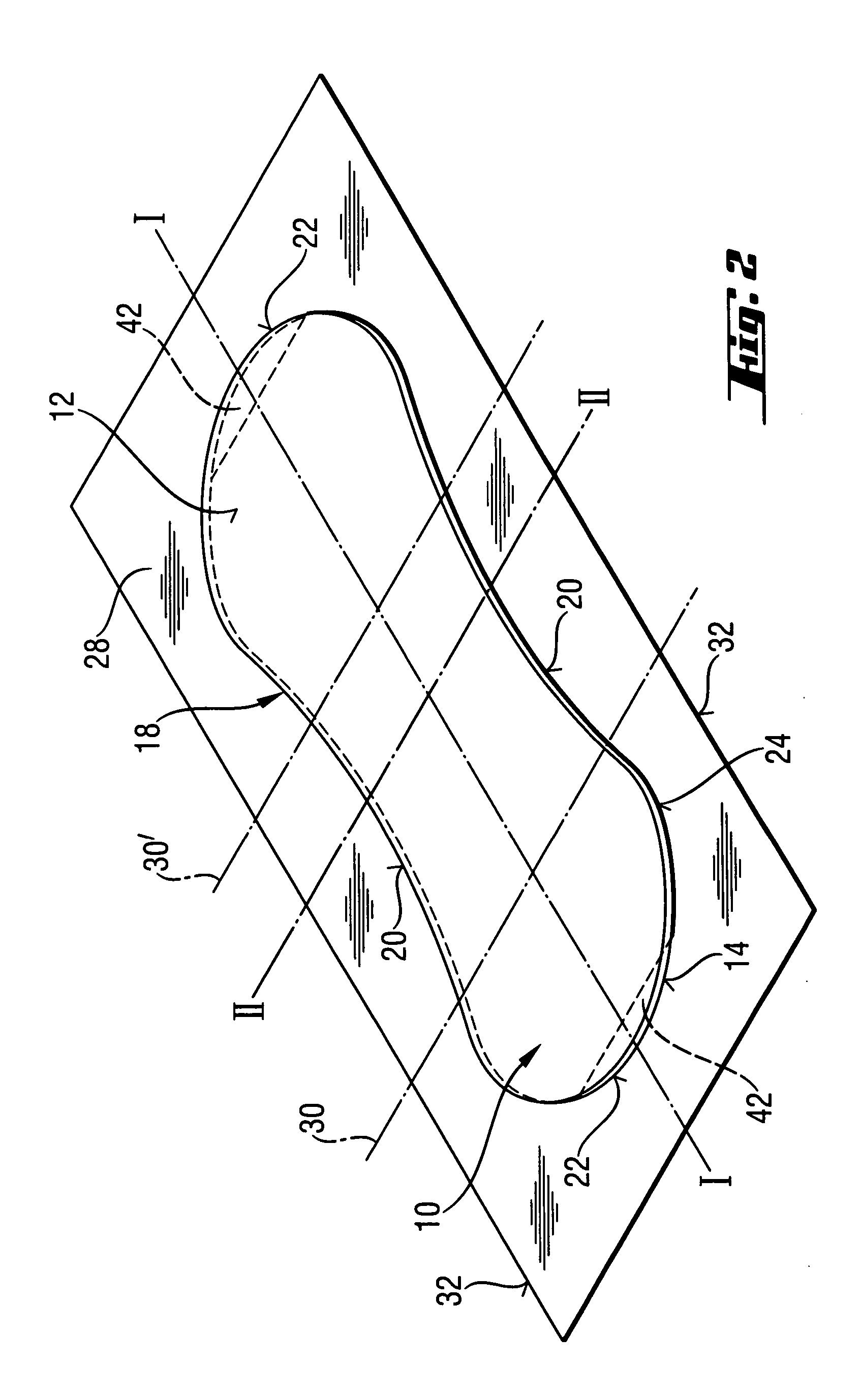

Method of and apparatus for manufacturing instant photographic film units

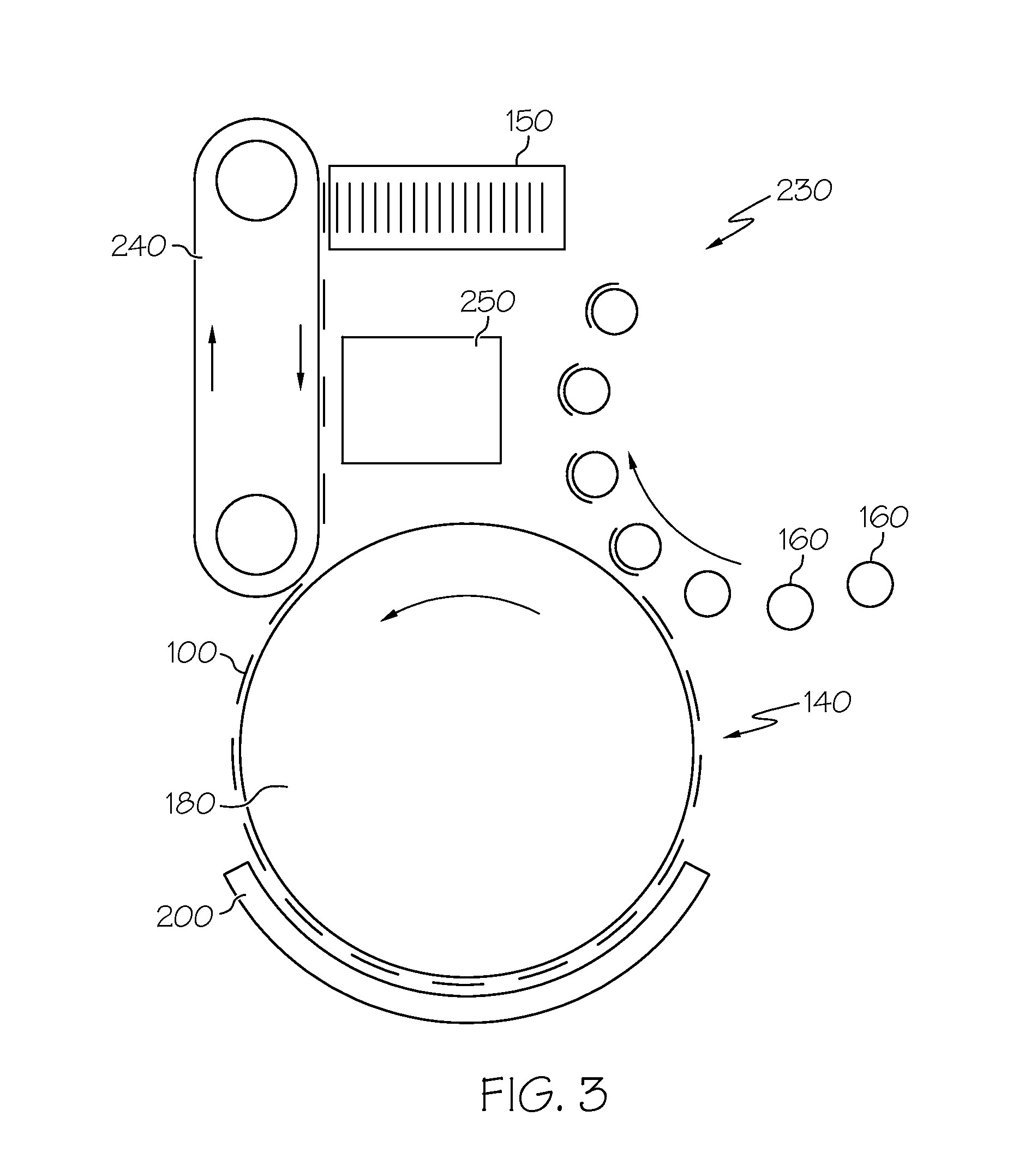

InactiveUS7267150B2Simple stepsReliably and highly accuratelyAdhesivesConnectionsSheet filmElectrical and Electronics engineering

An instant photographic film unit includes a mask sheet having an image frame and two sheets, one of which has a photosensitive layer, laminated and bonded together, and a developing liquid container disposed in a predetermined position for supplying a developing liquid between the two sheets to produce an image. The mask sheer and the two sheets are bonded together in a predetermined laminated state, with at least one of the mask sheet and the two sheets being in the form of a continuous web. The continuous web is cut off into self-developed instant photographic film units of a predetermined length. A predetermined number of instant photographic film units are automatically stacked and placed in a film pack.

Owner:FUJIFILM CORP

Method and apparatus for ultra thin wafer backside processing

ActiveUS20140076846A1Lamination ancillary operationsLayered product treatmentEngineeringElectrical and Electronics engineering

Owner:ALPHA & OMEGA SEMICON INC

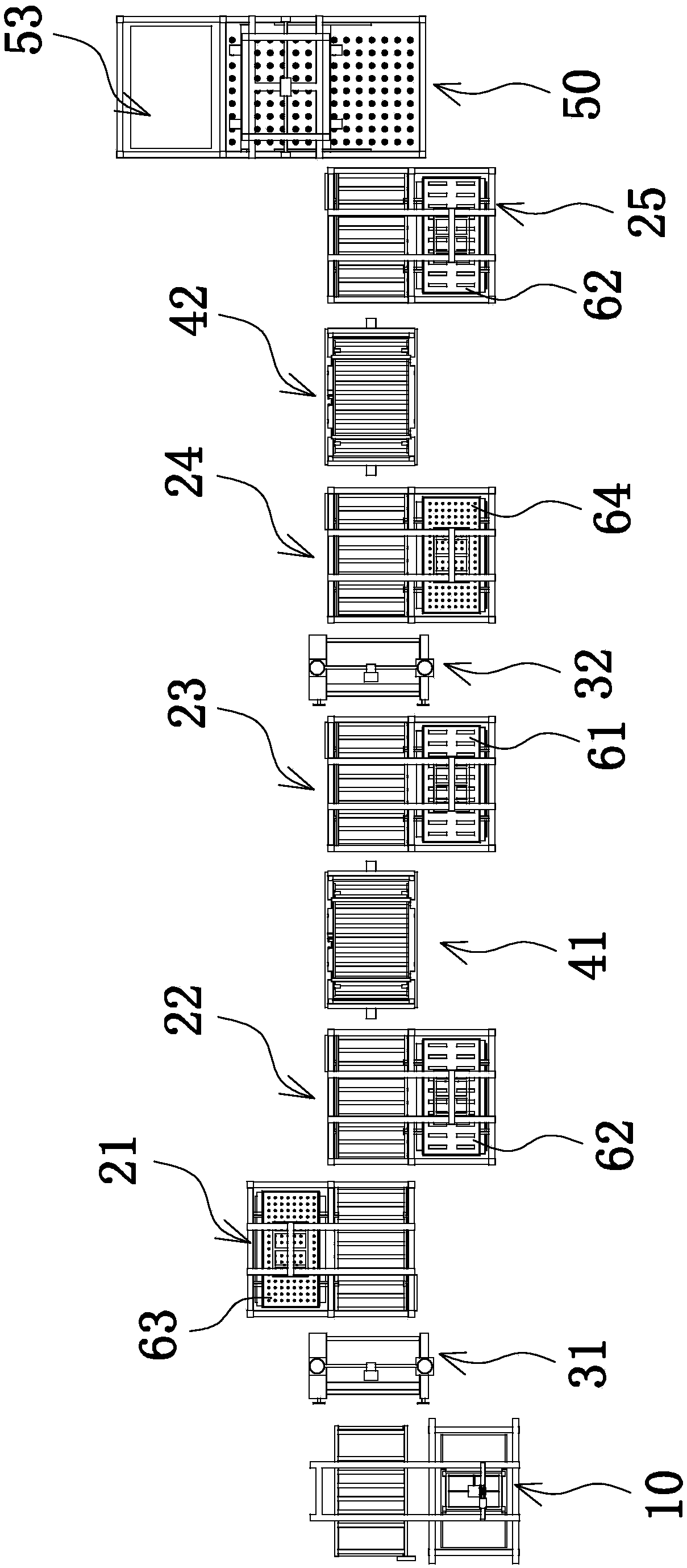

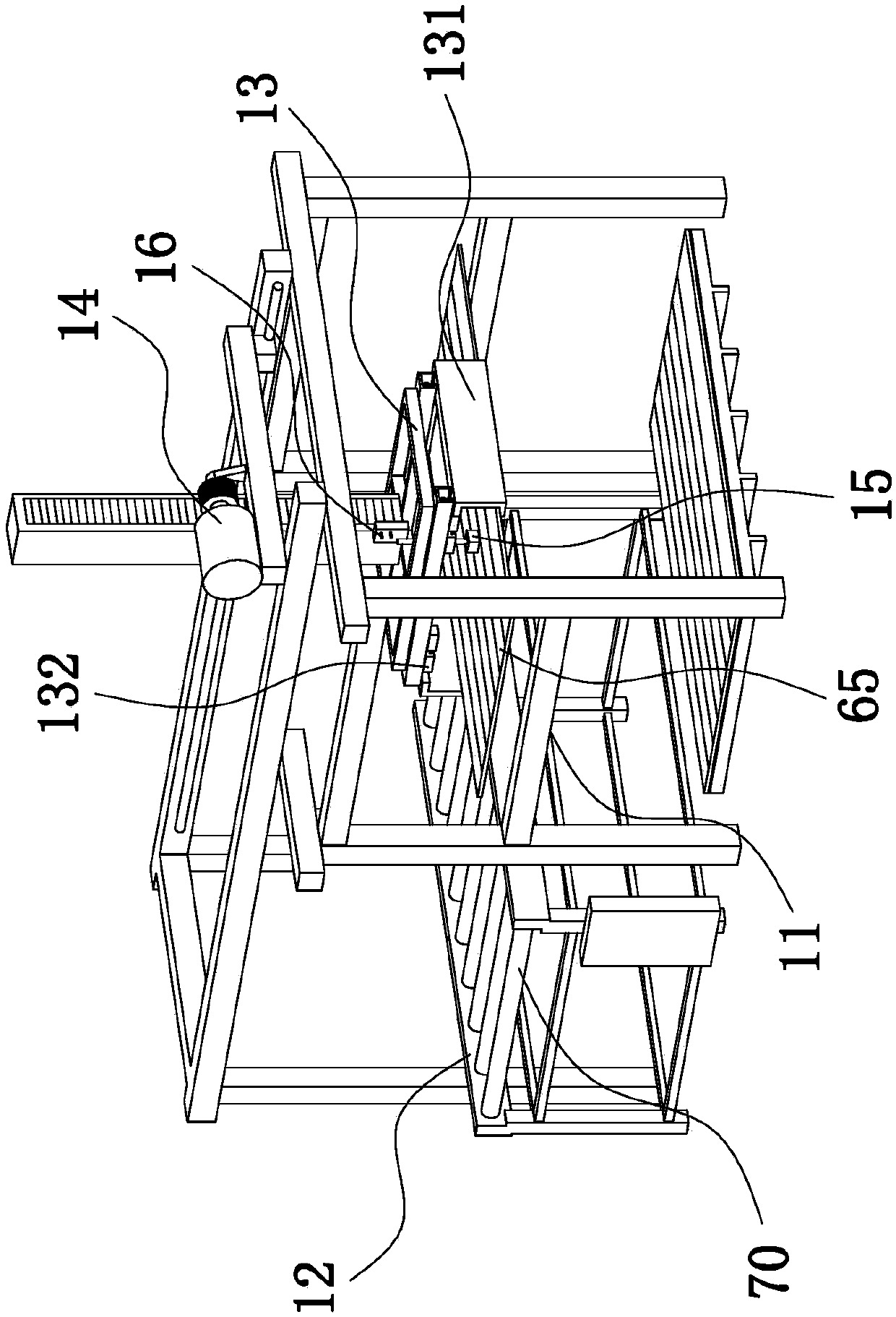

Automatic production system of rock wool sandwich board

PendingCN107891652AEasy to transportReasonable structural designLamination plant layoutLamination ancillary operationsMining engineeringSandwich board

Owner:ZHEJIANG XUANMING NEW MATERIALS

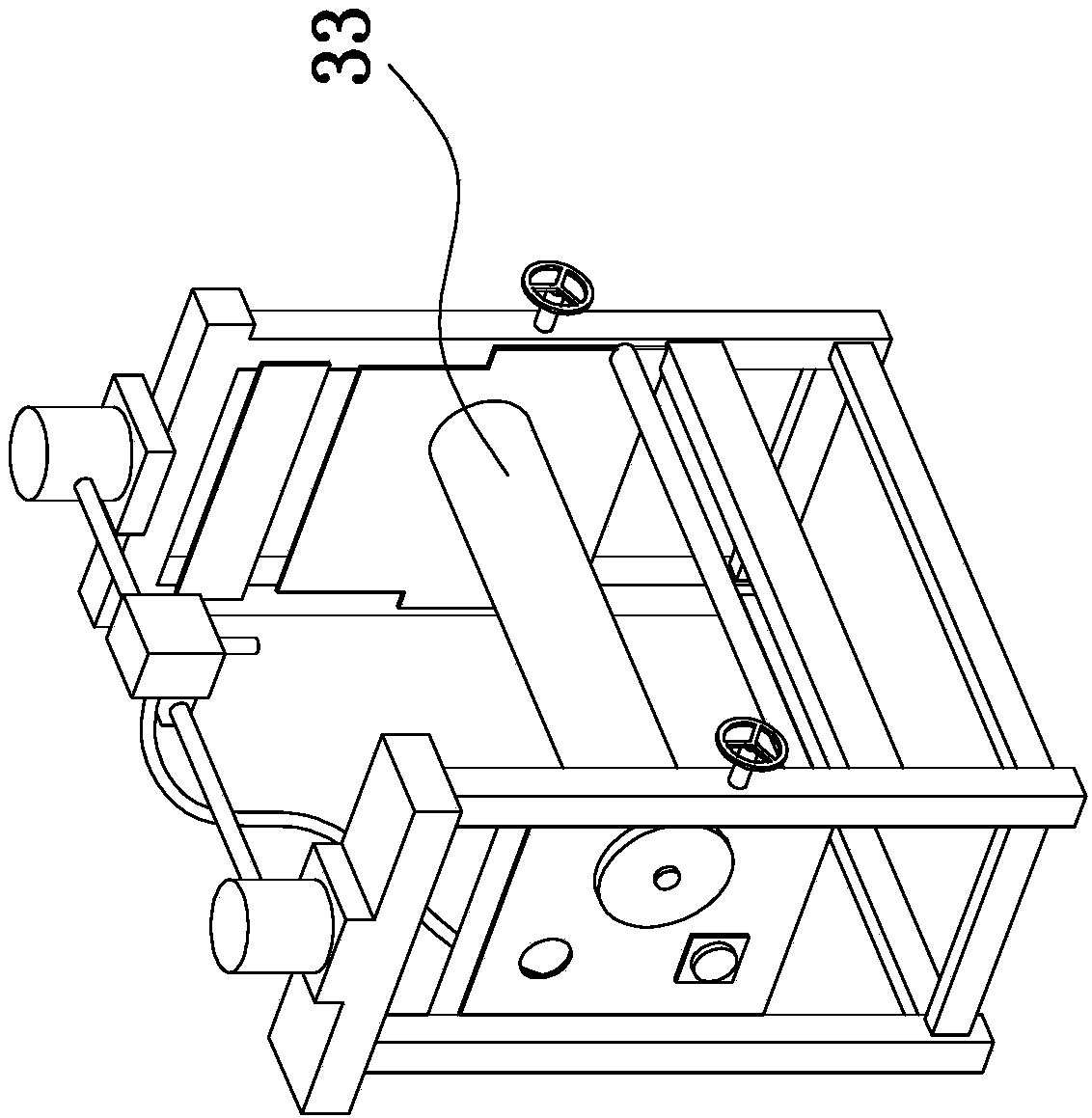

Composite sheet material production technology and production equipment

ActiveCN107160812ASimple structureIncrease productivityLamination ancillary operationsLaminationProduction lineCorona treatment

The invention discloses a composite sheet material production technology and a production equipment. The production equipment comprises a core material unreeling device, a core material conveying processing device, a gluing device, a combination device, a fine rolling combination device, and a subsequent production line which are connected successively; the core material conveying processing device comprises a first conveying device, a second conveying device, a corona processing device, a third conveying device, and a first machine frame; the first conveying device, the second conveying device, and the third conveying device are arranged on the first machine frame successively; and the corona processing device is arranged on the second conveying device. The composite sheet material production technology and the production equipment possess following advantages: structure is simple, process is novel, and the composite sheet material production technology is safe and reliable.

Owner:沈惠华

Cleanable articles and methods for making and using same

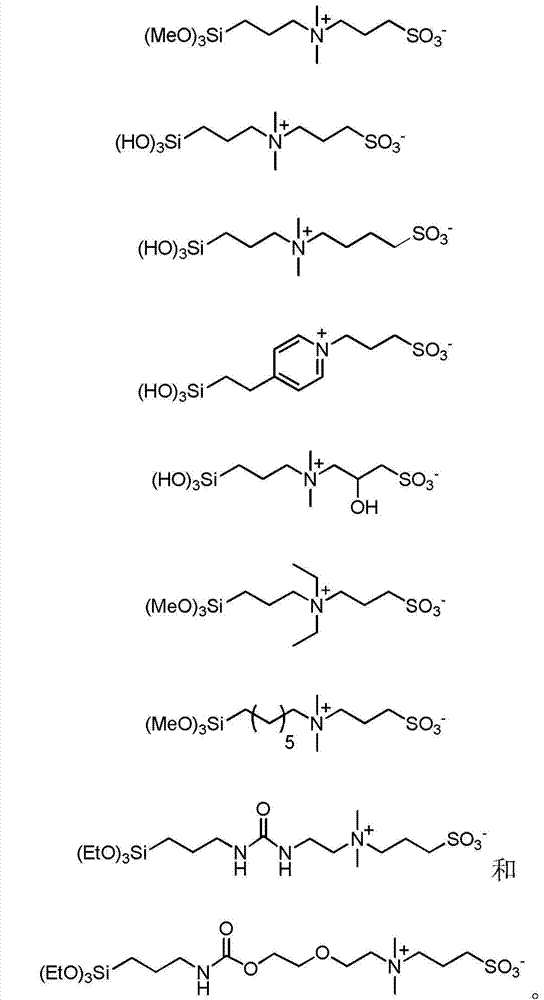

ActiveCN104736650AEfficient removalExcellent writabilityLamination ancillary operationsLayered product treatmentSiloxaneEngineering

Cleanable articles having overcoats with hydrophilic front surfaces and which are siloxane-bonded to an underlying body member. Also, methods of making and using such articles.

Owner:3M INNOVATIVE PROPERTIES CO

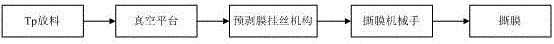

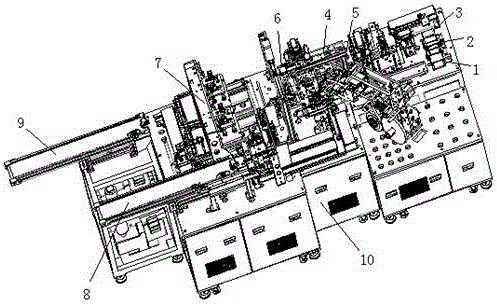

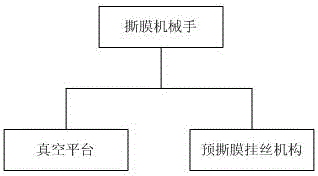

Pre-tearing film laminating device

InactiveCN106003999AFully automatedReduce difficultyLamination ancillary operationsLaminationManipulatorAlloy steel

Owner:SHENZHEN DEEP HON HAI AUTOMATION EQUIP CO LTD

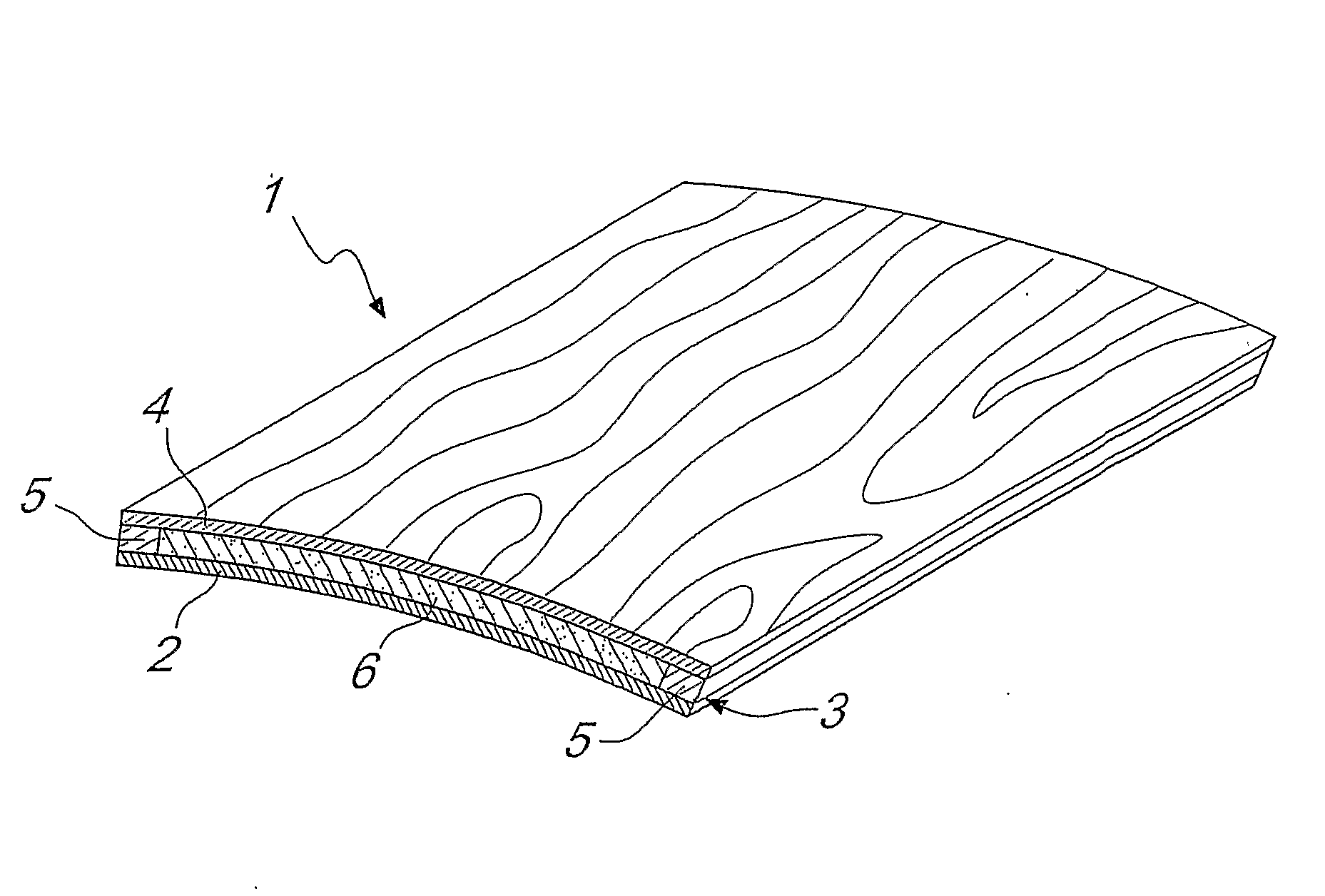

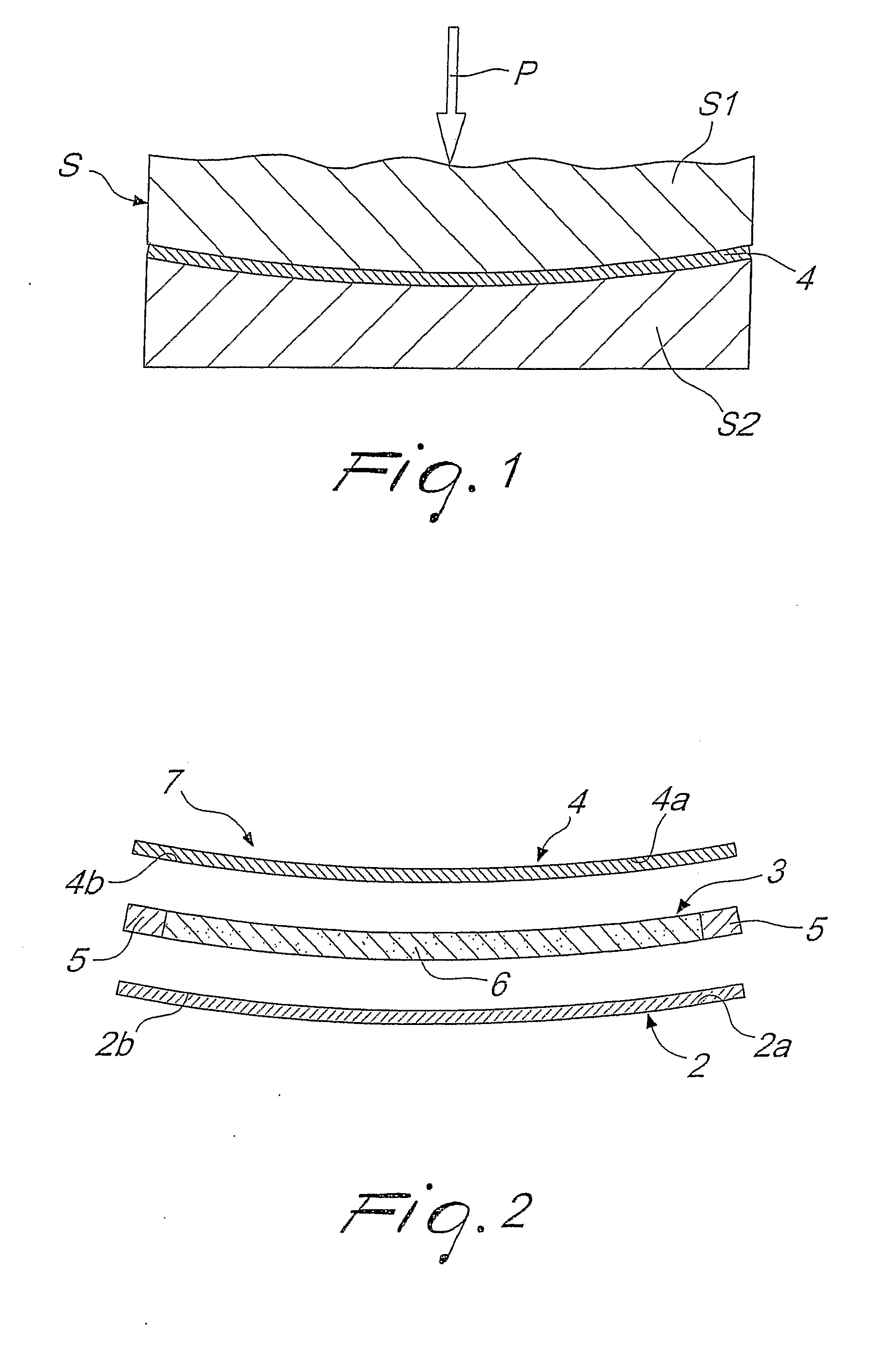

Method for Manufacturing Curved Components for Furniture, Particularly Doors for Furniture

InactiveUS20090218038A1Drawback can be obviatedLow production costLamination ancillary operationsLaminationMetallic materialsEngineering

Owner:TECNOFORM

Sealing material for preventing rodents and pests from passing through and manufacturing process thereof

ActiveCN104542568ASo as not to damageImprove toughnessLamination ancillary operationsLaminationCardingVermin

Owner:SUZHOU DANGEWEI IND

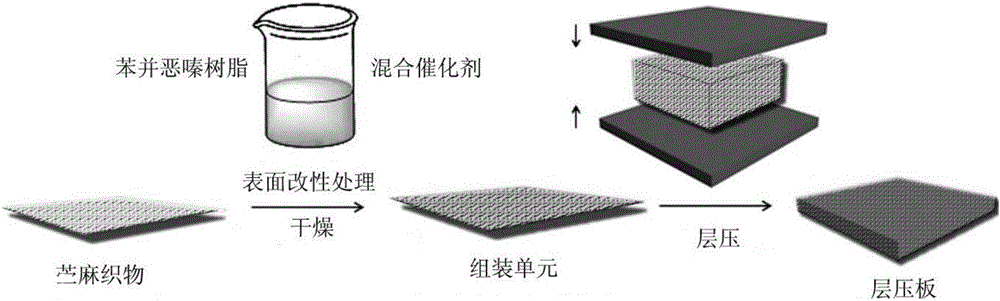

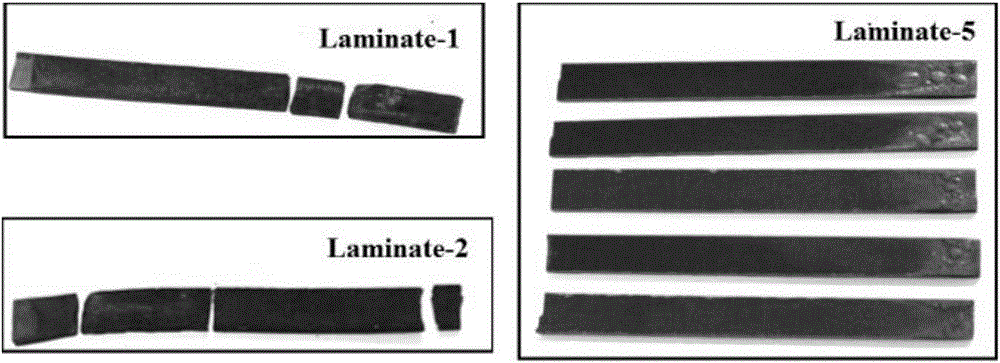

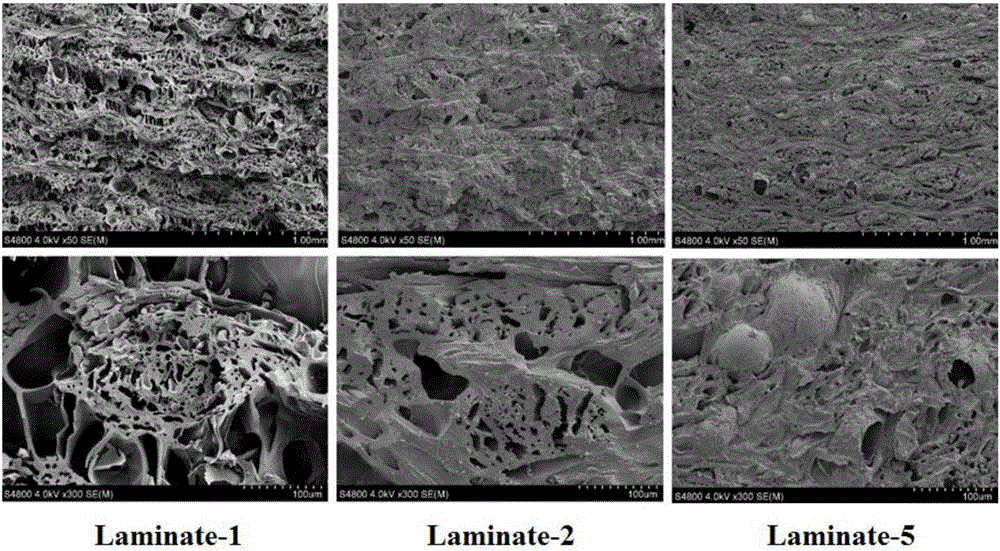

Flame-retardant modified ramie fabric/benzoxazine resin laminated board and preparation method thereof

ActiveCN106079723AImprove flame retardant performanceImprove performanceLamination ancillary operationsLayered product treatmentEngineeringFire retardant

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap