Method of manufacturing a shingle with reinforced nail zone

a manufacturing method and technology of shingles, applied in the direction of packaging, control of lamination, transportation and packaging, etc., can solve the problem of shingles experiencing li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

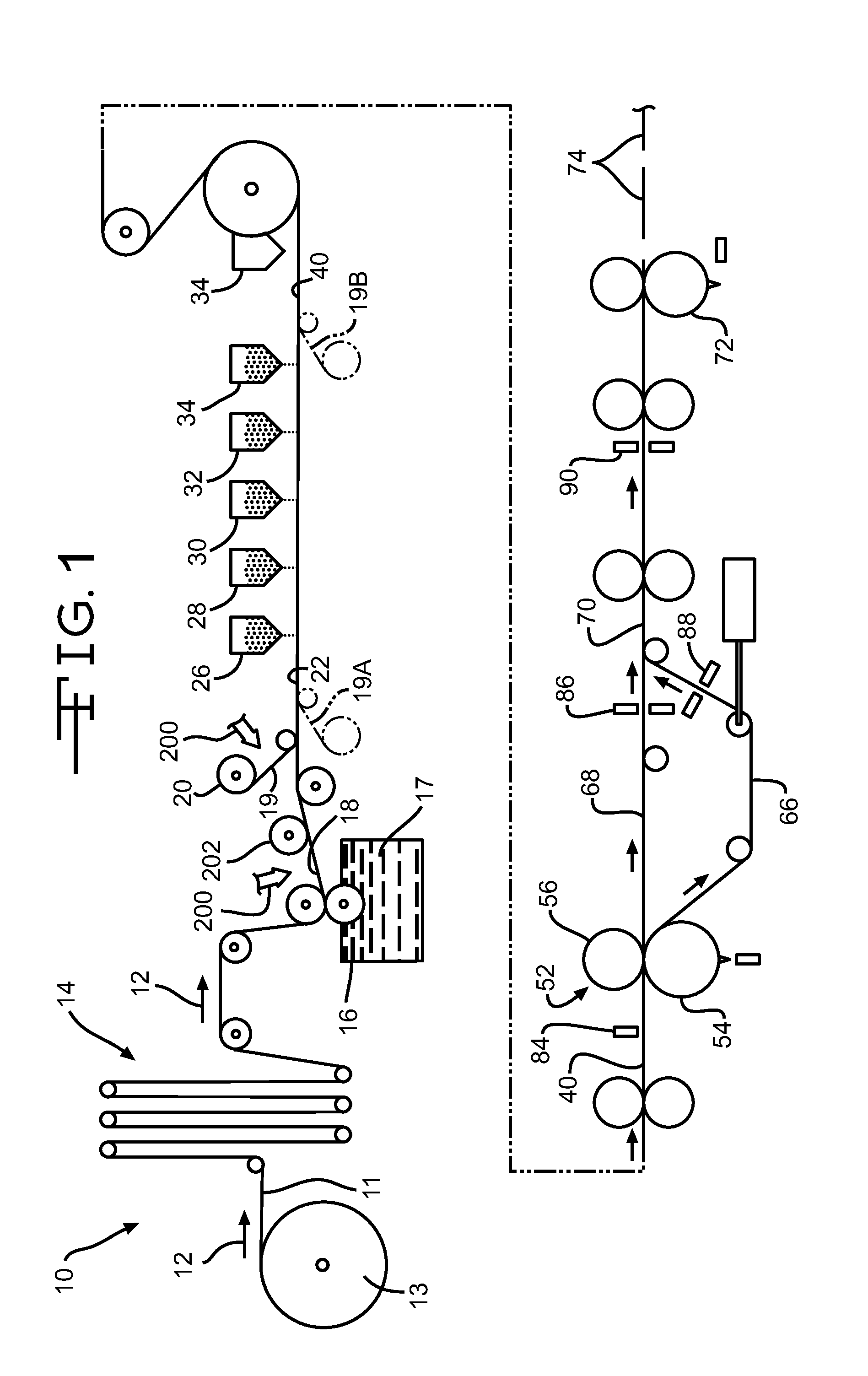

[0037]A continuous strip of a reinforcement material 19, as will be described in detail herein, may then be payed out from a roll 20. The reinforcement material 19 adheres to the first asphalt-coated sheet 18 to define a second asphalt-coated sheet 22. In a first embodiment, the reinforcement material 19 is attached to the sheet 18 by the adhesive mixture of the asphalt in the first asphalt-coated sheet 18. The reinforcement material 19, however, may be attached to the sheet 18 by any suitable means, such as other adhesives. As described in detail below, the material 19 may be formed from any material for reinforcing and strengthening the nail zone of a shingle, such as, for example, paper, film, scrim material, and woven or non-woven glass fibers.

[0038]The resulting second asphalt coated sheet 22 may then be passed beneath a series of granule dispensers 24 for the application of granules to the upper surface of the second asphalt-coated sheet 22. The granule dispensers may be of any t

second embodiment

[0046]In a second embodiment, the reinforcement material may be attached to a lower surface (the downwardly facing surface when viewing FIG. 1) of the mat 11, the first asphalt coated sheet 18, the second asphalt coated sheet 22, or the granule-covered sheet 40, as shown at 19A and 19B in FIG. 1. The reinforcement material 19A and 19B may be attached to the mat 11, the first asphalt coated sheet 18, the second asphalt coated sheet 22, or the granule-covered sheet 40 by any suitable means, such as hot, melted asphalt, other adhesives, or suitable fasteners. In such an embodiment, the reinforcement material 19A and 19B may be attached to the lower surface of the nail zone of either of the overlay sheet 68 or the underlay sheet 66, thereby reinforcing and strengthening the nail zone as described herein.

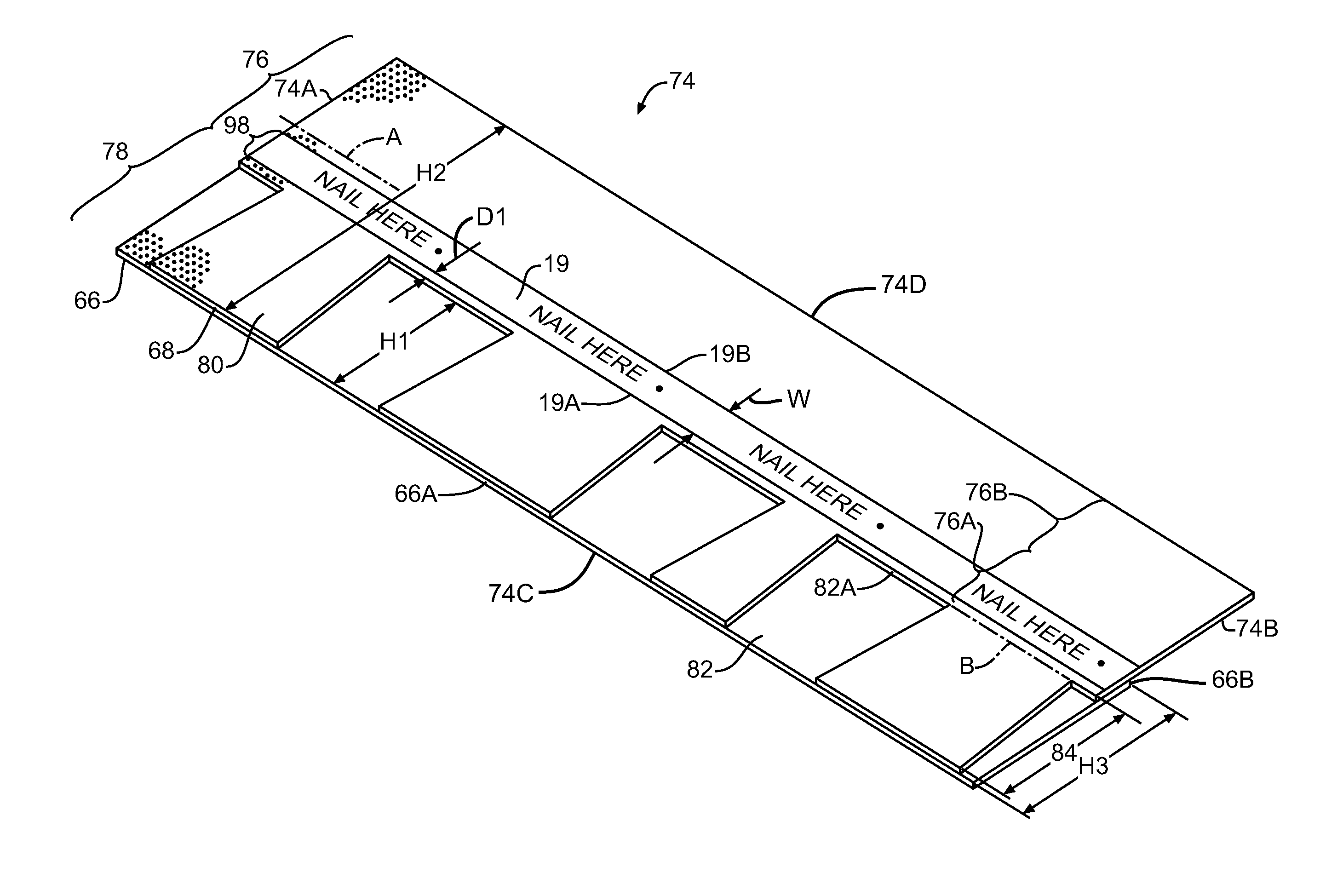

[0047]Referring now to FIGS. 2, 3, and 4, a first embodiment of a laminated roofing shingle is shown generally at 74. In the illustrated embodiment, the shingle 74 has a length L and includ

third embodiment

[0088]In a third embodiment, reinforcement material 119 may be formed from a layer of non-woven scrim 119B having a weight within the range of from about 0.50 oz / yd2 to about 1.0 oz / yd2. With this relatively heavier layer of scrim 119B, the layer of film 119A, such as the polypropylene or polyethylene films described above, may be configured to melt as the reinforcement material 119 is applied to the first asphalt-coated sheet 18. The heat absorbed in the melting process and the resulting increased viscosity of the now polymer modified filled asphalt coating 17 where the film 119A contacts the first asphalt coated sheet 18 substantially prevents the filled asphalt coating 17 from bleeding through the layer of non-woven scrim 119B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap