Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about "Lamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

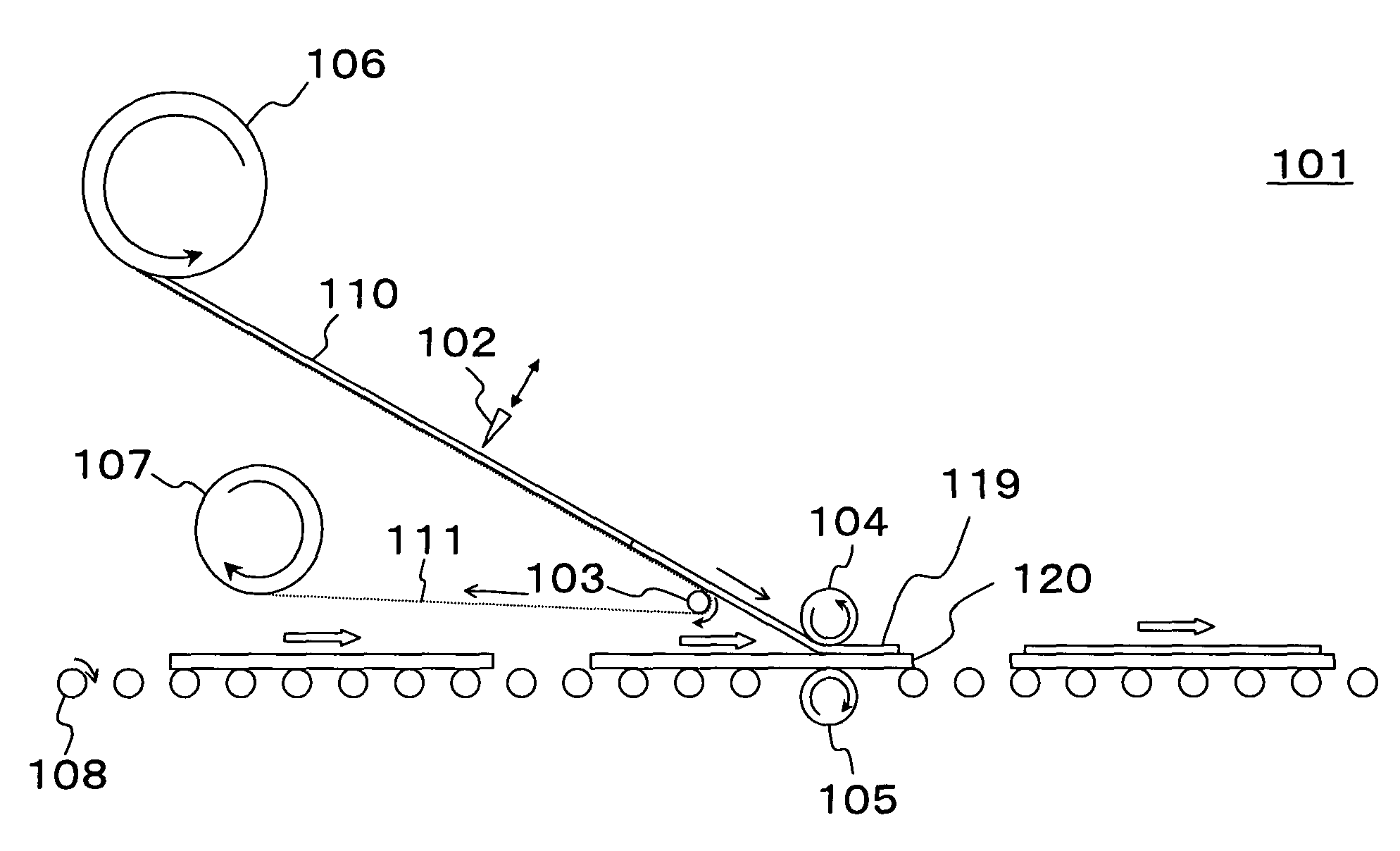

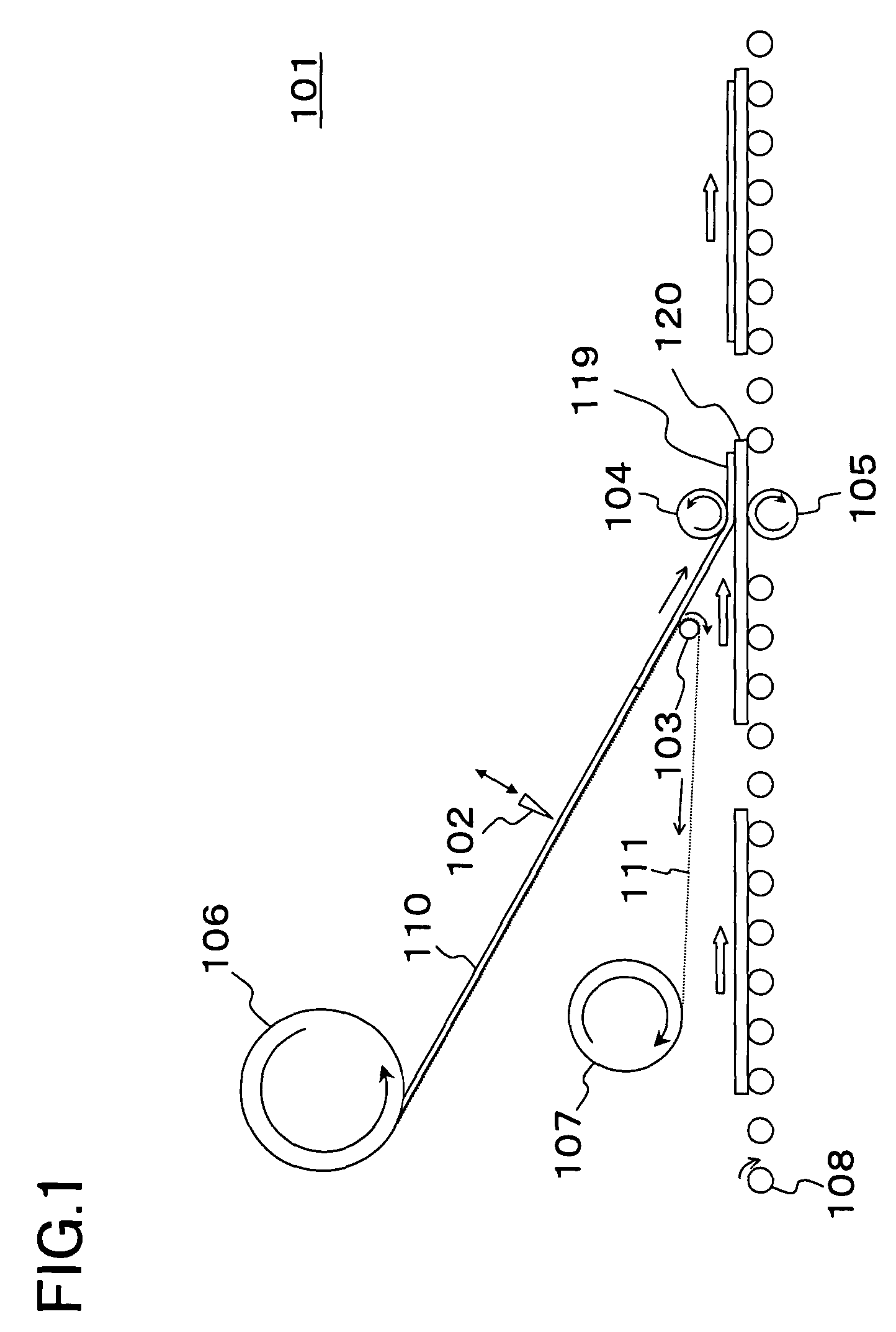

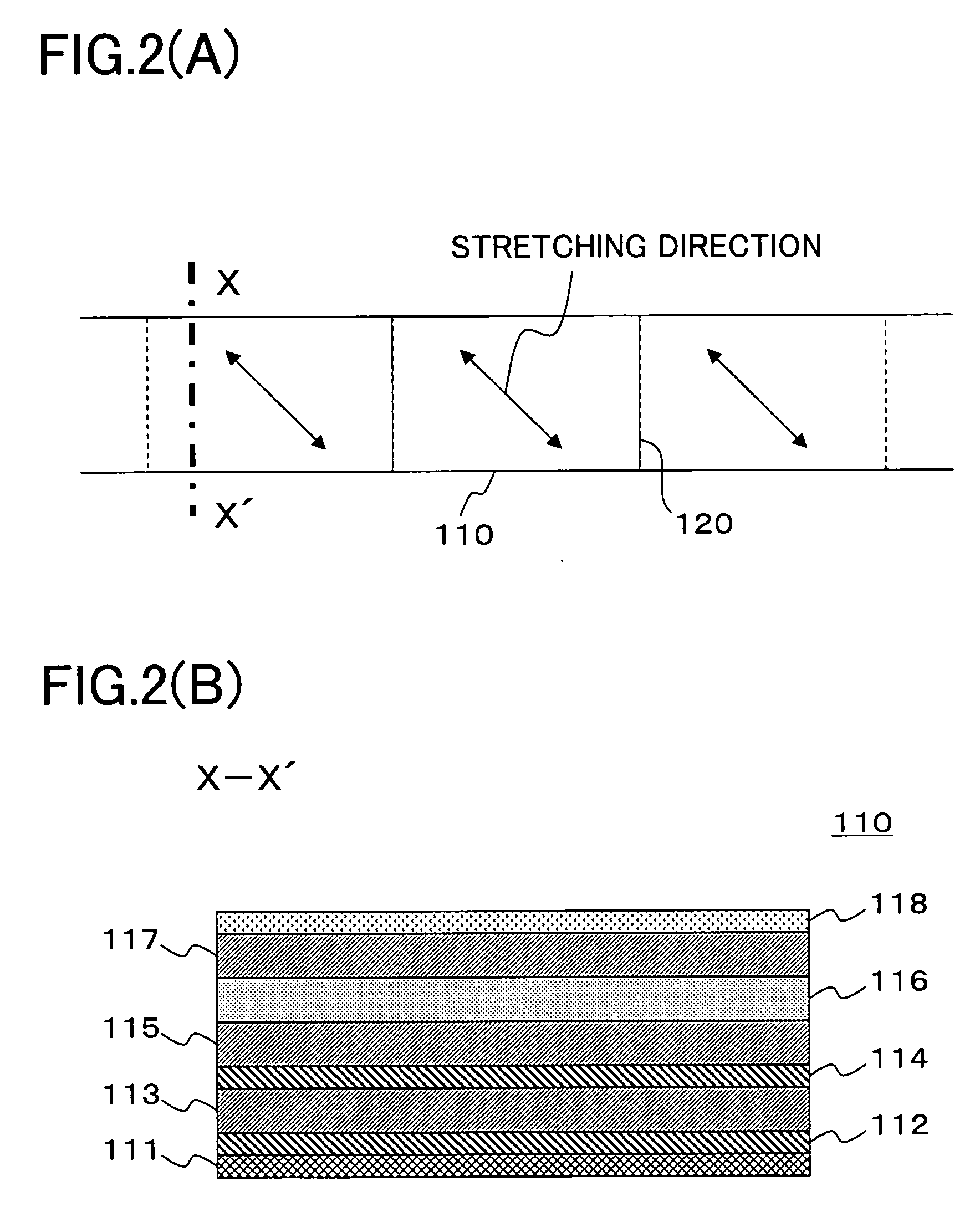

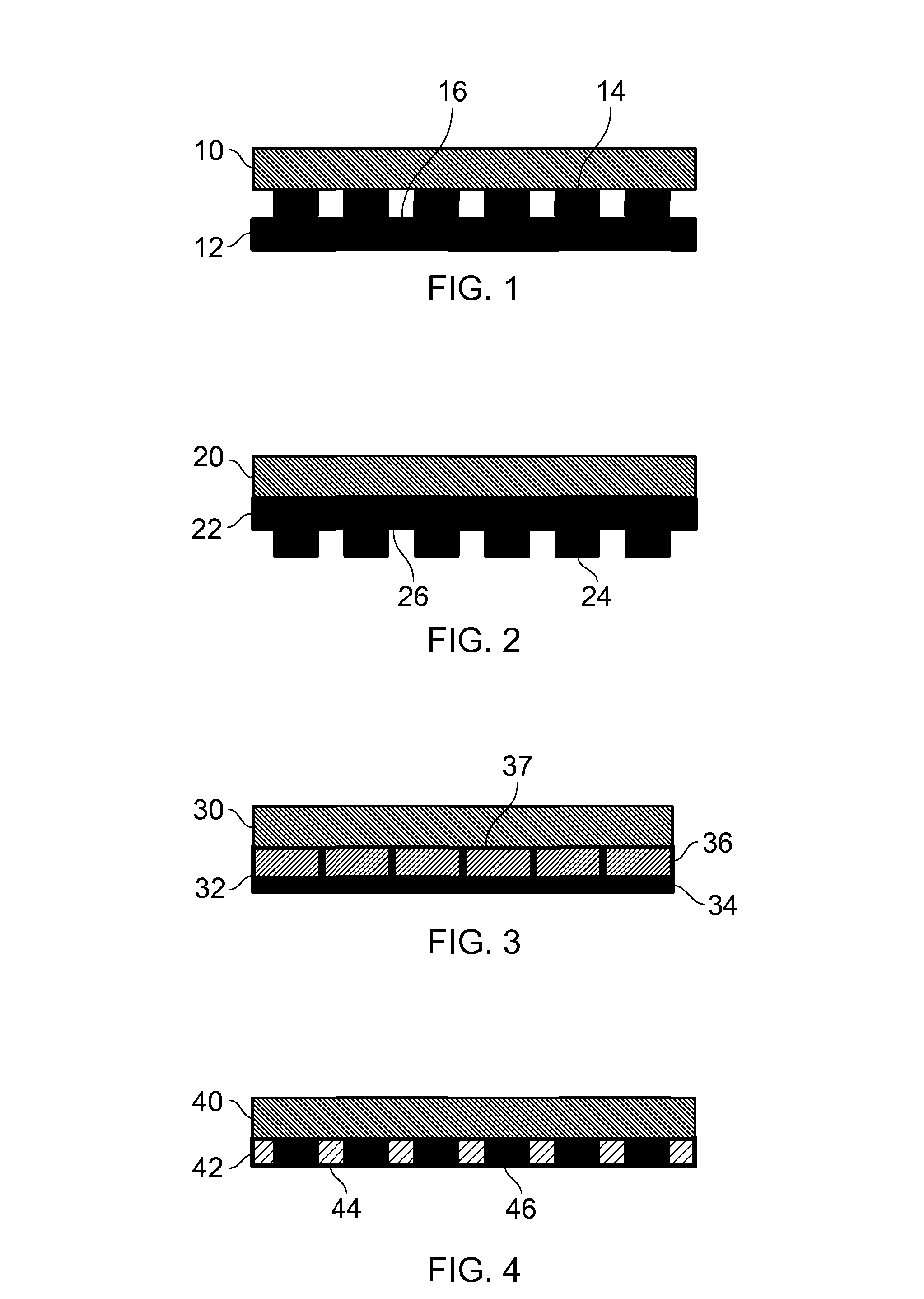

Method and apparatus for bonding polarizing plate

ActiveUS20050016670A1Easy to controlProhibit stop markLamination ancillary operationsDecorative surface effectsPolarizerEngineering

Owner:FUJIFILM CORP +1

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

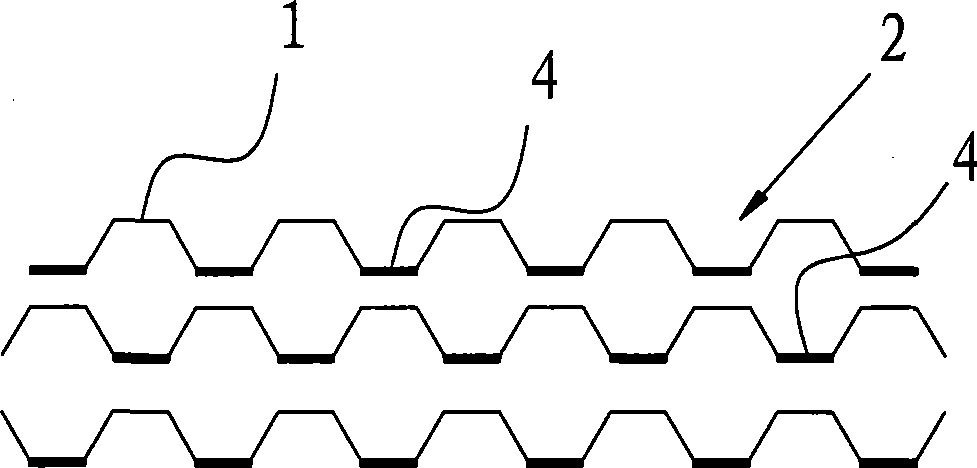

Ultrasonic bonding and embossing of an absorbent product

InactiveUS20050136224A1Easily and effectively madeEnhanced structural integrity and performanceMechanical working/deformationSynthetic resin layered productsEngineeringUltrasonic bonding

Ultrasonically bonded laminated absorbent products comprising a liquid permeable top sheet, a liquid impermeable back sheet, an absorbent core positioned between the liquid permeable top sheet and the liquid impermeable back sheet, and an adhesive composition are disclosed. The laminated structure further comprising an embossed pattern stamped onto the liquid permeable top sheet, the liquid impermeable back sheet, the absorbent core, or any combination thereof. The adhesive composition comprises a mixture of atactic and isotactic polymers such that it has melt and flow characteristics similar to those of the topsheet and backsheet.

Owner:KIMBERLY CLARK WORLDWIDE INC

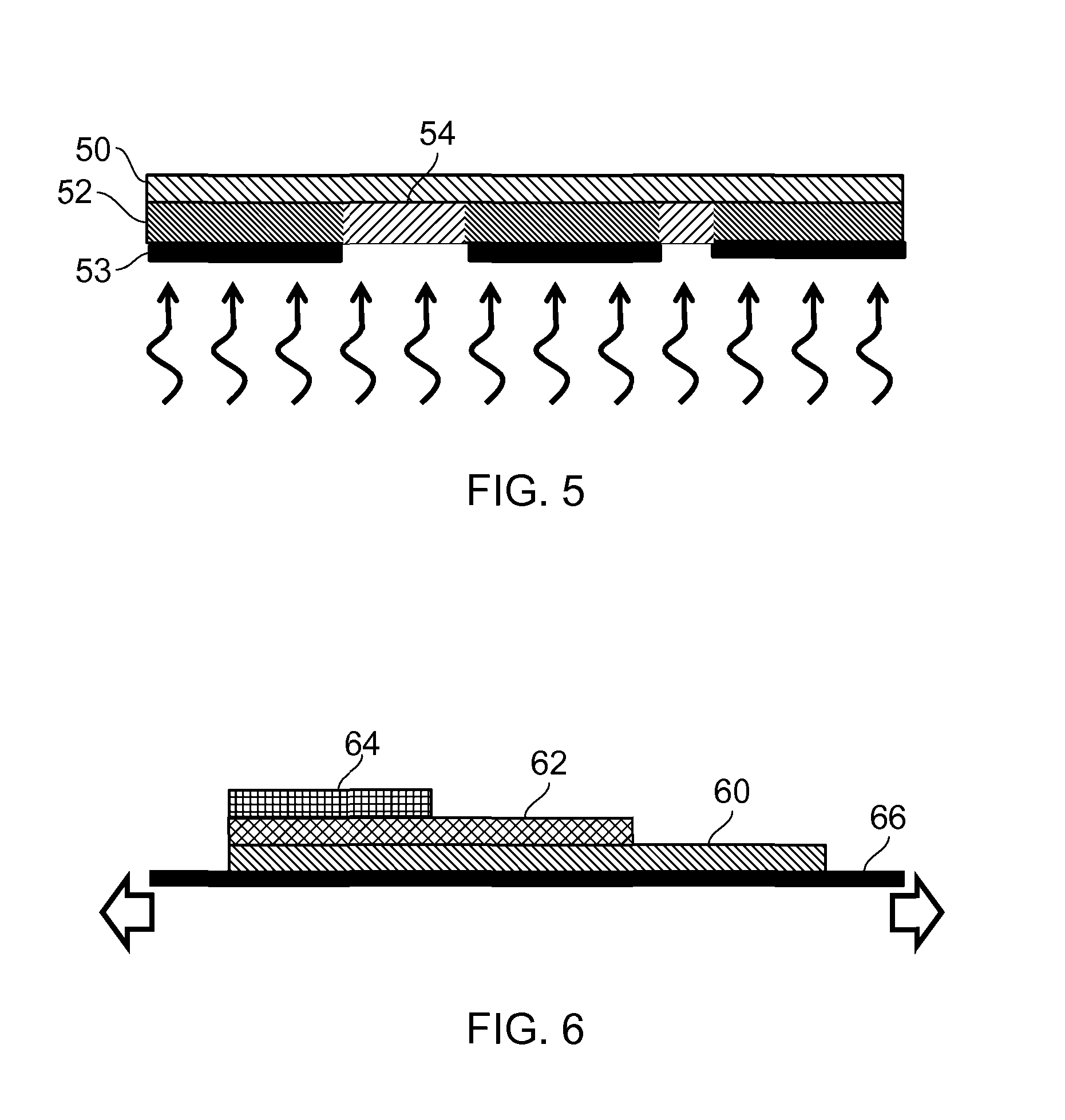

Composite Optical Materials for Mechanical Deformation

Owner:CAMBRIDGE ENTERPRISE LTD +1

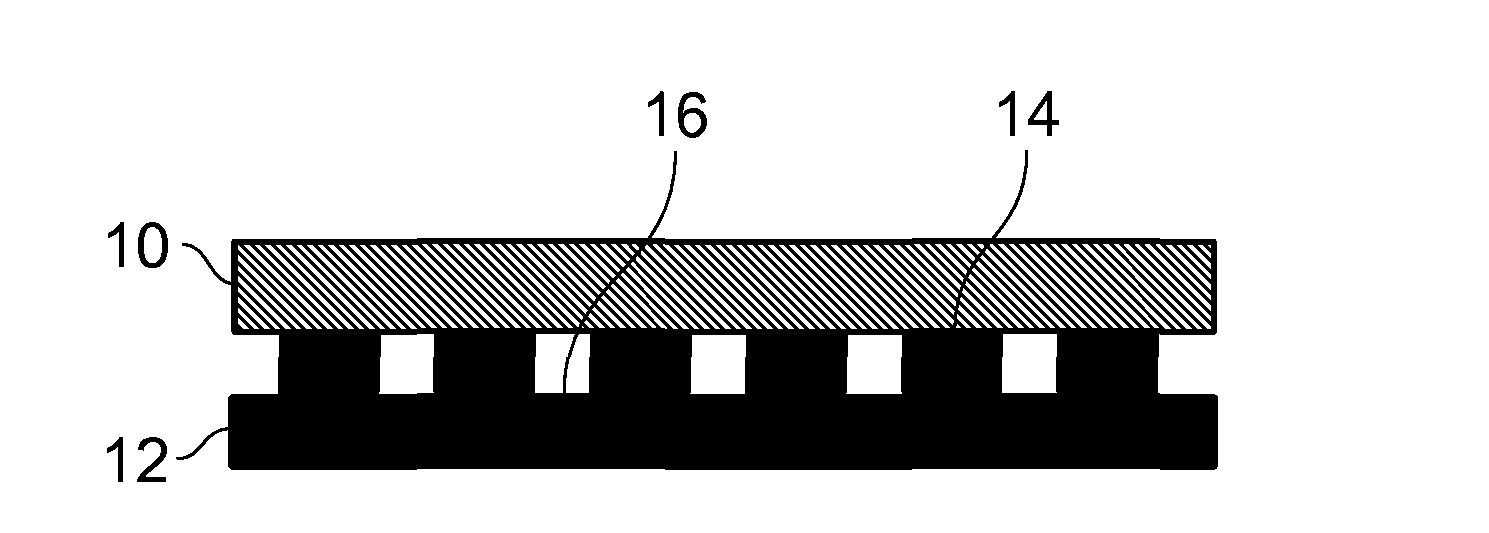

Sandwich panel with closed edge and methods of fabricating

InactiveUS20090255213A1Great strength to weight ratioLight weightLaminationLamination apparatusEngineeringSandwich panel

The edge of a construction element, such as a sandwich panel having a core and two outer layers, is closed such that forces acting on the construction element are directed to the outer layers and generally not through the panel core. A portion of the core may be removed to define a cavity within the construction element. A bonding material closes the edge by filling the cavity and forming a new edge that is substantially coplanar to the edges of the outer layers. The edge also can be closed by inserting the edge into a U-profile bracket and connecting the outer layers of the panel to side walls of the U-profile bracket.

Owner:MILLPORT ASSOC

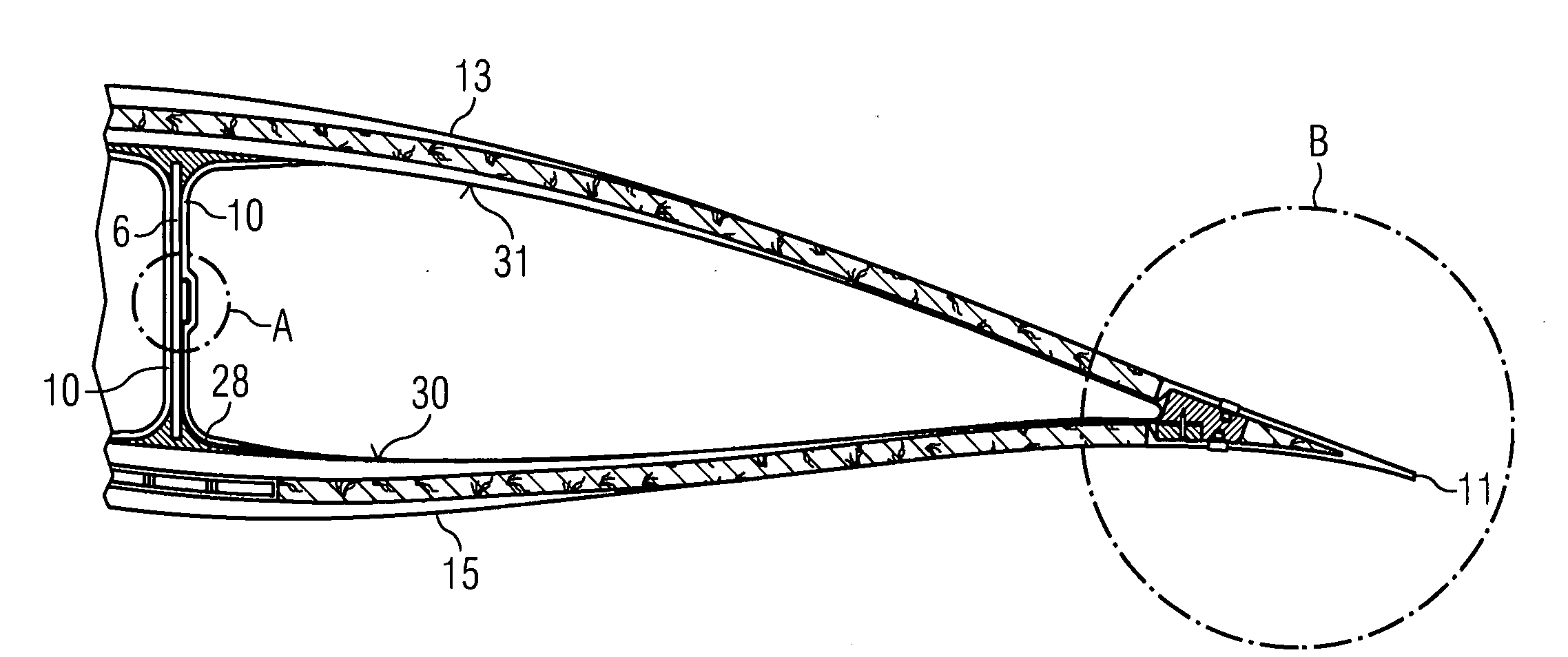

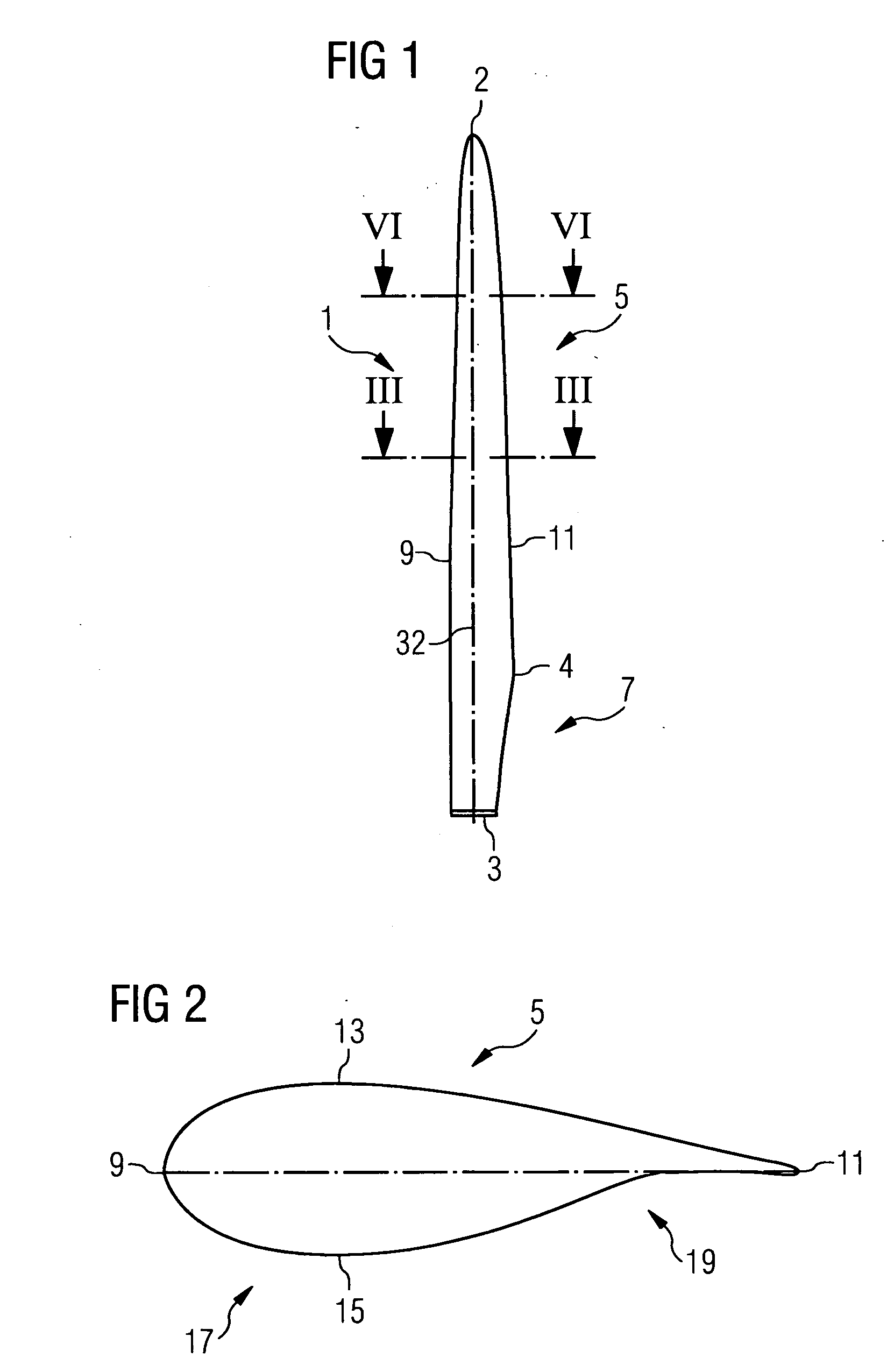

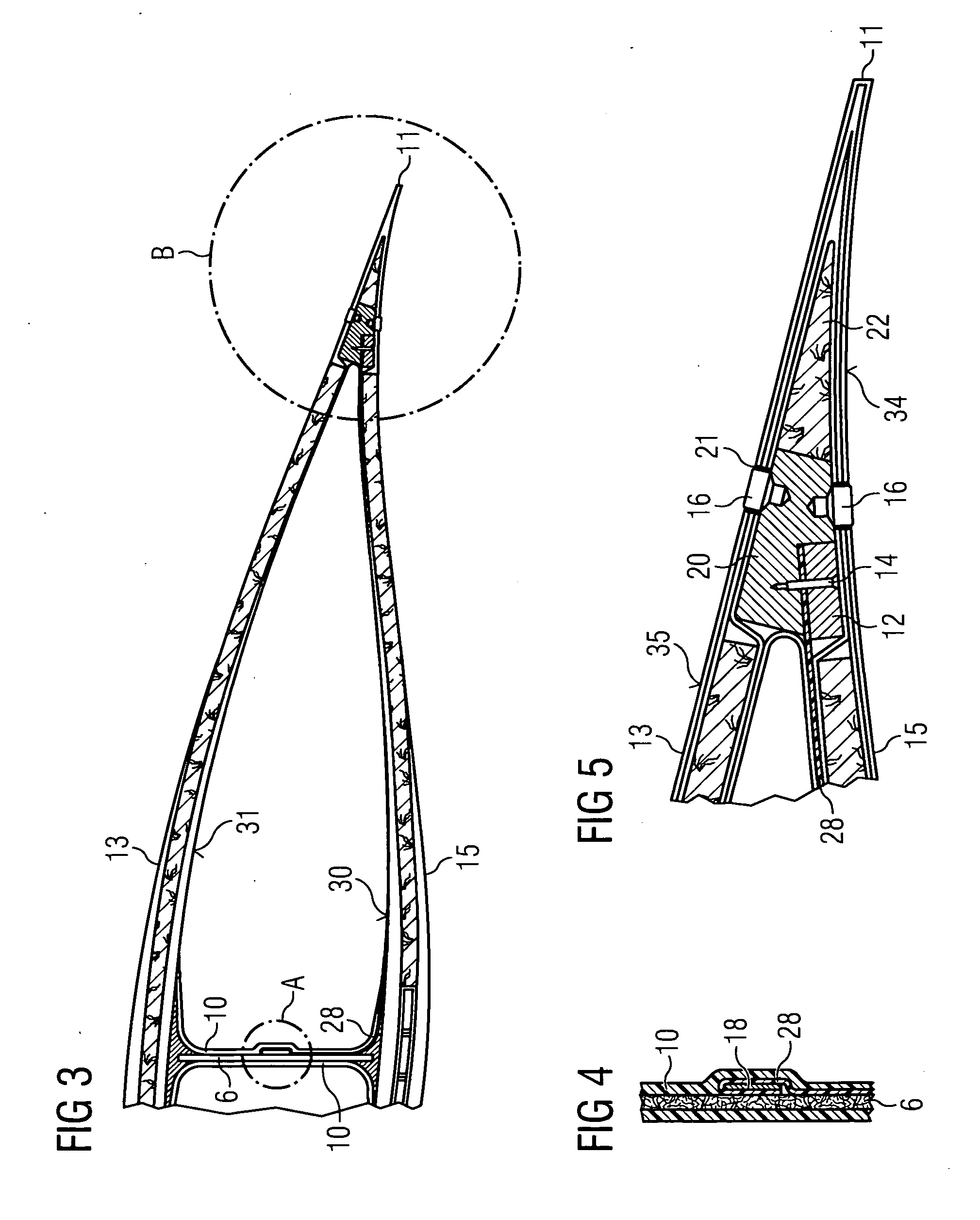

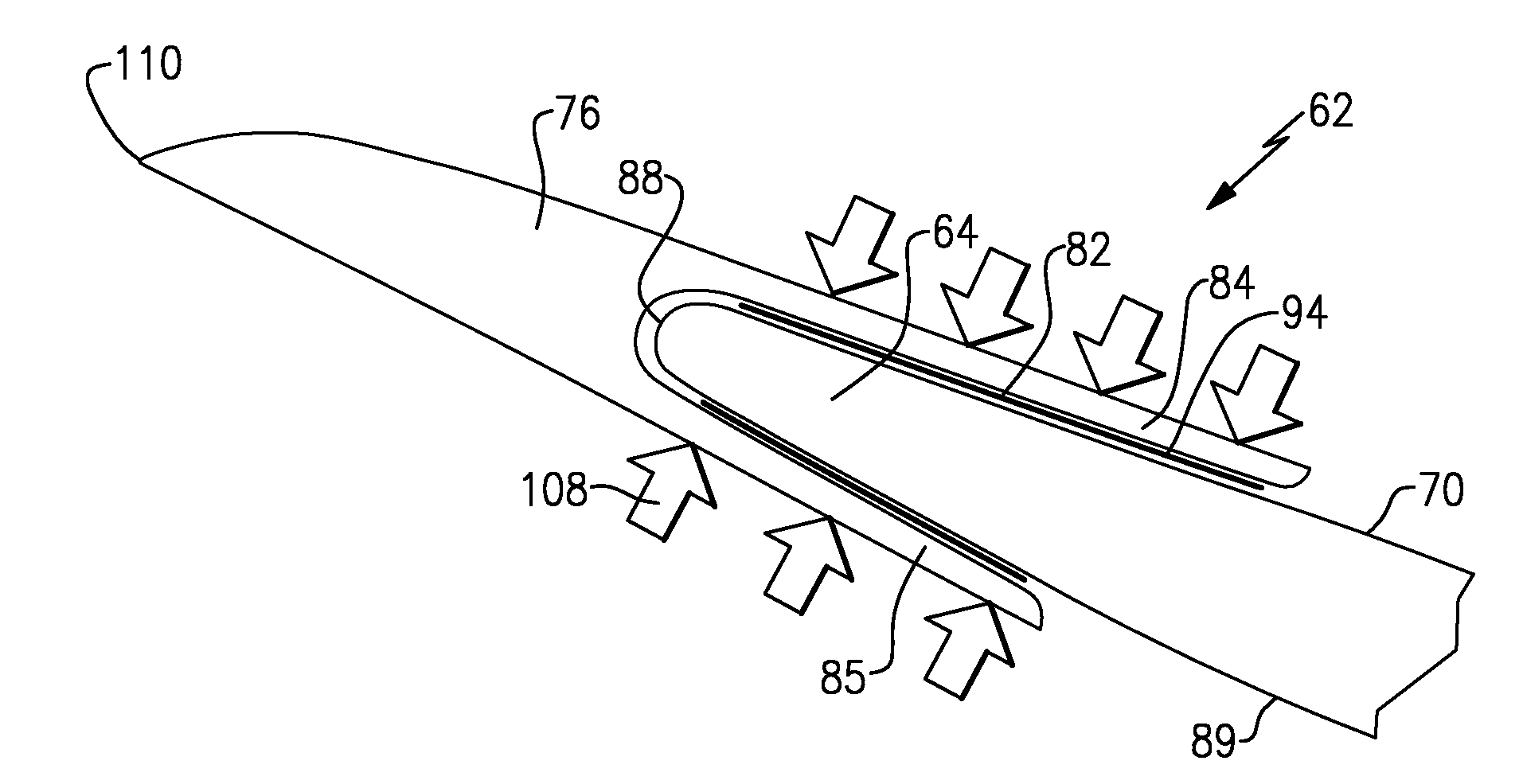

Wind Turbine Blade with an Integrated Lightning Conductor and Method for Manufacturing the Same

ActiveUS20090257881A1Reduce mechanical stressEasy to mergeFinal product manufactureLaminationElectrical conductorTurbine blade

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Activatable Adhesive, Labels, and Related Methods

InactiveUS20120216951A1Improve securityEasy to operateStampsNon-macromolecular adhesive additivesAdhesivePlasticizer

Owner:AVERY DENNISON CORP

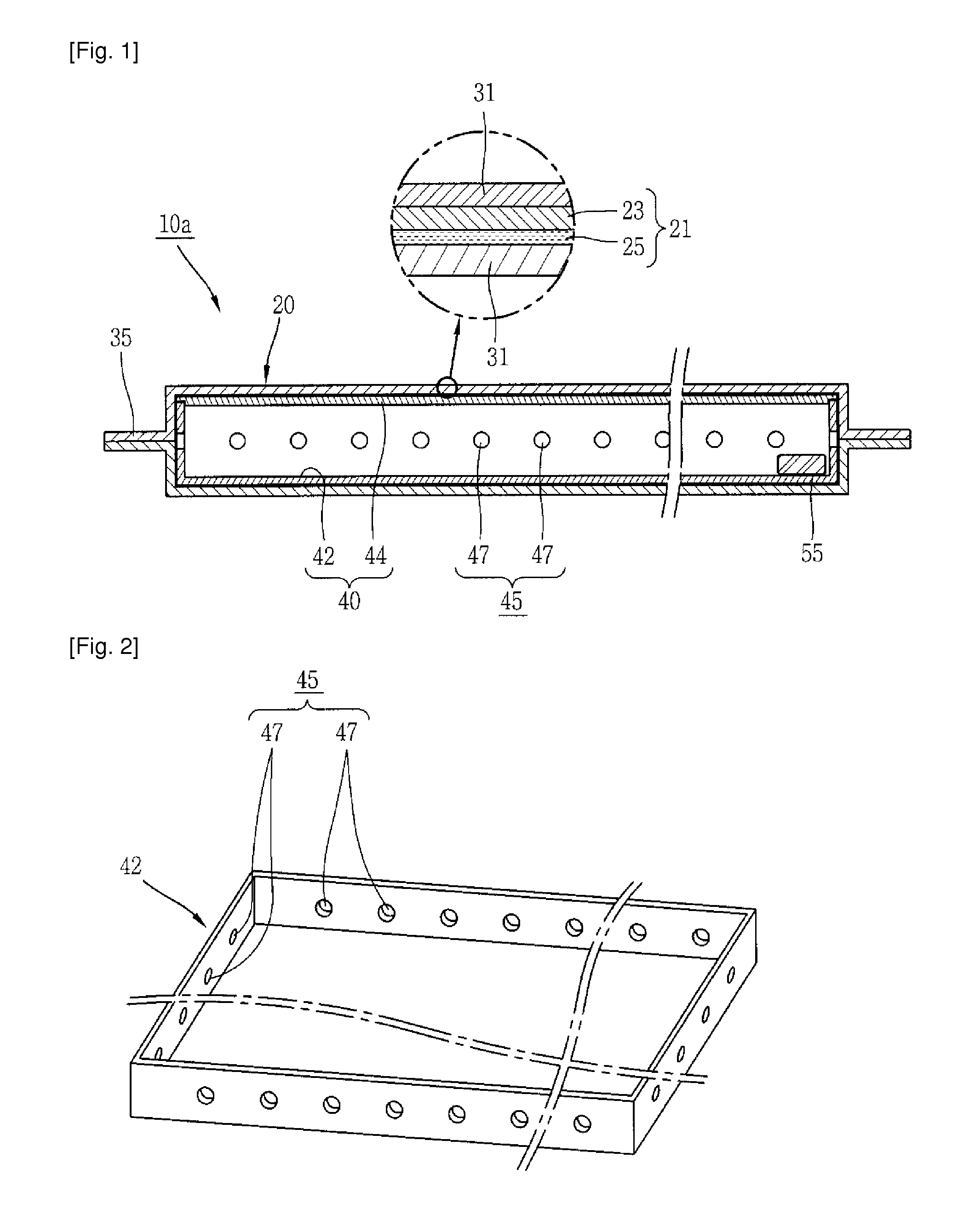

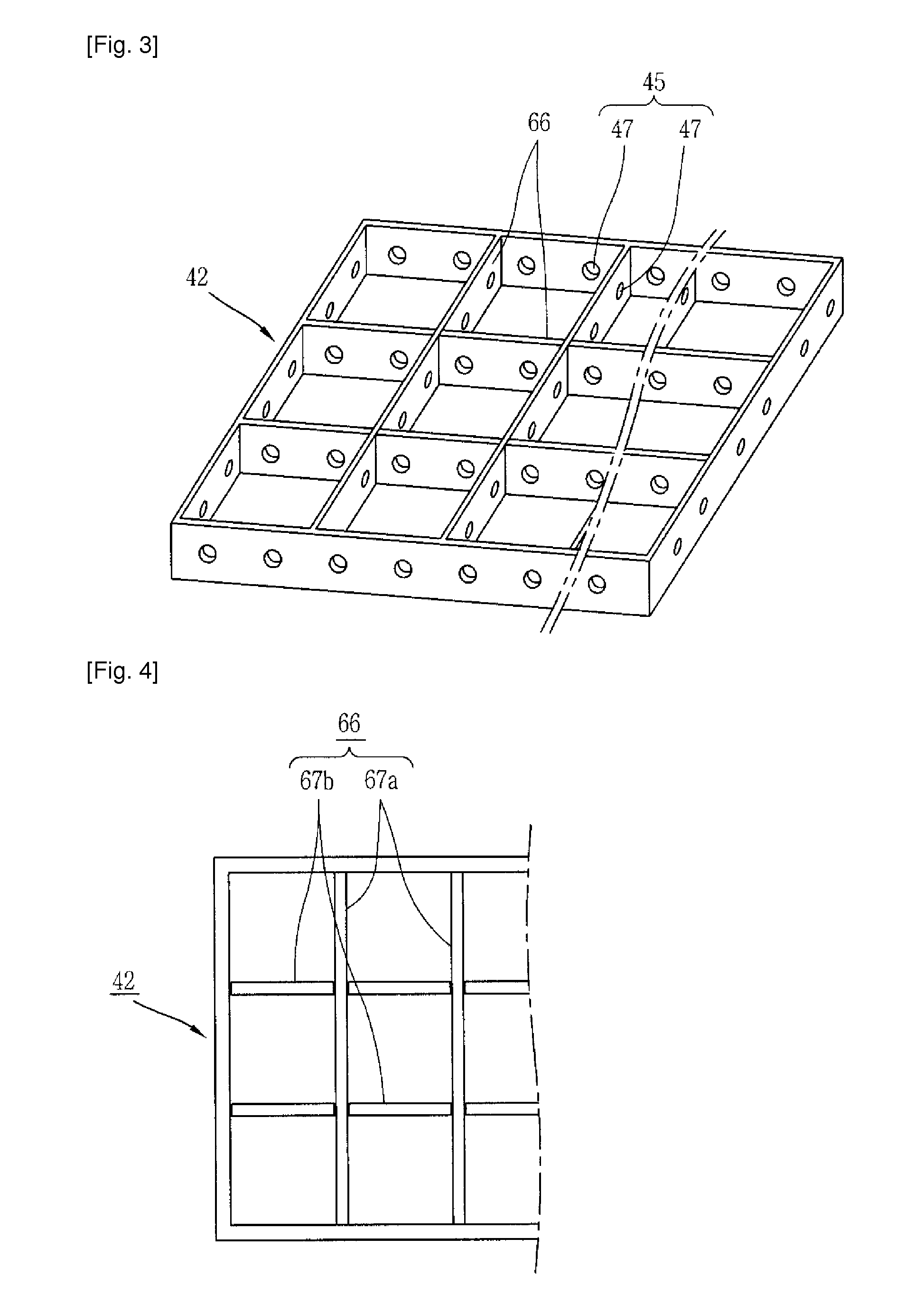

Vacuum insulation member, refrigerator having vacuum insulation member, and method for fabricating vacuum insulation member

ActiveUS20120125039A1Easy to manufactureReduce manufacturing costLamination ancillary operationsThermal insulationGlass fiberEngineering

Owner:LG ELECTRONICS INC

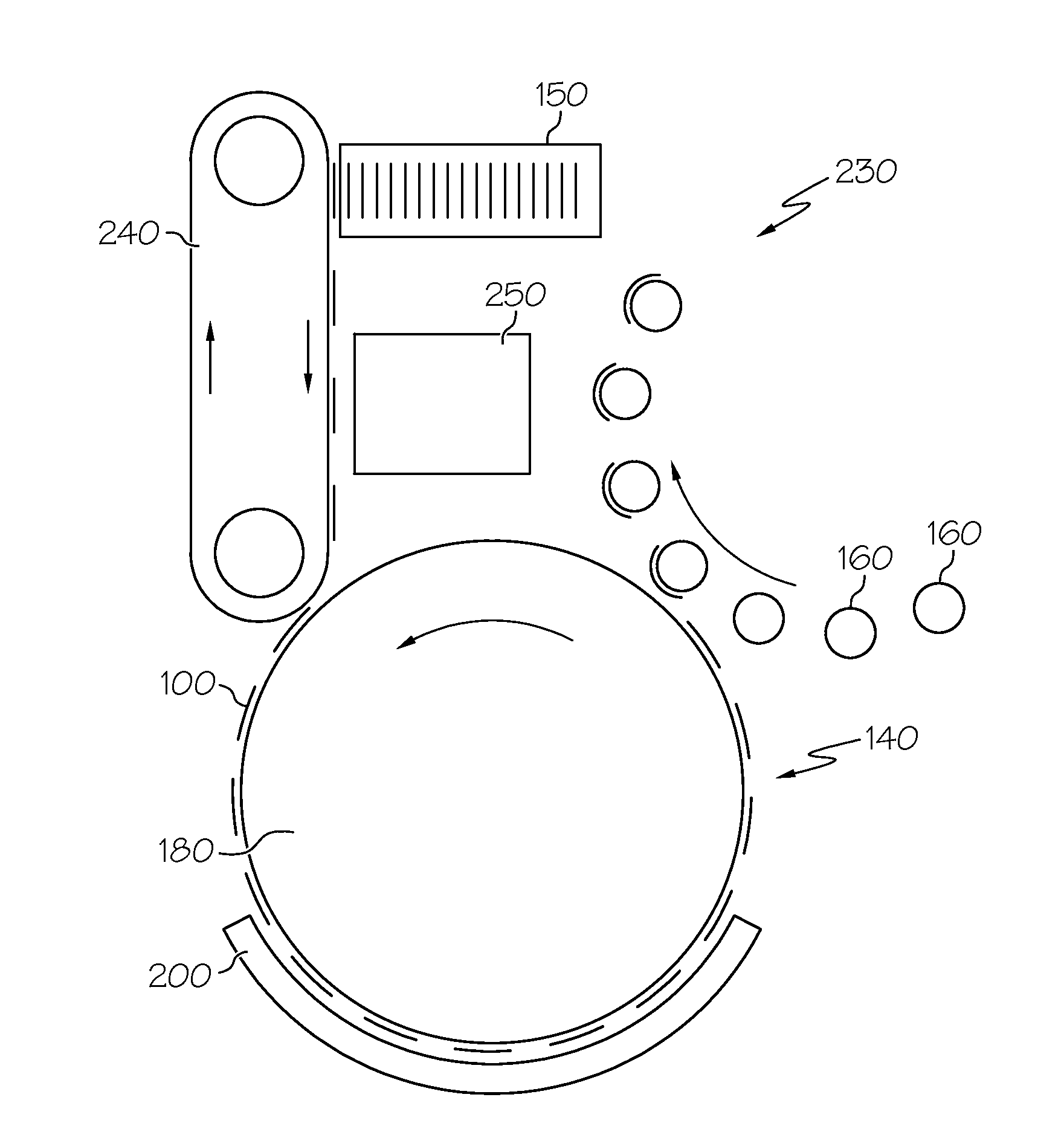

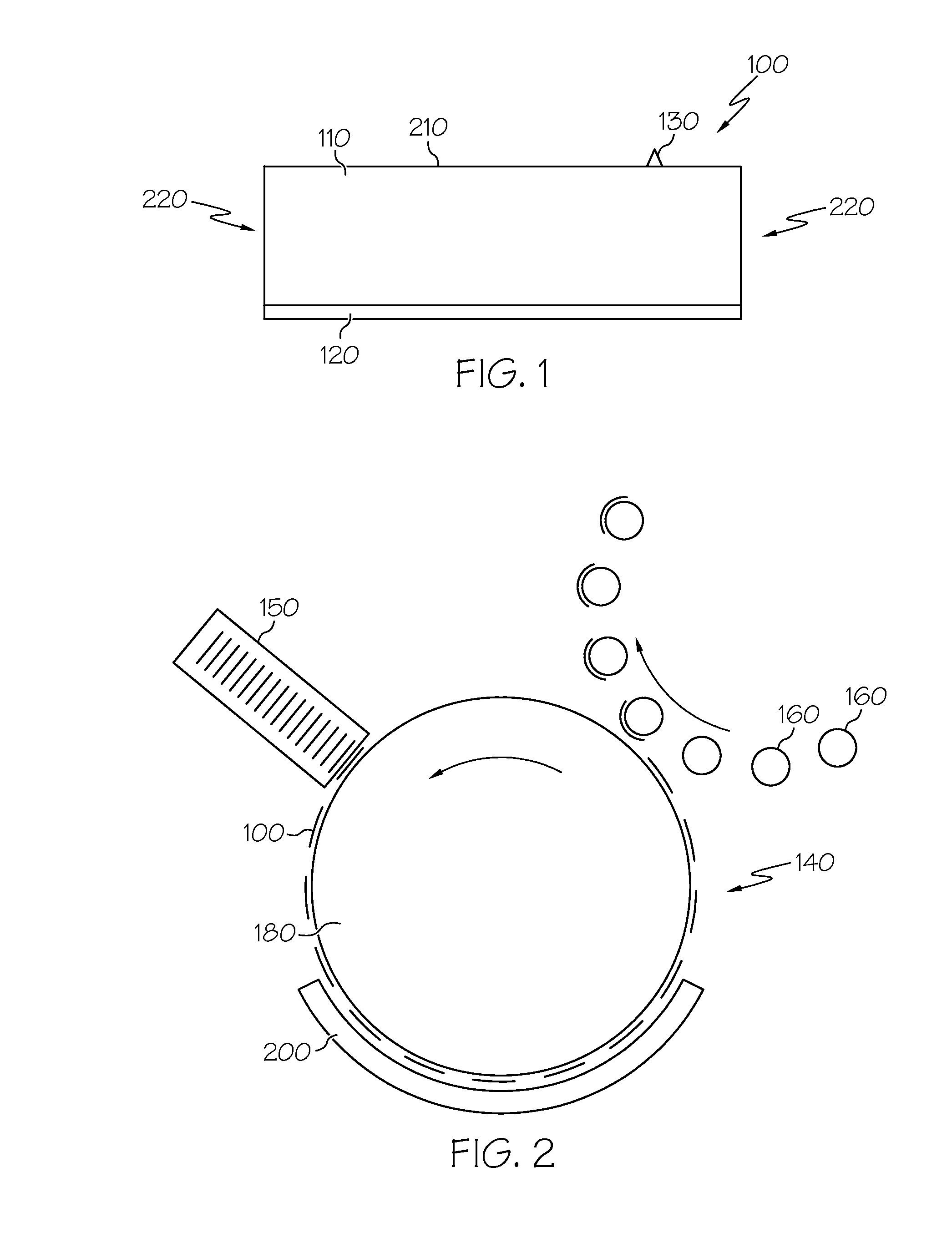

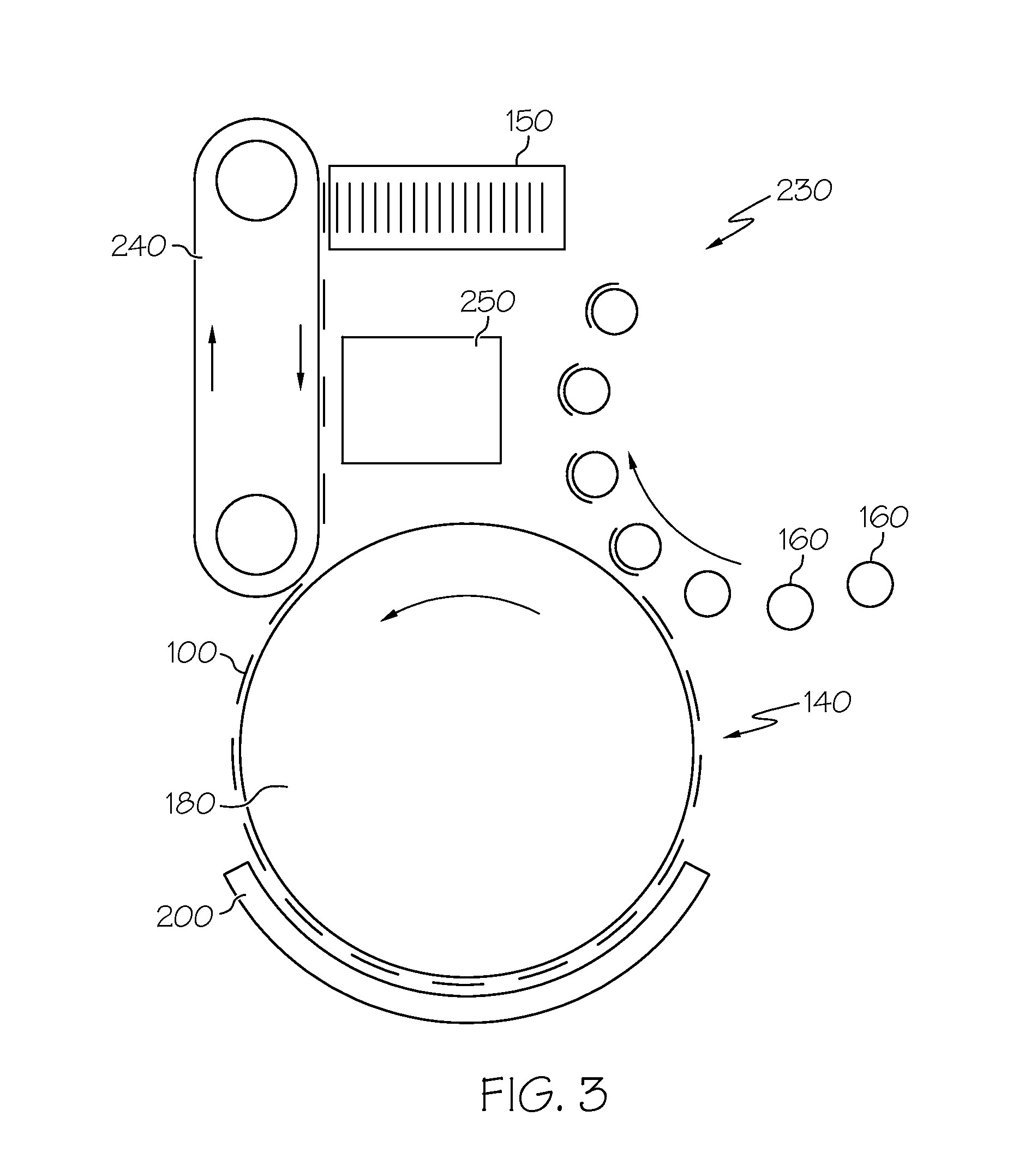

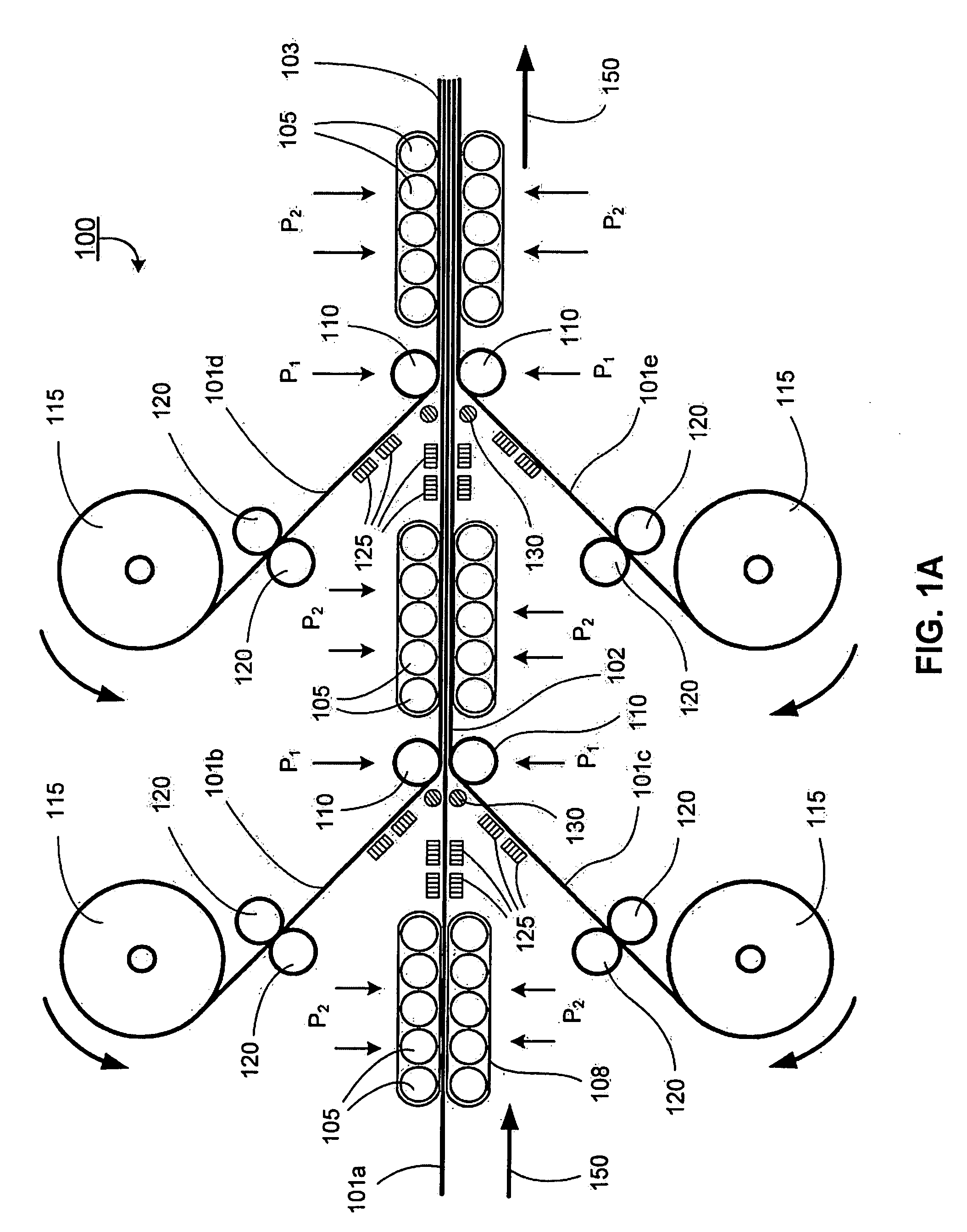

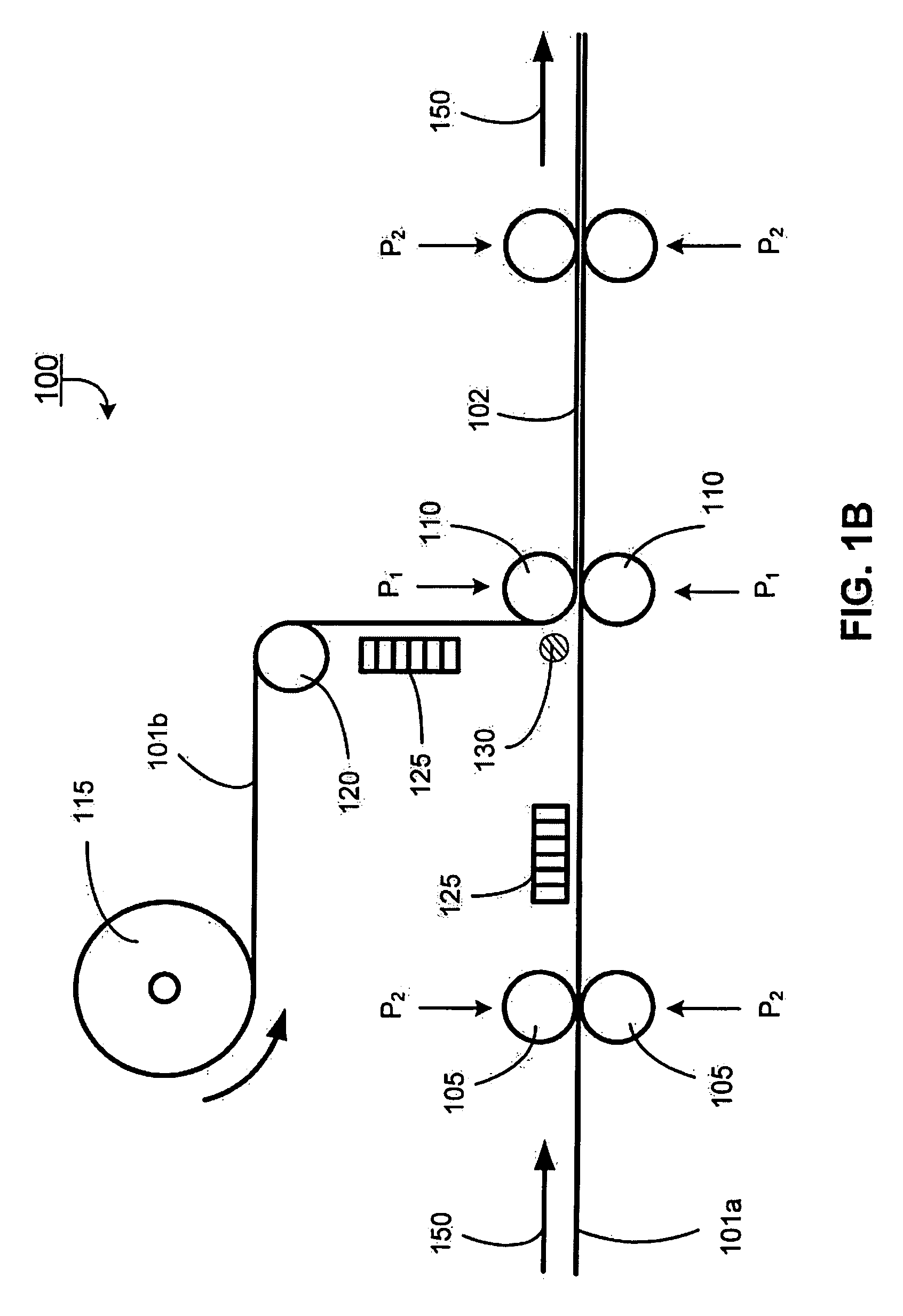

Methods and apparatuses for applying a handling tab to continuous glass ribbons

InactiveUS20120255672A1Reduce harmMaintain integrityMechanical working/deformationLaminationAdhesive beltEngineering

Methods and apparatuses for forming a handling tab on a glass substrate are disclosed. The method may include conveying a glass substrate in a conveyance direction. An adhesive tape ribbon may be positioned adjacent to the first lateral edge of the glass substrate such that an adhesive surface of the adhesive tape ribbon is spaced apart from the first lateral edge of the glass substrate and the adhesive surface is substantially perpendicular to the first surface and the second surface. The adhesive tape ribbon may be folded such that at least a portion of the glass substrate is positioned between the adhesive surface of a first portion of the adhesive tape ribbon and the adhesive surface of a second portion of the adhesive tape ribbon, and a third portion of the adhesive tape ribbon forms a handling tab extending beyond the first lateral edge of the glass substrate.

Owner:CORNING INC

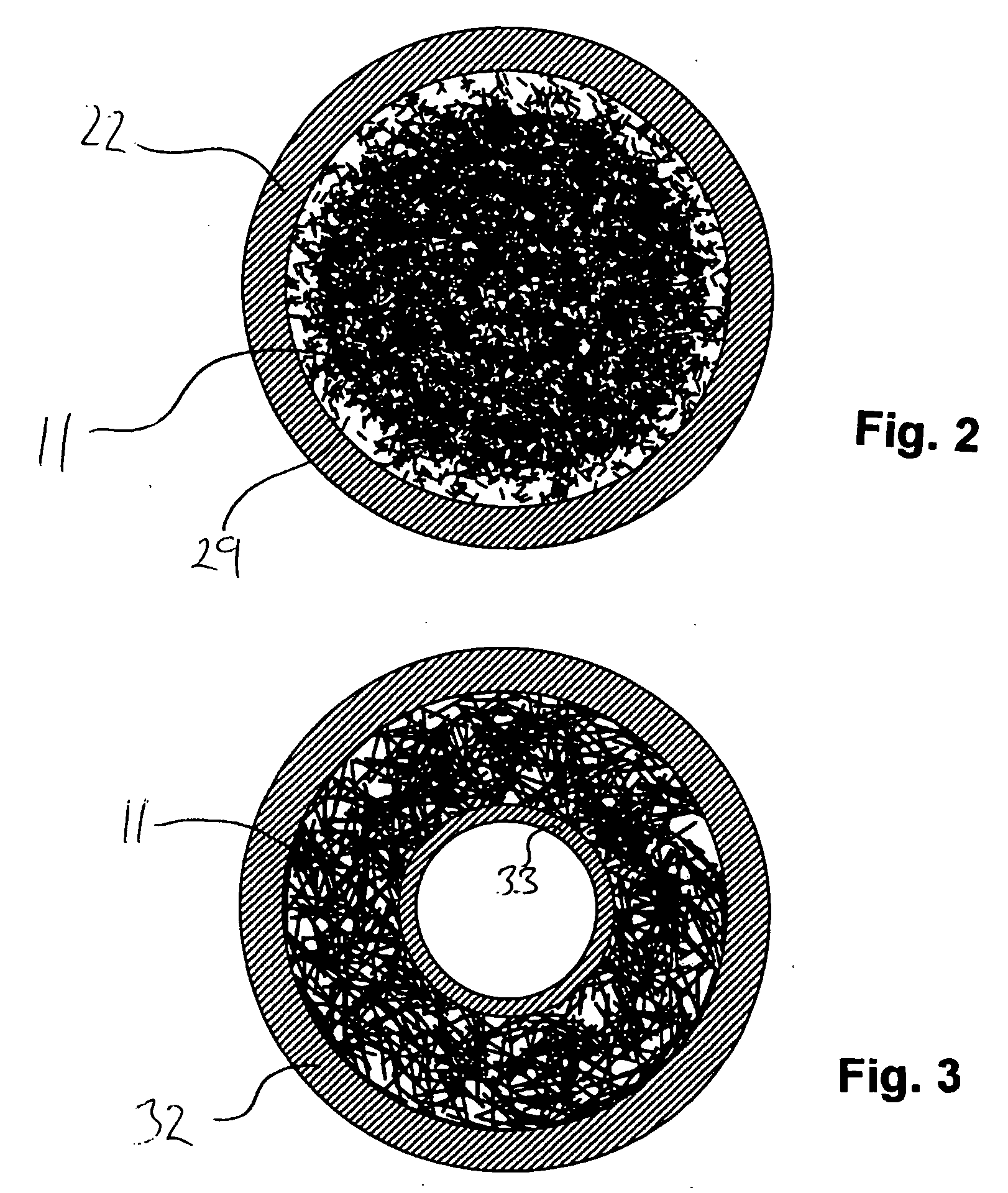

Tissue engineering scaffolds

InactiveUS20090227026A1Enhancement of cell seeding capacityNew-spun product collectionLaminationSurgeryBiomedical engineering

The present invention relates to tissue engineering scaffolds (TE scaffolds) that mimic the biomechanical behavior of native blood vessels, tissue engineered blood vessels (TEBVs) derived from the TE scaffolds, and methods of making and using the TE scaffolds and TEBVs.

Owner:ORGAGEN INC

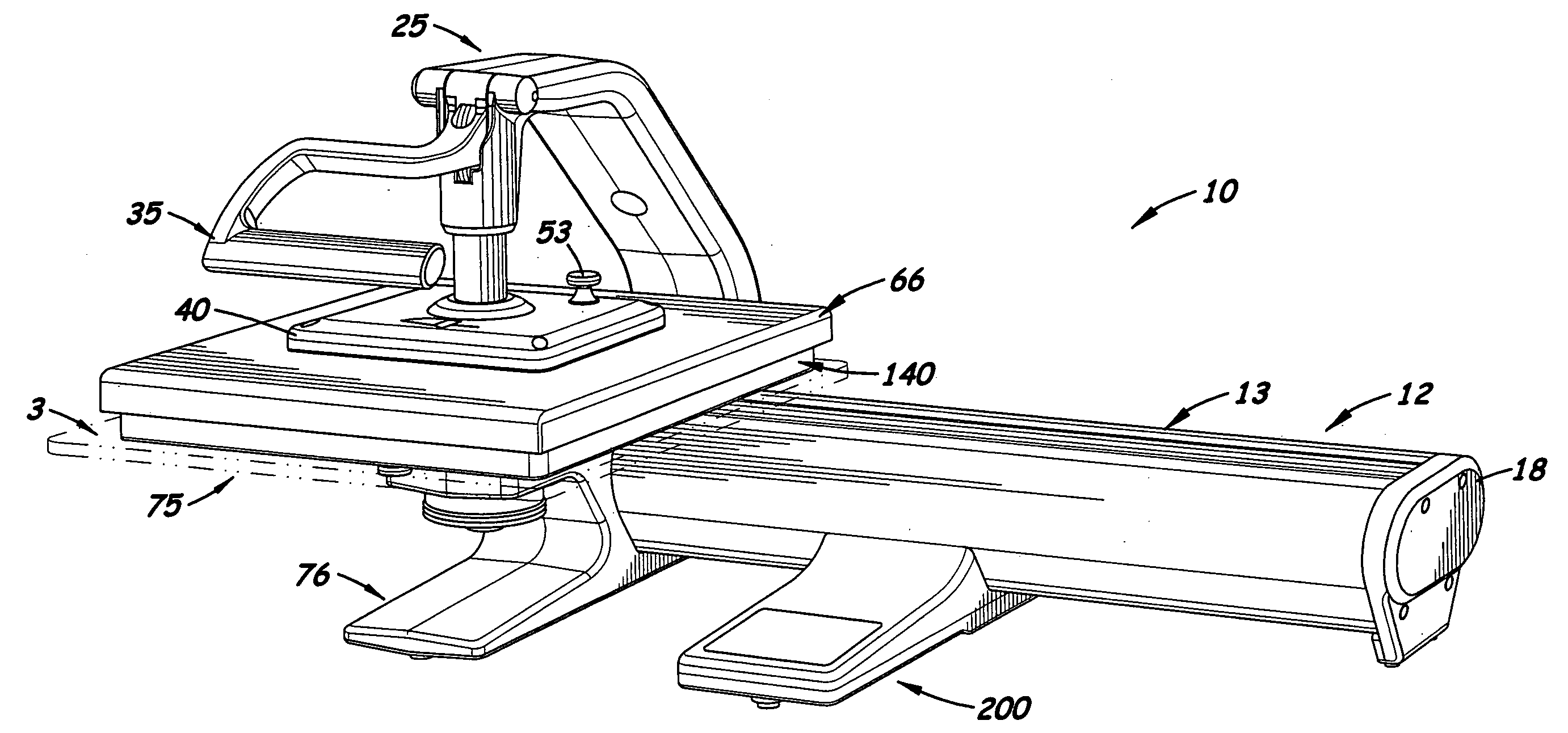

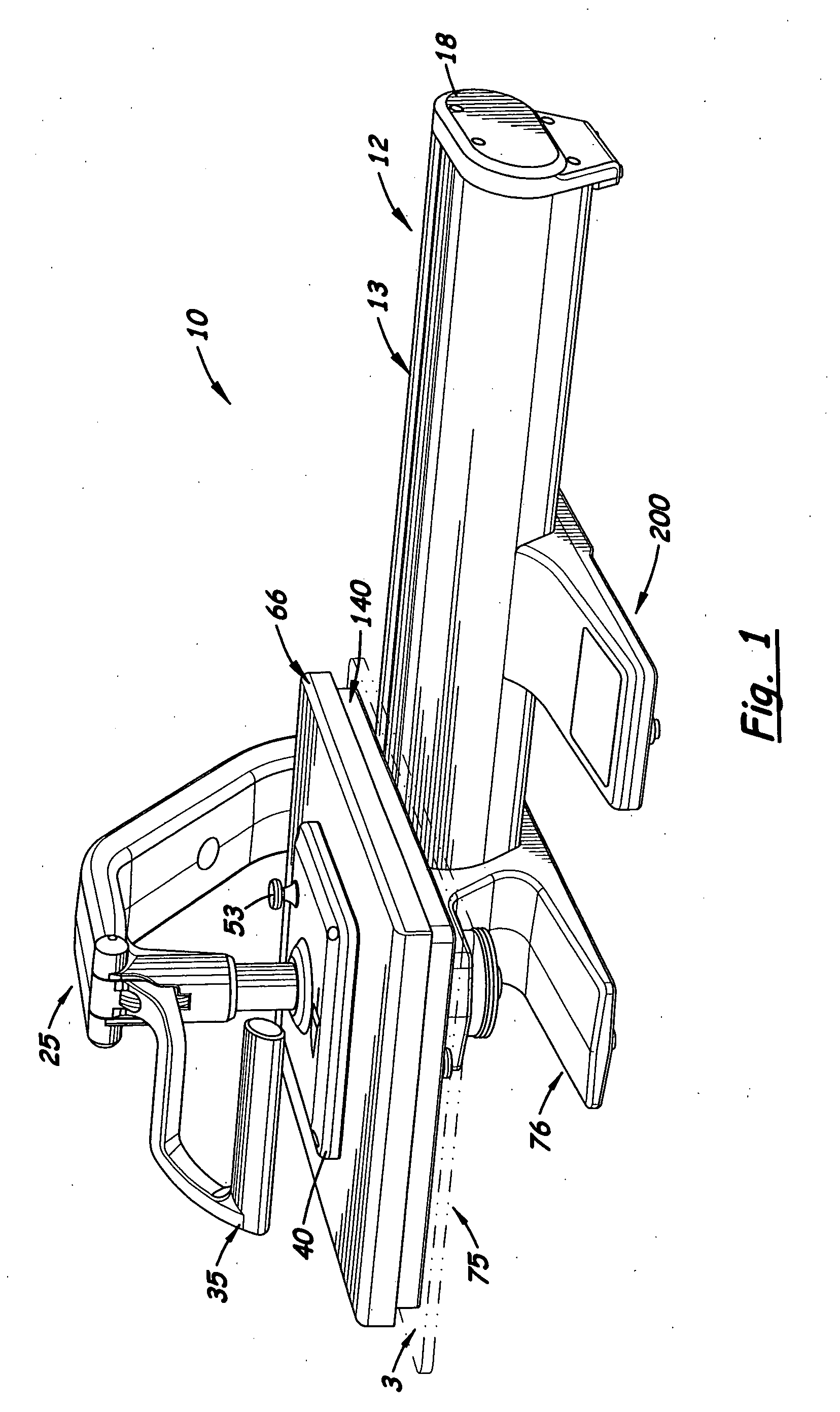

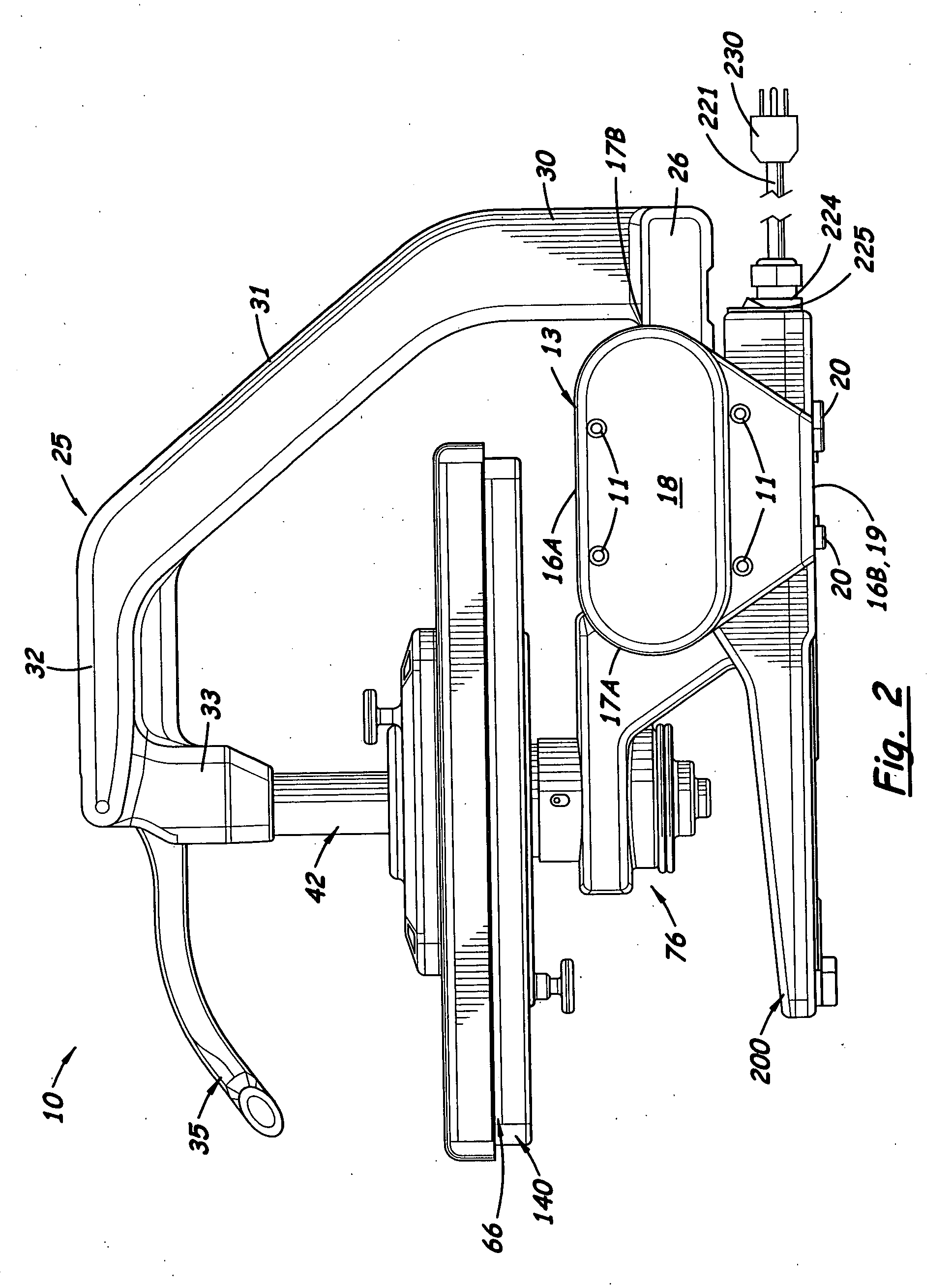

Lateral heat press with long sleeve lower platen

Owner:WOODS DANIEL

Lithium battery flexible packaging film and its manufacturing method

Owner:上海紫江彩印包装有限公司

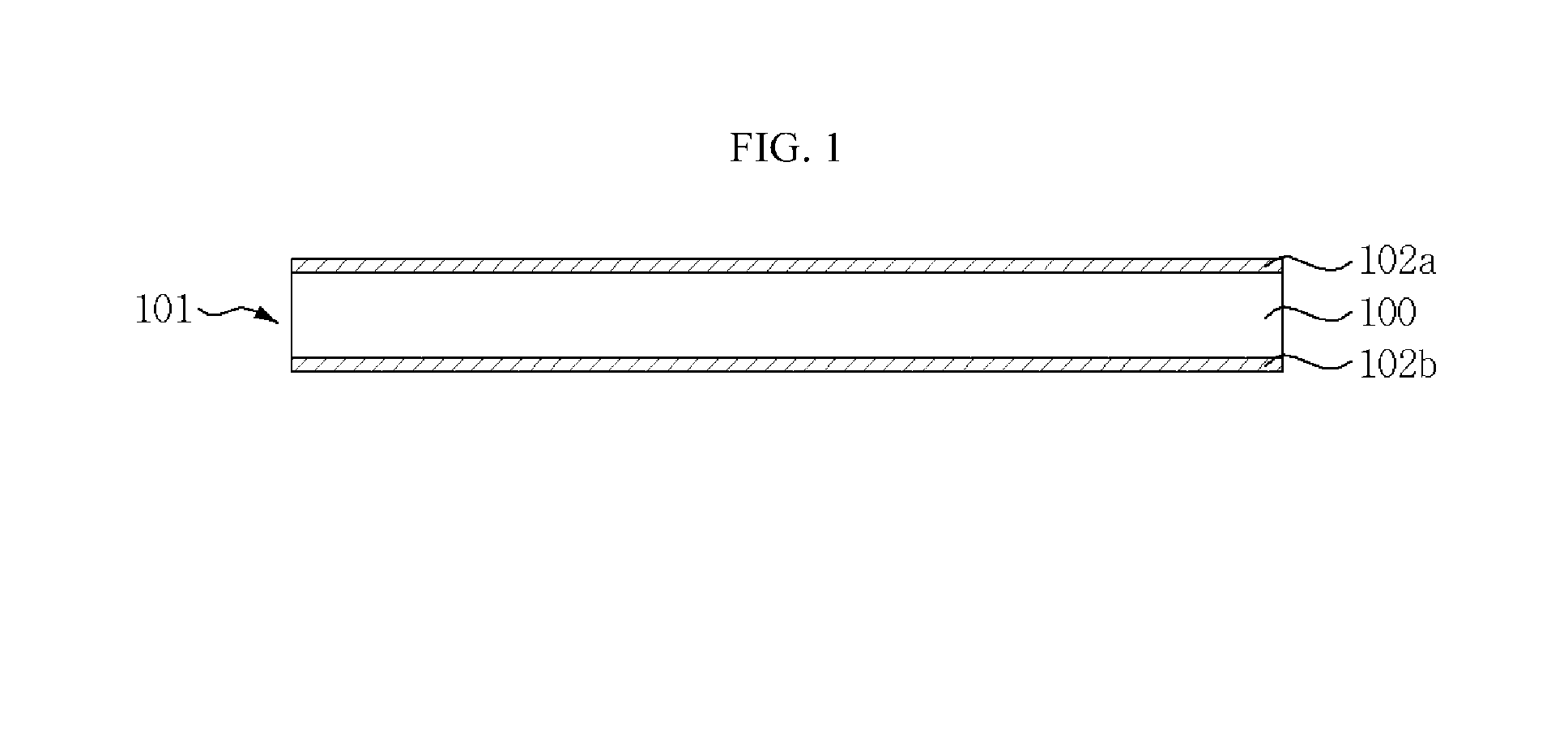

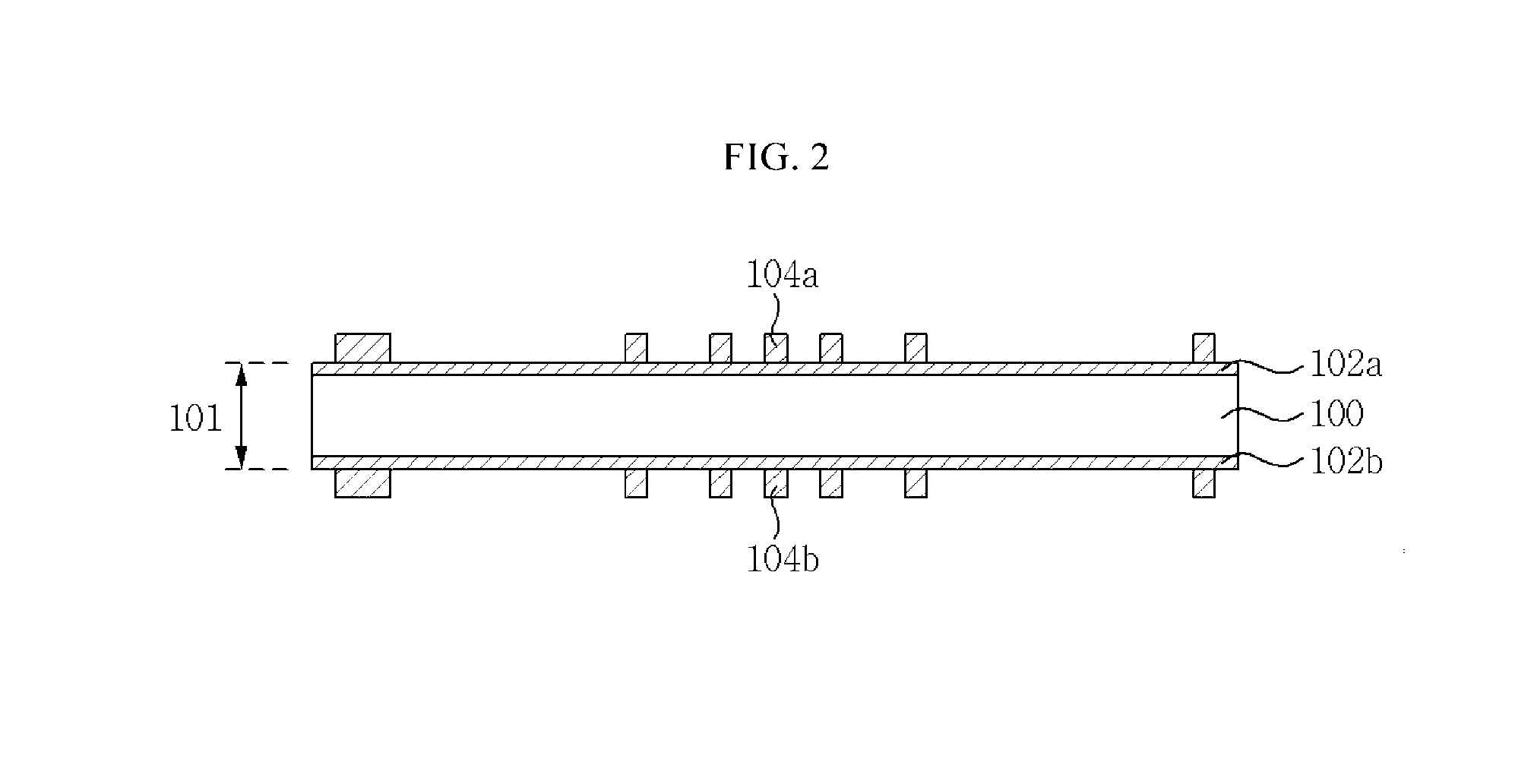

Embedded printed circuit board and method of manufacturing the same

InactiveUS20160174381A1Well formedSolid-state devicesElectrical connection printed elementsInsulation layerElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for compression moulding reinforced thermoplastic article

A method for manufacturing a polymeric article having an integrated reinforcing element. A thermoplastic material is introduced into a mould, after which reinforcing elements are inserted into the mould cavity. A second layer of the thermoplastic material is introduced into the mould, after which the mould is closed, pressing and heating the mould to melt the thermoplastic material and form the article. The thermoplastic layers may be provided in powder, sheet, or pellet form. The reinforcing elements may comprise reinforcing fibres or reinforcing fabrics. A polymeric track for a vehicle may be produced from this method.

Owner:POLARIS IND INC +1

High-precision pasting device and method based on CCD detection

ActiveCN105711223AHigh degree of automationAchieving processing powerControlling laminationLaminationMotor driveEngineering

The invention provides a high-precision pasting device and method based on CCD detection. The device comprises a product material strip feeding mechanism, a label material strip feeding mechanism, a pasting platform, a label sucking and pasting mechanism, a first CCD assembly, a second CCD assembly and a controller, wherein the first CCD assembly is arranged between a material tray assembly and the pasting platform and located above a product material strip moving path so as to shoot an image of a product material strip, and the second CCD assembly is arranged above a label taking station so as to shoot images of labels. The product material strip feeding mechanism comprises the material tray assembly, a material pulling roller and a servo motor driving the material pulling roller to rotate. The controller carries out contrastive analysis on the image of the product material strip and the images of the labels to control the label material strip feeding mechanism so that the labels can be accurately positioned at the label taking station. According to the high-precision pasting device and method based on CCD detection, the two CCD assemblies are adopted to shoot the image of the product material strip and the images of the labels respectively, contrastive analysis is carried out, and a label material strip is adjusted according to a comparison result so that the labels can be accurately positioned at the label taking station. In this way, the labels can be sucked and pasted at high precision, and the automation degree is high.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

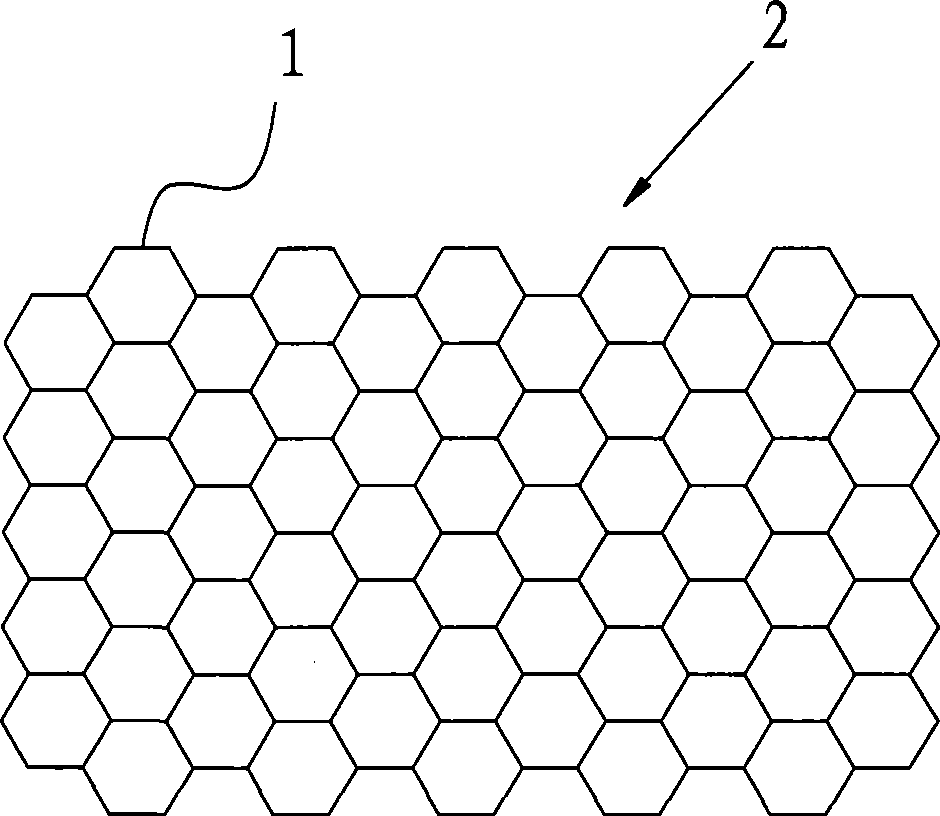

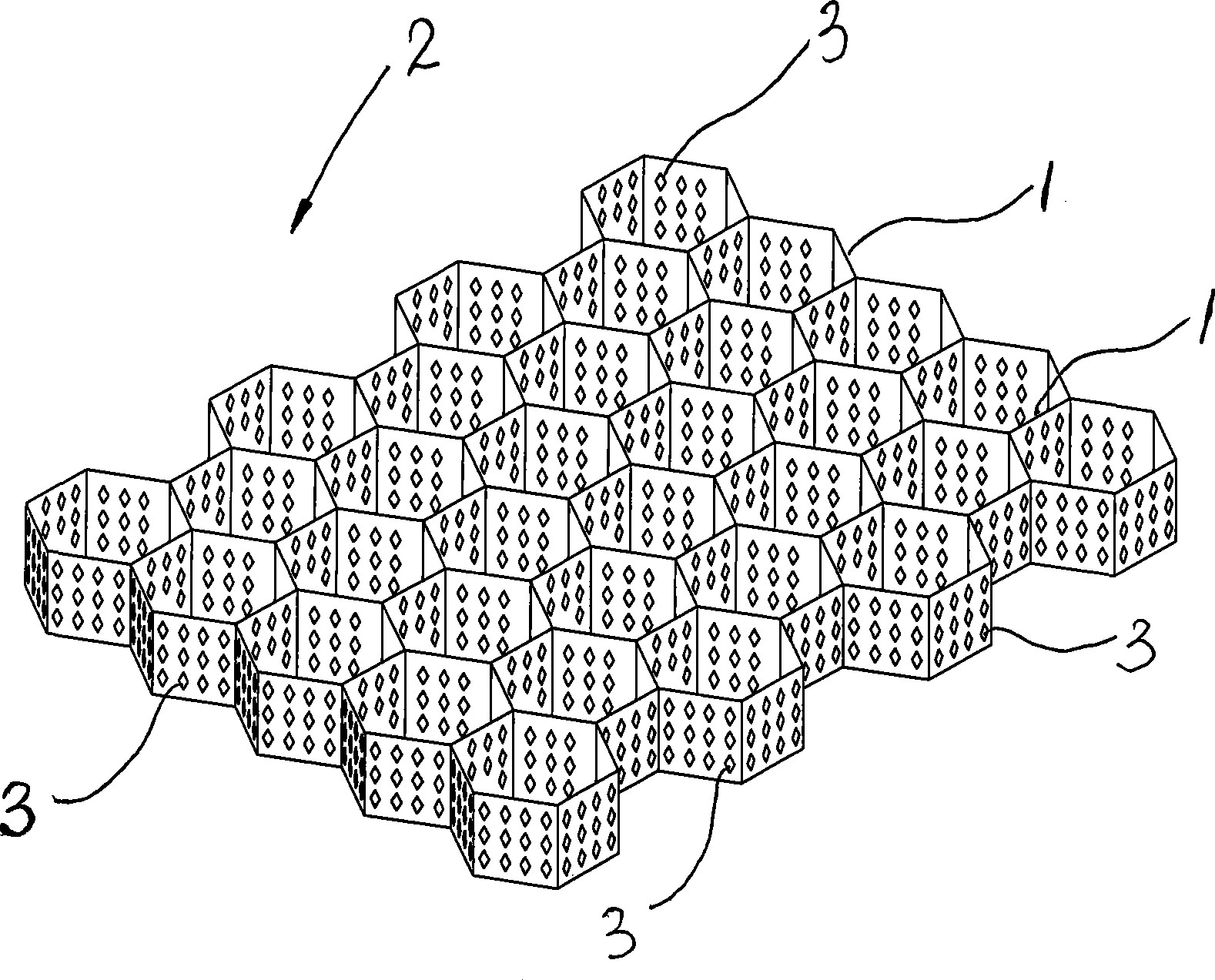

High intensity lightweight honeycomb core and production method thereof

Owner:苏州航通蜂窝科技有限公司

Tissue-adhesive materials

ActiveUS20090044895A1Improve adhesionEasy to useSurgical adhesivesCoatingsPolymer scienceContact layer

A multi-lamellar tissue-adhesive sheet comprises a structural layer or laminate conjoined to a tissue-contacting layer. The structural layer or laminate comprises one or more synthetic polymers having film-forming properties, and the tissue-contacting layer of material contains tissue-reactive groups. The synthetic polymers having film-forming properties are preferably biodegradable polyesters, and the tissue-reactive groups are most preferably NHS-ester groups.

Owner:TISSUEMED LTD

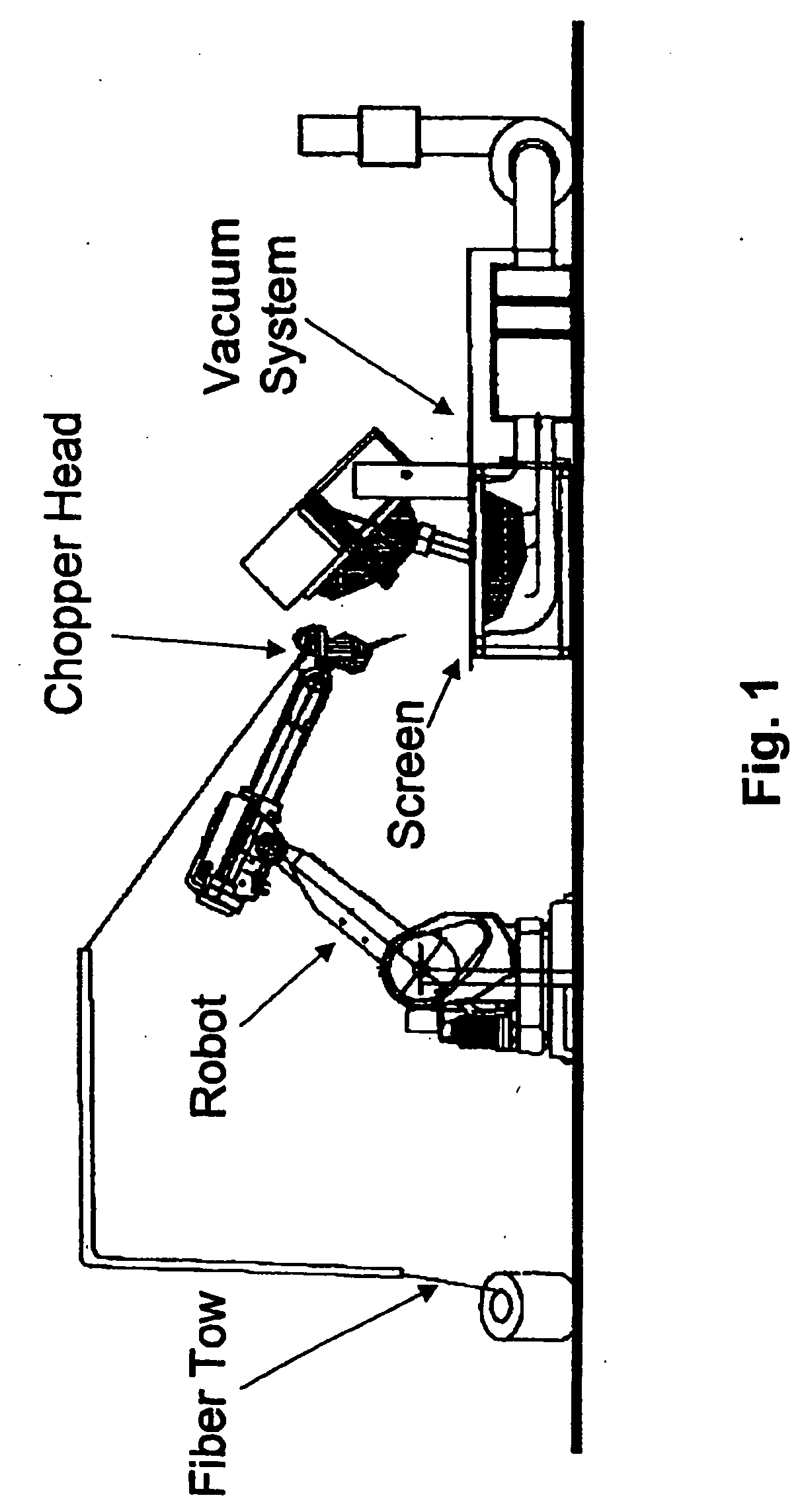

Manufacture of thick preform composites via multiple pre-shaped fabric mat layers

Owner:HONEYWELL INT INC +2

Reinforced coatings and methods of making the same

Owner:GENERAL ELECTRIC CO

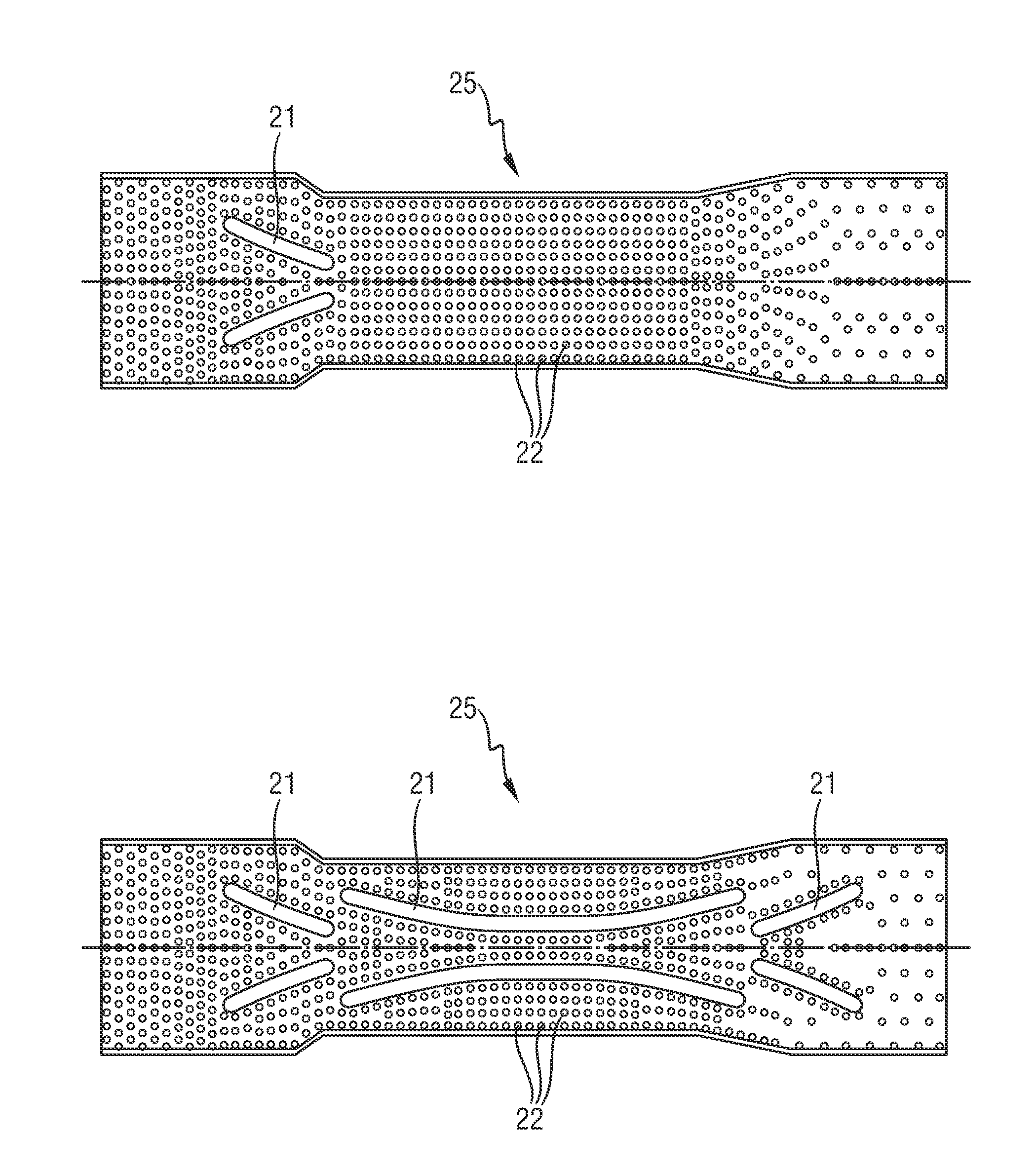

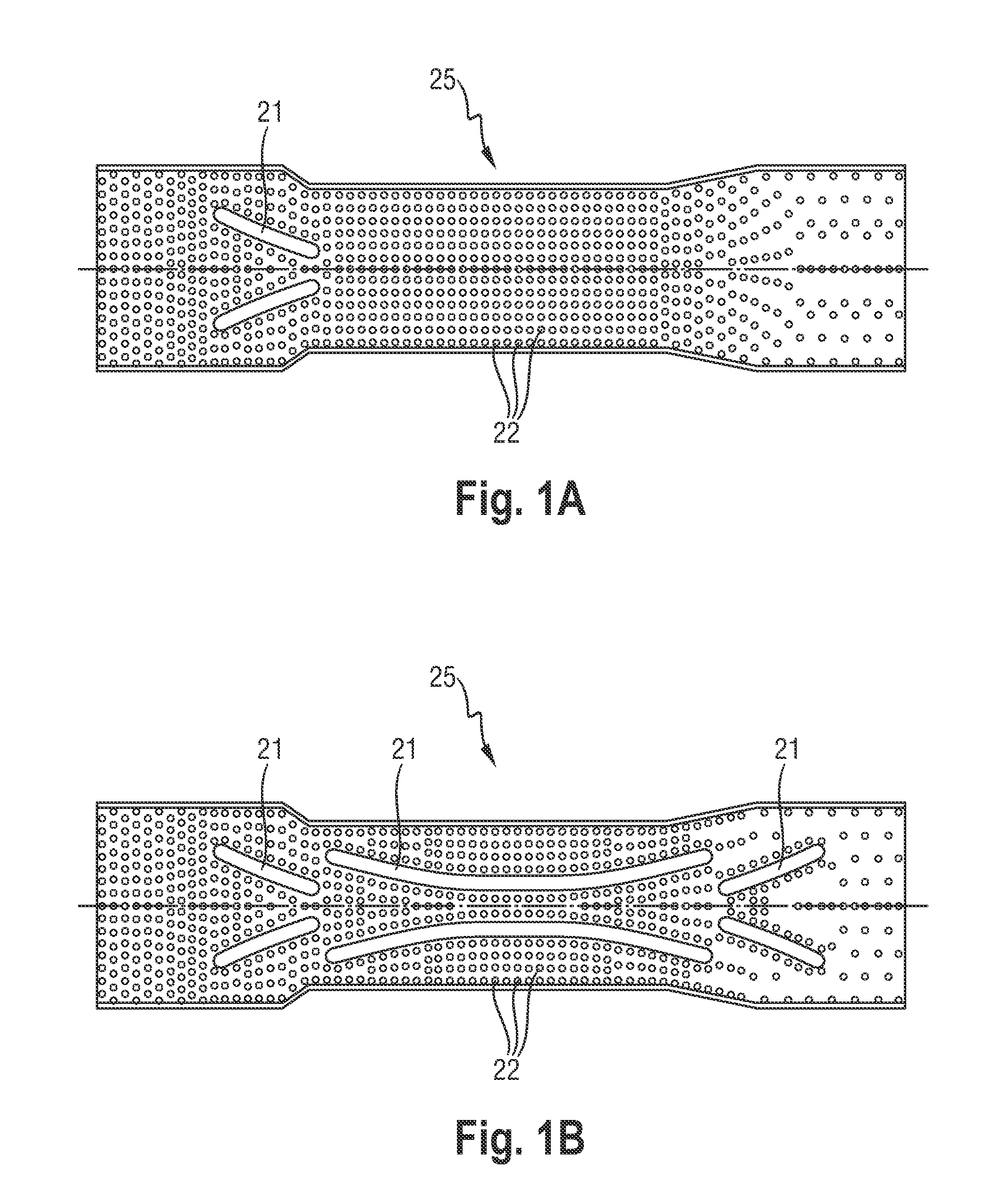

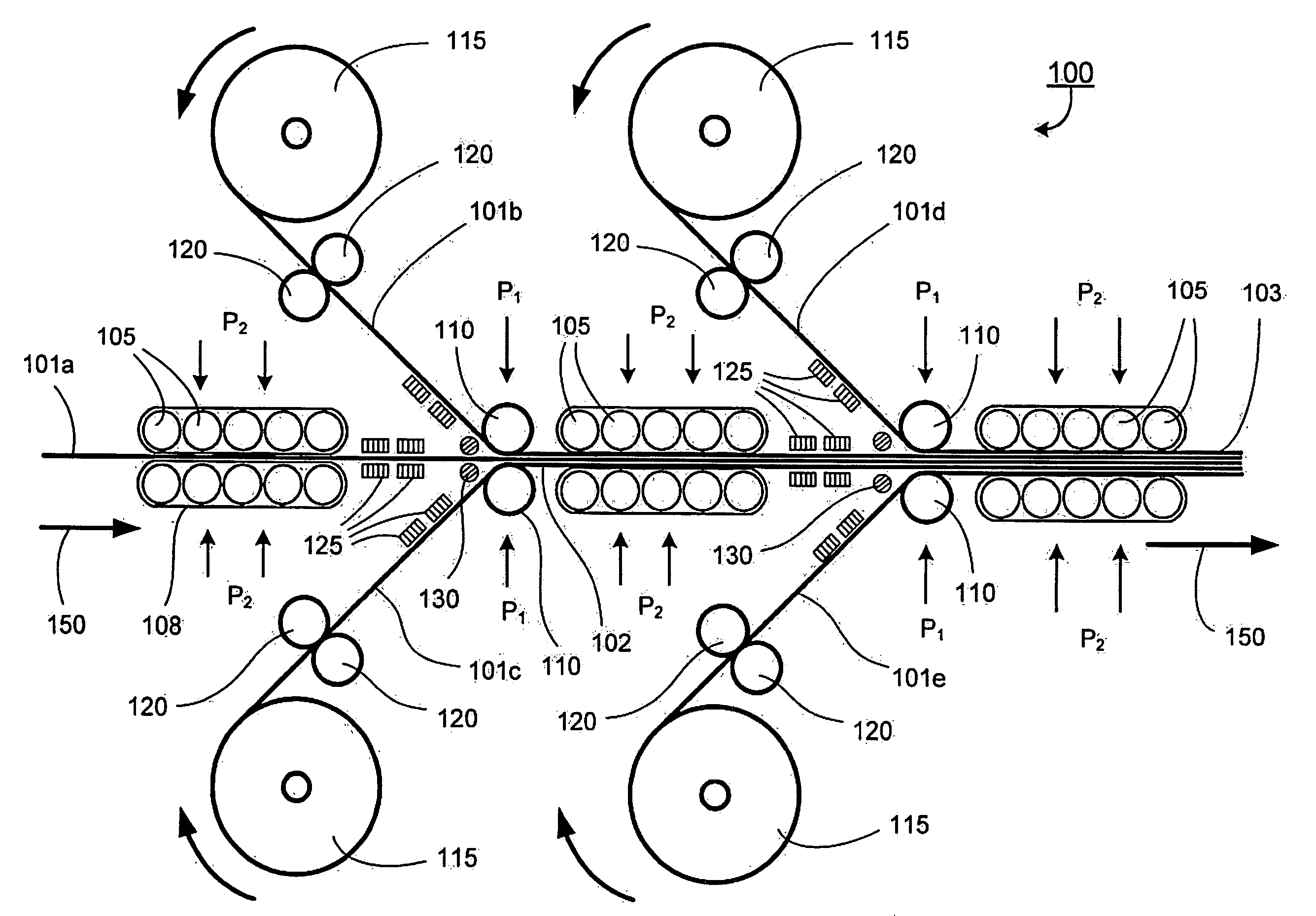

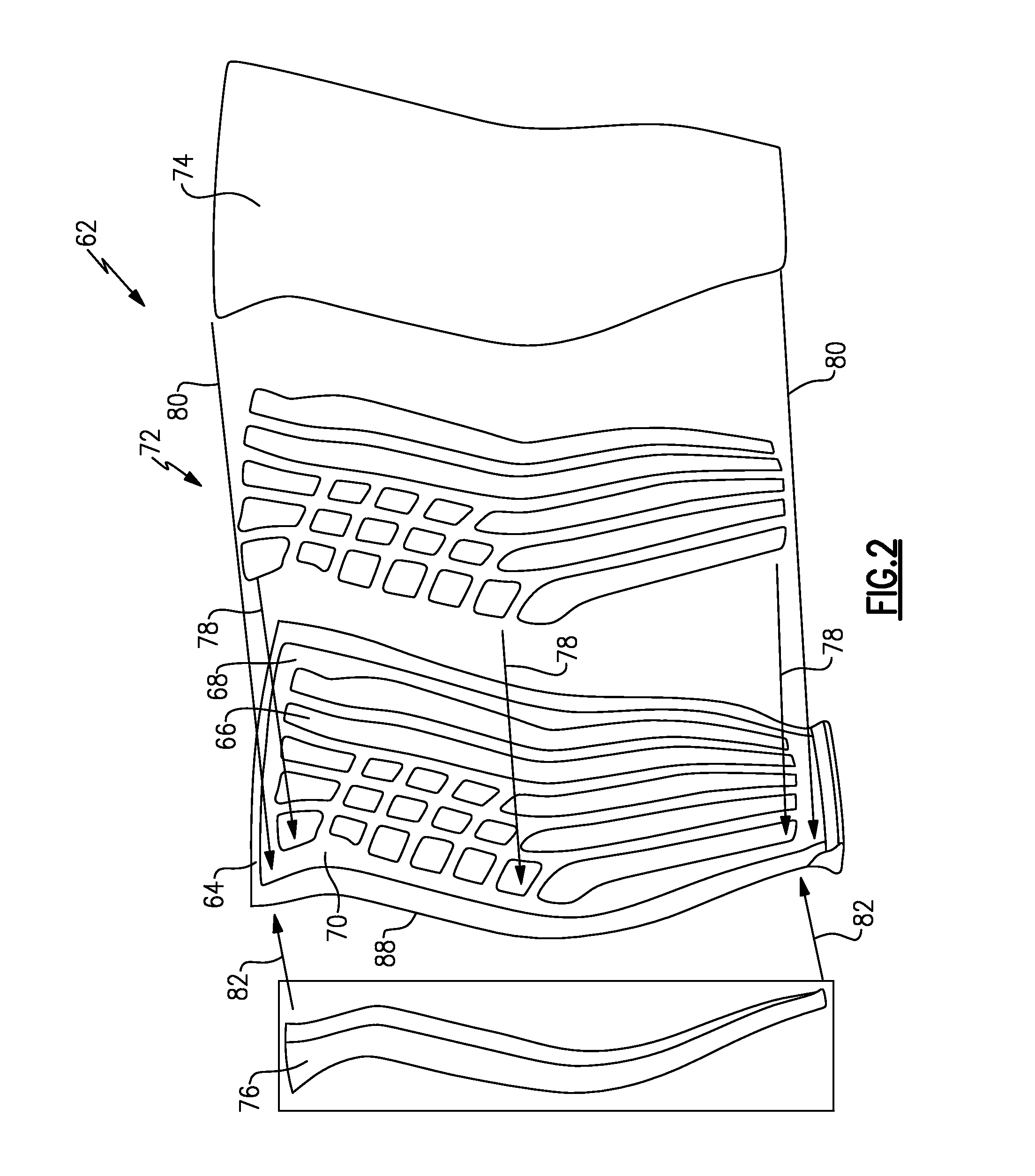

Method and Apparatus for Making an Absorbent Structure Comprising Channels

Owner:THE PROCTER & GAMBLE COMPANY

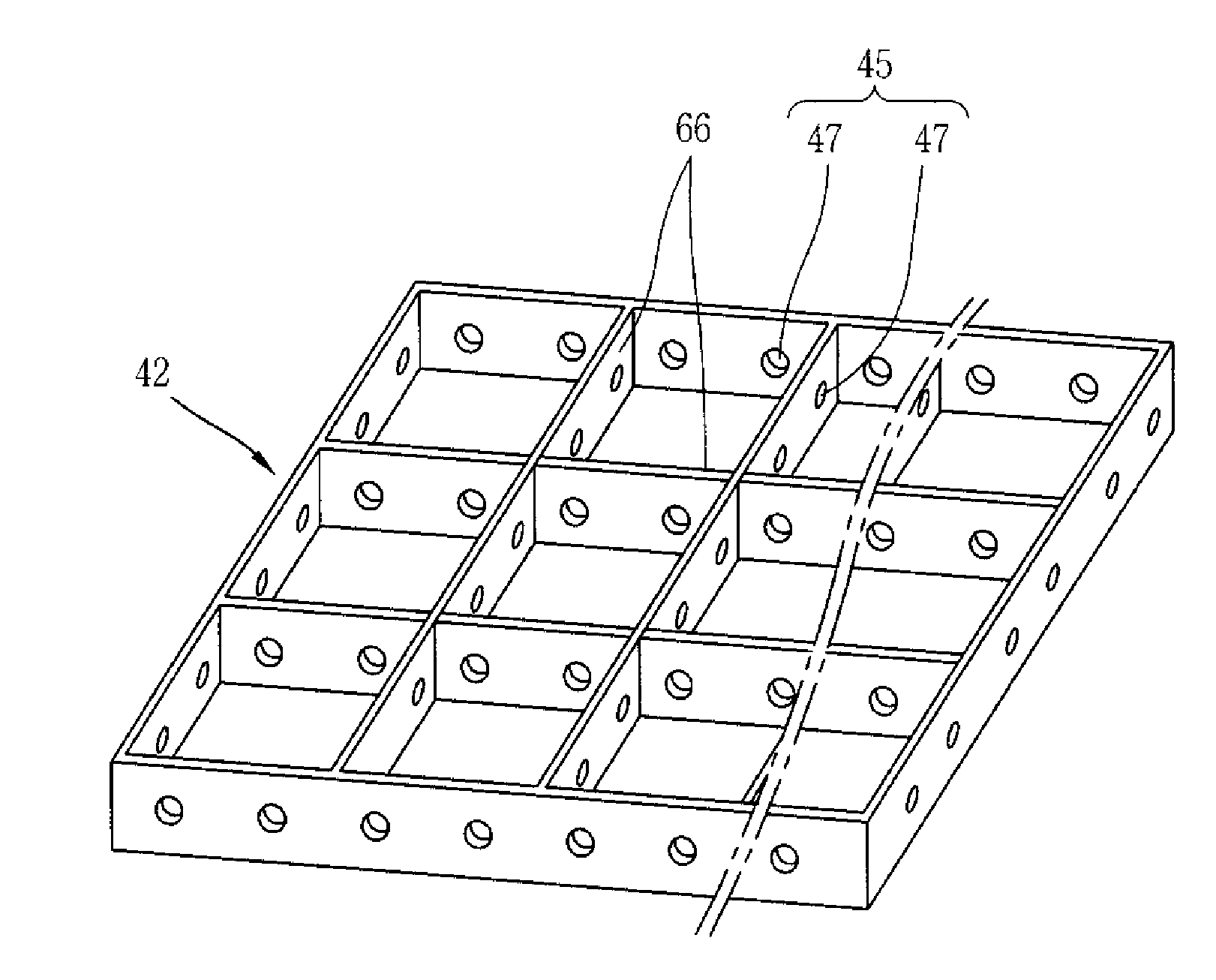

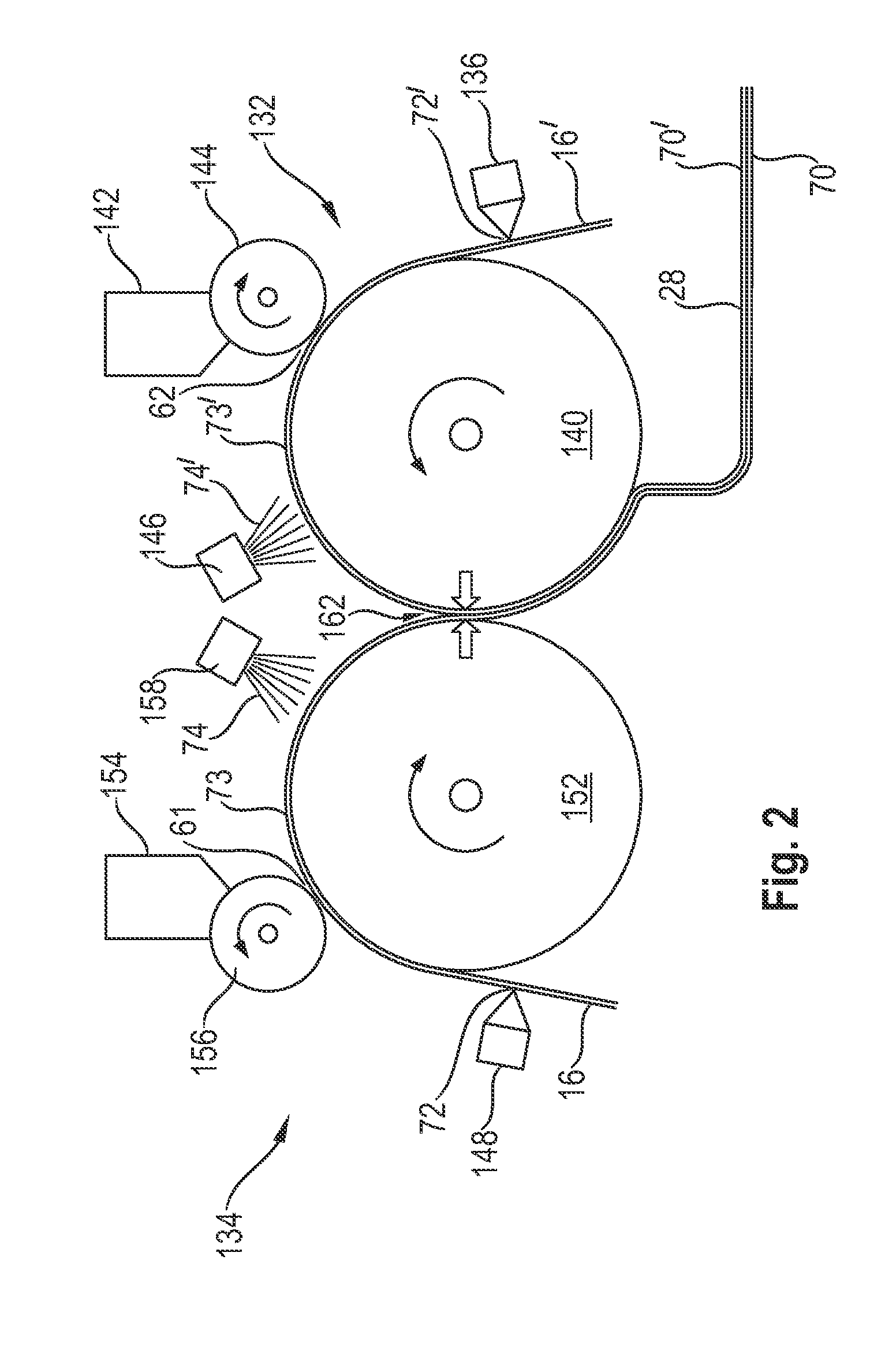

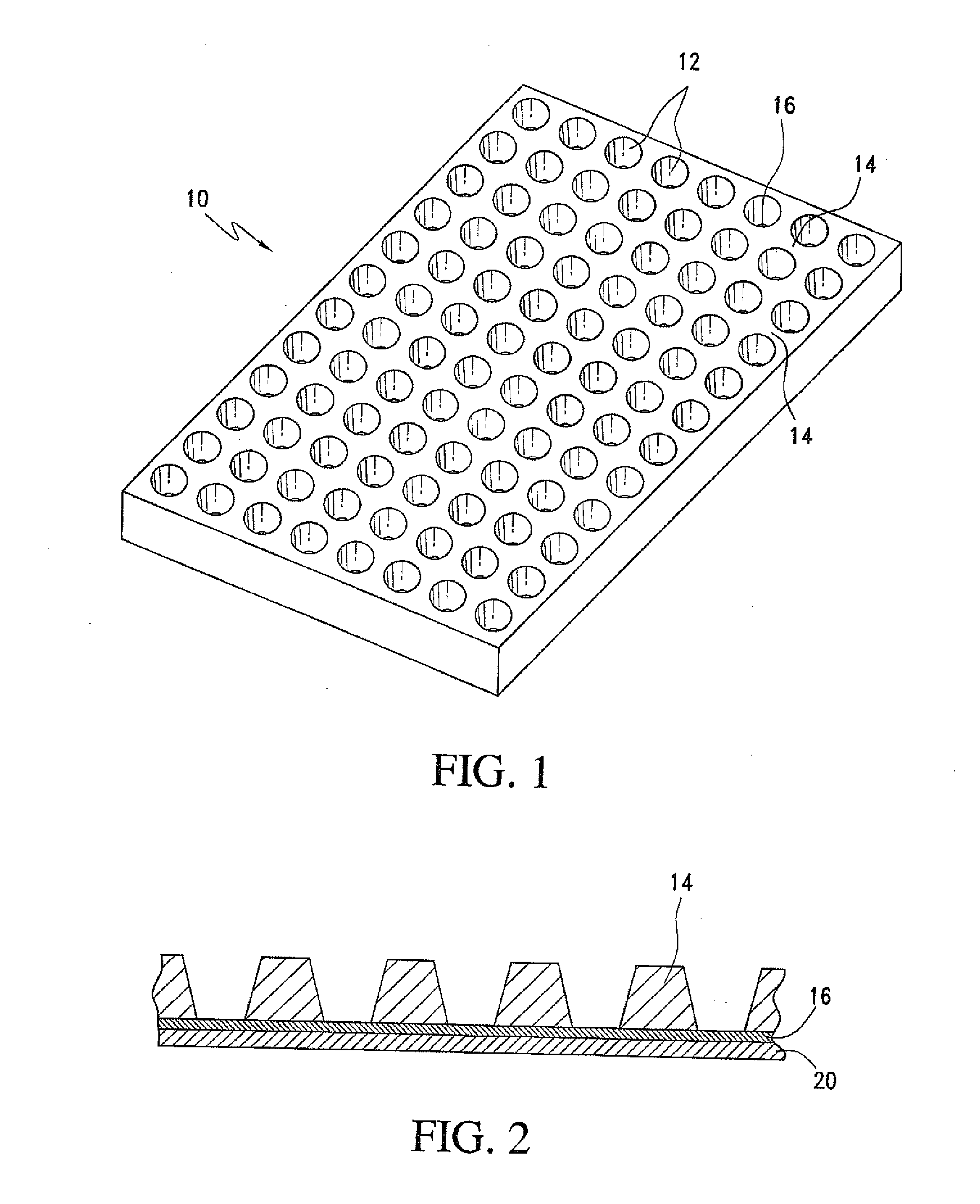

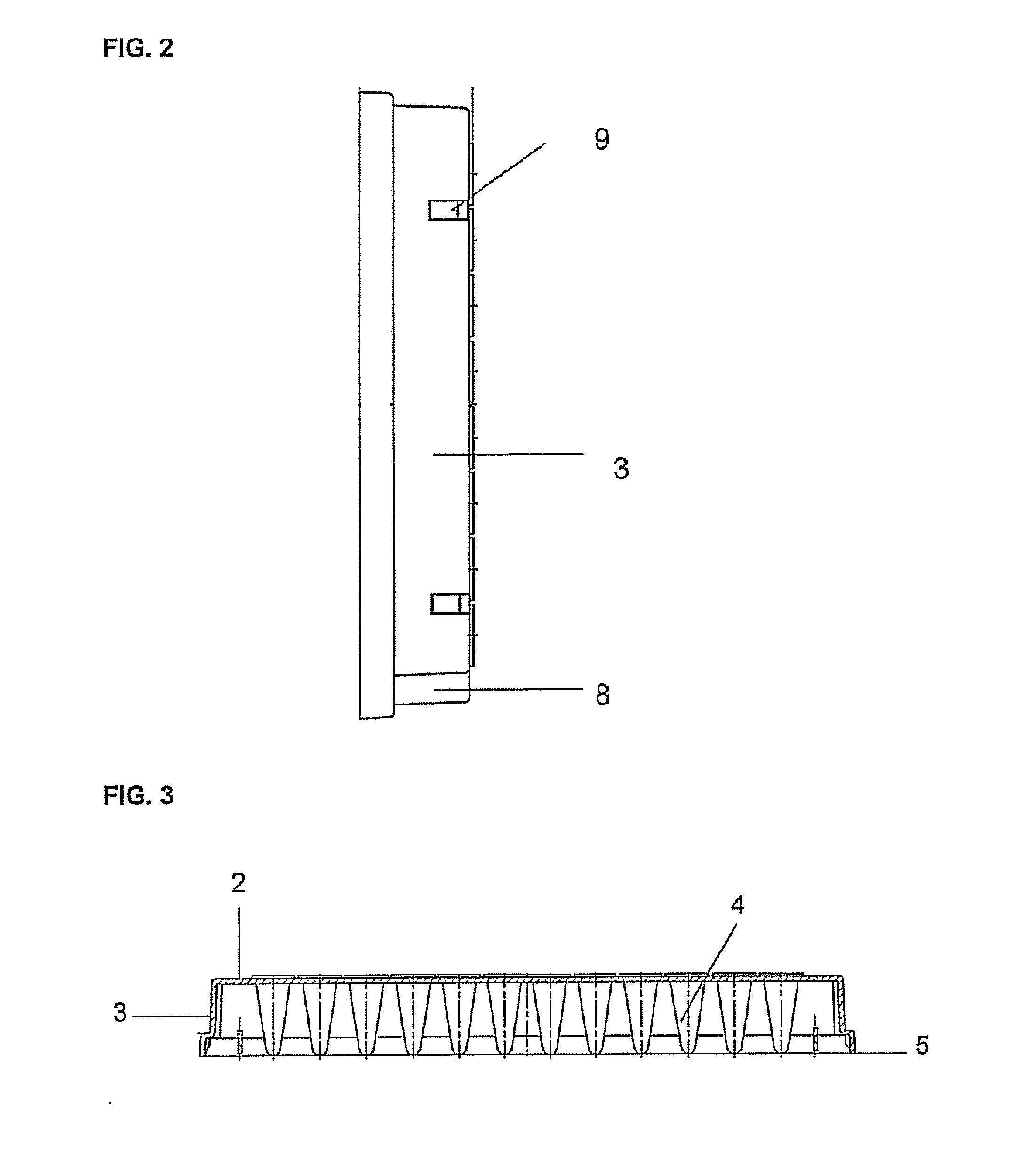

Pico liter well holding device and method of making the same

InactiveUS20100247386A1Reduce distortion problemsEngine sealsLamination ancillary operationsRefractive indexAqueous medium

Owner:SENG ENTERPRISES

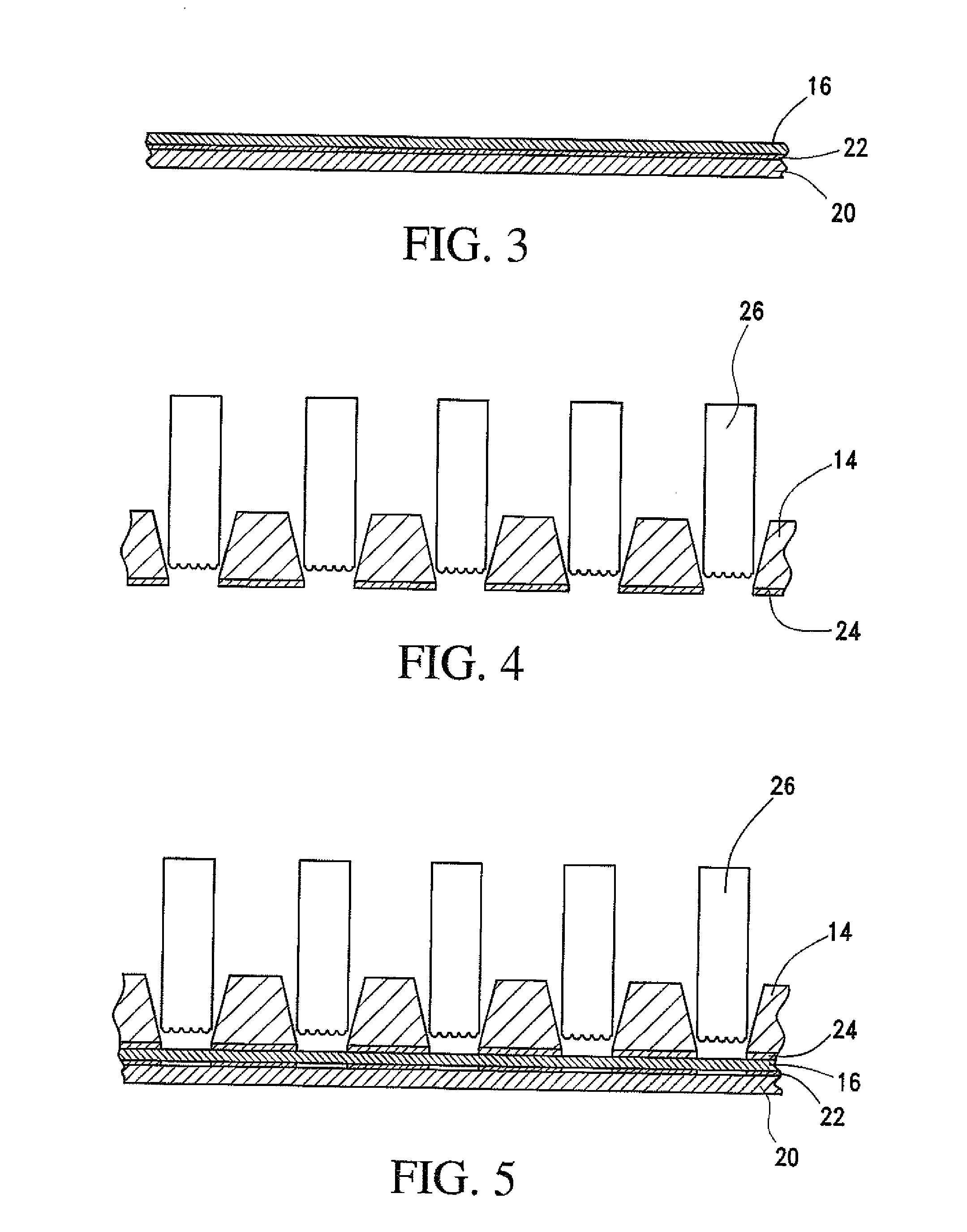

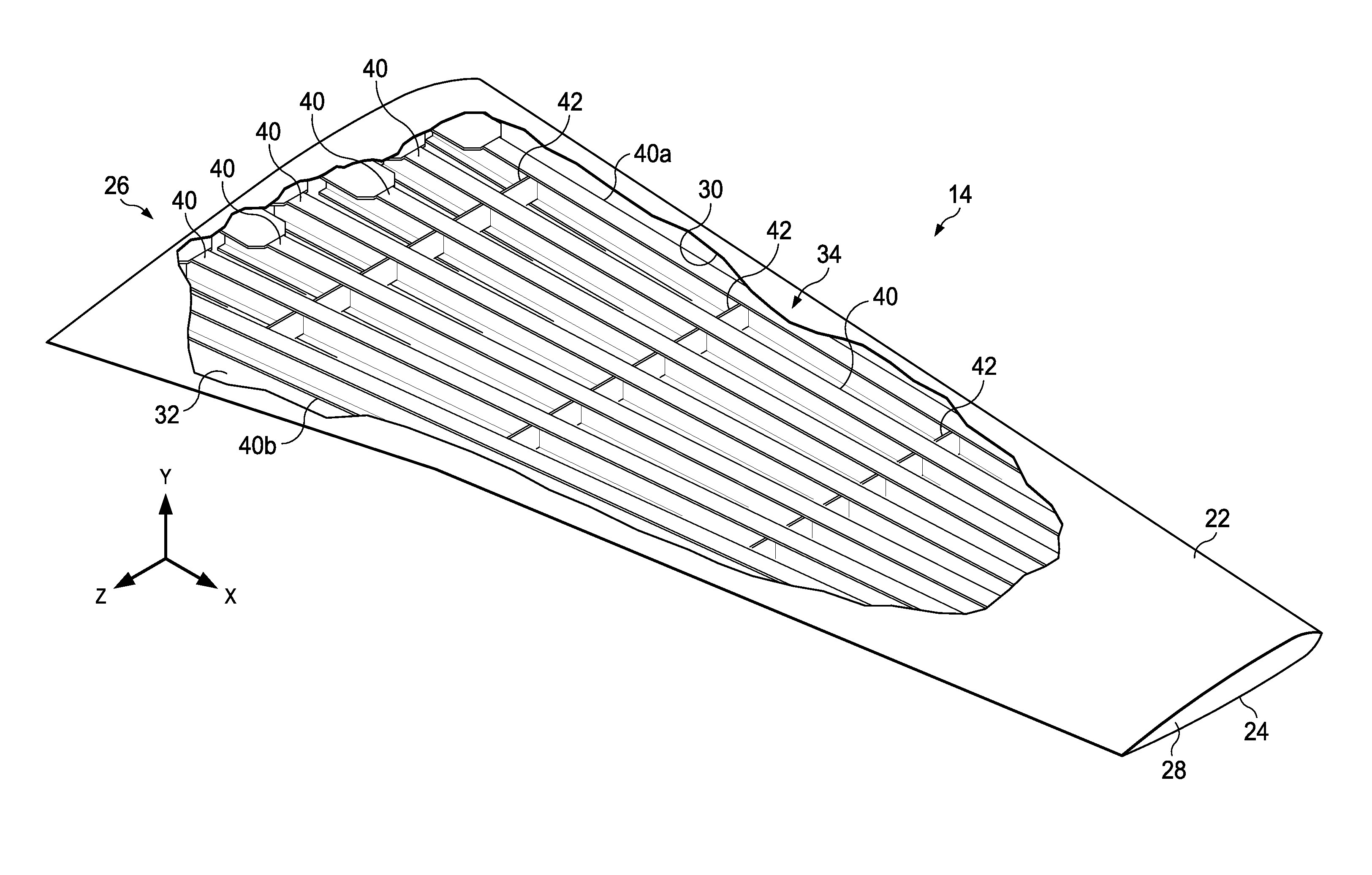

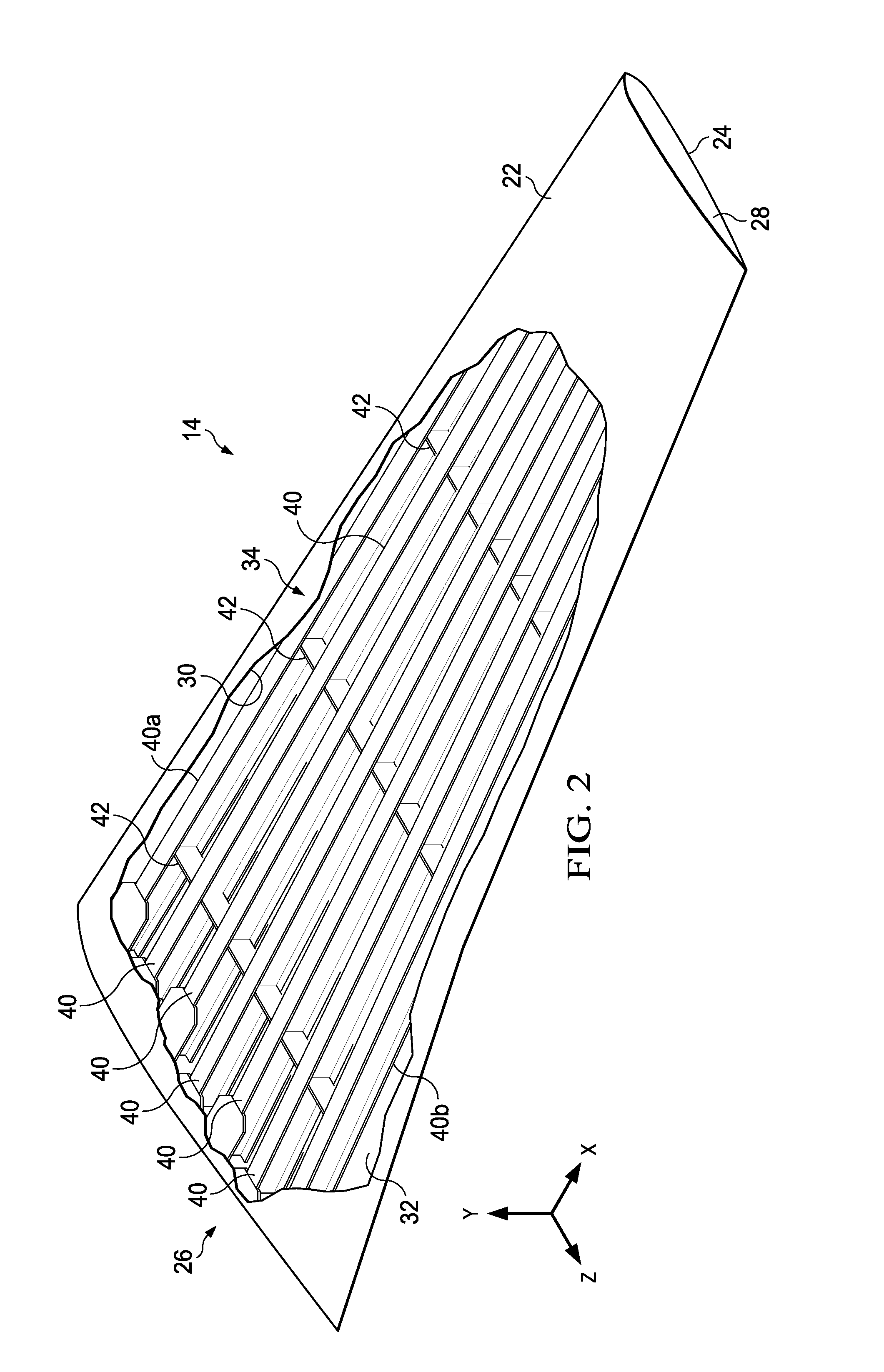

Bonded Composite Aircraft Wing

InactiveUS20140061385A1Improve load transfer efficiencyHigh stiffness-to-weight ratioAircraft stabilisationLaminationComposite gridOgive

Owner:THE BOEING CO

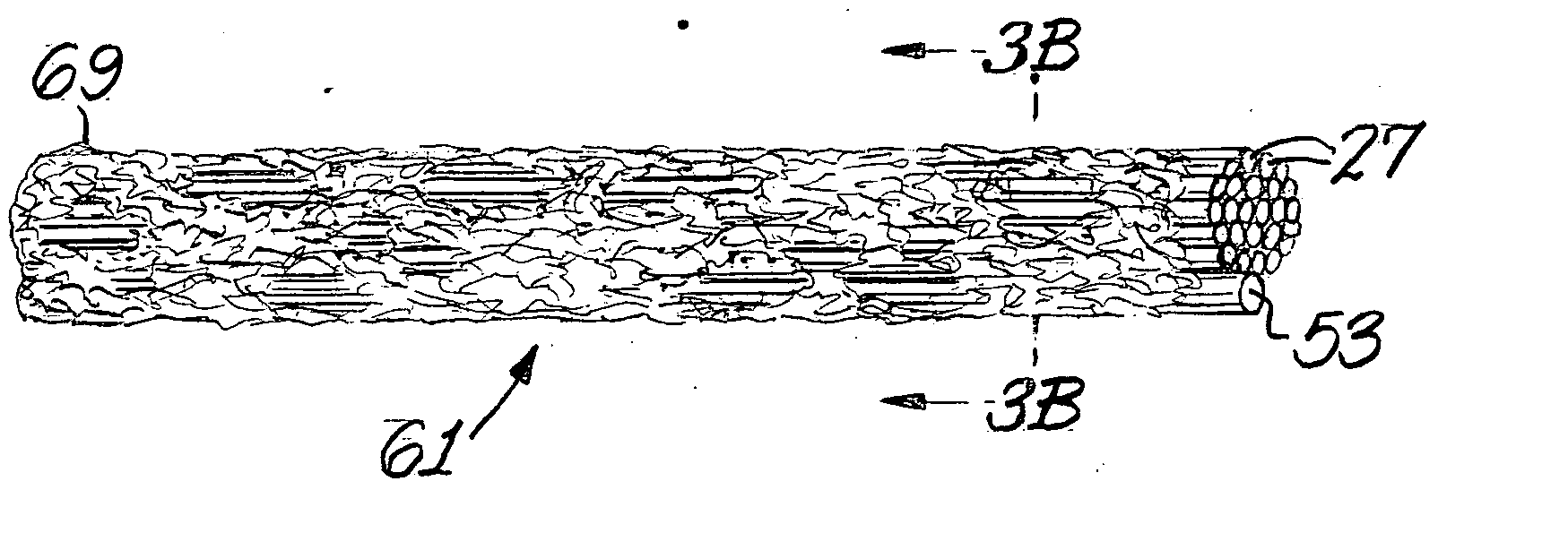

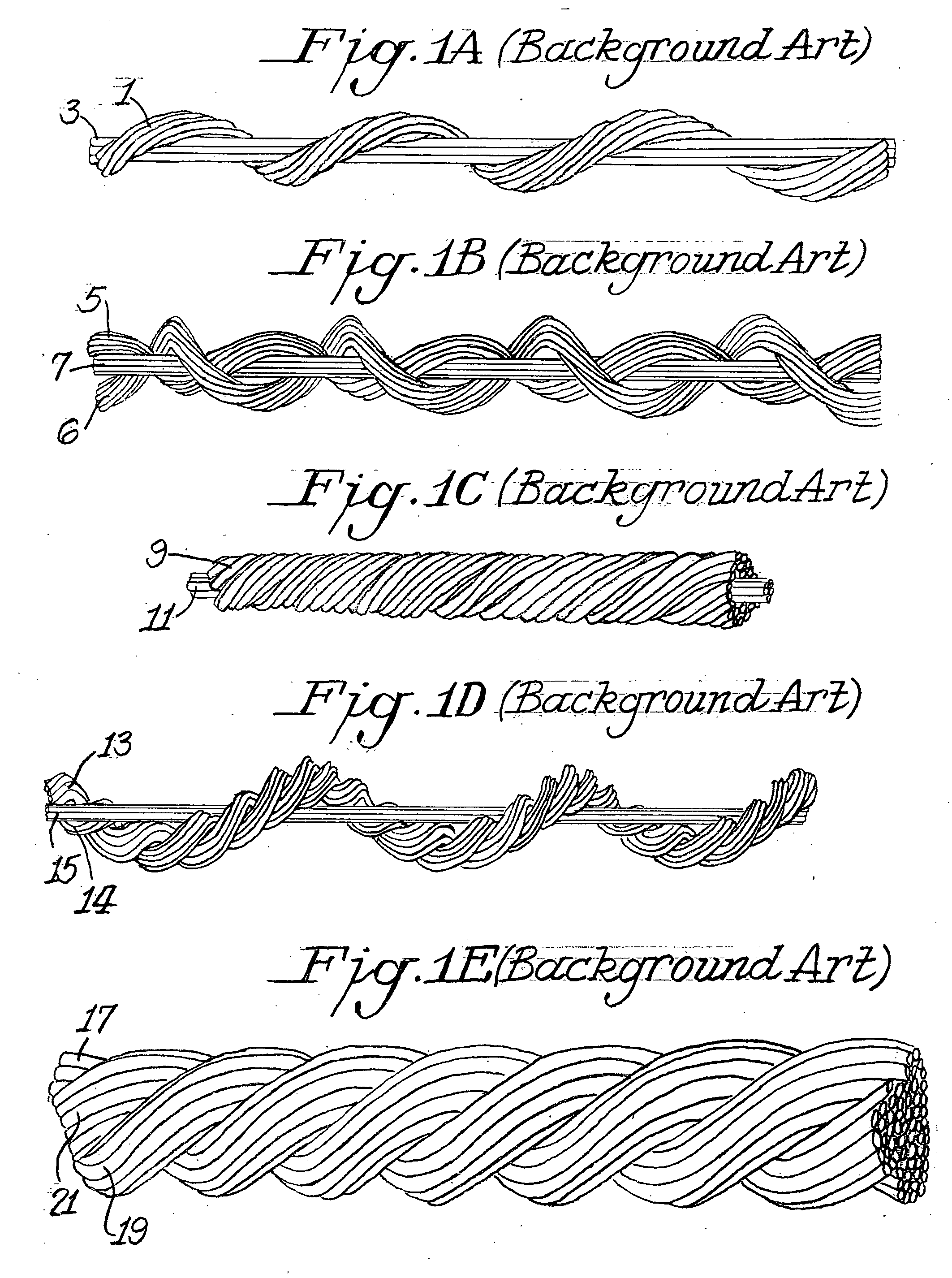

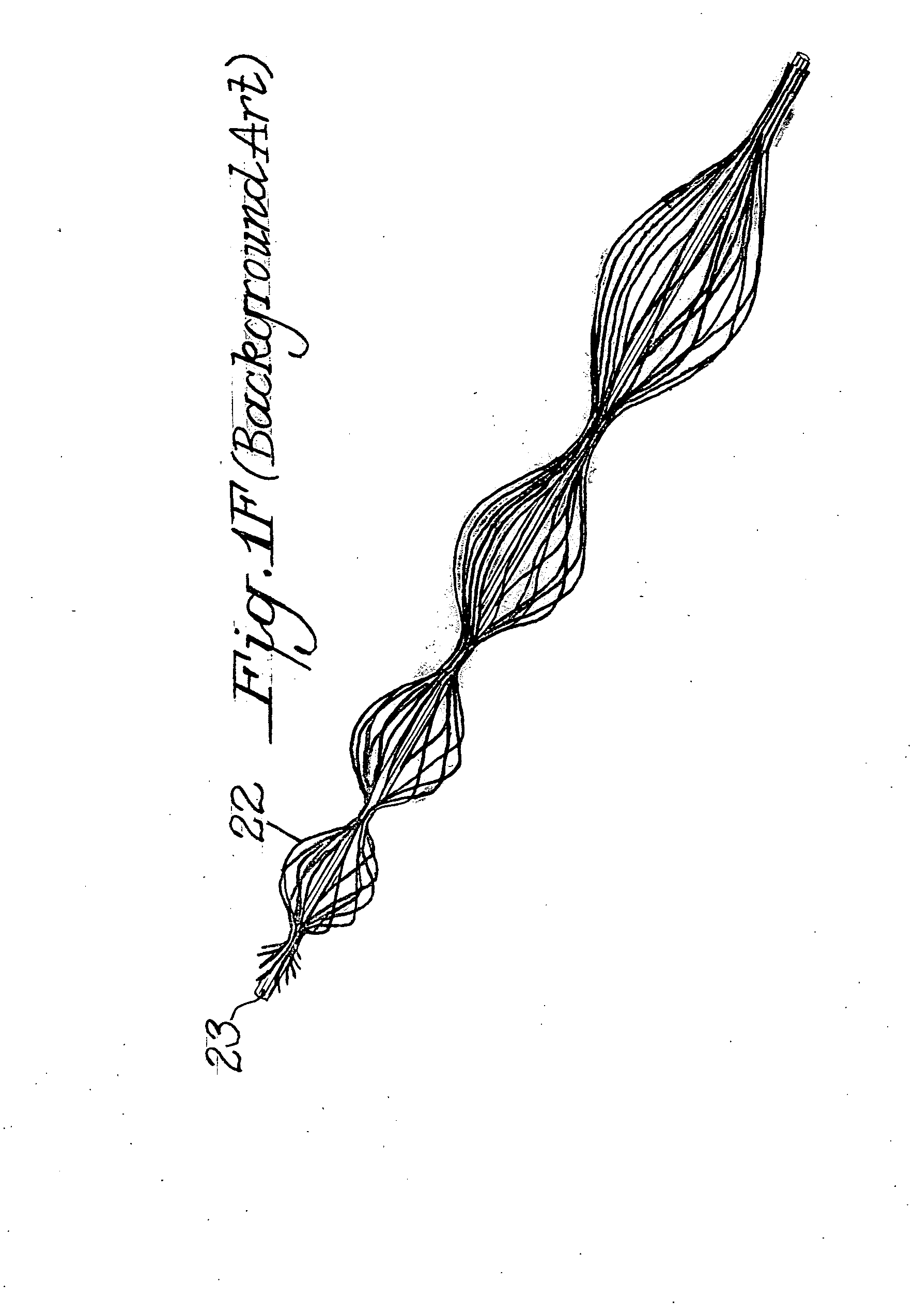

Size-covered composite yarns and method for making same

InactiveUS20050124245A1Appealing tactile propertyIncrease speedWarp knittingSynthetic resin layered productsYarnFiber

Owner:INVISTA NORTH AMERICA R L

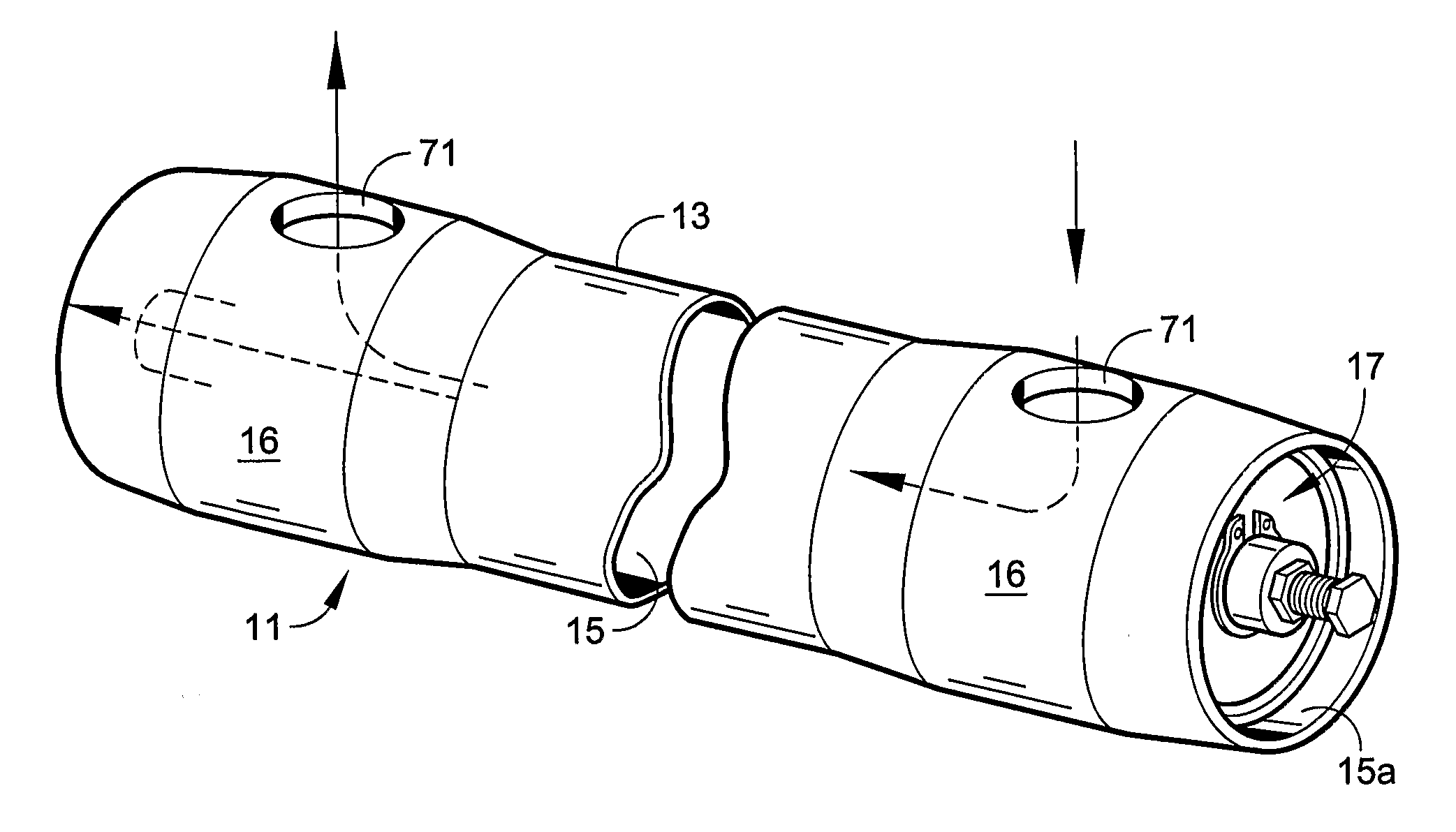

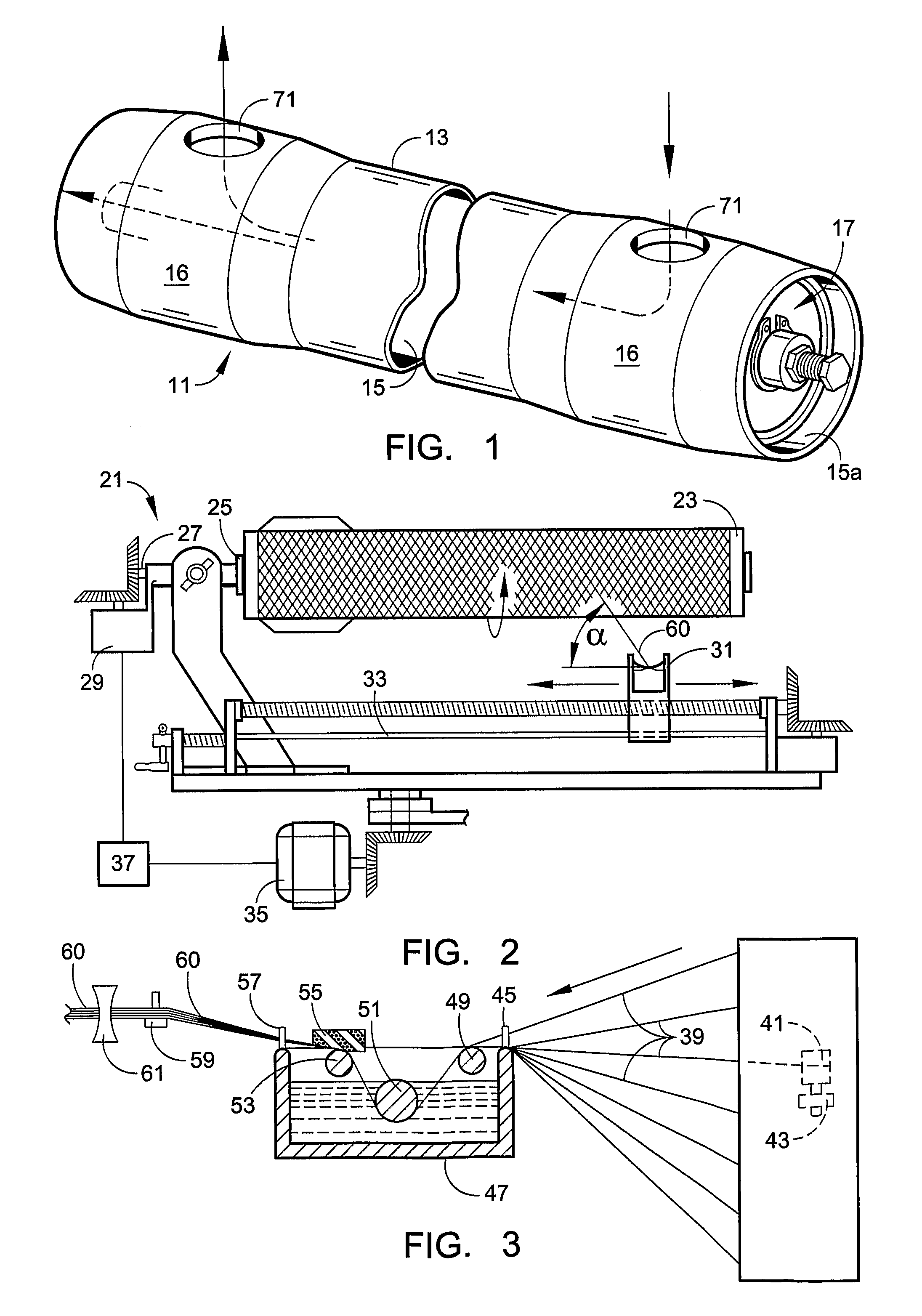

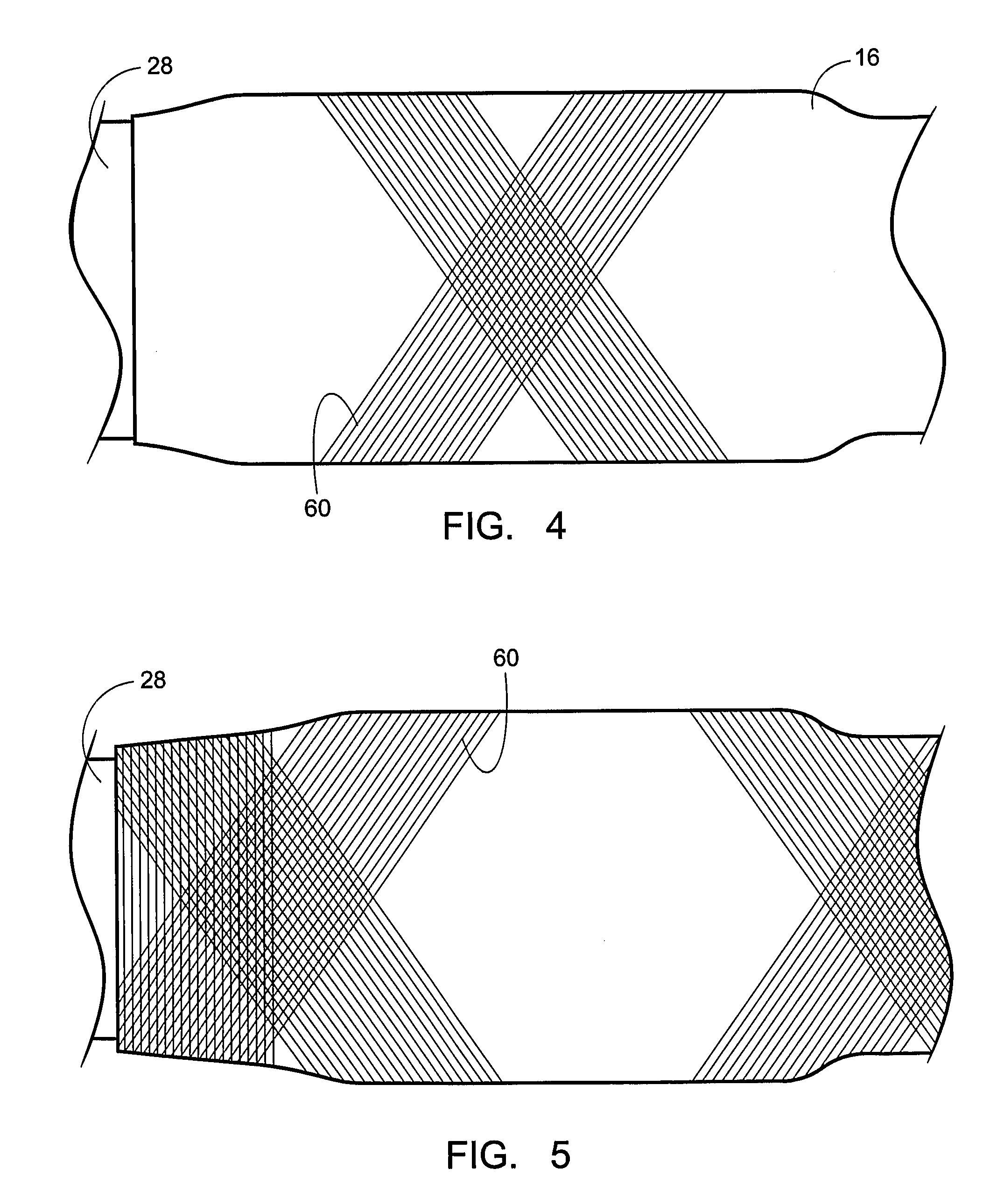

Side-Ported Filament Wound Pressure Vessels

ActiveUS20080093367A1Efficient constructionReduce labor costsVessel mounting detailsVessel manufacturingEngineeringFilament winding

Owner:PROTEC ARISAWA AMERICA

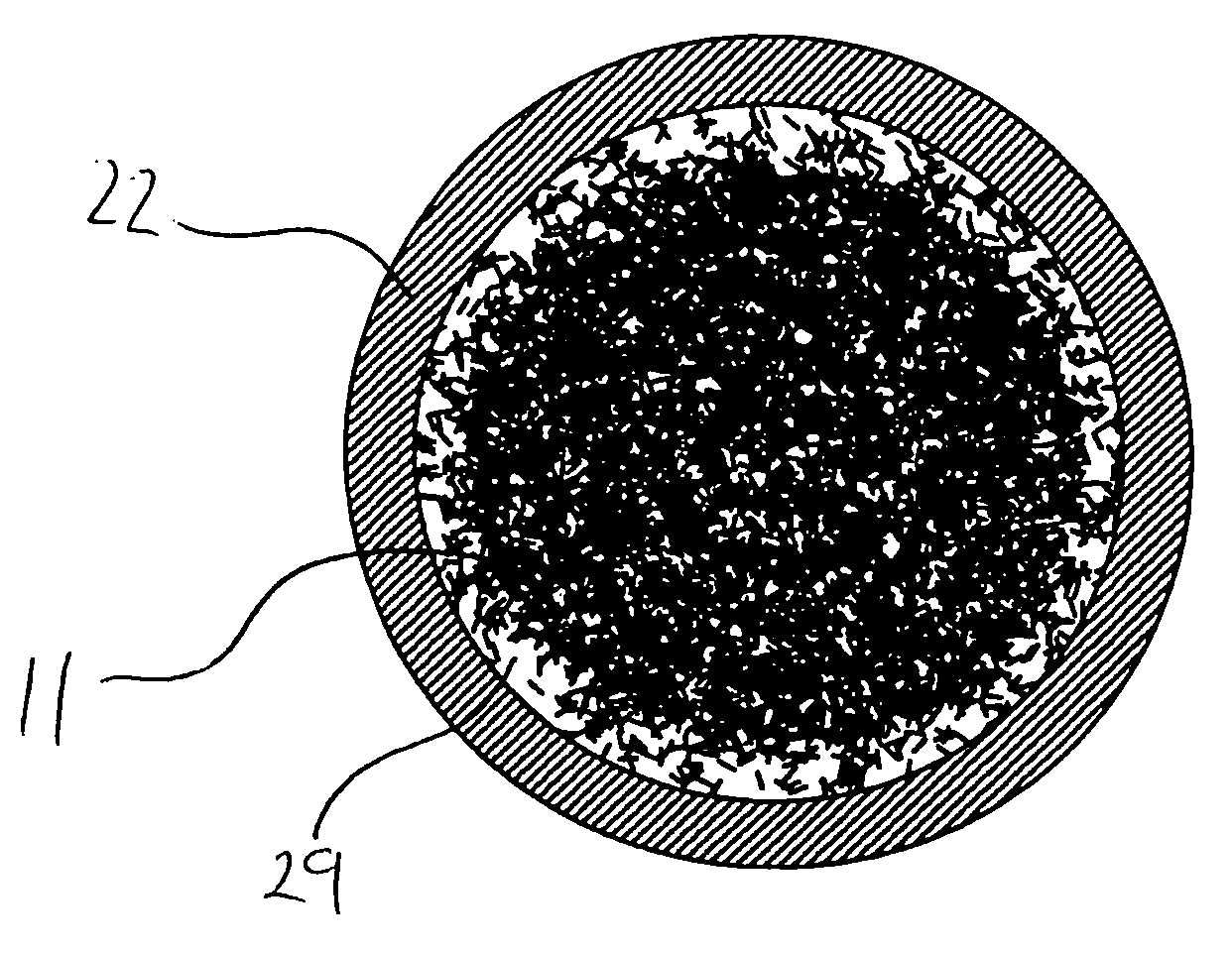

Systems and methods for manufacturing composite materials using thermoplastic polymers

InactiveUS20080254307A1Improve adhesionLamination ancillary operationsLayered product treatmentThermosetting polymerMelting point

Owner:HIGHPLEX

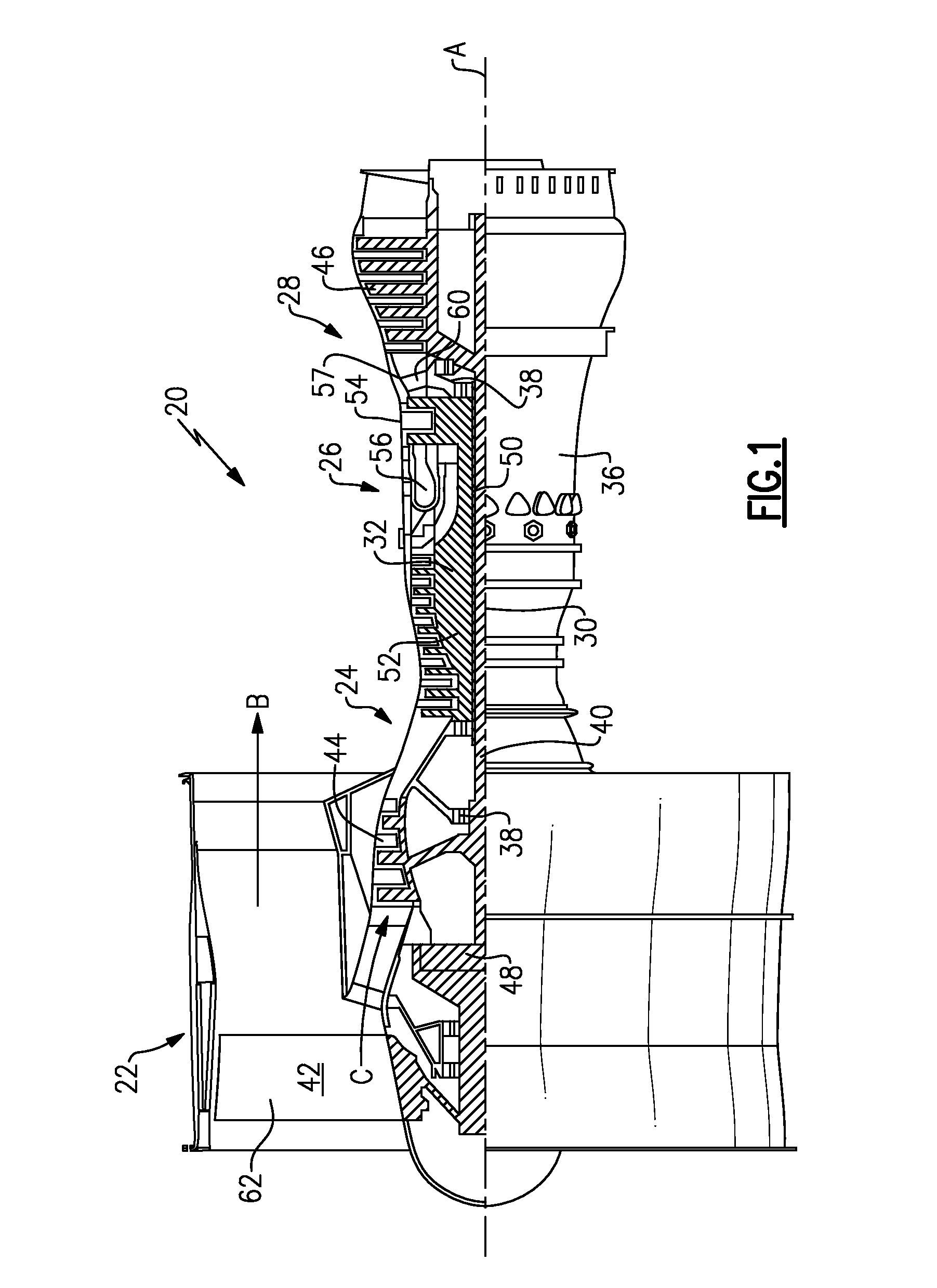

Method of bonding a leading edge sheath to a blade body of a fan blade

Owner:RAYTHEON TECH CORP

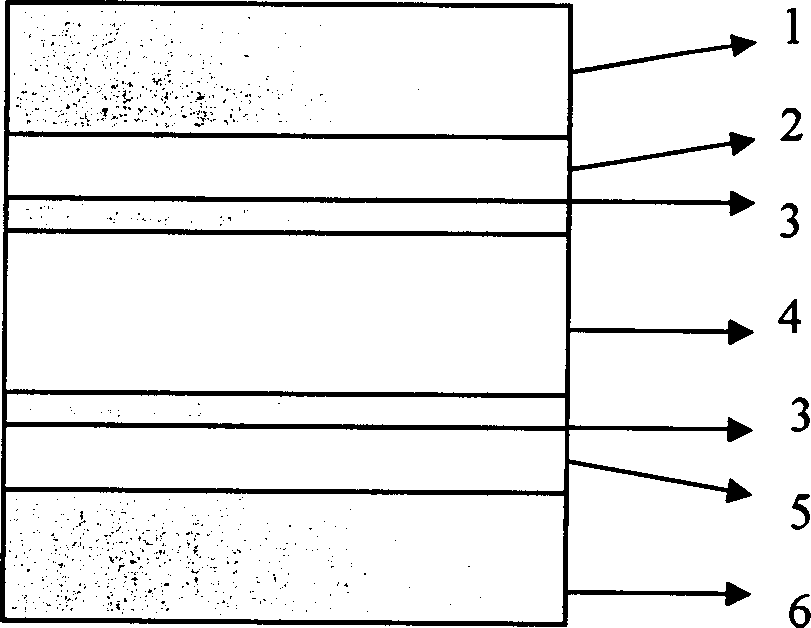

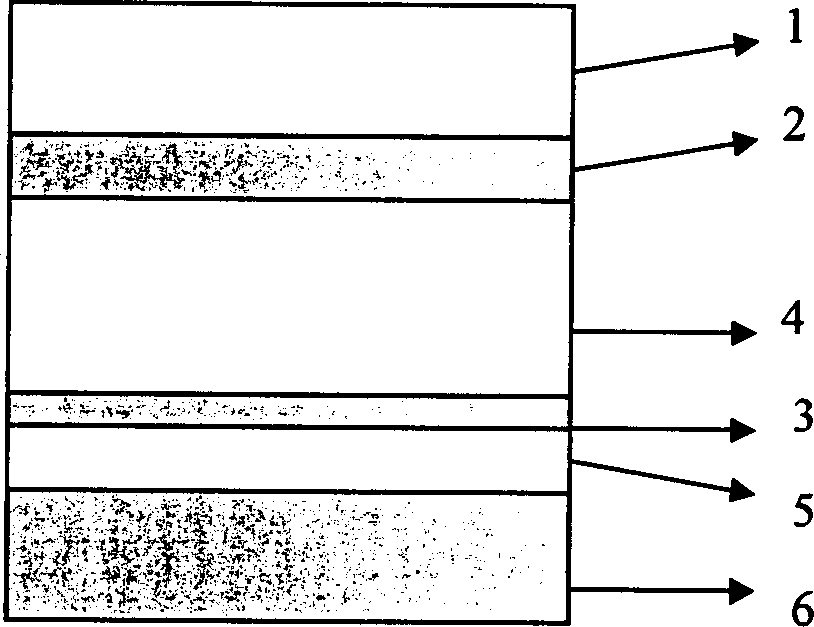

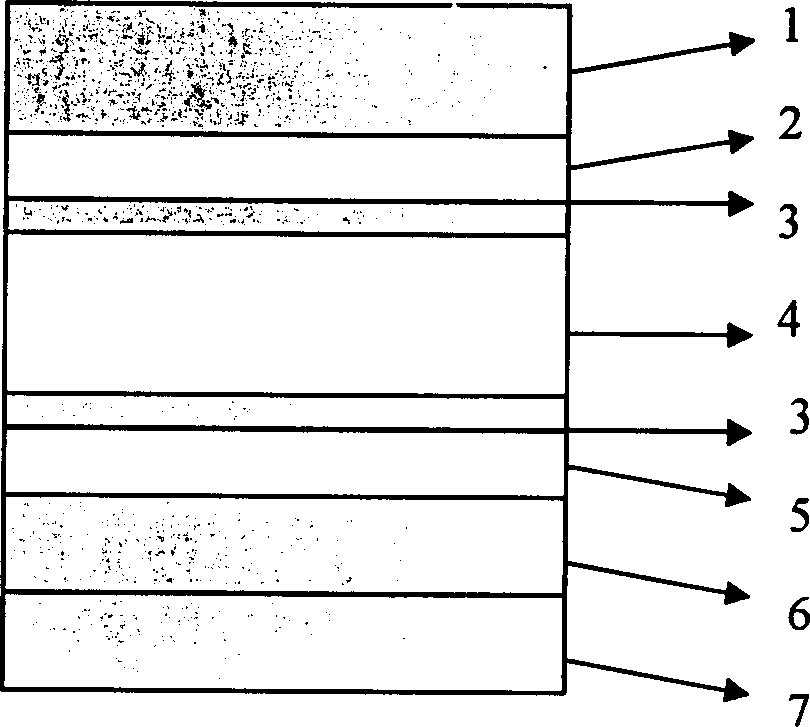

HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and preparation method of HDPE membrane

ActiveCN104401076AHigh mechanical strengthImprove performanceSynthetic resin layered productsLaminationLow-density polyethyleneFoaming agent

The invention discloses an HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and a preparation method of the membrane. The HDPE membrane composited by the high foaming of the LDPE comprises the HDPE membrane, wherein a sheet layer formed by the high foaming of the LDPE is arranged on the surface of the HDPE membrane, and a PE(Poly Ethylene) bonding layer is arranged between the HDPE membrane and the sheet layer; the sheet layer consists of the following components in percentage by weight: 95% of the LDPE, 3.5% of a nucleating agent, 1.39% of a foaming agent, 0.1% of an antisbrinking agent and 0.01% of an auxiliary addition agent. Compared with the prior art, the HDPE membrane composited by the high foaming of the LDPE is a novel environmental-friendly packaging material with high buffering capacity and shock resistant capacity, the membrane has the advantages that the flexibleness and the buffering capacity are good, the heat conductivity is low, the heat-shielding performance is excellent, the membrane does not pollute the environment, and the membrane belongs to the materials capable of being recycled.

Owner:SUZHOU JIUDING

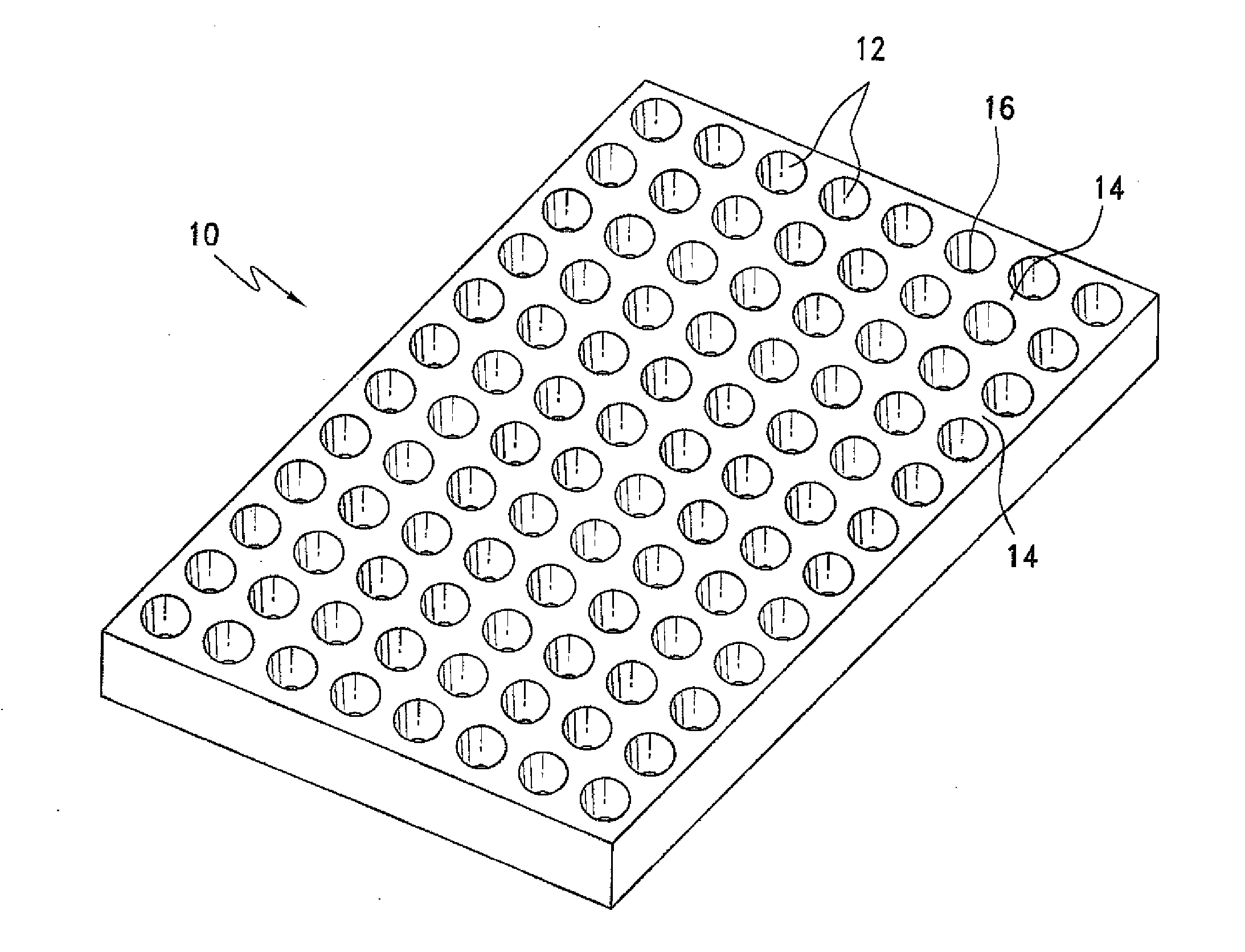

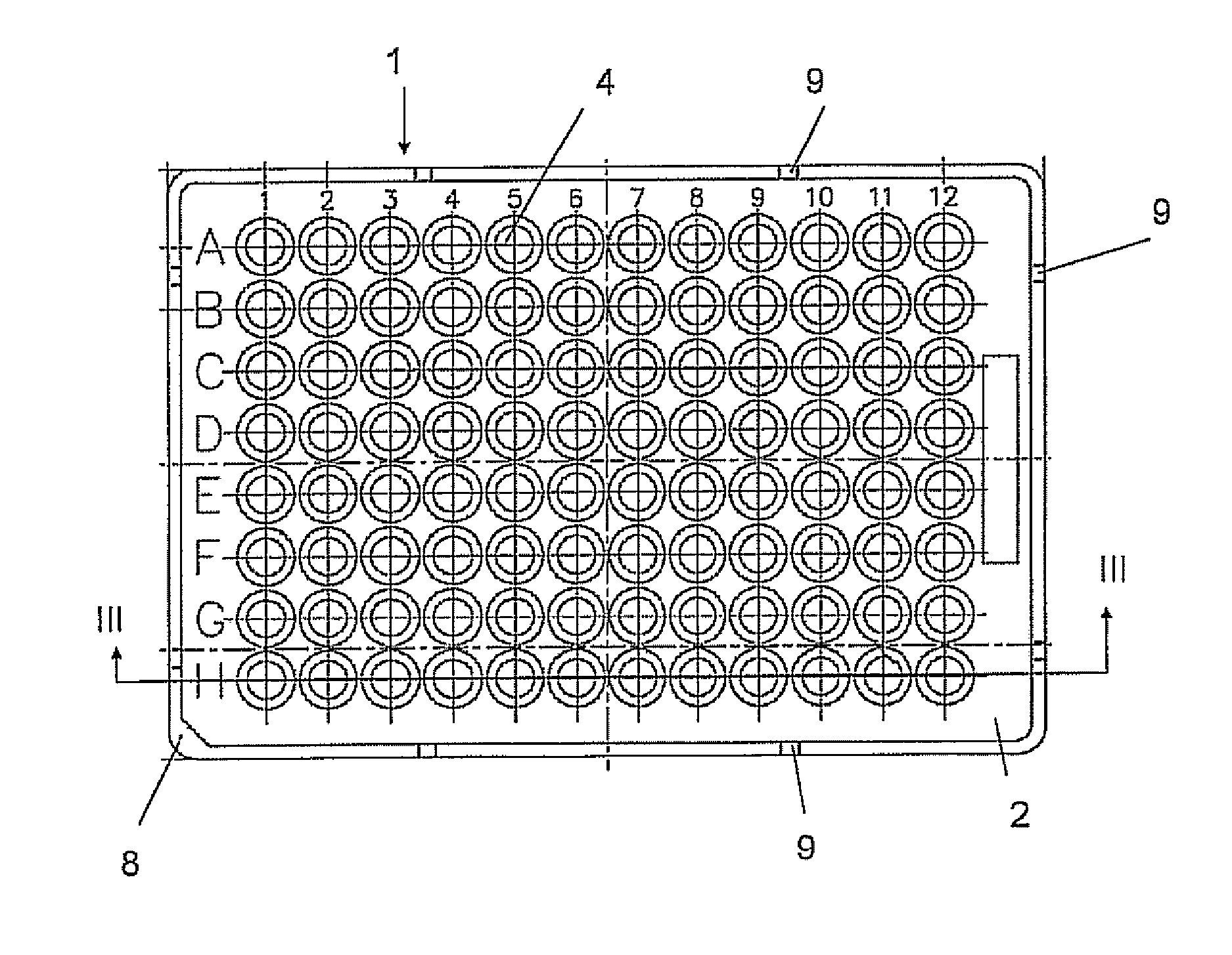

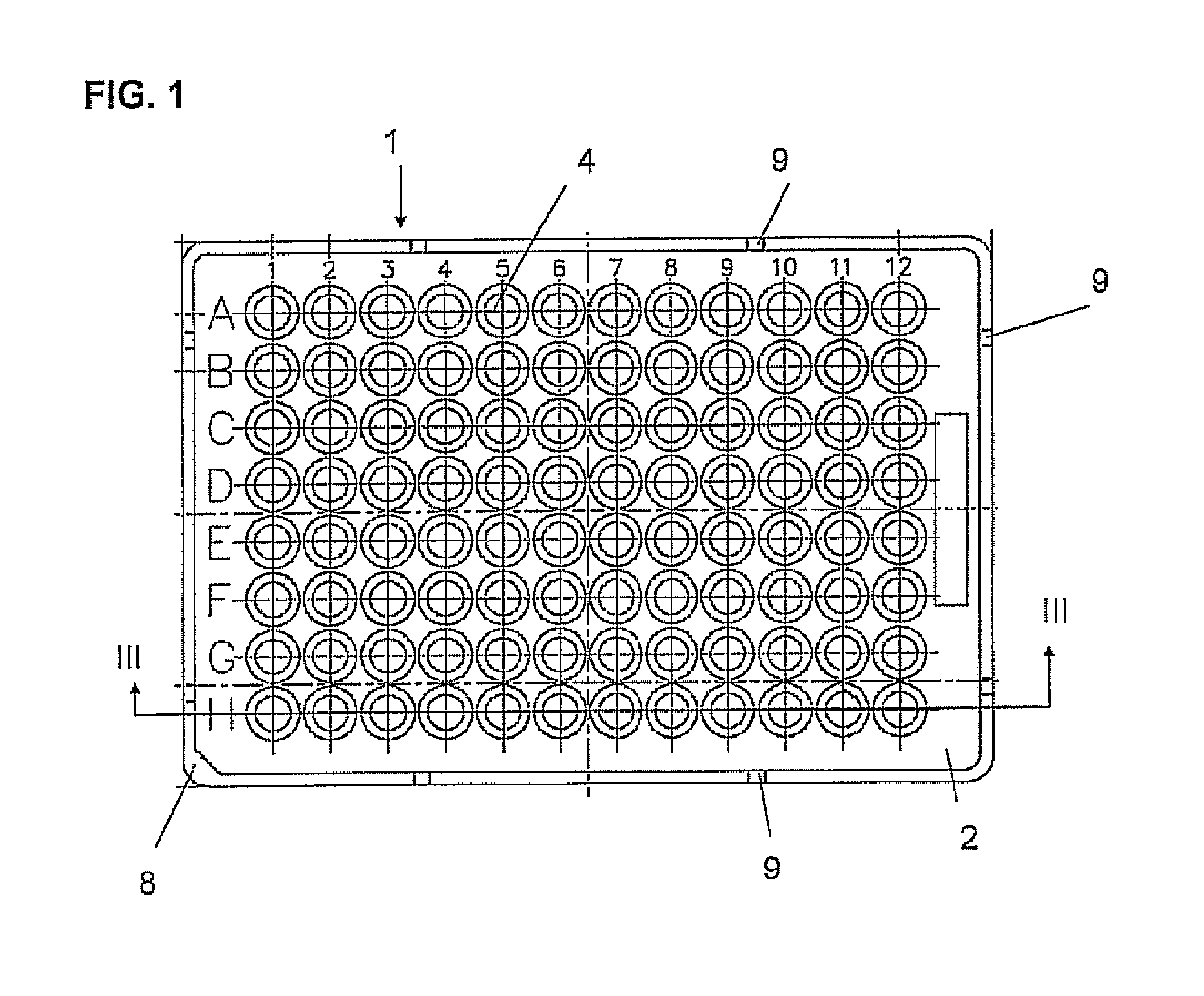

Sealing multiwell plates

InactiveUS20120058516A1Avoid pollutionLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:4TITUDE

Method of production of veneer assembly

InactiveUS20030221776A1LaminationAdhesive processes with adhesive heatingNuclear engineeringHeat press

Owner:ADHESIVES RES

Automatic tube-type specimen container supply apparatus

An automatic tube-type specimen container supply apparatus includes a container storing box a bottom of which has a tapered surface having a container collecting position in a lowest part thereof to collect a plurality of tube-type specimen containers in one spot, a container individually-sending mechanism which lifts up the collected specimen containers one by one along one-side wall located close to the position, an outlet which allows the specimen containers to be discharged outside the box, and a container carry-out mechanism including a conveyor to automatically carry out the discharged specimen containers. The container individually-sending mechanism includes a lifting plate driven up and down and having a top end with a tapered surface. The tapered surface has a space to place only one specimen container lying on a side thereof and descending toward an outside of the container storing box.

Owner:IDS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap