Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Sandwich panel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sandwich panel is any structure made of three layers: a low-density core, and a thin skin-layer bonded to each side. Sandwich panels are used in applications where a combination of high structural rigidity and low weight is required.

Sandwich panel with closed edge and methods of fabricating

InactiveUS20090255213A1Great strength to weight ratioLight weightLaminationLamination apparatusEngineeringSandwich panel

The edge of a construction element, such as a sandwich panel having a core and two outer layers, is closed such that forces acting on the construction element are directed to the outer layers and generally not through the panel core. A portion of the core may be removed to define a cavity within the construction element. A bonding material closes the edge by filling the cavity and forming a new edge that is substantially coplanar to the edges of the outer layers. The edge also can be closed by inserting the edge into a U-profile bracket and connecting the outer layers of the panel to side walls of the U-profile bracket.

Owner:MILLPORT ASSOC

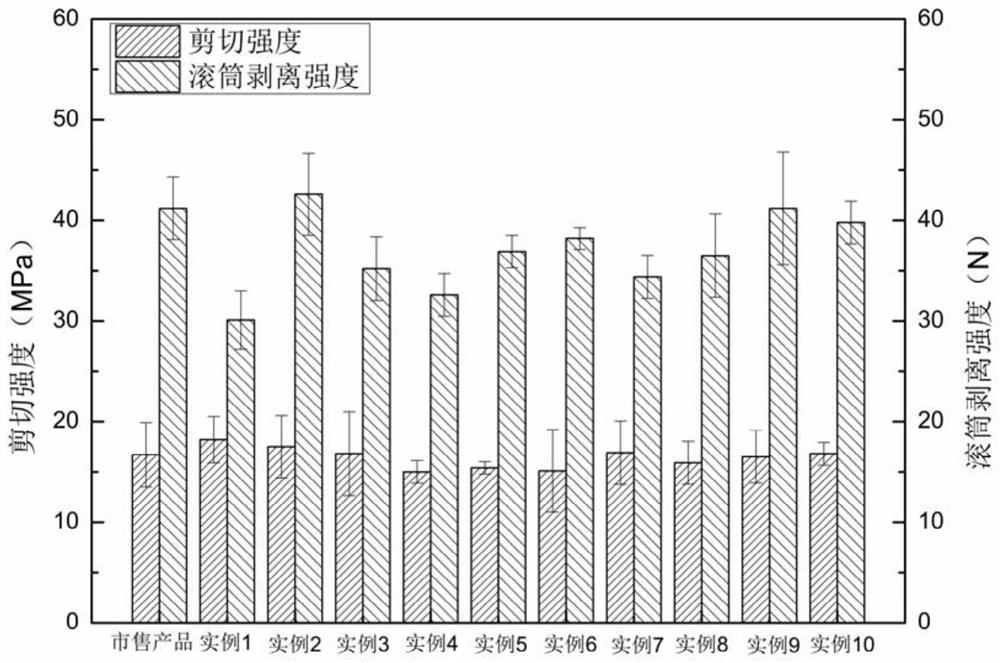

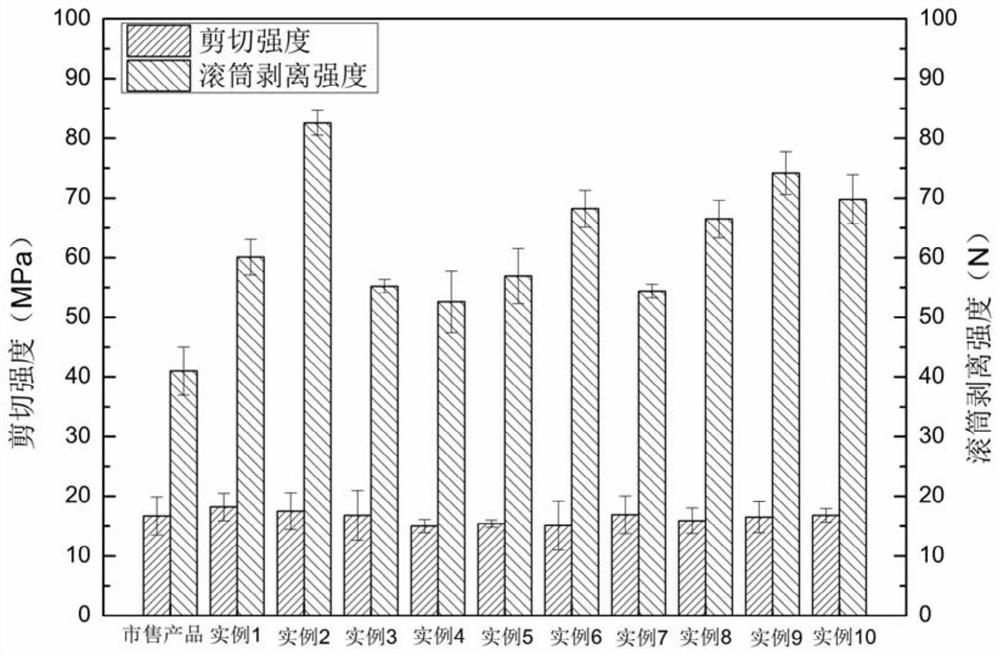

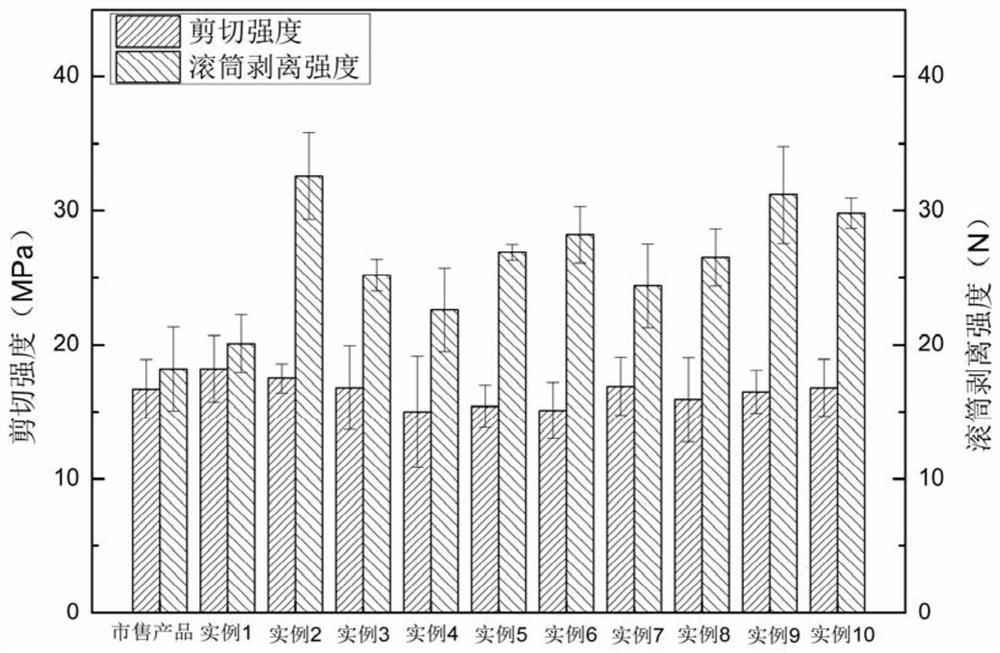

Lightweight high-toughness military shelter structural adhesive and preparation method thereof

InactiveCN111876118AHigh tensile strengthHigh impact strengthMacromolecular adhesive additivesEpoxy resin adhesivesFiberCarbon fibers

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Movable-type observatory meteorology observation container

InactiveCN105467470AReasonable structureEasy to moveWeather condition predictionObservatoryThermal insulation

Owner:SUZHOU FANRONG SPECIAL CONTAINER

Preparation method of negative thermal expansion metamaterial sandwich panel based on topological optimization design

PendingCN114091124AMultiple Design FreedomGeometric CADDesign optimisation/simulationThermal dilatationElement model

The invention discloses a preparation method of a negative thermal expansion metamaterial sandwich panel based on topological optimization design. The preparation method comprises the following steps: (1) establishing an overall structure model of the negative thermal expansion metamaterial sandwich panel; (2) establishing a metamaterial-based structure finite element model for filling the sandwich panel; (3) inputting basic material parameters, constraint values and a finite element model of the metamaterial-based structure; (4) calculating values of an equivalent thermal expansion coefficient and an equivalent elastic modulus of the metamaterial and corresponding partial derivatives; (5) establishing an explicit optimization model, and solving through linear programming; (6) judging whether the equivalent thermal expansion coefficient convergence precision is met or not, and if the equivalent thermal expansion coefficient convergence precision is not met, returning to the fourth step; and if the equivalent thermal expansion coefficient convergence precision is met, inverting the optimal continuous topological variable until the equivalent elastic modulus requirement is met, to obtain an optimal topological structure; and (7) modeling the filled metamaterial, and filling the negative thermal expansion metamaterial in a periodic array between clamping plates to form the negative thermal expansion sandwich plate. The method has more design freedom degrees and better performance.

Owner:BEIJING UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap