Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Air compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When tank pressure reaches its engineered upper limit, the air compressor shuts off. The compressed air, then, is held in the tank until called into use. The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air compressor must be differentiated from a pump because it works for any gas/air, while pumps work on a liquid.

Air compressor

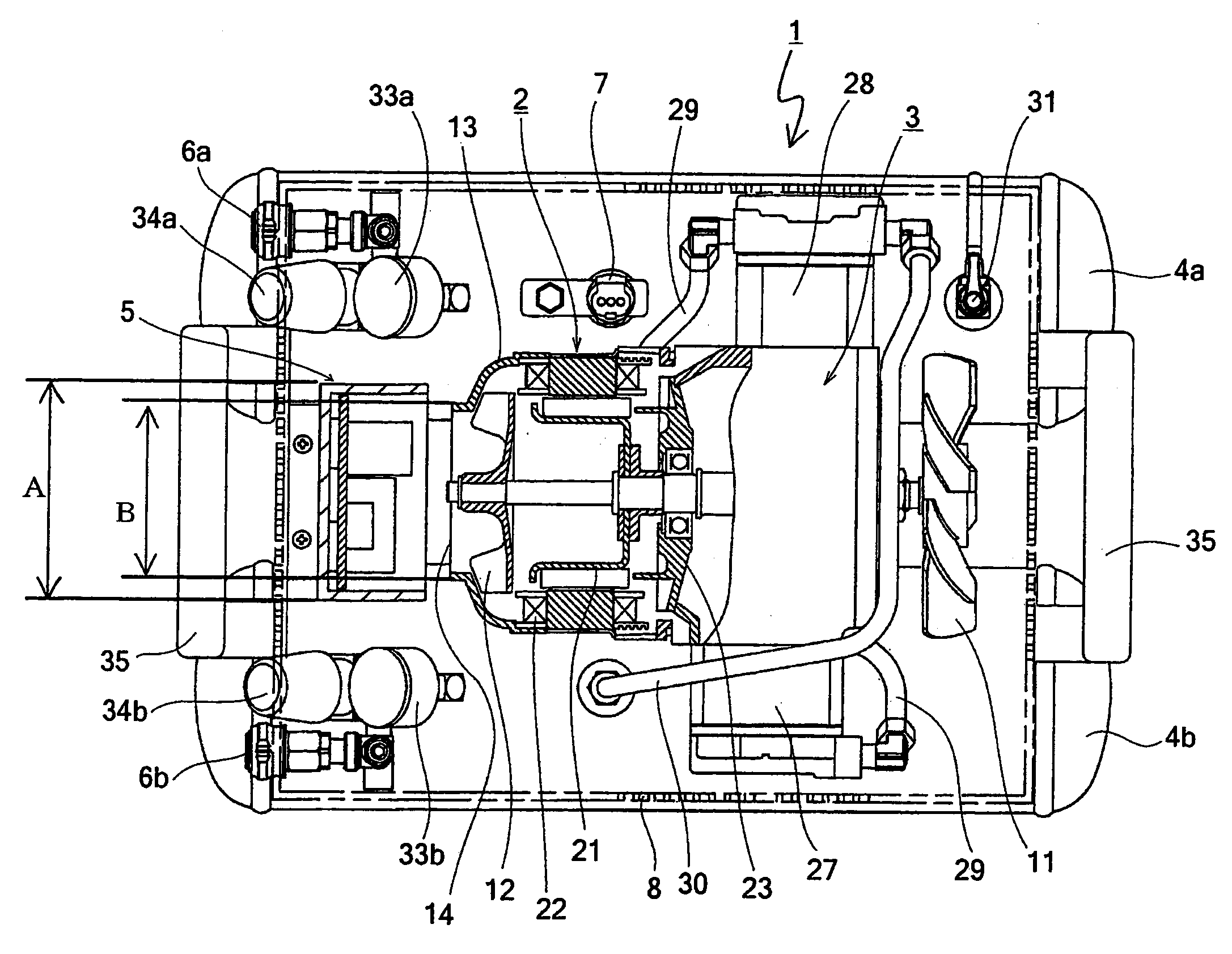

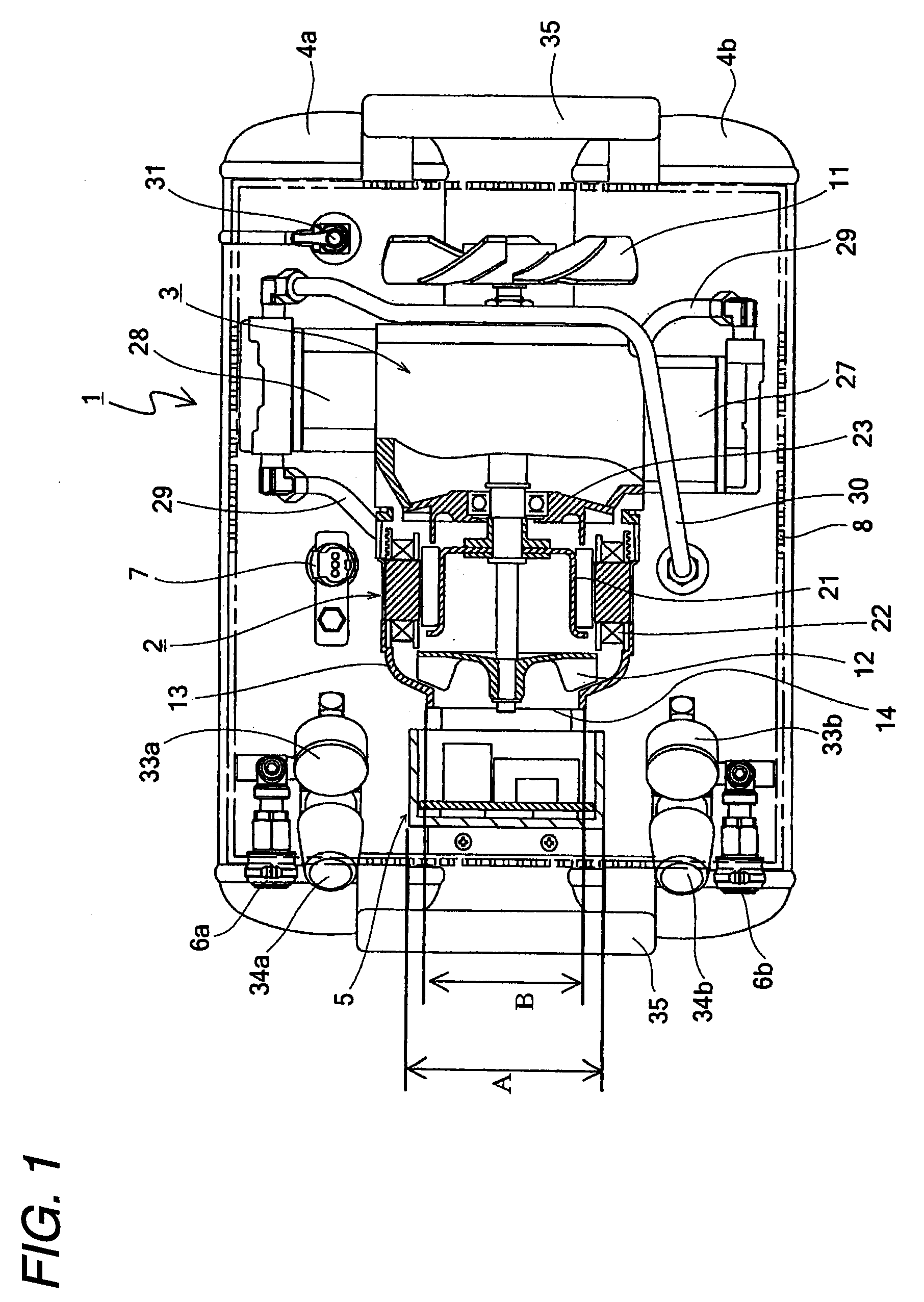

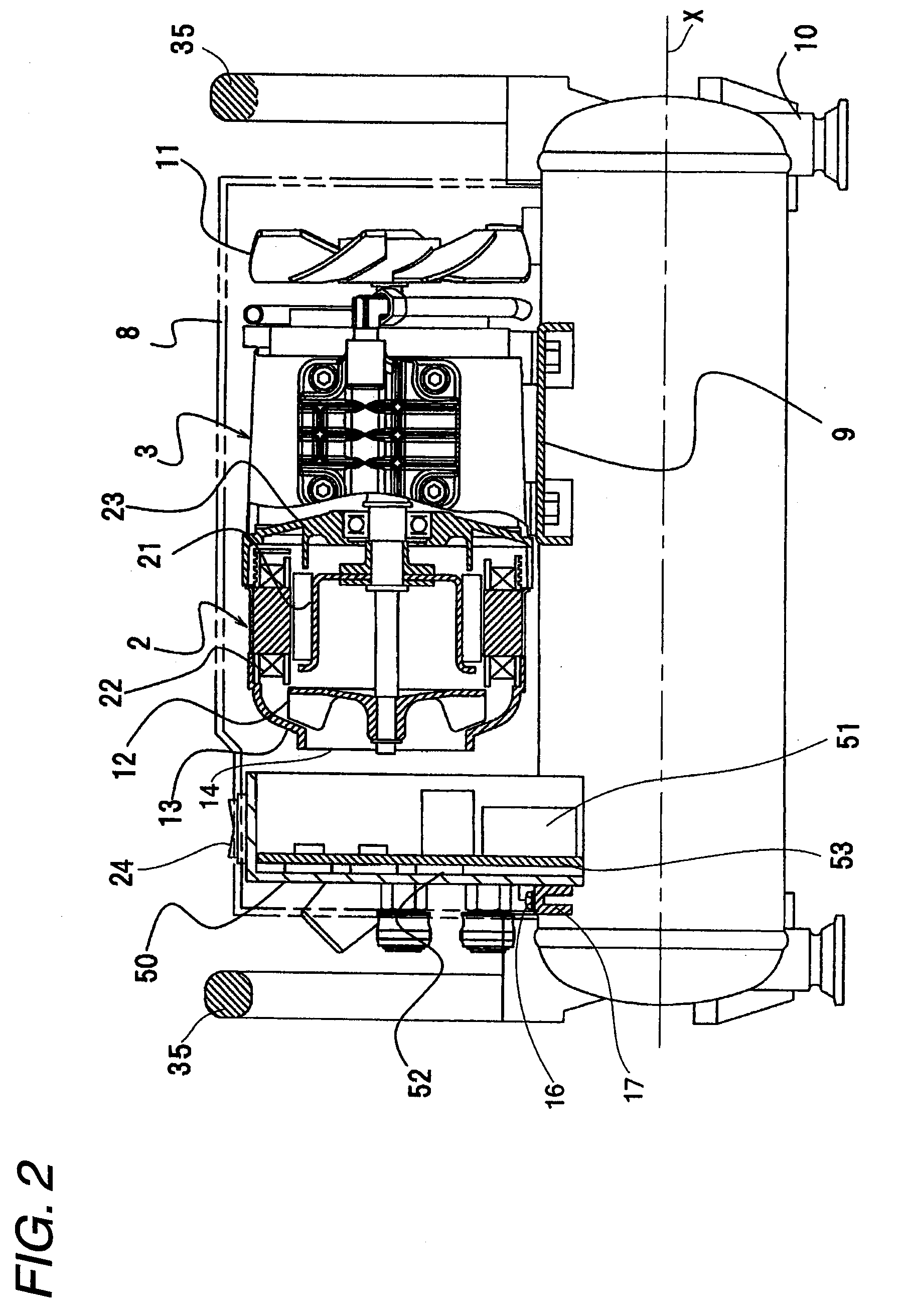

InactiveUS20090194177A1Positive displacement pump componentsCombustion enginesAir compressorControl circuit

Owner:HITACHI KOKI CO LTD

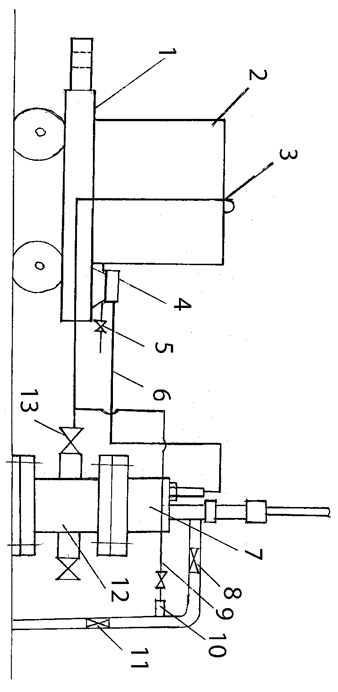

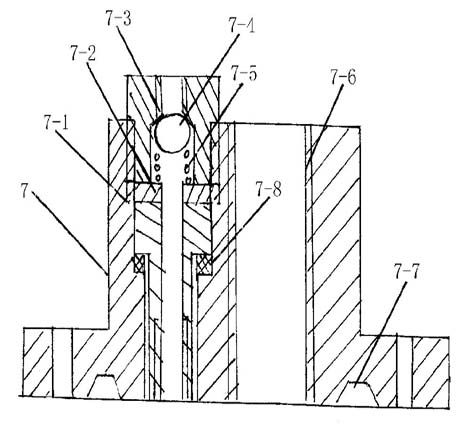

Device for performing surface treatment on pole piece of lithium battery

InactiveCN102151665AQuality improvementReduce the probability of short circuitCell electrodesCleaning using toolsPole pieceEngineering

The invention discloses a device for performing surface treatment on a pole piece of a lithium battery. In one piece-brushing process, the front side and the reverse side of the pole piece can be treated simultaneously, so that the treatment efficiency can be improved and the treatment quality can be guaranteed. The device comprises a machine frame, a workbench, an upper sponge, a lower sponge, a negative pressure device and an upper sponge driving cylinder; the lower sponge is fixed on the workbench; the upper sponge driving cylinder is arranged on the machine frame; a piston rod of the upper sponge driving cylinder faces downward; the bottom of the piston rod is fixedly connected with the upper sponge; the upper sponge is positioned above the lower sponge; the negative pressure device comprises an air compressor and a suction pipe; the suction pipe is inserted upward from the bottom of the workbench; and the pipe orifice of the suction pipe is positioned in the lower sponge. The process for brushing the piece is improved, a technology for automatically brushing the two sides of the piece simultaneously is adopted, two sponge plates which are correspondingly arranged up and down are used and when dust adsorbed to the sponge plates is more, the sponge plates can be replaced at any time. The device is high in quality for cleaning the pole piece, and high in yield, and can timely remove the dust and debris and obviously improve the quality of the pole piece, and the battery manufactured by the pole piece is low in short circuit rate.

Owner:JIANGSU YINGTAI ELECTRONICS

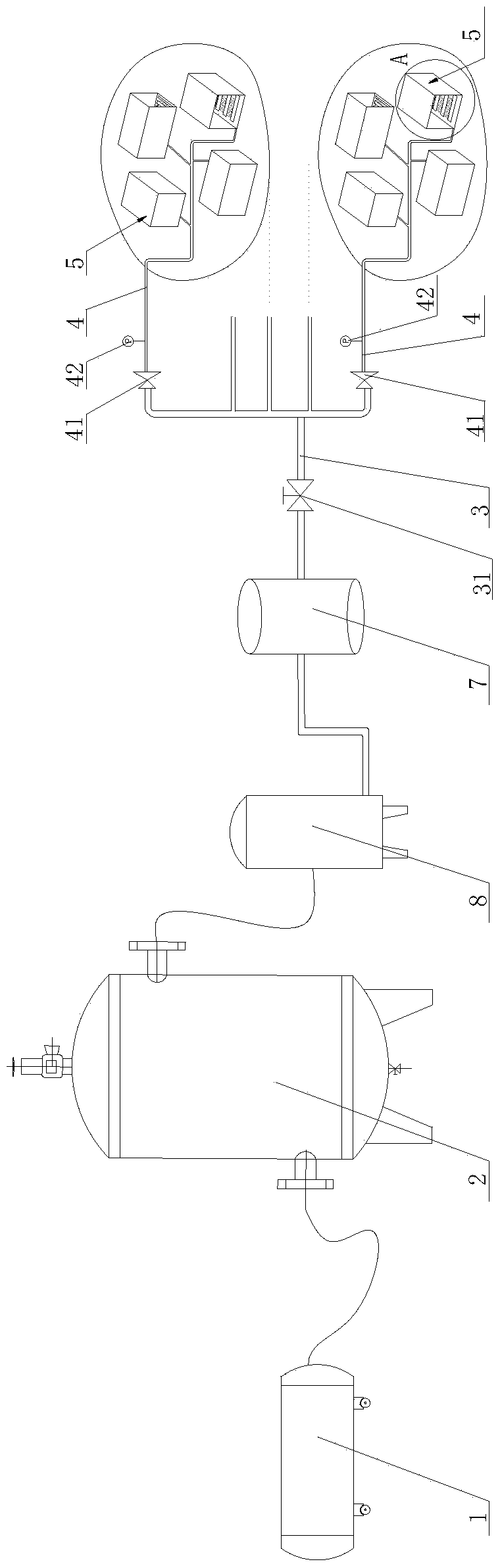

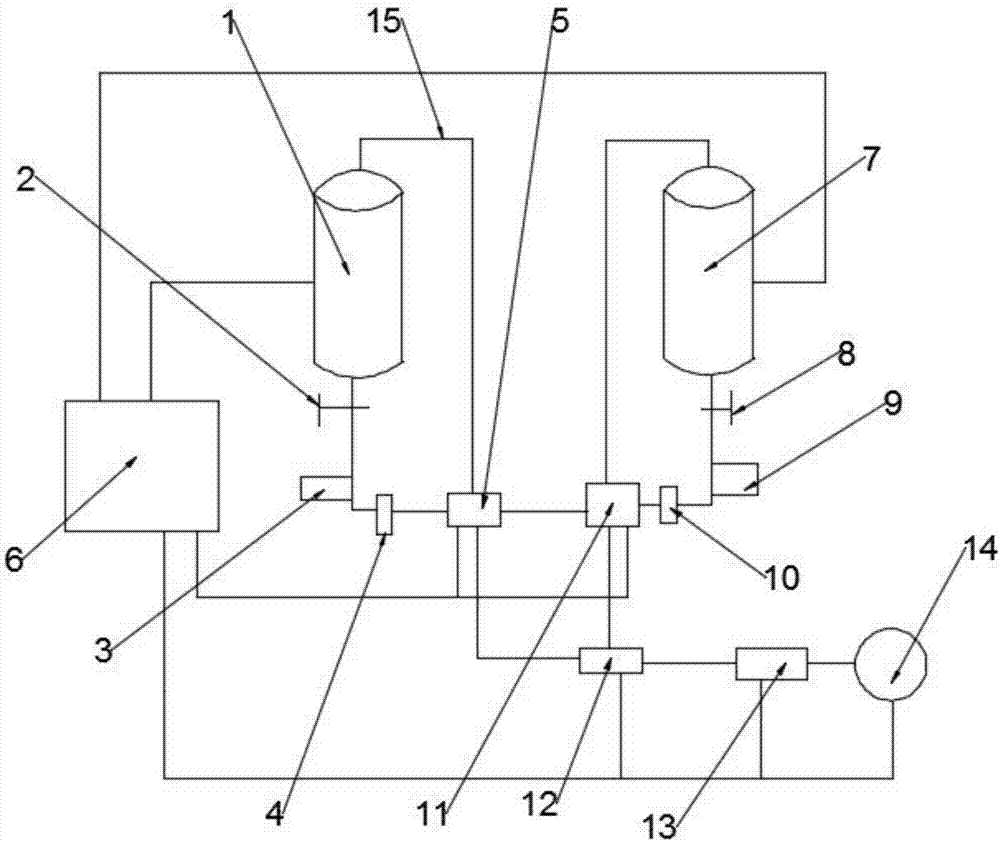

Fuel cell automobile air supply system based on organic Rankine cycle and control method thereof

ActiveCN109980251AIncrease net output powerReduce parasitic lossFuel cell heat exchangeReactant parameters controlAxial compressorPlate heat exchanger

The invention discloses a fuel cell automobile air supply system based on an organic Rankine cycle. The system comprises a boosting circuit and a waste heat utilization circuit, wherein the boosting circuit comprises a fuel cell stack, a turbine, a first compressor, a second compressor, a first intercooler, an air compressor, a heat exchanger and a second intercooler, which are sequentially connected; the waste heat utilization circuit comprises an organic working fluid pump, a heat exchanger and an expander connected in sequence; the first compressor is connected to the outside air, the expander is connected to the second compressor for driving the second compressor to operate; when the waste heat utilization circuit is opened, the waste heat of the air compressor flows into the heat exchanger to heat the organic working medium and drive the expander to compress the second compressor; when the waste heat utilization circuit is closed, the second compressor does not operate, and the boosting circuit is a low-pressure boosting circuit. The invention also provides a control method for a fuel cell automobile air supply system based on an organic Rankine cycle.

Owner:JILIN UNIV

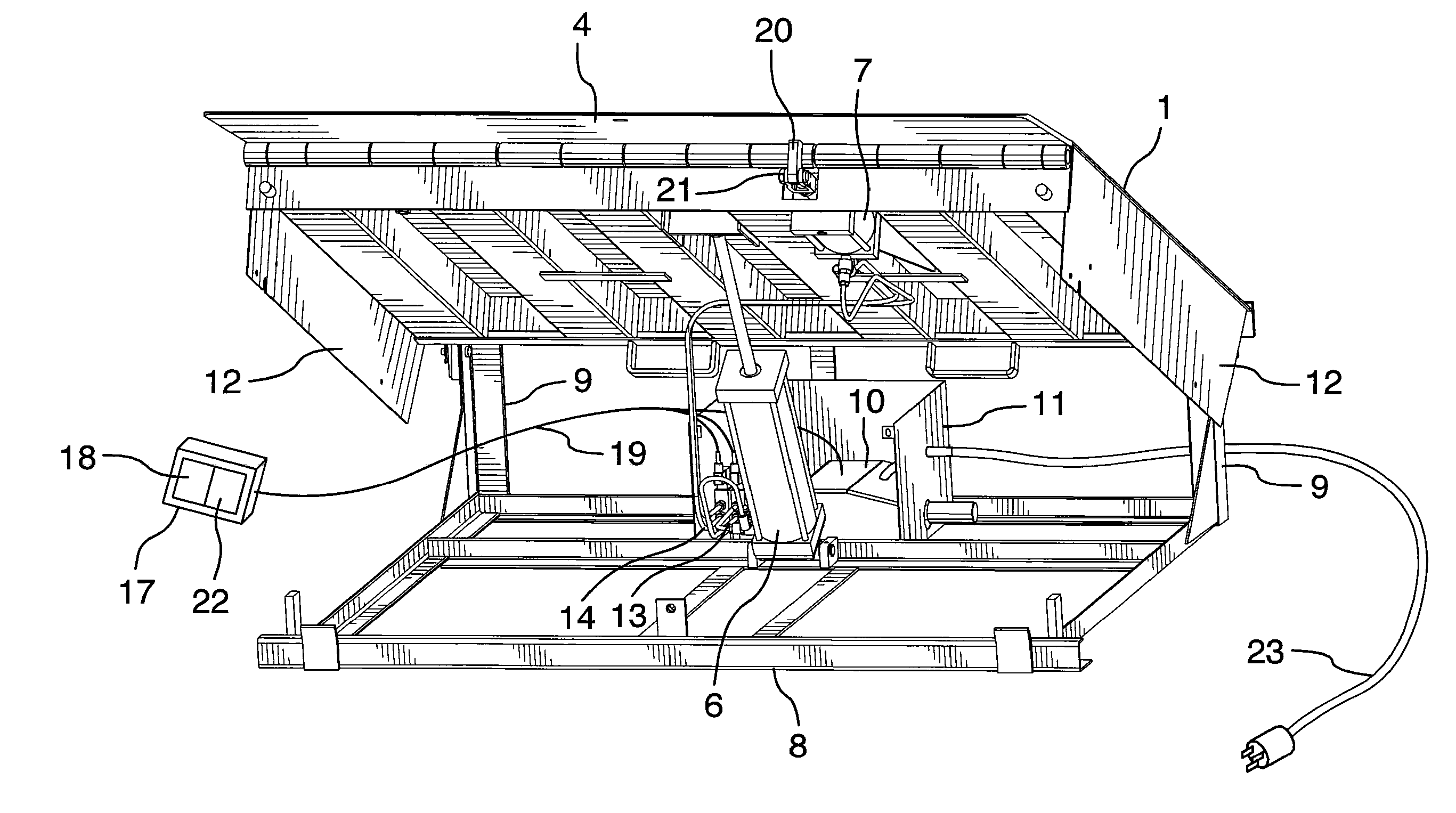

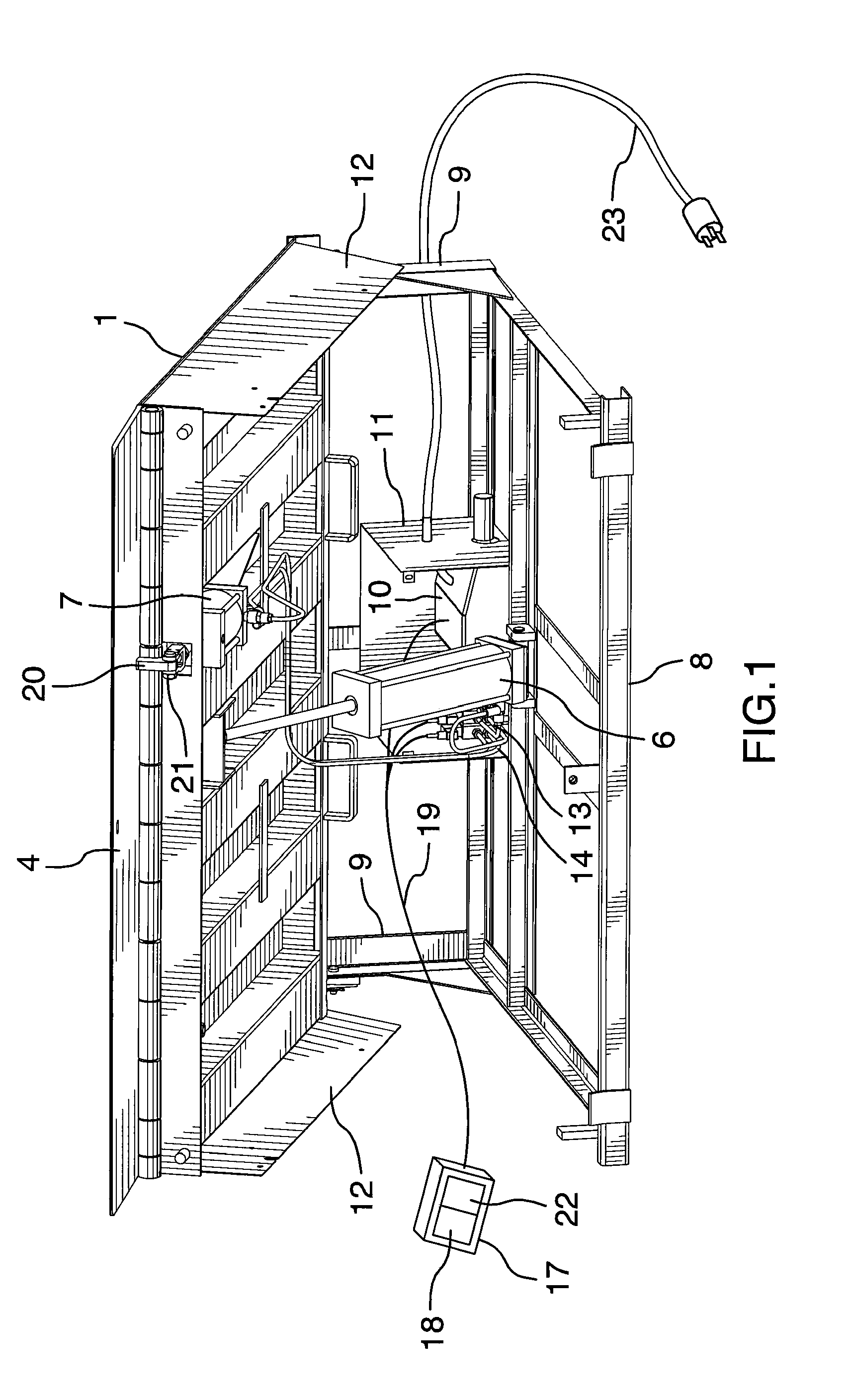

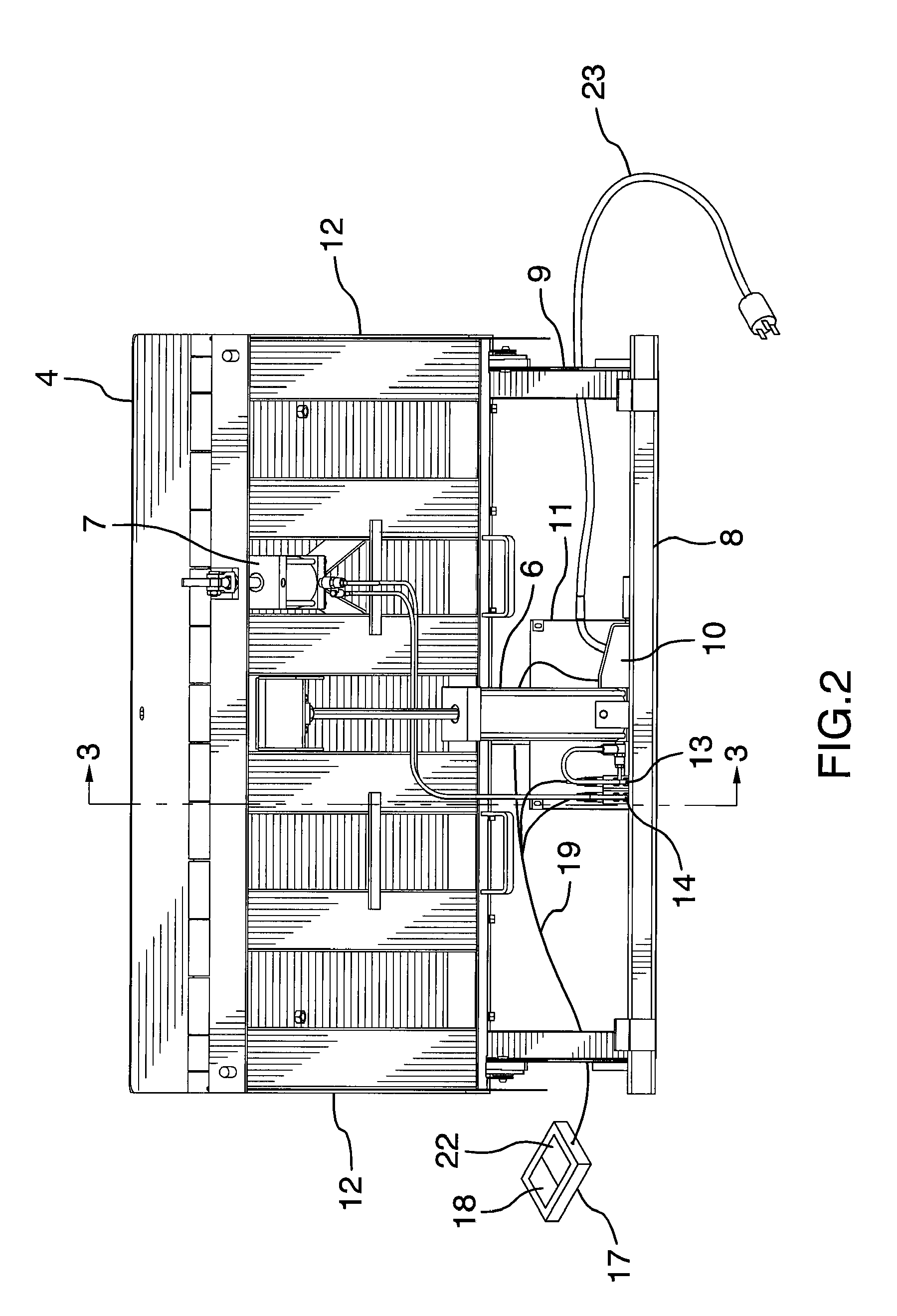

Dock leveler for loading dock with integral on-demand compressor and pneumatic actuator

Owner:BLUE GIANT EQUIPMENT CORPORATION

Movable type wall coating spraying device

InactiveCN107842183AAvoid layeringPrevent precipitationRotary stirring mixersTransportation and packagingAgricultural engineeringMovable type

Owner:蒋丹丹

Aquaculture oxygenation system

InactiveCN104285876AImprove dissolved oxygen efficiencyLow pricePisciculture and aquariaOxygen enhancedEnvironmental engineering

Owner:ZHANGJIAGANG HUASHEN JINZHOU MACHINERY MFG

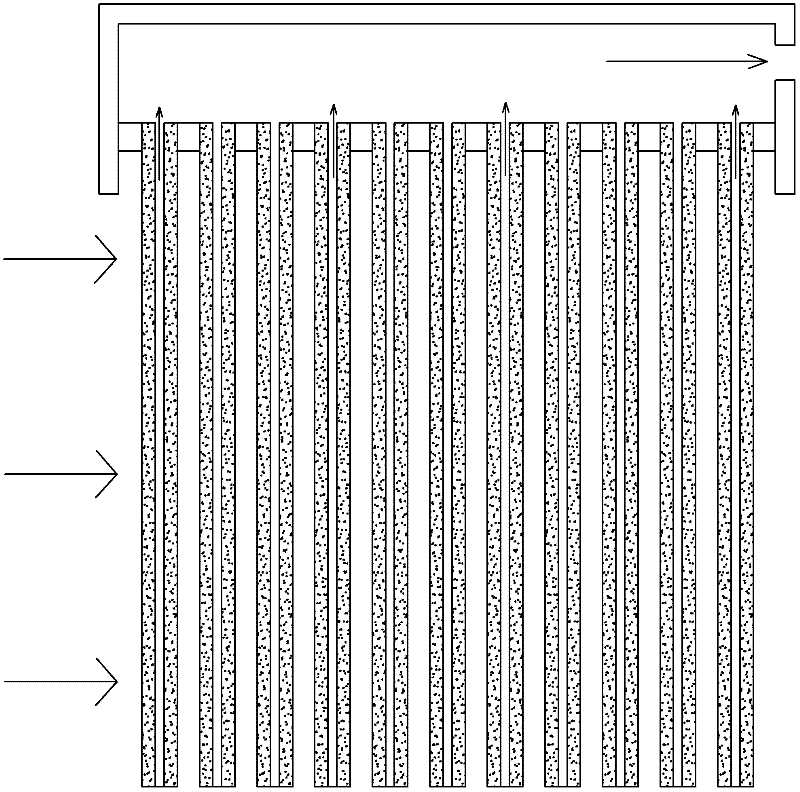

Duct system of sea wind (air) air conditioner by deep sea water cooling

InactiveCN1786597AImprove working environmentImprove the living environmentLighting and heating apparatusAir conditioning systemsOcean bottomEngineering

Owner:孙洪福

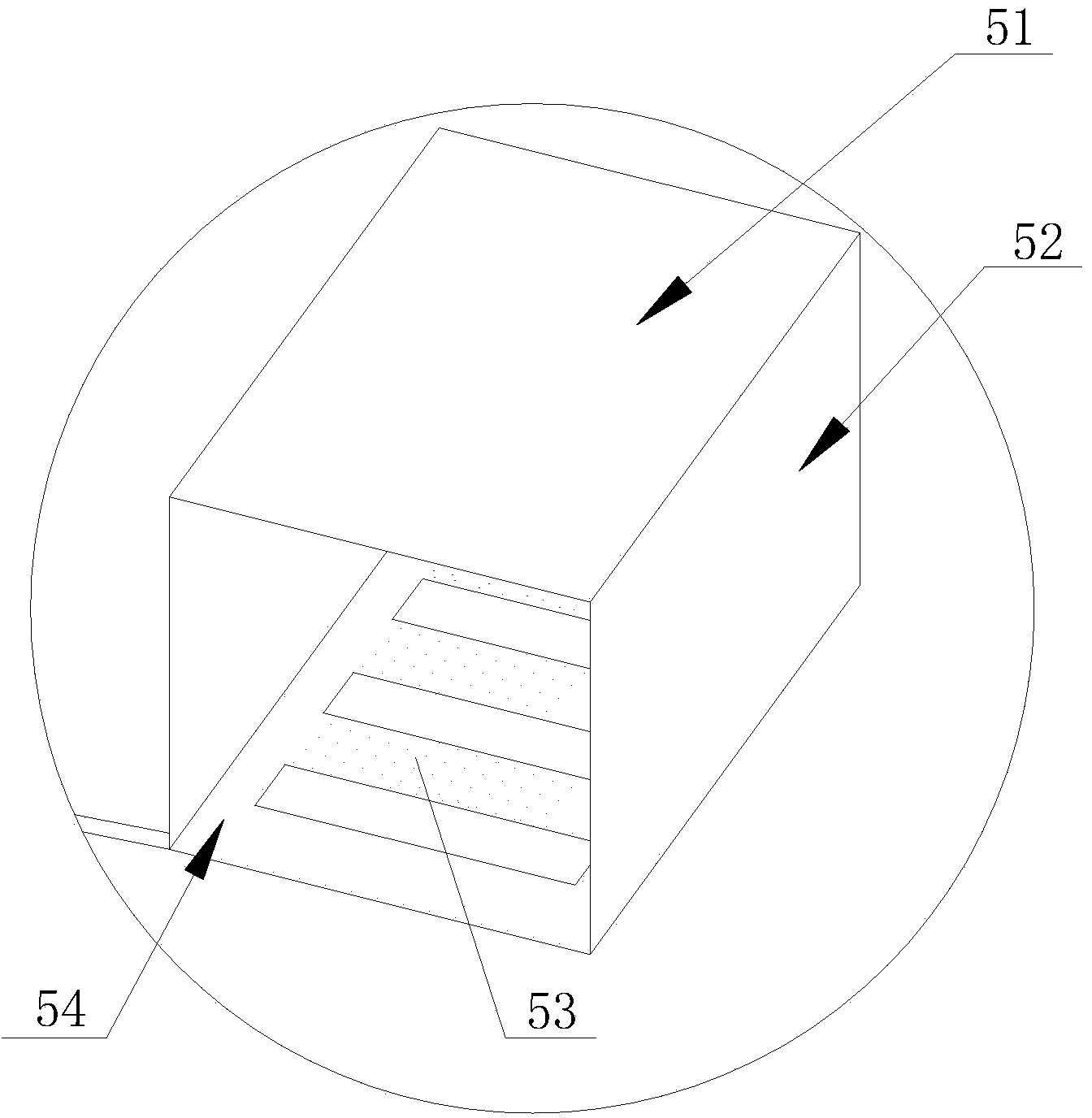

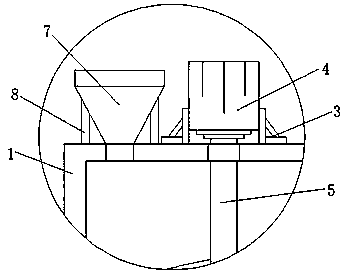

Device for preparing double-shell microcapsules

PendingCN108160014AEasy to manufactureEfficient manufacturingMicroballoon preparationMicrocapsule preparationSolubilityPeristaltic pump

A device for preparing double-shell microcapsules comprises a core material liquid inlet, a wall material liquid inlet, a vibrating system, a concentric nozzle, a collector, a stirrer, a peristaltic pump I, a second layer coating chamber, a rotatable screen, a coating liquid inlet, a peristaltic pump II, an atomizing nozzle, an air compressor, a temperature control system and the like. The deviceis simple; through control over the liquid inlet speeds of the core material liquid inlet and the wall material liquid inlet and the vibrating frequency of the vibrating system, the sizes of microcapsule cores are controlled, so that the microcapsules with uniform sizes are prepared and damage during microcapsule preparation is reduced; through hardening liquid filtration and hot air fluidization,rapid moulding of first-layer microcapsules is achieved; through control over the atomizing pressure and the coating liquid solubility, the shell thickness of second-layer coating is controlled. A preparation technology is simple, the reaction condition is mild, the control is easy, and the repeatability is relatively good; in addition, because of a sealing property of the device, influence of the environment on the microcapsules is greatly reduced, so that the double-shell microcapsules can be effectively prepared and the preparation time is greatly shortened.

Owner:NANCHANG UNIV

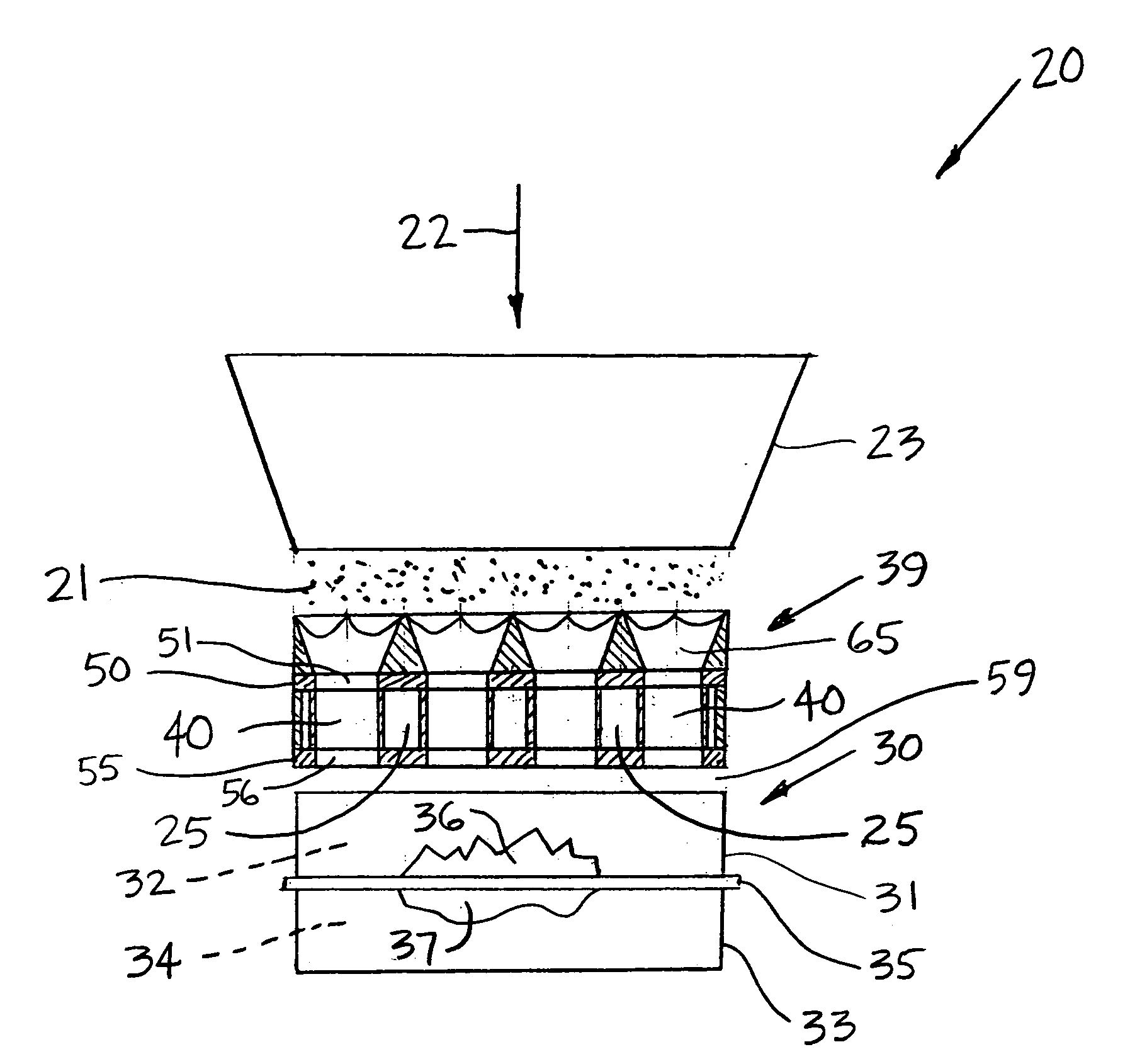

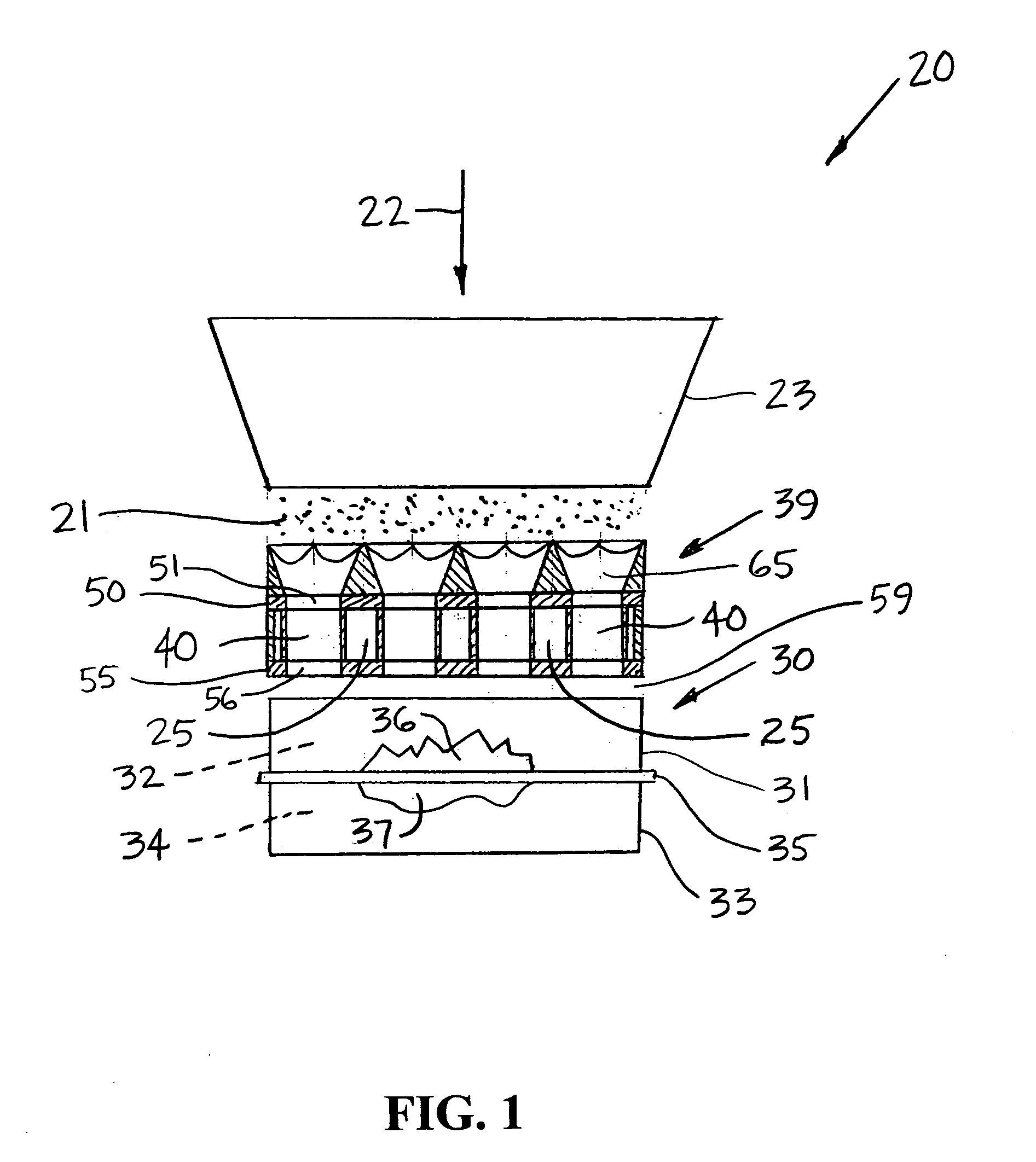

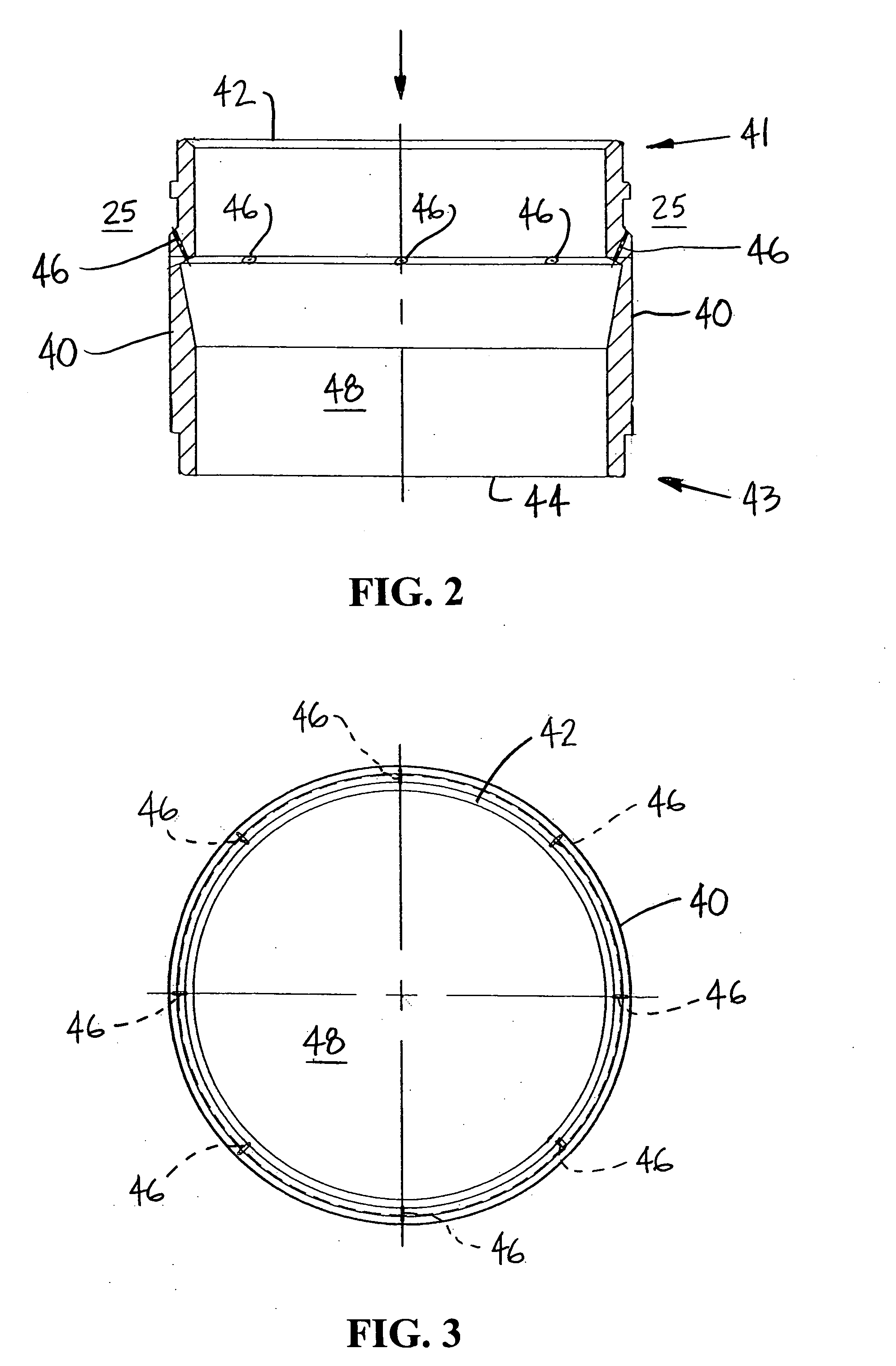

Method and apparatus for transferring sand into flask of molding machine

ActiveUS20080023171A1Reduce eliminateFoundry mouldsMoulding machinesMolding machineAccelerated particle

Owner:HUNTER AUTOMATED MACHINERY

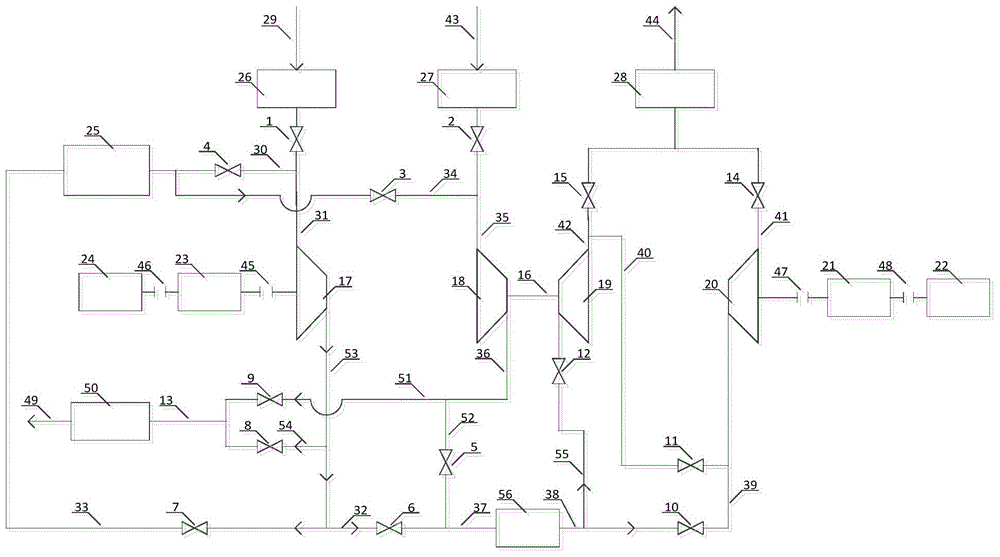

Multifunctional compound supercharging test system

ActiveCN104155114AInternal-combustion engine testingMatching testSingle stage

Owner:HARBIN ENG UNIV

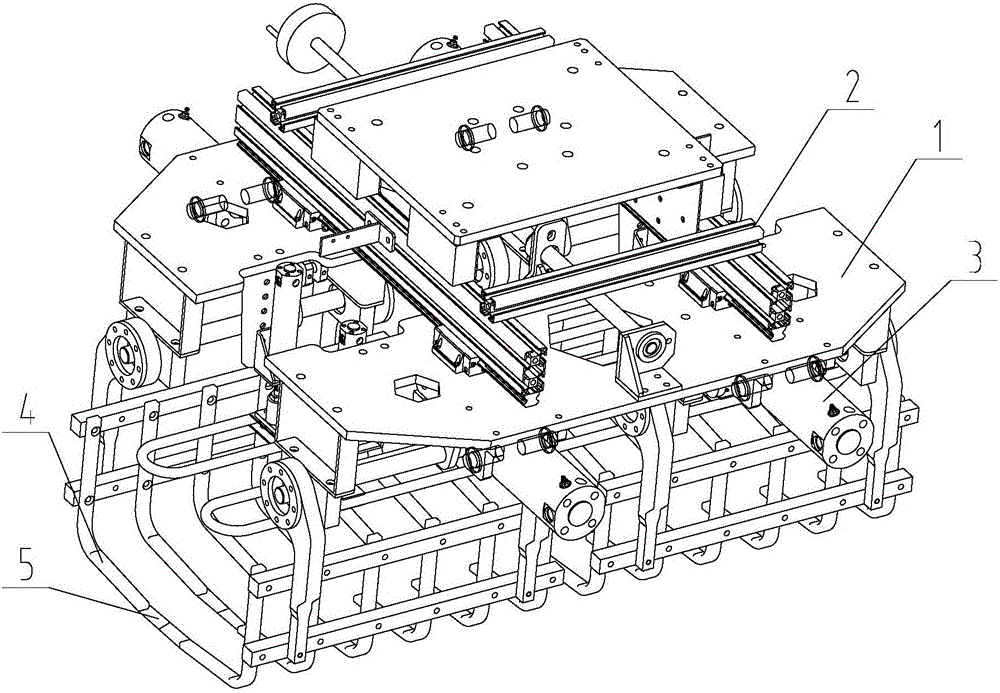

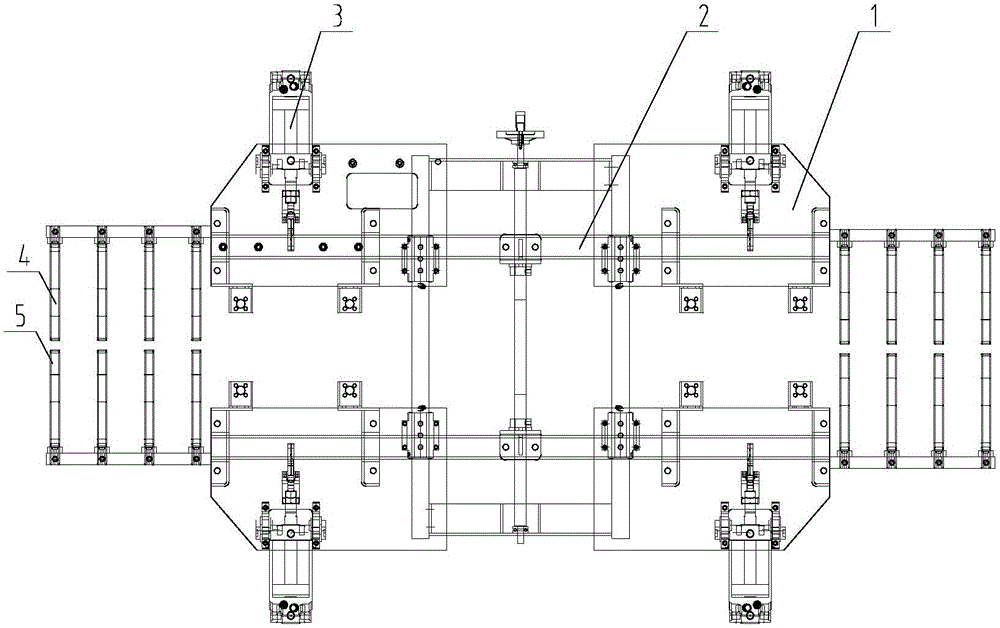

Intelligent robot gripper for stacking system

ActiveCN105084021AFree crawlingAchieve fixationProgramme-controlled manipulatorGripping headsRubber ringGlass fiber

Owner:东莞智动力电子科技有限公司

Vehicular air purifier

InactiveCN102555734AEfficient separationReduce noiseHuman health protectionAir-treating devicesFiberAir purifiers

Owner:曾国明

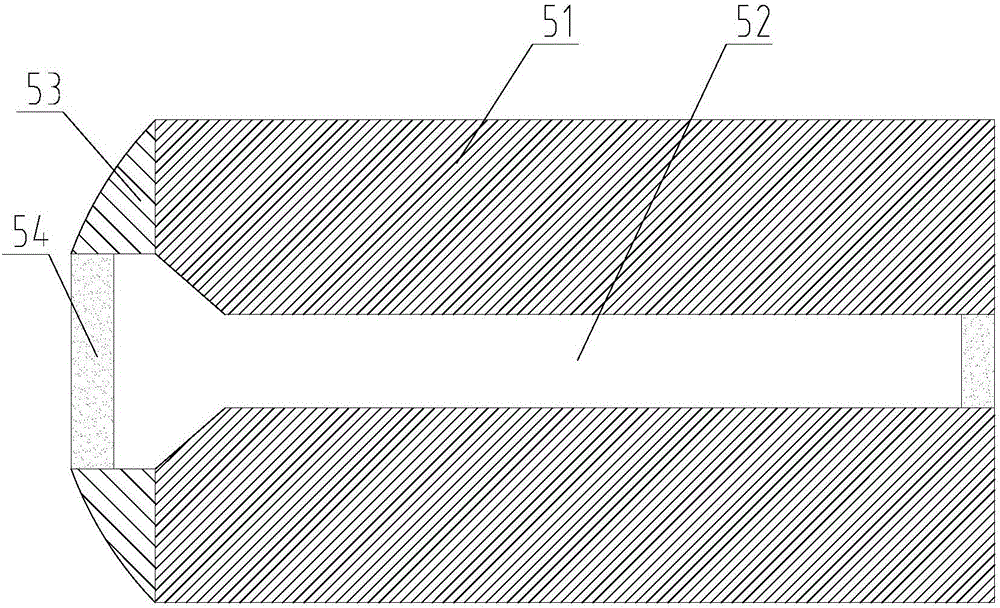

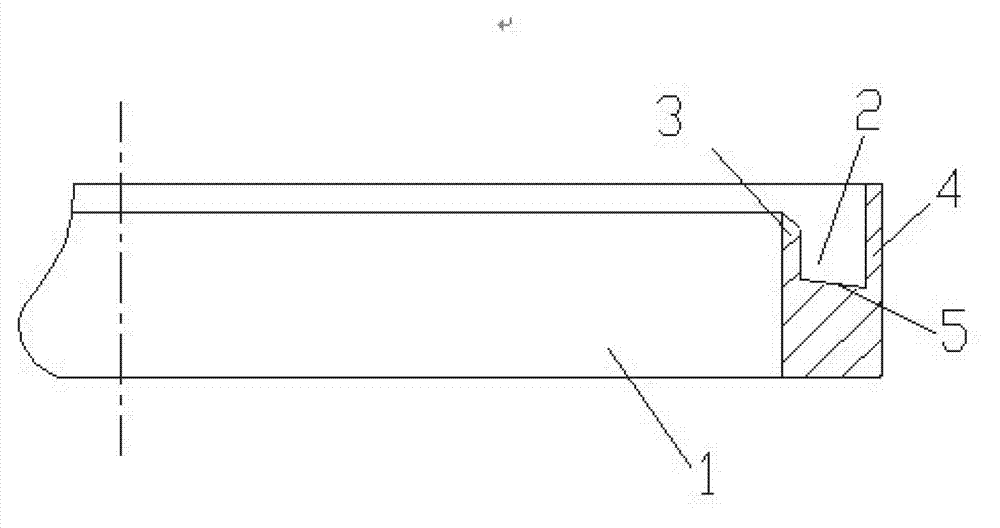

Oil scraper ring

InactiveCN102900651APrevent flying outPrevent backflowPositive displacement pump componentsPositive-displacement liquid enginesLow speedEngineering

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

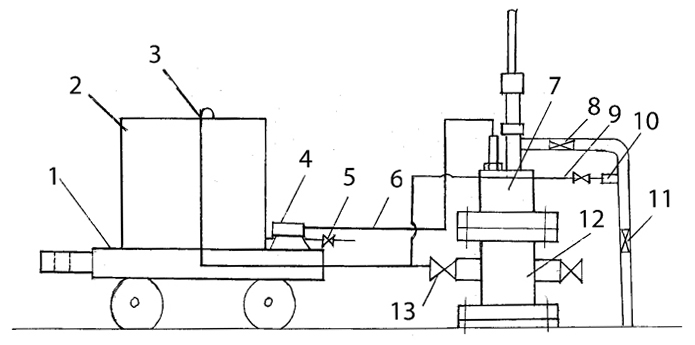

Well mouth eccentric pressurizing sleeve oil recycling mobile device of production well

InactiveCN102003163ANo pollution in the processConvenient and quick oil collectionFluid removalSealing/packingArticulated vehicleAir compressor

Owner:徐大庆

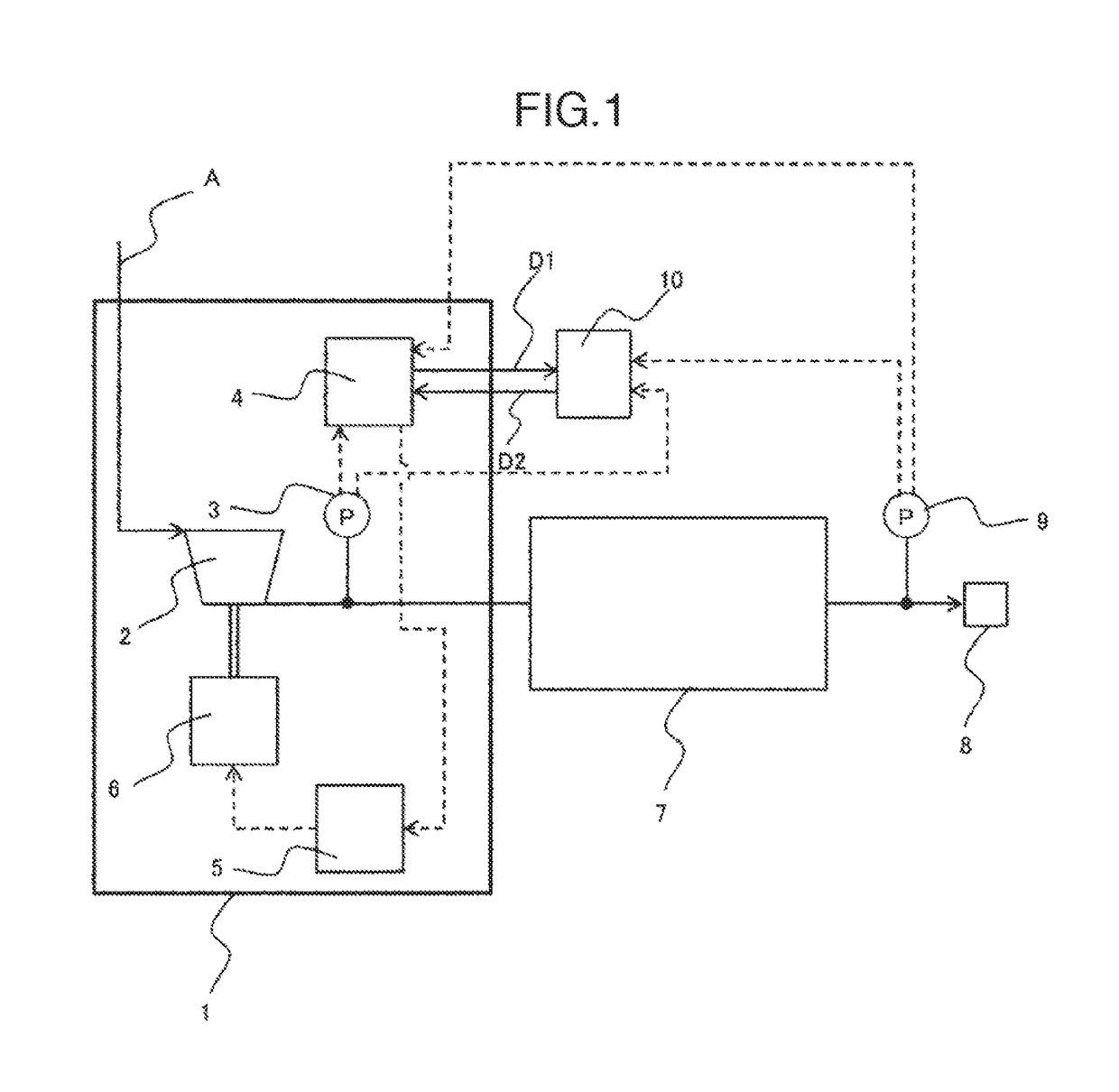

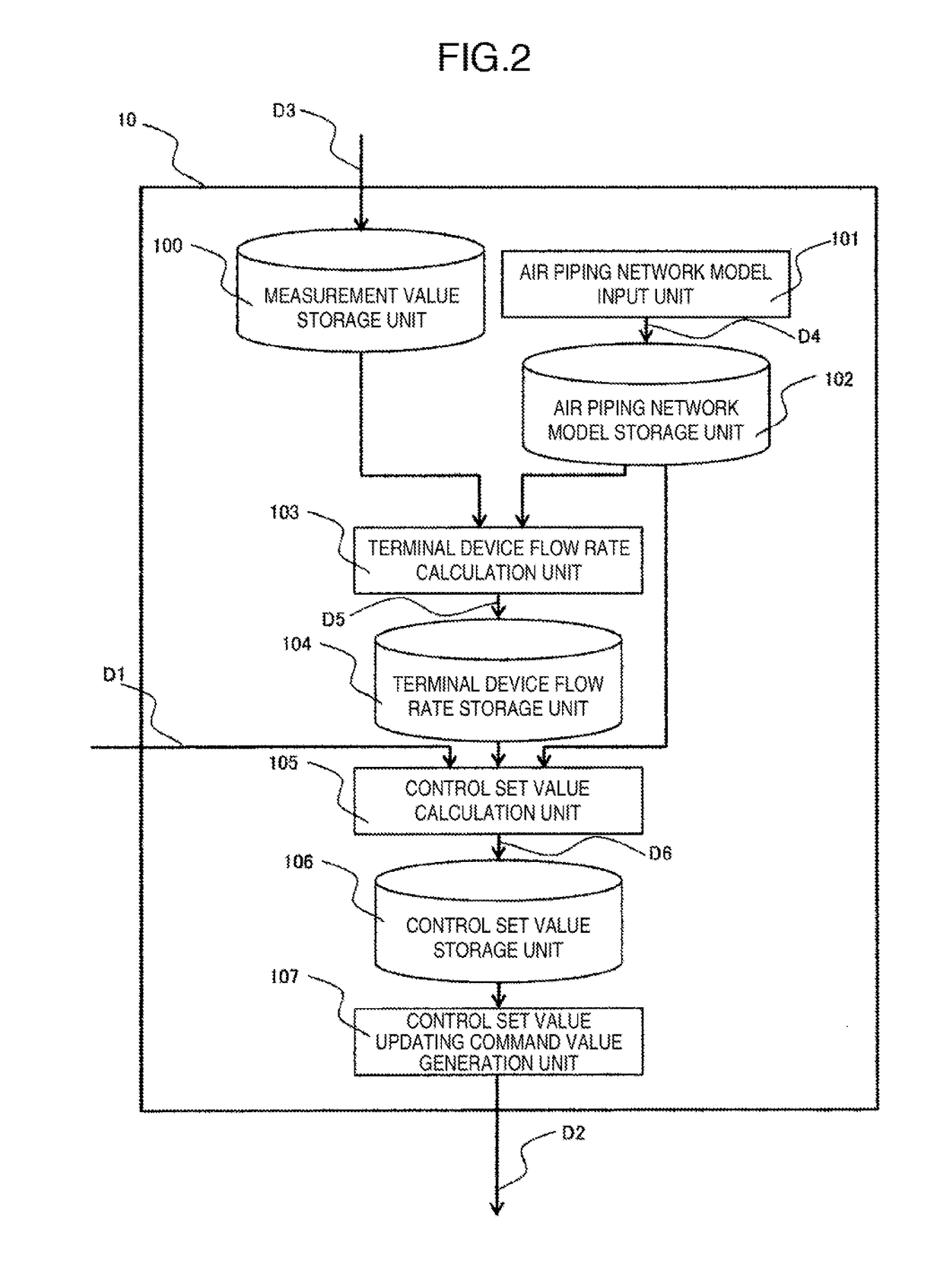

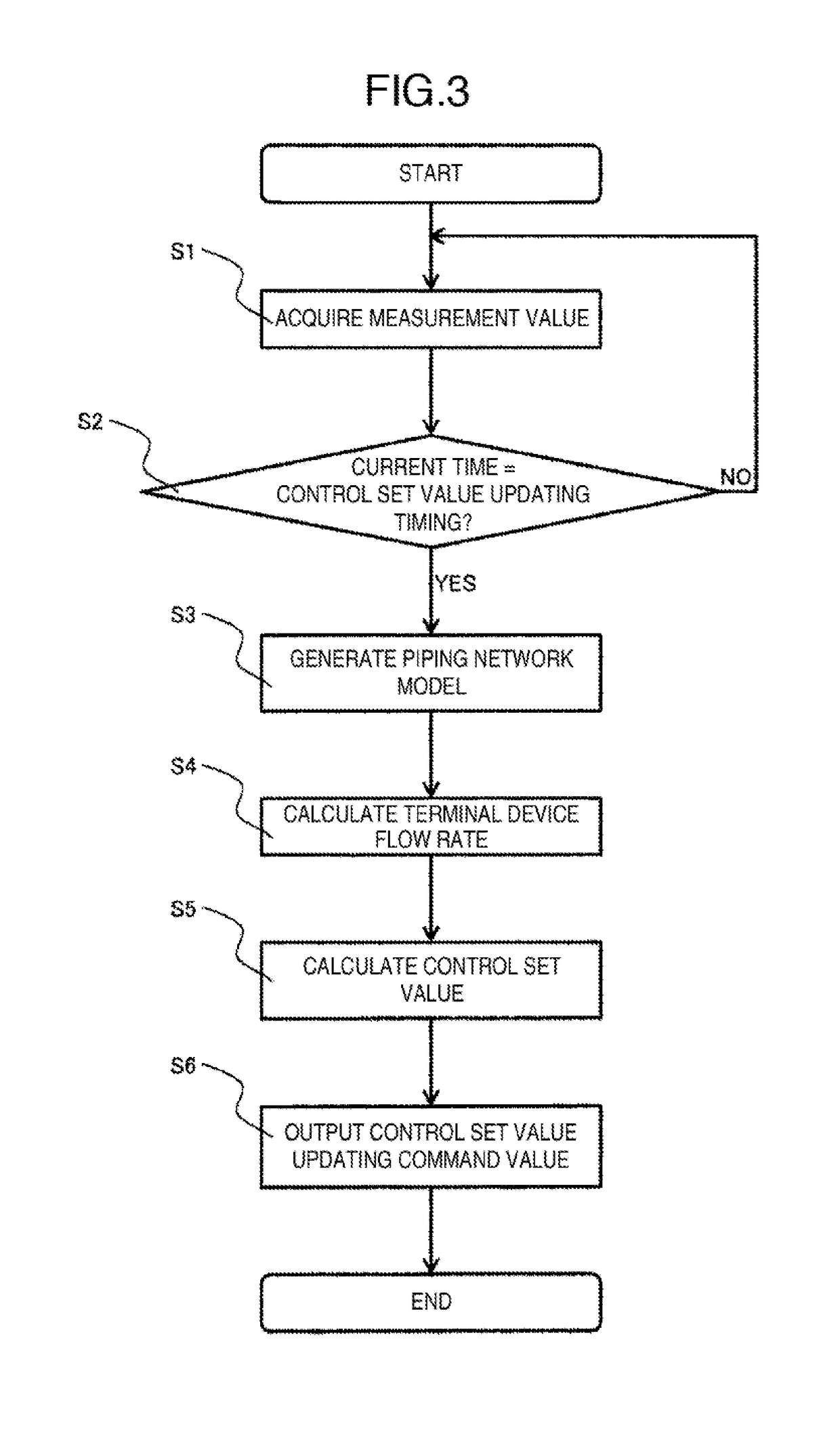

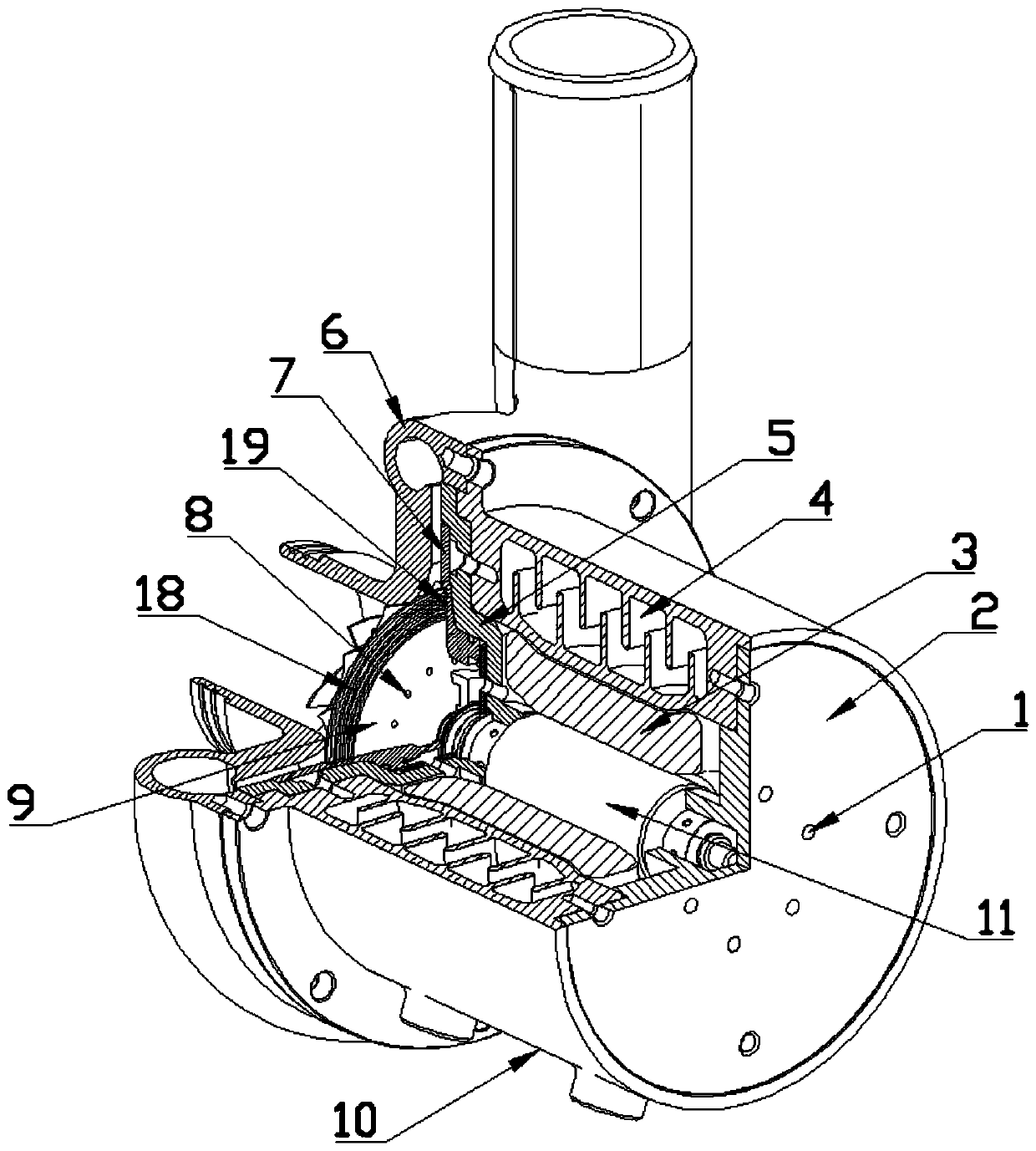

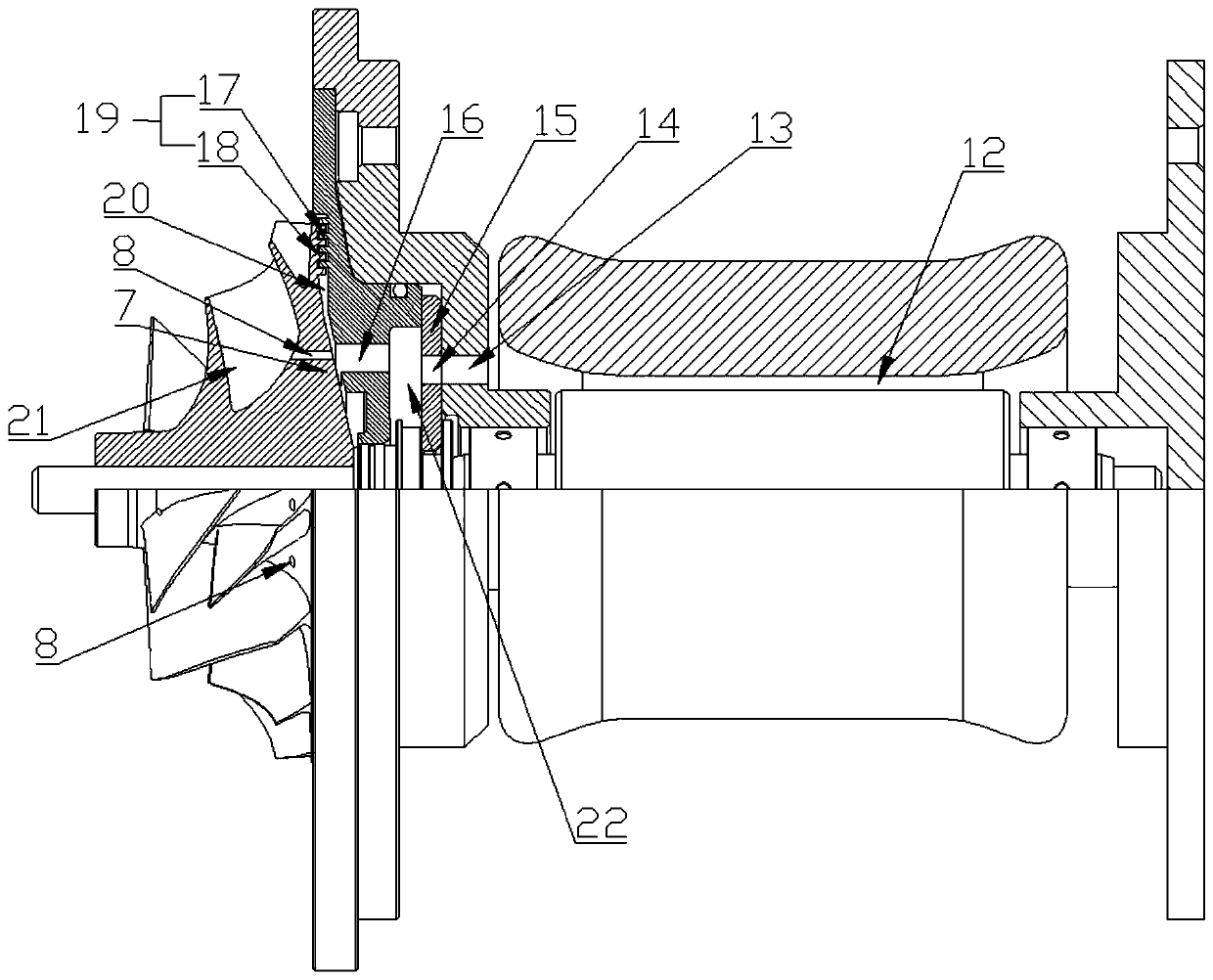

Pneumatic System Operation Control Device and Control Method

ActiveUS20180372086A1Suppress fluctuationsReduce power consumptionExternal parameterFluid parameterControl setTerminal equipment

Owner:HITACHI IND EQUIP SYST CO LTD

VOC runner performance testing device

InactiveCN107727795AWill not cause secondary pollutionMeet the needs of wheel testingGas treatmentDispersed particle separationCombined testDesorption

The invention discloses a VOC runner performance testing device. According to the device, a large circulating pipe, a VOC solvent box and an air compressor are sequentially connected by virtue of airpipes; the large circulating pipe is sequentially connected with a fresh air mixing box, a VOC adsorption runner, a fan and an air exhausting device; a middle circulating pipe is sequentially connected with the VOC adsorption runner, a purifier, a heat exchanger, a heat exchange unit and a fan; a small circulating pipe is sequentially connected with the heat exchange unit and a catalytic combustion device; the heat exchanger is connected with the large circulating pipe by virtue of an air pipe penetrating through the VOC adsorption runner, and is connected with the air exhausting device by virtue of an air pipe. Compared with the prior art, the VOC runner performance testing device disclosed by the invention has the advantages that the VOC runner can be subjected to comprehensive evaluation, secondary pollution is avoided, and requirements on various runner tests are met. Moreover, the device disclosed by the invention is creative, is provided with the novel large circulating pipe, middle circulating pipe and small circulating pipe, is capable of comprehensively testing the treatment capacity and desorption ability of the VOC runner and is high in efficiency and excellent in effect.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

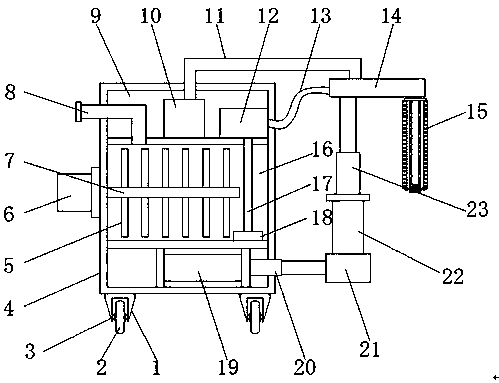

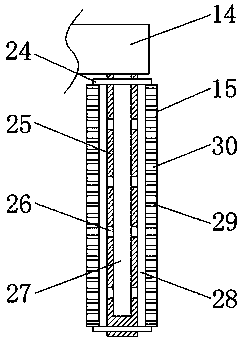

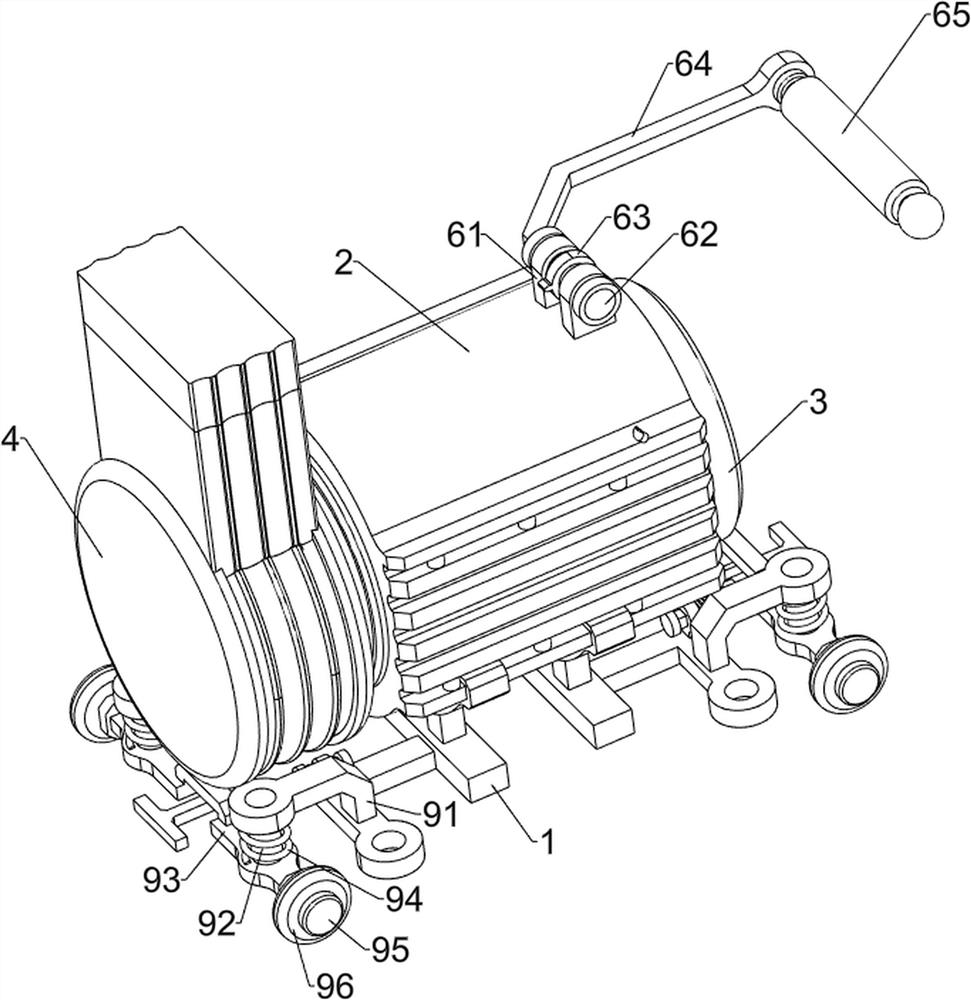

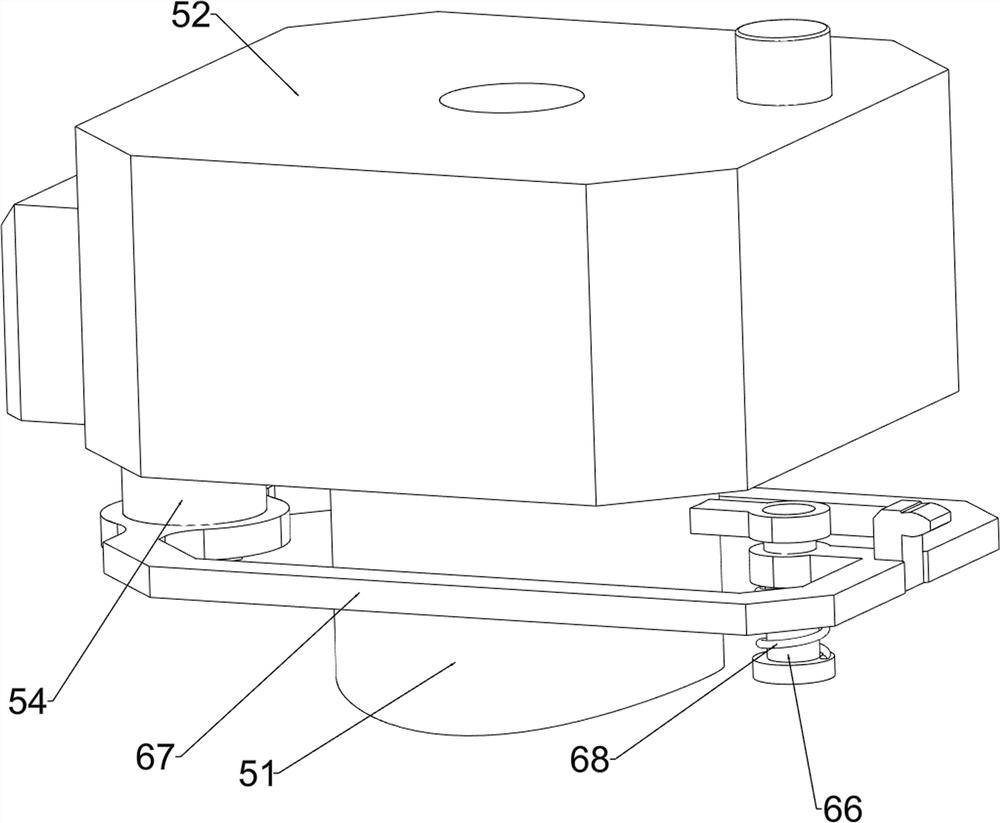

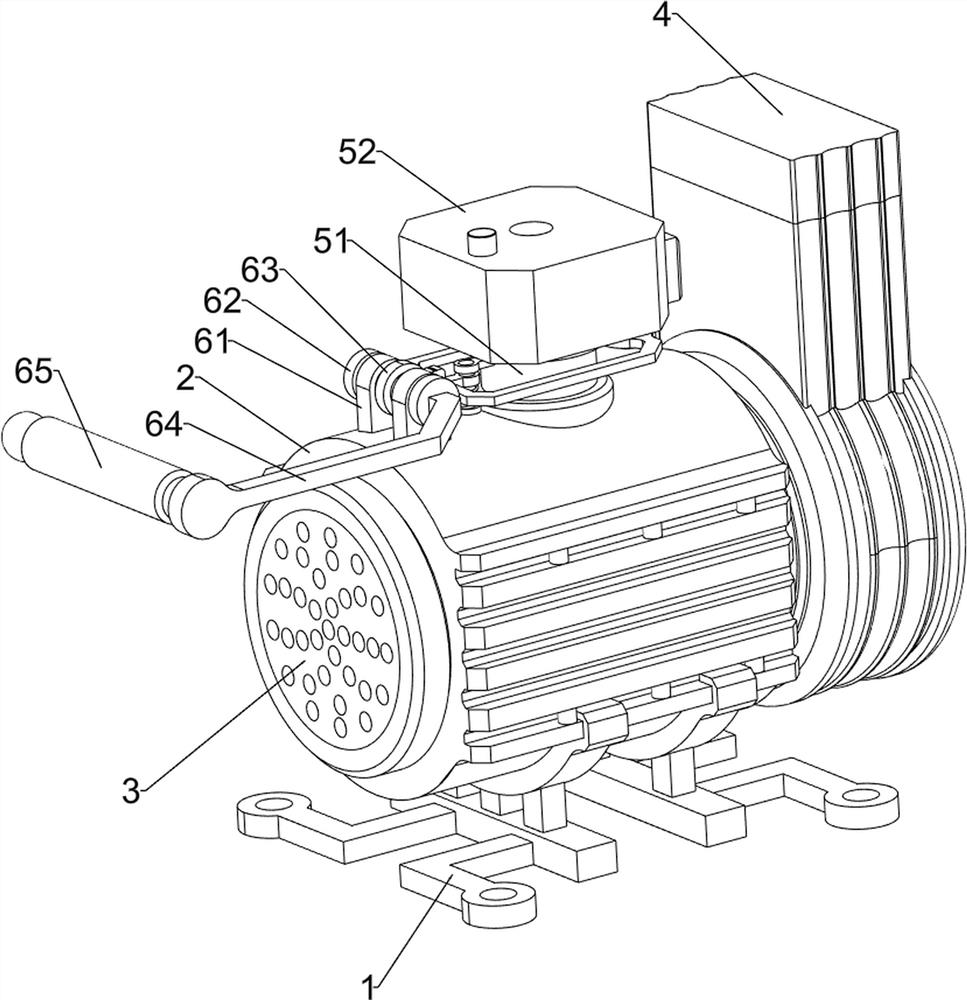

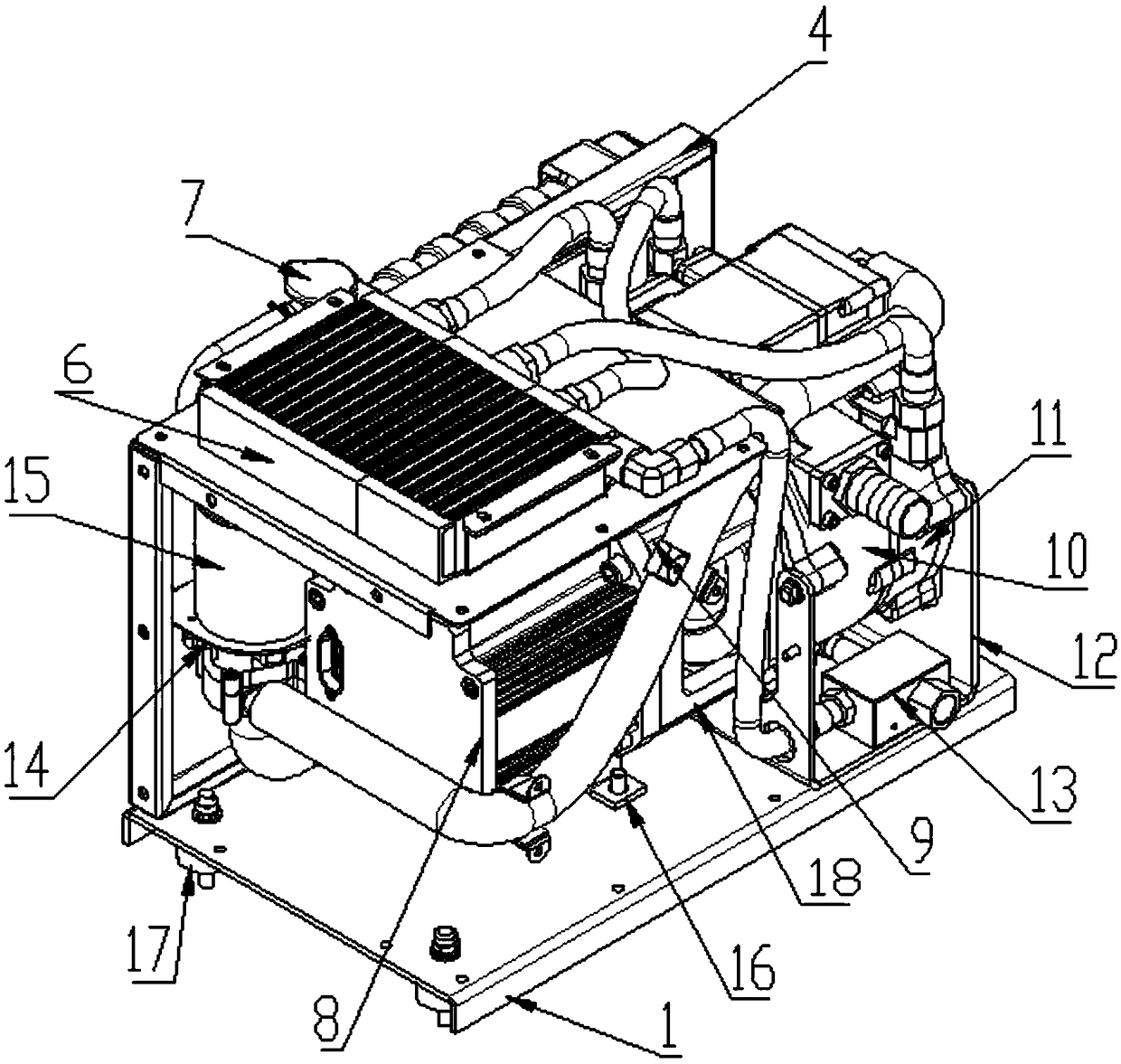

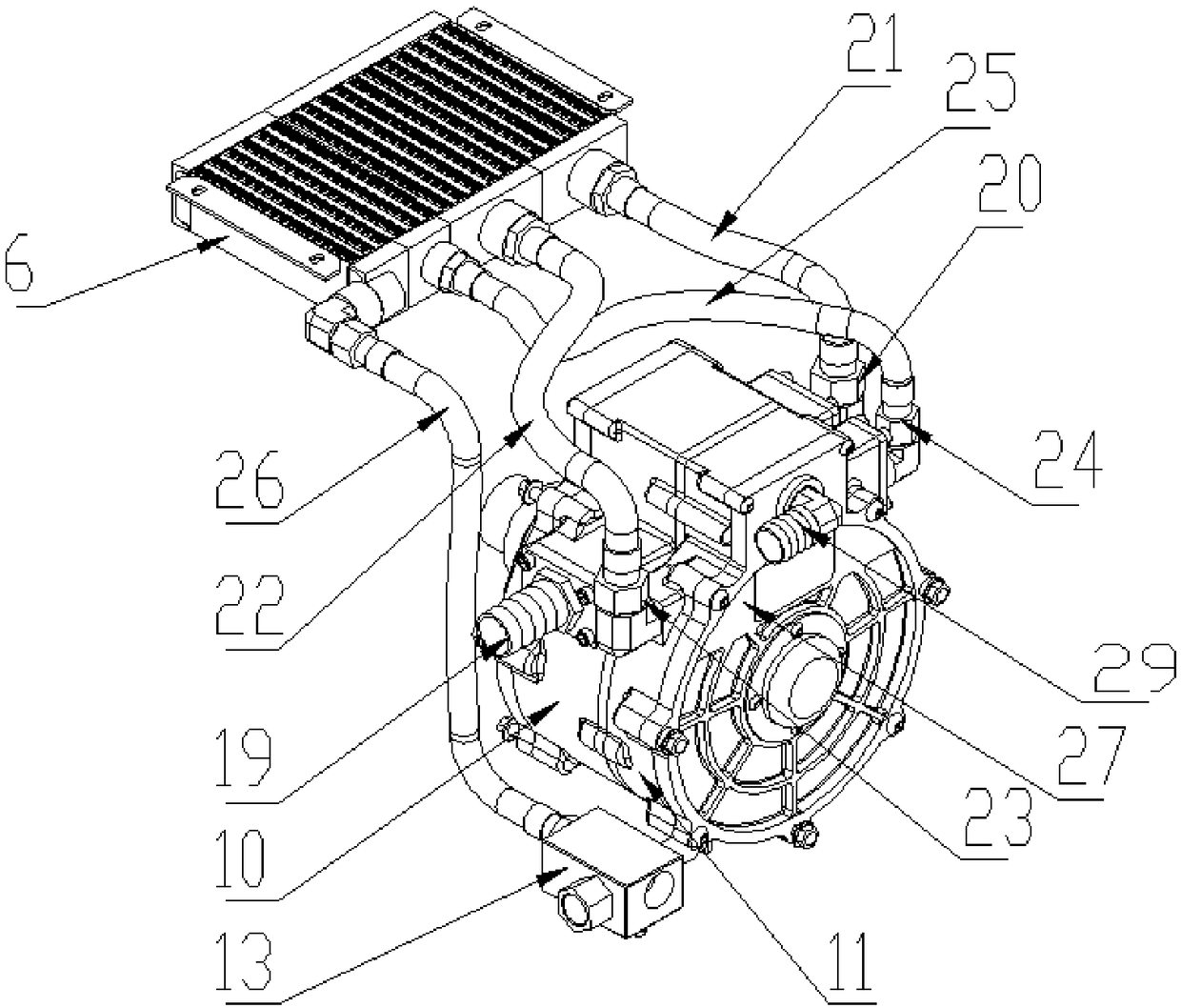

External heat dissipation portable oilless air compressor

PendingCN114483545ATo achieve the purpose of cooling and coolingImprove cooling efficiencyPortable framesPositive displacement pump componentsAir compressionAir purifiers

Owner:赖桂林

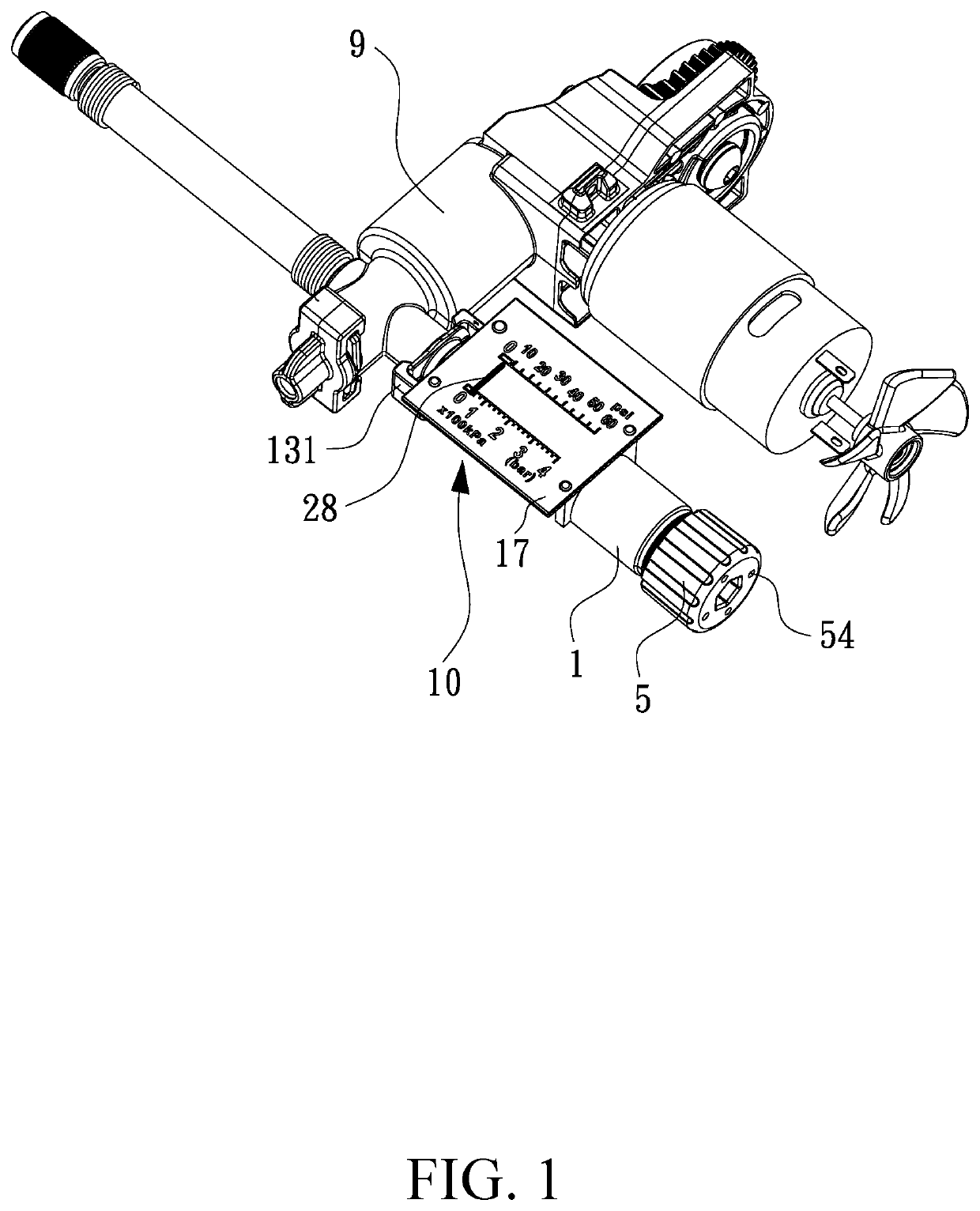

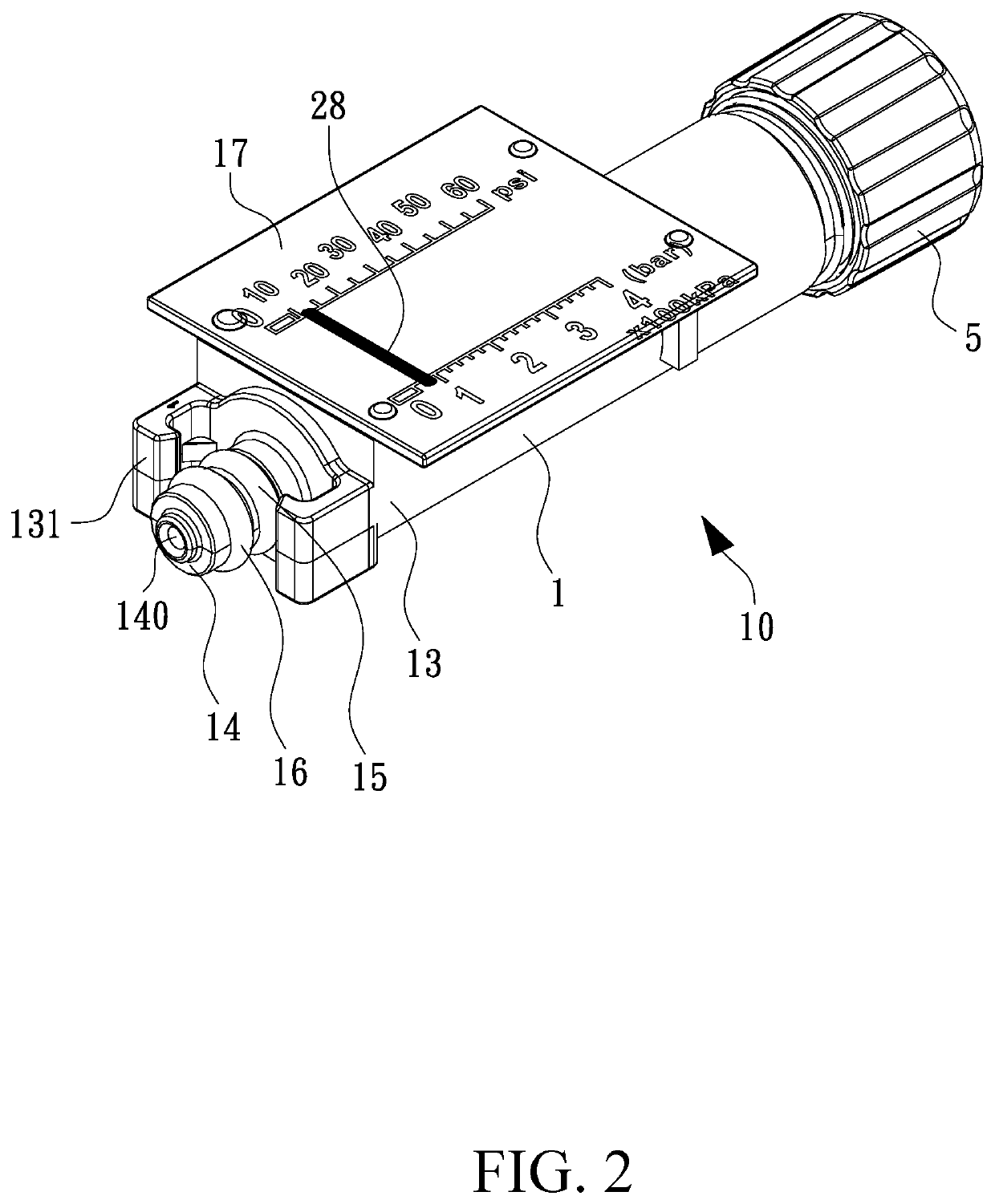

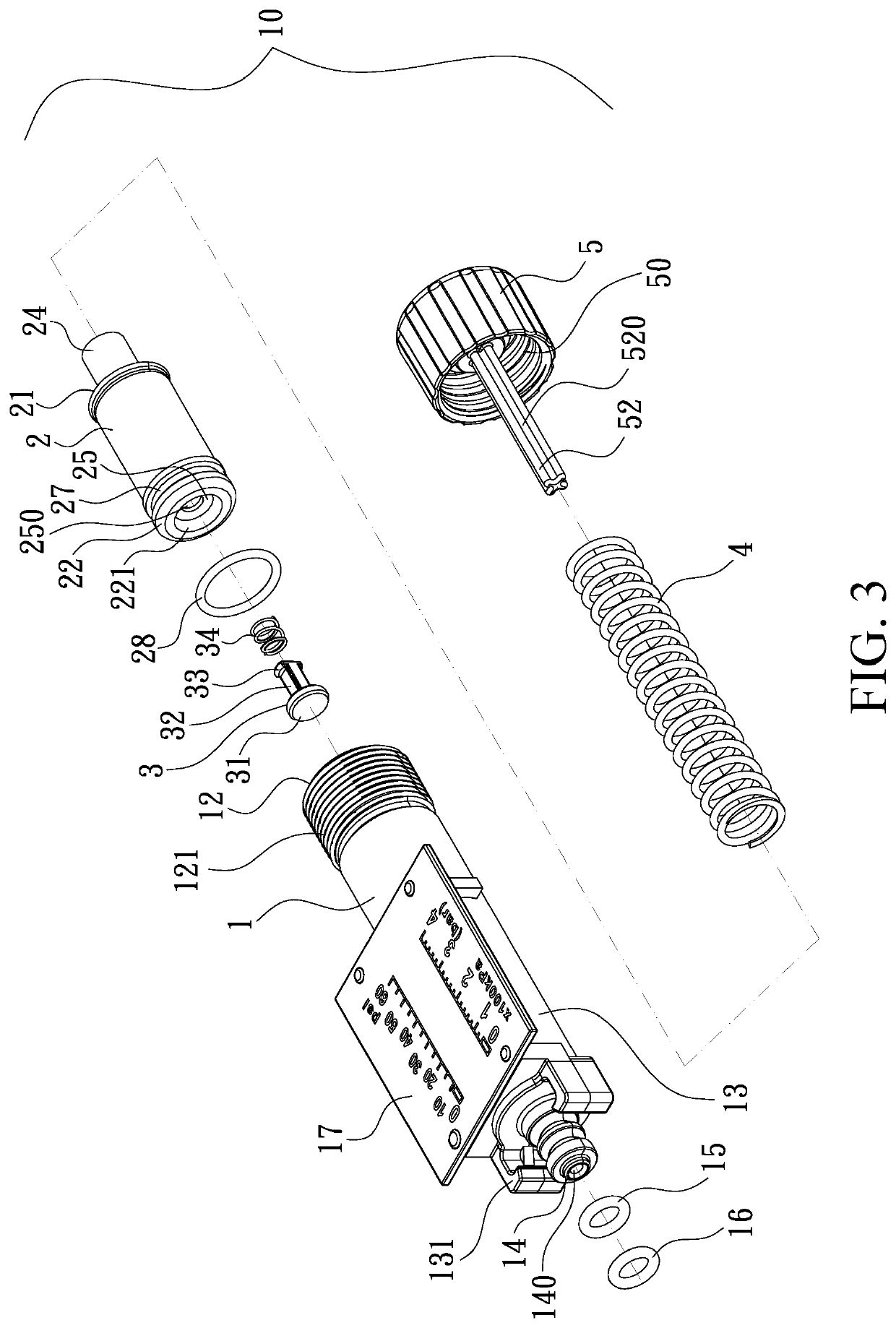

Pressure gauge capable of releasing pressure safely

ActiveUS20210190621A1Eliminating safety valveFluid parameterFluid pressure measurement by mechanical elementsEngineeringAir compressor

Owner:UNIK WORLD IND CO LTD

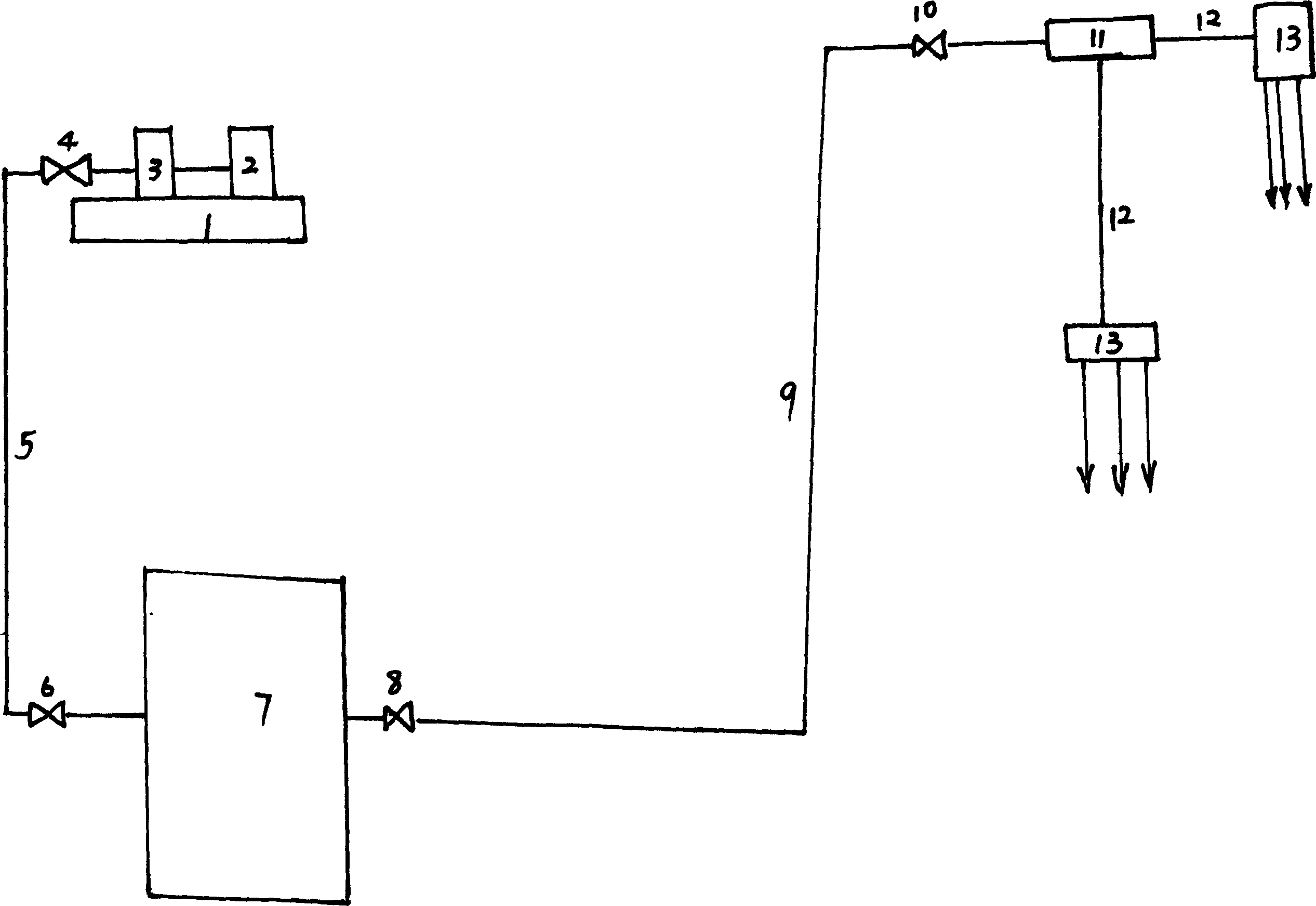

Granule test device

The invention relates to a granule test device which comprises an air compressor, wherein the air compressor is connected with an air storage tank through an air pipe; the air storage tank is connected with an oil-water filter through an air pipe; the oil-water filter is connected with an air dryer through an air pipe; the air dryer is connected with a granule test machine through an air pipe; the granule test machine is connected with a dust collection bottle through an air pipe; the dust collection bottle is connected with a dust collector. The granule test device is simple in structure, low in cost, wide in dynamic measurement range, free from gear shift in the whole process, high in measurement speed, good in repeatability, convenient to operate and low in requirement on test conditions and operators.

Owner:CHONGQING JIAZE MACHINERY

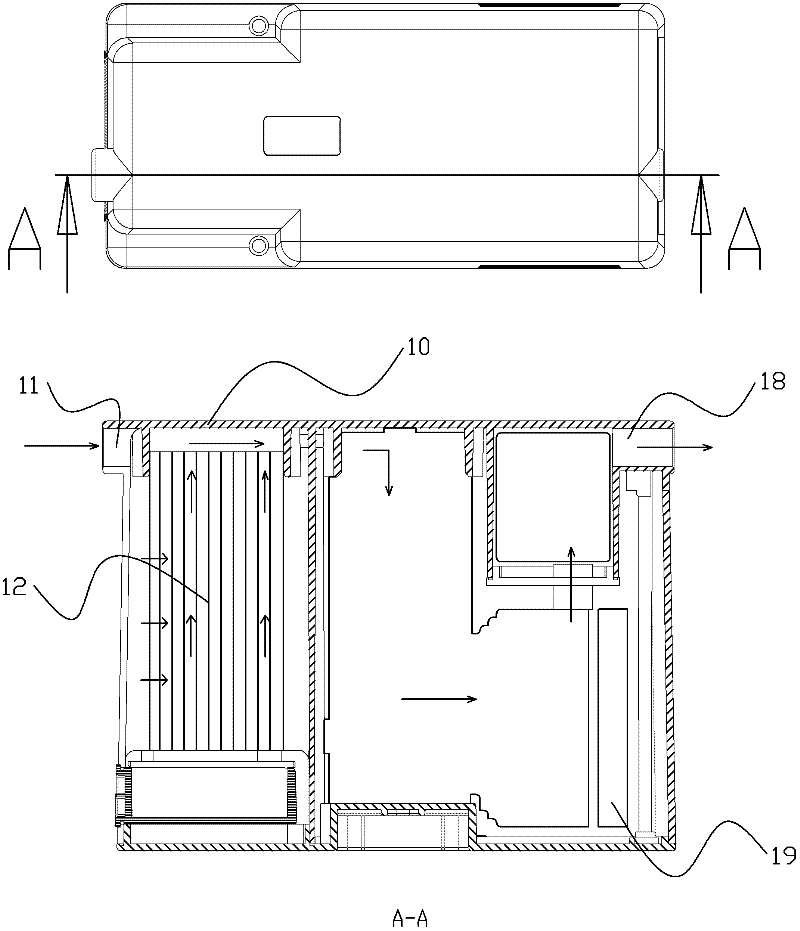

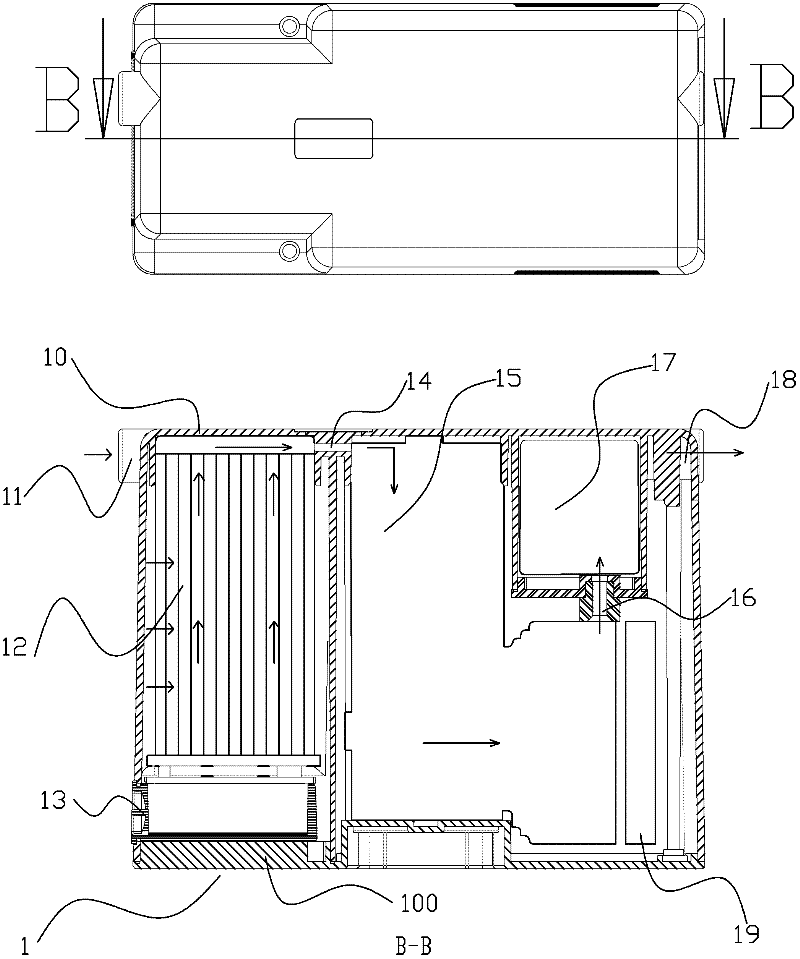

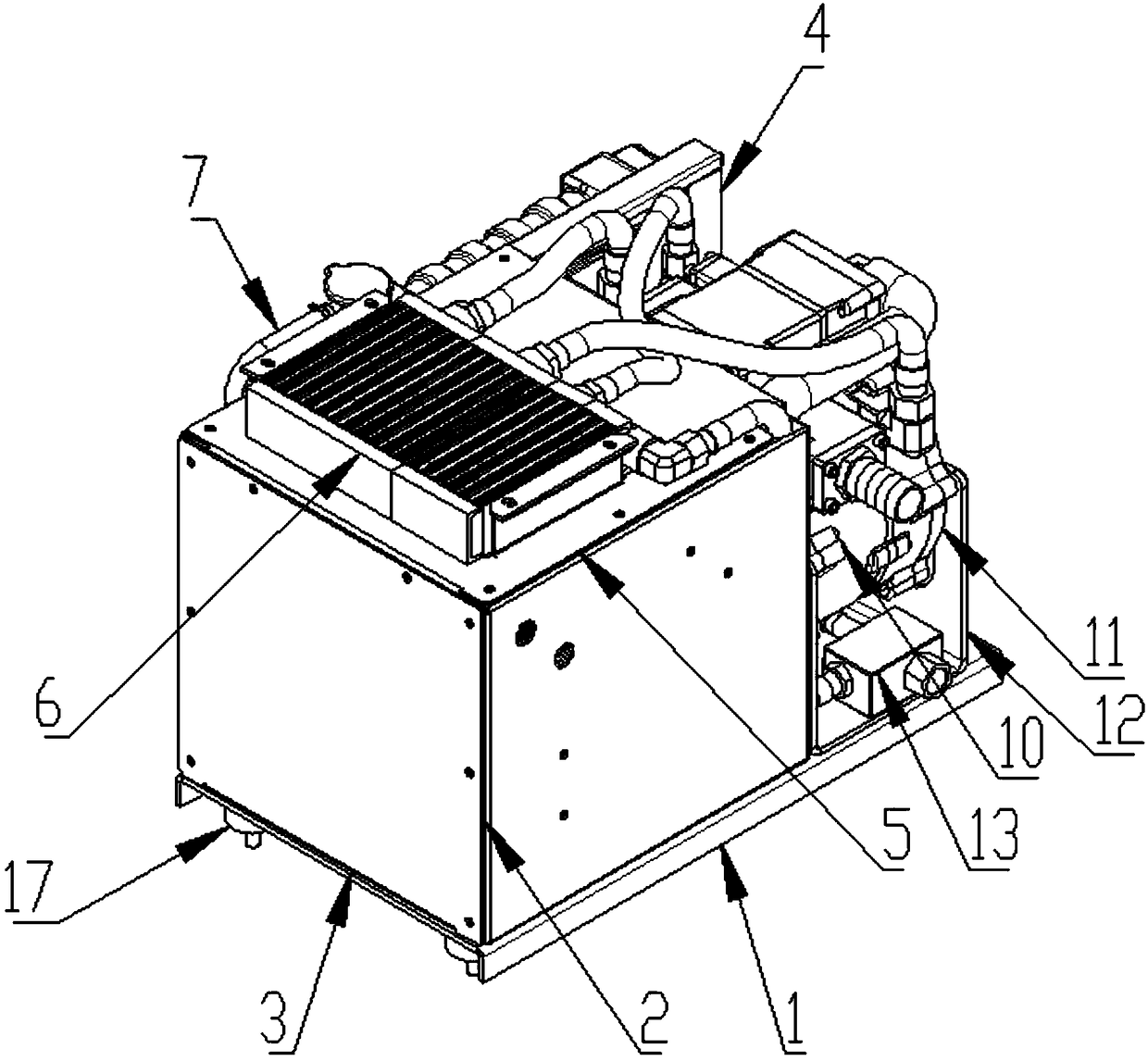

Electric air compressor with motor rotor cooling system

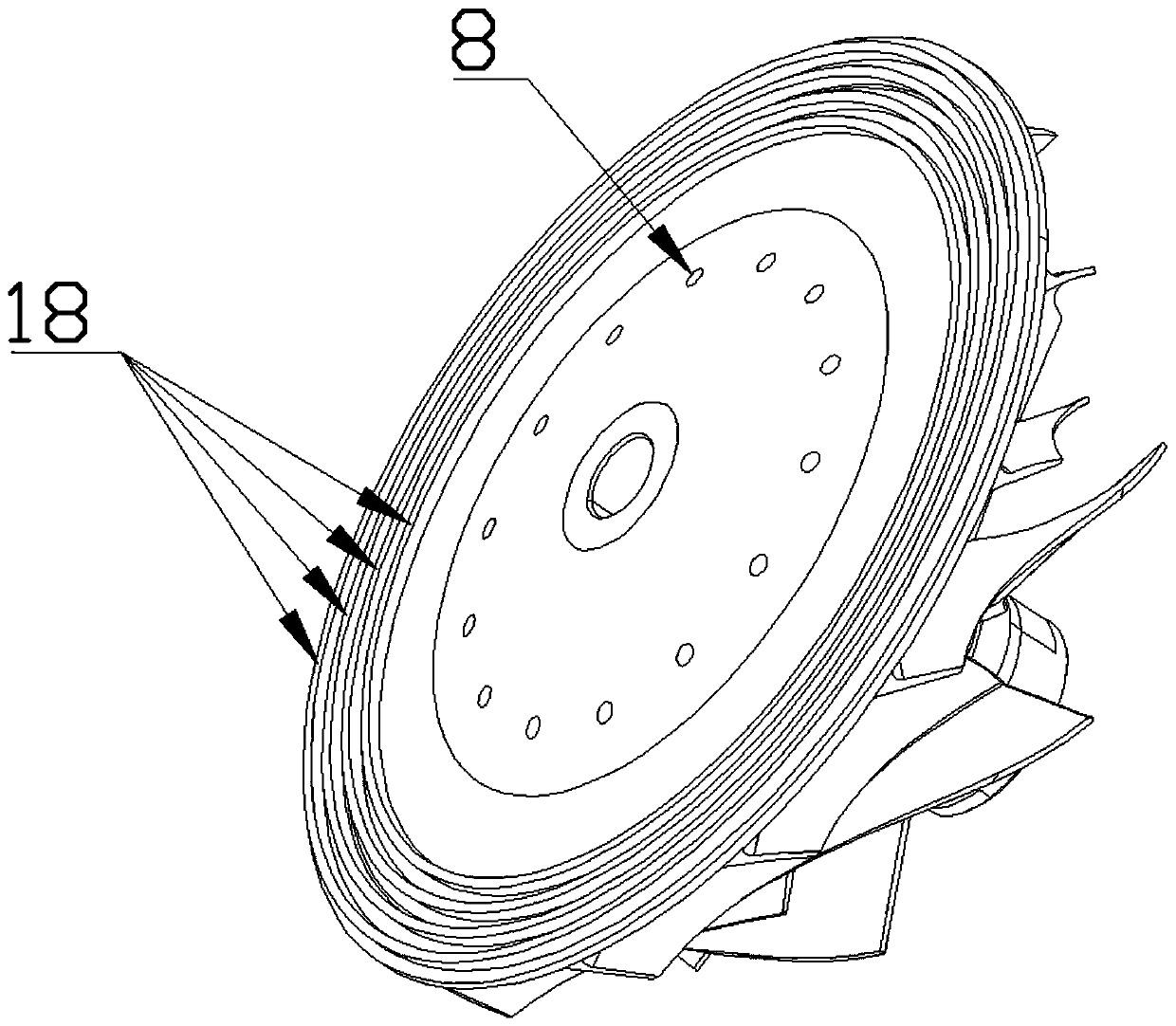

InactiveCN110145479AAchieve self-coolingReduce manufacturing costPump componentsPump installationsImpellerThrust bearing

Owner:DALIAN MARITIME UNIVERSITY

Environment-friendly wheat seed pre-stirring and dedusting device

InactiveCN110121979AAvoid pollutionAchieve dust removal effectDirt cleaningSeed coating/dressingCouplingEngineering

Owner:田桂华

Low-noise magnetic-suspension centrifugal air compressor

Owner:广东艾高装备科技有限公司

Movable-type observatory meteorology observation container

InactiveCN105467470AReasonable structureEasy to moveWeather condition predictionObservatoryThermal insulation

Owner:SUZHOU FANRONG SPECIAL CONTAINER

Novel air intake structure of air compressor

InactiveCN112324638AAchieve installationEasy to installPositive displacement pump componentsPositive-displacement liquid enginesEngineeringAir compressor

The invention belongs to the field of auxiliary equipment of air compressors and in particular relates to a novel air intake structure of an air compressor. In order to solve the problem in the priorart, the invention provides a scheme as follows: the novel air intake structure of the air compressor comprises an air intake pipe, a condenser and a mounting seat, wherein a flange plate is fixedly mounted at the bottom end of the air intake pipe, two first cavities are separately formed in two sides of the mounting seat, vertical holes are formed in the inner walls of the tops of the first cavities, a same first rotating bar is rotatably mounted on the inner walls of two sides of the first cavities, an eccentric wheel is fixedly connected to the first rotating bar in a sleeving manner, a first transmission wheel is fixedly connected to the first transmission bar in a sleeving manner, and moving rods are slidably mounted on the inner walls of the sides, far away from each other, of the two first cavities. The novel air intake structure of the air compressor solves defects in the prior art, so that people can mount the air intake pipe quickly and conveniently, and the damaged condenseris also detached, maintained and replaced conveniently, and therefore, demands of people are met.

Owner:孙巧玲

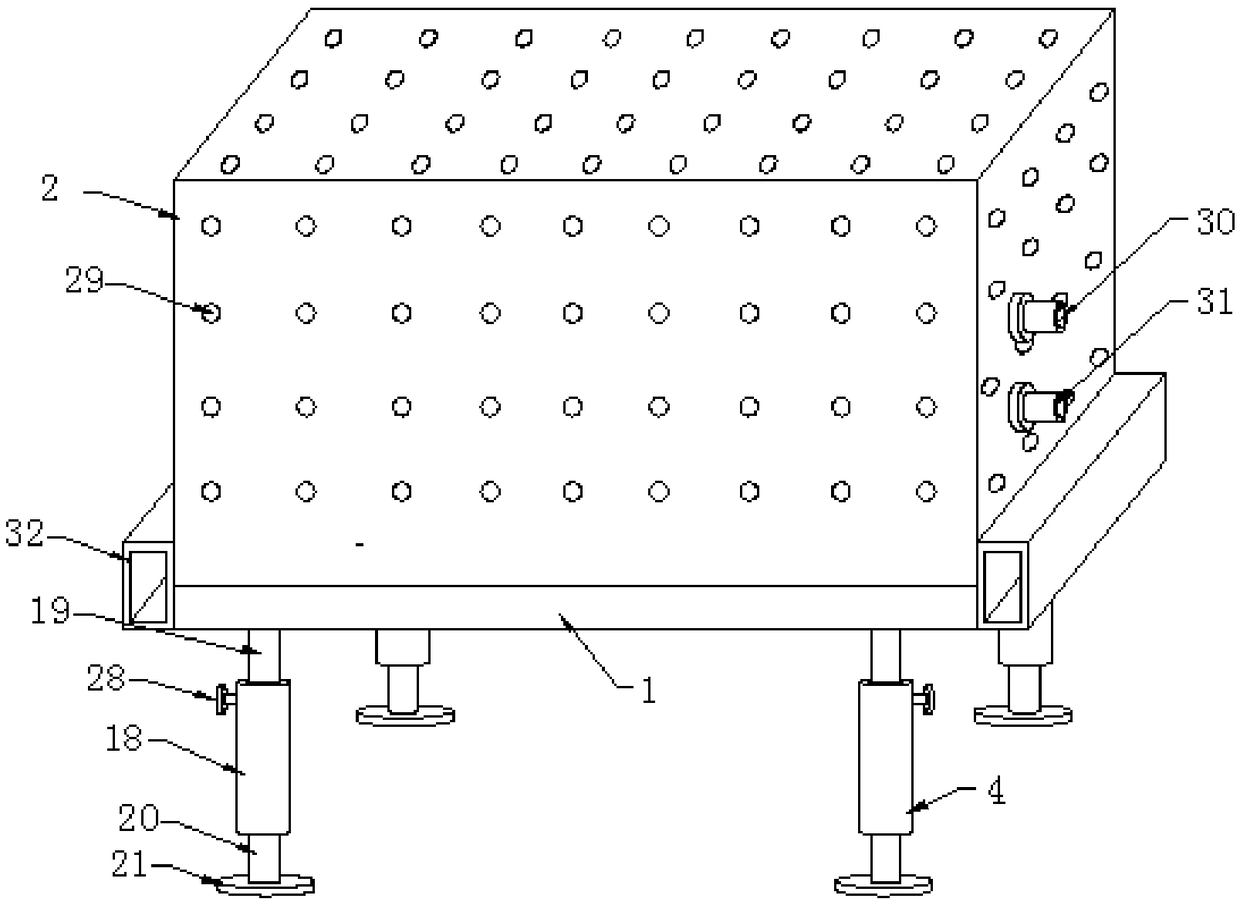

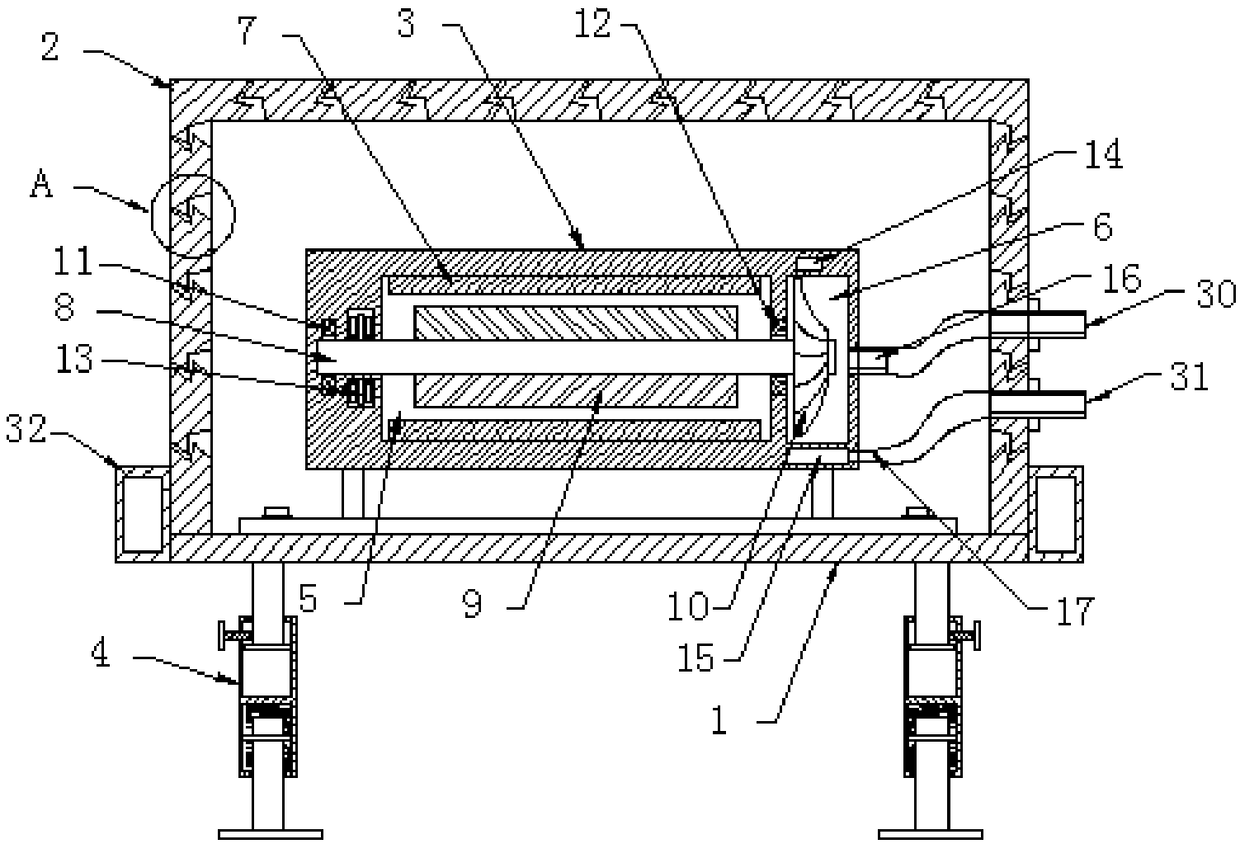

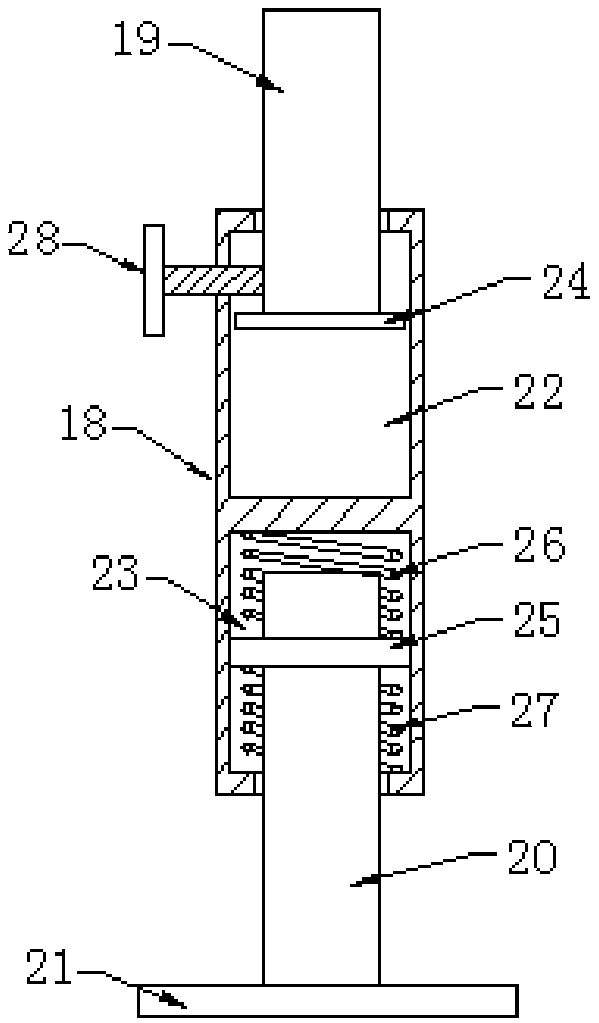

Oil-free double-rotor heat dissipation type air compressor

PendingCN108999787AReduce power consumptionExtended service lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsCouplingWorking temperature

Owner:江西氟斯新能源科技有限公司

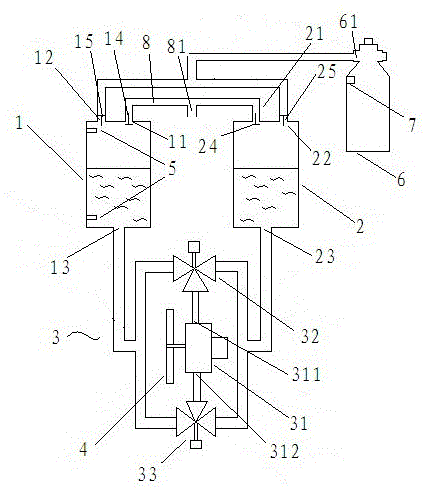

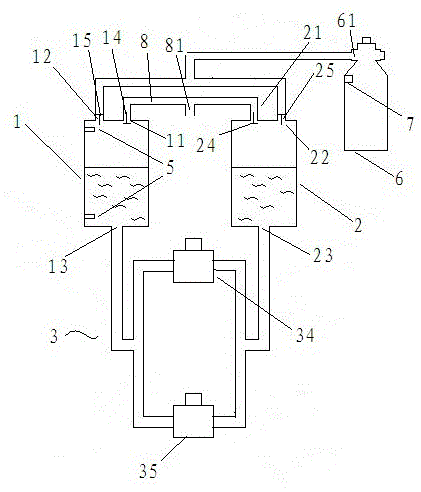

Liquid pump type air compressor

InactiveCN105649956AImprove airtightnessImprove compression efficiencyPositive displacement pump componentsPump installationsWater storageEngineering

Owner:万建雄 +4

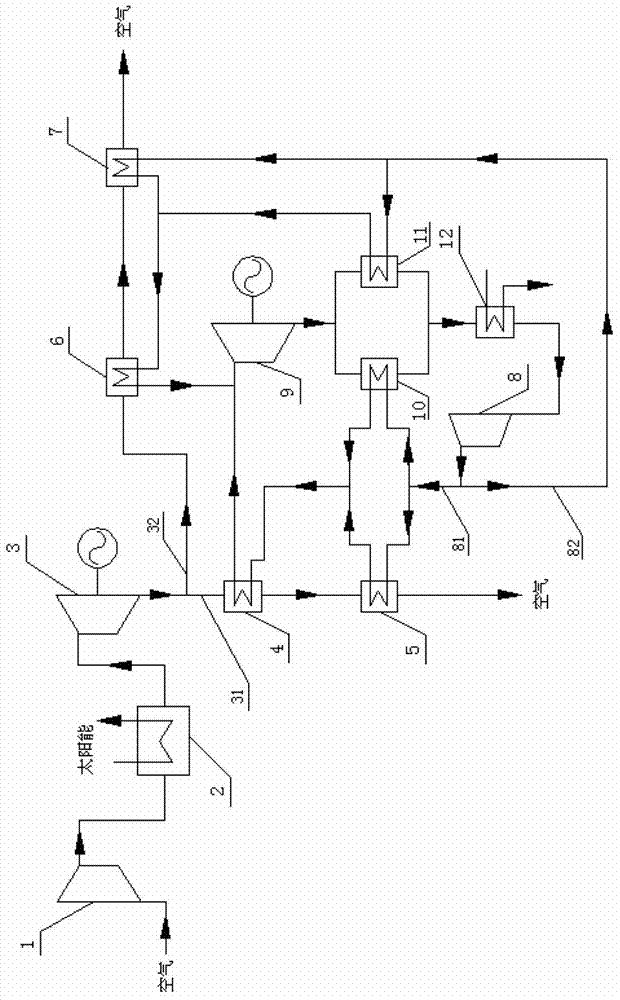

Solar air-carbon dioxide combined cycle power generation system

The invention discloses a solar air-carbon dioxide combined cycle power generation system. The system comprises an air compressor, a high-temperature solar boiler, an air turbine generator set, a high-temperature heat exchanger, a low-temperature heat exchanger, a high-temperature heat storer, a low-temperature heat storer, a carbon dioxide compressor, a carbon dioxide turbine generator set, a regenerator I, a regenerator II and a cooler. The system uses the characteristic of high average heat absorbing temperature of open air circulation and the characteristics of low circulating temperature and low compression power of closed supercritical carbon dioxide circulation; a solar thermal power generation system generates electricity in a combined cycle power mode at day time; meanwhile, afterheat of part of exhaust is used for medium / low-temperature heat storage; and the system performs single closed carbon dioxide cycle power generation by dint of heat release of a heat storage system at night. The system has such characteristics as high power generation efficiency, low water consumption, low operation cost and good environmental protecting performance, meanwhile, effectively solves the CO2 heat exchange pinch point problem, and has the function of continuously and stably generating electricity for a long time.

Owner:JIMEI UNIV

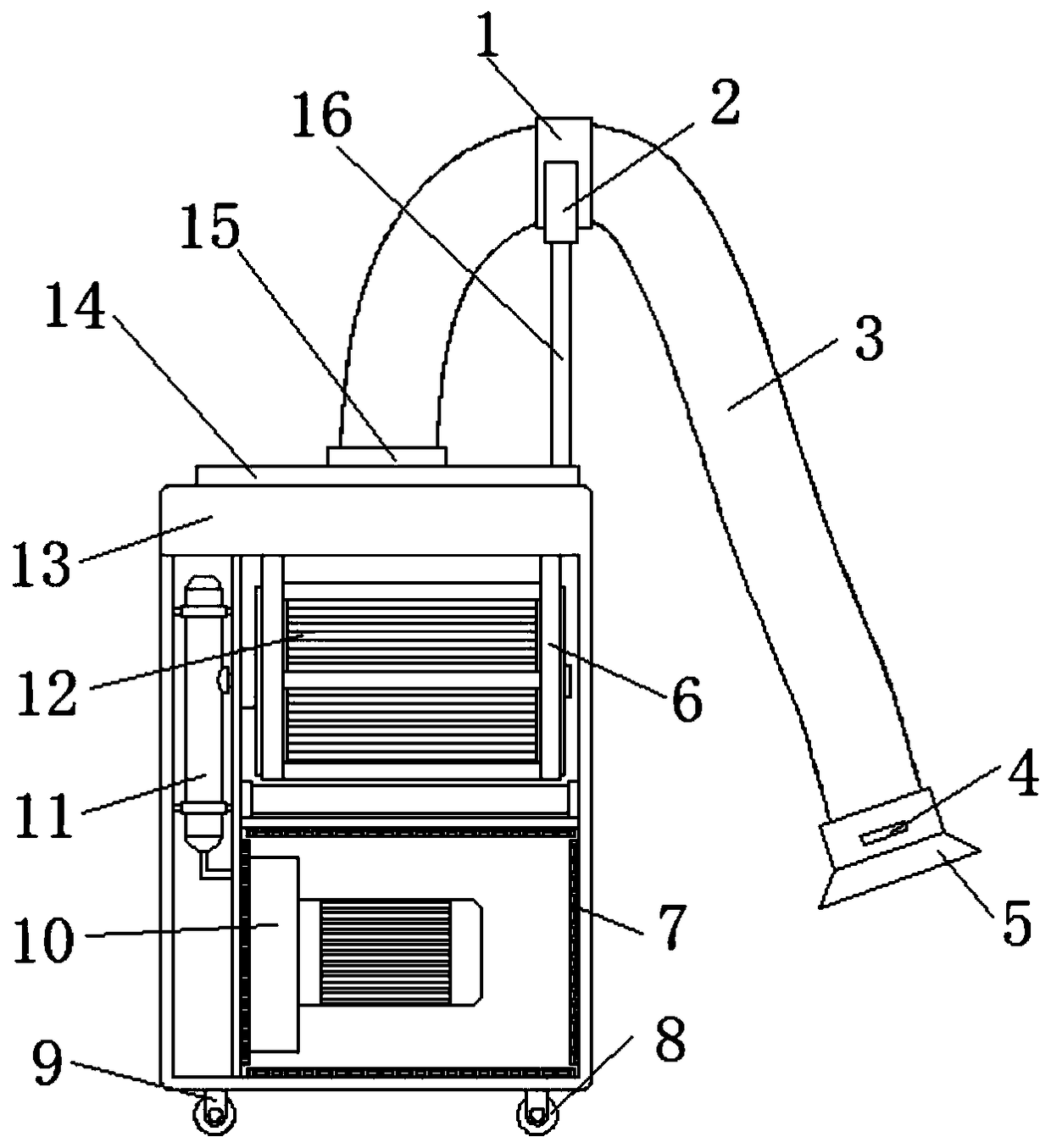

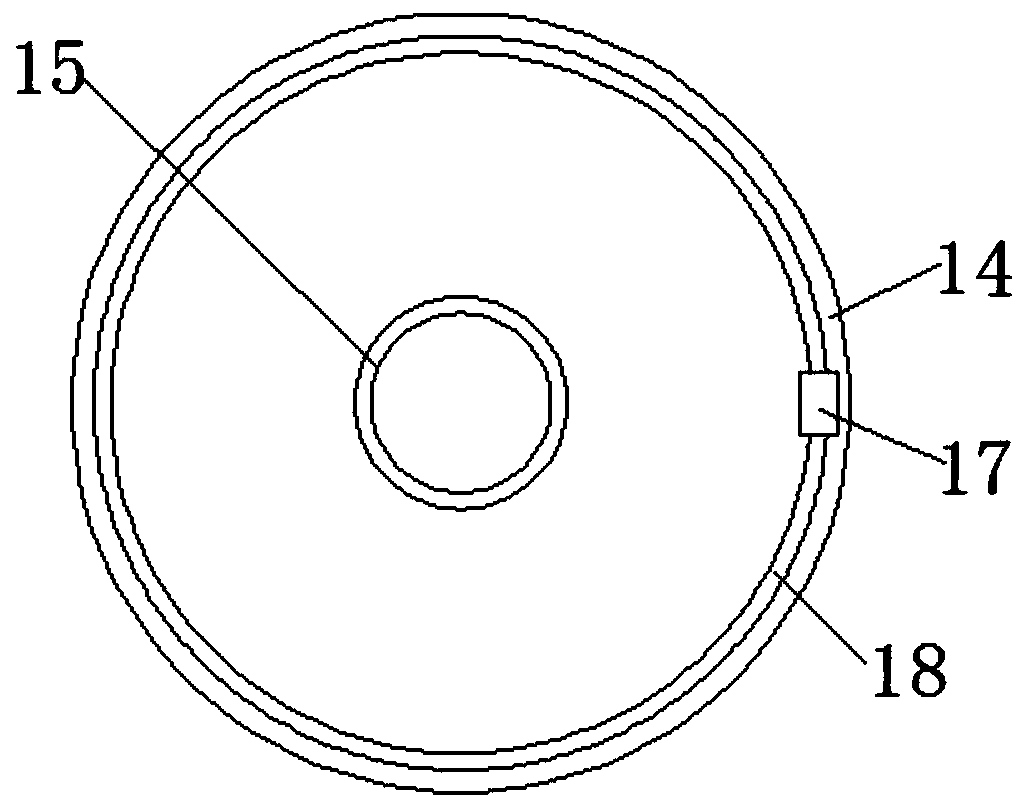

Purifier for machining and welding of air compressor

InactiveCN108971179ADoes not cause ventilation problemsDispersed particle filtrationDirt cleaningClamp connectionGas compressor

Owner:合肥市科惠特智能科技有限公司

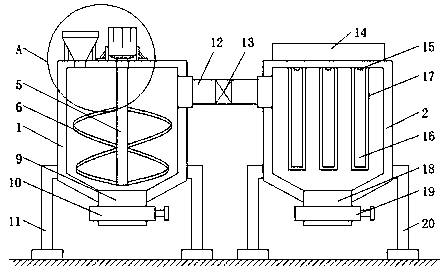

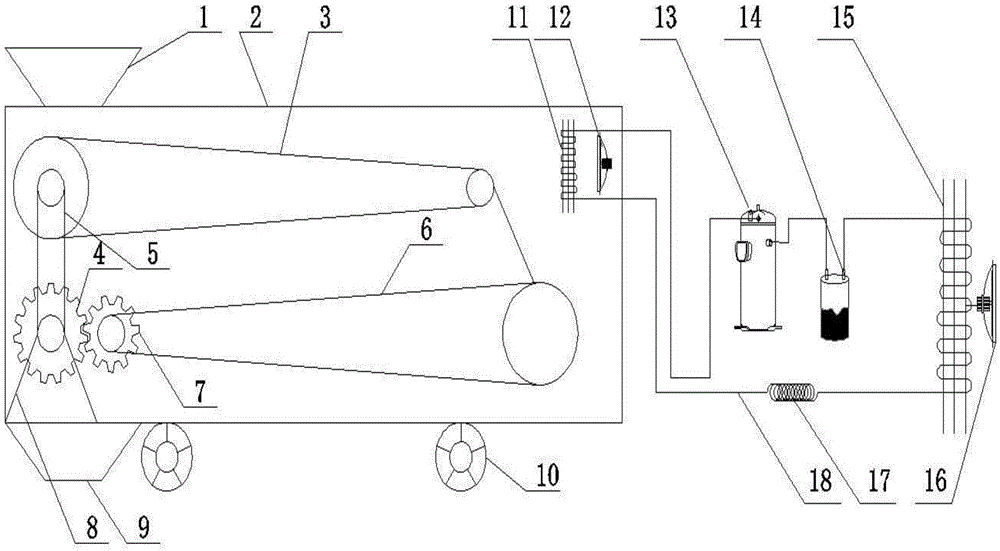

Dryer for refuse treatment

InactiveCN104633670AIncrease drying distanceSmall footprintIncinerator apparatusVapor–liquid separatorDrive wheel

Owner:XIAN ALL SAFE SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap