Dryer for refuse treatment

A technology for garbage disposal and dryer, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of increased energy consumption for garbage drying, unfavorable popularization of garbage disposal, etc., and achieve obvious energy saving effect and improve drying effect. , The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

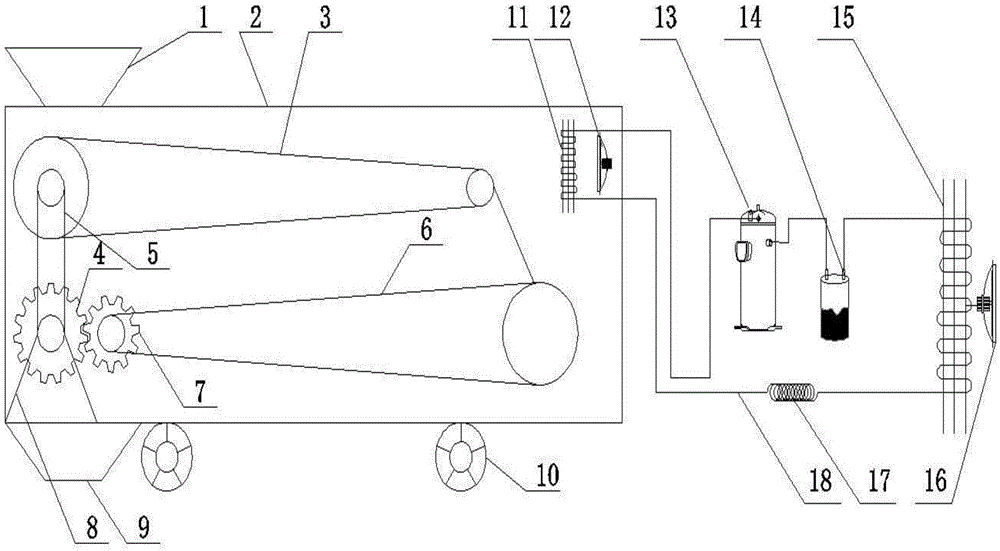

[0020] Such as figure 1 A dryer for garbage disposal is shown, which includes a rectangular shell 2 with a hollow structure and a heat pump system for raising the temperature inside the shell 2. A feed hopper 1 is provided on the top side of the shell 2, so that The bottom opening of the feed hopper 1 extends to the inside of the housing 2, and a first conveyor belt 3 for transporting garbage from left to right is arranged below the bottom opening of the feed hopper 1 inside the housing 2. The two ends of the transmission belt 3 are respectively set on the left and right transmission wheels, and the diameter of the left transmission wheel set with the first transmission belt 3 is larger than the diameter of the right transmission wheel, and it is located below the first transmission belt 3 inside the housing 2. For the second conveyor belt 6 that transports the garbage from right to left, the two ends of the second conveyor belt 6 are respectively set on the other two left and ri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap