Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155 results about "Drive shaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a mechanical component for transmitting torque and rotation, usually used to connect other components of a drive train that cannot be connected directly because of distance or the need to allow for relative movement between them.

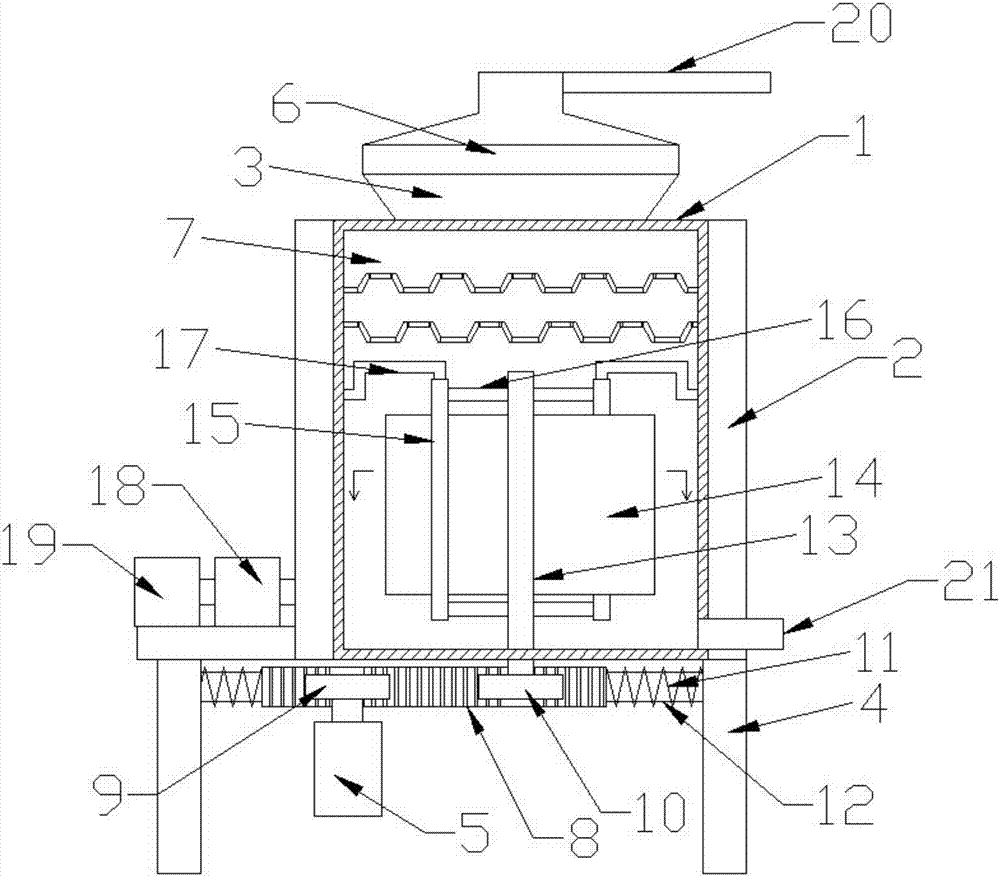

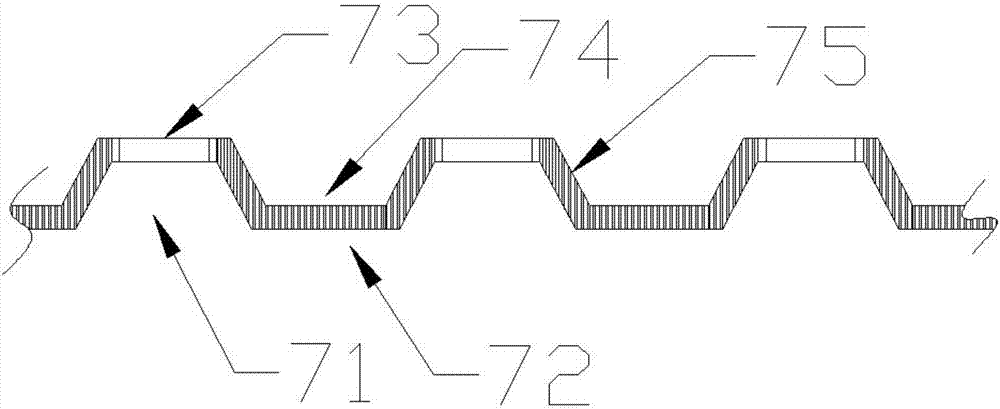

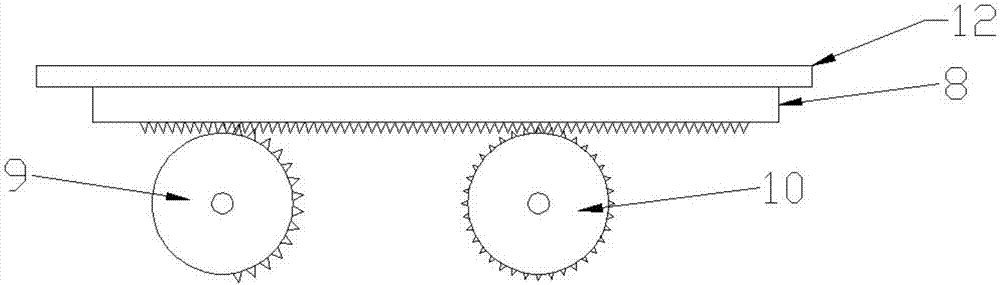

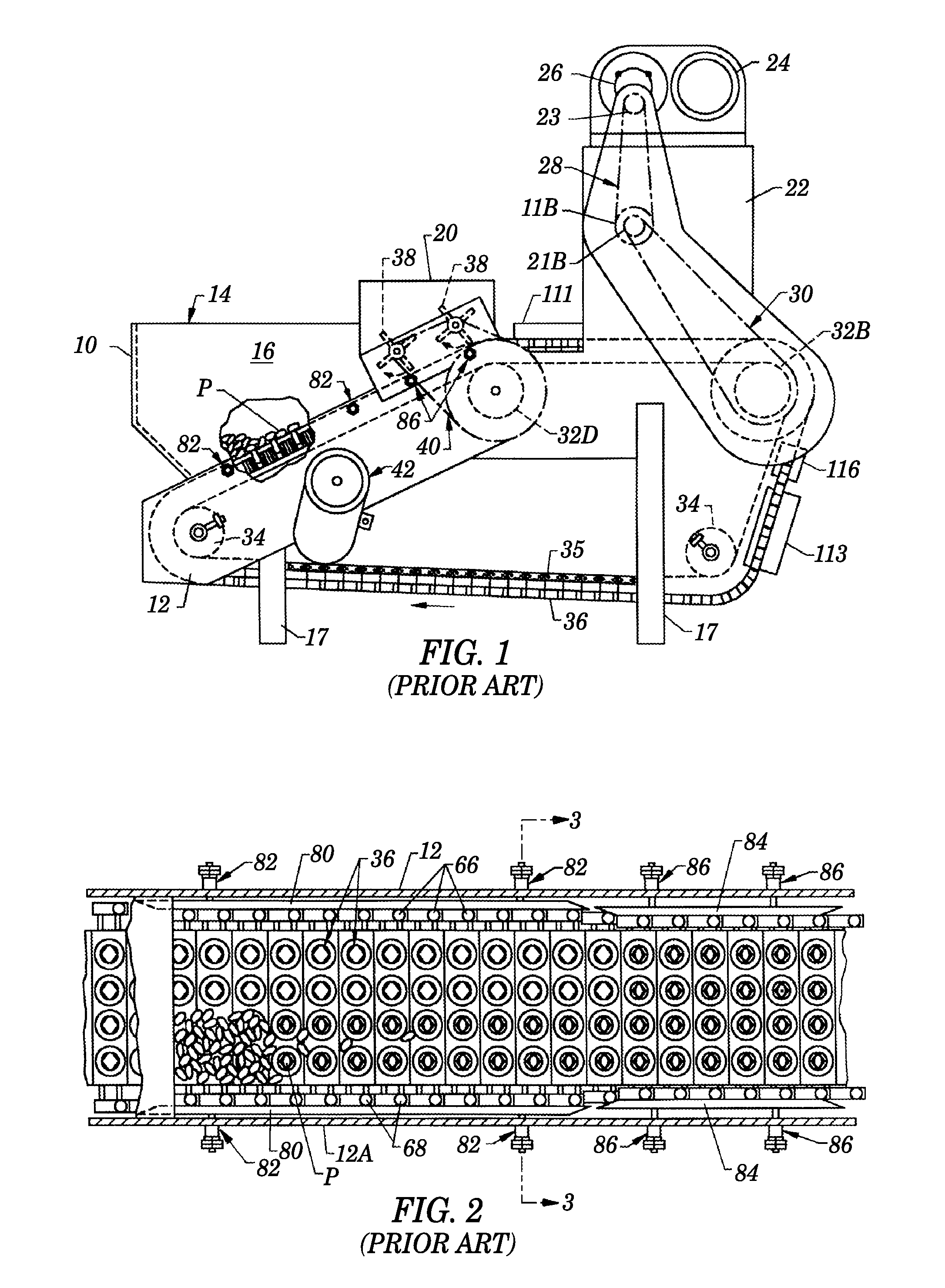

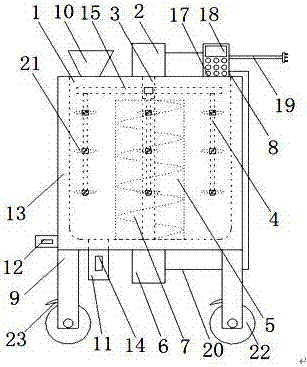

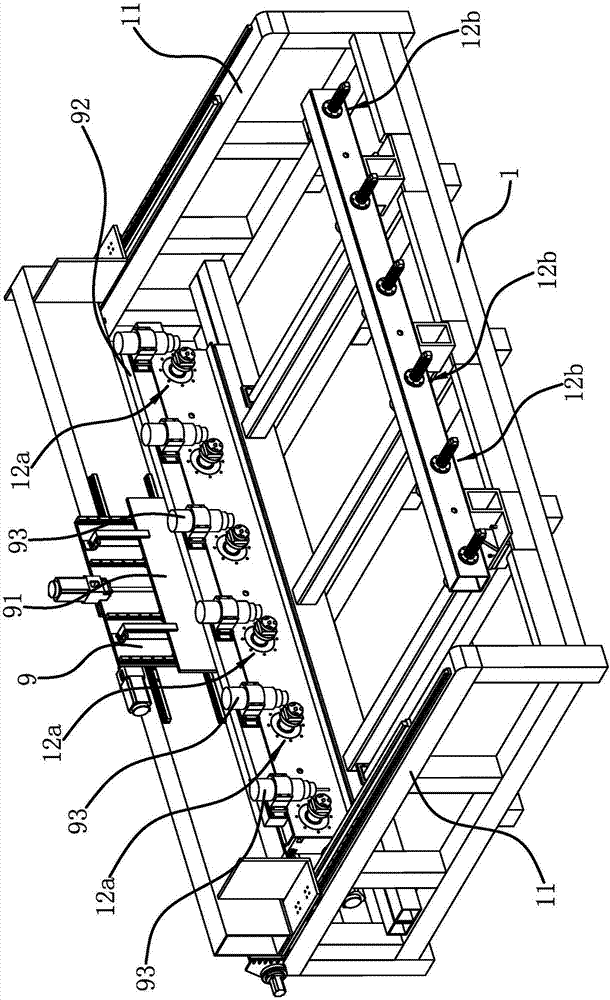

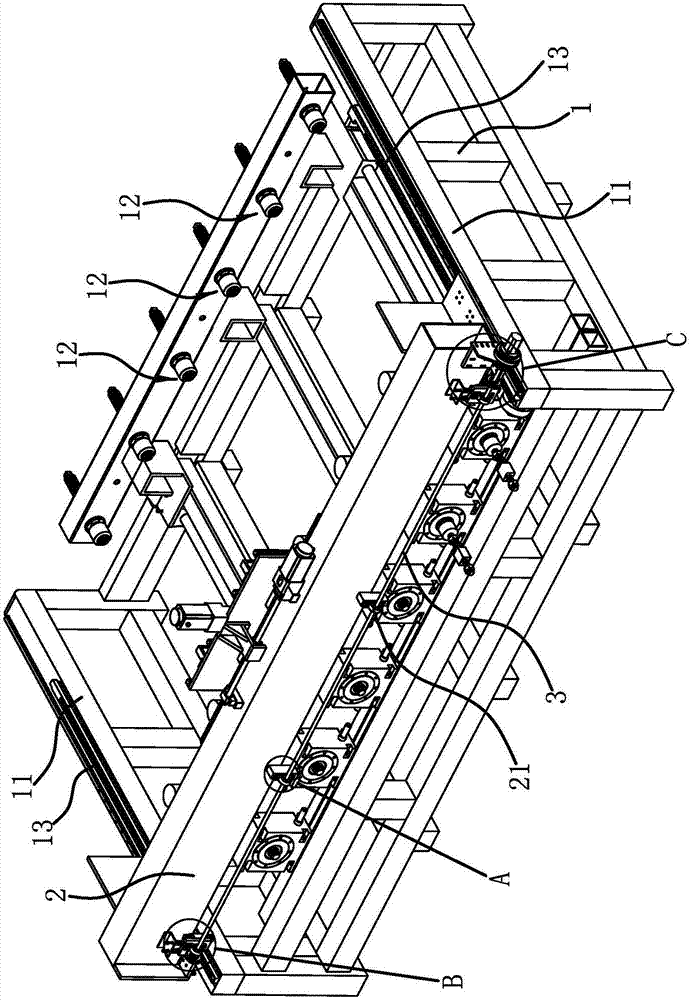

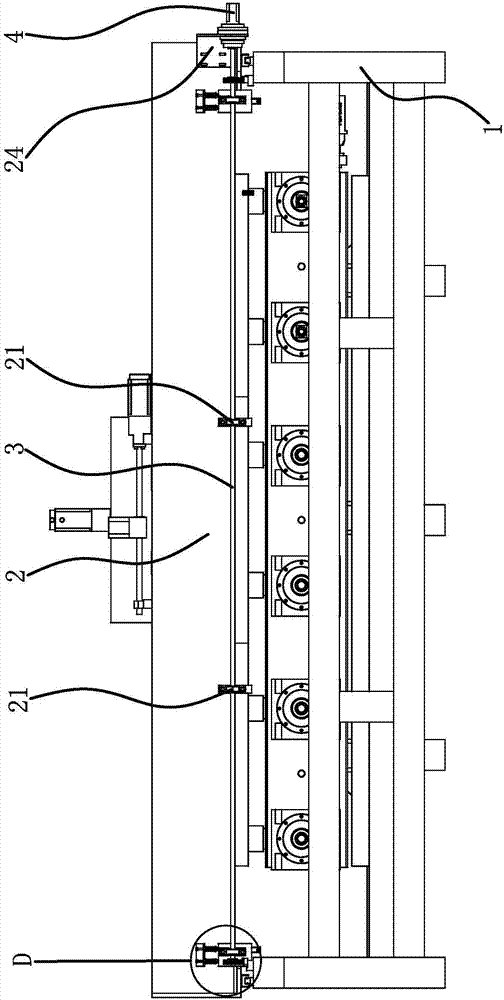

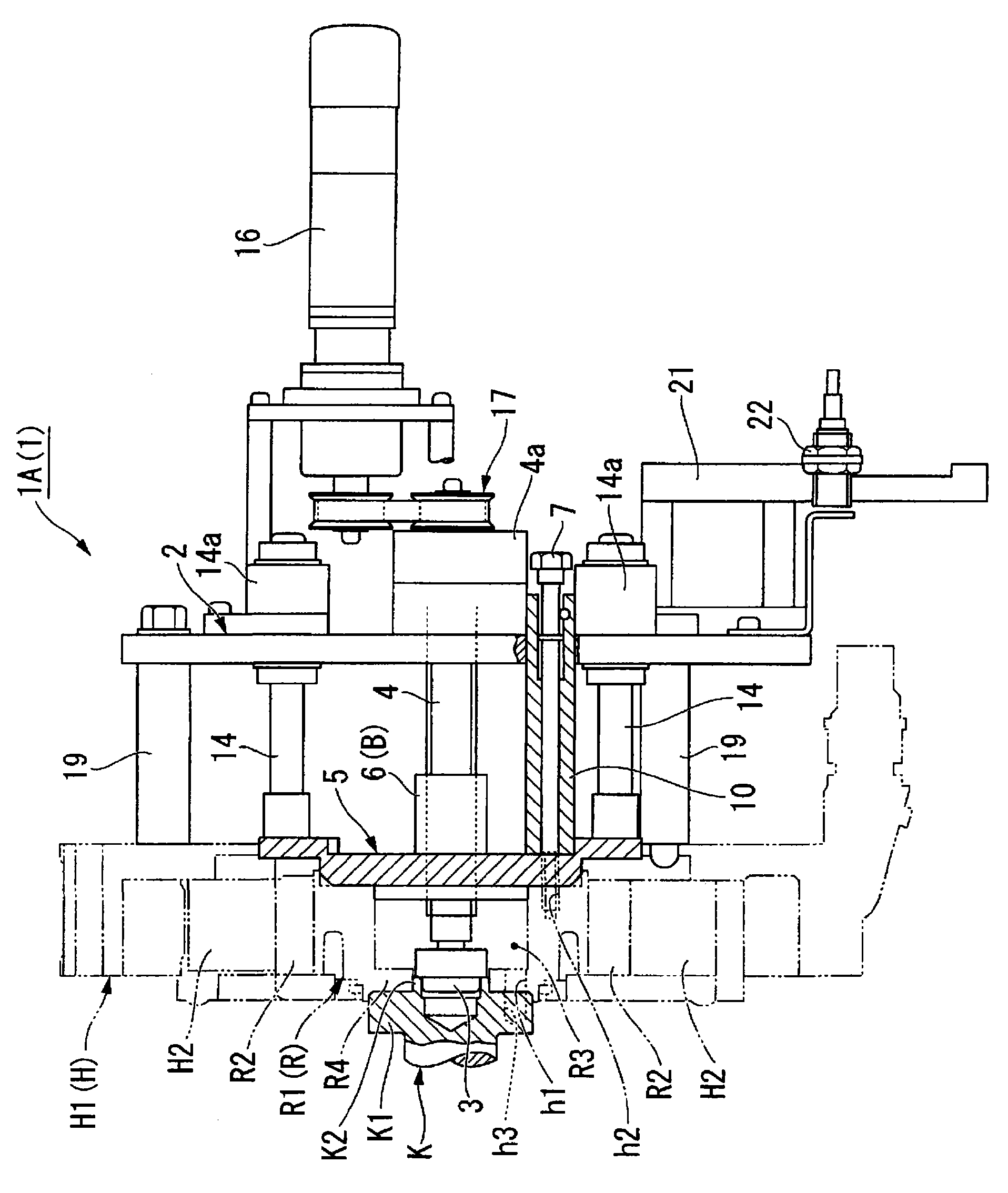

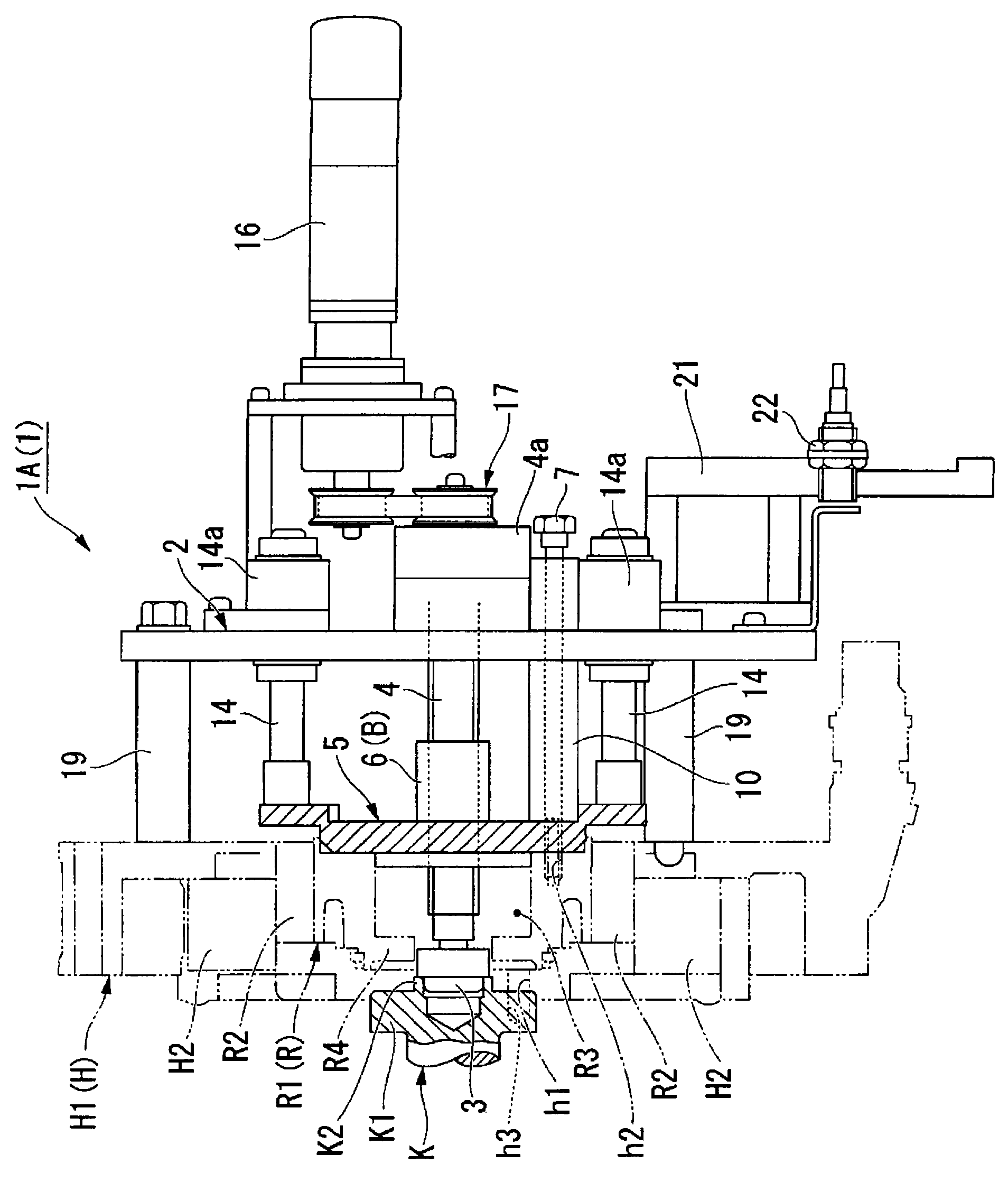

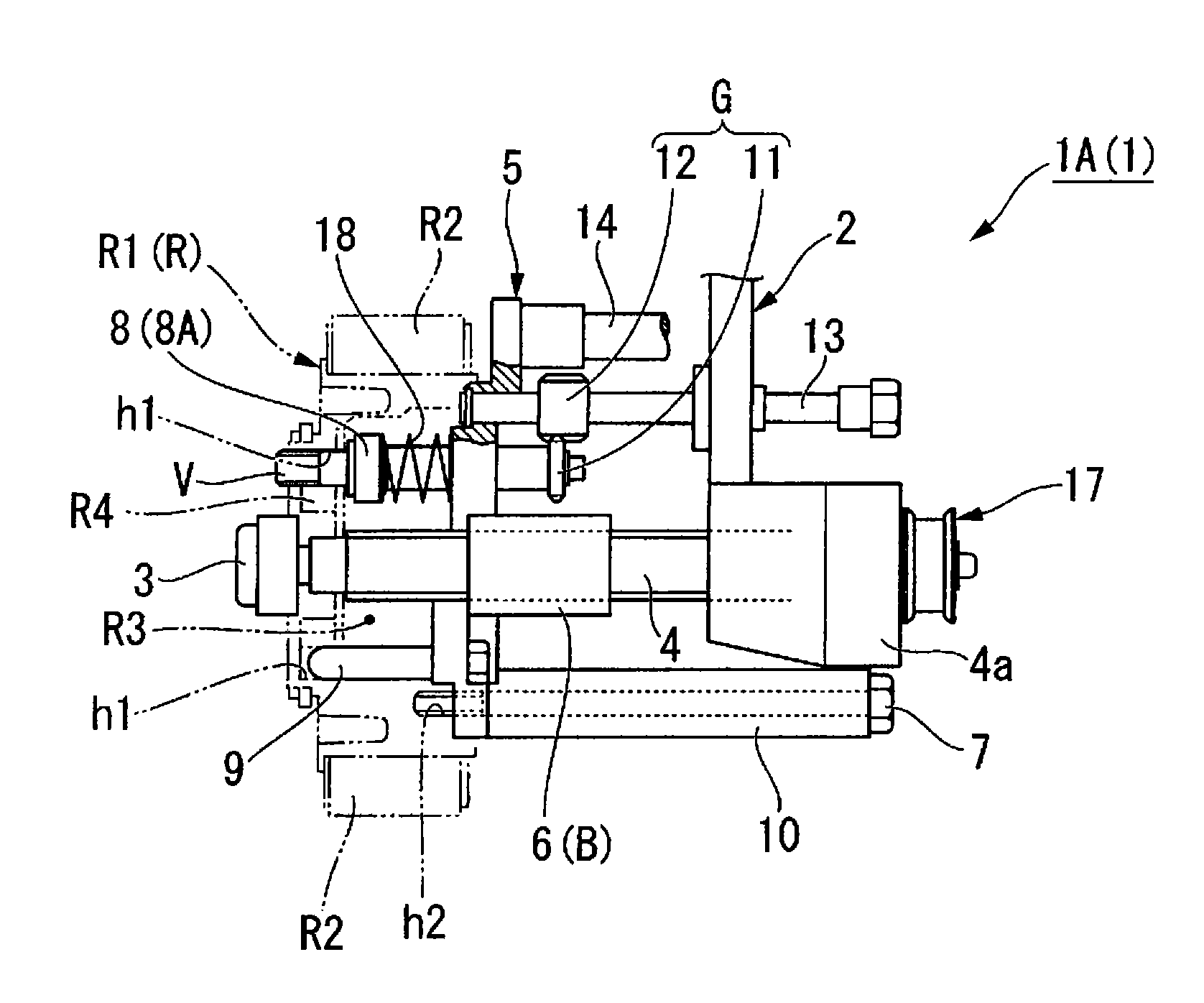

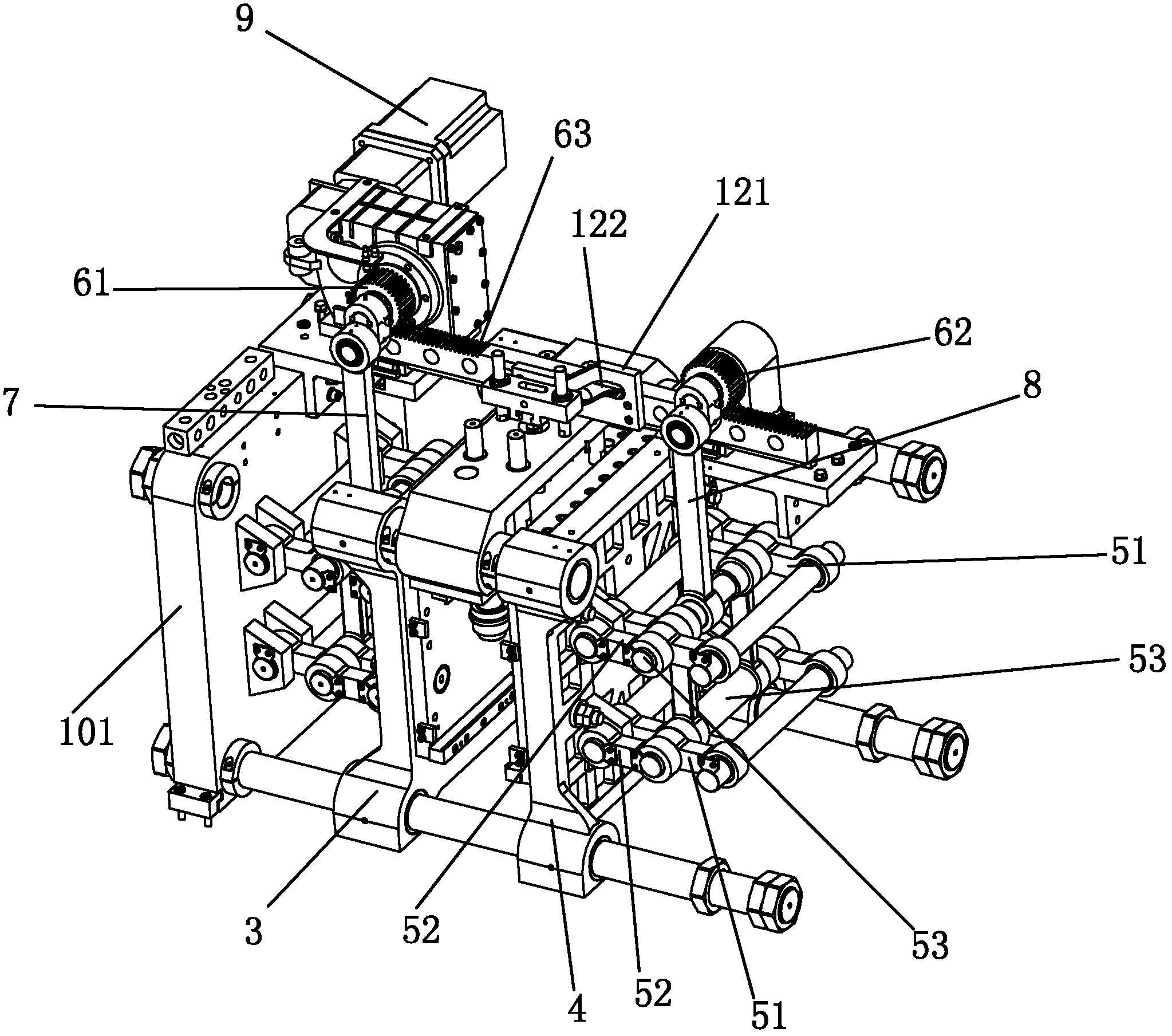

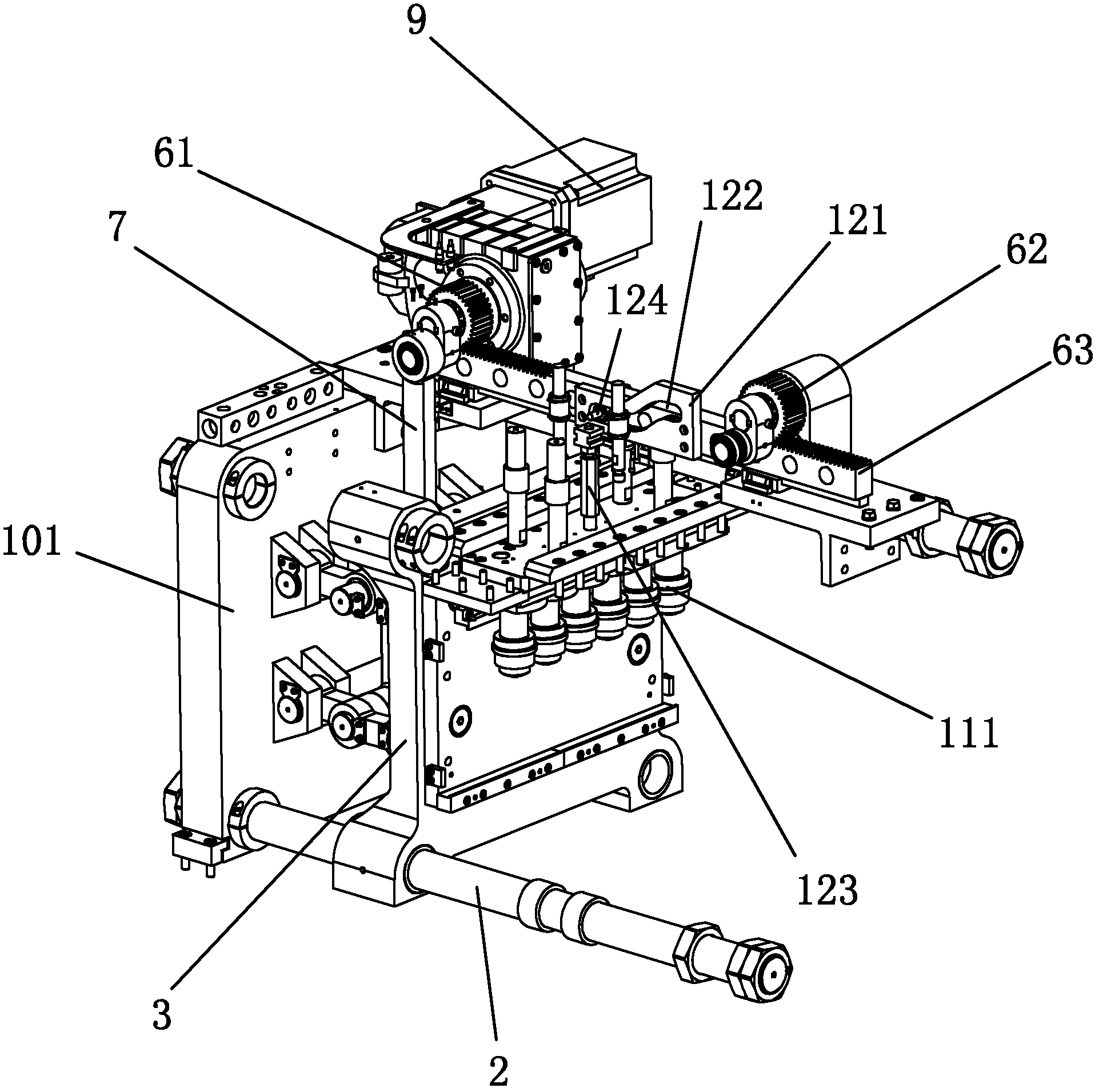

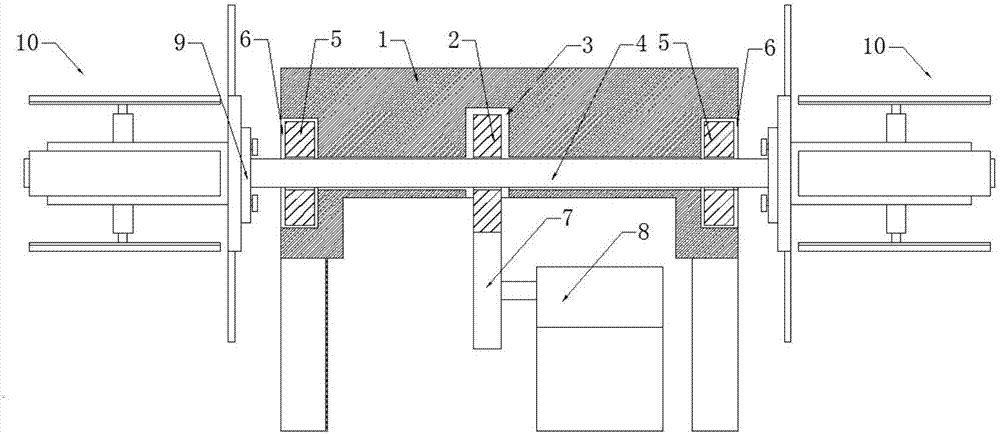

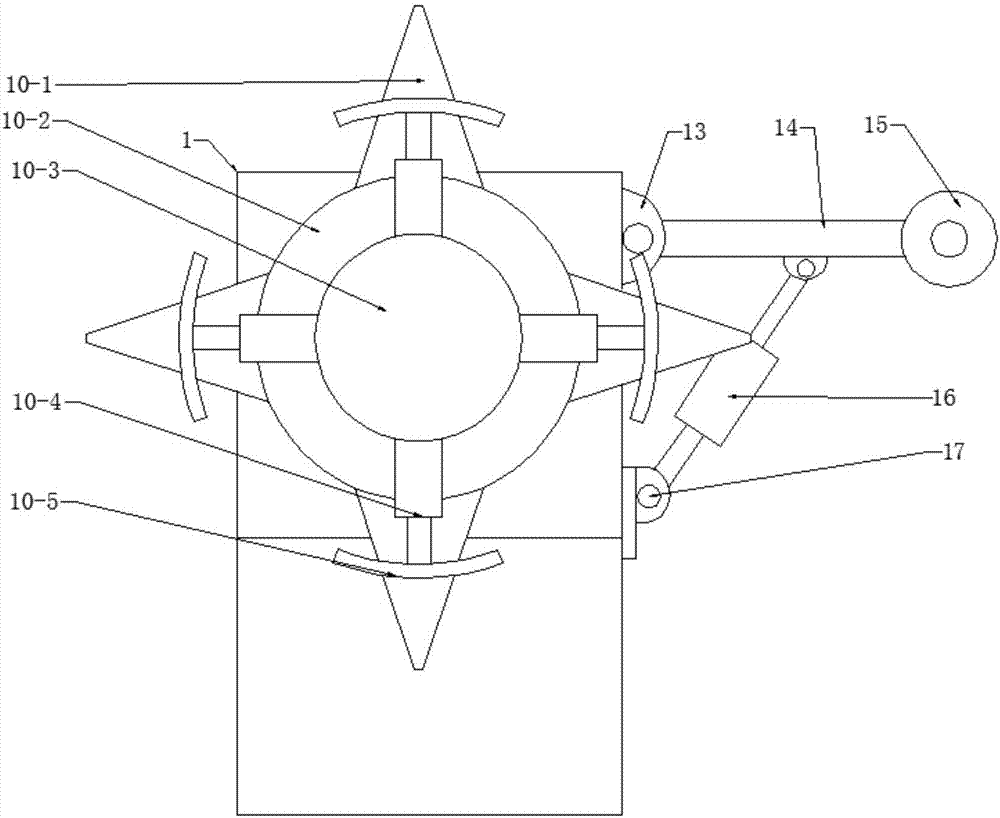

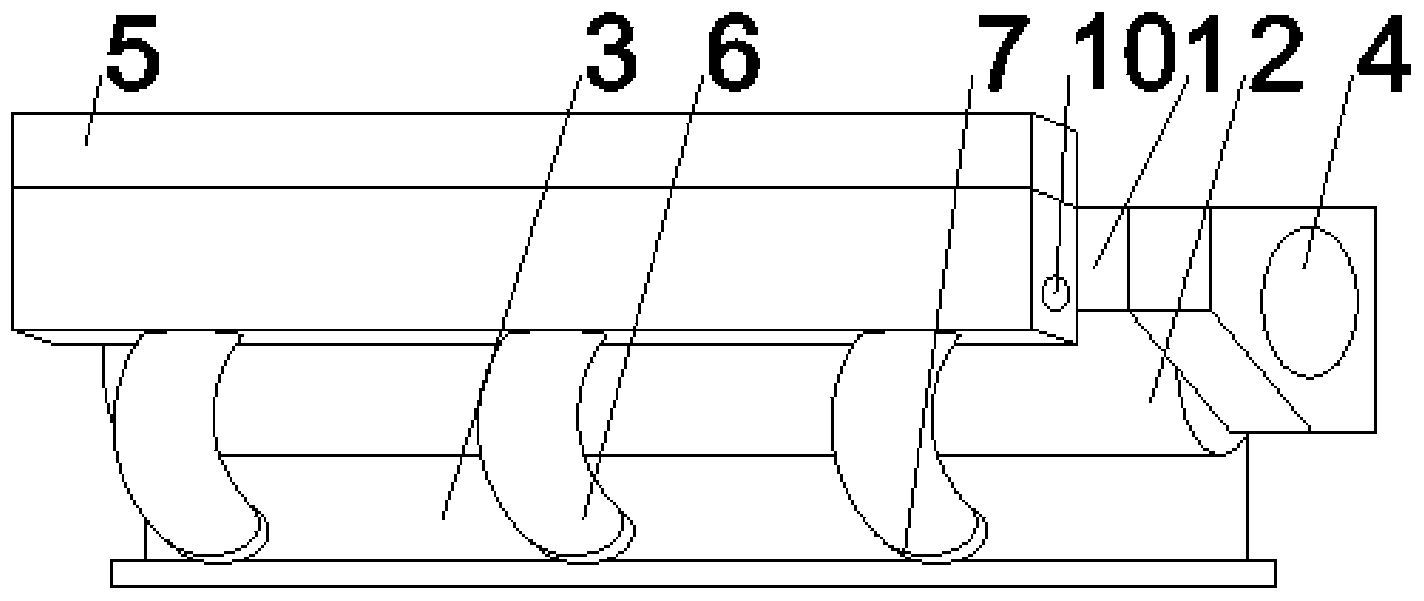

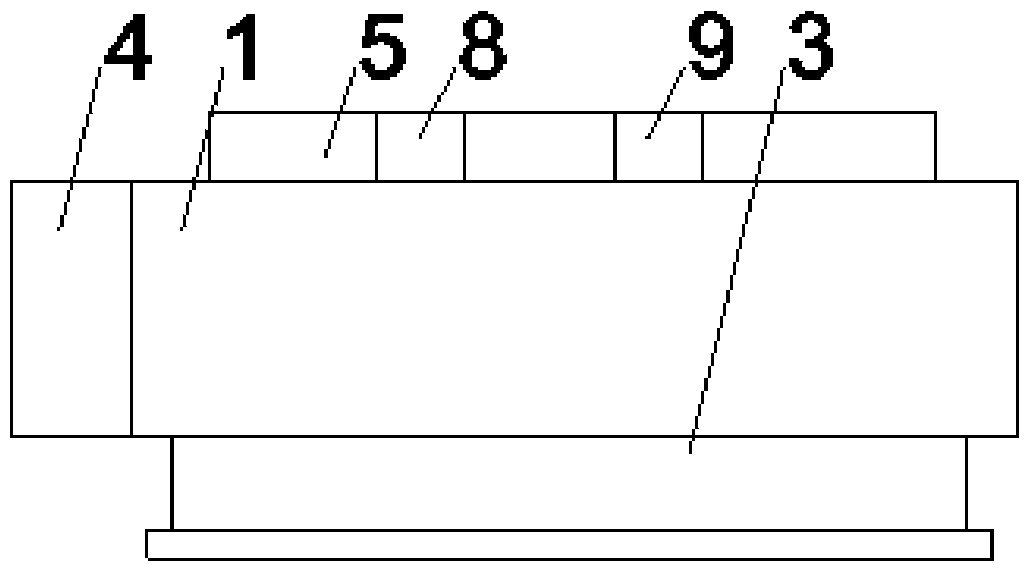

Hemming machine

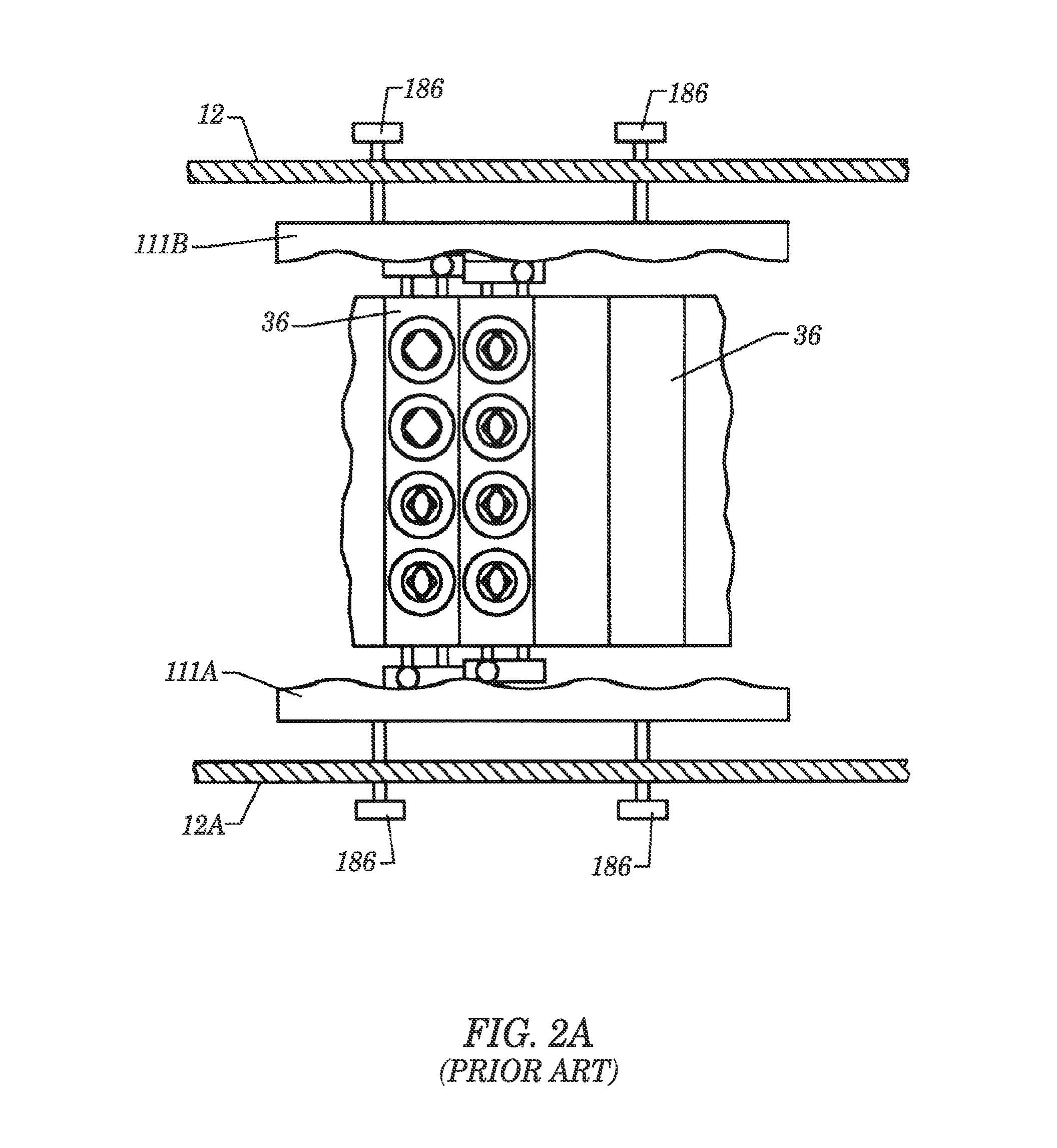

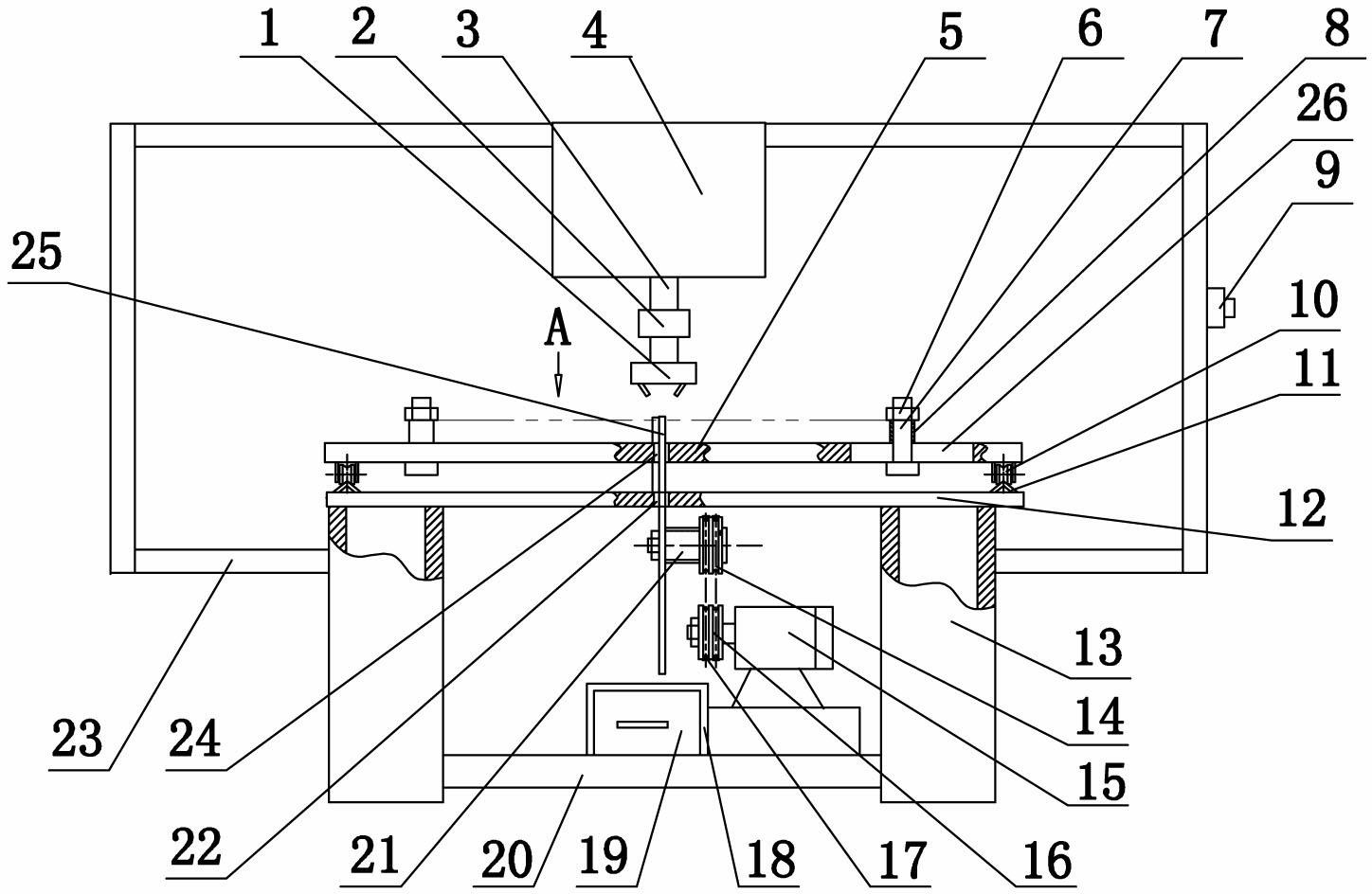

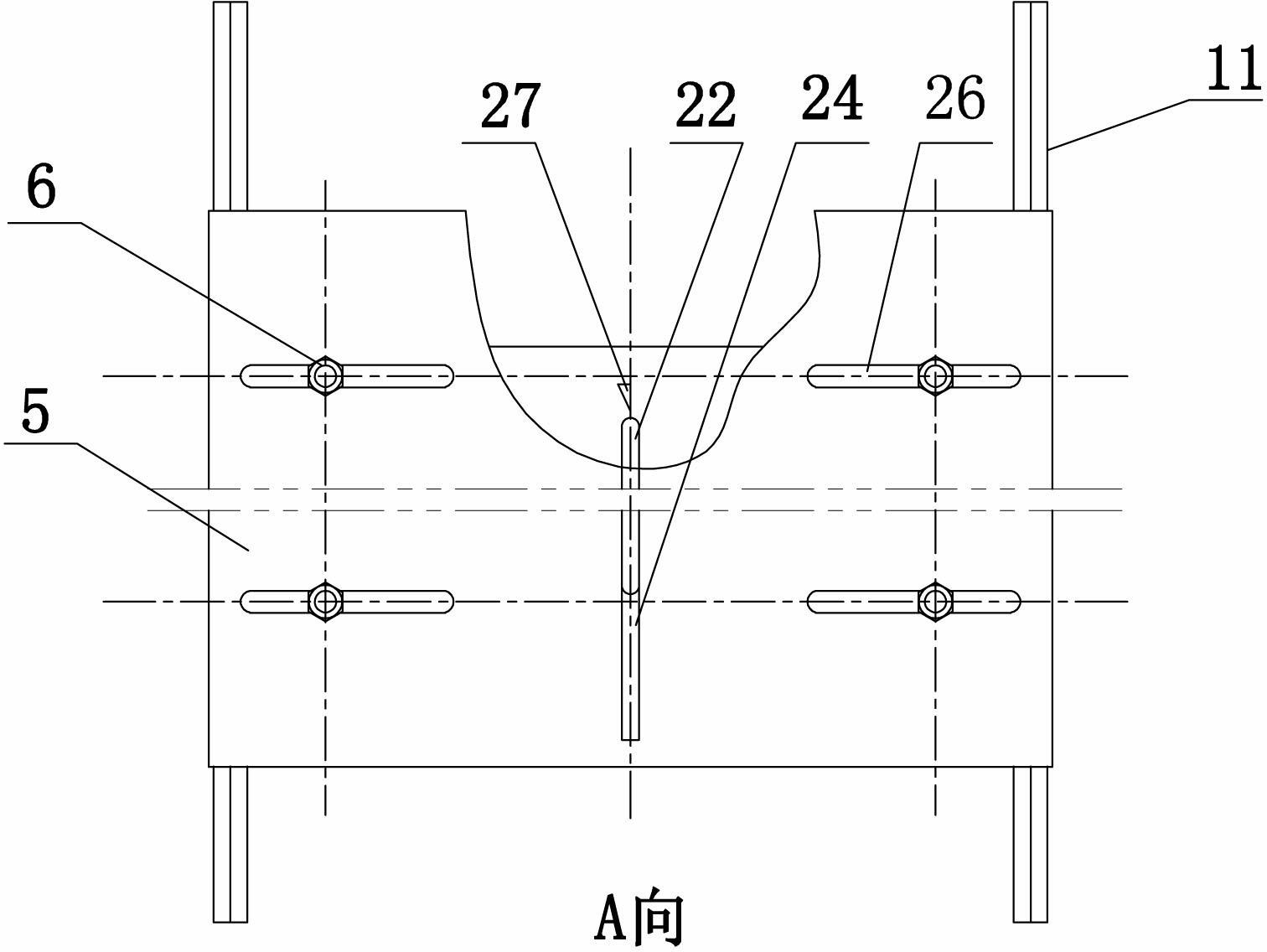

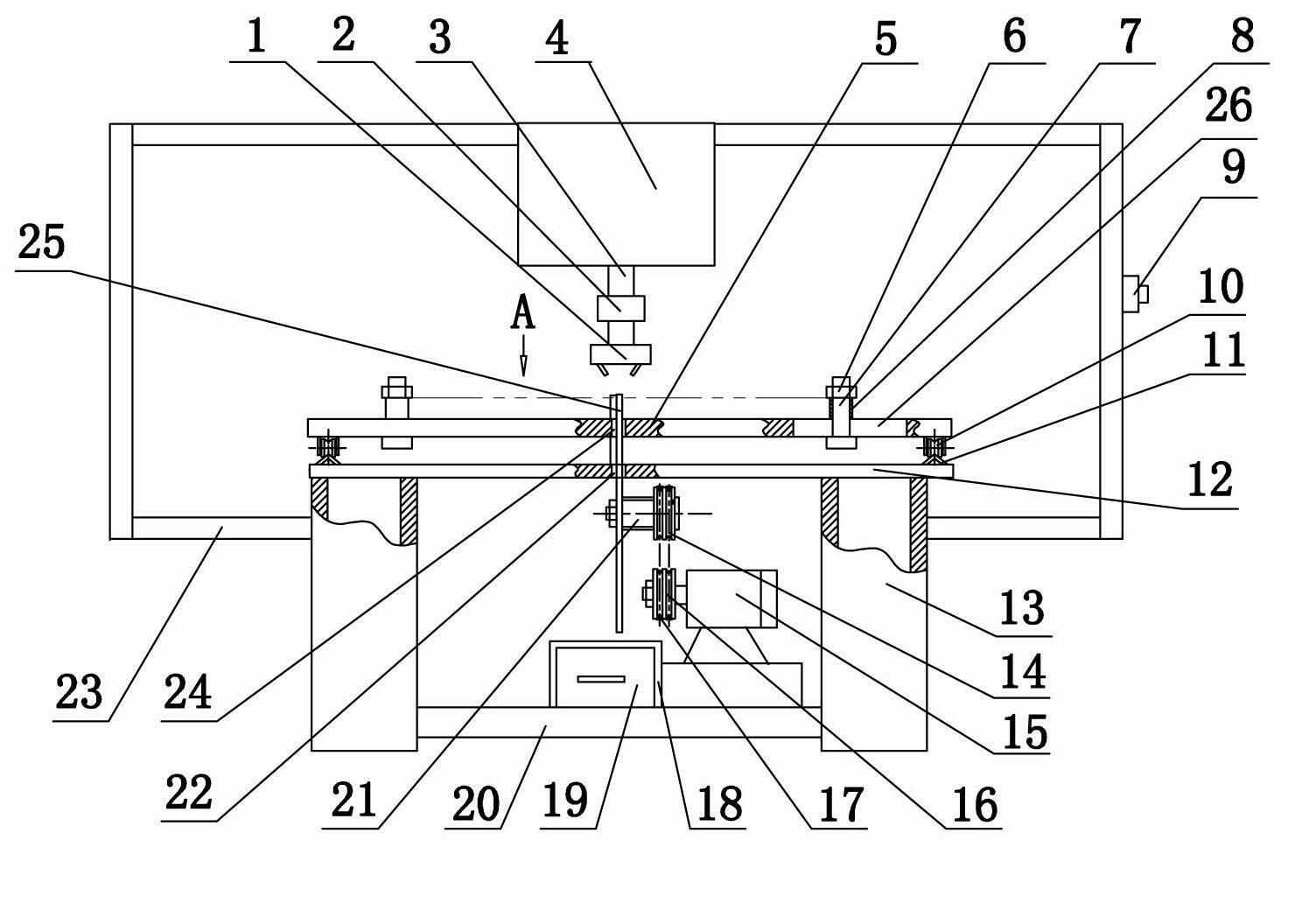

A hemming machine is disclosed having a base, a nest adapted to support a part to be hemmed, a nest carrier which supports the nest and in which both the nest and nest carrier are vertically movably mounted to the base. At least one hemming die is laterally slidably mounted to the base and movable between an extended position in which the die overlies a portion of the nest, and a retracted position in which the die is spaced laterally outwardly from the nest. A lock unit selectively locks the nest carrier against vertical movement relative to the base in at least one, and preferably two positions, so that, with the nest carrier locked against movement relative to the base, inflation of a hydraulic bladder sandwiched between the nest and nest carrier displaces the nest vertically upwardly from the carrier so that the part carried by the nest is compressed against the hemming dies and performs the hemming operation. Preferably, a single drive shaft not only displaces the nest and nest carrier, but also powers the hydraulic circuit to inflate the bladder and thus upwardly displace the nest relative to the nest carrier with an amplified force required to achieve the final flattening of the hem.

Owner:VALIANT CO LTD

Power cable coiling device

Owner:陈佳敏

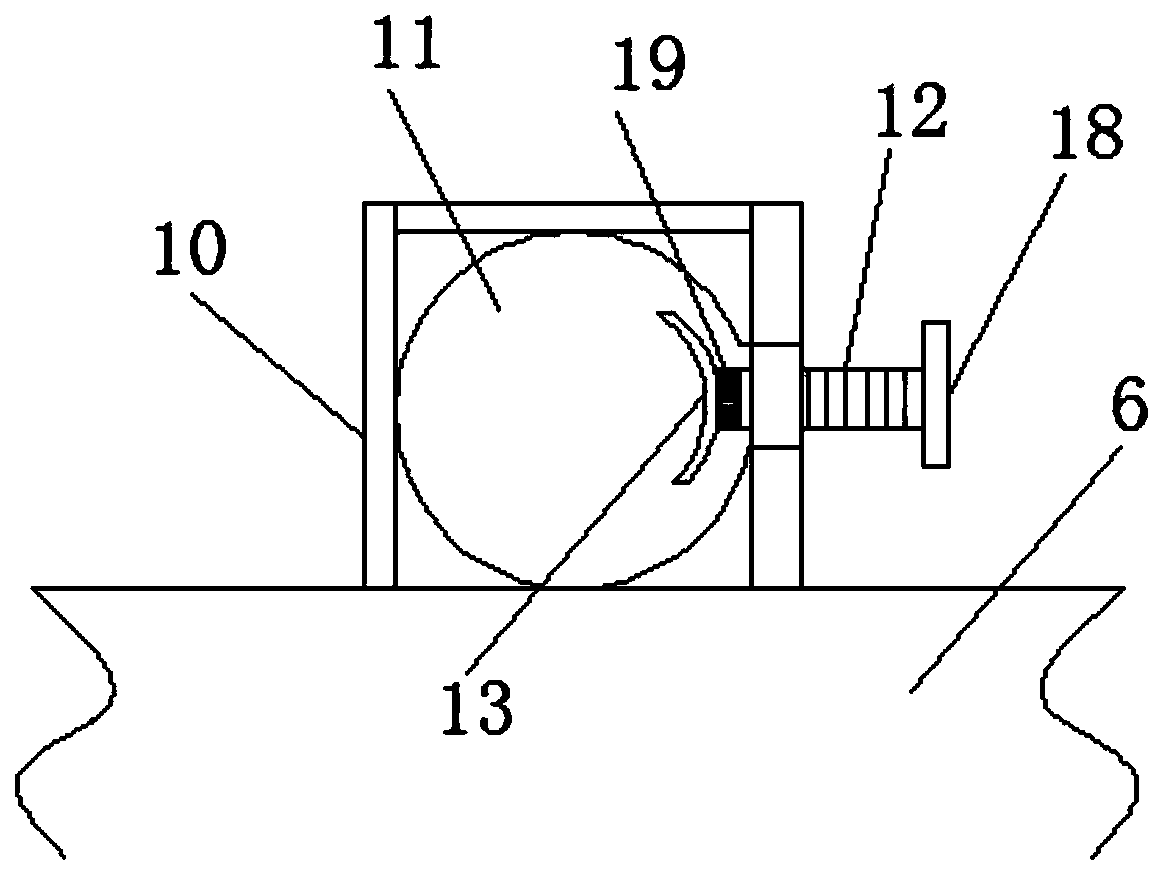

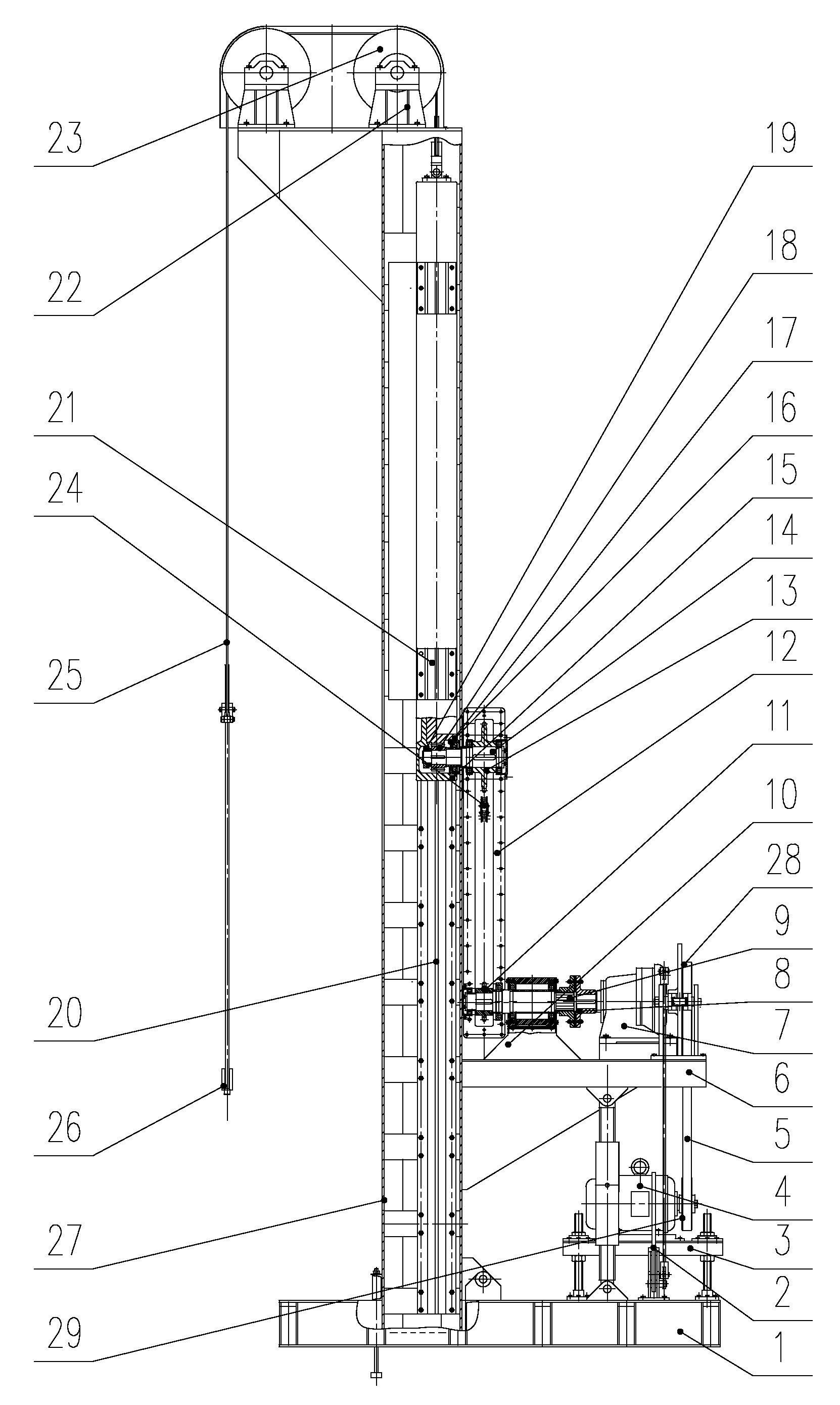

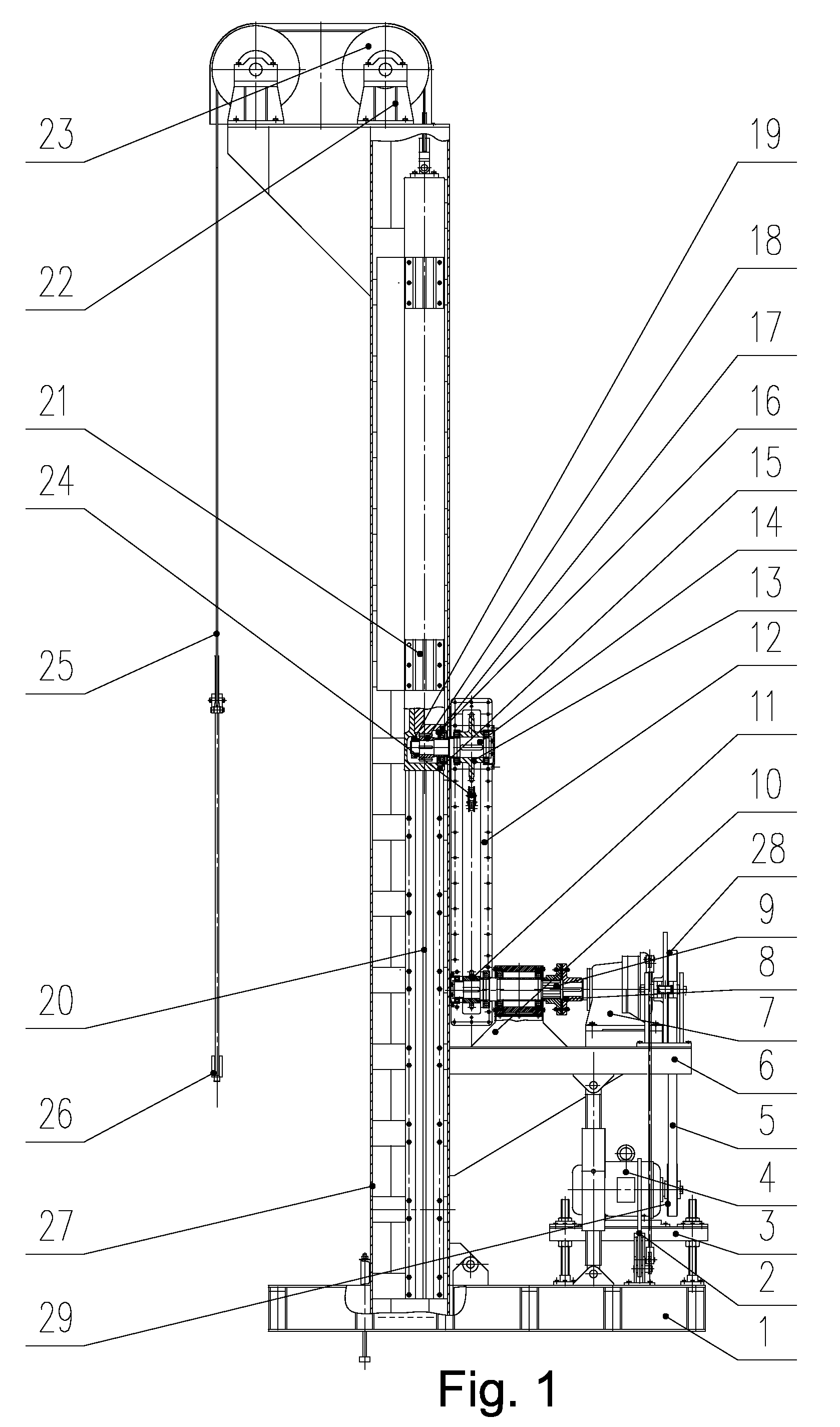

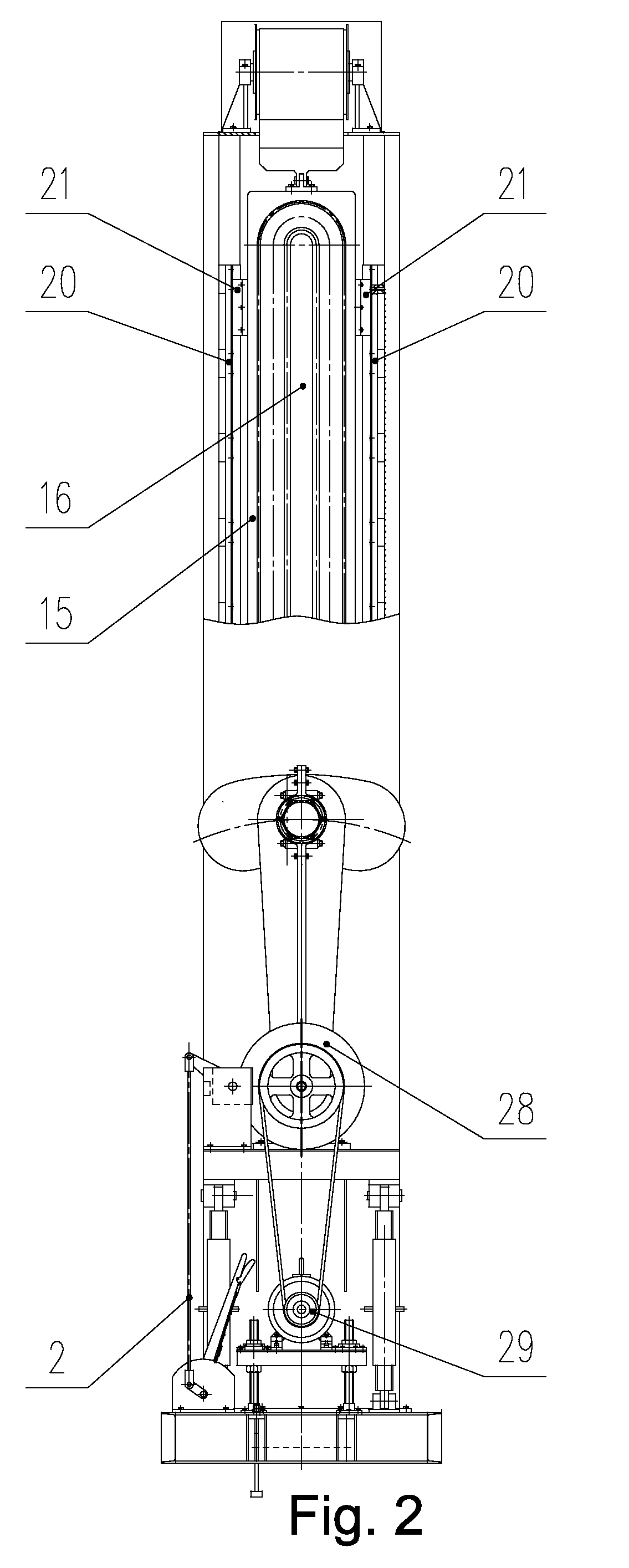

Ring Rack Oil Pumping Machine

Owner:SINOPEC GROUP SHENGLI GASOLINEEUM ADMINISTRATION TRANSPORT CORP

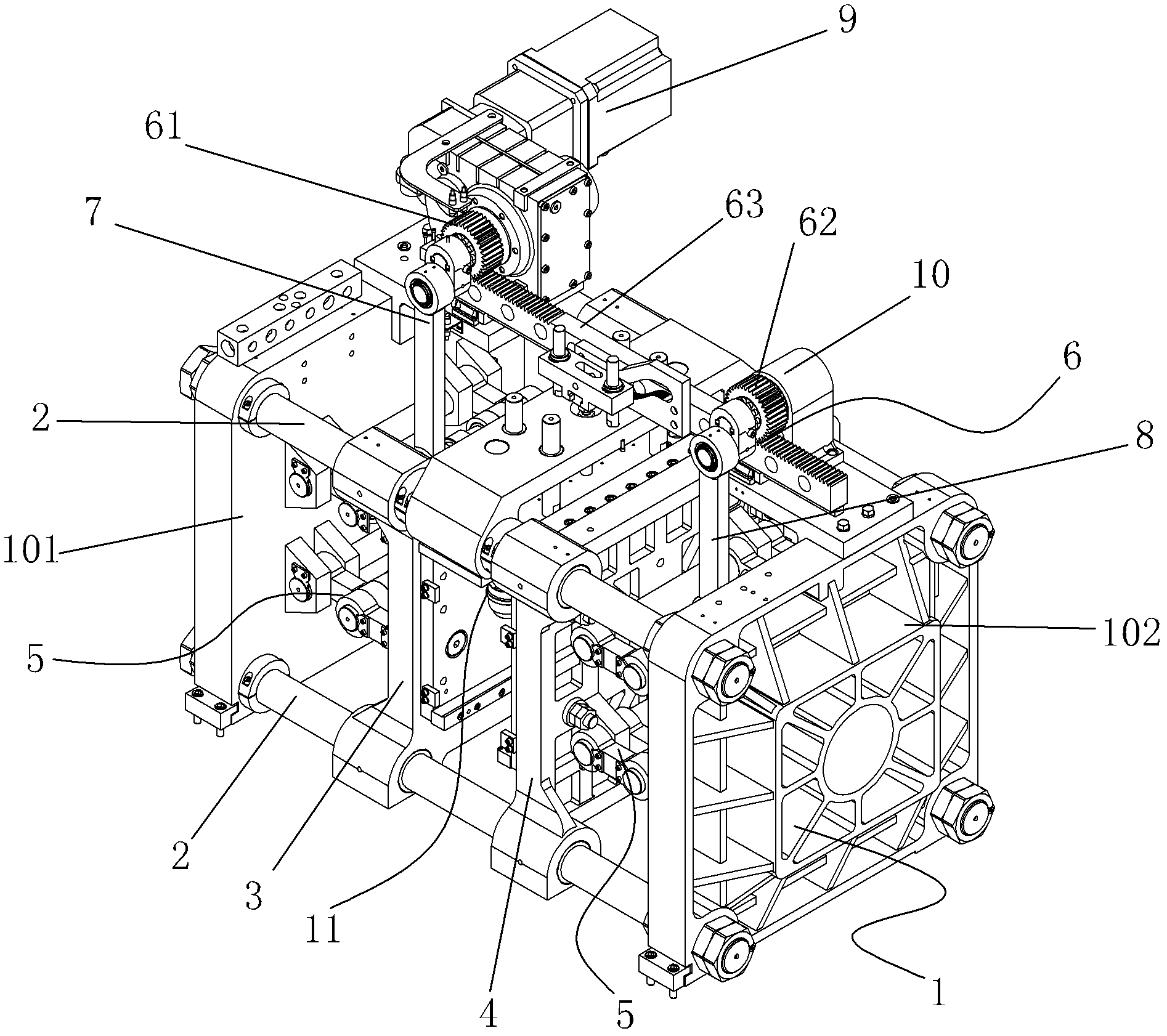

Double-motor driving device with parking brake of electric forklift

InactiveCN103522885AMeet input power requirementsBroaden the tonnage classElectric propulsion mountingGearing controlBrake torqueMotor drive

The invention relates to a double-motor driving device with a parking brake of an electric forklift. The double-motor driving device comprises a speed reducer and driving motors, wherein the speed reducer comprises an output shaft, a left input shaft and a right input shaft which are parallel to each other. An output gear is arranged on the output shaft, a left input gear is arranged on the left input shaft, a right input gear is arranged on the right input shaft, and the left input gear and the right input gear are both meshed with the output gear constantly. The extending-out end of the output shaft is connected with the input shaft of the speed reducer through a transmission shaft, the extending-out end of the left input shaft is provided with a braking drum and the parking brake respectively, the other end of the left input shaft is connected with a left driving motor through a spline, the right input shaft is connected with a right driving motor through a spline, and the left driving motor and the right driving motor are arranged side by side. According to the double-motor driving device, two small-power motors are utilized to output moment in a coupling mode, therefore, needs of input power of the finished vehicle are met, the layout is utilized reasonably, and large brake torque required by the large-tonnage forklift is achieved by means of the attached parking brake.

Owner:ANHUI HELI CO LTD

Planetary drill bit assembly for balancing reactive torque of drilling equipment in well drilling

ActiveCN101871328AImprove stabilityIncreased directional control capabilitiesDrilling rodsDirectional drillingWell drillingDrive shaft

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

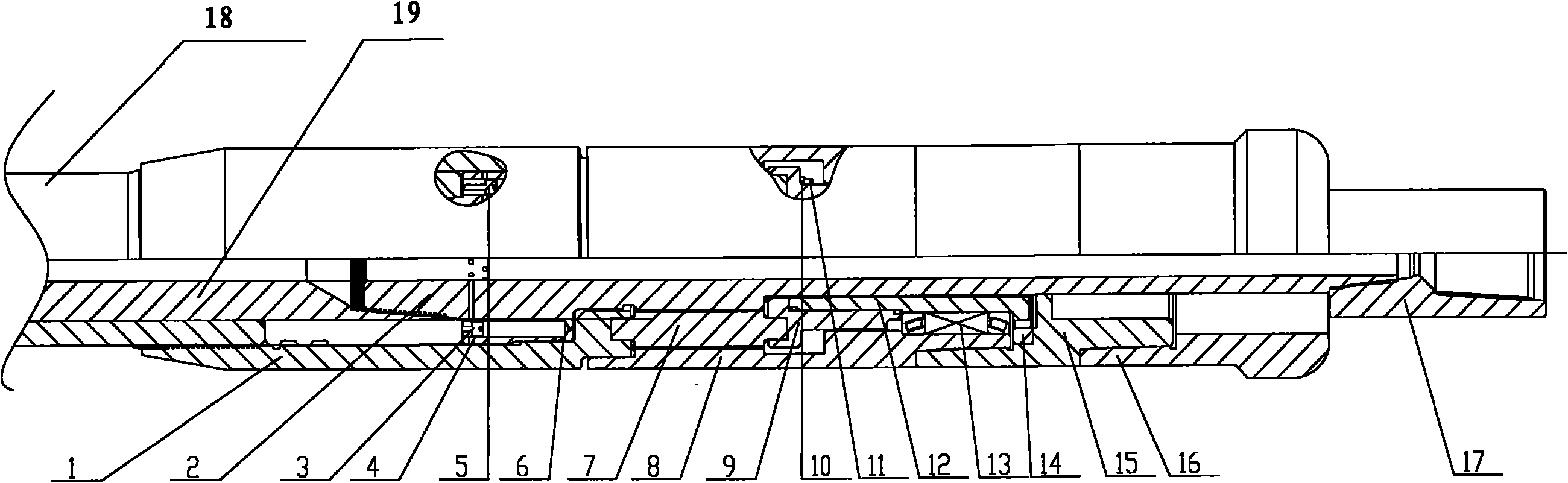

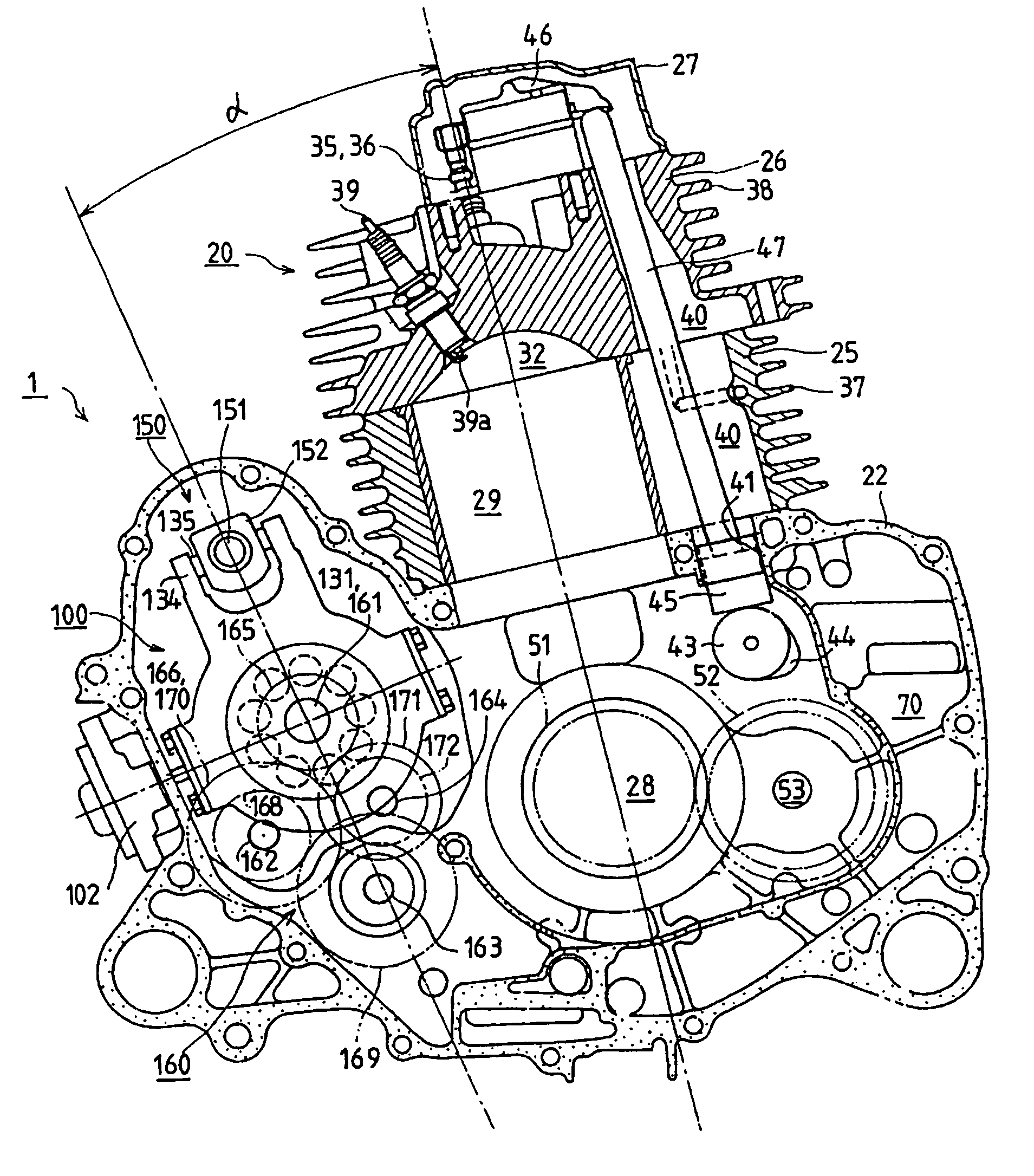

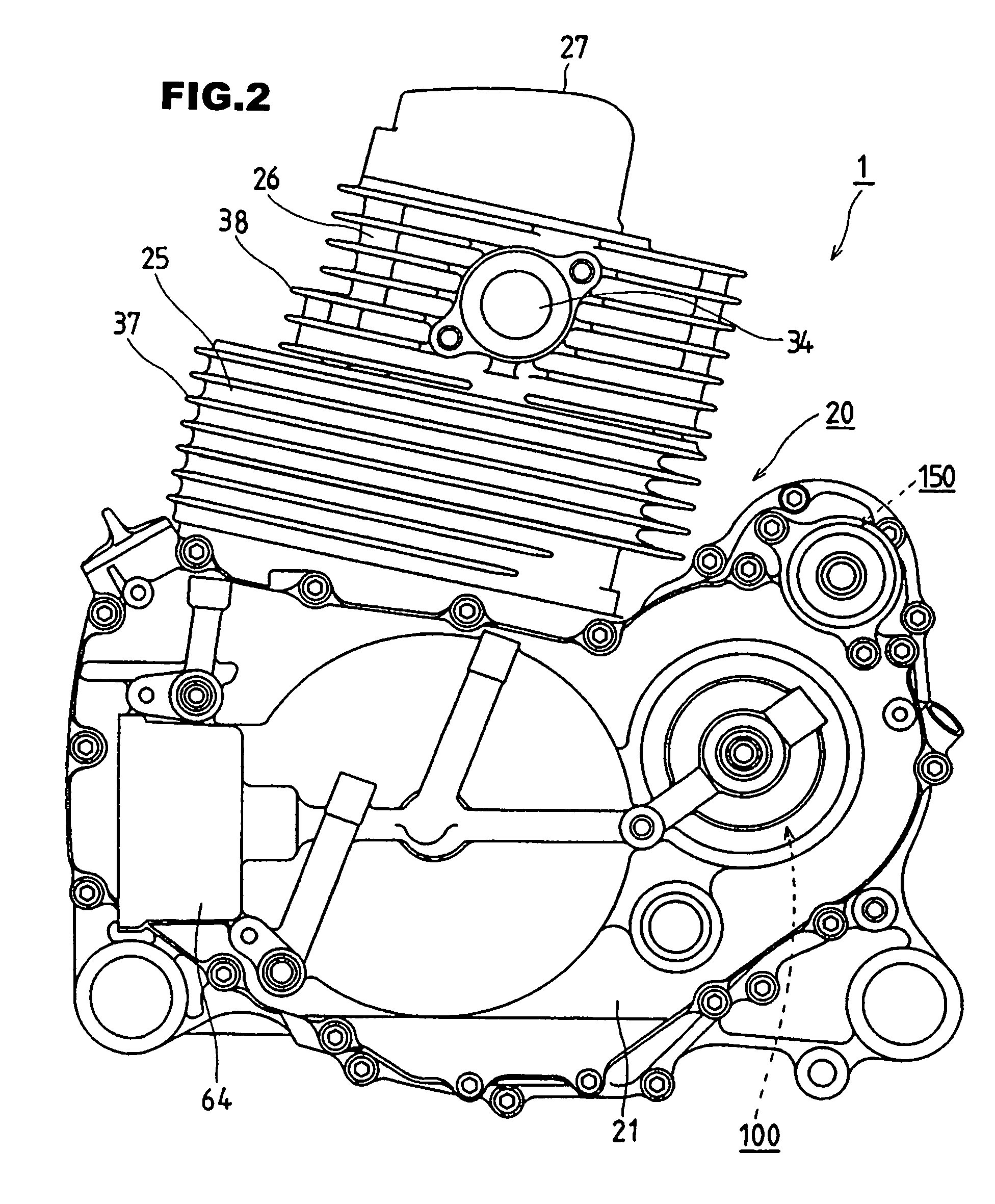

Power unit for vehicle with internal combustion engine

InactiveUS7188697B2Improve installabilityReduce widthWheel based transmissionFrictional rollers based transmissionExternal combustion engineDrive shaft

Owner:HONDA MOTOR CO LTD

Electric cable cutter

InactiveUS20140007433A1Reduce thicknessSmall sizeApparatus for cutting/splicing cablesCuttersDrive shaftCoupling

Owner:TOA INTERSYST

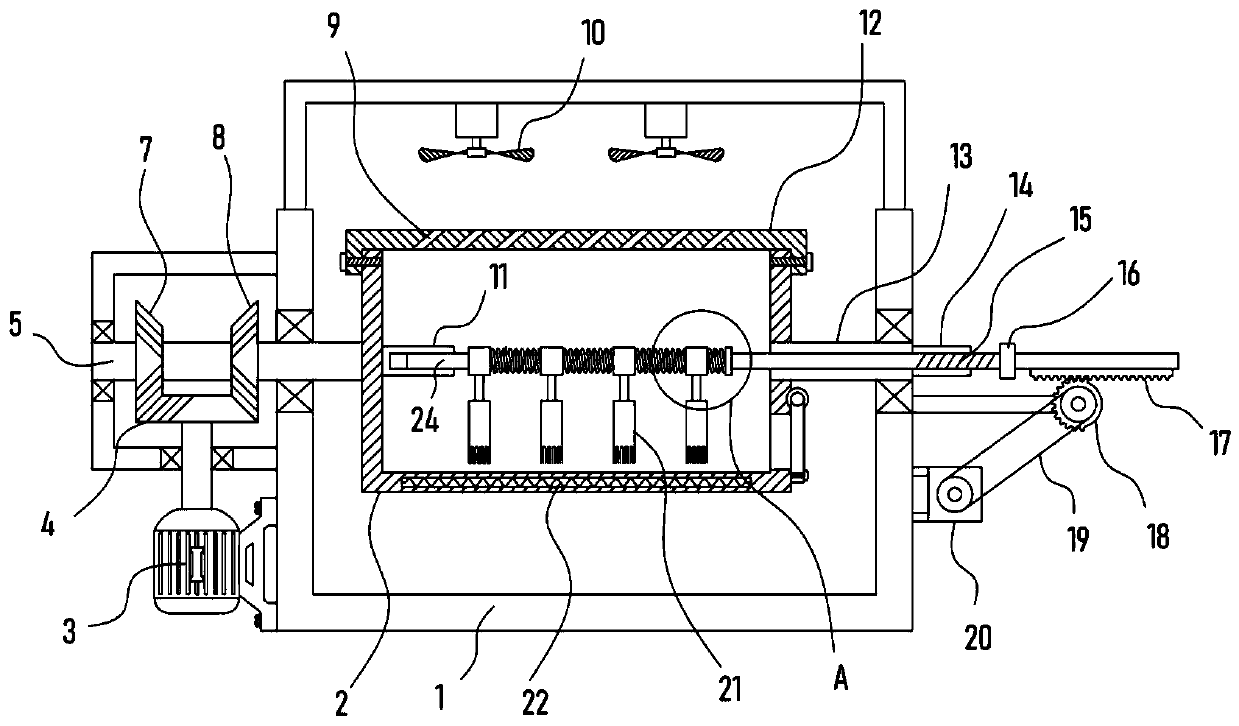

Feed processing dryer capable of stirring in positive and negative rotation mode

InactiveCN107280051AEasy to storeSmooth and safe deliveryFeeding-stuffRotary stirring mixersDrive shaftEngineering

Owner:王淑兰

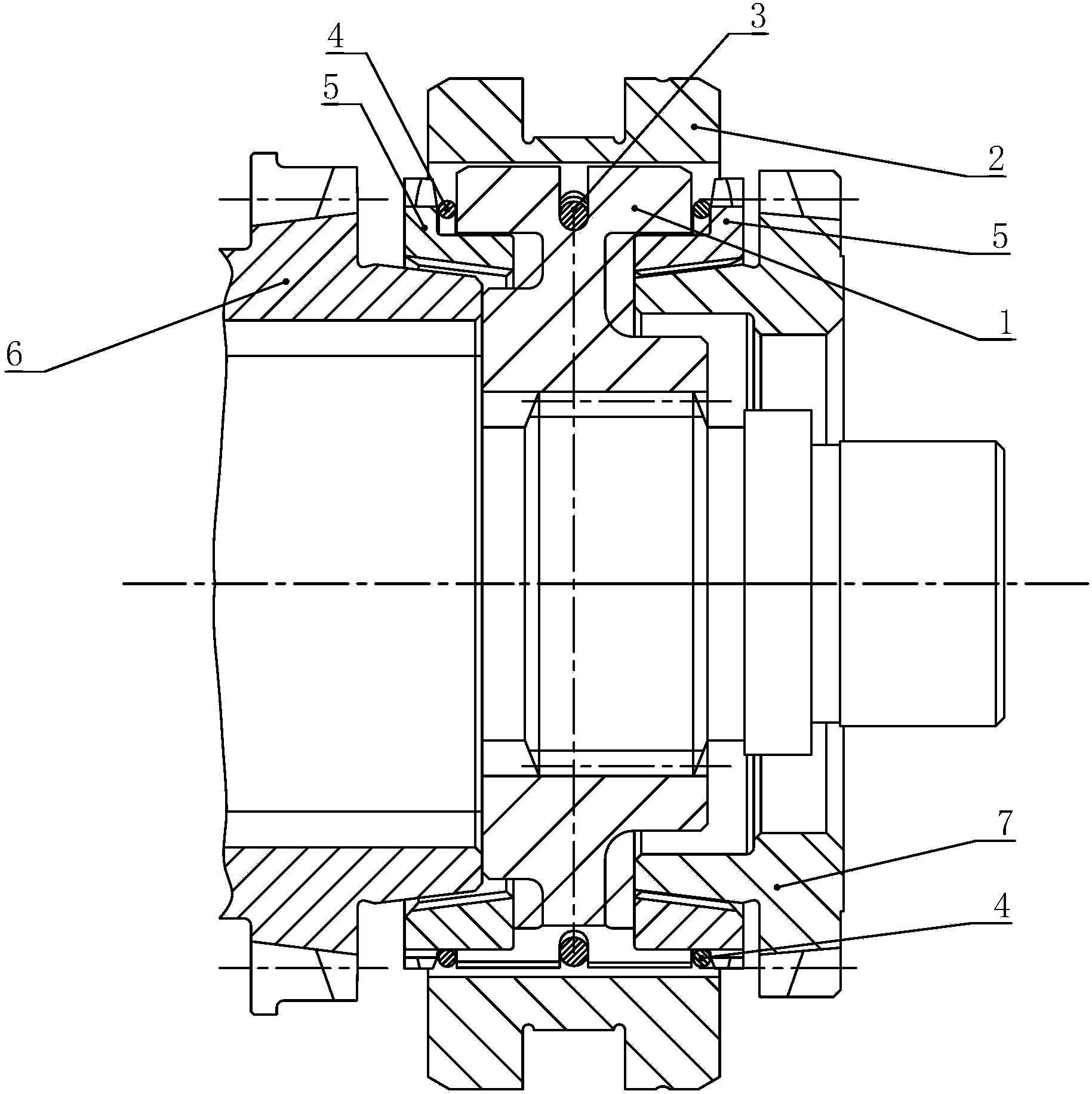

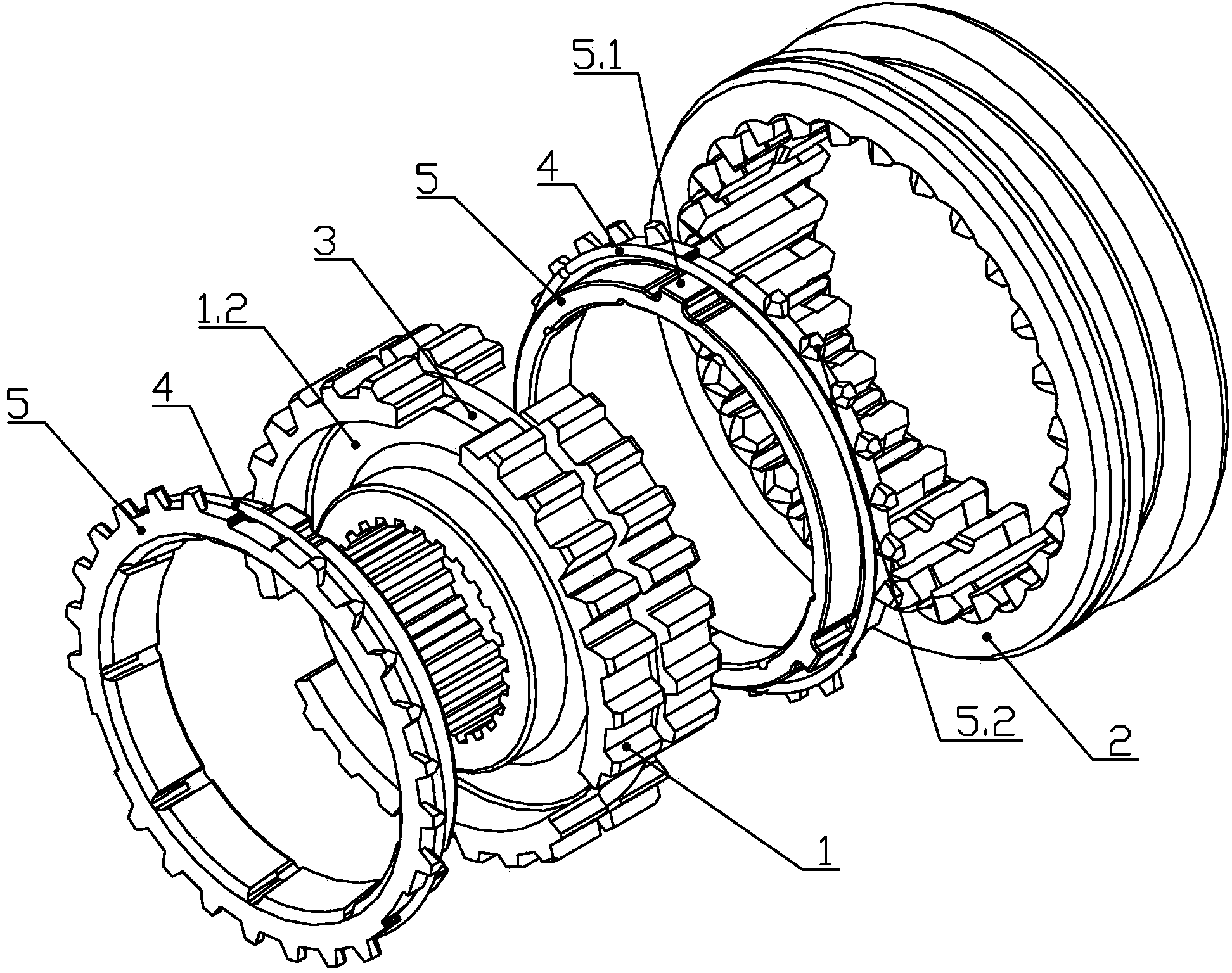

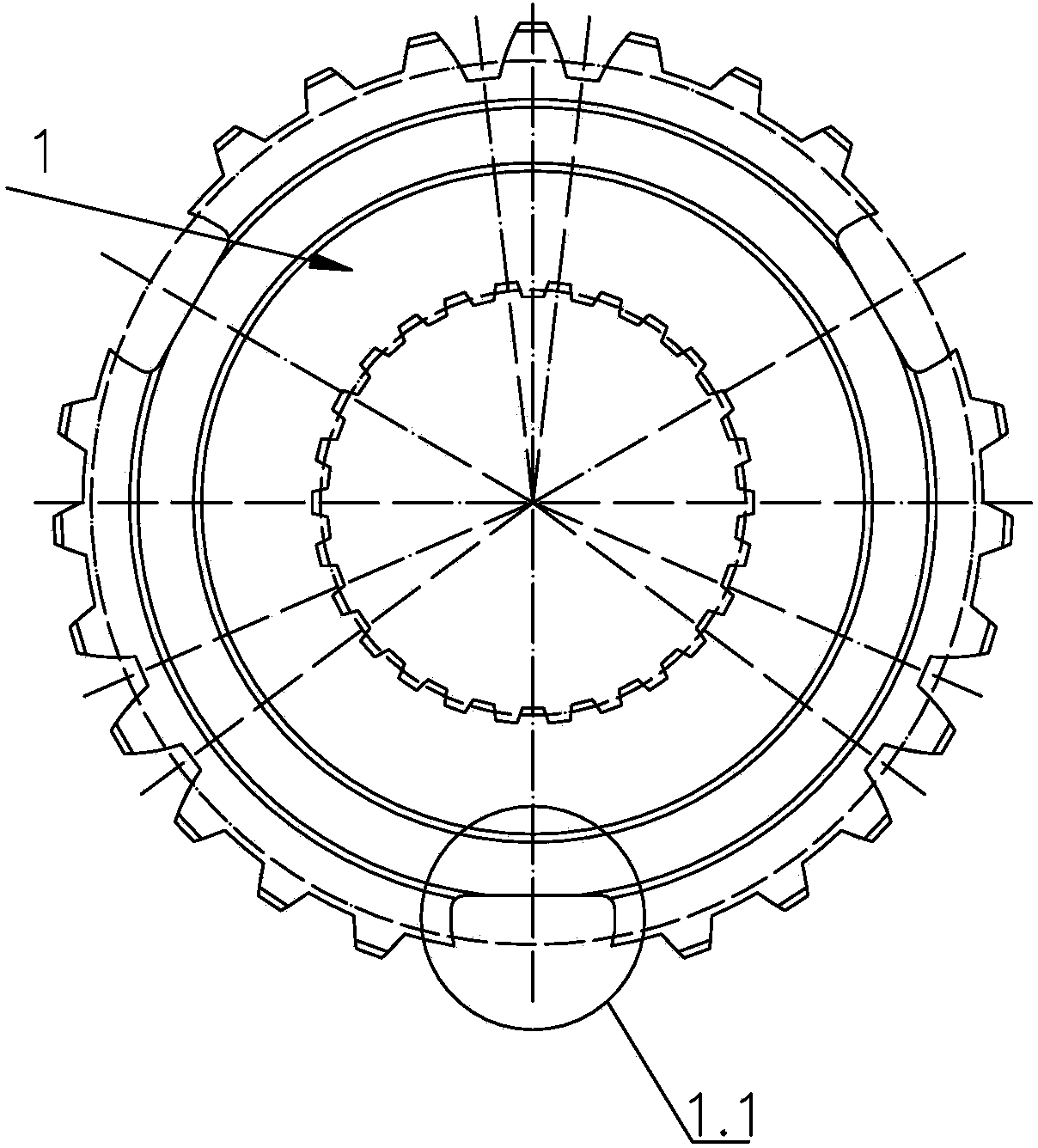

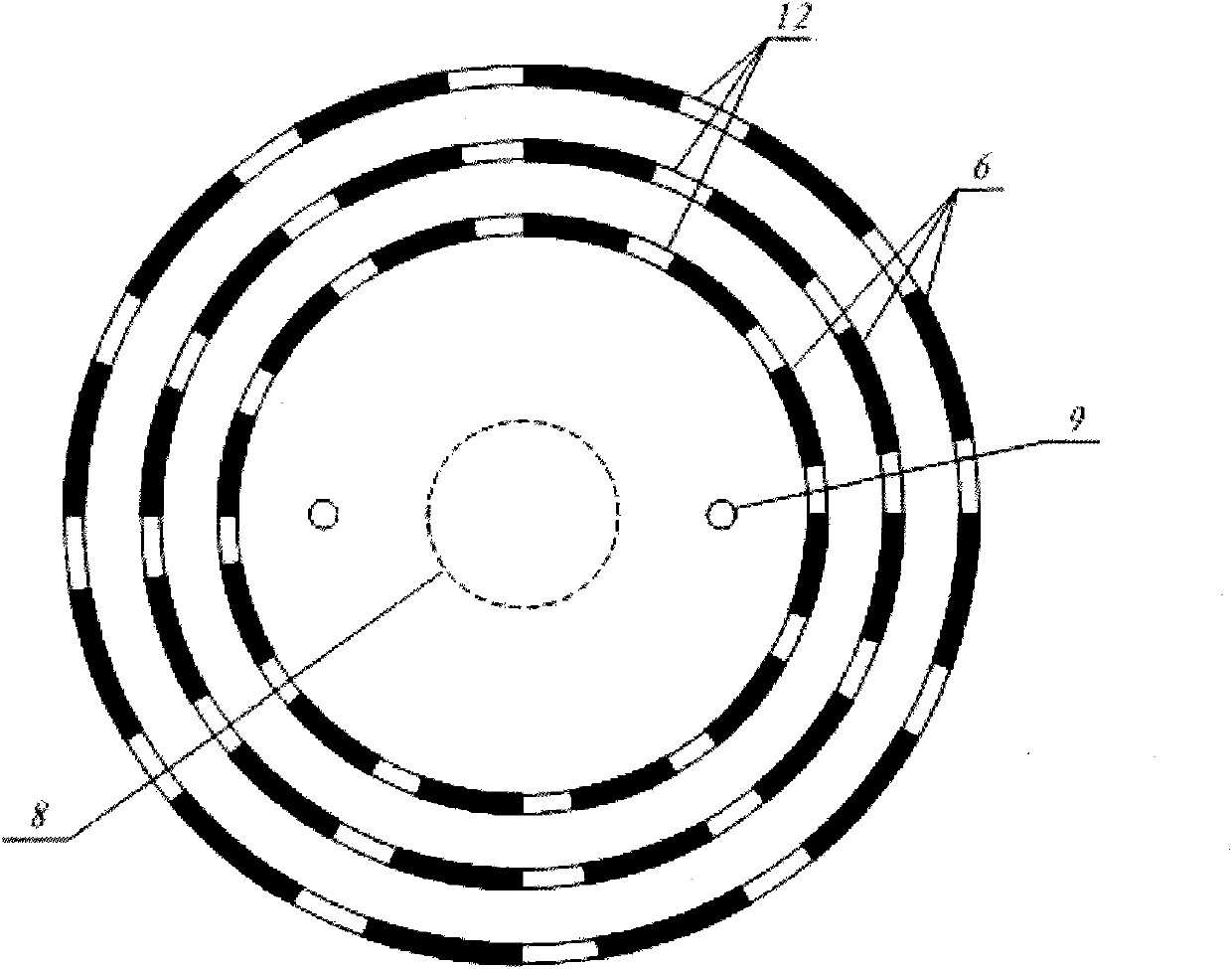

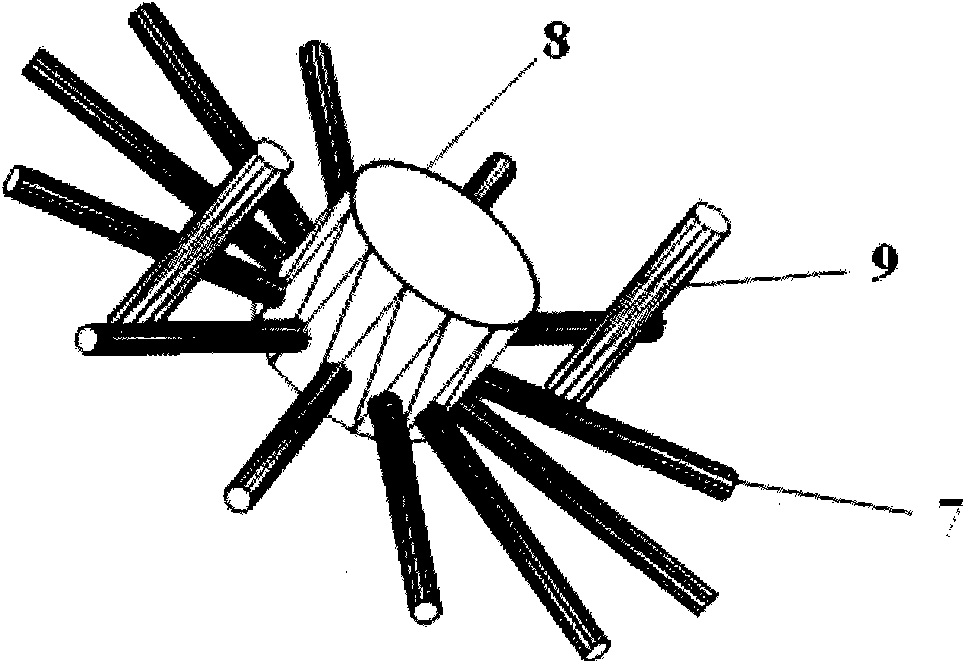

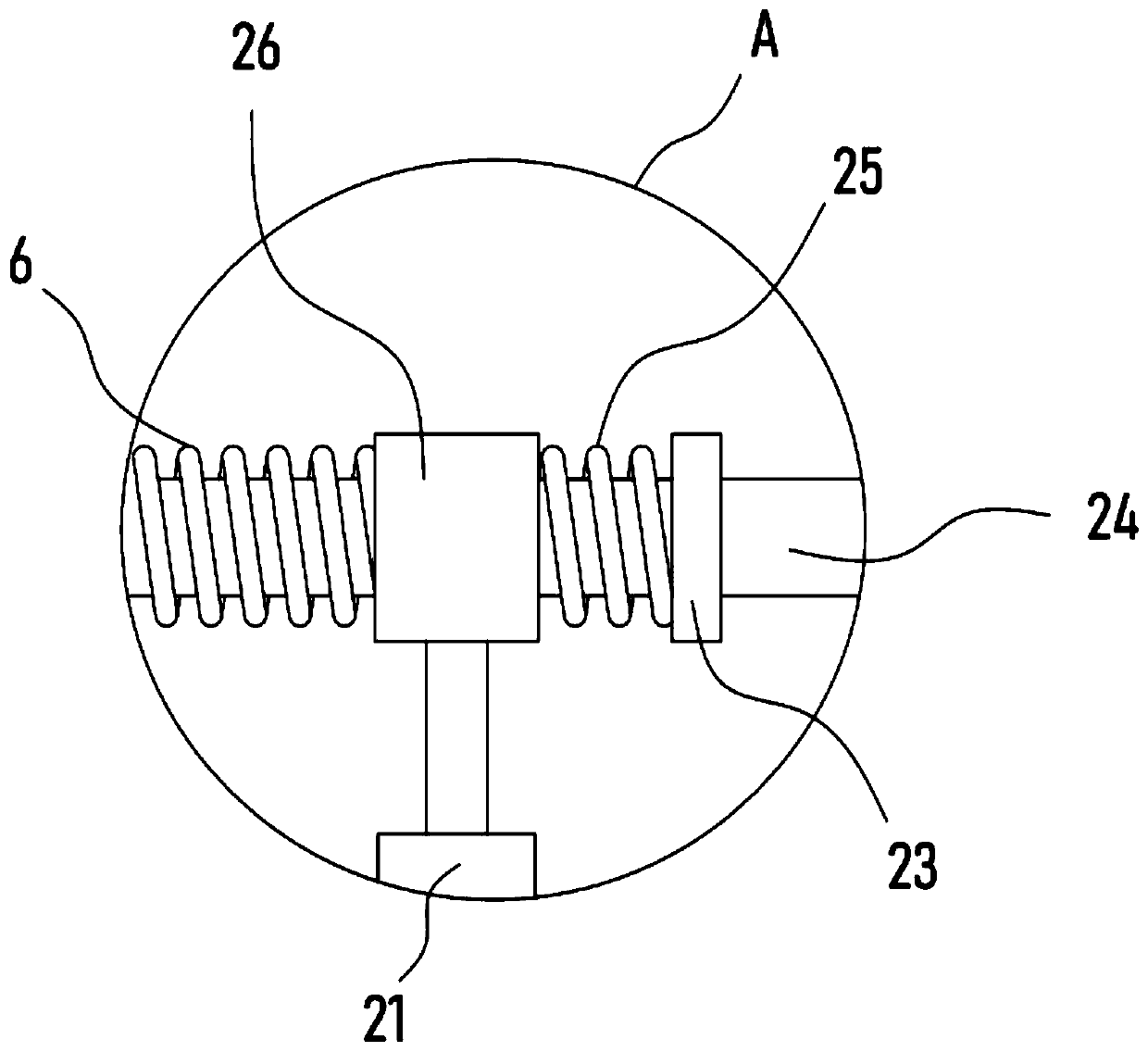

Double-circumference synchronizer with springs

ActiveCN103527665ACompact structureFriction torque pre-adjustmentMechanical actuated clutchesFriction torqueDrive shaft

Owner:WUHAN UNIV OF TECH

Vehicle Energy Harvesting System

InactiveUS20190044413A1Piezoelectric/electrostriction/magnetostriction machinesMachines/enginesReciprocating motionDrive shaft

An energy harvesting system (100) for harvesting energy from vehicles travelling on a road (102). The system (100) includes a plurality of flexible hoses (104) which are embedded in a road overlay (106). Each hose (104) holds a hydraulic fluid, e.g. water, such that, when a vehicle wheel (108) passes over the hose (104), the fluid is displaced. The system (100) further comprises a plurality of double-acting hydraulic fluid cylinders (109) which are in fluid flow communication with the fluid in the hoses (104) and are configured to convert pressure applied to the fluid into rotary motion which drives an electrical generator. One hose is connected to each end of the cylinder (109) to drive it in opposite directions to induce linear reciprocating motion which is converted to rotary motion by way of a mechanical drivetrain. Due to the double action, it drives at least two drive shafts simultaneously.

Owner:EPITOME PROPERTY INVESTMENTS PTY LTD

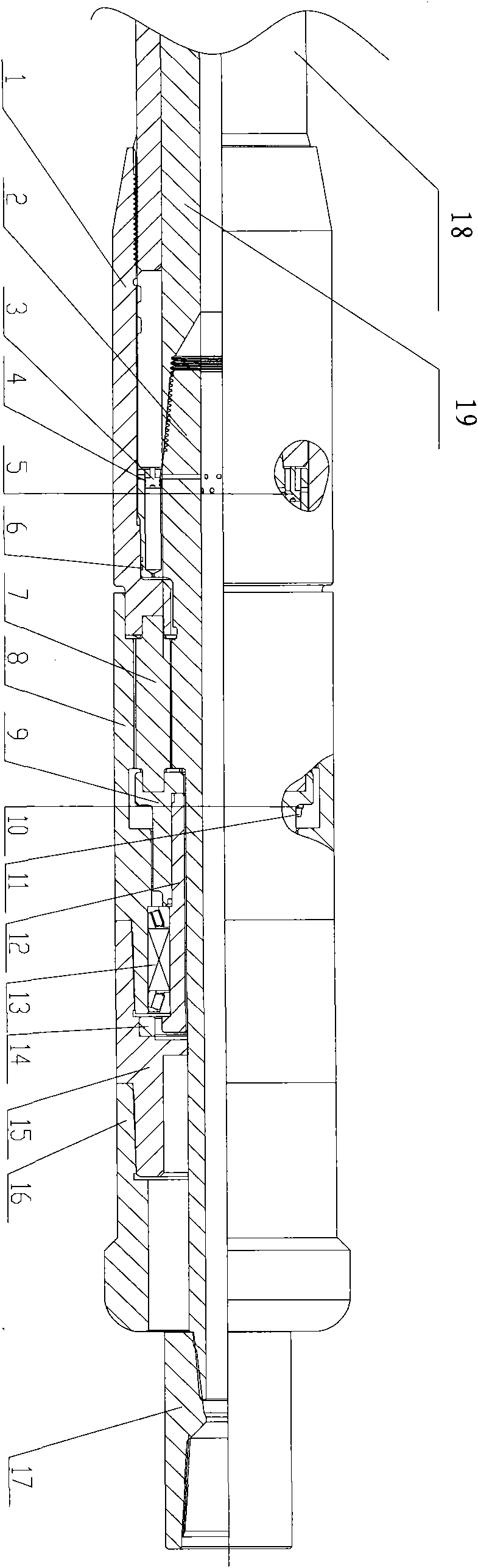

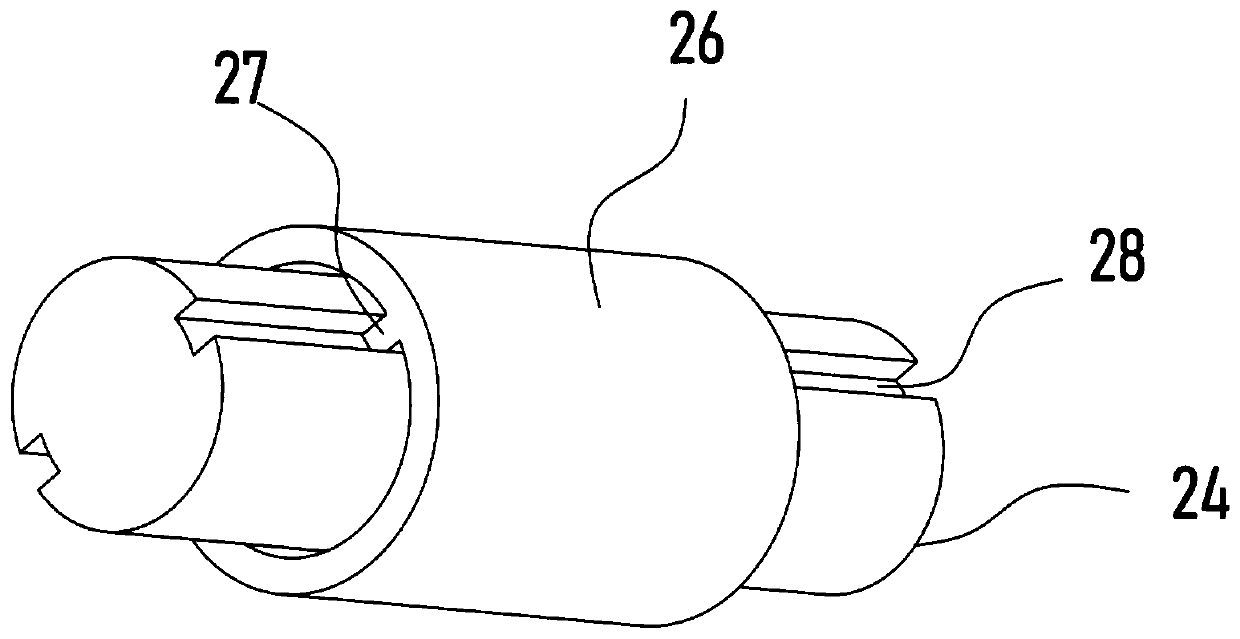

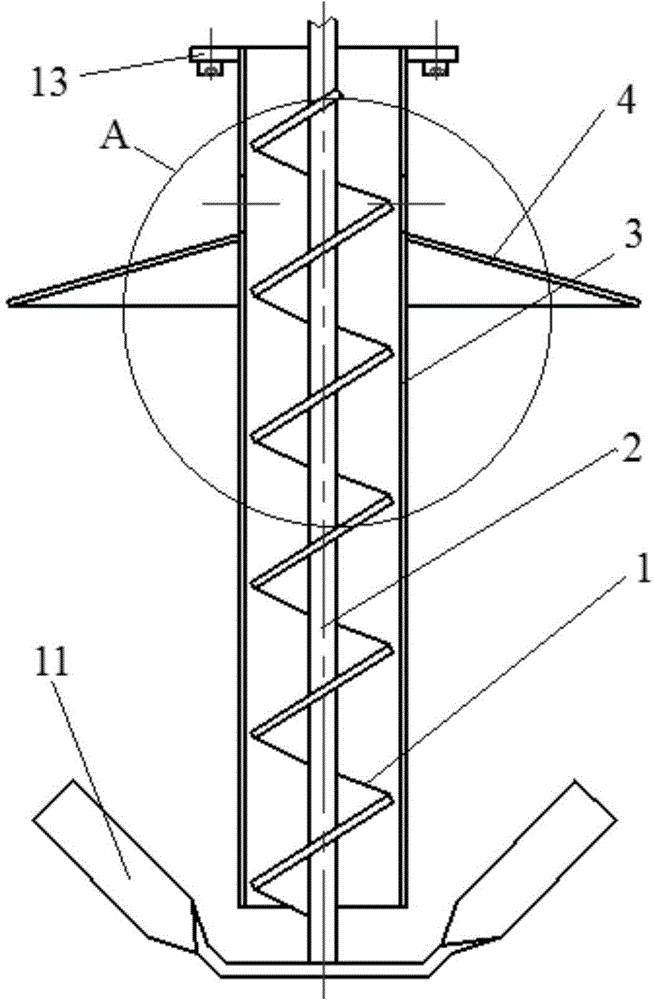

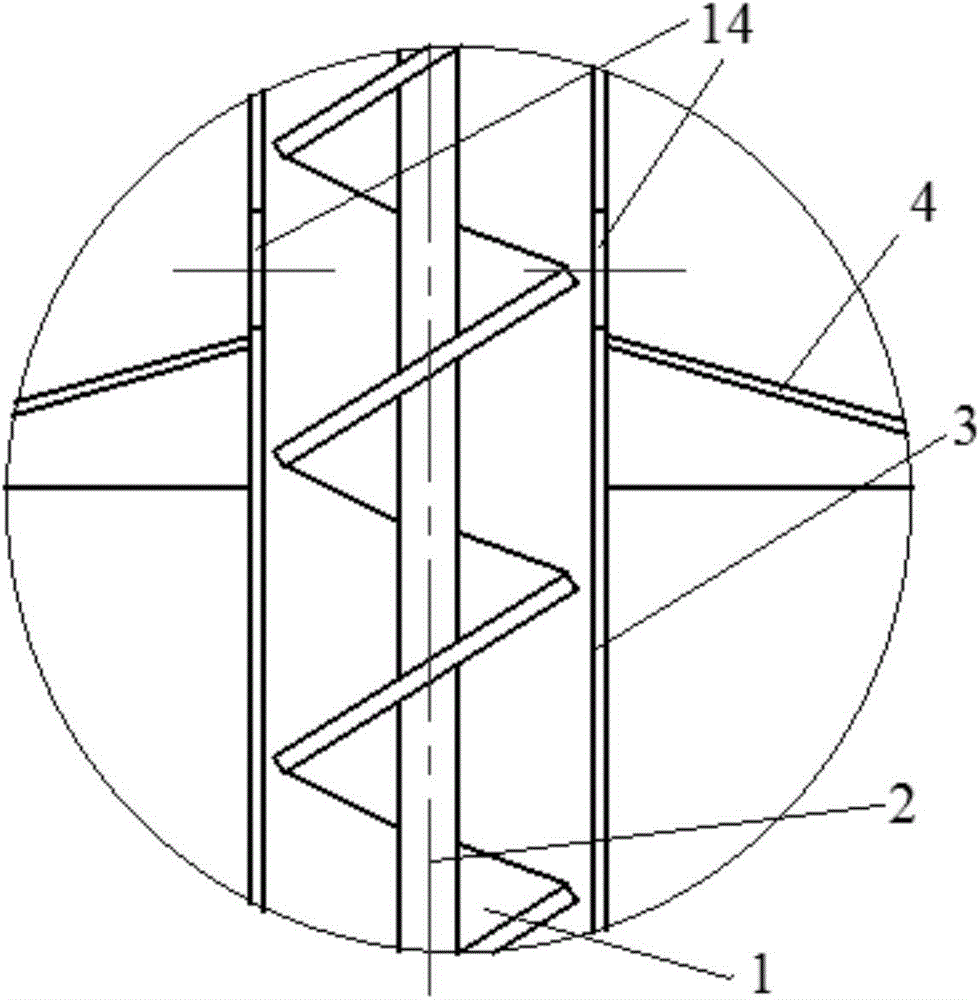

Descaling tool, descaling device and descaling method for pipe

The invention provides a descaling tool for a pipe, which comprises a tool main body. The main body comprises a cylindrical cutting part and a connecting part which axially stretches from the cutting part, wherein the cutting part is provided with a plurality of spiral grooves which are uniformly distributed on the external circumferential surface of the cutting part around a central axis of the cutting part. The invention further provides a descaling device for the pipe, which comprises a driver and the descaling tool, wherein the driver is provided with a drive shaft, the descaling tool is the descaling tool provided by the invention, and the descaling tool is connected with the drive shaft. A descaling method for the pipe comprises the following steps: a) placing the descaling tool into the pipe; and b) driving the descaling tool to rotate and move linearly in the pipe. The descaling tool, the descaling device and the descaling method provided by the invention can fully avoid the problem of corrosion on the pipe and achieve higher descaling efficiency.

Owner:CHINA SHENHUA ENERGY CO LTD +2

High-shear reactor with feed distribution device

InactiveCN101947427AAvoid cloggingUniform particle size distributionIsocyanic acid derivatives preparationOrganic compound preparationDrive shaftSolid particle

Owner:TIANJIN UNIV +1

Ceramic glaze drying device

ActiveCN110044137APromote shakingFull heating effectDrying solid materials with heatDrying gas arrangementsWater vaporDrive shaft

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

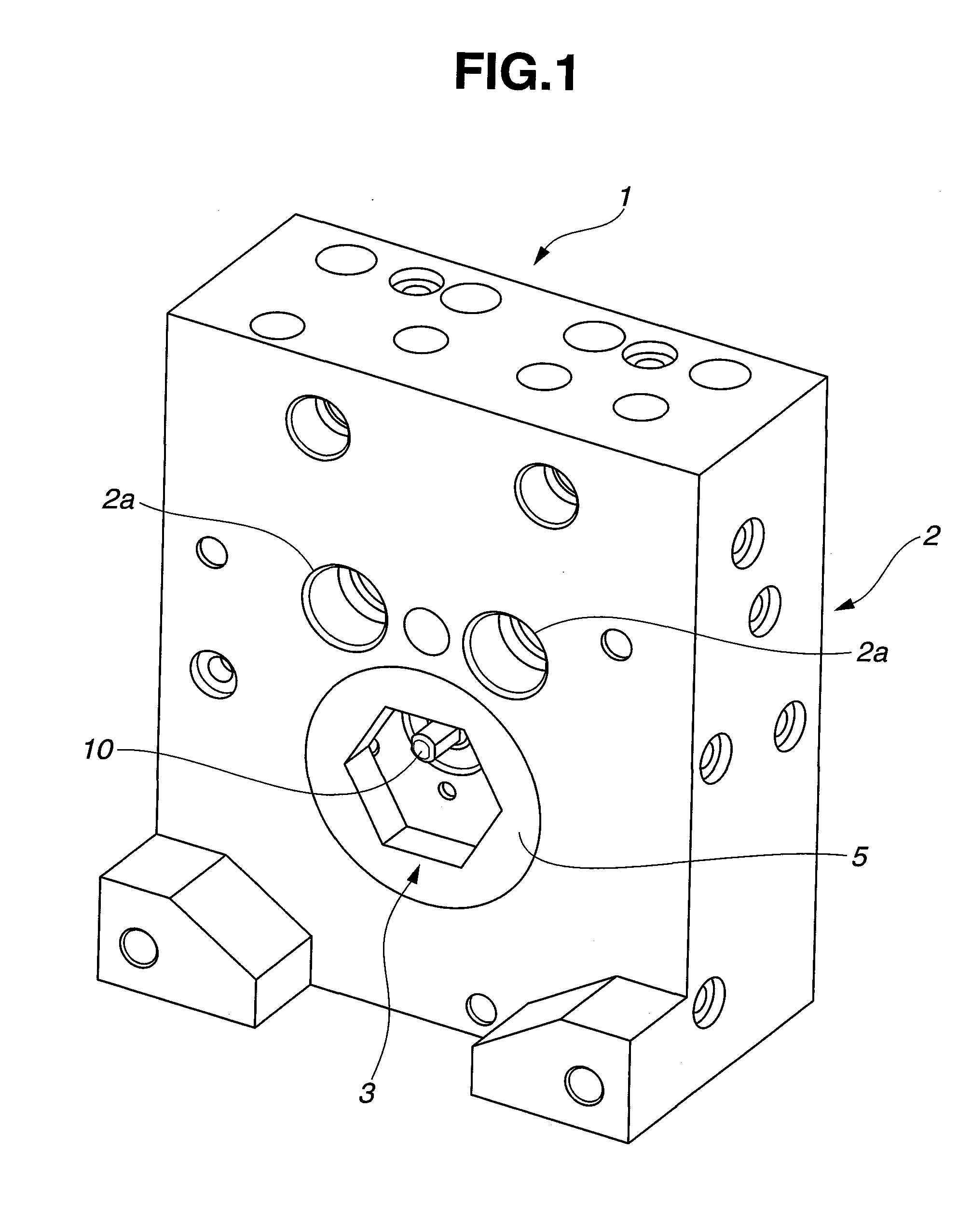

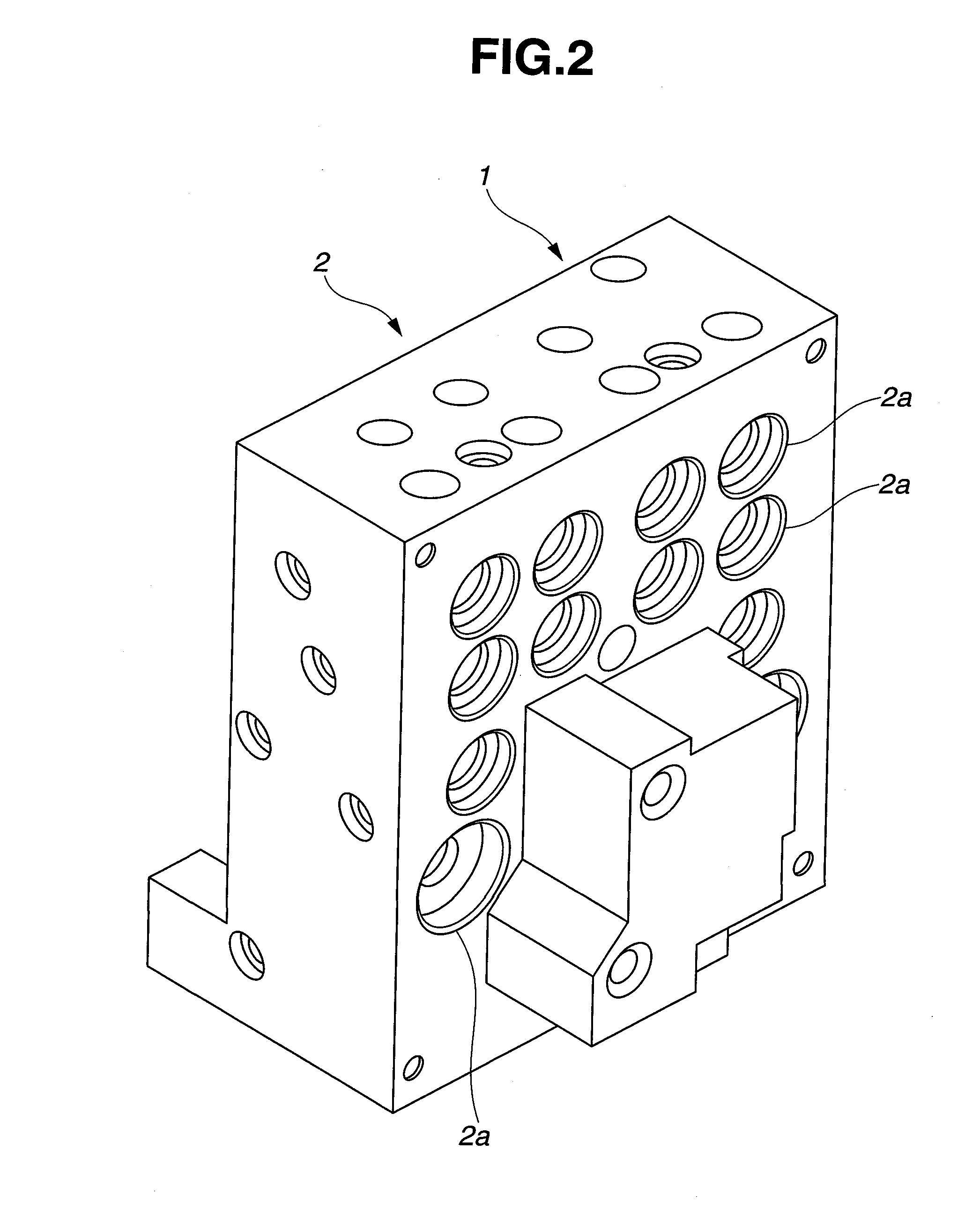

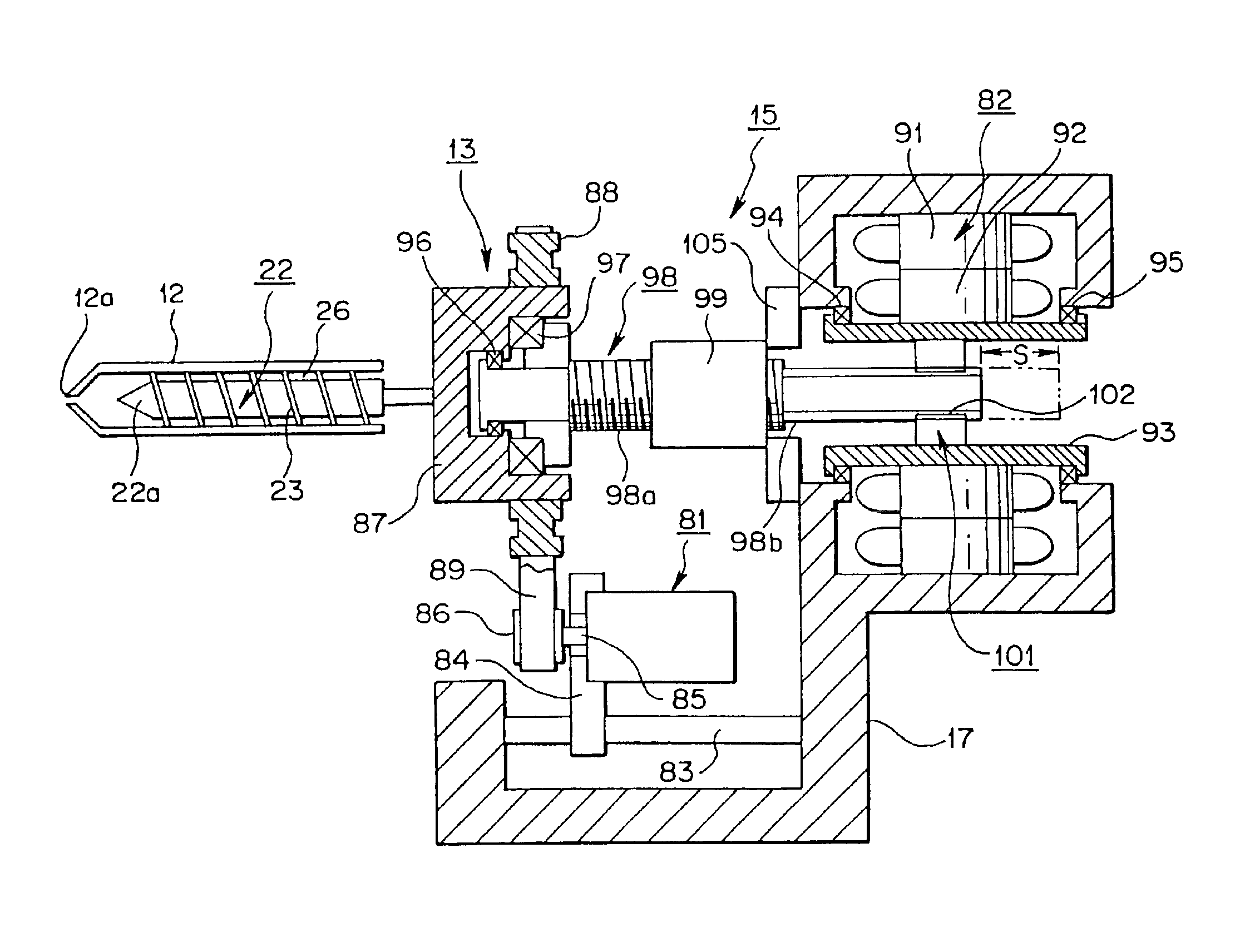

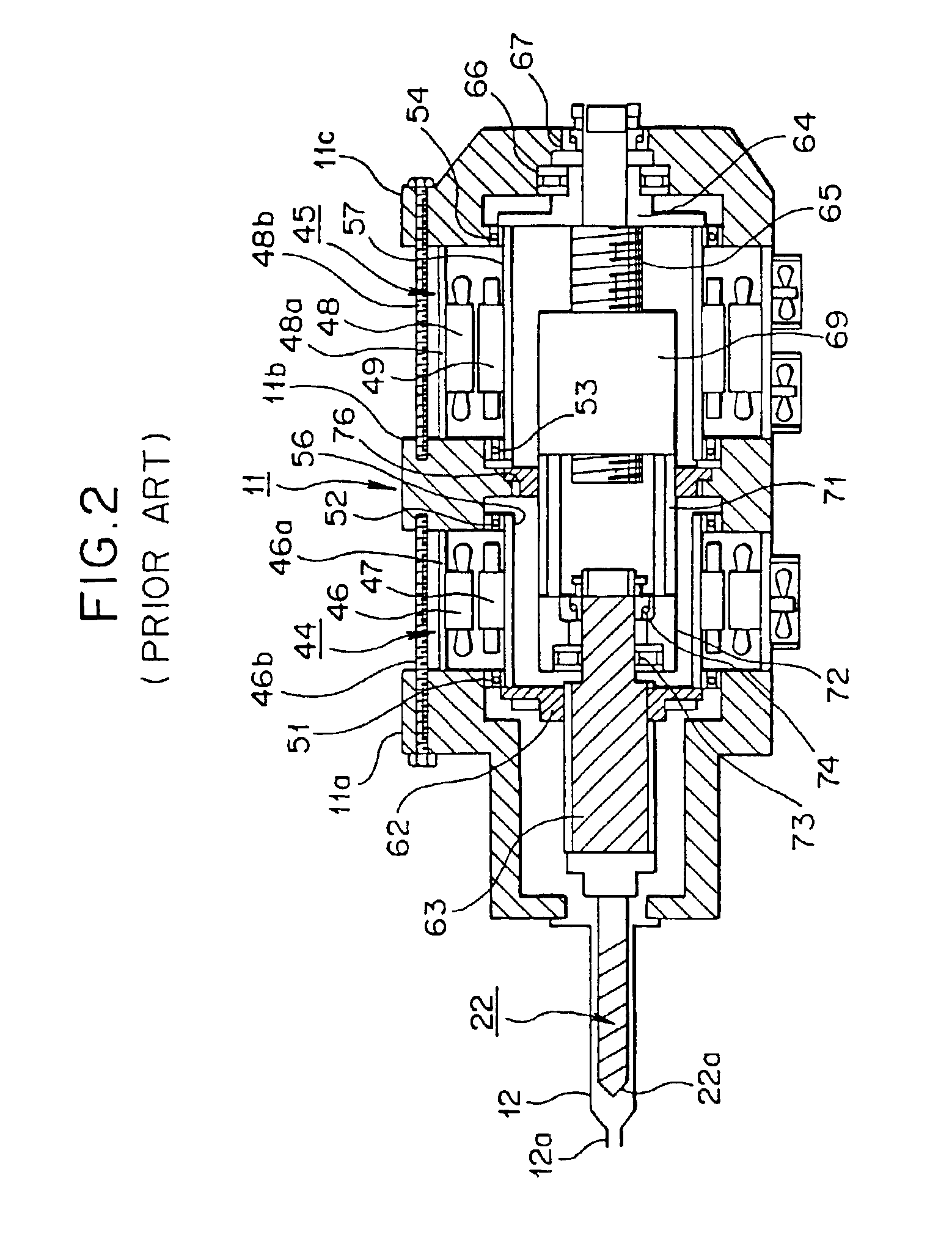

Plasticizing apparatus

The invention discloses a plasticizing apparatus. The apparatus comprises a motor, a driving device, a driving shaft, a plasticizing front board supported at the front end of the driving shaft through a deep groove ball bearing, and a plasticizing backboard supported at the back end of the driving shaft through an aligning roller bearing, the plasticizing backboard is upwardly provided with a motor fixing board for fixedly mounting the motor, a positioning projection used for fixation is arranged at the front end of the motor, the motor fixing board is provided with a positioning hole for the penetration of the positioning projection, the driving device comprises a small belt wheel fixedly mounted on the output shaft of the motor, a large belt wheel fixedly mounted on the driving shaft, and a synchronous belt connecting the small belt wheel with the large belt wheel, the central portion of the back end of the driving shaft is in threaded connection with a screw, the screw penetrates through the plasticizing backboard, and a thrust ball bearing is arranged between the head portion of the screw and the plasticizing backboard. The plasticizing apparatus adopting the motor to drive has the characteristics of small energy consumption, small noise, stable output torque, simple structure, low cost, small inertia and good performances.

Owner:NINGBO HAIZHOU MASCH CO LTD

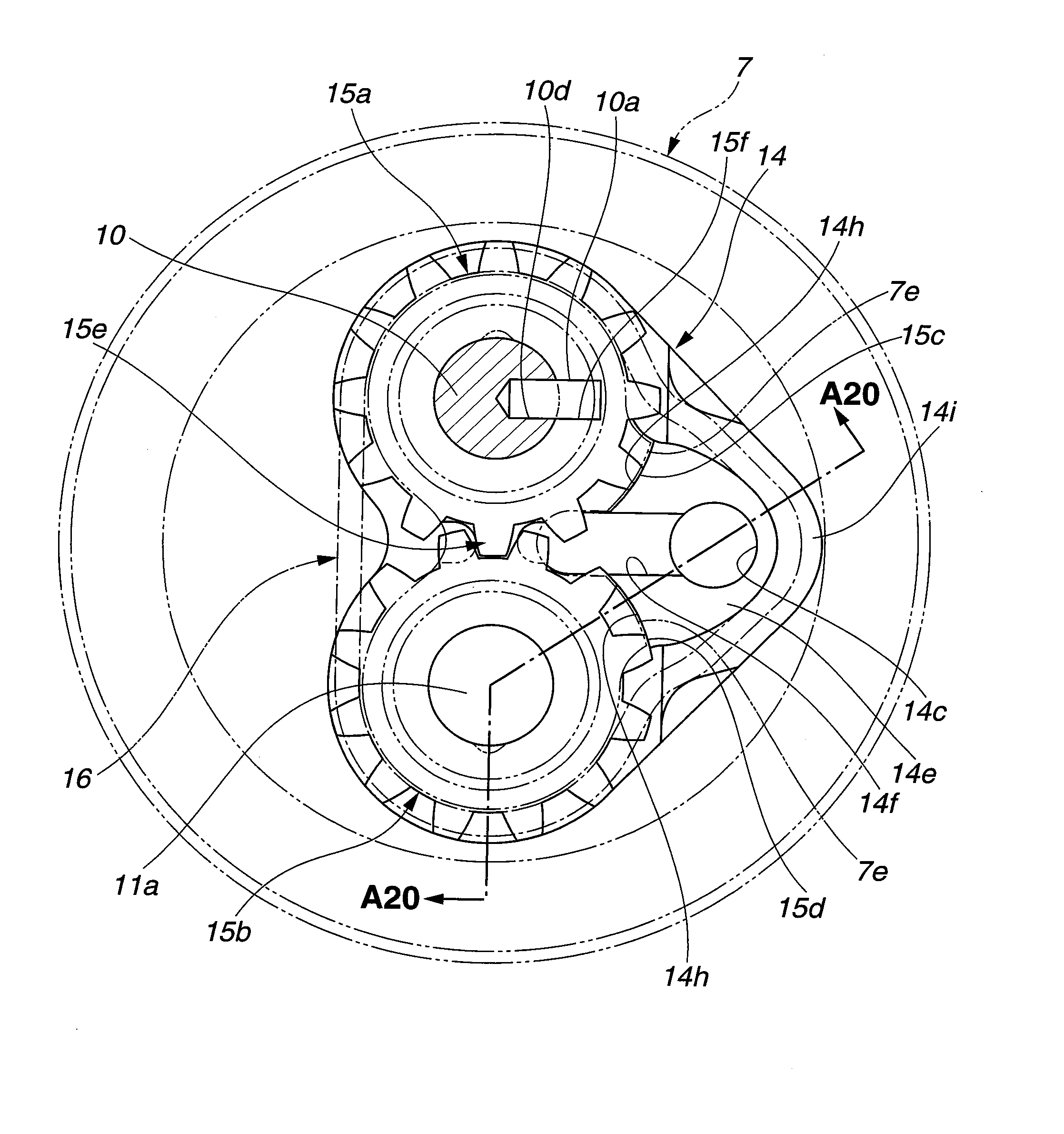

Gear Pump

ActiveUS20100124513A1Deteriorate ease in assembly processIncrease manufacturing costOscillating piston enginesSealing arrangement for pumpsGear pumpDrive shaft

Owner:HITACHI ASTEMO LTD

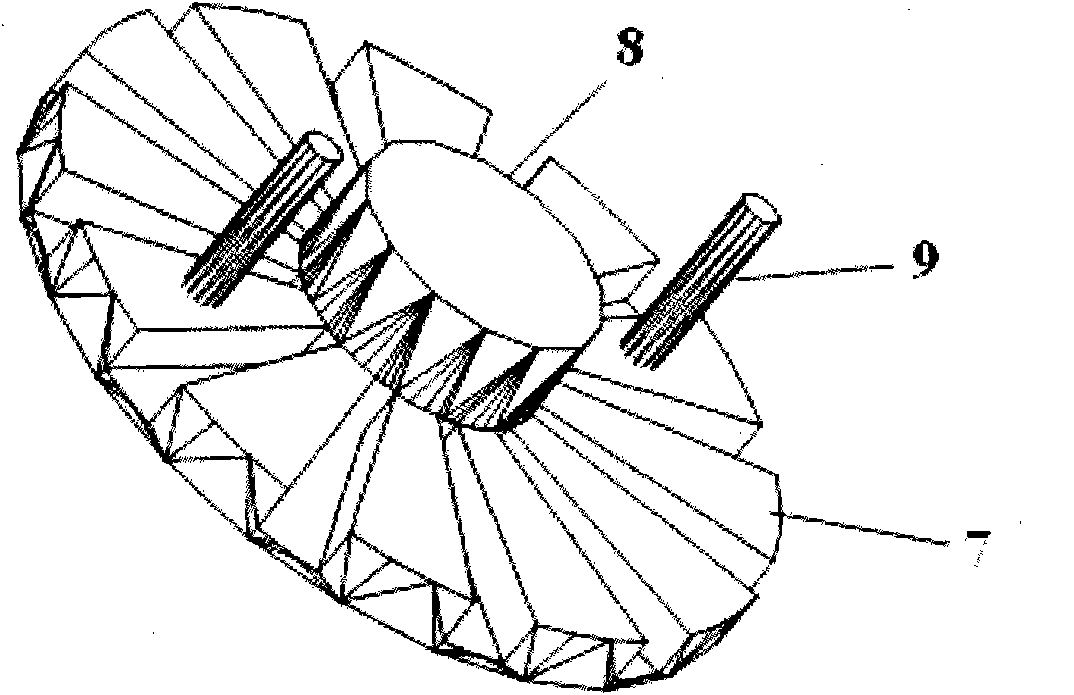

Gear configuration operable in various angles

A gear configuration allows force (torque) coming from a drive shaft to be transmitted to a driven shaft through two hemispherical gears that are placed at the end of the shafts and touch each other in variable, but constantly equal distance from the poles. This constant equal distance from the poles can be maintained through synchronization gears that are positioned against each other on both sides of U-shaped elements. These U-shaped elements also keep the shafts in position, where each U-shaped element on each of the shafts are connected by a ring formed hinge element, consequently keeping the hemispheres in connection

Owner:URGENC HASAN GOZDER

Pitter Apparatus with Rotary Operated Drive System

ActiveUS20110232508A1Shorten the counting processReduce in quantityKitchen fruit stoningFruit coringDrive shaftEngineering

Owner:ASHLOCK A DIV OF VISTAN

Adhesive tape cutting machine

Owner:ANSTEEL GRP MINING CO LTD

Mixing equipment for coating preparation and use method of mixing equipment

InactiveCN107413233AImprove processing speedImprove mix qualityRotary stirring mixersTransportation and packagingDrive shaftProcess engineering

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Carving machine

ActiveCN107089086AGuaranteed synchronicityDoes not affect rotationModel makingDrive shaftElectric machinery

Owner:玉环圣弘法数控雕刻设备有限公司

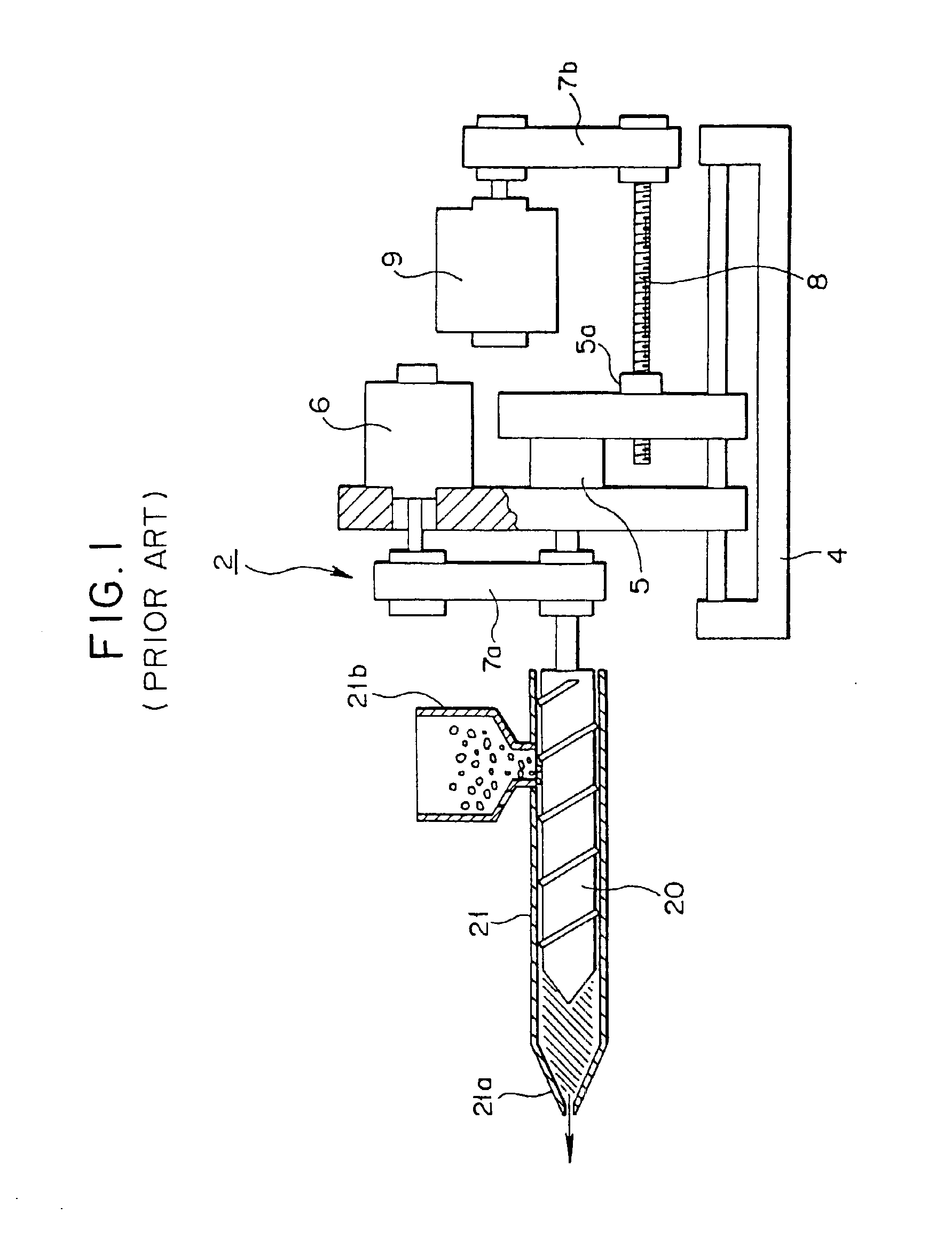

Injection molding machine

InactiveUS7234928B2Easy to assembleEasy maintenanceAuxillary shaping apparatusFood shapingLinear motionDrive shaft

Owner:SUMITOMO HEAVY IND LTD

Efficient defoaming solvent-free composite mixing unit cylinder

InactiveCN104941493AGuaranteed defoaming efficiencyQuality assuranceMixersFoam dispersion/preventionVacuum pumpingCoupling

Owner:XIAN UNIV OF TECH

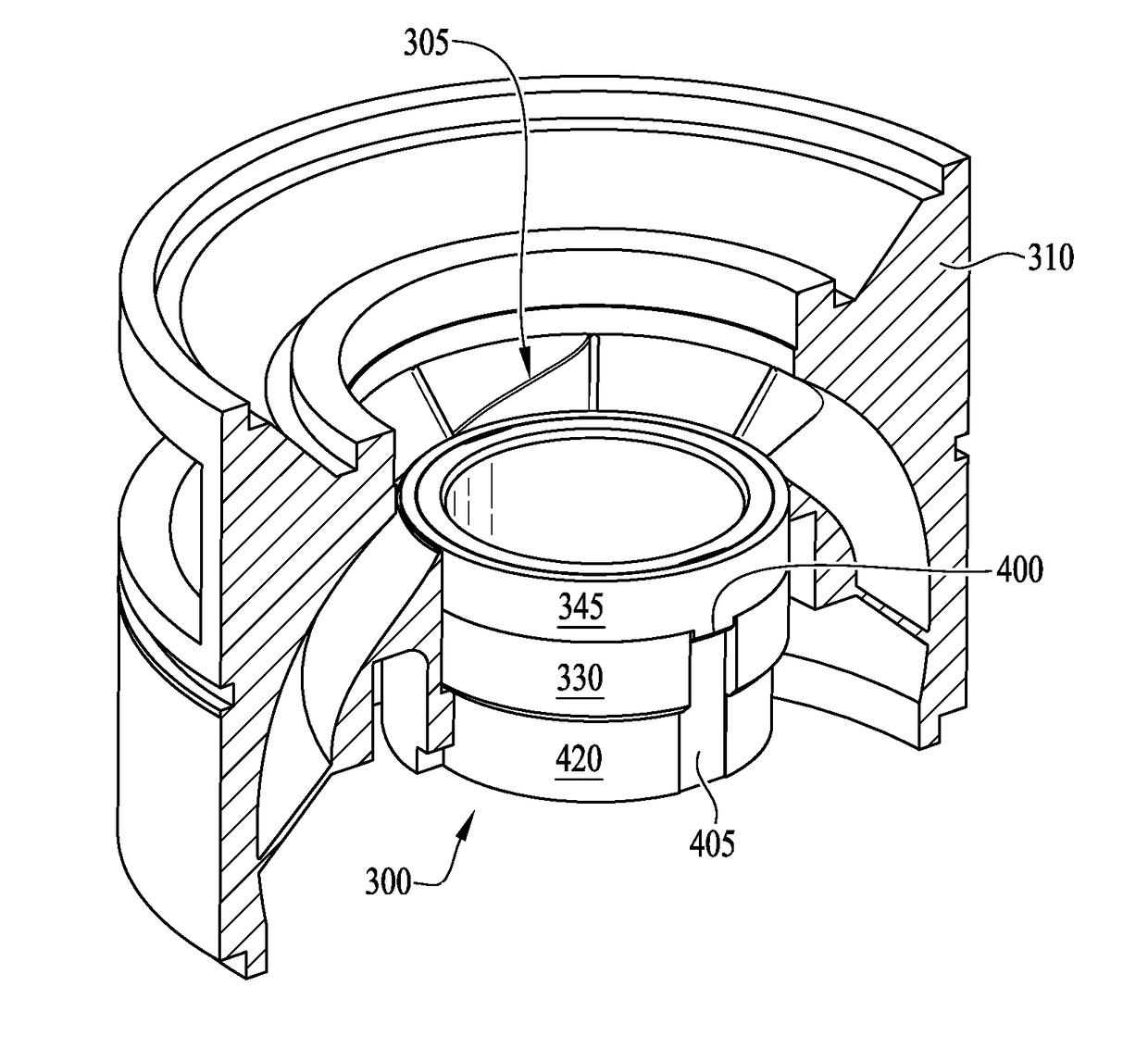

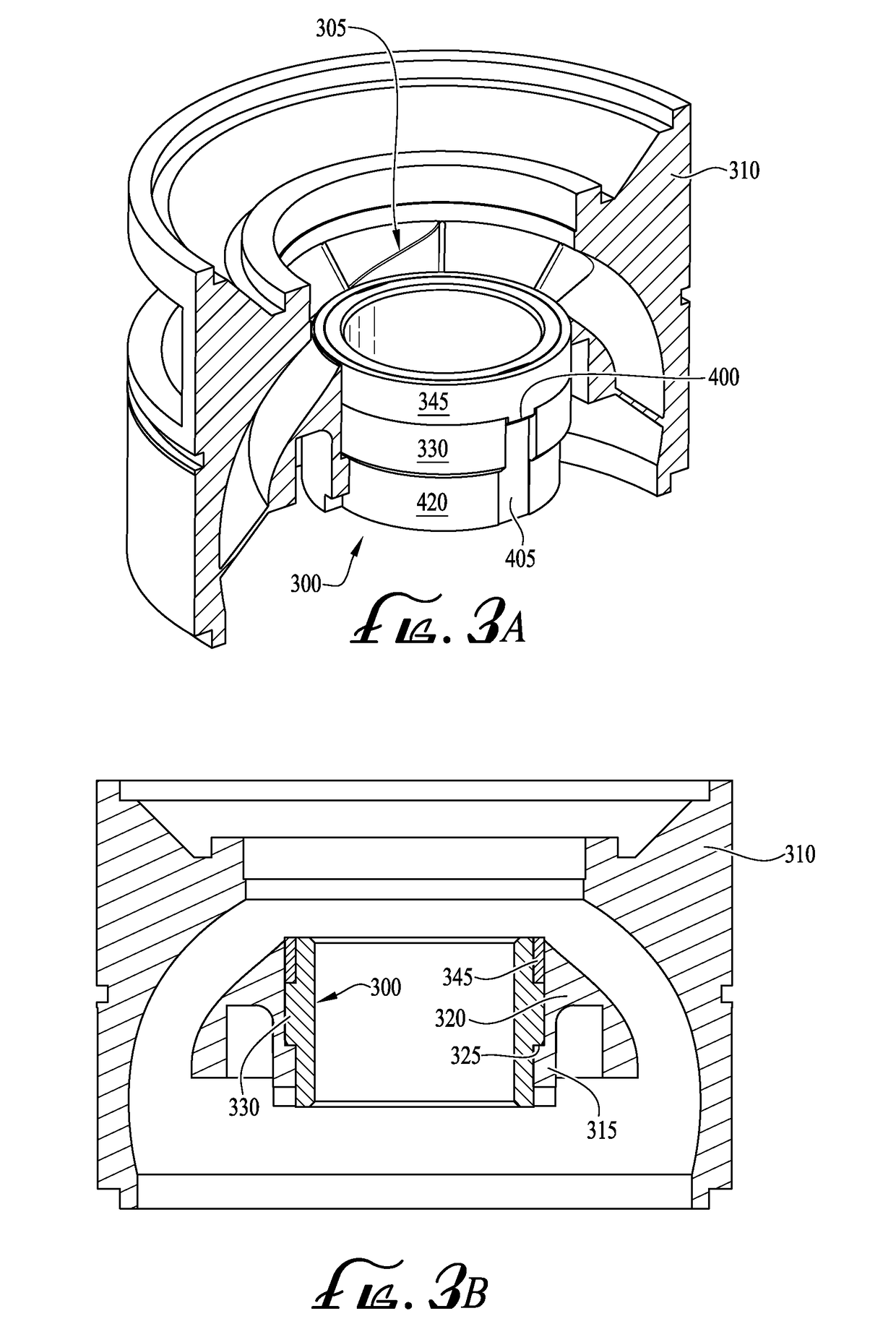

Press-fit thrust bearing system and apparatus

ActiveUS20180291917A1Avoid displacementPrevent rotationPump componentsBearing assemblyDrive shaftThrust bearing

Owner:HALLIBURTON ENERGY SERVICES INC

Forging method of driving shaft for gearbox

ActiveCN102989982AExtend your lifeReduce contaminationMetallic material coating processesEngine componentsChemical compositionDrive shaft

Owner:CHANGLI FORGING

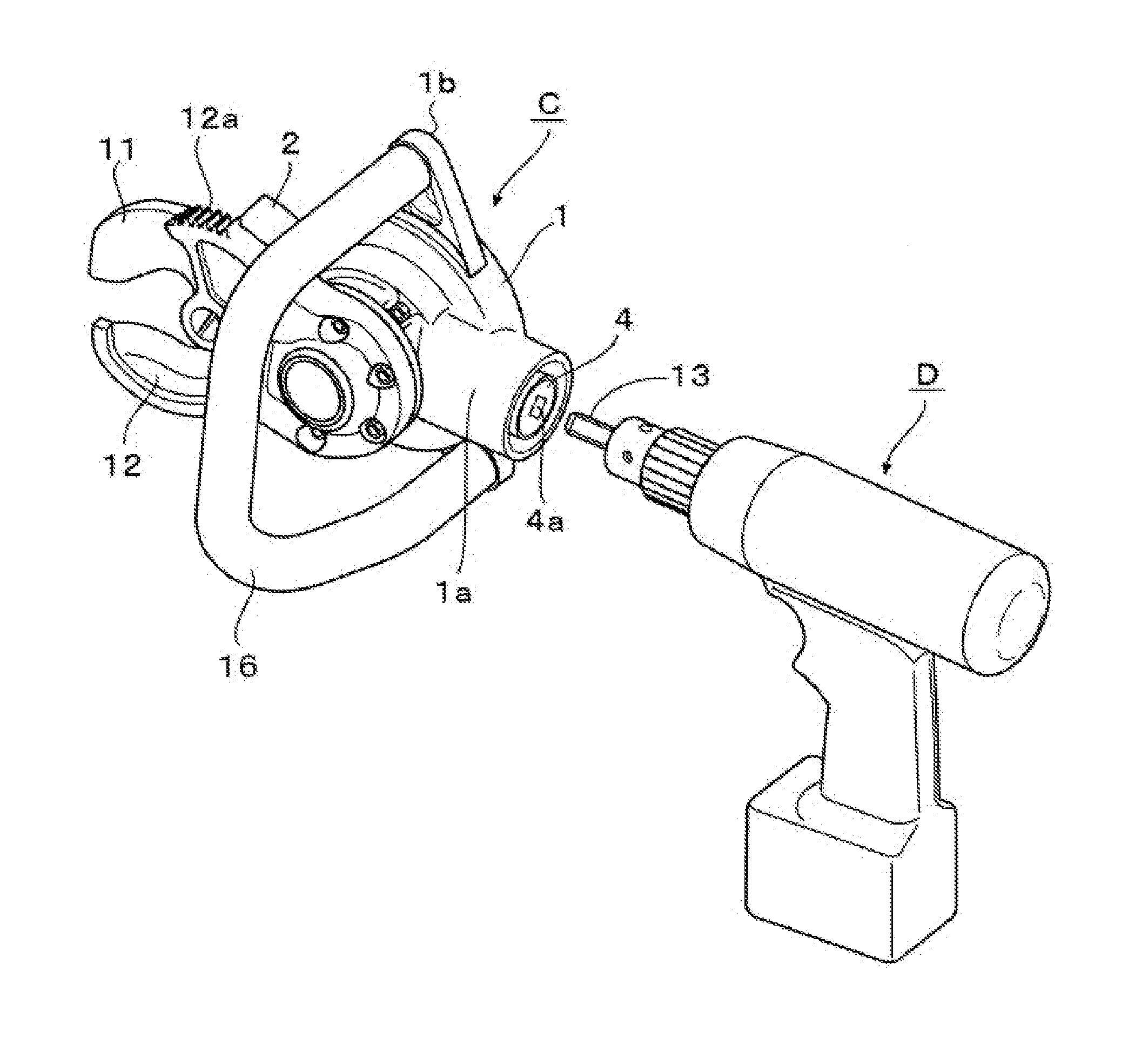

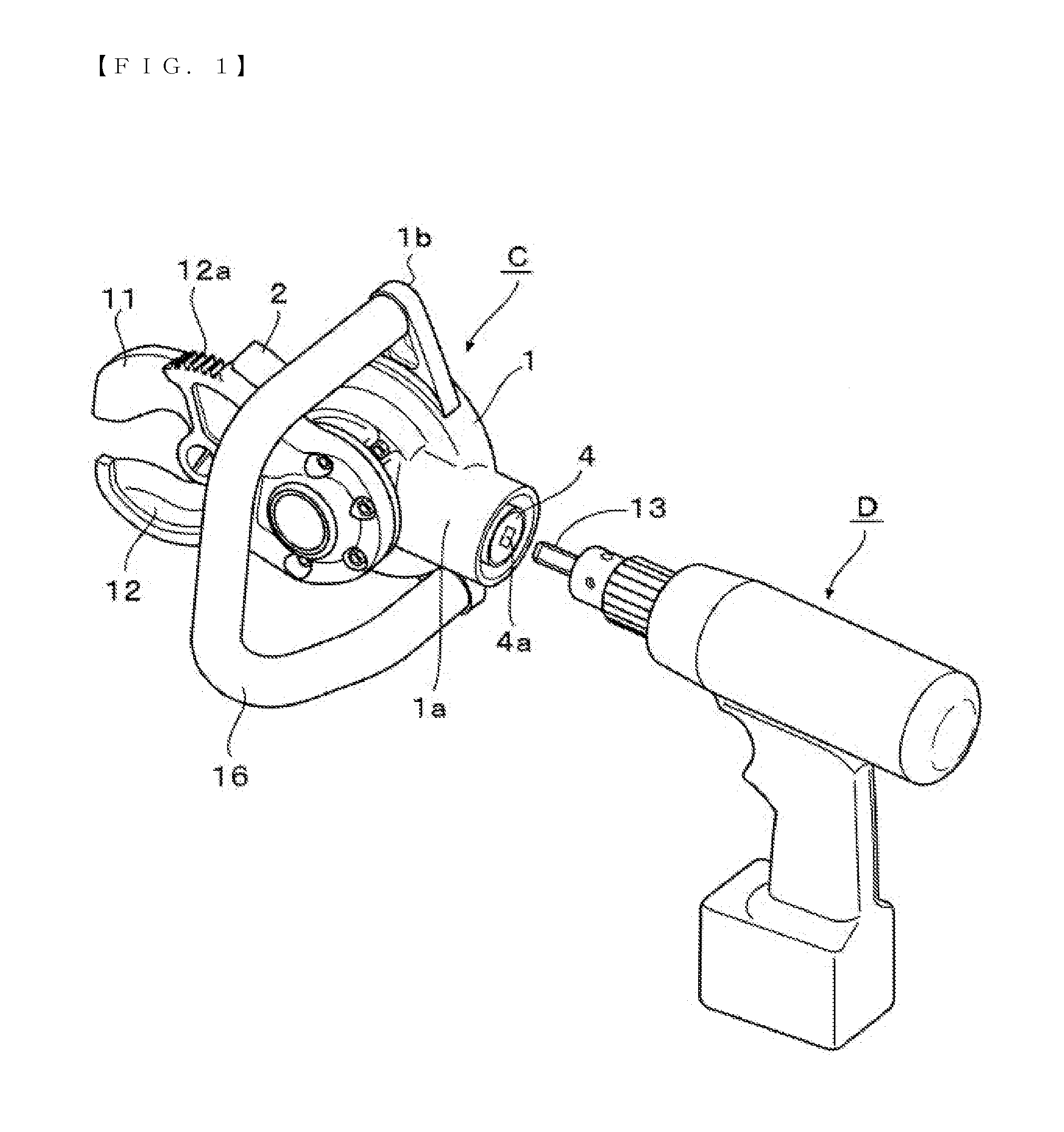

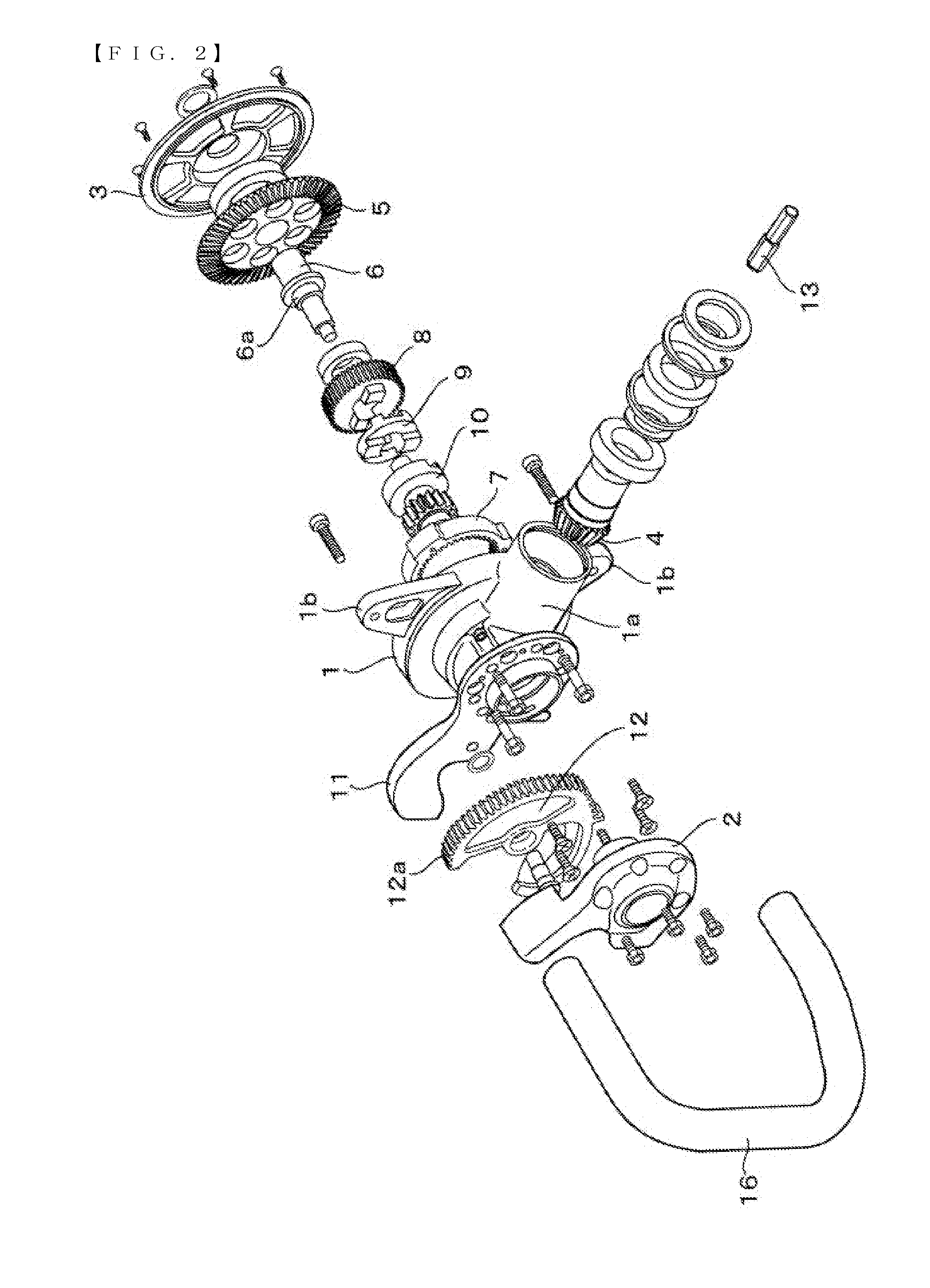

Rotor mounting device and rotor mounting method

InactiveCN101689792AManufacturing stator/rotor bodiesMechanical energy handlingCrankshaftDrive shaft

Owner:HONDA MOTOR CO LTD

Mold opening and closing mechanism of blow molding machine

Owner:GUANGDONG FRIEND MACHINERY

Rotary pump device

InactiveCN102410210AReduce assembly errorsImprove efficiencyRotary piston pumpsRotary piston liquid enginesRotary pumpDrive shaft

A rotary pump device is provided in which a drive shaft (54) is inserted into a center hole (71a) of a cylinder (71) that forms rotor chambers (100a, 100b), and into outer rotors (19a, 39a) and inner rotors (19b, 39b) of rotary pumps (19, 39). In the rotary pump device, seal mechanisms (111, 112) that include hollow-shaped resin members (111a, 112a) and annular rubber members (111b, 112b) are arranged on an opposite side to the cylinder (71) with respect to the rotary pumps. Metal rings (111f, 112f) are arranged in hollow portions (111h, 112h) of the resin members (111a, 112a) in the seal mechanisms (111, 112) so that the drive shaft (54) is inserted into an inner periphery of the metal rings (111f, 112f) with a minimum clearance.

Owner:ADVICS CO LTD

Strip steel feeding device for motor stator and rotor production

Owner:当涂县华胜电子元件制造厂

Adjustable socket structure

An adjustable socket structure contains a body including a first groove, a second groove, a first notch, a number of slots; a plurality of paws, each including a sliding block, and the sliding block including a first hole; a number of connecting rods, each being movably fixed in the second groove and including a first axial shank and a second axial shank; a driving shaft including an axial portion and a disk portion, wherein the axial portion includes a square bore, and the disk portion is rotated in the first groove and includes an outer diameter larger that the axial portion and three second holes so that the driving shaft is rotated to actuate the paws to move in the slots respectively by using the connecting rods; a helical retaining ring retained in the first notch to abut against a rear end of the disk portion of the driving shaft.

Owner:LIANG YI MING

Electric curtain with self-cleaning function

ActiveCN104033095AWith self-cleaning functionImprove interior aestheticsDoor/window protective devicesPoint-like light sourceDrive shaftEngineering

Owner:NANTONG KANGERLE MEDICAL MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap