Mixing equipment for coating preparation and use method of mixing equipment

A technology for mixing equipment and coatings, applied in mixers, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve the problems of low work efficiency, small scope of application, high labor intensity of operators, etc. Effectiveness of utilization efficiency, improved mixing quality, accelerated processing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

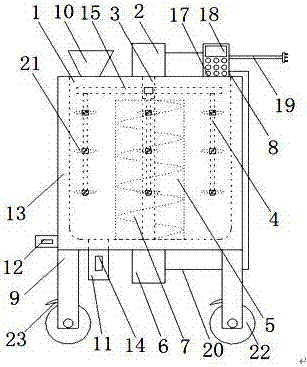

[0019] as attached figure 1 with 2 Shown:

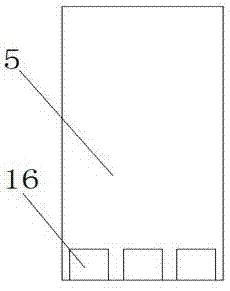

[0020] A paint preparation and mixing equipment, including a mixing tank 1, a motor one 2, a transmission shaft 3, a stirring rod 4, a transition cylinder 5, a motor two 6, an auger 7 and a controller 8, characterized in that: the mixing tank 1 Set on the bracket 9, the mixing tank 1 is provided with a feed bin 10, a discharge pipe 11, and a medium through pipe 12. The motor one 2 is set on the top of the mixing tank 1, and the transmission shaft 3 is set on the mixing tank 1. In the barrel 1, the transmission shaft 3 is connected with the motor one 2, and a connecting plate 15 is arranged on the transmission shaft 3, the stirring rod 4 is arranged on the connecting plate 15, and the transition cylinder 5 is arranged on the mixing barrel 1 Inside, the motor two 6 is arranged at the bottom of the mixing barrel 1, the auger 7 is arranged in the transition barrel 5, and the auger 7 is connected with the motor two 6, and the controller 8

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap