Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about "Mixer accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

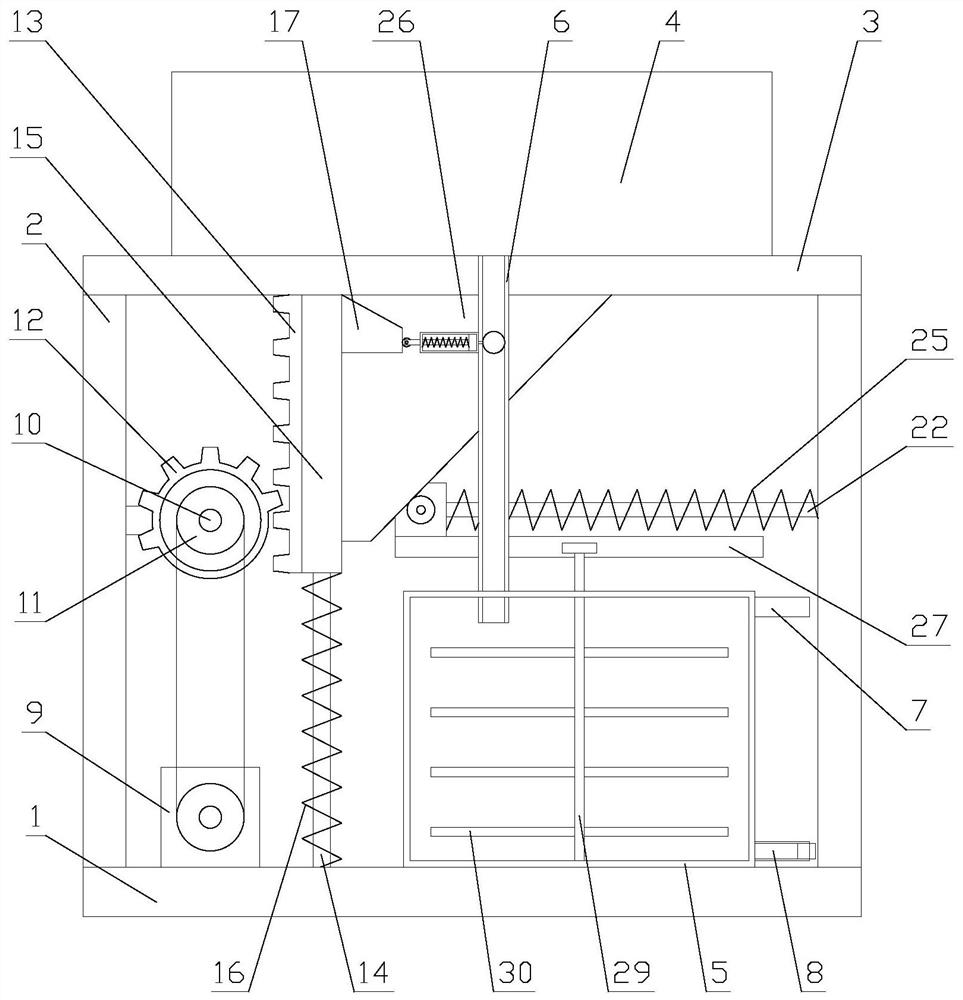

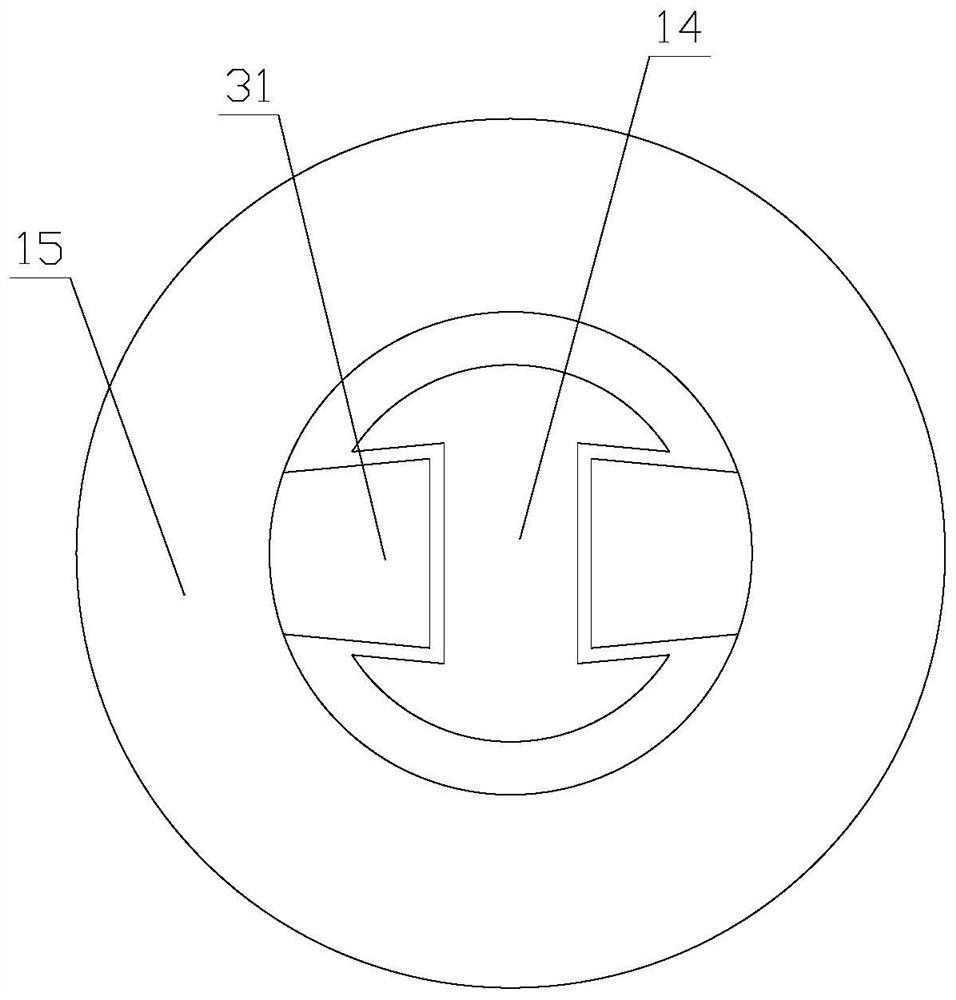

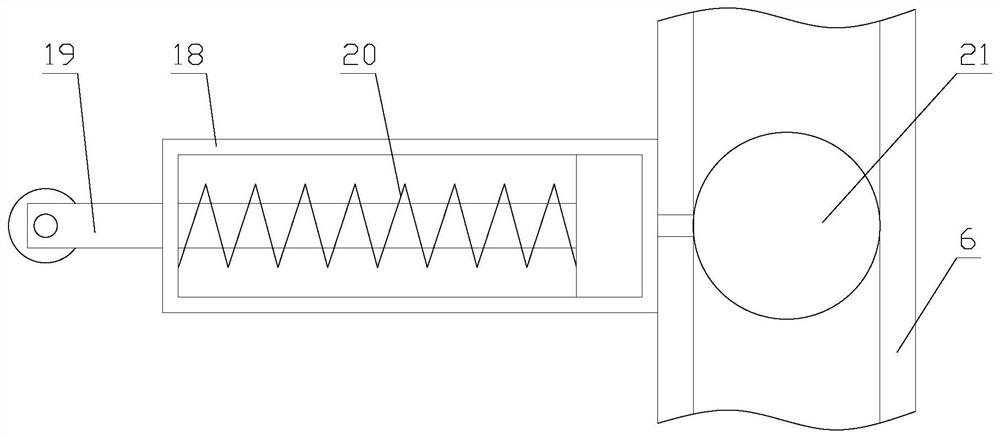

Hand-held wand mixer

InactiveUS6974244B1Easily removed and exchangedEfficiently transmittedRotary stirring mixersMixer accessoriesEngineeringHand held

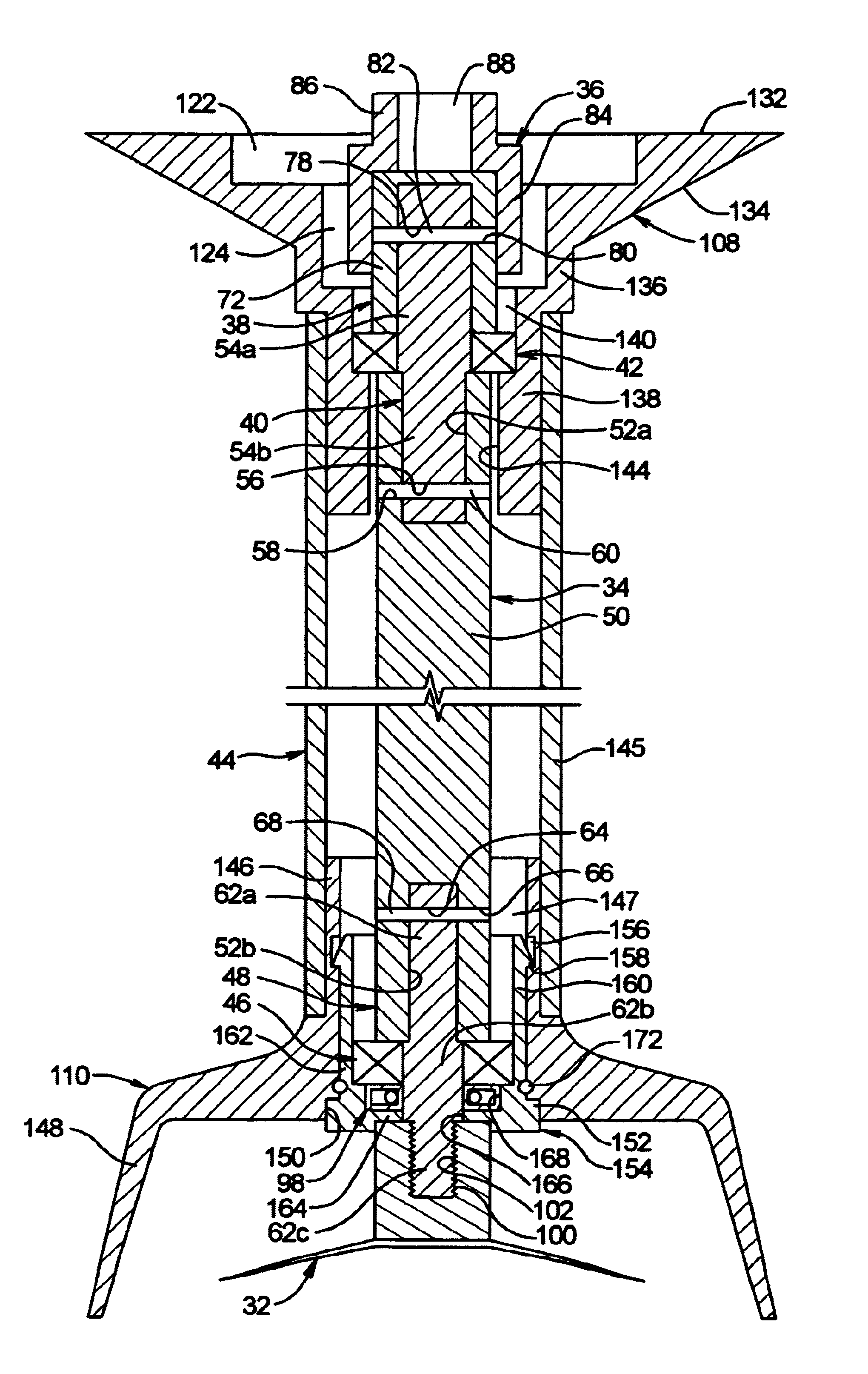

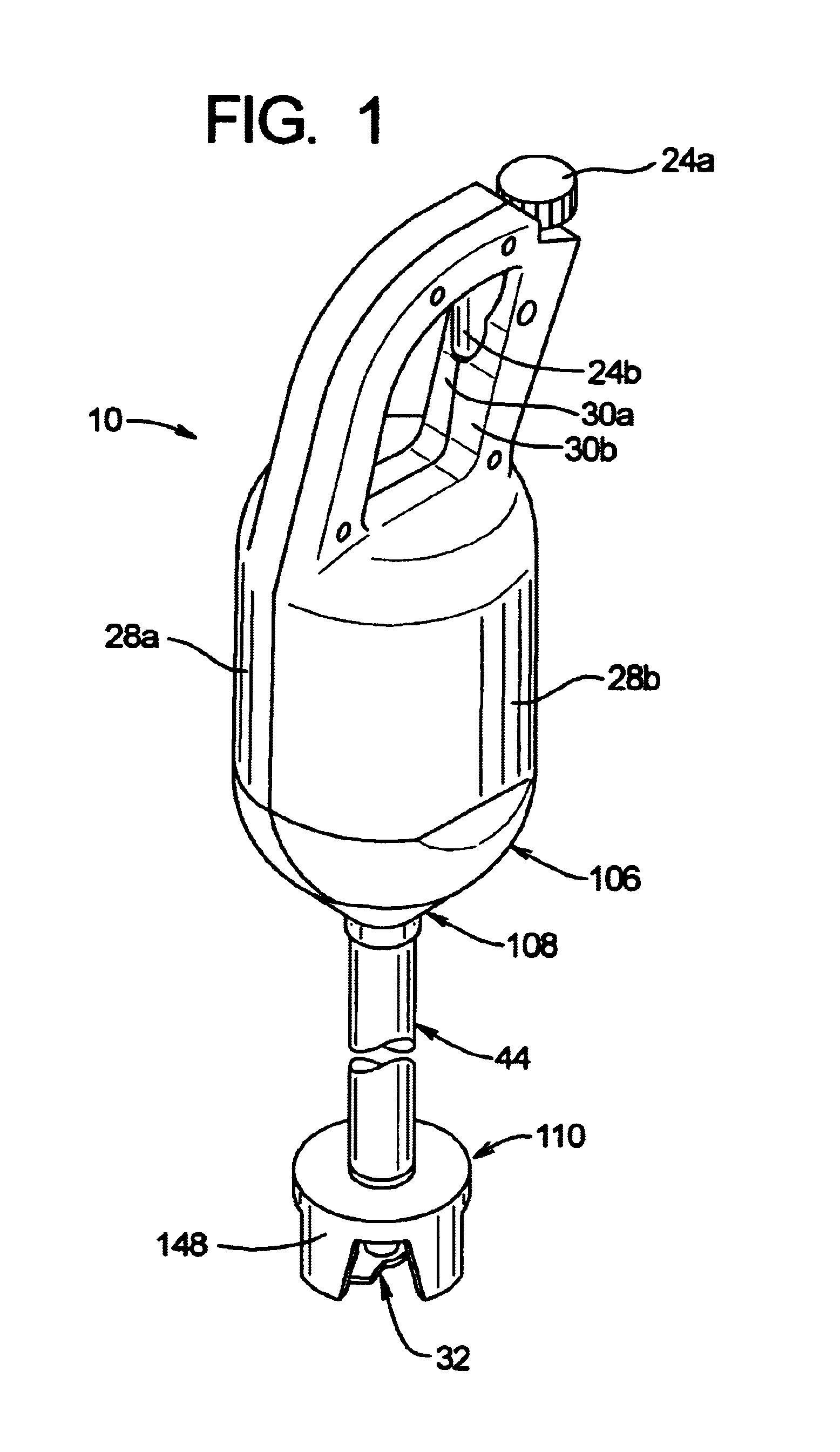

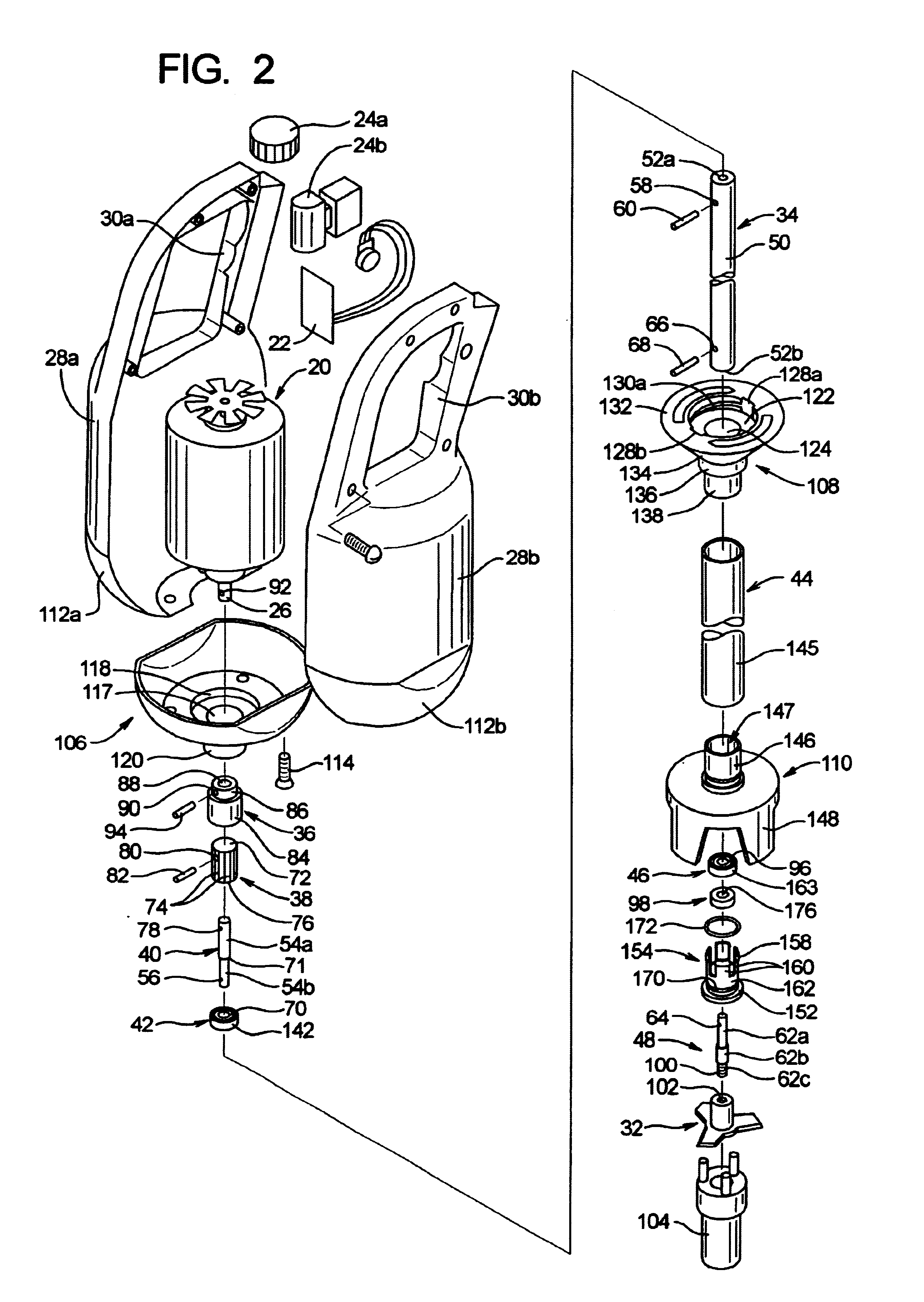

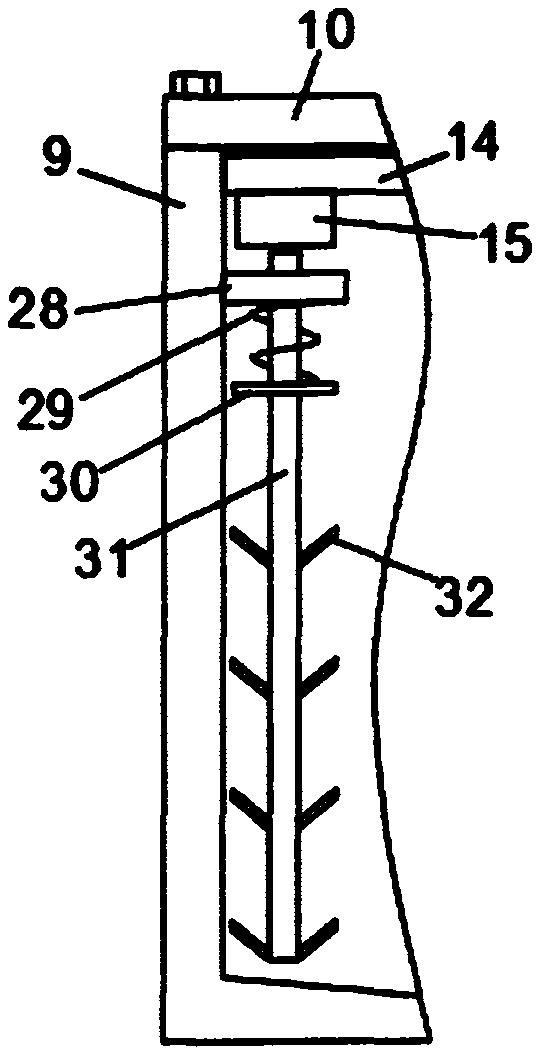

A wand mixer having a wand assembly that is detachable from the motor assembly as a single unit. The wand assembly includes a drive shaft that is enclosed within a tubular housing having a seal at the lower end for preventing entry of fluids and debris. First and second bearings at the ends of the tubular housing support both ends of the shaft so as to prevent deformation and damage of the seal when the wand assembly is removed from the motor assembly for cleaning. The wand assembly mounts to the motor assembly using a bayonet-type connection, and the motor and drive shafts are interconnected by an externally splined member that is received axially in an internally splined sleeve. The wand assembly can therefore be removed or mounted to the motor assembly by a convenient, manual turning and axial movement of the components.

Owner:LIN KING YUAN

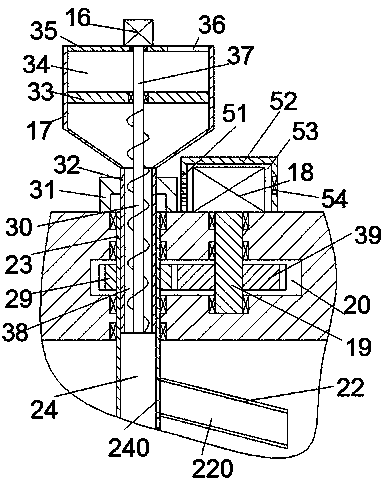

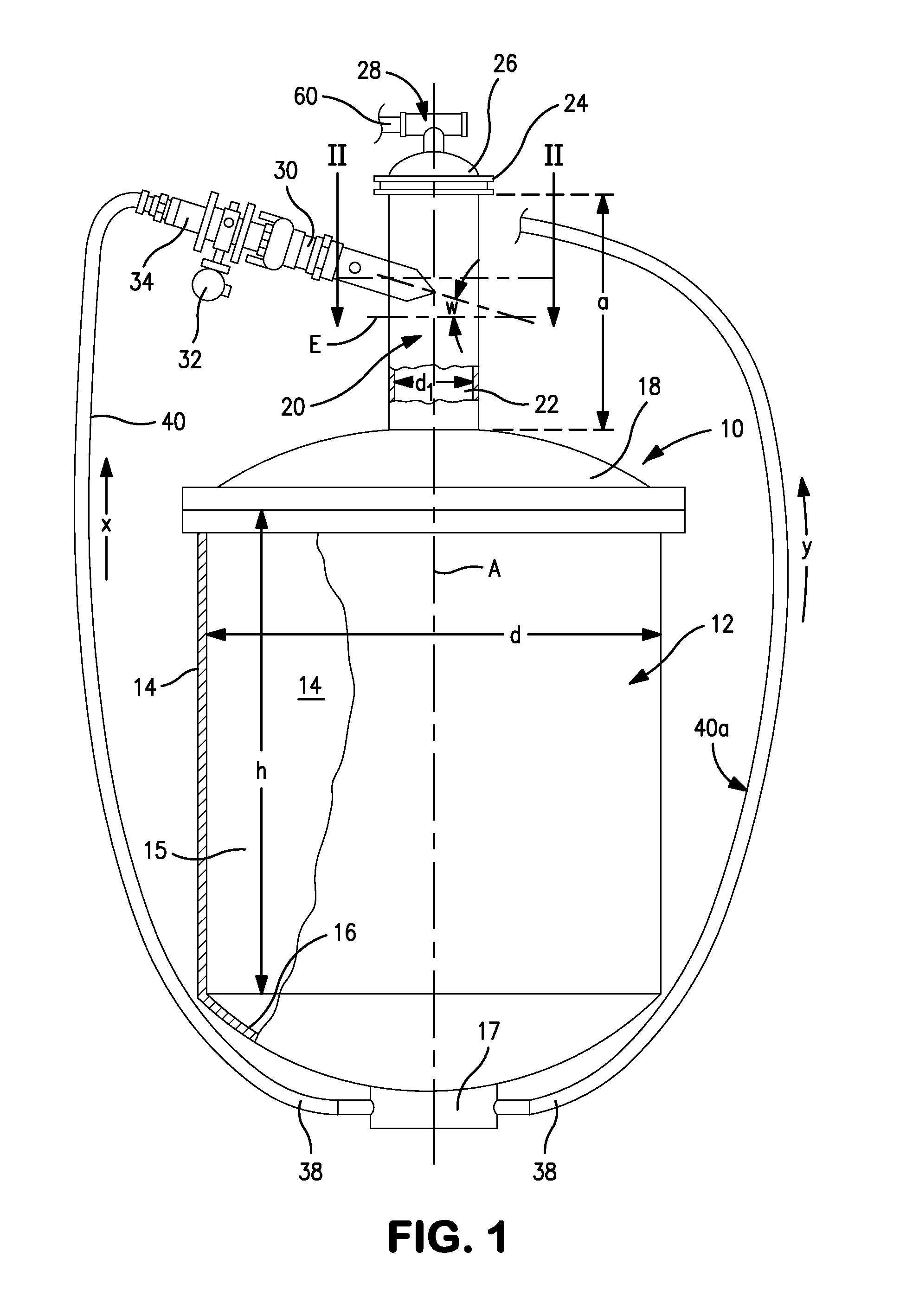

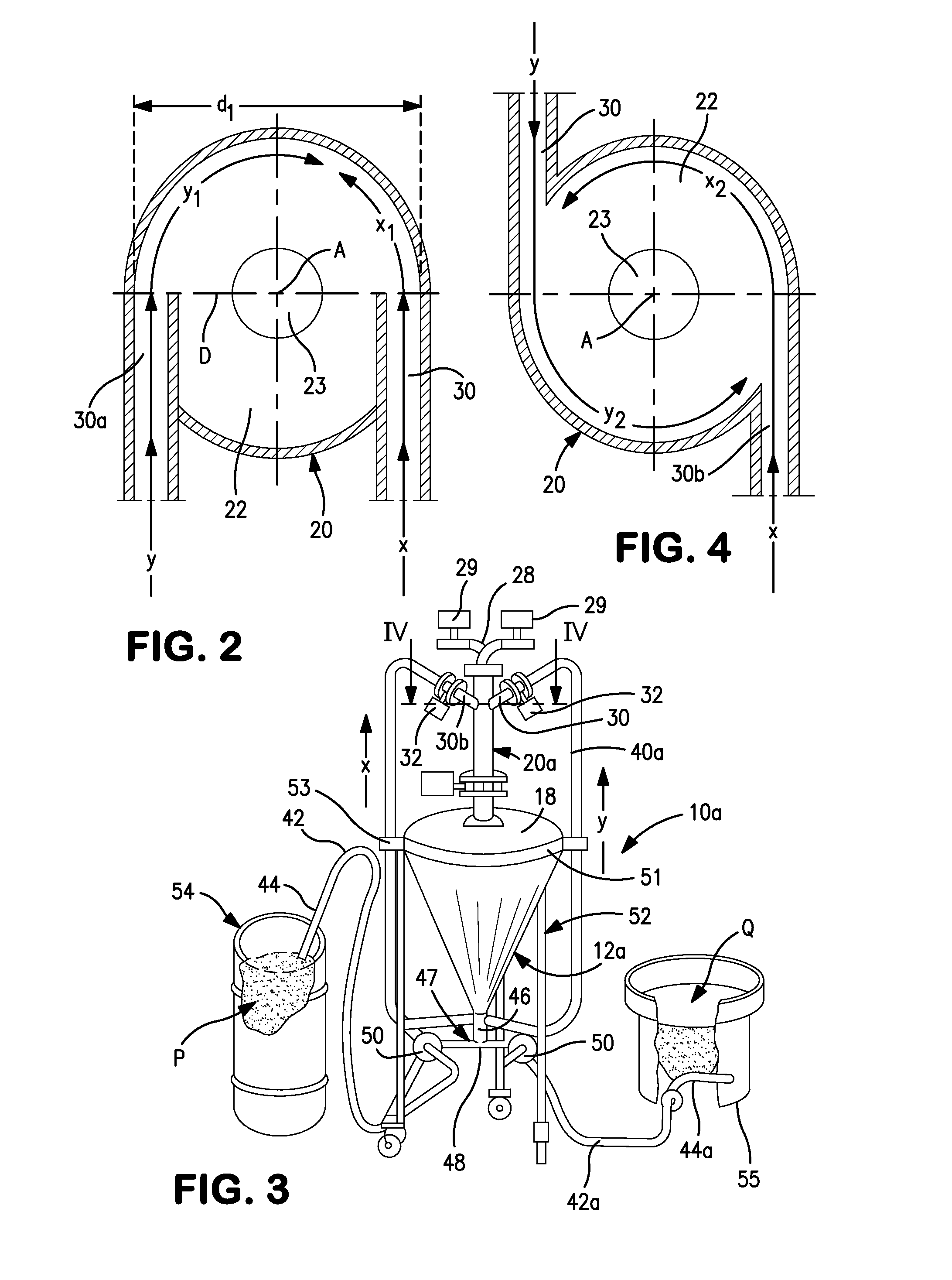

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High energyEfficient mixingMixing/kneading structural elementsFlow mixersSpray nozzleImpact area

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE GMBH & CO KG

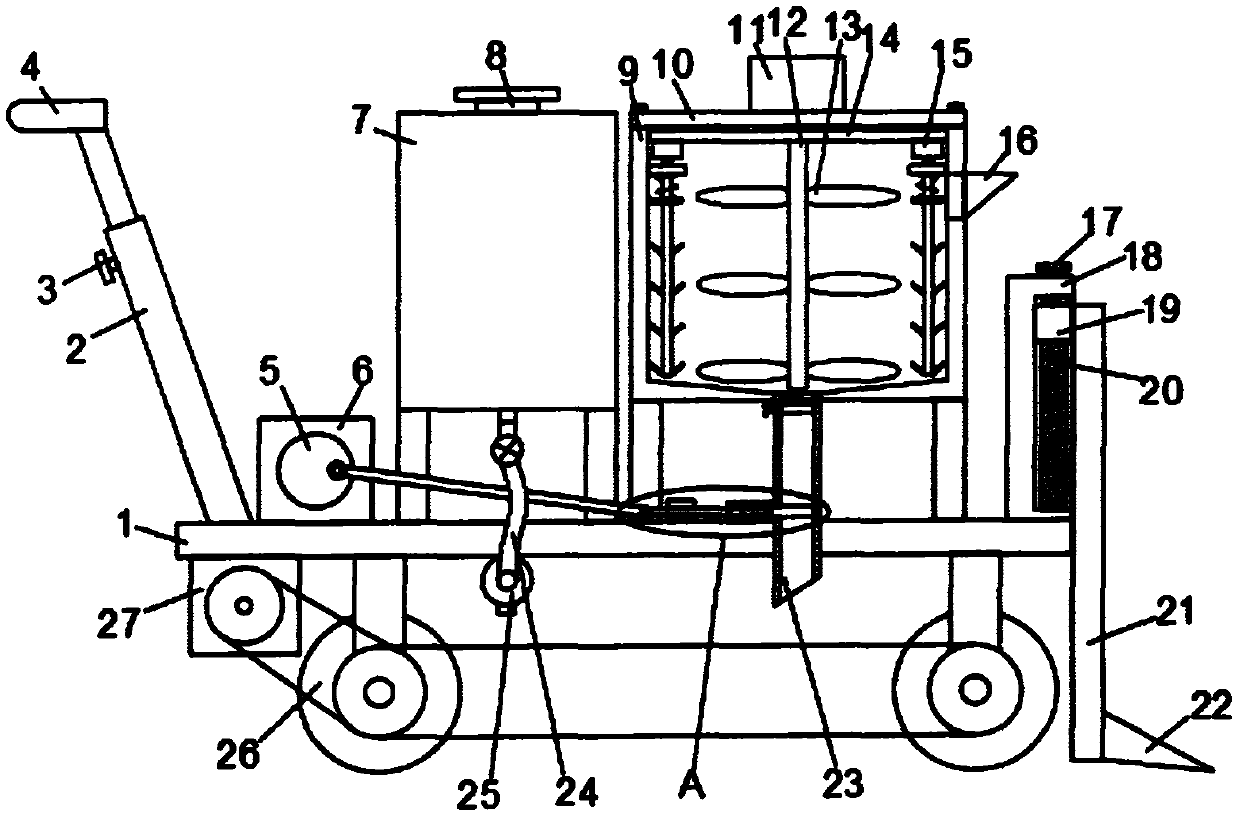

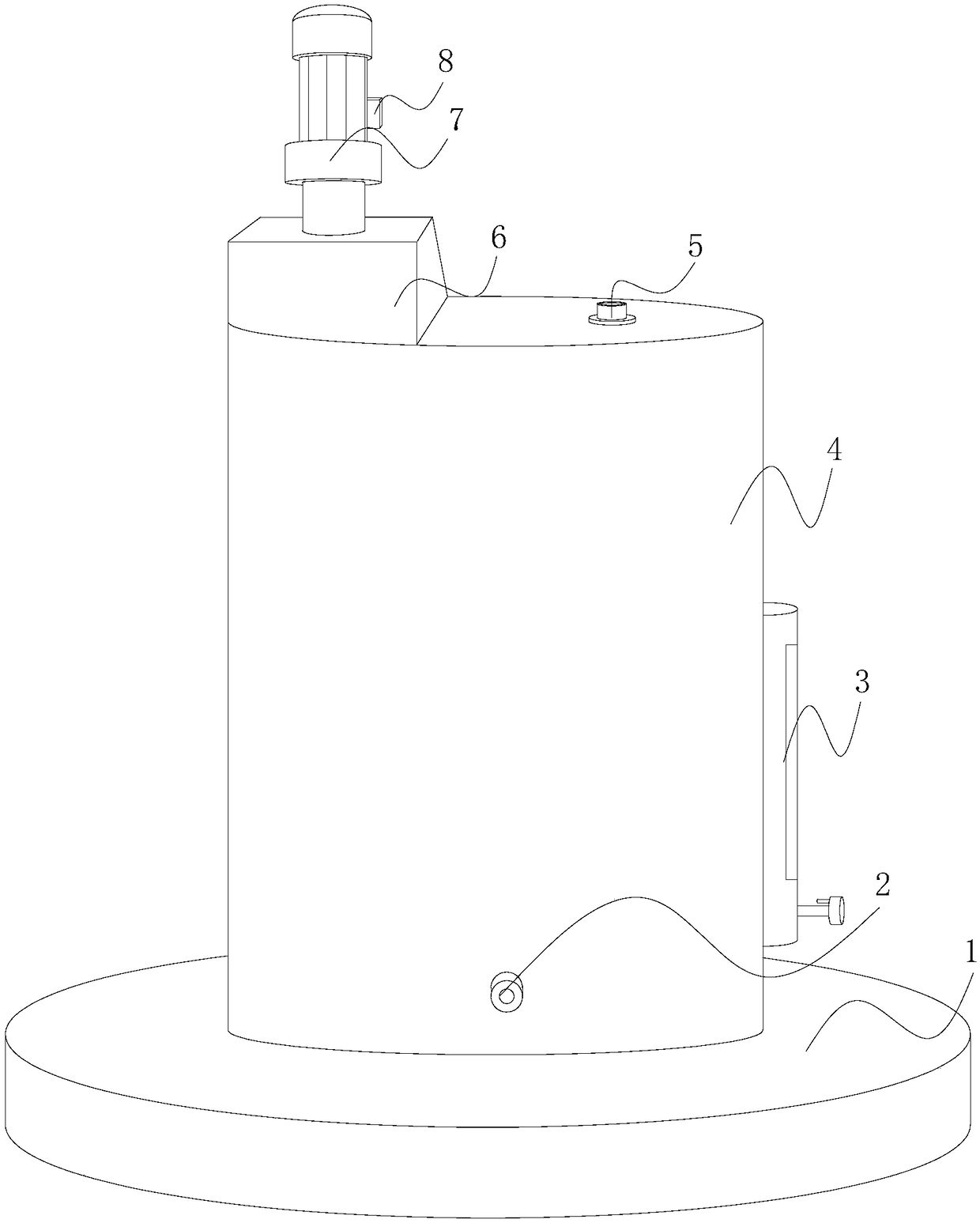

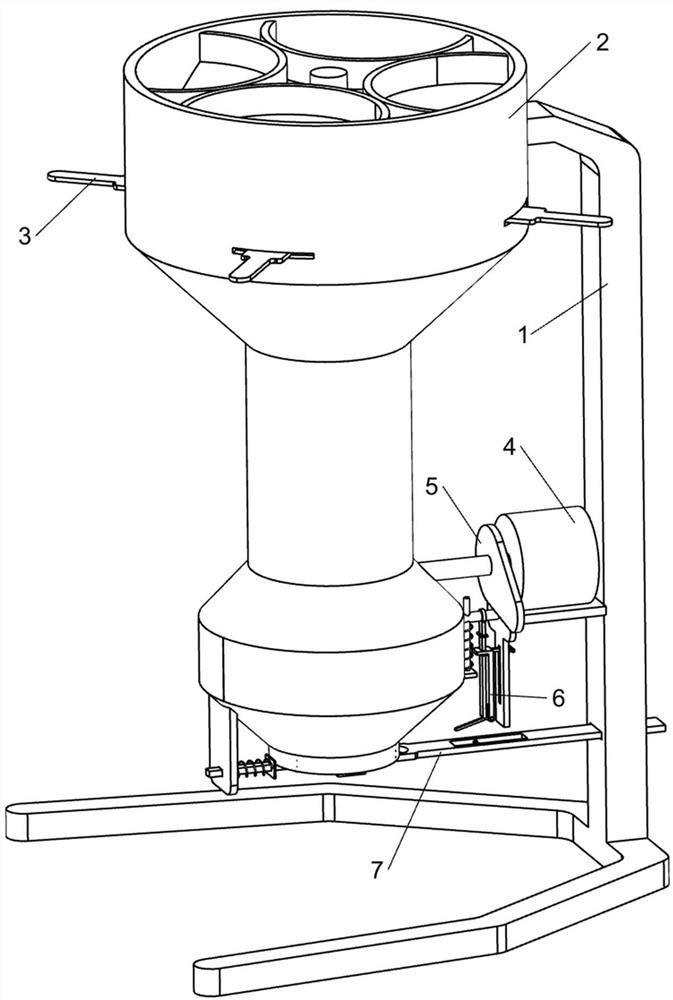

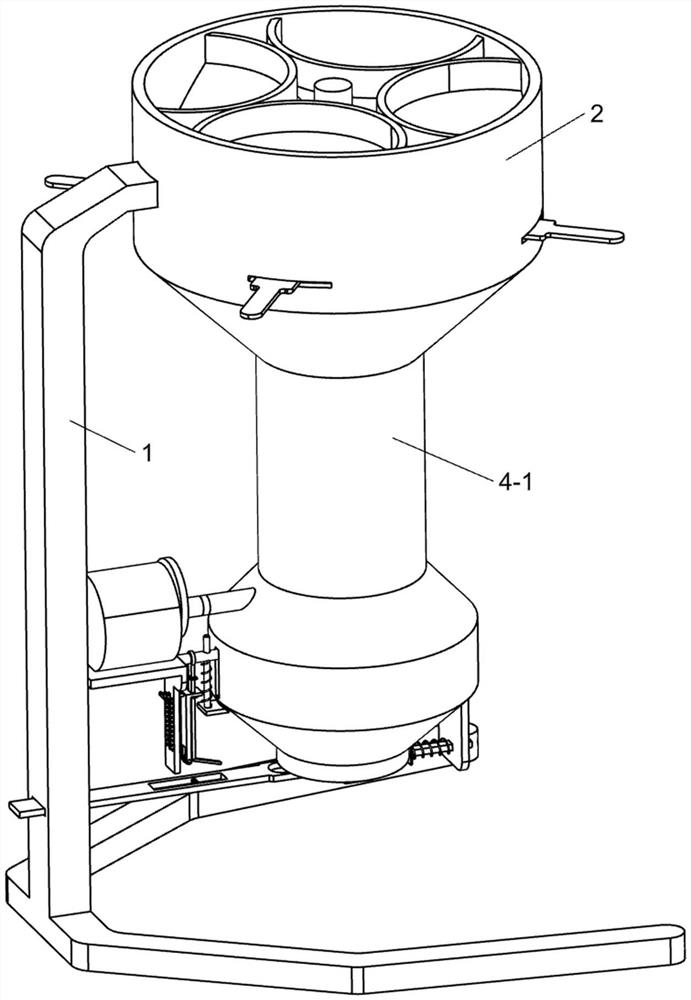

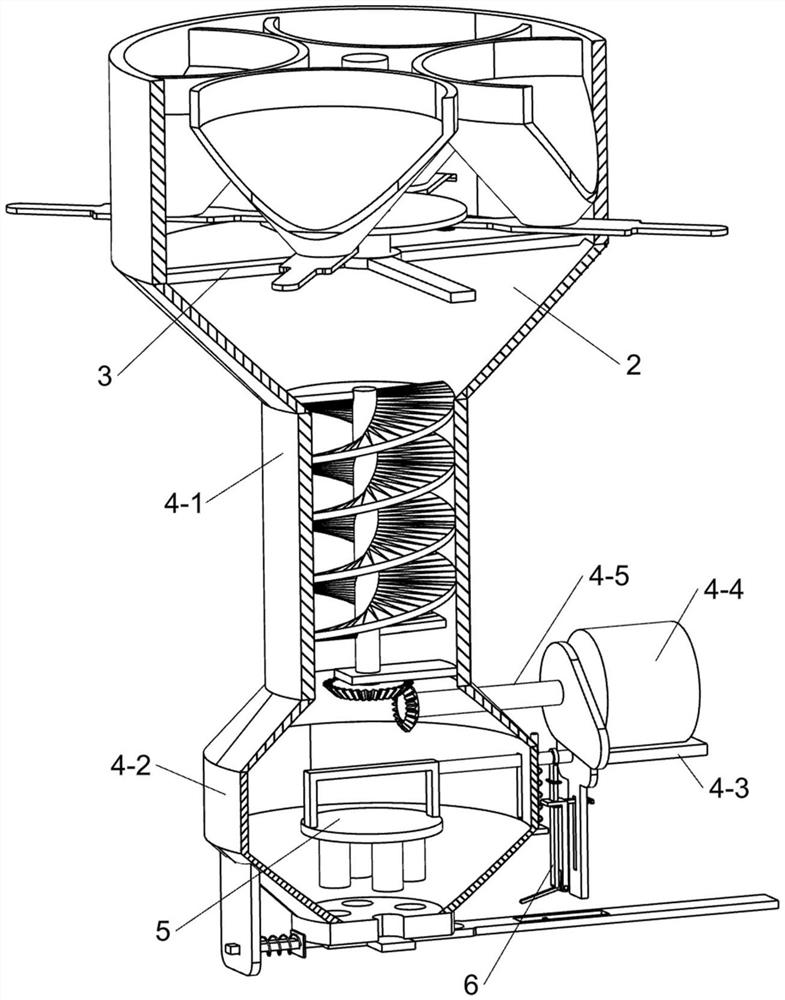

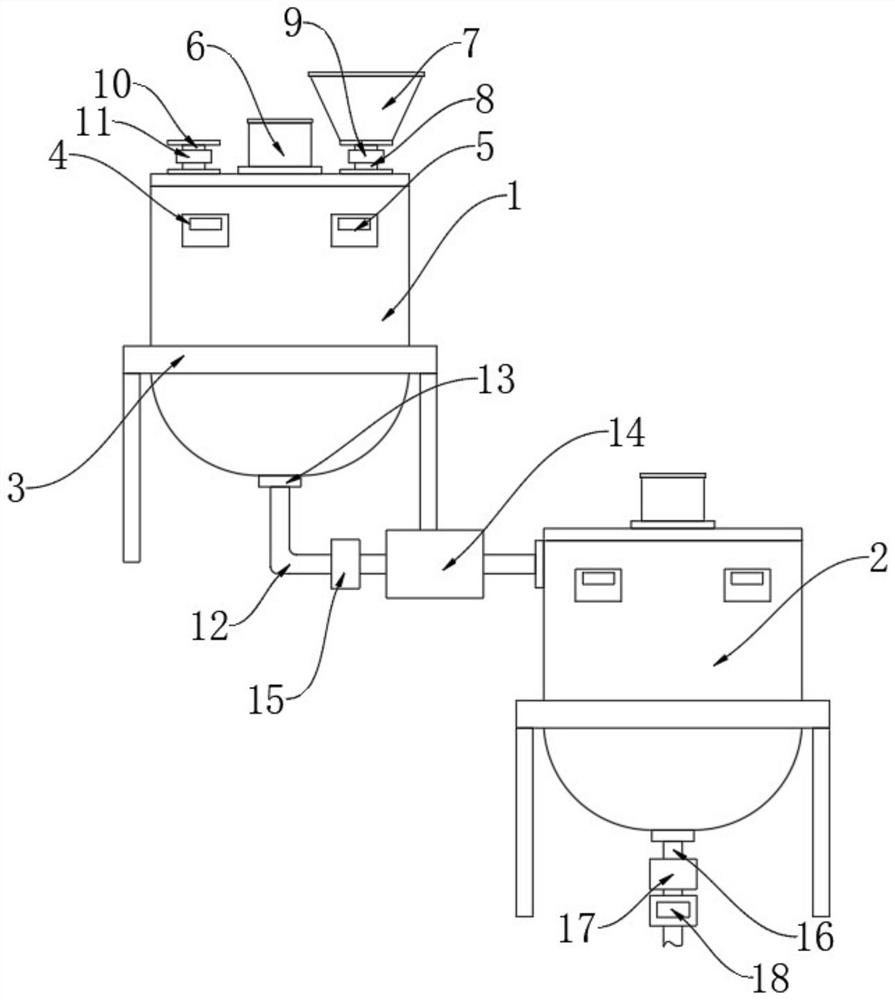

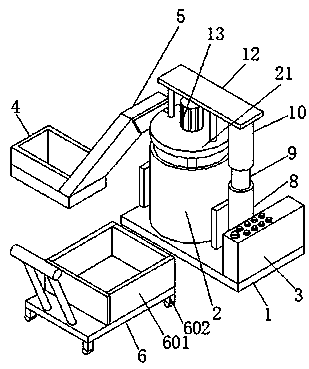

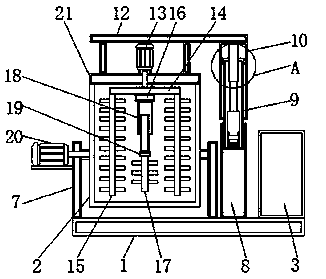

Automatic fertilization device for agriculture science and technology

InactiveCN110178509AImprove mixing uniformityImprove stirring efficiencyRotary stirring mixersTransportation and packagingEngineeringMixing effect

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

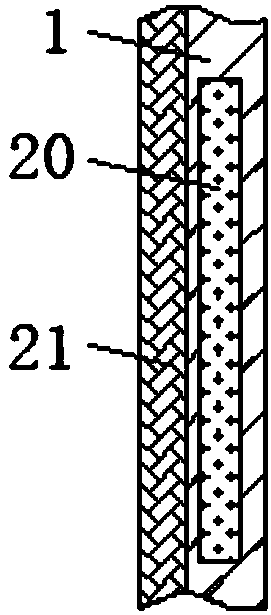

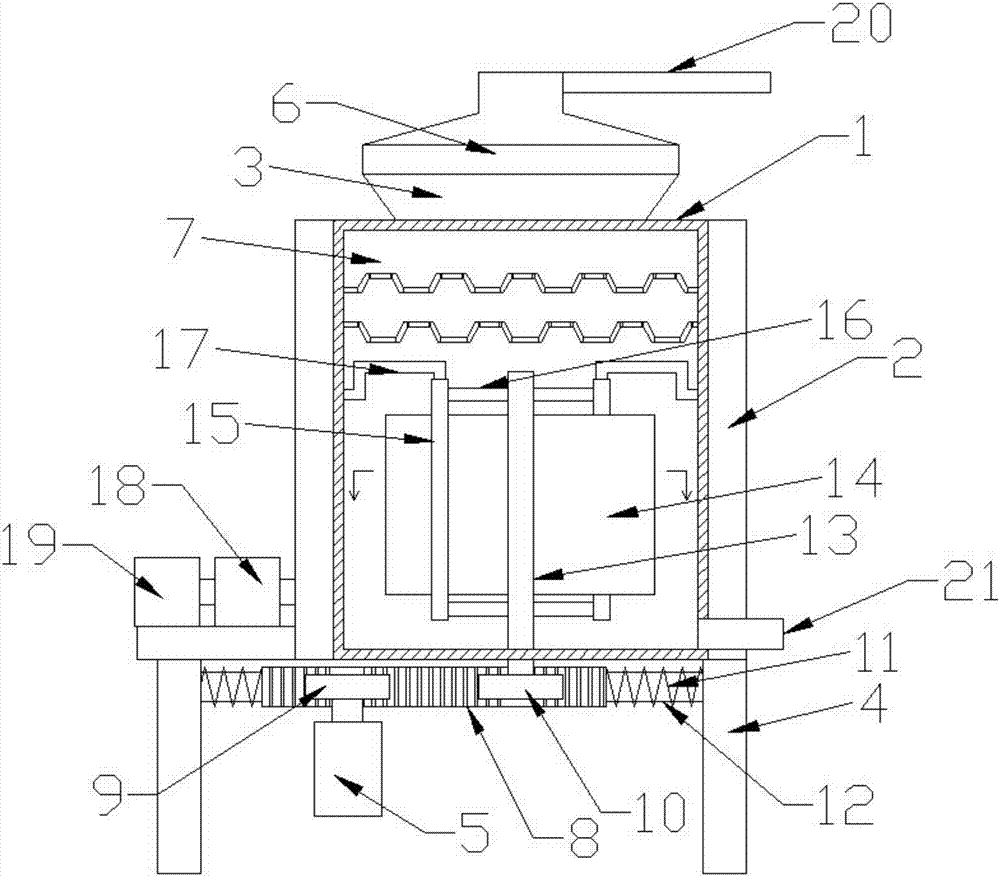

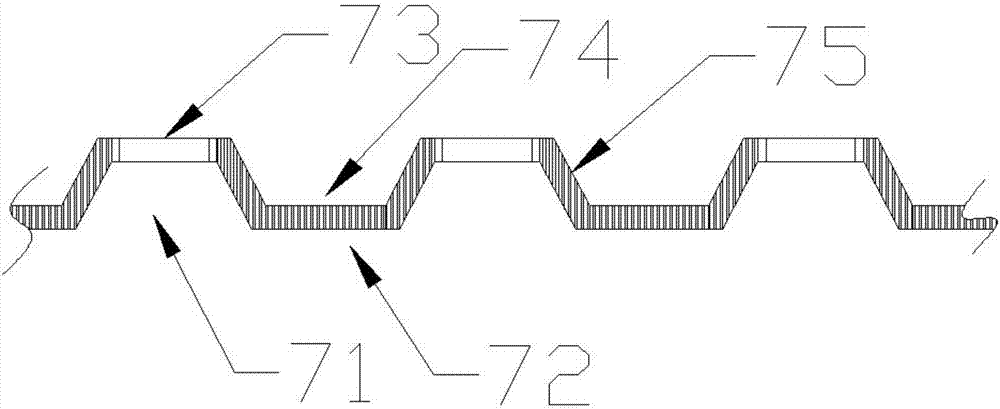

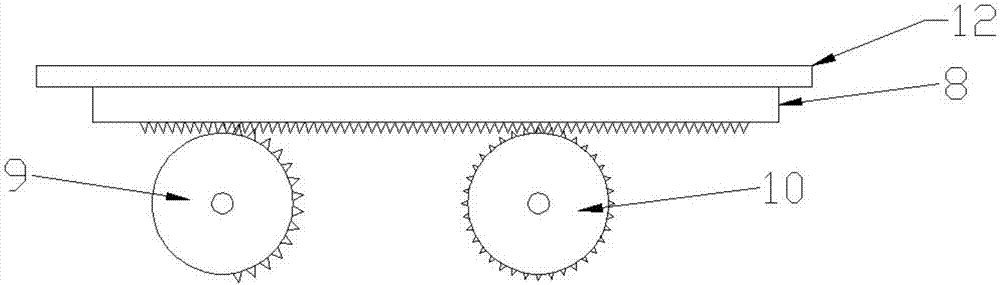

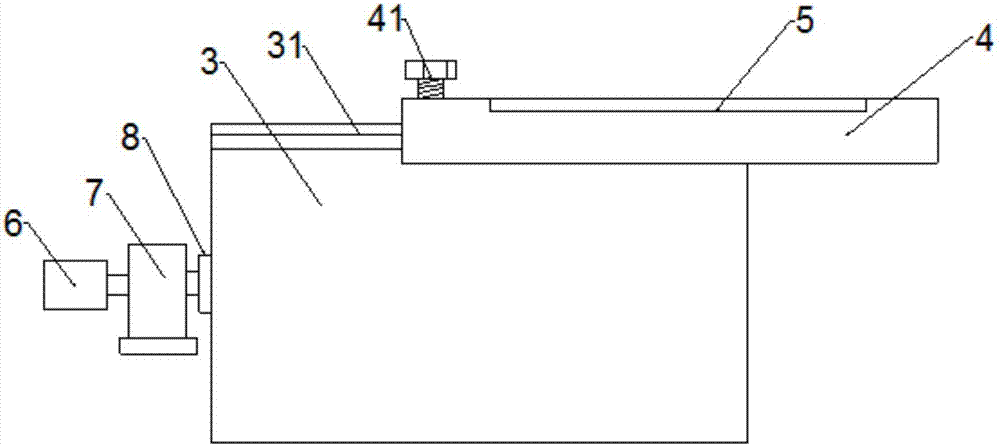

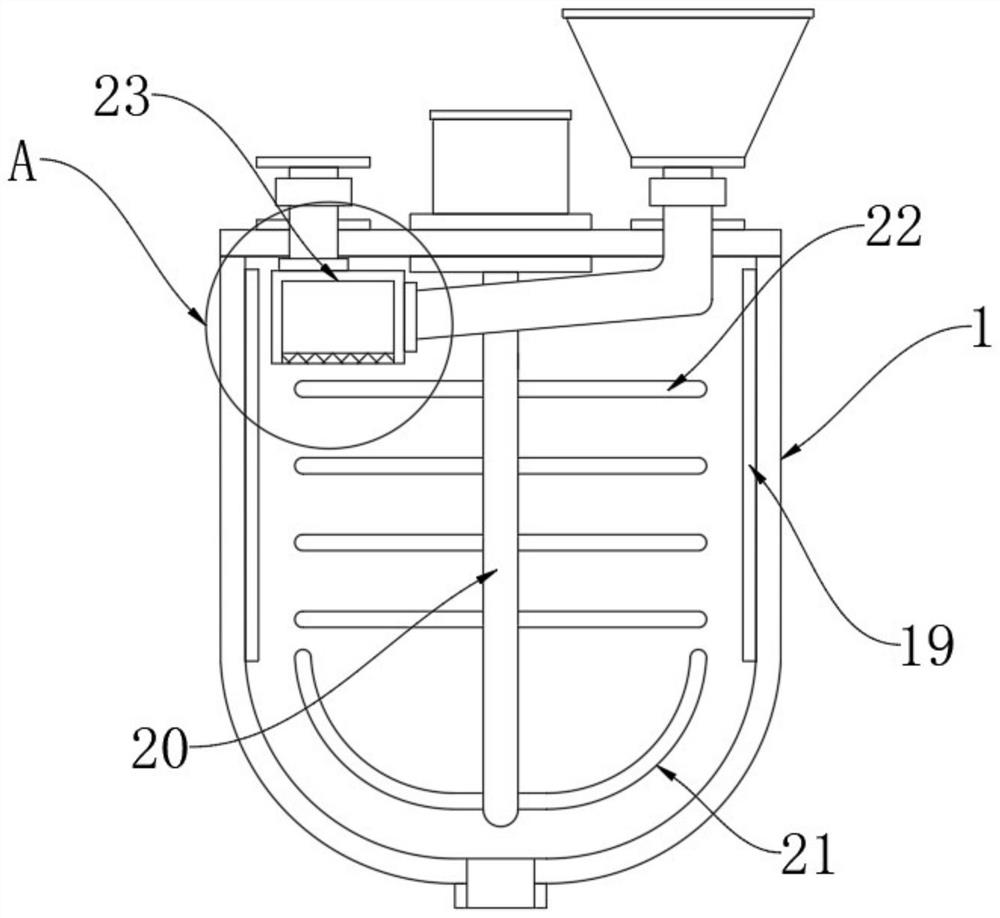

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

Feed processing dryer capable of stirring in positive and negative rotation mode

InactiveCN107280051AEasy to storeSmooth and safe deliveryFeeding-stuffRotary stirring mixersDrive shaftEngineering

Owner:王淑兰

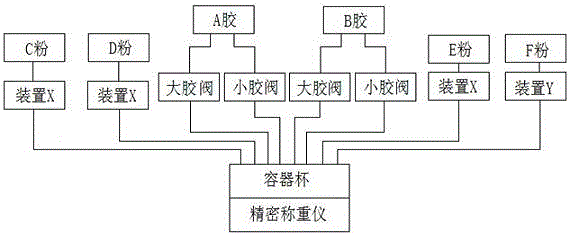

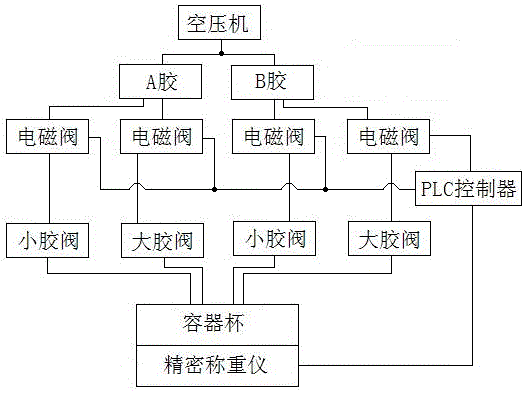

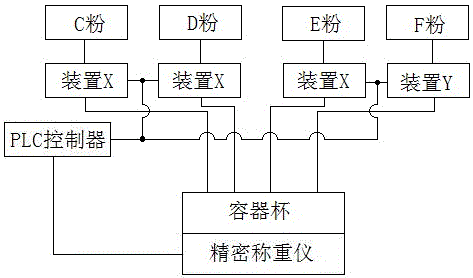

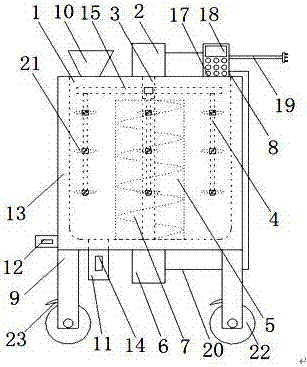

LED gelatine powder precision automatic burdening method

Owner:深圳市靶心配比科技有限公司

Mixing equipment for coating preparation and use method of mixing equipment

InactiveCN107413233AImprove processing speedImprove mix qualityRotary stirring mixersTransportation and packagingDrive shaftProcess engineering

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Traditional Chinese medicine extraction stirring device facilitating residue-liquid separation

ActiveCN113144672AEasy to separateEasy extractionRotary stirring mixersTransportation and packagingMedicinal herbsEngineering

Owner:XUCHANG UNIV

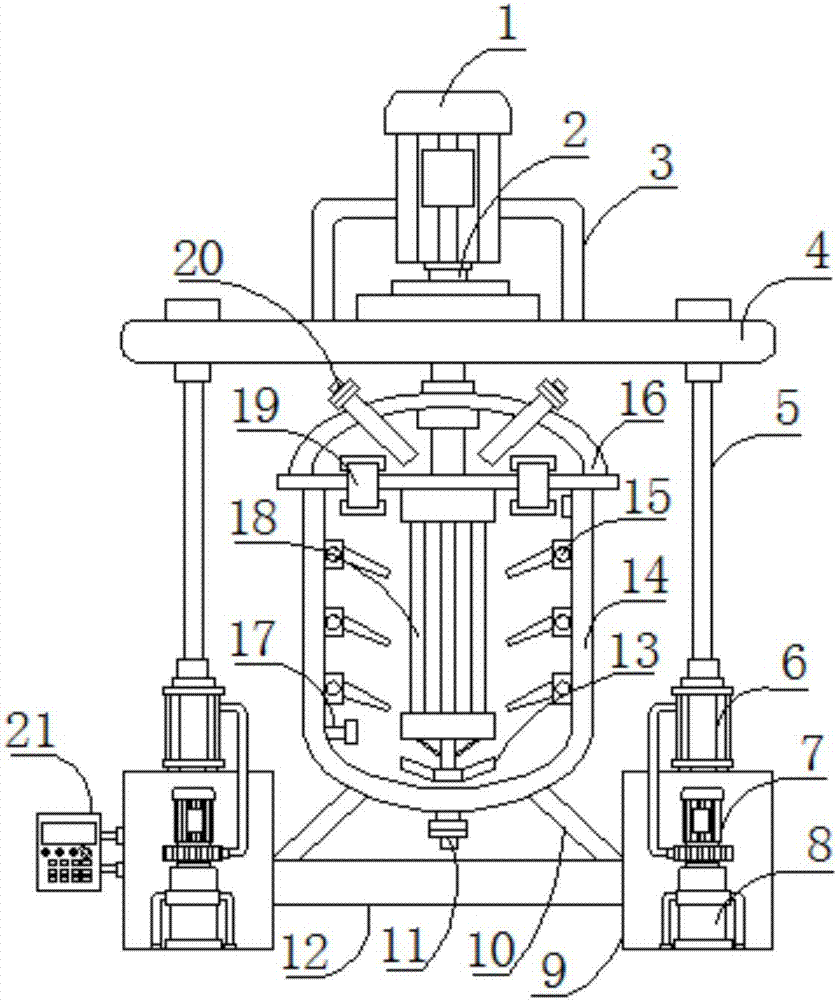

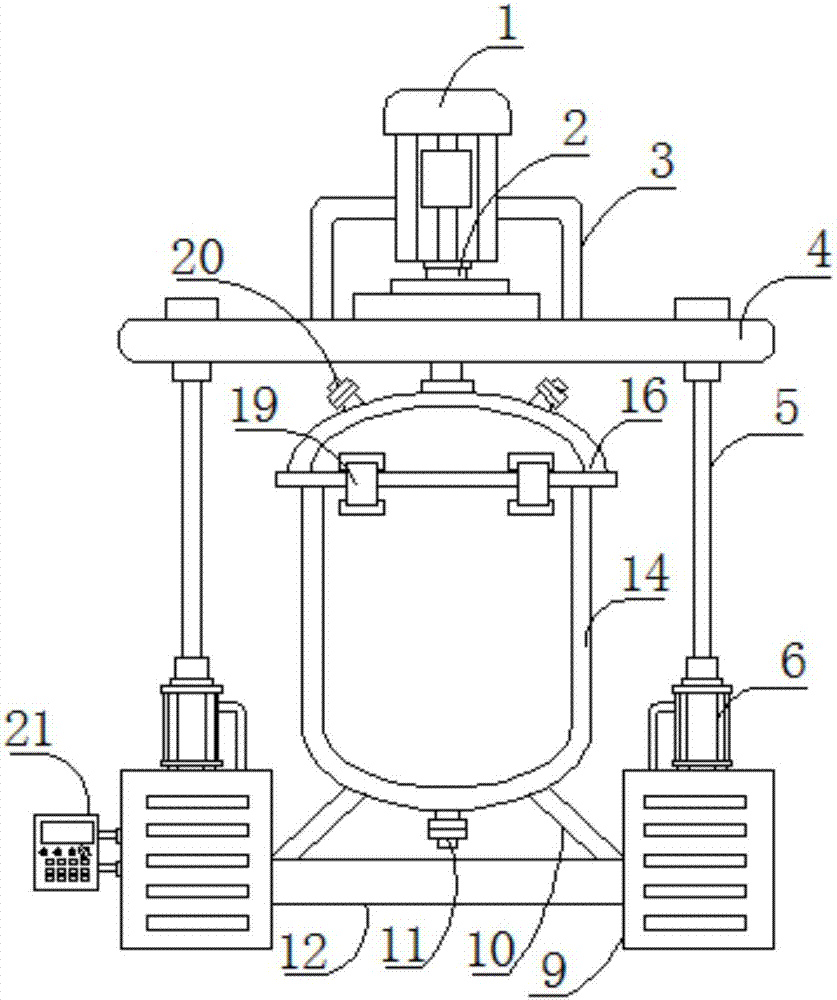

Left/right swinging type feed mixing equipment

InactiveCN107970819AImprove the mixing effectExpand the mixing rangeFeeding-stuffRotary stirring mixersEngineeringCentrifugal force

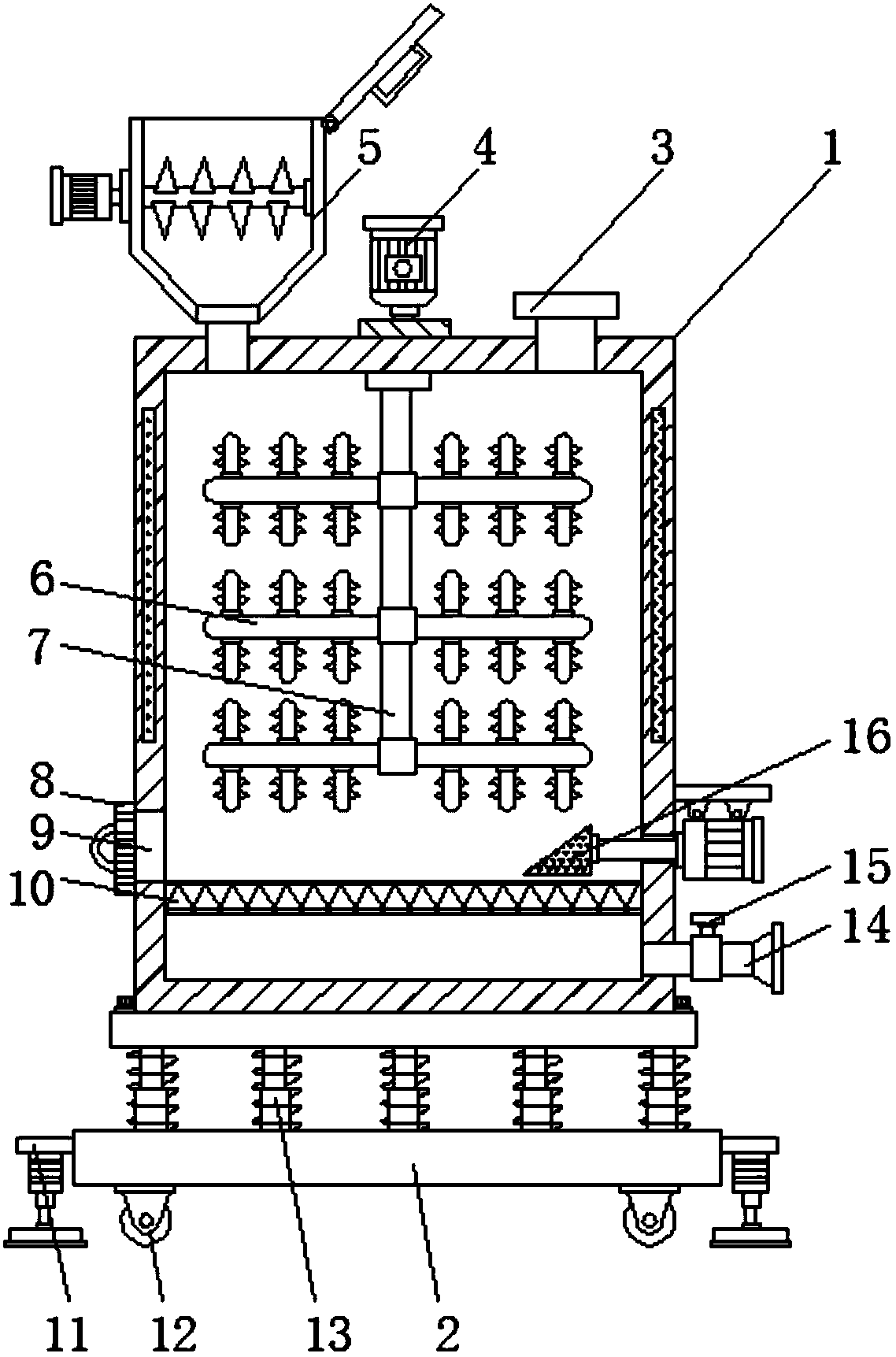

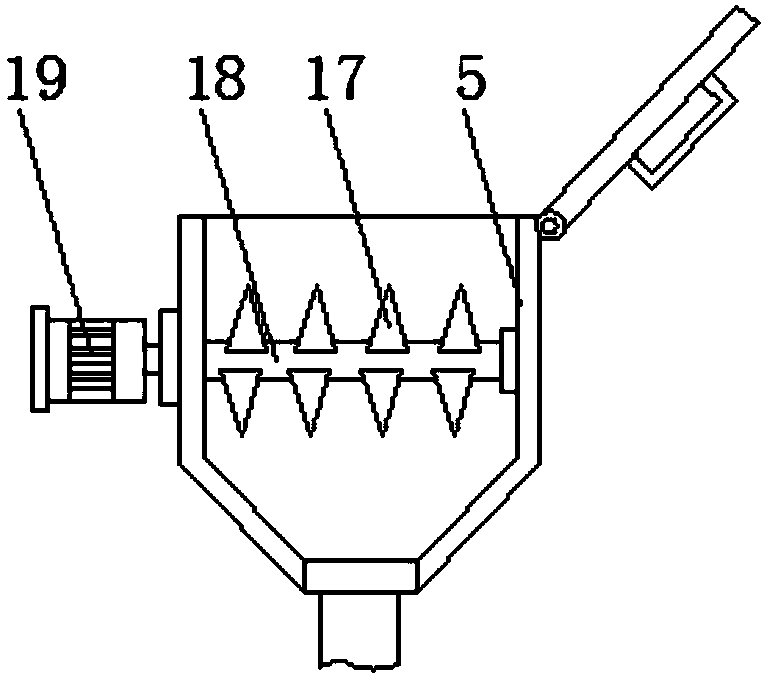

The invention discloses left / right swinging type feed mixing equipment which comprises a shell, wherein mounting bases are symmetrically and fixedly connected with the outer side wall of the shell; support columns are fixedly connected with the mounting bases; support plates are fixedly connected with top ends of the support columns; support bases are fixedly connected with the middle parts of thelower sides of the support plates; swinging columns are moveably hinged with the support bases; first motors are fixedly connected with the bottom ends of the swinging columns; first rotating shaftsare fixedly connected with output shafts of the first motors; two stirring devices are fixedly and symmetrically connected with bottom ends of the first rotating shafts; the stirring devices comprisehorizontal rods. The equipment has the beneficial effects that moving blocks on the stirring devices are moved away from the first rotating shafts because of a centrifugal force, at the same time thefirst springs are compressed, and then stirring bulges are driven by the moving blocks to change the stirring range; with the combination of pull devices and second springs, the stirring devices are swung leftwards and rightwards, so that the stirring range is effectively increased, and the feed mixing effect is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

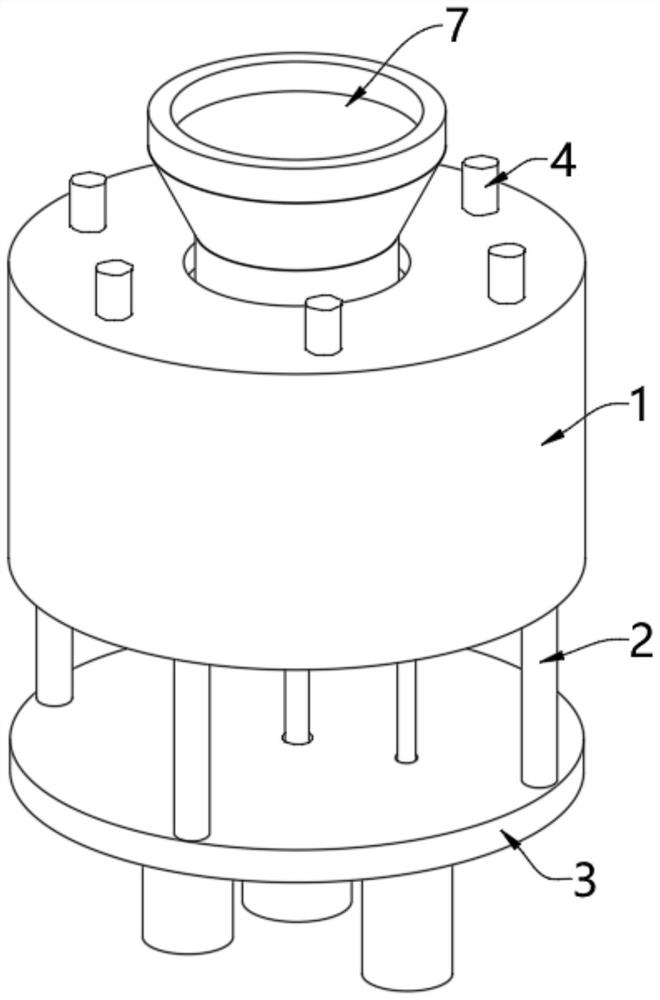

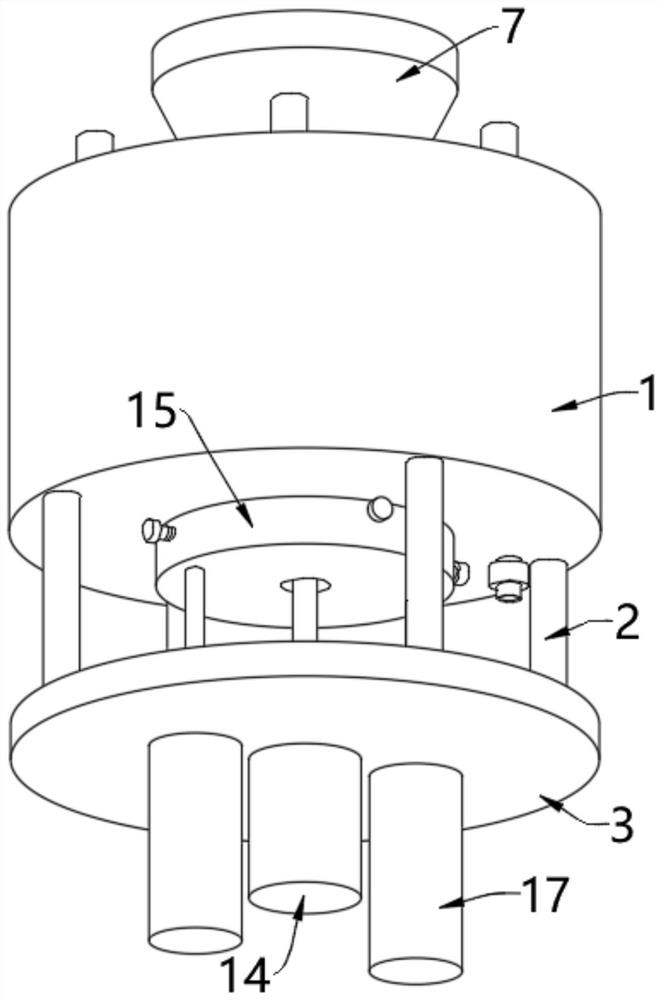

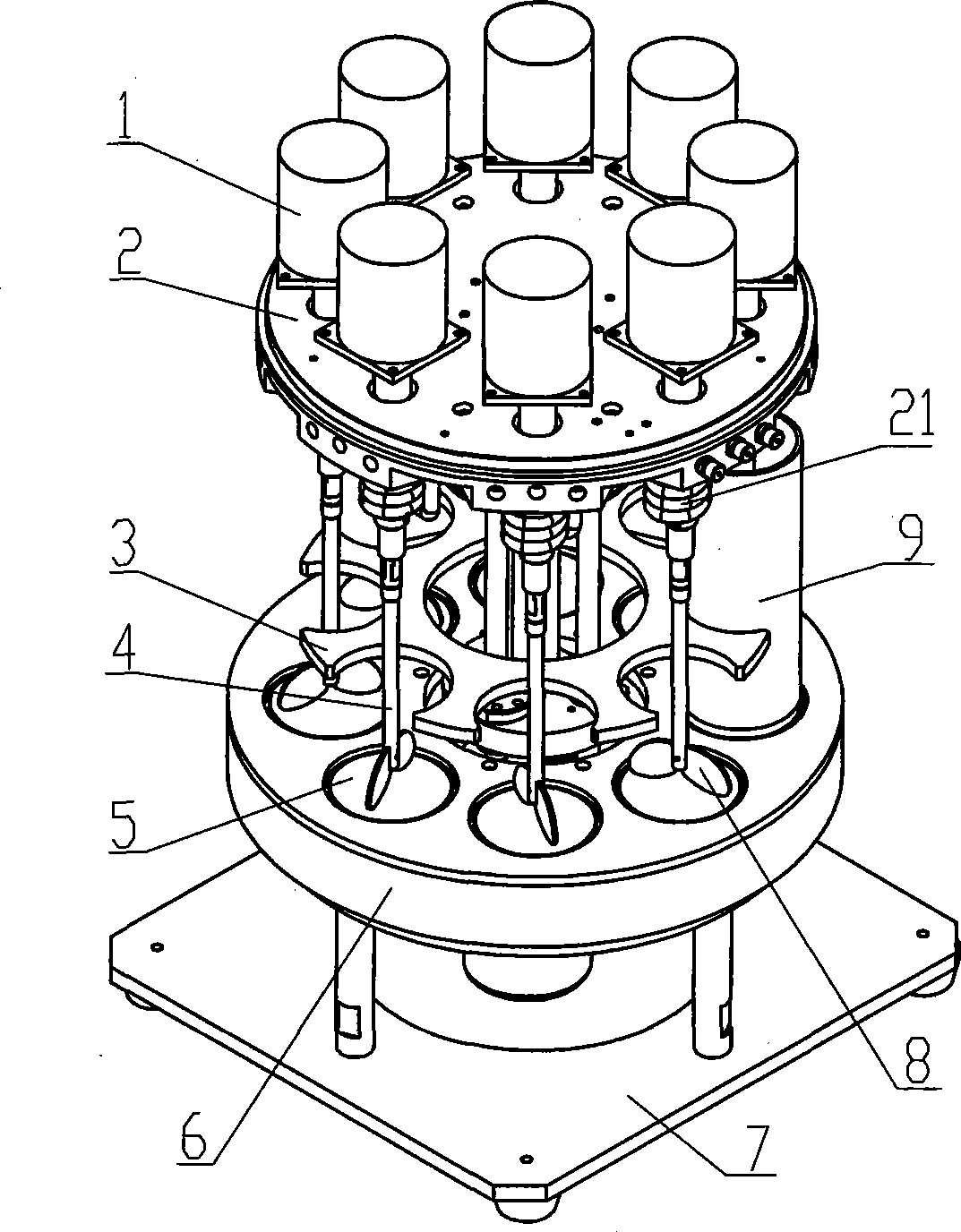

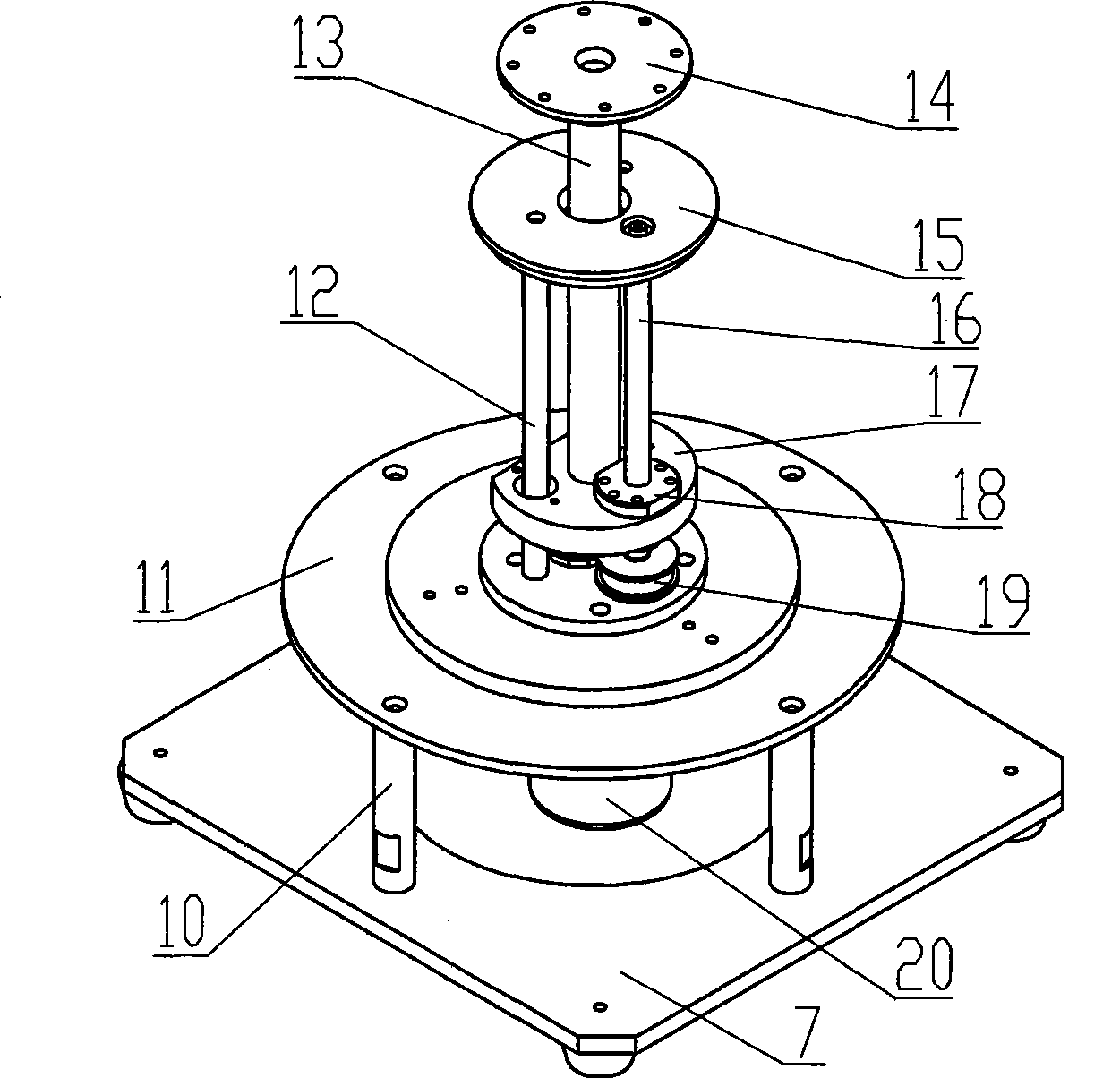

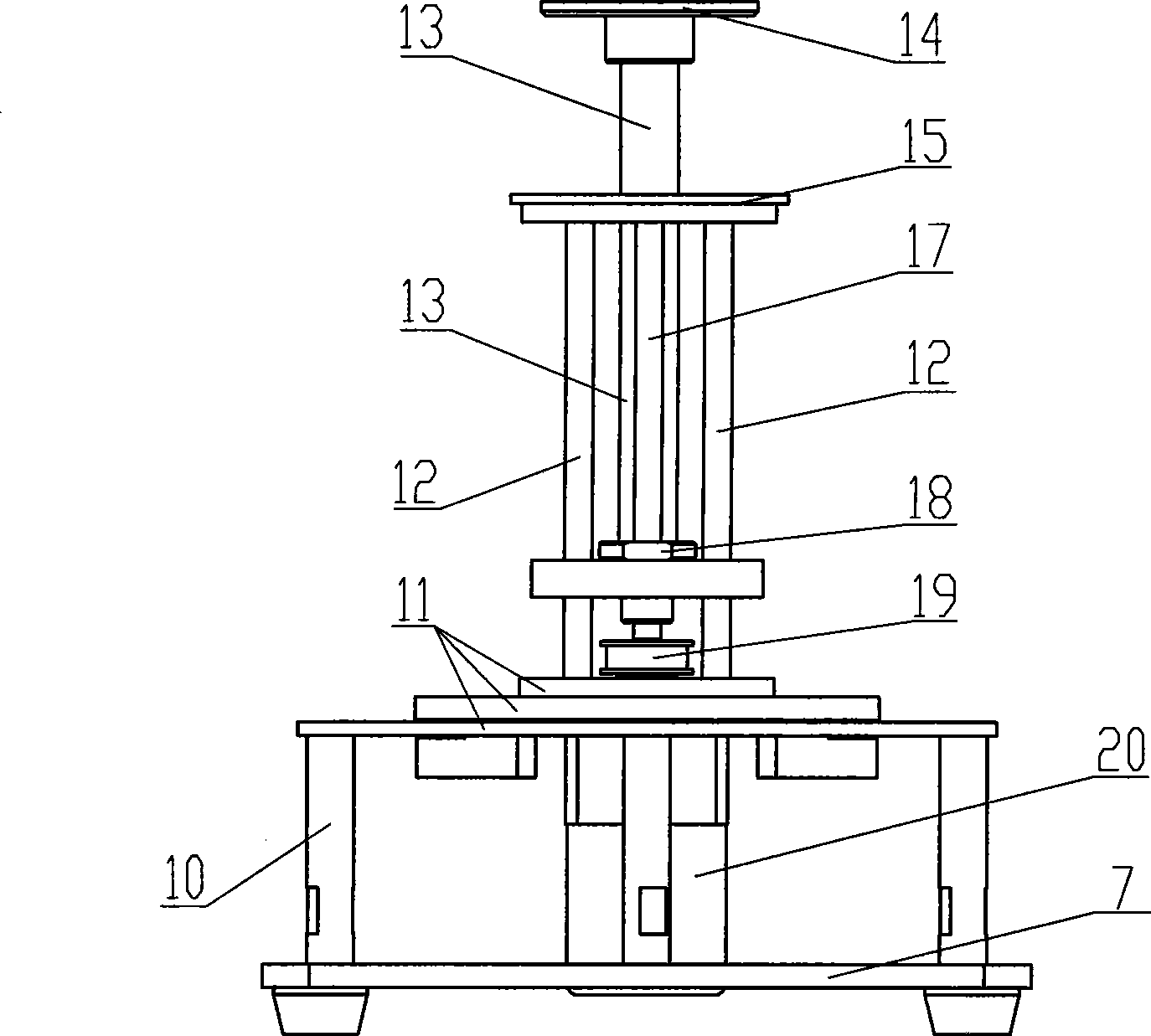

Parallel polymerization synthesis device

InactiveCN101362071AEasy to useSave research timeRotary stirring mixersMixer accessoriesResearch efficiencyReaction temperature

Owner:深圳市新和创智能科技有限公司

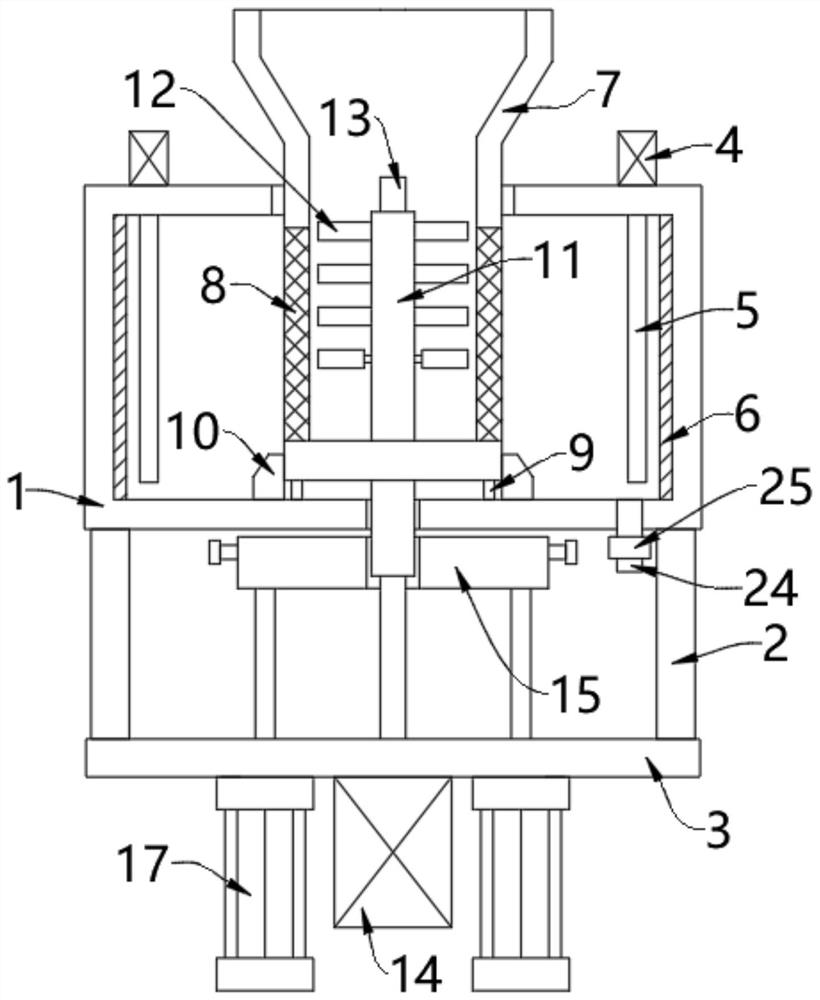

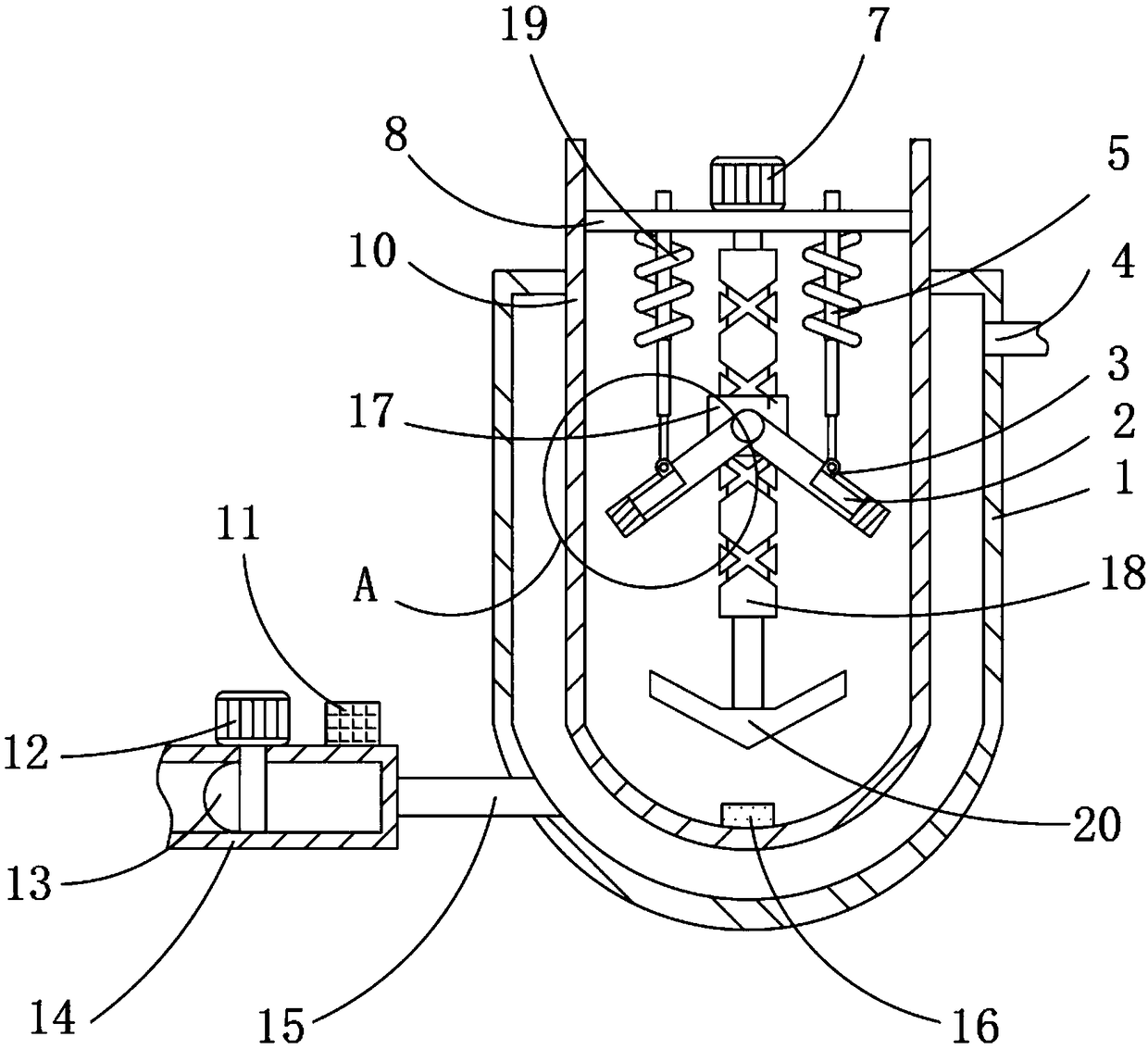

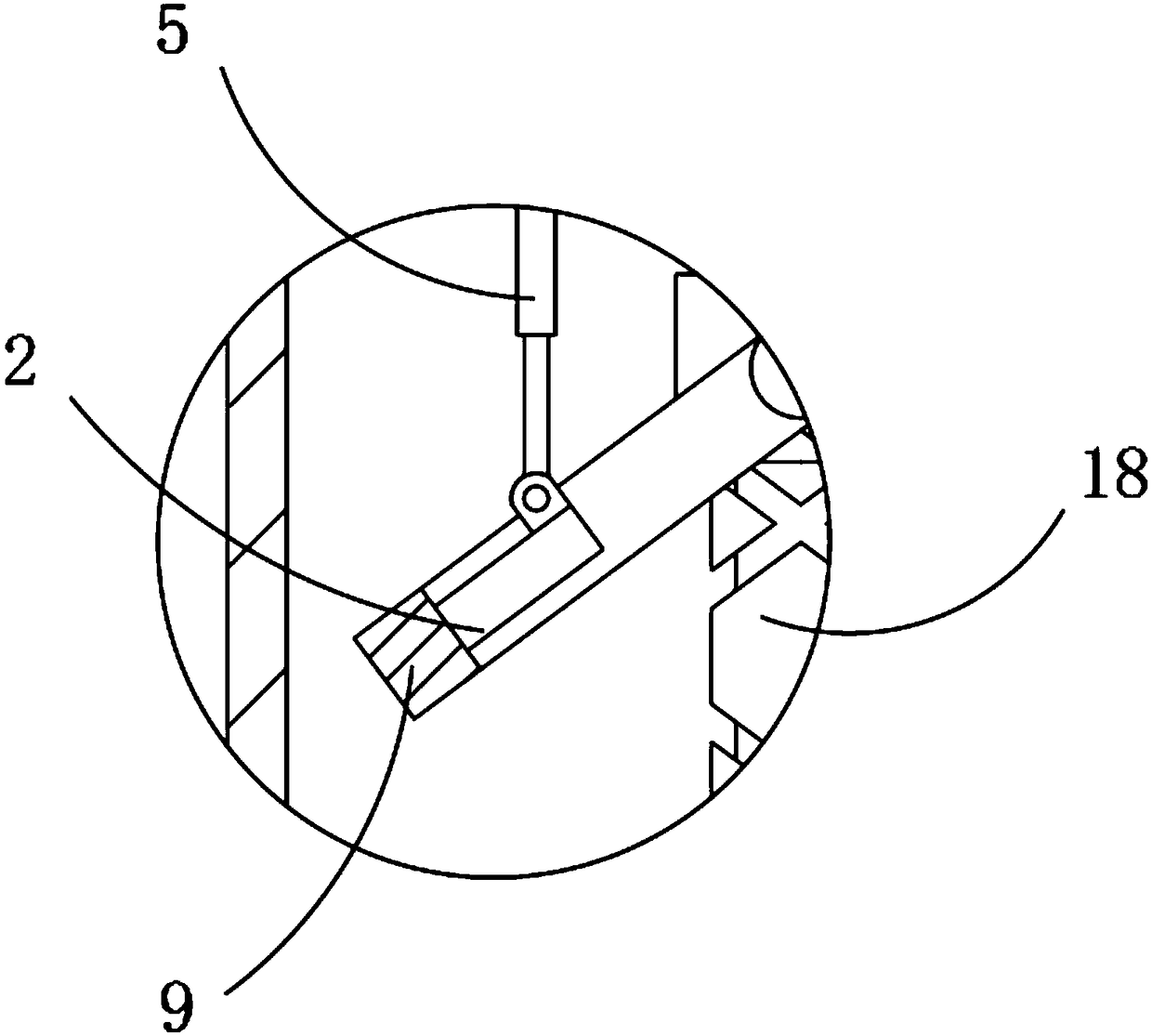

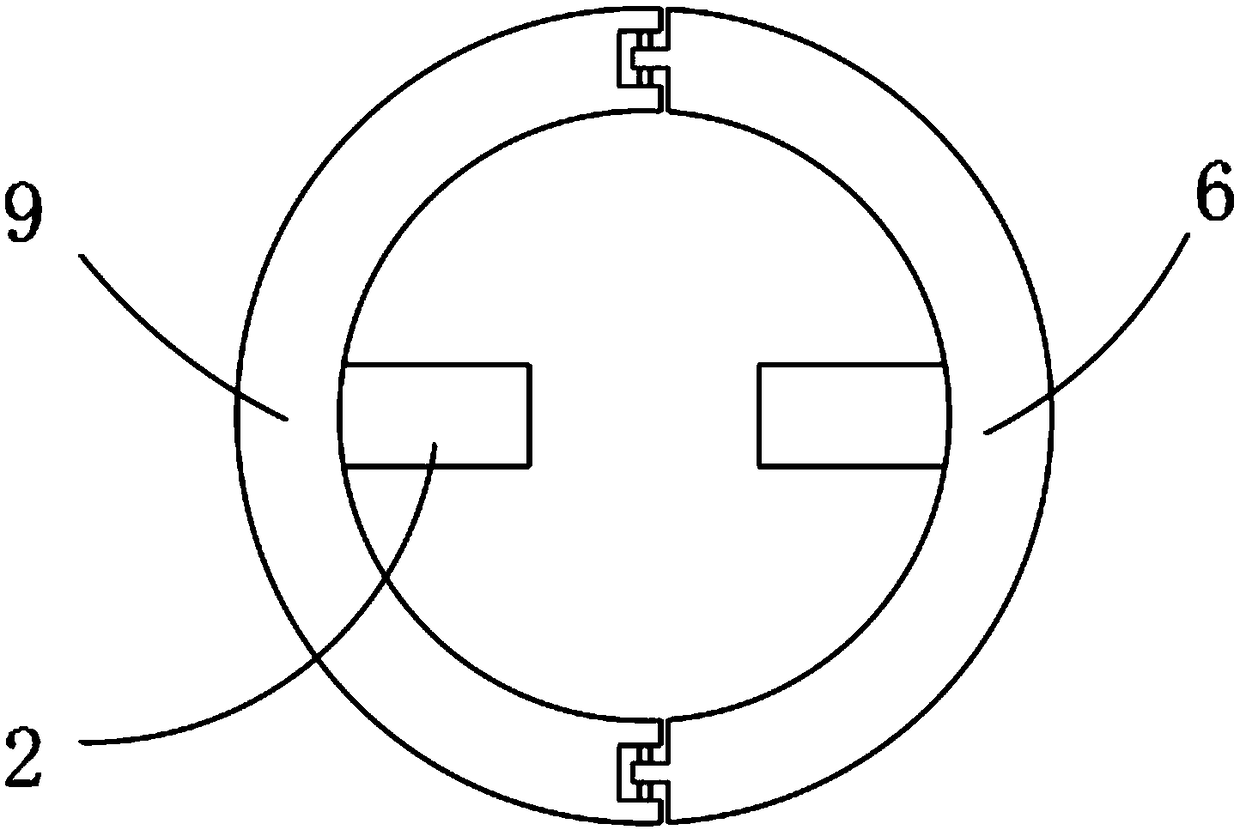

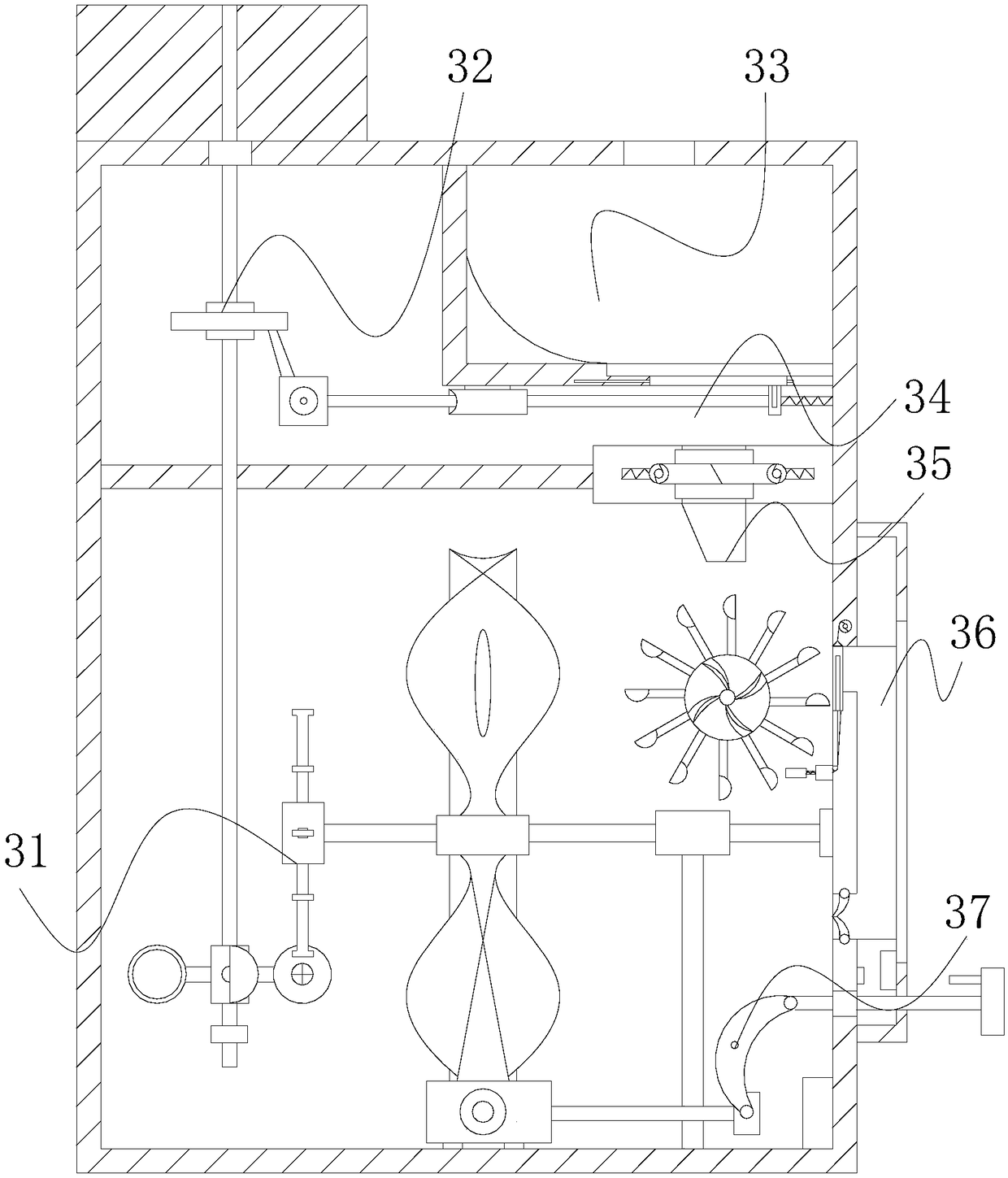

Multifunctional stirring device for biological pharmacy

ActiveCN112237881AWell mixedEasy to stir and mixTransportation and packagingMixer accessoriesPharmacyReciprocating motion

The multifunctional stirring device for biological pharmacy comprises a box body; a partition plate is fixedly connected to the upper end of an inner cavity of the box body, two feeding hoppers are fixedly connected to the left side of a top plate of the box body in a front-back symmetrical mode, and lower end openings of the feeding hoppers penetrate through the top plate of the box body and extend into the box body to communicate with upper end holes of feeding pipes; the lower opening of the feeding pipe penetrates through the partition plate and extends to the lower part of the partition plate; the top end of the left side wall of the inner cavity of the box body is fixedly connected with a motor; according to the invention, the motor drives a first rotating shaft to rotate, the firstrotating shaft rotates to drive a first connecting rod to rotate, then a first sliding block drives a second connecting rod to do left-right reciprocating motion, and further, the second sliding blockdrives the third connecting rod to swing with the second fixing rod as the axis, the check block synchronously swings along with the third connecting rod and is matched with the feeding hopper, and therefore raw materials are controlled to intermittently fall into the feeding pipe downwards.

Owner:XIAN TIANYI QINKUN PHARMA

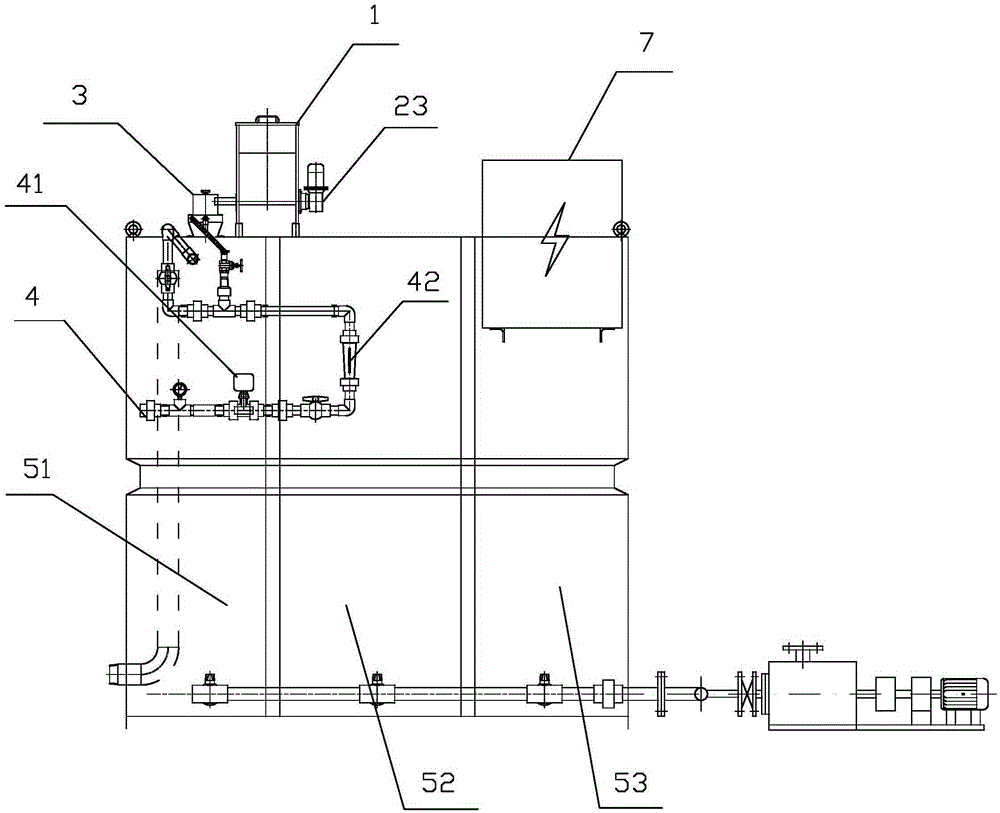

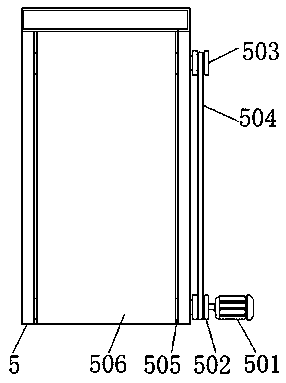

Continuous type full-automatic chemical feeding device

Owner:扬州绿都环境工程设备有限公司

Printing and dyeing raw material mixing device

InactiveCN108686574AWell mixedRotary stirring mixersTransportation and packagingEconomic benefitsEngineering

Owner:ZHEJIANG XINGFEIER TECH CO LTD

Stirring and emulsifying equipment for preparing energy-saving color paste

InactiveCN107469656AImprove centrifugal extrusionIncreased force between impactsRotary stirring mixersMixing methodsHydraulic cylinderLiquid layer

Owner:长兴利其科技有限公司

Dying device

InactiveCN109279053ASimple structureHigh degree of automationRotary stirring mixersMixer accessoriesPower modeGear wheel

Owner:岑浩明

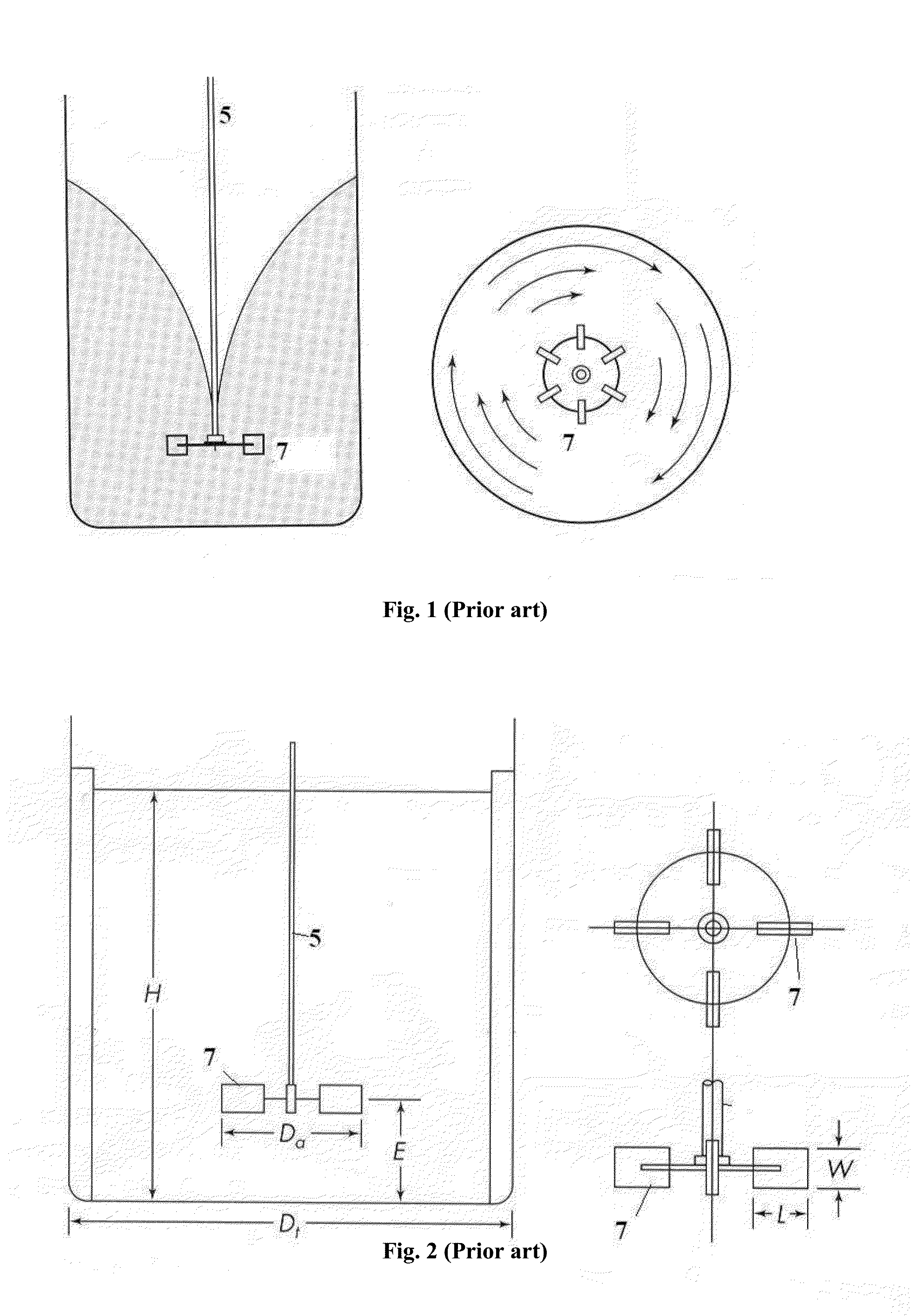

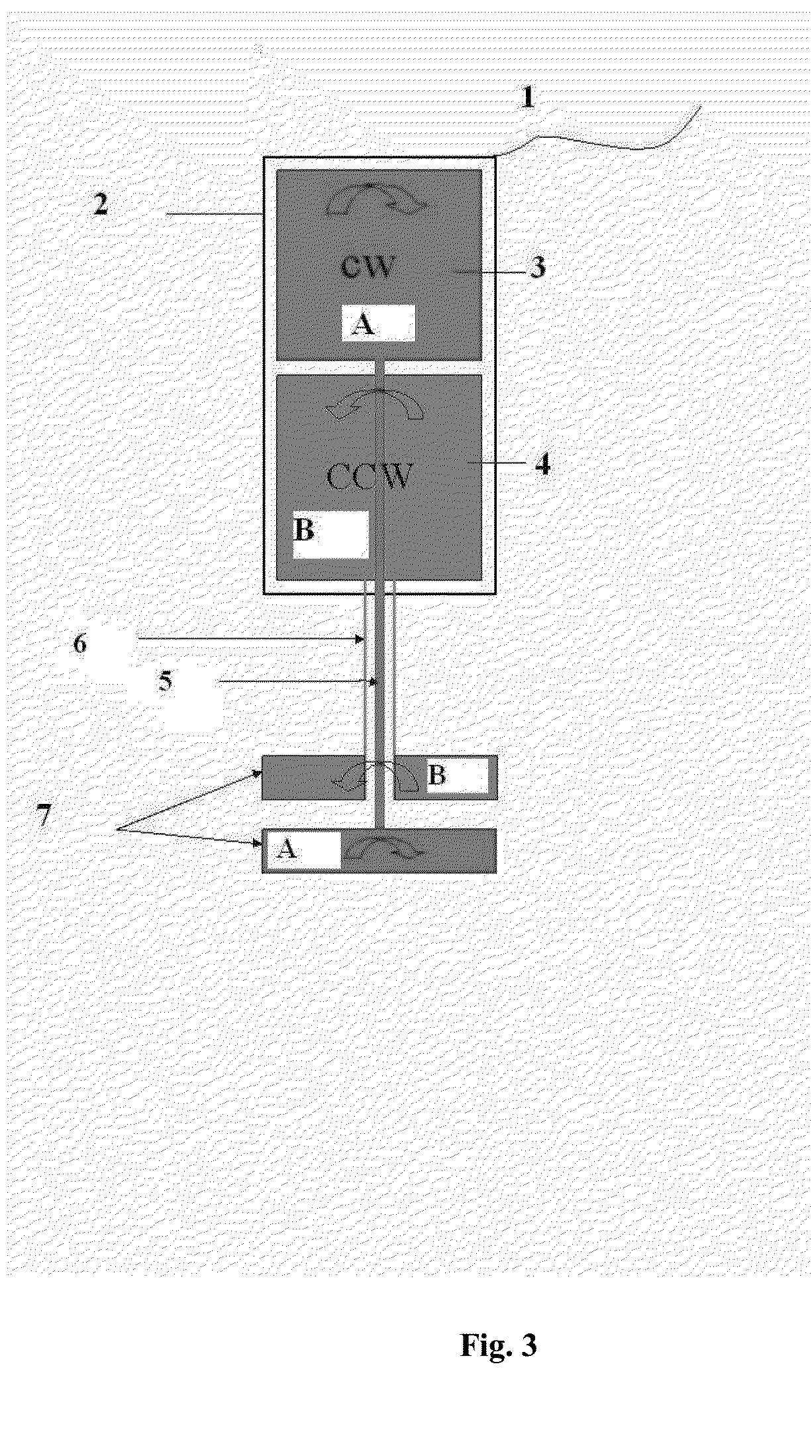

Enhancement of agitation by an innovative blender

InactiveUS20160038892A1Less energyQuick combinationRotary stirring mixersTransportation and packagingImpellerChemical compound

Owner:KORAI GASHTASEB MARDANI +2

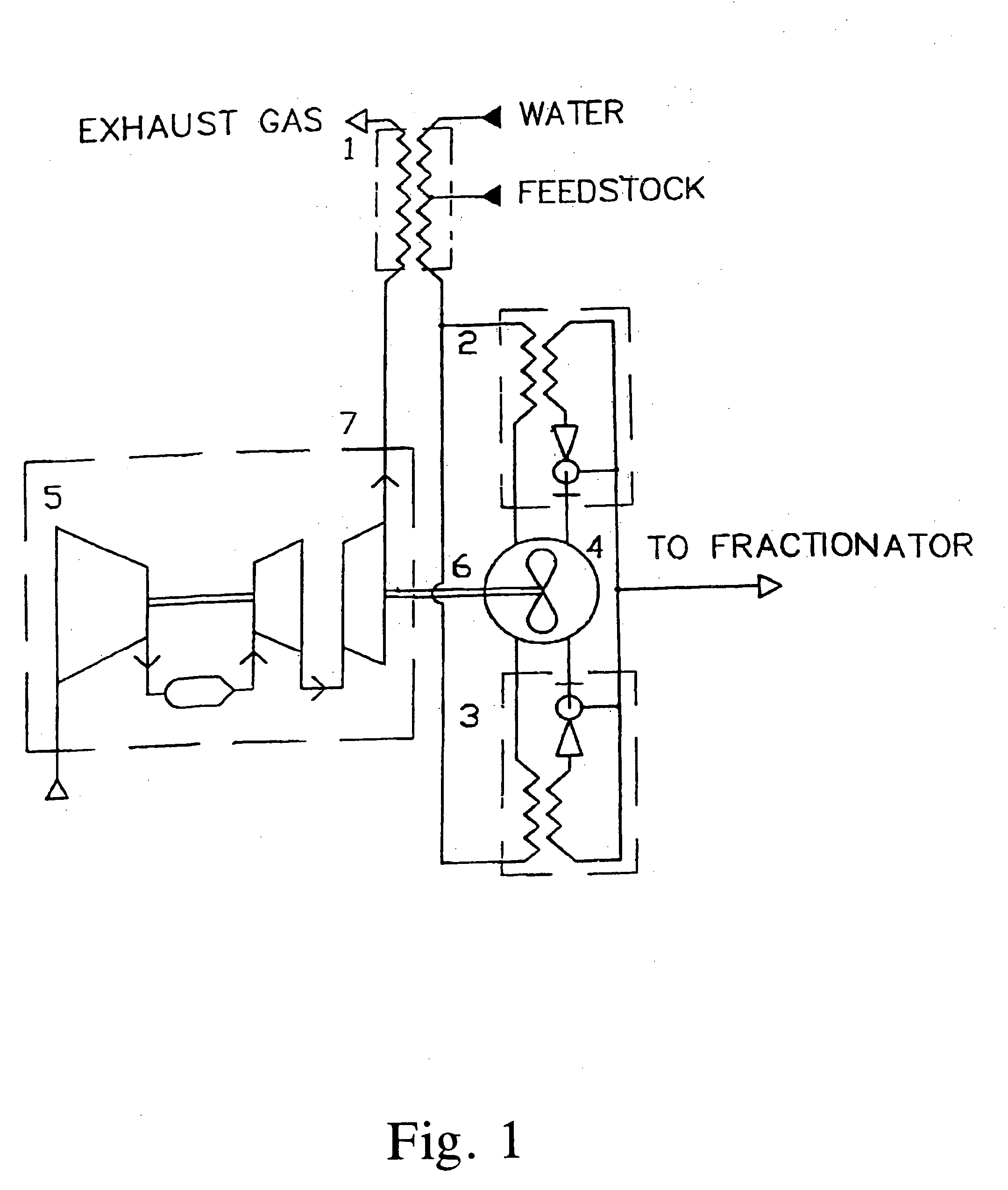

Process for producing low-molecular olefins by pyrolysis of hydrocarbons

InactiveUS20050137440A1Reduce energy consumptionEfficient use ofThermal non-catalytic crackingFlow mixersFractionationDiluent

Owner:COOLBROOK

Efficient stirring device for paint production

Owner:湖州御筵科技有限公司

Pesticide mixing device with good effect

InactiveCN112999918ARealize quantitative inflowRealize online stirring and mixingRotary stirring mixersTransportation and packagingEngineeringBiology

Owner:深圳市俊达通办公智能科技有限公司

Stirring and tabletting device capable of adjusting proportion of raw materials of powder coating

ActiveCN113002050AEasy to process and grindAutomatic separationRotary stirring mixersTransportation and packagingMetallurgyTableting

Owner:安徽柏枝新材料有限公司

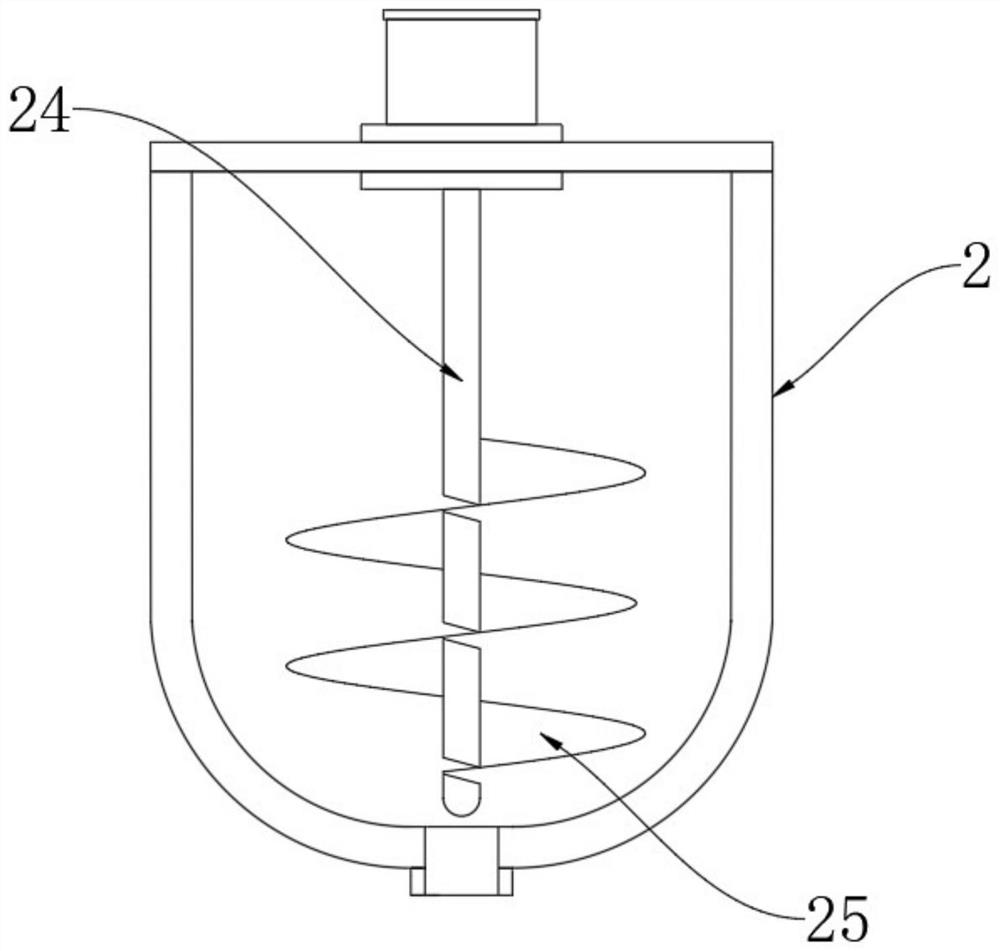

Easily-cleaned spiral stirring machine for processing bean curd skins

InactiveCN107469667AWell mixedWon't breakRotary stirring mixersTransportation and packagingInlet valveAgricultural engineering

Owner:龙里县兴溢诚豆制品有限公司

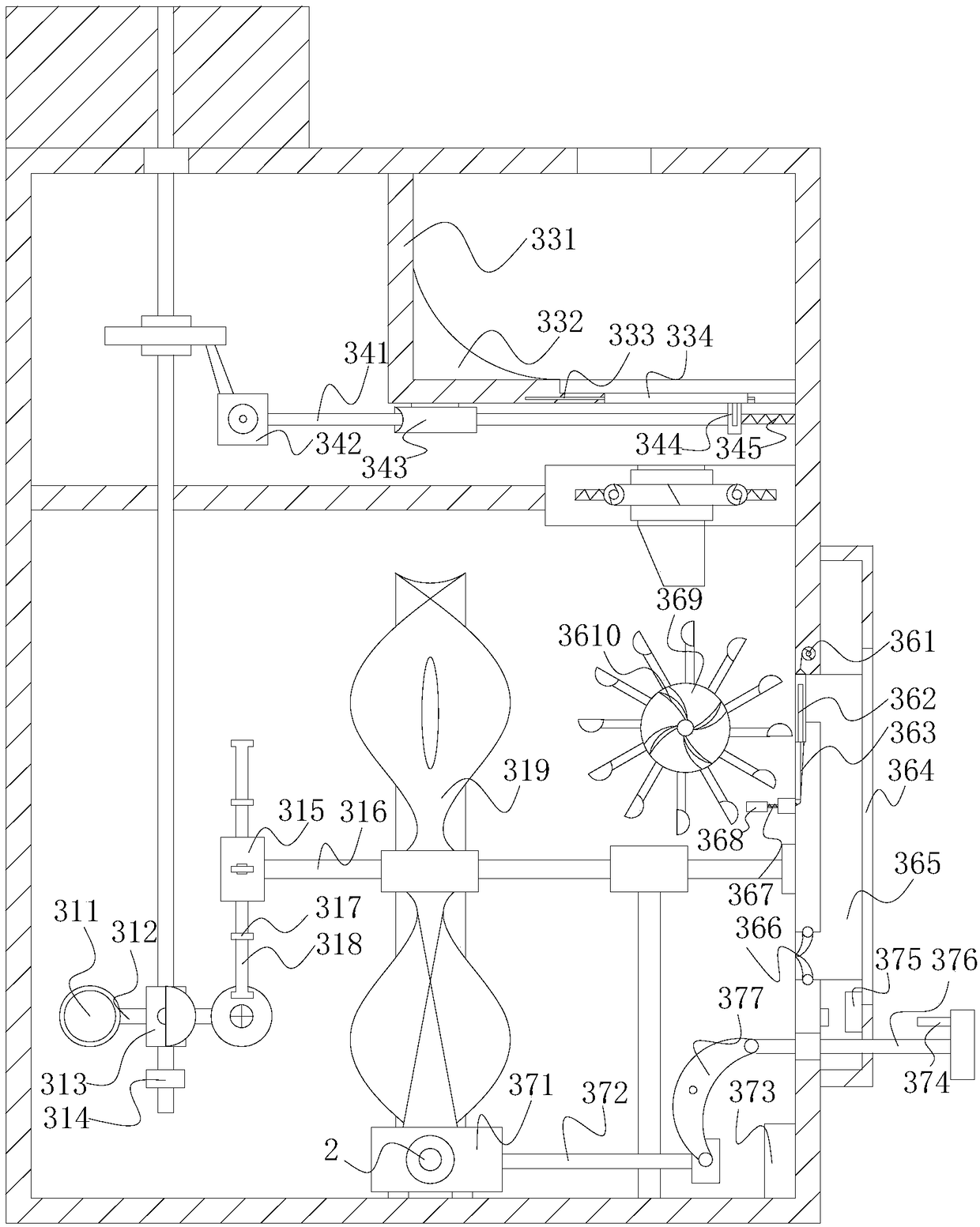

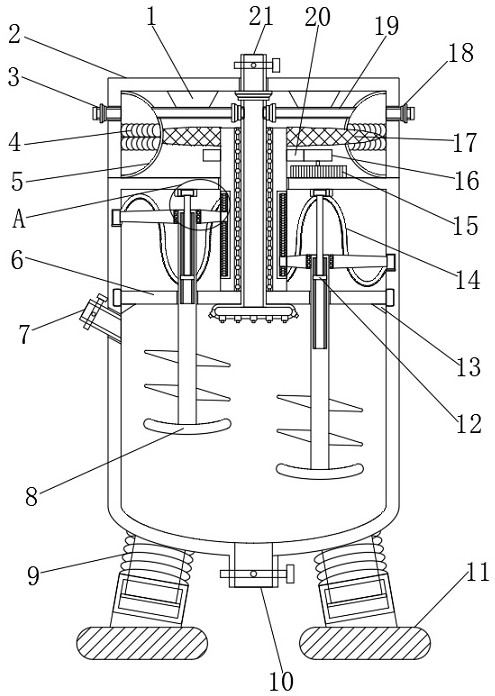

Production equipment of medicine capable of enhancing immunologic function

InactiveCN108554246AHigh speedImprove mixing efficiencyRotary stirring mixersTransportation and packagingFixed frameEngineering

Owner:NINGBO HANGZHOU BAY NEW DISTRICT NO 9 TECH SERVICE

Device for pneumatic treatment of powder materials

Owner:DIETRICH ENG CONSULTANTS

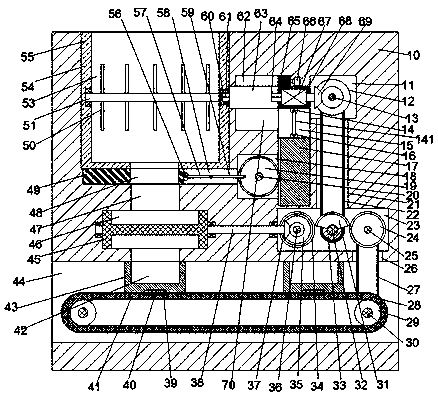

Building coating mixing device

InactiveCN111203137AAffect performanceSimple structureRotating receptacle mixersTransportation and packagingAgitatorPhysics

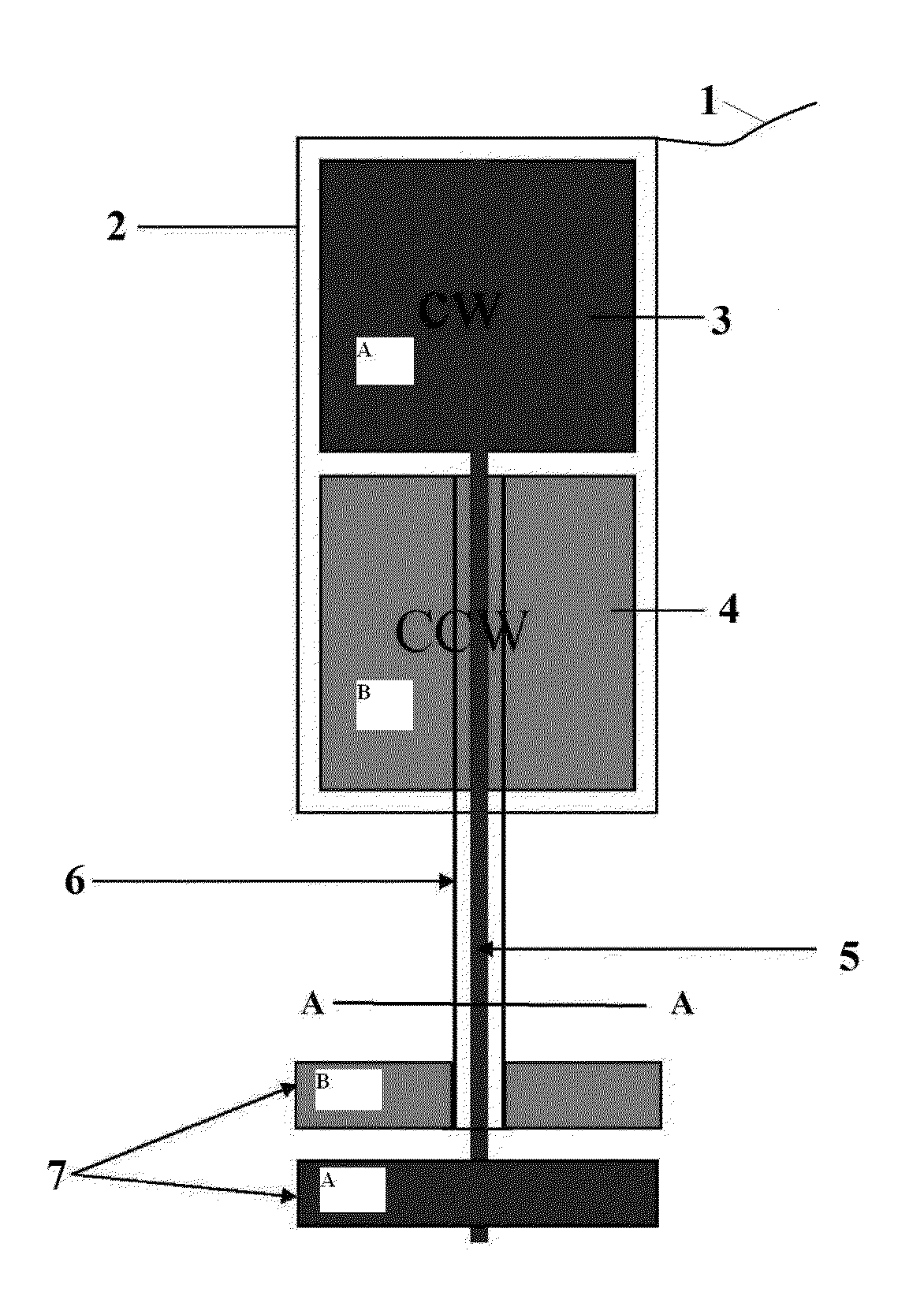

The invention relates to the field of building coatings, and discloses a building coating mixing device. The building coating mixing device comprises a body, a rotating cavity is formed in the body; afirst transmission cavity is formed in the lower end of the rotating cavity; a hollow first rotating shaft extending upwards to the rotating cavity is rotationally mounted on the upper end wall of the first transmission cavity; a stirring cavity fixedly connected with the first rotating shaft is formed in the rotating cavity; a second rotating shaft which penetrates through the center of the first rotating shaft and upwards extends into the stirring cavity is rotationally mounted on the lower end wall of the first transmission cavity; four stirring rods fixedly connected with the second rotating shaft are uniformly arranged in the stirring cavity; after raw materials are added into the device, a crushing assembly is controlled by a motor to crush large-particle solid raw materials so thatthe large-particle solid raw materials can be better mixed, meanwhile, a stirrer and the stirring cavity are driven to rotate reversely, the mixing speed is increased, and when different kinds of coatings need to be mixed, the device can be cleaned firstly.

Owner:NINGBO MUCHUN AUTOMATION TECH CO LTD

Addition process and addition equipment of coagulant for industrial wastewater

InactiveCN111847612APlay a role in the best wayGuaranteed accuracyRotary stirring mixersTransportation and packagingIron sulfateIndustrial waste water

Owner:淮南市天旭环保材料工程有限公司

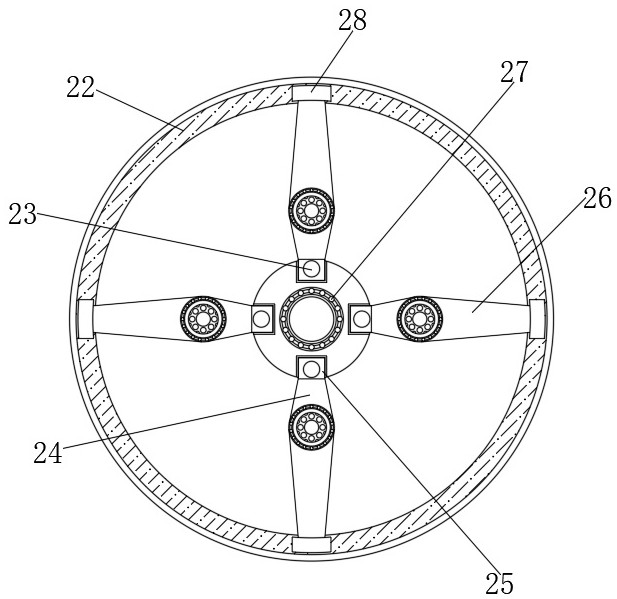

Papermaking additive uniform dilution device for papermaking

PendingCN112796163AFully dilutedQuality assuranceRotary stirring mixersTransportation and packagingCircular discElectric machine

Owner:王永利

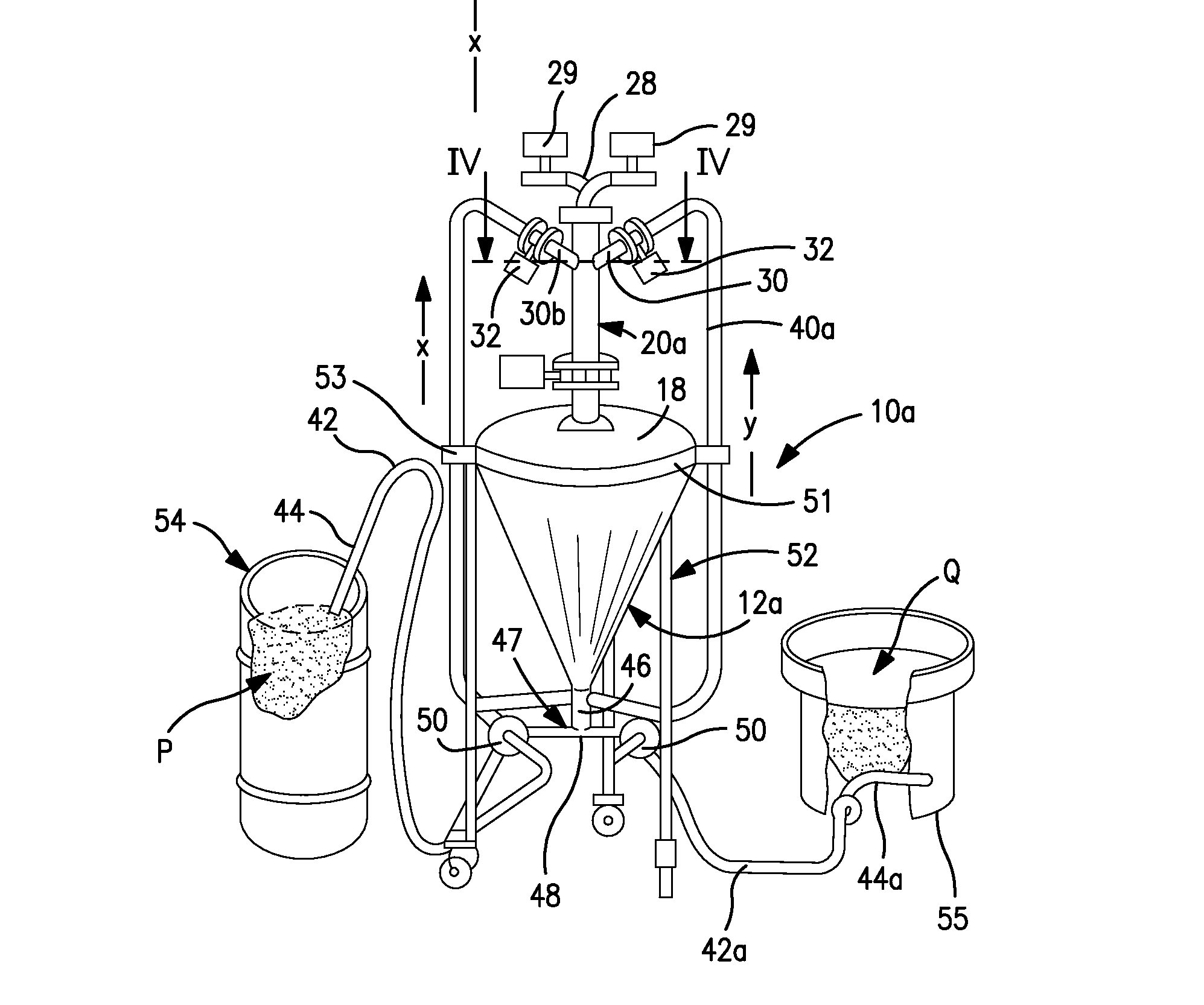

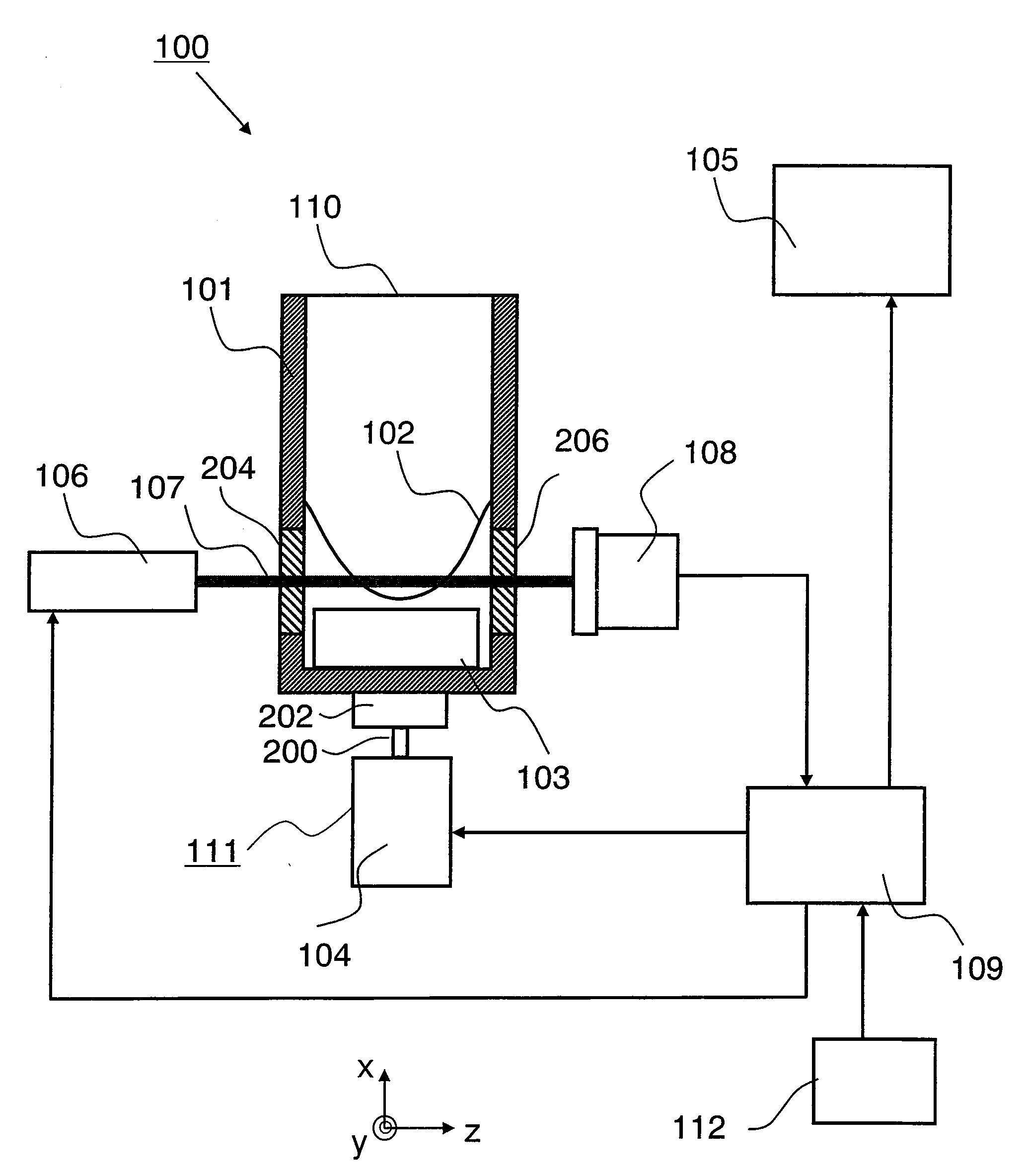

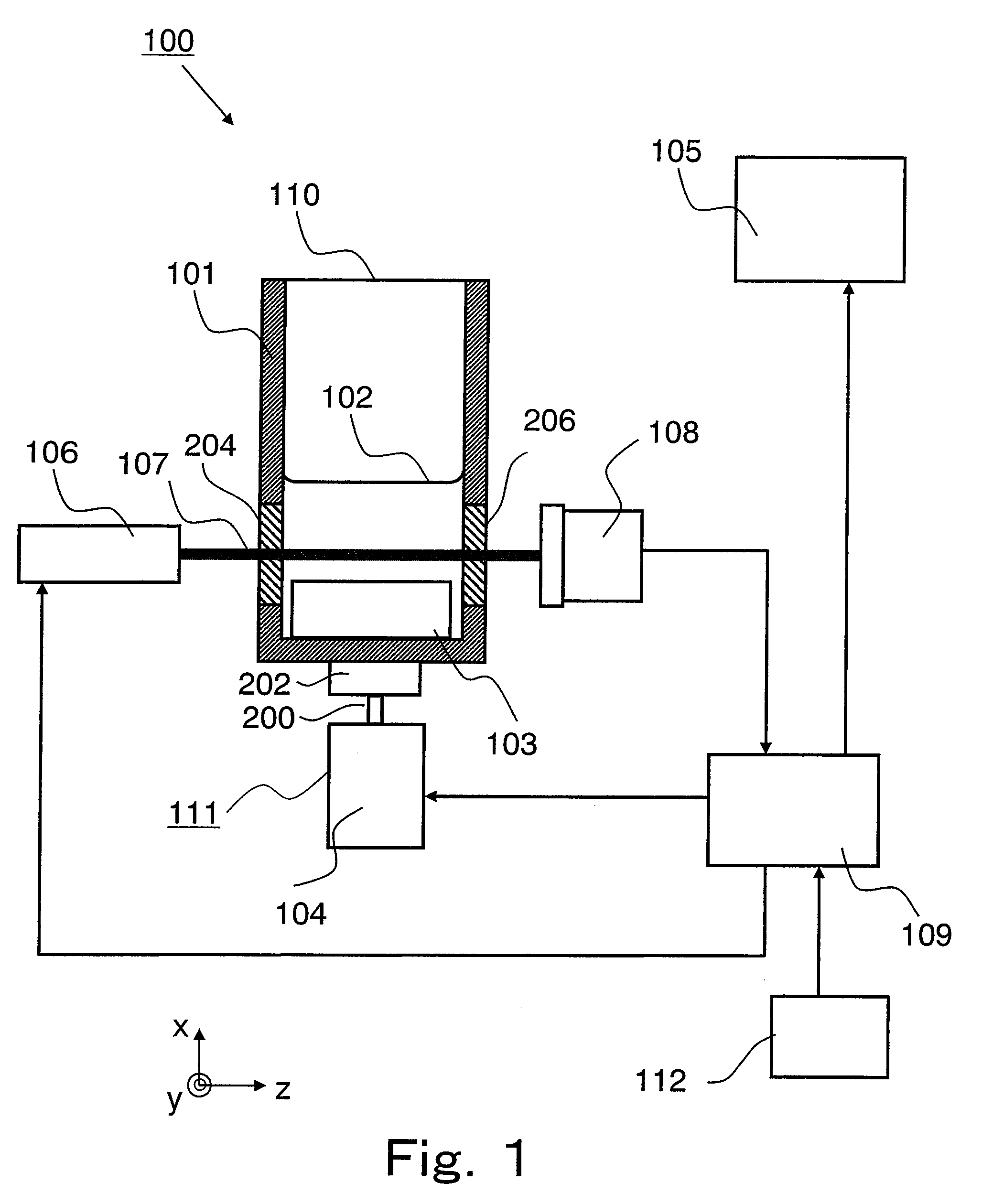

Method for mixing a liquid in an automatic analyzer

ActiveCN107179414AShaking/oscillating/vibrating mixersTransportation and packagingCouplingAutomated analyzer

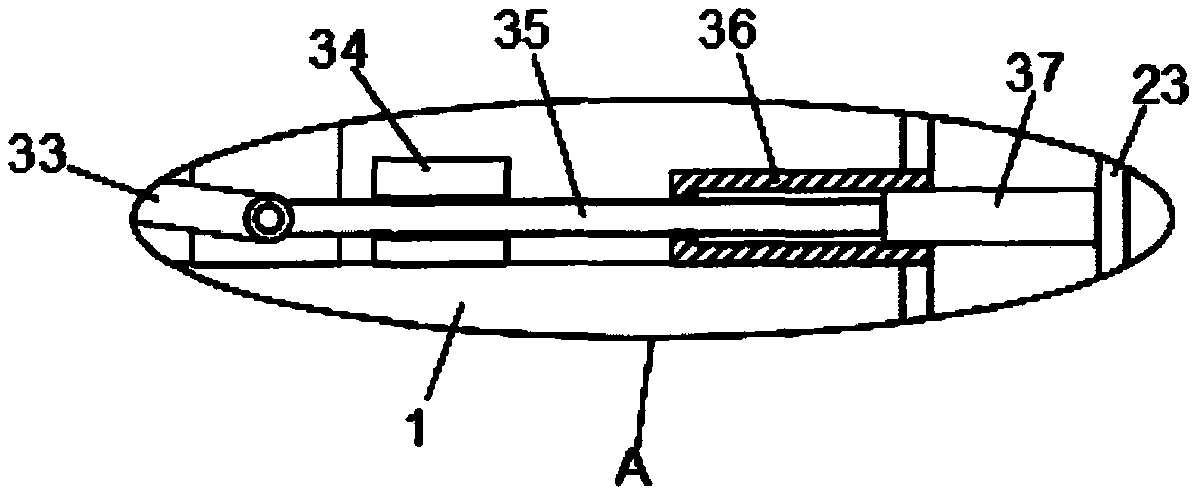

The present invention lies in the field of automated analyzers and relates to a method for mixing liquids in liquid containers. The arrangement for automated mixing comprises a shaking device (13) and a gripper (11) which is connected by way of a flexible connecting element (36) to a transfer arm (10) and which serves for receiving a liquid container (30). The coupling of gripper (11) and shaking device (13) is realized by way of an eccentrically movable coupling pin (33) and a coupling hole (34) provided for this purpose.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS PRODS

Stirring state detecting method

Owner:PANASONIC CORP

Intelligent building stone stirring device replacing manual operation and placement method

InactiveCN111468003AStir wellAvoid damageRotary stirring mixersTransportation and packagingElectric machineConstruction engineering

Owner:江苏枂硕电子科技有限公司

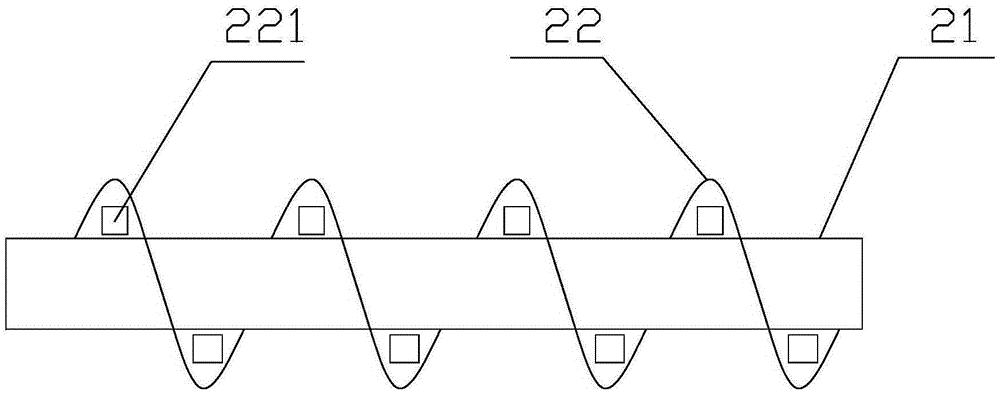

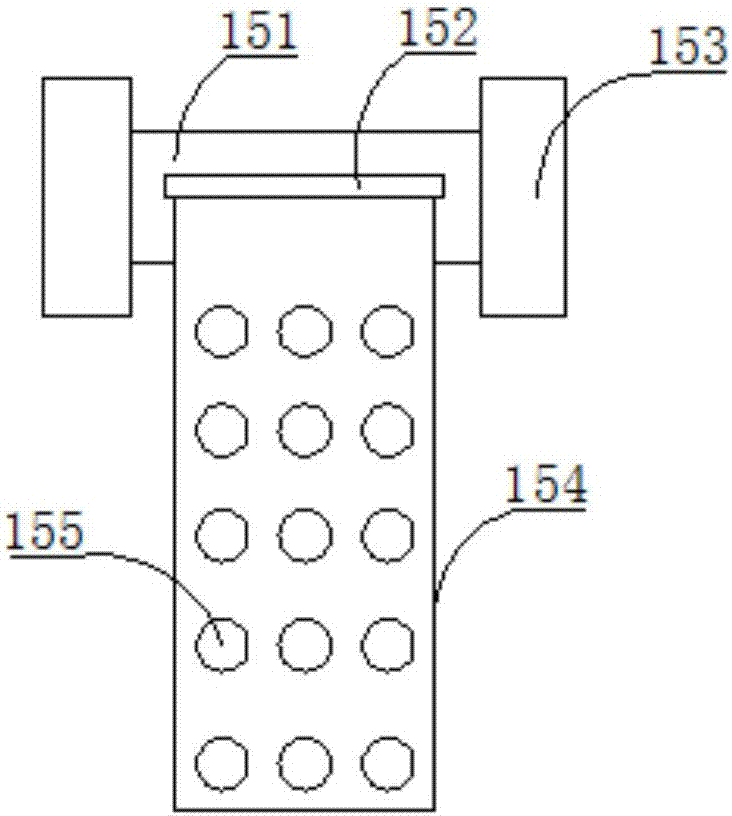

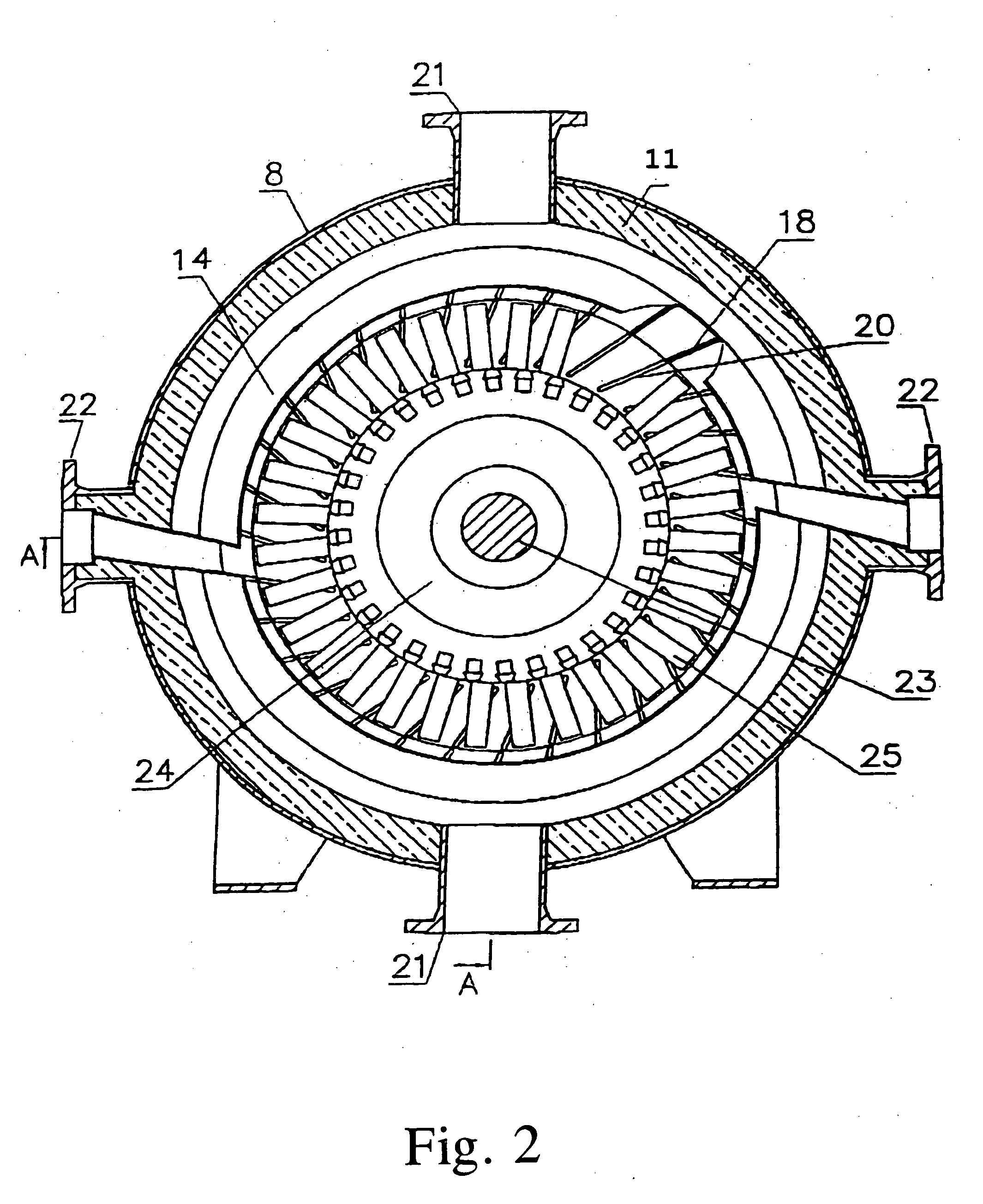

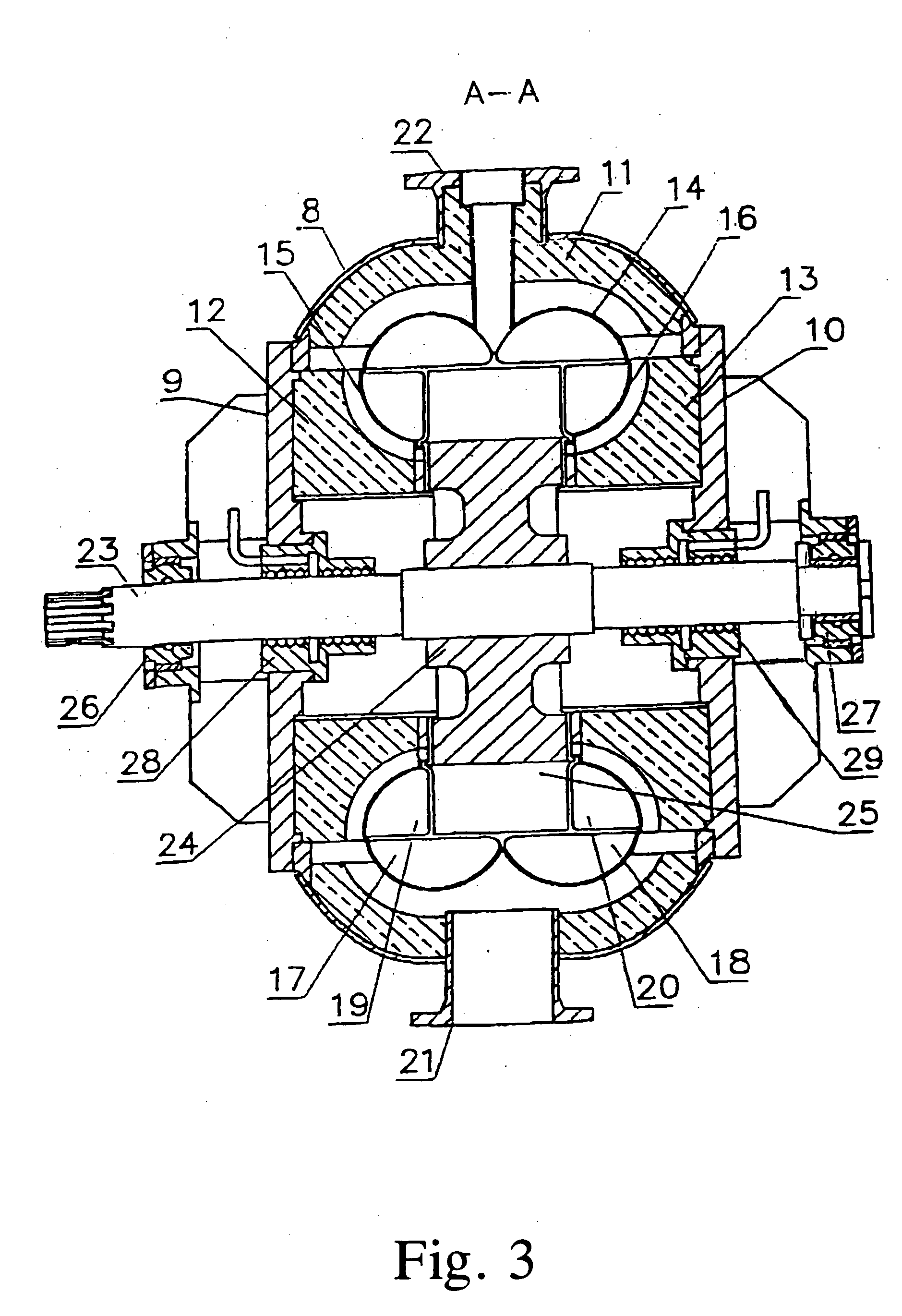

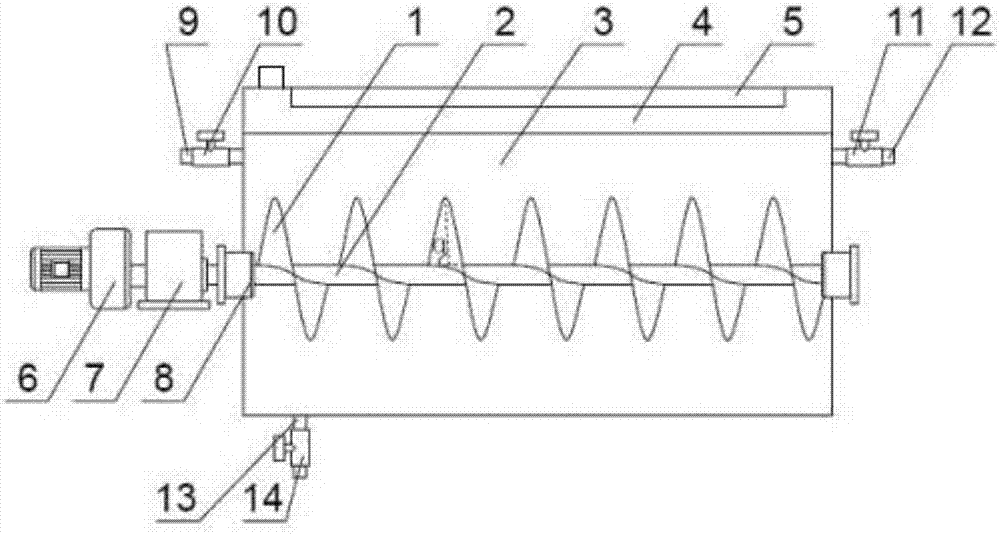

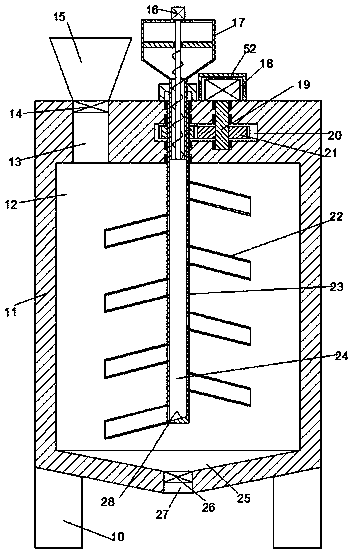

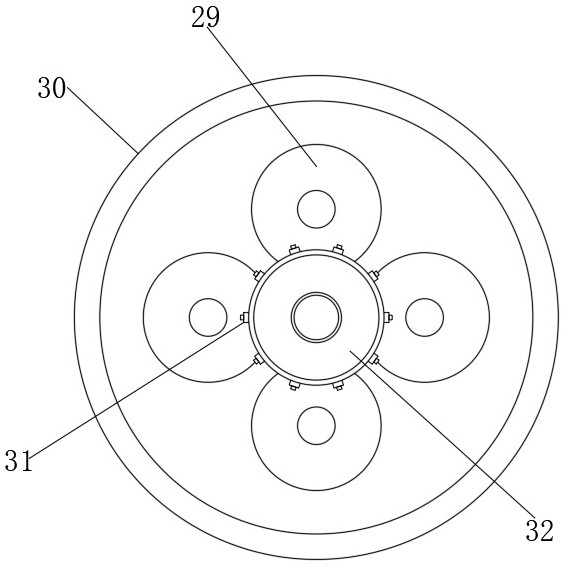

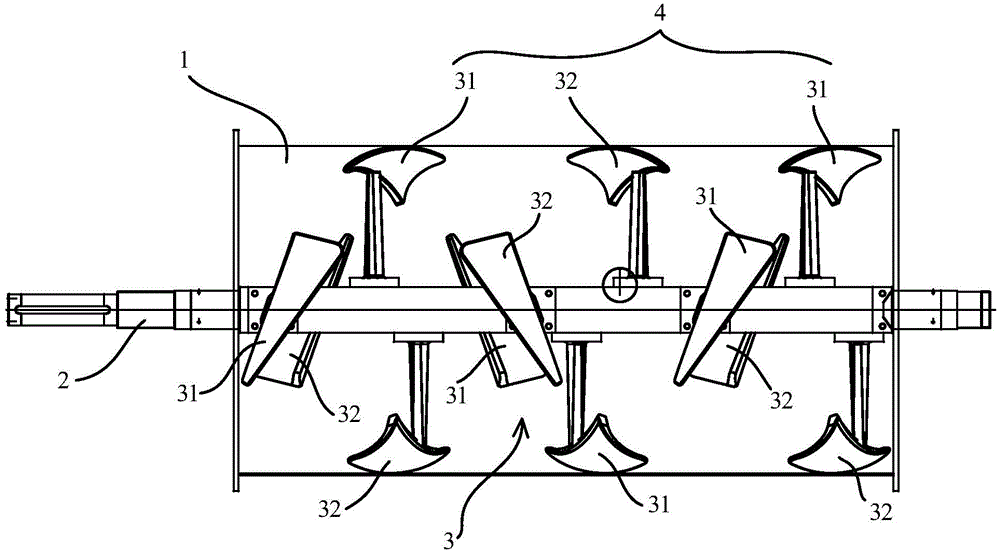

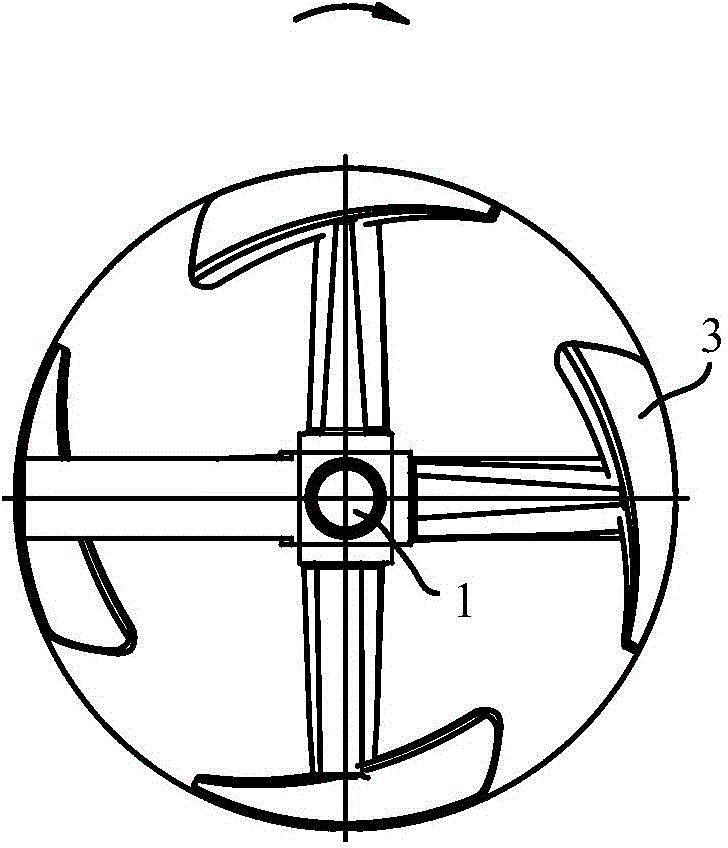

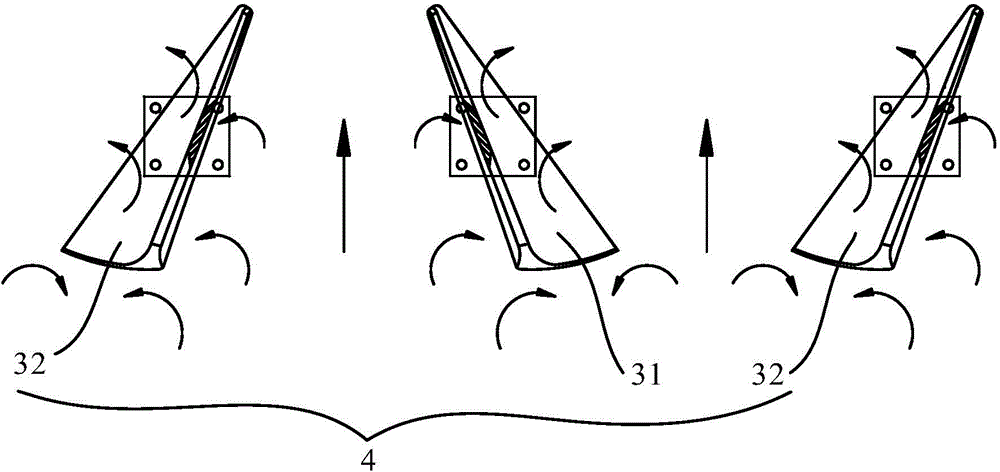

A plough share refiner

ActiveCN106031848ATo achieve the function of convective mixingMeet refining requirementsRotary stirring mixersMixer accessoriesAgricultural engineeringPlough

A plough share refiner is provided. The plough share refiner comprises a cylinder, a main shaft penetrating the center of the cylinder and a plurality of plough shares disposed on the main shaft. The plough shares comprise first plough shares and second plough share. The first plough shares incline towards one direction of the axis of the main shaft, and the second plough shares incline towards the other direction of the axis of the main shaft. A plough share group is disposed on at least one circumferential direction of the main shaft. In the group, the first plough shares and the second plough shares are arranged successively to form an opposite, contrary and alternatively arranged form. The plough share refiner has a function of allowing materials to achieve convective mixing in a mixing container, and the plough shares shear the materials and violently turn and throw the materials inward, thus meeting refining requirements. The plough share refiner covers main mixing functions of horizontal type spiral ribbon mixers and colter mixers, reduces the mixing time and is low in occupied space.

Owner:SHUANGLONG GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap