Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Pharmacy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmacy is the science and technique of preparing, dispensing, and reviewing drugs and providing additional clinical services. It is a health profession that links health sciences with pharmaceutical sciences and aims to ensure the safe, effective, and affordable use of drugs. The professional practice is becoming more clinically oriented as most of the drugs are now manufactured by pharmaceutical industries. Based on the setting, the pharmacy is classified as a community or institutional pharmacy. Providing direct patient care in the community of institutional pharmacies are considered clinical pharmacy.

Online water pollution source tracing method

InactiveCN110412006ARealize online traceabilityEasy accessRaman scatteringMaterial analysis by electric/magnetic meansPapermakingSource tracing

Owner:BEIJING UNIV OF CHEM TECH +1

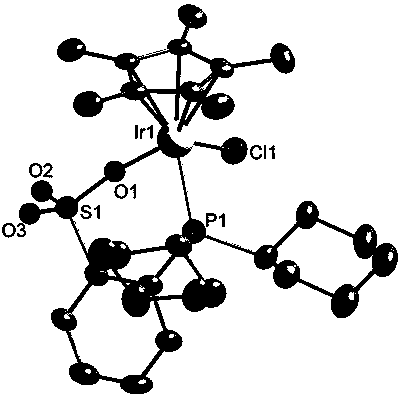

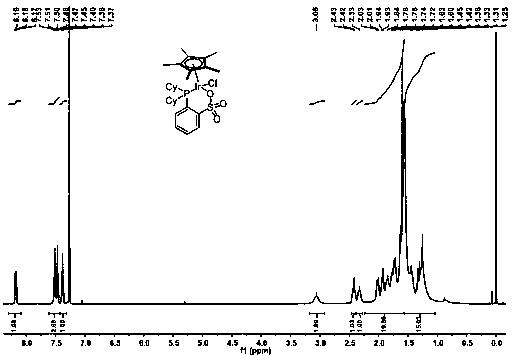

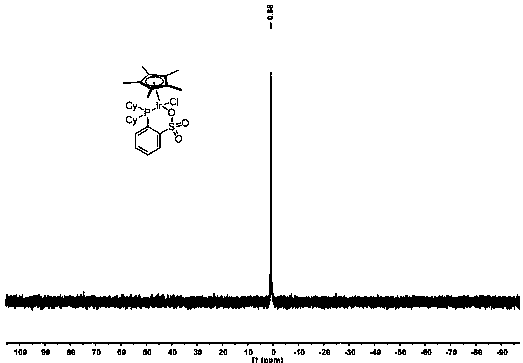

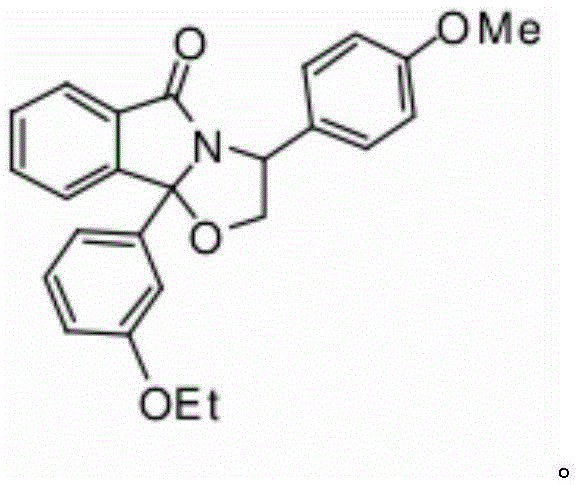

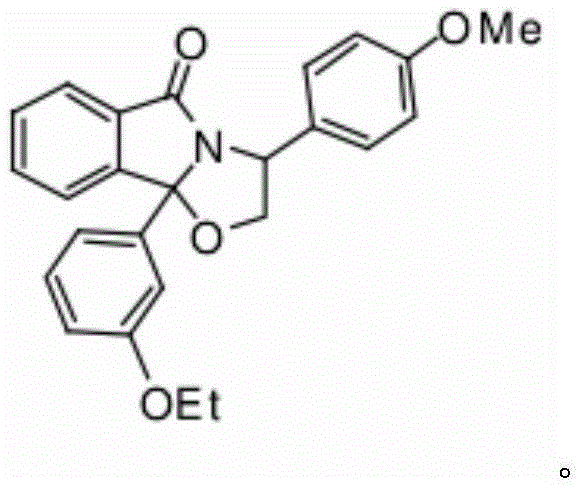

Semi-sandwich structure iridium complex with anticancer activity, preparation method and application thereof

ActiveCN107652330AHigh anticancer activityLittle side effectsAntineoplastic agentsMetallocenesIridiumPharmacy

Owner:QUFU NORMAL UNIV

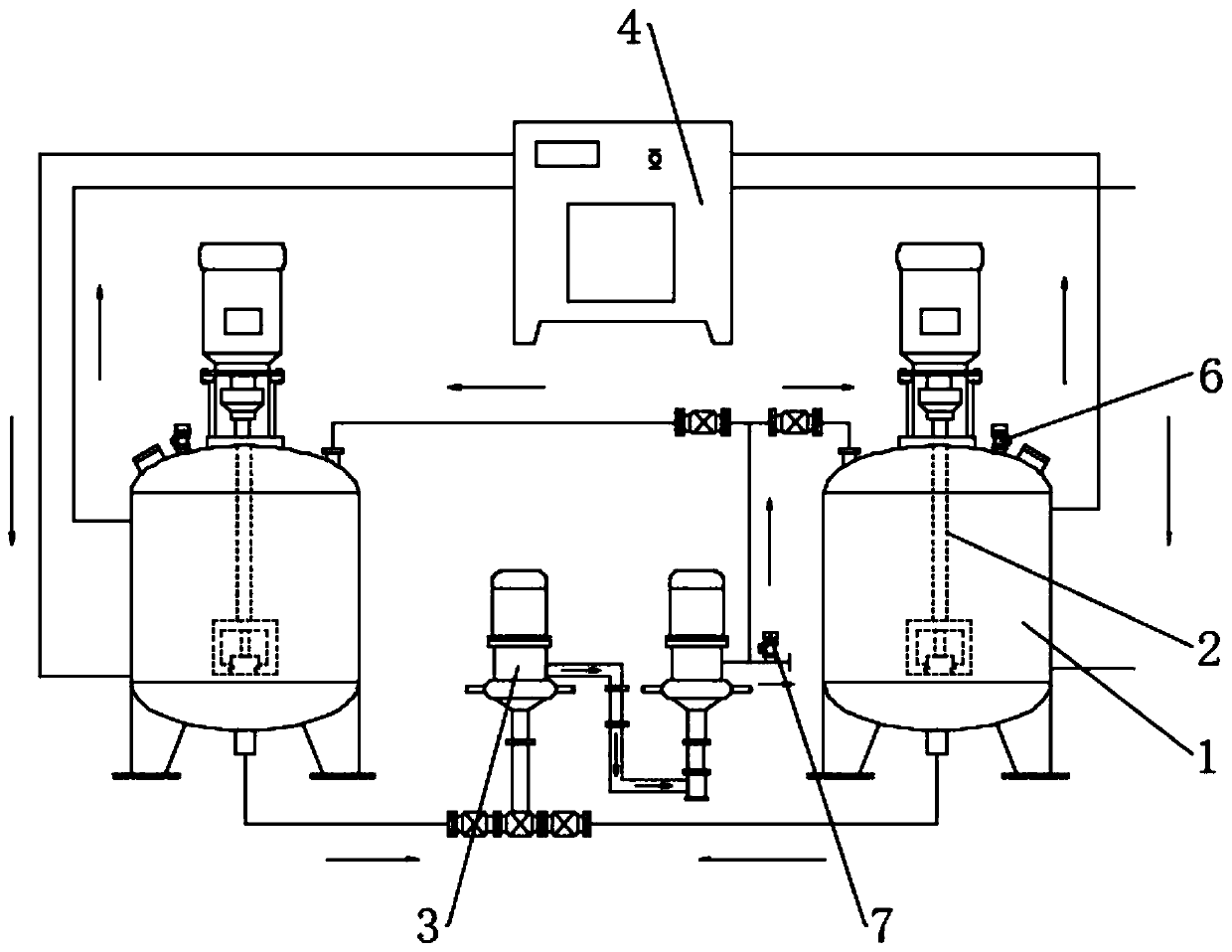

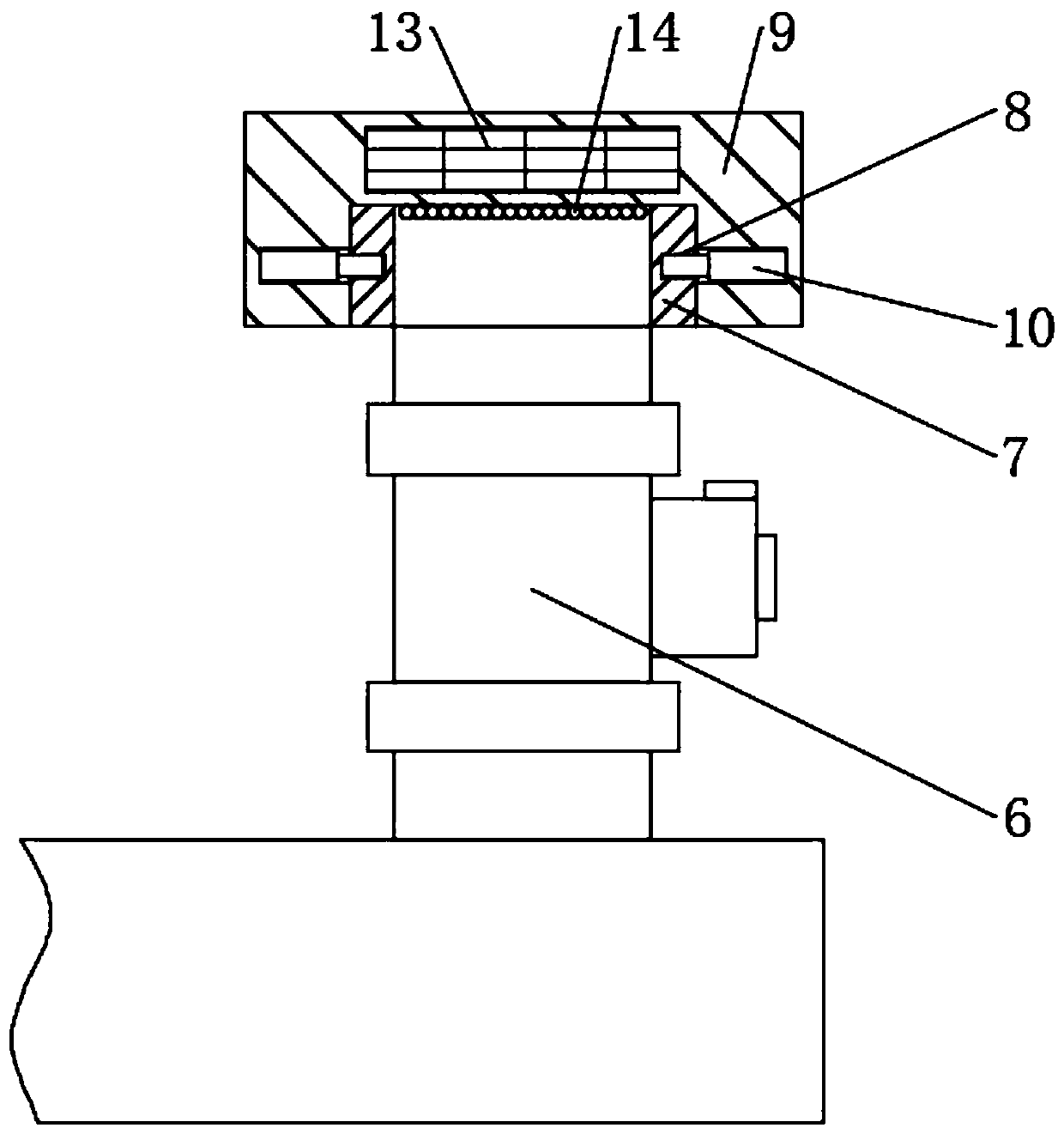

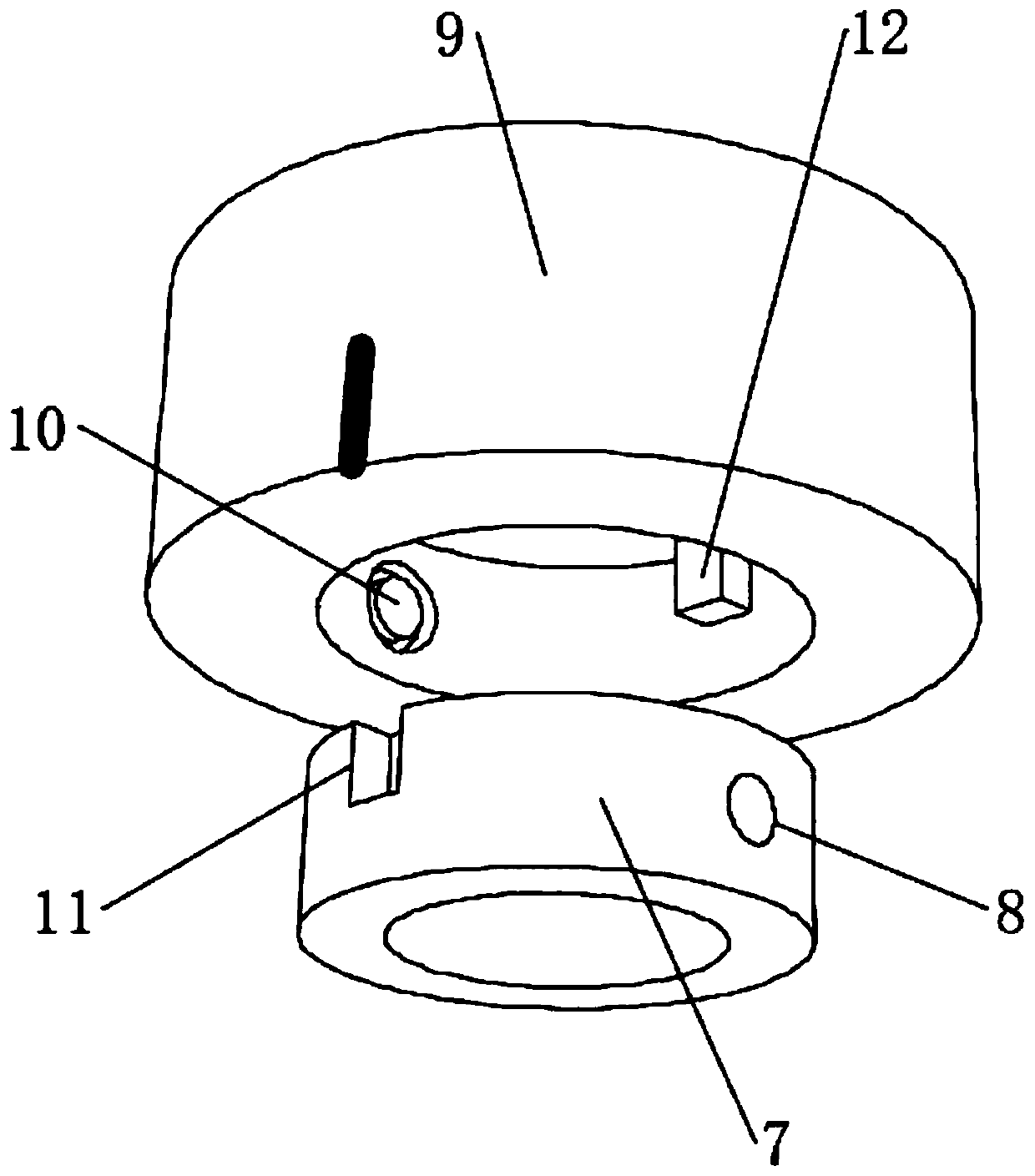

Multifunctional stirring device for biological pharmacy

ActiveCN112237881AWell mixedEasy to stir and mixTransportation and packagingMixer accessoriesPharmacyReciprocating motion

The multifunctional stirring device for biological pharmacy comprises a box body; a partition plate is fixedly connected to the upper end of an inner cavity of the box body, two feeding hoppers are fixedly connected to the left side of a top plate of the box body in a front-back symmetrical mode, and lower end openings of the feeding hoppers penetrate through the top plate of the box body and extend into the box body to communicate with upper end holes of feeding pipes; the lower opening of the feeding pipe penetrates through the partition plate and extends to the lower part of the partition plate; the top end of the left side wall of the inner cavity of the box body is fixedly connected with a motor; according to the invention, the motor drives a first rotating shaft to rotate, the firstrotating shaft rotates to drive a first connecting rod to rotate, then a first sliding block drives a second connecting rod to do left-right reciprocating motion, and further, the second sliding blockdrives the third connecting rod to swing with the second fixing rod as the axis, the check block synchronously swings along with the third connecting rod and is matched with the feeding hopper, and therefore raw materials are controlled to intermittently fall into the feeding pipe downwards.

Owner:XIAN TIANYI QINKUN PHARMA

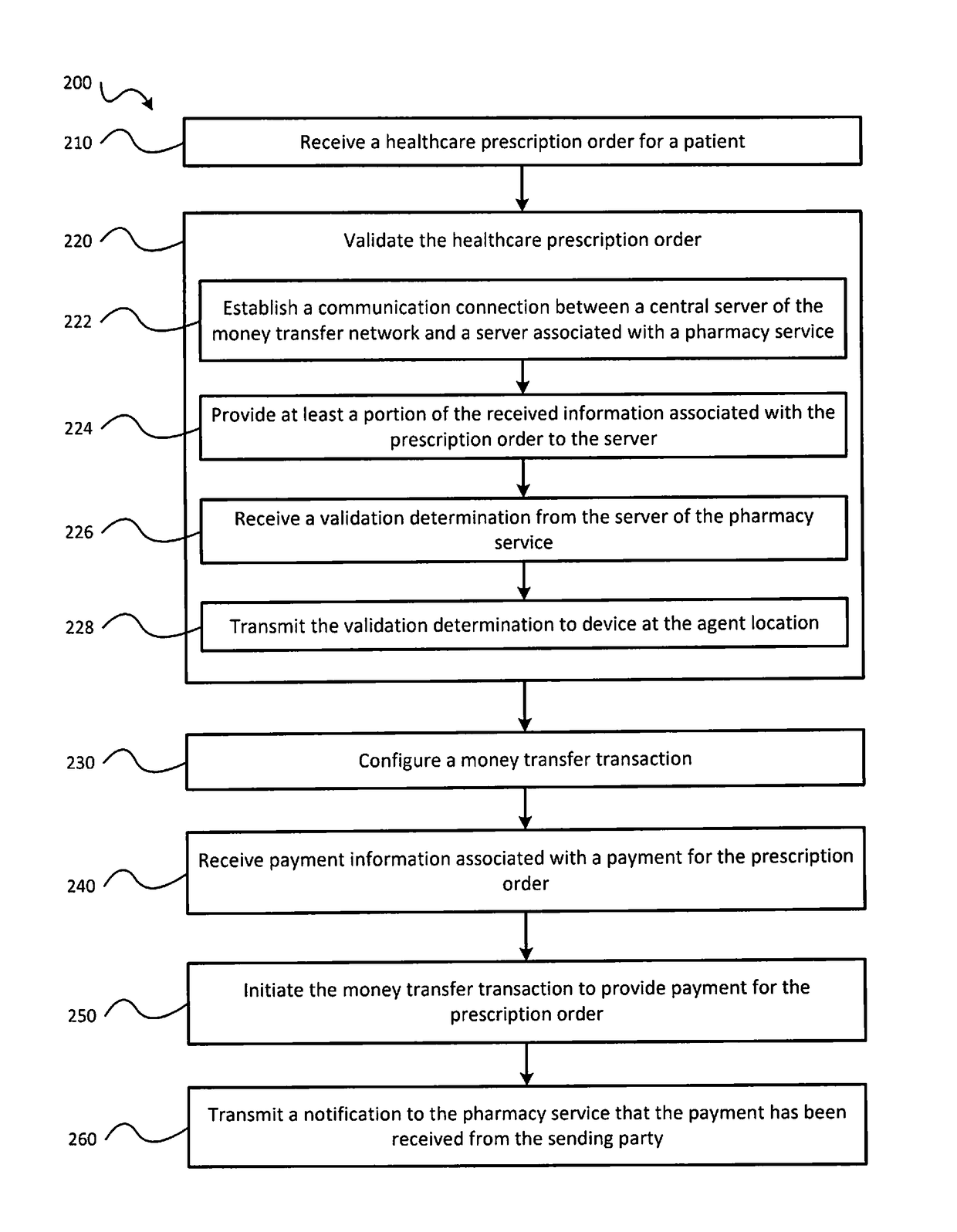

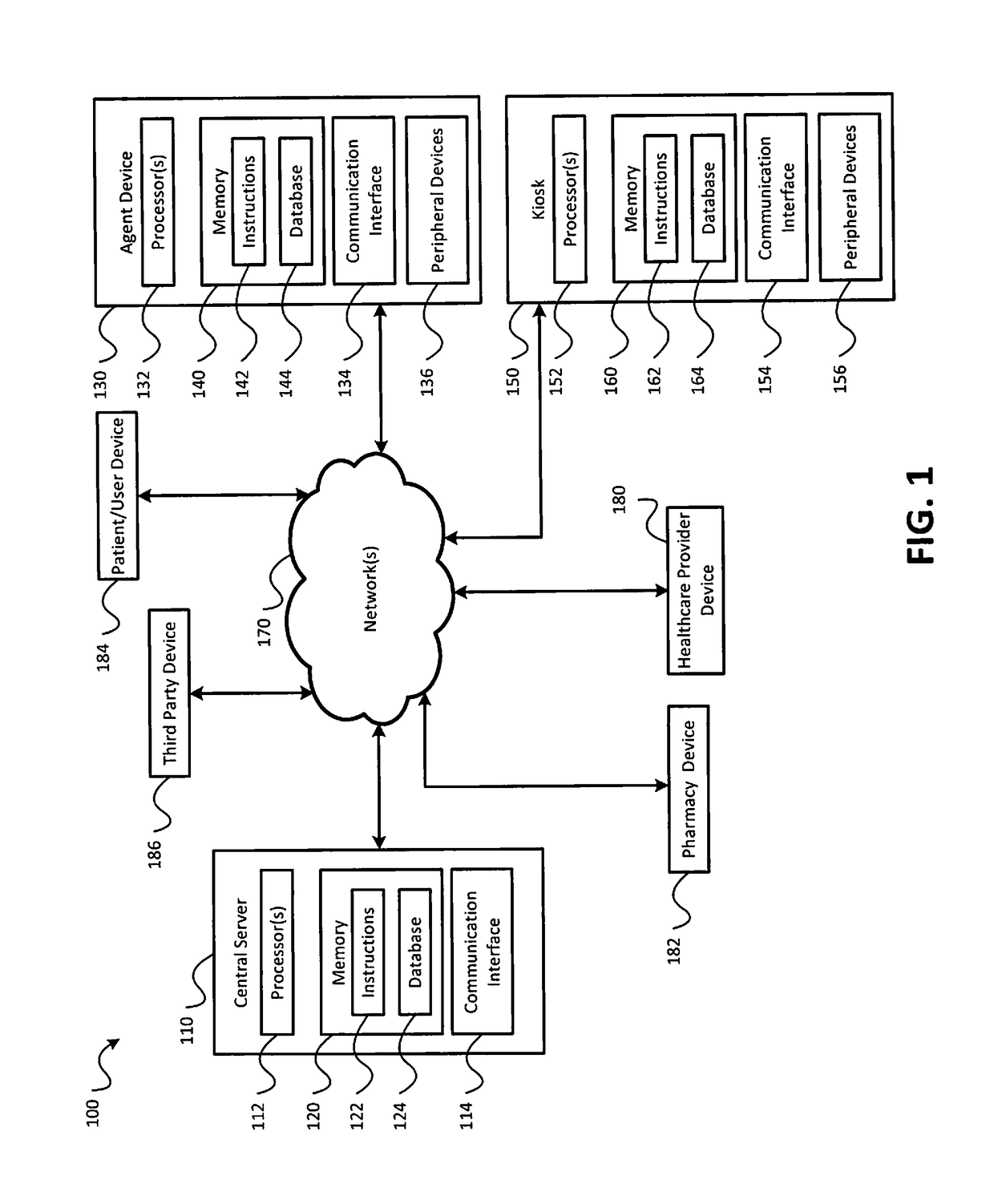

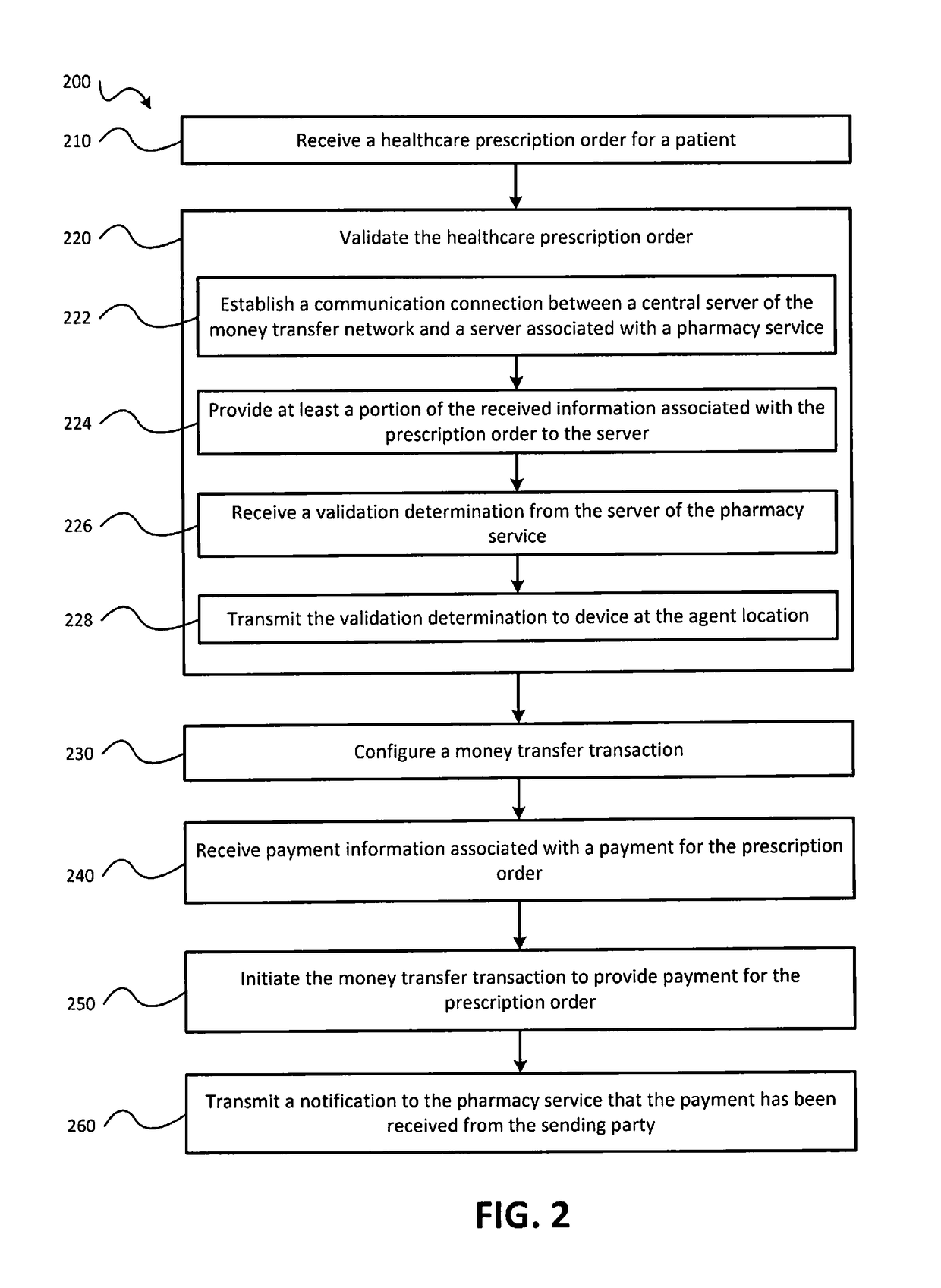

Healthcare prescription delivery techniques using a money transfer network

ActiveUS20170091414A1Optimize allocationEasy to payDrug and medicationsOffice automationThird partyPharmacy

Owner:MONEYGRAM INT

Drug combination for treating chronic cardiac failure

InactiveCN105330676AImprove heart function indexOrganic active ingredientsOrganic chemistryPharmacyPharmaceutical drug

Owner:孙景芝

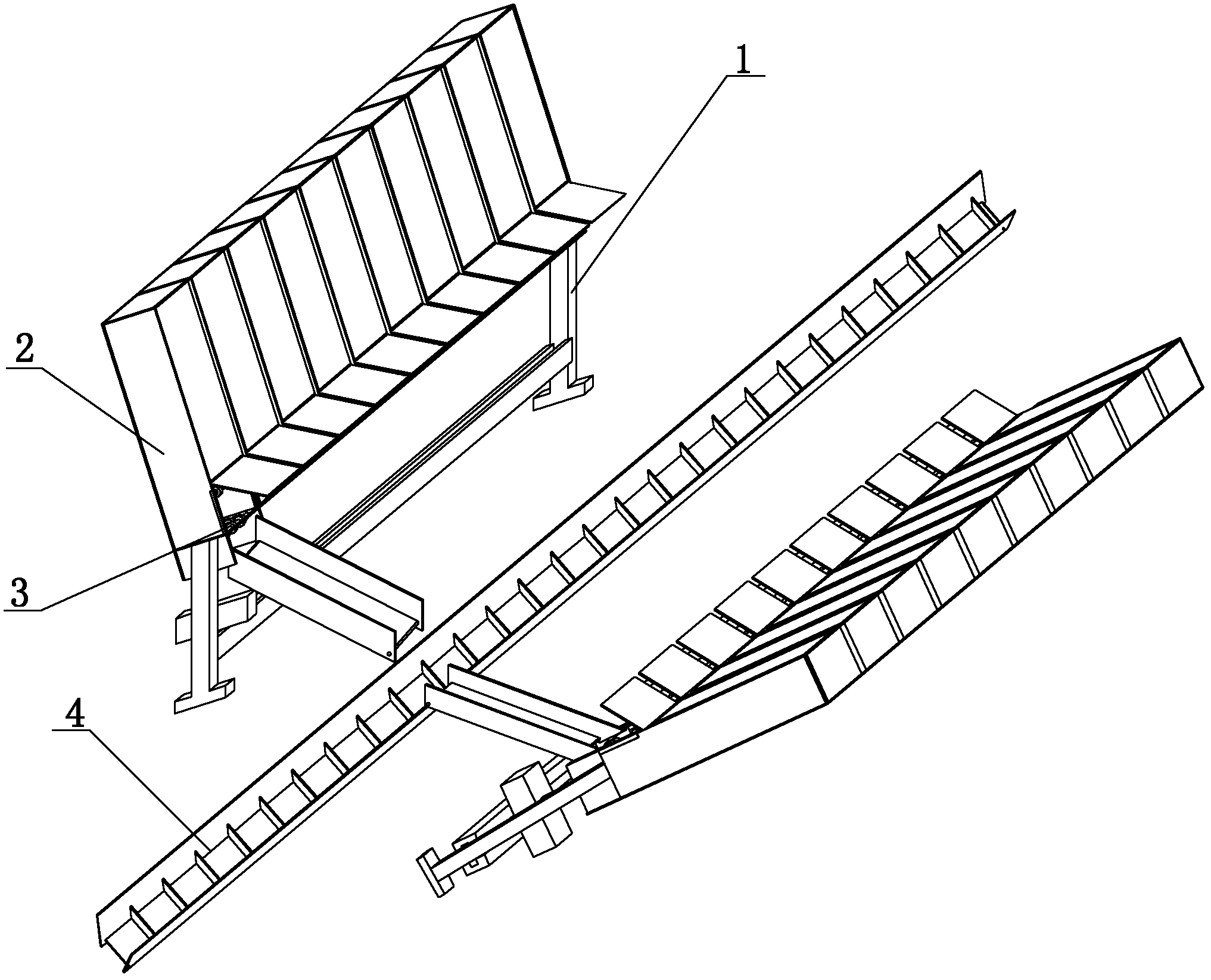

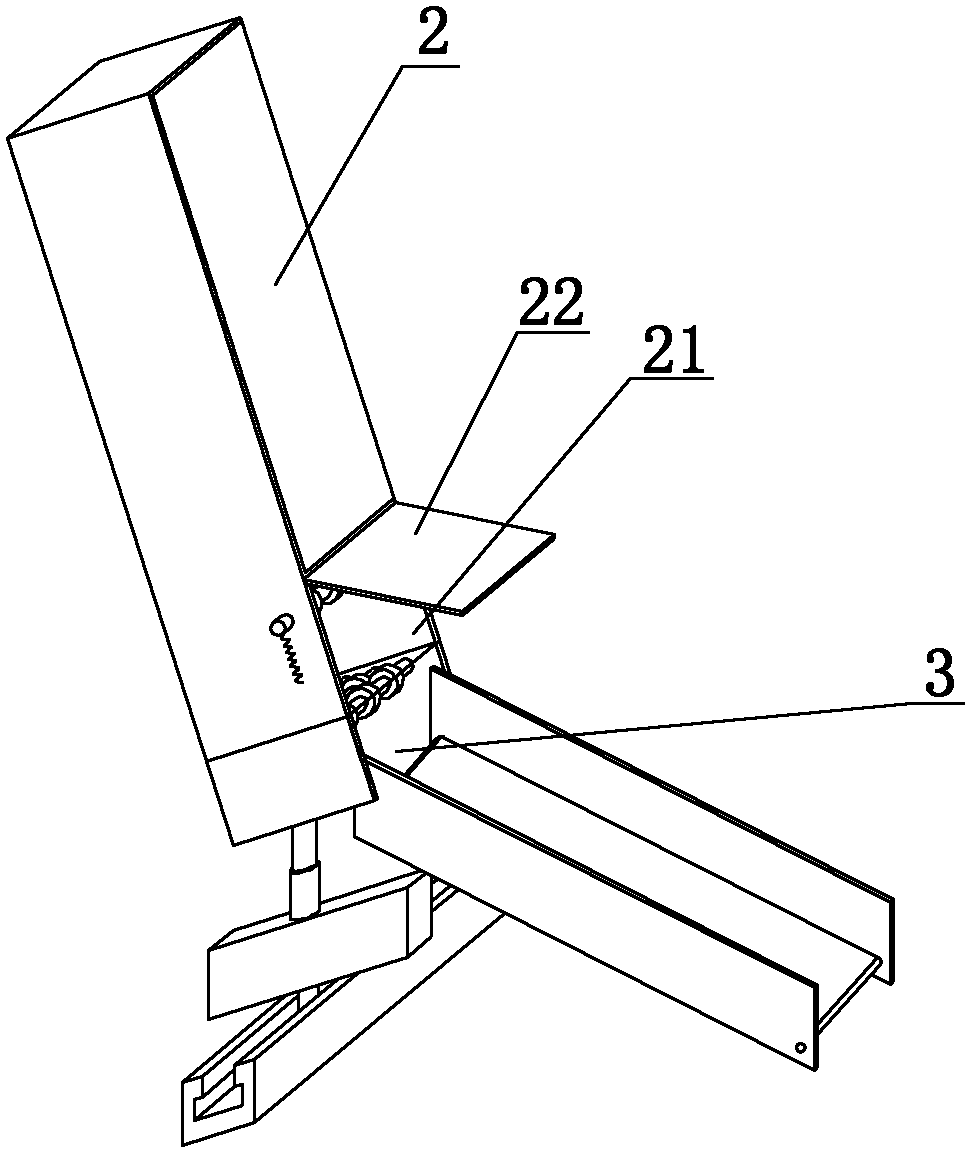

Rolling-wheel medicine output device of automated traditional Chinese medicine (TCM) pharmacy

Owner:SUZHOU XINHENG AUTOMATION TECH

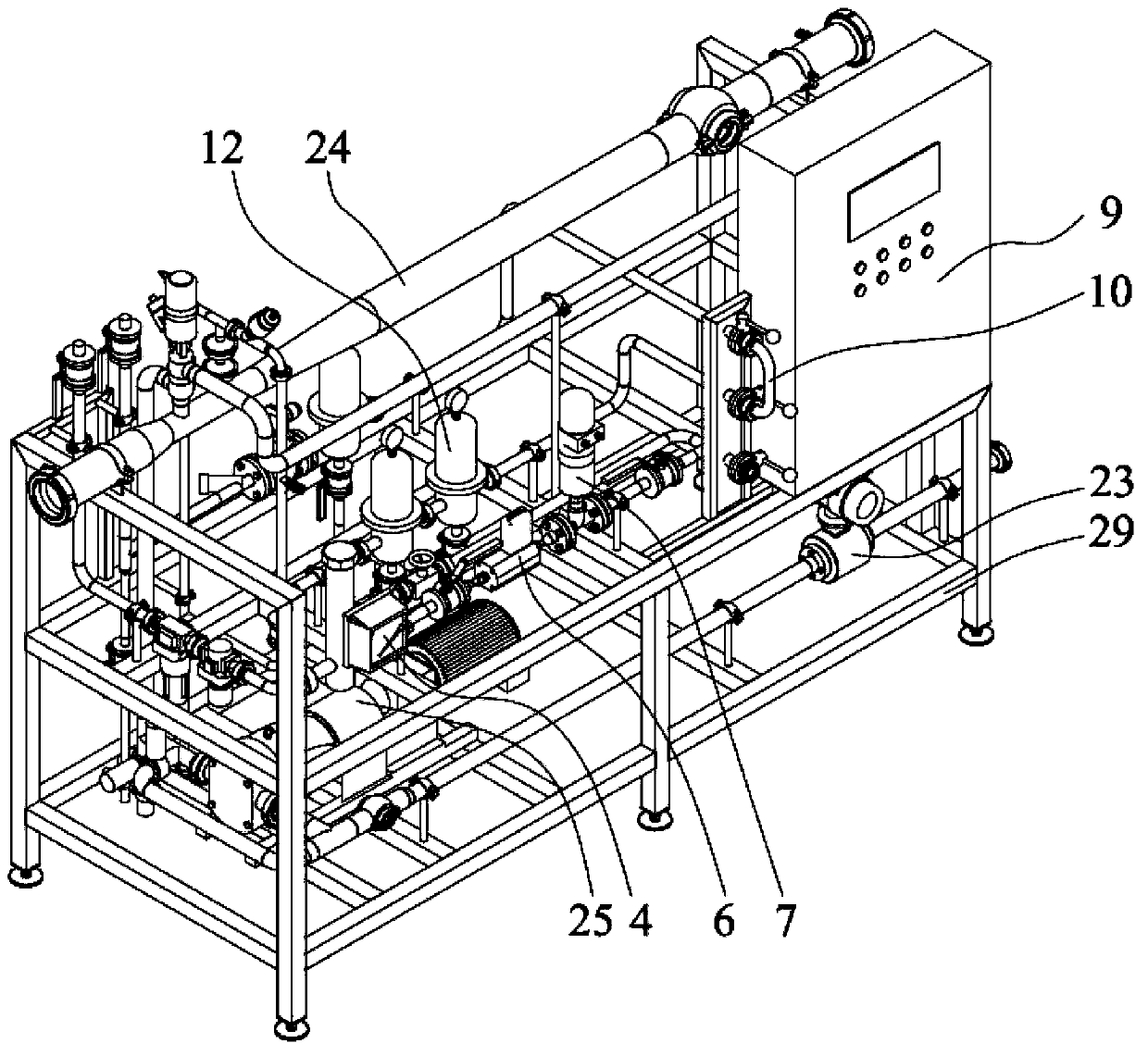

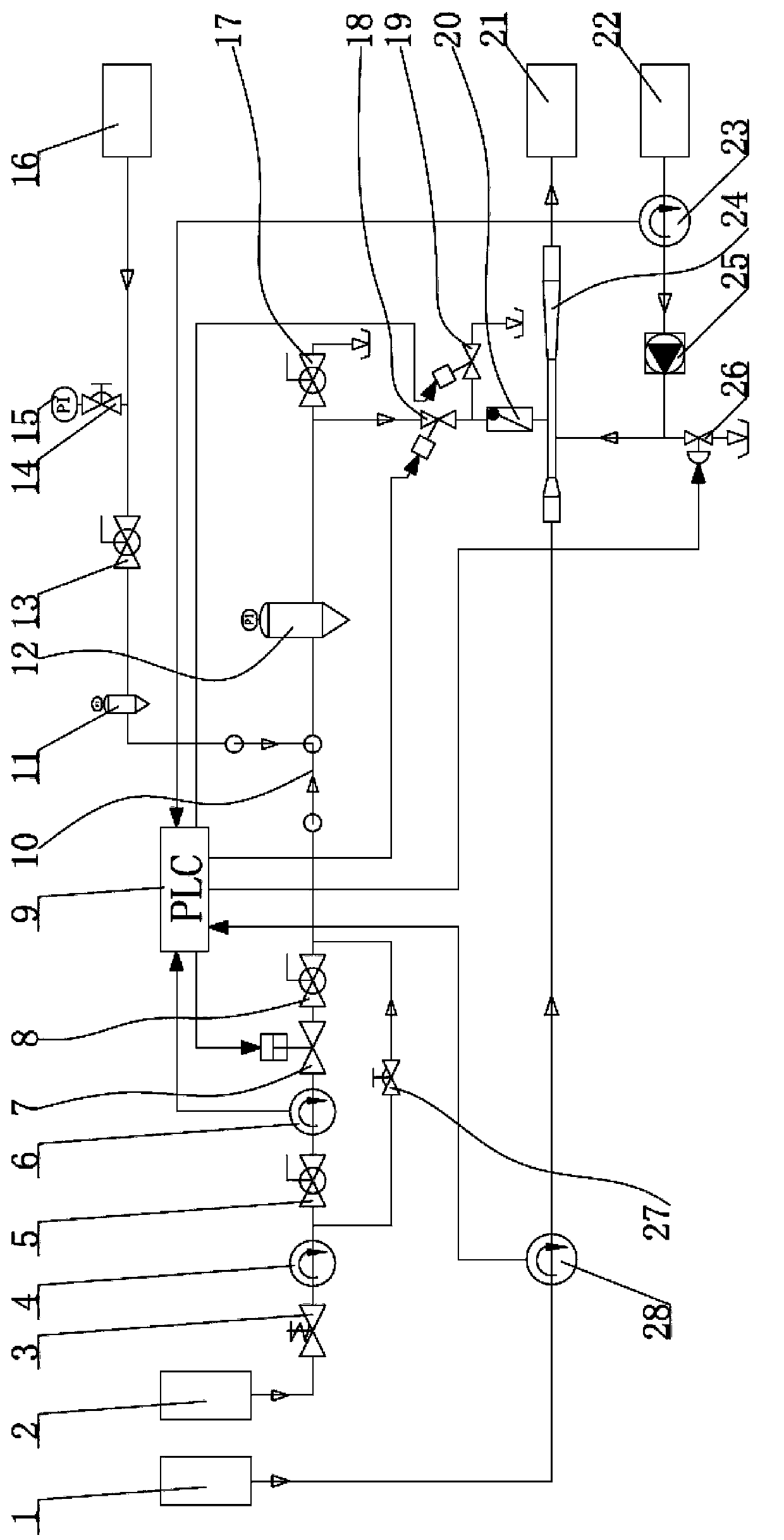

Full-automatic wort oxygenated yeast adding machine and wort oxygenated yeast adding method

InactiveCN102816662BAvoiding problems with feedback regulation hysteresisMethod is feasibleWort preparationHuman error probabilityLoop control

Owner:ANHUI HUAYI BIOLOGICAL EQUIP TECH

Direct cooling type intelligent automation numerical control low-temperature dispersion smashing and grinding complete facility

PendingCN110681452AImprove frictional heating phenomenonImproved grinding and dispersion effectGrain treatmentsNumerical controlPharmacy

Owner:WENZHOU HAO STAR MACHINERY EQUIP MFG

Medicament screening device for pharmacy

InactiveCN113019910AAchieve primary screeningAvoid pollutionGas current separationGradingPharmacyMedicine

The invention discloses a medicament screening device for pharmacy. The medicament screening device comprises a bottom plate, a swing flow dividing structure, a connecting pipe and a clearing structure. The swing flow dividing structure is arranged on the top side of the bottom plate, the clearing structure is erected above the bottom plate, and the clearing structure communicates with the swing flow dividing structure through the connecting pipe. Medicament needing to be screened is supplemented into a screening box through a feeding pipe, an emptying pump and a pressurizing air pump work synchronously, the interior of an air blowing box is pressurized through the emptying pump, the impulsive force generated by air pressure is controlled to be lower than the mass of tablets, when drugs slide along the inner wall of a screening hopper, powder slag can be blown through air holes, the emptying pump works to empty a storage box, the internal air pressure of the storage box is reduced, powder slag in the medicament can be discharged through a dust discharging pipe, primary screening of the medicament is achieved, the powder slag in the medicament is removed, subsequent screening can be convenient, medicament screening interference is reduced, the powder slag can be recycled in a concentrated manner, and the powder slag is prevented from being polluted.

Owner:张春丽

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap