Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Gas current separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

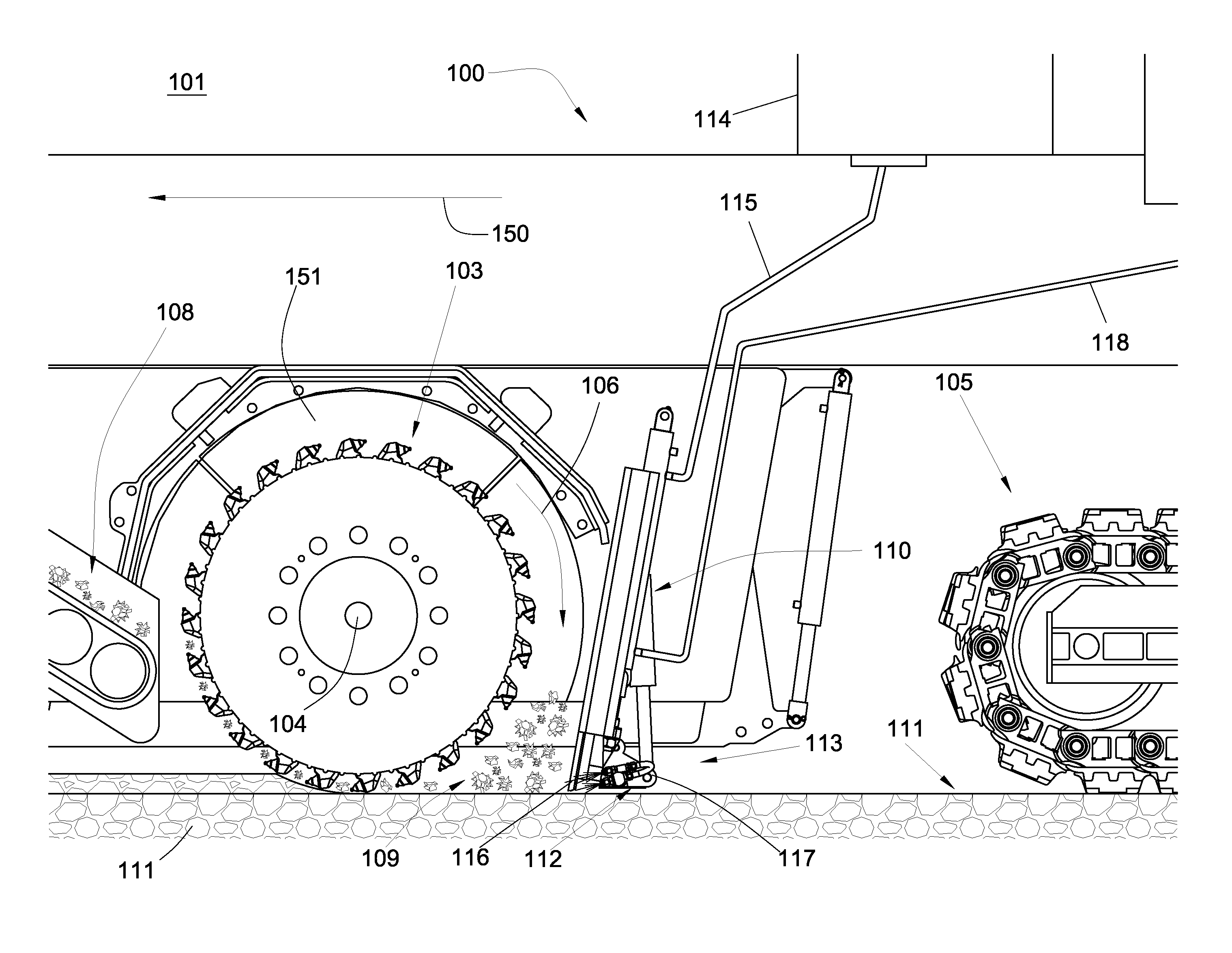

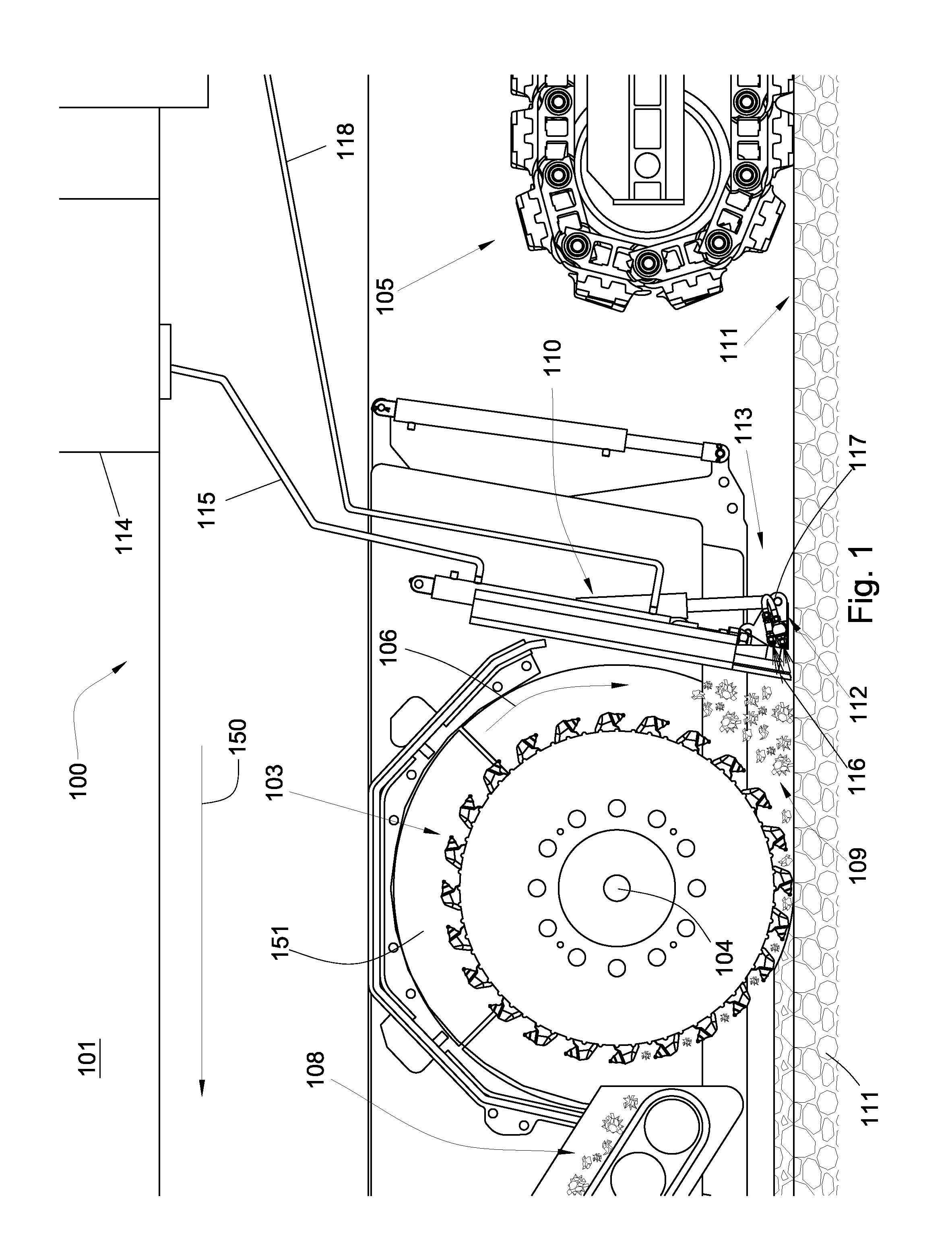

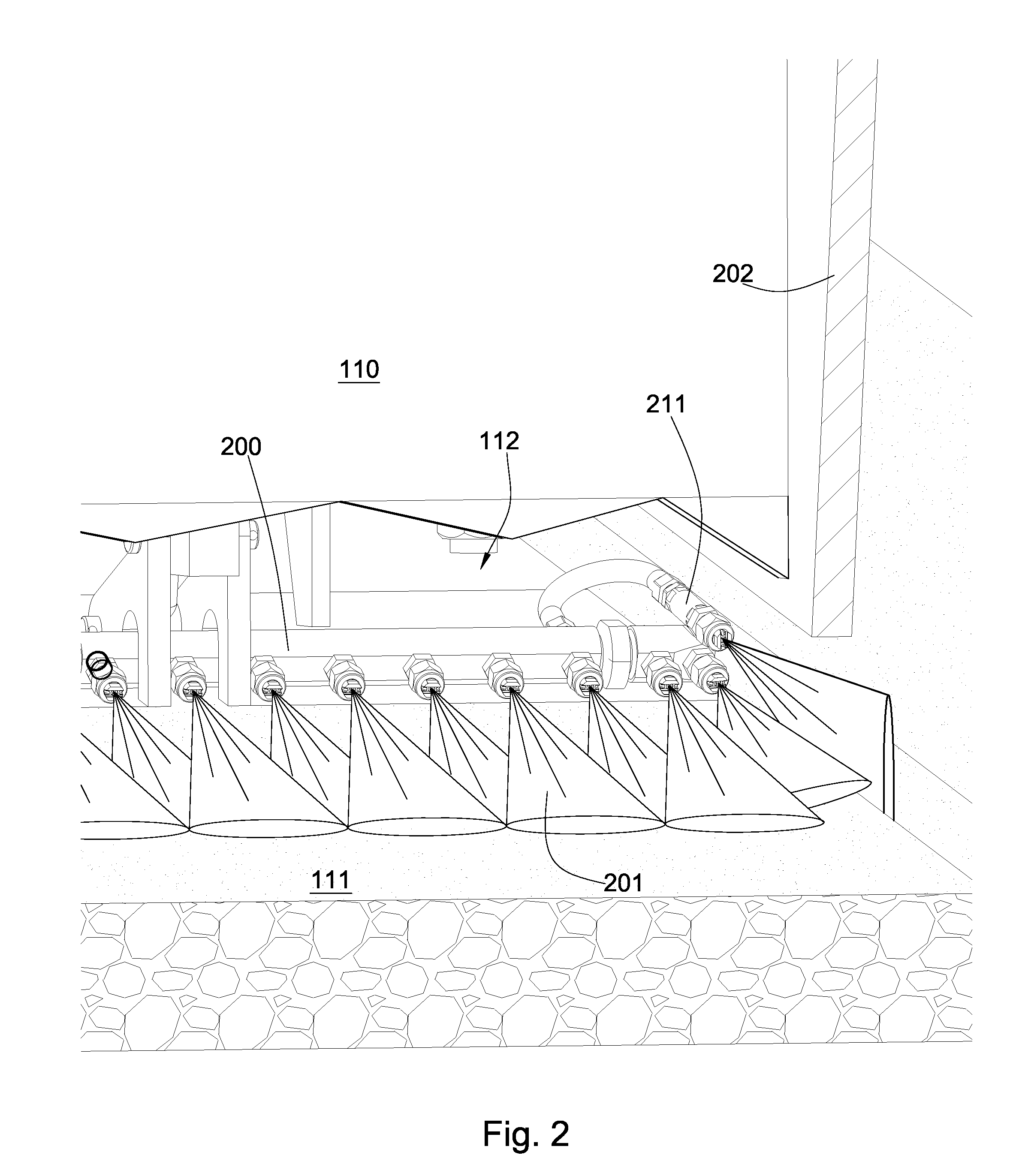

Nozzles Incorporated into a Milling Machine

Owner:NOVATEK IP

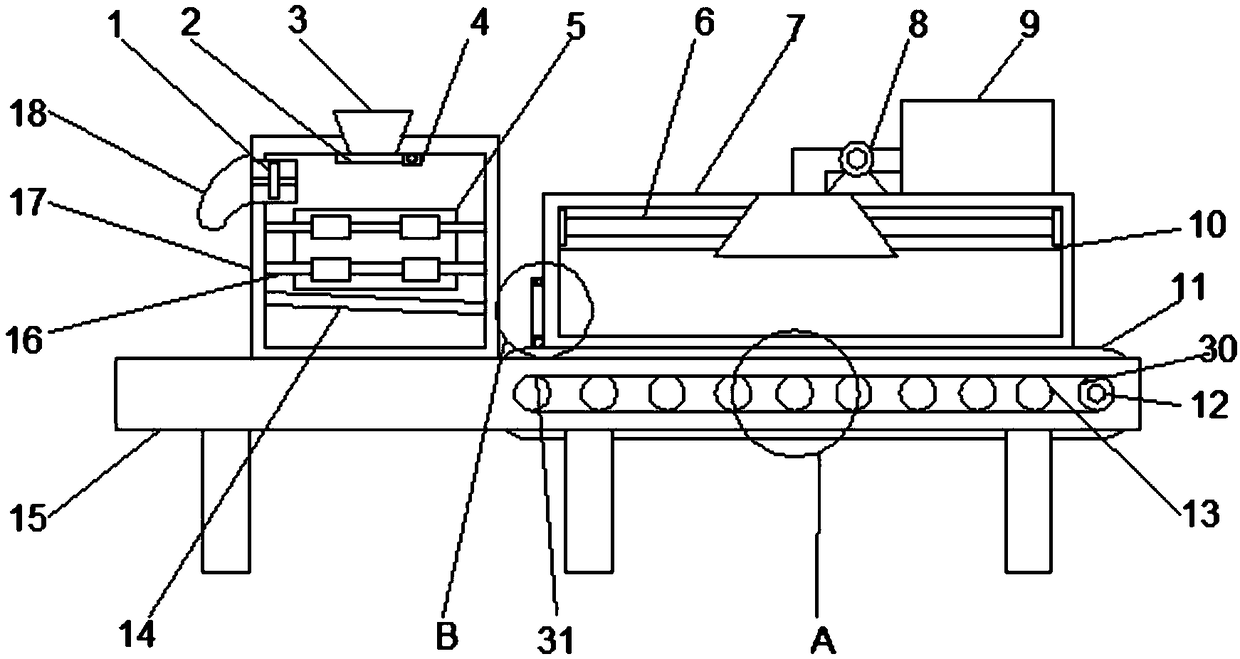

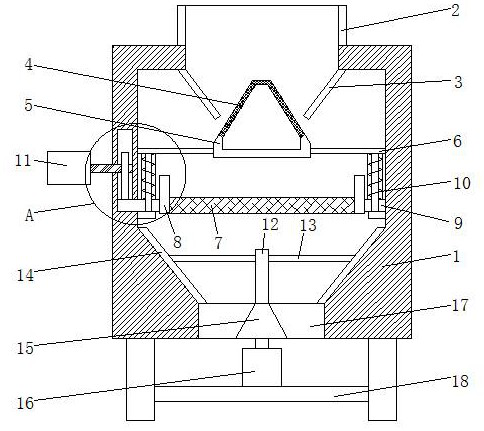

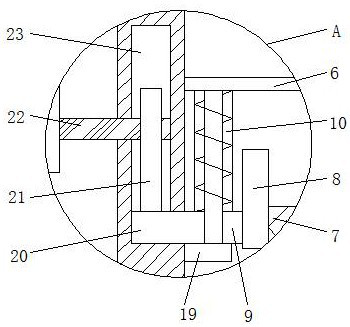

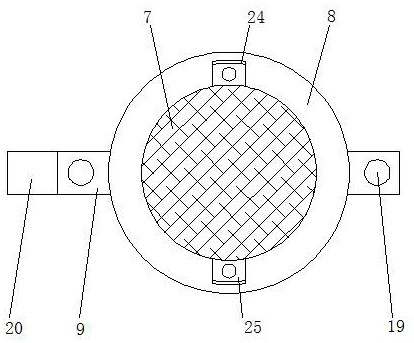

Air separation device and method of garbage

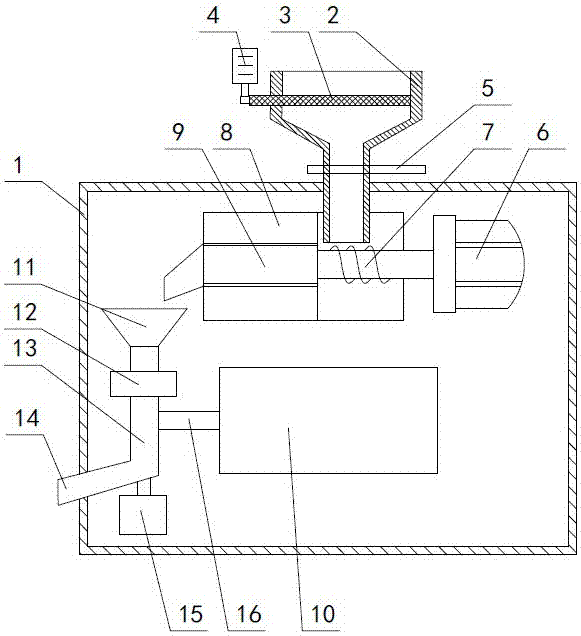

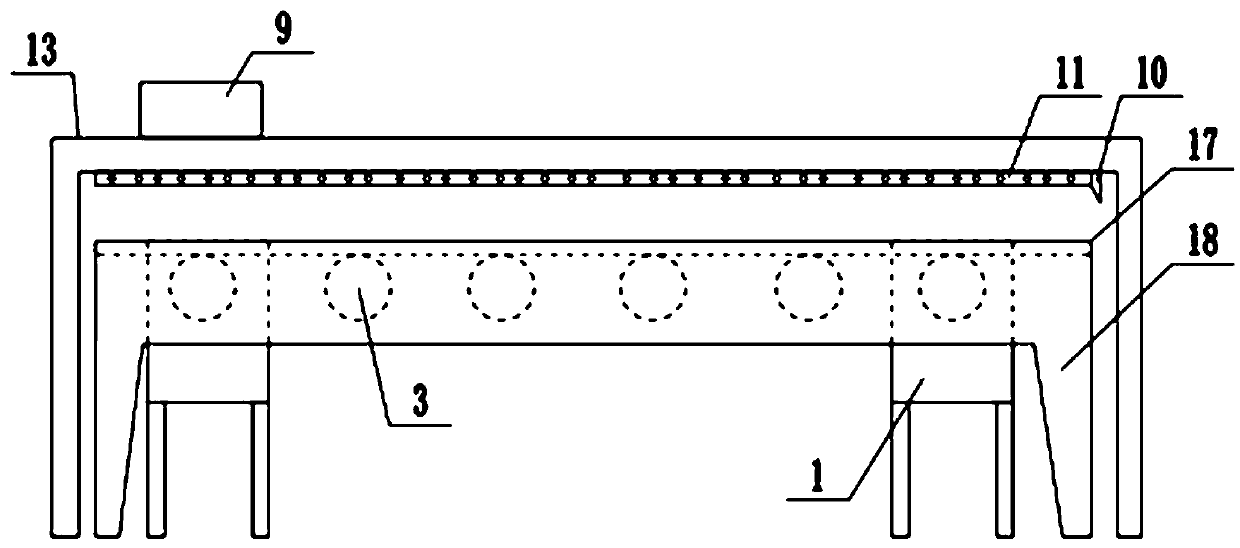

InactiveCN101823019AObvious superiorityImprove sorting efficiencyGas current separationWet separationAir volumeMagnetic separator

Owner:BEIJING HAOHAI TIANJI TECH +1

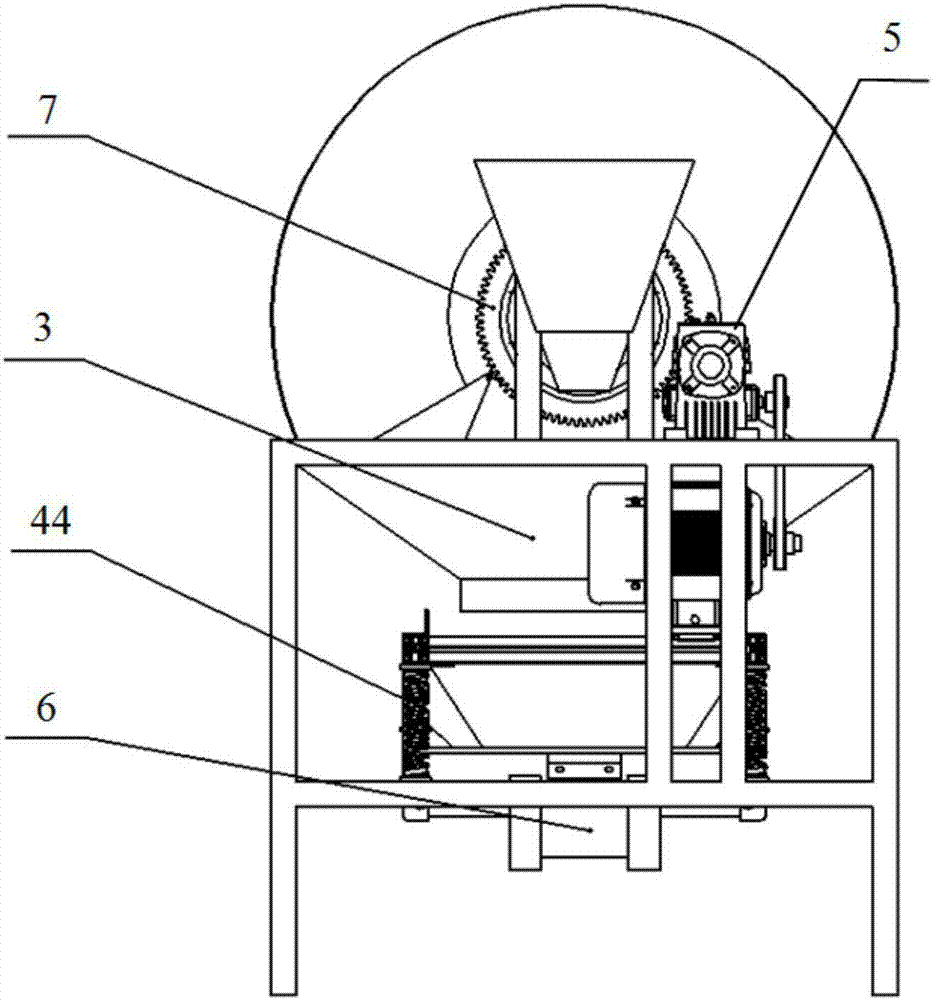

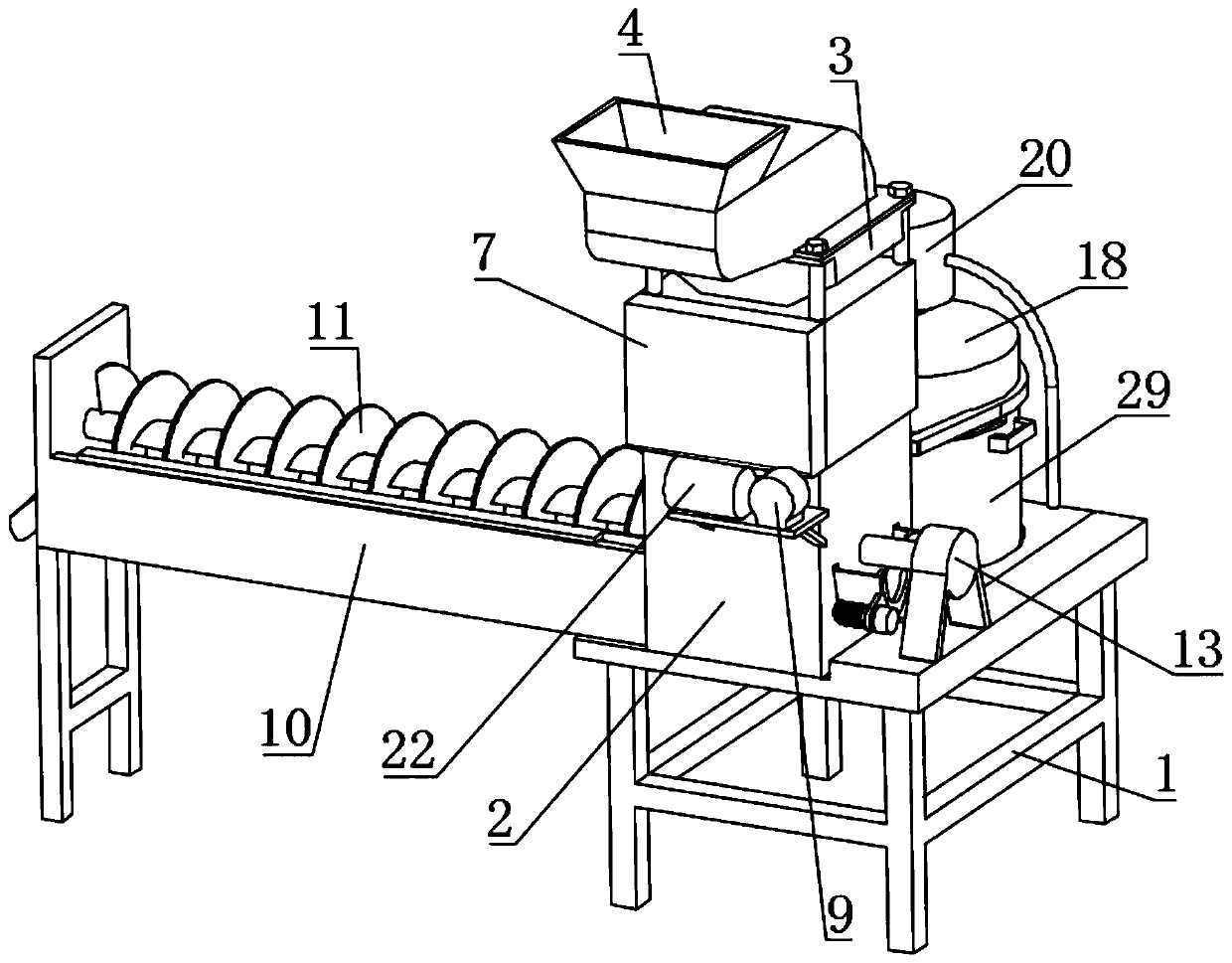

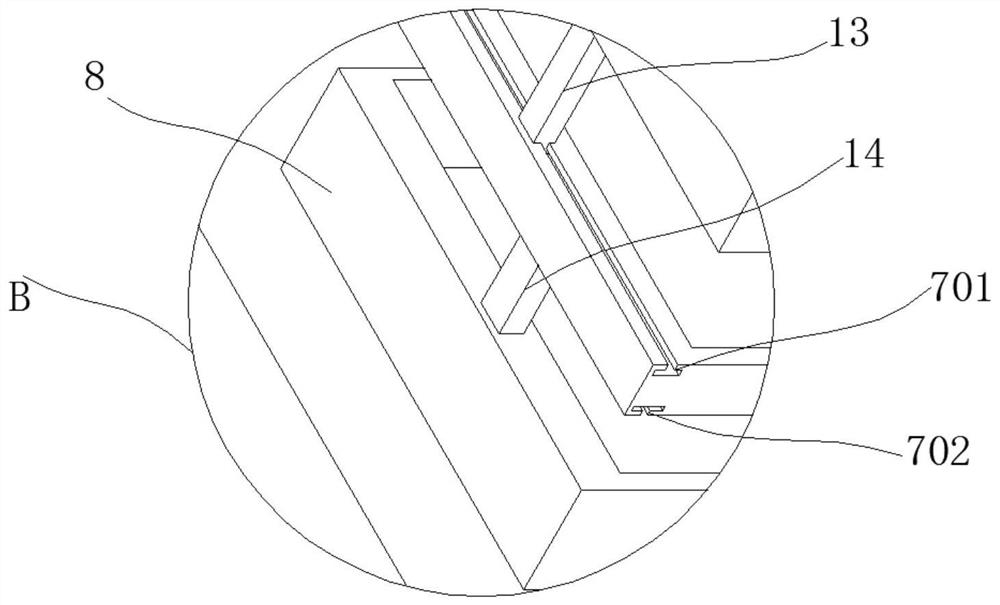

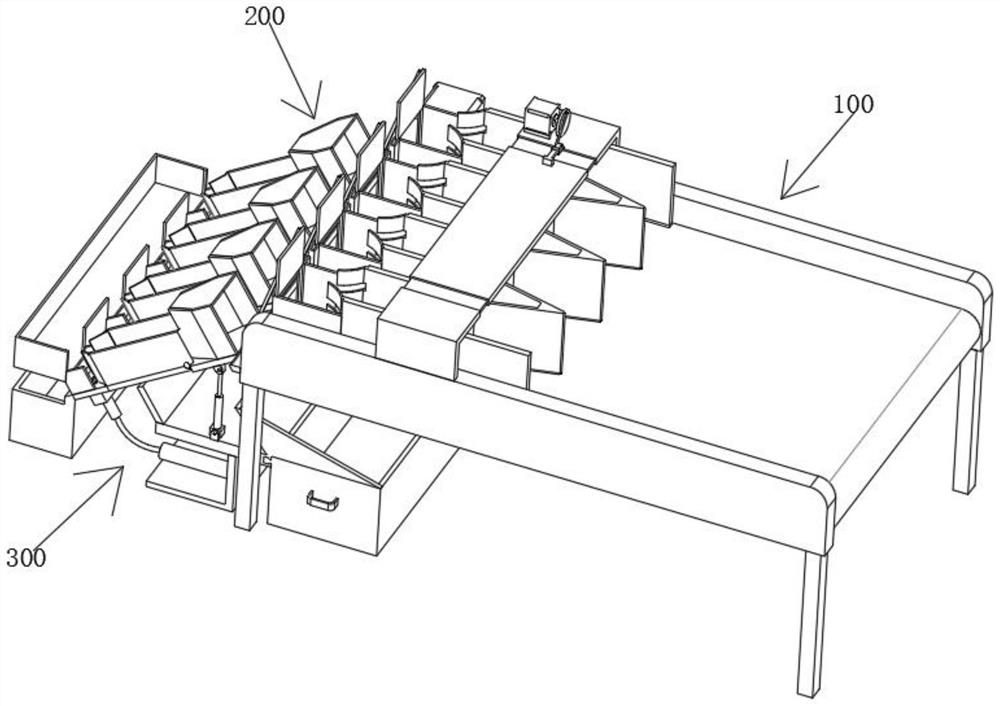

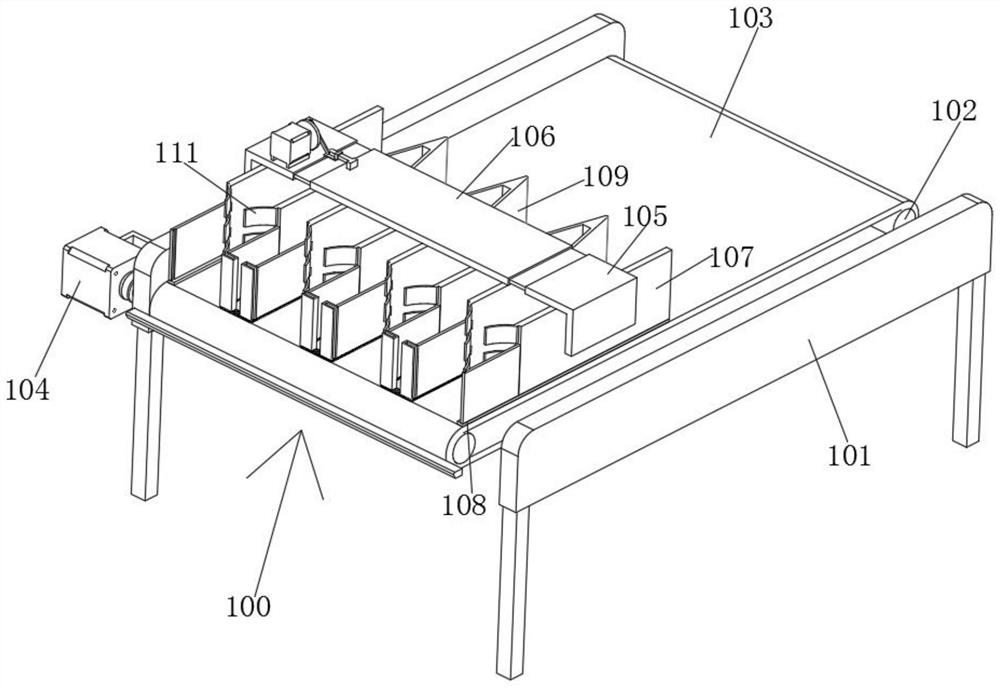

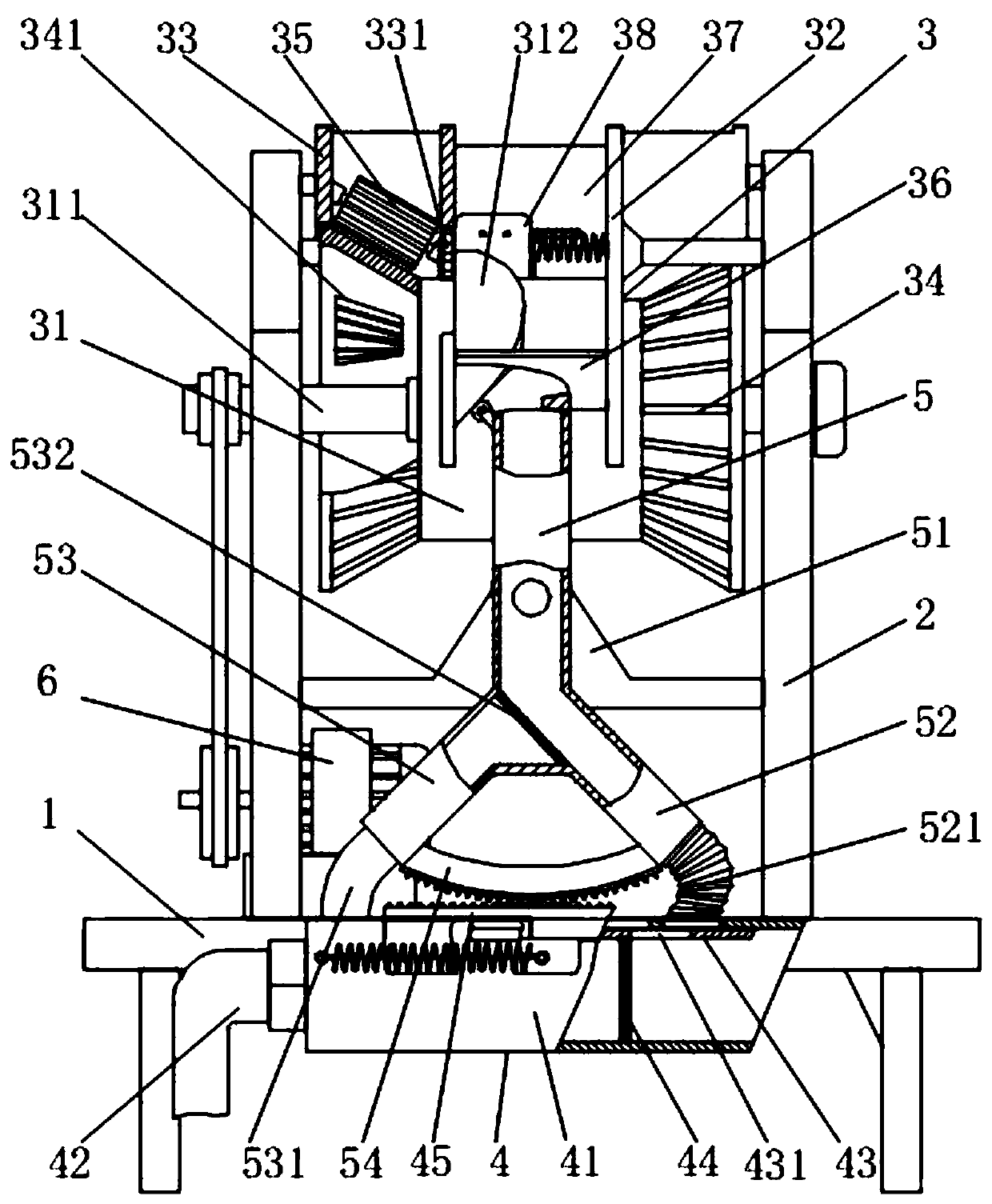

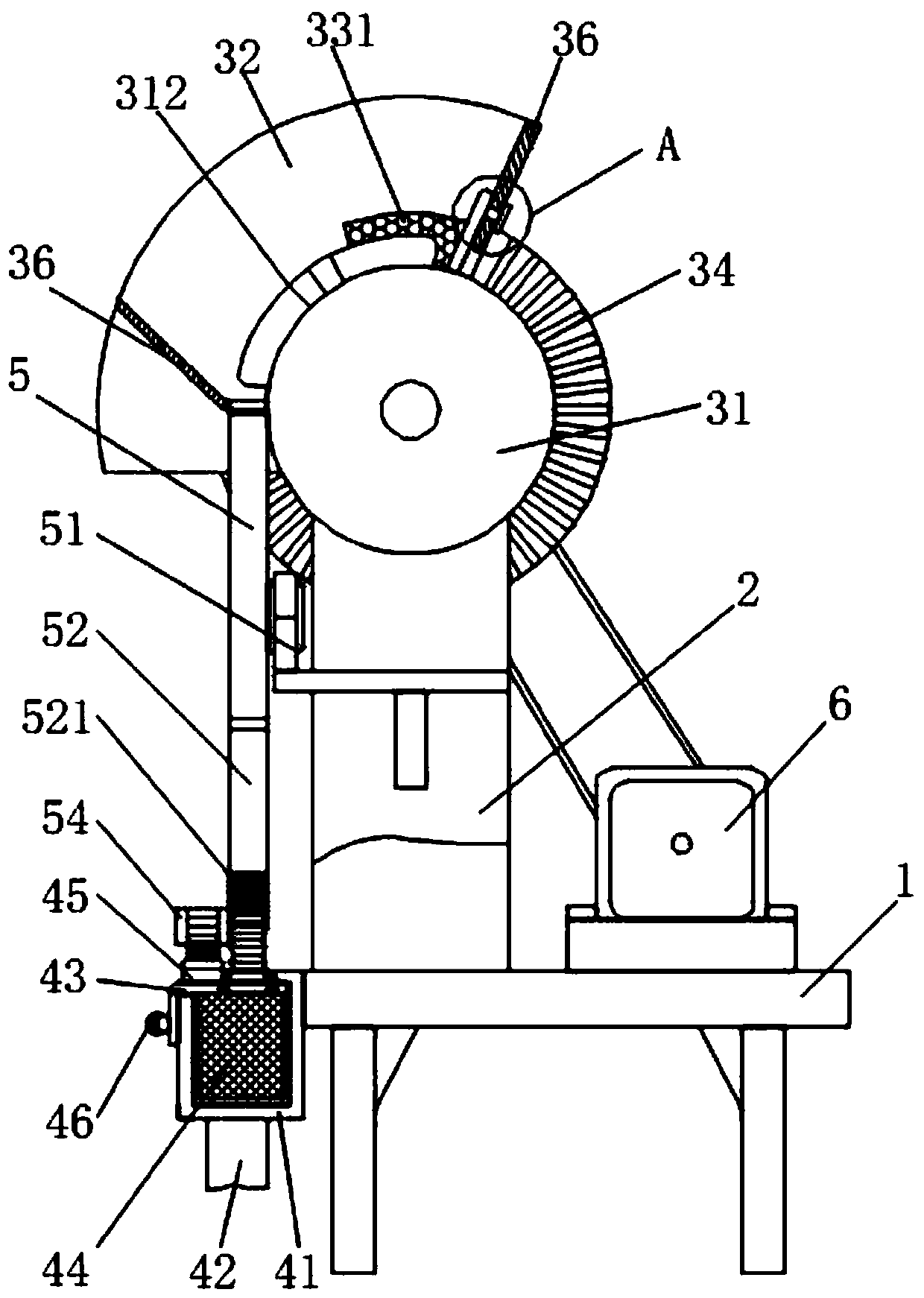

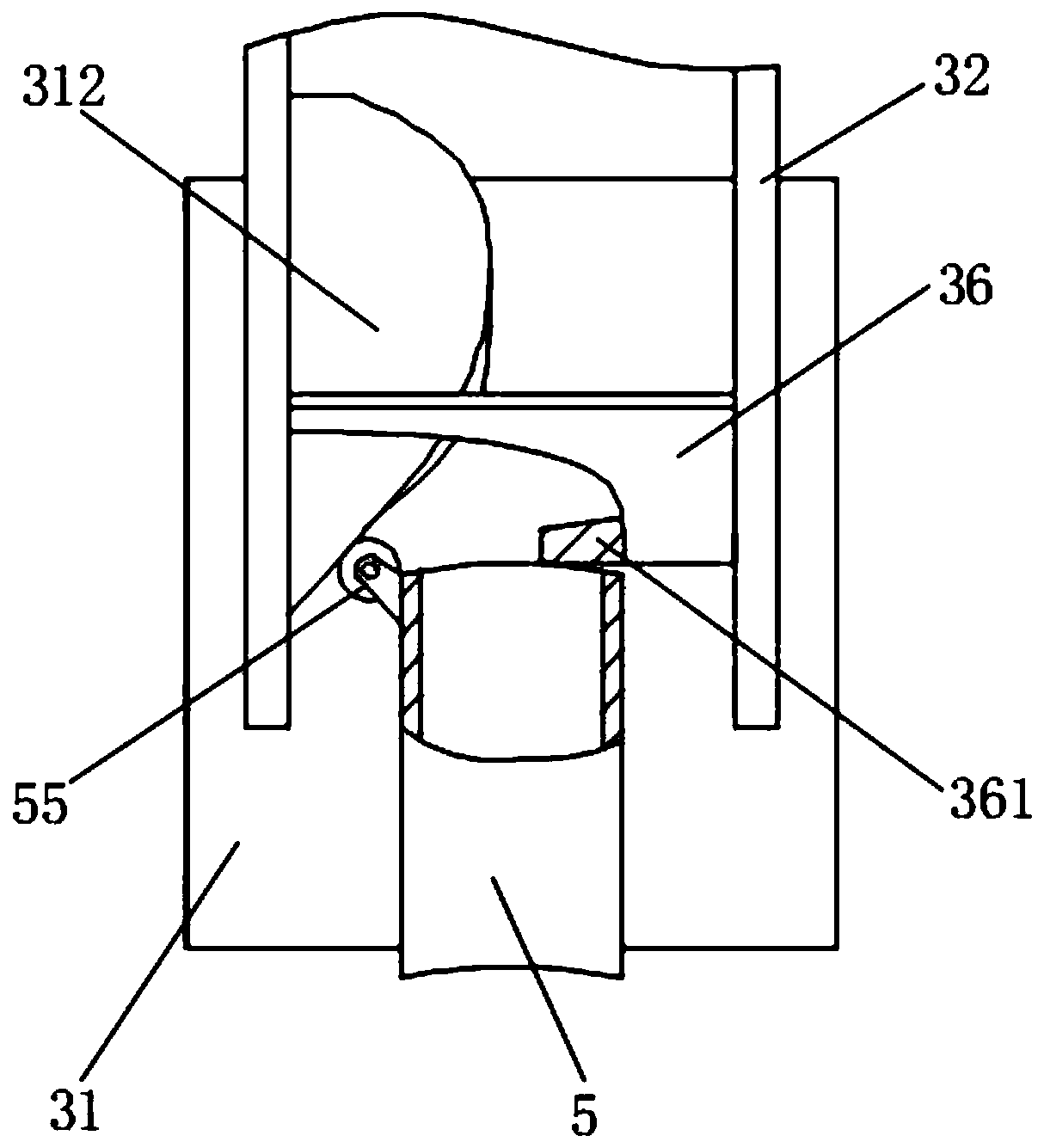

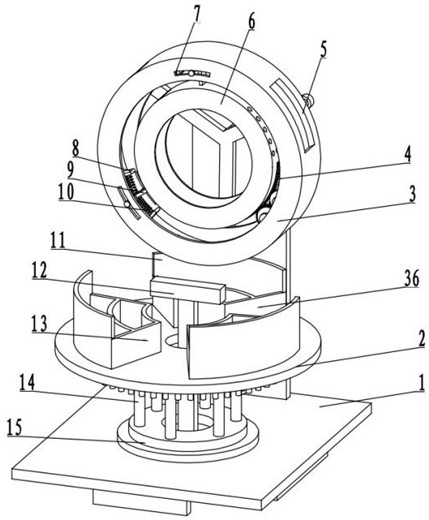

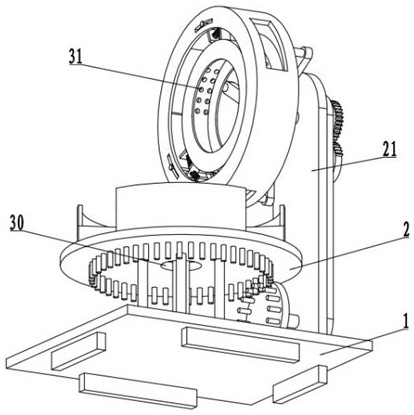

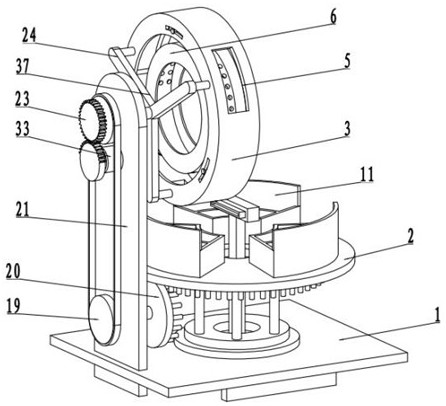

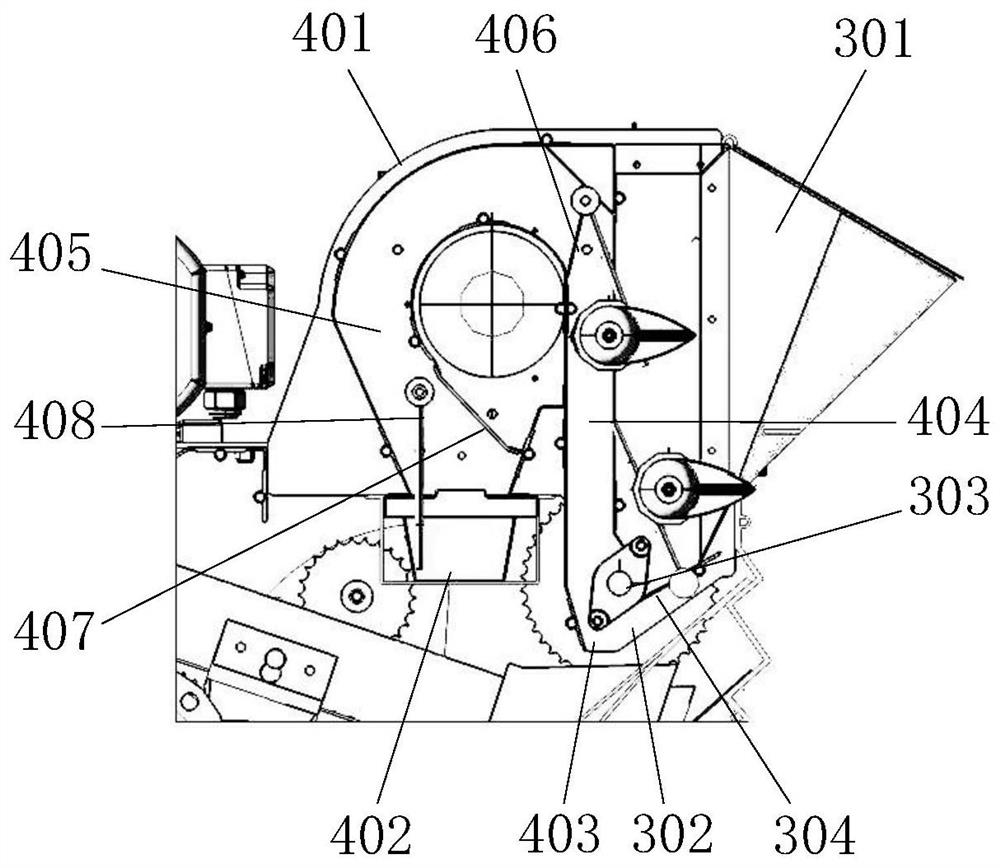

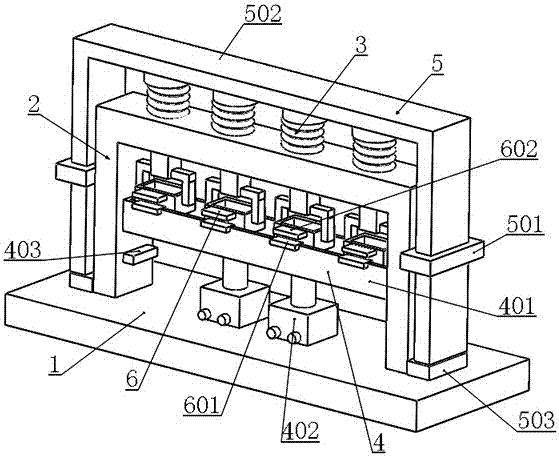

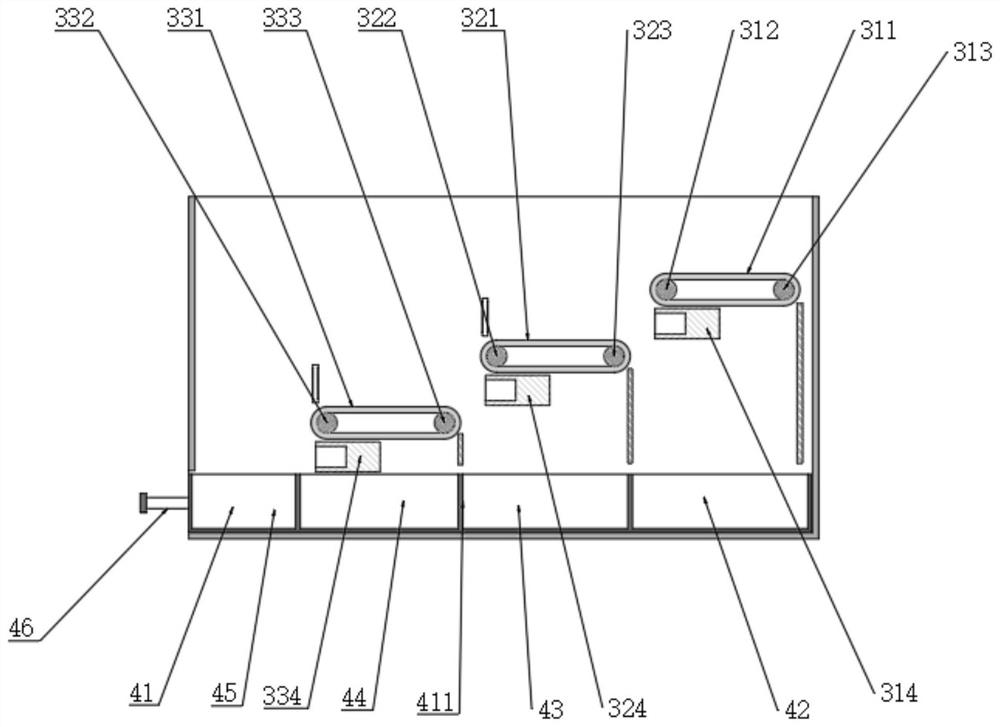

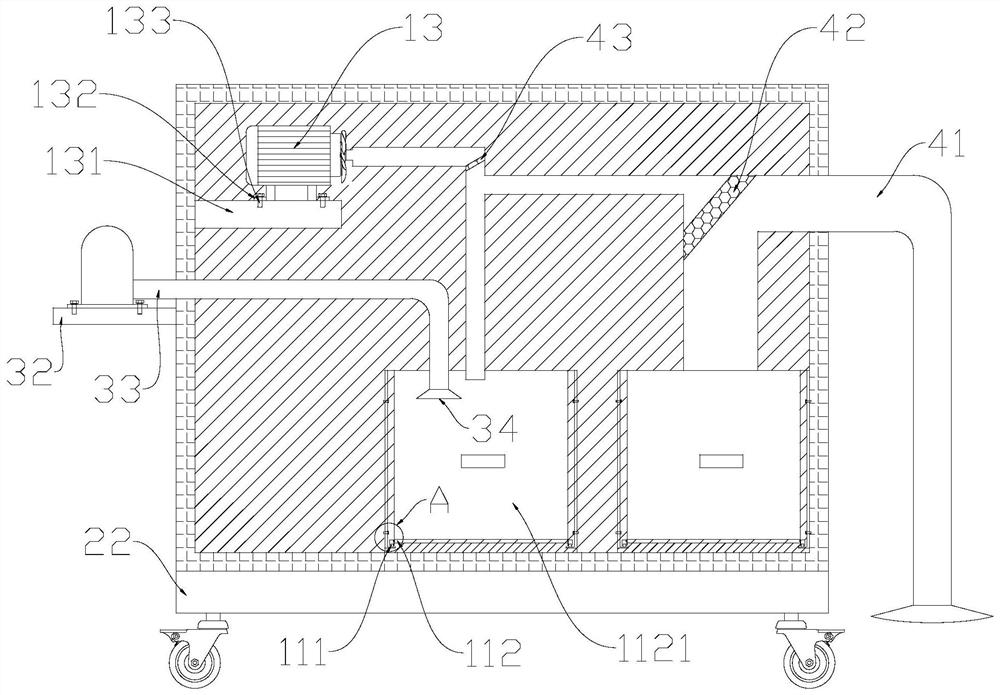

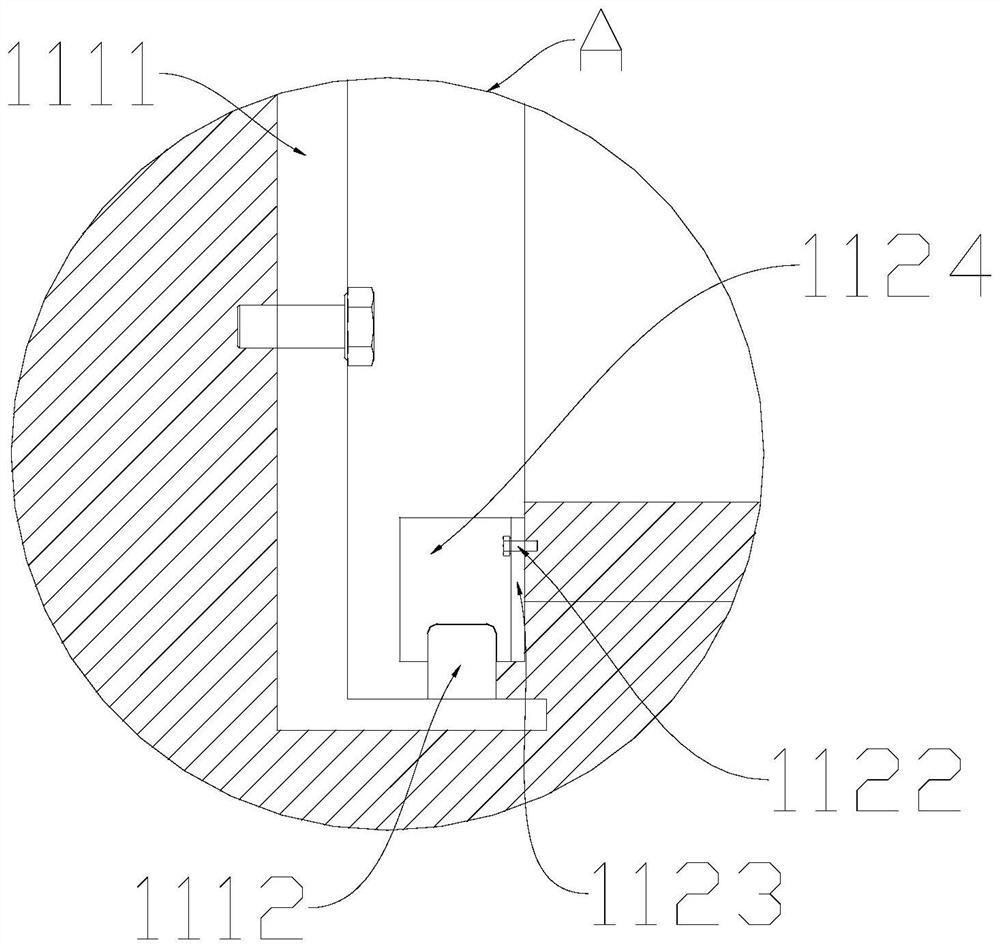

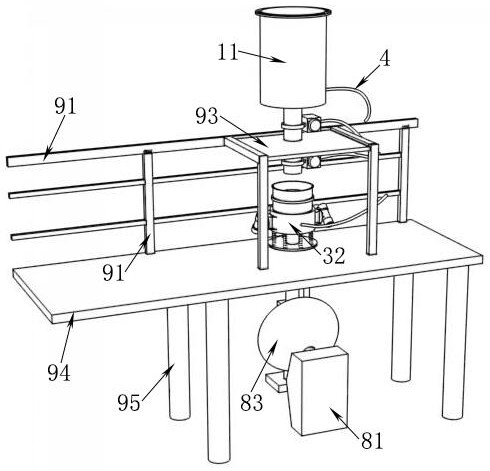

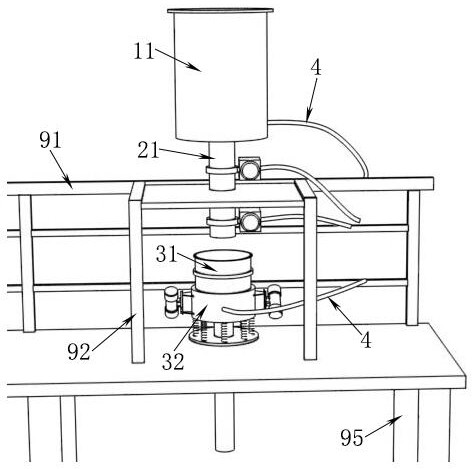

Comprehensive treating device for disassembling old shoes and recycling useful materials in old shoes

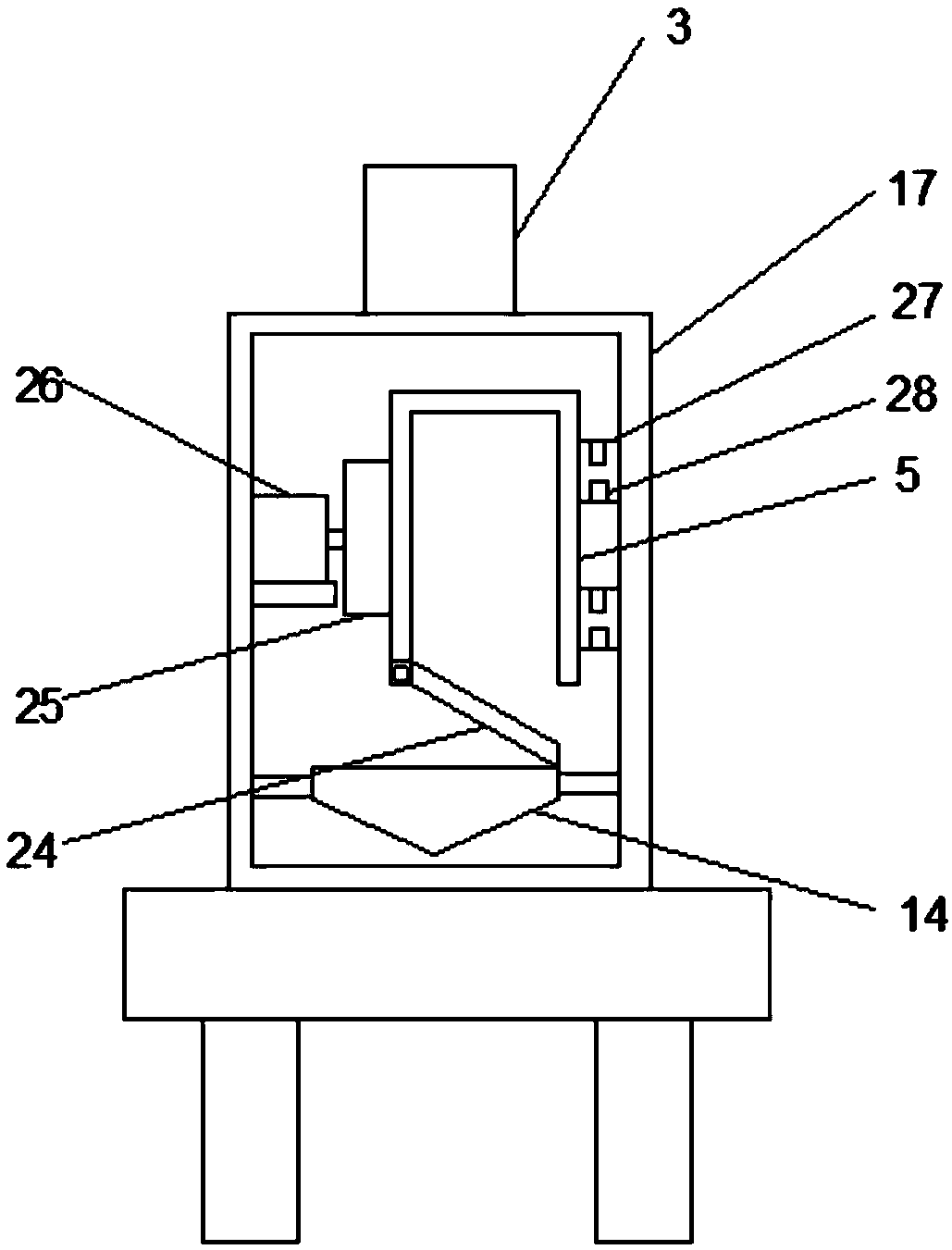

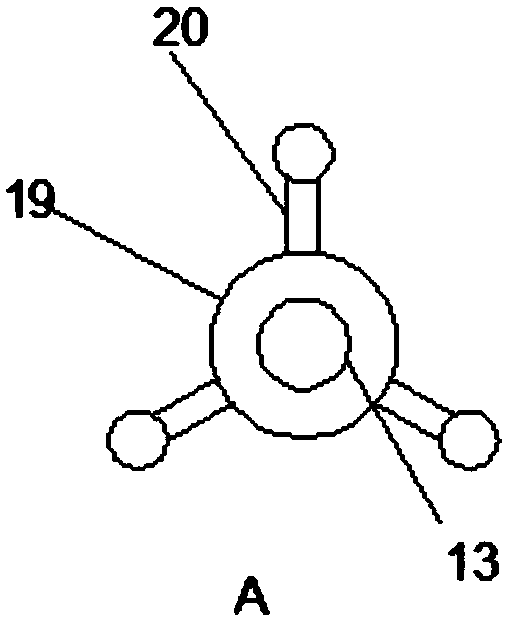

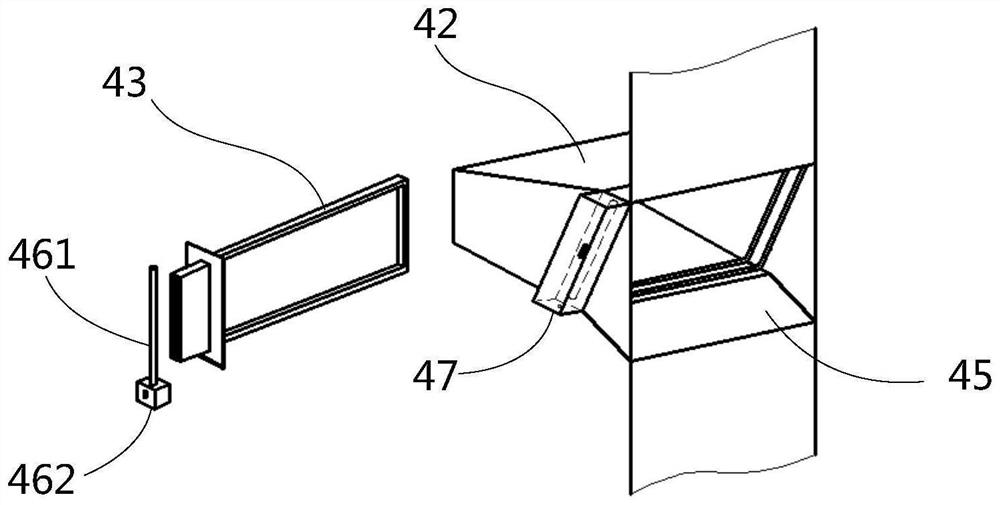

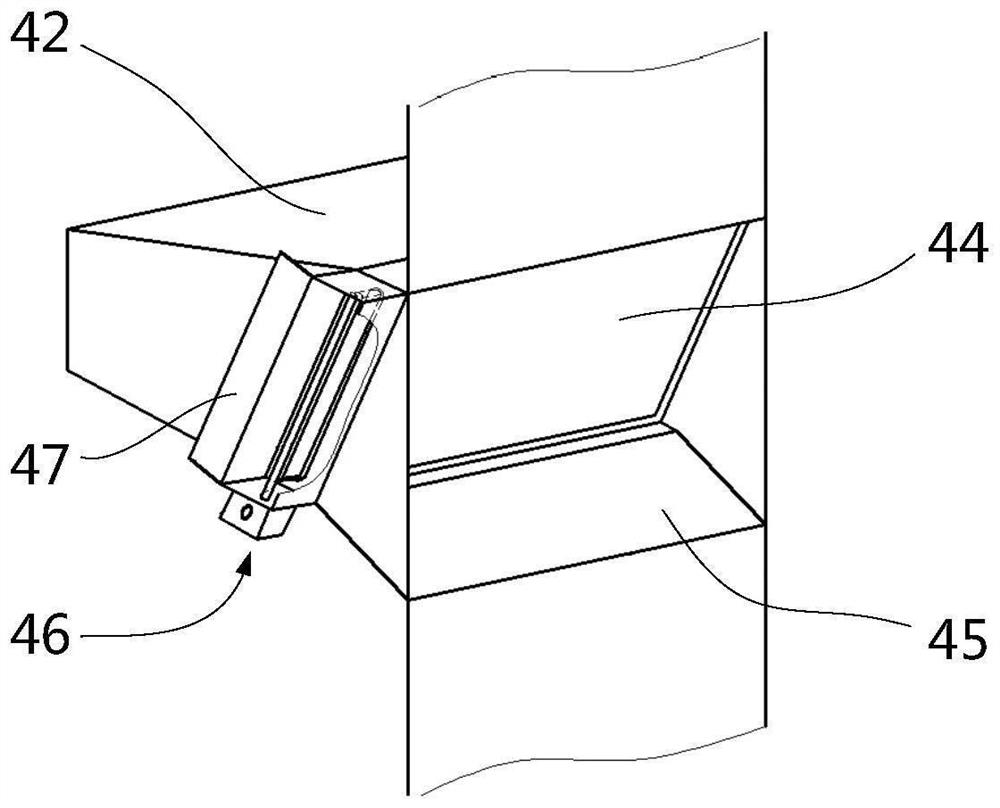

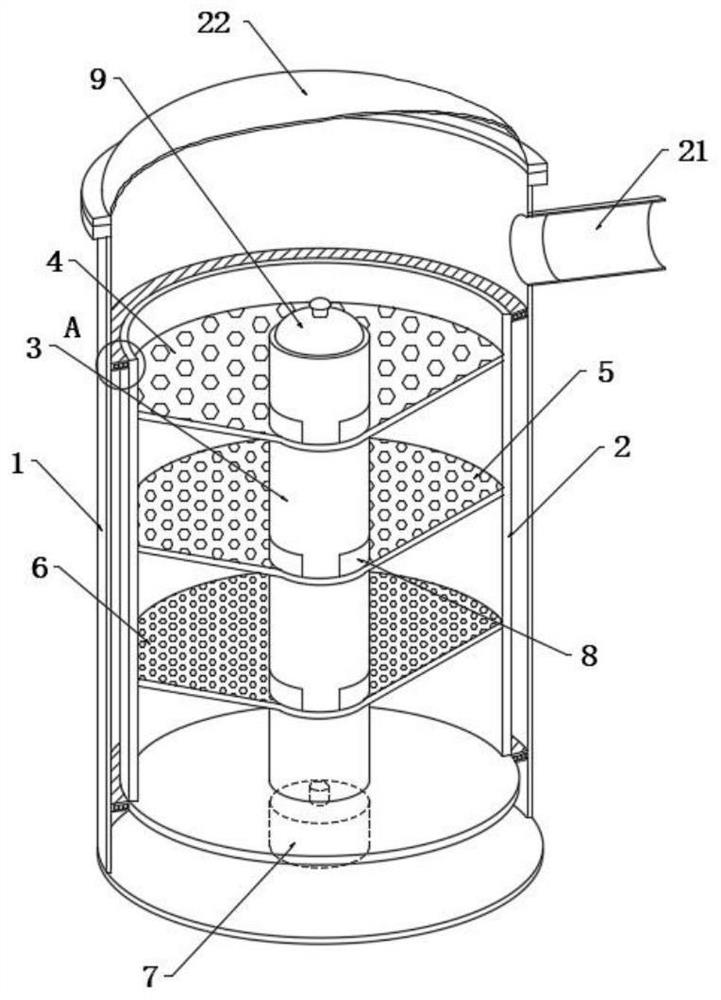

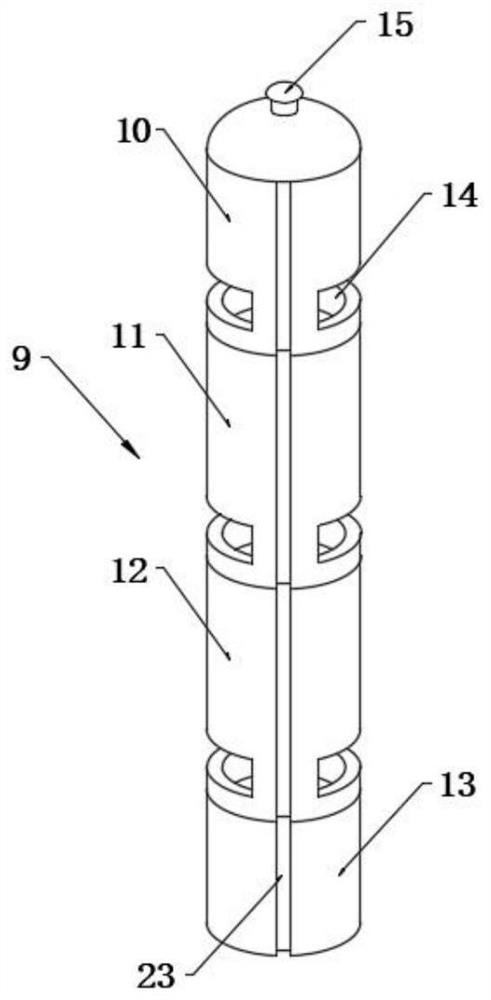

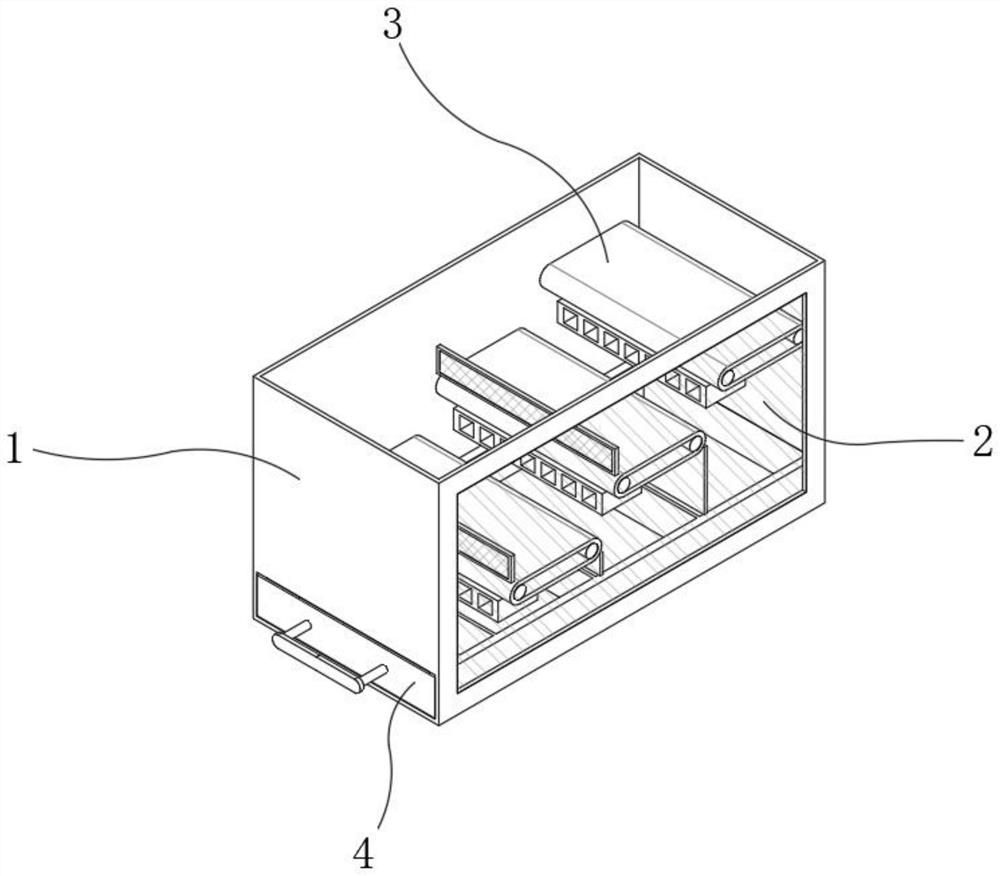

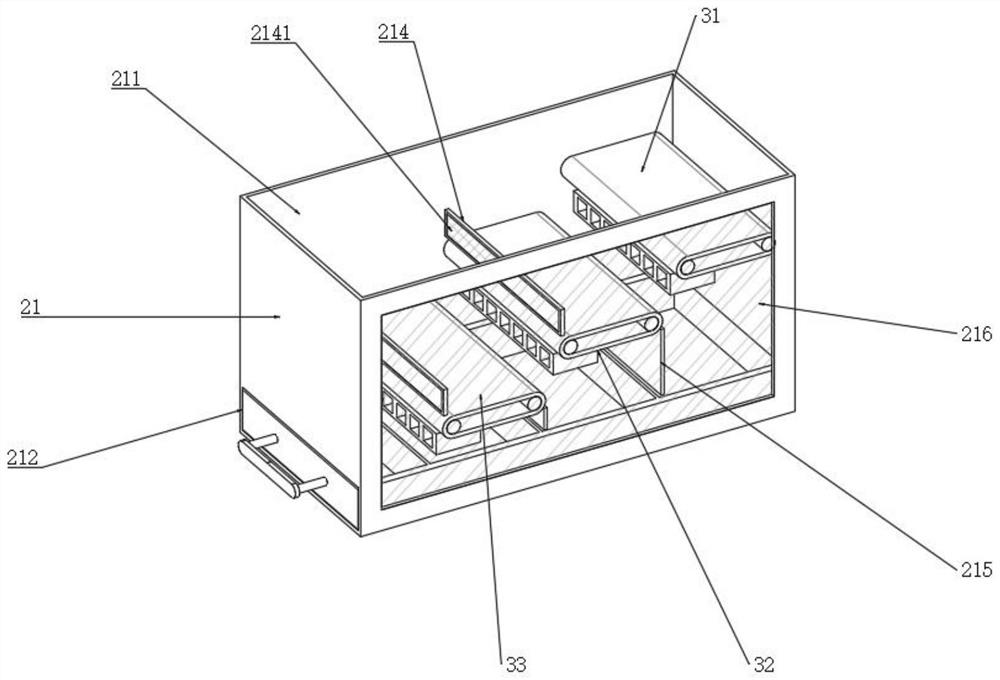

InactiveCN108453953ASolve problems that are difficult to recycle efficientlyEasy to recycleGas current separationPlastic recyclingResource utilizationEngineering

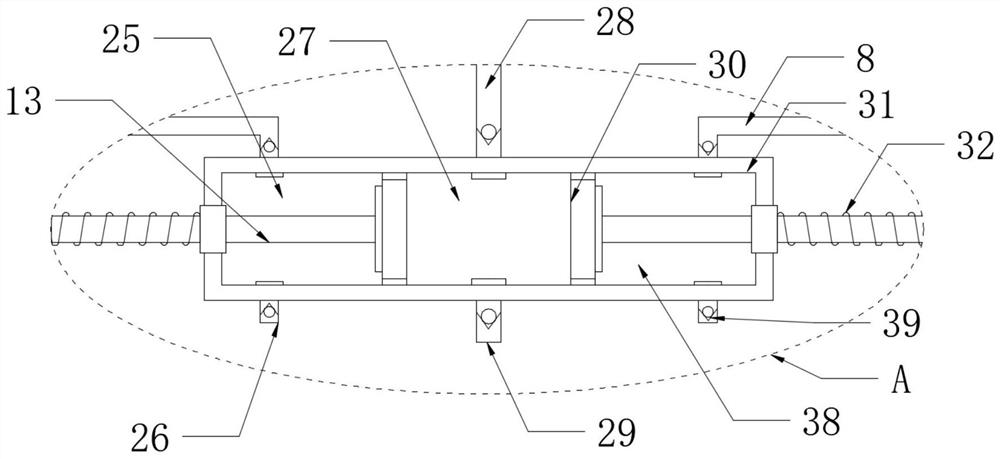

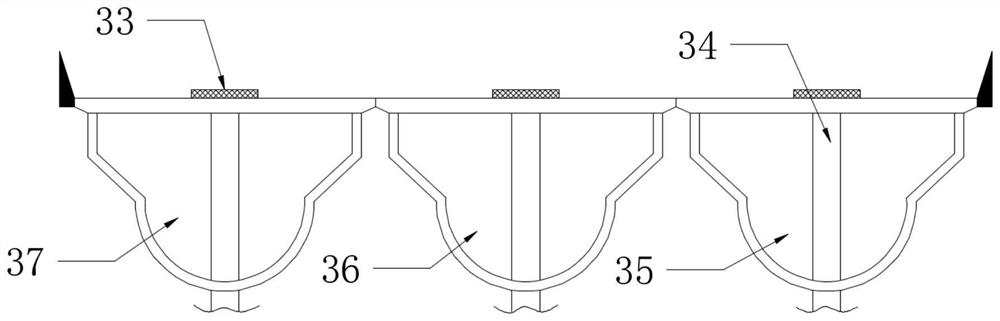

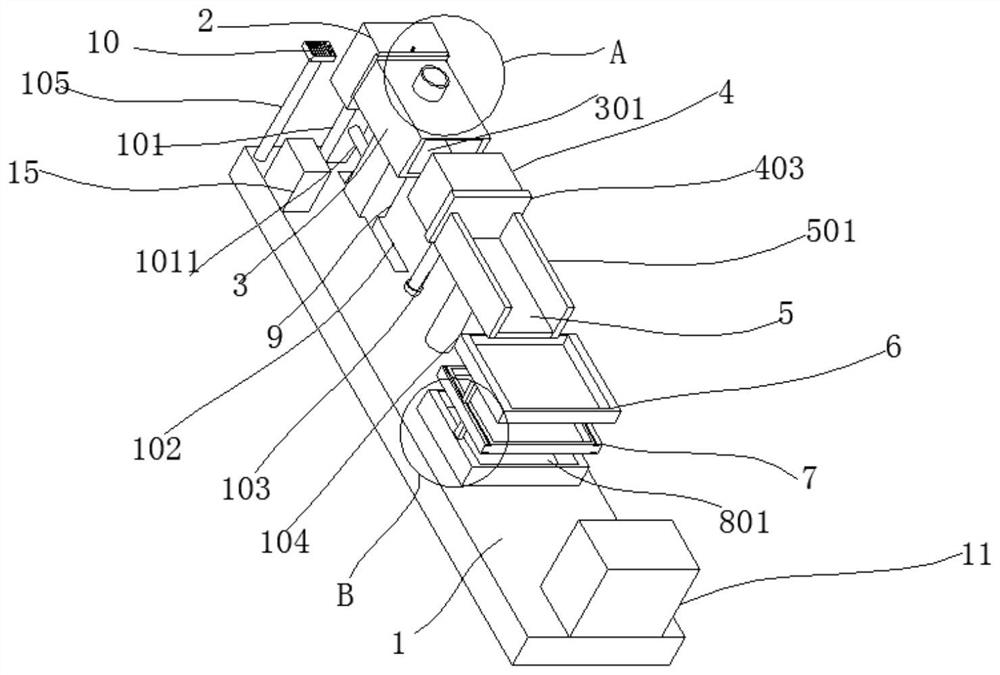

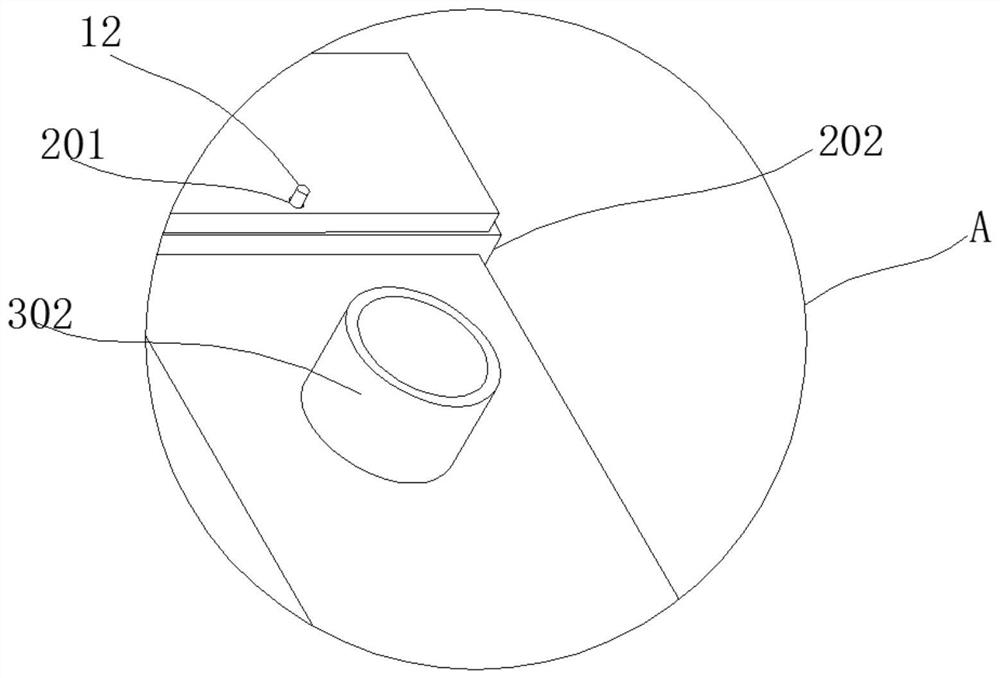

The invention relates to a comprehensive treating device for disassembling oil shoes and recycling useful materials in the old shoes. The comprehensive treating device comprises a coarse smashing module, a fine smashing module and a screening and separation module, wherein in the coarse smashing module, a plurality of saw blades are evenly arranged on two shafts and can perform opposite meshed high-speed rotation to coarsely smash the oil shoes; in the fine smashing module, four roller wheels are arranged in a cavity body regularly, two groovy rollers with the same inner diameter can achieve primary fine smashing on the old shoes through opposite meshed differential-speed rotation, two polishing rollers with the different inner diameters and two groovy rollers with the different inner diameters can achieve secondary fine smashing on the old shoes through opposite meshed equal-speed rotation, the screening and separating module can utilize an air blower to blow air to layer different masses of old shoe particles in the cavity body, and then the old shoe particles are classified and recycled. The comprehensive treating device disclosed by the invention can effectively smash waste shoes, the sizes of the smashed particles can be set as an adjustable mode according to need, the smashed materials can be screened and collected according to different masses, a resource utilization rate is improved, and environmental pollution caused by directly incinerating or burying the old shoes and resource waste are reduced.

Owner:WUHAN UNIV OF TECH

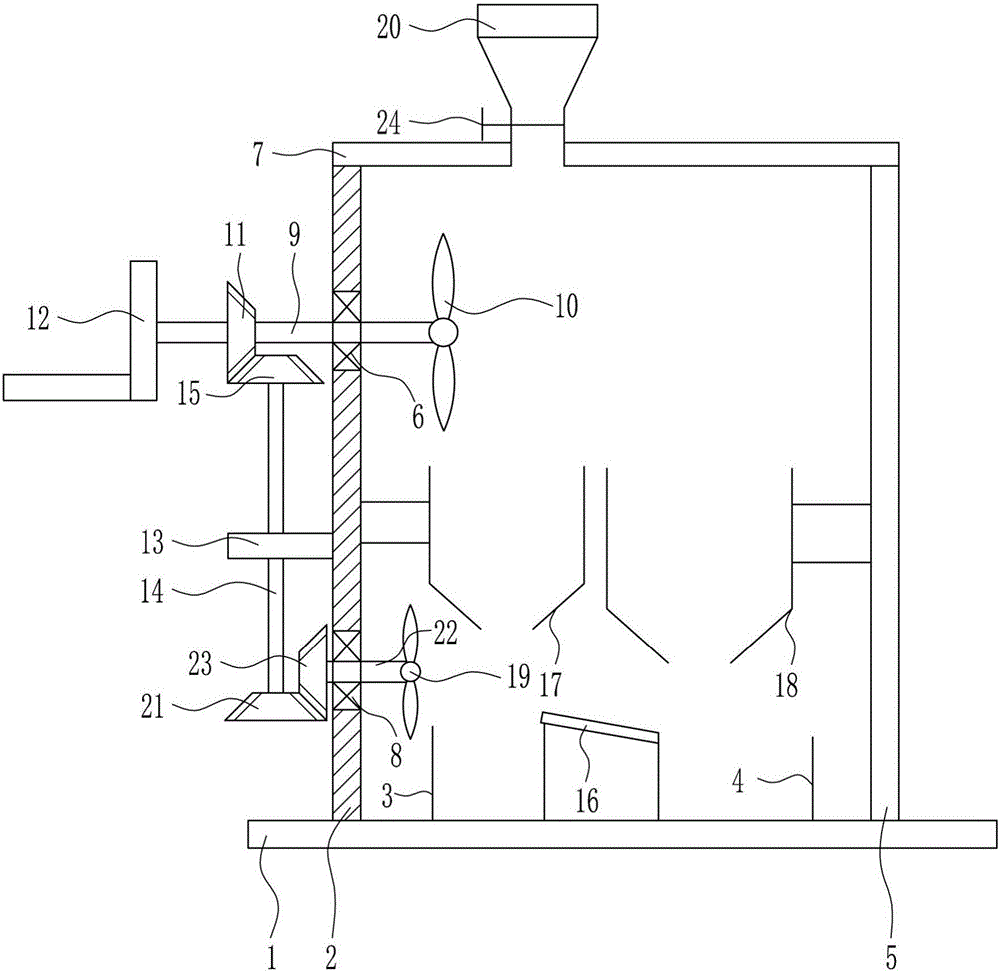

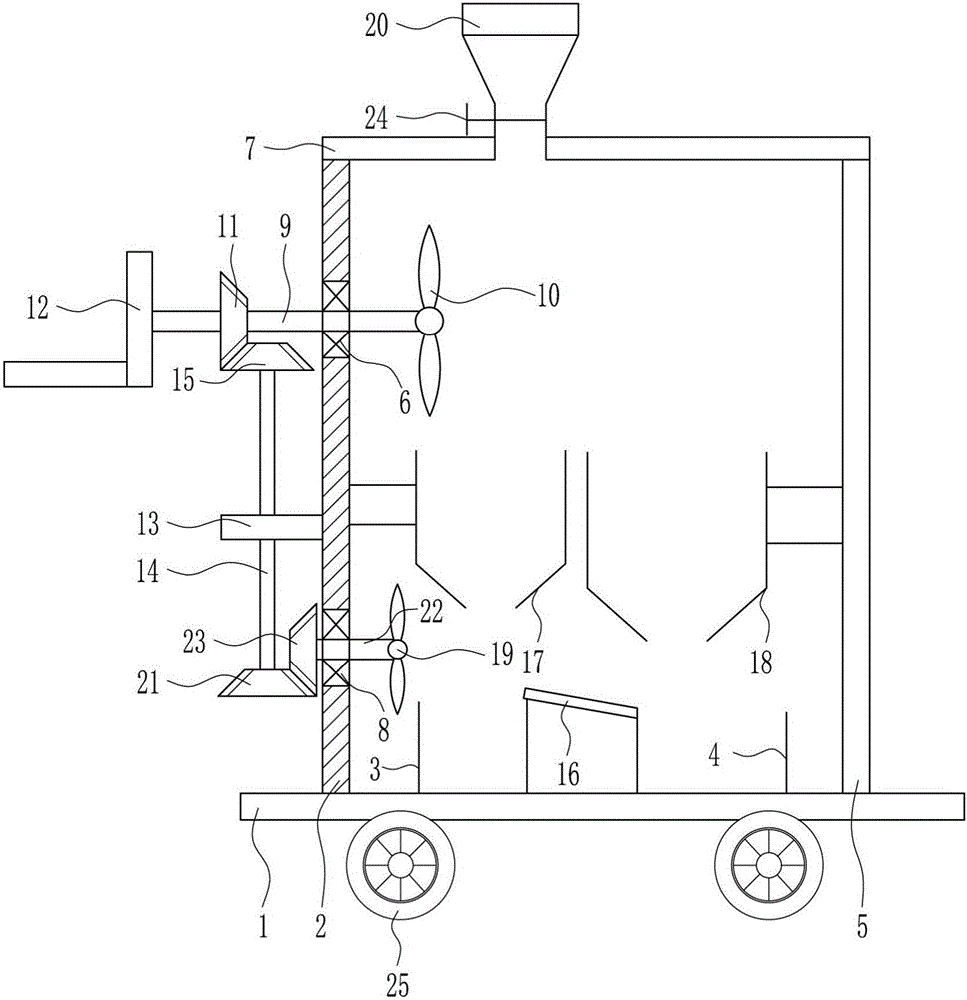

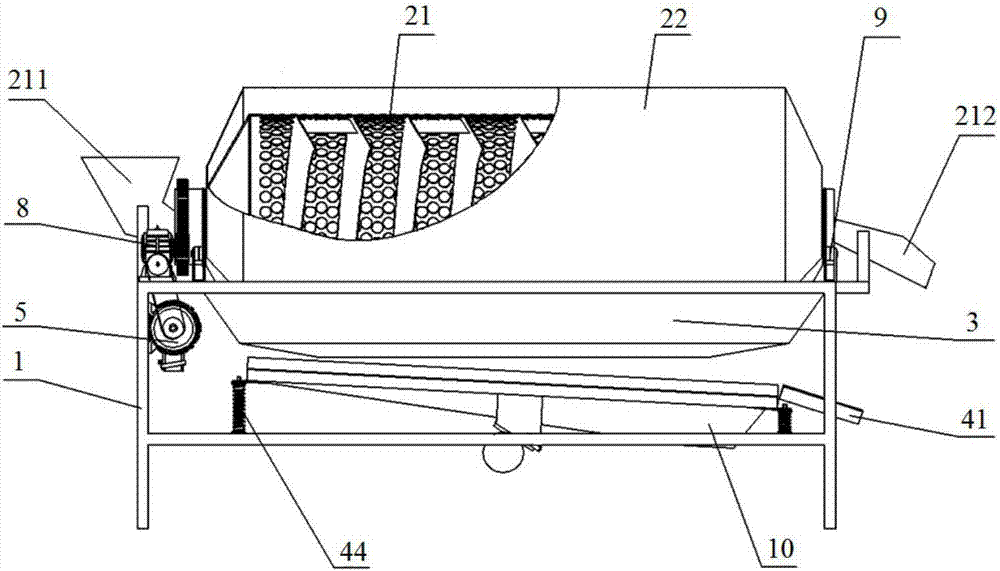

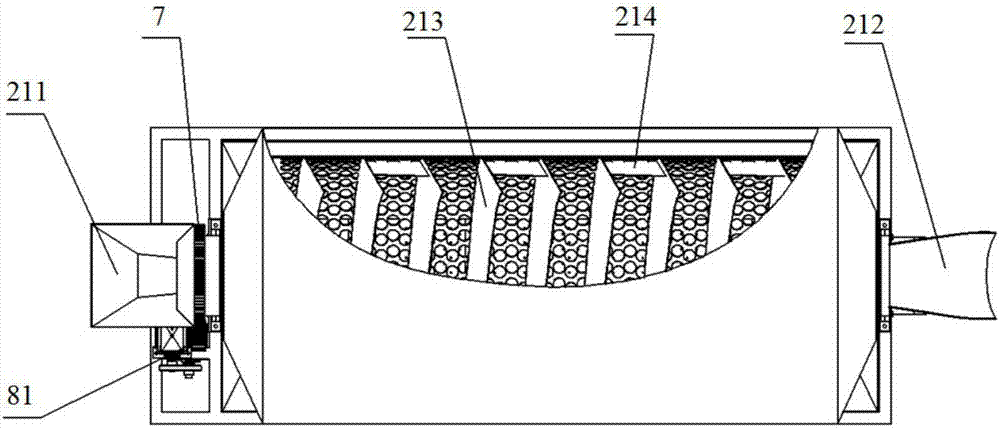

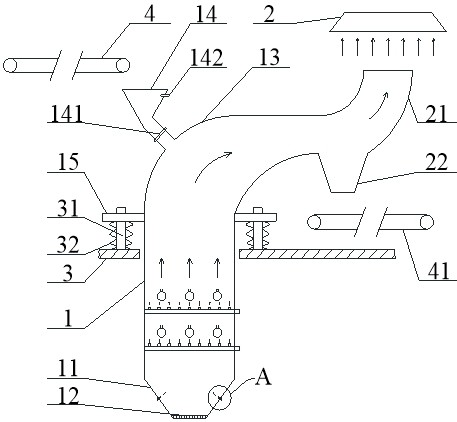

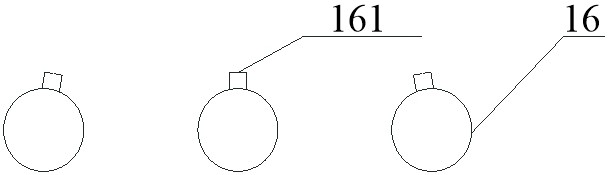

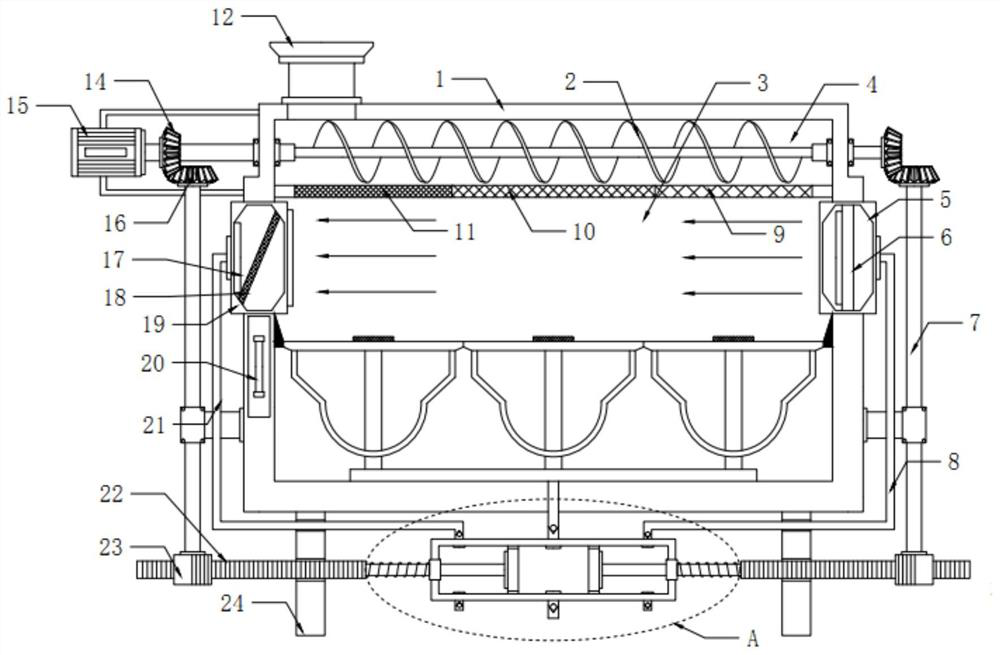

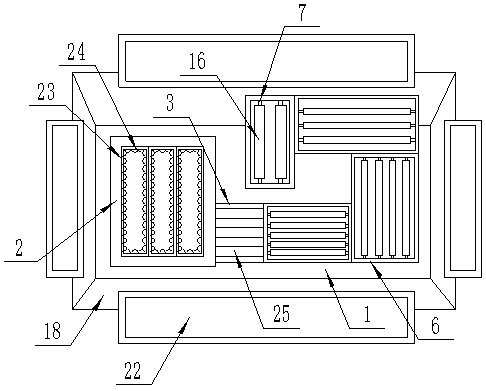

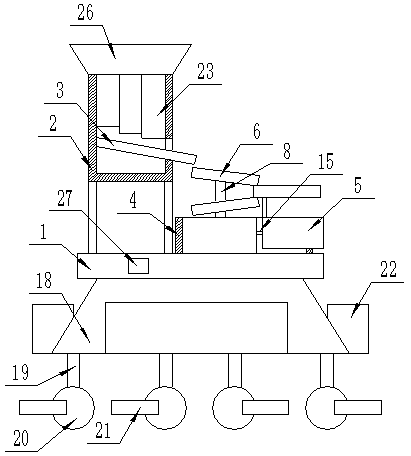

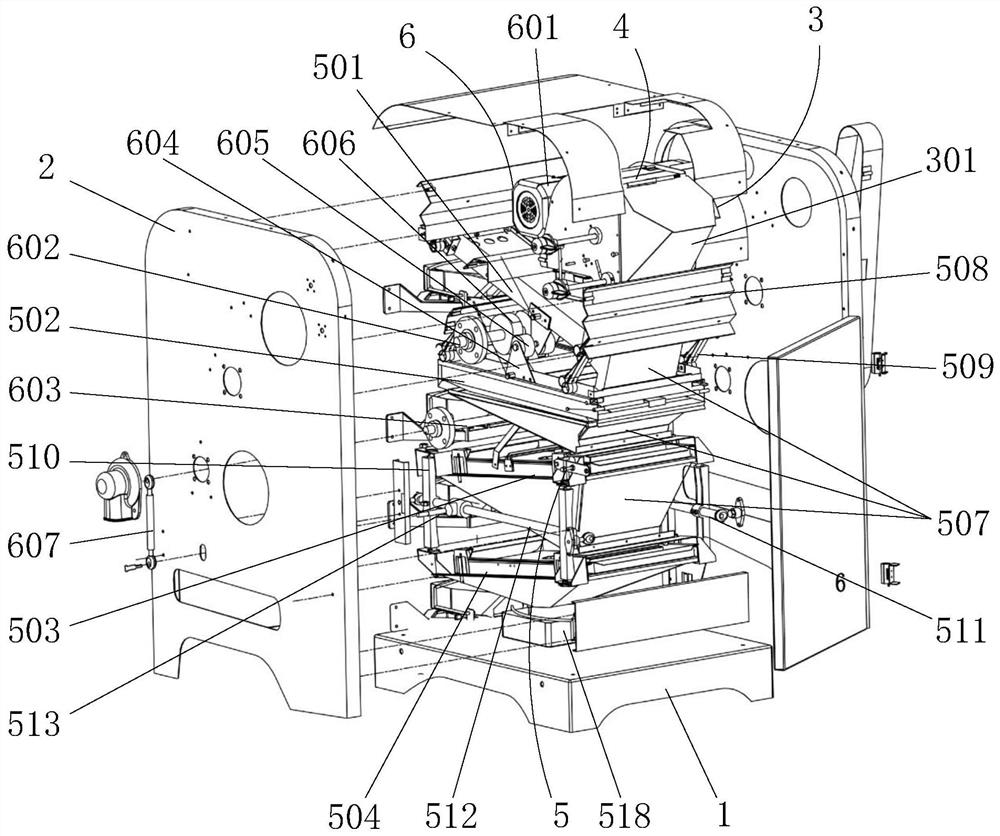

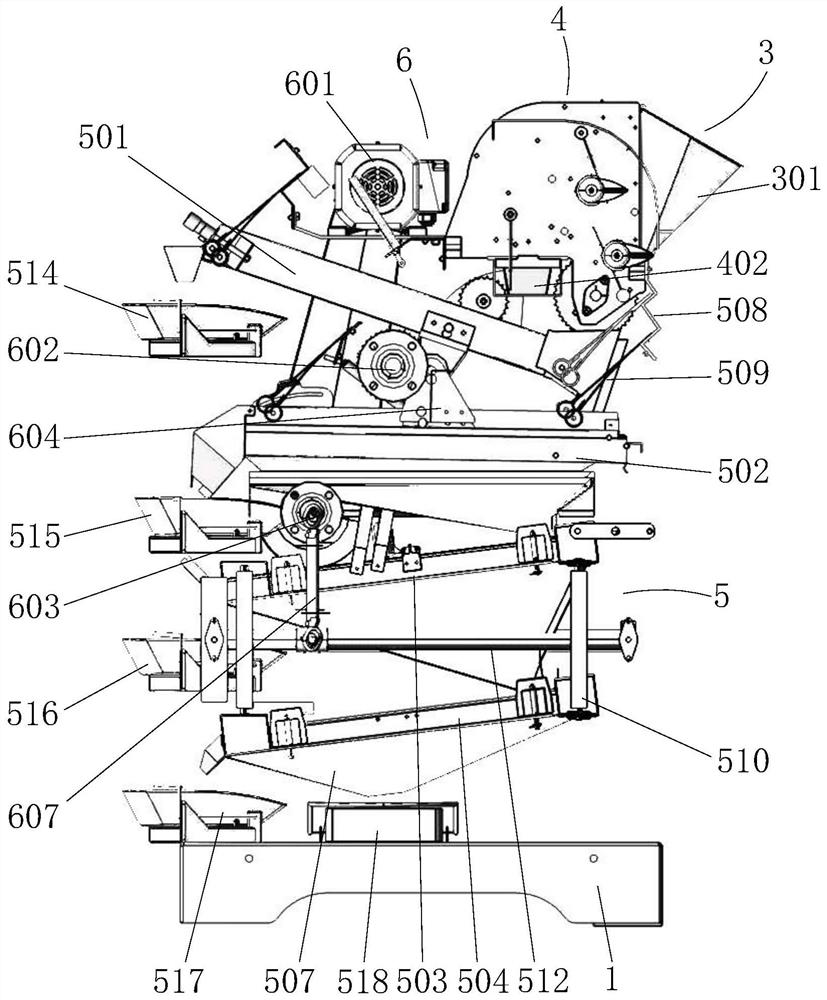

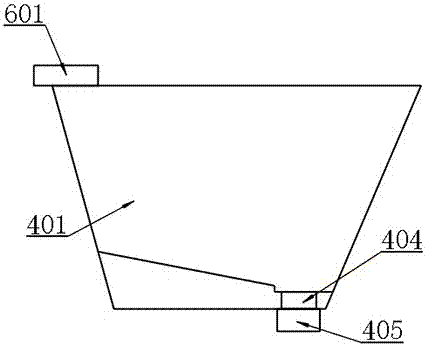

Comprehensive rubbish sorting technology and comprehensive rubbish sorting machine

InactiveCN104722494AAchieve separationRealize sortingSievingGas current separationMagnetic separatorEngineering

A comprehensive garbage sorting technology includes the steps of garbage grinding, bag breaking, magnetic separation, primary winnowing, two-grade sorting in a rotary screen and secondary winnowing. A comprehensive garbage sorting machine comprises a plate-type feeder, a garbage grinding and bag breaking machine and a magnetic separator are mounted in a feeding section and a discharging section of the plate-type feeder respectively, a first winnower and a first U-shaped belt conveyer are sequentially arranged below the discharging end of the plate-type feeder, the rotary screen comprising a first screening section and a second screening section is arranged at the rear end of the plate-type feeder, a first discharging hopper and a second discharging hopper are arranged below the first screening section and the second screening section of the rotary screen respectively, a second U-shaped belt conveyer and a third U-shaped belt conveyer are arranged below the two discharging hoppers respectively, a fourth U-shaped belt conveyer is arranged at the rear end of the rotary screen, and a second winnower is mounted below the discharging end of the rotary screen. The comprehensive garbage sorting technology and the comprehensive garbage sorting machine have the advantages that magnetic metal, building garbage, organic matters and the like in garbage can be sorted out step by step, thorough separation of various materials in household garbage is achieved, and recovery and utilization of useful materials are facilitated.

Owner:TIANJIN BAILI SUN ENVIRONMENTAL PROTECTION EQUIP CO LTD

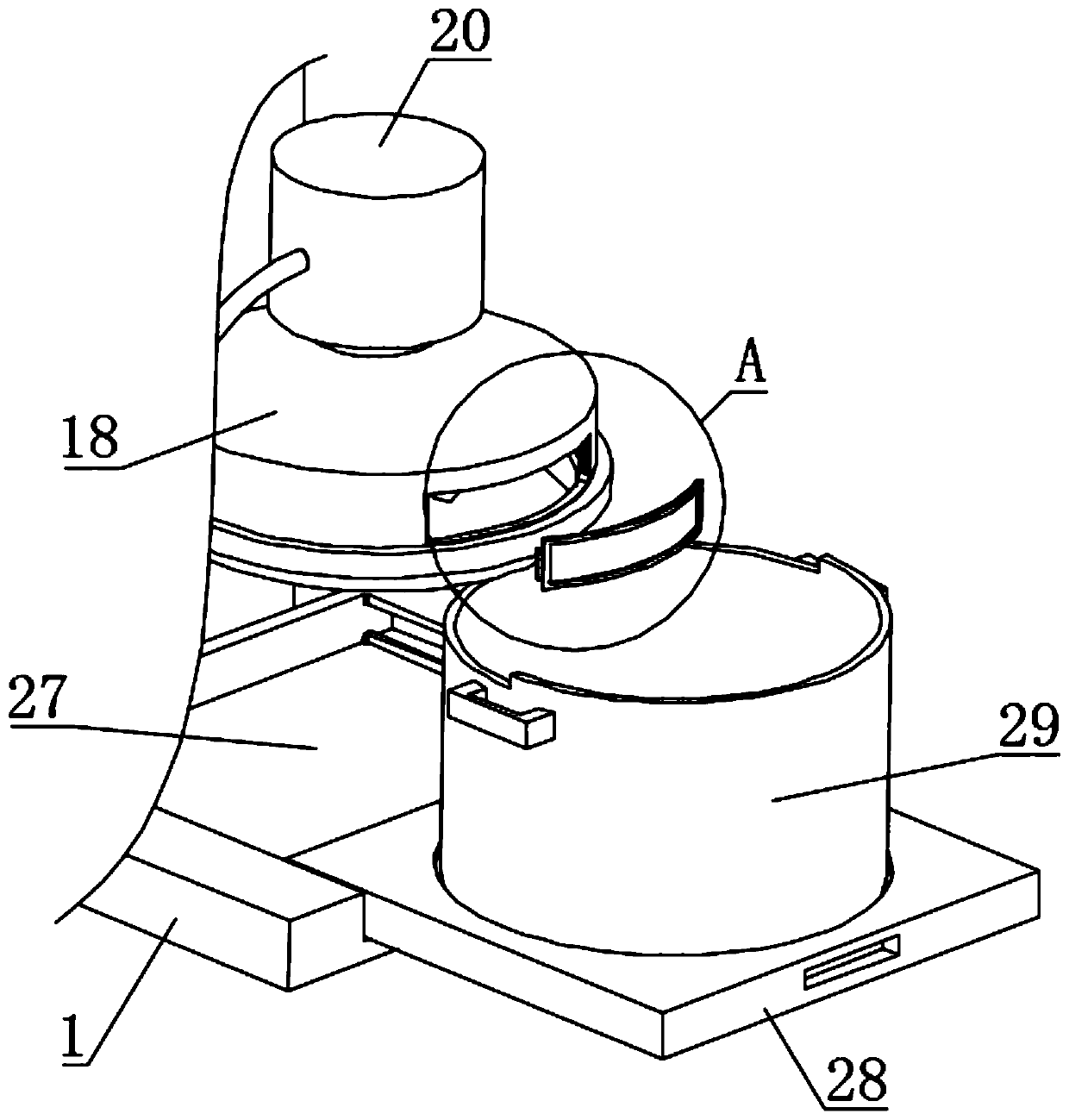

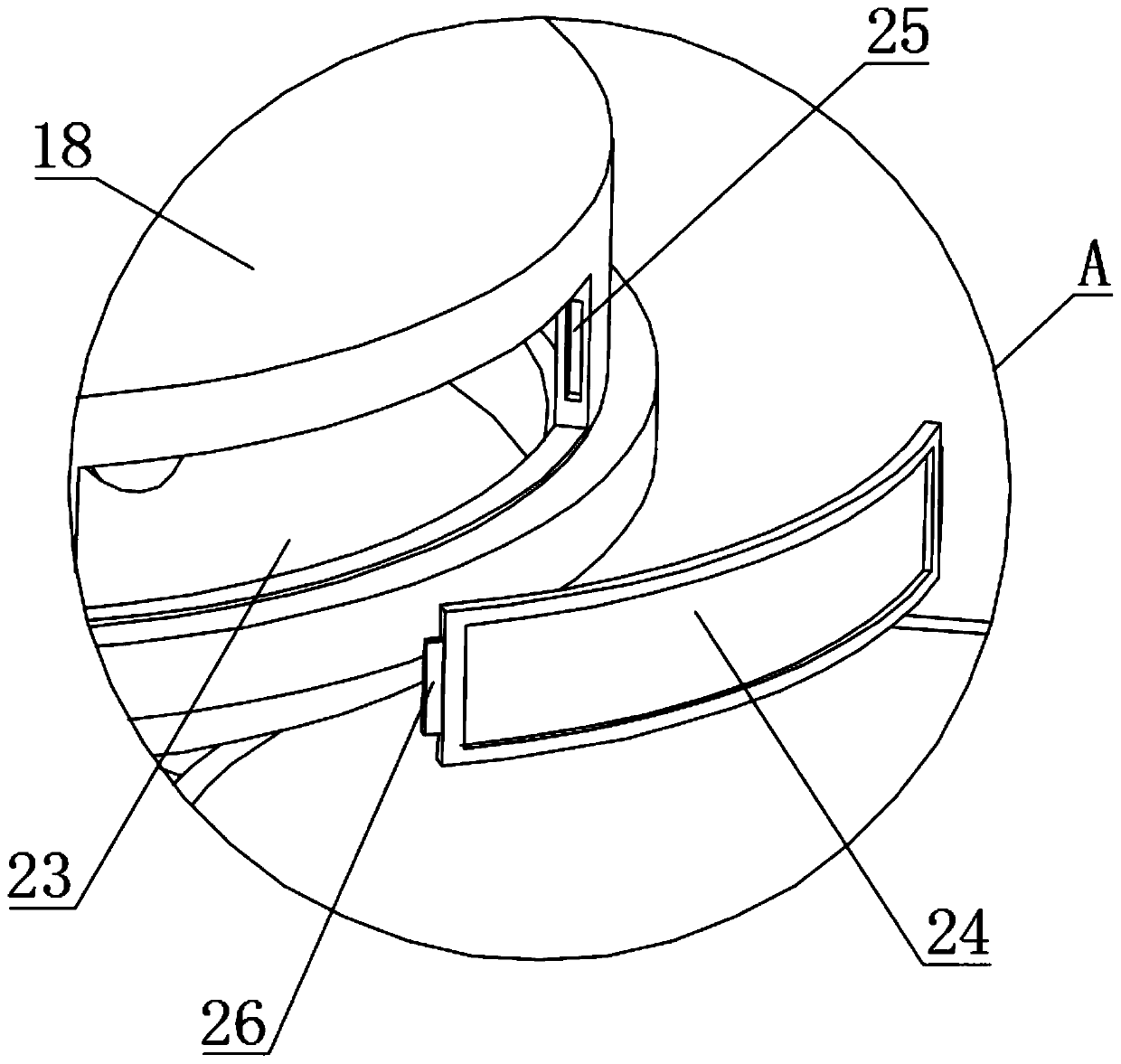

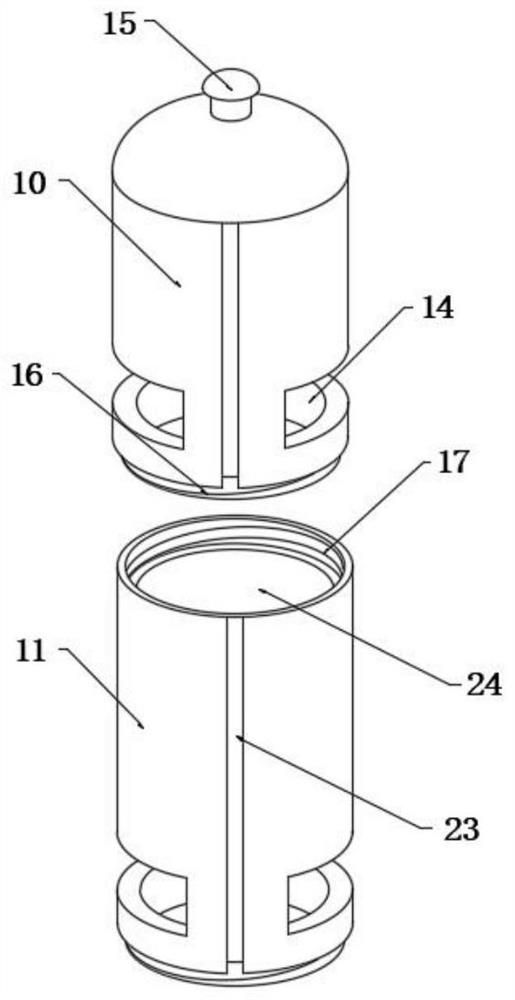

Cyclone classifier, flash drying system using the cyclone classifier, and toner prepared by the flash drying system

A cyclone classifier for classifying a particulate material, including an outer cylinder having a waistless part and an inverted-cone part vertically connected to an underside of the waistless part, and an inner cylinder which includes an exhaust opening such that the inner cylinder has a position-adjustable bottom end.

Owner:RICOH KK

Rice husking machine

Owner:四川东工电机有限公司

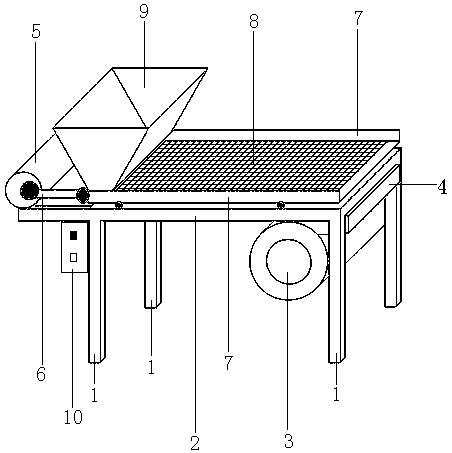

Seed screening device for energy-saving big agricultural data breeding

InactiveCN106733639ASimple structureGood filtering effectGas current separationAgricultural engineeringAgriculture

The invention belongs to the technical field of big agricultural data, particularly relates to a seed screening device for energy-saving big agricultural data breeding, and aims to provide a seed screening device which is simple in structure, good screening effect and low manufacturing cost. The seed screening device comprises a bottom plate, a left support, a first collection frame, a second collection frame, a right support, a first bearing block, a top plate, a second bearing block, a first rotating shaft, a first blade and the like, and the left support, the first collection frame, the second collection frame and the right support are sequentially welded at the top of the bottom plate from left to right. According to the seed screening device for energy-saving big agricultural data breeding, a rocking handle is manually rocked, so that the first blade and a second blade rotate, and seeds are screened.

Owner:裴迎新

Multifunctional lotus nut screening machine

InactiveCN107051882AImprove qualityImprove separation rateSievingGas current separationVibration controlHusk

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Grain conveying and screening machine

InactiveCN109351624AEasy to storeTransport dust wellSievingGas current separationEngineeringMechanical engineering

Owner:安徽粮友机械科技有限公司

Dry-method sand-fruit separation device

Owner:山东凯欣绿色农业发展股份有限公司

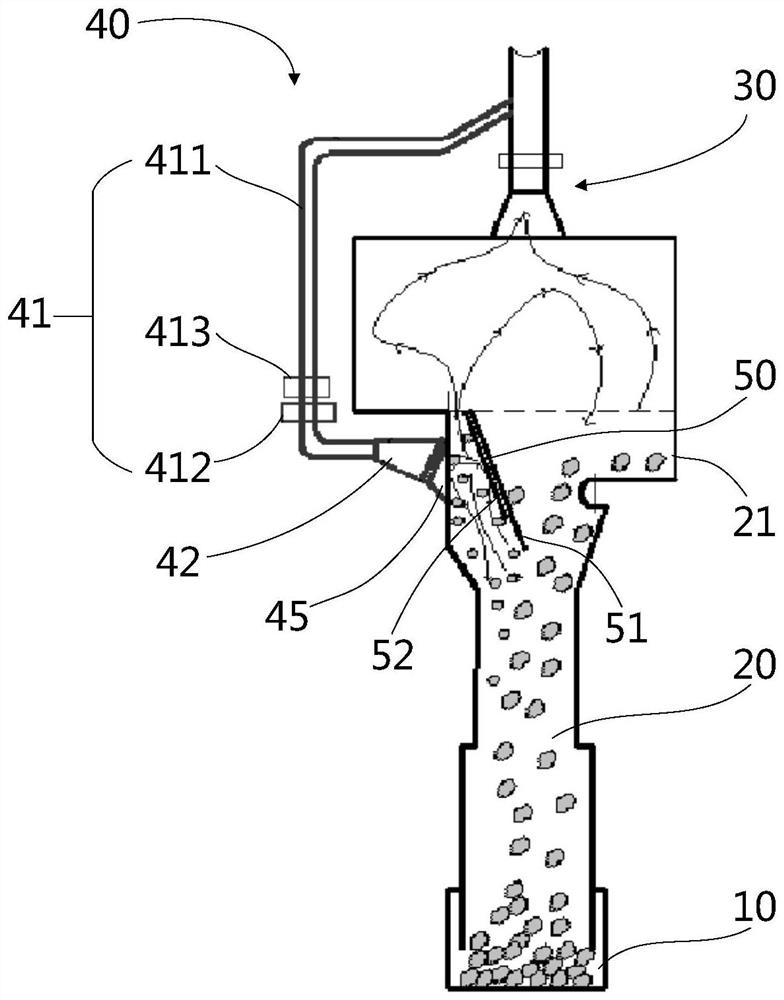

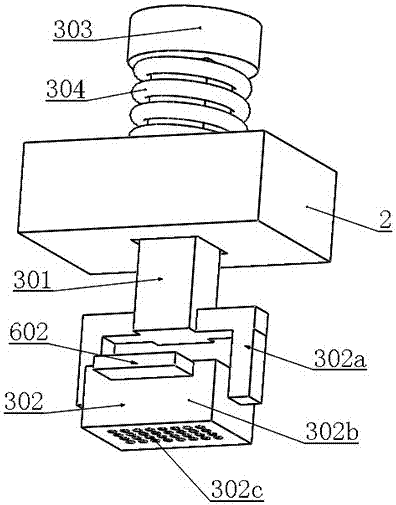

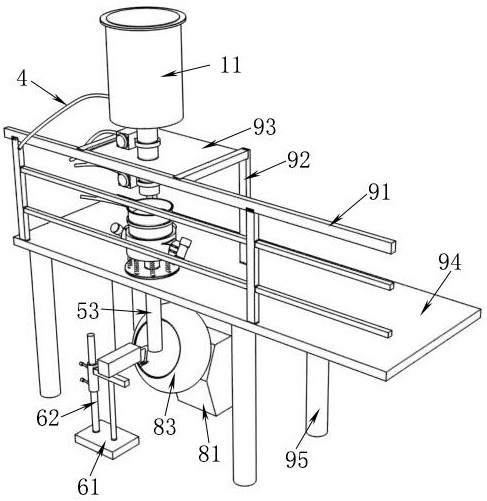

High-precision automatic roundness screening device and method for micro-particles

The invention discloses a high-precision automatic roundness screening device and method for micro-particles. The device and method are characterized in that to-be-screened micro-particles are placedinto a funnel, the flow of the micro-particles flowing into a nozzle is controlled by controlling the opening degree of an electromagnetic valve, the frequency of pulse airflow in the nozzle is controlled through the flow, the flow of the pulse airflow is controlled through a speed sensor, and thus the whole process is controlled. The micro-particles sprayed out of the nozzle enter a first screening plate through a flow guiding groove, waste falls into a waste trough, and the micro-particles with good roundness enter a second screening plate, flow into an oblique funnel and then fall into a finished product trough through a guide pipe in the funnel. The device and method have the beneficial effects that the efficiency and the finished product rate of original devices are improved to a great extent, and the device is controllable and high in precision.

Owner:ZHANGJIAGANG CHUANGBO METAL TECH CO LTD

Medicinal material sorting machine

Owner:FANGXIAN COUNTY ZHONGYI EQUIP

Grading and dust removal system used for mineral pretreatment

Owner:CENT SOUTH UNIV

Traditional Chinese medicine material sorting table used for processing of traditional Chinese medicine decoction pieces

PendingCN112742719AFast deliveryReduces clogging of discharge pipesSievingGas current separationMedicinal herbsEngineering

Owner:日照市精神卫生中心

Antistatic polymer sheet machining raw material cleaning device

Owner:安徽高伟新材料科技有限公司

Rice screening and processing device

Owner:王仕贵

Apple screening and classification device

ActiveCN108940876AProtectEasy to carrySievingGas current separationAgricultural engineeringSmall footprint

Owner:刘彬

Quick sorting machine for coal gangues with different sizes

PendingCN114505236APrevent fallingAvoid damageGas current separationCleaningMining engineeringProcess engineering

Owner:原瑜

Automatic peanut shell and skin separator

ActiveCN111588046AEasy to separateImprove processing efficiencyGas current separationHuskingElectric machineryStructural engineering

Owner:义乌市高洋机械设备有限公司

Tea leaf processing device and tea leaf processing method

InactiveCN113877797ALight in massIncrease productionSievingGas current separationEngineeringMechanical engineering

The invention discloses a tea leaf processing device and a tea leaf processing method. The tea leaf processing device comprises a screening mechanism, a box body and a controller, the screening mechanism is installed on the box body, one end of the screening mechanism extends into the box body, a fan is fixedly installed on one side of the box body, the output end of the fan penetrates through the box body, and the output end of the fan is fixedly connected with the box body. Through the arrangement of the fan, a baffle and the screening mechanism, tea leaves are added into the screening mechanism, after screening, large-size tea leaves are discharged from a discharging port, light-weight and small-size tea leaves and impurities fall down from a discharging pipe, the fan is started through the controller, and the fan blows the light-weight and small-size tea leaves onto a second filter screen on one side of the baffle, and impurities fall into the other side of the baffle, so that the light-weight and small-size tea leaves can be collected in the screening process, the resource waste is avoided, and the yield of the tea leaves is improved.

Owner:TIANFANG TEA IND CO LTD

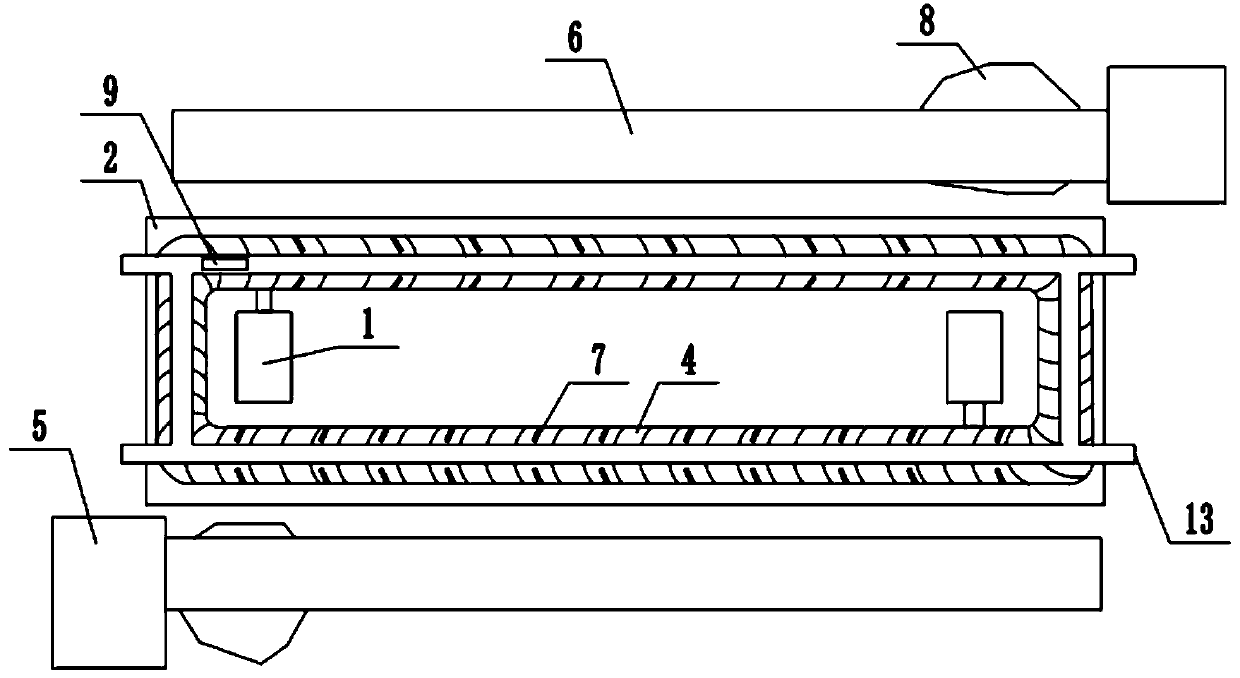

Tobacco leaf packaging and pre-pressing system and method and tobacco leaf packaging and pre-pressing machine

ActiveCN114304696AReduce the spray volumeReduce floatingTobacco preparationGas current separationAir velocityDust control

Owner:FUJIAN LONGYAN JINYE REDRYING

Screening device for waxberry processing

Owner:青田县云端农业开发有限公司

Impurity removing machine

Owner:ZHEJIANG BETHLEHEM APP

Feather screening system and method for badminton production

ActiveCN107214085AShorten the manual screening processImprove classification efficiencyGas current separationSortingScreening methodEngineering

Owner:安徽明亮面业股份有限公司

Grading device for montmorillonite drying agent production

InactiveCN107486389AEasy to collectEffective grading operationSievingGas current separationMontmorilloniteMechanical engineering

Owner:安吉高纯蒙脱石有限公司

Transmission device special for municipal waste

Owner:广西大自然再生资源有限公司

Tobacco shred repeated winnowing device

PendingCN114798445AReduce lossEasy to handleGas current separationEconomic benefitsProcess engineering

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Textile waste collecting device for textile production of chemical fabric

PendingCN112893317AEasy to take outEasy to cleanCombination devicesGas current separationElectric machineryEnvironmental engineering

Owner:莫晨良

Ceramic powder balling method and device

Owner:湖南杰瑞精密陶瓷有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap